High loft nonwoven with balanced properties

a non-woven, high loft technology, applied in the direction of woven fabrics, textiles and papermaking, weaving, etc., can solve the problems of high initial loft of fabric with false loft, limited conventional process, and high cross-direction tensile strength of webs, so as to improve strength, improve fire retardancy, and achieve balanced strength properties in machine and cross-direction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

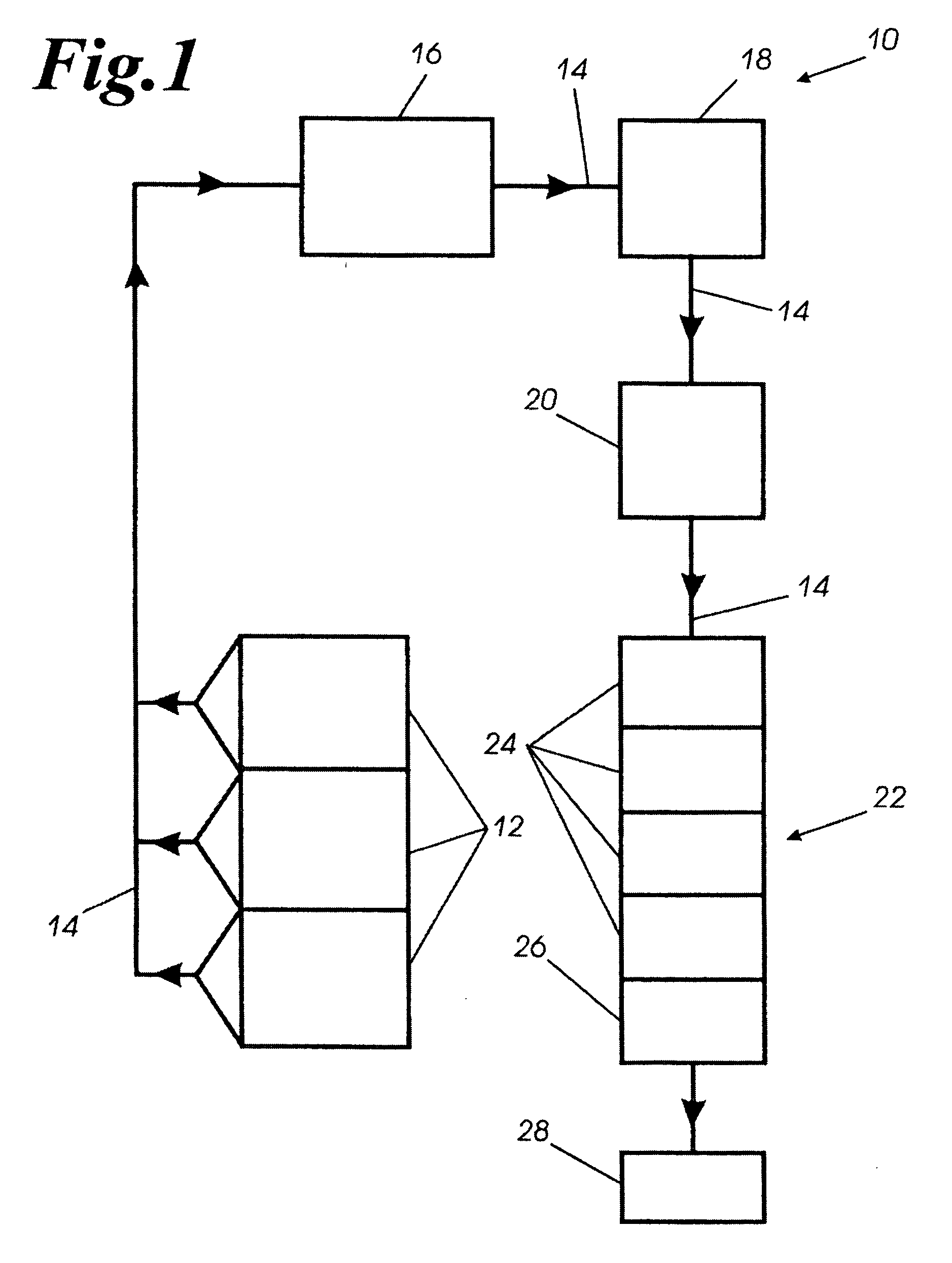

Image

Examples

example 1

[0046] Referring to Table 1, the quality of a Control high loft nonwoven fabric and three Sample fabrics are compared. Each of the fabrics had a weight of 0.75 oz / ft2 and a weight percent blend of: 20% 4 dpf (denier per filament) low melt binder fiber, 30% 25 dpf PET, and 50% 15 dpf PET. The Samples were processed with different number of layers, with the Control, First Sample, Second Sample and Third Sample respectively having 2, 2, 3 and 4 layers. In order to maintain the same weight (oz / ft2), the process rate was adjusted, with the Control, First Sample, Second Sample, and Third Sample respectively processed at 1278 lbs / hr, 1775 lbs / hr, 1896 lbs / hr and 1896 lbs / hr.

TABLE 1Percent Loft Recovery for 0.75 oz / ft2 Control and SamplesApplied Load (lbs)Loft (inches)Percent Loft (%)ControlBlend (20% 4 dpf low melt, 30% 25 dpf PET, and 50% 15 dpf PET)Rate: 1278 lbs / hr Weight: 0.75 oz / ft2 Number of Laps: 2Zero1.75100 51.3979.4101.1867.4151.0358.9200.9353.1Load removed1.6896.0(% loft recov...

example 2

[0050] Referring to Table 3, a Control high loft, nonwoven fabric and two Sample fabrics are compared wherein each of the fabrics had a weight of 1.0 oz / ft2 and a weight percent blend of: 20% 4 dpf low melt binder fiber, 30% 25 dpf PET, and 50% 15 dpf PET. The Samples were processed wiith different number of laps, with the Control, First Sample and Second Sample having 3, 3 and 4 laps, respectively. The process rate was adjusted in order to maintain the same weight (oz / ft2), with the Control, First Sample and Second Sample respectively processed at 920 lbs / hr, 1050 lbs / hr and 1100 lbs / hr.

TABLE 3Percent Loft Recovery for 1.0 oz / ft2 Control and SamplesApplied Load (lbs)Loft (inches)Percent Loft (%)ControlBlend (20% 4 dpf low melt, 30% 25 dpf PET, and 50% 15 dpf PET)Rate: 920 lbs / hr Weight: 1.0 oz / ft2 Number of Laps: 3Zero2.82100 52.1475.9101.7562.1151.4350.7201.3 46.1Load removed2.7 95.7(% loft recovery)Sample 1Blend (20% 4 dpf low melt, 30% 25 dpf PET, and 50% 15 dpf PET)Rate: 1050...

example 3

[0054] Because the drafter provides a more balanced fabric (with respect to certain physical properties), it is possible to lower the amount of binder and still achieve good tensile strength properties. Table 5 compares the Control having 20% binder and the Samples each of which had a weight of 1.0 oz / ft2 and a weight percent blend of: 10% 4 dpf low melt binder fiber, 35% 25 dpf PET, and 55% 15 dpf PET.

TABLE 5Loft Recovery for 1.0 oz / ft2 Control and 10% Low MeltBinder Fiber SamplesApplied Load (lbs)Loft (inches)Percent Loft (%)ControlBlend (20% 4 dpf low melt, 30% 25 dpf PET, and 50% 15 dpf PET)Rate: 920 lbs / hr Weight: 1.0 oz / ft2 Number of Laps: 3Zero2.82100 52.1475.9101.7562.1151.4350.7201.3 46.1Load removed2.7 95.7(% loft recovery)Sample 1 (10% Low melt fiber)Blend (10% 4 dpf low melt, 35% 25 dpf PET, and 55% 15 dpf PET)Rate: 1050 lbs / hr Weight: 1.0 oz / ft2 Number of Laps: 3Zero2.41100 51.7673.0101.4359.3151.2551.9201.1146.1Load removed2.2593.4(% loft recovery)Sample 2 (10% Low m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com