Pneumatic micro-valve integrated in micro-flow control chip

A microfluidic chip, microvalve technology, applied in valve devices, engine components, mechanical equipment, etc., can solve the problems of high price, difficult to carry, bulky appearance, etc., and achieve the effect of low cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following embodiments.

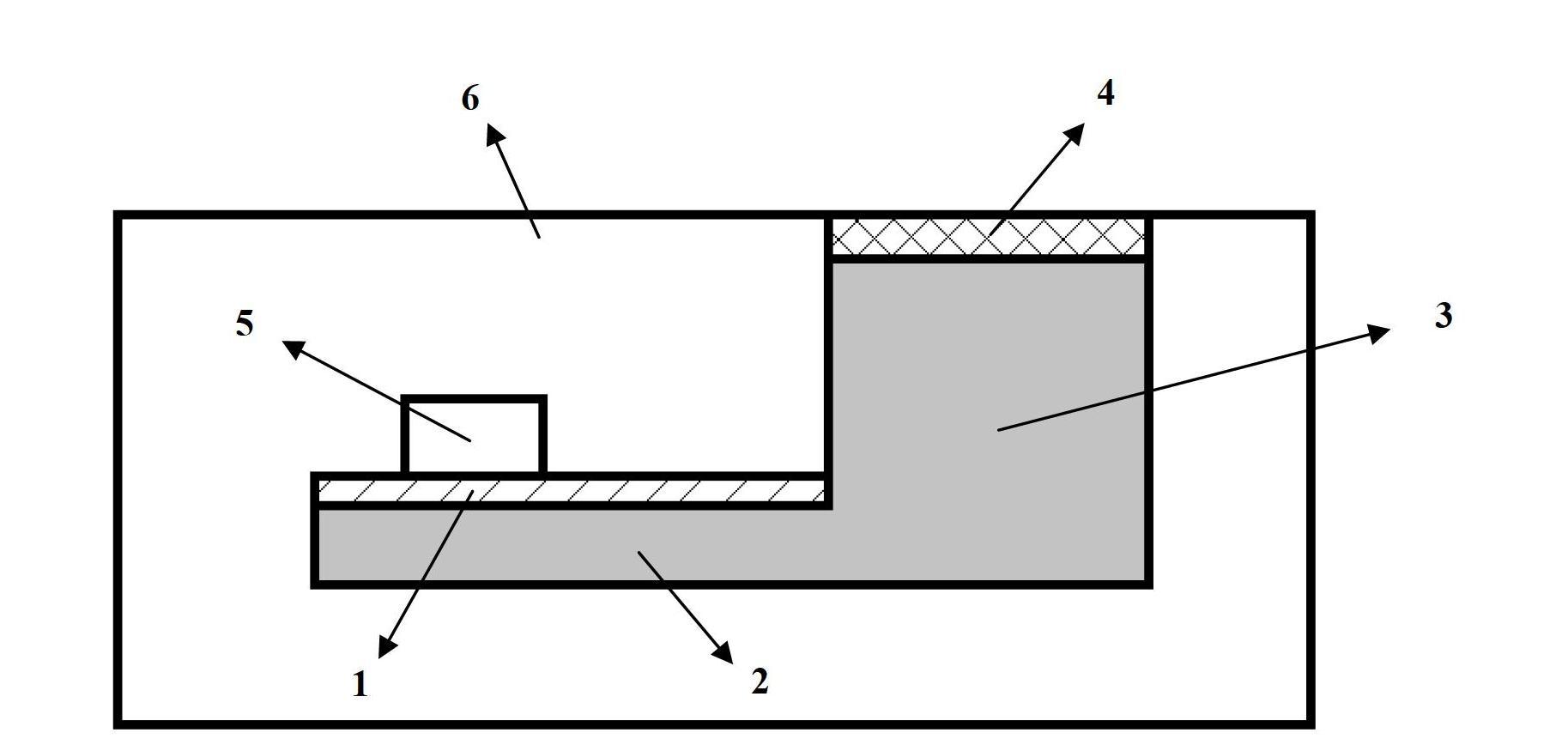

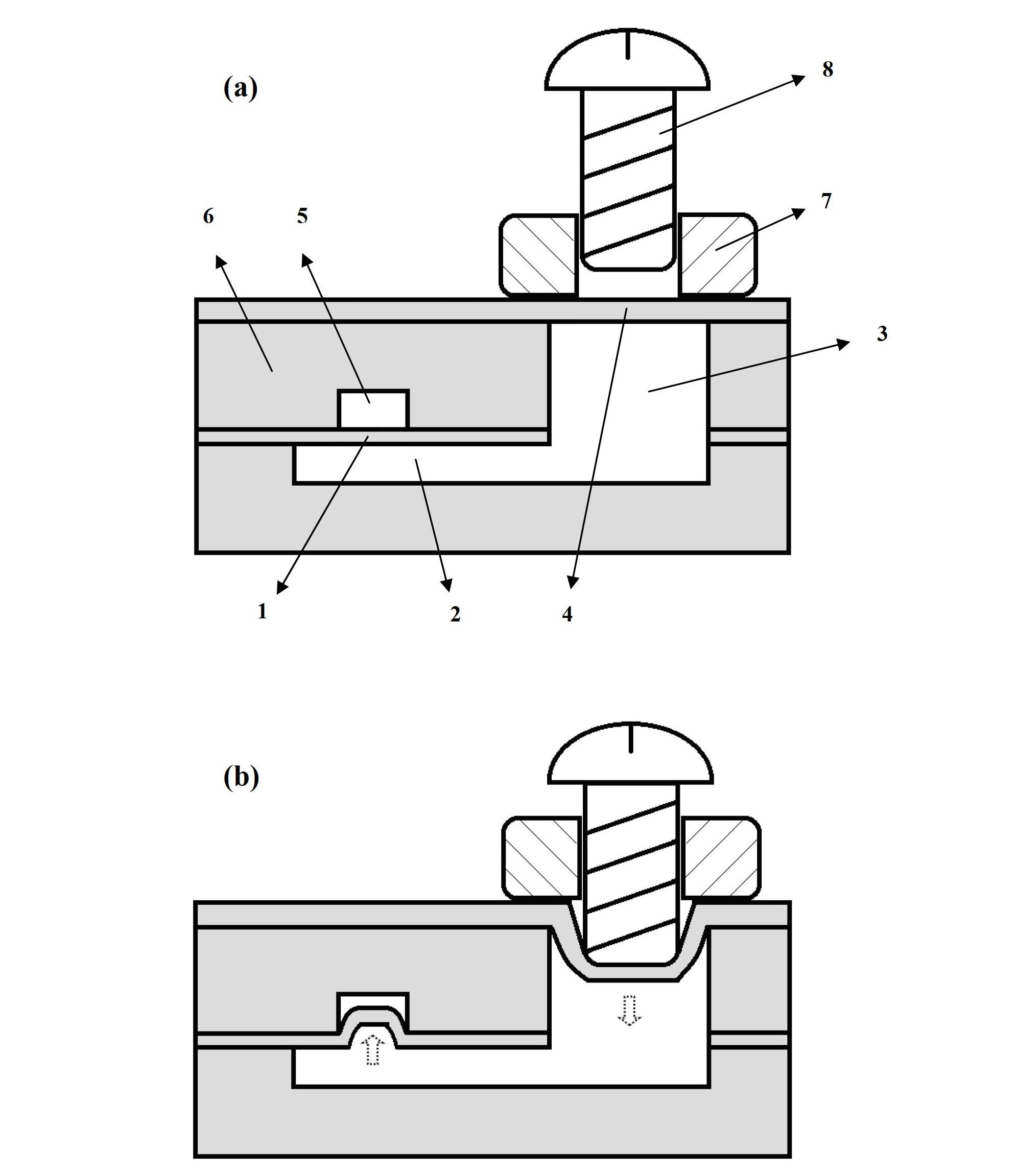

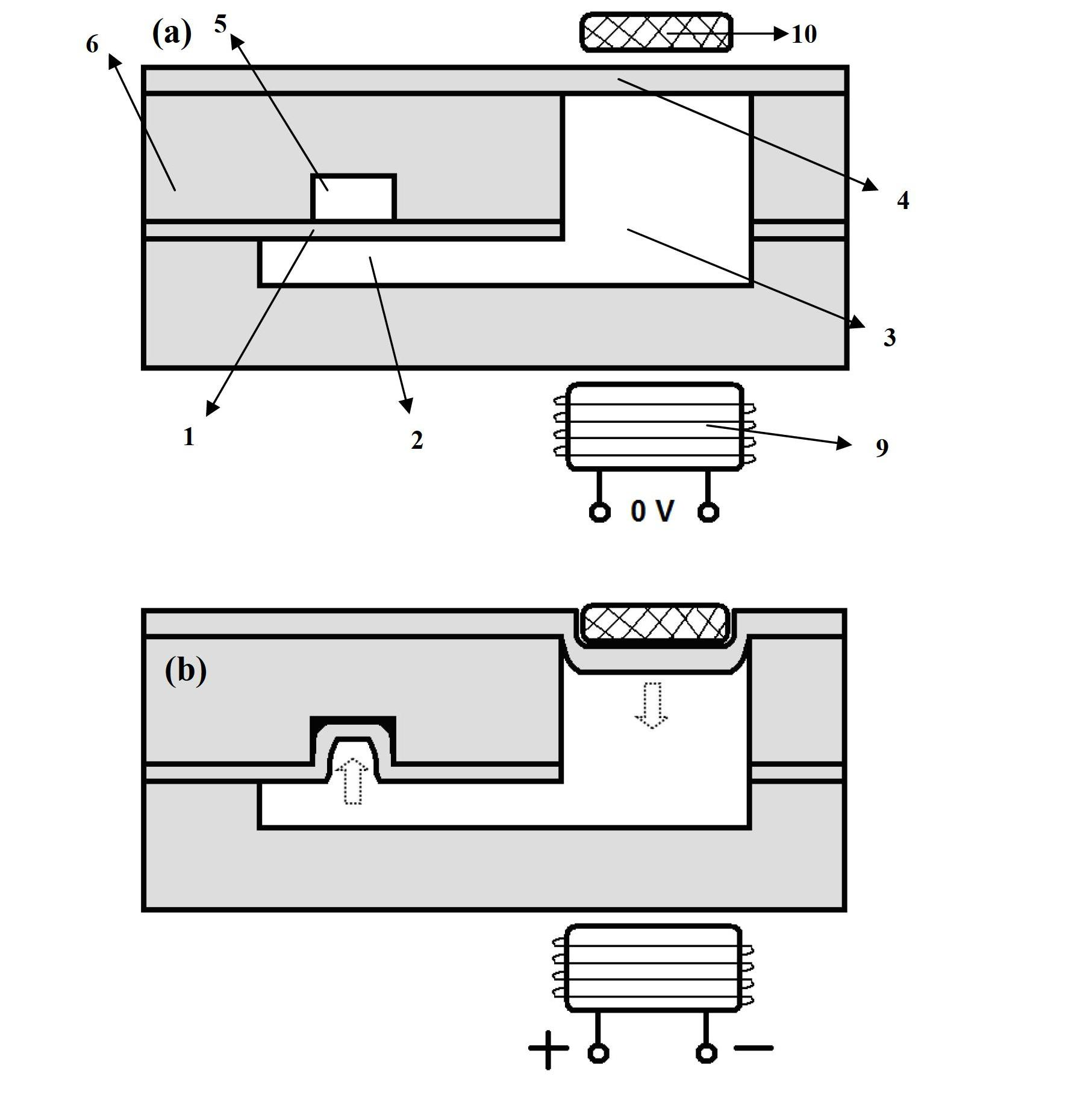

[0022] Such as figure 1 As shown, the pneumatic microvalve integrated in the microfluidic chip provided by the present invention includes a closed cavity composed of a control channel 2 and a compressible air bag 3, and the closed cavity is filled with compressed air; The side wall is an elastic film 1, which is made of deformable material silicone rubber, with a curvature of 200 μm, and the side wall is a common wall where the control channel 2 and the fluid channel 5 of the microfluidic chip 6 intersect. The control channel 2 is located at Below the fluid channel 5; the control channel 2 communicates with one end of the compressible air bag 3, and the other end of the compressible air bag 3 communicates with the outside world, and the end is closed by the elastic film 4, which is also made of Mad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com