Mold positioning structure

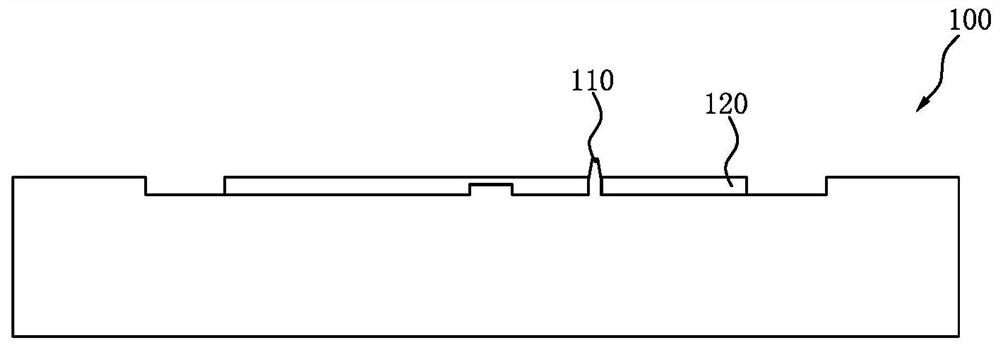

A technology for positioning structures and molds, applied in the direction of coating, etc., can solve the problems of positioning column 110 wear, loose metal parts, and non-compliance with production requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to further illustrate the technical means and effects adopted by the present invention, a detailed description will be given below in conjunction with a preferred embodiment of the present invention and its accompanying drawings.

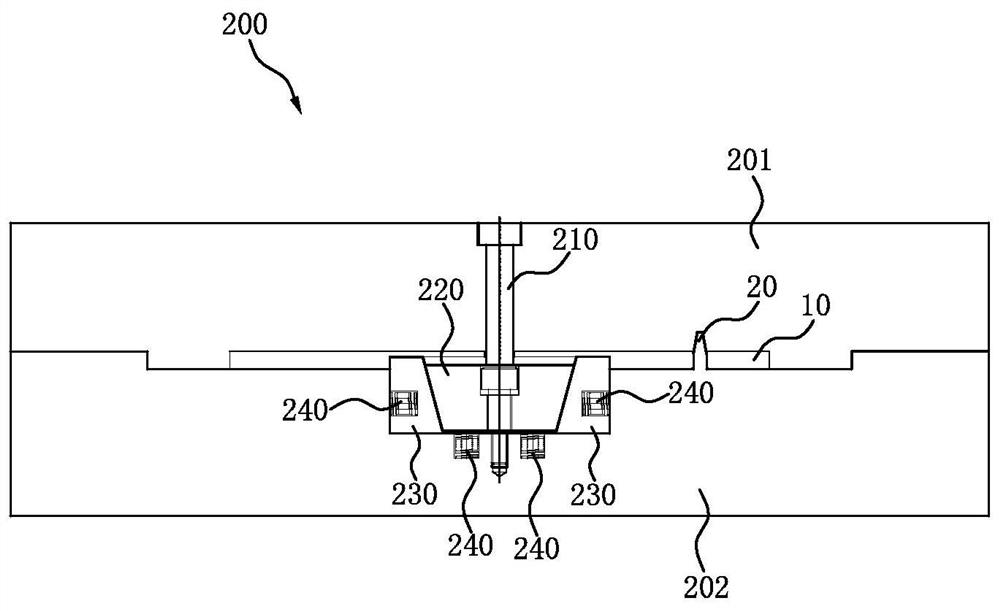

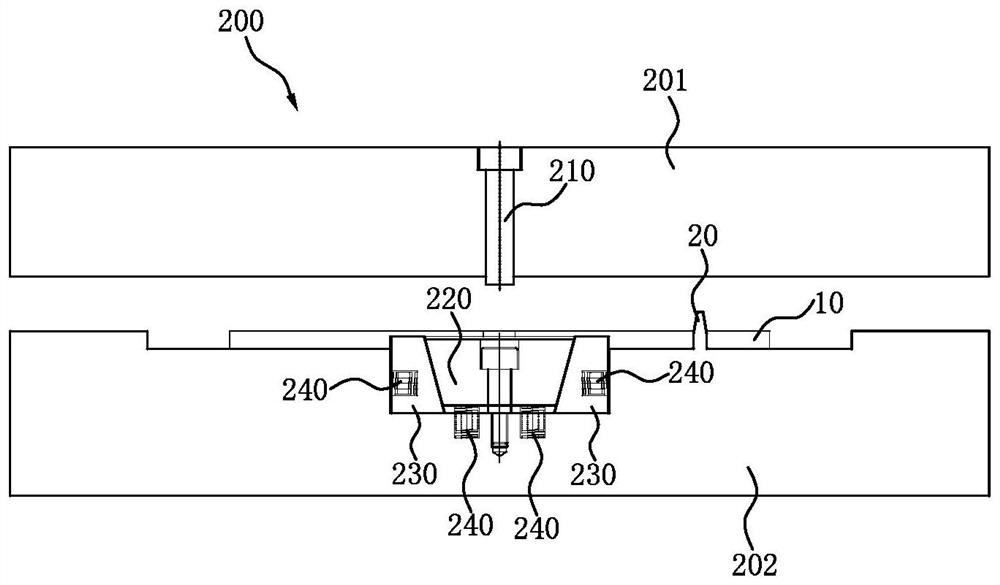

[0020] see figure 2 , figure 2 It is a structural schematic diagram of the positioning structure of the mold of the present invention in the mold clamping state. In this embodiment, the positioning structure 200 of a mold provided by the present invention is set in a mold for embedding plastic parts in metal parts 10, and the mold includes a female mold core 201, a male mold core 202 and a positioning column 20. The positioning structure 200 of the mold includes:

[0021] Ejector pin 210, which is arranged on the bottom surface of the female mold core 201;

[0022] A shifting block 220, which is arranged in the male mold core 202 and is located below the push rod 210;

[0023] Two positioning blocks 230, which are arranged in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com