Betel Nut Cutting Machine

A cutting machine and betel nut technology, applied in the direction of metal processing, etc., can solve problems such as difficult to achieve cutting standards and quality, large difference in fruit grains, time-consuming and labor-intensive, etc., to meet market development needs, improve cutting efficiency, and adapt to a wide range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

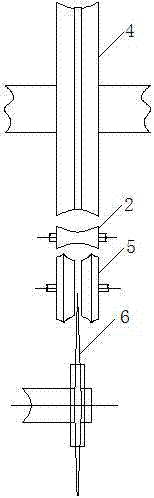

[0027] refer to Figure 1-Figure 2 , the present embodiment includes an automatic feeding device 1, an orientation adjuster 2, a counterweight 3, a fruit feed wheel 4, a cutting positioner 5 and a cutting device 6, and the automatic feeding device 1 is located in front of the orientation adjuster 2, so The orientation adjuster 2 includes a series of concave wheels arranged in a straight line, the concave wheels are driven by the first motor through a belt, the fruit feeding wheel 4 is located above the orientation adjuster 2, and the fruit feeding wheel 4 passes through the belt Driven by the second motor, the fruit feeding wheel 4 is fixedly connected to the second motor and connected to the counterweight 3 through a connecting piece, so as to automatically realize the up and down adjustment of the fruit feeding wheel 4, and the cutting positioner 5 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com