Touch screen laminating process and structure

A touch screen and lamination technology, applied in instruments, computing, electrical and digital data processing, etc., can solve the problems of increasing production costs, reducing the transmittance and display clarity of touch screen products, and large lamination thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

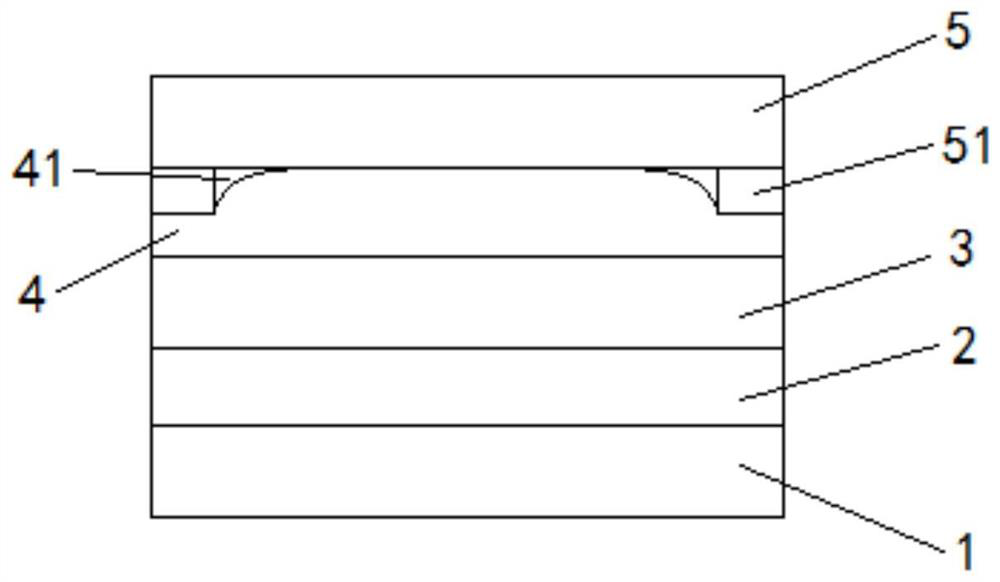

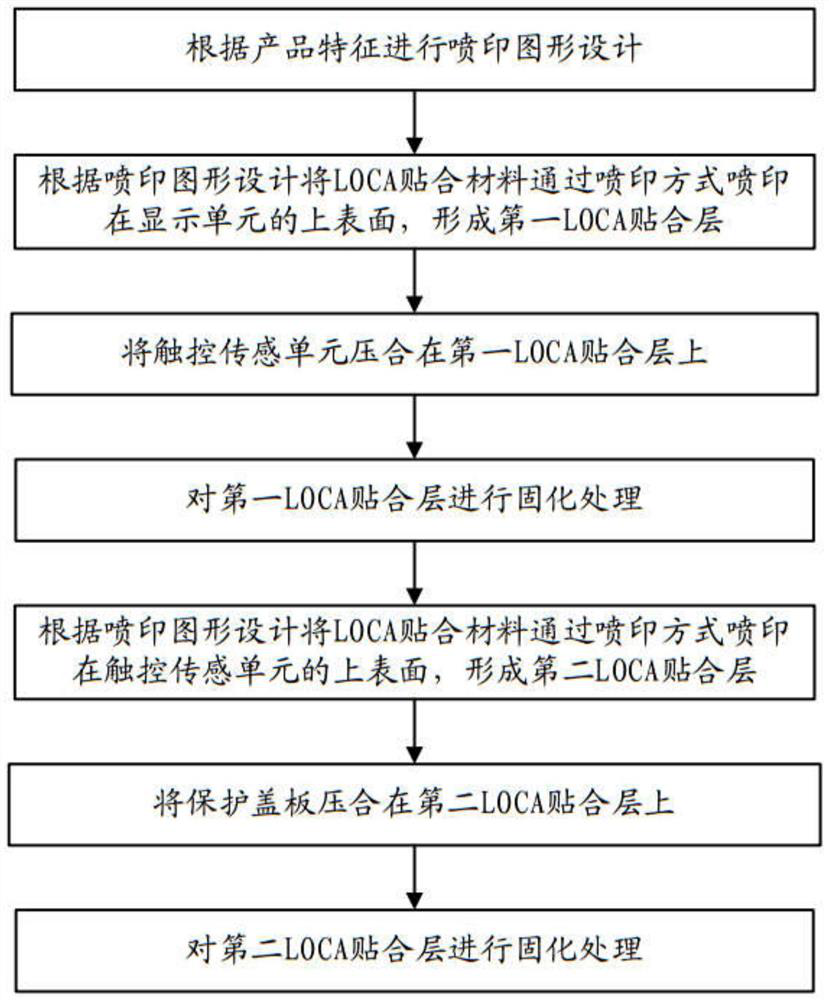

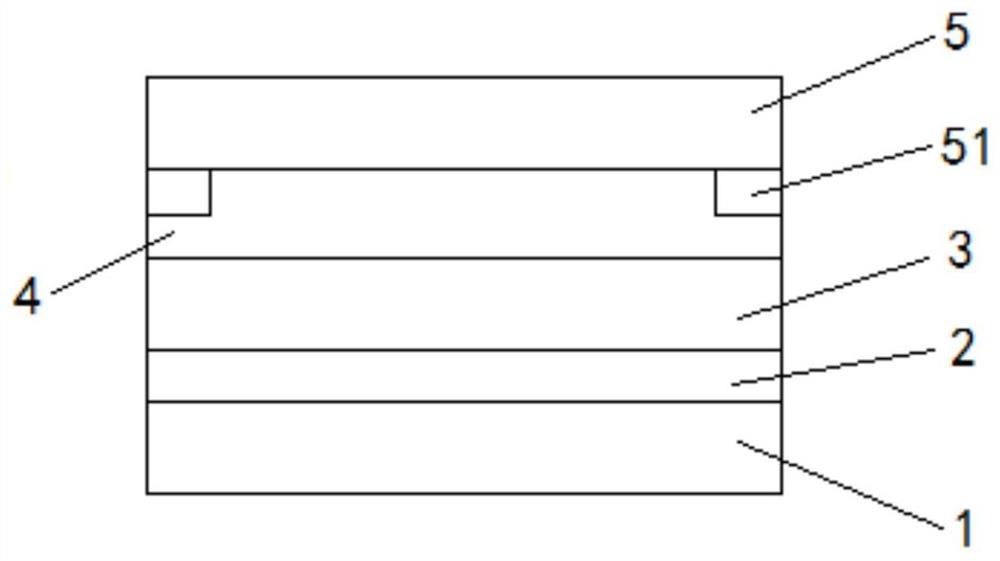

[0035] see figure 2 and image 3 , a touch screen bonding process, comprising:

[0036] S1. Carry out printing graphic design according to product features;

[0037] Specifically, it includes the design of the area where the LOCA bonding material is printed and the thickness of the corresponding printing LOCA bonding material in different areas.

[0038] S2. Print the LOCA bonding material on the upper surface of the display unit by spray printing according to the graphic design of the spray printing to form the first LOCA bonding layer;

[0039] Since the LOCA bonding material is a liquid bonding material, the jet printing equipment can print on the upper surface of the display unit to form a layer of LOCA bonding layer with a uniform thickness through precise printing volume control. The OCA fit layer is thinner and more uniform.

[0040] The thickness of the first LOCA bonding layer is 50-100 nm, which can ensure the bonding effect of the display unit and the touch sen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com