Heating and cooling system for injection molding machine

A cooling system and molding machine technology, applied in the field of injection molding machine heating and cooling systems, can solve problems such as limited effect, slow heating speed, and inability to heat, and achieve the effects of increasing production capacity, avoiding turbulent flow, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

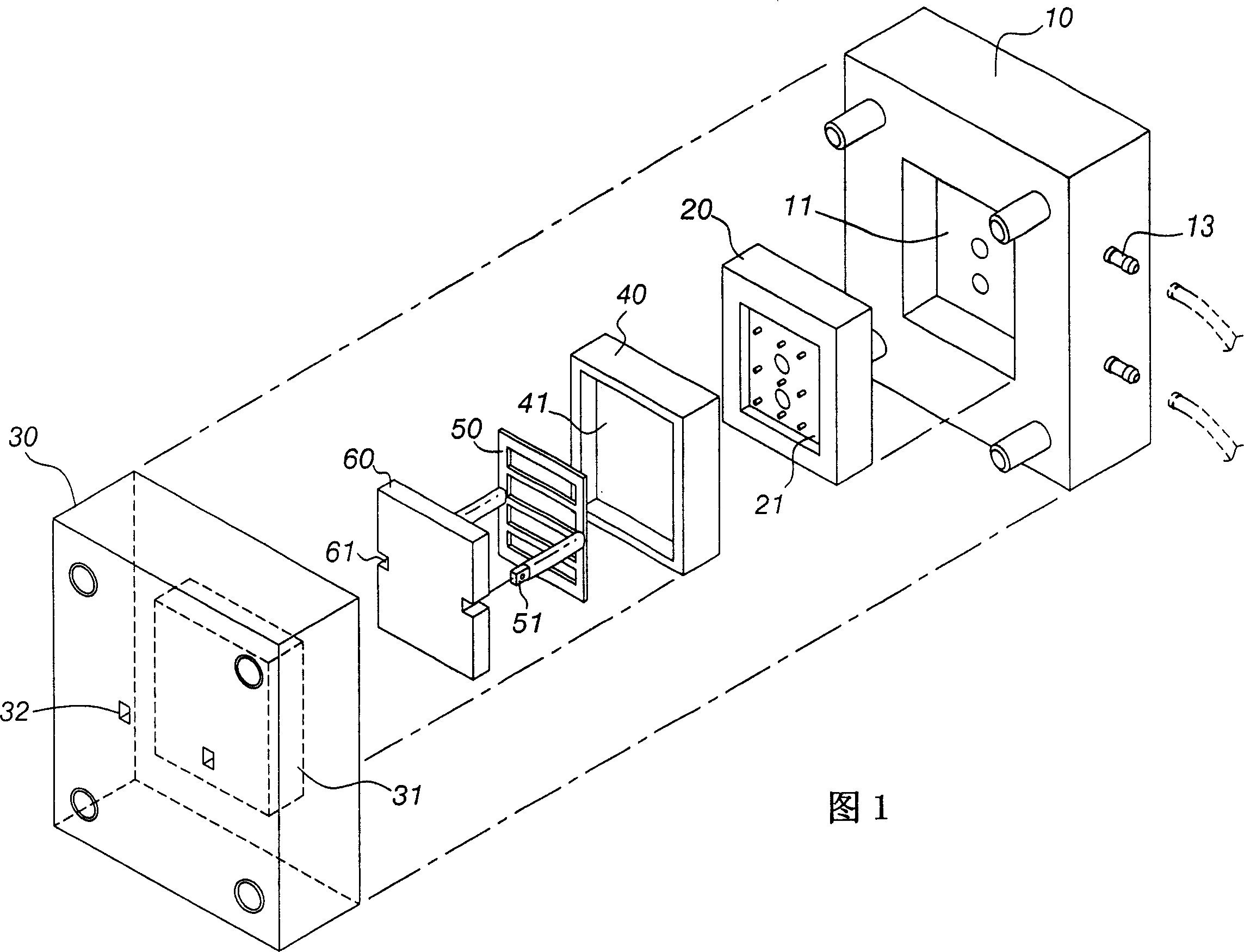

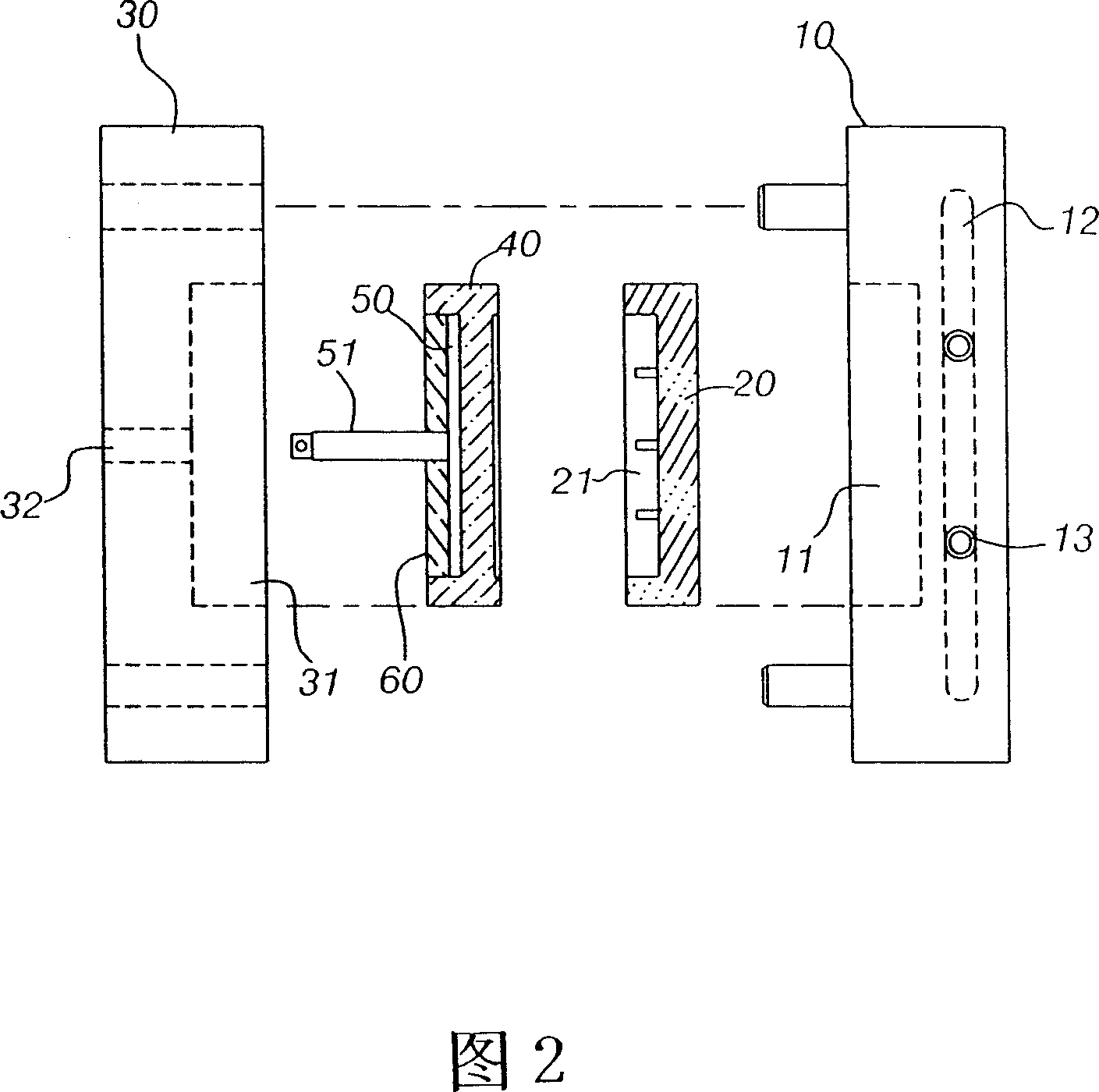

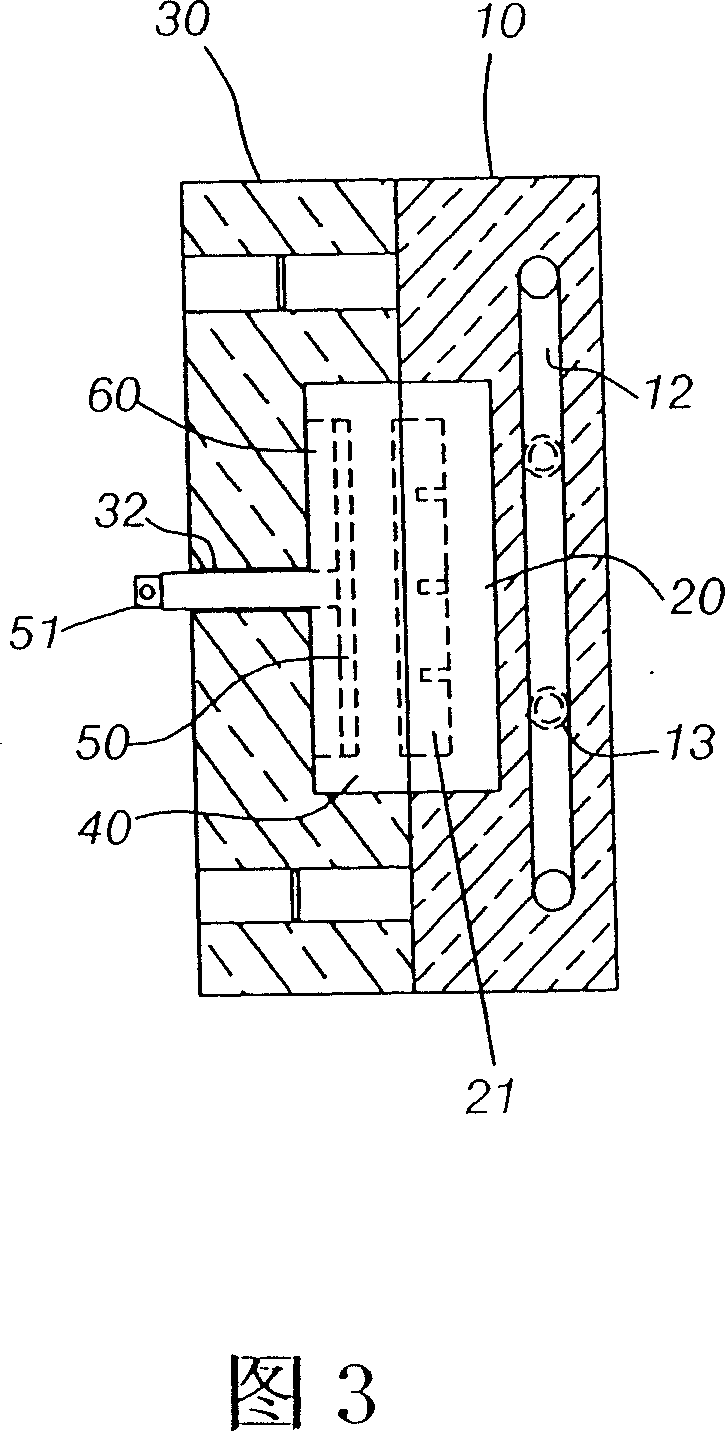

[0030] As shown in Fig. 1 and Fig. 2, the heating and cooling system of the injection molding machine of the present invention includes: a first clamping mold base 10, a first module 20, a second clamping mold base 30, a second module 40, a Heater 50 and a partition 60, wherein:

[0031] The inner surface of the first clamping base 10 is provided with a recess 11 for the first module 20 to be fixed, the interior is provided with a fluid pipe 12 surrounding the recess 11, the exterior is provided with a pipe joint 13 connected to the fluid pipe 12, and the pipe joint 13 When the cooling fluid is input into the fluid pipe 12 , the cooling fluid can perform heat exchange on the first module 20 on the first clamping base 10 . The outer surface of the first module 20 has a mold cavity space 21 of a predetermined shape. During implementation, the cooling fluid input by the fluid pipeline 12 may be cooling liquid or high-speed air flow.

[0032] The second clamping base 30 can be d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com