Touch screen and manufacturing method thereof

A manufacturing method and a touch screen technology, applied in the field of touch technology, can solve the problems affecting the display effect of a display module, the deformation of the display module, water lines, etc., and achieve the effect of eliminating the edge water ripple phenomenon.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

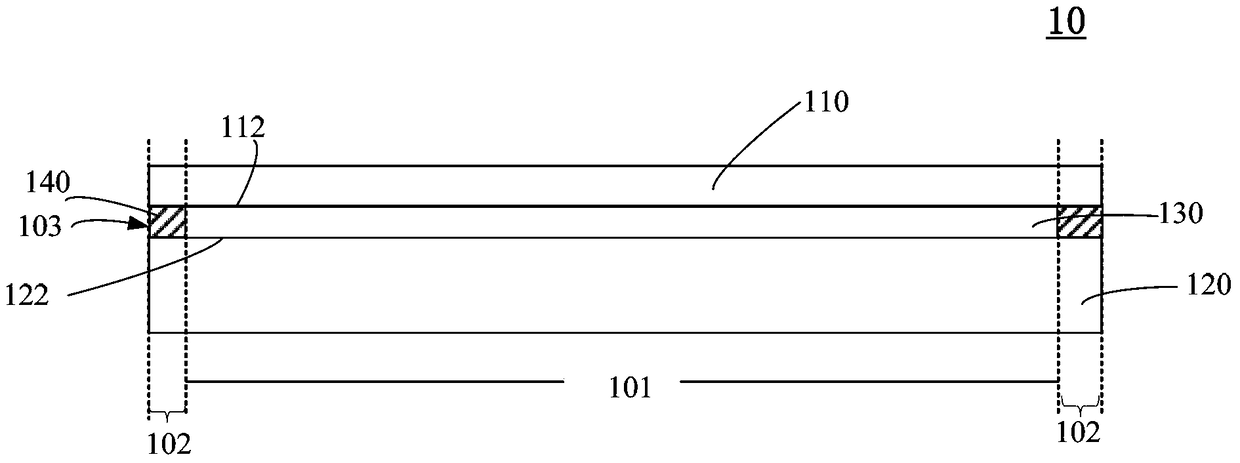

[0036] like figure 1 as shown, figure 1 A schematic structural diagram of the touch screen according to the first embodiment of the present invention is shown. The touch screen 10 defines a central bonding area 101 and a peripheral area 102, the peripheral area 102 surrounds the central bonding area 101, the touch screen 10 includes a touch module 110 and a display module 120, the touch module 110 and the display module The groups 120 are bonded to each other in the central bonding area 101 , and there is a gap 103 between the touch module 110 and the display module 120 in the peripheral area 102 , and the gap 103 is filled with the colloid layer 140 . The colloid layer 140 provides corresponding supporting force for the edge of the touch module 110 when it is pressed, so that the display module 120 will not be deformed due to the pressure, thereby eliminating the phenomenon of water ripples at the edge. At the same time, it avoids uneven force between the touch module 110 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com