Die for die casting

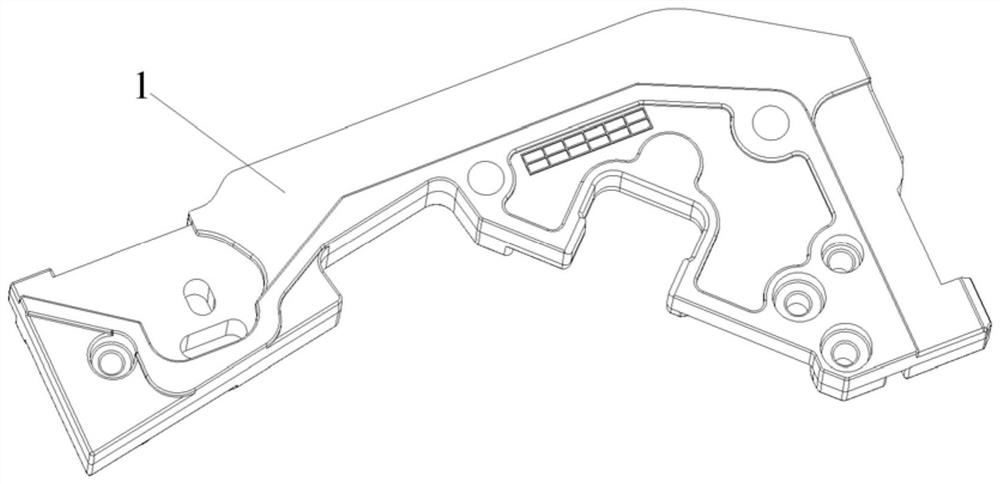

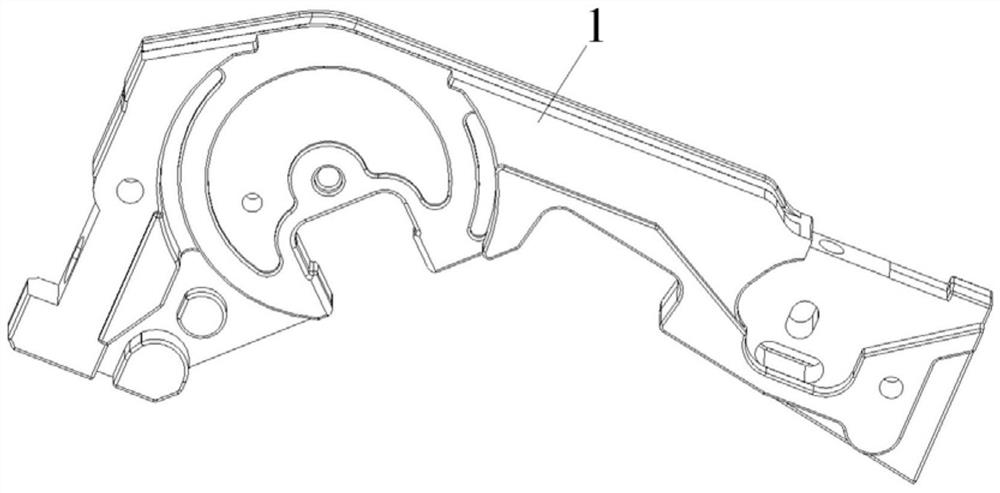

A mold and movable mold technology, applied in the field of die casting molds, can solve the problems of shrinkage deformation, difficult production and processing of the frame 1, poor stability of the frame structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

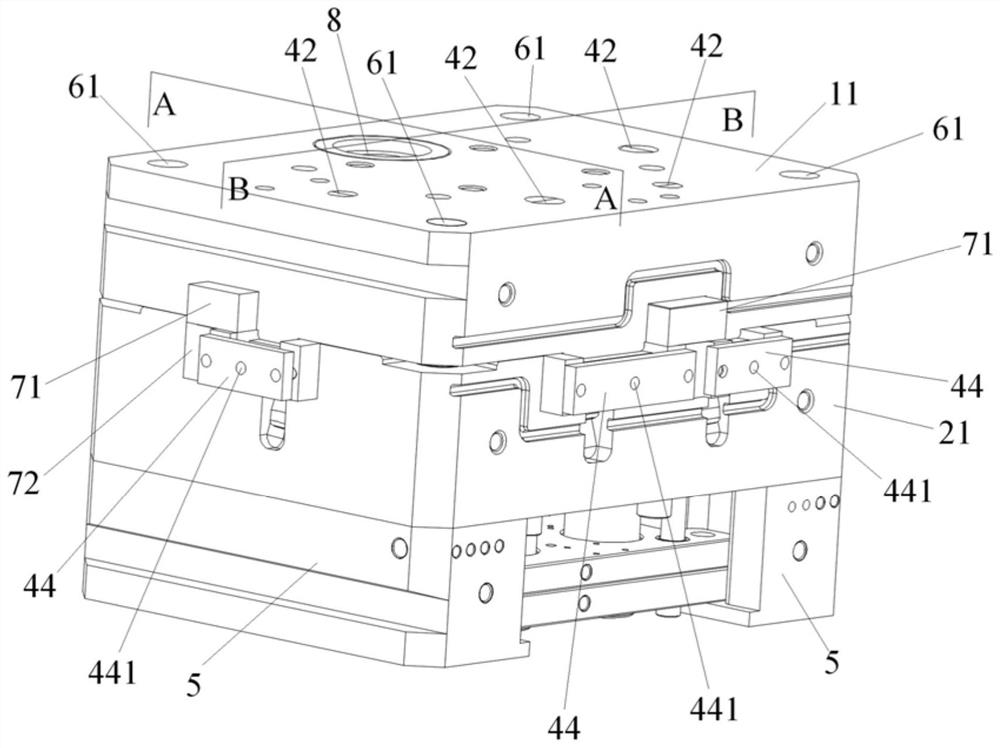

[0020] Below, combined with Figure 3-6 The mold for die casting of the present invention will be described in detail.

[0021] Such as Figure 3-6As shown, the mold for die-casting of the present invention includes a fixed mold, a movable mold, a mold foot and an exhaust mechanism. Die groove, and the fixed mold core 12 is provided with a mold cavity towards the fixed joint surface of the movable mold; , the movable mold core 22 is provided with a mold core and a plurality of slag ladle grooves 221 on the movable joint surface facing the fixed mould. During mould-closing, the core on the movable core 22 stretches into the corresponding cavity to form a cavity for die-casting to form the frame 3 . Preferably, two mold cores are arranged on the movable mold core 12, and a slag ladle groove 221 is respectively arranged at the two ends and the slope end of each mold core. When the runner 222 on the core 22 is poured into the mold cavity, the air in the runner 222 and the mold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com