Mechanism used for separating product from fixed mould and capable of limiting slide block by adopting perpendicular locking surface for fixed mould and deep rib

A technology of fixed mold and slider, applied in the field of mold release mechanism, can solve the problems of unfavorable maintenance and maintenance, complex elastic block structure, low yield and other problems, and achieve the effects of simple structure, low cost and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

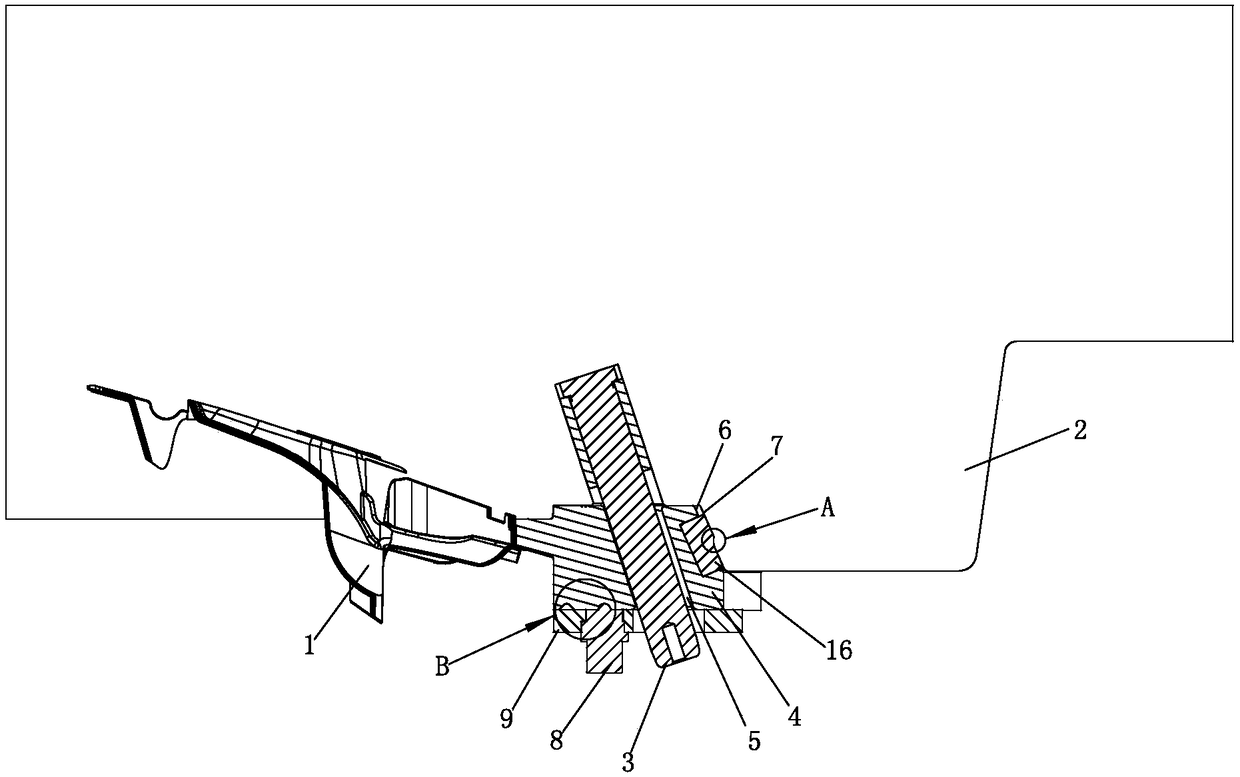

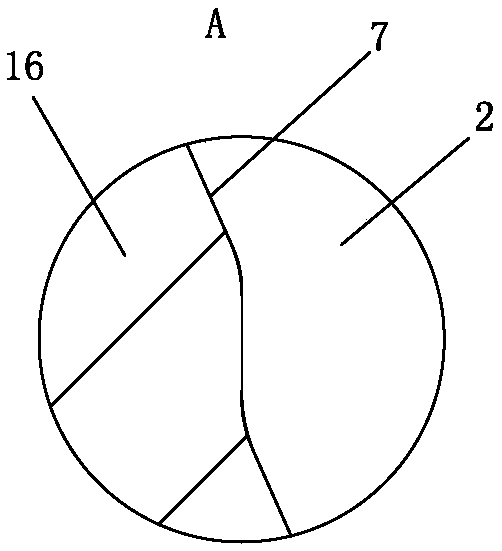

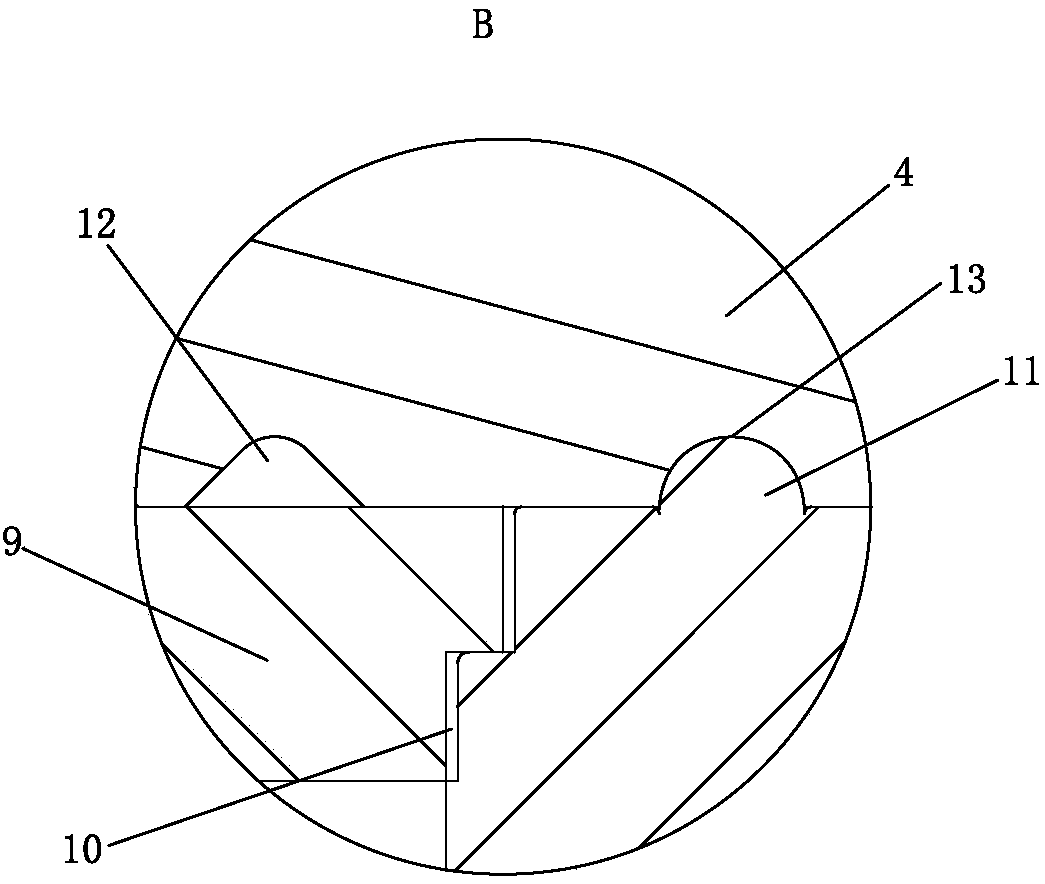

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0024] Such as Figure 1-7 As shown, the present invention provides a product fixed mold deep rib slider facing directly to lock and disengage from the fixed mold mechanism, which includes a cavity 1, an inclined guide post 3 arranged on the fixed mold 2 and a slide block slidably arranged on the movable mold 4. The end surface of the slider 4 near the cavity 1 is a deep rib corresponding to the side wall of the cavity 1, that is to say, the end surface of the slider 4 near the cavity 1 forms the cavity 1 together with the fixed mold 2 and the movable mold. The end face of the slider 4 near the cavity 1 is a part of the side wall corresponding to the deep rib, and is located above the product edge corresponding to the cavity 1. The value after subtracting 1.0 to 3.5mm from the height (2.5mm in this example, can also be 1.0mm, 2.0mm, 3.0mm or 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com