System and method for supplying coating coated with fiber drawing resin

A resin coating and feeding system technology, applied in the field of double-pipe alternate feeding system, can solve the problems of flow fluctuation, affecting the uniformity of coating coating, and the switching action is not smooth enough, so as to ensure uninterrupted feeding, The effect of stable feeding and clean paint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

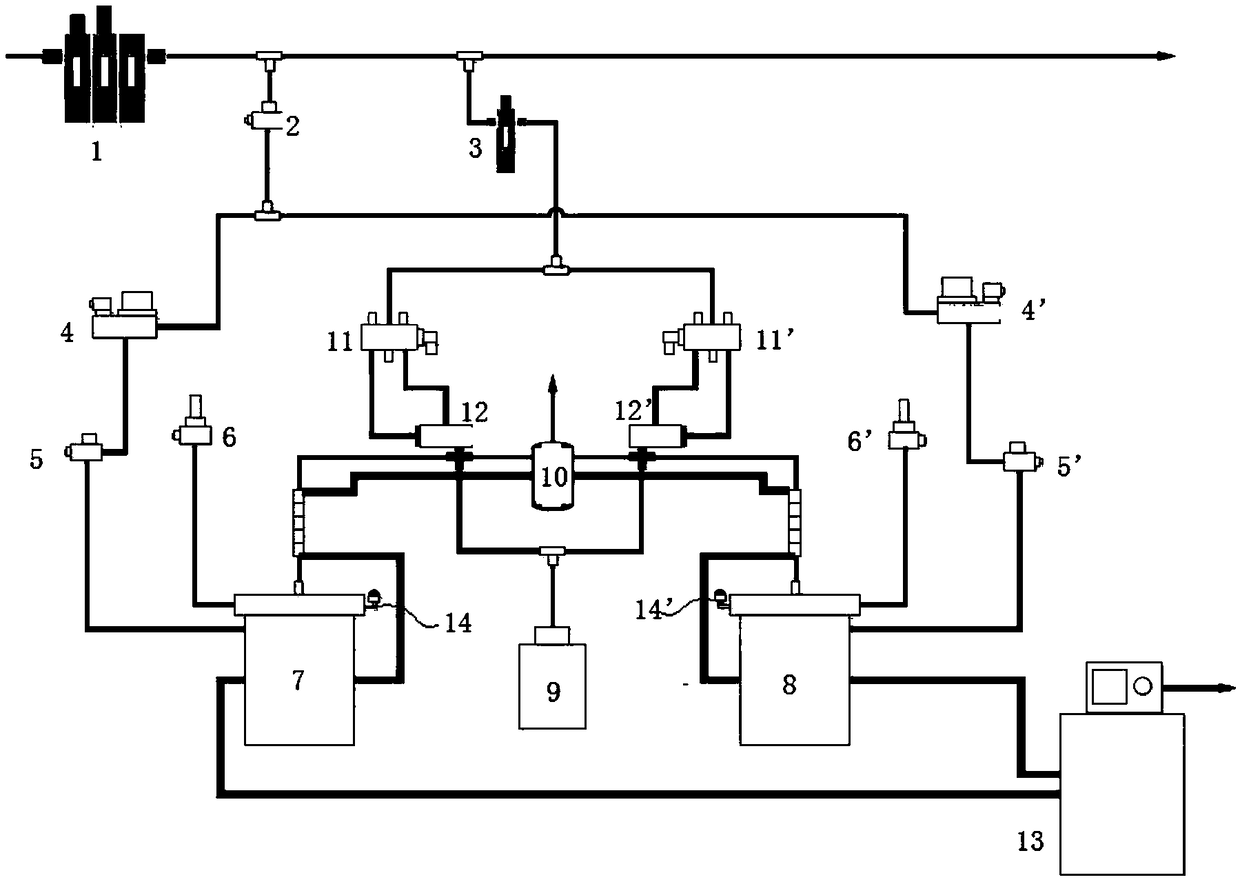

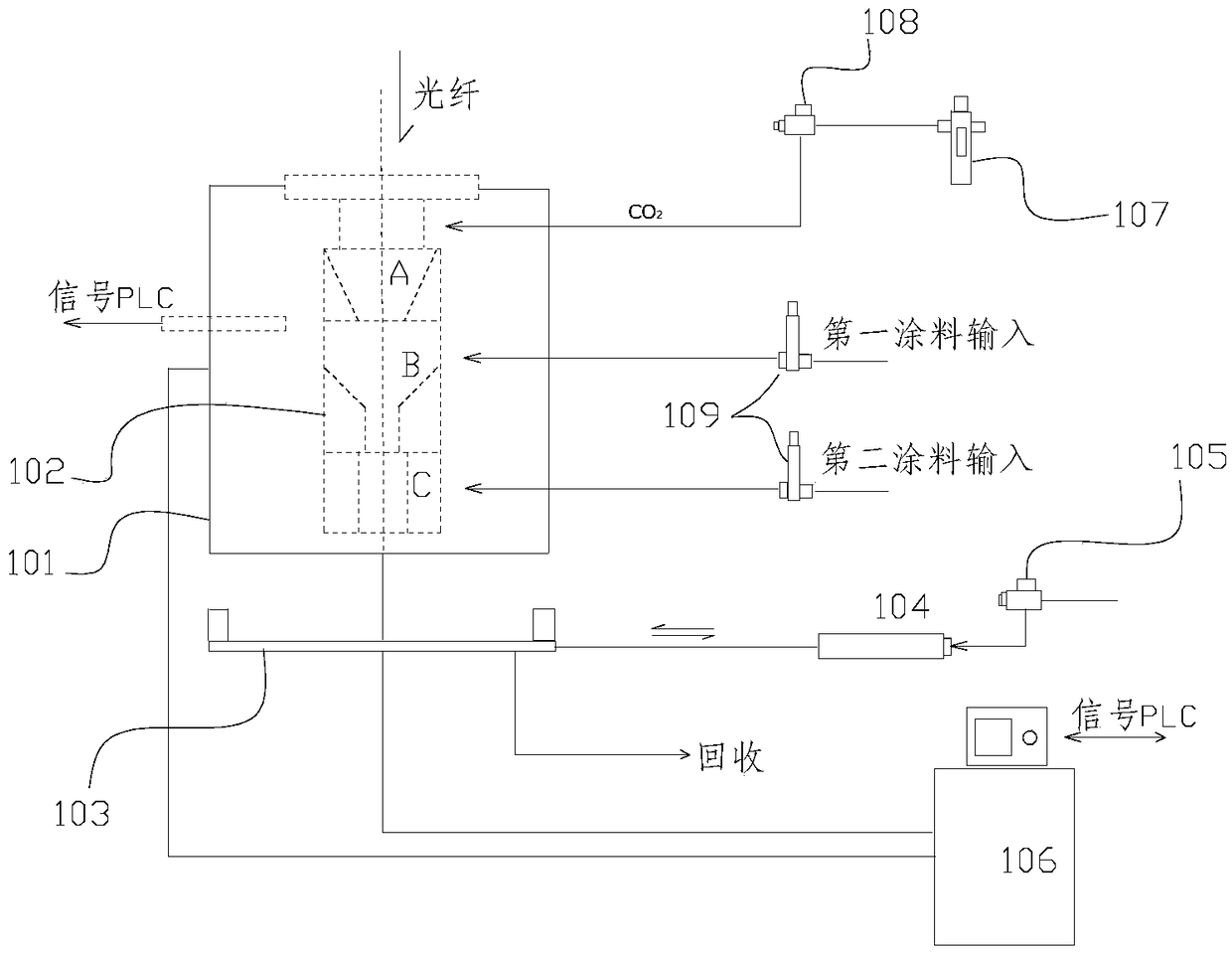

[0027] Such as figure 1 As shown, a paint supply system coated with resin for optical fiber drawing includes a first paint tank 7, a second paint tank 8, a recovery tank 9, a paint filter 10, an air source input pipe, and is respectively connected to the air source input pipe The air supply pipeline and the pneumatic pipeline, and the air source filter 1 is arranged on the pipeline of the air source input pipe.

[0028] The gas supply pipeline is connected to the gas source input pipe, and the main solenoid valve 2 is arranged on the gas supply pipeline. The first gas supply branch pipe and the second gas supply branch pipe arranged in parallel are separated from the gas supply pipeline, and the first gas supply branch pipe is connected to the first paint tank 7 , used to input compressed air to the first paint tank 7 to feed the material, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com