Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Strength can be balanced" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

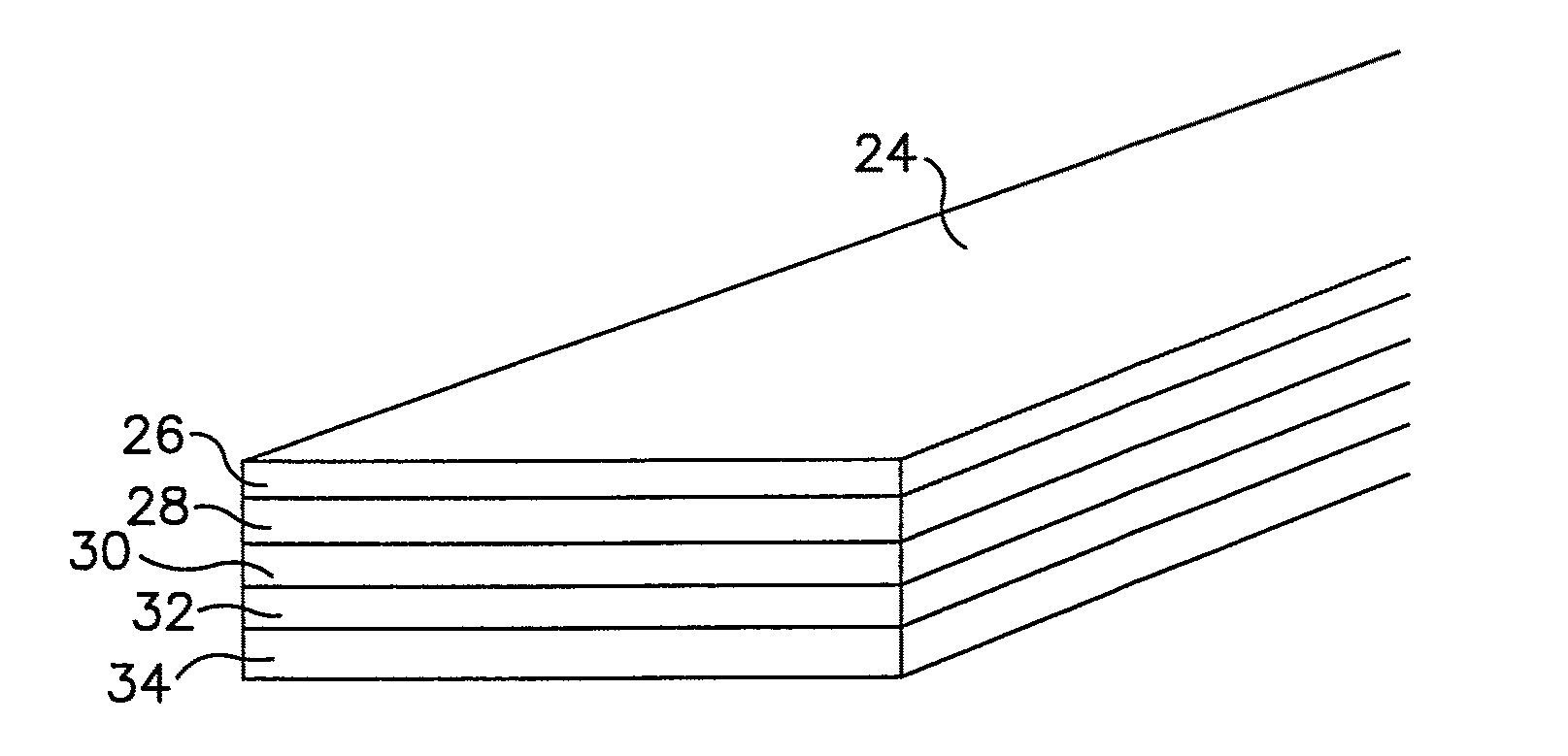

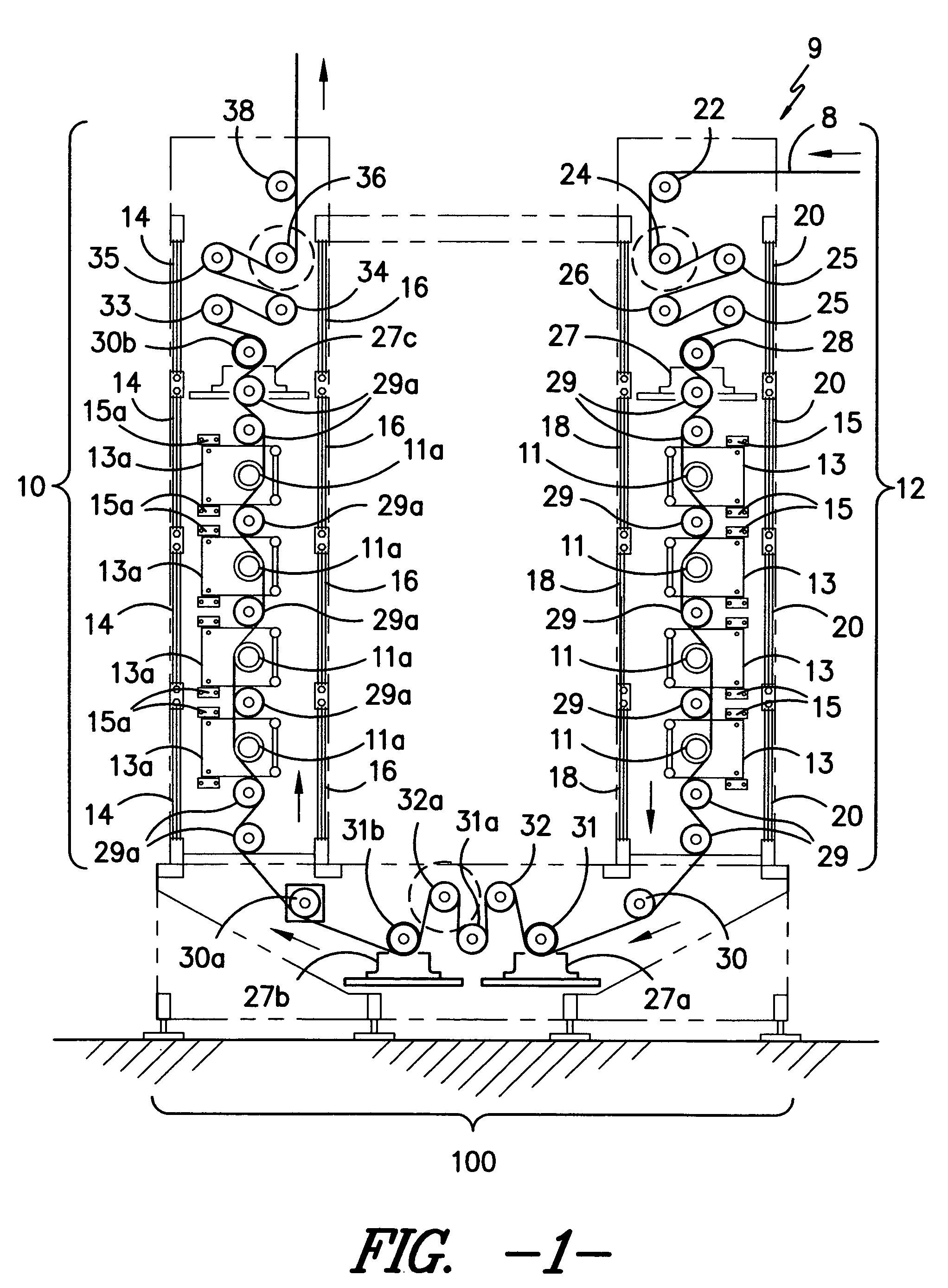

High loft nonwoven with balanced properties

InactiveUS20060063458A1Improve flame retardant performanceHigh strengthWoven fabricsNon-woven fabricsPolyesterProduction rate

The present invention relates to process for making a light-weight, high loft nonwoven fabric. The process adds a drafter to a conventional nonwoven process in order to increase the production rate. Additionally, the invented process improves the quality of the manufactured fabric by increasing the tensile strength in the machine direction, providing balanced strength in the machine and cross directions, and enhancing resiliency. The process blends polyester fiber with a low melt fiber or low melt bicomponent fiber to form a web. The web is optionally carded and cross lapped before being drafted. Thereafter, the web is heated in an oven having sufficient heat to melt the low melt fiber then cooled to set the properties.

Owner:SYLVAN CHEM CO

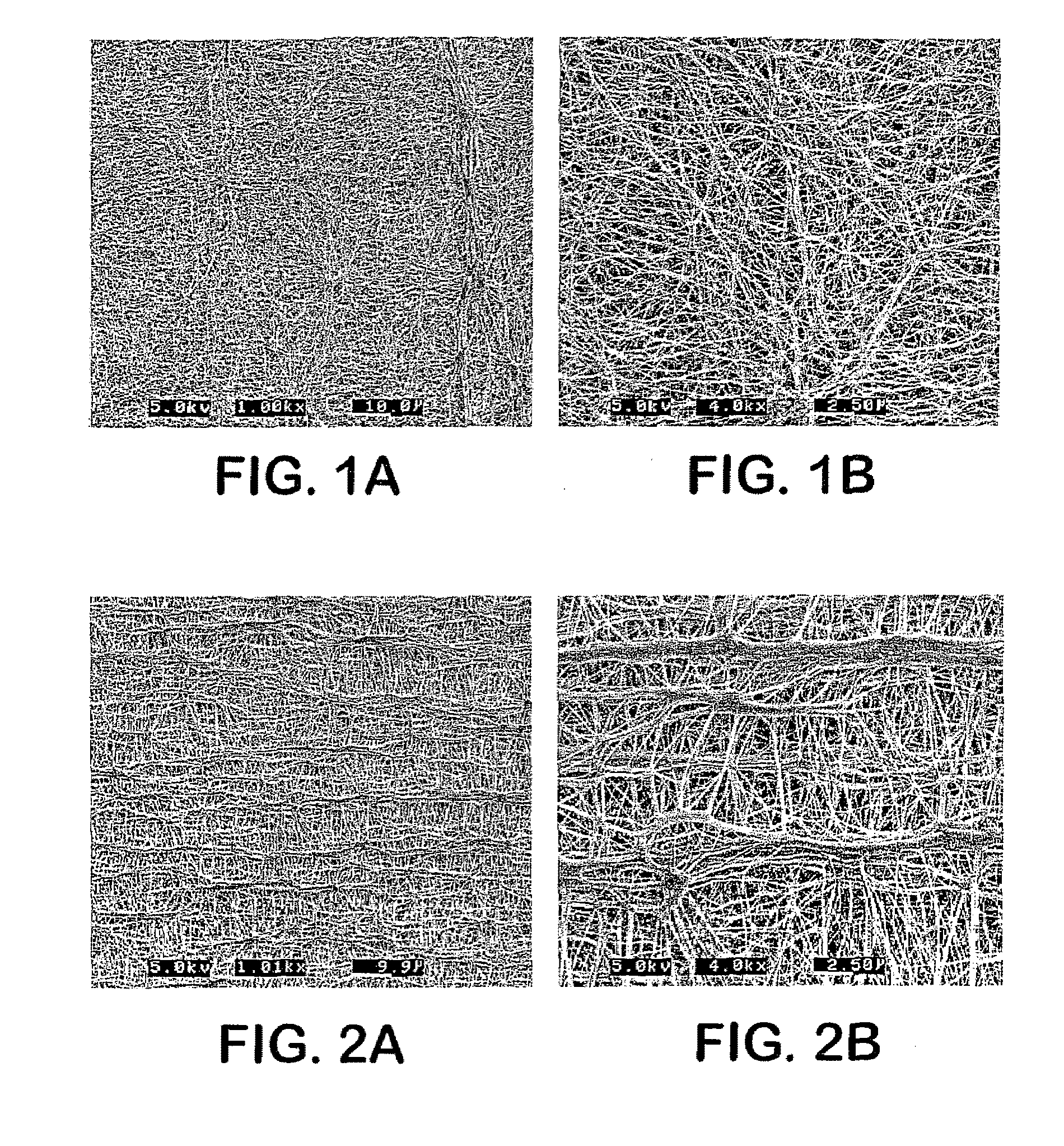

Face finishing of fabrics containing selectively immobilized fibers

InactiveUS6260247B1Highly cost-effectiveEliminates pillingFibre treatmentBall sportsUltimate tensile strengthBiomedical engineering

Owner:MILLIKEN & CO

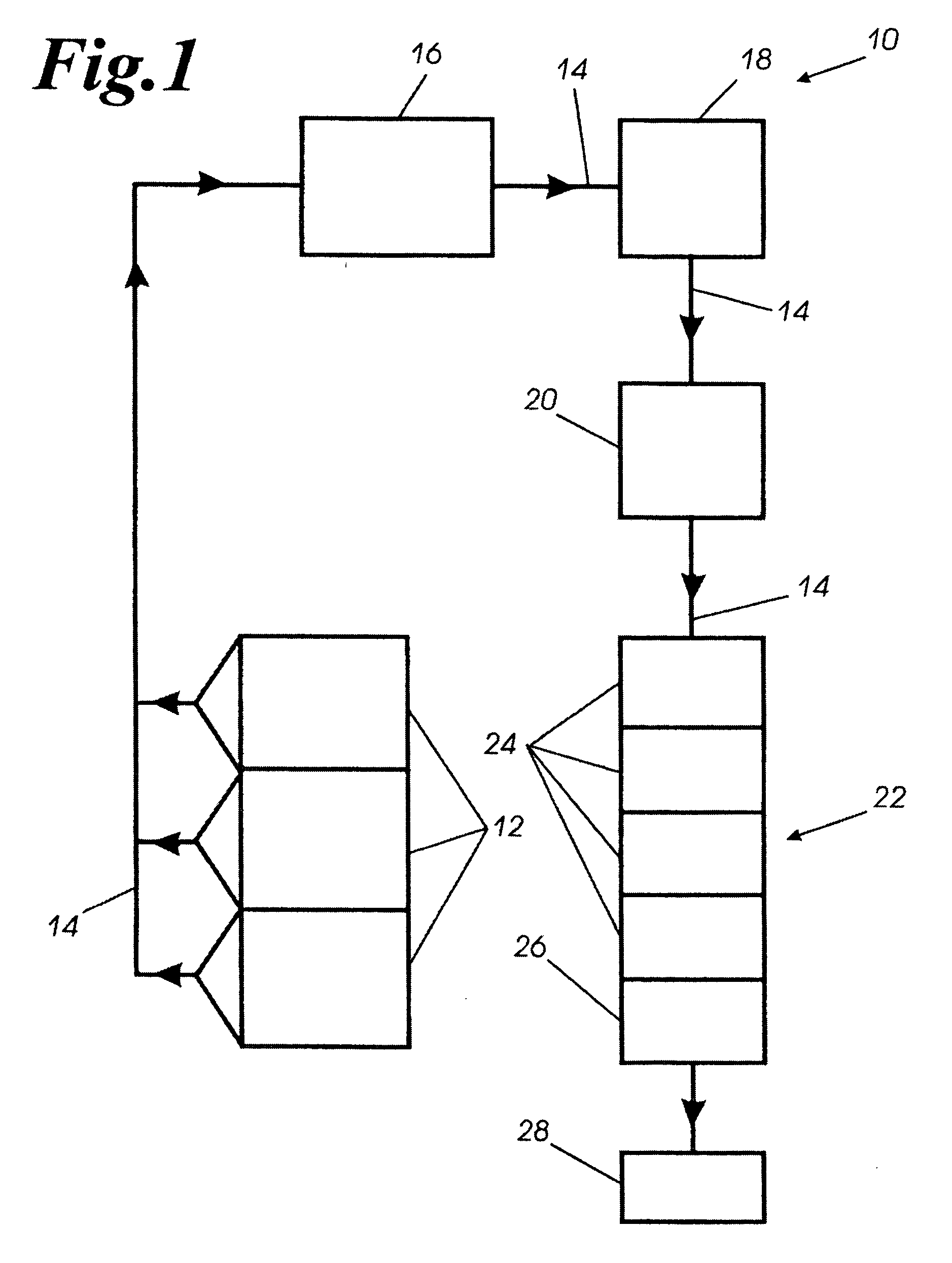

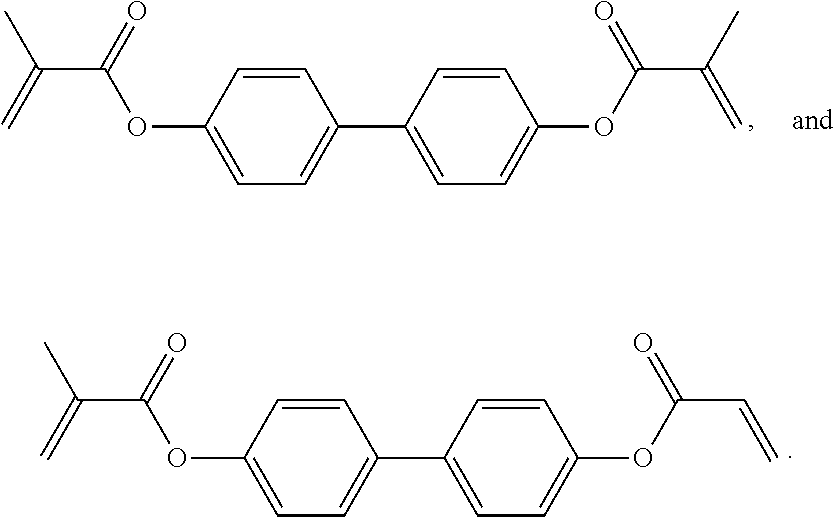

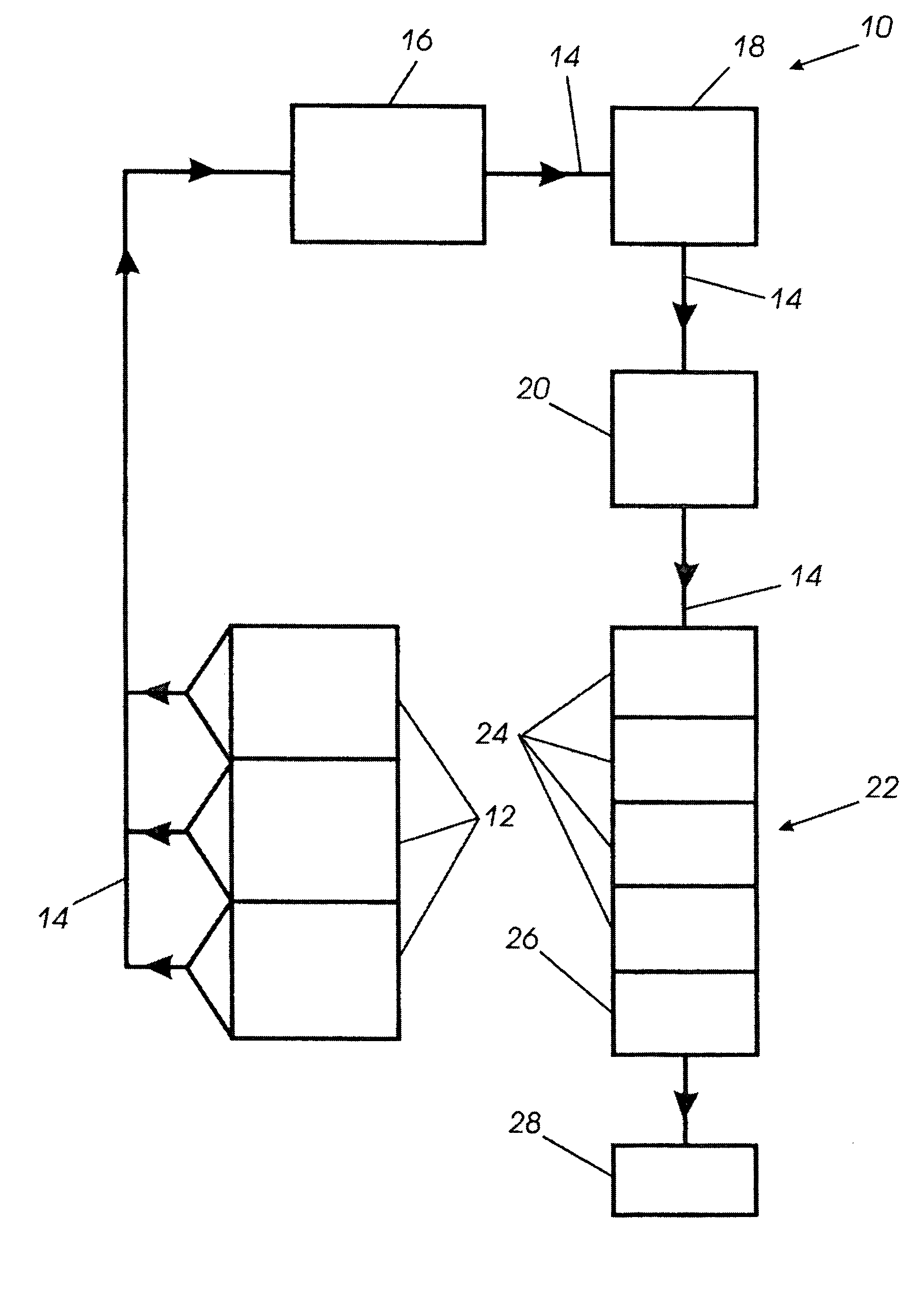

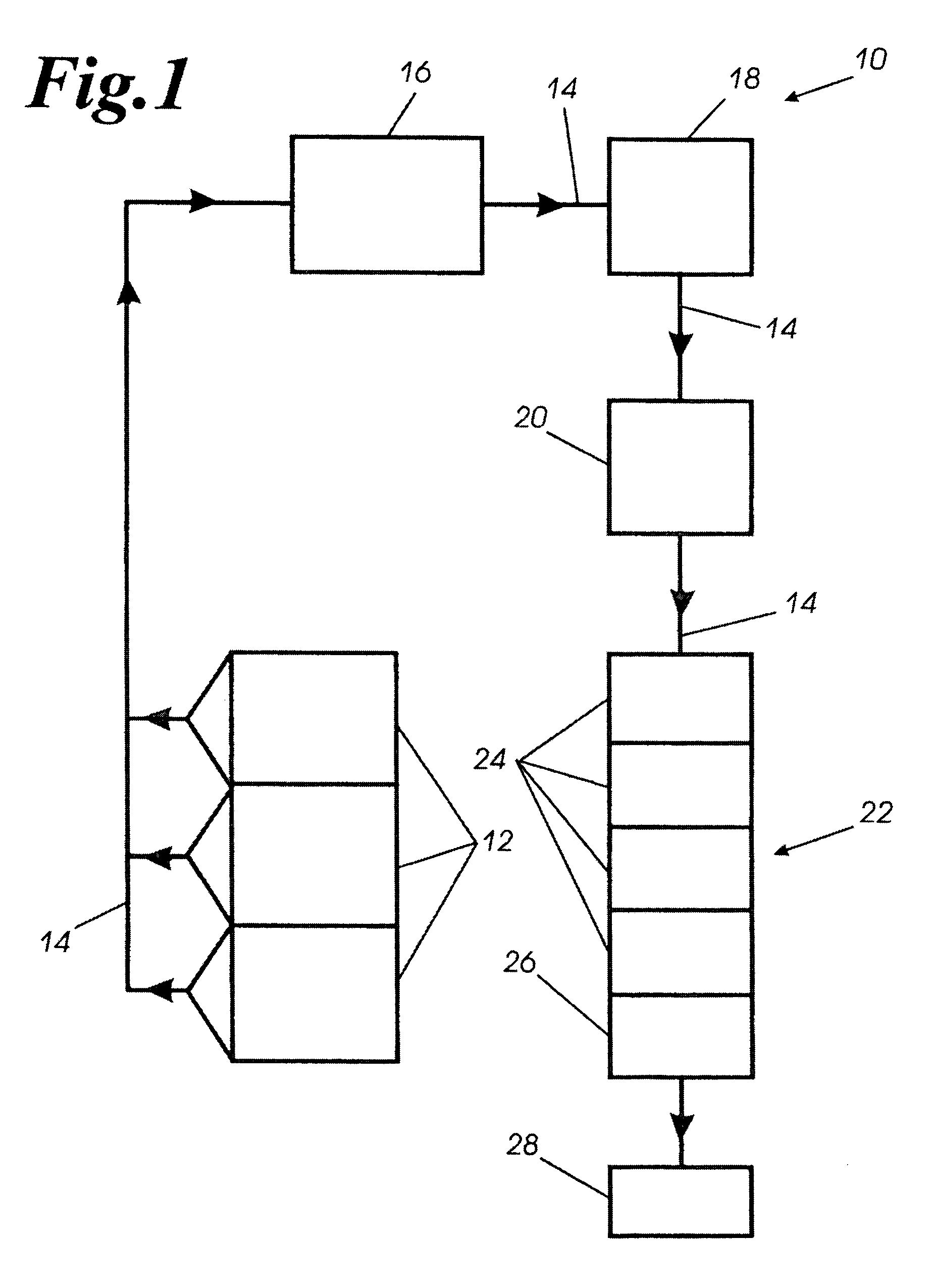

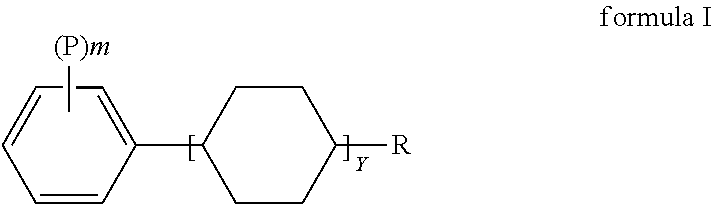

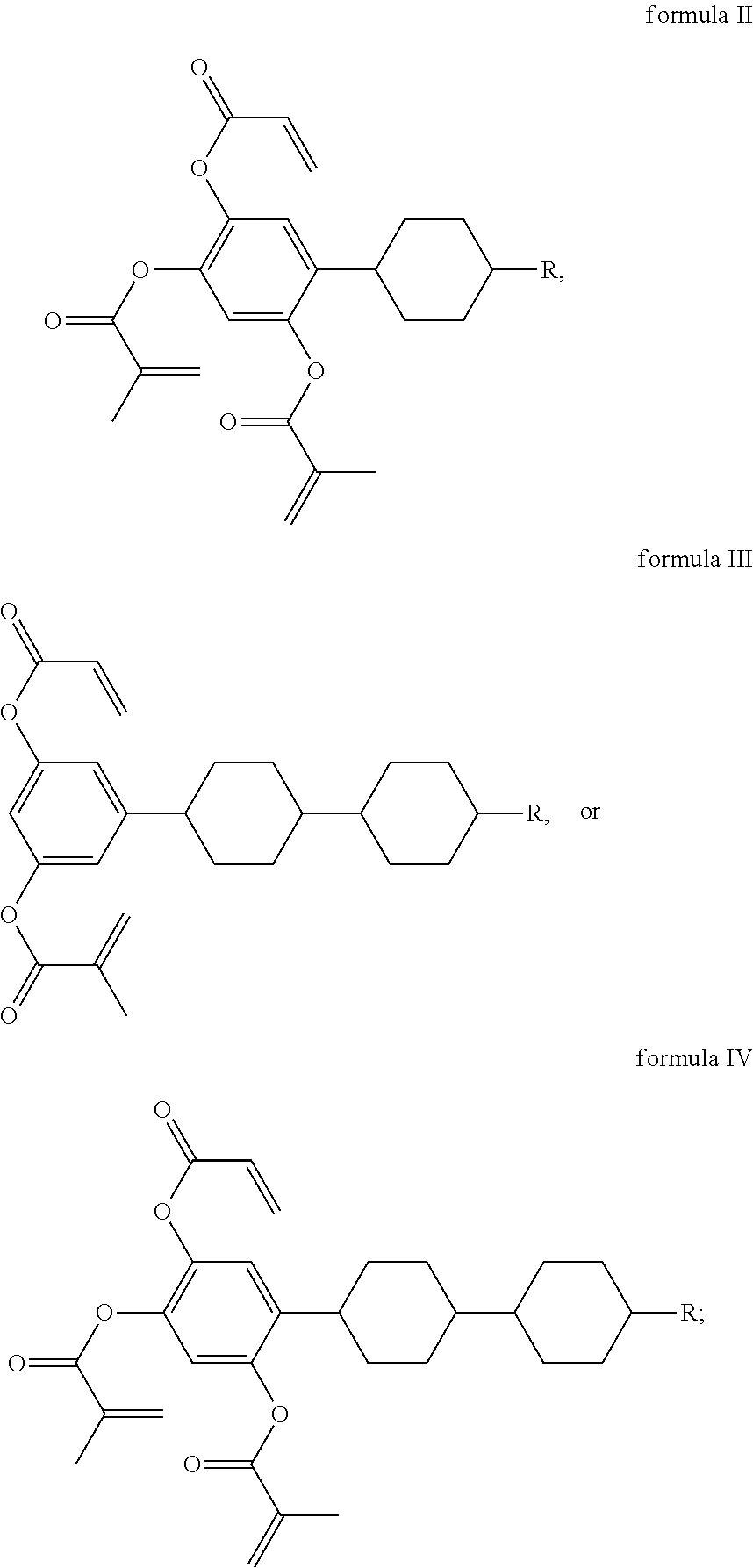

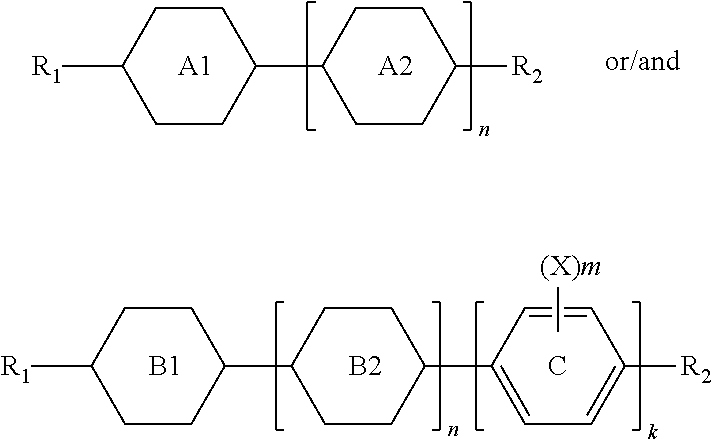

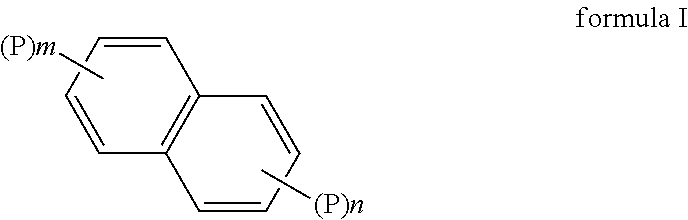

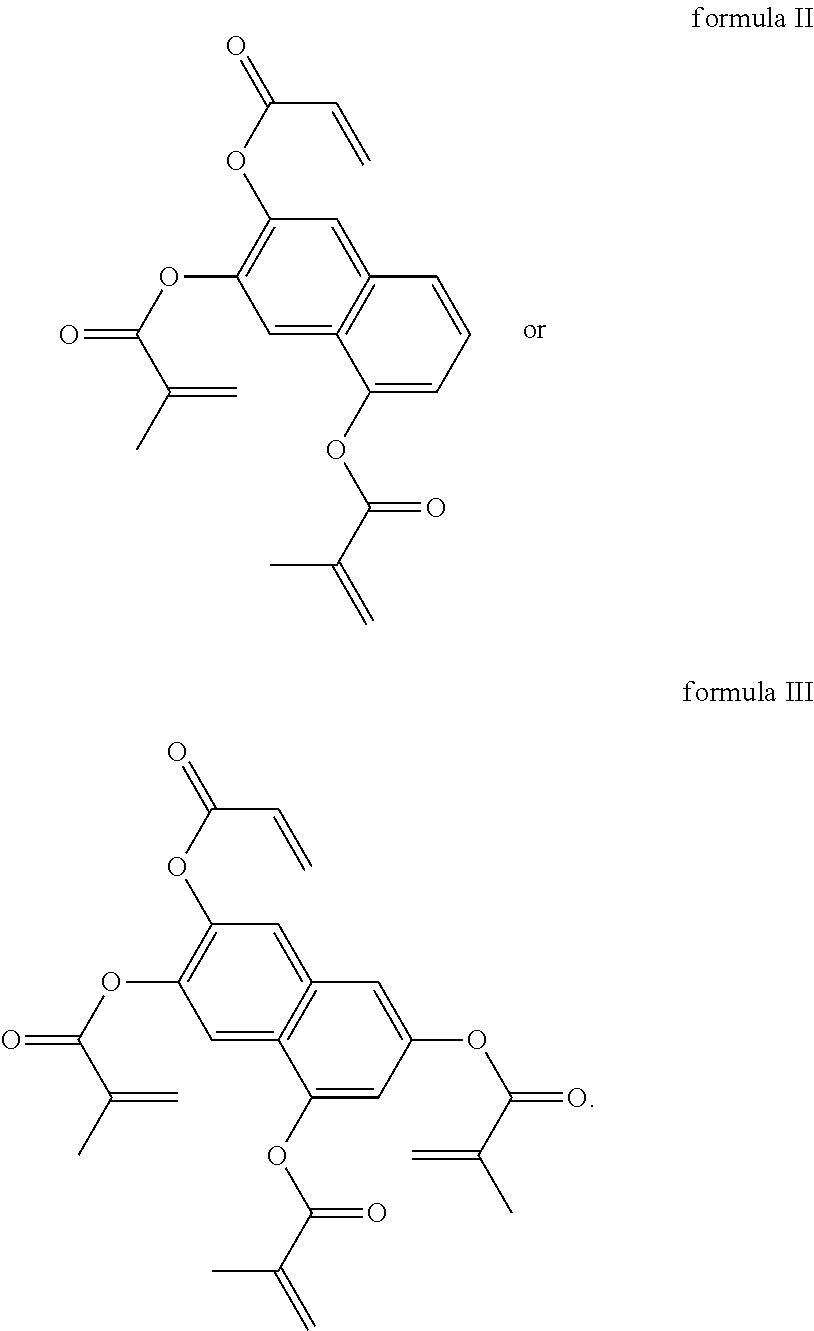

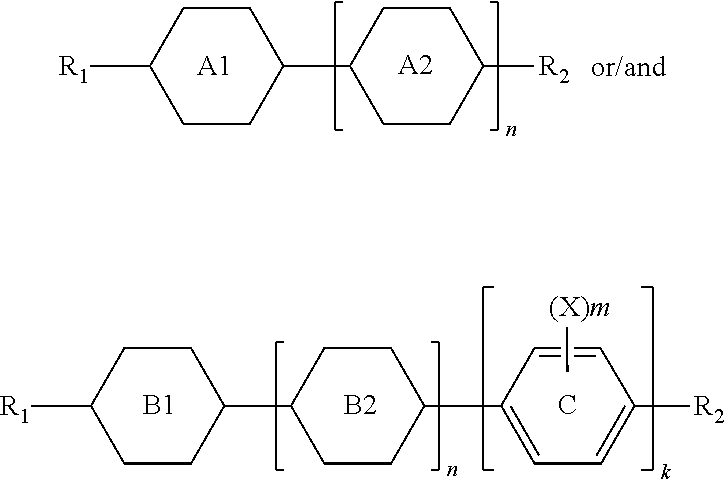

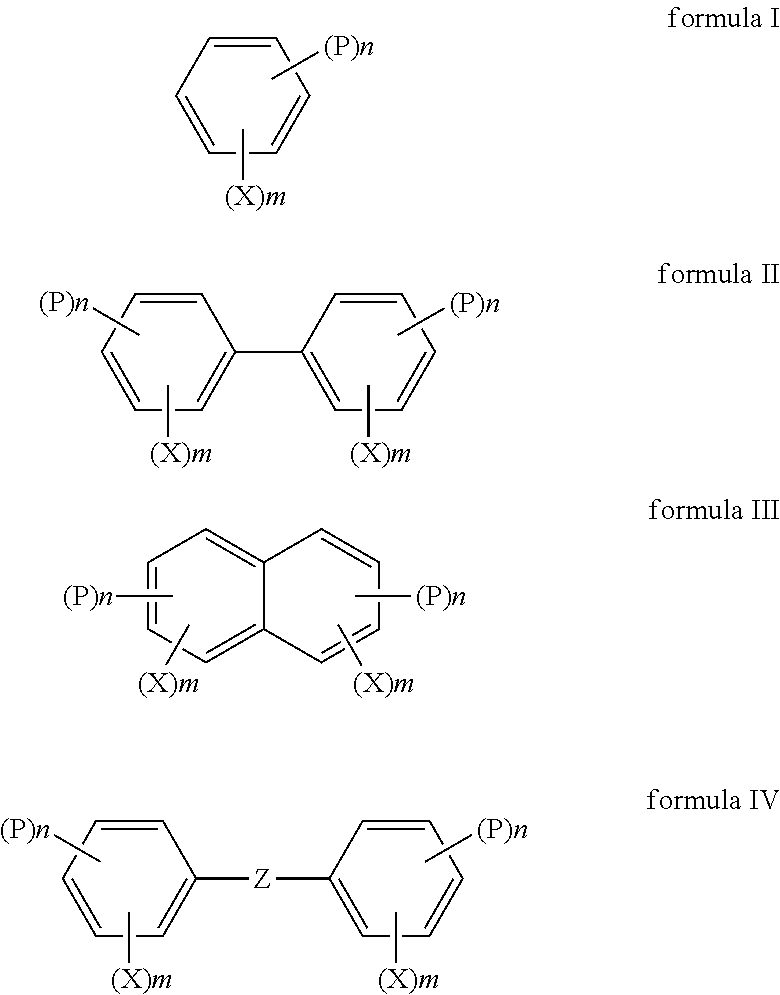

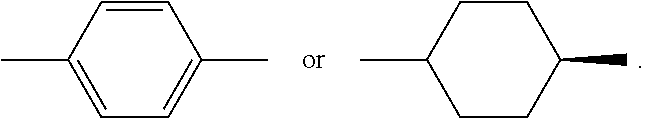

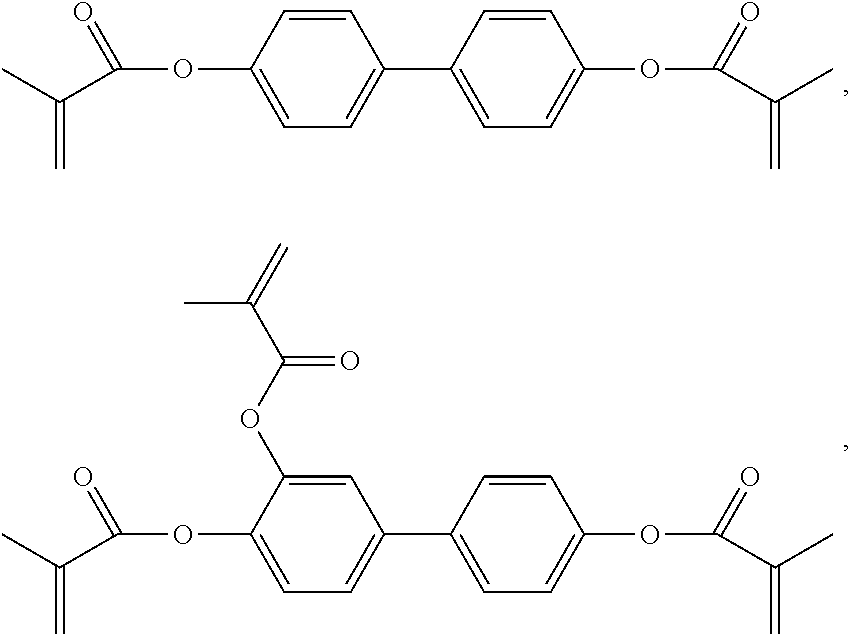

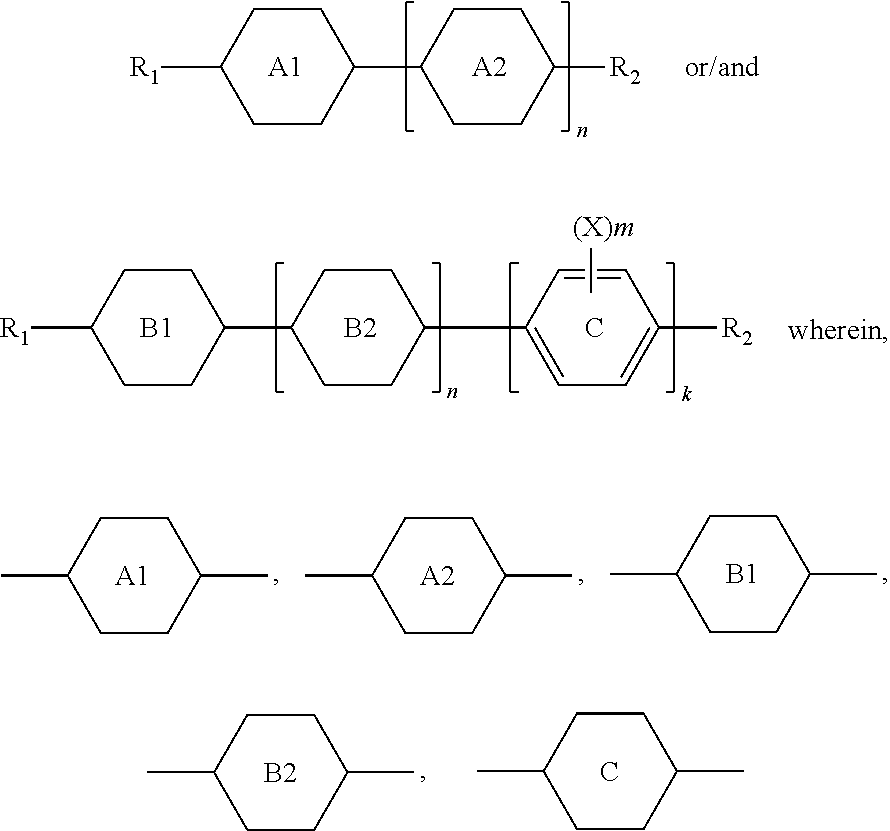

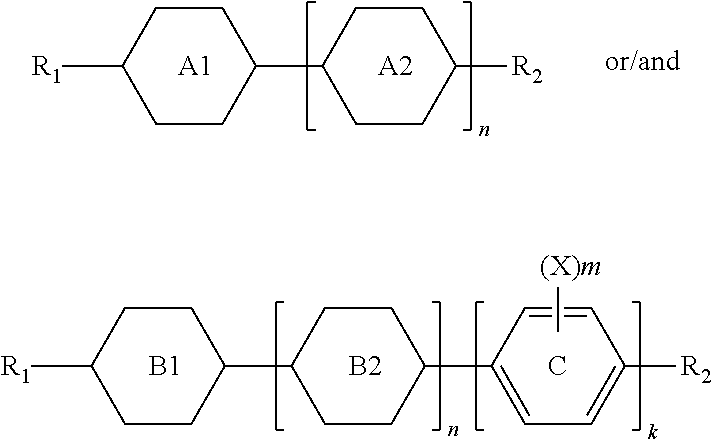

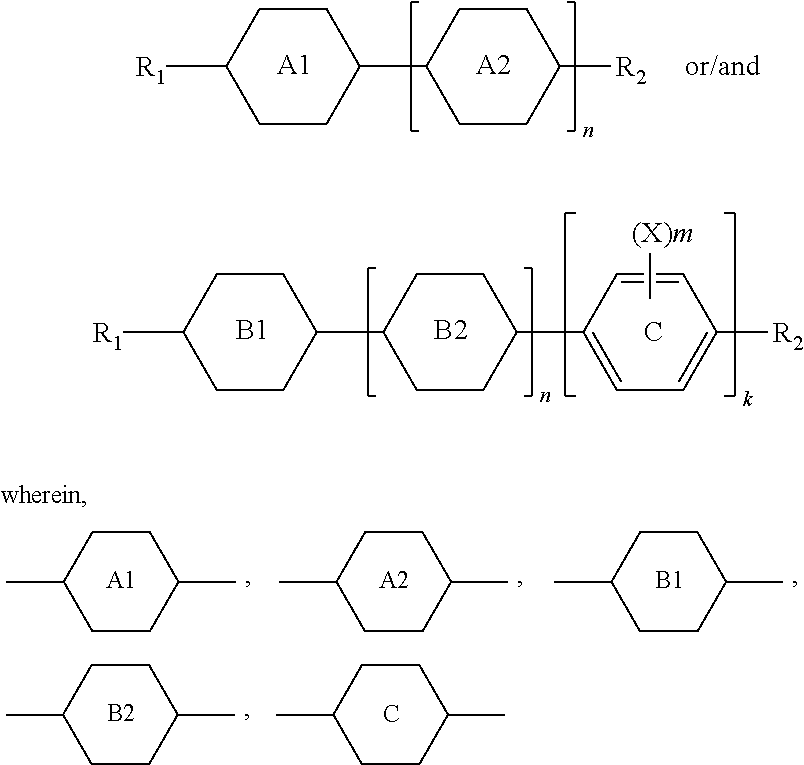

Mixture for Liquid Crystal Medium and Liquid Crystal Display Using the Same

InactiveUS20140085593A1High levelStrength be balanceLiquid crystal compositionsNon-linear opticsHigh contrastLiquid-crystal display

The present invention provides a mixture for liquid crystal medium and a liquid crystal display using the same. The mixture for liquid crystal medium comprises: at least one anisotropic liquid crystal material and two polymerizable monomers which will polymerize under UV irradiation. The weight percentage of the polymerizable monomers accounts for 0.1% to 1% of the total mixture for liquid crystal medium. In the mixture for liquid crystal medium and a liquid crystal display using the same according to the present invention, by using two or more polymerizable monomers which will polymerize under UV irradiation and the appropriate content ratio, the polymer bump with small size and good uniformity can be obtained within the mixture for liquid crystal medium after the polymerization, which avoids the bad liquid crystal alignment and the light spot occurred at the dark state of the liquid crystal panel, and then increases the response rapid of the liquid crystal panel to obtain high contrast ratio and stable mass production.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Method of making high loft nonwoven

InactiveUS20060076106A1Quality improvementIncrease ratingsLamination ancillary operationsLaminationPolymer scienceNatural fiber

Owner:SYLVAN CHEM CO

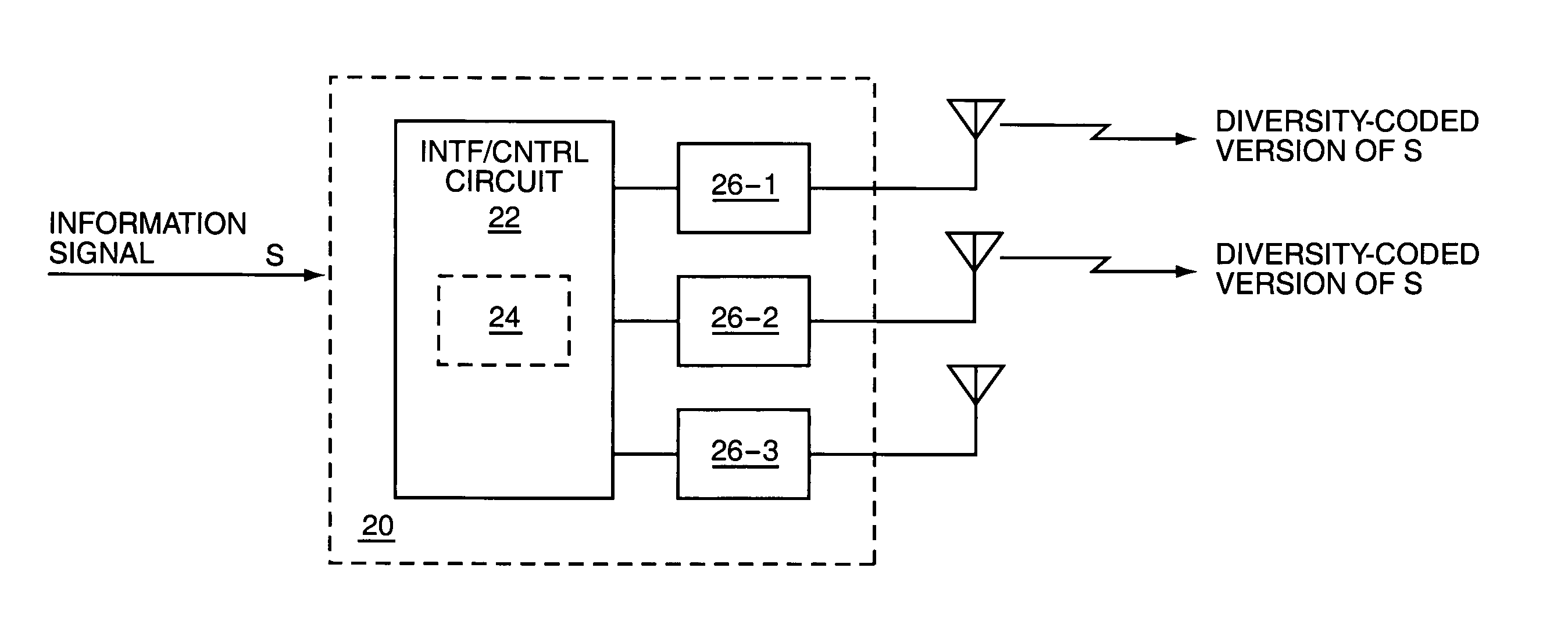

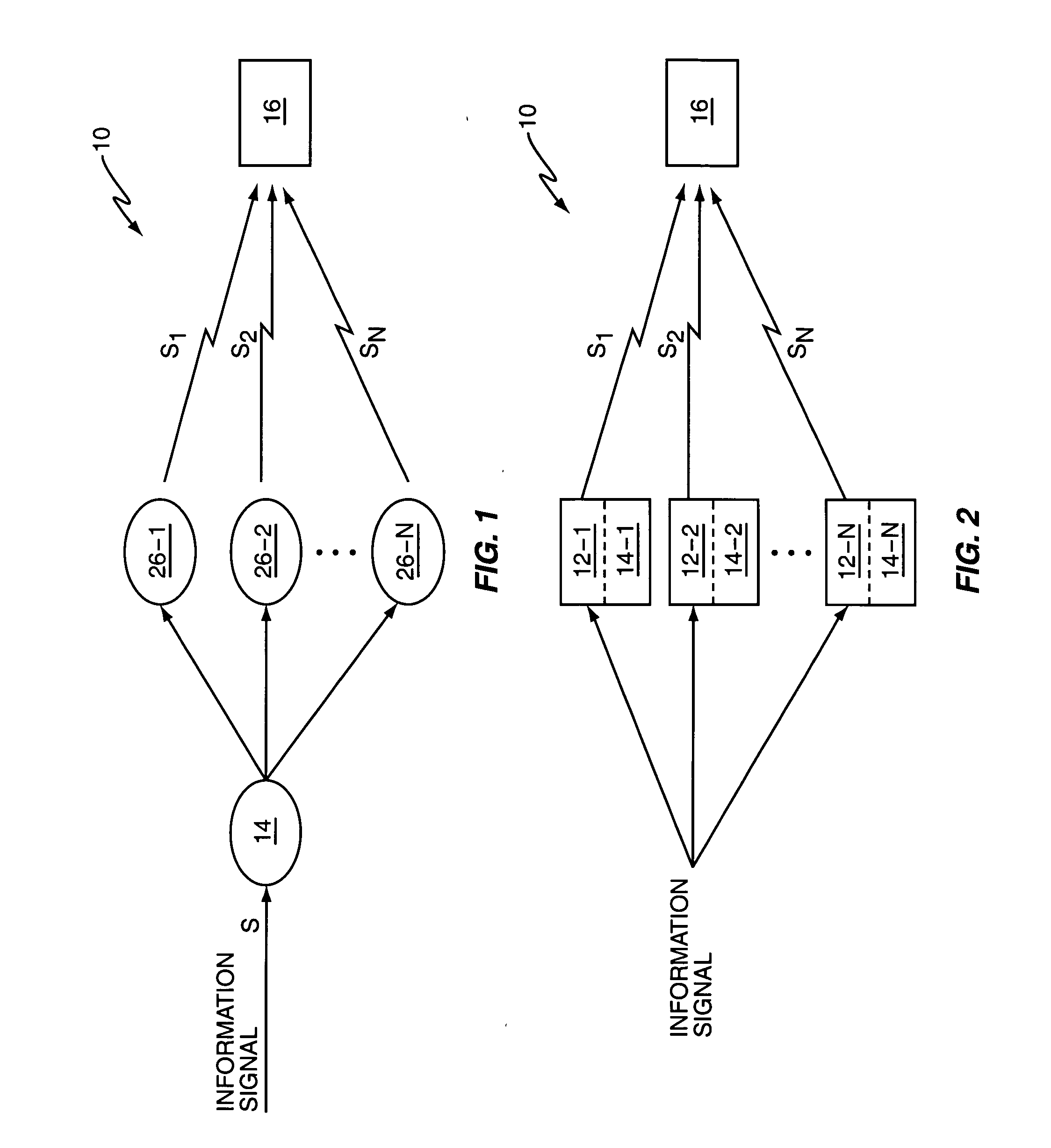

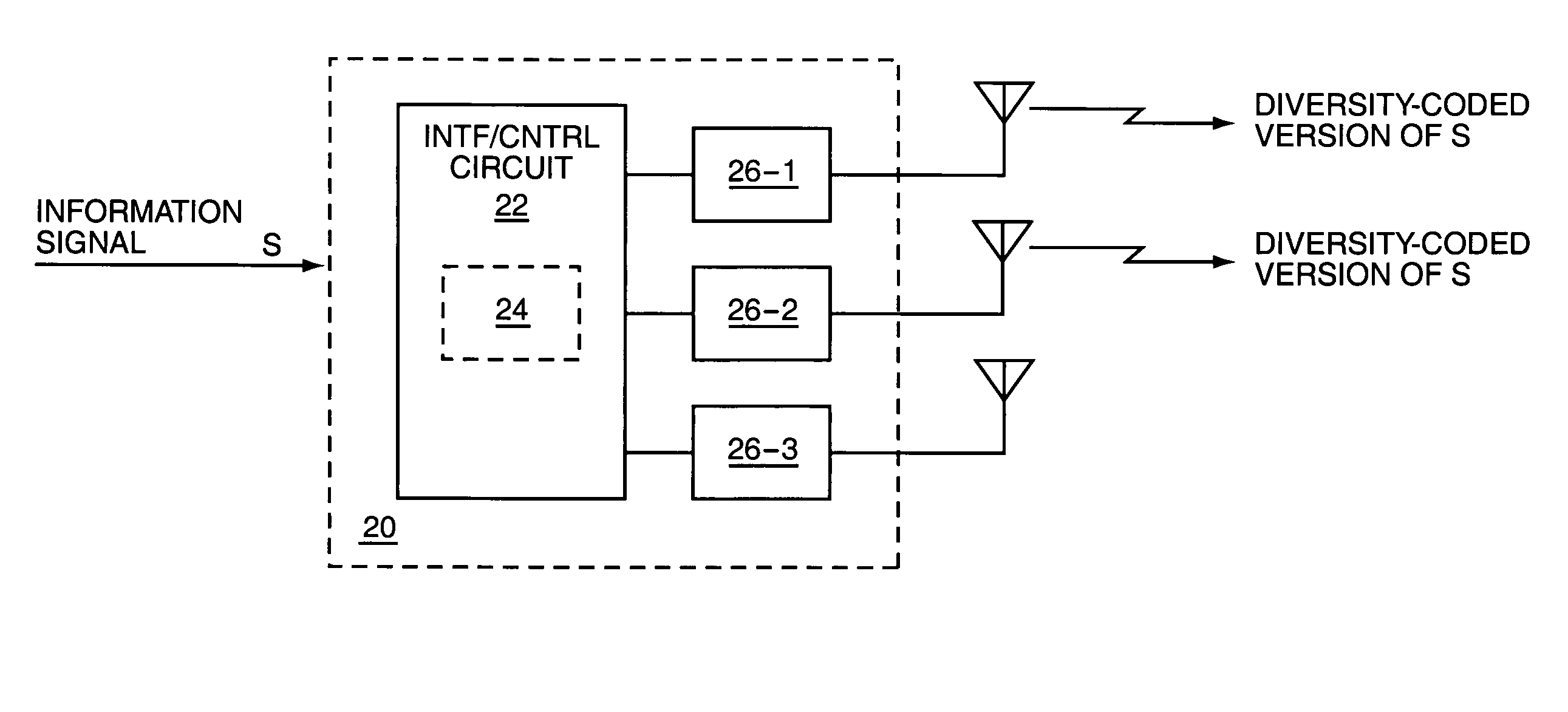

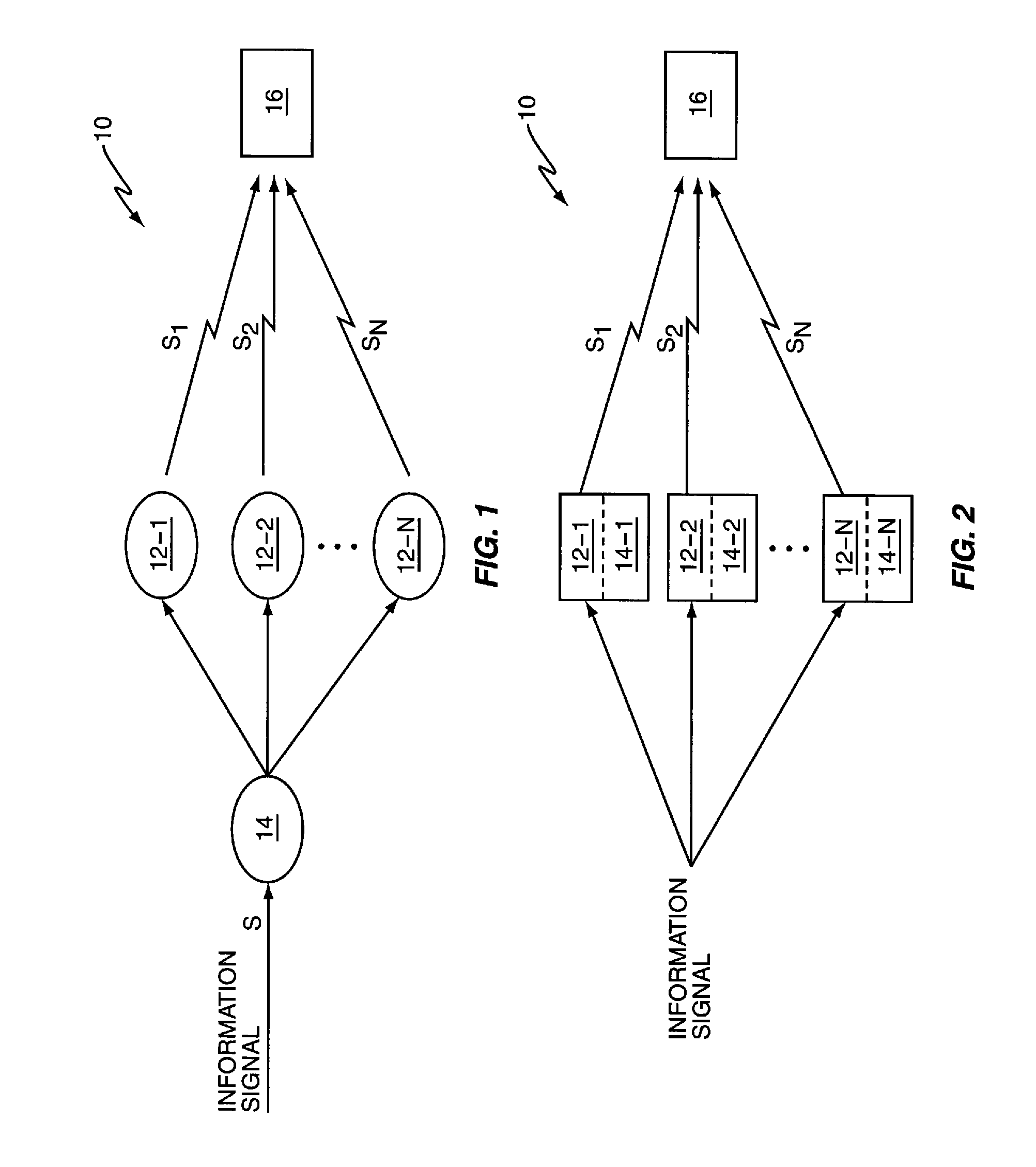

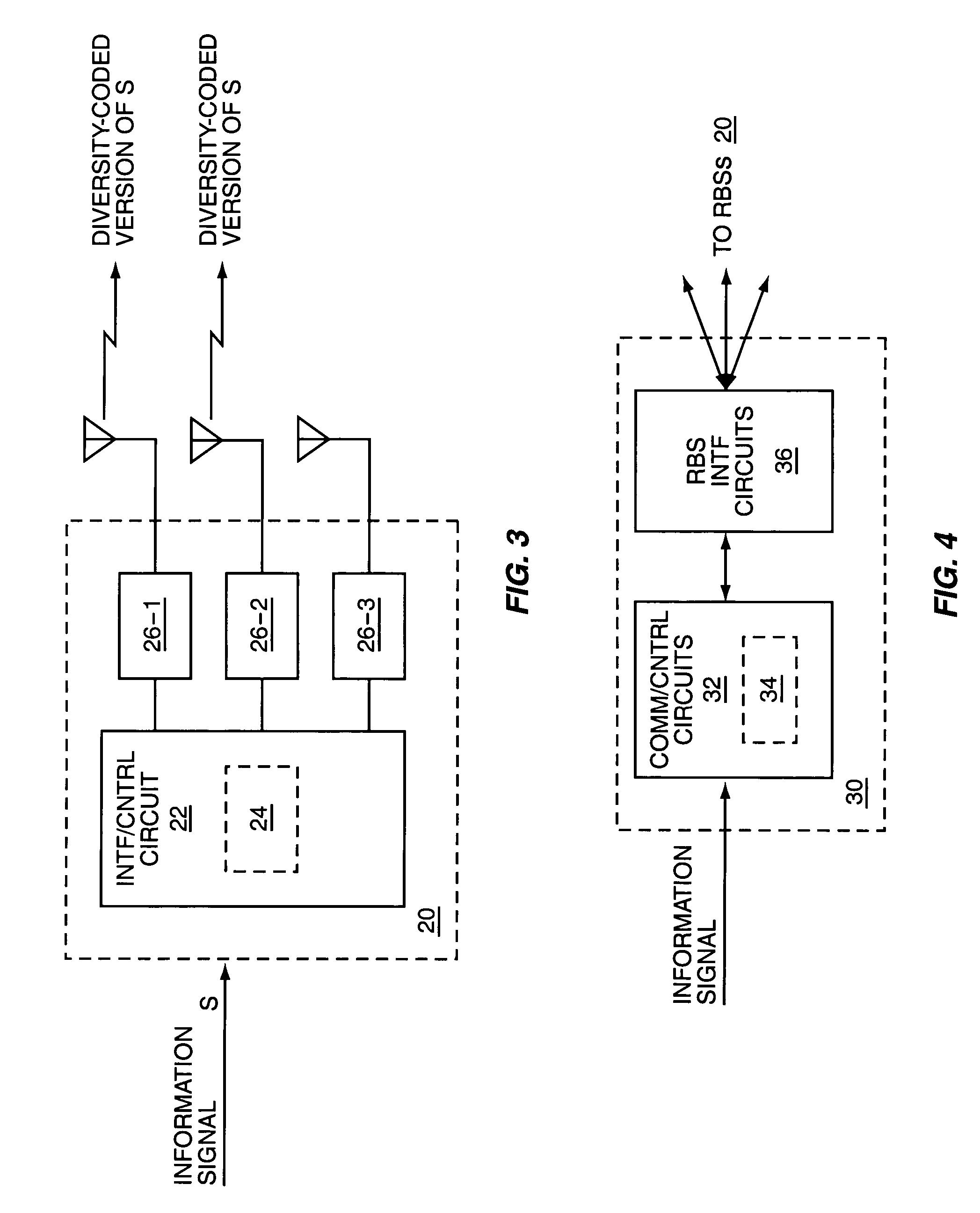

Distributed transmit diversity in a wireless communication network

ActiveUS20060233275A1Strength can be balancedIncrease diversity gainSpatial transmit diversityModulated-carrier systemsCell siteBroadcast multicast

A wireless communication network is configured to provide distributed diversity transmissions, wherein different diversity-coded versions of the same information signal are transmitted from each of two or more network sectors. The diversity-coded versions of the information signal are based on space-time or space-frequency codes, and the information signal may comprise a dedicated channel signal targeted to an individual user or a broadcast signal targeted to one or more users. Thus, spaced-apart network transmitters, which may be located at the same cell site, or at different cell sites, are configured to transmit diversity-coded versions of a given information signal and, in this manner, the advantages of space-time and / or space frequency transmission coding may be applied across multiple sectors of a communication network. Such transmissions may be used to improve soft and softer handoff reception of dedicated channel signals, and to improve reception of Broadcast-Multicast Services (BCMCS) signals, or the like.

Owner:TELEFON AB LM ERICSSON (PUBL)

Faced finished fabrics containing immobilized fibers

InactiveUS6230376B1Highly cost-effectiveEliminates pillingFibre treatmentFilament handlingUltimate tensile strengthBiomedical engineering

Owner:MILLIKEN & CO

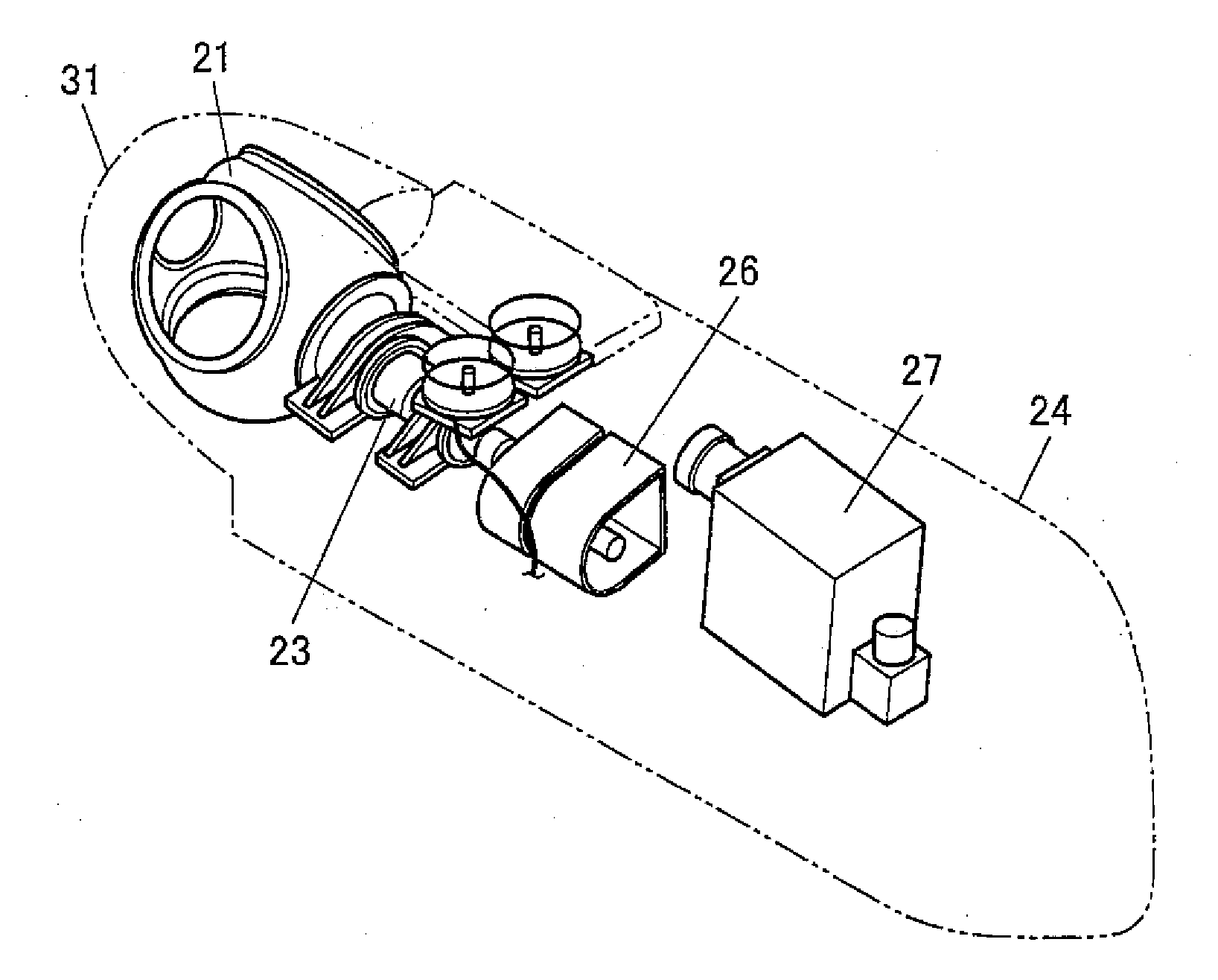

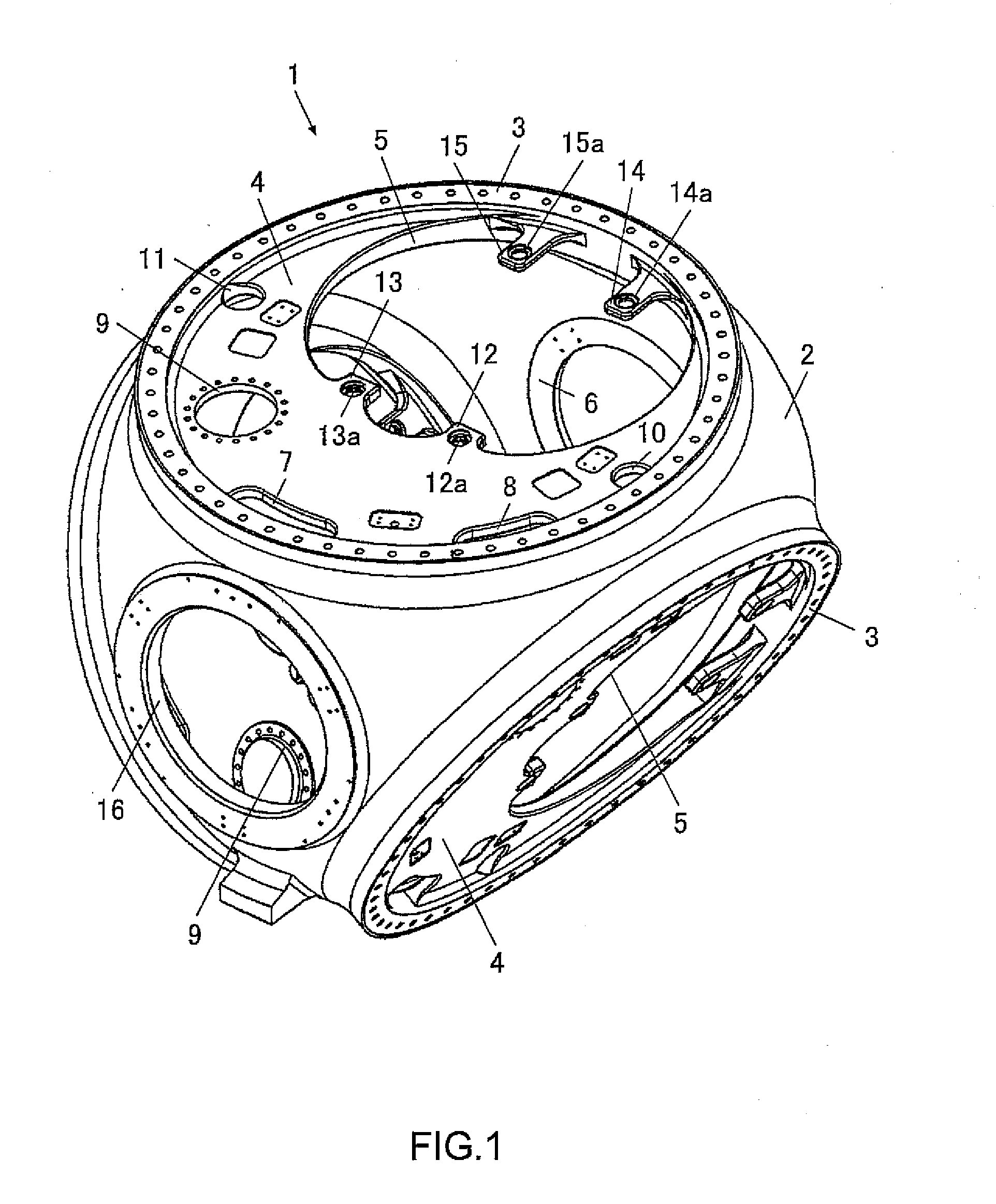

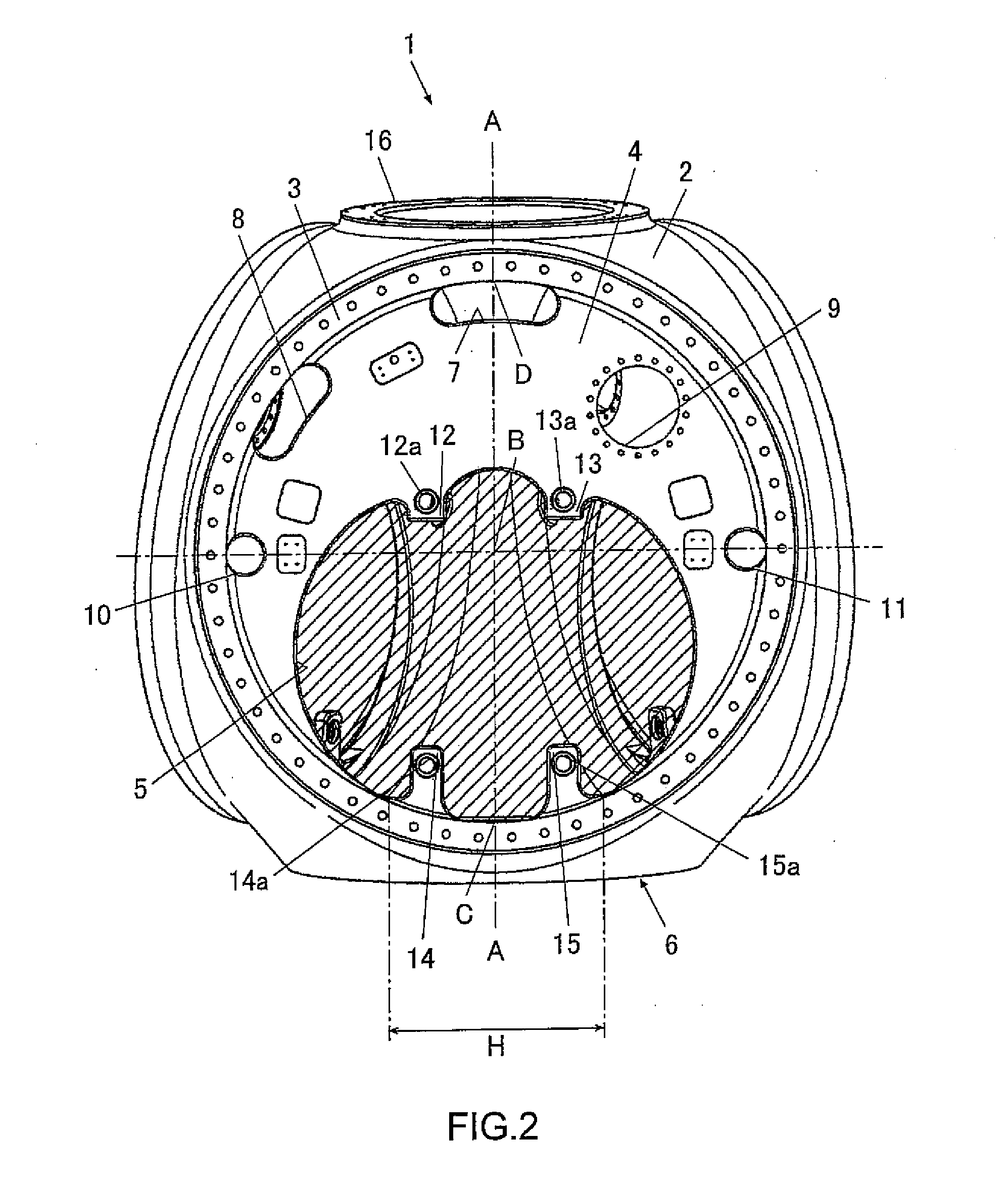

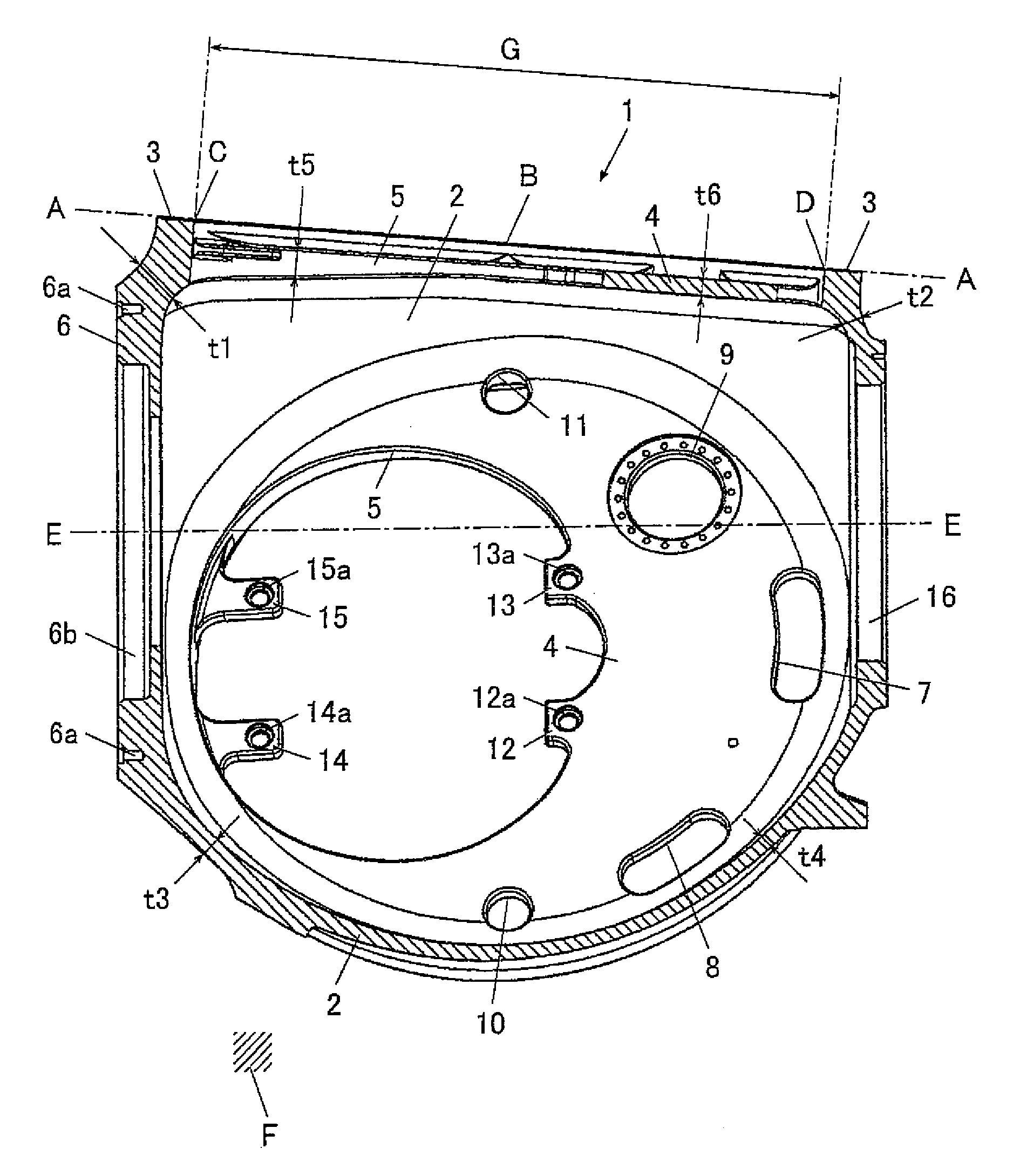

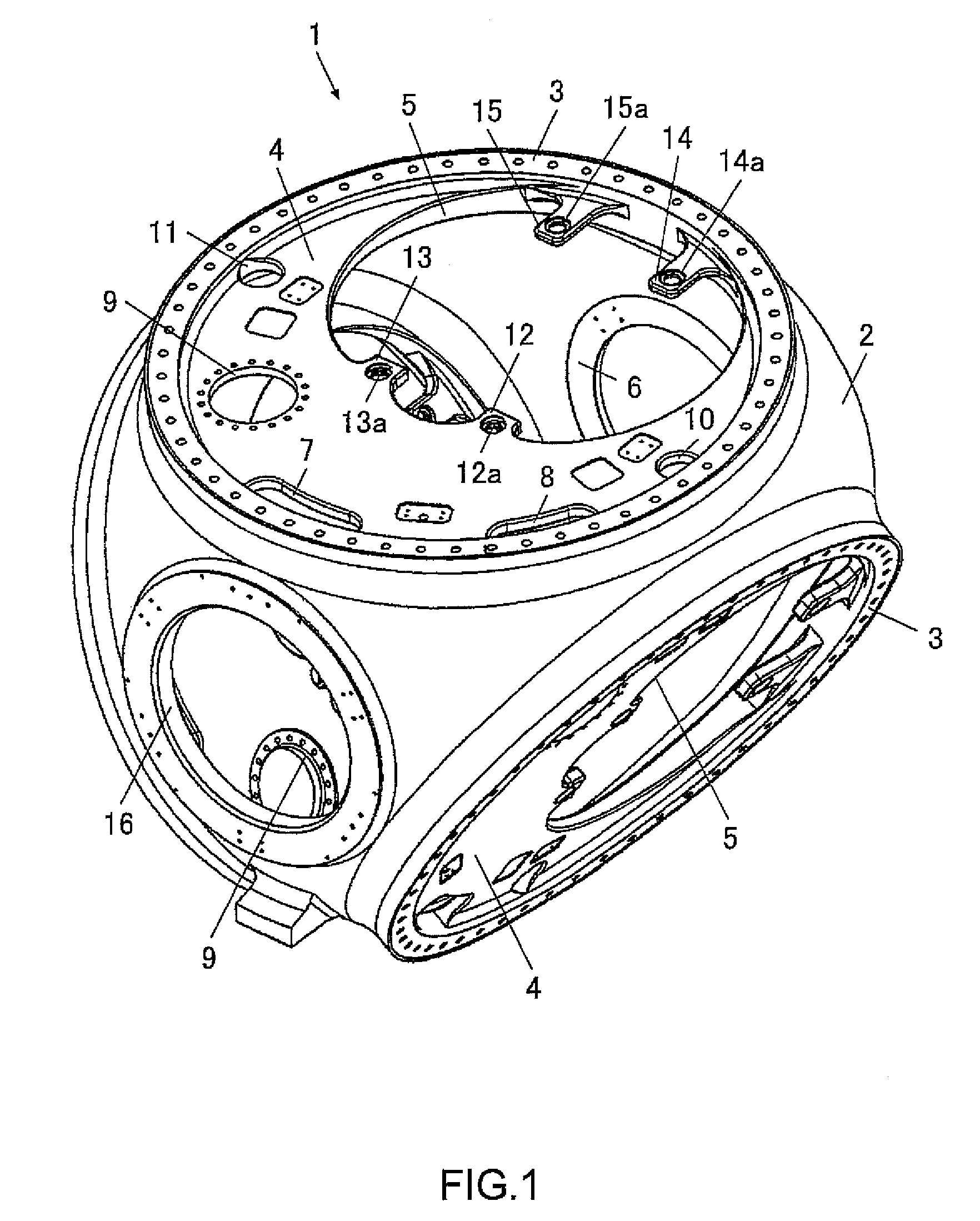

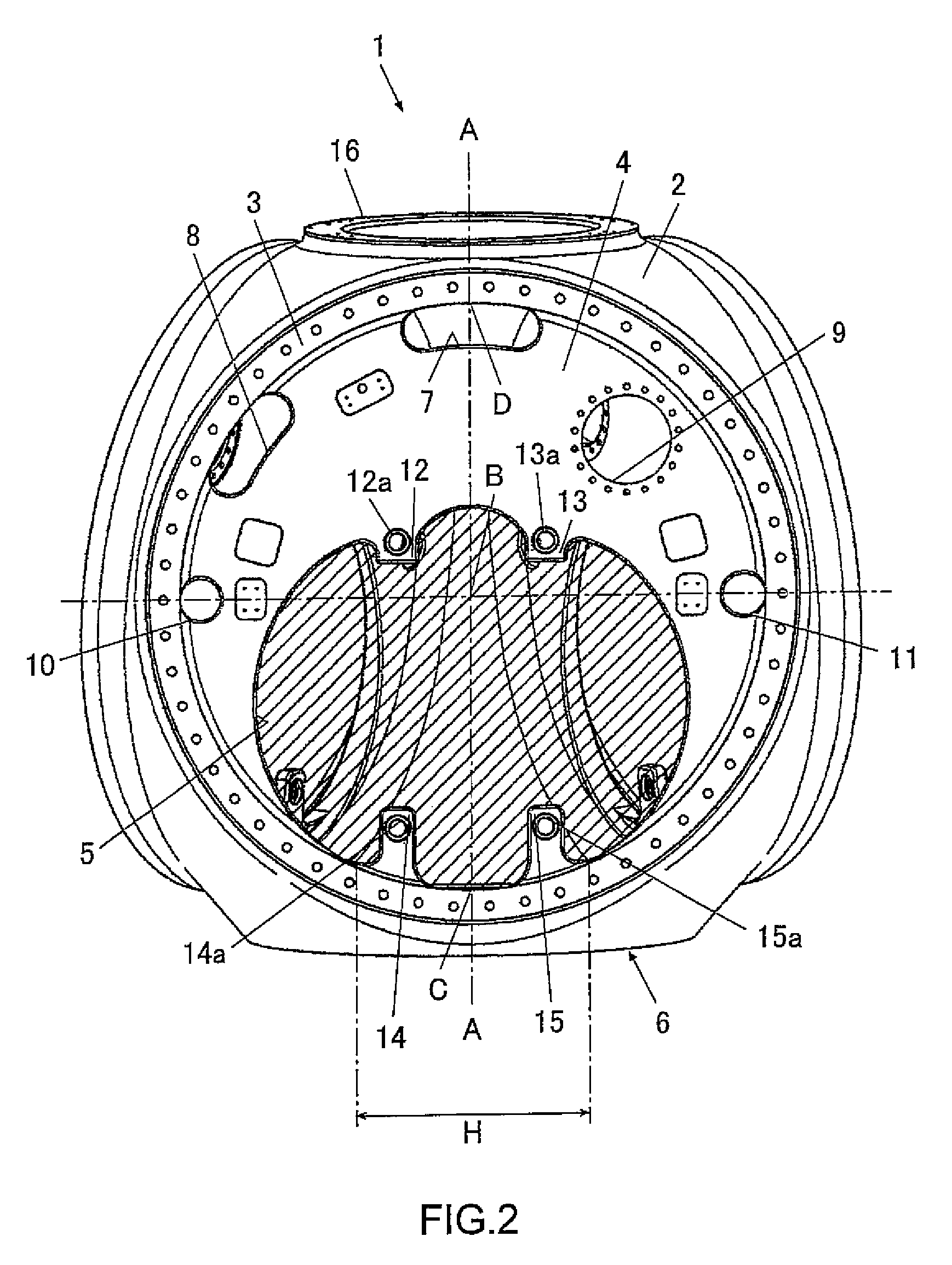

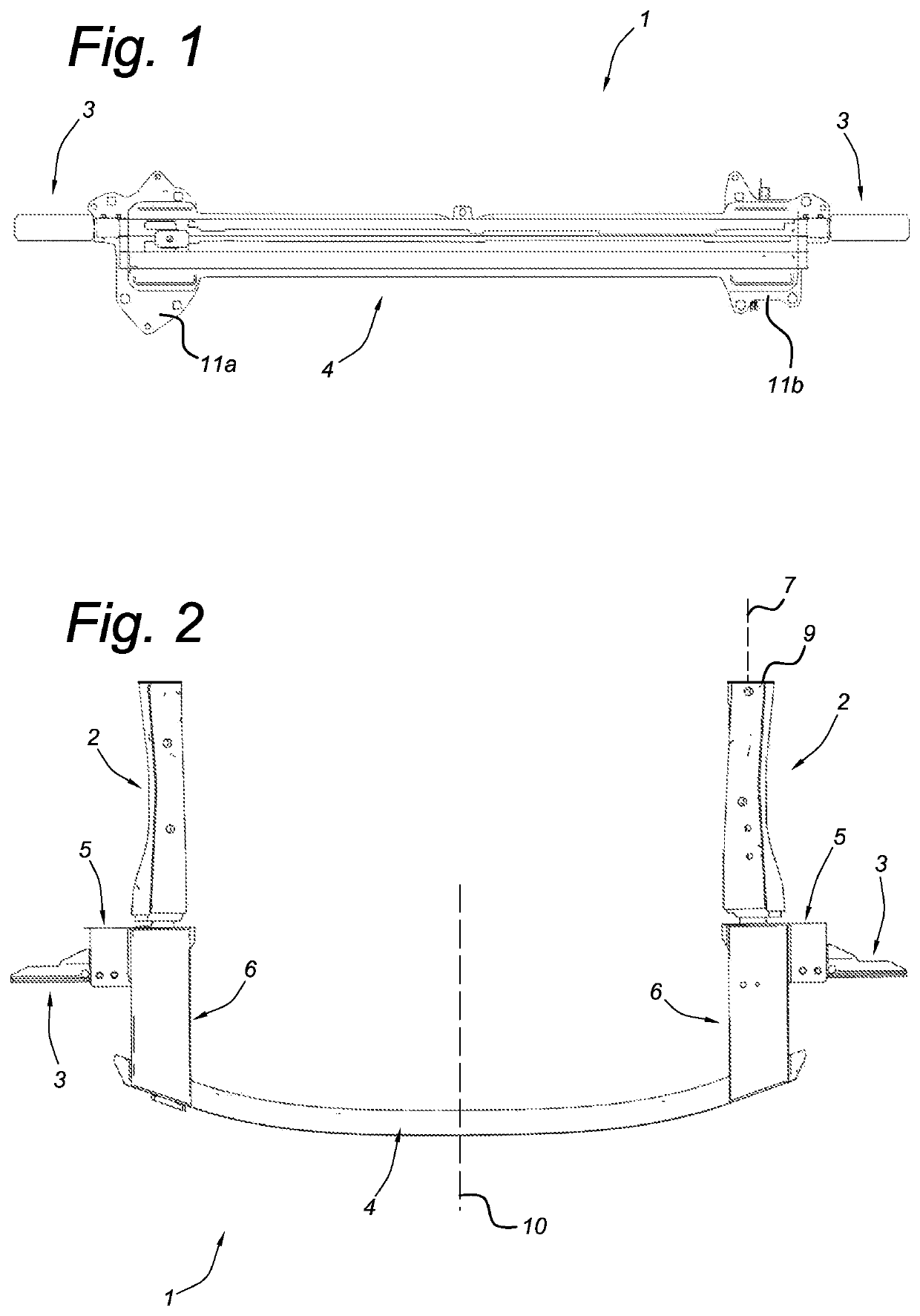

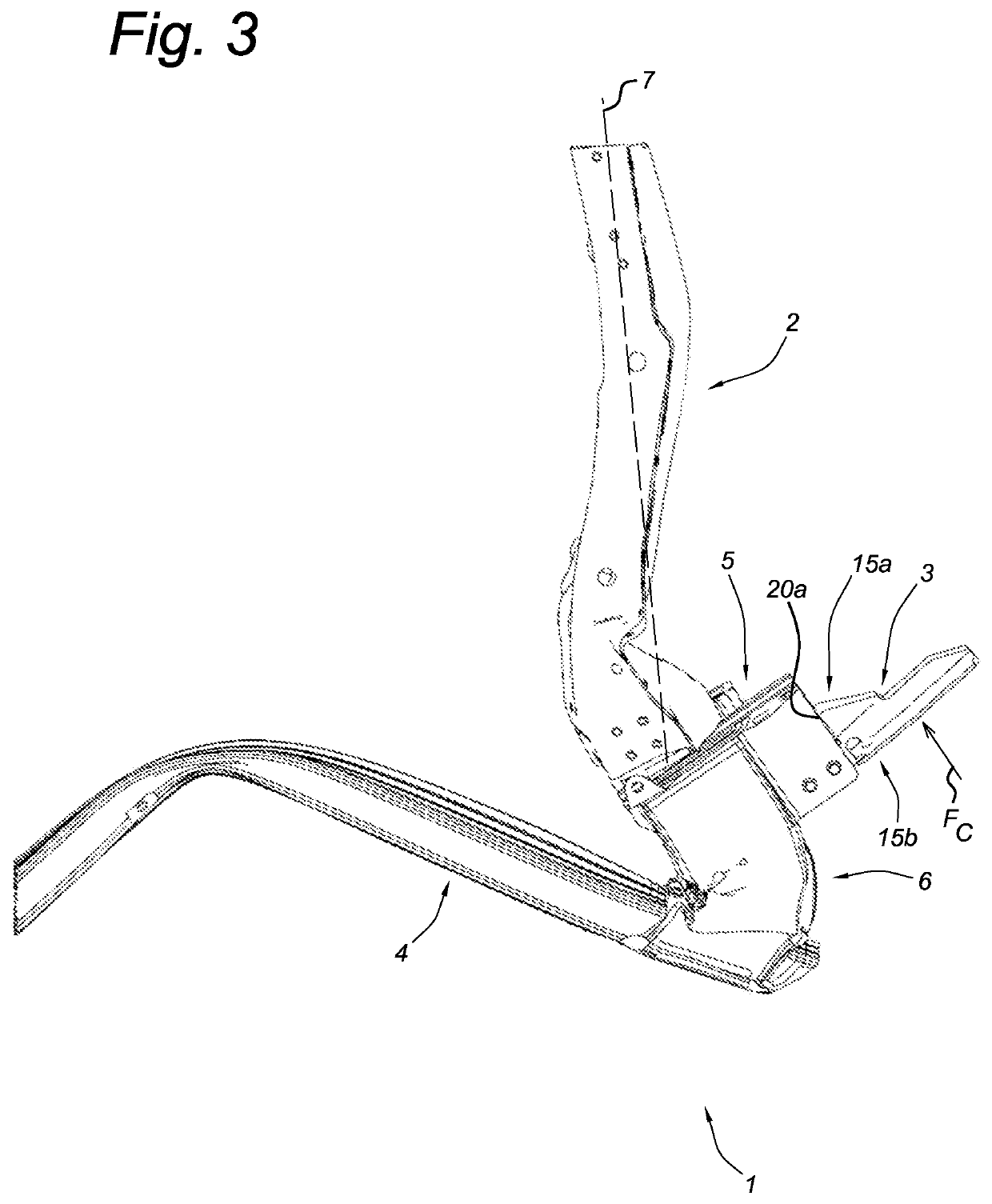

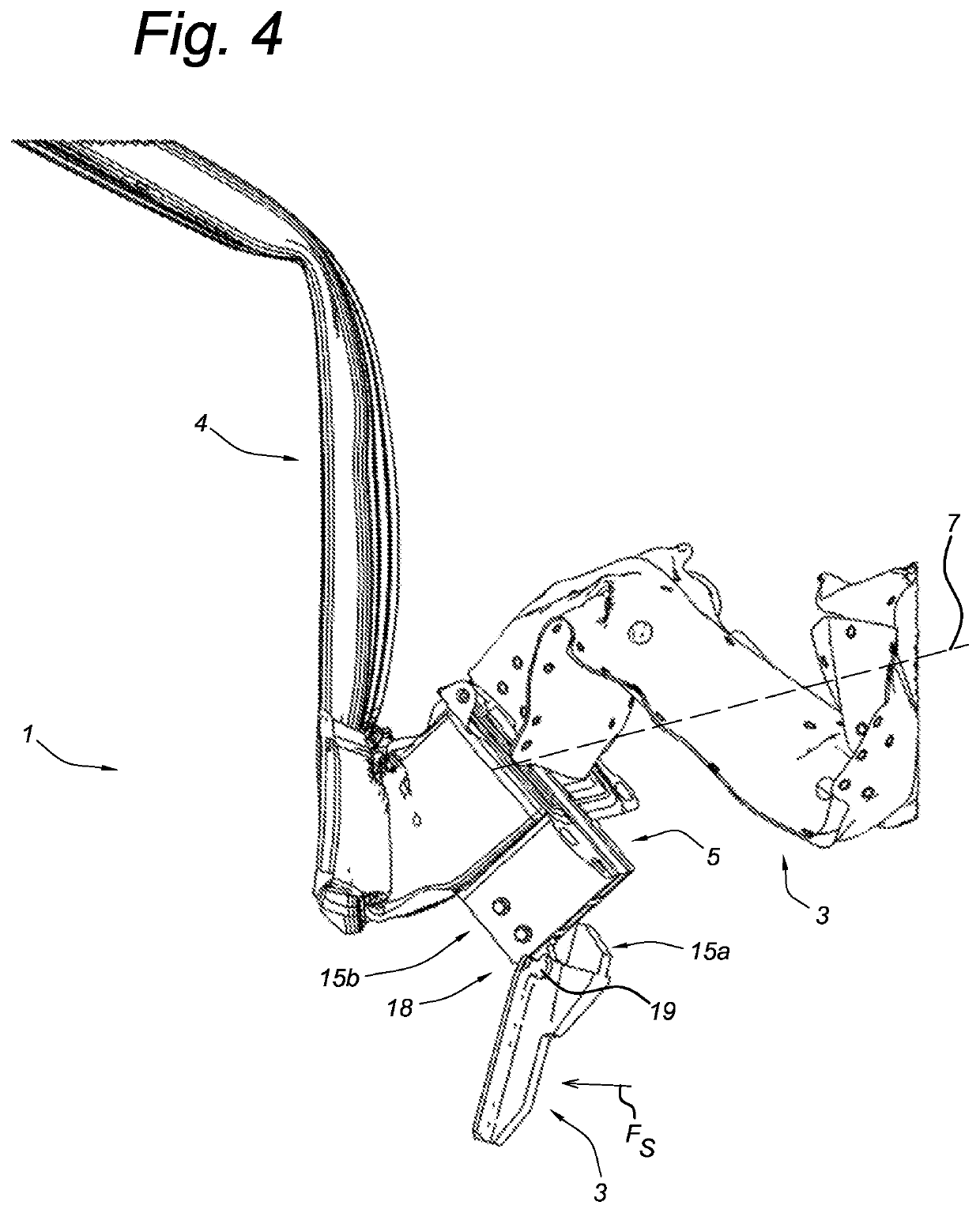

Hub for a horizontal axis wind turbine

ActiveUS20080118356A1Uniform forceStrength can be balancedPump componentsWind motor assemblyHorizontal axisTurbine

To provide a lightweight hub of a horizontal axis wind turbine with a balanced strength, the hub 1 related to the present invention comprises a reinforcement plate 4 coupled to the spherical shell 2 on the peripheral edge in the round region G inside the circular flange 3 used to secure a blade. In addition to being off-center at the point C side, an off-center opening 5, that contains the center B of the region G, is formed in the region G. The reinforcement plate 4 is formed at the remainder portion of the region G after removing the off-center opening 5. By means of an unequal arrangement of the reinforcement plate 4 and the opening 5 on the inside of the circular flange 3, severe imbalances due to the casting of the hub 1 are cancelled and a balanced strength is obtained, making it also easier to reduce the weight.

Owner:HITACHI LTD

Range-dyed face finished fabrics exhibiting non-directional surface fiber characteristics

InactiveUS6716775B1Highly cost-effectiveEliminates pillingPattern makingLayered productsFiberTime-Consuming

Range-dyed fabrics that possess excellent hand characteristics and simultaneously exhibit substantially nondirectional appearances are provided. Such a combination permits the production and utilization of an extremely comfortable apparel fabric that can be attached to any other similar type of fabric to form a target apparel article without the time-consuming need to align such component fabrics to ensure an overall aesthetic appearance is met for the target apparel article. In general, such a fabric is produced through the initial immobilization of individual fibers within target fabrics and subsequent treatment through abrasion, sanding, or sueding of at least a portion of the target fabric. Such a procedure produces a fabric of short pile height and desirable hand. Upon range-dyeing the target fabric exhibits the extra benefit of nondirectional surface characteristics. The ability to produce such specific fabrics without the need for jet-dyeing thus provides a significant cost advantage to the manufacturer and consumer.

Owner:MILLIKEN & CO

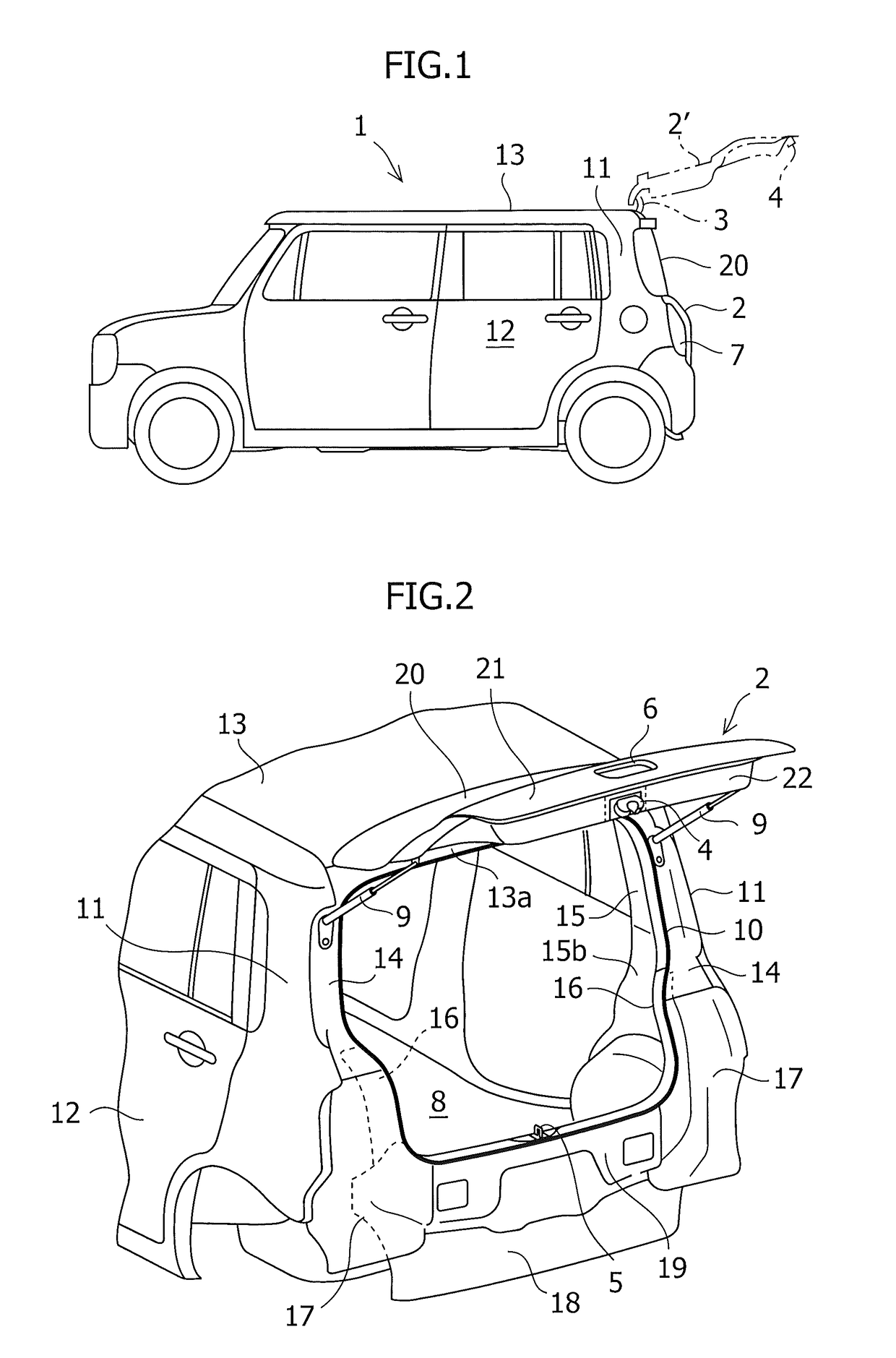

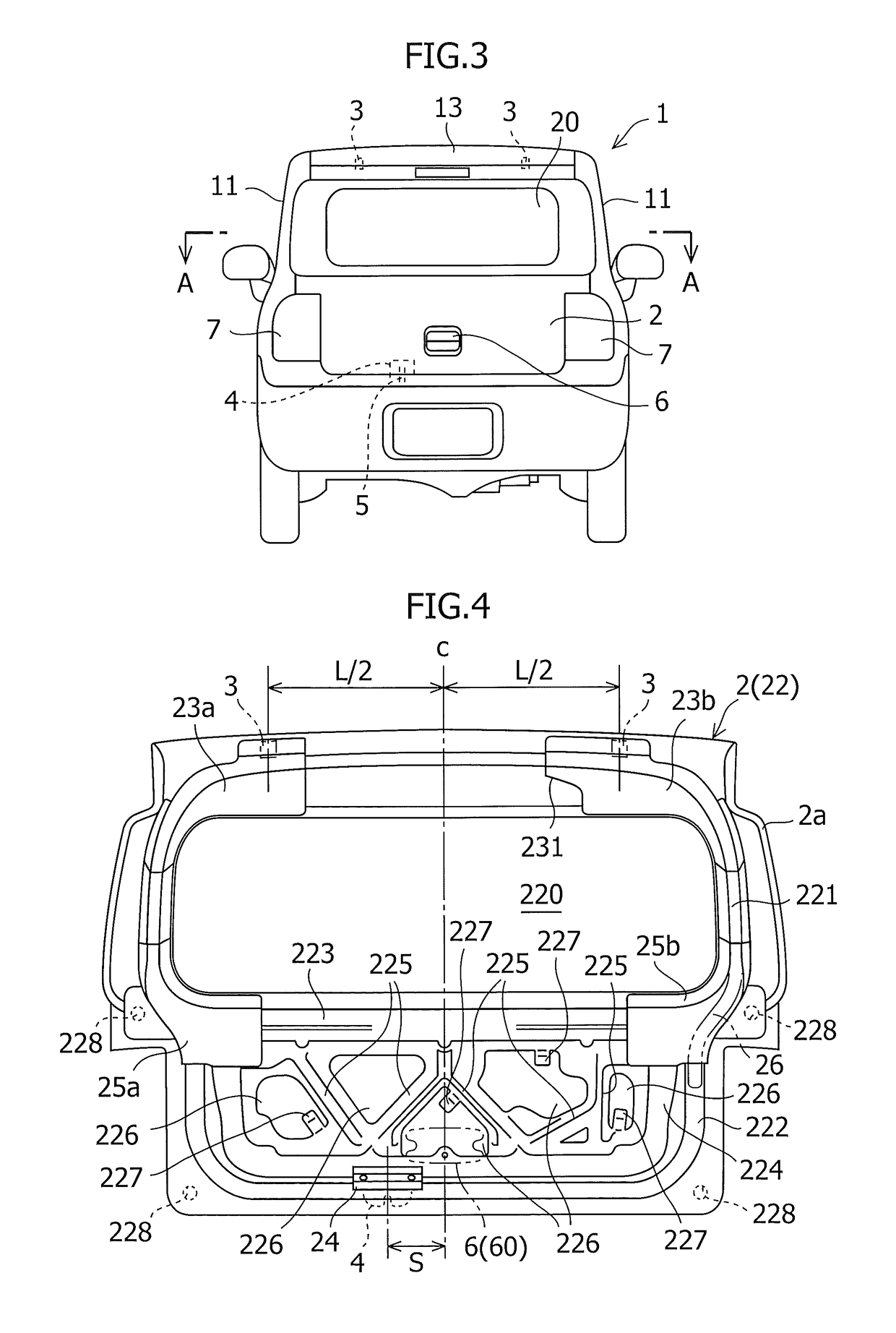

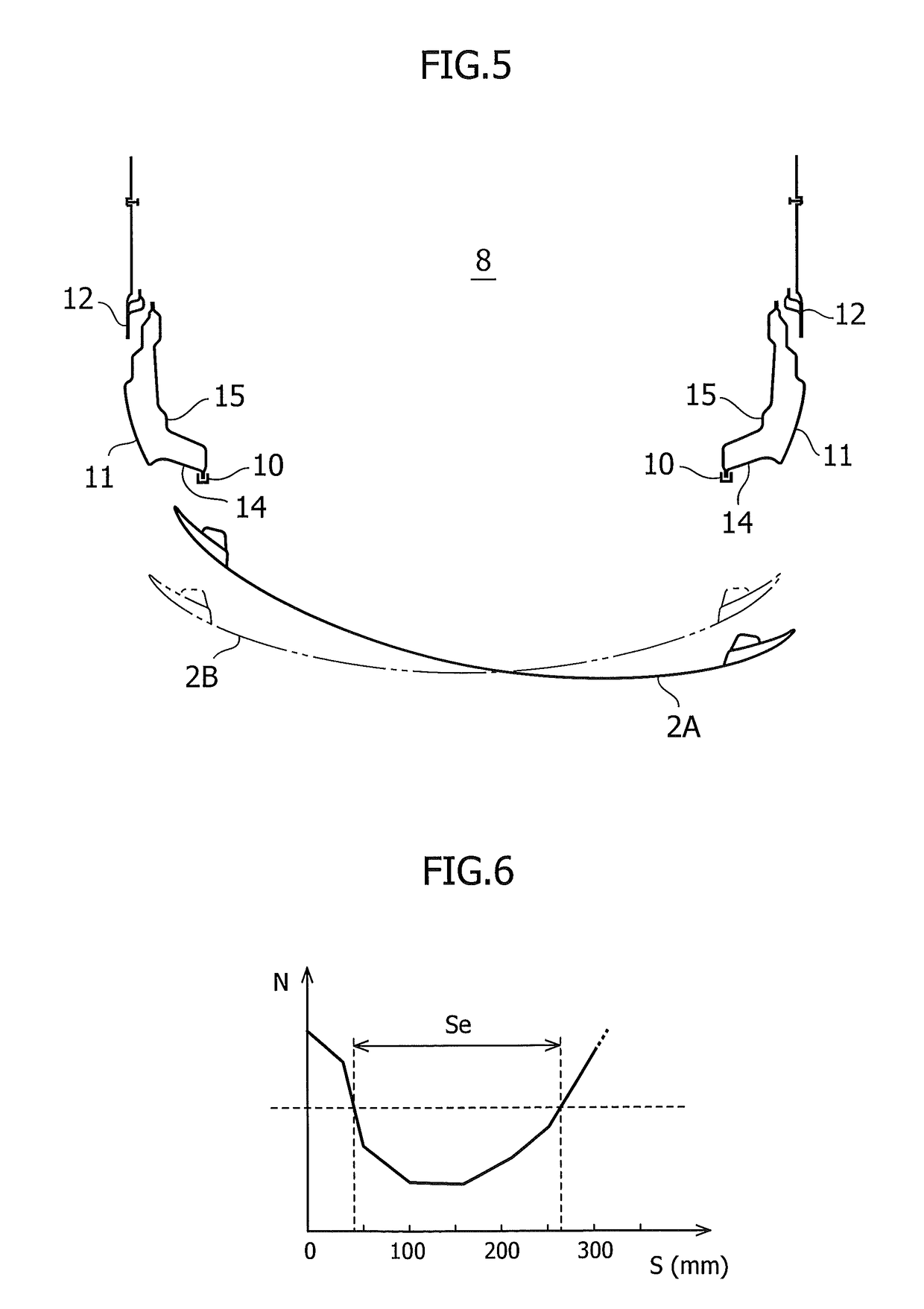

Vehicle body rear structure

InactiveUS8469439B2Reduce noiseImprove economyEngine sealsNoise-prevention/anti-rattling lockingEngineeringBack door

A vehicle body rear structure has a back door for opening and closing a rear opening of a vehicle body, and a latch engageable with and disengageable from a striker fixed in a lower portion of the rear opening, the back door being pivotally connected to an upper portion of the rear opening via two hinges provided so as to be spaced in the vehicle width direction, and the latch being provided in a lower end portion of the back door, the latch and the striker are offset from the center to the side in the vehicle width direction.

Owner:SUZUKI MOTOR CORP

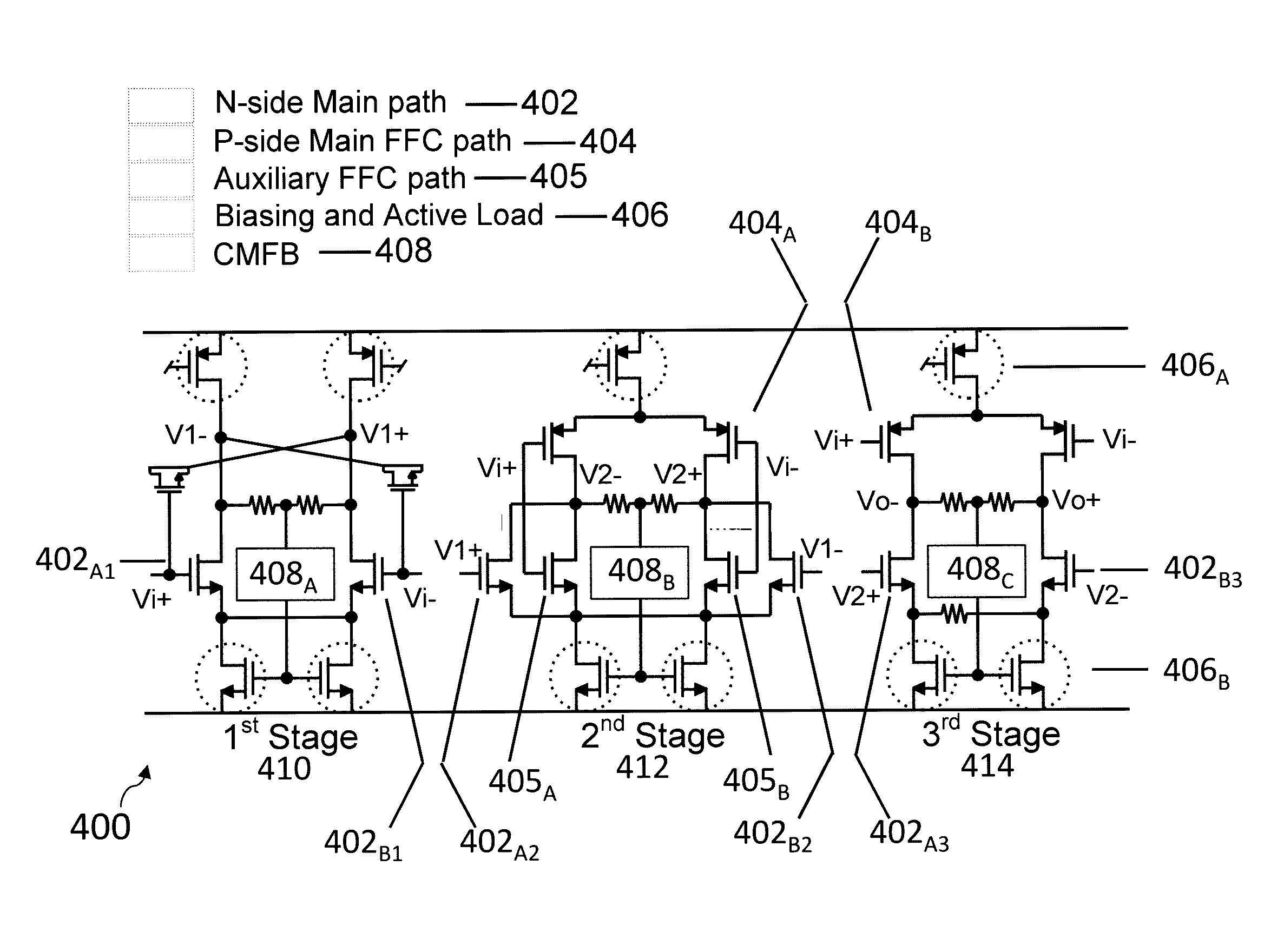

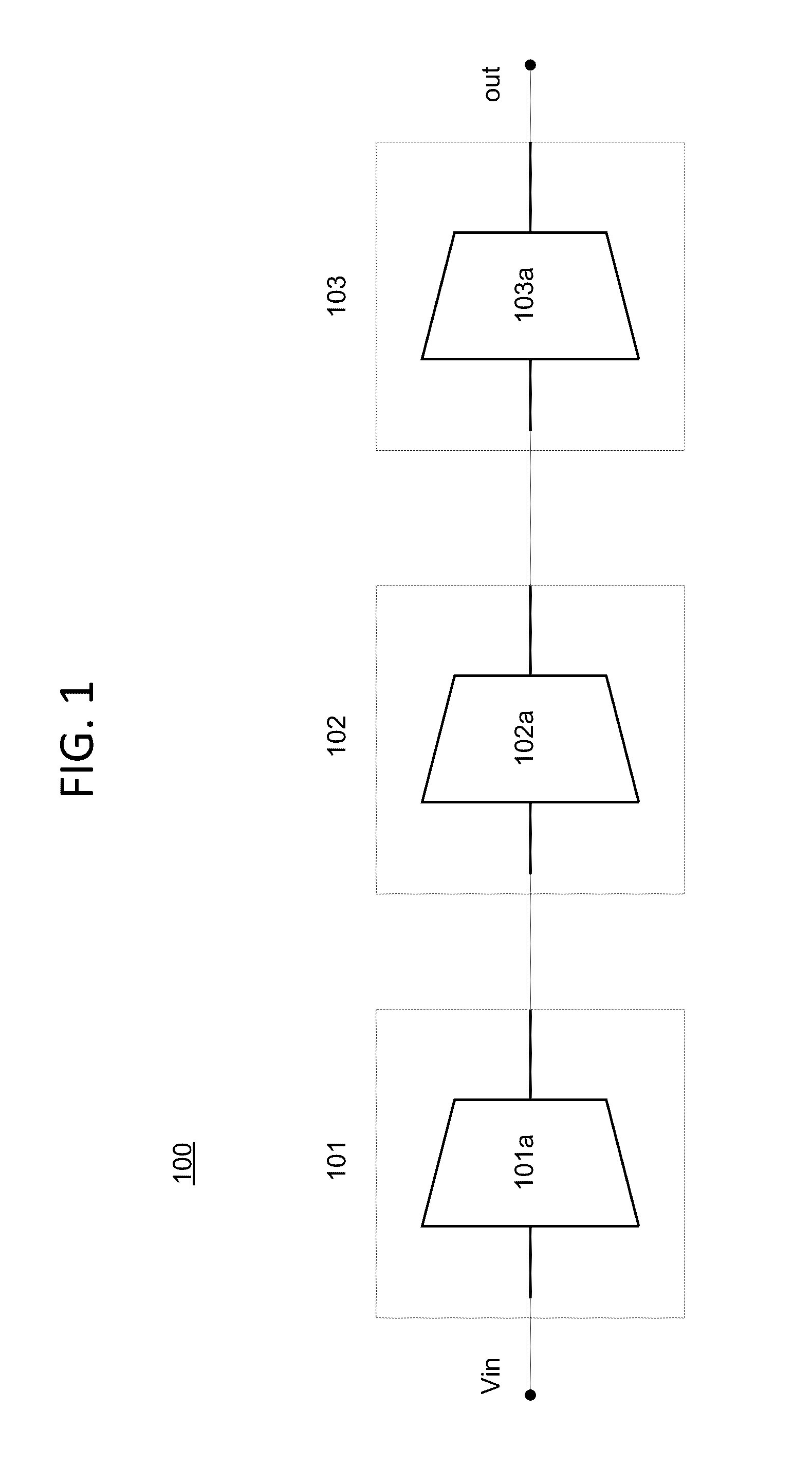

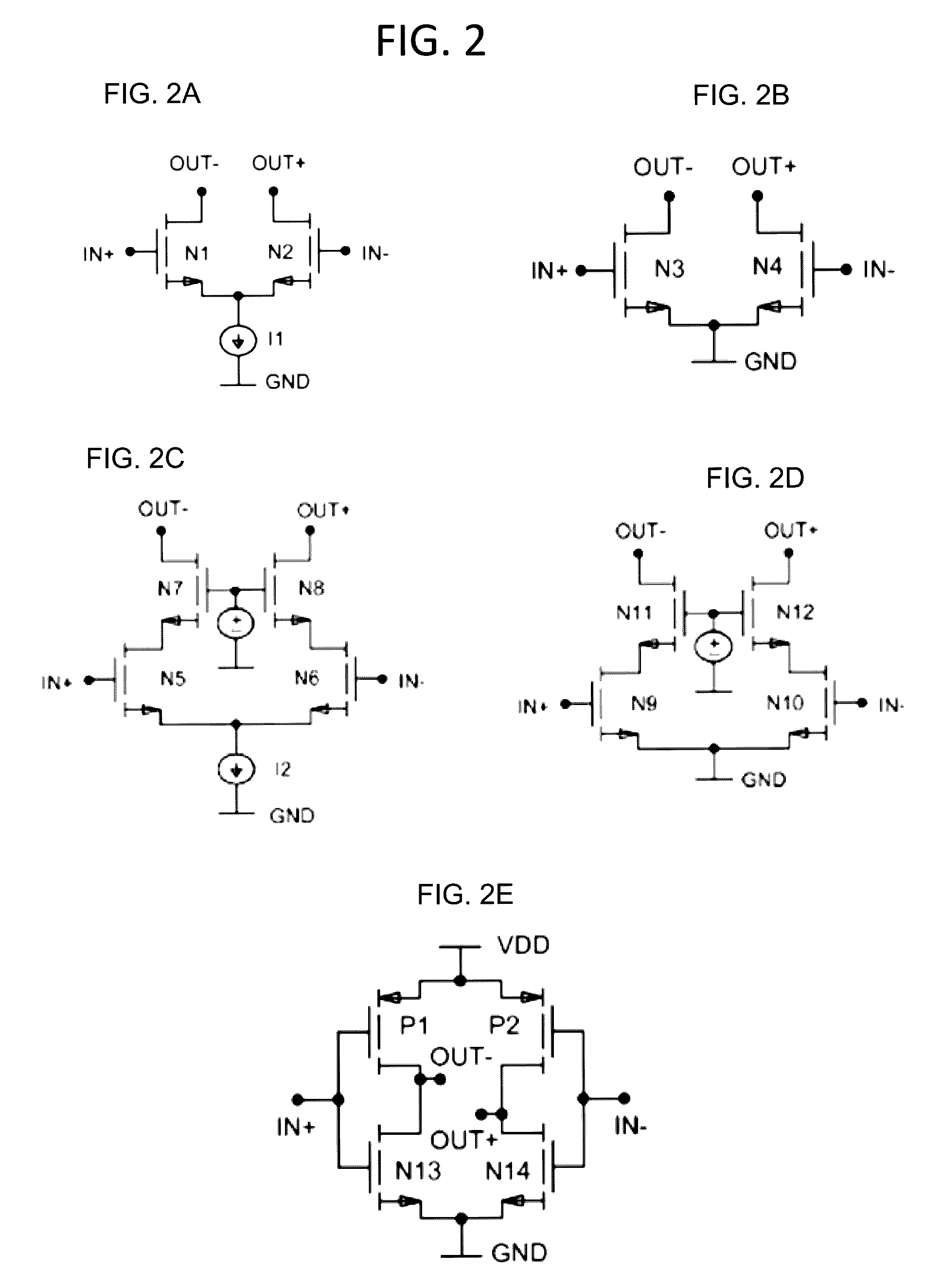

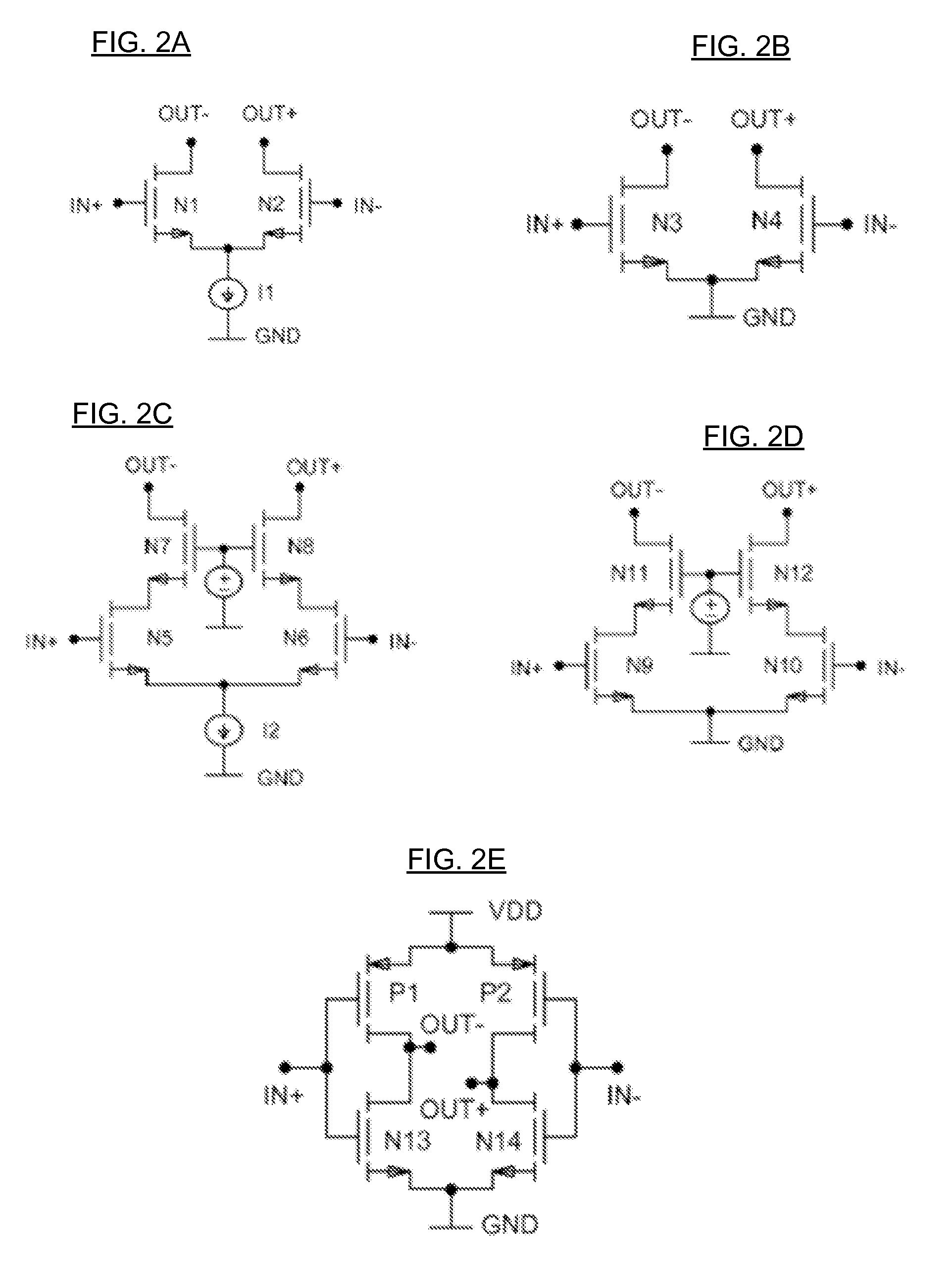

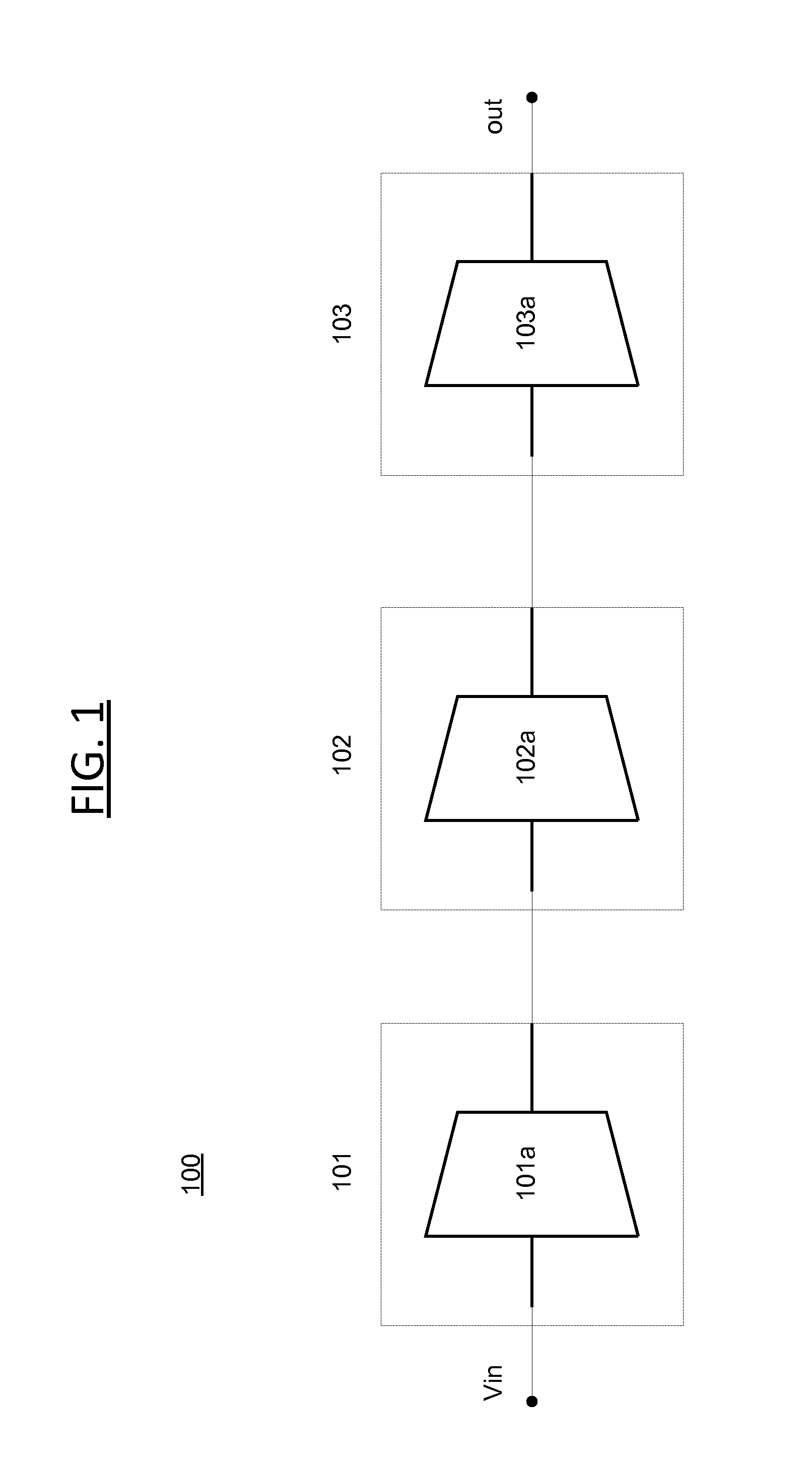

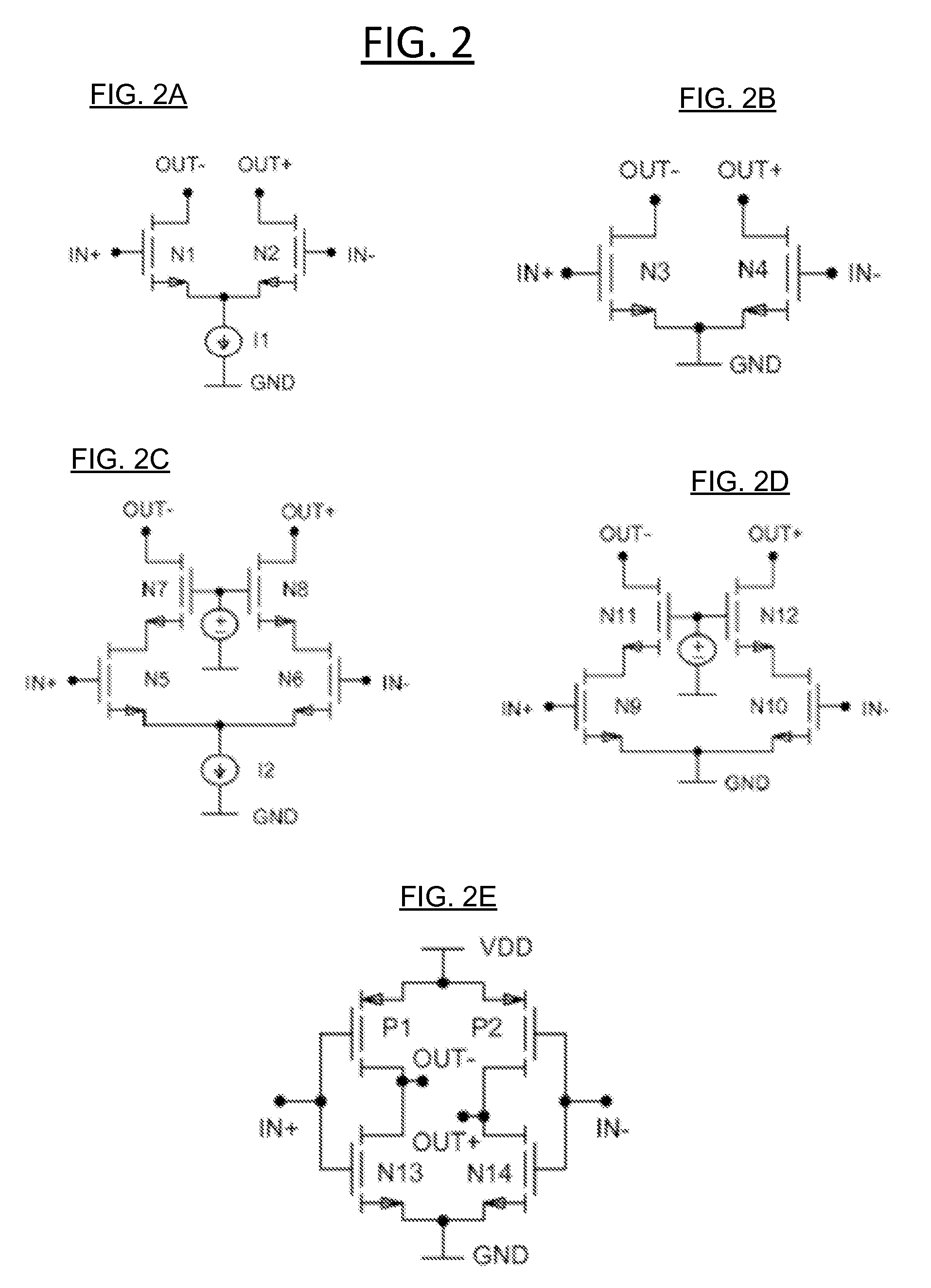

Implicit feed-forward compensated op-amp with split pairs

InactiveUS9577593B2Improve performanceHigh gain and desired phase marginPower amplifiersAmplifier modifications to reduce detrimental impedenceCMOSAudio power amplifier

Disclosed are systems implementing an implicit Feed-Forward Compensated (FFC) op-amp, where the main FFC port is realized by the P-side of the CMOS input structure of the 2nd and 3rd stages of the op-amp, while the main signal path is through the N-side. According to some embodiments, to balance the relative strengths of the main path and feed-forward paths, the 2nd-stage NMOS input pair is split into two pairs, one is used to route the main path while the other is used for auxiliary FFC. The disclosed implicit FCC op-amp is unconditionally stable with adequate phase lead. According to some embodiments, the disclosed op-amp, which may be a wide-band op-amp, can be used in highly linear applications operative at intermediate frequency (IF), such as signal buffers for high-performance data converters or radio-frequency (RF) modulators and demodulators, continuous-time (CT) filters or sigma-delta data converters.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Implicit feed-forward compensated op-amp with split pairs

InactiveUS20150295551A1High loop gainHigh stability performanceDifferential amplifiersAmplifier detailsCMOSAudio power amplifier

Disclosed are systems implementing an implicit Feed-Forward Compensated (FFC) op-amp, where the main FFC port is realized by the P-side of the CMOS input structure of the 2nd and 3rd stages of the op-amp, while the main signal path is through the N-side. According to some embodiments, to balance the relative strengths of the main path and feed-forward paths, the 2nd-stage NMOS input pair is split into two pairs, one is used to route the main path while the other is used for auxiliary FFC. The disclosed implicit FCC op-amp is unconditionally stable with adequate phase lead. According to some embodiments, the disclosed op-amp, which may be a wide-band op-amp, can be used in highly linear applications operative at intermediate frequency (IF), such as signal buffers for high-performance data converters or radio-frequency (RF) modulators and demodulators, continuous-time (CT) filters or sigma-delta data converters.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

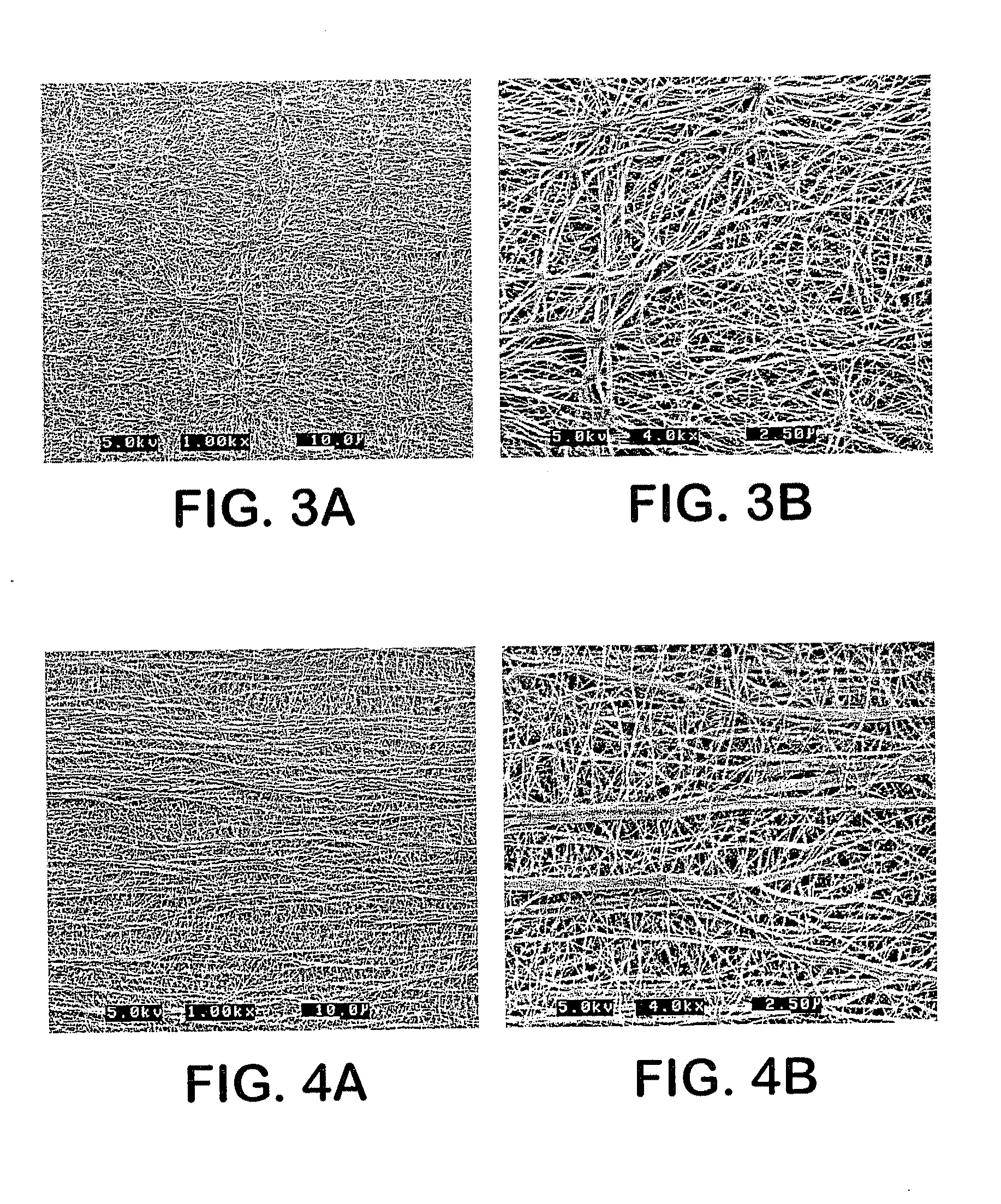

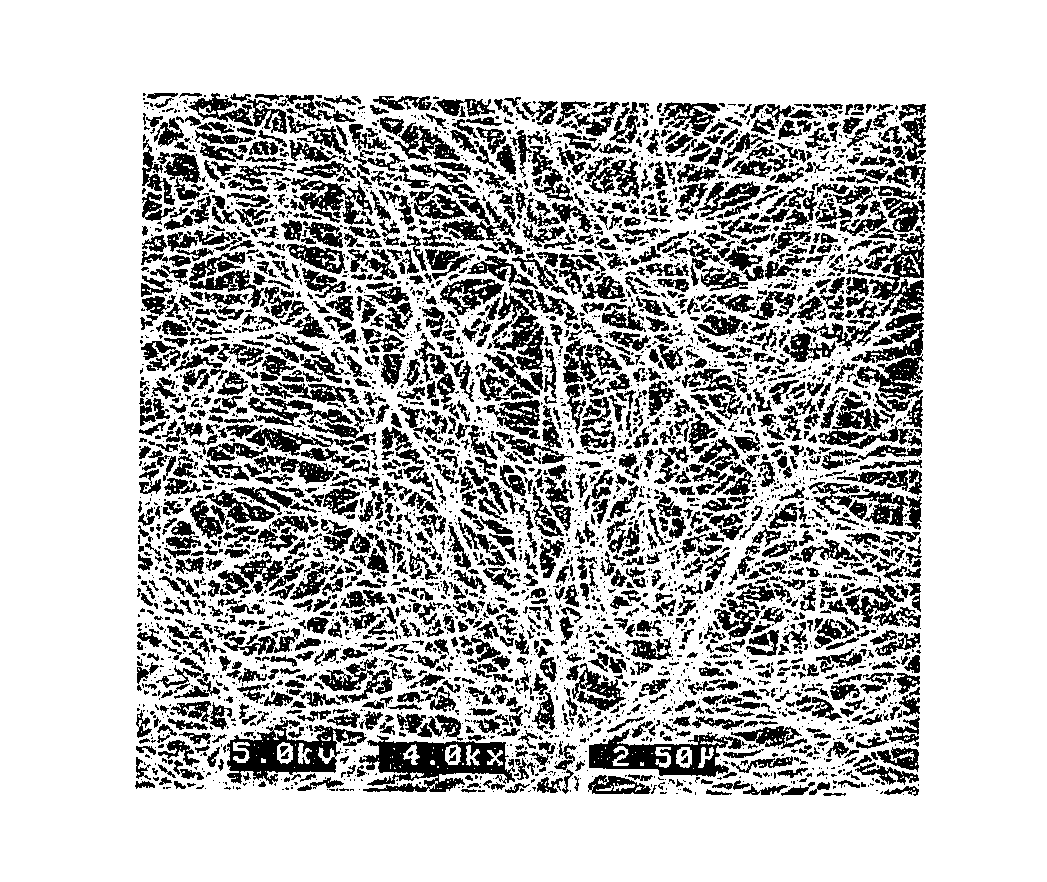

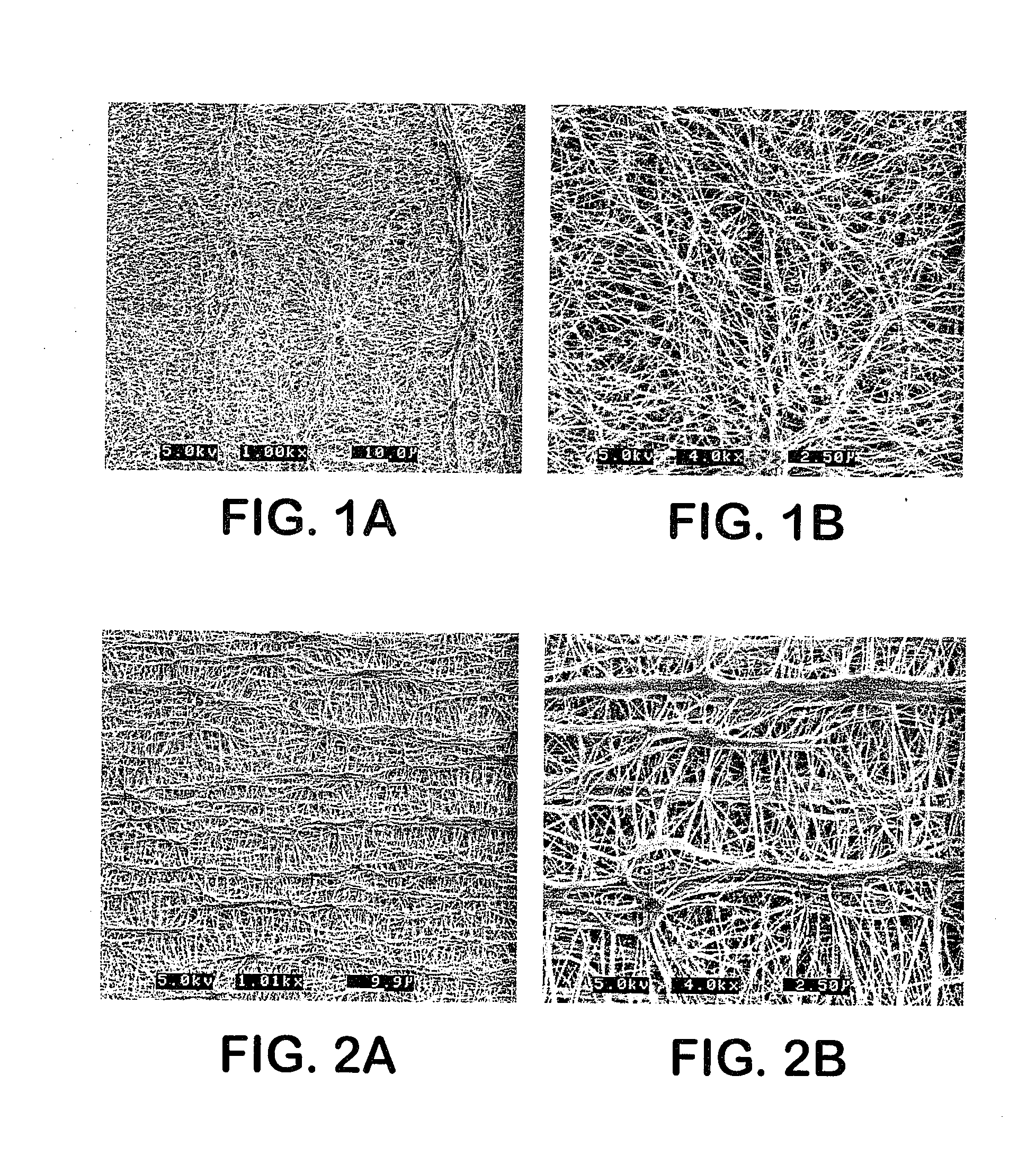

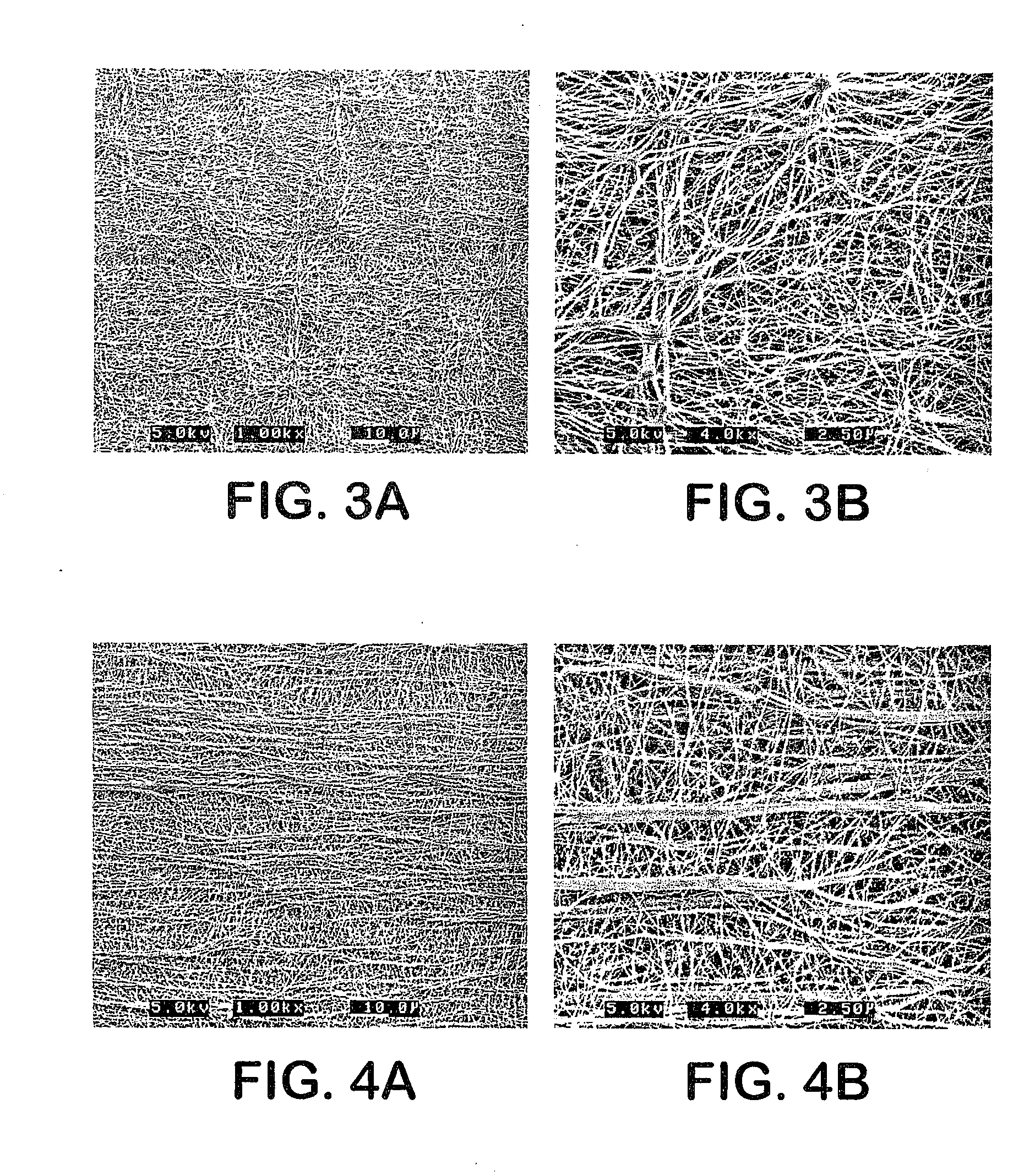

PTFE Membranes and Gaskets Made Therefrom

InactiveUS20100009180A1Improve mechanical propertiesStrength can be balancedDomestic sealsEngine sealsExpanded PTFEMechanical property

Improved expanded PTFE materials and improved gasket materials made therefrom, the gaskets being capable of forming a seal with greater bolt load retention than is possible with existing PTFE gaskets. The expanded PTFE membranes of the invention can be tailored to exhibit a matrix tensile strength in at least one direction of at least 25,000 psi, a matrix tensile strength ratio in two orthogonal directions of between 0.025 and 4, an orientation index of 50° or less, and a density of 2.0 g / cc or less. The improved gaskets exhibit improved mechanical properties such as high bolt load retention, low creep, high tensile strength, low stress to seal and high crystallinity index.

Owner:WL GORE & ASSOC INC

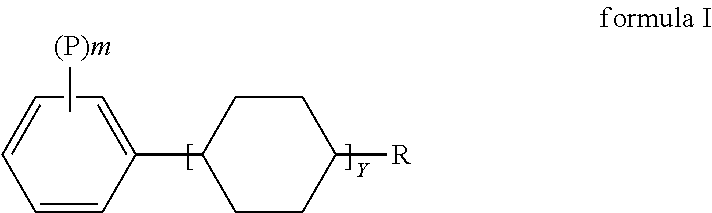

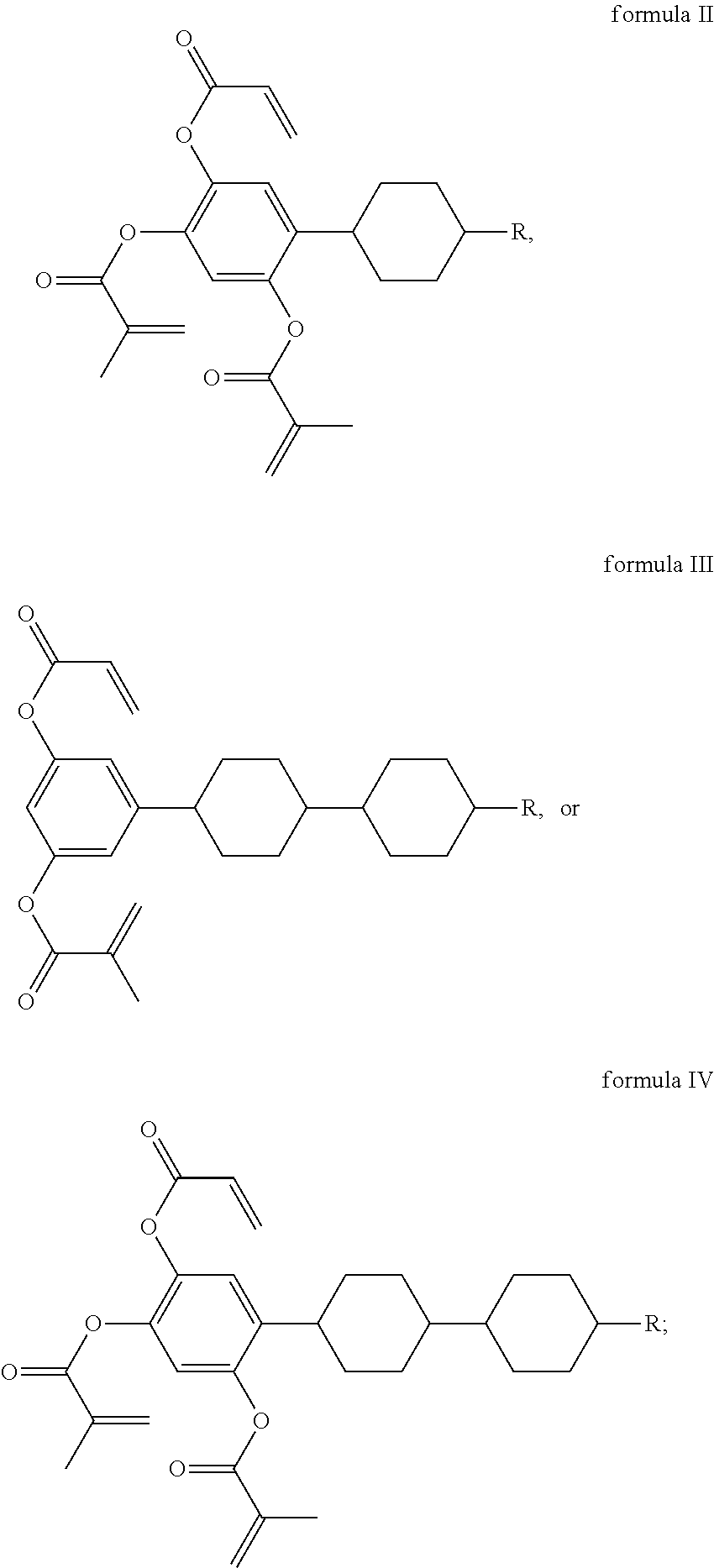

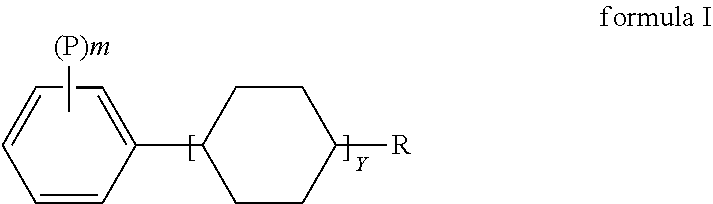

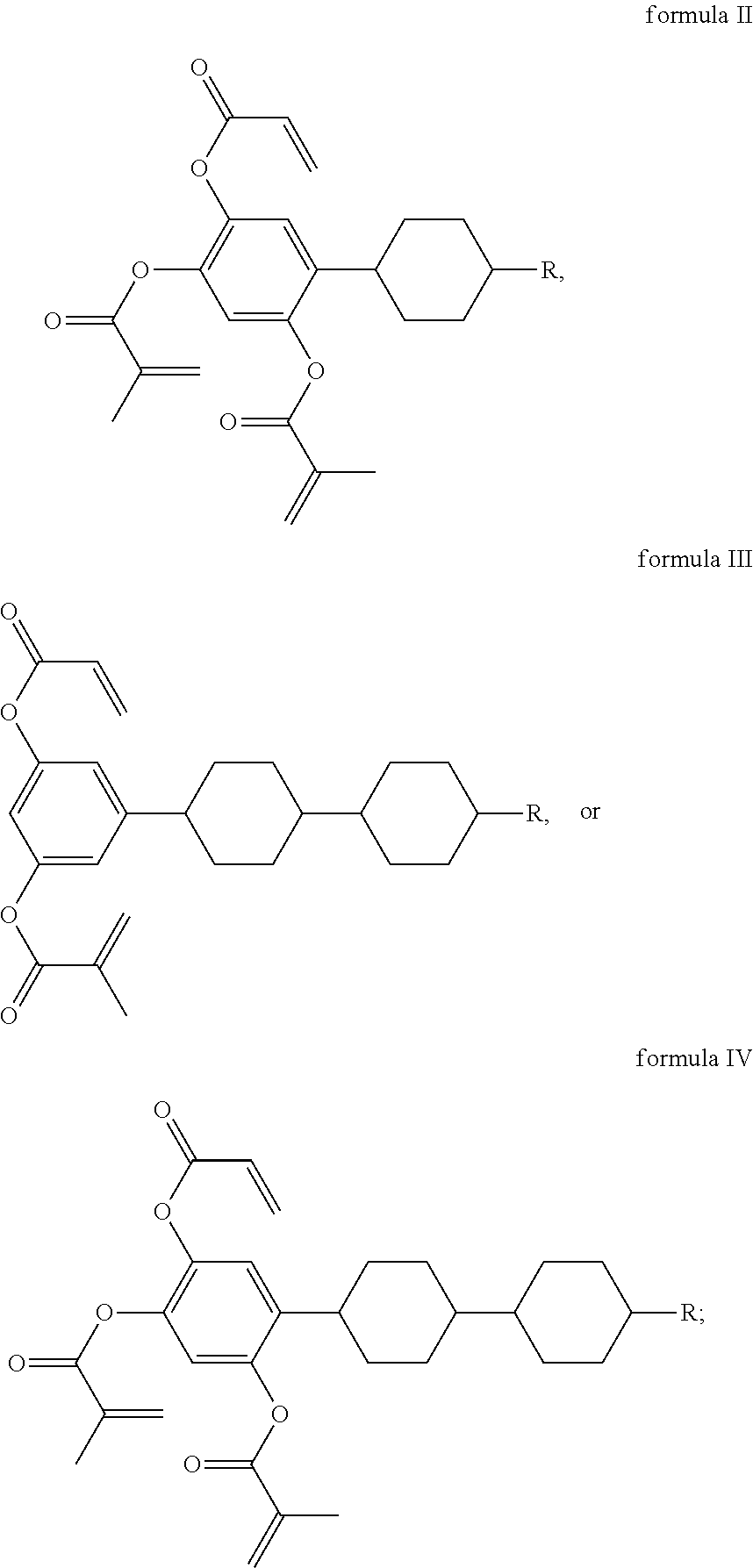

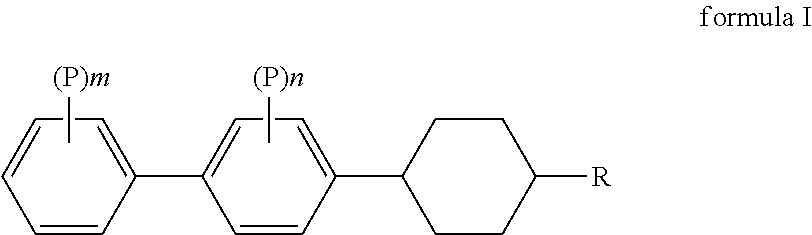

Mixture for liquid crystal medium and liquid crystal display using the same

ActiveUS8753537B2Strength can be balancedImprove the level ofLiquid crystal compositionsNon-linear opticsCrystallographyLiquid-crystal display

The present invention provides a mixture for liquid crystal medium and a liquid crystal display using the same. The mixture for liquid crystal medium comprises: at least one anisotropic liquid crystal material and a polymerizable monomer which will polymerize under UV irradiation. The weight percentage of the polymerizable monomer accounts for 0.1% to 1% of the total mixture for liquid crystal medium. In the mixture for liquid crystal medium and a liquid crystal display using the same according to the present invention, by using a polymerizable monomer which will polymerize under UV irradiation and the appropriate content ratio, the polymer bump with small size and good uniformity can be obtained within the mixture for liquid crystal medium after the polymerization, which avoids the bad liquid crystal alignment and the light spot occurred at the dark state of the liquid crystal panel, and then increases the response rapid of the liquid crystal panel to obtain high contrast ratio and stable mass production.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Mixture for Liquid Crystal Medium and Liquid Crystal Display Using the Same

InactiveUS20140176896A1Improve the level ofStrength can be balancedLiquid crystal compositionsNon-linear opticsCrystallographyLiquid-crystal display

The present invention provides a mixture for liquid crystal medium and a liquid crystal display using the same. The mixture for liquid crystal medium comprises: at least one anisotropic liquid crystal material and a polymerizable monomer which will polymerize under UV irradiation. The weight percentage of the polymerizable monomer accounts for 0.1% to 1% of the total mixture for liquid crystal medium. In the mixture for liquid crystal medium and a liquid crystal display using the same according to the present invention, by using a polymerizable monomer which will polymerize under UV irradiation and the appropriate content ratio, the polymer bump with small size and good uniformity can be obtained within the mixture for liquid crystal medium after the polymerization, which avoids the bad liquid crystal alignment and the light spot occurred at the dark state of the liquid crystal panel, and then increases the response rapid of the liquid crystal panel to obtain high contrast ratio and stable mass production.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Distributed transmit diversity in a wireless communication network

ActiveUS7787552B2Strength can be balancedIncrease diversity gainSpatial transmit diversityModulated-carrier systemsCell siteBroadcast multicast

A wireless communication network is configured to provide distributed diversity transmissions, wherein different diversity-coded versions of the same information signal are transmitted from each of two or more network sectors. The diversity-coded versions of the information signal are based on space-time or space-frequency codes, and the information signal may comprise a dedicated channel signal targeted to an individual user or a broadcast signal targeted to one or more users. Thus, spaced-apart network transmitters, which may be located at the same cell site, or at different cell sites, are configured to transmit diversity-coded versions of a given information signal and, in this manner, the advantages of space-time and / or space frequency transmission coding may be applied across multiple sectors of a communication network. Such transmissions may be used to improve soft and softer handoff reception of dedicated channel signals, and to improve reception of Broadcast-Multicast Services (BCMCS) signals, or the like.

Owner:TELEFON AB LM ERICSSON (PUBL)

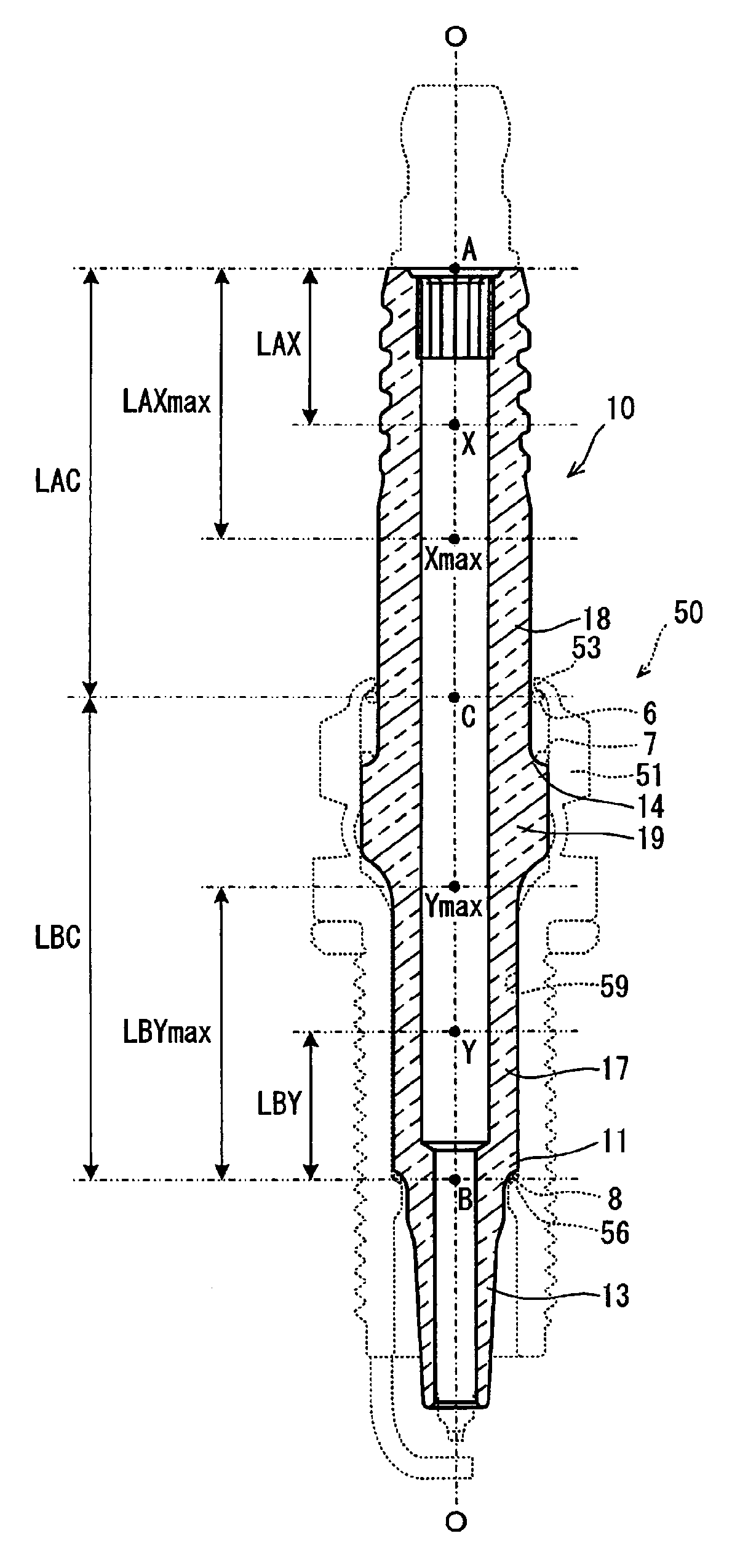

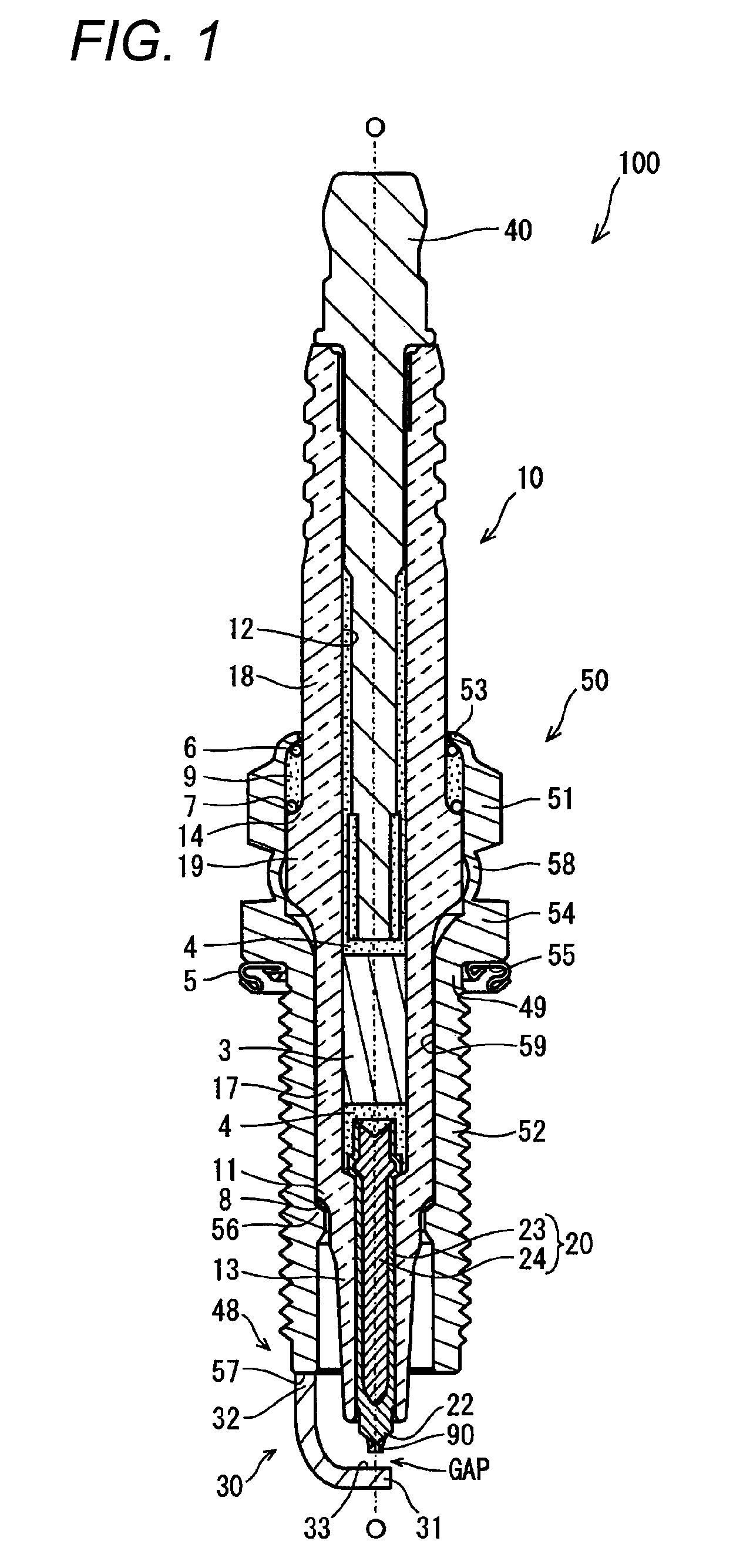

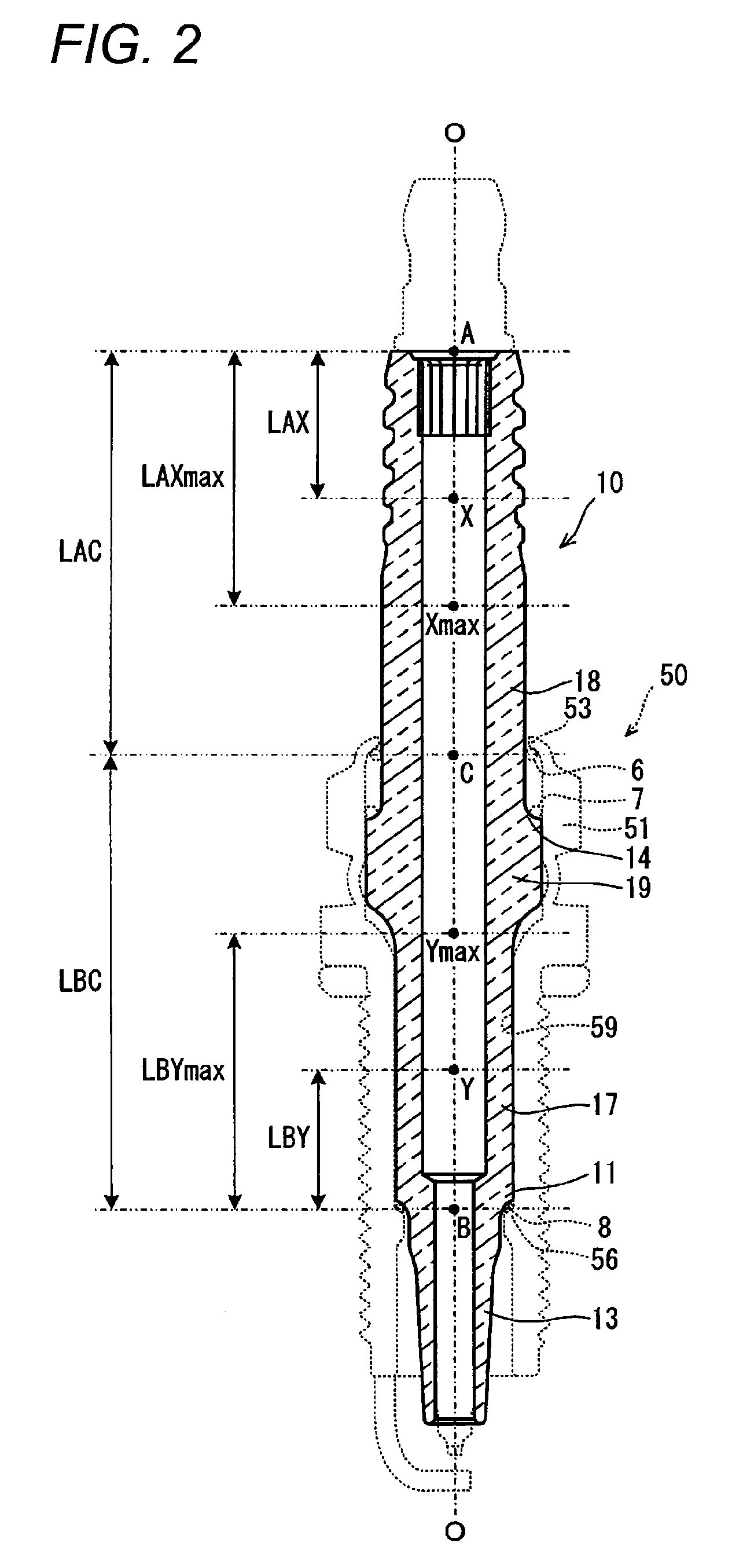

Spark plug

ActiveUS8143773B2Improve local stress concentrationInhibit the generation of cracksSparking plugsFuel injection apparatusSpark plugEngineering

Owner:NGK SPARK PLUG CO LTD

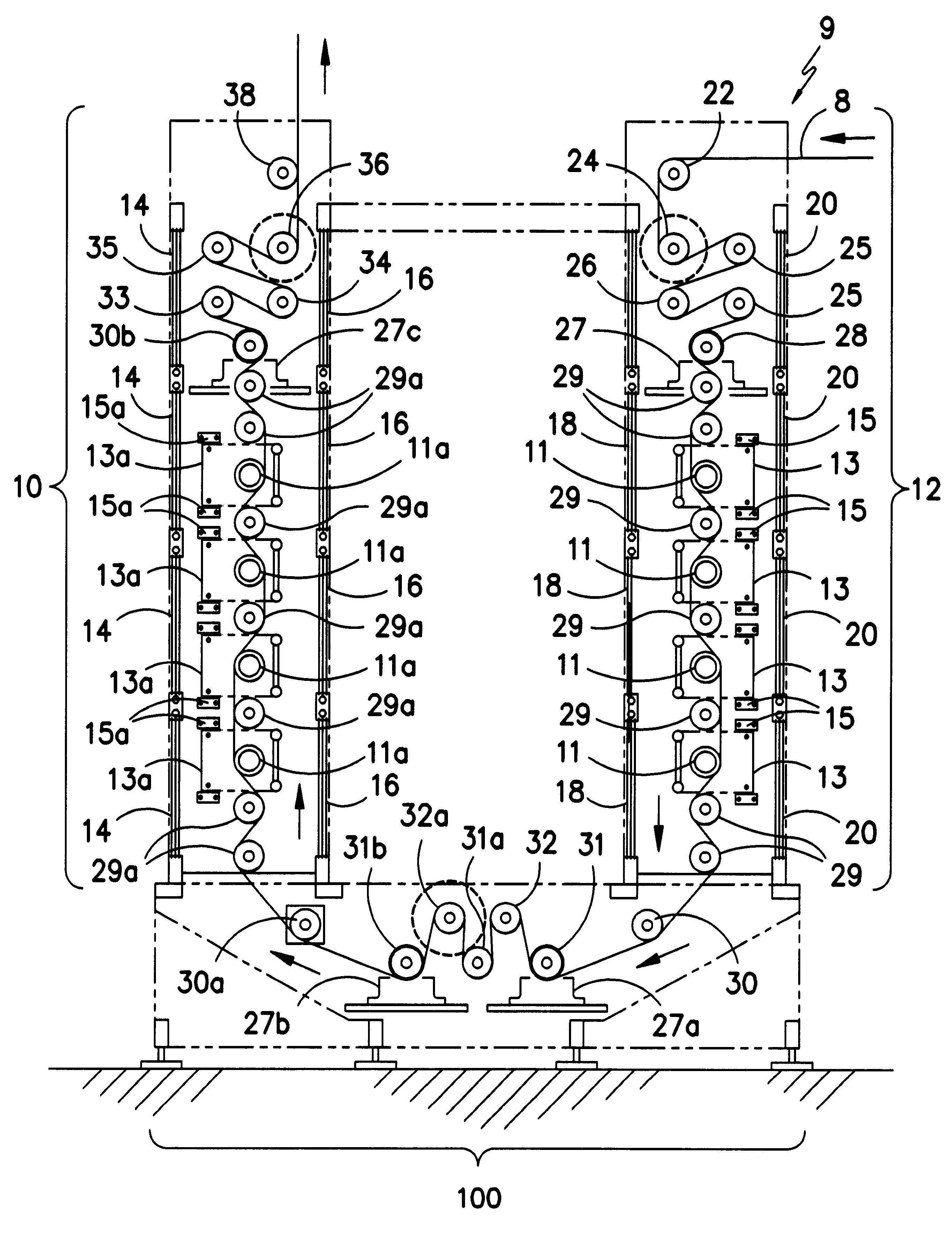

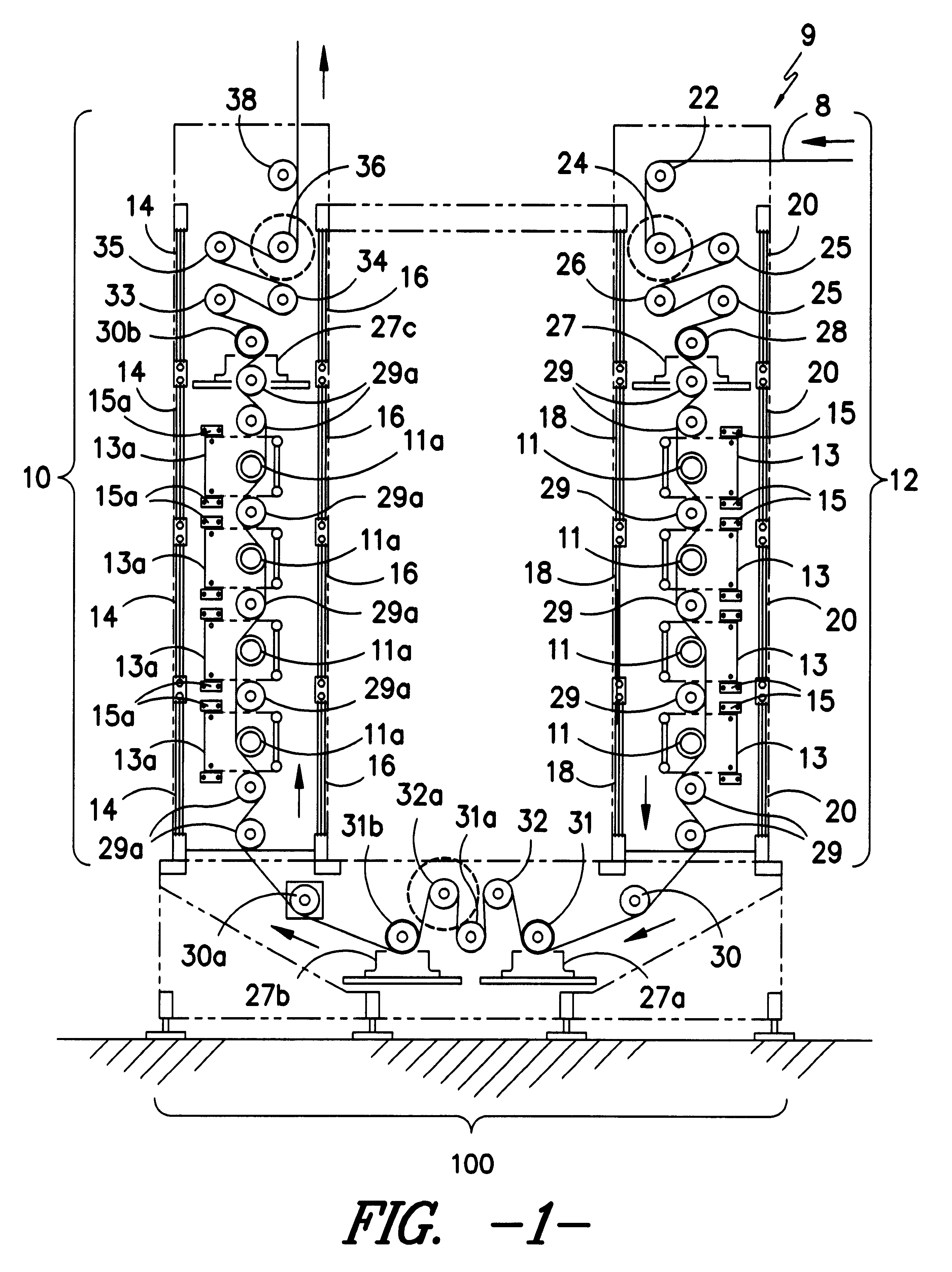

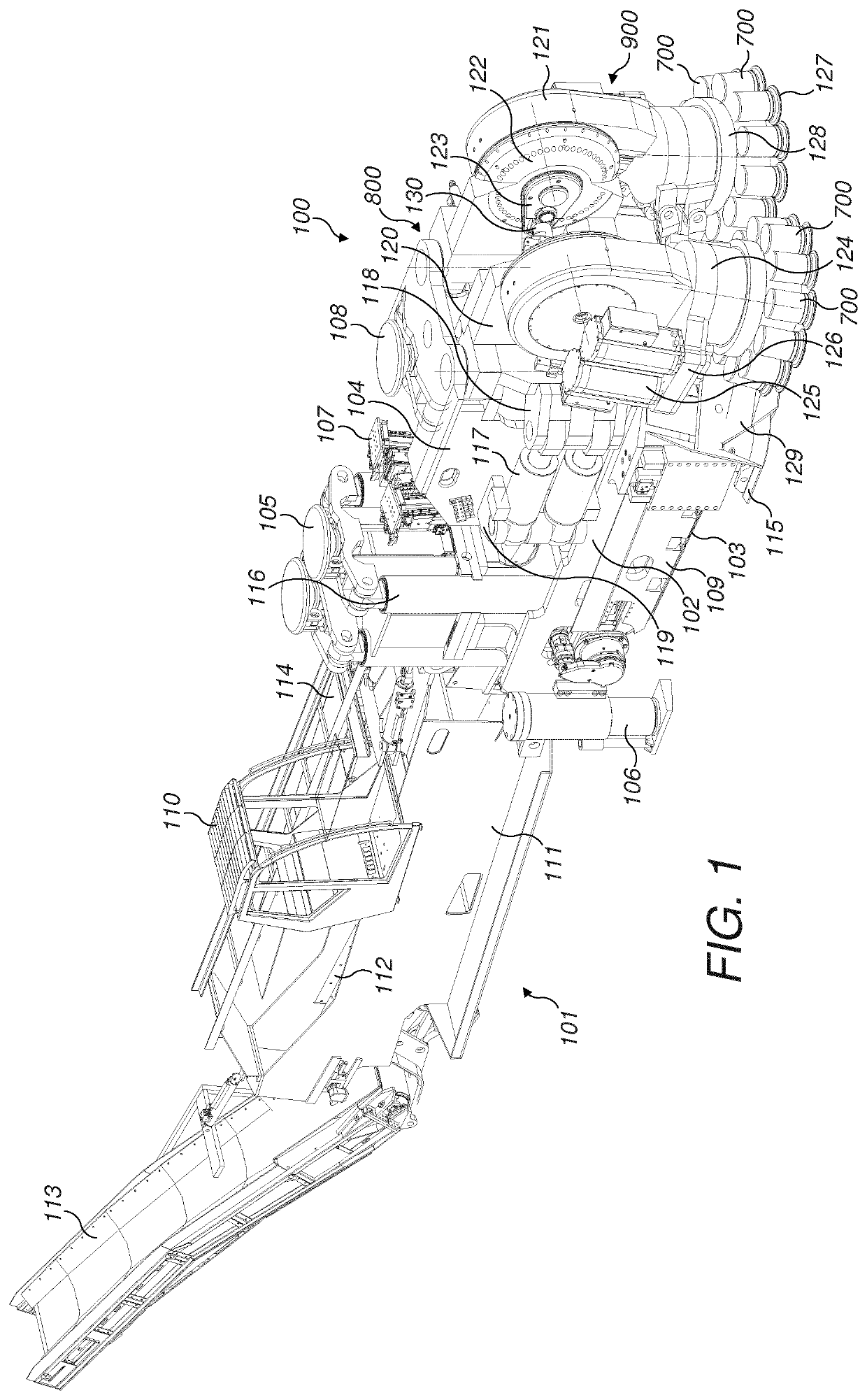

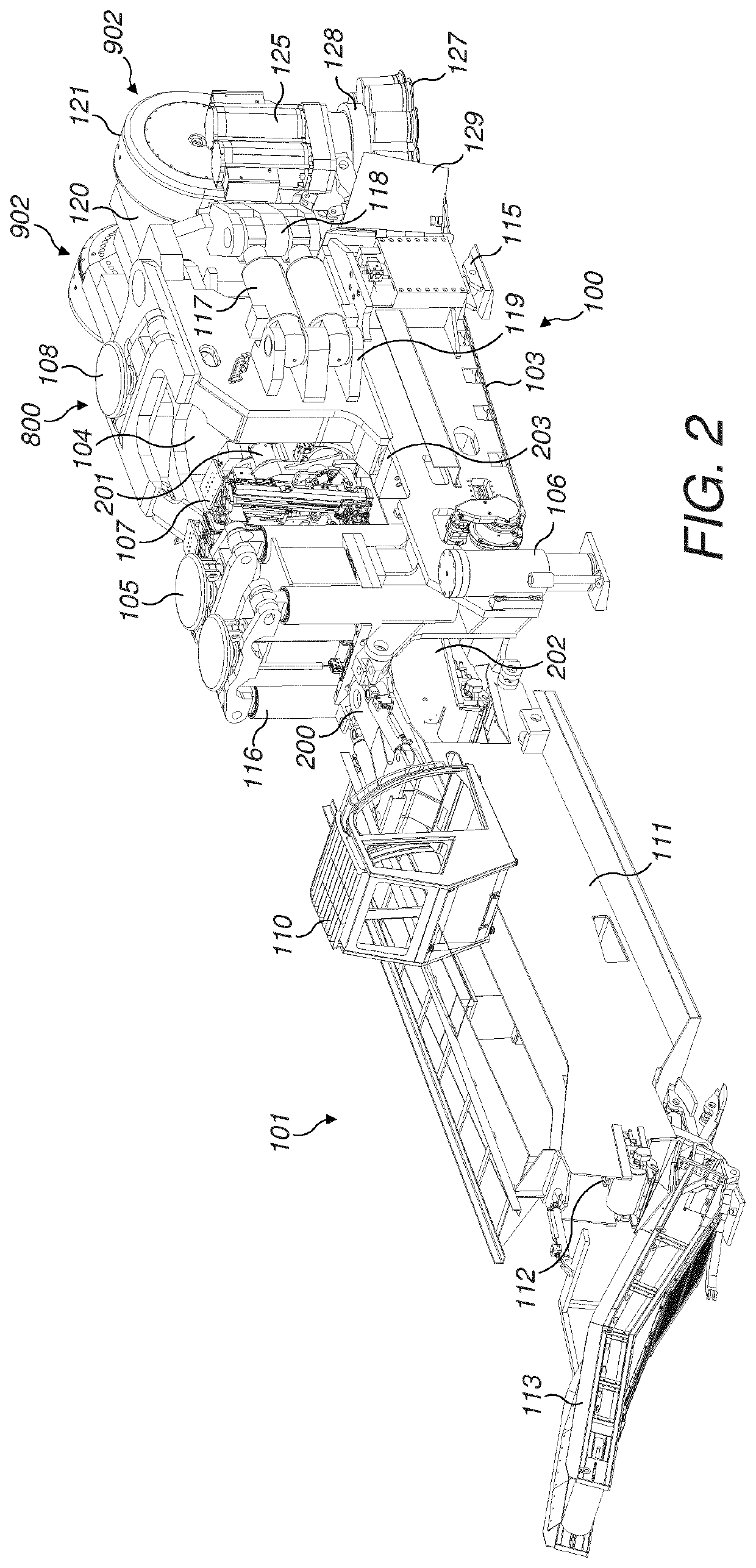

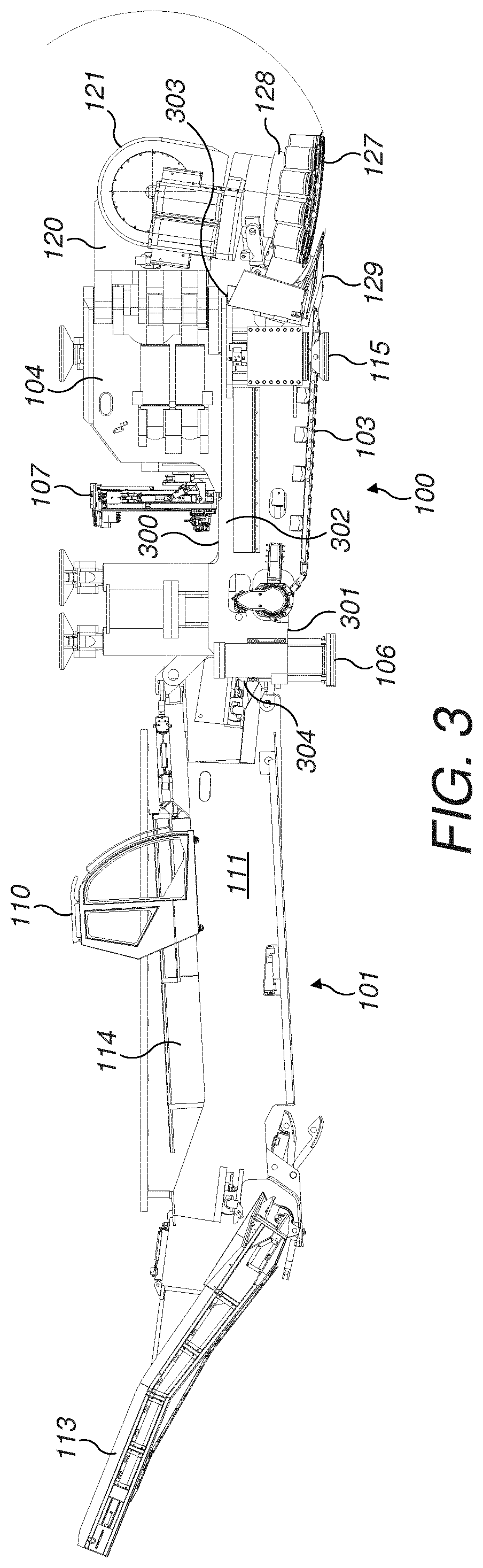

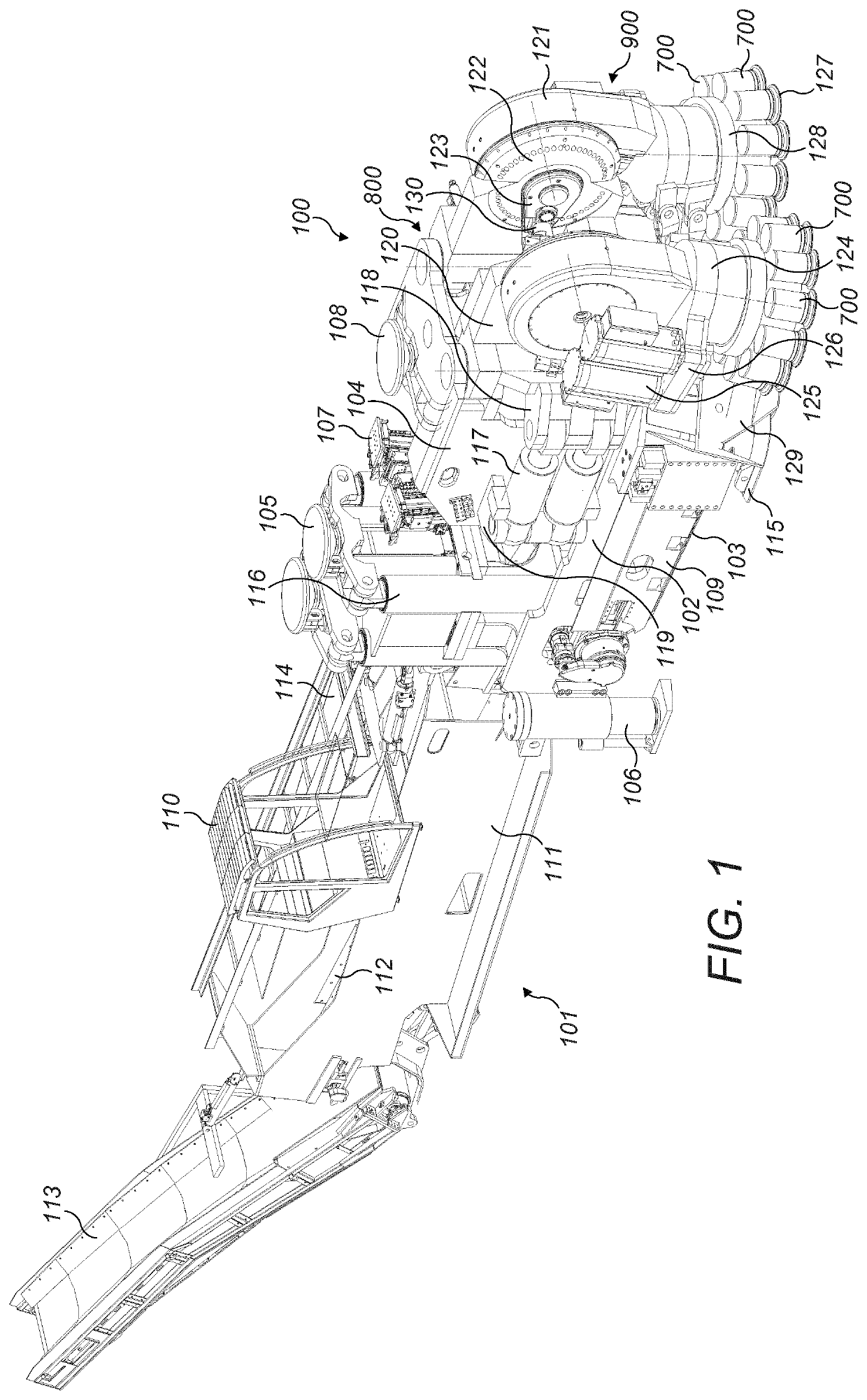

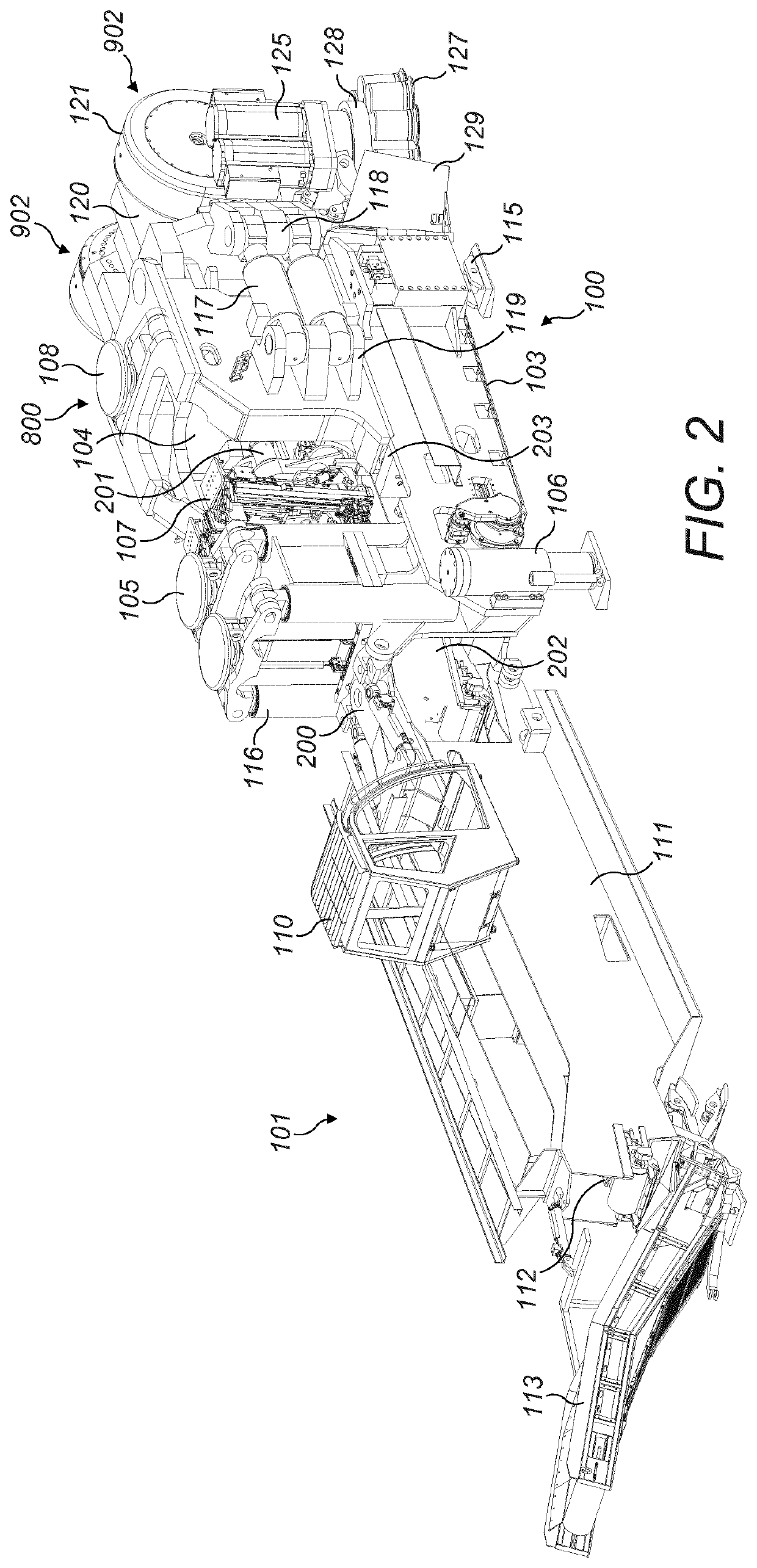

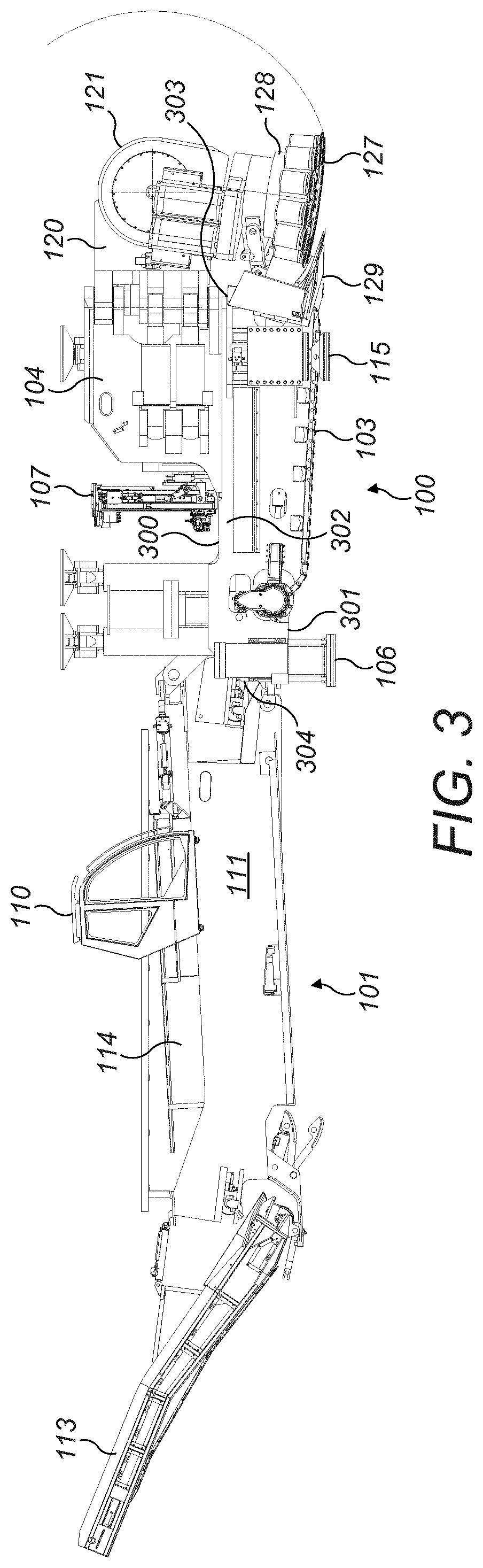

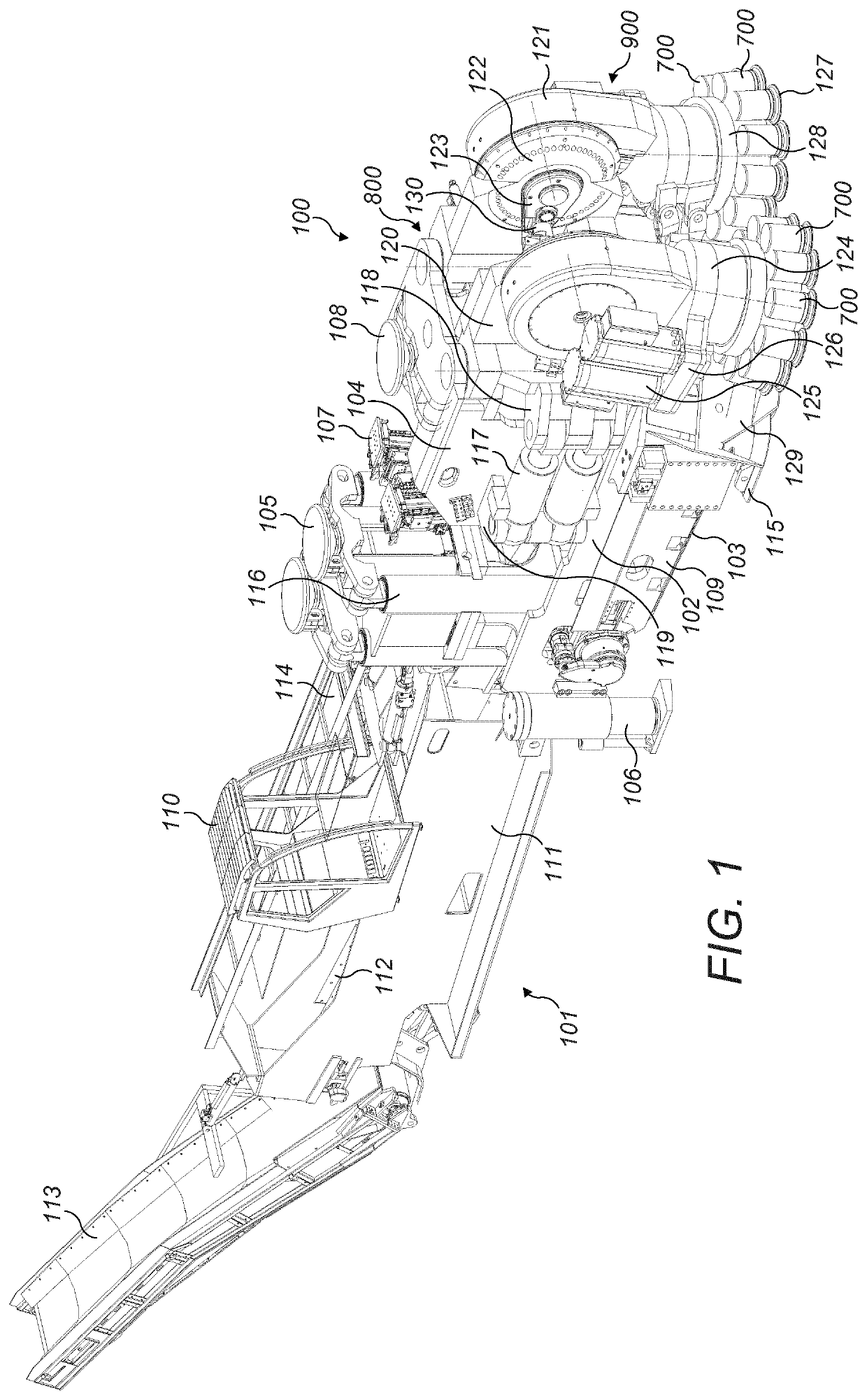

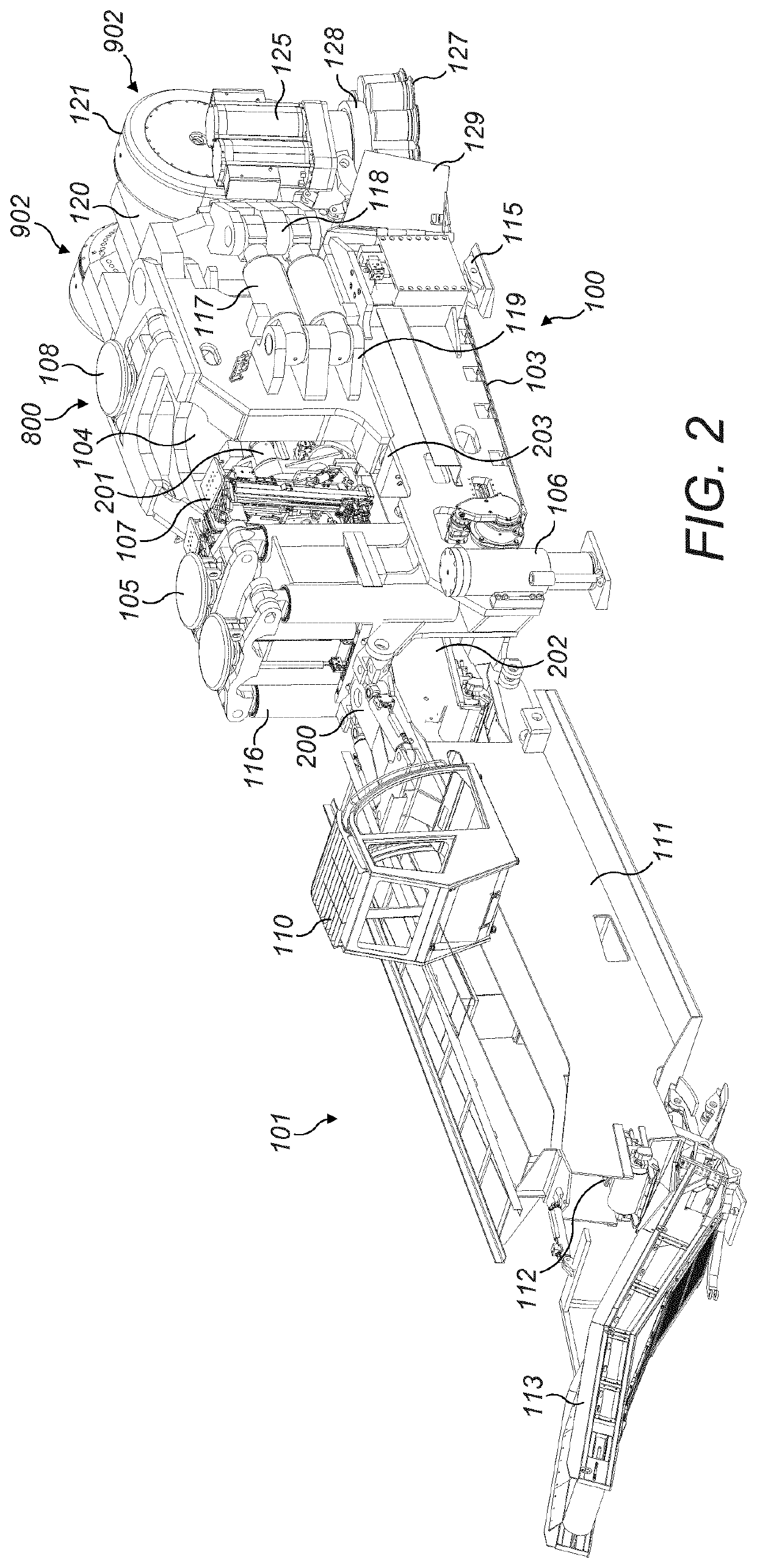

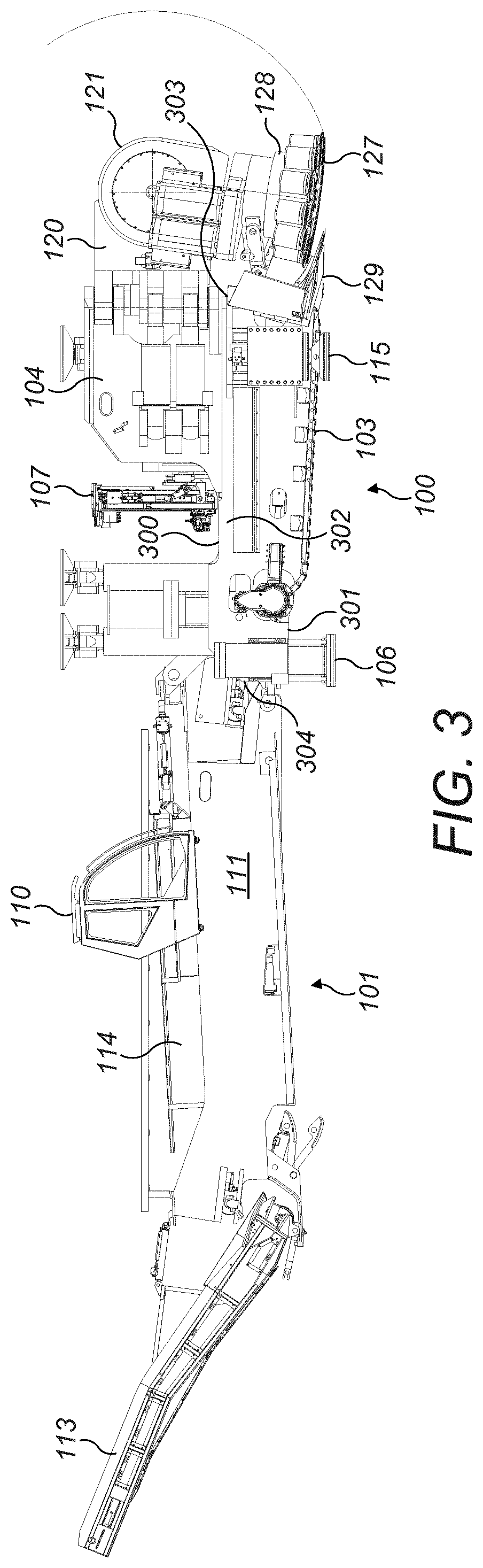

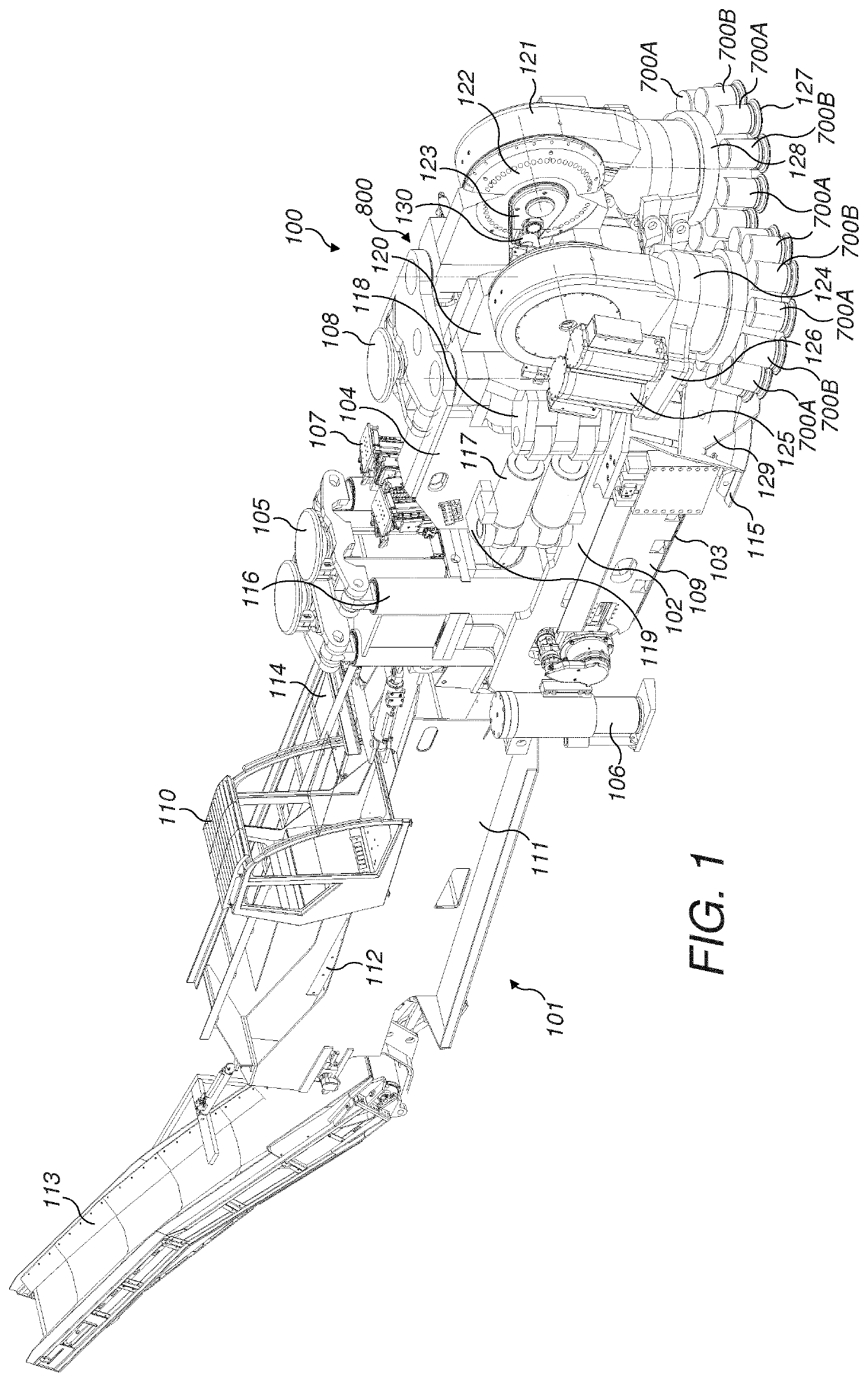

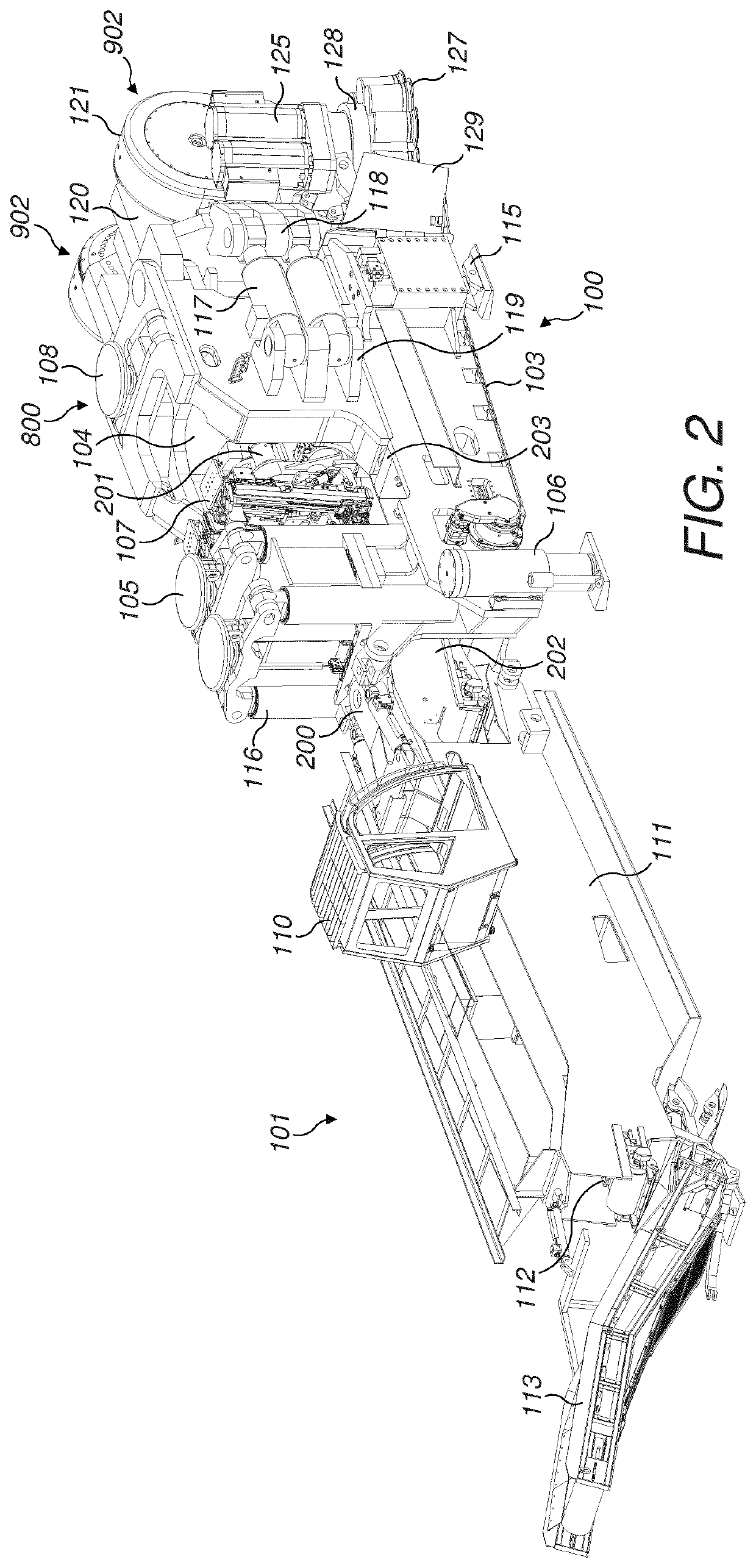

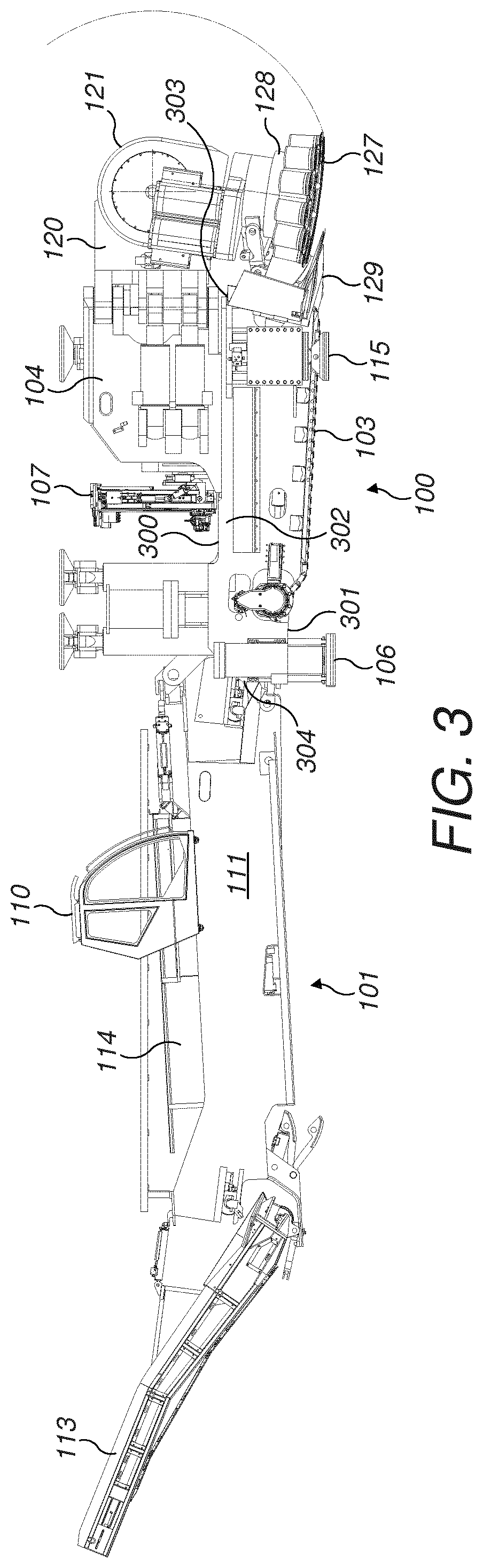

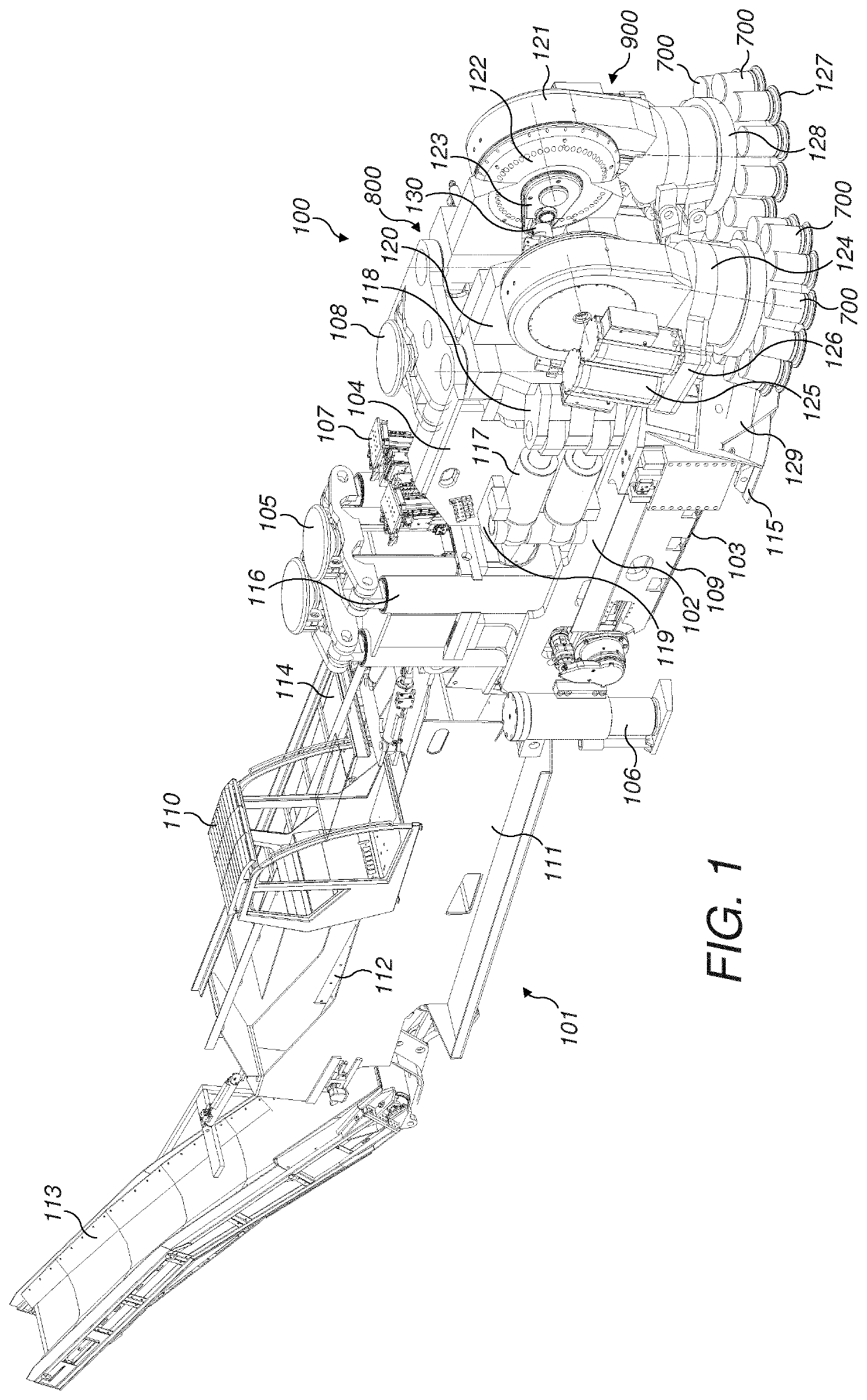

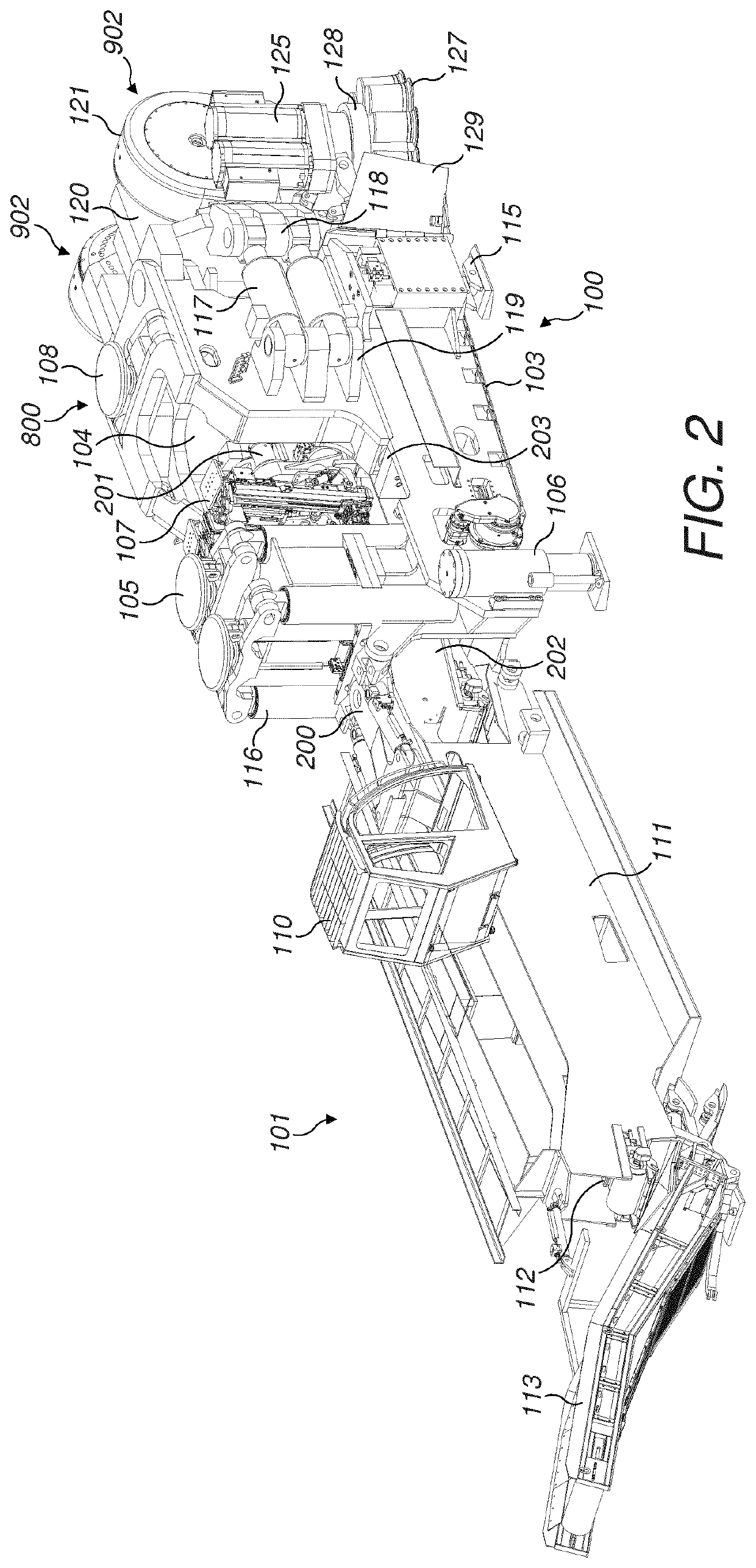

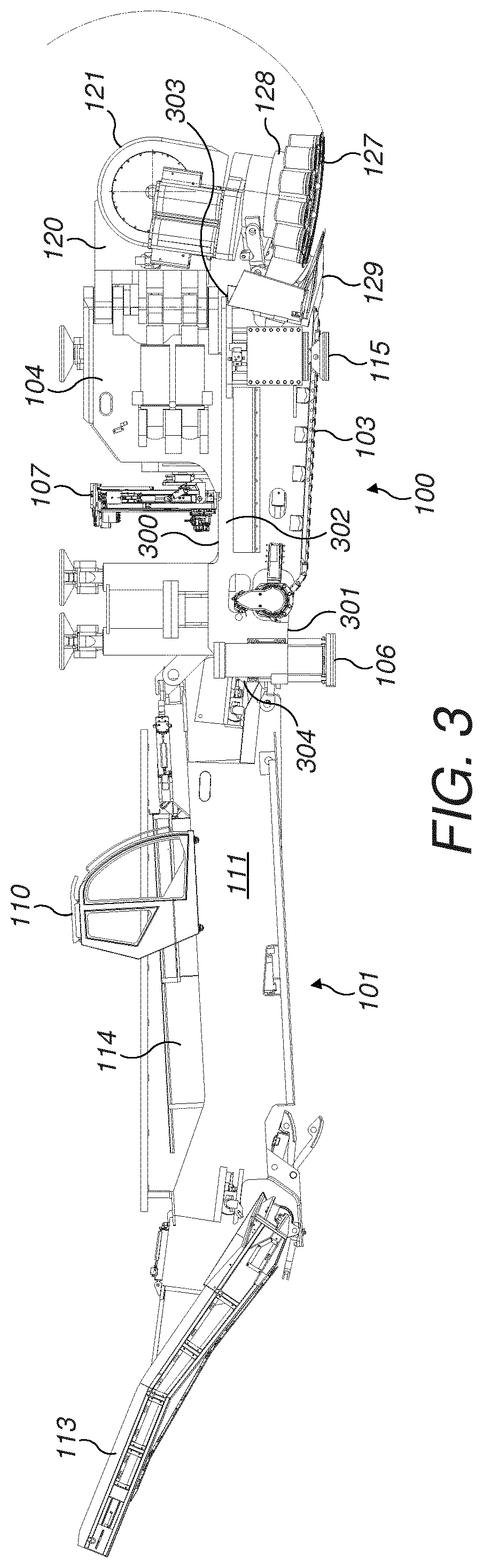

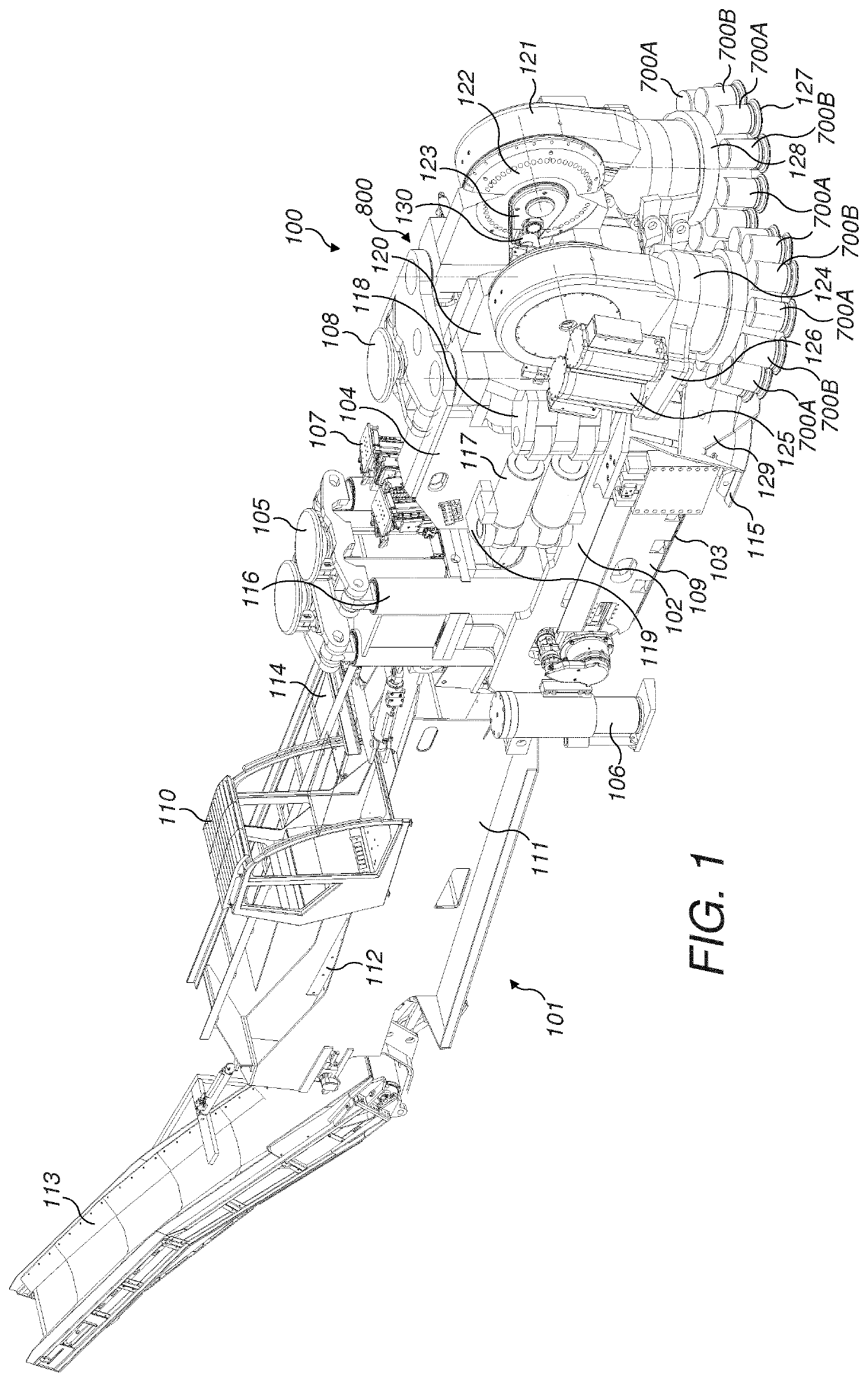

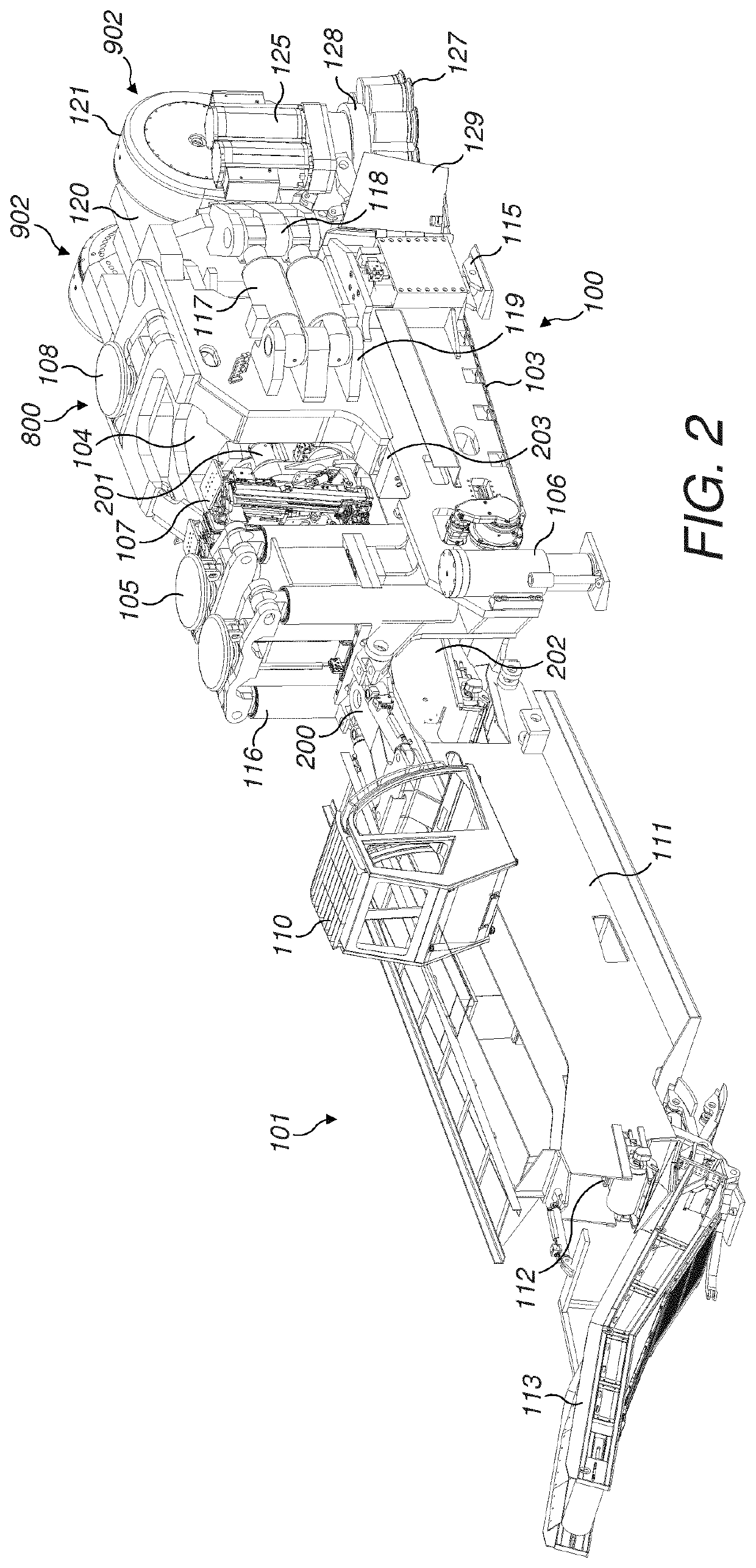

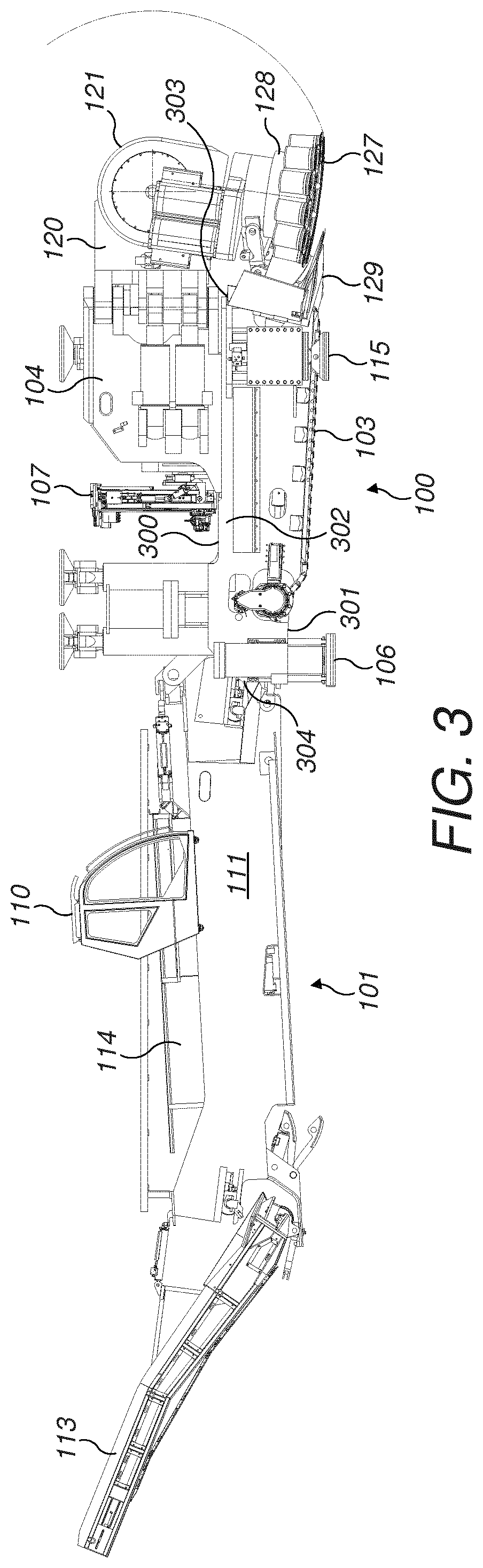

Cutting apparatus

ActiveUS11203931B2Optimised cutting geometry for the cutting apparatusOptimize geometryDrill bitsSlitting machinesEngineeringPhysics

A cutting apparatus includes a support structure and first and second cutting assemblies. Each cutting assembly includes a rotatable cutting head and a mounting assembly for movably attaching the cutting head to the support structure. The cutting head is movable about a first pivot axis of the mounting assembly in a sideways direction relative to the support structure, and about a second pivot axis in an upwards-downwards direction. Each cutting head includes a plurality of cutting units, which each have a rotatable shaft and a cutter mounted thereon. The cutter includes a disc body and a plurality of buttons mounted in a radially peripheral portion of the disc body. At least some of the buttons have a central longitudinal axis that subtends an angle α to a reference axis, which extends perpendicularly outwards from an axis of the shaft, the angle α being ≥to 20° and ≤to 34°.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Cutting apparatus

ActiveUS20200141236A1Reduce generationReduced tool wearDrill bitsSlitting machinesEngineeringPhysics

A cutter for a cutting unit used in cutting apparatus suitable for creating tunnels or subterranean roadways. The cutter includes a disc body having an underside, an upper side arranged substantially opposite to the underside, and a radially peripheral part. A plurality of buttons for abrading rock are mounted in the radially peripheral part of the disc body and protrude outwardly therefrom to engage rock during an undercutting operation, wherein at least some of the buttons have a cutting part having a dome-shaped cutting surface.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Mixture for liquid crystal medium and liquid crystal display using the same

ActiveUS9127198B2Strength can be balancedImprove the level ofLiquid crystal compositionsNon-linear opticsCrystallographyLiquid-crystal display

The present invention provides a mixture for liquid crystal medium and a liquid crystal display using the same. The mixture for liquid crystal medium comprises: at least one anisotropic liquid crystal material and two or more polymerizable monomers which will polymerize under UV irradiation. The liquid crystal material comprises an alkenyl compound which is stable to the polymerization reaction during the polymerization of the polymerizable monomers. The weight percentage of the polymerizable monomers accounts for 0.1% to 1% of the total mixture for liquid crystal medium. In the mixture for liquid crystal medium and a liquid crystal display using the same according to the present invention, by using two or more polymerizable monomers which will polymerize under UV irradiation and the appropriate content ratio, the polymer bump with small size and good uniformity can be obtained within the mixture for liquid crystal medium after the polymerization, which avoids the bad liquid crystal alignment and the light spot occurred at the dark state of the liquid crystal panel, and then increases the response rapid of the liquid crystal panel to obtain high contrast ratio and stable mass production.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Hub for a horizontal axis wind turbine

ActiveUS8142166B2Uniform forceStrength can be balancedPump componentsWind motor assemblyHorizontal axisTurbine

Owner:HITACHI LTD

Method of producing non-directional range-dyed face finished fabrics

InactiveUS20040107552A1Highly cost-effectiveEliminates pillingFibre treatmentDyeing processFiberTime-Consuming

Range-dyed fabrics that possess excellent hand characteristics and simultaneously exhibit substantially nondirectional appearances are provided. Such a combination permits the production and utilization of an extremely comfortable apparel fabric that can be attached to any other similar type of fabric to form a target apparel article without the time-consuming need to align such component fabrics to ensure an overall aesthetic appearance is met for the target apparel article. In general, such a fabric is produced through the initial immobilization of individual fibers within target fabrics and subsequent treatment through abrasion, sanding, or sueding of at least a portion of the target fabric. Such a procedure produces a fabric of short pile height and desirable hand. Upon range-dyeing the target fabric exhibits the extra benefit of nondirectional surface characteristics. The ability to produce such specific fabrics without the need for jet-dyeing thus provides a significant cost advantage to the manufacturer and consumer.

Owner:MILLIKEN & CO

Cutting apparatus

ActiveUS11092009B2Optimised cutting geometry for the cutting apparatusReduce generationDrill bitsSlitting machinesPhysicsPush-button

A cutter for a cutting unit used in cutting apparatus suitable for creating tunnels or subterranean roadways. The cutter includes a disc body having an underside, an upper side arranged substantially opposite to the underside, and a radially peripheral part. A plurality of buttons for abrading rock are mounted in the radially peripheral part of the disc body and protrude outwardly therefrom to engage rock during an undercutting operation, wherein at least some of the buttons have a cutting part having a dome-shaped cutting surface.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Cutting apparatus

ActiveUS20200131904A1Optimised cutting geometry for the cutting apparatusOptimize geometrySlitting machinesTunnelsEngineeringPush-button

A cutting head for cutting apparatus suitable for creating tunnels or subterranean roadways and the like. The cutting head includes a rotatable cutting head body and a plurality of cutting units mounted thereon. The cutting units include at least first and second different types of cutting units. The first type of cutting unit has a first rotatable cutter having a first disc body and a first arrangement of buttons for abrading rock. The first buttons are mounted in a radially peripheral portion of the disc body and protrude outwardly therefrom. The second type of cutting unit has a second rotatable cutter having a second disc body and a second arrangement of buttons. The second buttons are mounted in a radially peripheral portion of the disc body and protrude outwardly therefrom. The different types of cutting units differ from one another by at least the arrangements of their buttons.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Vehicle front structure for improved compatibility during a frontal crash

ActiveUS20210370859A1Increase contactPrevent closureSuperstructure subunitsBumpersHead-on collisionClassical mechanics

The present disclosure relates to a Vehicle front structure as defined above is provided, in which the front structure comprises: a side member for supporting a vehicle bumper beam, the side member extending along a longitudinal axis between a first end for connecting to the vehicle bumper beam and a second end for connecting to a bulkhead, and a lateral extension member extending substantially perpendicular with respect to the longitudinal axis of the side member and outward with respect to the vehicle front structure, the lateral extension member is connected to the side member such that the lateral extension member can exert a bending moment to the side member, and a bending strength of the lateral extension member in backward direction towards the side member is higher compared to a bending strength in the forward direction away from the side member.

Owner:VOLVO CAR CORP

Mixture for liquid crystal medium and liquid crystal display using the same

InactiveUS9028713B2Strength can be balancedImprove the level ofLiquid crystal compositionsNon-linear opticsCrystallographyLiquid-crystal display

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Mixture for Liquid Crystal Medium and Liquid Crystal Display Using the Same

ActiveUS20140085589A1Strength can be balancedImprove the level ofLiquid crystal compositionsCrystallographyLiquid-crystal display

The present invention provides a mixture for liquid crystal medium and a liquid crystal display using the same. The mixture for liquid crystal medium comprises: at least one anisotropic liquid crystal material and a polymerizable monomer which will polymerize under UV irradiation. The weight percentage of the polymerizable monomer accounts for 0.1% to 1% of the total mixture for liquid crystal medium. In the mixture for liquid crystal medium and a liquid crystal display using the same according to the present invention, by using a polymerizable monomer which will polymerize under UV irradiation and the appropriate content ratio, the polymer bump with small size and good uniformity can be obtained within the mixture for liquid crystal medium after the polymerization, which avoids the bad liquid crystal alignment and the light spot occurred at the dark state of the liquid crystal panel, and then increases the response rapid of the liquid crystal panel to obtain high contrast ratio and stable mass production.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Cutting apparatus

ActiveUS20200123900A1Reduced tool wearOptimize geometryDrill bitsSlitting machinesEngineeringMechanical engineering

A cutting apparatus includes a support structure and first and second cutting assemblies. Each cutting assembly includes a rotatable cutting head and a mounting assembly for movably attaching the cutting head to the support structure. The cutting head is movable about a first pivot axis of the mounting assembly in a sideways direction relative to the support structure, and about a second pivot axis in an upwards-downwards direction. Each cutting head includes a plurality of cutting units, which each have a rotatable shaft and a cutter mounted thereon. The cutter includes a disc body and a plurality of buttons mounted in a radially peripheral portion of the disc body. At least some of the buttons have a central longitudinal axis that subtends an angle α to a reference axis, which extends perpendicularly outwards from an axis of the shaft, the angle α being ≥to 20° and ≤to 34°.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Mixture for liquid crystal medium and liquid crystal display using the same

ActiveUS8815117B2Strength can be balancedImprove the level ofLiquid crystal compositionsThin material handlingCrystallographyLiquid-crystal display

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Cutting apparatus

ActiveUS11047235B2Optimised cutting geometry for the cutting apparatusOptimize geometrySlitting machinesTunnelsEngineeringPush-button

A cutting head for cutting apparatus suitable for creating tunnels or subterranean roadways and the like. The cutting head includes a rotatable cutting head body and a plurality of cutting units mounted thereon. The cutting units include at least first and second different types of cutting units. The first type of cutting unit has a first rotatable cutter having a first disc body and a first arrangement of buttons for abrading rock. The first buttons are mounted in a radially peripheral portion of the disc body and protrude outwardly therefrom. The second type of cutting unit has a second rotatable cutter having a second disc body and a second arrangement of buttons. The second buttons are mounted in a radially peripheral portion of the disc body and protrude outwardly therefrom. The different types of cutting units differ from one another by at least the arrangements of their buttons.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

PTFE membranes and gaskets made therefrom

InactiveUS20080029964A1Improve mechanical propertiesStrength can be balancedEngine sealsDomestic sealsExpanded PTFELow stress

Improved expanded PTFE materials and improved gasket materials made therefrom, the gaskets being capable of forming a seal with greater bolt load retention than is possible with existing PTFE gaskets. The expanded PTFE membranes of the invention can be tailored to exhibit a matrix tensile strength in at least one direction of at least 25,000 psi, a matrix tensile strength ratio in two orthogonal directions of between 0.025 and 4, an orientation index of 50° or less, and a density of 2.0 g / cc or less. The improved gaskets exhibit improved mechanical properties such as high bolt load retention, low creep, high tensile strength, low stress to seal and high crystallinity index.

Owner:WL GORE & ASSOC INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com