Curtain wall center-pillar beam connection method and connecting device

A technology for beams and columns, which is applied in the field of connection methods and devices for columns and beams in curtain walls, can solve the problems of aluminum alloy core sleeves not being universal, high cost of mold opening, time wasting, etc., and achieve saving mold opening time, installation Convenient, time-saving and cost-effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

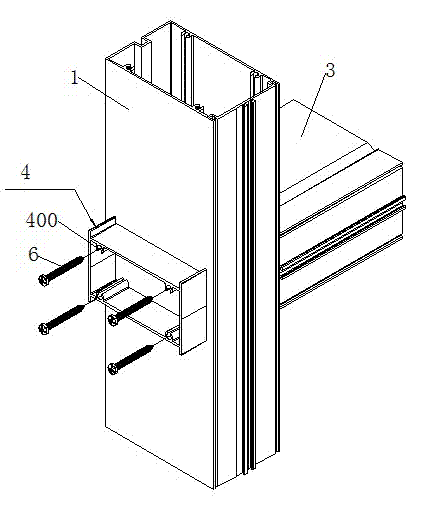

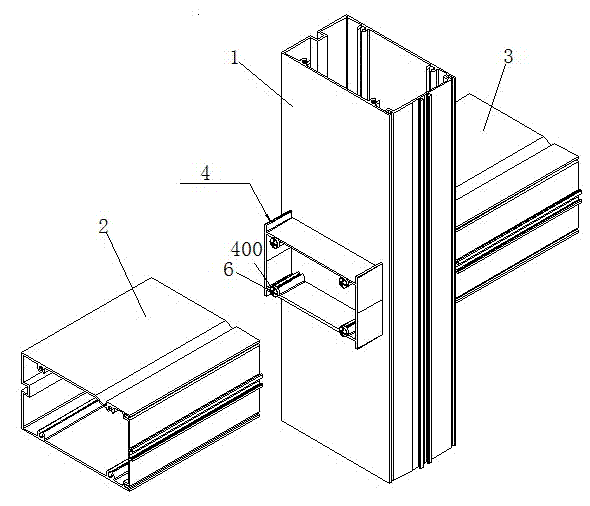

[0030] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

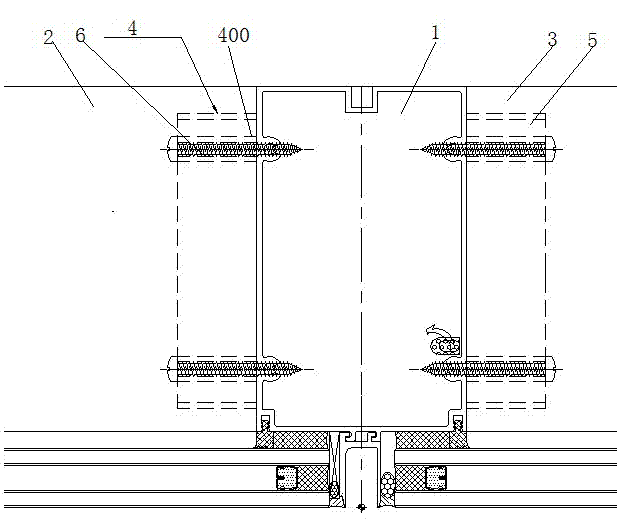

[0031] like Figure 5 — Figure 8 As shown, the columns 10 and beams 20 and 30 in the curtain wall are all aluminum alloy profiles, from figure 2 , image 3 The cross-sectional shapes of both can be seen in . The connection method of the crossbeams 20, 30 and the central pillar 10 is the same, and only the crossbeam 20 is used as an example for illustration below.

[0032] The beam 20 is provided with four first mounting holes 21 extending longitudinally through the beam 20 . The four first mounting holes have the same structure and are arranged symmetrically at four corner positions of the cross-section of the beam 20 .

[0033] The method for connecting columns and beams in the curtain wall includes the following steps:

[0034] (1) Obtain a material head 80 with the same structure as the beam 20 to be installed as an installation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com