Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Shorten mold opening time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environment-friendly polyurethane adhesive used for bonding granulated cork and preparation method thereof

ActiveCN101787252AImprove performanceNo smellNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyurethane adhesiveEnvironmentally friendly

The invention relates to an environment-friendly polyurethane adhesive used for bonding a granulated cork. The invention is characterized in that the environment-friendly polyurethane adhesive consists of MDI, modified MDI, polyether glycol, an antiaging agent and a polymerization inhibitor; according to the mass percentage, the proportion of the MDI, the modified MDI, the polyether glycol and the antiaging agent is 20-30:30-40:30-40:1-5, and the addition of the polymerization inhibitor is 10PPM. When in use, the adhesive and the granulated cork are mixed according to the mass proportion of 1:10-1:5. The adhesive is inodorous and environmentally friendly and can be used at different seasons. When the adhesive is used for bonding the granulated cork, the mold opening time is greatly shorter than the TDI adhesive, and the product property is good.

Owner:SHANDONG INOV POLYURETHANE

Manufacturing method of ceramic chip with fine mold textures

ActiveCN112142328ASolve the deformationRich styleCeramic materials productionTextile printerComposite material

The invention provides a manufacturing method of a ceramic chip with fine mold textures. The manufacturing method comprises the following steps: spraying ground glaze on a biscuit; spraying matte glaze; carrying out ink-jet printing and deep ink jet printing; spraying matte transparent glaze; sintering; and finishing. By adjusting the formula and the glazing amount of the matte glaze layer and thematte transparent glaze layer, the problems that a ceramic chip is easy to deform and permeate water can be well solved. According to the invention, the deep ink is utilized to discharge the matte transparent glaze to form the concave mold texture, the texture for jet printing of the deep ink is made by a computer, the texture style processed by the computer can be diversified, and the lines canbe made very fine; the pattern texture is located below the matte transparent glaze layer, and the matte transparent glaze layer can protect the pattern texture against abrasion. Pattern textures anddeep ink textures are processed by a computer in the same design, and the pattern textures and the deep ink textures can be well matched and processed, so that the final presentation effect is more optimized.

Owner:FOSHAN SANSHUI NEW PEARL CONSTR CERAMICS IND +1

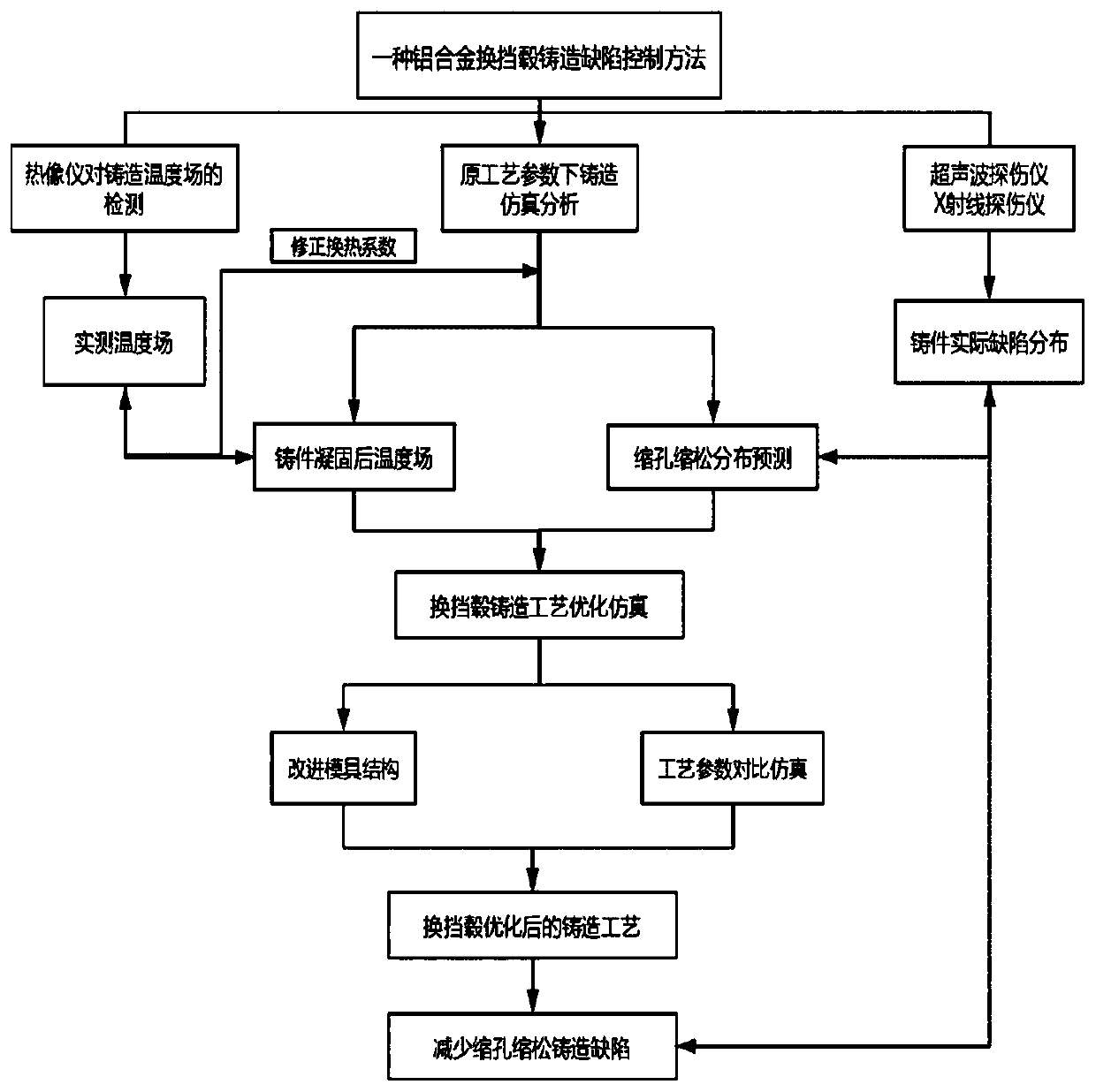

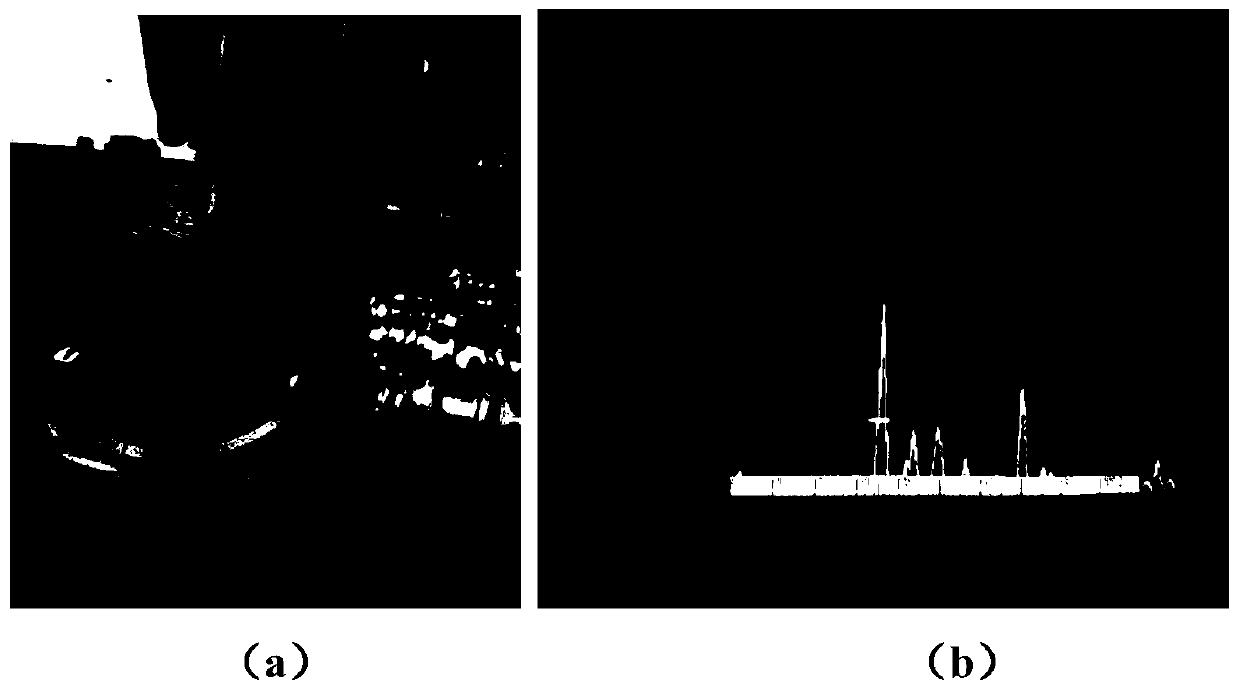

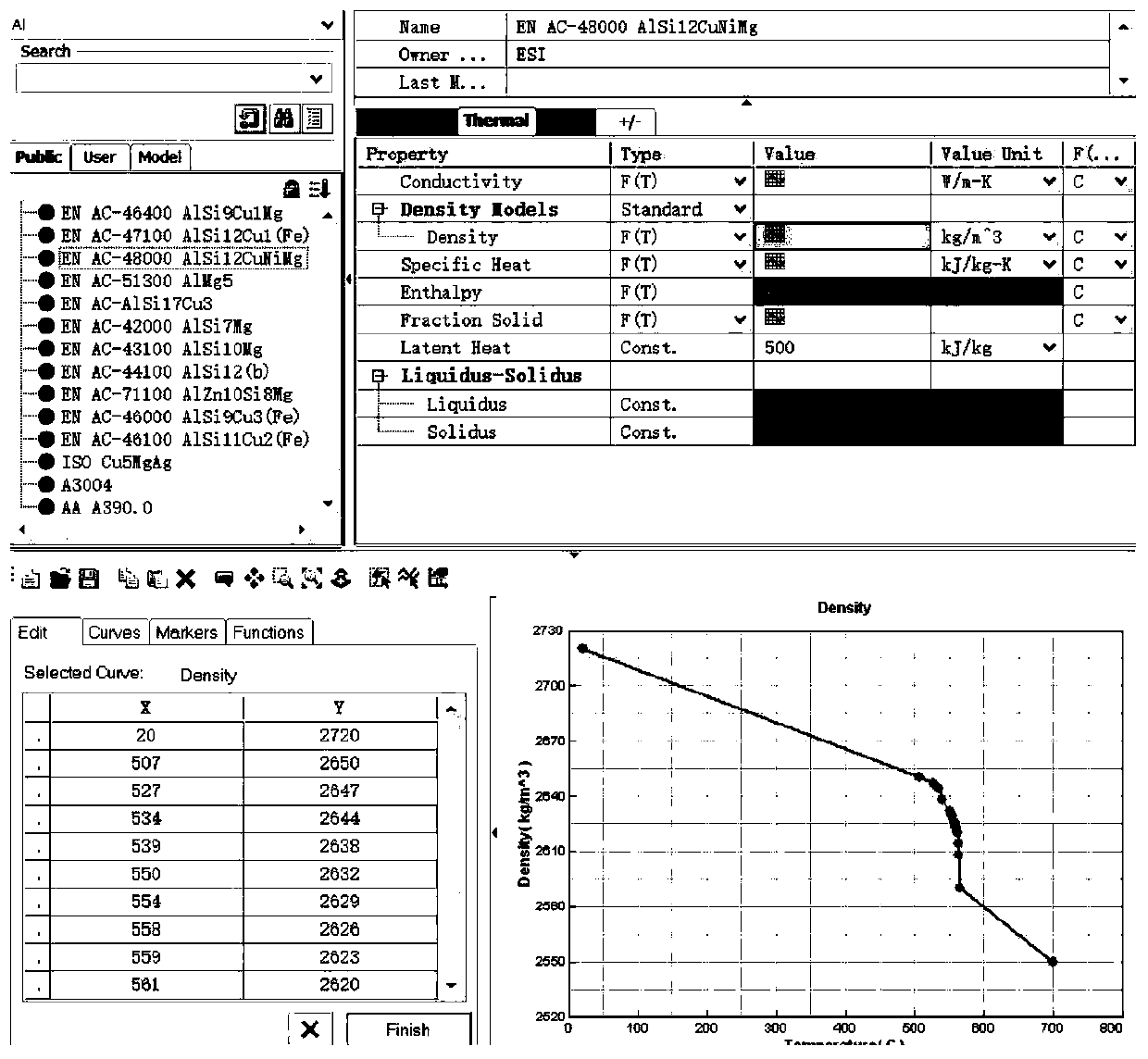

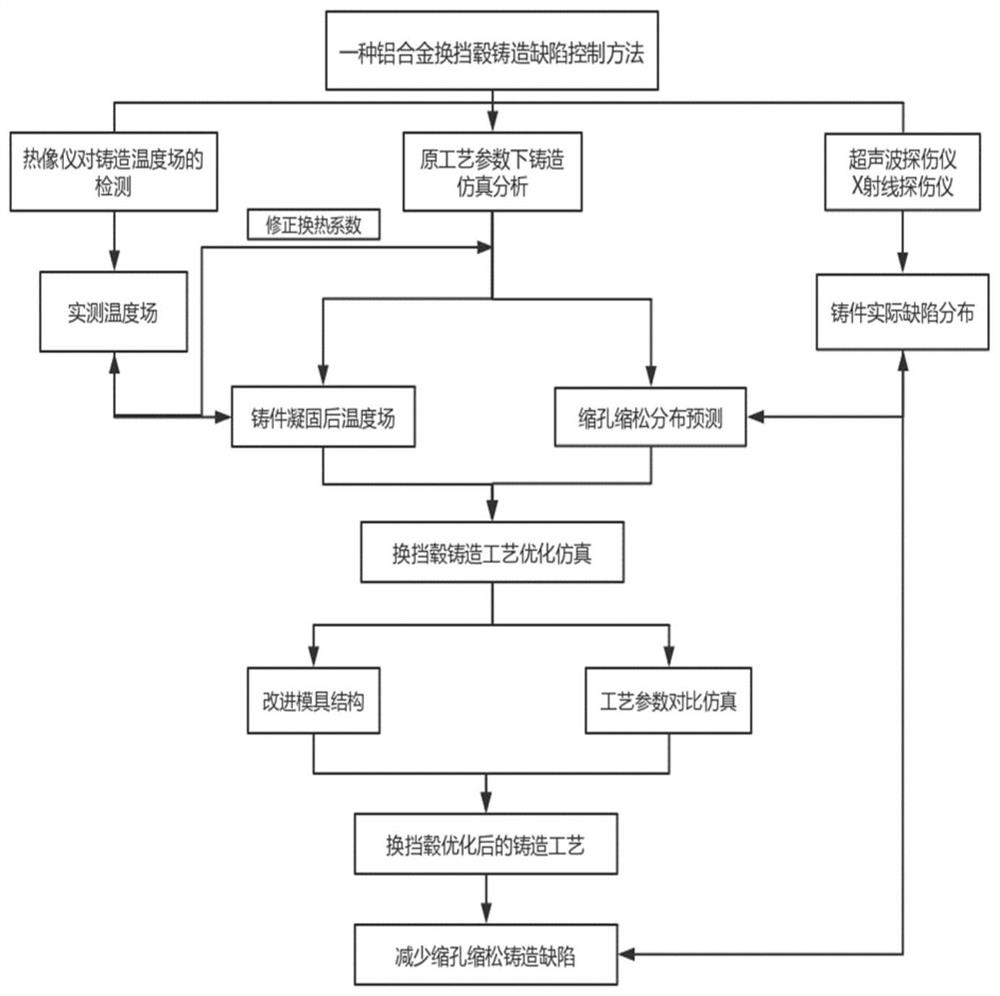

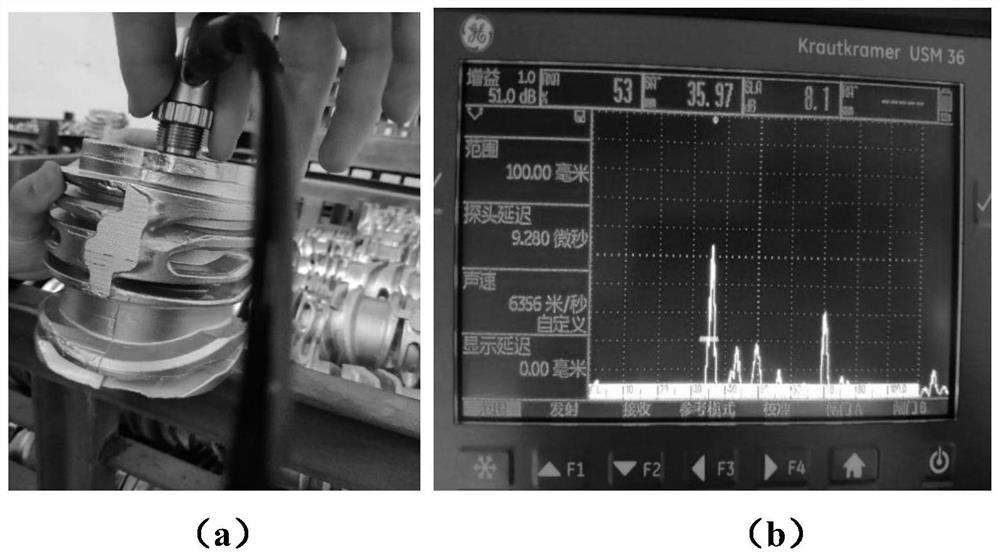

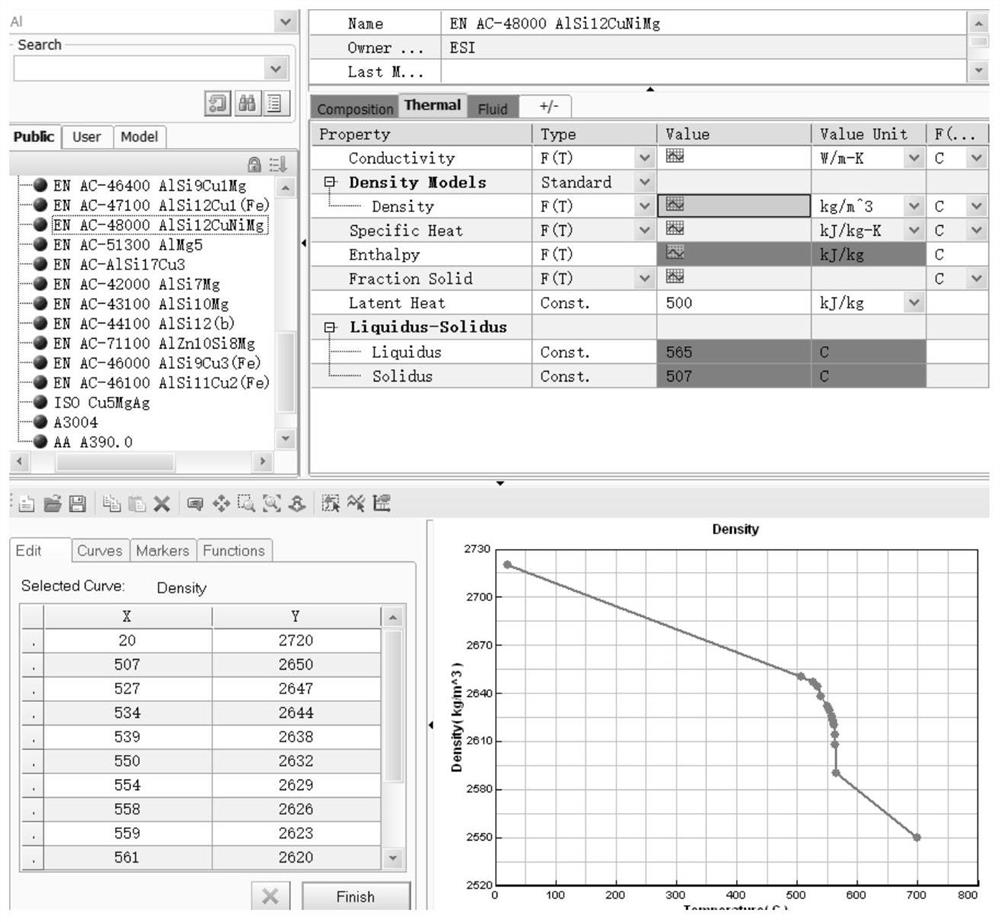

Aluminum alloy gear shifting hub casting defect control method

ActiveCN110976830AQuality improvementTo achieve the purpose of shrinkage cavity shrinkage defect controlMolten metal pouring equipmentsFoundry mouldsLiquid metalCasting defect

The invention provides an aluminum alloy gear shifting hub casting defect control method and belongs to the technical field of liquid metal forming. The aluminum alloy gear shifting hub casting defectcontrol method comprises the steps of detecting the casting temperature in the actual casting die opening process to obtain a casting temperature field; conducting defect detection on actually cast aluminum alloy gear shifting hub casting products to obtain shrinkage porosity casting defect forming areas in the actual casting process; establishing a casting process finite element simulation analysis model, simulating the gear shifting hub die filling and solidifying process through professional casting simulation software ProCAST, comparing the simulation result with an actual detection result and carrying out necessary correction on parameters; and conducting simulation analysis and optimization on technological parameters such as dies, casting temperatures, die preheating temperatures and casting speeds through the simulation model, and obtaining qualified castings with the aluminum alloy gear shifting hub casting shrinkage porosity casting defects improved effectively through trialcasting. Thus, the purposes of improving gear shifting hub casting defects and improving the casting quality are achieved.

Owner:UNIV OF SCI & TECH BEIJING +1

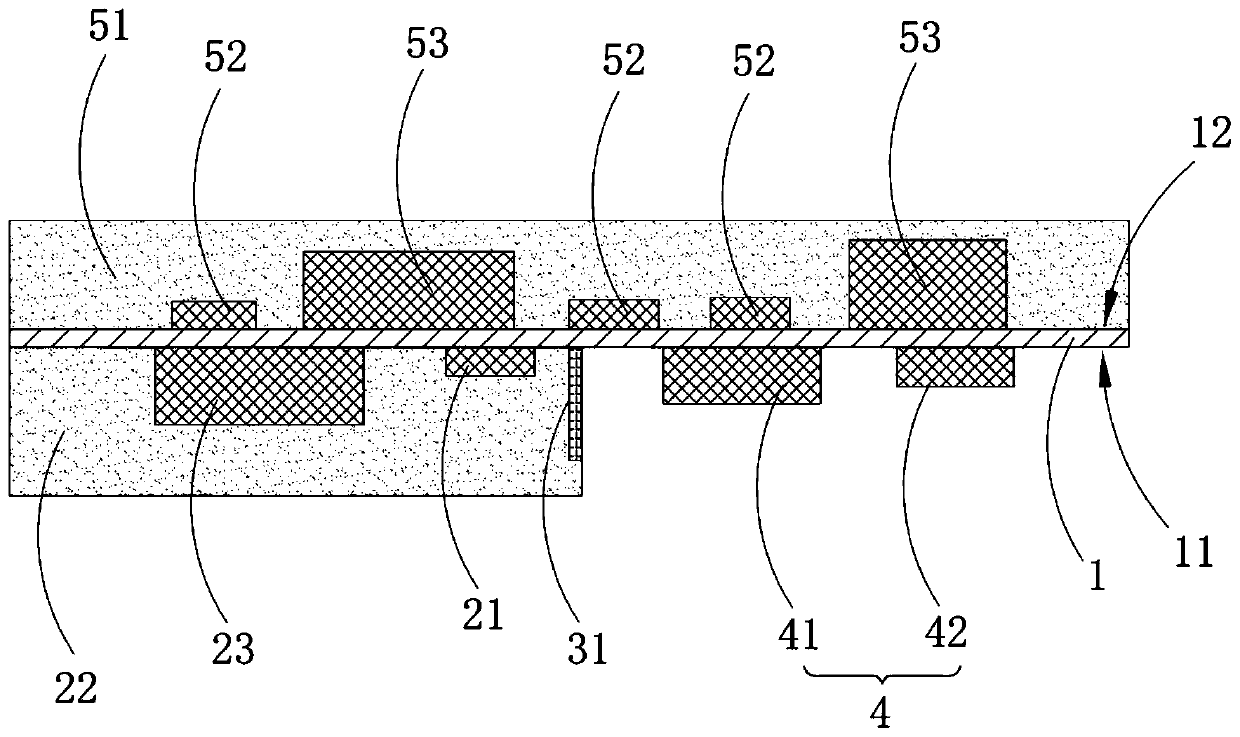

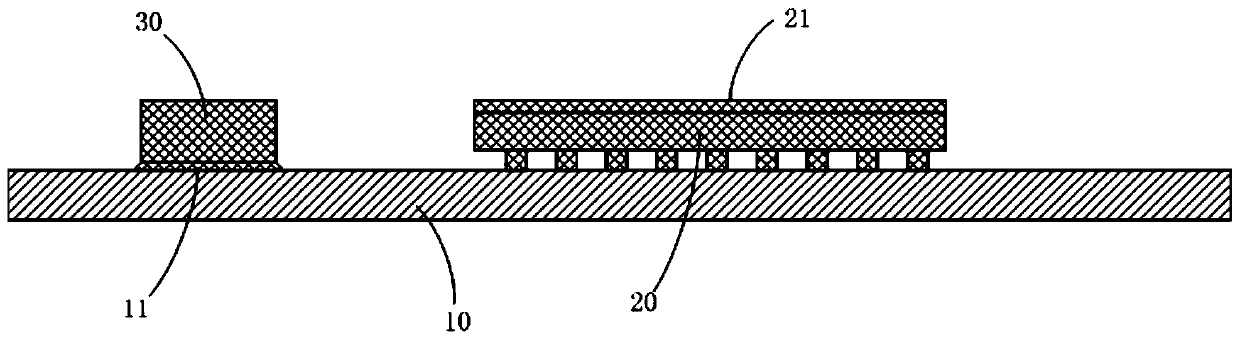

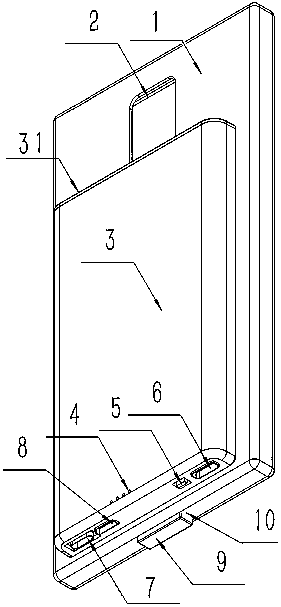

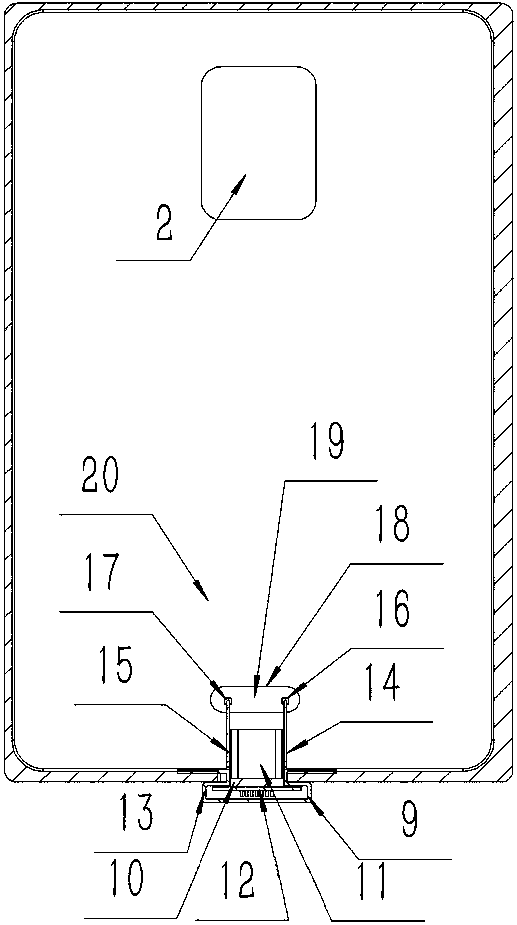

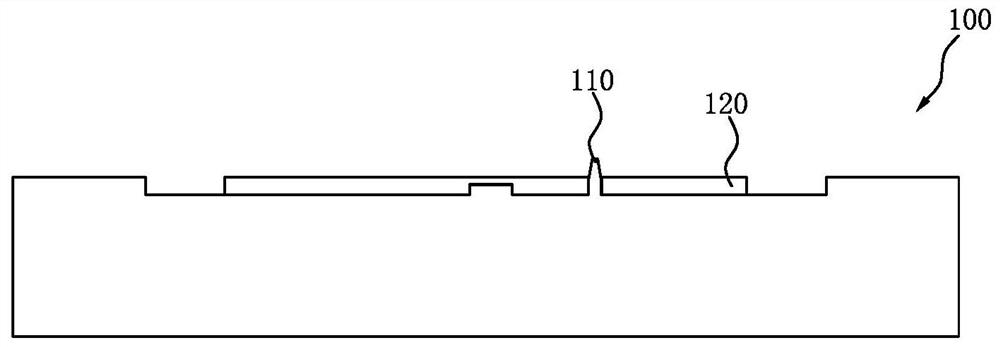

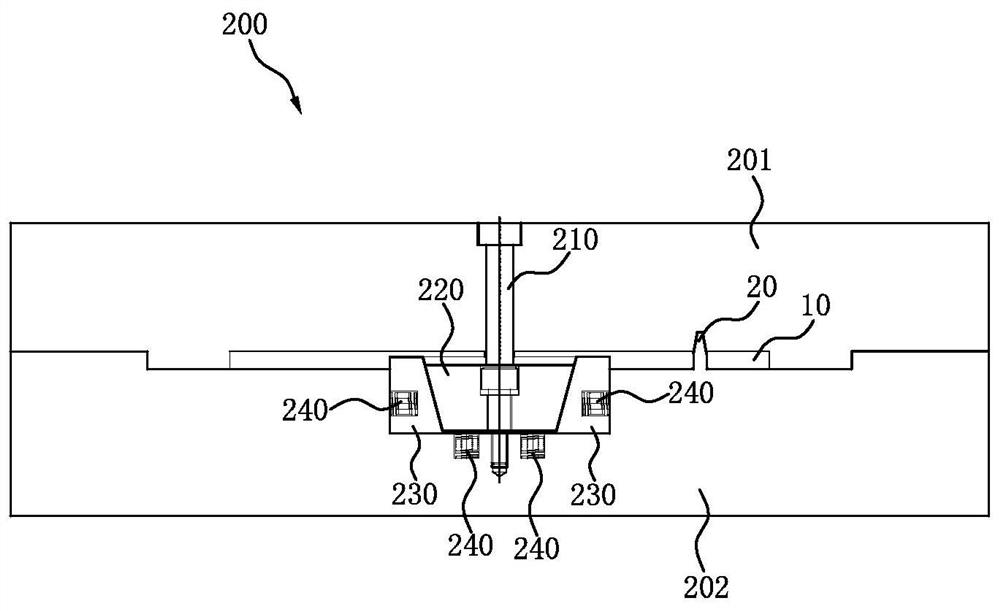

Packaging structure and packaging method of chip

ActiveCN111383927AReduce the cost of mold openingShorten mold opening timeSemiconductor/solid-state device detailsSolid-state devicesStructural engineeringElectrical and Electronics engineering

The invention discloses a chip packaging structure and method, and the method comprises the following steps: installing a first chip and a first element assembly on a first surface of a substrate; installing a cover body structure on the first surface to enable the cover body structure to cover the first element assembly; carrying out plastic package on the first surface of the substrate to form afirst pre-plastic package layer, the first chip and the cover body structure being located in the first pre-plastic package layer; and cutting the first pre-plastic package layer, the cover body structure and the substrate to expose the first element assembly to obtain a first plastic package layer in which the first chip is located. A common mold can be adopted in the plastic packaging process,a special-shaped mold does not need to be used, the mold opening cost and the mold opening time of the mold can be greatly reduced, the dispensing process is easy to control, and the production efficiency is improved.

Owner:QINGDAO GOERTEK INTELLIGENT SENSOR CO LTD

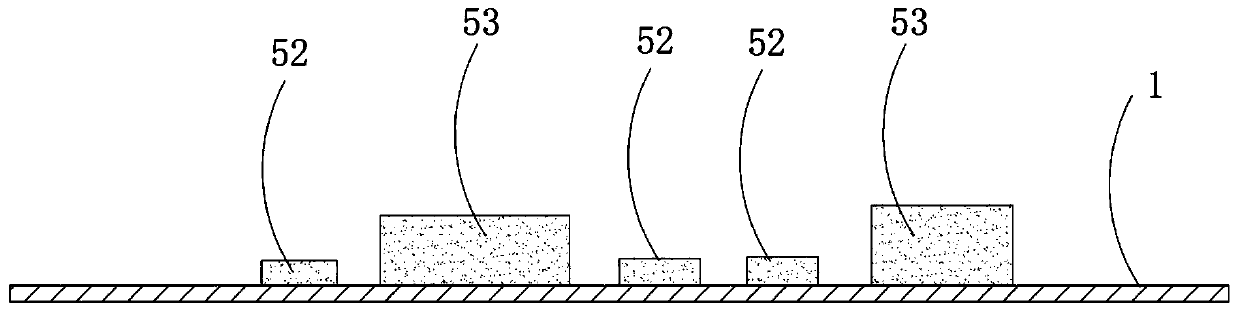

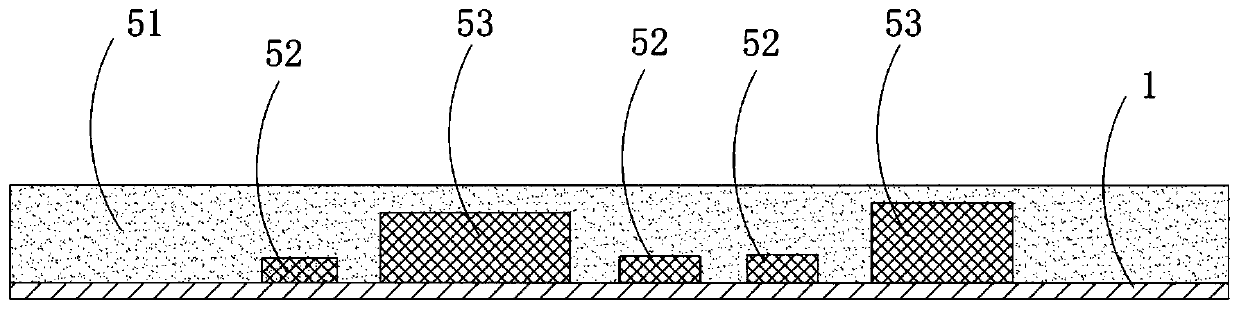

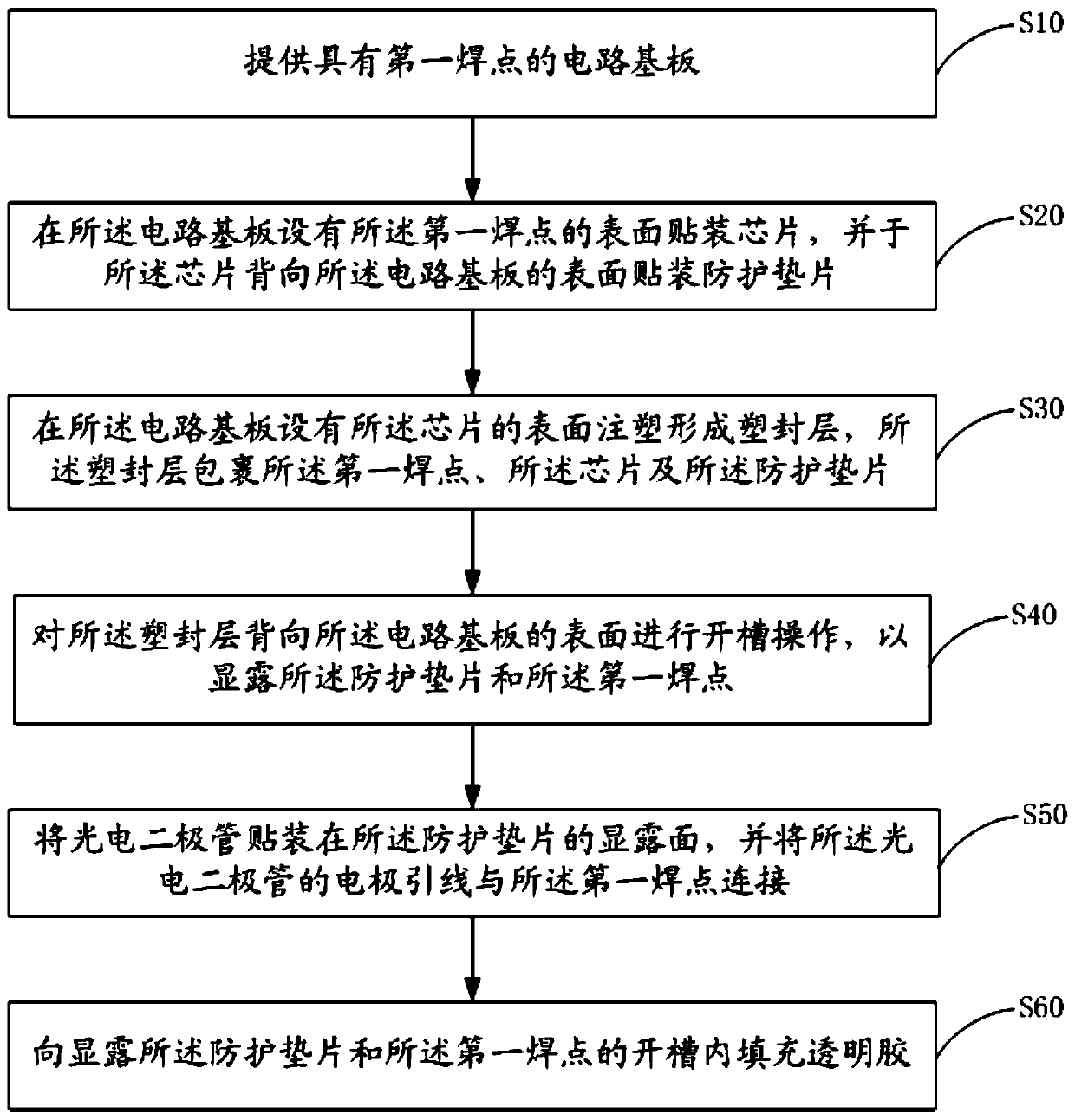

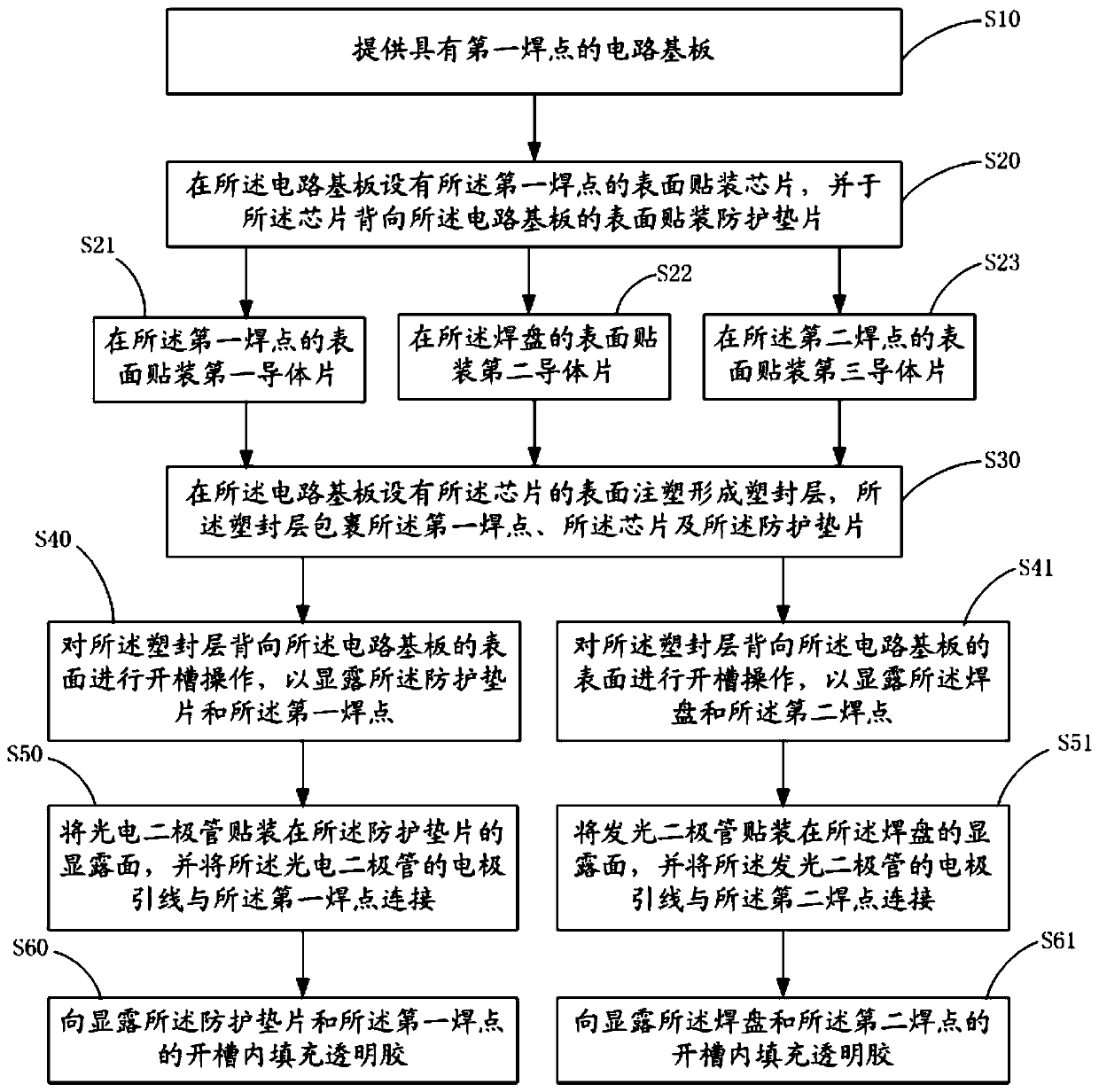

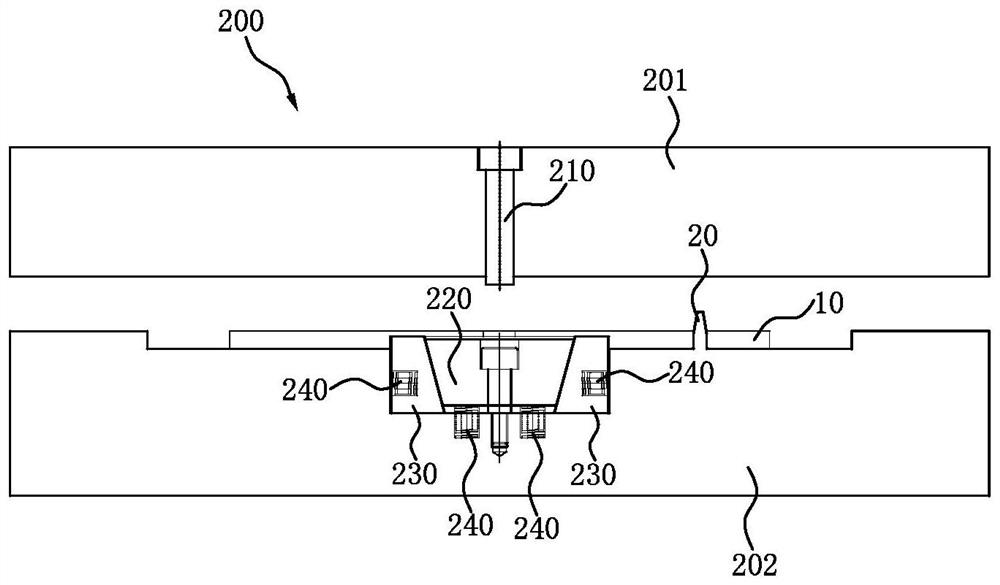

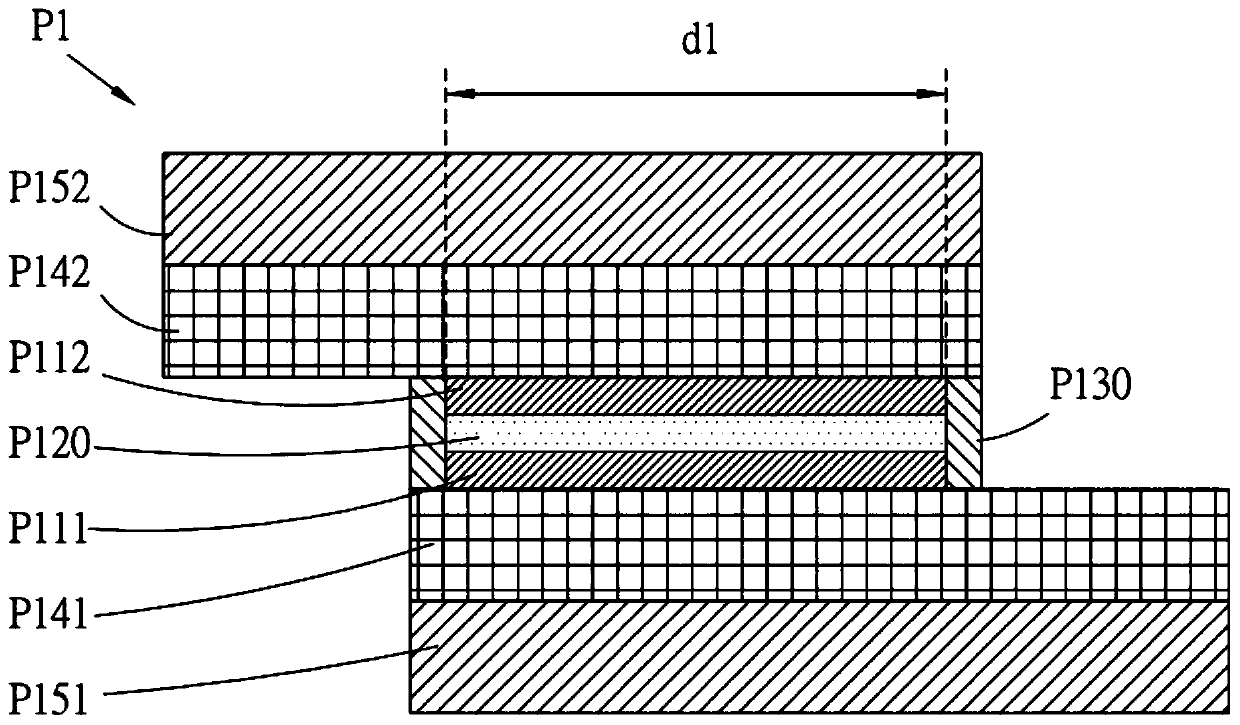

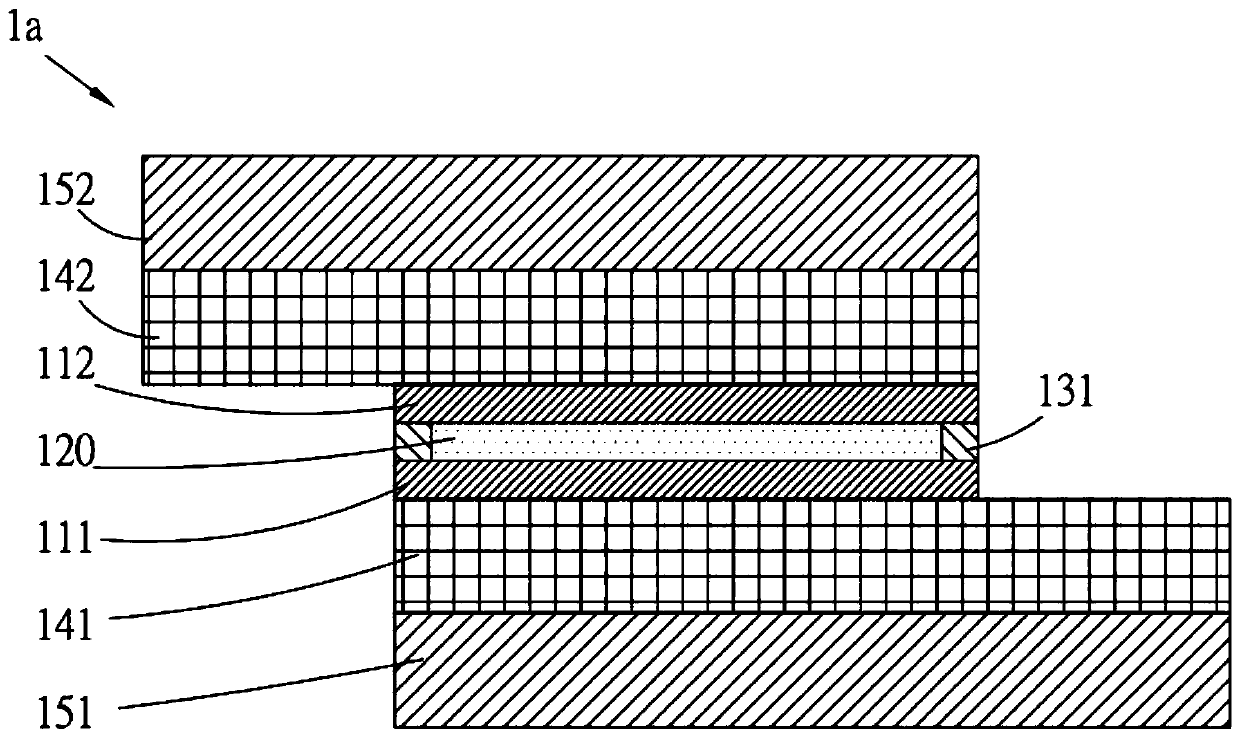

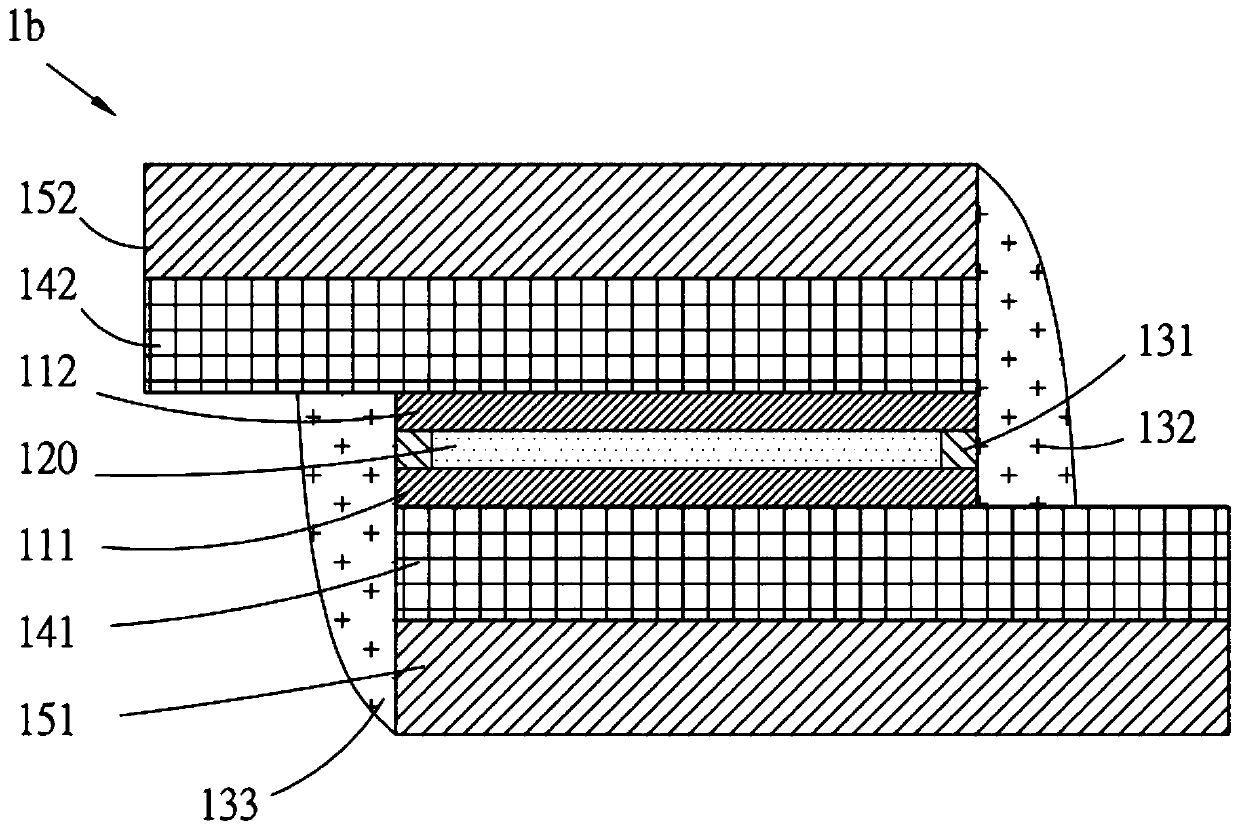

Packaging structure of optical module and packaging method thereof

ActiveCN111009475AShorten mold opening timeReduce the cost of mold openingSemiconductor/solid-state device detailsSolid-state devicesOptical ModuleSurface mounting

The invention discloses a packaging structure of an optical module and a packaging method thereof. The packaging method of the optical module comprises the following steps: providing a circuit substrate with a first welding spot; mounting a chip on the surface, provided with the first welding spots, of the circuit substrate, and mounting a protective gasket on the surface, back to the circuit substrate, of the chip; forming a plastic package layer on the surface, provided with the chip, of the circuit substrate in an injection molding mode, and the plastic package layer wraps the first weldingspots, the chip and the protective gasket; slotting the surface, back to the circuit substrate, of the plastic package layer so as to expose the protective gasket and the first welding spot; and mounting a photodiode on the exposed surface of the protective gasket, and connecting an electrode lead of the photodiode with the first welding spot. According to the technical scheme of the invention, the problems of high development cost, long development period, high processing difficulty of the surface-mounted cover and many defects of a special-shaped mold in a packaging method in the prior artare solved.

Owner:QINGDAO GOERTEK INTELLIGENT SENSOR CO LTD

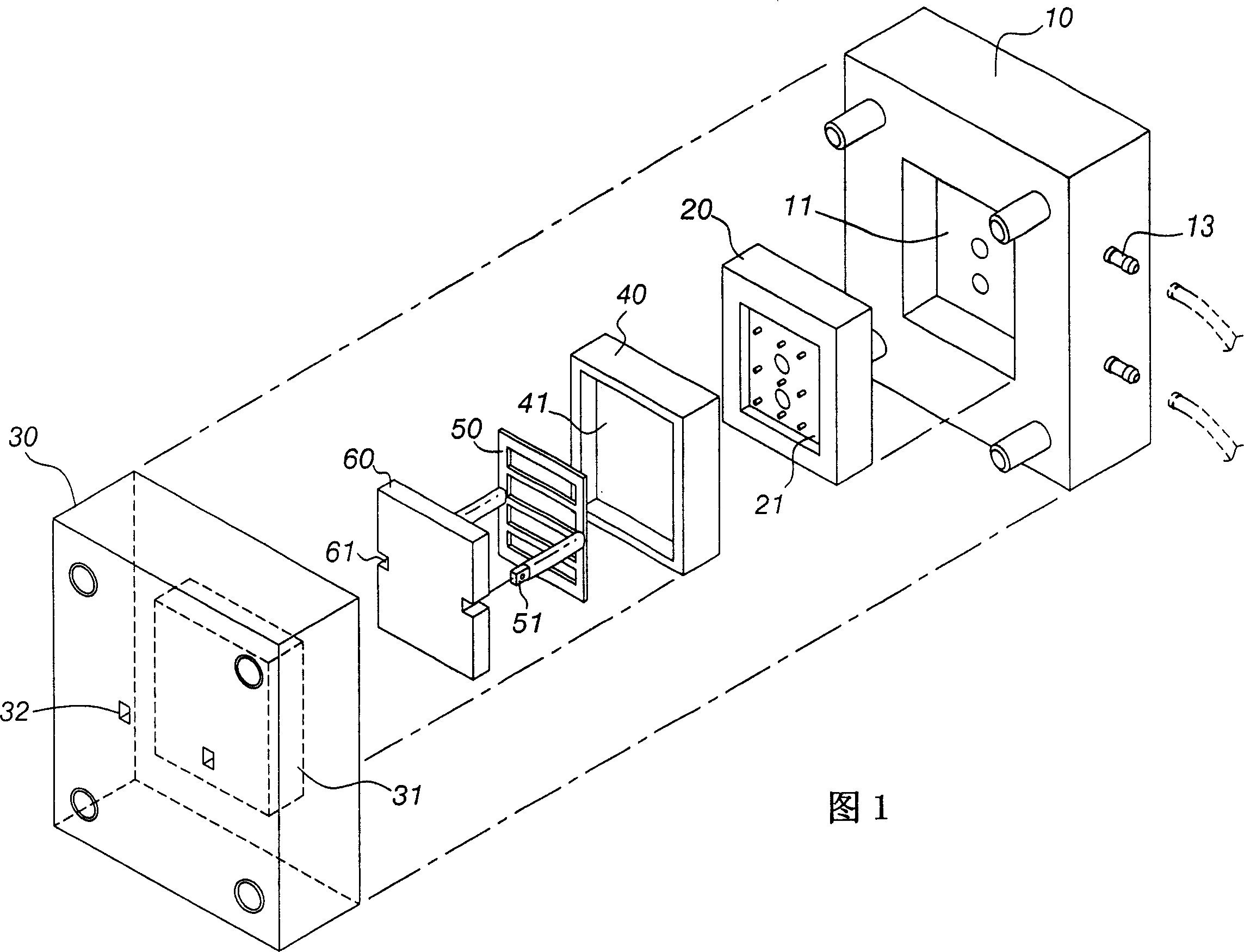

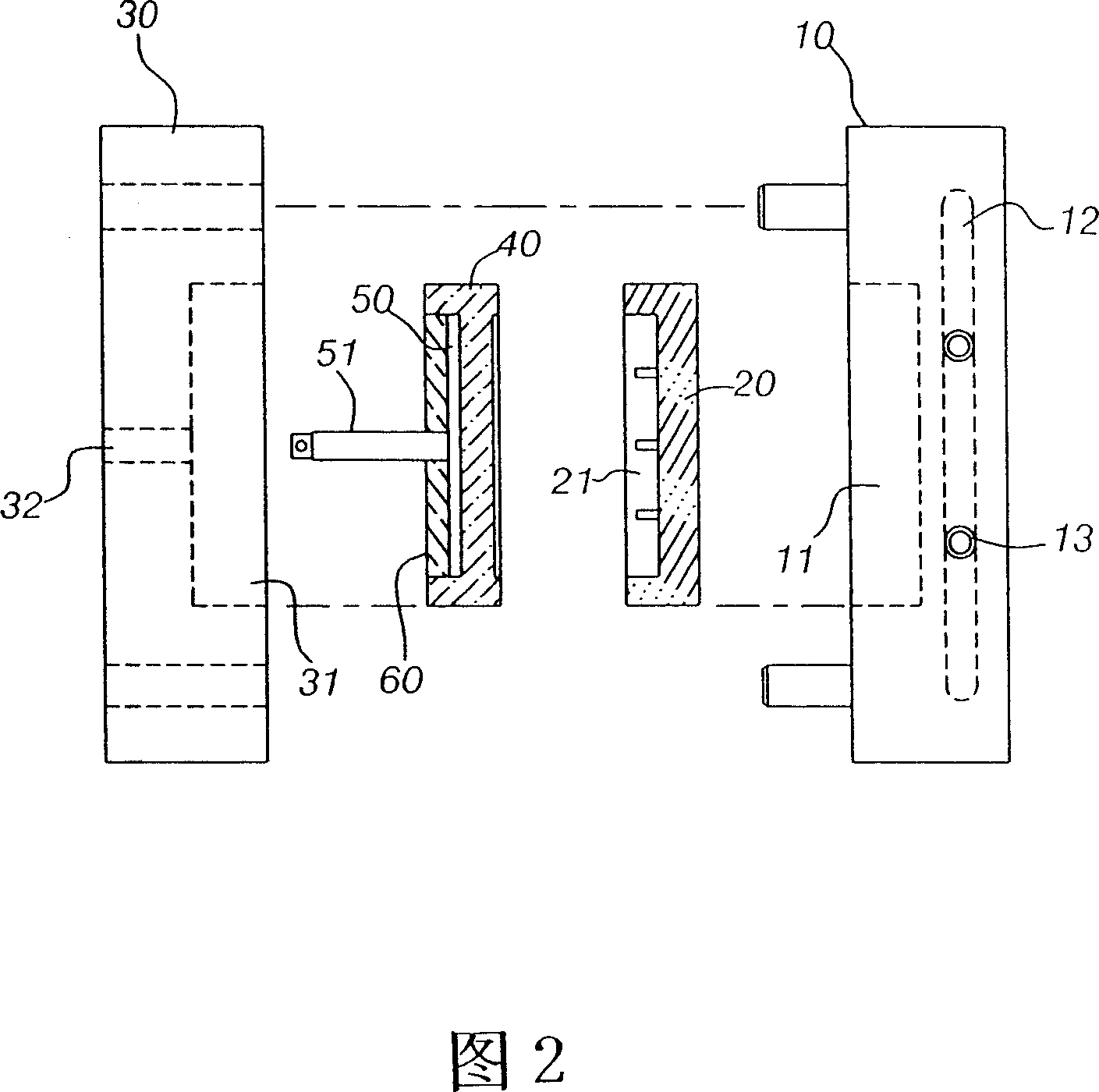

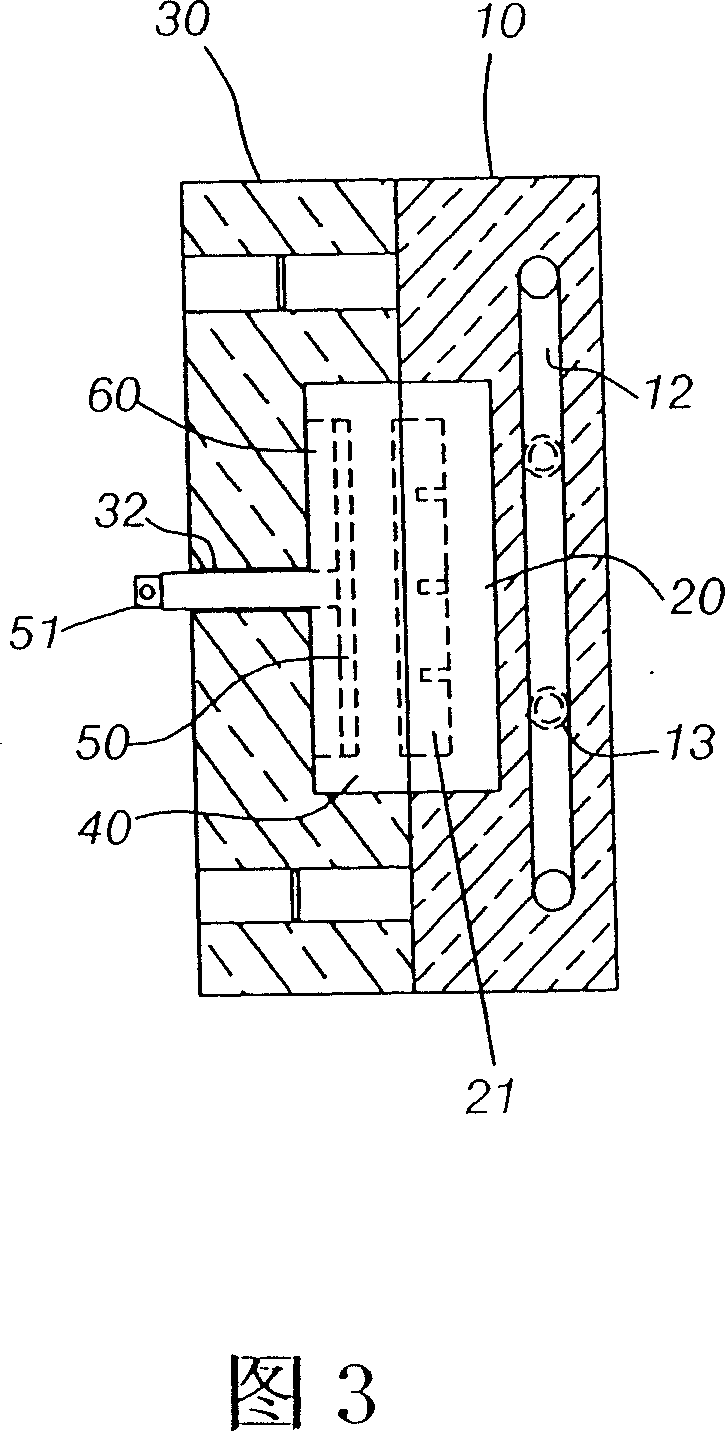

Heating and cooling system for injection molding machine

The present invention relates to one kind of heating and cooling system for injection molding machine. In the mold locking unit comprising one first mold seat and one second mold seat capable of being closed and opened, there are at least one heater set between the second mold seat and the second mold block and one fluid pipe inside the first mold seat. The heating and cooling system can heat and cool the mold fast, and this can eliminate faults of the molded product, reduce mold opening time and raise production capacity.

Owner:张智凯

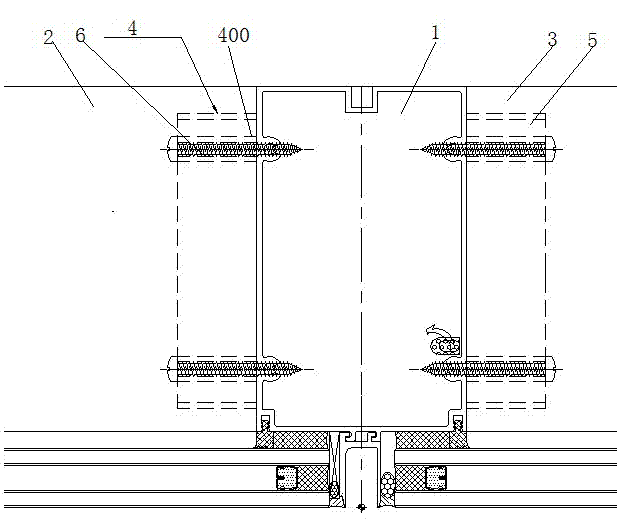

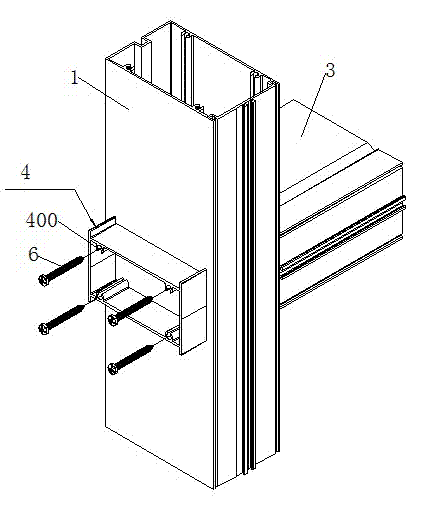

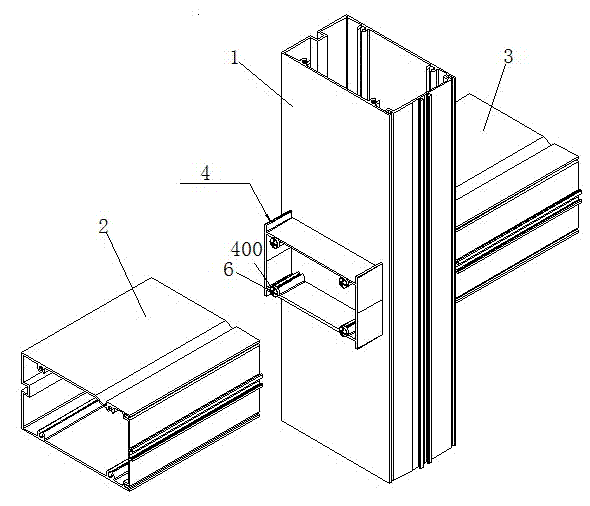

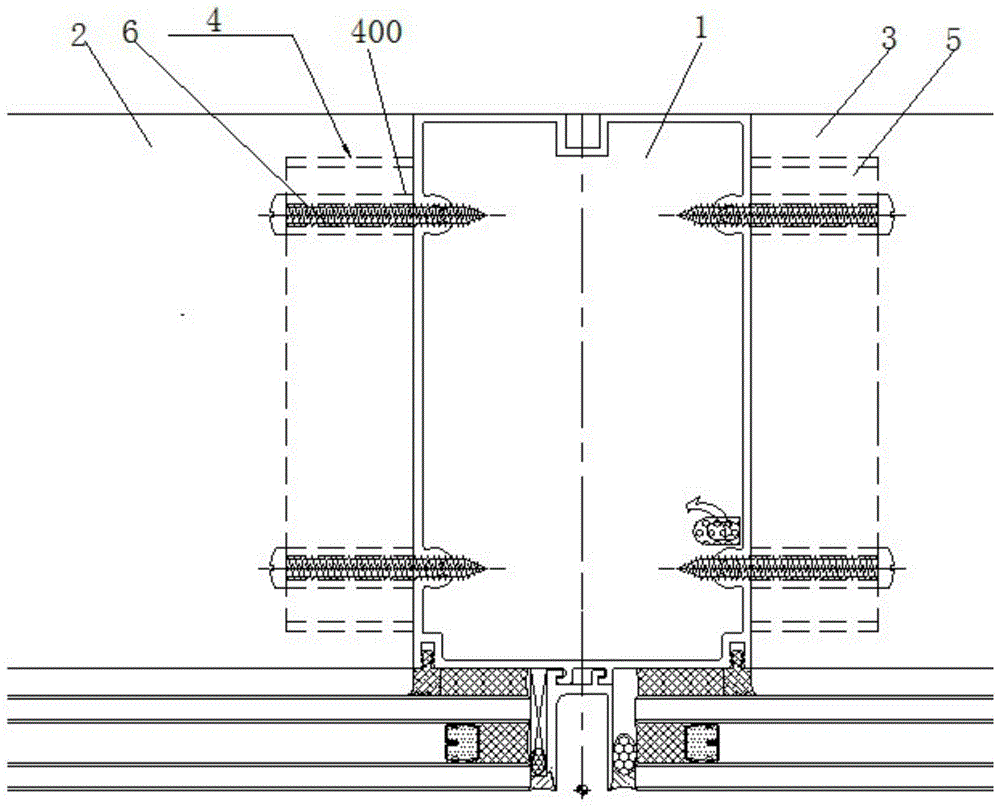

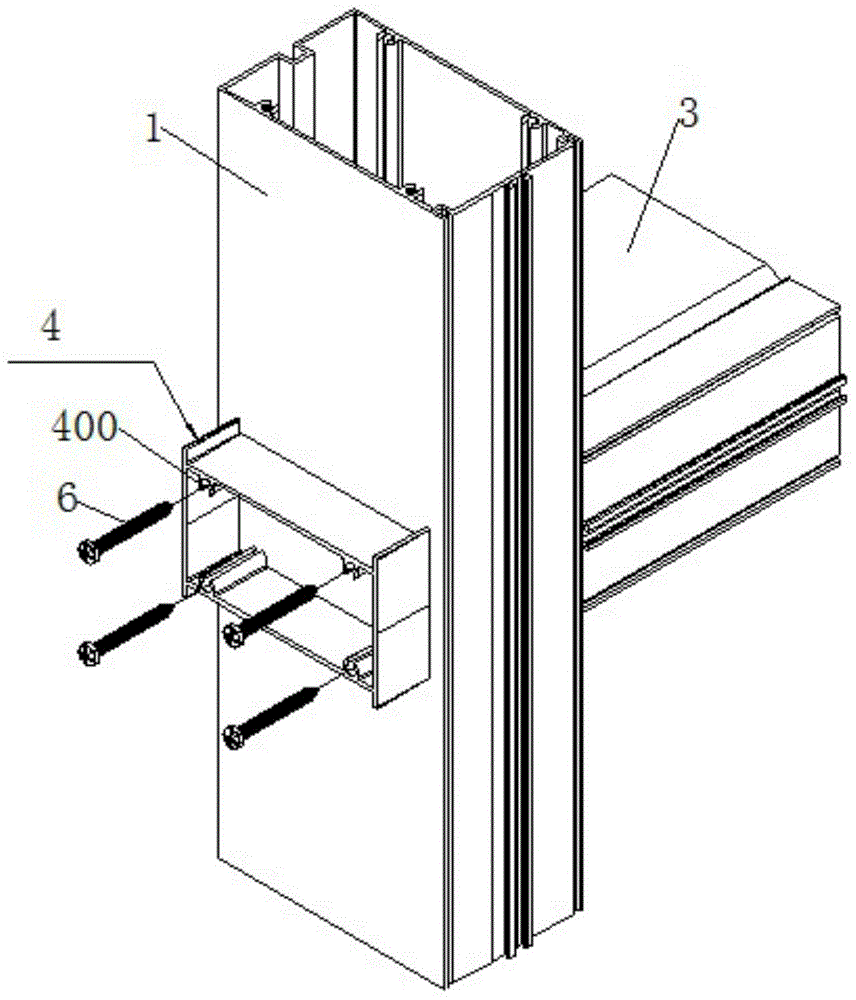

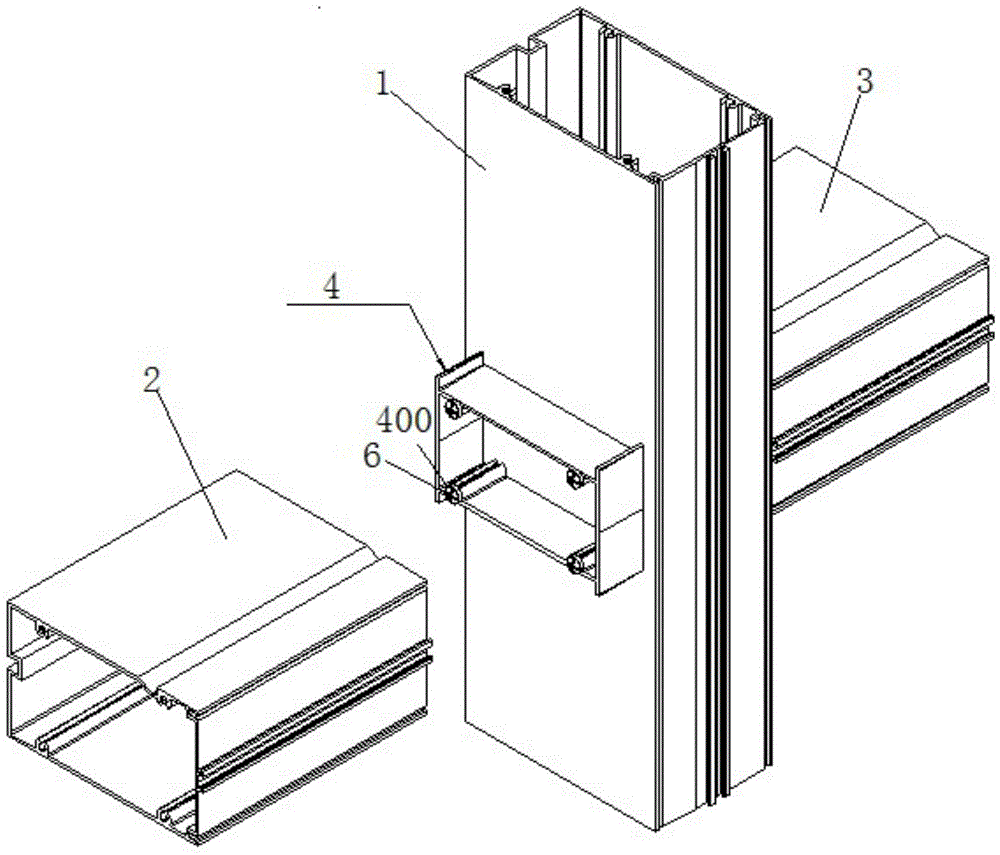

Curtain wall center-pillar beam connection method and connecting device

The invention relates to a curtain wall center-pillar beam connection method. A first mounting hole is longitudinally and penetratingly arranged on a beam. The connection method comprises the following steps: (1) acquiring stub bars, shared the same structure with a to-be-mounted beam, as mounting auxiliaries with second mounting holes; (2) manufacturing connecting bolts; (3) acquiring bolts matching with a third mounting hole; (4) placing mounting auxiliaries at the mounting positions of the beam of the center pillar, inserting each connecting bolt into corresponding second mounting holes, screwing the bolts into a third mounting hole so as to fix the connecting bolts on the center pillar; (5) longitudinally pulling out and removing the mounting auxiliaries; and (6) inserting the to-be-mounted beam on the connecting bolts. The connecting bolts comprise a beam connecting portion and a bolt mounting portion, the beam connecting portion is matched with the first mounting hole of the beam, and the third mounting hole is arranged on the bolt mounting portion. The invention further relates to a curtain wall center-pillar beam connecting device.

Owner:JANGHO GRP

Die for die casting

The invention relates to the technical field of dies, and provides a die for die casting. The die for die casting aims to reduce the difficulty of frame producing and machining, improve the qualifiedrate of finished products, and is used for die casting production of the frame. In a fixed die, a mold cavity is formed in a fixed die core and is mounted in a fixed die groove in the middle of a fixed die plate. In a moving mold, a moving die core is provided with a mold core and a slag ladle groove and is mounted in a moving die groove in the moving die plate. The die core corresponds to the position of the mold cavity. The slag ladle groove is close to the end portion of the mold core. A die foot is located at the bottom of the moving die plate and is fixedly connected with the two ends ofthe moving die plate. In an exhausting mechanism, a fixed exhausting plate is mounted on and fixed to the fixed die plate, a moving exhausting plate is mounted on and fixed to the moving die plate, and a fixed exhausting groove in the moving exhausting plate communicates with the slag ladle groove. During die closing, the fixed exhausting plate is buckled with the moving exhausting plate, and a fixed exhausting groove in the fixed exhausting plate is in butt joint with a moving exhausting groove to form an exhausting channel. By using the die for die casting, deformation can be reduced, the machining difficulty is reduced, and the yield of finished products is improved.

Owner:SHANGHAI PRECISE IND

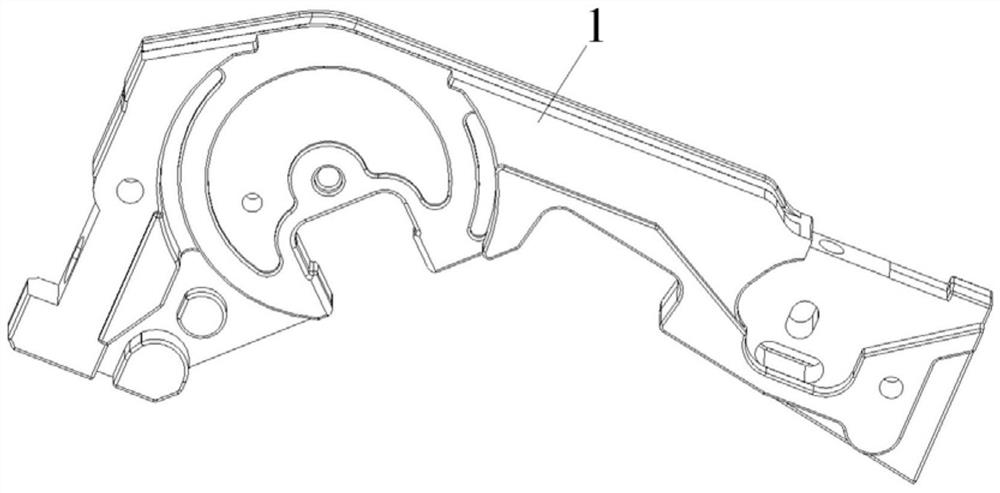

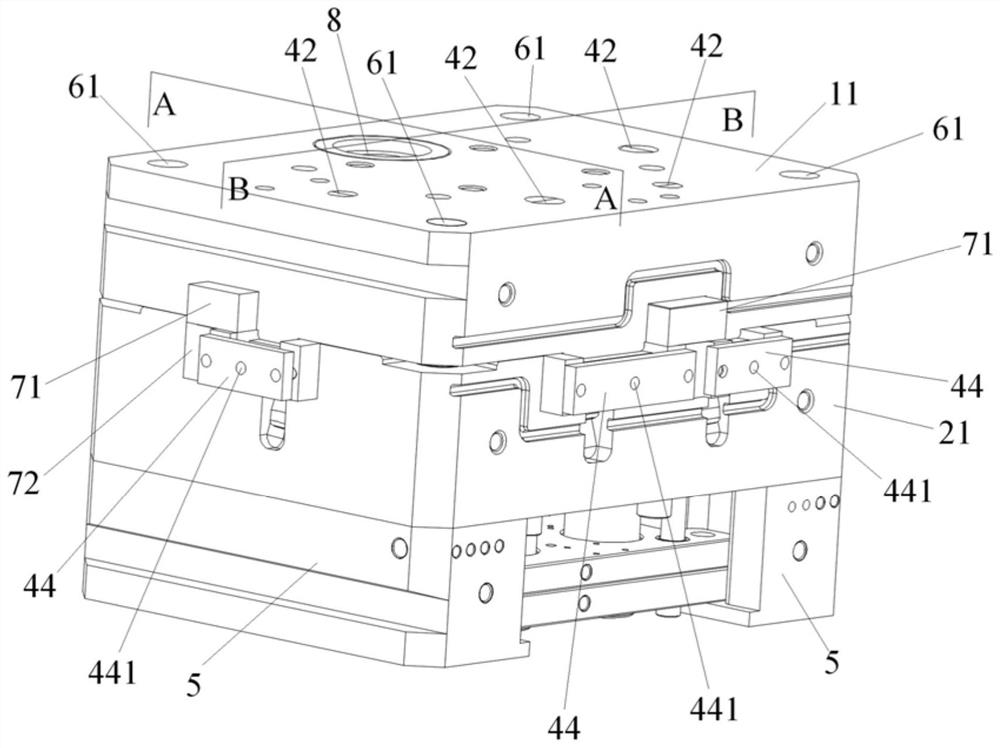

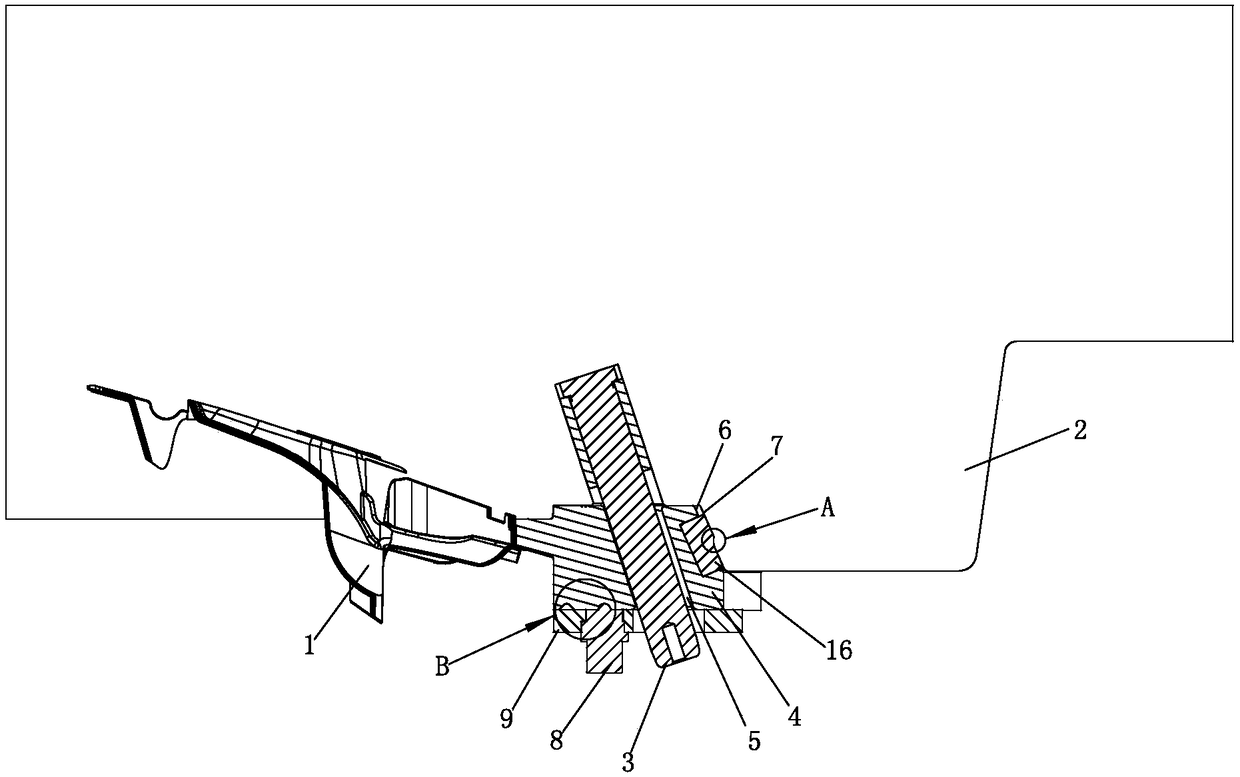

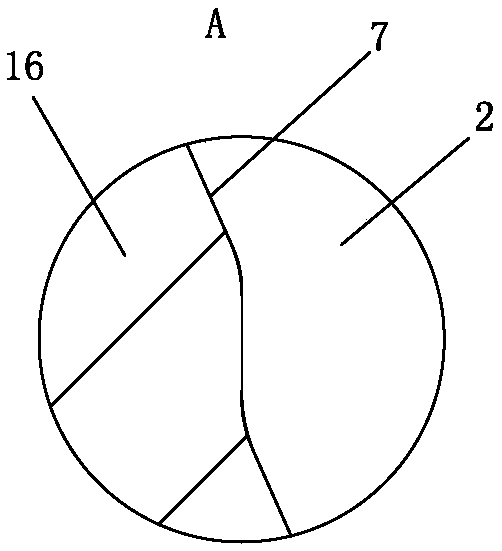

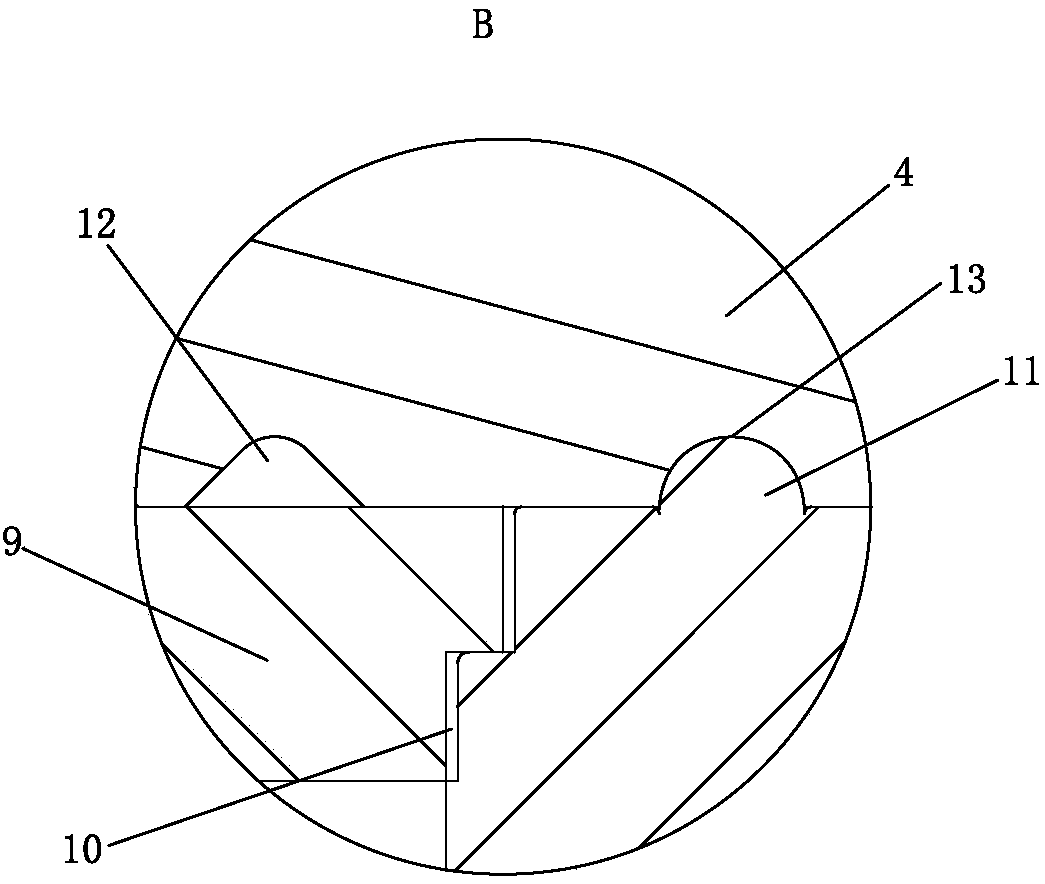

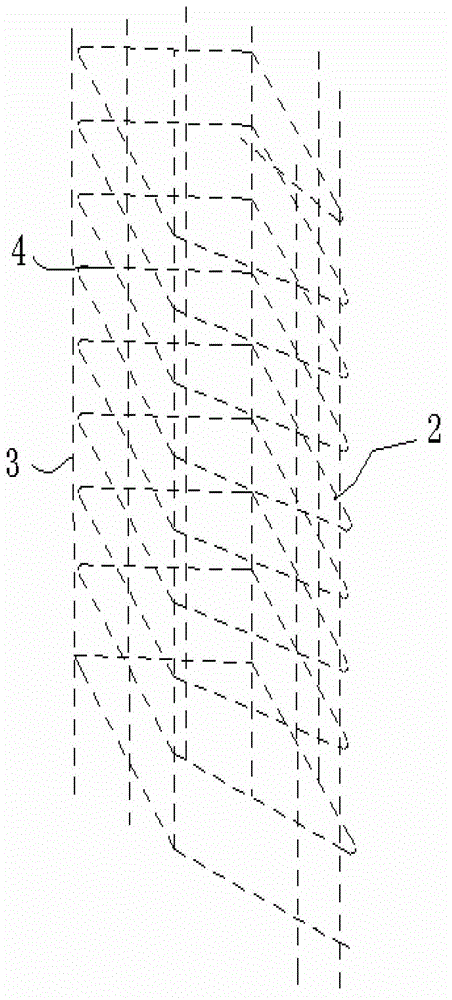

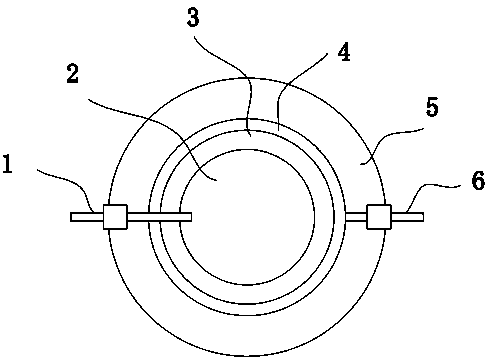

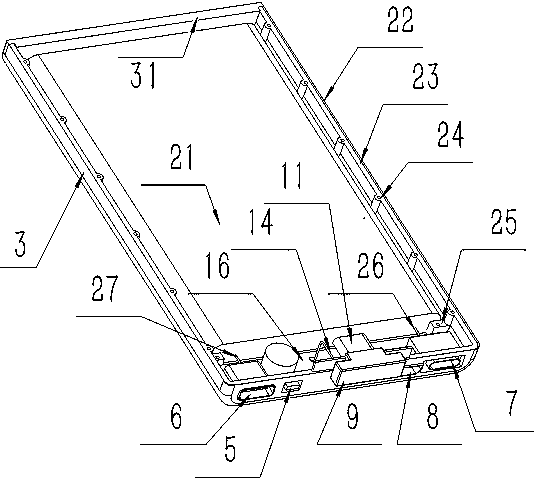

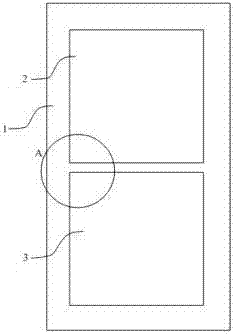

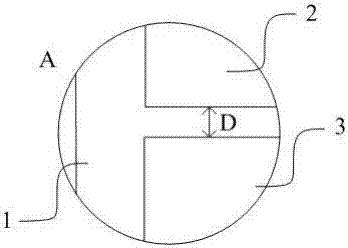

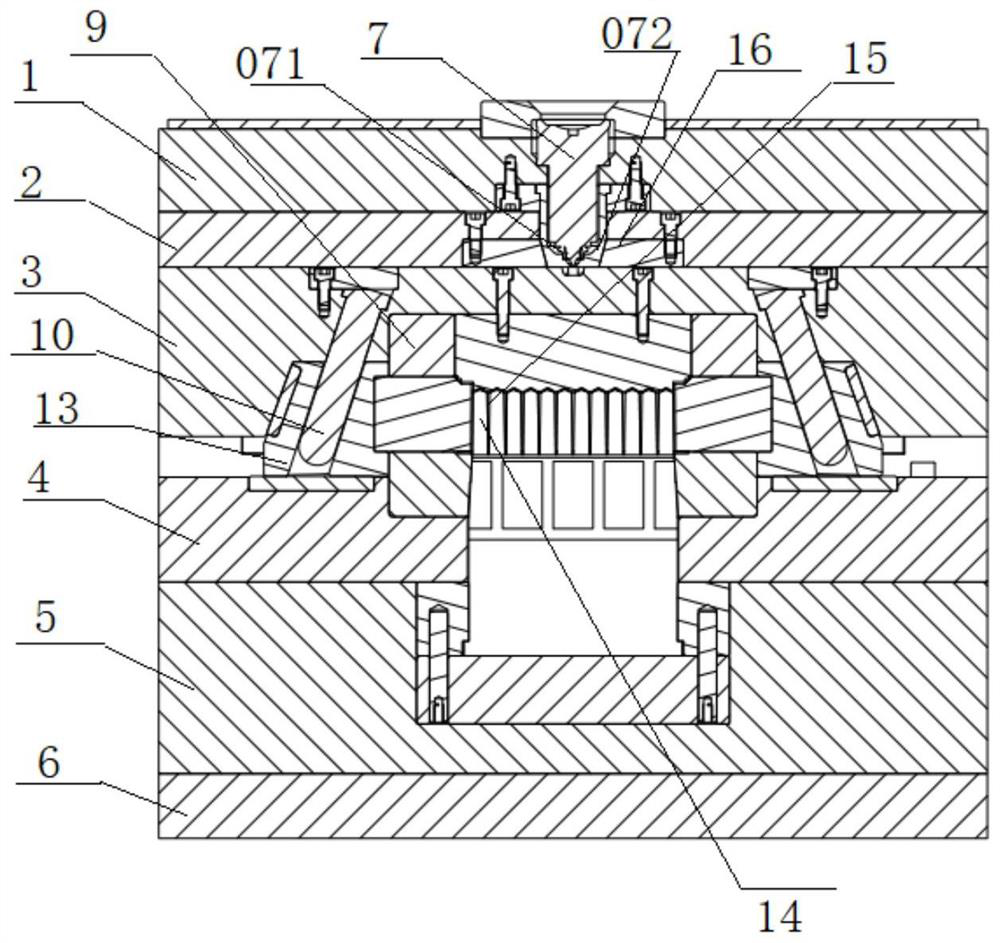

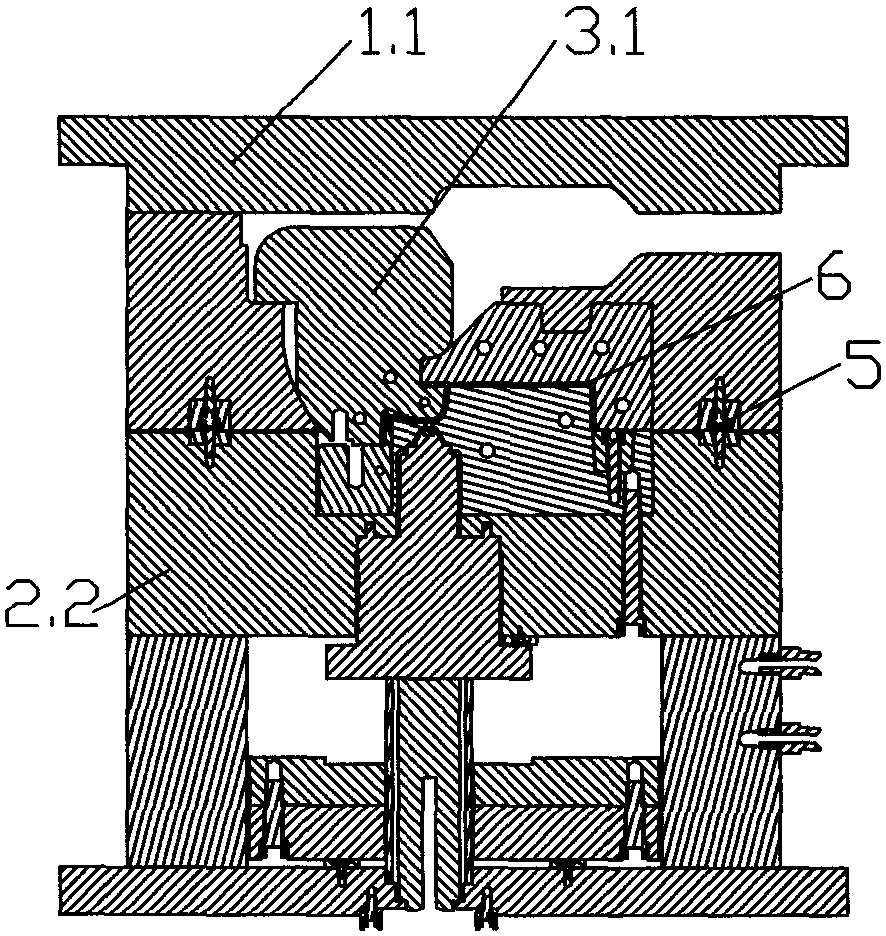

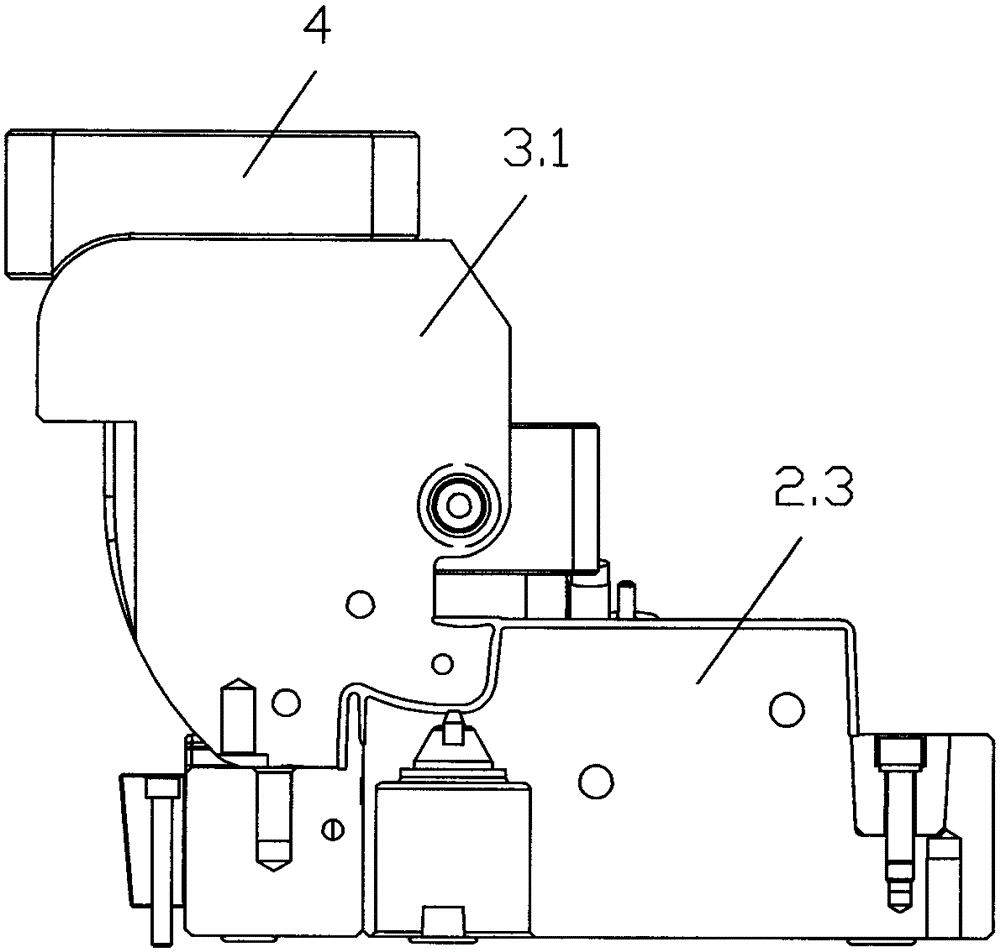

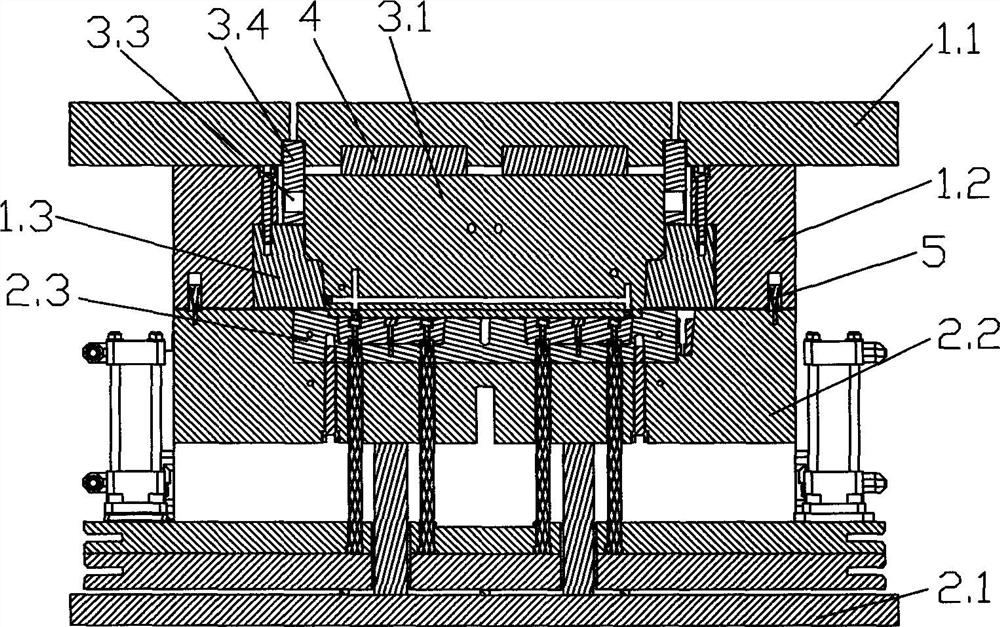

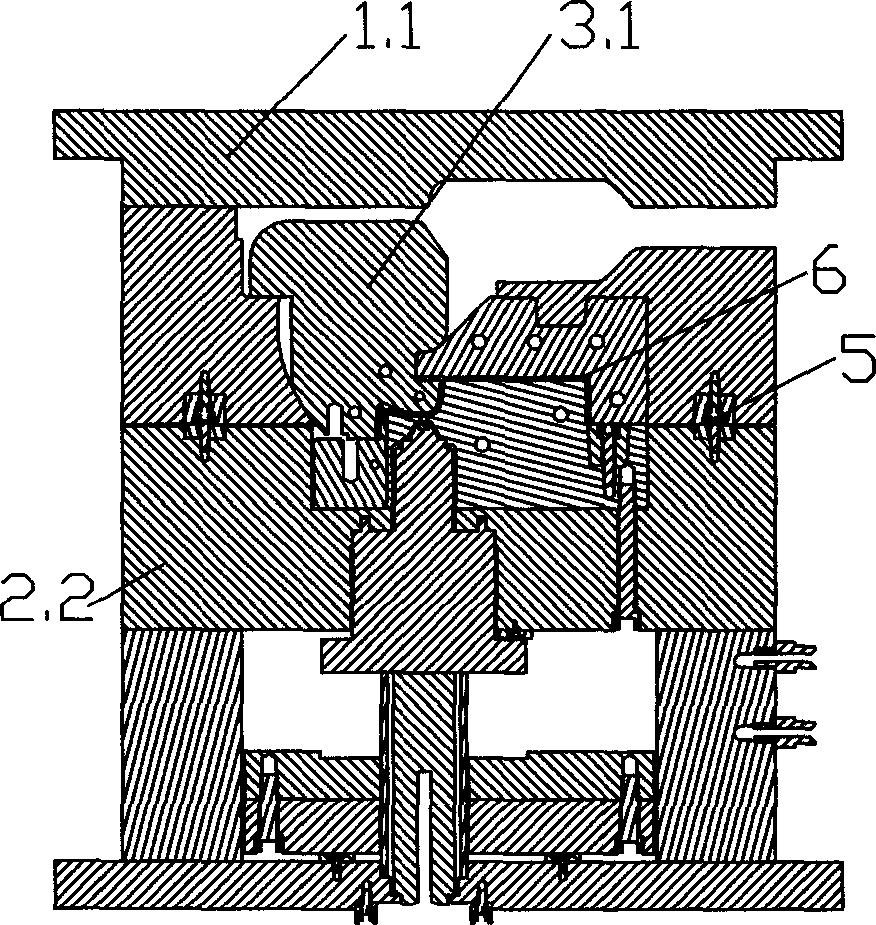

Mechanism used for separating product from fixed mould and capable of limiting slide block by adopting perpendicular locking surface for fixed mould and deep rib

The invention discloses a mechanism used for separating a product from a fixed mould and capable of limiting a slide block by adopting a perpendicular locking surface for the fixed mould and a deep rib. The mechanism comprises a mould cavity (1), an inclined guide post (3) arranged on the fixed mould (2) and the slide block (4) which is arranged on a movable mould in a sliding mode, wherein one end, close to the mould cavity (1), of the slide block (4) is a side wall, which corresponds to the mould cavity (1), of the deep rib, and is positioned above a position, which corresponds to the mouldcavity (1), of a product edge; height of one end, close to the mould cavity (1), of the slide block (4) is a value obtained by subtracting 1.0-3.5mm from height of the deep rib; a stroke limiting mechanism is arranged between the slide block (4) and the movable mould; an inclined hole (5) which is in sliding fit to the inclined guide post (3) is formed in the slide block (4); the inclined hole (5)is greater than the outer diameter of the inclined guide post (3); one end, away from the mould cavity (1), of the slide block is equipped with an inclined surface (6); and a pressing surface (7) which presses the slide block (4) when the pressing surface is matched with the inclined surface (6) for closing the mould is arranged on the fixed mould (2). Compared with the prior art, the mechanism has characteristics of being simple in structure, convenient to maintain and repair, and capable of increasing the product yield.

Owner:NINGBO FANGZHENG TOOL

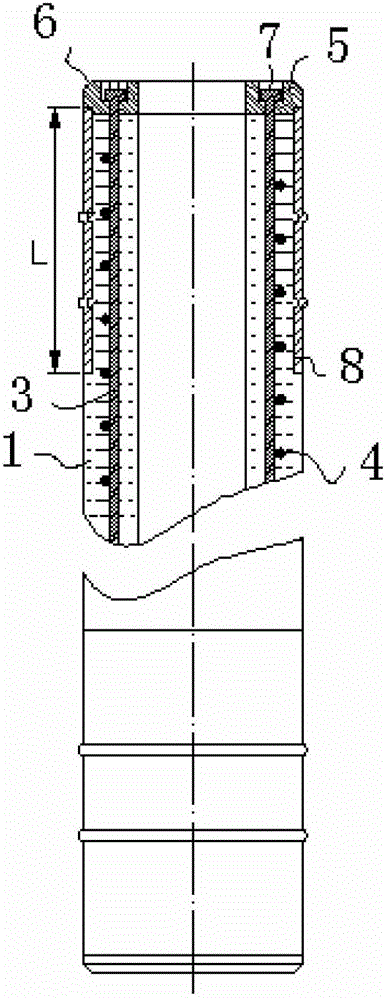

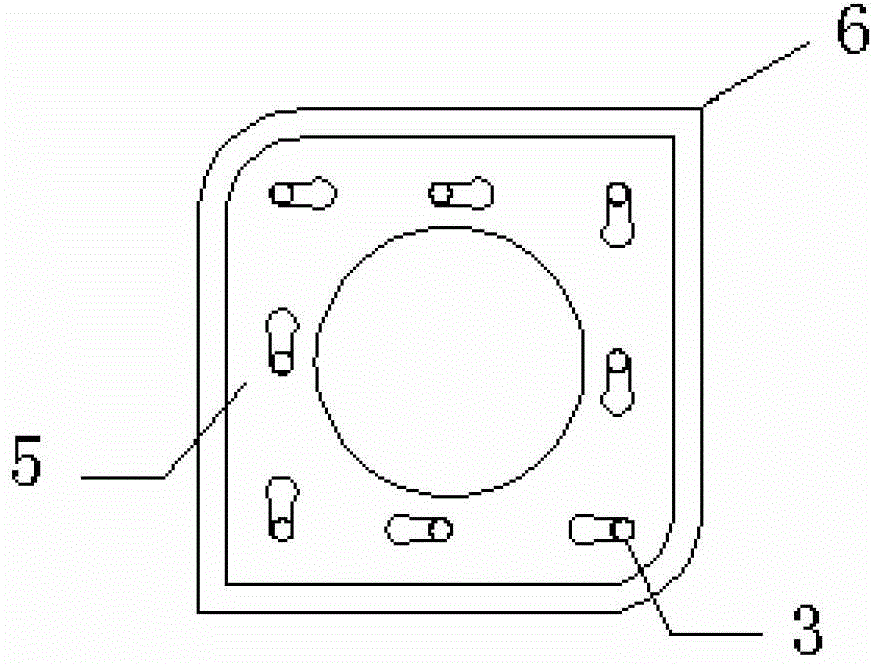

Prestressed centrifugal square pile

InactiveCN102747728AAdvanced preparation technologyHigh strength guarantee rateBulkheads/pilesRebarDuctility

The invention provides a prestressed centrifugal square pile. The square pile comprises a pile body formed by concrete and a reinforcement cage, wherein the reinforcement cage comprises a main reinforcement and a reinforcement stirrup; the reinforcement stirrup is spirally and continuously welded on the main reinforcement; both ends of the pile body are provided with end plates connected with the reinforcement cage; a hoop is arranged at a joint of the end plate and the pile body; the pile body is square in appearance and corners on four sides of the pile body are provided with a pair of stress relieving arc angles and a pair of right angles; the radius R of the arc angles is 5-9mm; the length L of the hoop is 110mm-320mm; the hoop is provided with 2-4 bulges with the radius of 1-3mm along the axial direction of the pile body; the main reinforcement is parallel to an outline of the pile body and is provided with an upset head at the joint with the end plate. The prestressed centrifugal square pile has the advantages of material saving, light self weight, no easy damage, good pile body ductility, high pile bearing capacity and good bending resistance. The pile body has a high concrete strength of C60-C80; the bearing capacity provided by a single pile is 30% higher than the ordinary process, the economical efficiency is high, and the cost is saved by nearly 25%.

Owner:TIANJIN JIANCHENGJIYE GRP

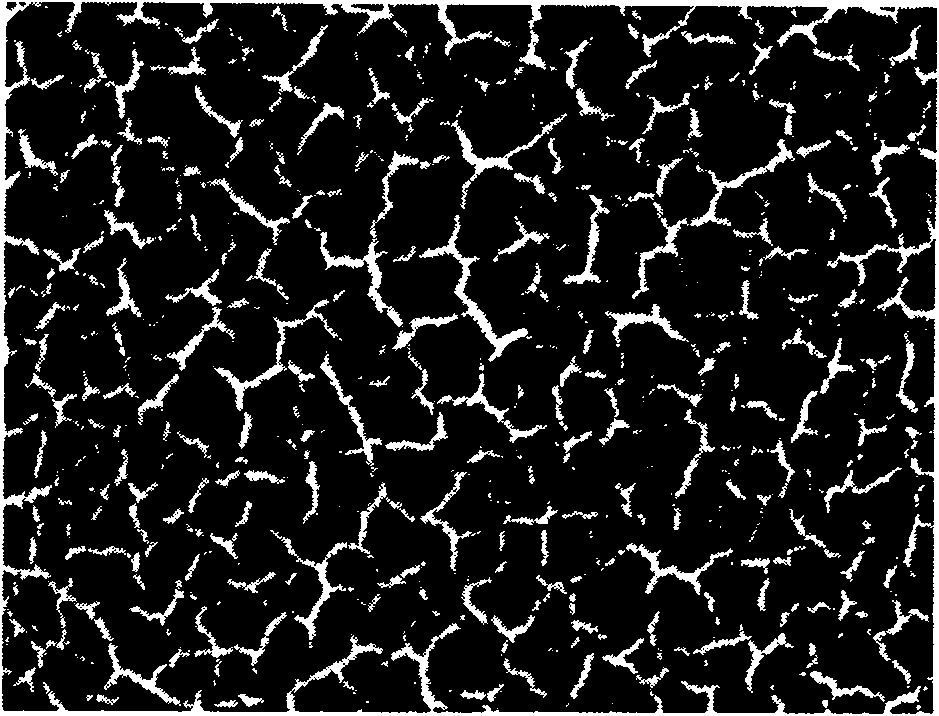

Method for spray coating of crackle lacquer

InactiveCN100581658CImprove adhesionSame adhesionPretreated surfacesArtistic surface treatmentPolymer scienceCrazing

The invention relates to a method for plating crack paint, which comprises a, plating the polypropylene bottom paint on the surface of product made from modified polypropylene material, the bottom paint can be grey, black, or grey-white bottom paint; b, drying said bottom paint and plating the acroleic acid bottom paint that diluted by dimethylbenzene solvent, drying; c, plating the polypropylene crack paint diluted by the crack solution on the acroleic acid bottom paint, drying; d, plating the polyurethane paint diluted by polyurethane solvent and added with solidifier on the polypropylene crack bottom, and drying. The invention has low cost.

Owner:BYD CO LTD

A Control Method for Casting Defects of Aluminum Alloy Shift Hub

ActiveCN110976830BCredibleEffectiveMolten metal pouring equipmentsFoundry mouldsLiquid metalCasting defect

The invention provides an aluminum alloy gear shifting hub casting defect control method and belongs to the technical field of liquid metal forming. The aluminum alloy gear shifting hub casting defectcontrol method comprises the steps of detecting the casting temperature in the actual casting die opening process to obtain a casting temperature field; conducting defect detection on actually cast aluminum alloy gear shifting hub casting products to obtain shrinkage porosity casting defect forming areas in the actual casting process; establishing a casting process finite element simulation analysis model, simulating the gear shifting hub die filling and solidifying process through professional casting simulation software ProCAST, comparing the simulation result with an actual detection result and carrying out necessary correction on parameters; and conducting simulation analysis and optimization on technological parameters such as dies, casting temperatures, die preheating temperatures and casting speeds through the simulation model, and obtaining qualified castings with the aluminum alloy gear shifting hub casting shrinkage porosity casting defects improved effectively through trialcasting. Thus, the purposes of improving gear shifting hub casting defects and improving the casting quality are achieved.

Owner:UNIV OF SCI & TECH BEIJING +1

A profiled lithium battery and a preparation method thereof

InactiveCN108963318AQuick cutShorten mold opening timeFinal product manufactureLi-accumulatorsEngineeringLithium battery

The invention discloses a special-shaped lithium battery and a preparation method thereof, include a lithium battery body, A lithium battery body include a positive electrode ear, positive plate, negative ear, A negative electrode sheet, a diaphragm, and a packaging film, A positive tab is connected to the positive tab, The negative electrode lug is connected with the negative electrode piece, thepositive electrode piece is installed on the upper end of the negative electrode piece, and the separator and the packaging film are wrapped and arranged on the exterior of the positive and negativeelectrode piece. The invention adopts a simple way to quickly complete the cutting of the complex abnormal electrode piece and the separator, and compared with the die cutting of the abnormal electrode piece and the electrode piece, the mold opening time can be saved and the mold opening cost can be reduced.

Owner:JUHEYUAN SCI & TECH CO LTD

Modular back clamping battery

InactiveCN108565932ALower cost of capitalSave time and costBatteries circuit arrangementsElectric powerModularityEngineering

Intelligent mobile phones are different due to appearance, and therefore back clamping batteries are forced to be varied. The number of Android mobile phone manufacturers and the number of models arelarge, the scale of single mobile phones in the market is small, if a model is formed for the back clamp battery of each model of Android mobile phones, the investment cost is high, the time is long and the inventory pressure is large, and the back clamping batteries are not available for most Android mobile phones. Compared with the back clamping batteries, the application range of mobile phone protective shells is wider, the number of the manufacturers is large and the mobile phone protective shells are easier to obtain. The back clamping batteries are modular, the mobile phone protective shells sold in the market replace back clamping connecting covers, and charging back clamps can be provided for the large-screen intelligent mobile phones quickly at a low cost as long as the intelligent mobile phone protective shells are found.

Owner:深圳创新黑科技有限公司

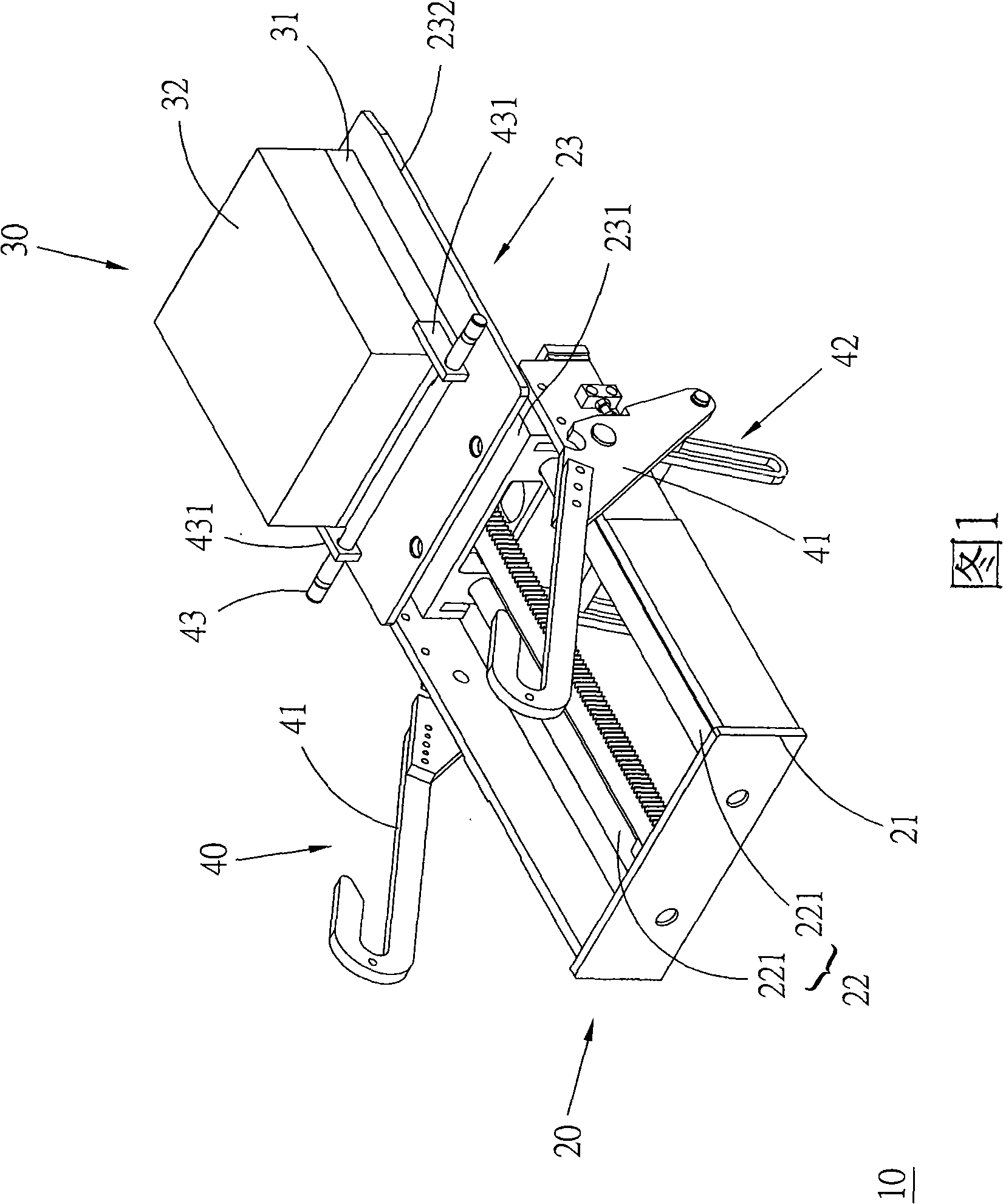

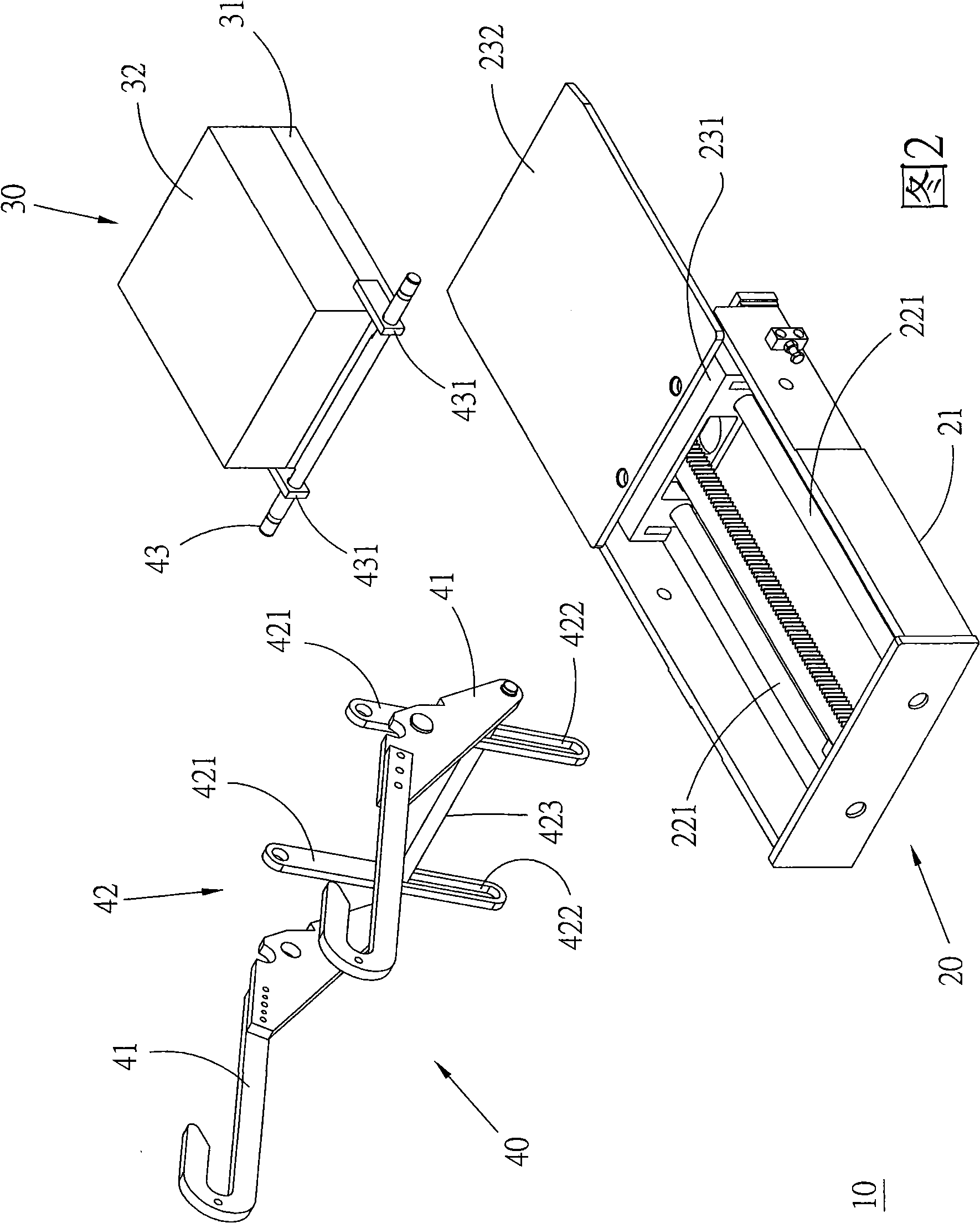

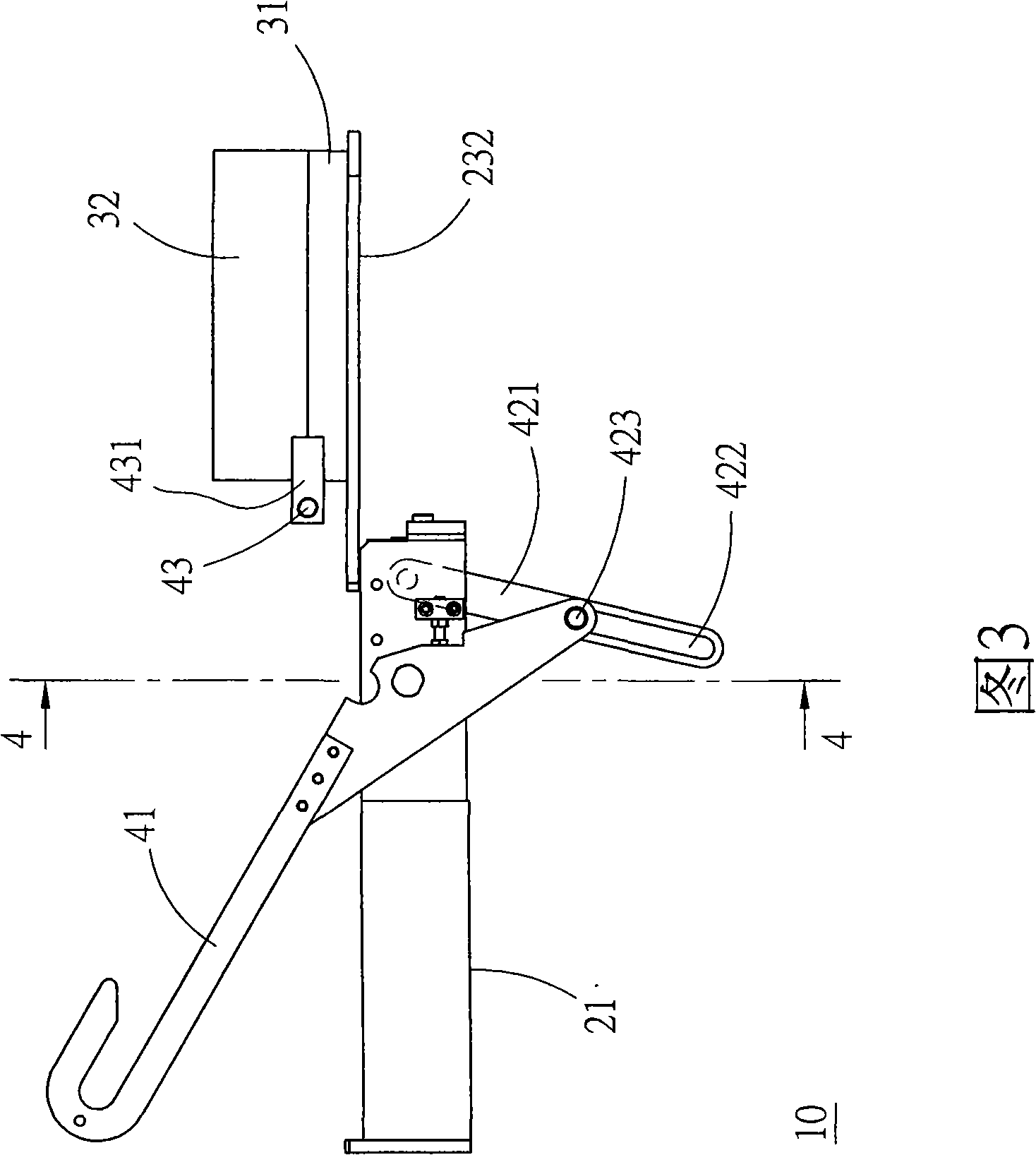

Rocking arm type die-sinking device

The invention relates to a rocking arm type die-sinking device, which comprises a base, a die holder set and a rocking arm set, wherein the base is provided with a guiding part and a moving part which is arranged on the guiding part in a sliding mode and is guided by the guiding part to perform reciprocating linear displacement between the positions of an inlet seat and an outlet seat; the die holder set is arranged on the moving part, can perform reciprocating displacement between the positions of the inlet seat and the outlet seat along with the movement of the moving part, and is provided with a movable die holder which can be pivoted between the positions of a closed die and an open die along a direction vertical to the displacement of the moving part; and the rocking arm set is provided with at least one rocking arm with a preset length and is pivoted on the base, a pivot of the rocking arm is parallel with and corresponding to the pivot around which the movable die holder rotates, and the rocking arm set is provided with a connected moving part which is connected between the rocking arm and the moving part, and a connecting piece which is arranged on the movable die holder for connecting the rocking arm; thus, when the moving part moves from the inlet seat to the outlet seat, the connected moving part pivots the rocking arm so as to drive the movable die holder to be lifted and turned from the closed die to the open die through the connecting piece.

Owner:陈法胜

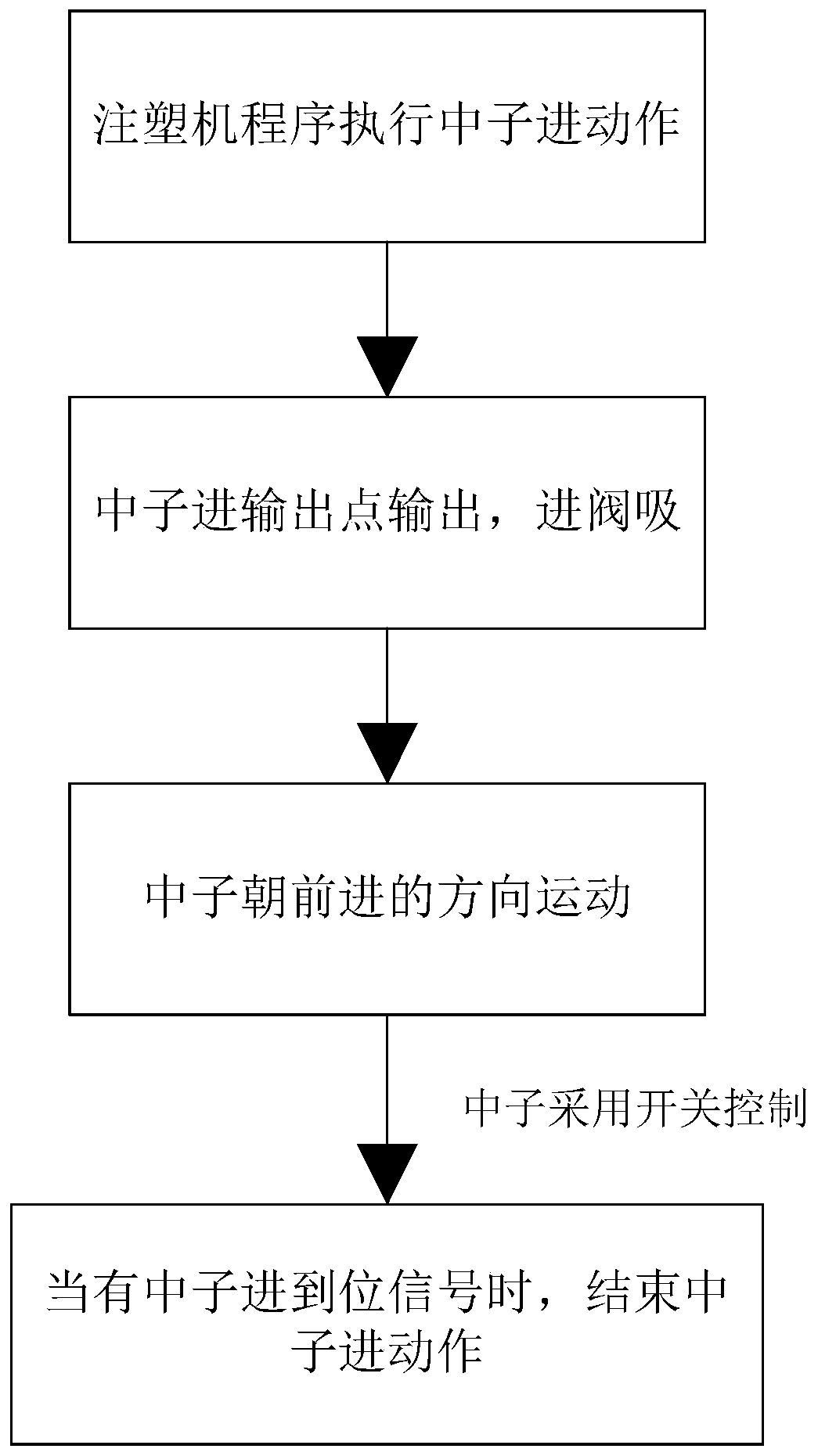

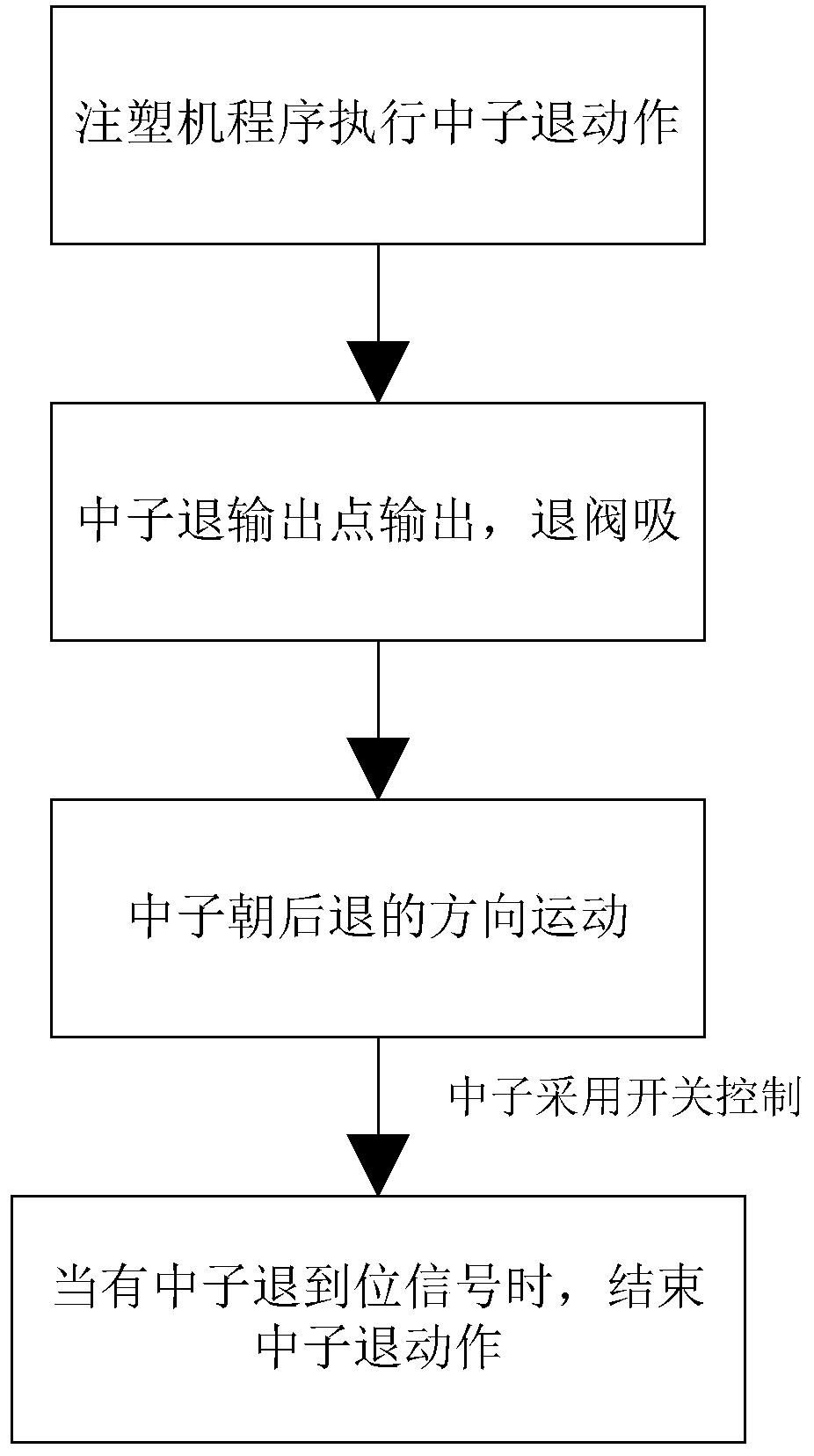

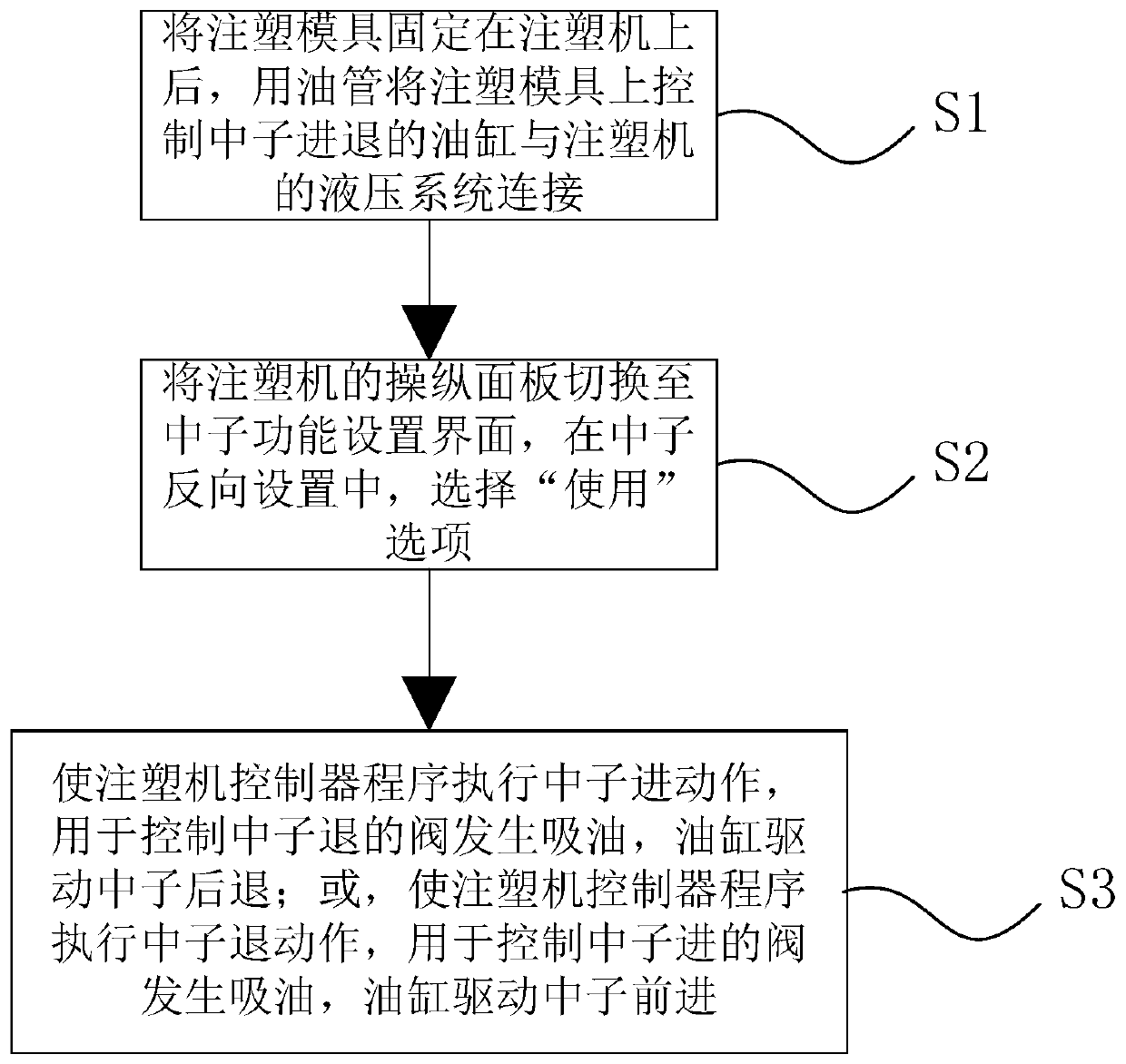

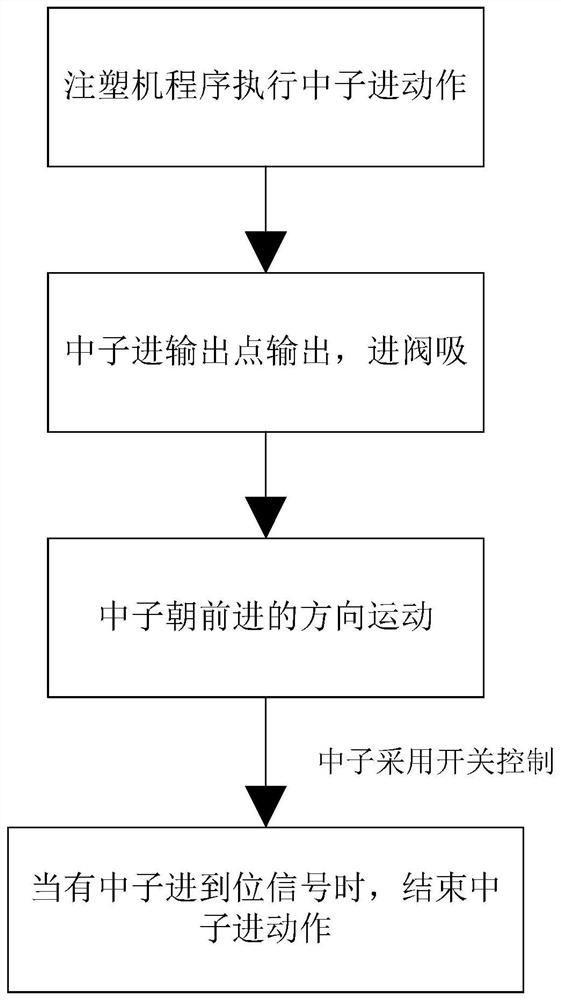

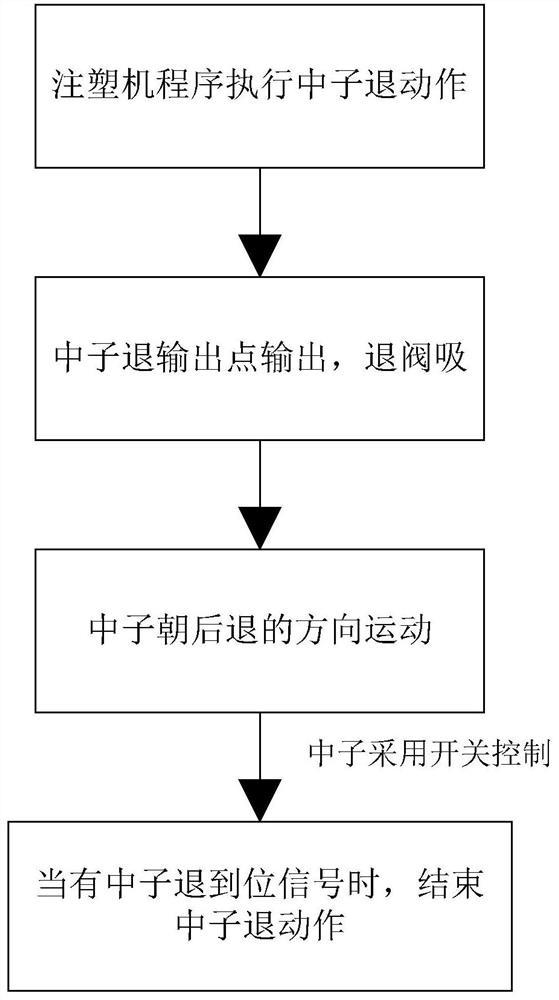

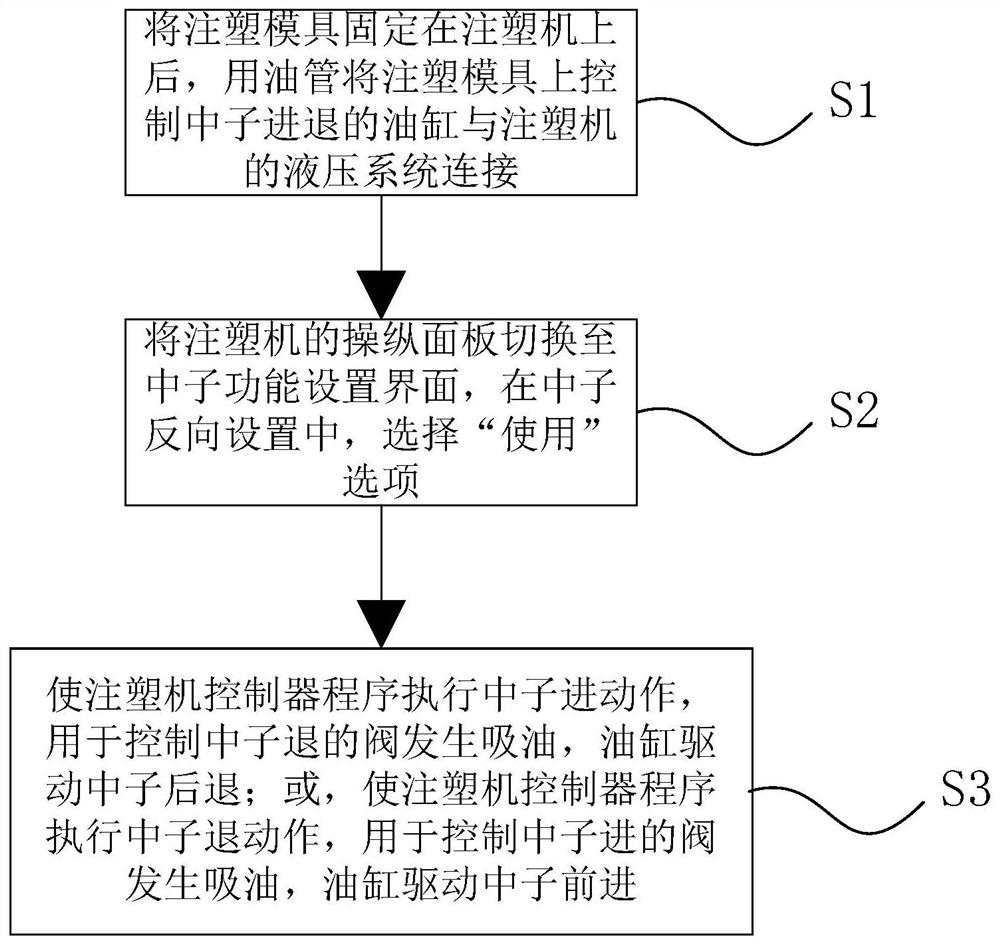

Reverse control method for neutron action of injection molding machine

The invention relates to the technical field of injection molding machines and discloses a reverse control method for neutron action of an injection molding machine. The reverse control method comprises the following steps of fixing an injection molding die on the injection molding machine, and then connecting an oil cylinder for controlling neutrons to advance and retreat on the injection moldingdie with a hydraulic system of the injection molding machine; switching a control panel of the injection molding machine to a neutron function setting interface, and selecting a use option in the reverse setting of the neutrons; executing the advancing action of the neutrons by using injection molding machine controller programs, absorbing by using a valve for controlling the neutrons to retreat,and driving the neutrons to retreat by using the oil cylinder; or performing the neutrons retreating action by using the injection molding machine controller programs, absorbing the oil by using a valve for controlling the neutrons to advance, and driving the neutrons to advance by using the oil cylinder. The reverse control method disclosed by the invention has the advantages that the injectionmolding machine has the neutron reversing function, and a high-pressure oil pipe does not need to be exchanged, so that personal security is ensured; and in addition, information interference to othermolds is avoided.

Owner:HAITIAN PLASTICS MACHINERY GRP

Mold positioning structure

ActiveCN111823482AEasy to manufactureReduce manufacturing costsCoatingsEngineeringMechanical engineering

The invention discloses a mold positioning structure which is arranged in a mold embedding a plastic piece into a metal piece. The mold comprises a female mold core, a male mold core and a positioningcolumn. The positioning structure of the mold comprises an ejector rod, a poking block, two positioning blocks and elastic elements, wherein the ejector rod is arranged on the bottom surface of the female mold core; the poking block is arranged in the male mold core and located on the lower portion of the ejector rod; the two positioning blocks are arranged in the male mold core and are located on the two sides of the poking block correspondingly, the poking blocks slides up and down on the two positioning blocks, and one of the positioning blocks is away from the metal piece by a certain distance; and the elastic elements are arranged among the male die core, the poking block and the positioning blocks and push the poking block and the positioning blocks to move through elastic deformation. According to the mold positioning structure, through cooperation of the ejector rod, the poking block, the positioning blocks and the elastic elements, the situation that forming of the metal piece fails due to sliding can be avoided.

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

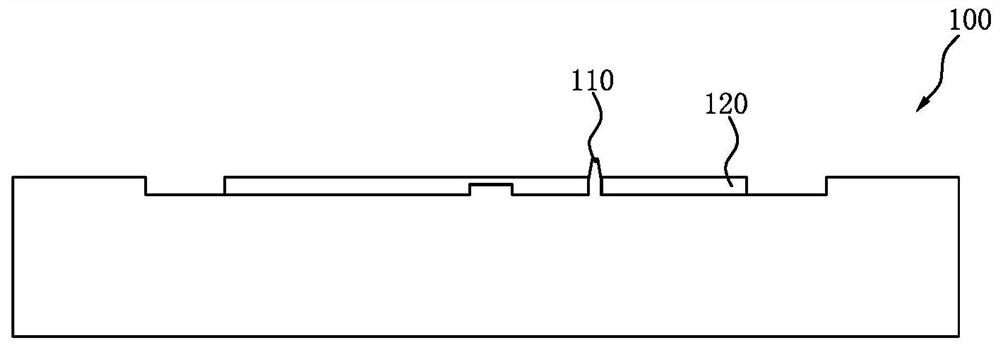

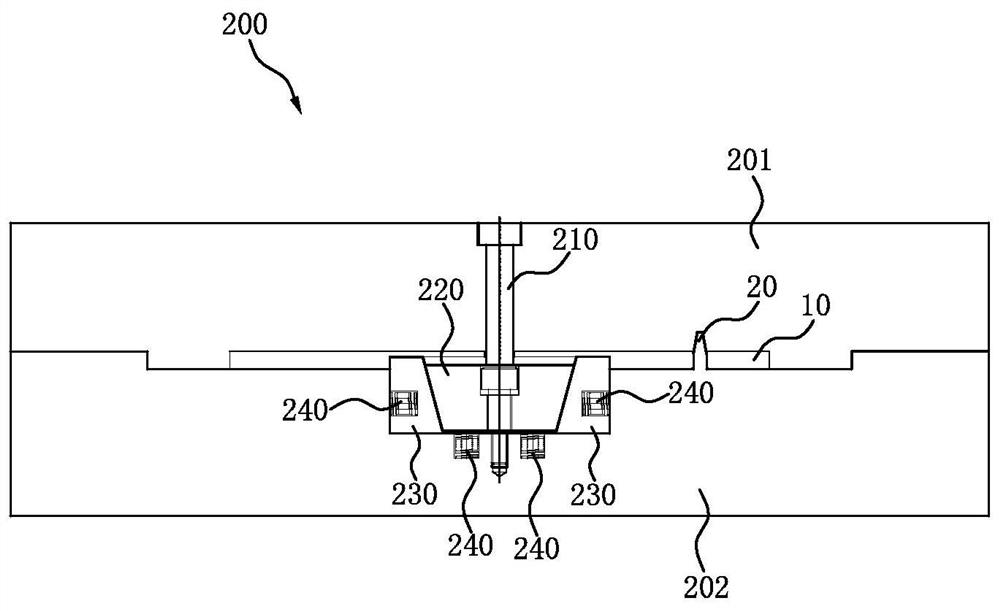

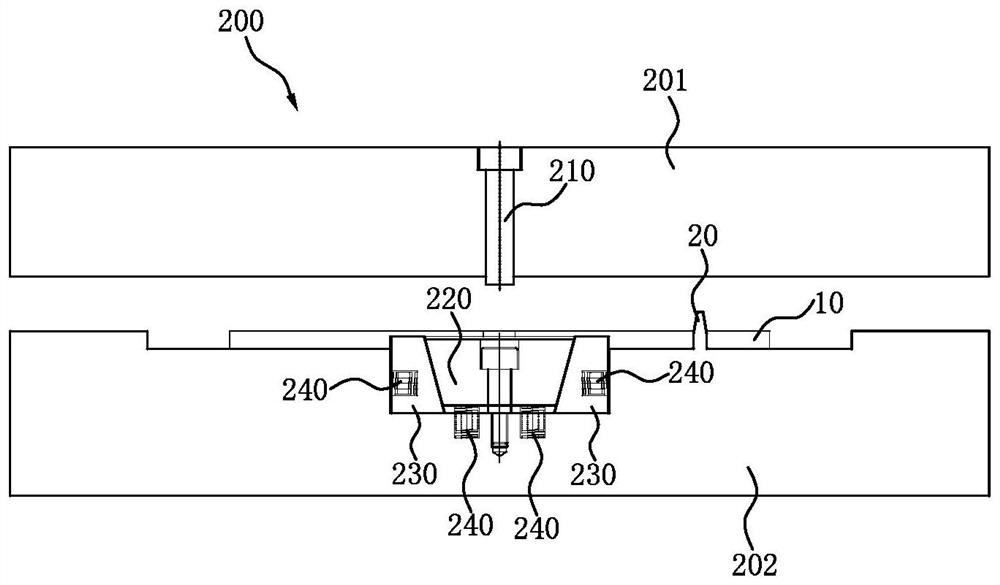

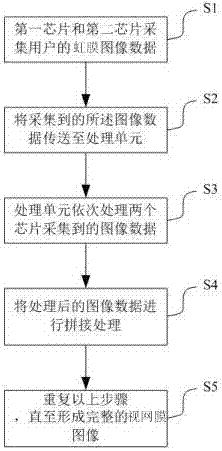

Data collection system processing method and data collection system

InactiveCN107194307AReduce design costReduce mold costGeometric image transformationAcquiring/recognising eyesData acquisitionProcessing element

The invention discloses a data collection system processing method and a data collection system and relates to the field of data collection technology. The data collection system processing method comprises the steps that a first chip and a second chip collect information image data of a user; the collected image data is transmitted to a processing unit; and the processing unit sequentially processes the image data collected by the two chips, and the processed image data is subjected to splicing processing to form an information image. According to the data collection system processing method and the data collection system, the two small area-array chips are spliced into a large area-array chip, the image data is collected respectively, processed in a centralized mode and spliced into the data collection image, therefore, the user does not need to design a large area-array chip after designing the small area-array chips, design cost and model opening cost are reduced, and model opening time is shortened.

Owner:NANTONG SHENGLIN GEER ELECTRONICS TECH CO LTD

Deep-hole plate preparation mold and method

Owner:苏州赛普生物科技股份有限公司

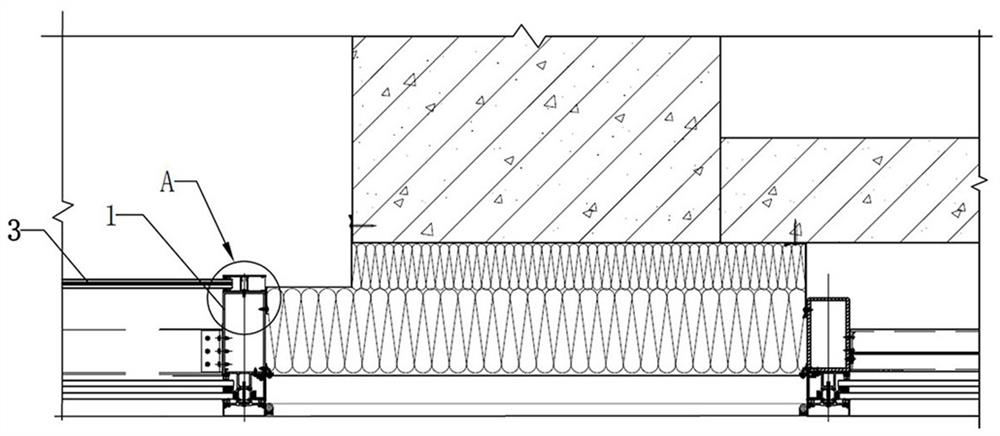

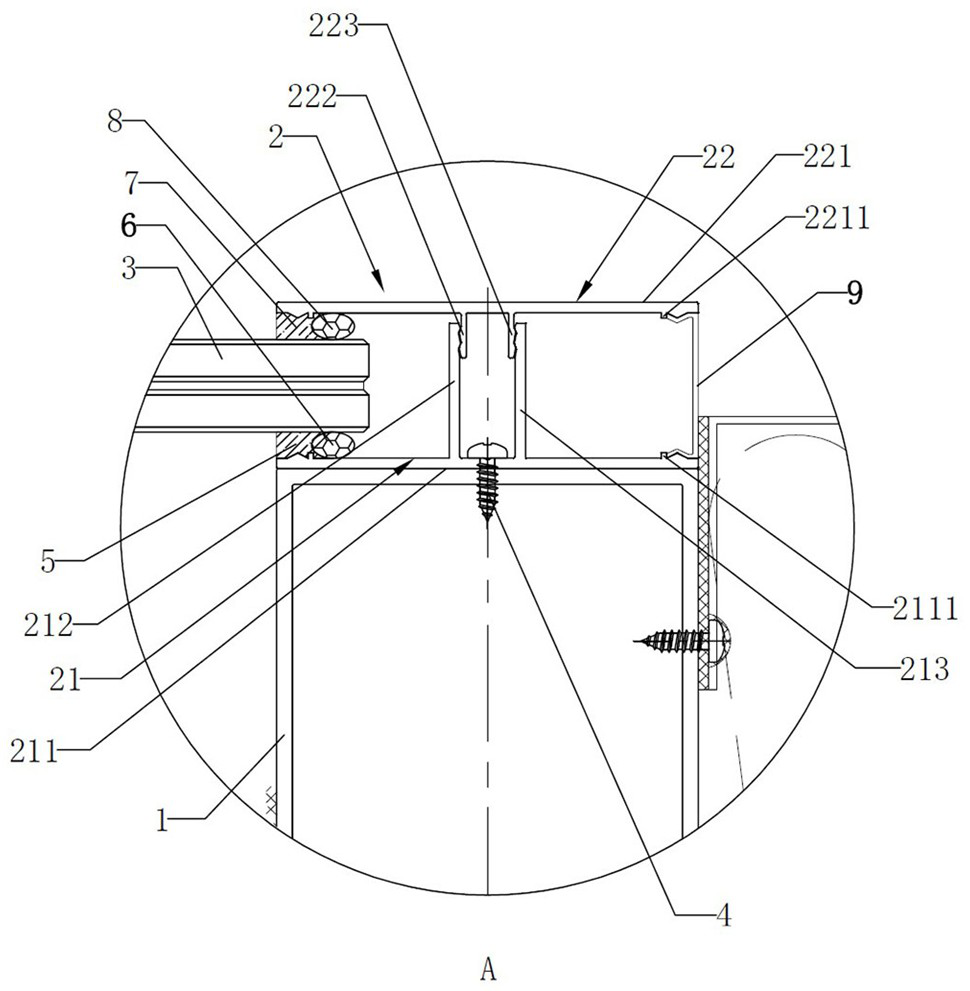

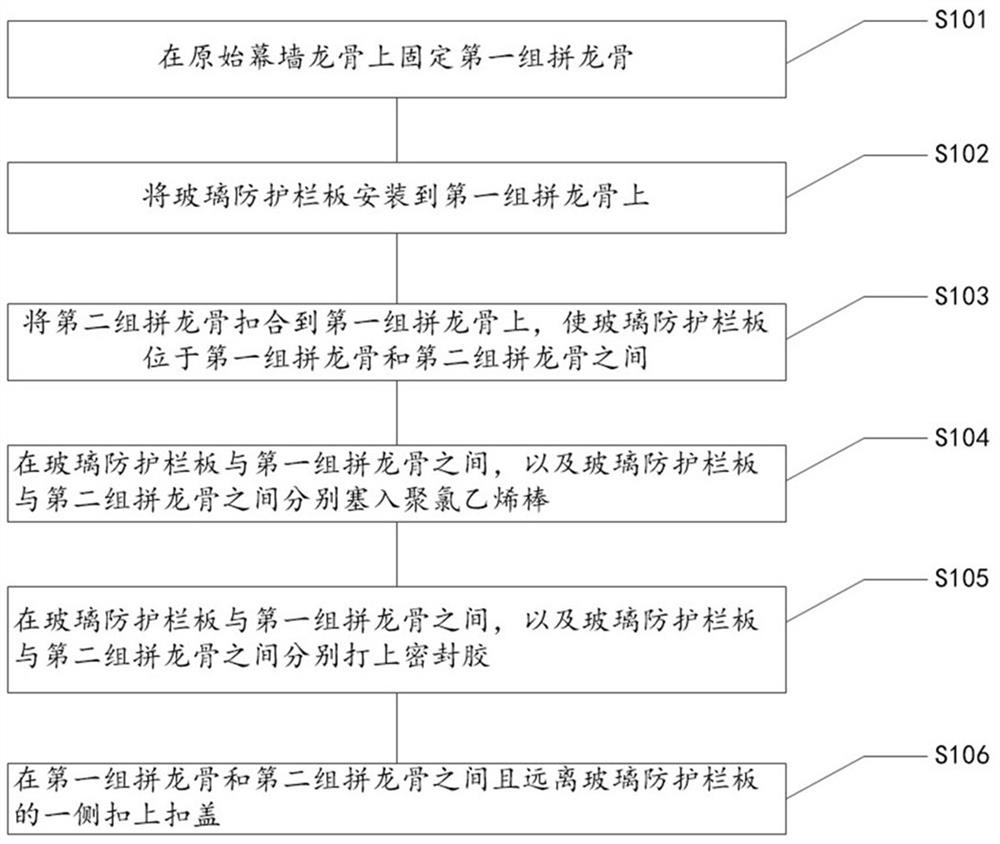

Assembled curtain wall keel and construction method thereof

The embodiment of the application discloses an assembled curtain wall keel and a construction method thereof, relates to the technical field of curtain walls. The technical scheme is as follows: the assembled curtain wall keel comprises an original curtain wall keel, an assembly type keel fixed on the original curtain wall keel and a glass protective fence plate detachably connected to the assembled keel. The embodiment of the application is suitable for mounting the glass protective guard plate.

Owner:BEIJING URBAN CONSTR SIXTH GRP

A method for reverse control of neutron action in injection molding machine

Owner:HAITIAN PLASTICS MACHINERY GRP

Industrial automatic data acquisition system

InactiveCN109634232AReduce design costReduce mold costProgramme total factory controlData processing systemData acquisition

The invention discloses an industrial automatic data acquisition system. The system comprises an information acquisition system, a data transmission system, a data processing system, a data splicing system and a data forming system; the information acquisition system is used for acquiring information image data of a user through chips, the data transmission system transmits the information image data acquired by the information acquisition system to the data processing system, the data processing system is used for processing the collected information image data, and the data splicing system is used for carrying out splicing processing on the data; and the data forming system is used for repeating the operations of the information acquisition system, the data transmission system, the dataprocessing system and the data splicing system to form a complete information image. After the image data are collected correspondingly and processed in a centralized mode, then the image data are spliced into the data acquisition image, the design cost and the mold opening cost are saved, and the mold opening time is shortened.

Owner:江苏三力岩土科技有限公司

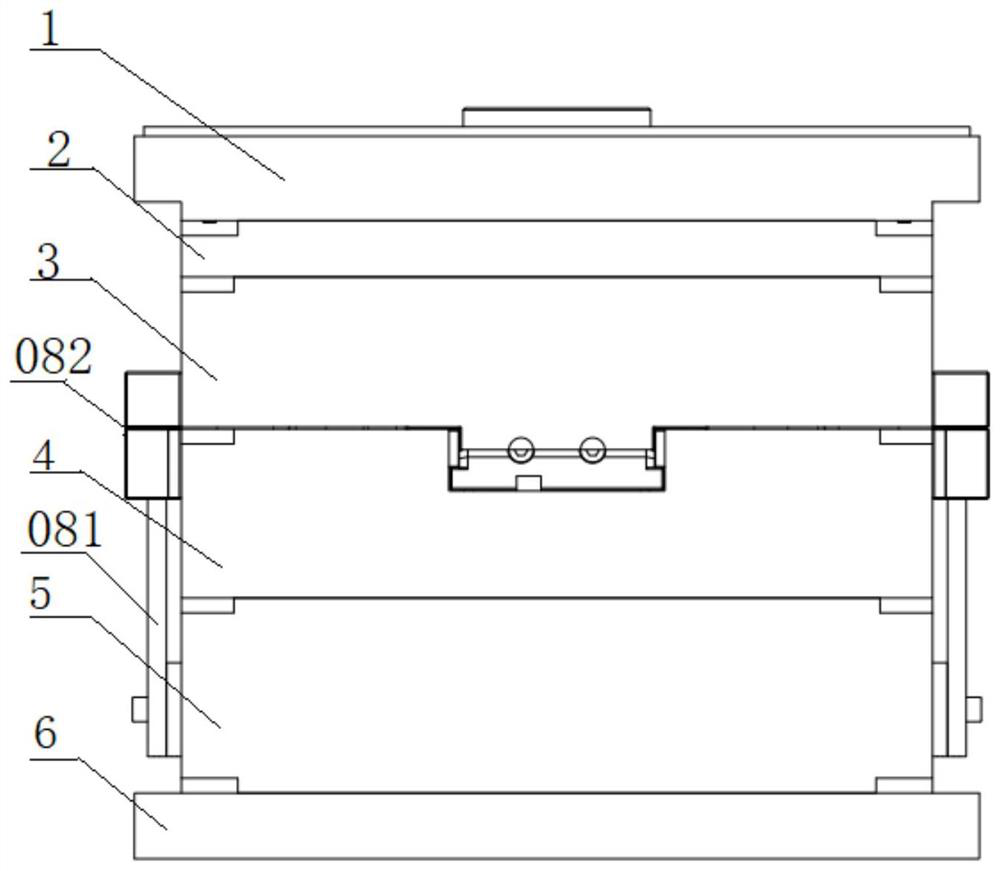

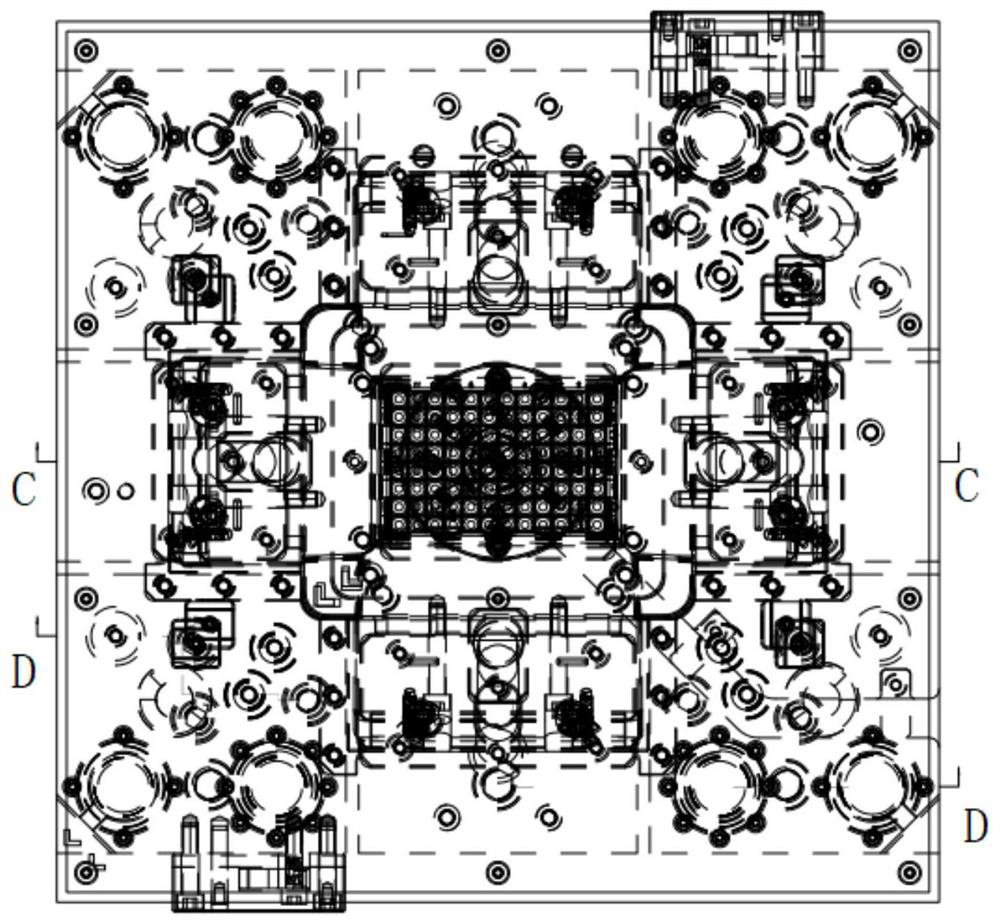

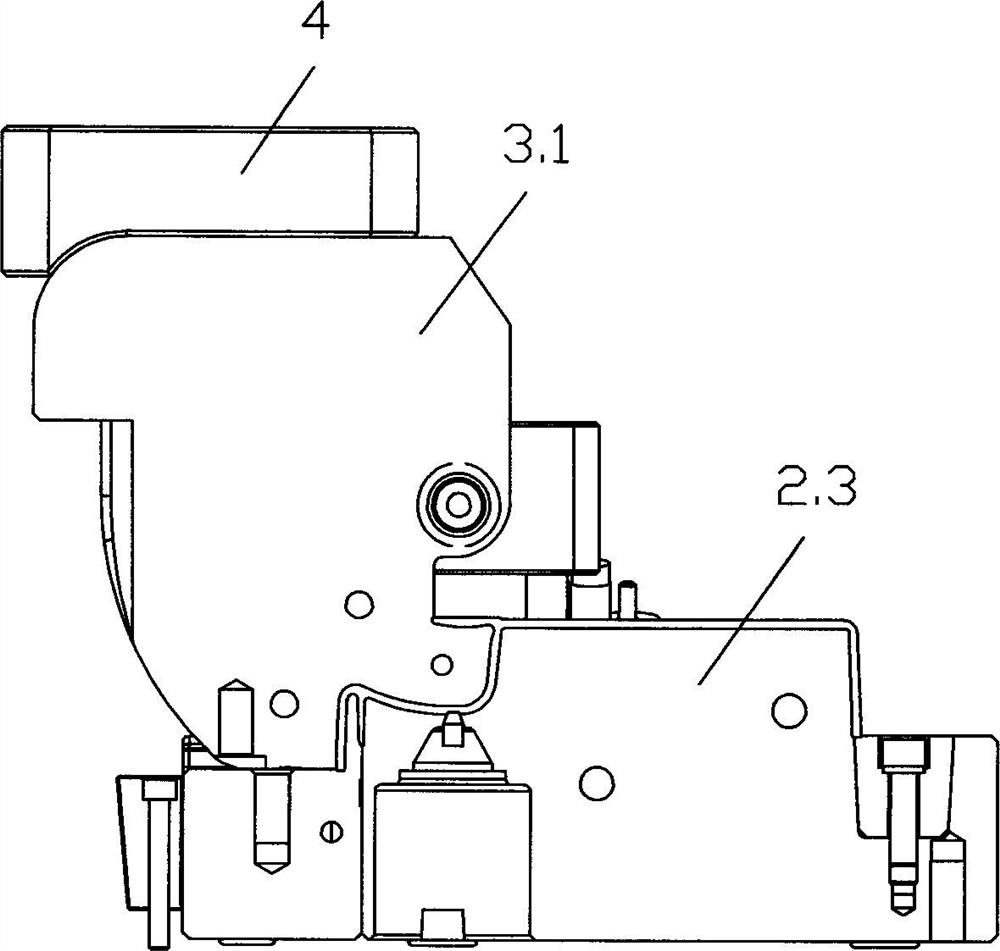

Mould with swing rotation mechanism

The invention discloses a mold with an oscillating rotating mechanism. The mold comprises a fixed die and a movable die, wherein the fixed die comprises a panel, a fixed die frame and a fixed die core, the movable die comprises a soleplate, a movable die frame, a movable die core and an ejection mechanism, a product forming cavity is formed on the junction of the fixed die core and the movable die core, and an oscillating rotating mechanism is arranged in the fixed die core. Two insert blocks (an oscillating core pulling mechanism and a core pulling block) for forming an arc handle and a lock position of a finished product are assembled together, the two insert blocks are driven to oscillate by the panel in mold stripping, the two insert blocks are separated from the product, the separation can be completed by one step, and the die sinking time can be saved; the mold is simple in structure and small in size and can be formed through a small-tonnage injection molding machine. The cost is low, the yield can be improved by one third for each time compared with that of the traditional product, and the production efficiency is high. The mold belongs to the technical field of molds.

Owner:NINGBO HUABAO PLASTICS & RUBBER MOLD

Curtain wall center-pillar beam connection method and connecting device

The invention relates to a curtain wall center-pillar beam connection method. A first mounting hole is longitudinally and penetratingly arranged on a beam. The connection method comprises the following steps: (1) acquiring stub bars, shared the same structure with a to-be-mounted beam, as mounting auxiliaries with second mounting holes; (2) manufacturing connecting bolts; (3) acquiring bolts matching with a third mounting hole; (4) placing mounting auxiliaries at the mounting positions of the beam of the center pillar, inserting each connecting bolt into corresponding second mounting holes, screwing the bolts into a third mounting hole so as to fix the connecting bolts on the center pillar; (5) longitudinally pulling out and removing the mounting auxiliaries; and (6) inserting the to-be-mounted beam on the connecting bolts. The connecting bolts comprise a beam connecting portion and a bolt mounting portion, the beam connecting portion is matched with the first mounting hole of the beam, and the third mounting hole is arranged on the bolt mounting portion. The invention further relates to a curtain wall center-pillar beam connecting device.

Owner:JANGHO GRP

Die with swinging and rotating mechanism

The mold comprises a fixed mold and a movable mold, the fixed mold comprises a panel, a fixed mold frame and a fixed mold core, the movable mold comprises a bottom plate, a movable mold frame, a movable mold core and an ejection mechanism, a product forming cavity is formed by the combination surface of the fixed mold core and the movable mold core, and the swing rotating mechanism is arranged in the fixed mold core. The two inserts (the swing core-pulling mechanism and the core-pulling block) for forming the arc-shaped handle and the buckling position of the finished product are combined together and are driven by the panel to swing during demolding, so that the two inserts are separated from the product at one time, and the mold opening time is saved; therefore, the mold is simple in structure, small in size, capable of being formed by a small-tonnage injection molding machine, low in cost and high in production efficiency, and products produced in each shift are improved by more than 1 / 3 compared with the original products.

Owner:苏州润飞精密塑胶科技有限公司 +1

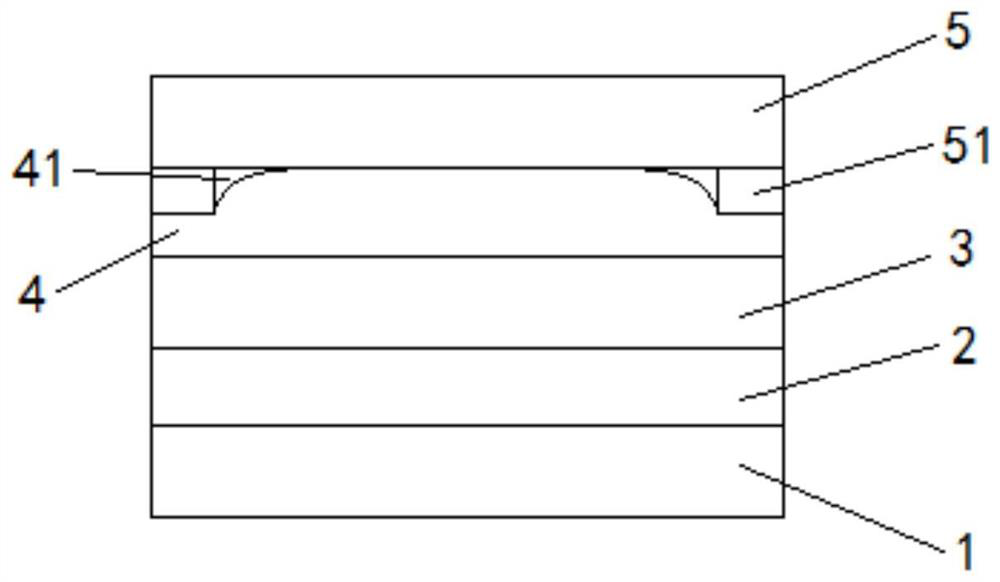

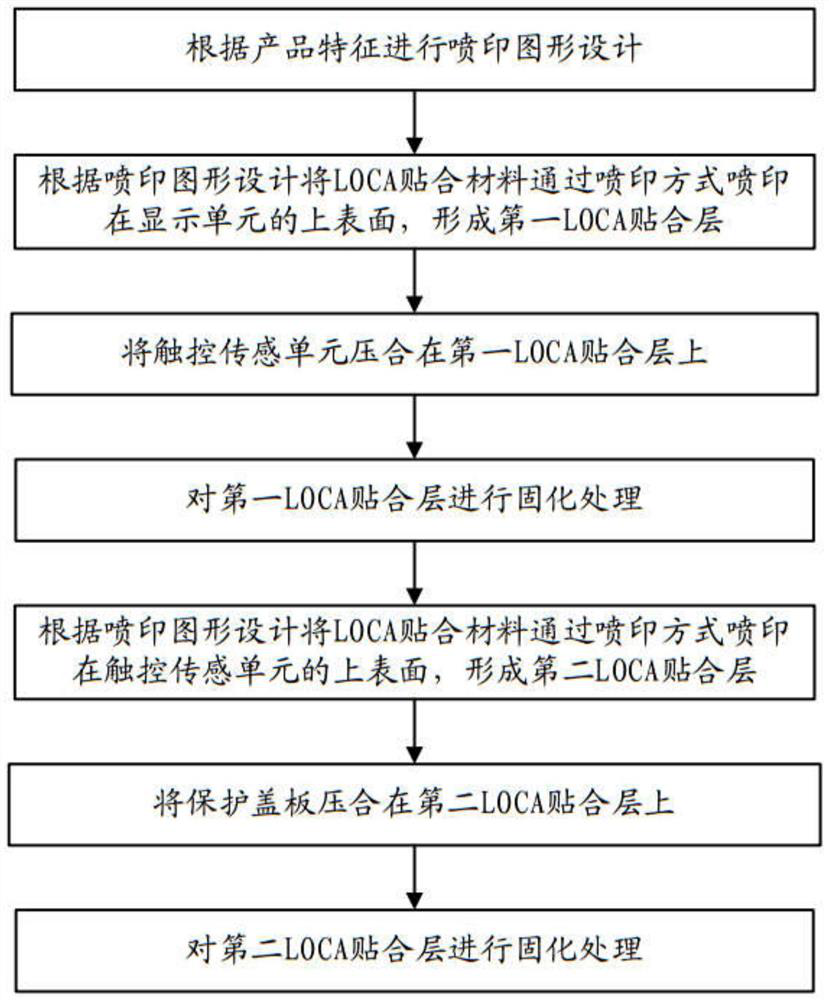

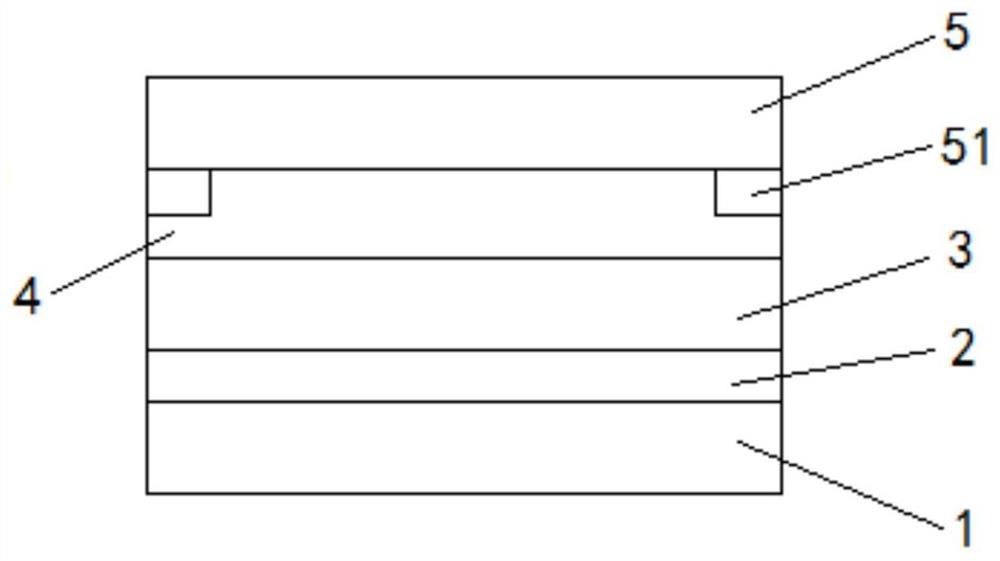

Touch screen laminating process and structure

PendingCN113391725AReduce the cost of mold openingShorten mold opening timeInput/output processes for data processingGraphicsMechanical engineering

The invention provides a touch screen laminating process and structure. The touch screen laminating process comprises the following steps: S1, carrying out jet printing pattern design according to product characteristics; S2, jet-printing an LOCA bonding material on the upper surface of the display unit in a jet-printing manner according to the jet-printing graphic design to form a first LOCA bonding layer; S3, pressing the touch sensing unit on the first LOCA laminating layer; S4, carrying out curing treatment on the first LOCA laminating layer; S5, according to the jet printing pattern design, jet printing an LOCA bonding material on the upper surface of the touch sensing unit in a jet printing mode to form a second LOCA bonding layer; S6, pressing the protective cover plate on the second LOCA laminating layer; and S7, carrying out curing treatment on the second LOCA laminating layer. The process has the beneficial effects that the process for jet printing the attaching layer on the product in a jet printing mode is provided, the mold opening cost and the mold opening manufacturing time are reduced, the attaching quality, the attaching efficiency and the yield are greatly improved by accurately controlling the jet printing quantity and the accurate position for jet printing, and benefit maximization is achieved.

Owner:深圳市华仁三和科技有限公司

Environment-friendly polyurethane adhesive used for bonding granulated cork and preparation method thereof

ActiveCN101787252BImprove performanceNo smellNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyurethane adhesivePolymerization

The invention relates to an environment-friendly polyurethane adhesive used for bonding a granulated cork. The invention is characterized in that the environment-friendly polyurethane adhesive consists of MDI, modified MDI, polyether glycol, an antiaging agent and a polymerization inhibitor; according to the mass percentage, the proportion of the MDI, the modified MDI, the polyether glycol and the antiaging agent is 20-30:30-40:30-40:1-5, and the addition of the polymerization inhibitor is 10PPM. When in use, the adhesive and the granulated cork are mixed according to the mass proportion of 1:10-1:5. The adhesive is inodorous and environmentally friendly and can be used at different seasons. When the adhesive is used for bonding the granulated cork, the mold opening time is greatly shorter than the TDI adhesive, and the product property is good.

Owner:SHANDONG INOV POLYURETHANE

The positioning structure of the mold

ActiveCN111823482BEasy to manufactureReduce manufacturing costsCoatingsStructural engineeringMechanical engineering

The invention discloses a positioning structure of a mold, which is arranged in a mold for embedding plastic parts in metal parts. The mold includes a female mold core, a male mold core and a positioning column. The positioning structure of the mold includes: a push rod, It is set on the bottom surface of the female mold core; a shift block is set in the male mold core and is located below the ejector rod; two positioning blocks are set in the male mold core, and the two positioning blocks are respectively Located on both sides of the shifting block, the shifting block slides up and down between the two positioning blocks, one of the positioning blocks is at a certain distance from the metal part; elastic elements are respectively arranged on the male mold core and the metal part Between the shifting block and the positioning block, the elastic element pushes the shifting block and the positioning block to move through elastic deformation. The positioning structure of the mold of the present invention, through the cooperation between the ejector rod, the shifting block, the positioning block and the elastic element, can prevent the metal parts from forming failure caused by sliding during forming.

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

Dimming panel and manufacturing method of dimming panel

The invention discloses a dimming panel and a manufacturing method of the dimming panel. The dimming panel comprises a first guide layer, a liquid crystal layer, a first colloid and a second guide layer. The liquid crystal layer is arranged on the first guide layer. The first colloid is arranged on the first guide layer and surrounds the liquid crystal layer. The second guide layer is arranged onthe liquid crystal layer and completely covers the upper surface of the first colloid. According to the dimming panel and the manufacturing method of the dimming panel, mold opening customization forthe first guide layer is not needed, so that the production cost of a product is reduced.

Owner:JIANGSU IRON ANCHOR GLASS LTD BY SHARE LTD

Dental science and technology data acquisition system

InactiveCN110931092AReduce design costReduce mold costMedical imagesInstrumentsData processing systemData acquisition

The invention discloses a dental science and technology data acquisition system. The system comprises an information acquisition system, a data transmission system, a data processing system, a data splicing system and a data forming system; the information acquisition system uses a chip to acquire information image data of a user; the data transmission system transmits information image data acquired by the information acquisition system to the data processing system; the data processing system processes the acquired information image data and splices the data, and the data forming system repeats the operations of the information acquisition system, the data transmission system, the data processing system and the data splicing system to form a complete information image; after image data are collected respectively, the image data are spliced into a data collection image after centralized processing, so the design cost, the mold opening cost and the mold opening time are reduced.

Owner:徐州安紫齿科技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com