A method for manufacturing a capacitive screen sensor without etching marks

A production method and capacitive screen technology, applied in the direction of electrical digital data processing, input/output process of data processing, instruments, etc., can solve the problems of increasing cost, adding reflective layer, etc., to achieve water ripple elimination and avoid different effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

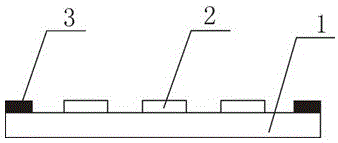

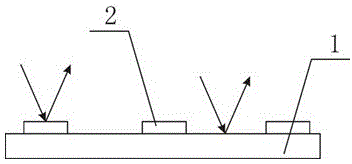

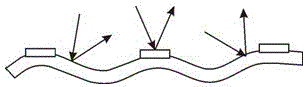

[0021] Embodiment 1: see Figure 1 to Figure 4 The thin film capacitor Sensor is composed of: a transparent substrate 1 is provided with a conductive layer 5, the conductive material around the conductive layer 5 is etched and provided with an electrode 3, the central conductive material of the conductive layer 5 is etched and provided with a pattern, and its Pattern area The schematic diagram of reflection and etching area etching reflection is as follows figure 2 shown.

[0022] The Sensor manufacturing process of the traditional thin-film structure is as follows:

[0023] Conductive film→baking shrinkage→conductive layer 5 is etched to form Pattern2→electrode 3 fabrication (involving baking).

[0024] In this manufacturing process, the etching of the conductive layer 5 at the electrode 3 is completed at the same time as the etching of the conductive layer 5 at the Pattern 2. However, after the electrode 3 is fabricated, a baking process will be involved, which will cause...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com