Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47results about How to "Reinforced joints" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

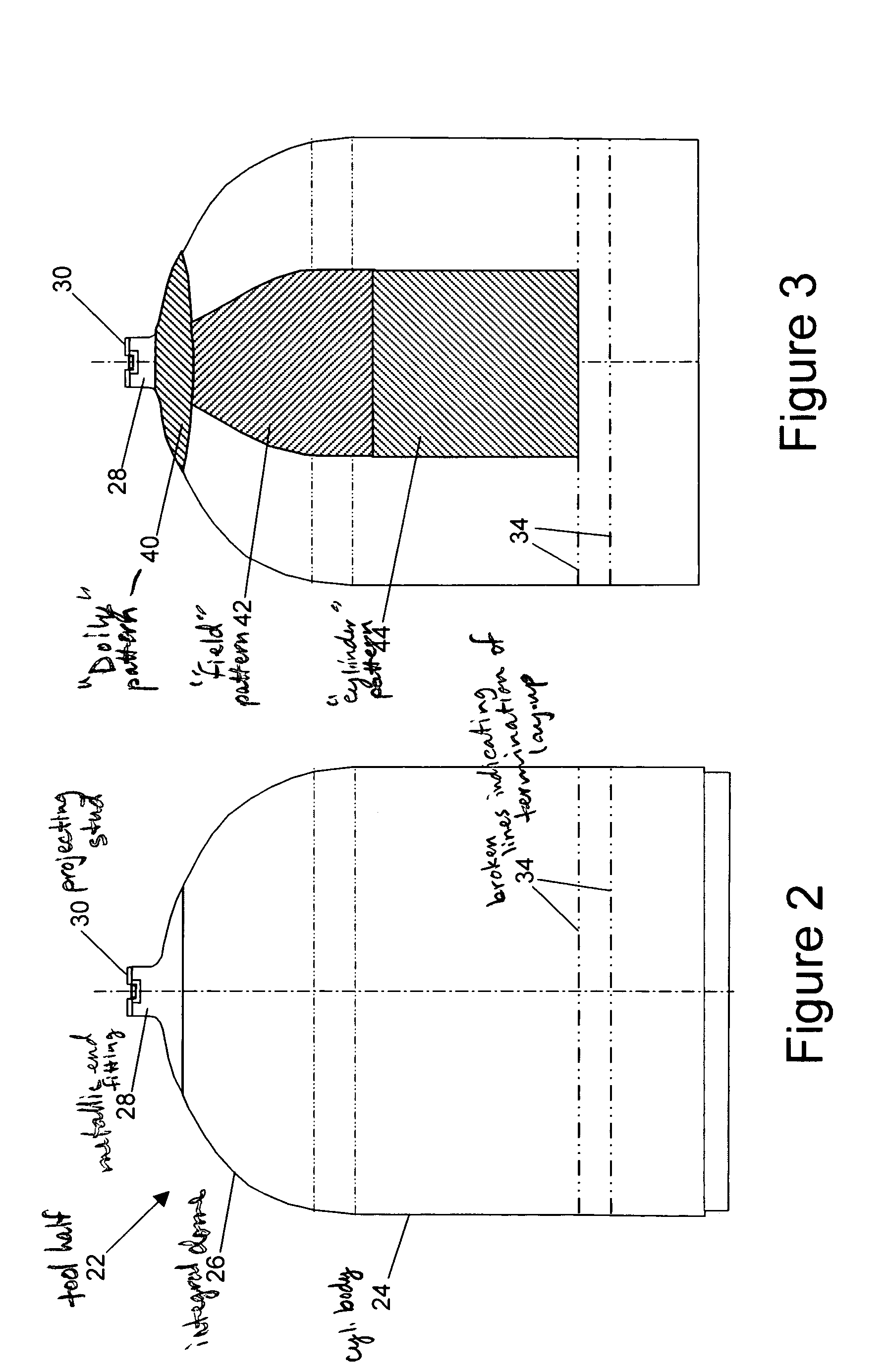

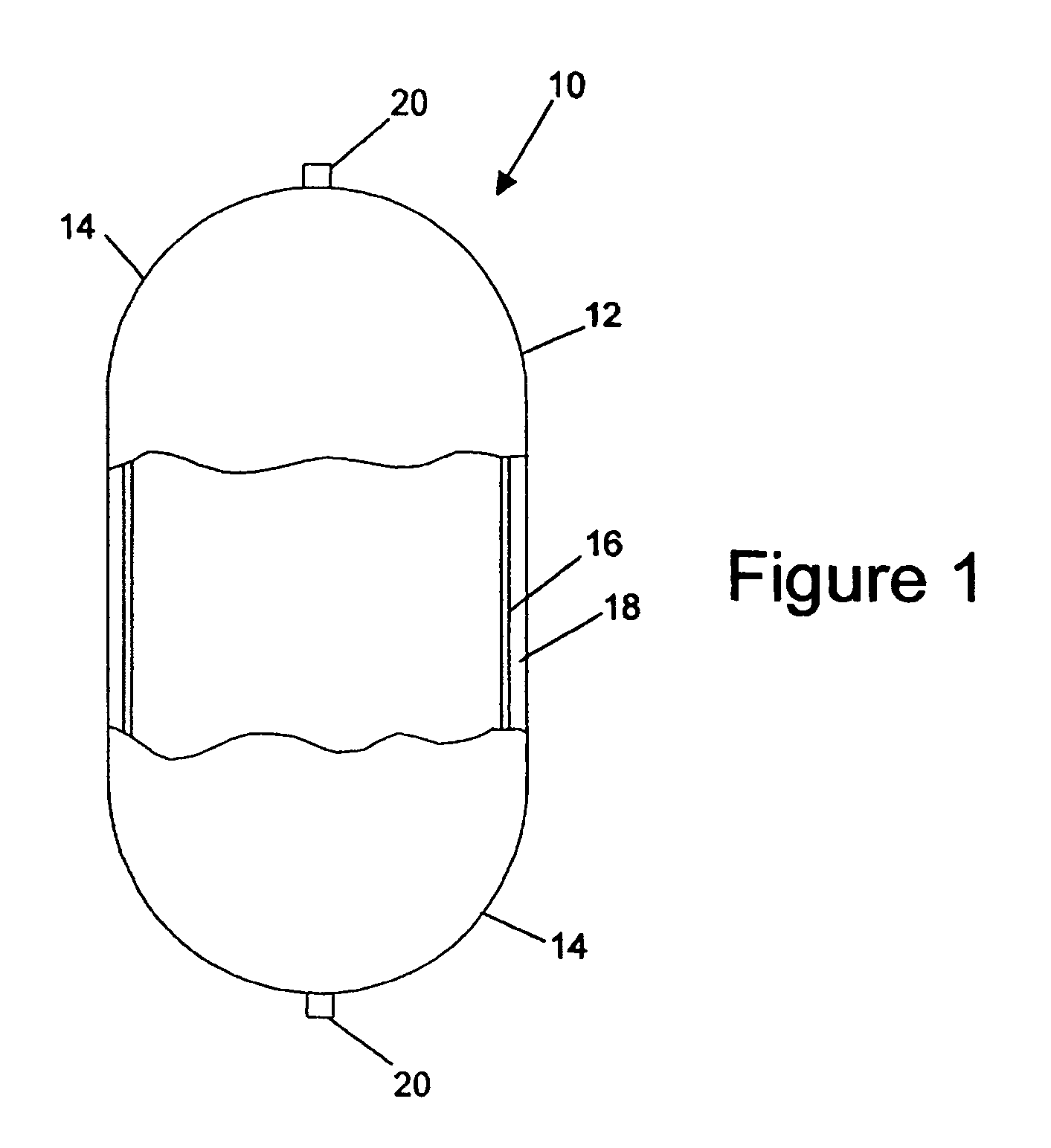

Composite pressure tank and process for its manufacture

InactiveUS20070205201A1Reduce weightLow costVessel mounting detailsVessel manufacturingBody shapeMaterials science

A pressure vessel and method for producing a pressure vessel is disclosed. The pressure vessel comprises a liner shell fabricated from composite material applied to a soluble mandrel having a body shaped to pattern an interior of the pressure vessel, the liner shell having an opening, a boss having an aperture therethrough, the boss sealingly bonded to the liner shell with the aperture adjacent the opening, and an outer shell fabricated from plies of composite material filament impregnated with matrix material wound over the liner shell and the boss, but not over the aperture.

Owner:MICROCOSM INC

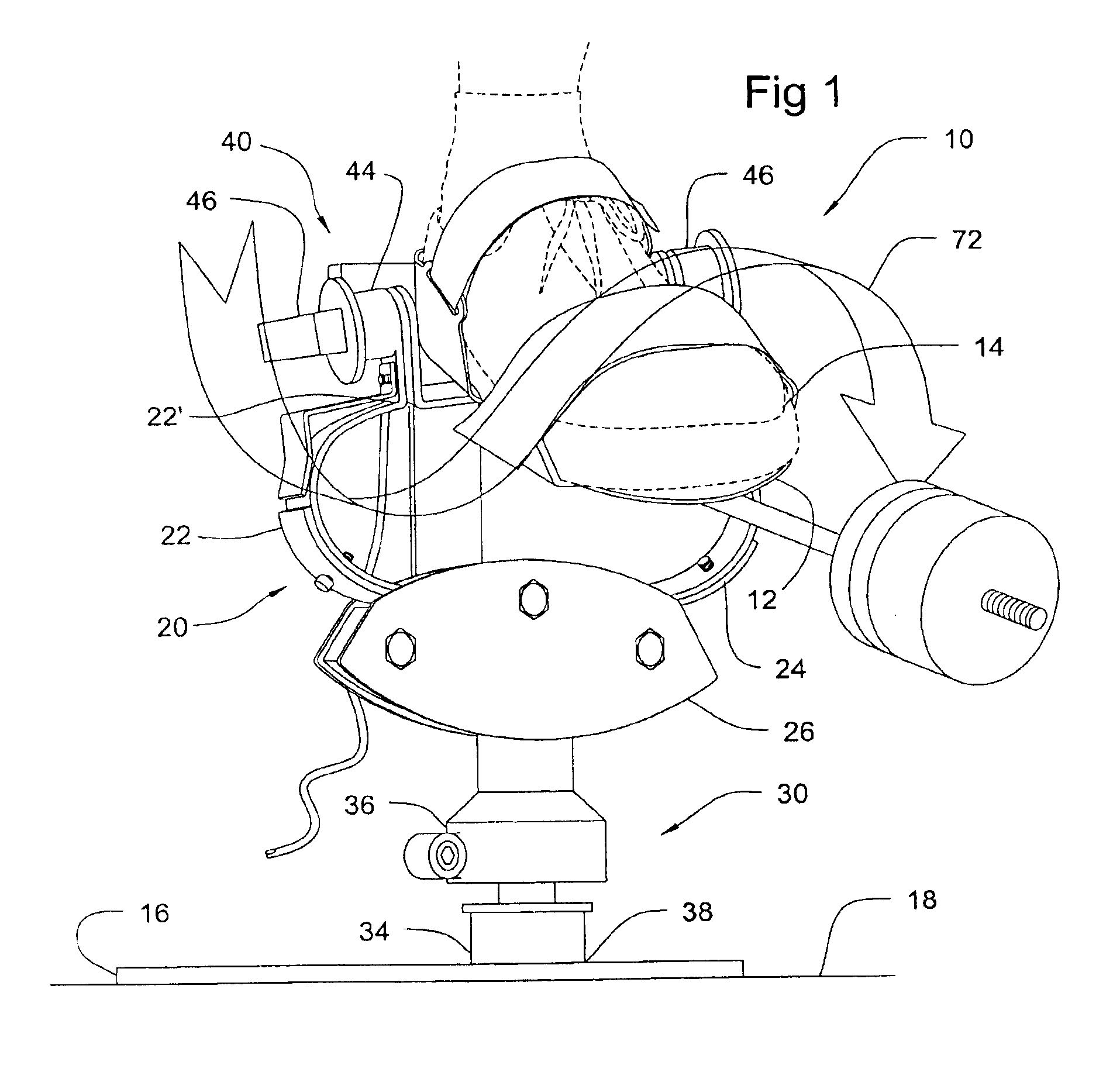

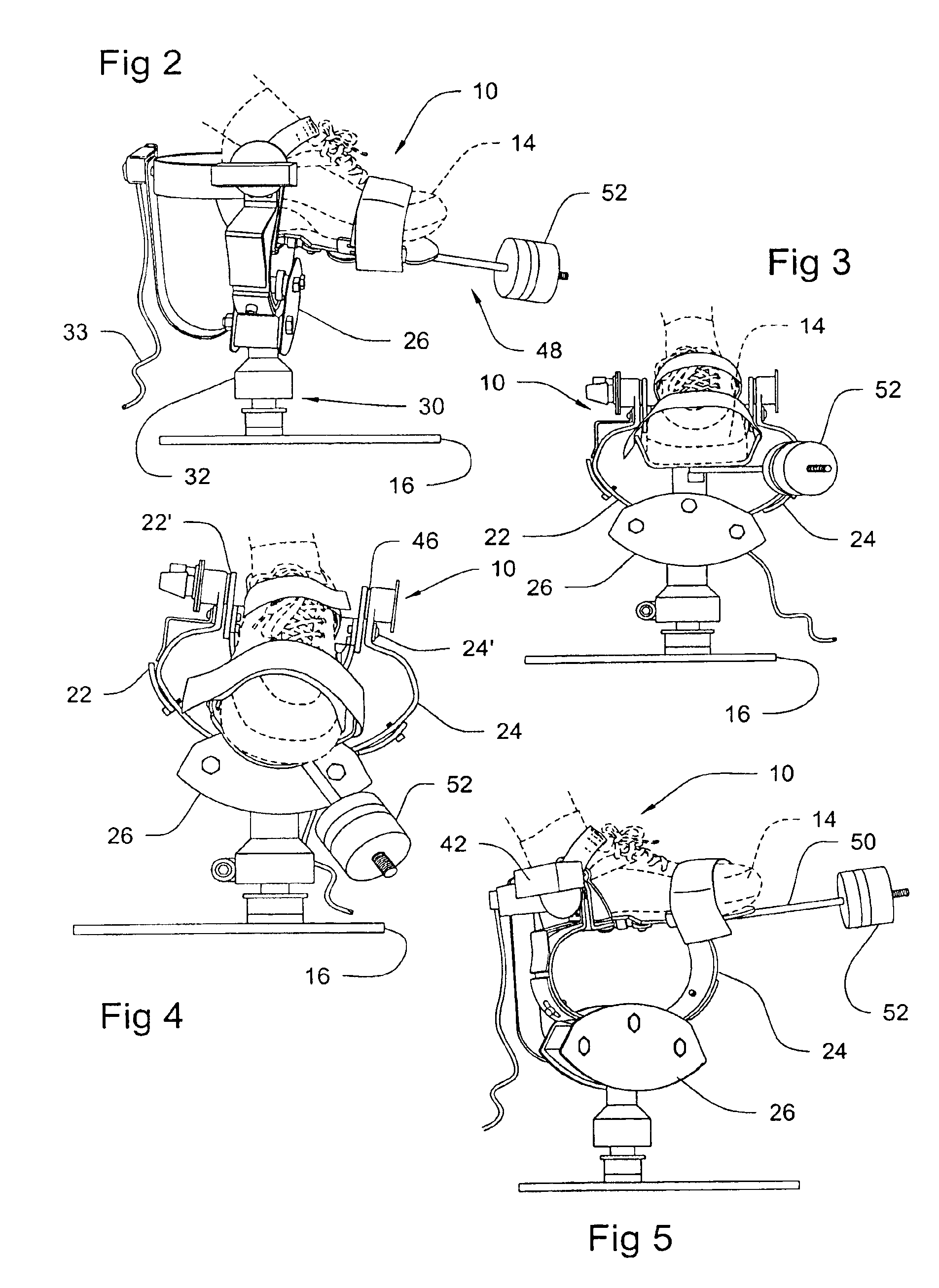

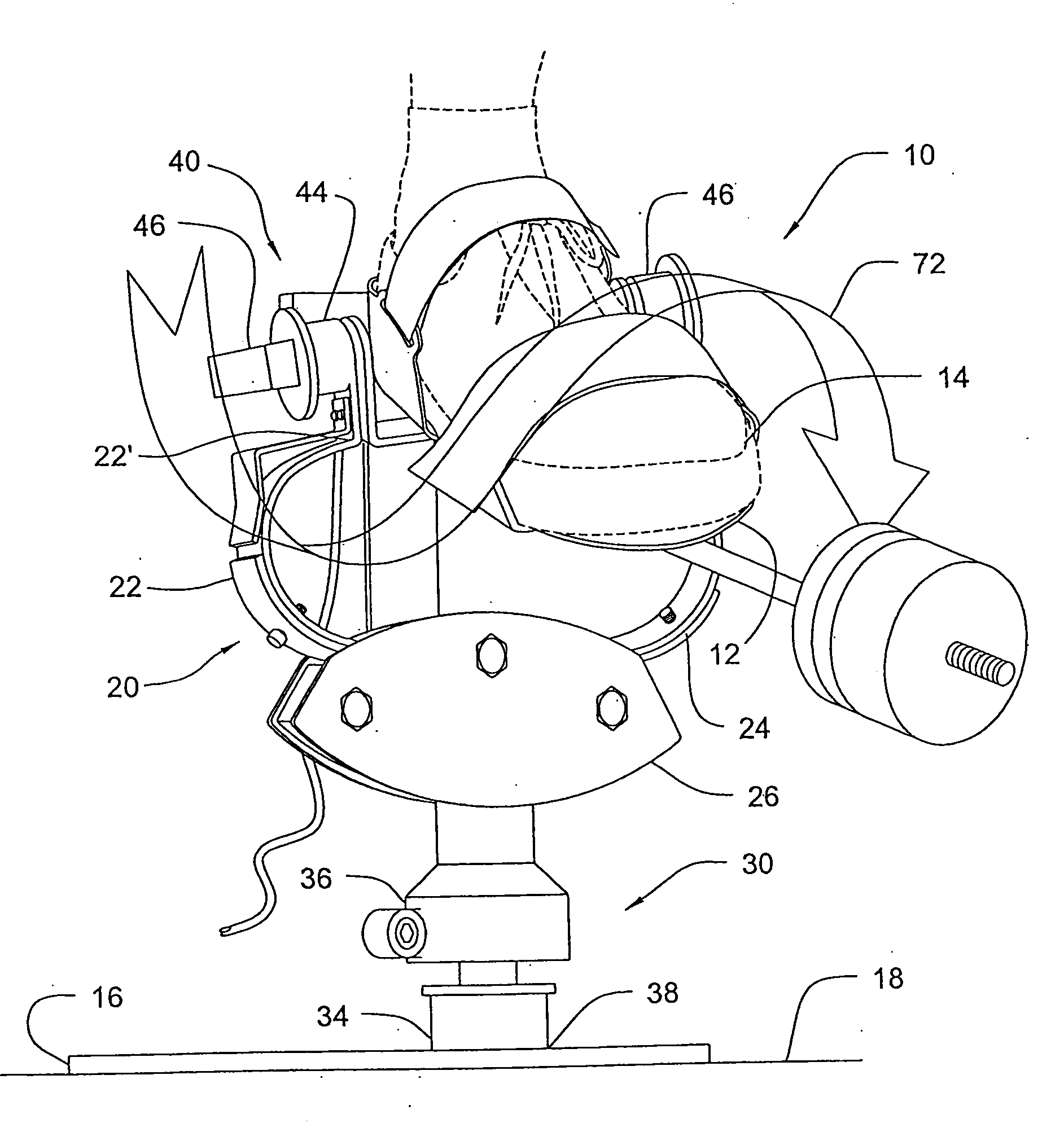

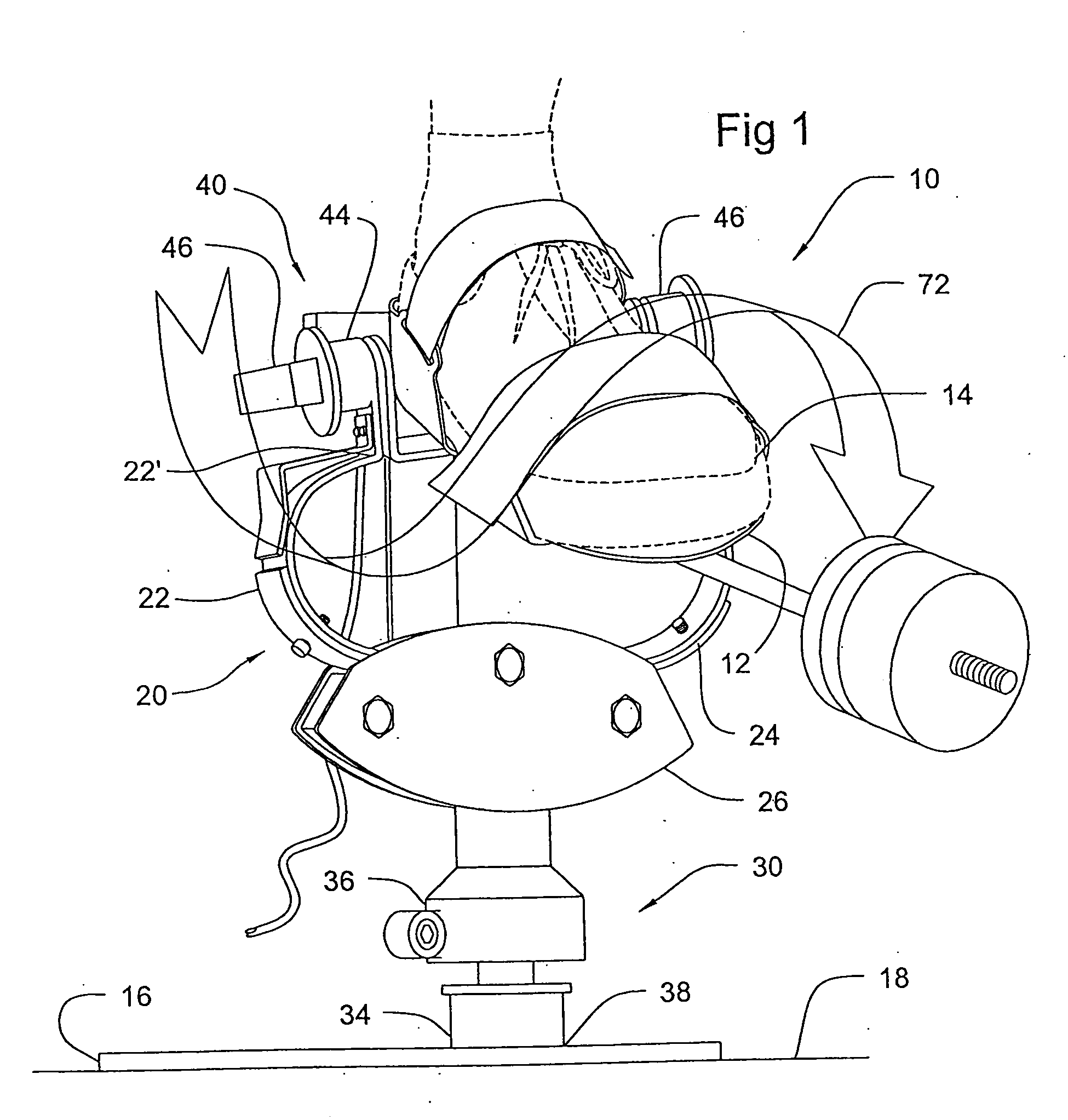

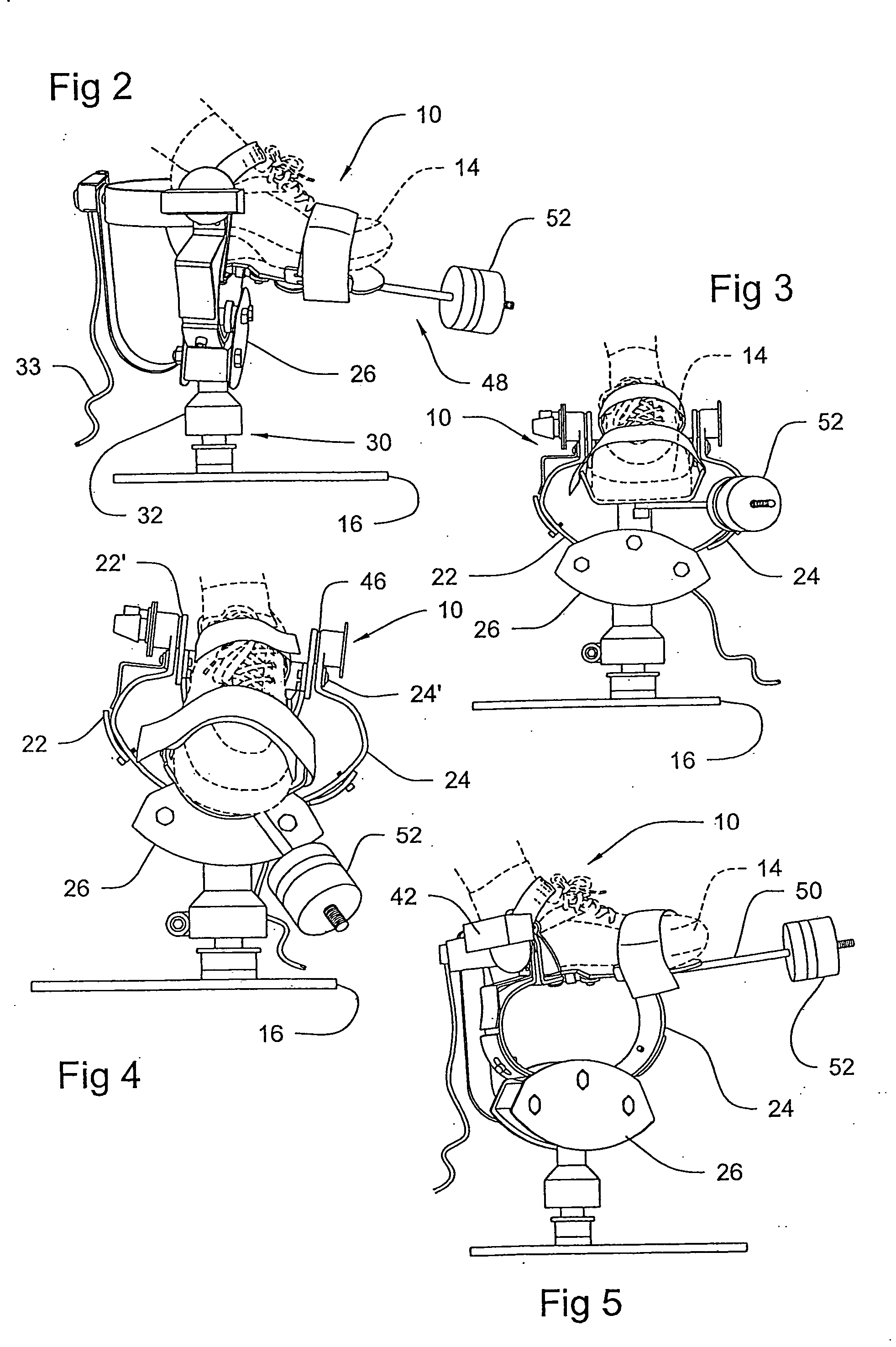

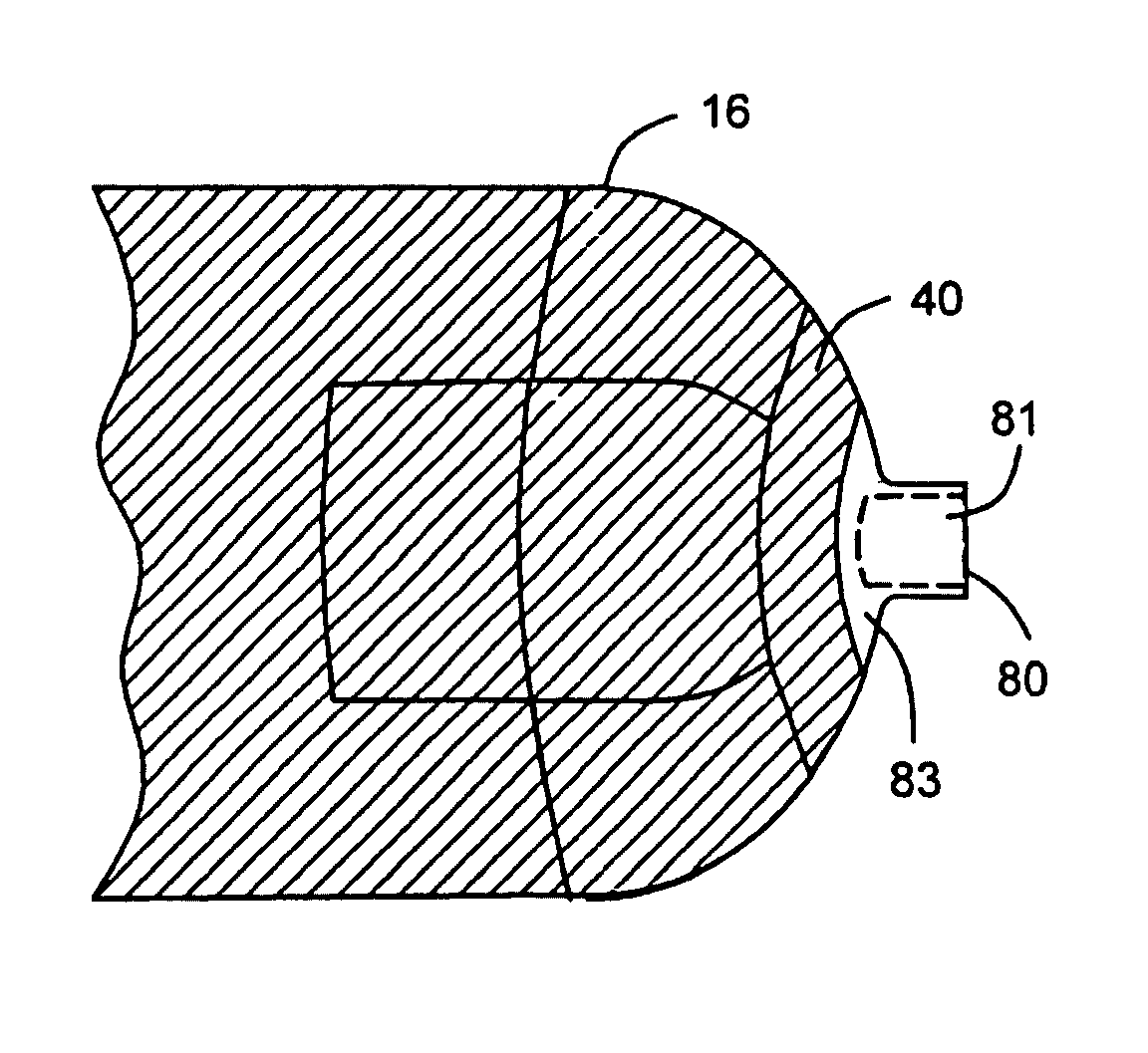

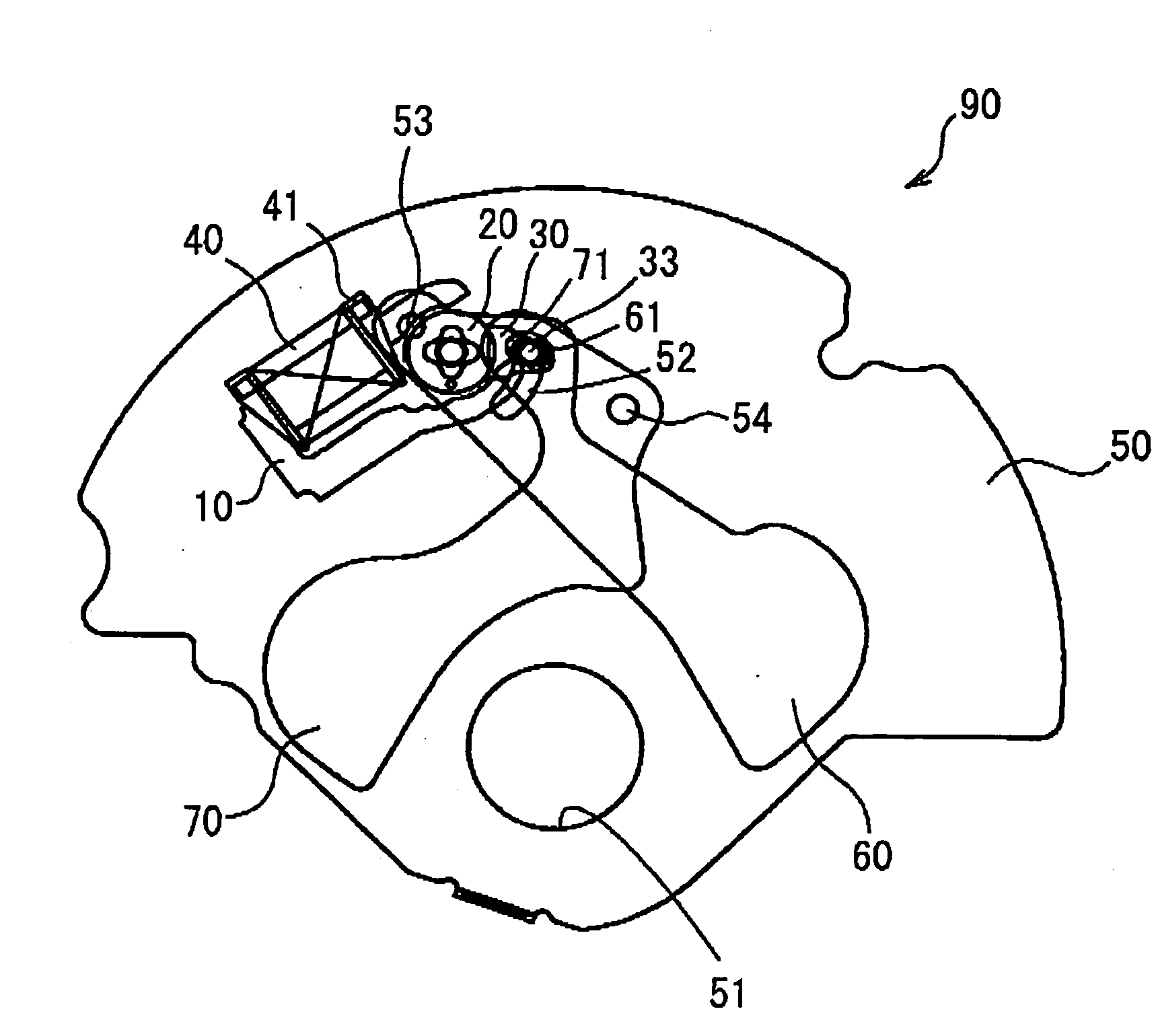

Leg-ankle-foot exercise assembly

InactiveUS6878102B1Increase performanceImprove abilitiesResilient force resistorsChiropractic devicesFoot exercisesPhysical exercise

An exercise assembly structured to direct the foot-ankle-leg, knee, etc. and associated portions of a person's body through a plurality of different paths of movement, wherein each path of movement comprises an at least partially different configuration such that exercise resulting from the various movements will be concentrated on predetermined portions of the body being exercised. The platform is suspended by a support assembly interconnected to a base and is preferably, but not exclusively, directed through the aforementioned paths of movement manually by the user. A sensor assembly including a processor may determine and store selected movements of the platform for graphical or other visual display to the user and for programmed duplication of the sensed paths movement when desired. A weight assembly including at least one but preferably a plurality of different weights are interconnected to the platform and extend outwardly therefrom to provide additional resistive forces to the user's foot, ankle, and leg as they are exercised.

Owner:COMMISSO LUIS ALBERTO

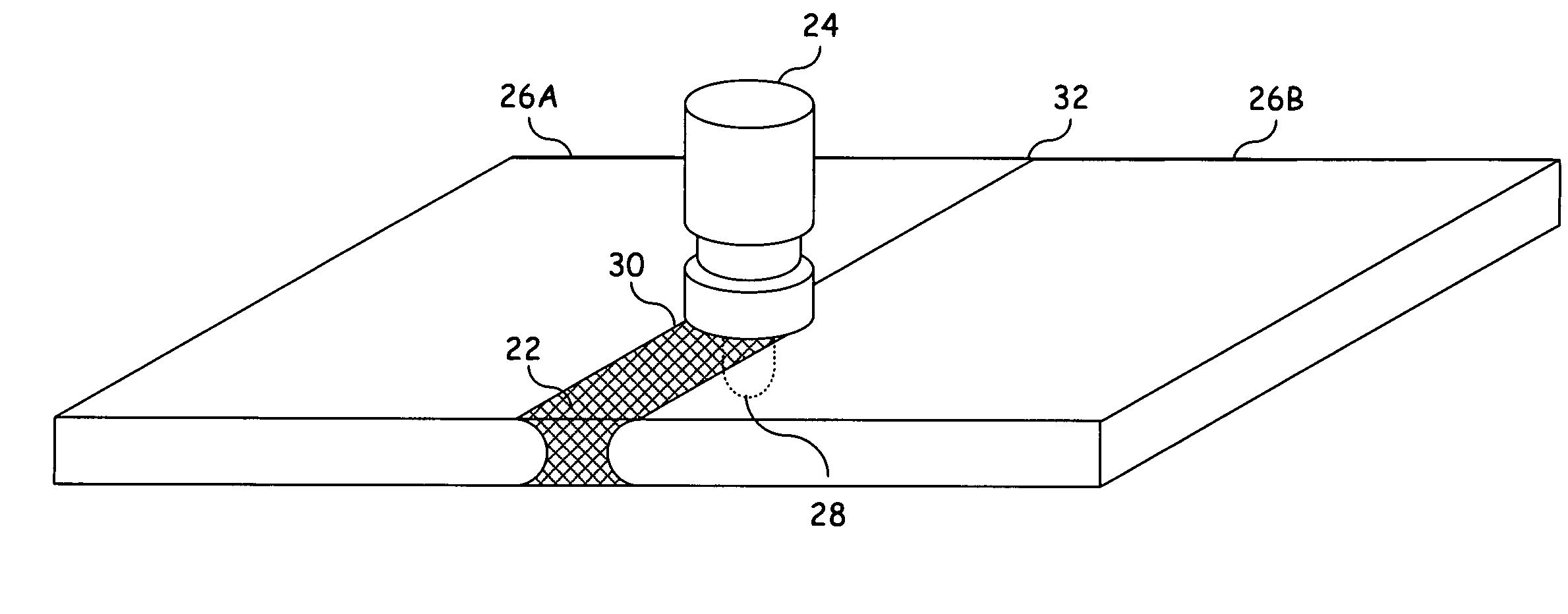

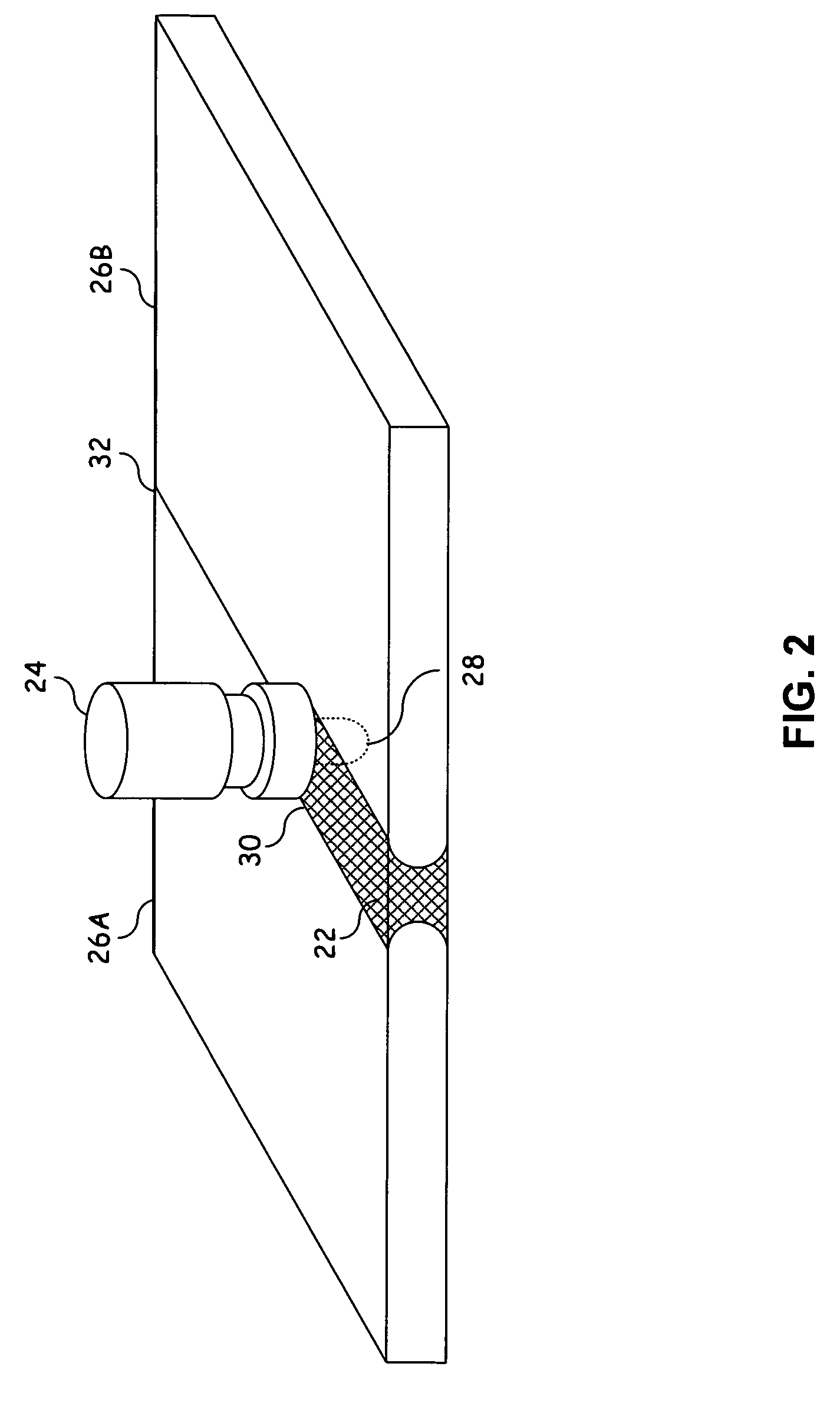

Friction stir welding process having enhanced corrosion performance

InactiveUS20080047222A1Prevent and inhibit corrosionPrevent and inhibit and oxidationStrutsGirdersEngineeringFriction stir welding

A three dimensional joint is formed by coupling (joining) a first structural member and a second structural member. This involves first aligning a first structural member to a second structural member. The first structural member has a channel with which to receive a portion of the second structural member. Certain embodiments may place corrosively inert materials within the mating surfaces to prevent or inhibit corrosion or oxidation. Once aligned, the first structural member and second structural member may be friction stir welded at the channel to plasticize the material adjacent to the channel of both the first structural member and the second structural member to form a friction stir weld joint. Embodiments may then coat the plasticized surfaces of the FSW joint with cold sprayed materials to inhibit corrosion. Should a crack occur within either the plasticized or non-plasticized materials, cold sprayed material may be deposited within and on the crack to retard or arrest the growth of the crack.

Owner:LOCKHEED MARTIN CORP

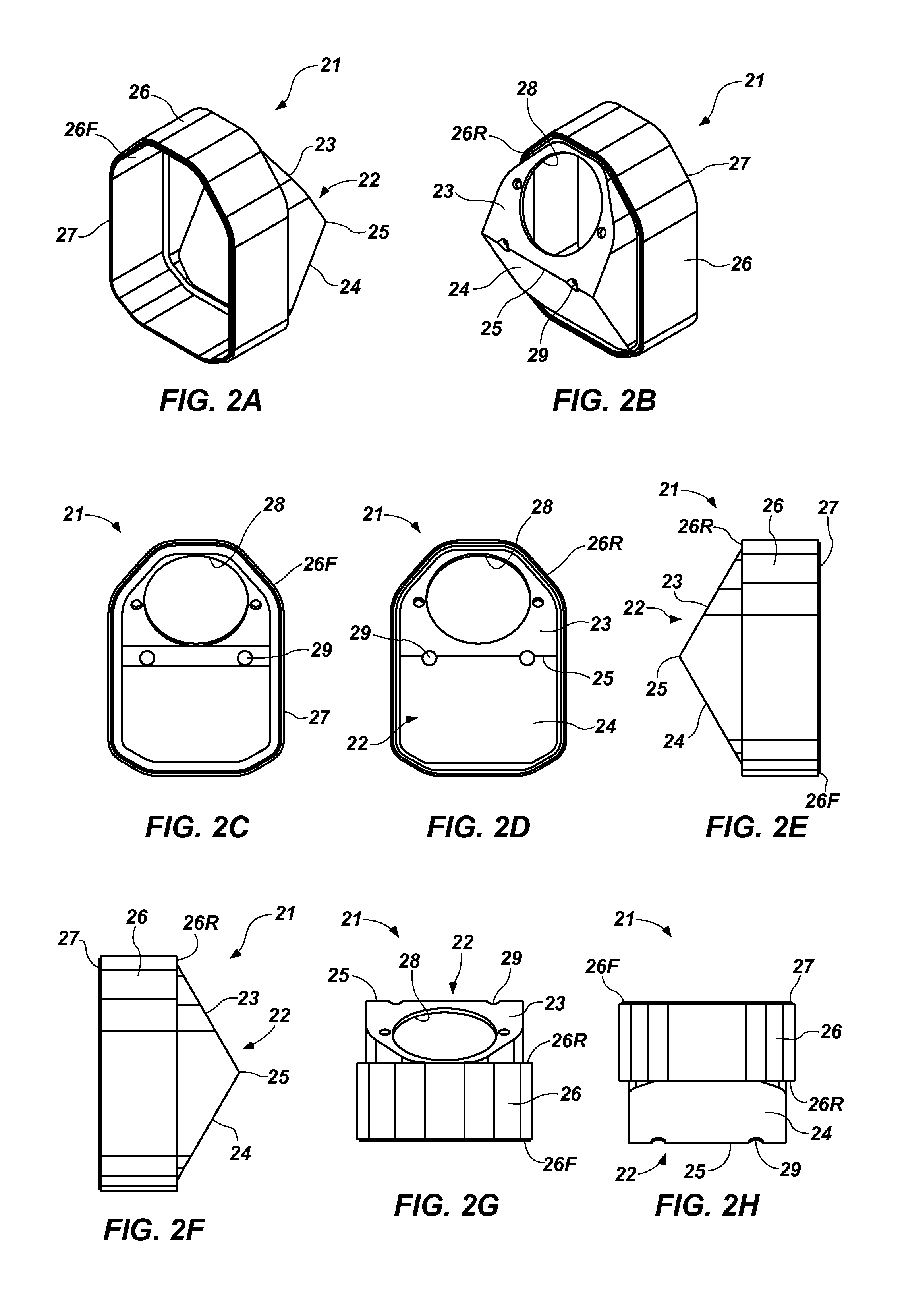

Sound suppressor for a firearm

A sound suppressor for a firearm, such as a shotgun, may include a rear end cap, a plurality of baffle units and a front end cap that are configured to be assembled in an end-to-end arrangement. These elements may be secured to one another with one or more elongated coupling elements that extend through the end-to-end arrangement, along with one or more complementary securing elements. Such a sound suppressor may lack an outer housing. A plurality of guide rods may extend through an interior of such a sound suppressor in a manner that provides the framework for a passage for a projectile as it moves through the sound suppressor. A barrel coupling element that may be used with a sound suppressor is also disclosed, as are methods for tailoring the length of a sound suppressor and for customizing the types and arrangement of baffles used in the sound suppressor.

Owner:SILENCERCO

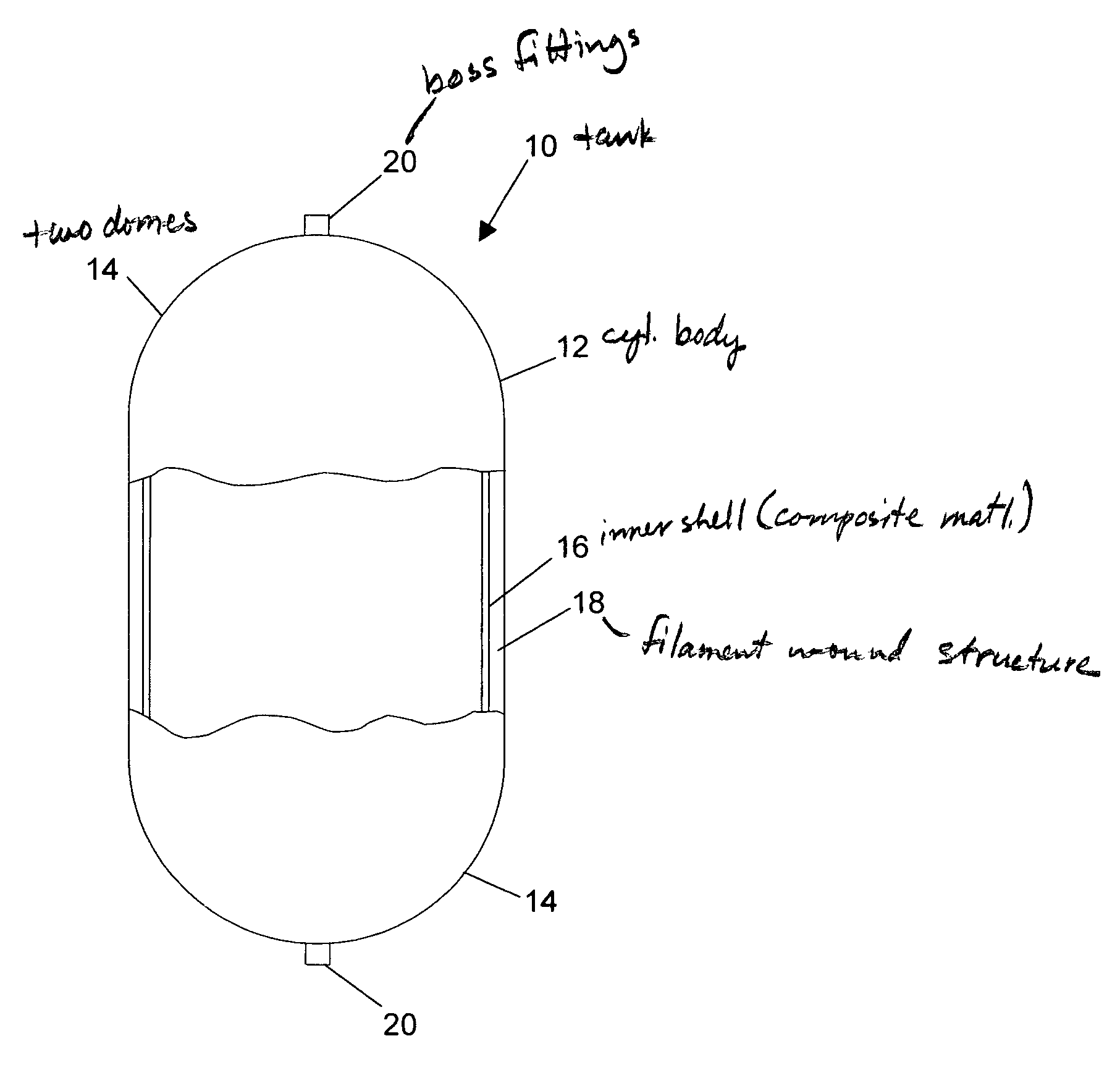

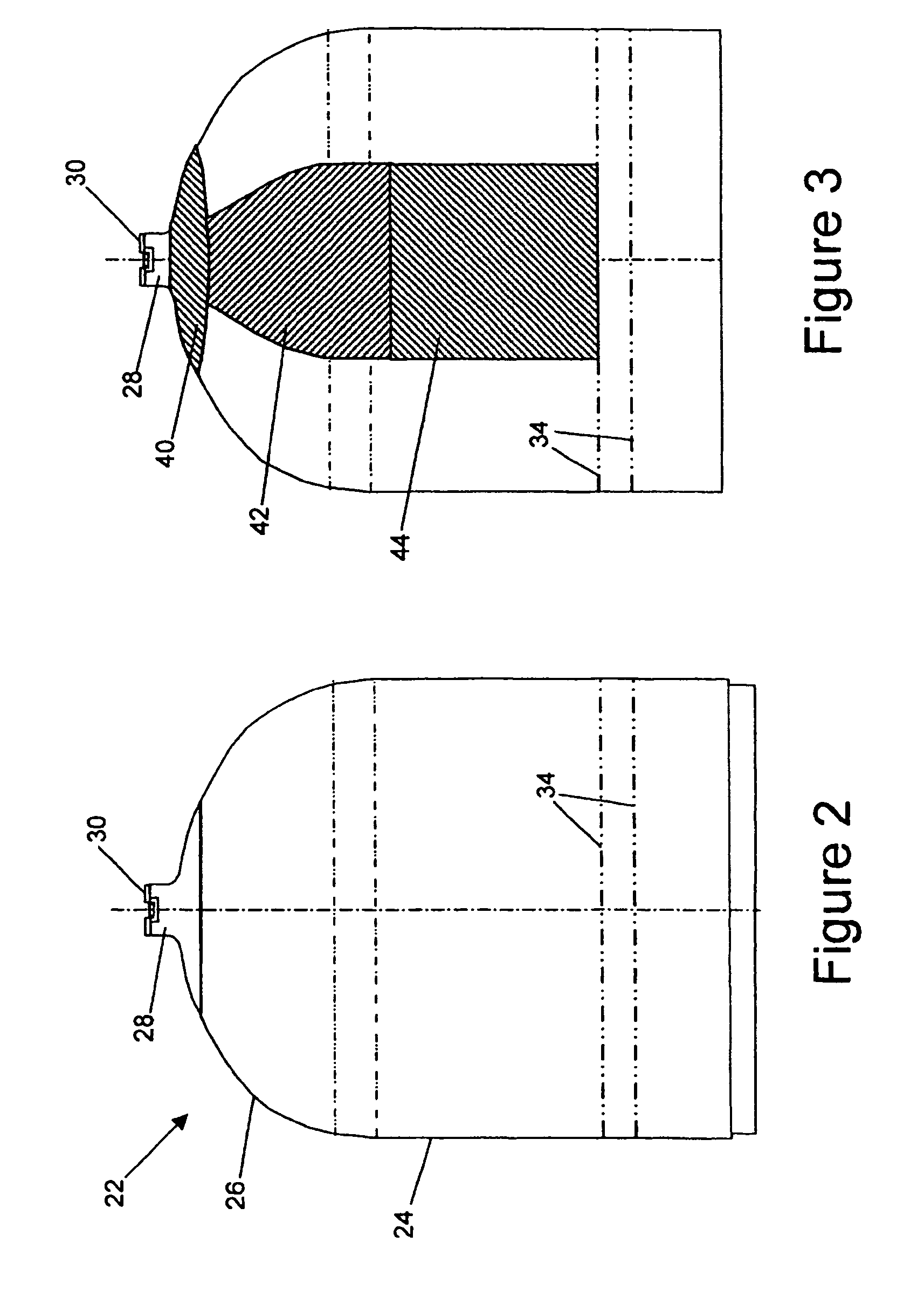

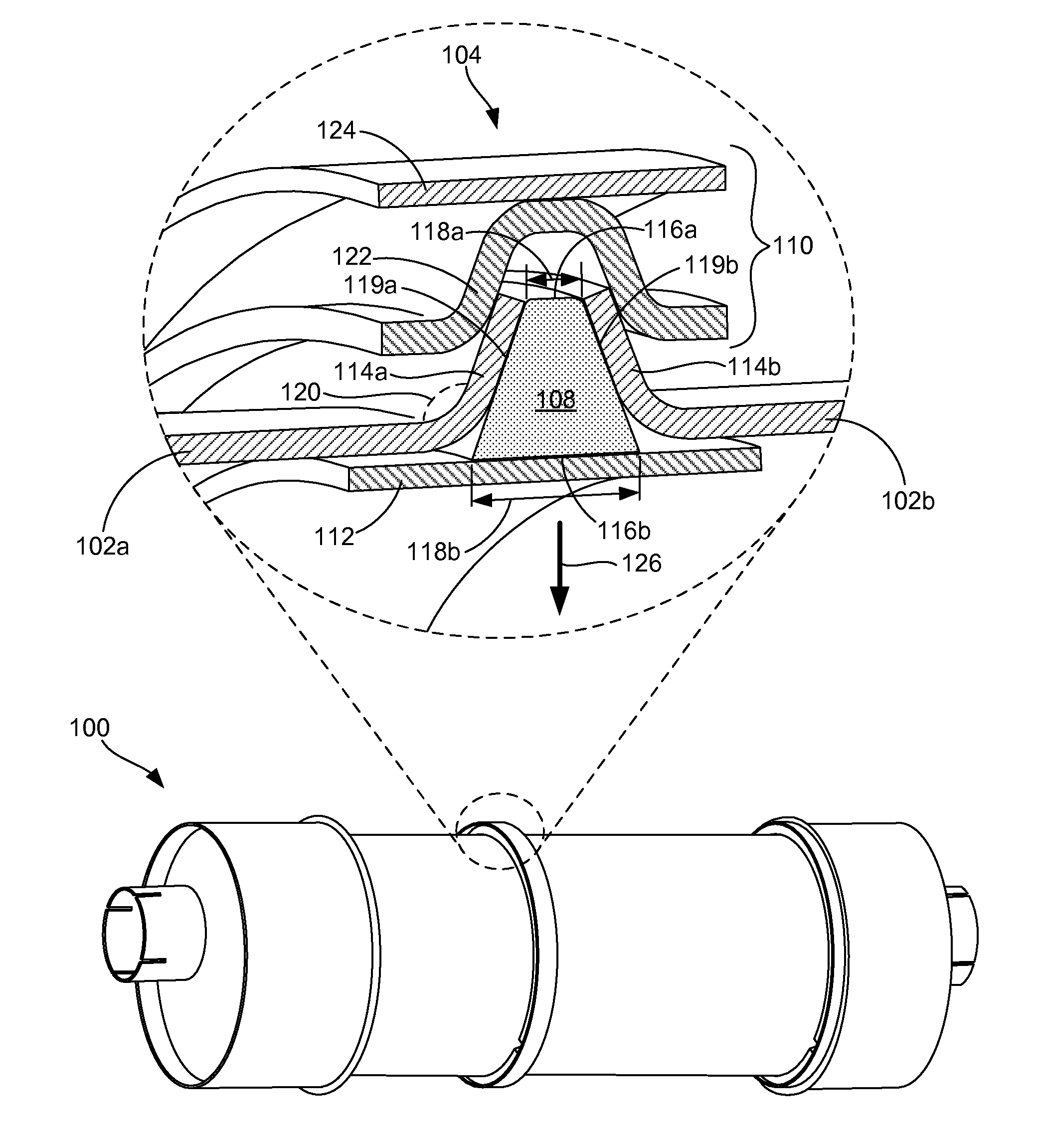

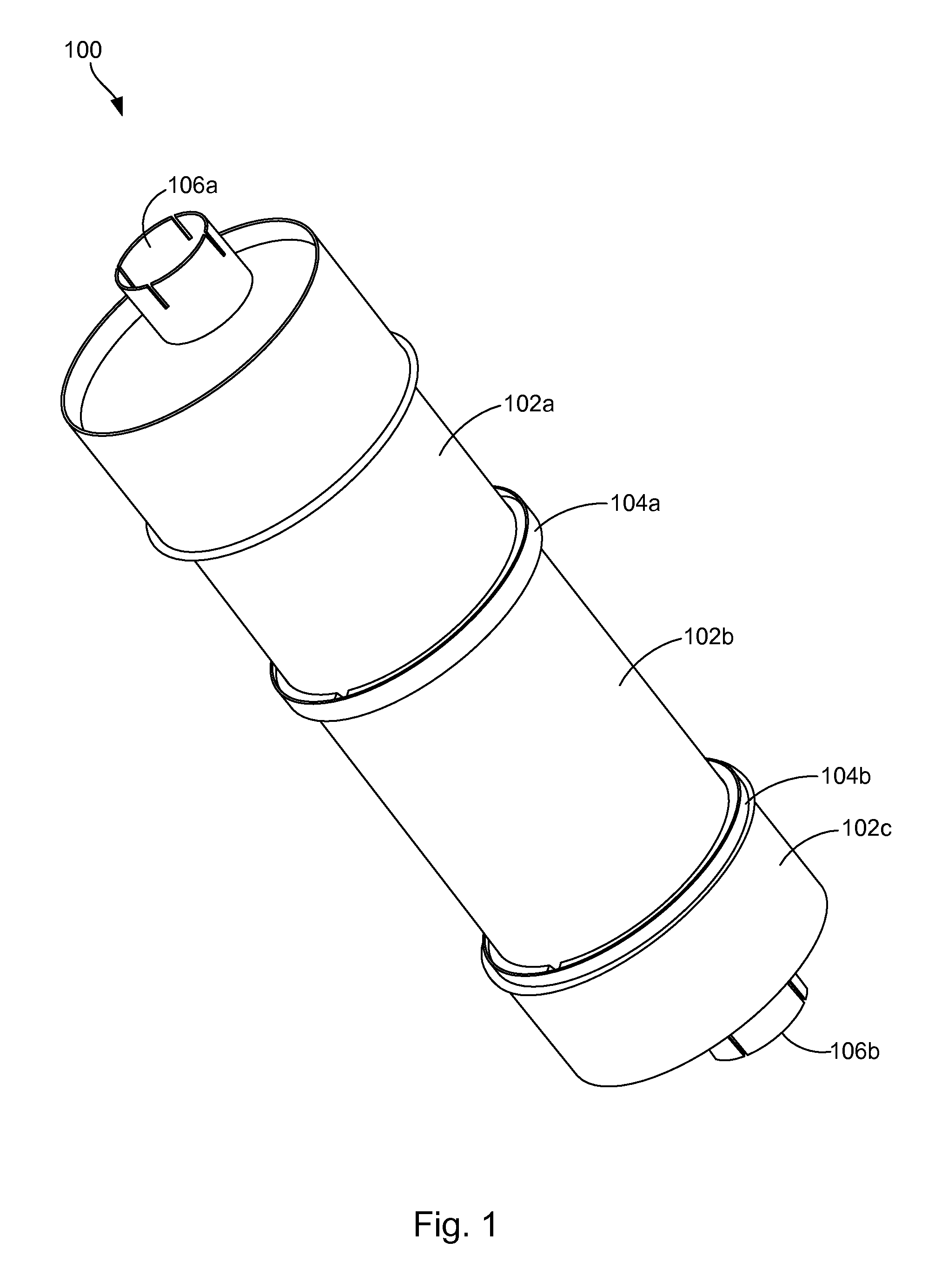

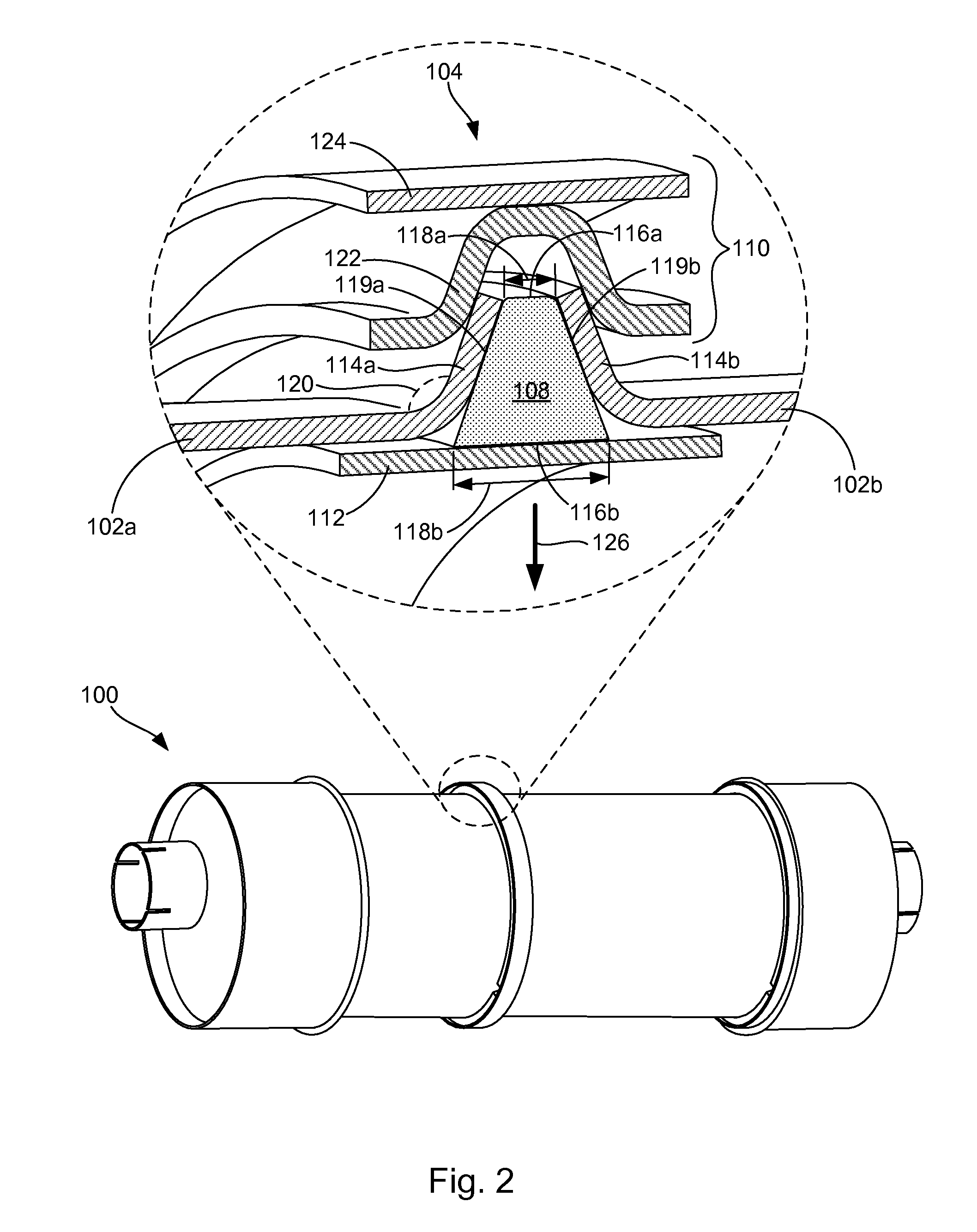

Composite pressure tank and process for its manufacture

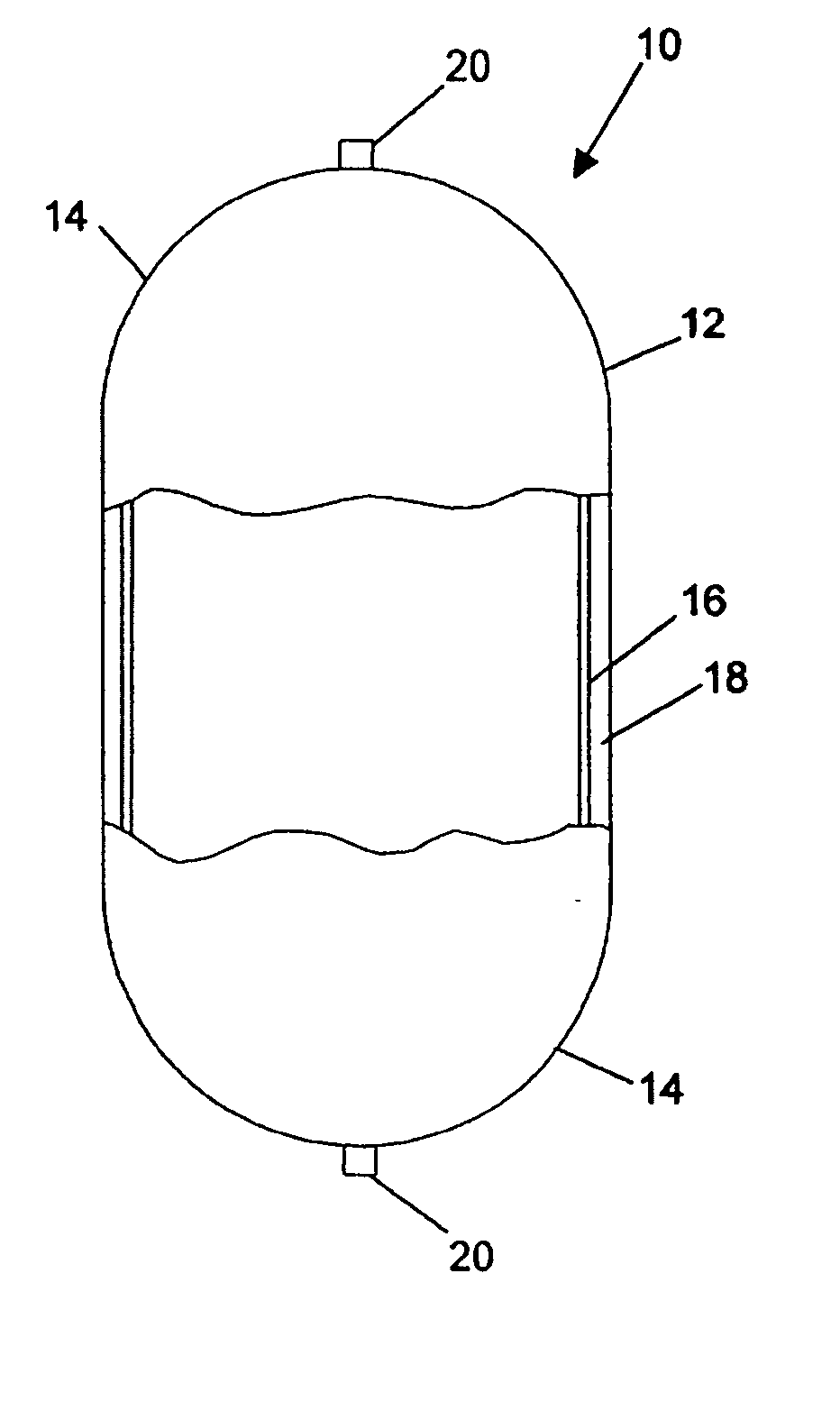

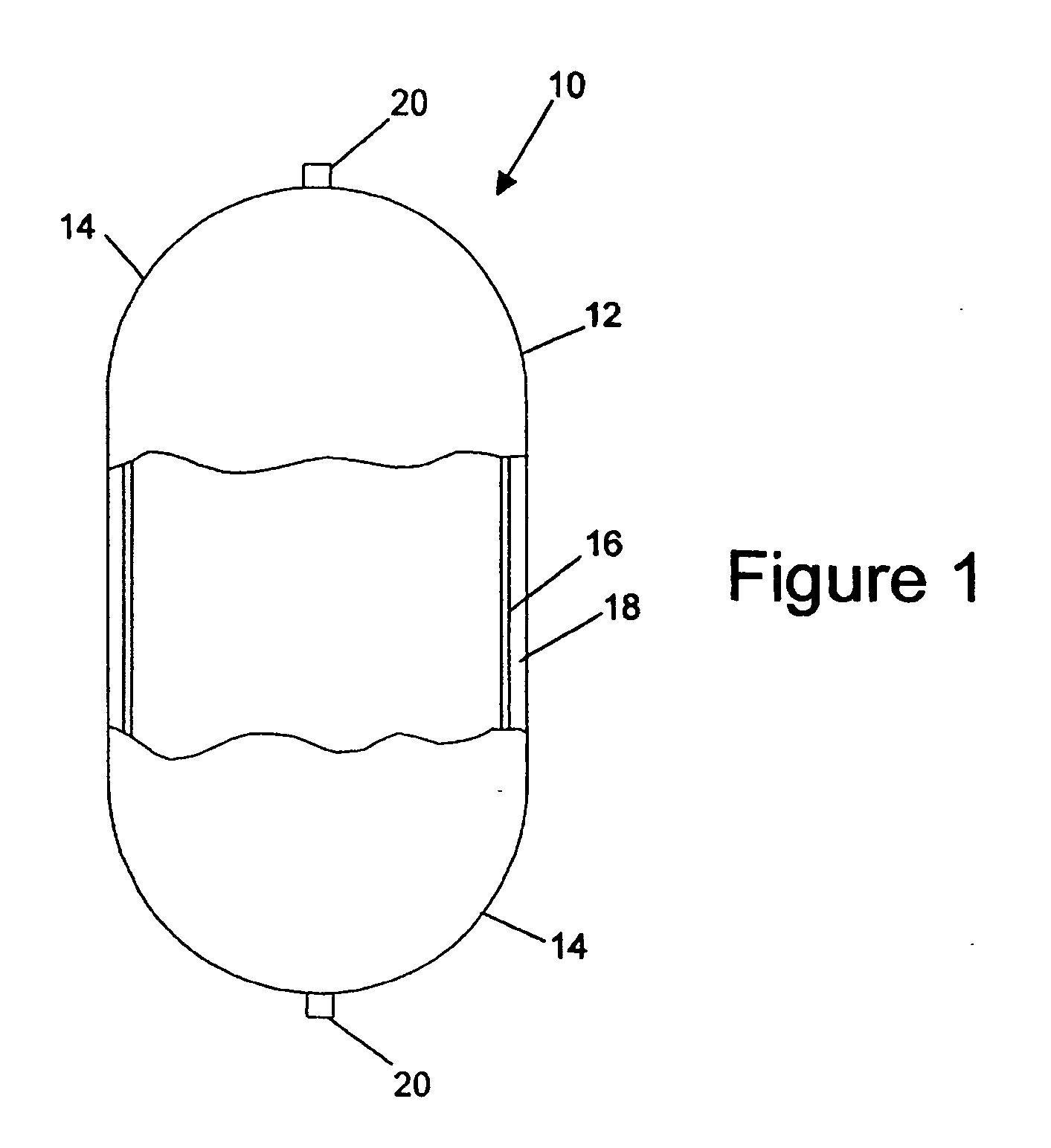

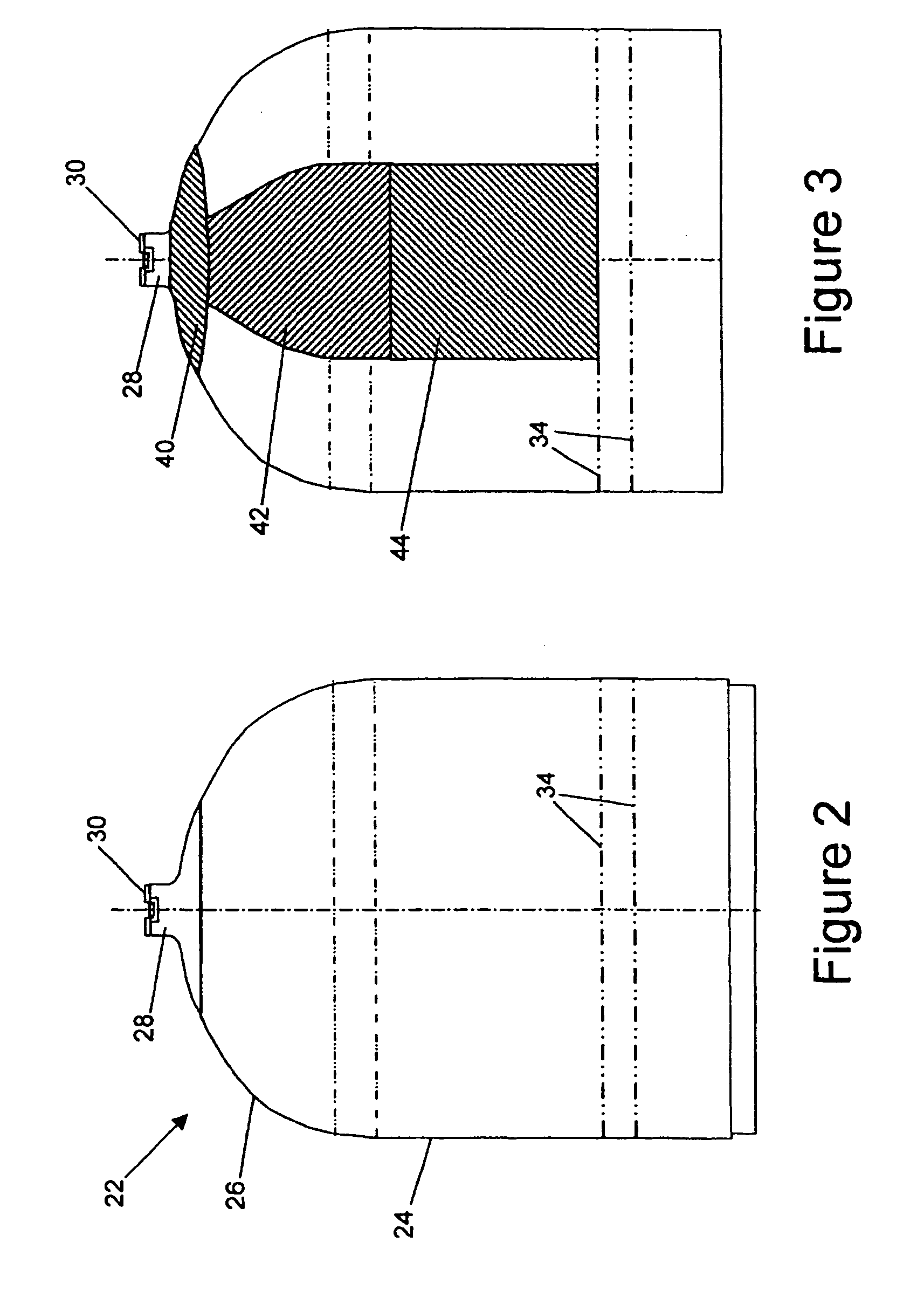

InactiveUS7195133B1Relieve pressureReduce penetrationVessel mounting detailsVessel manufacturingEngineeringFilament winding

A pressure vessel (10) and a process for its fabrication, the vessel (10) having a liner shell (16) formed from composite materials cured out-of-autoclave, and an outer structure (18) formed by winding or laying up additional layers of composite material over the liner shell. The liner shell (16) is formed as two halves, each with an opening into which a boss fitting (20) is installed. The two halves may be separately formed by a lay-up process, or first formed as a whole liner shell by filament winding, the whole liner shell then being cut in half to permit installation of the boss fittings (20). After curing, the halves are assembled and the outer structure (18) is wrapped over the liner shell (16) and also cured out-of-autoclave. The resulting pressure vessel (10) can be used for reliable storage of cryogenic or other materials, yet is light in weight and not costly.

Owner:MICROCOSM INC

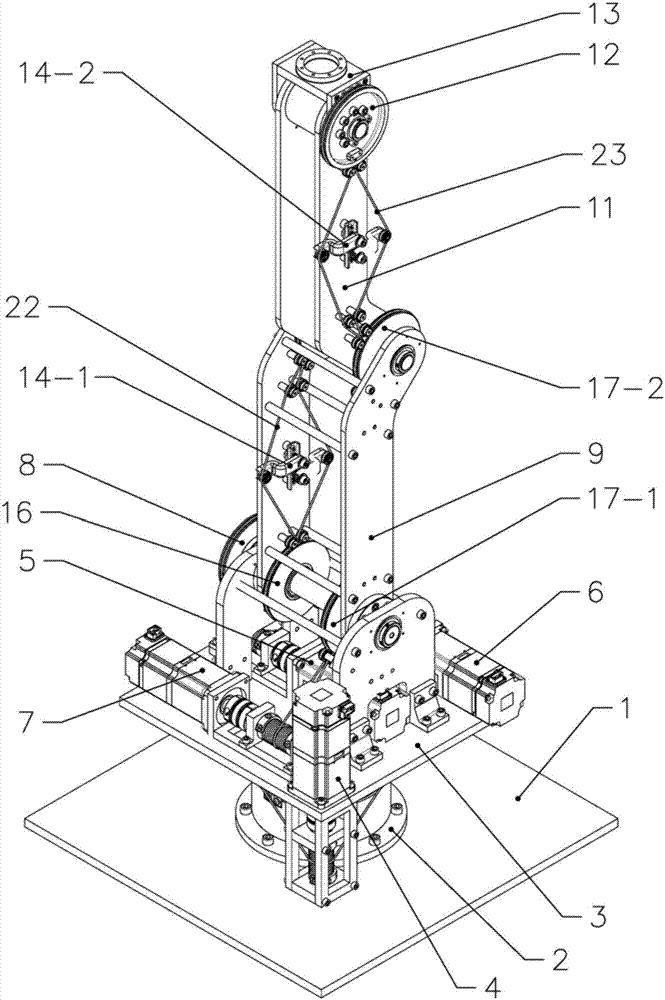

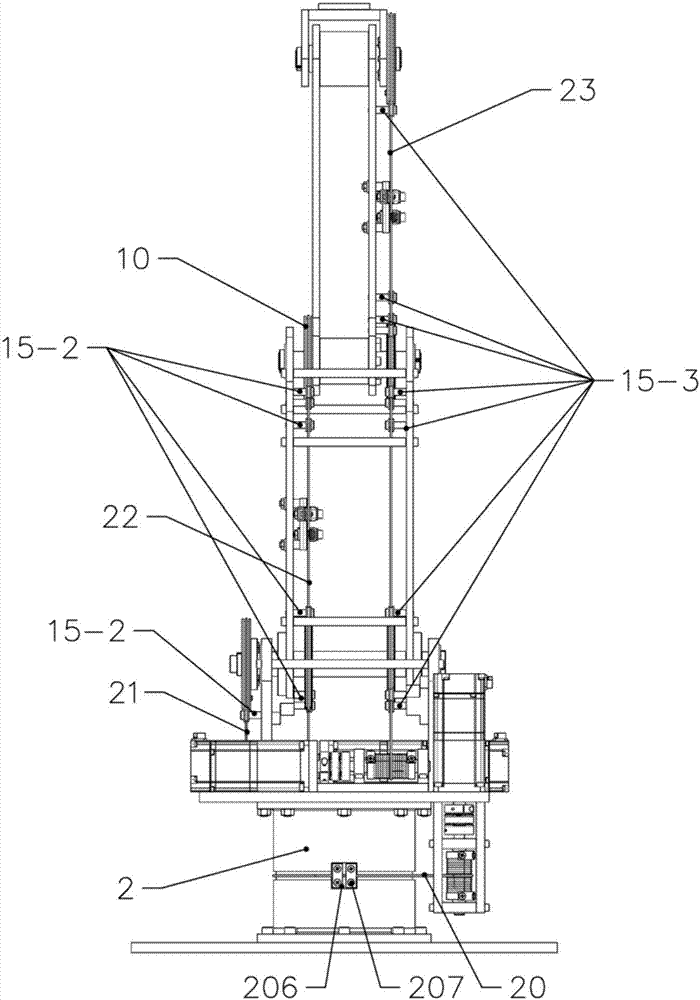

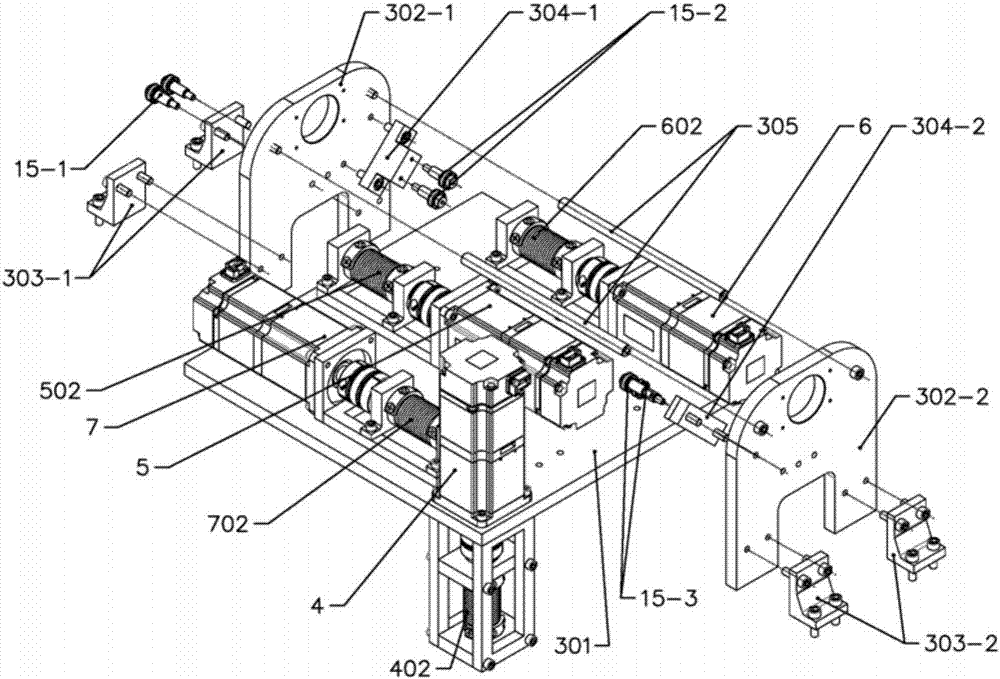

Rope-driven multi-degree-of-freedom series manipulator and driving method thereof

ActiveCN107253182AReduce size and massReduce loadProgramme-controlled manipulatorDrive wheelControl engineering

The invention discloses a rope-driven multi-degree-of-freedom series manipulator and a driving method thereof, and belongs to the field of manipulators. The rope-driven manipulator comprises a base, a waist joint unit, a waist platform, a large arm unit, a small arm unit, a tail end platform unit and the like. One ends of steel wire ropes are fixed to driven wheels at joints, the other ends of the steel wire ropes are fixed to a driving unit winch at the waist platform, so that the driving force is transferred from the winch at the waist platform to the driven wheels at the joints at the rear end by means of the ropes and accordingly drives the joint units to conduct rotation movement around joint shafts correspondingly. The joint driving ropes are guided by guide pulleys and bypass the joint shafts at the front end sequentially, by arranging the specified diameters of shaft guide wheels, a driving method is built, thus any joint at the front end of the manipulator rotates while the posture of the tail end of the manipulator remains unchanged relative to the world coordinate system. The buffer effect of making contact of the manipulator with the environment is increased through the flexibility of the ropes, and the rope-driven multi-degree-of-freedom series manipulator is especially suitable for occasions with the high requirements for the interaction safety of the manipulator, people and the environment.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Leg-ankle-foot exercise assembly

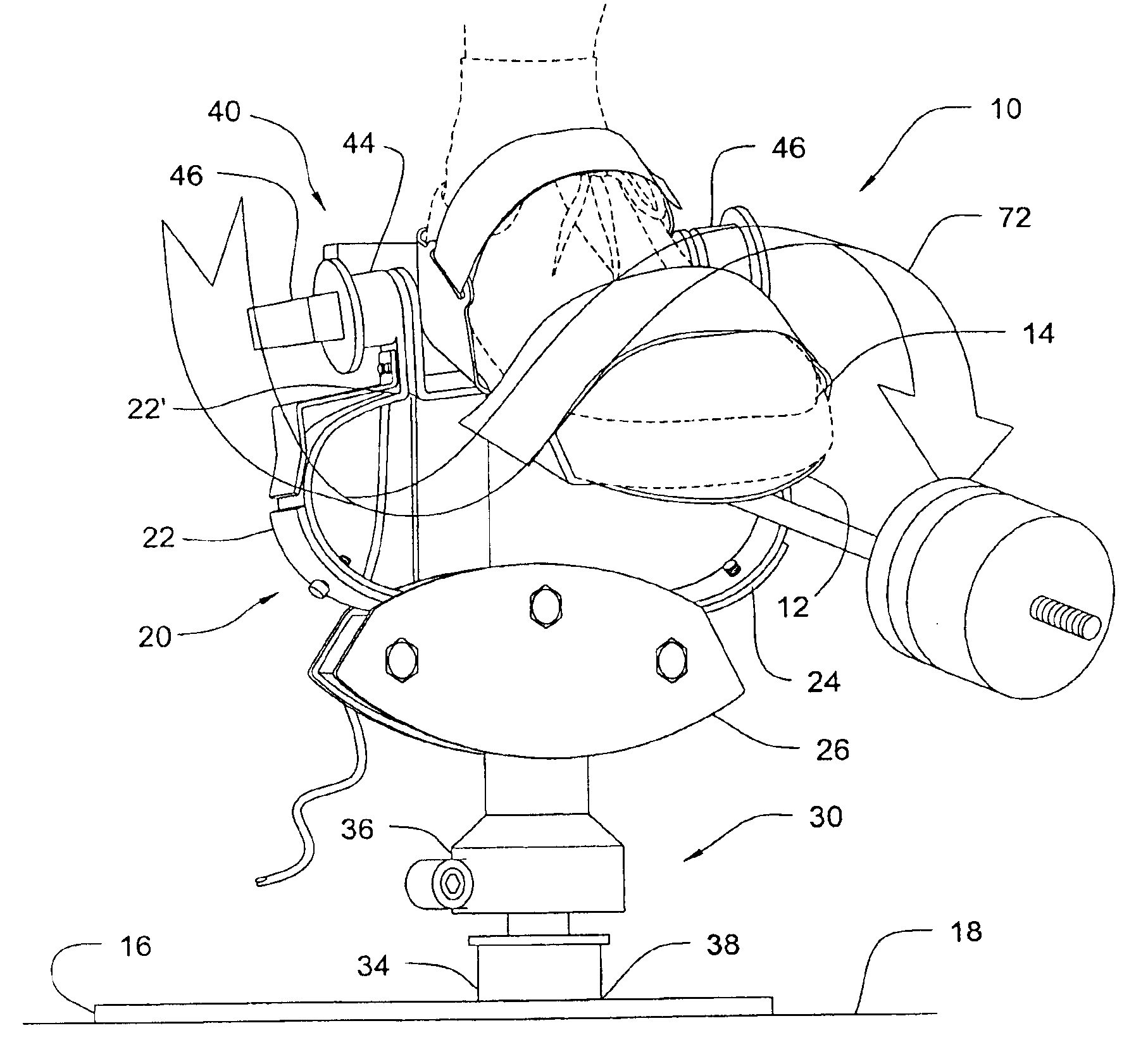

InactiveUS20050239611A1Improve abilitiesExtended range of motionChiropractic devicesWeightsGraphicsEngineering

An exercise assembly structured to direct the foot-ankle-leg, knee, etc. and associated portions of a person's body through a plurality of different paths of movement, wherein each path of movement comprises an at least partially different configuration such that exercise resulting from the various movements will be concentrated on predetermined portions of the body being exercised. The platform is suspended by a support assembly interconnected to a base and is preferably, but not exclusively, directed through the aforementioned paths of movement manually by the user. A sensor assembly including a processor may determine and store selected movements of the platform for graphical or other visual display to the user and for programmed duplication of the sensed paths movement when desired. A weight assembly including at least one but preferably a plurality of different weights are interconnected to the platform and extend outwardly therefrom to provide additional resistive forces to the user's foot, ankle, and leg as they are exercised.

Owner:COMMISSO LUIS ALBERTO

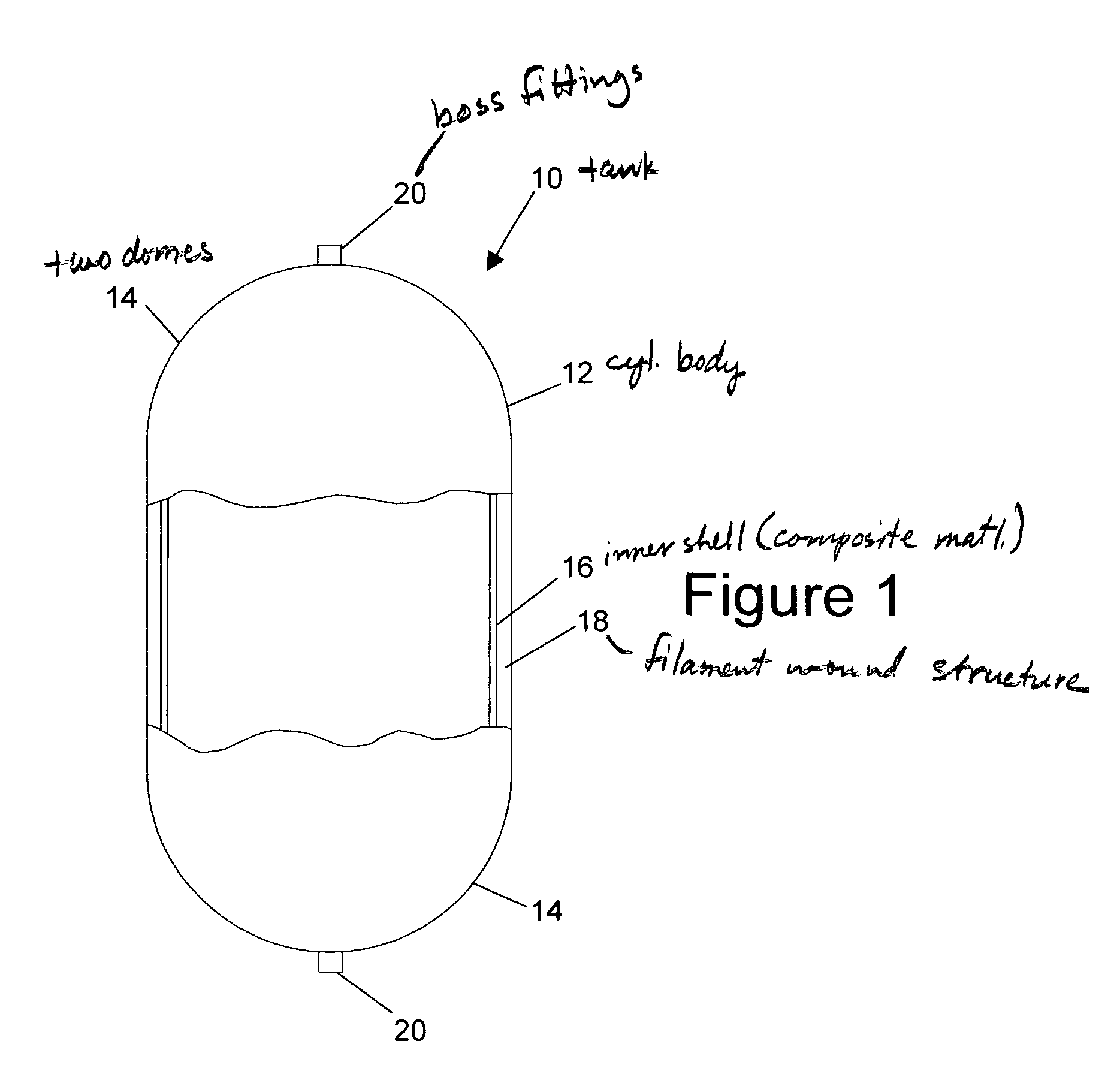

Composite pressure tank and process for its manufacture

InactiveUS7803241B2Relieve pressureReduce penetrationVessel mounting detailsVessel manufacturingMaterials sciencePressure vessel

A pressure vessel and method for producing a pressure vessel is disclosed. The pressure vessel comprises a liner shell fabricated from composite material applied to a soluble mandrel having a body shaped to pattern an interior of the pressure vessel, the liner shell having an opening, a boss having an aperture therethrough, the boss sealingly bonded to the liner shell with the aperture adjacent the opening, and an outer shell fabricated from plies of composite material filament impregnated with matrix material wound over the liner shell and the boss, but not over the aperture.

Owner:MICROCOSM INC

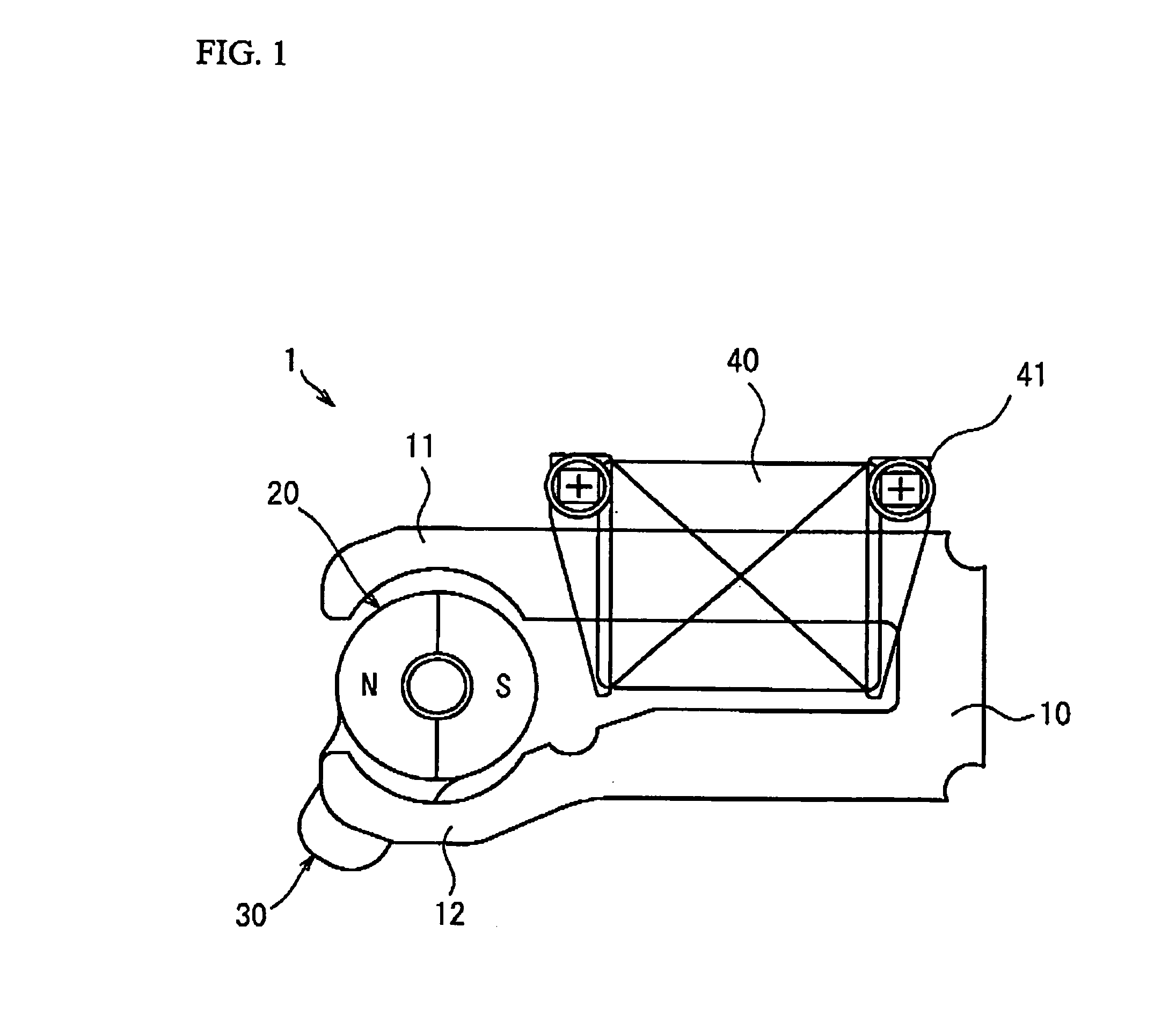

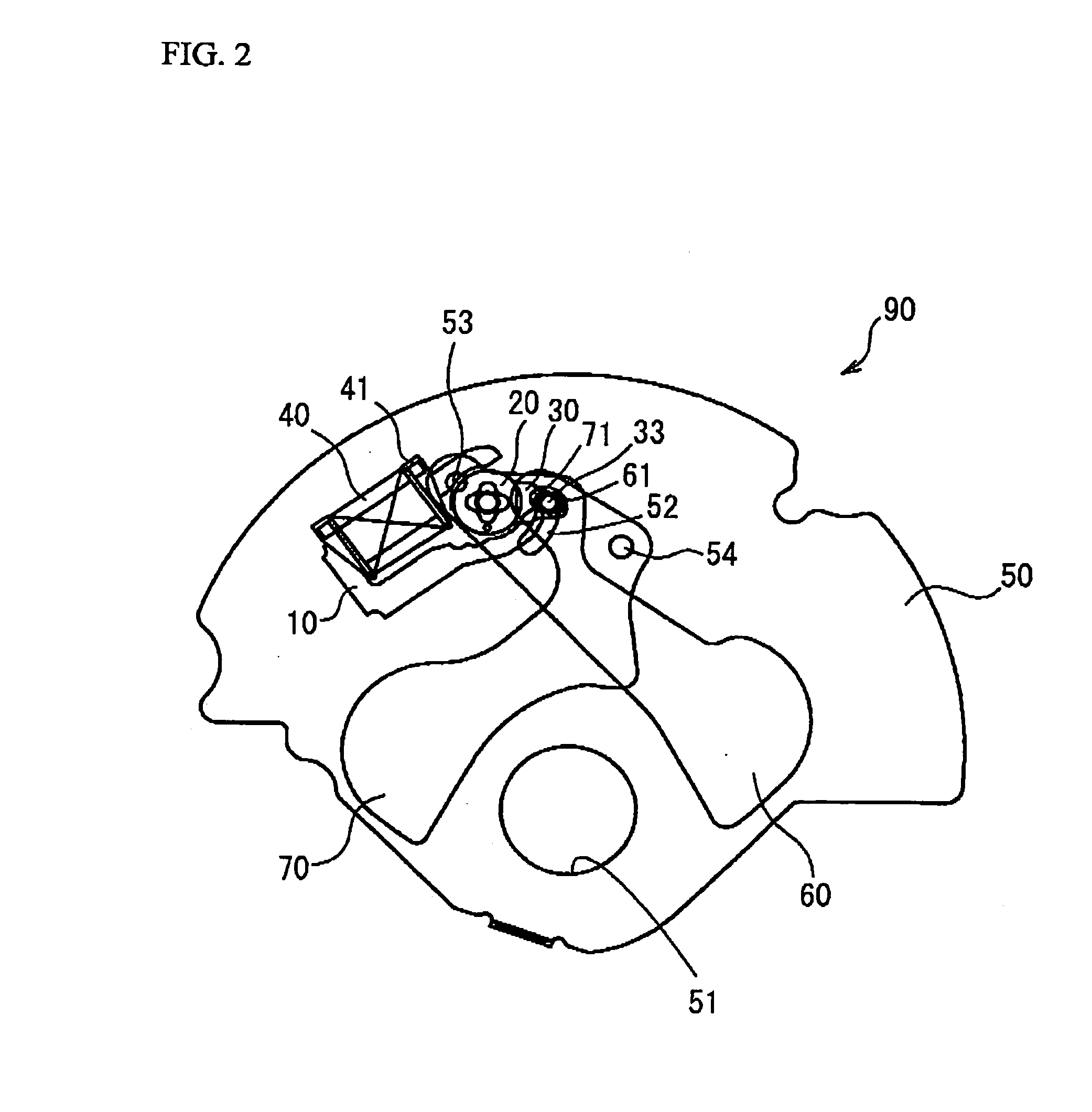

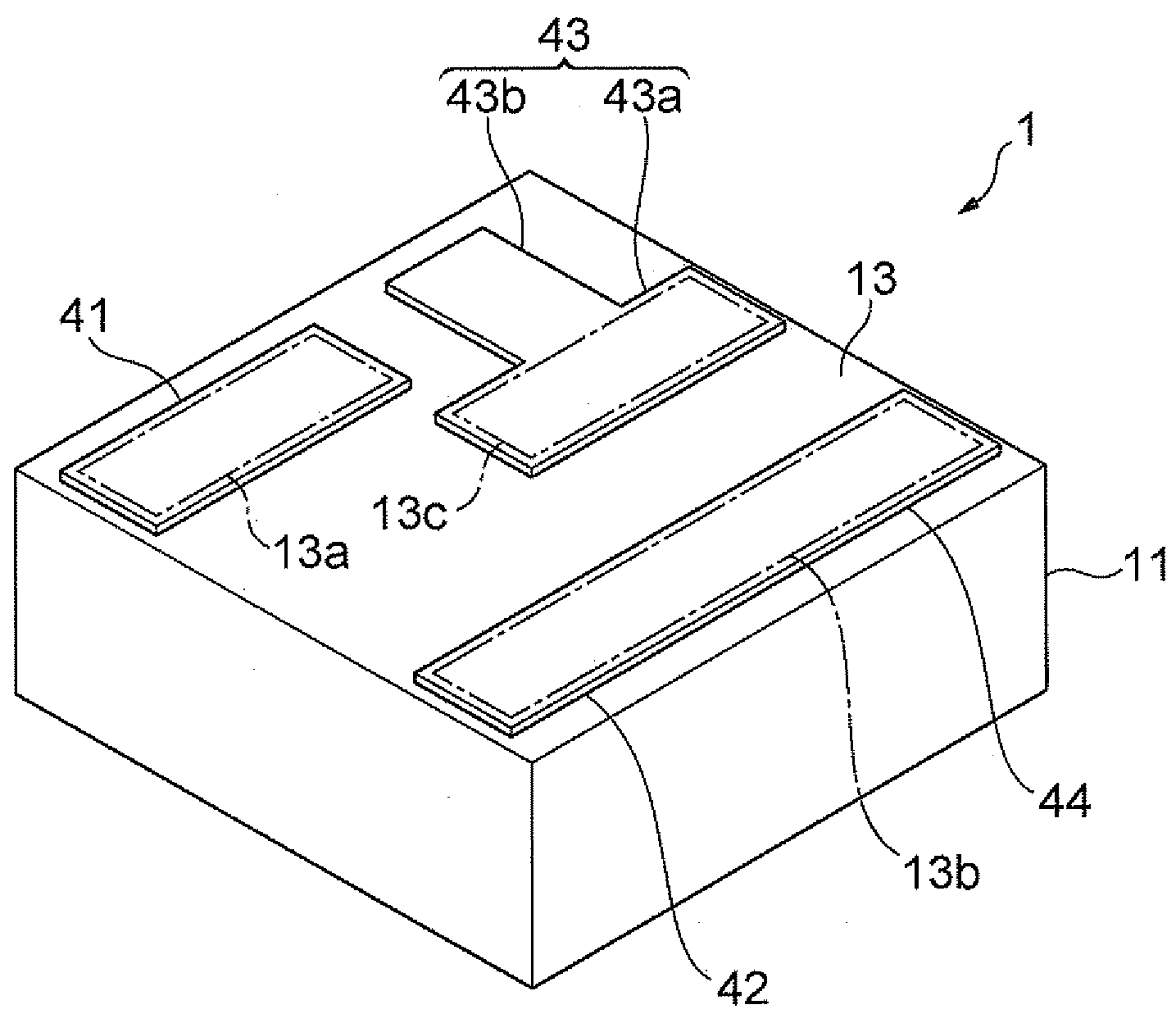

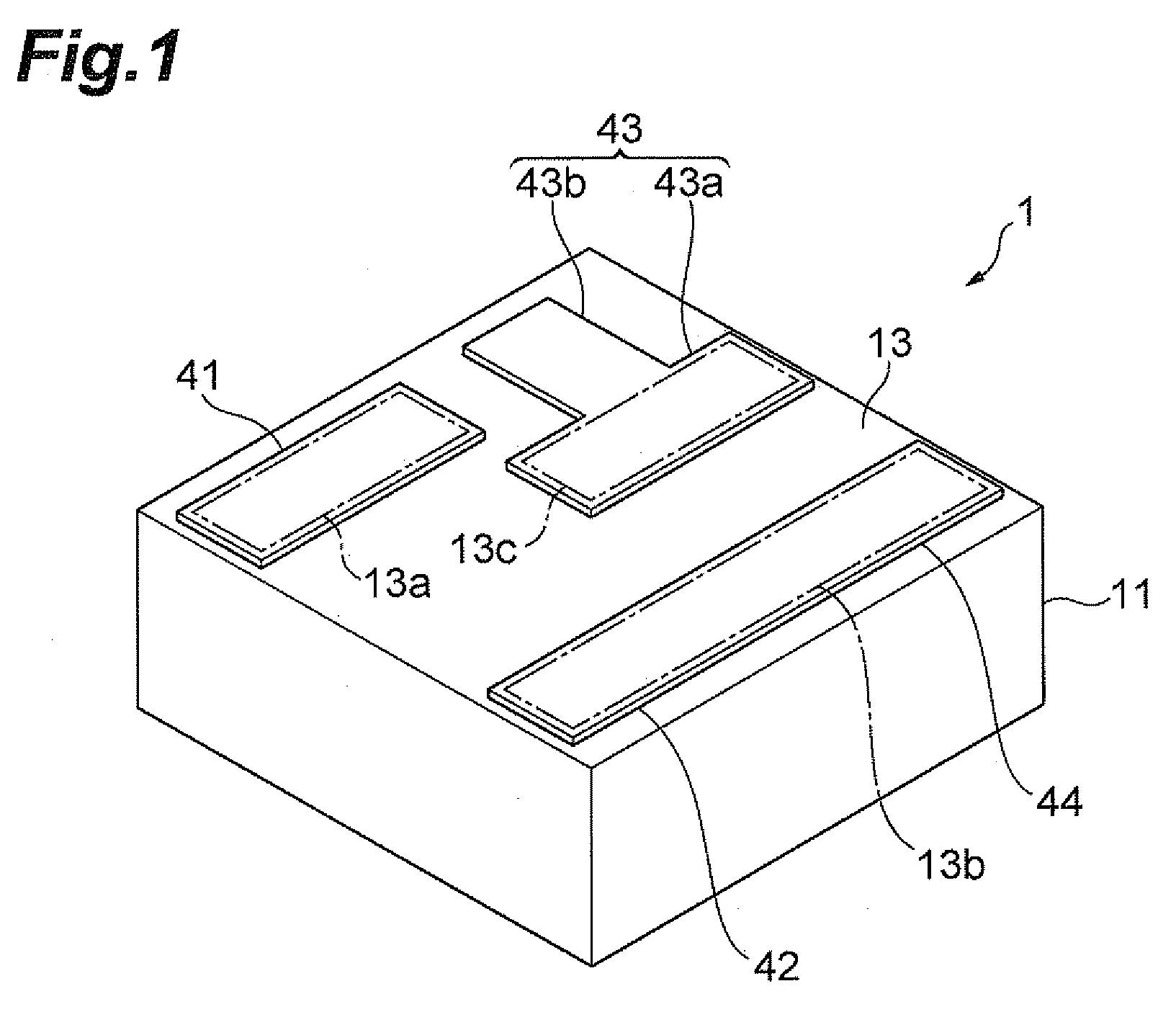

Actuator, shutter driving device for camera and method of manufacturing actuator

InactiveUS20080240707A1Reinforced jointsAvoid displacementMagnetic circuit rotating partsShuttersMagnetic tension forceMagnetic poles

An actuator includes: a coil for excitation; a stator excited with different magnetic poles by energization of the coil; a rotor magnetized with different magnetic poles in a circumferential direction, and rotated by magnetic force generating between the rotor and the stator; and an outputting member rotated in conjunction with the rotor and outputting rotational movement of the rotor to a member. The outputting member fits onto the rotor, and the rotor has at least one of a recess portion and a projection portion at a fitting surface of the rotor. The outputting member is jointed with the rotor so as to have a shape corresponding to the at least one of the recess portion and the projection portion by welding.

Owner:SEIKO PRECISION CO LTD

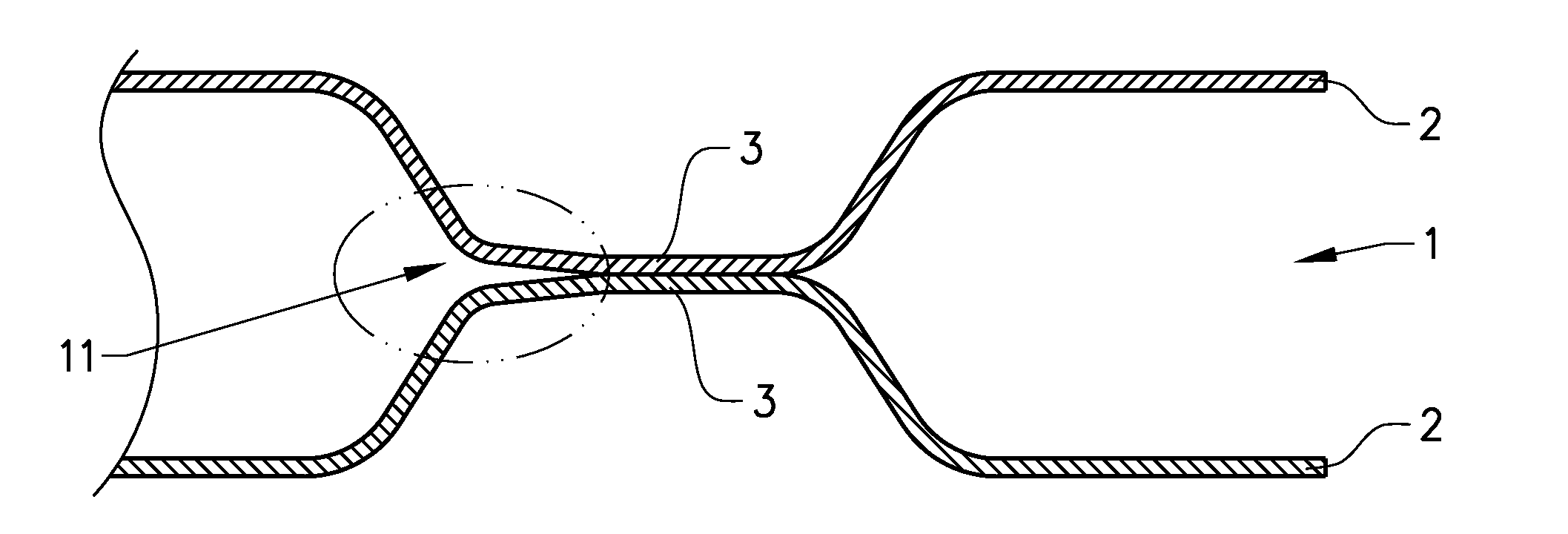

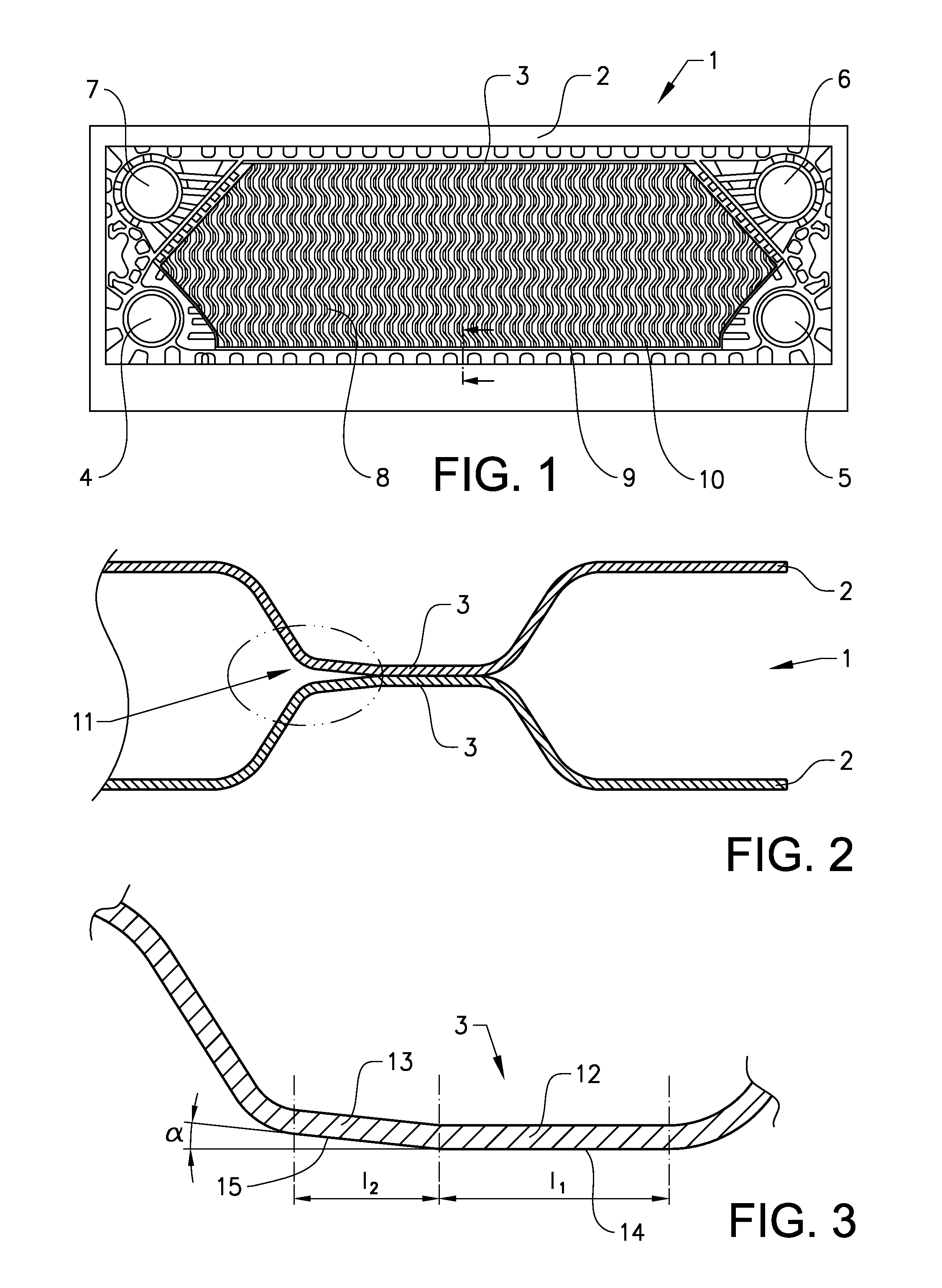

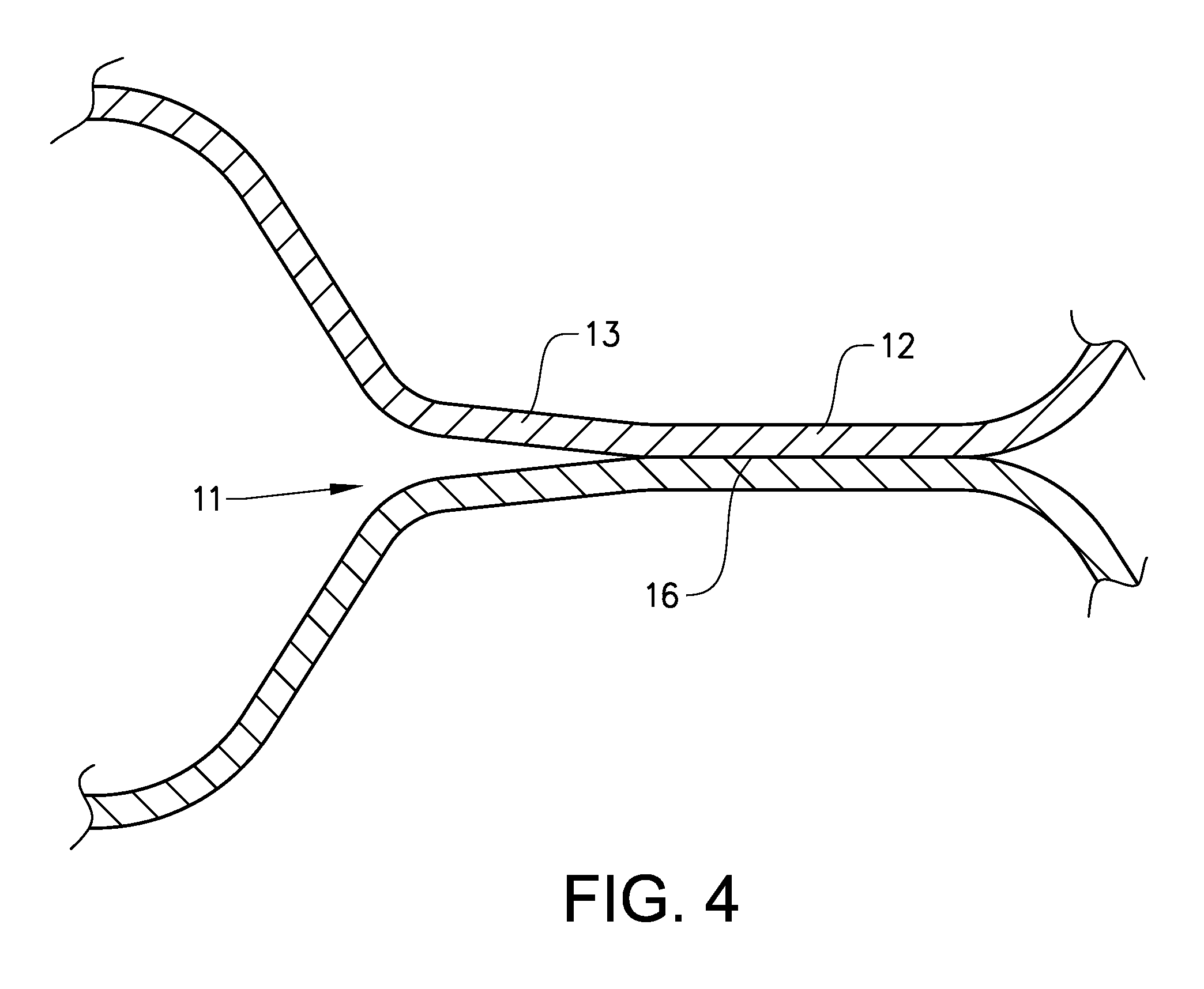

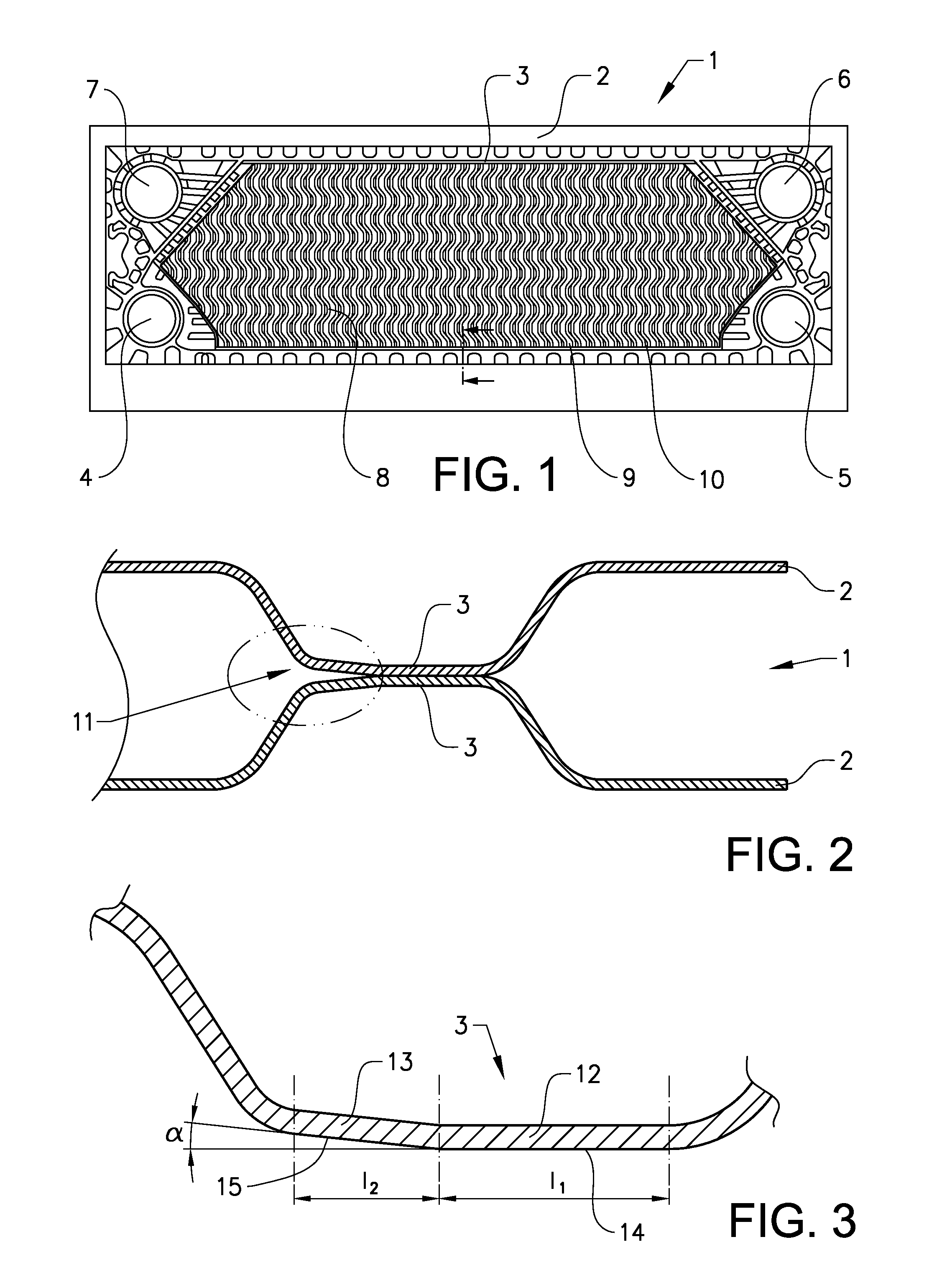

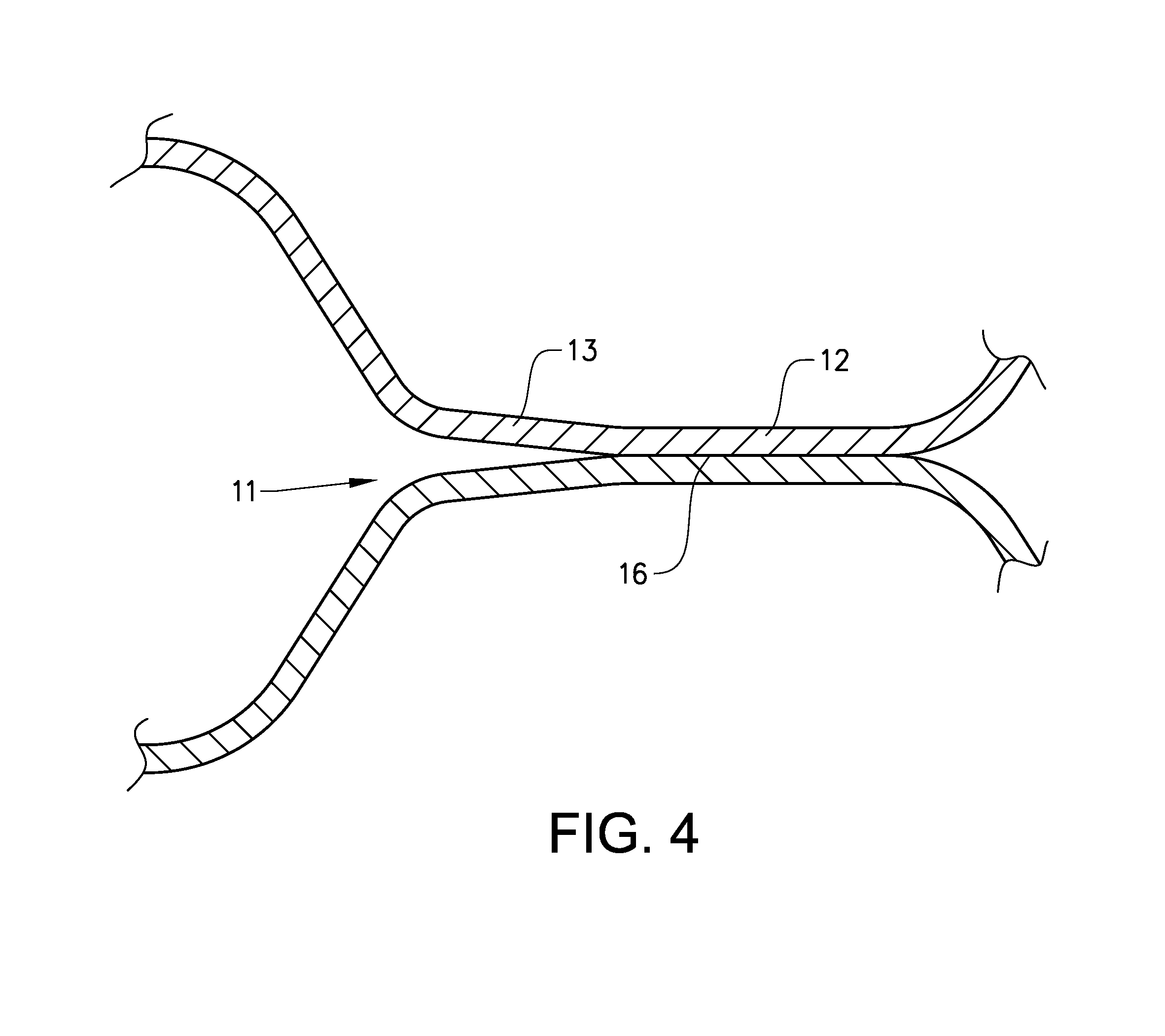

Heat Exchanger

ActiveUS20100258288A1Smooth sectionEasy to assembleSoldering apparatusMetal working apparatusEngineeringRidge

A plate for the use in a heat exchanger cassette, where the plate comprises a corrugated pattern having a plurality of ridges (9) and valleys (10), and where the plate comprises a sealing gasket groove (3) encircling a heat transfer surface (8) that will be part of a contact-free fluid channel when two cassettes comprising at least one plate each are positioned adjacent each other, wherein the sealing gasket groove (3) comprises a base surface with a first, flat section (12) and a second, bent section (13), and where the bent section is angled with the angle α. The advantage of the inventive plate is that an airtight heat exchanger cassette can be obtained in an easy and cost-effective way.

Owner:ALFA LAVAL CORP AB

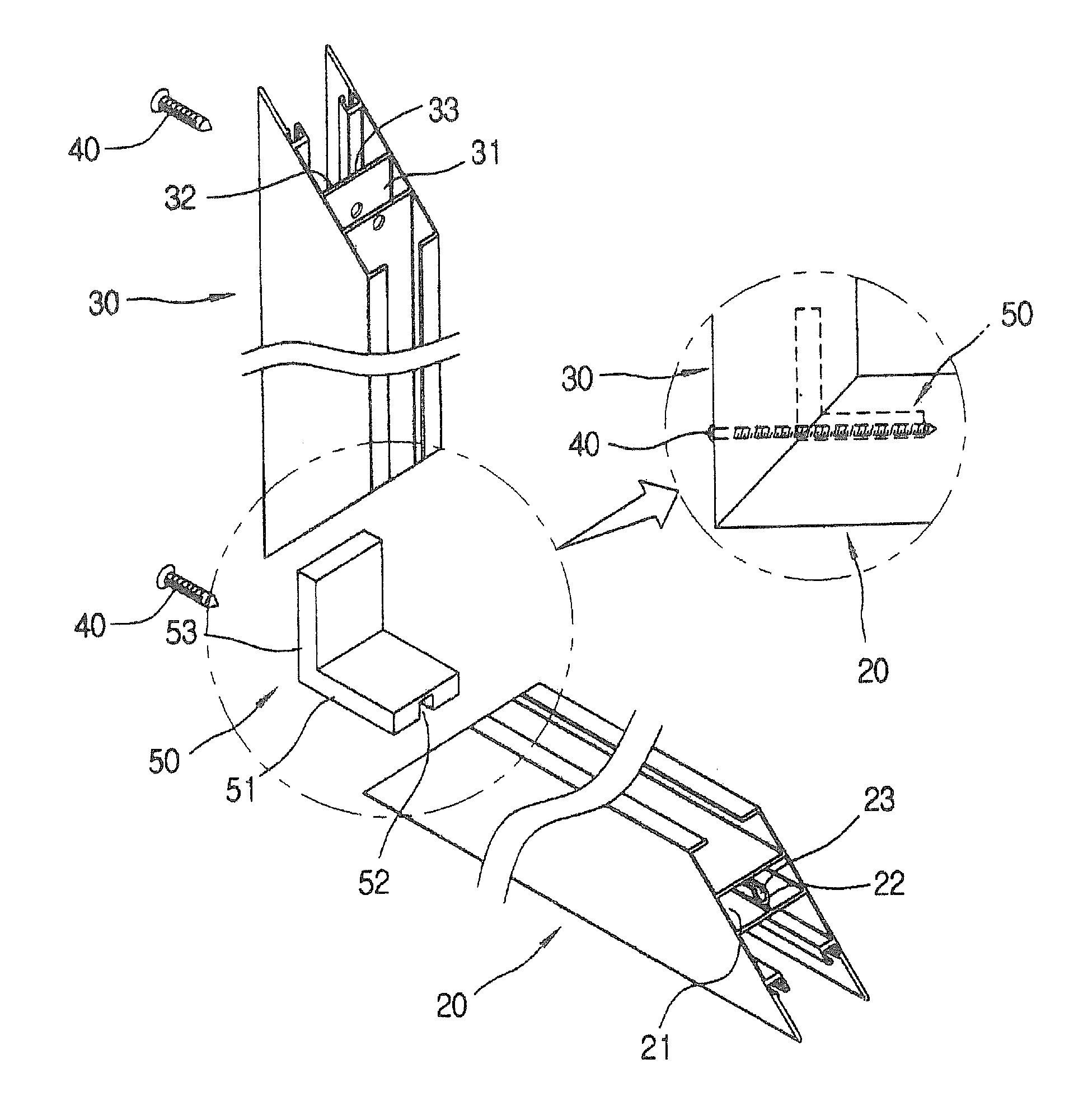

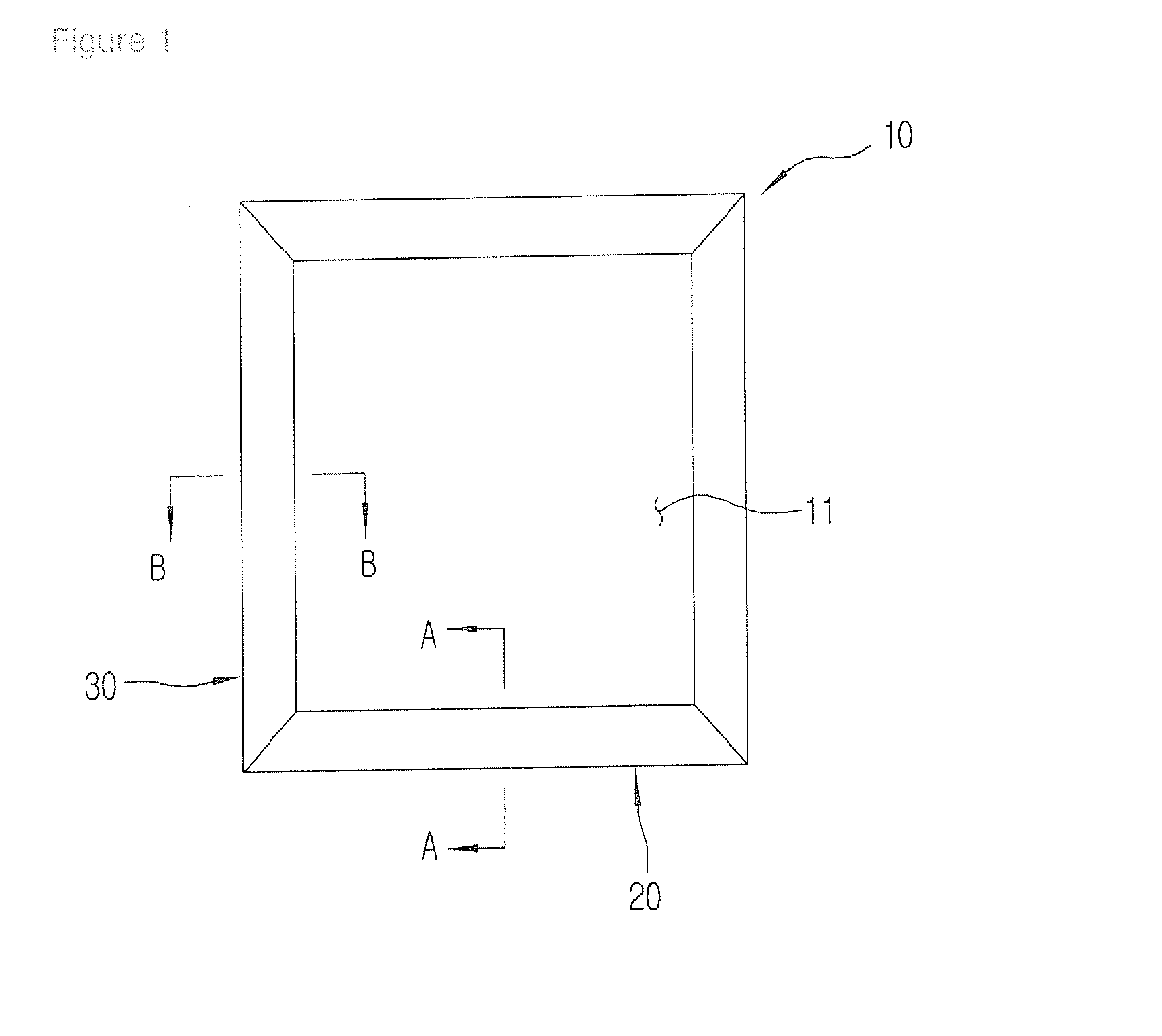

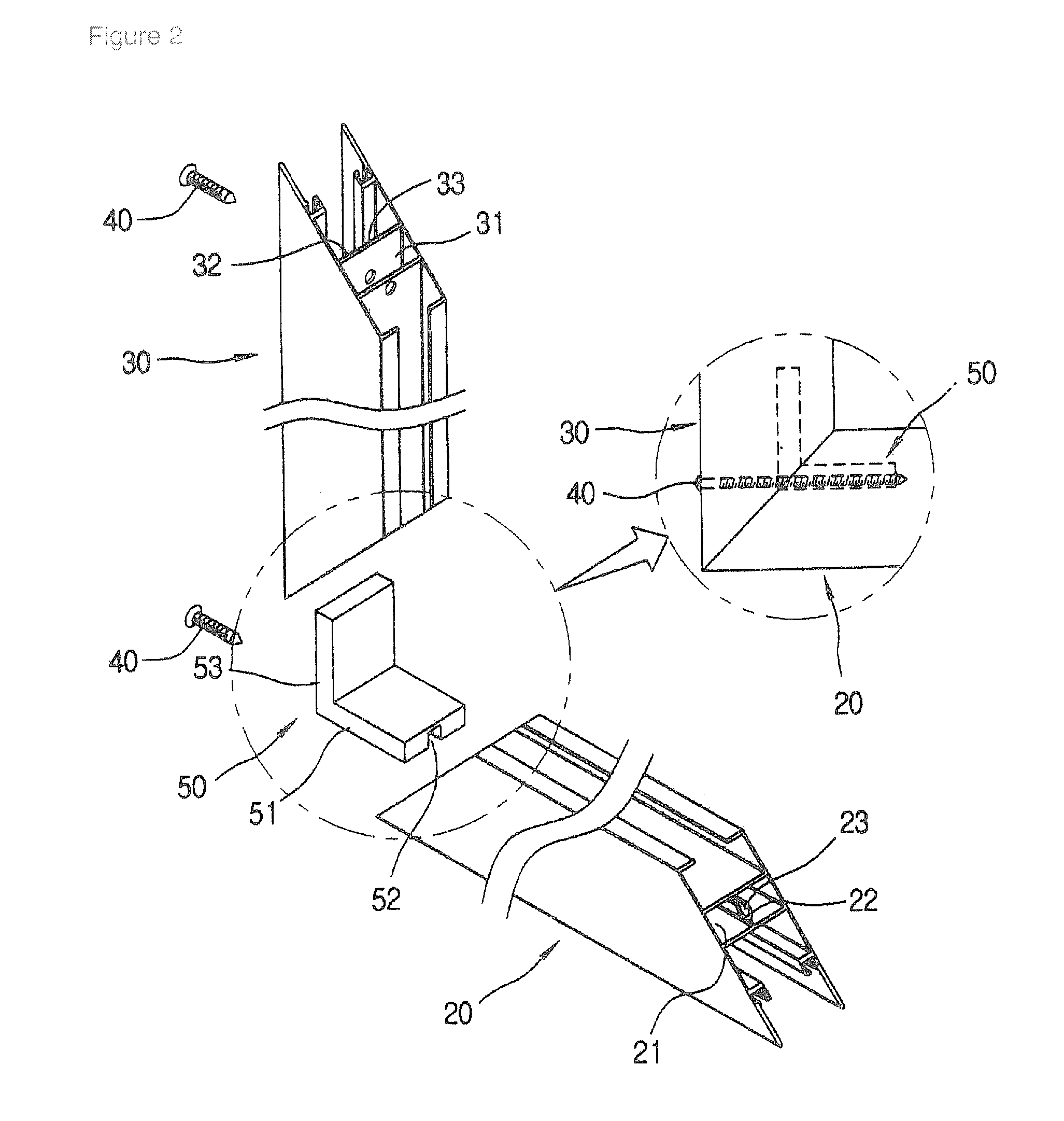

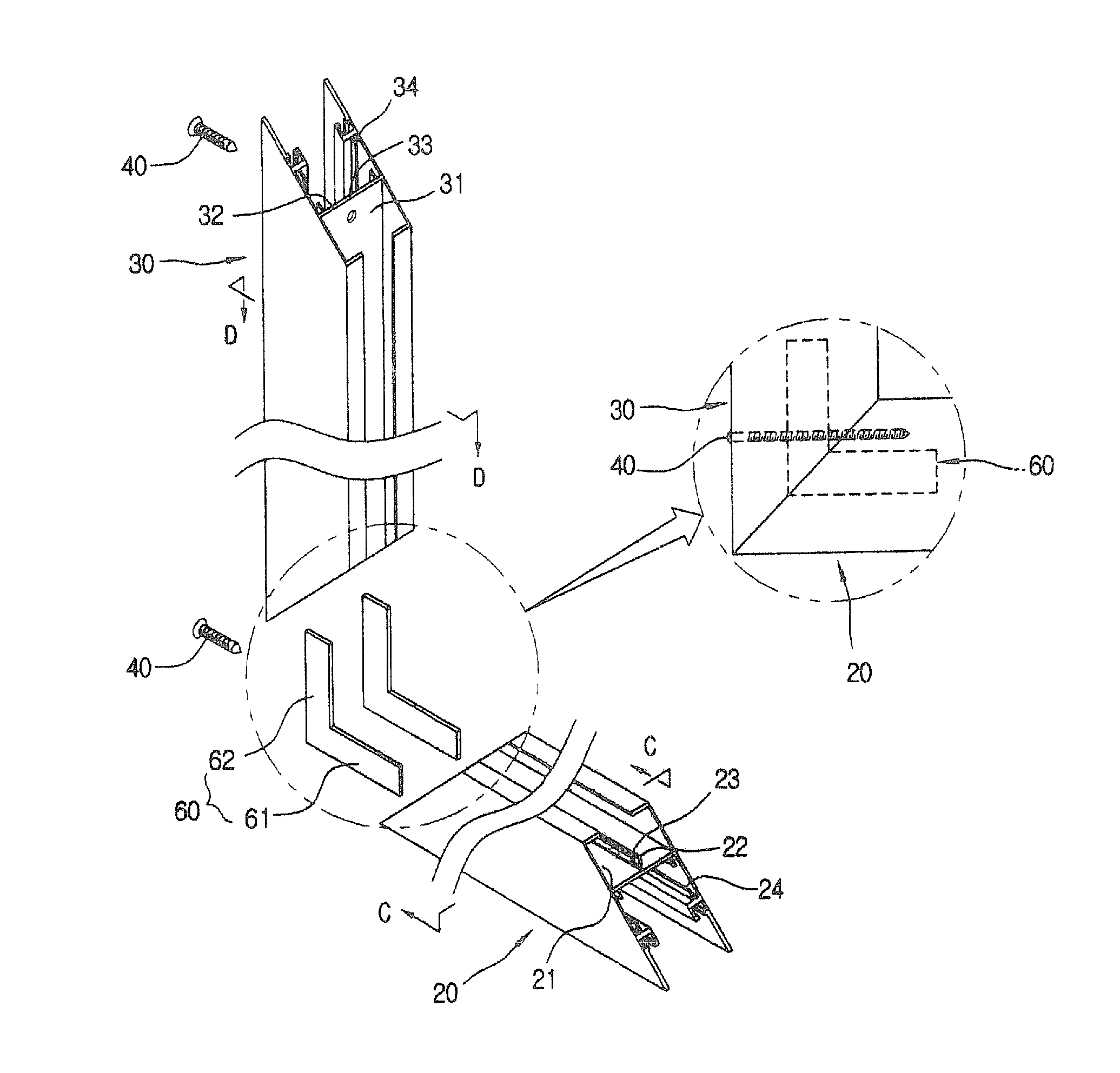

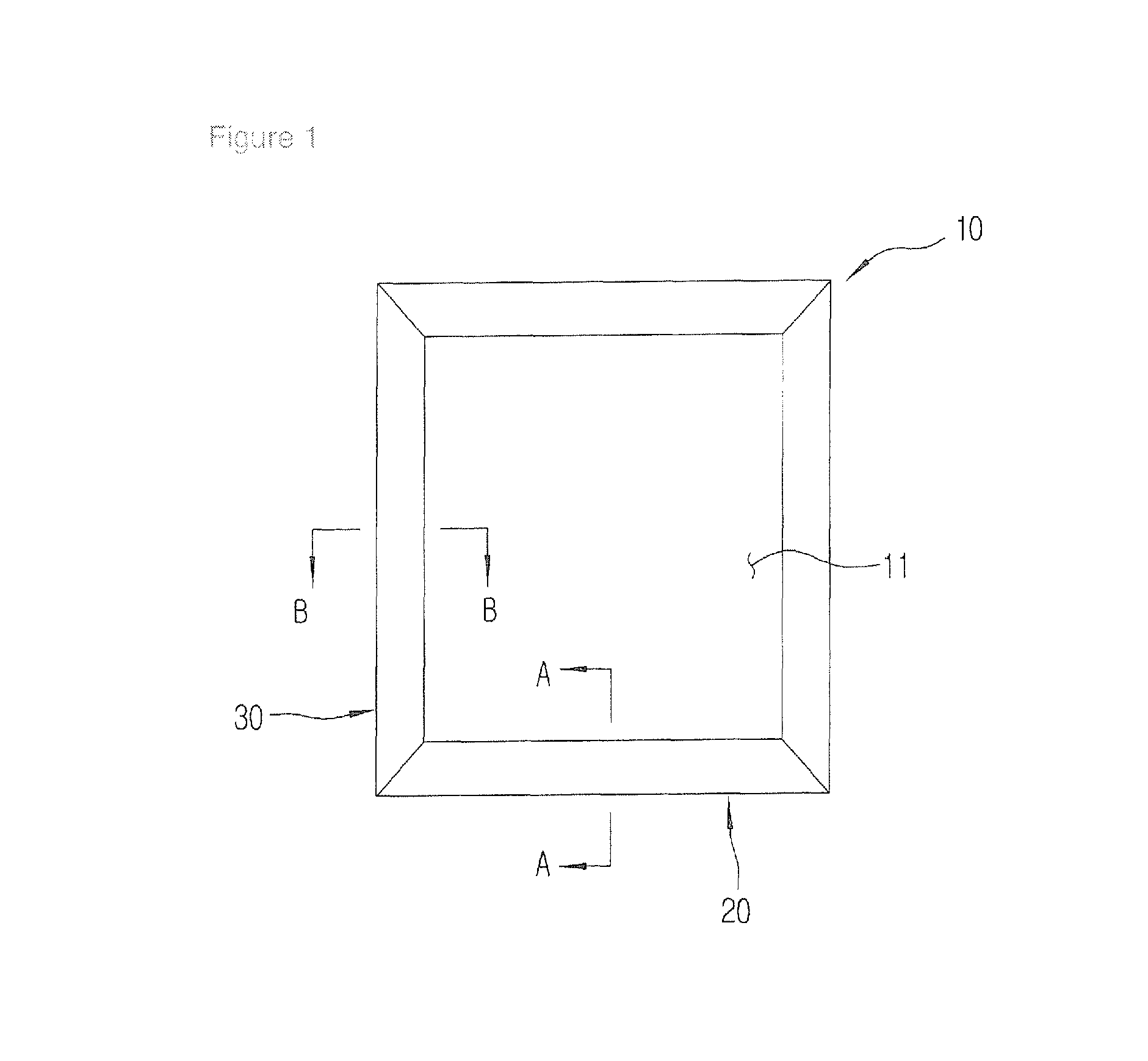

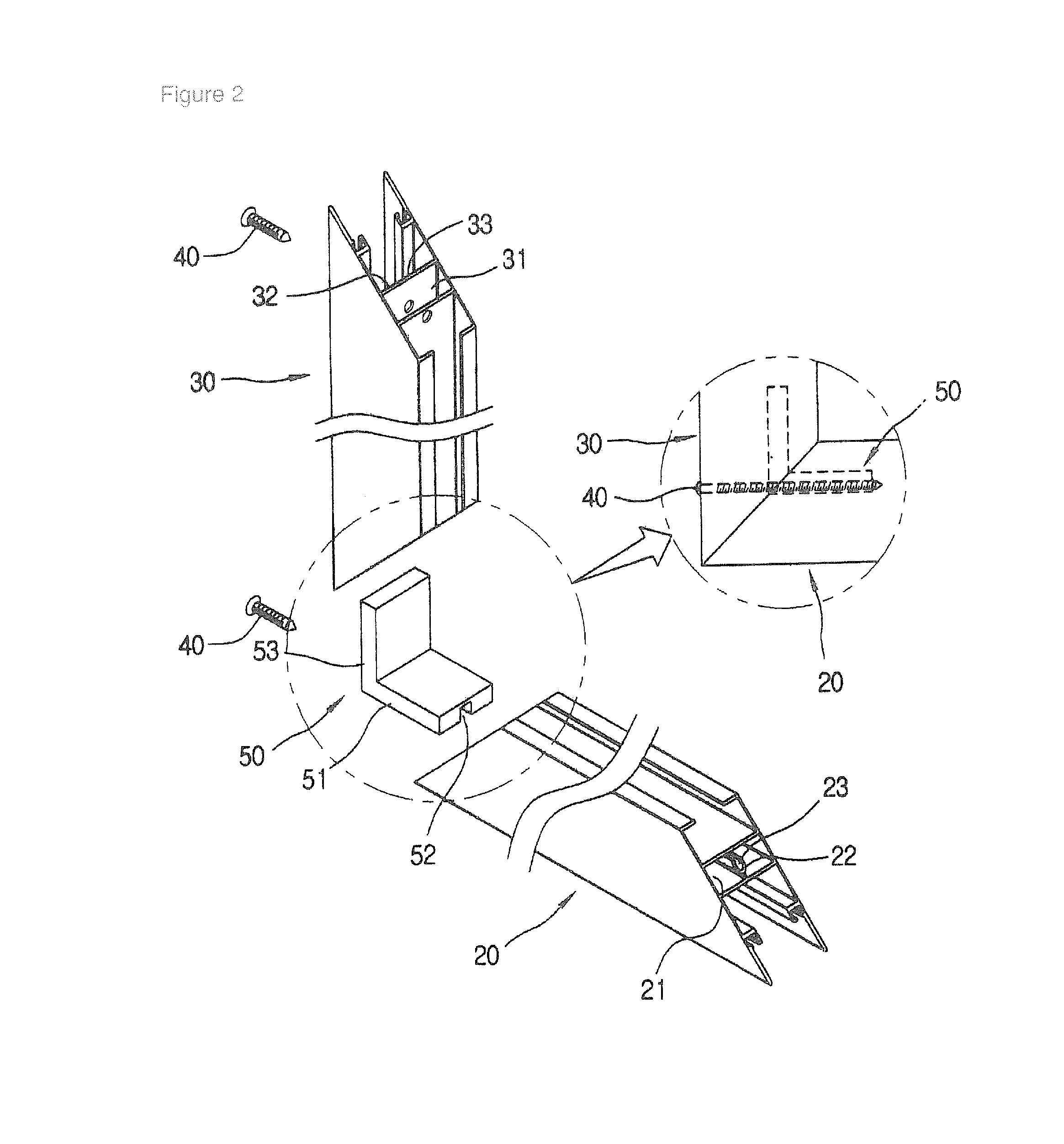

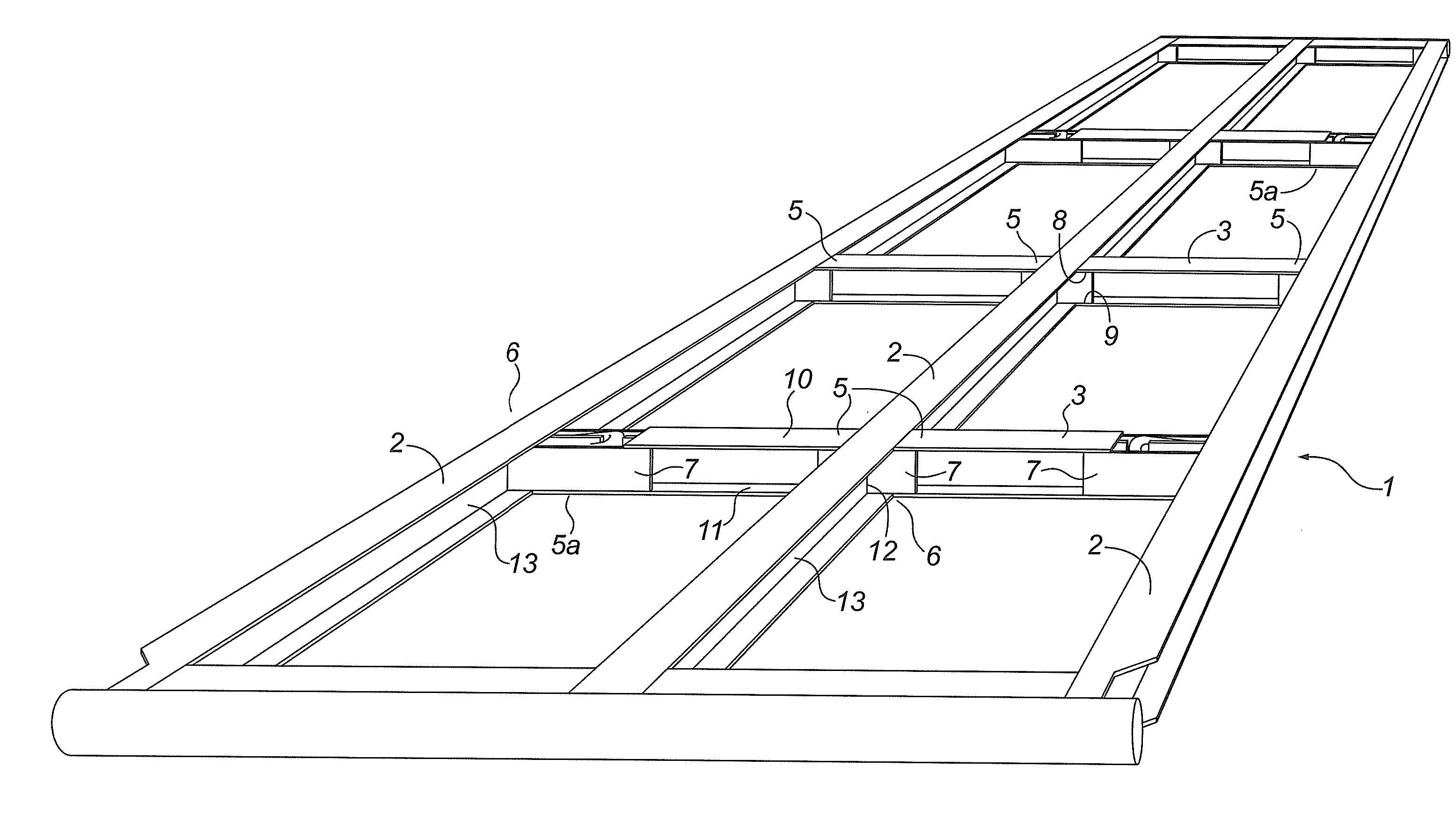

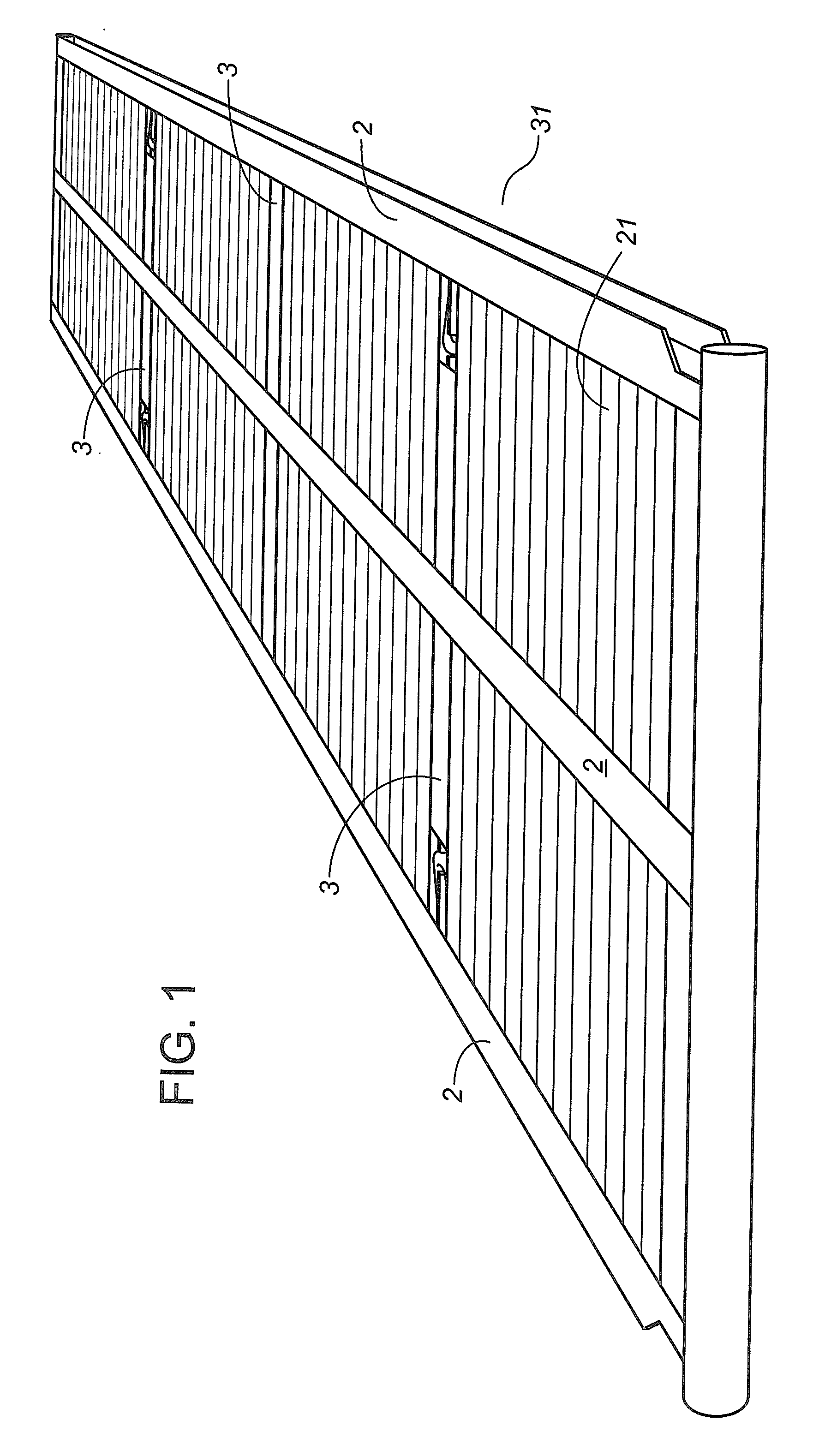

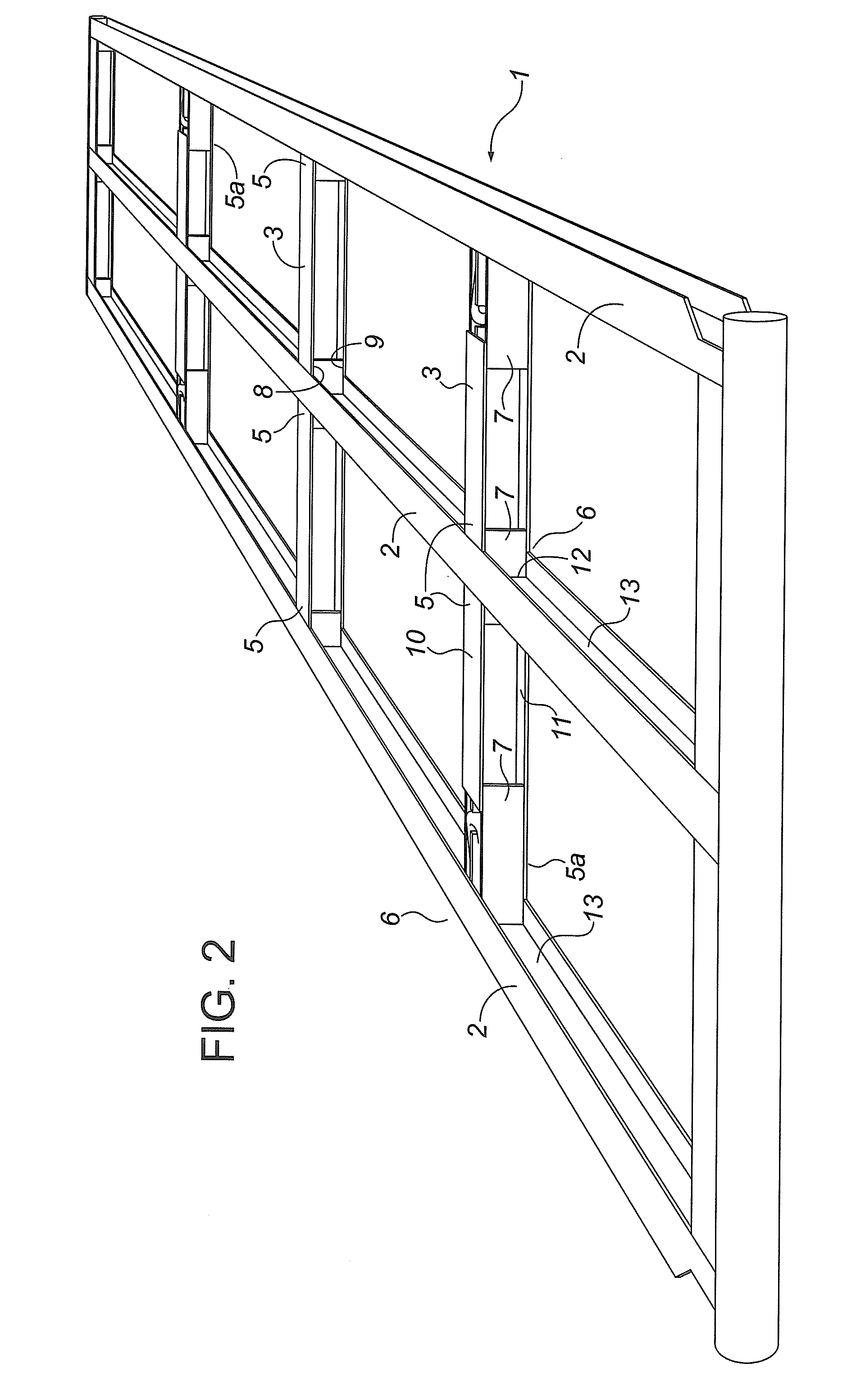

Windows and doors assembly structure having a joint portion of 45 degrees

ActiveUS20140360124A1Easy to disassembleThickness minimizationCorner/edge jointsWindow/door framesVertical barEngineering

There is provided a prefabricated window / door structure with interconnecting 45 degree joints where a horizontal bar has its both ends cut at an angle of 45 degrees and includes: a first connection space formed in the direction of the length of the horizontal bar so that the inner space of the horizontal bar is open to the outside, and a screw fastening part with a screw fastening groove protruding in the first connection space; a vertical bar has its both ends cut at an angle of 45 degrees to form a joint of 45 degrees when each of the ends of the vertical bar faces each of the ends of the horizontal bar and includes: a second connection space formed in the direction of the length of the vertical bar so that the inner space of the vertical bar is open to the outside, and a screw hole formed on a side wall in the second connection space, to be aligned with the screw fastening groove; and a support block includes: a first support part to be inserted into the first connection space of the horizontal bar and a second support part to be inserted into the second connection space of the vertical bar. The first support part includes a fastening part receiving channel formed to receive the screw fastening part when the first support part is inserted into the first connection space.Accordingly, since the horizontal bar and the vertical bar are simply attached to and / or detached from each other, it is easy to install and repair the window / door. Further, since the thickness of the horizontal bar and the vertical bar is able to be minimized, the window / door is light in weight. In addition, the joint of the horizontal bar and the vertical bar is more strongly reinforced by the reinforcing piece(s).

Owner:IDA +1

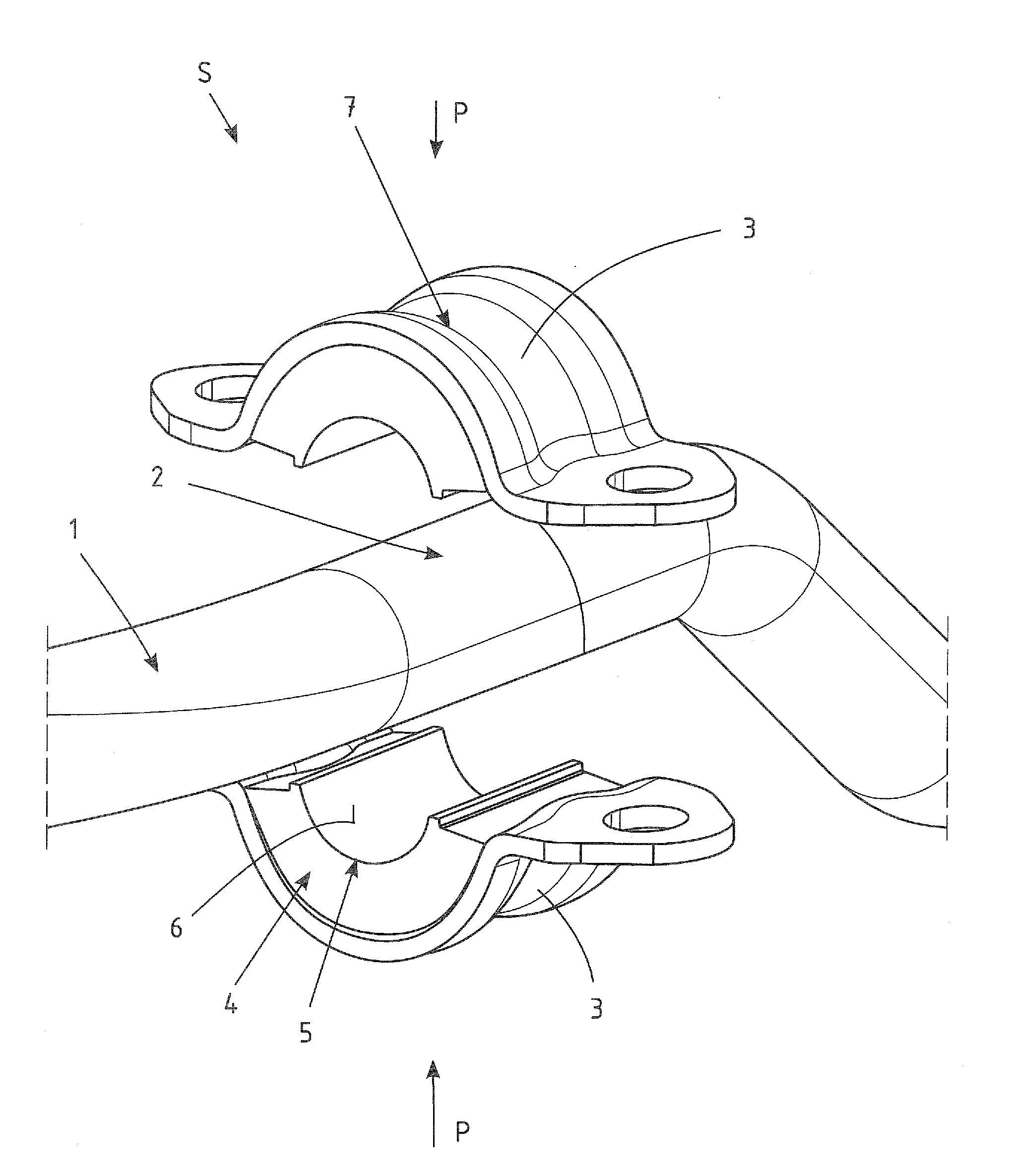

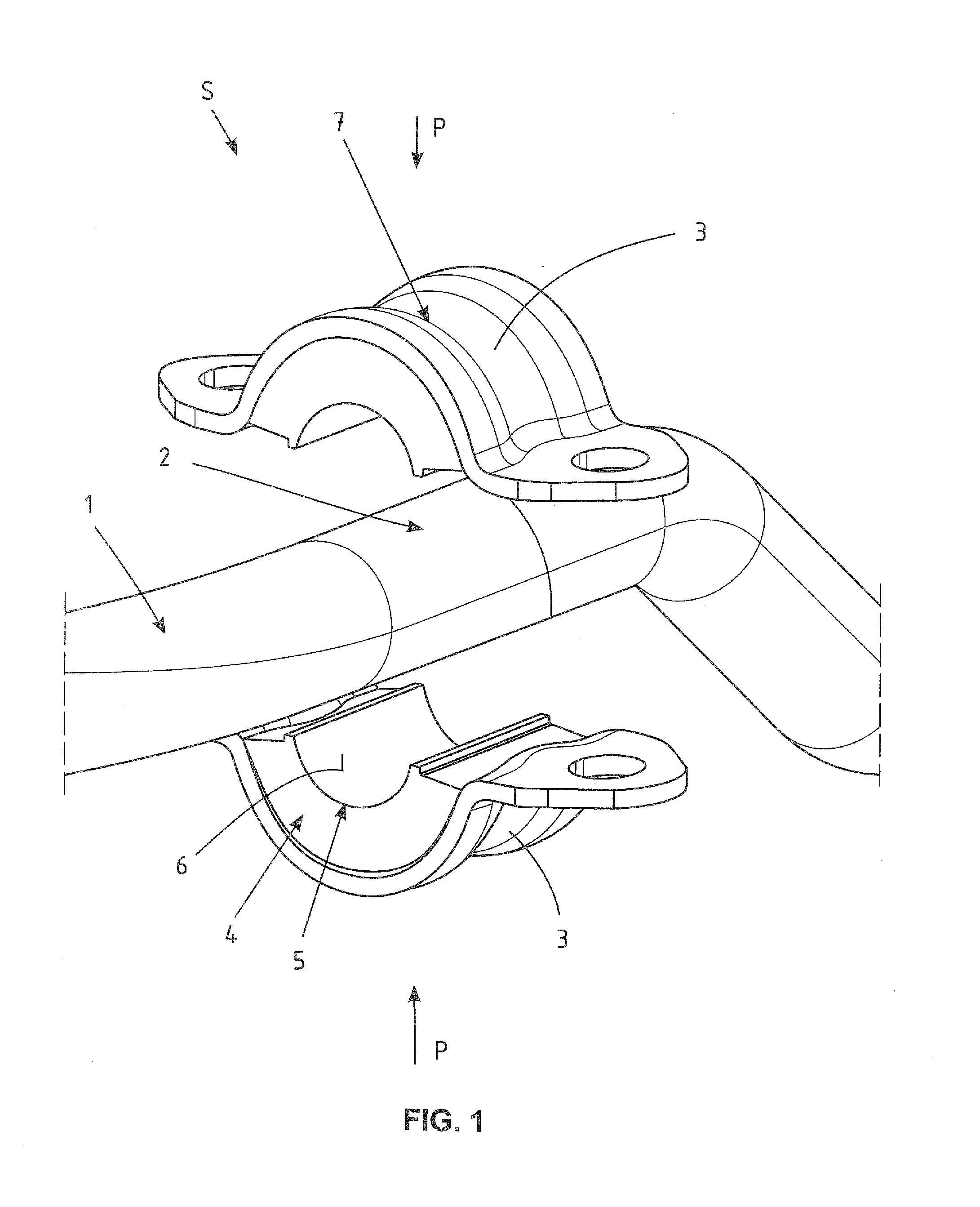

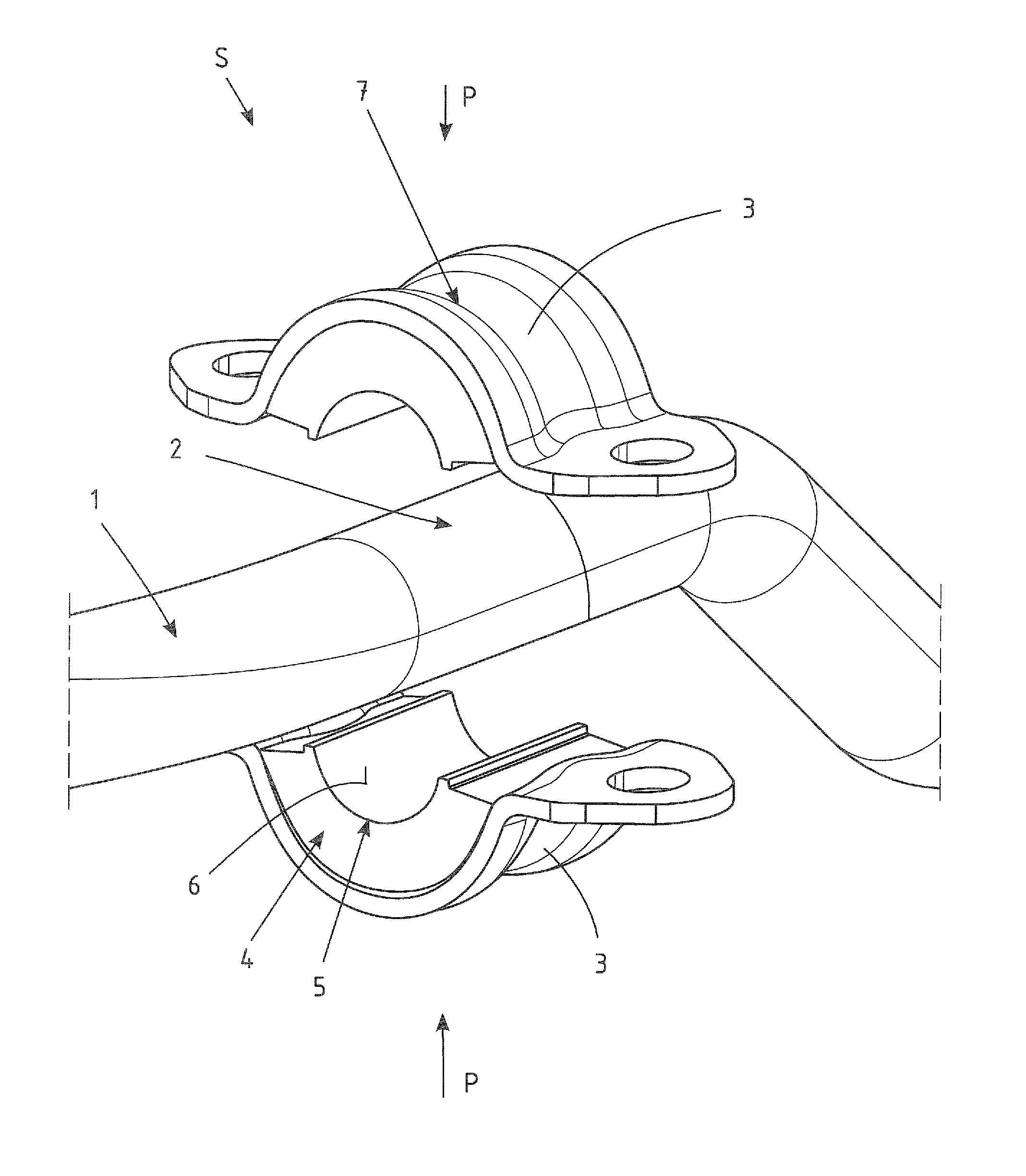

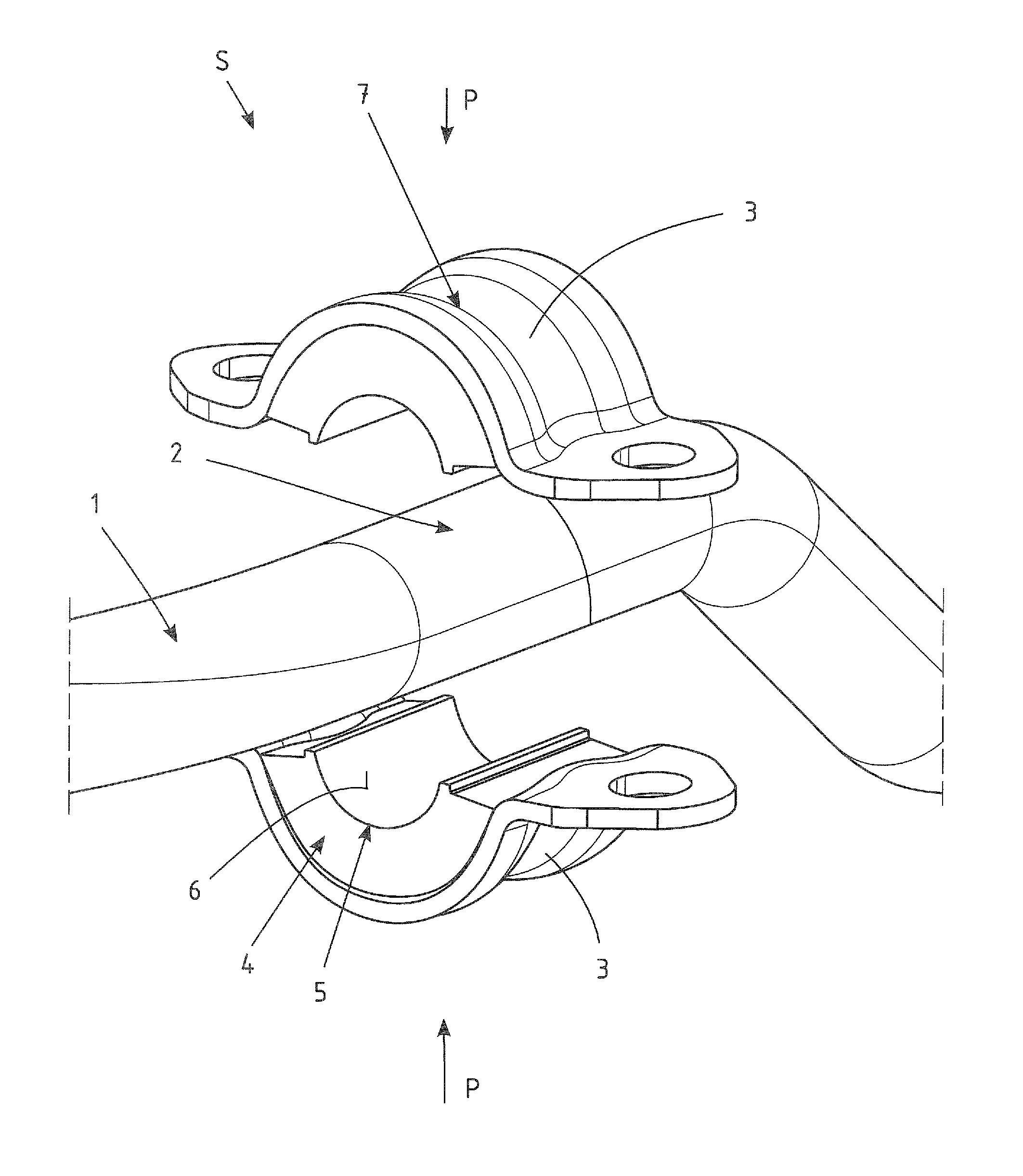

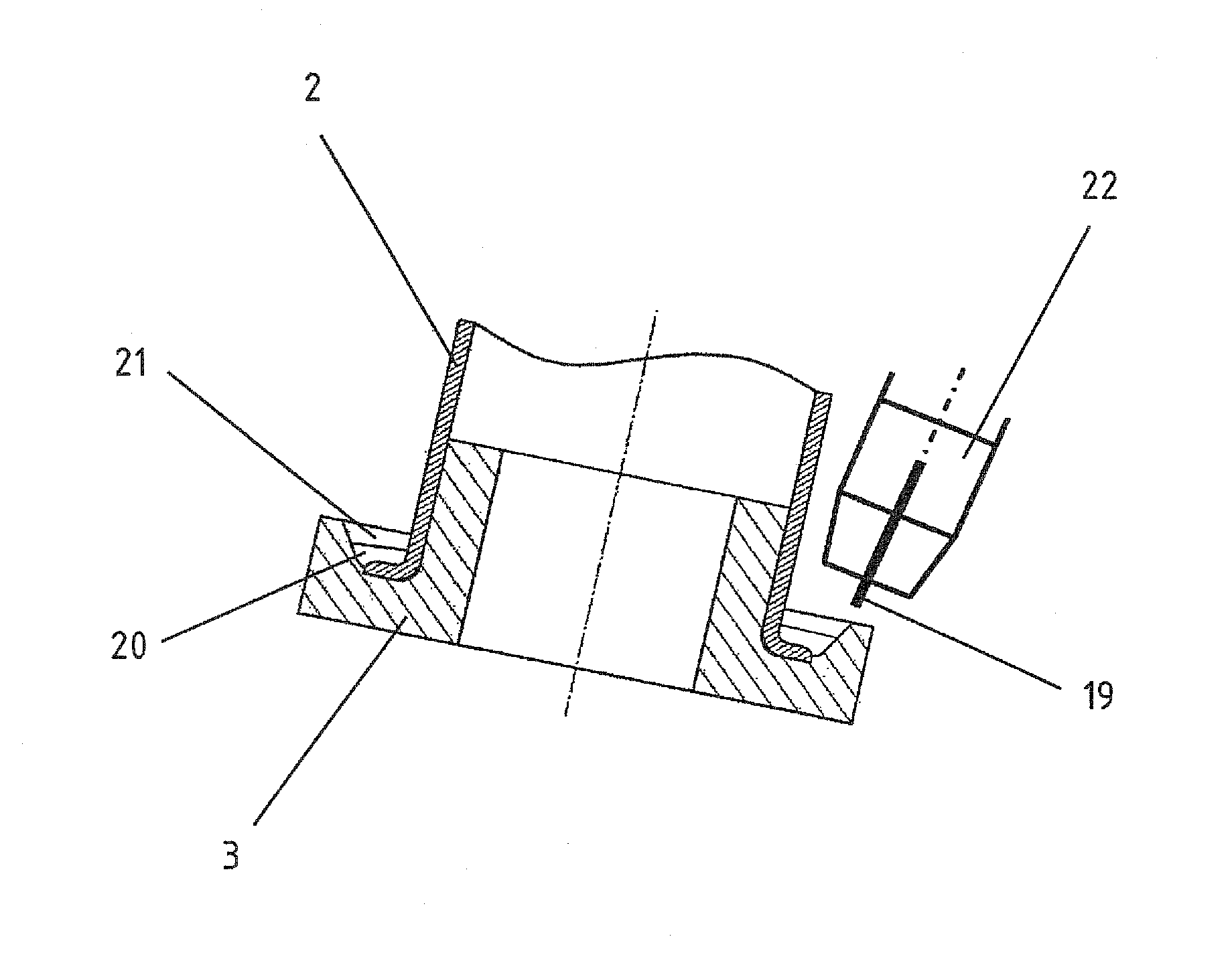

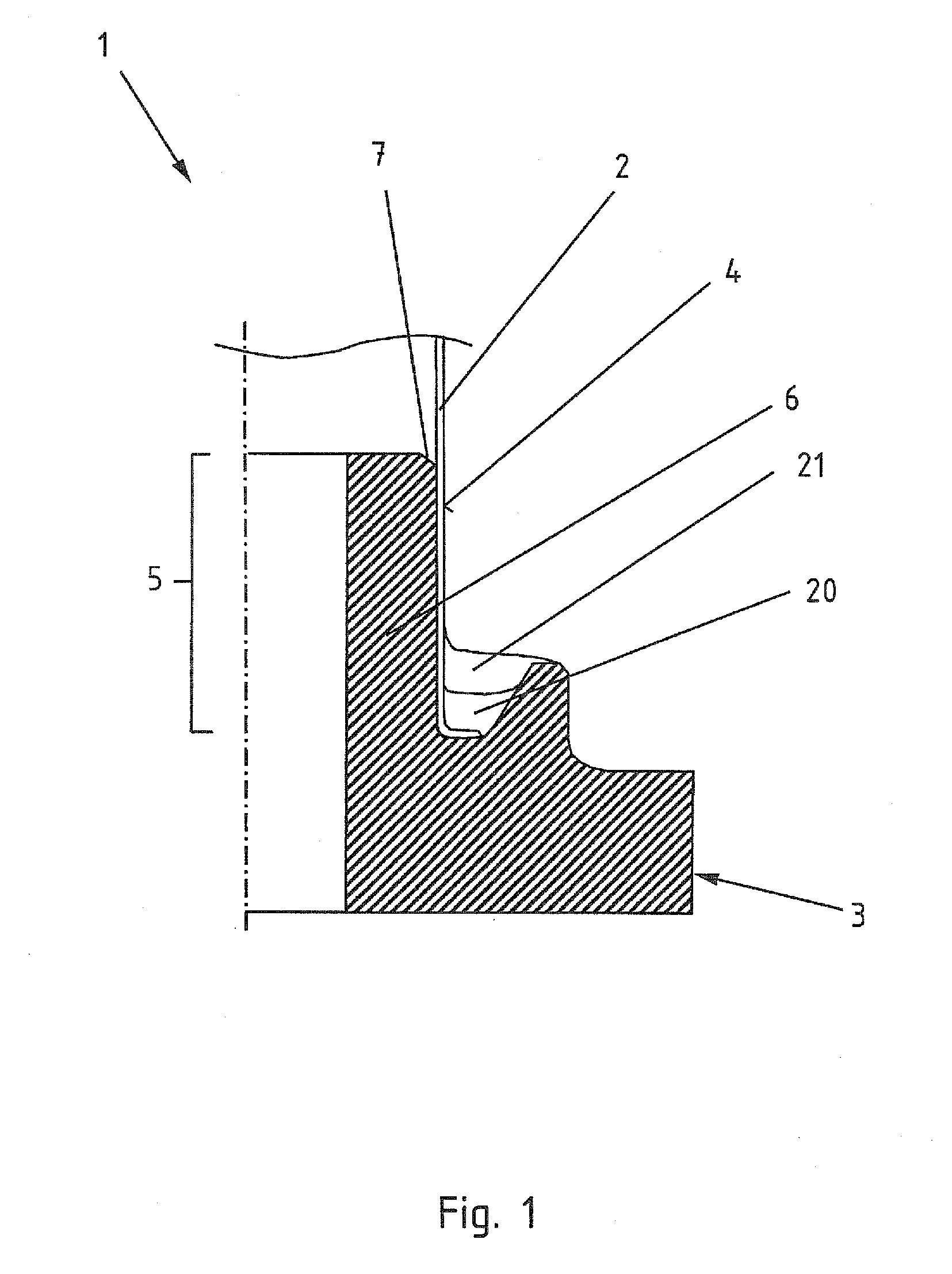

Method of producing a stabilizer with a stabilizer bearing

InactiveUS20120024463A1Improve bonding qualityShorten cycle timeAdhesivesElectrical componentsElastomerAdhesive

In a method of producing a stabilizer for a motor vehicle, a stabilizer bearing portion of a stabilizer is chemically pre-treated by applying an adhesive. The stabilizer and two vulcanized elastomer-metal bearing half-shells are then placed in a joining apparatus for subsequent bonding of the bearing half-shells with the stabilizer bearing portion.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

Windows and doors assembly structure having a joint portion of 45 degrees

InactiveUS9091119B2Easy to installPromote repairCorner/edge jointsWindow/door framesVertical barEngineering

There is provided a prefabricated window / door structure with interconnecting 45 degree joints where a horizontal bar has its both ends cut at an angle of 45 degrees and includes: a first connection space formed in the direction of the length of the horizontal bar so that the inner space of the horizontal bar is open to the outside, and a screw fastening part with a screw fastening groove protruding in the first connection space; a vertical bar has its both ends cut at an angle of 45 degrees to form a joint of 45 degrees when each of the ends of the vertical bar faces each of the ends of the horizontal bar and includes: a second connection space formed in the direction of the length of the vertical bar so that the inner space of the vertical bar is open to the outside, and a screw hole formed on a side wall in the second connection space, to be aligned with the screw fastening groove; and a support block includes: a first support part to be inserted into the first connection space of the horizontal bar and a second support part to be inserted into the second connection space of the vertical bar. The first support part includes a fastening part receiving channel formed to receive the screw fastening part when the first support part is inserted into the first connection space.Accordingly, since the horizontal bar and the vertical bar are simply attached to and / or detached from each other, it is easy to install and repair the window / door. Further, since the thickness of the horizontal bar and the vertical bar is able to be minimized, the window / door is light in weight. In addition, the joint of the horizontal bar and the vertical bar is more strongly reinforced by the reinforcing piece(s).

Owner:IDA +1

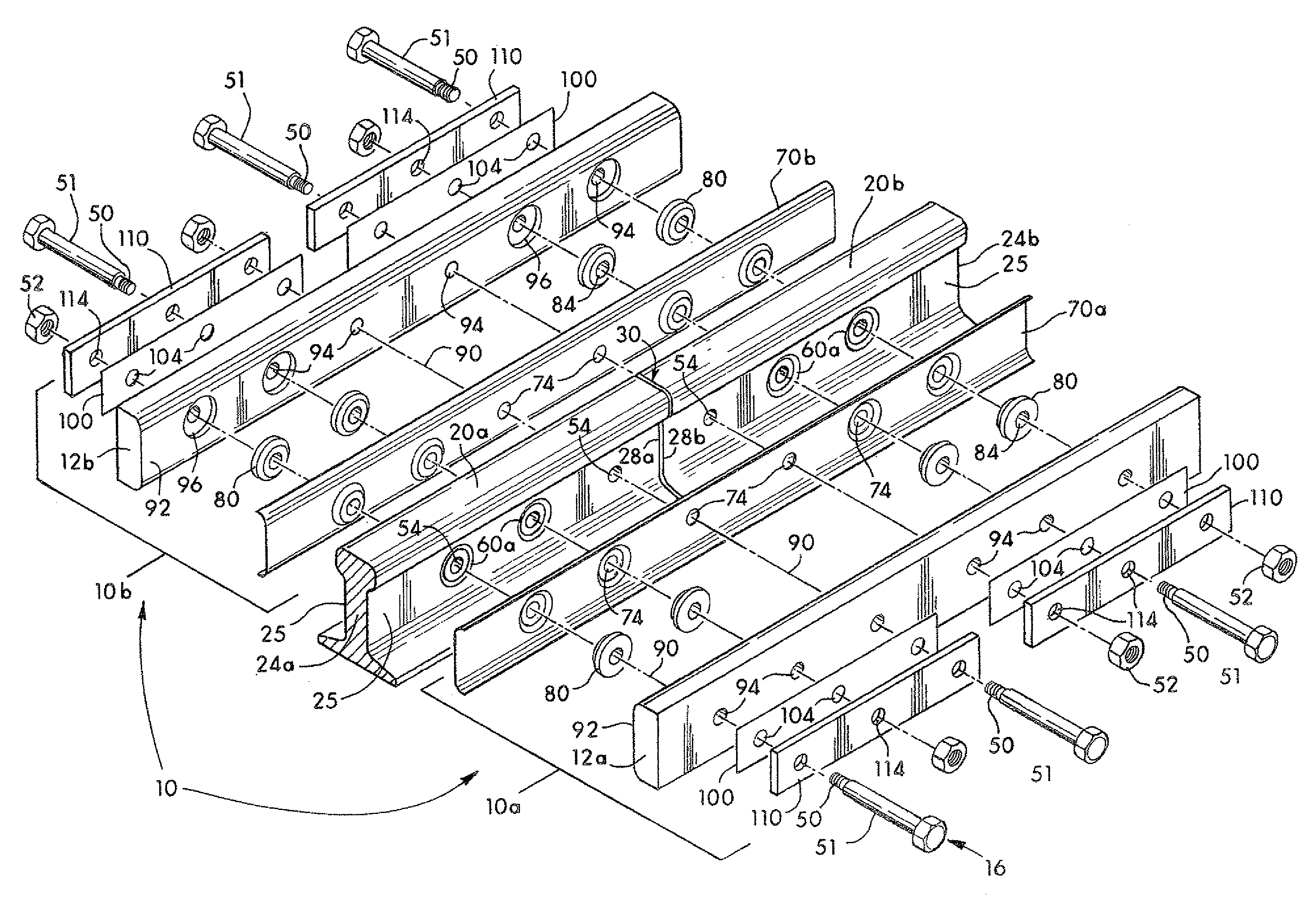

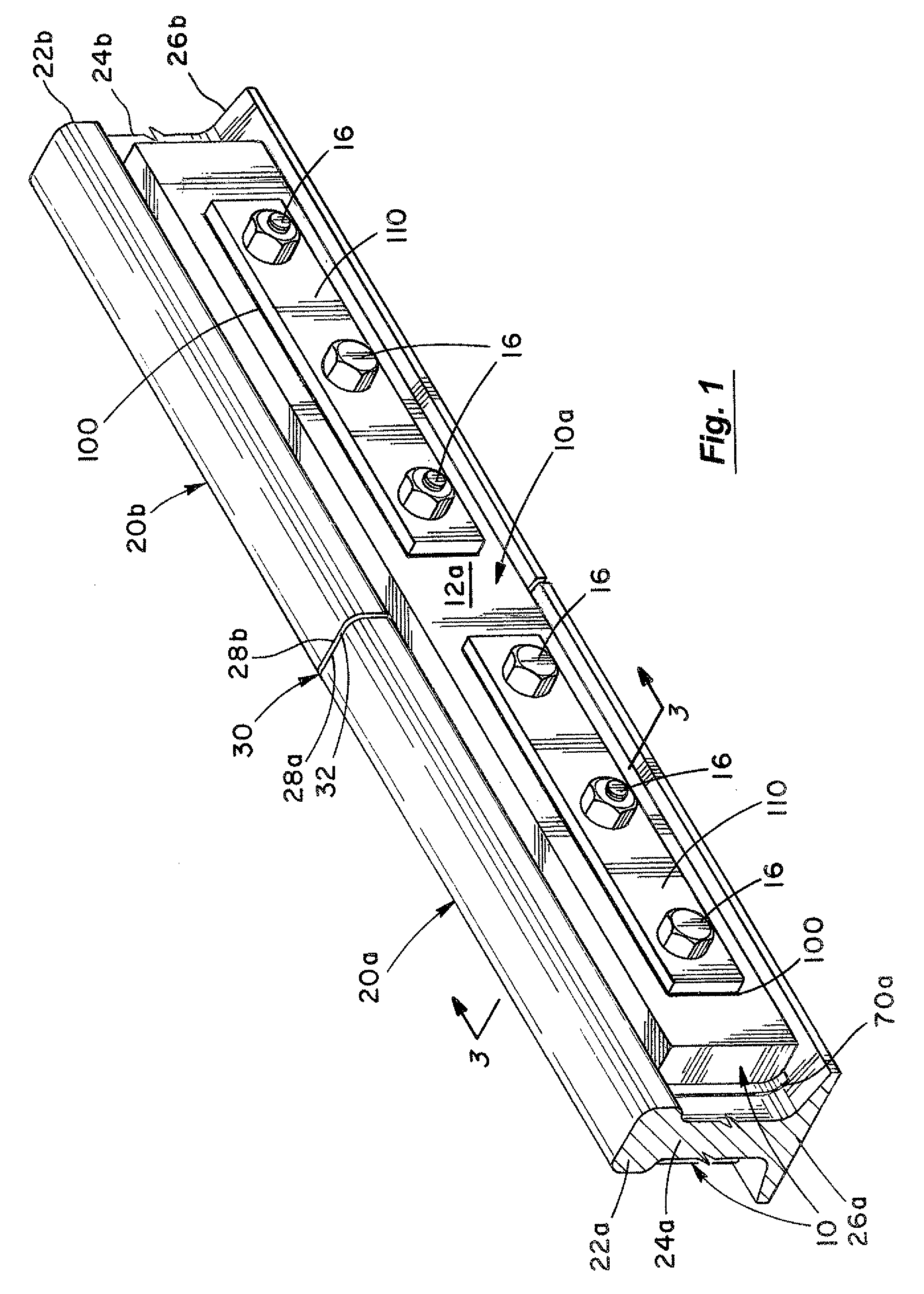

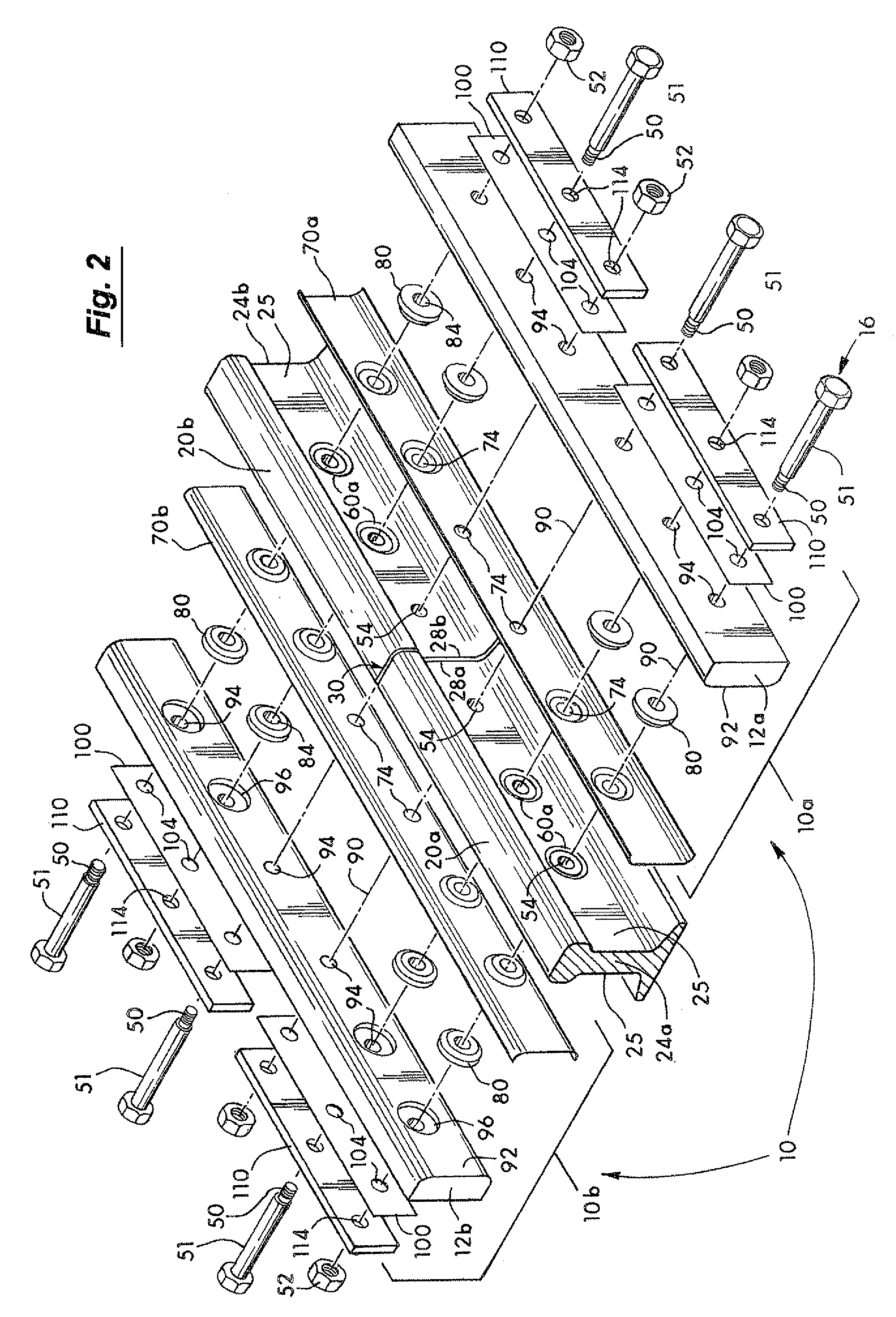

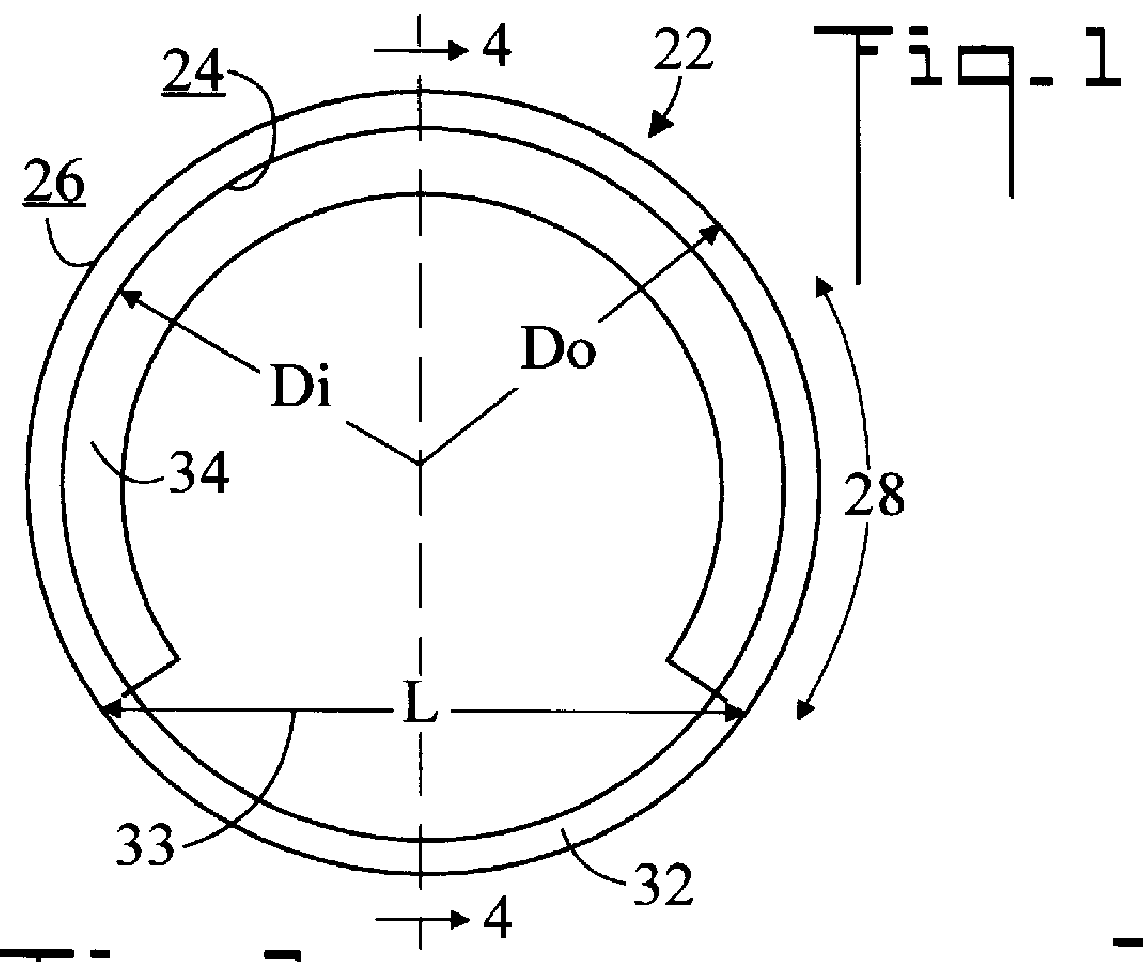

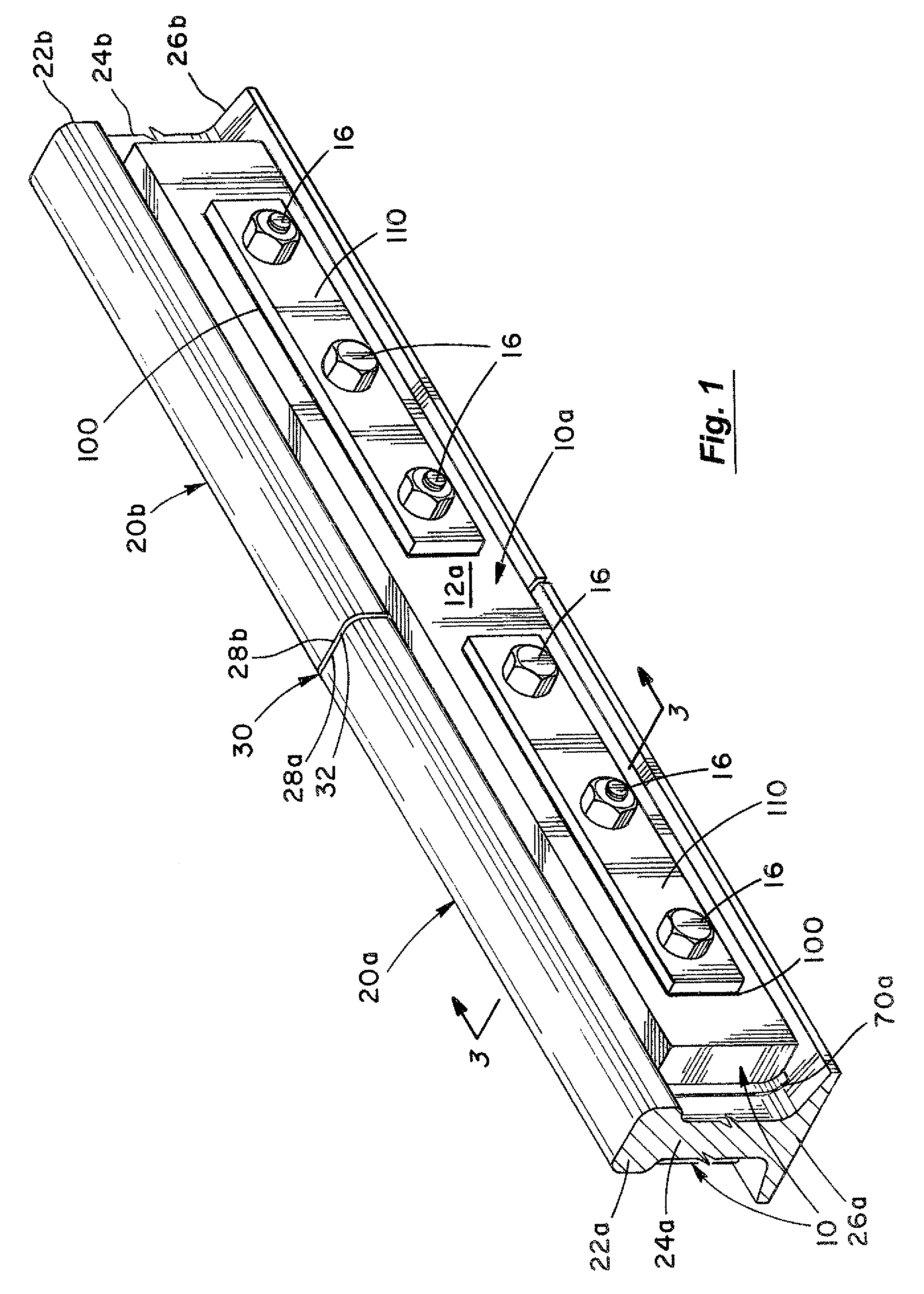

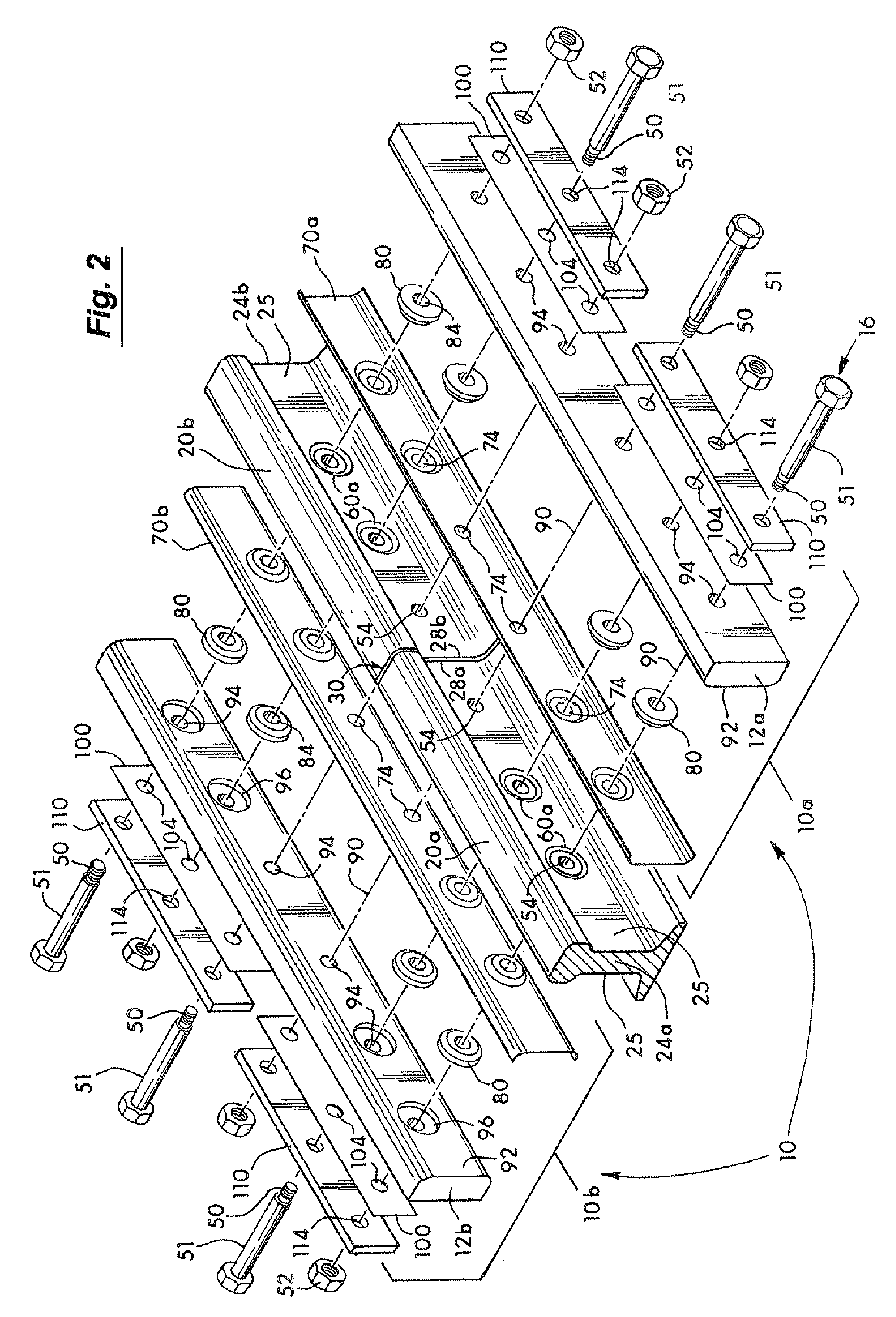

Rail joint assembly using embedded load transfer keys and method therefor

A rail joint assembly joining the ends of two rails together includes a pair of joint bars. Each joint bar having one side configured to the rail web side. Mechanical fasteners mount the joint bars to the web sides. Pairs of load bearing keys are embedded in web counter bores at predetermined depths into the webs and embedded in adjacent joint bar counter bores at predetermined depths into the joint bars. The pairs of keys in the webs and the joint bars transfer railway loads through the joint and substantially strengthen the rail joint assembly.

Owner:TRANSPORTATION TECH CENT

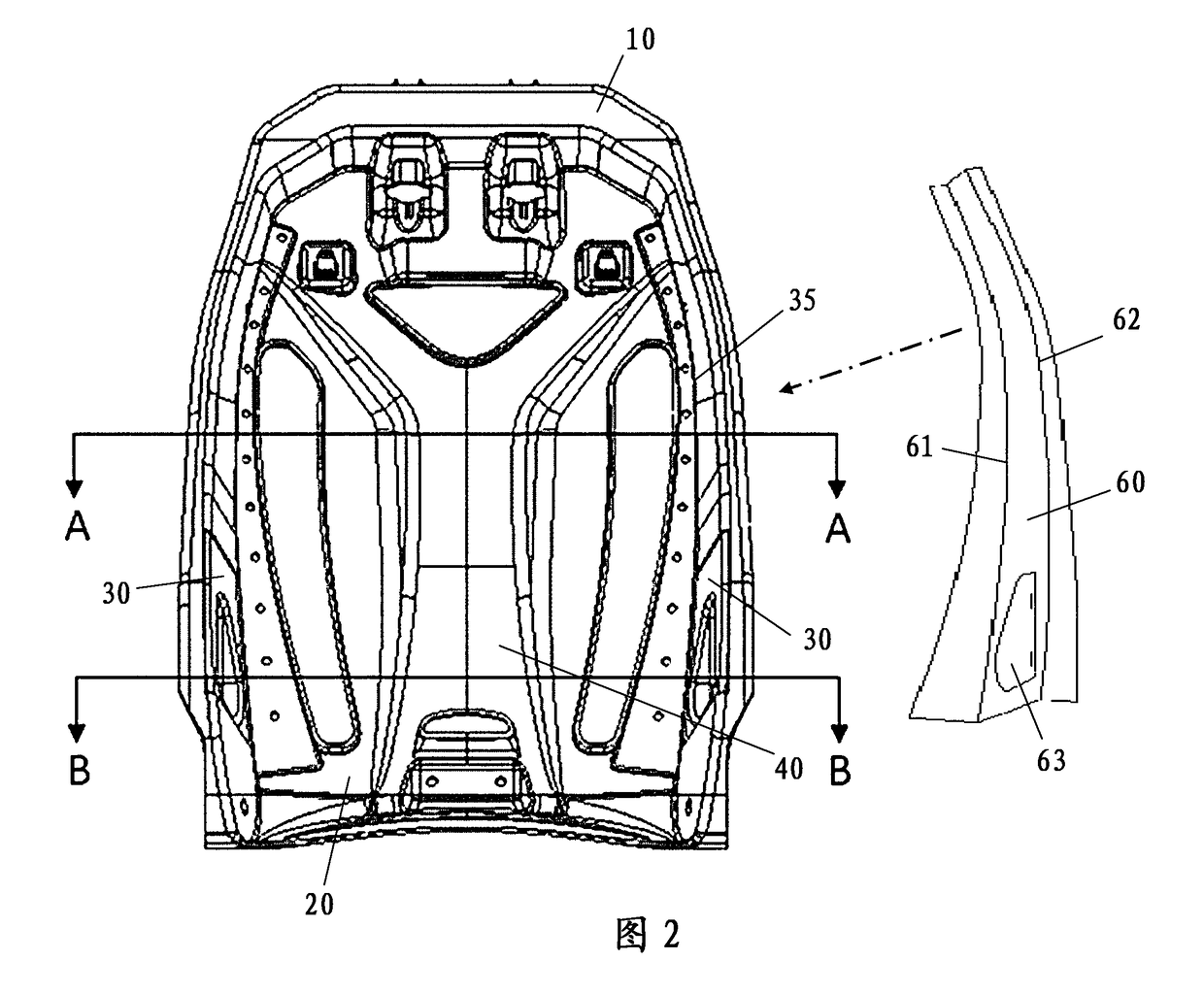

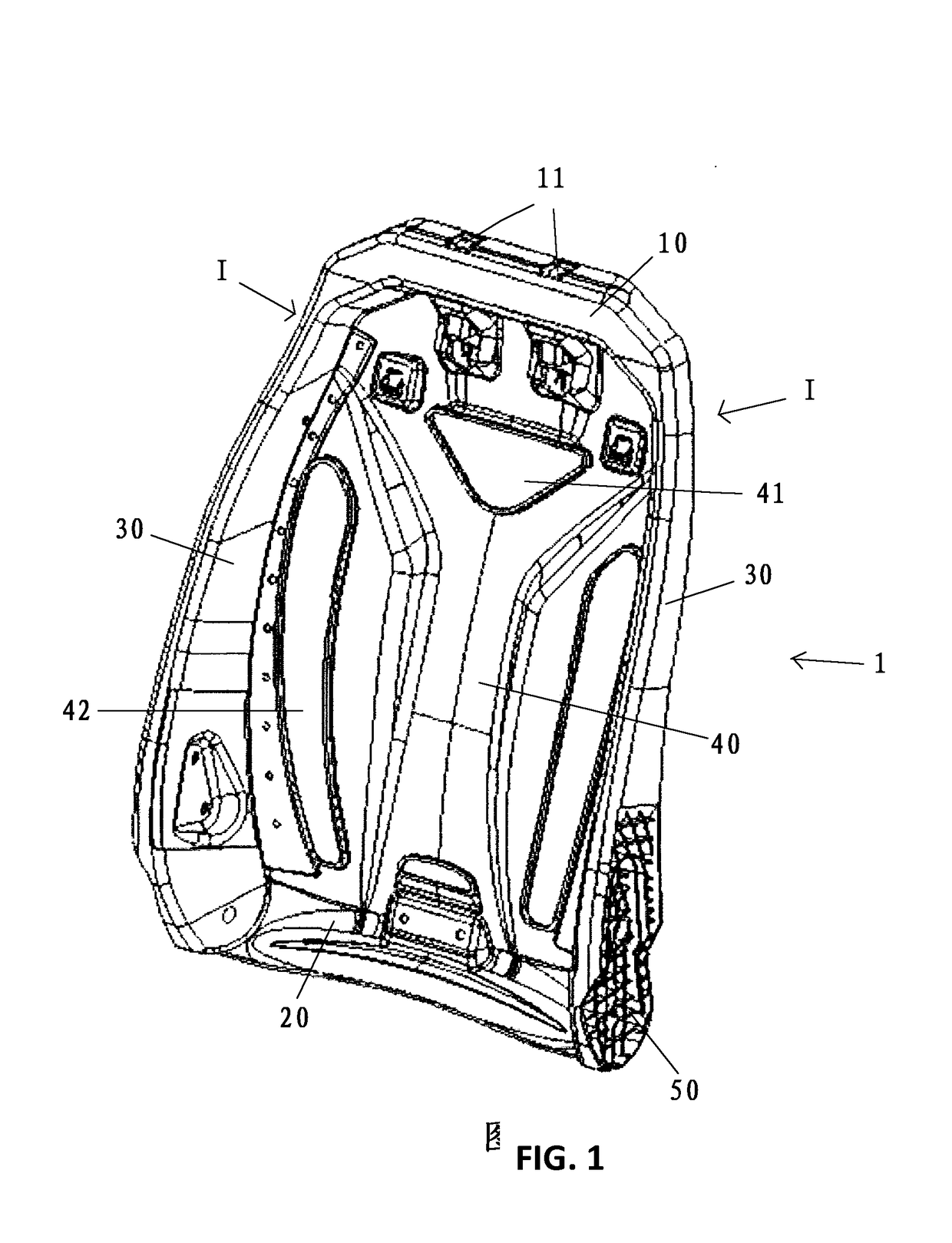

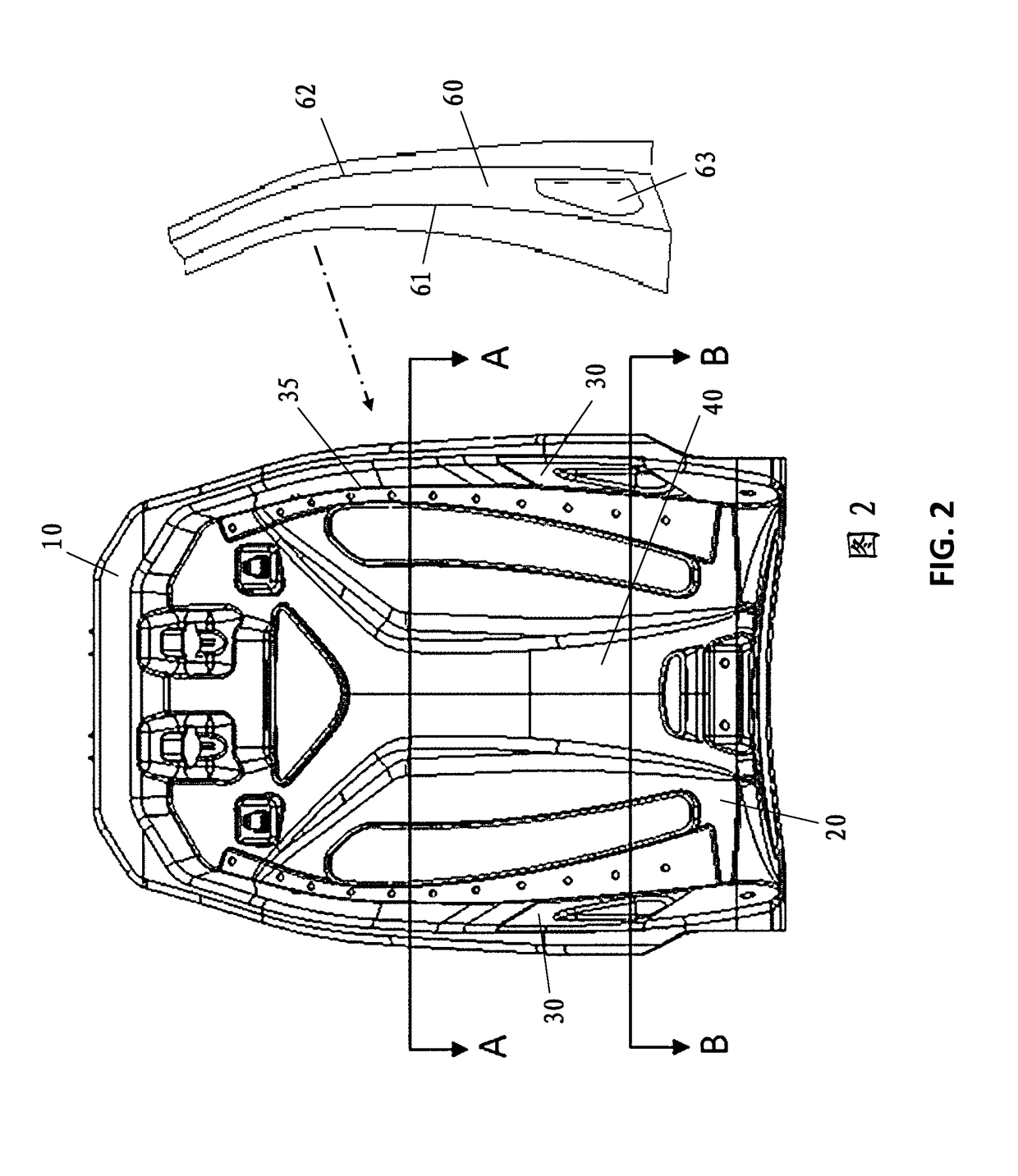

Seat backrest and seat including the same

A seat backrest is provided, comprising a framework (1) including an upper portion (10), a lower portion (20), a central support portion (40) and two side portions (30) formed integrally by injection molding a thermoplastic material; and an elongated reinforcement (60) embedded in the side portion (30) and the central support portion (40) by overmolding and extending along the side portion (30), the reinforcement (60) being configured to bend along a boundary (35) between the side portion (30) and the central support portion (40). A seat including the backrest is also provided.

Owner:BASF AG

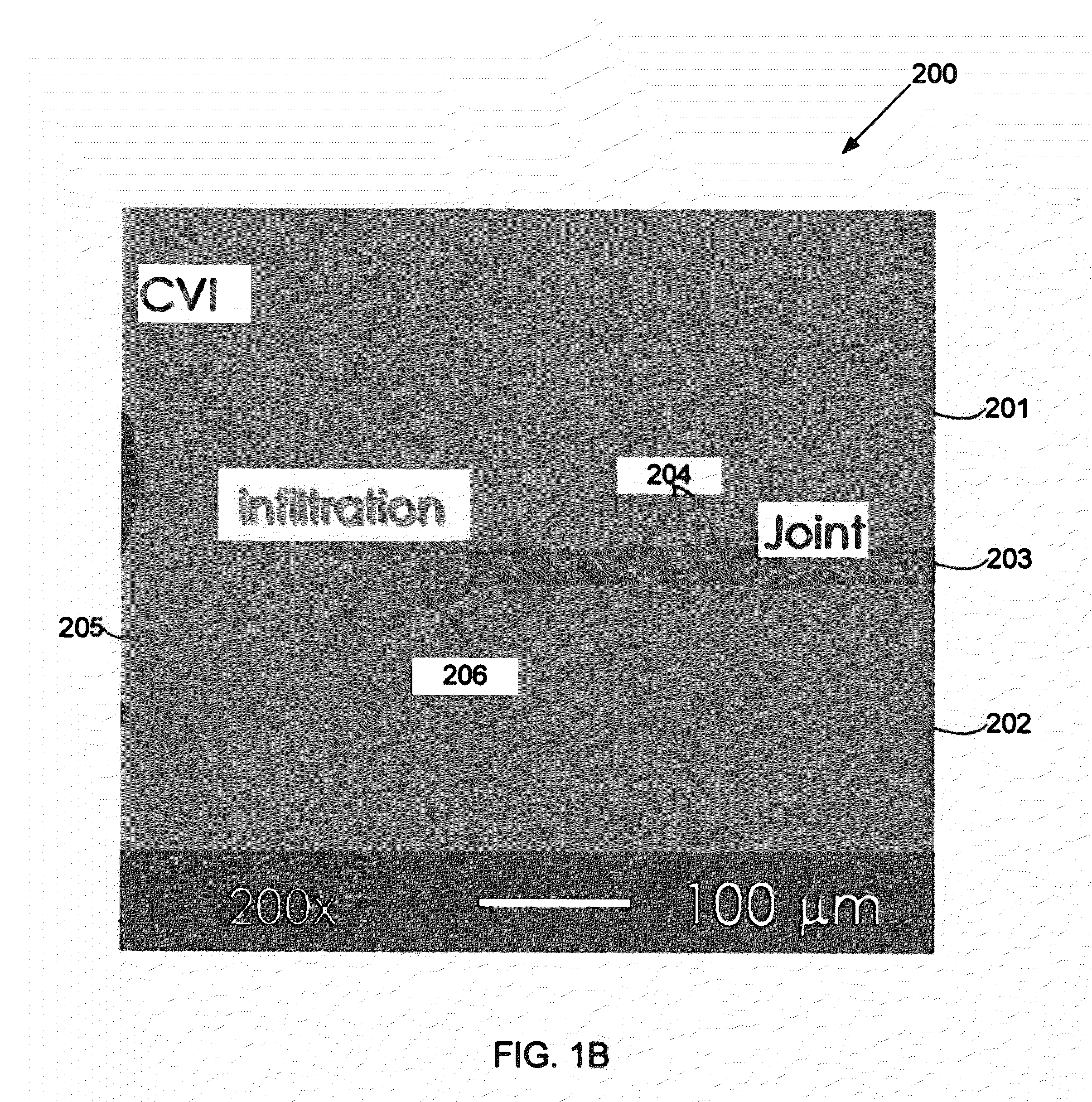

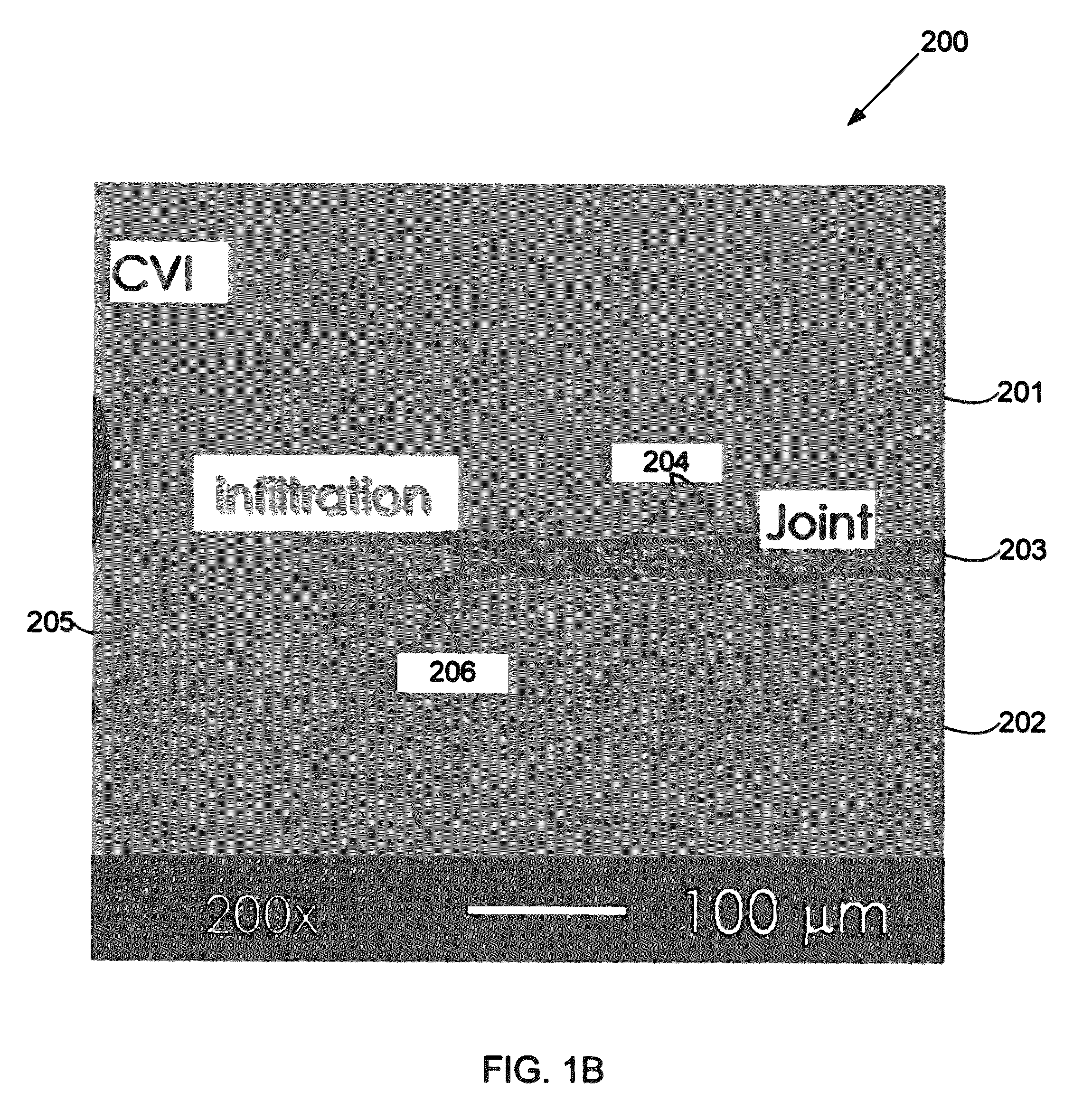

High durability joints between ceramic articles, and methods of making and using same

ActiveUS20130266363A1Increased durabilitySame characteristicsLaminationLamination apparatusSilicon carbide

Embodiments of the present invention provide high durability joints between ceramic articles, particularly between beta-silicon carbide (β-SiC) articles, and methods of making and using the same. In one embodiment, a joint between first and second articles each comprising a ceramic polymorph comprises a matrix comprising the ceramic polymorph and extending between the first and second articles; a plurality of inclusions comprising the ceramic polymorph and being distributed throughout the matrix; and a sealing layer comprising the ceramic polymorph and being respectively disposed on the first and second articles and the matrix.

Owner:GENERAL ATOMICS

Rig mat

ActiveUS20080053343A1Reinforced jointsEasy constructionFoundation engineeringTablesEngineeringGusset plate

Owner:ALBERTA RIG MATS

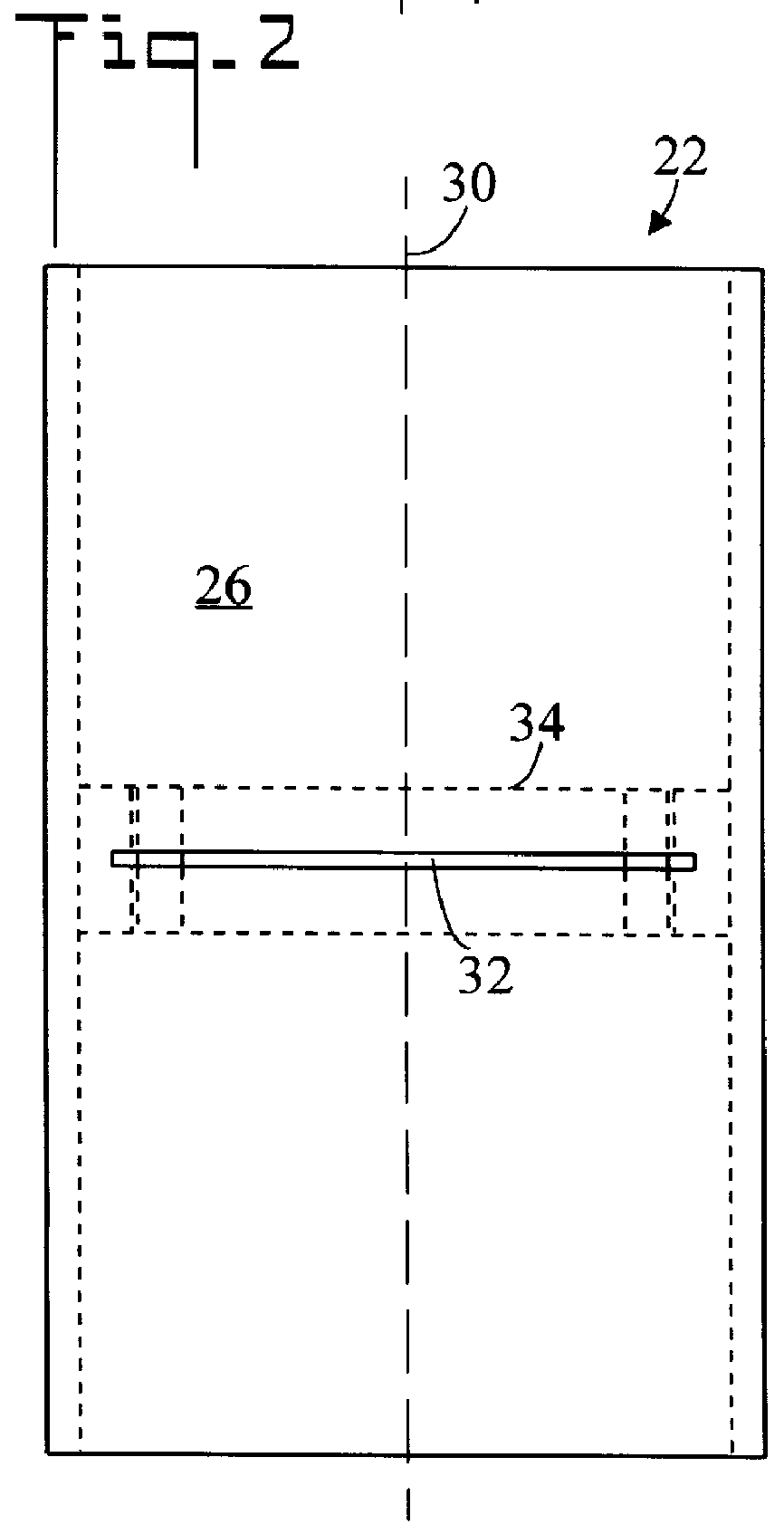

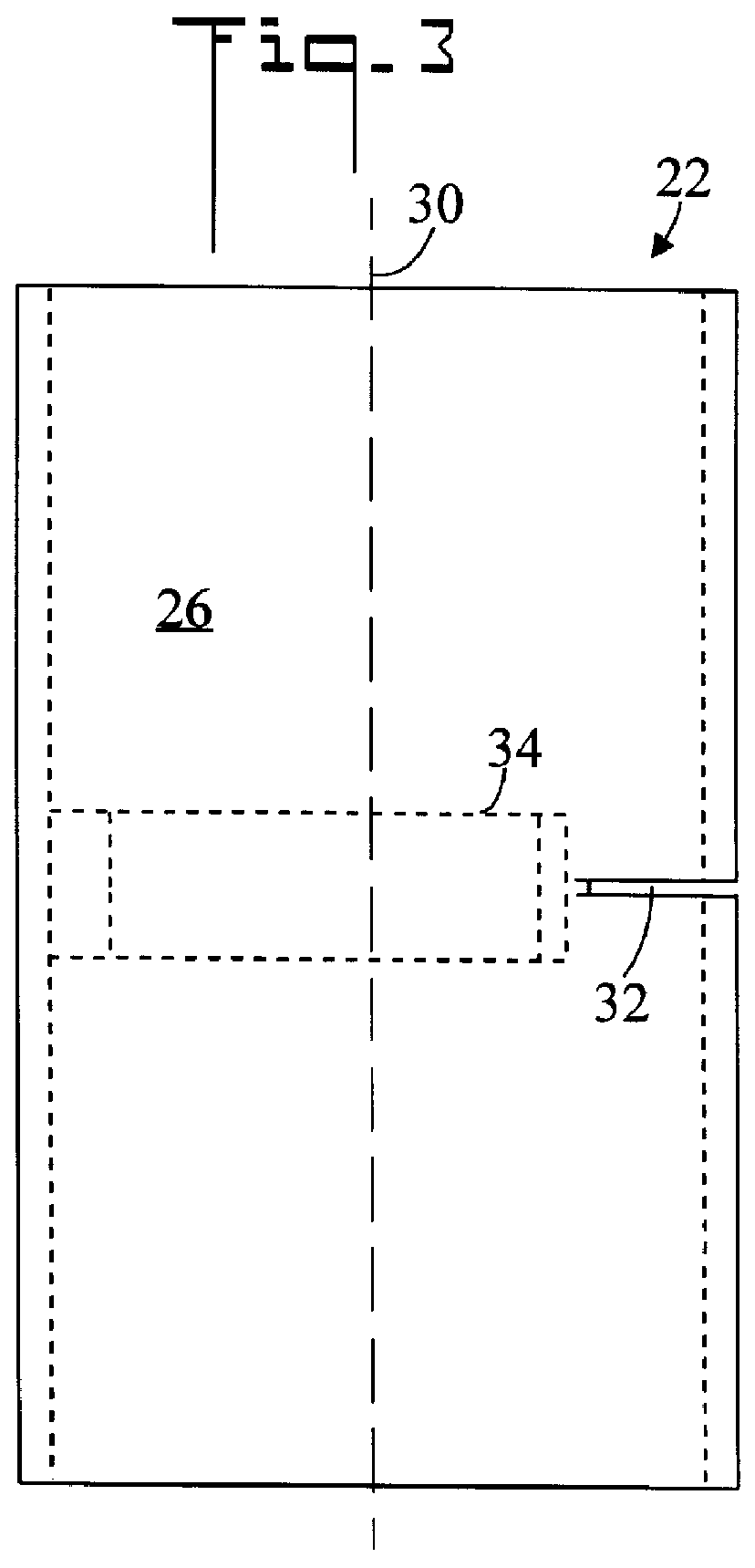

Plumbing coupling and method of use

InactiveUS6116262AQuickly and inexpensively installAvoid flowPipe laying and repairContainer filling methodsCouplingEngineering

A plumbing coupling (20) for connecting two lengths of pipe (500) includes a cylindrical body (22) having a circumferential through-slit (32) extending part of the way around its perimeter (28). A closure plate (36) is selectively insertable into the through-slit (32) so as to abut the inner surface (24) of body (22) and block the flow of water through the plumbing coupling (20). A sleeve (42) is selectively wrapable around body (22) to tightly seal the closure plate (36). To conduct a pressure test, closure plate (36) is inserted and sleeve (42) attached. To return the plumbing line to normal use, middle portion (43) of sleeve (42) is peeled back, closure plate (36) is removed, and middle portion (43) of sleeve (42) is reattached. Body (22) is fabricated from a resilient material which conforms to edge (38) of closure plate (36).

Owner:CORRALEJO GREGORY J

Rail joint assembly using embedded load transfer keys and method therefor

A rail joint assembly joining the ends of two rails together includes a pair of joint bars. Each joint bar having one side configured to the rail web side. Mechanical fasteners mount the joint bars to the web sides. Pairs of load bearing keys are embedded in web counter bores at predetermined depths into the webs and embedded in adjacent joint bar counter bores at predetermined depths into the joint bars. The pairs of keys in the webs and the joint bars transfer railway loads through the joint and substantially strengthen the rail joint assembly.

Owner:TRANSPORTATION TECH CENT

High durability joints between ceramic articles, and methods of making and using same

ActiveUS9132619B2Increased durabilitySame characteristicsLaminationLamination apparatusMaterials scienceSilicon carbide

Embodiments of the present invention provide high durability joints between ceramic articles, particularly between beta-silicon carbide (β-SiC) articles, and methods of making and using the same. In one embodiment, a joint between first and second articles each comprising a ceramic polymorph comprises a matrix comprising the ceramic polymorph and extending between the first and second articles; a plurality of inclusions comprising the ceramic polymorph and being distributed throughout the matrix; and a sealing layer comprising the ceramic polymorph and being respectively disposed on the first and second articles and the matrix.

Owner:GENERAL ATOMICS

Tapered annular gasket and joint for use of same

An apparatus is disclosed that includes a gasket having an annular shape and characterized by an outer circumference and an inner circumference. The gasket is further characterized by an inner thickness, proximate the inner circumference, tapering to an outer thickness, proximate the outer circumference. The inner thickness of the gasket is substantially greater than the outer thickness. The gasket includes a first contact surface extending between the inner and outer circumferences, and a second contact surface, opposite the first contact surface, extending between the inner and outer circumferences.

Owner:CUMMINS FILTRATION IP INC

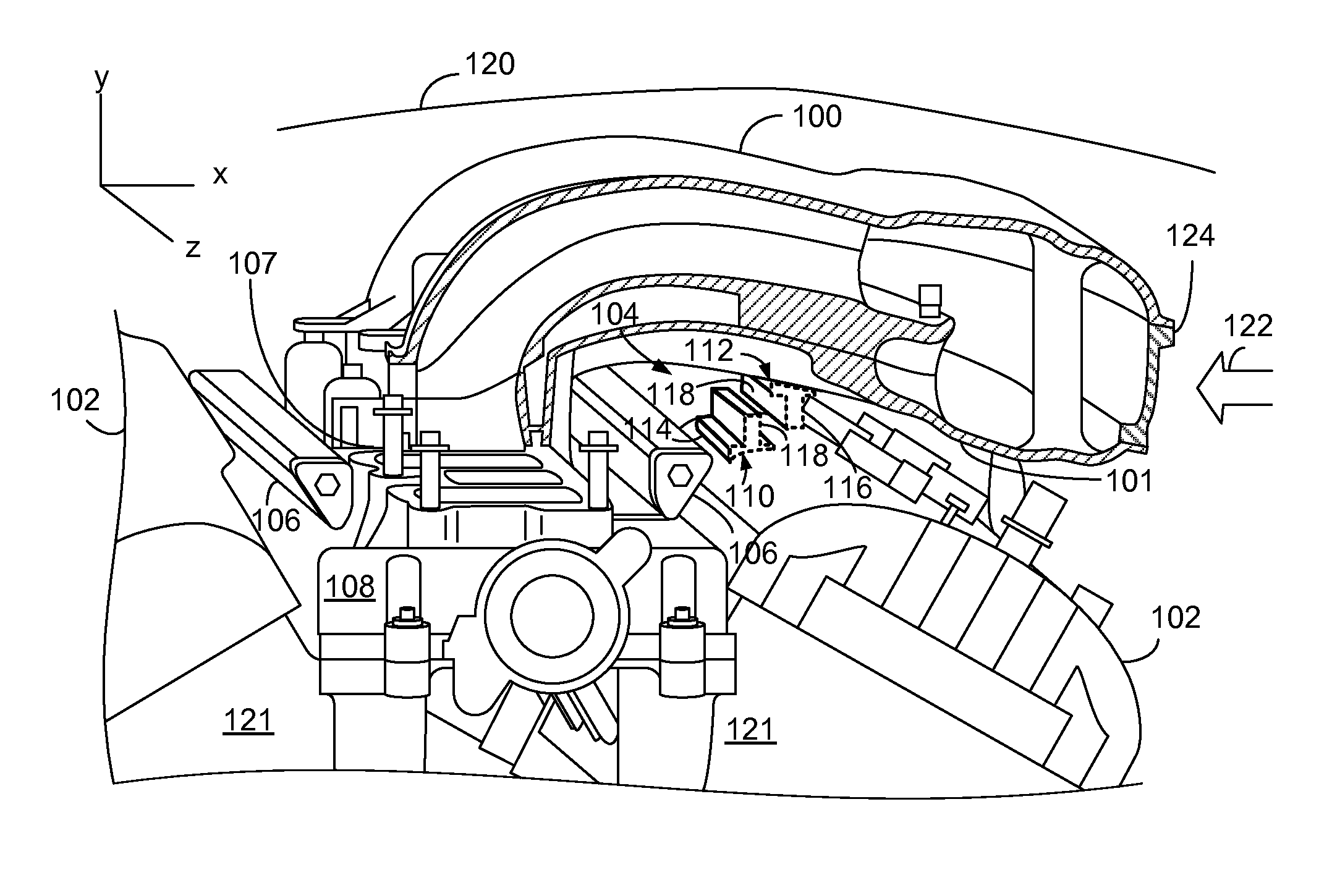

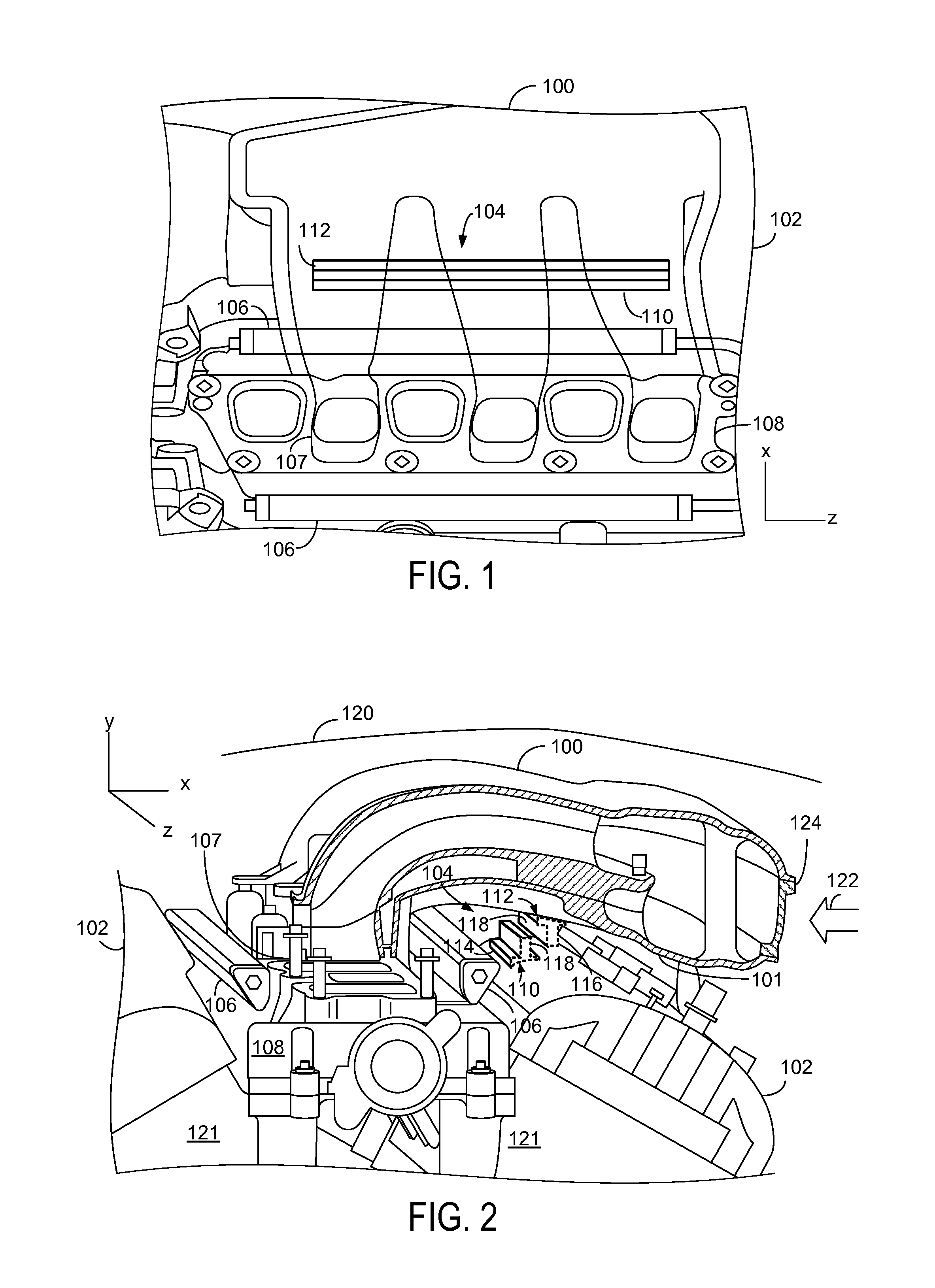

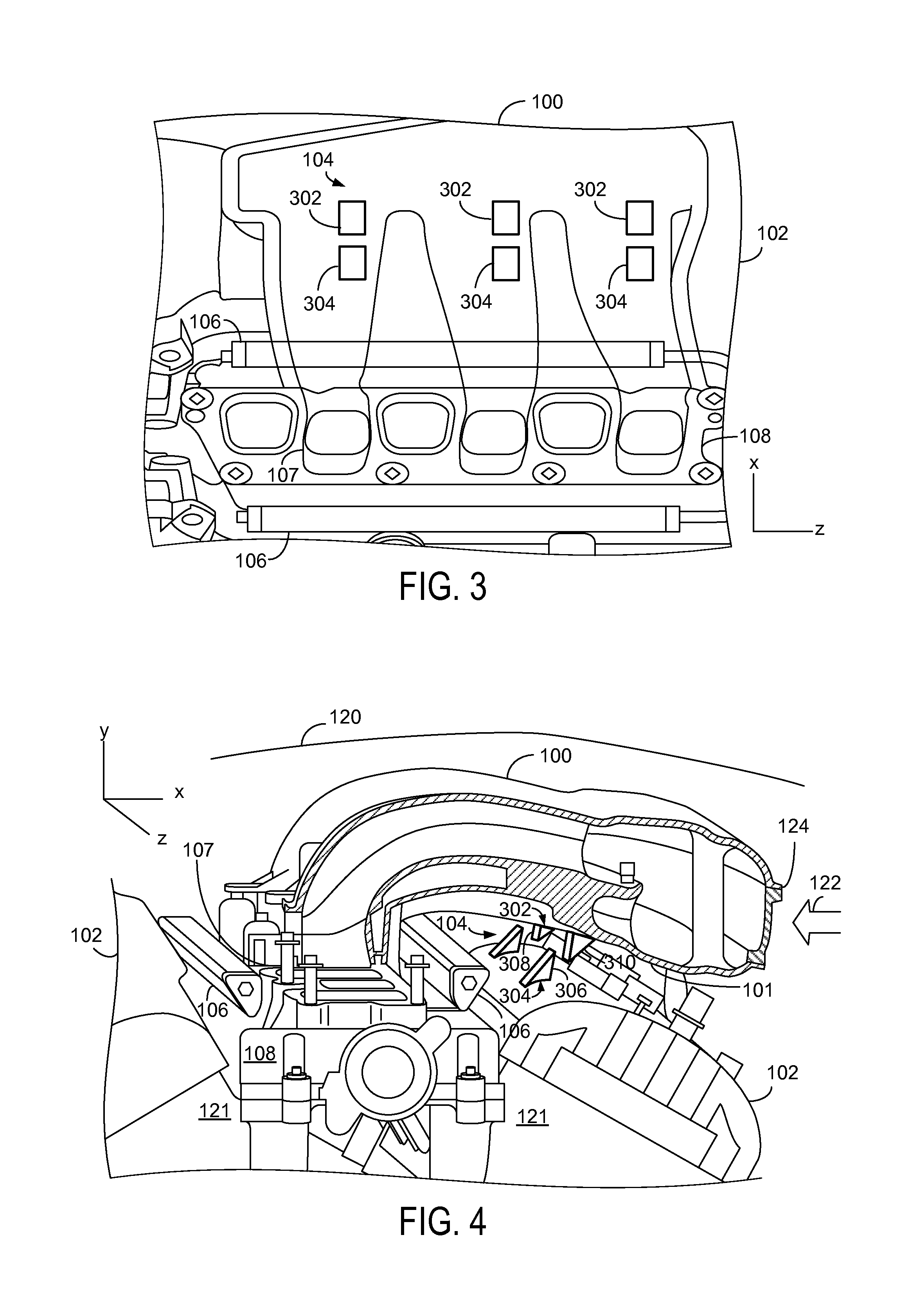

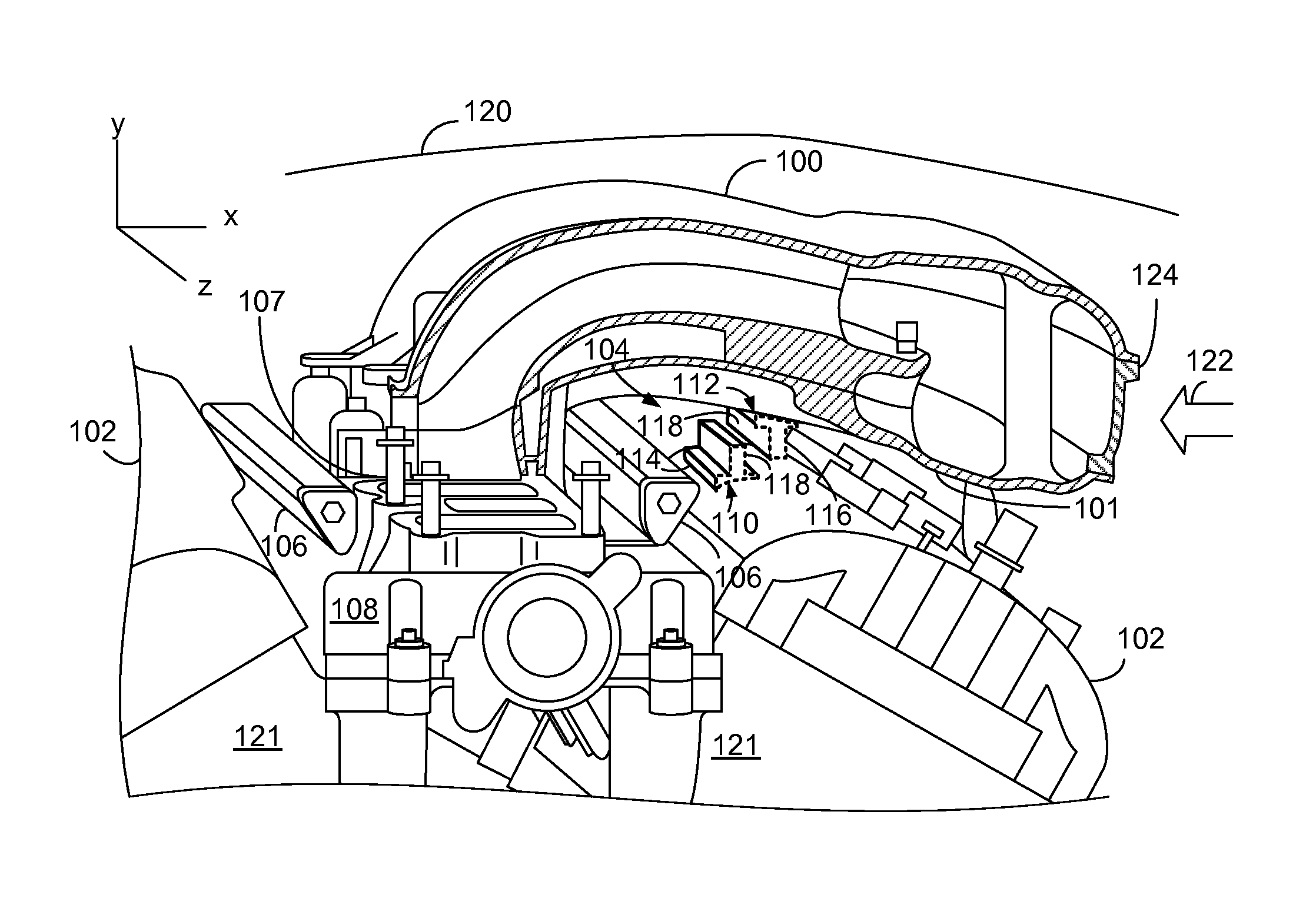

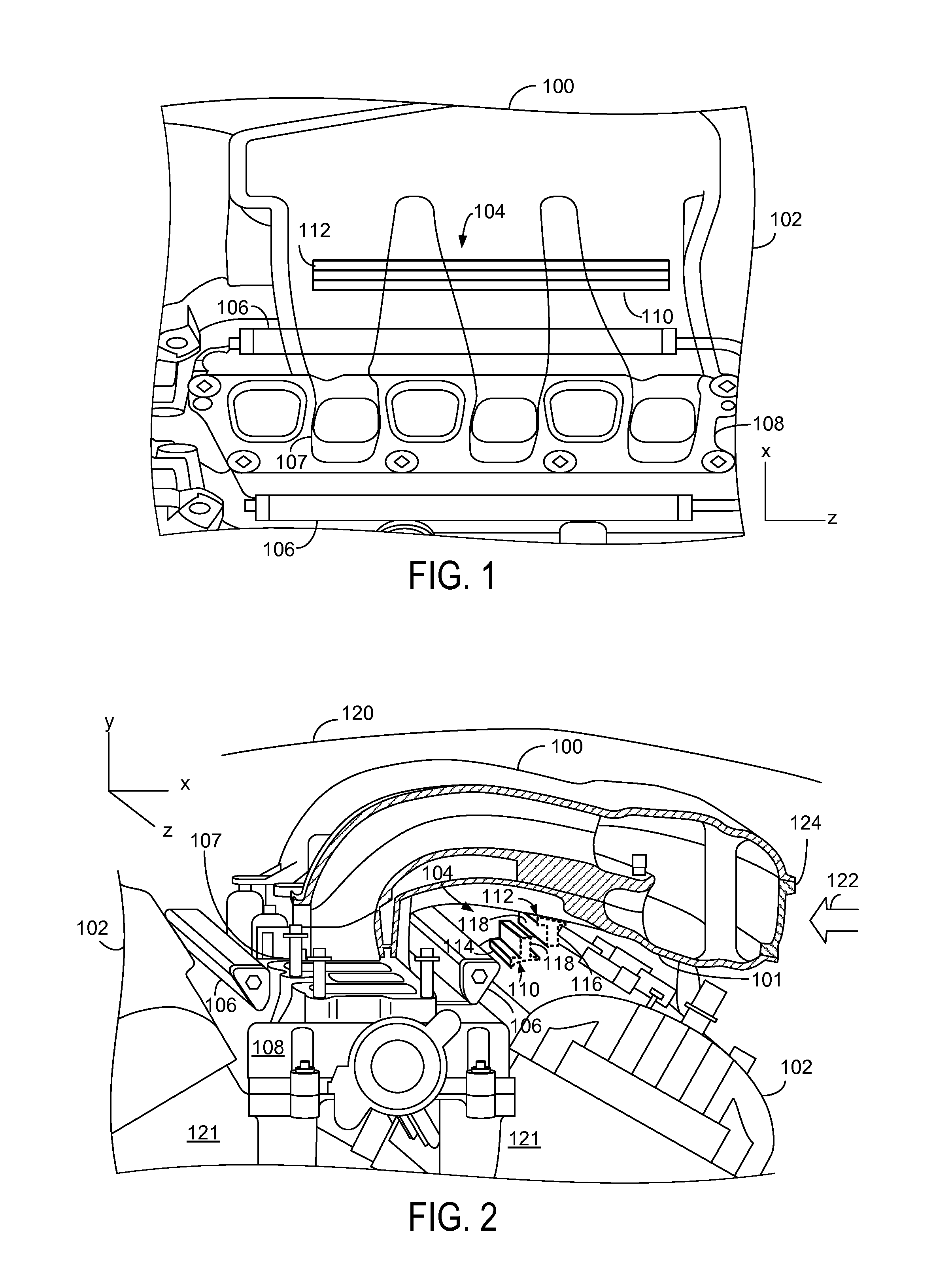

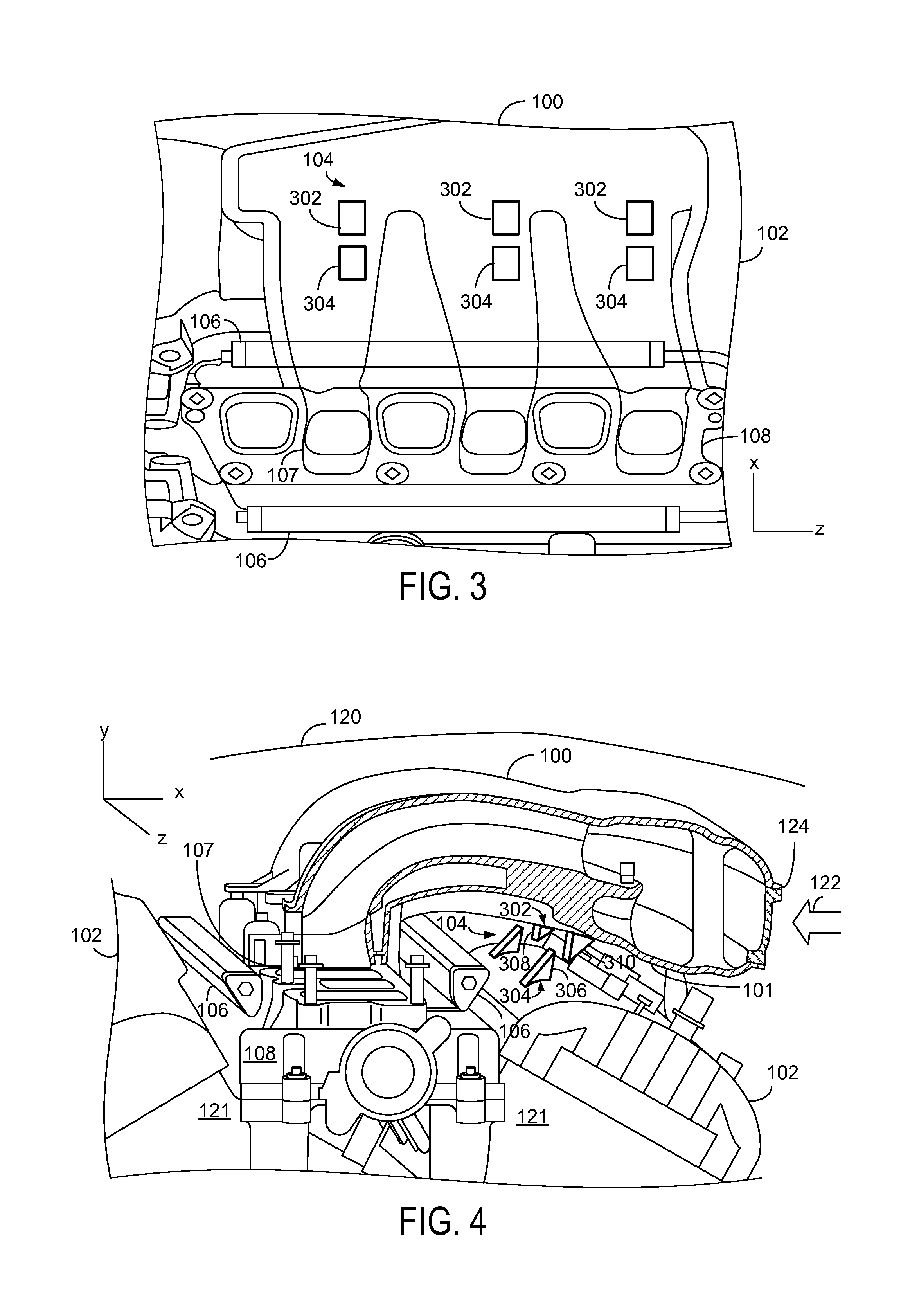

Component catch for crash robustness

ActiveUS20140352642A1Reduce shear forceAchieve technical effectsCasingsFuel injection apparatusEngineeringCam

Systems are disclosed to restrain movement of engine components in the event of a collision. A system may comprise an upper intake manifold; a cam cover; a shear catch located between the upper intake manifold and the cam cover; an upper component of the shear catch is arranged on the upper intake manifold; a lower component of the shear catch is arranged on the cam cover; and the upper component and the lower component are arranged opposite each other such that they engage when the upper intake manifold is subjected to shear forces. Variations to the size, arrangement, and shape of a shear catch are disclosed herein.

Owner:FORD GLOBAL TECH LLC

Method of producing a stabilizer with a stabilizer bearing

InactiveUS8454774B2Improve reliabilityGood reproducibilityAdhesivesElectrical componentsElastomerAdhesive

In a method of producing a stabilizer for a motor vehicle, a stabilizer bearing portion of a stabilizer is chemically pre-treated by applying an adhesive. The stabilizer and two vulcanized elastomer-metal bearing half-shells are then placed in a joining apparatus for subsequent bonding of the bearing half-shells with the stabilizer bearing portion.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

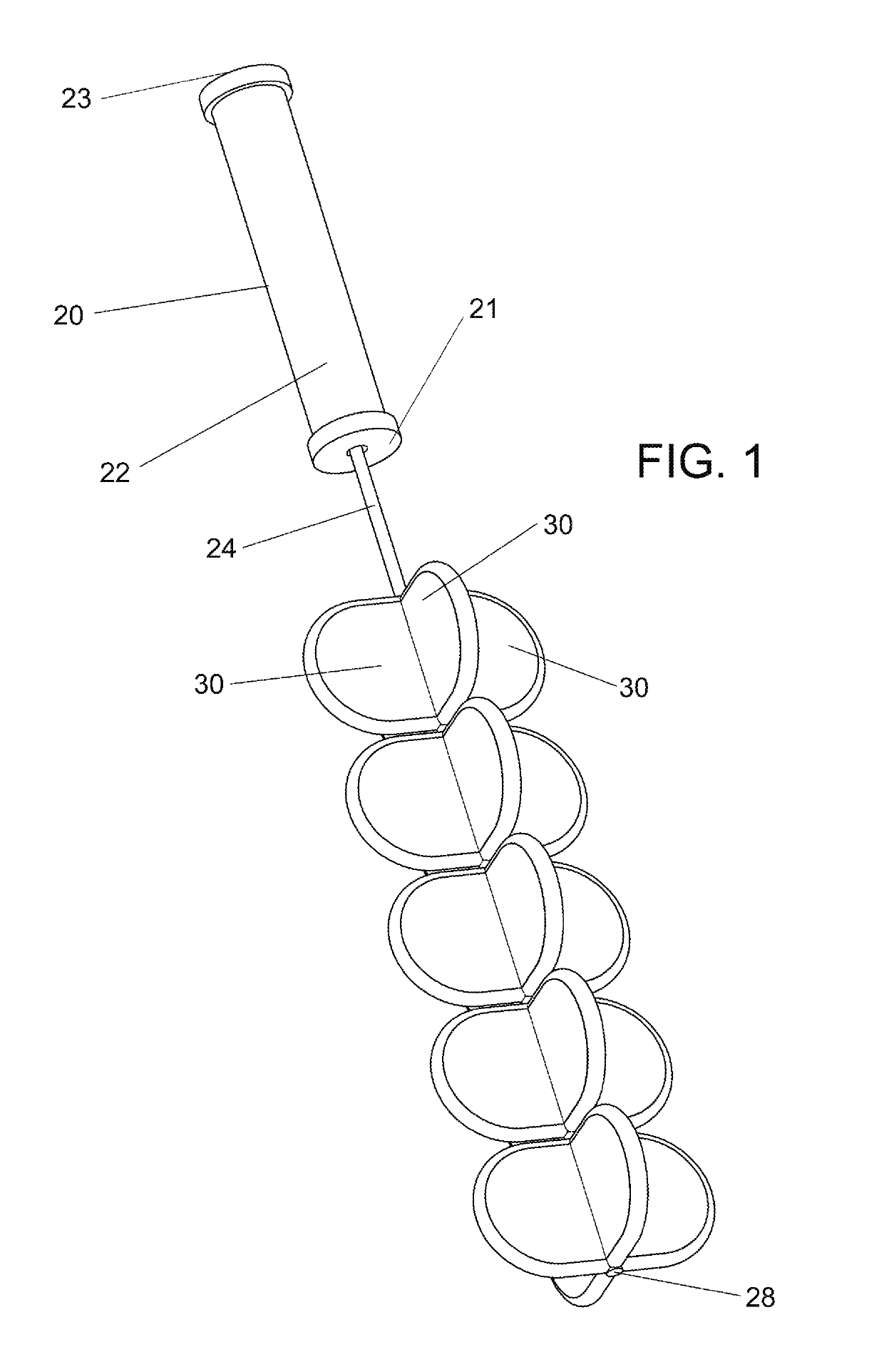

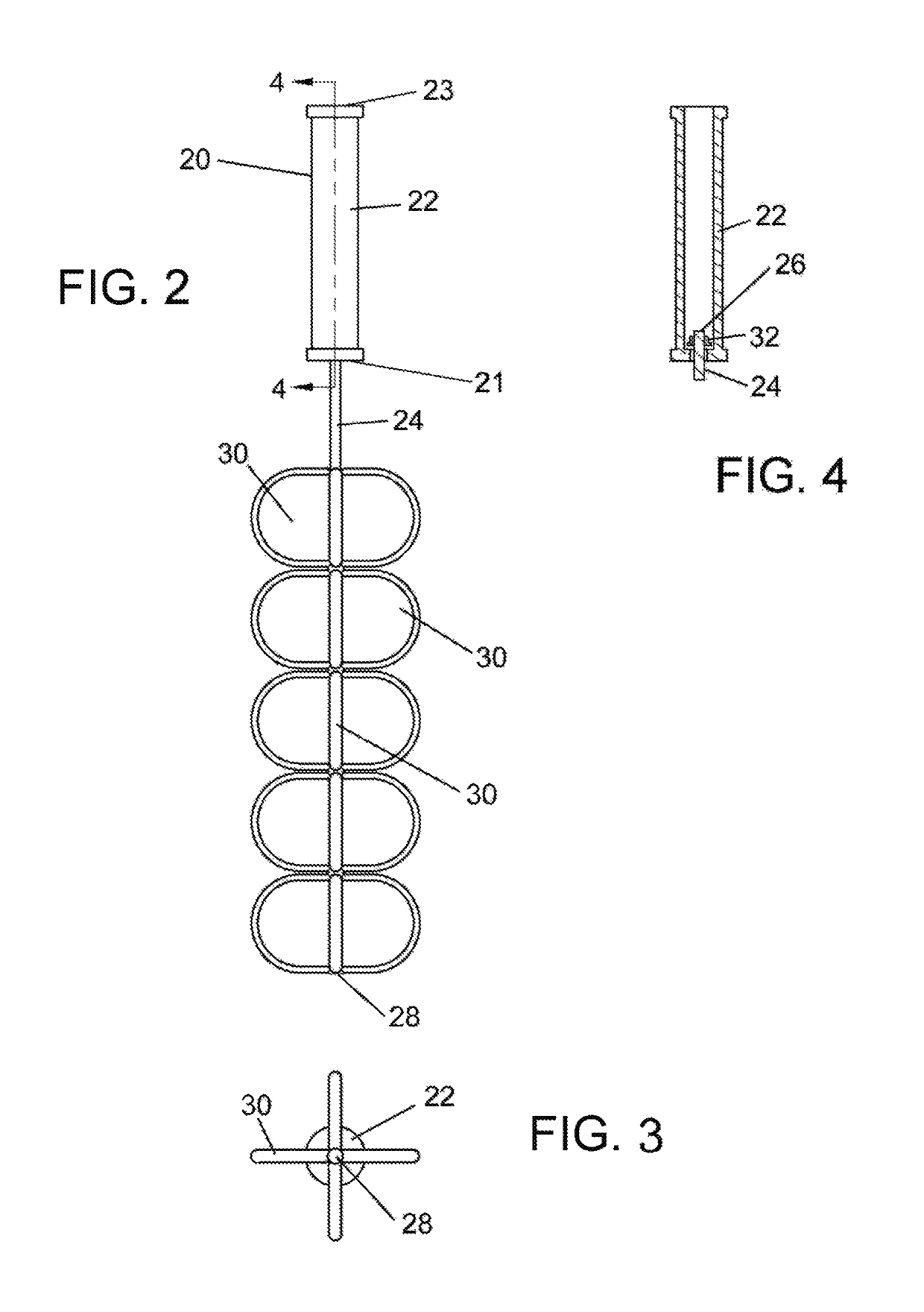

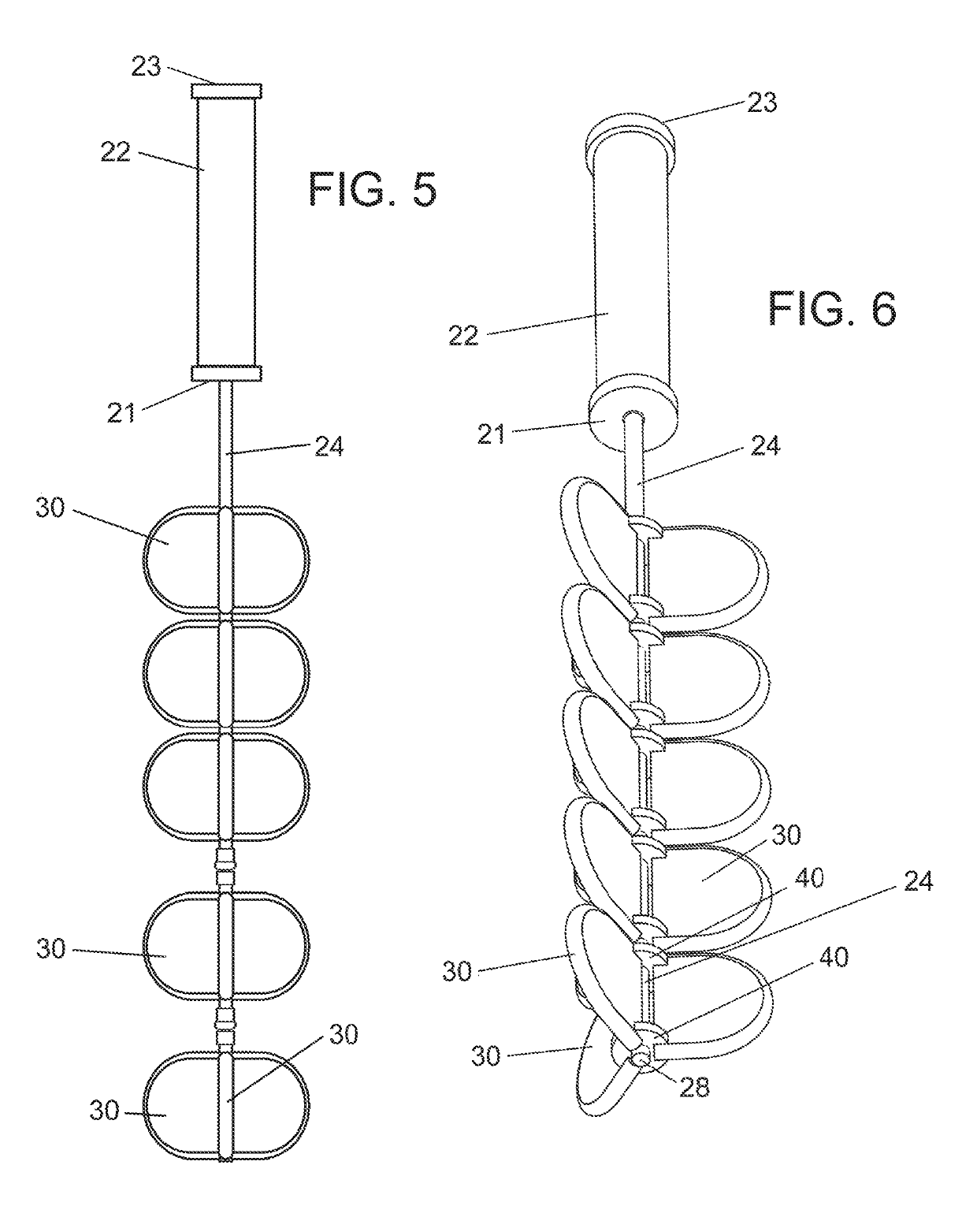

Resistance exercise device

ActiveUS10426988B1Effective resistanceLower resistanceClubsMuscle exercising devicesCouplingEngineering

A resistance exercise device includes: an elongated handle having first and second handle ends; an elongated element having first and second ends defining a longitudinal axis, at least part of the elongated element being flexible; a coupling connecting the elongated element near the first end to the elongated handle near the first handle end; and resistance fins attached to the elongated element, disposed around and along part of the elongated element, and oriented outwardly from the longitudinal axis, the elongated element and attached resistance fins being at least generally symmetrical along the longitudinal axis, whereby when whirled, the elongated element and the attached resistance fins prevent rotation about the longitudinal axis and produce a substantially continuous resistance exercise. A method of exercising includes: providing the resistance exercise device; holding the elongated handle by a user; and whirling the elongated element and attached fins about the elongated handle.

Owner:DAVIES PHILLIP

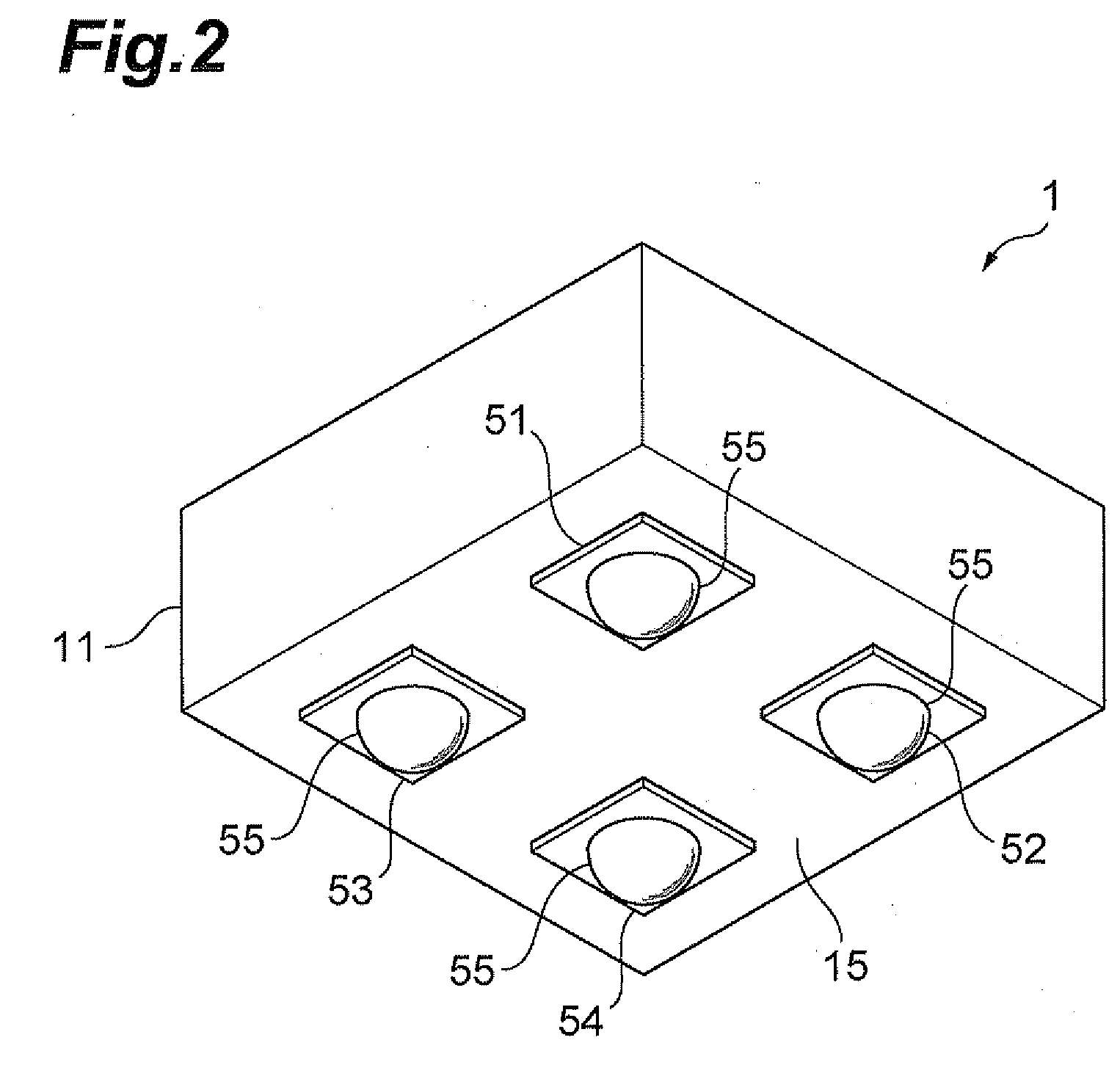

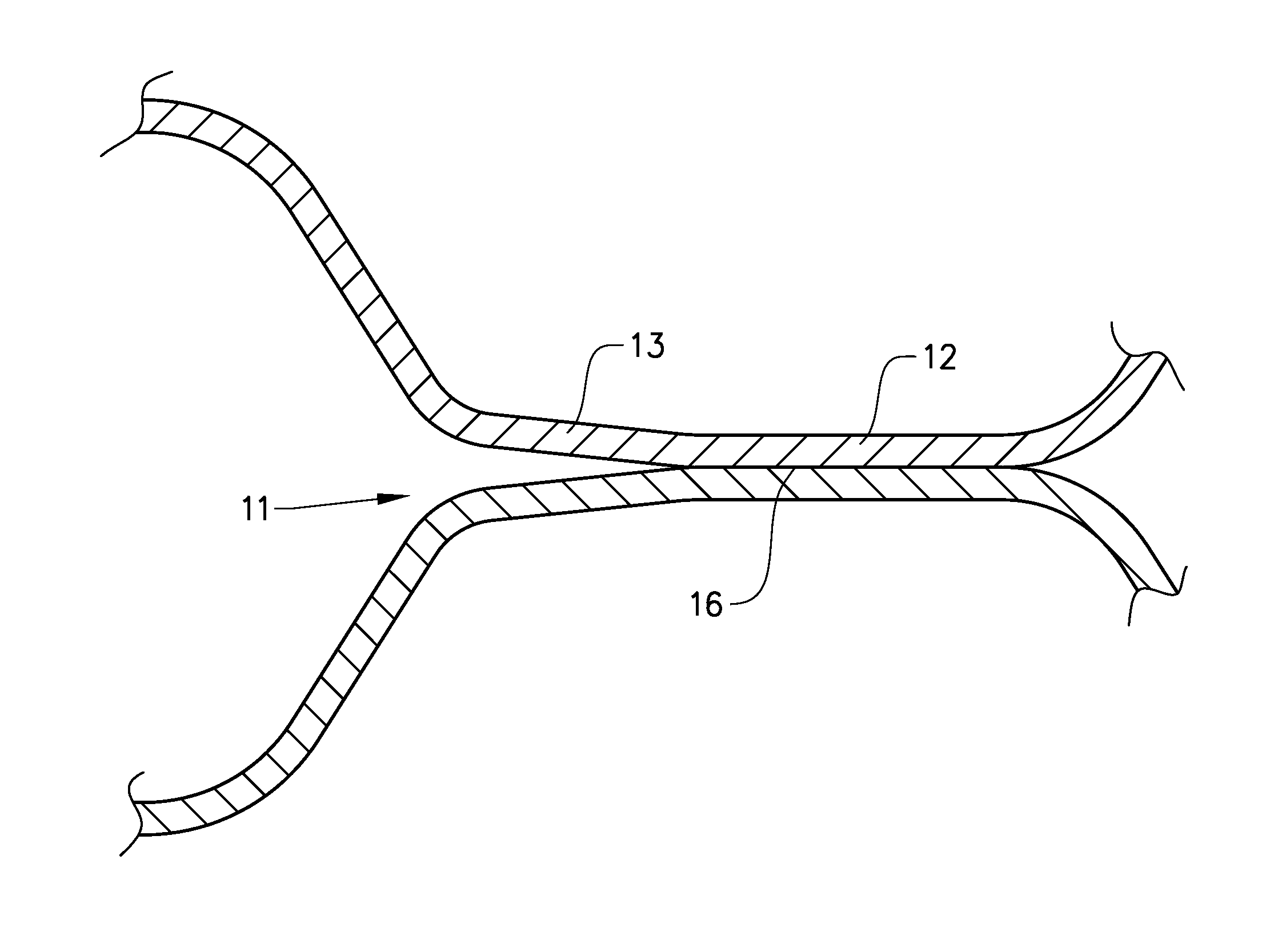

Chip-type electronic component

ActiveUS20090296312A1Improve joint strengthLarge contact areaFixed capacitor electrodesFixed capacitor dielectricExternal connectionElectrical conductor

A chip-type electronic component has: a ceramic element body; a plurality of first and second internal electrodes arranged in the ceramic element body so as to be opposed at least in part to each other; a first external connection conductor to which the plurality of first internal electrodes are connected; a second external connection conductor to which the plurality of second internal electrodes are connected; first and second terminal electrodes; a first internal connection conductor arranged in the ceramic element body and connecting the first external connection conductor and the first terminal electrode; and a second internal connection conductor arranged in the ceramic element body and connecting the second external connection conductor and the second terminal electrode. The number of the first internal connection conductor is set to be smaller than the number of the first internal electrodes and the number of the second internal connection conductor is set to be smaller than the number of the second internal electrodes.

Owner:TDK CORPARATION

Heat exchanger

ActiveUS8939195B2Joint of the cassette is improvedCost-effective and reliableSoldering apparatusMetal working apparatusContact freeEngineering

Owner:ALFA LAVAL CORP AB

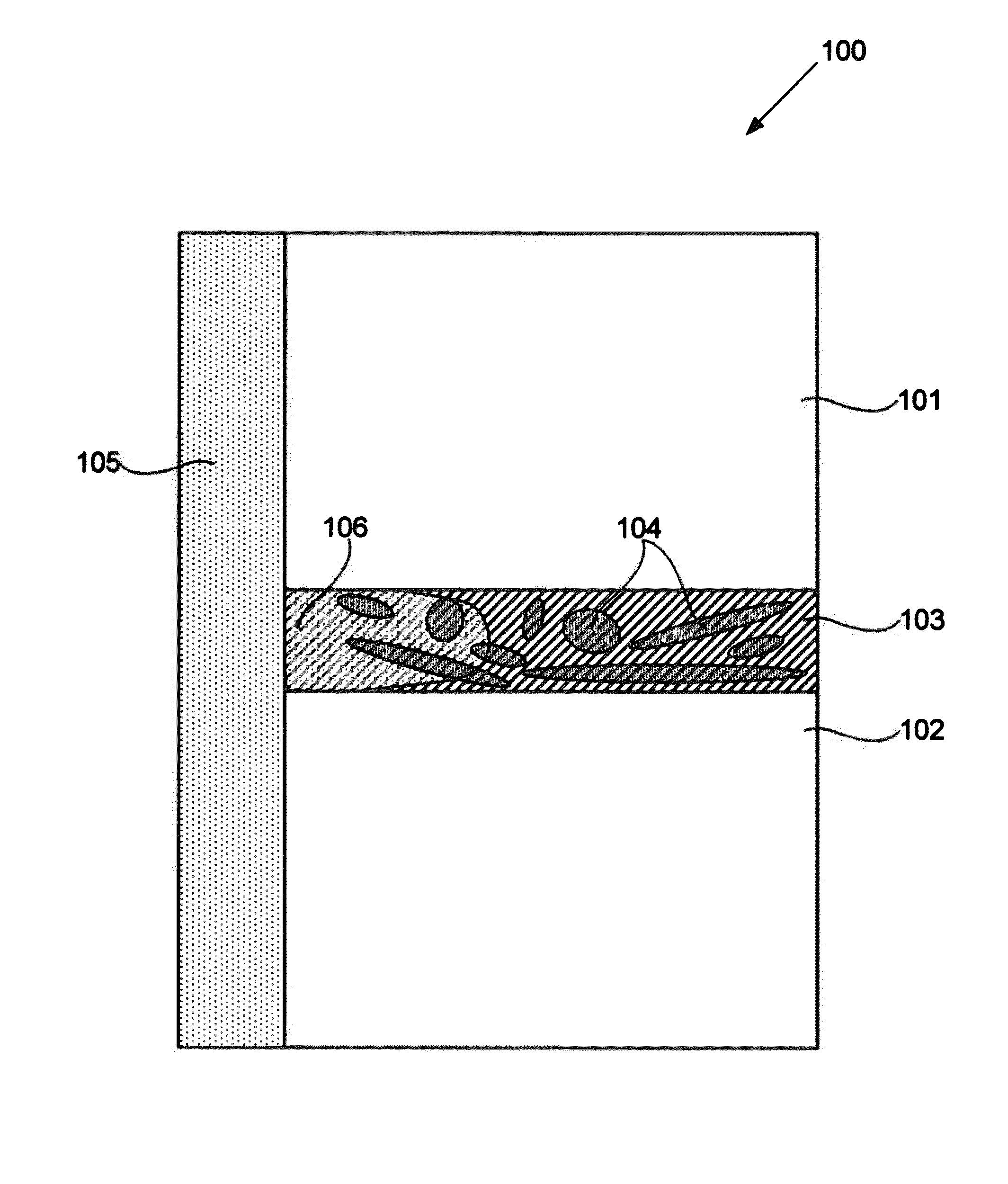

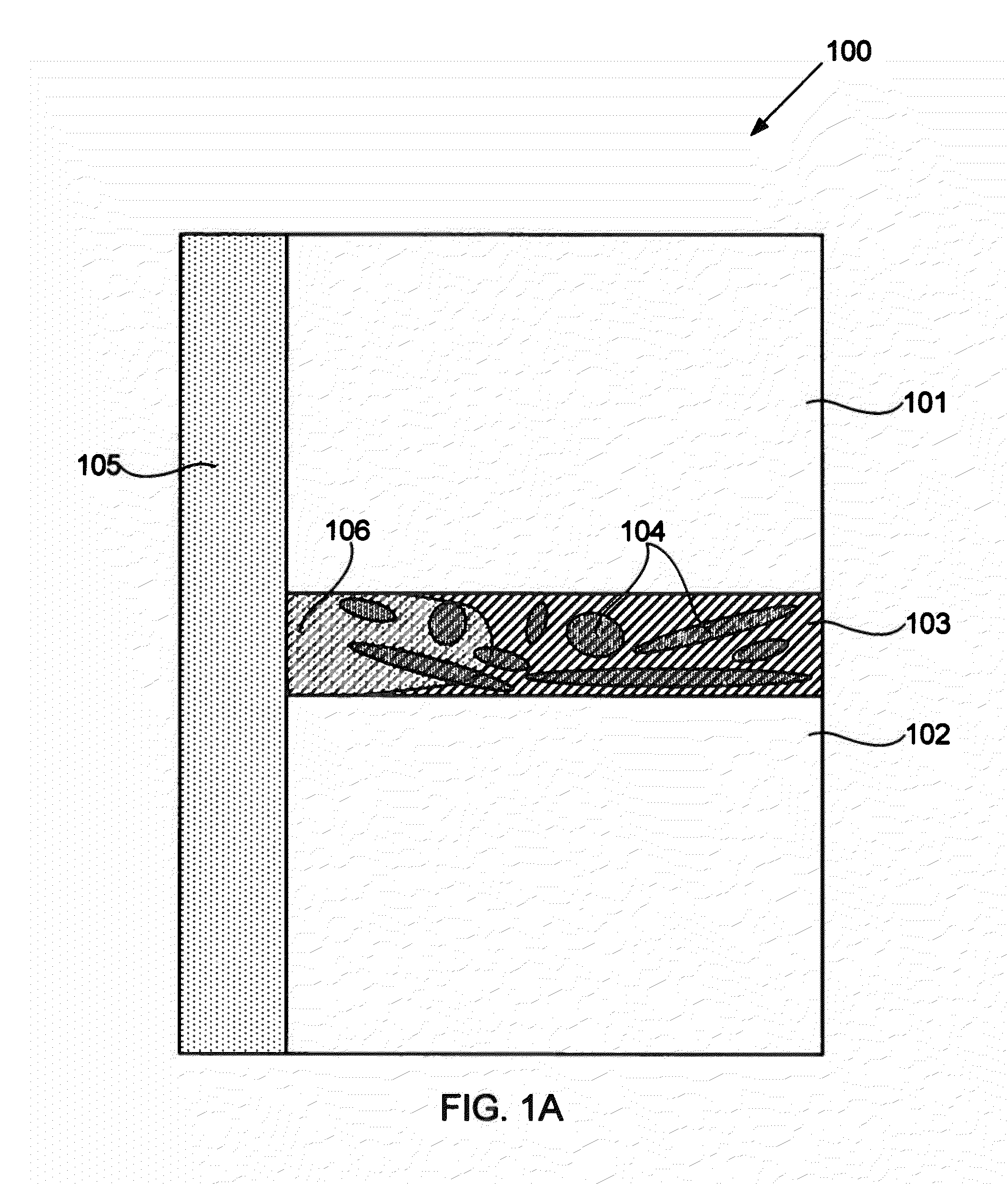

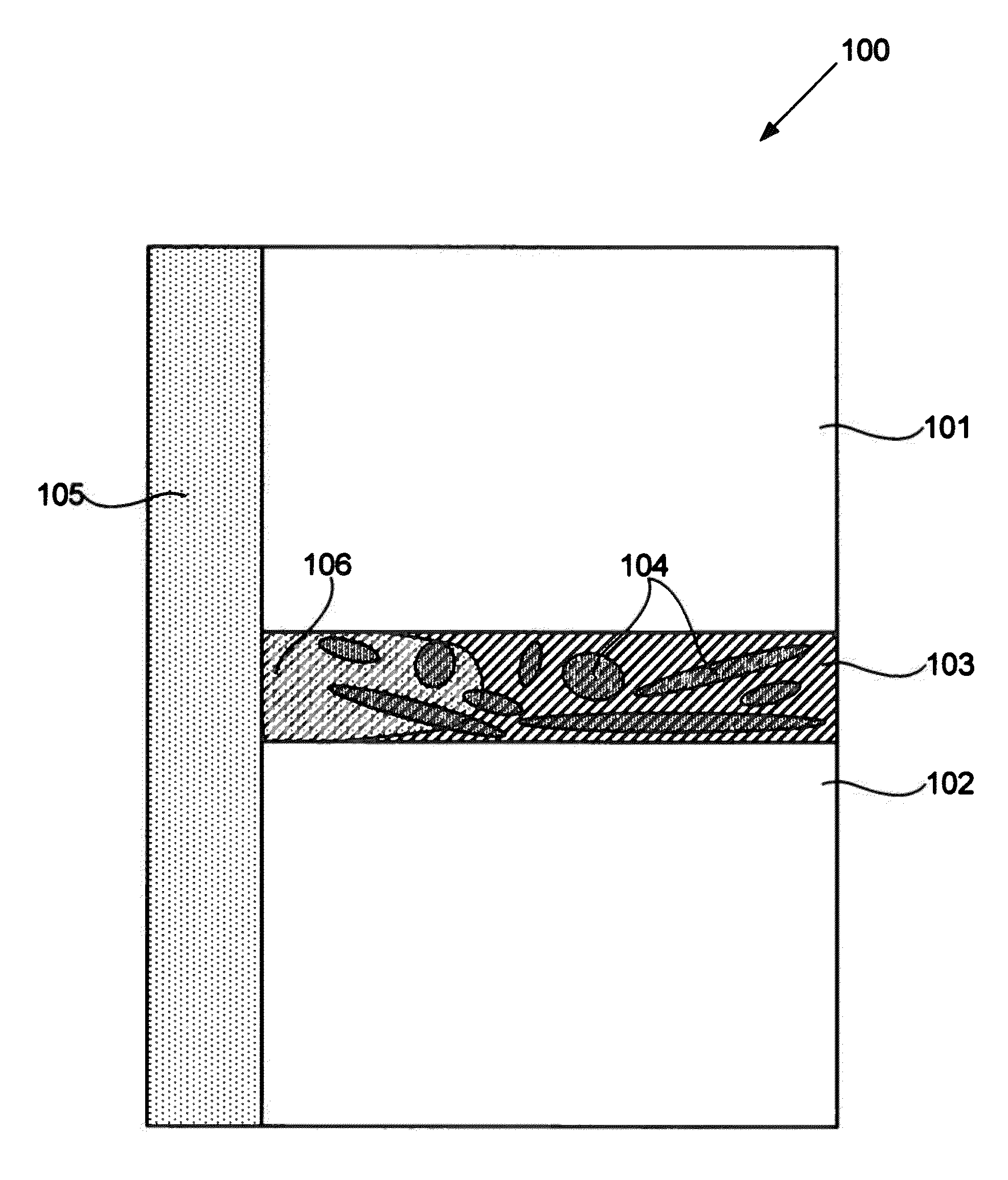

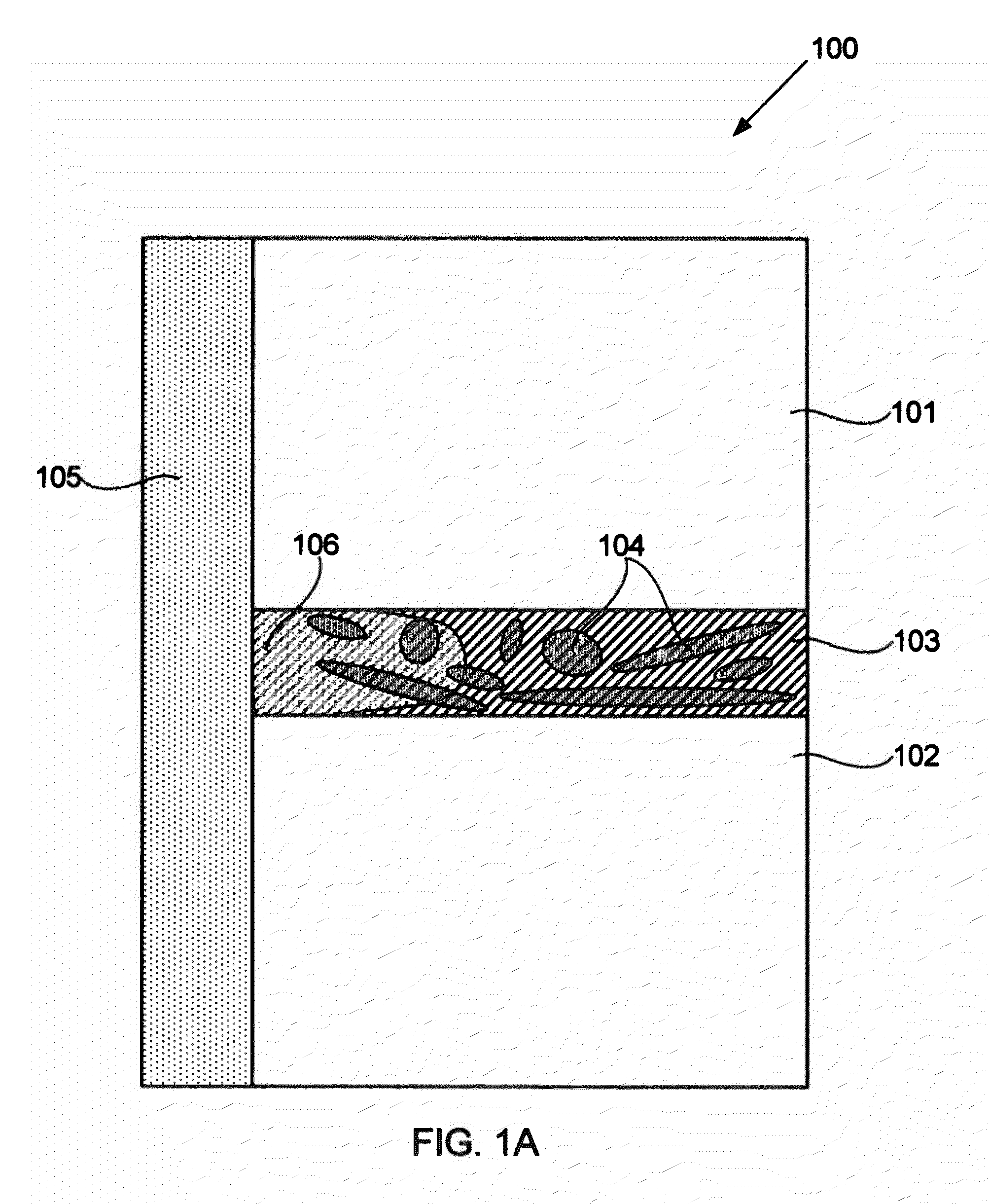

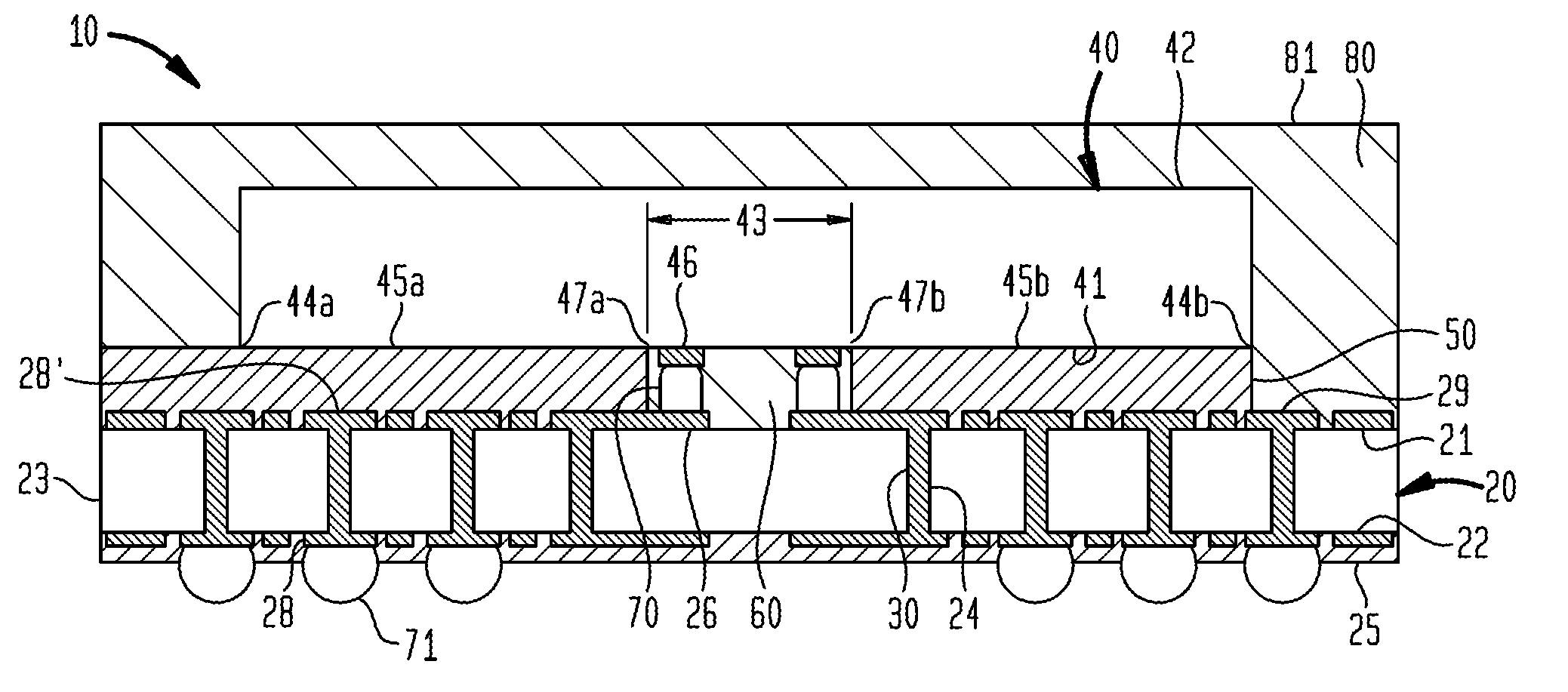

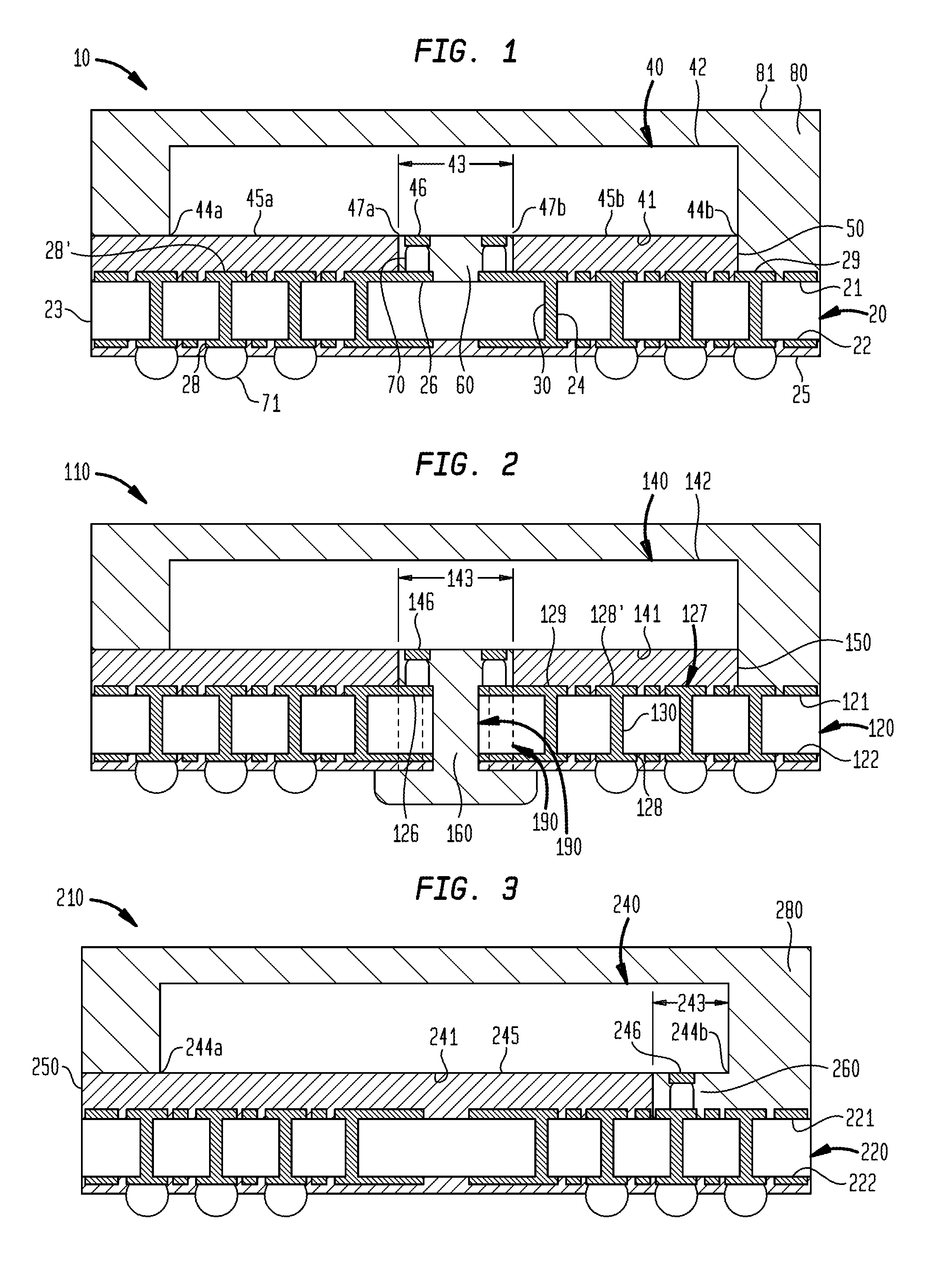

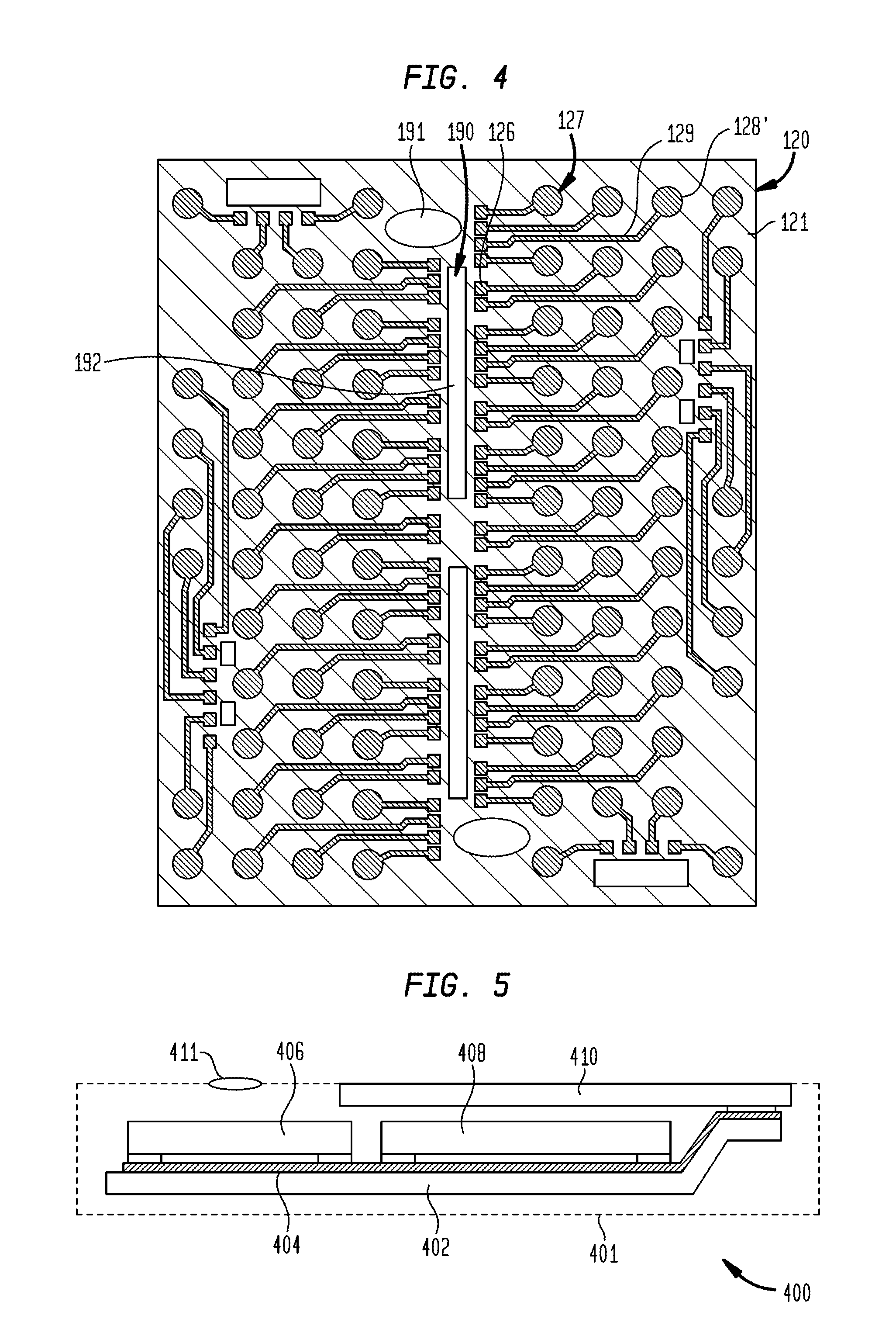

Flip chip package for DRAM with two underfill materials

ActiveUS8637992B2Reinforced jointsSemiconductor/solid-state device detailsSolid-state devicesEngineeringYoung's modulus

A microelectronic package can include a substrate having a first surface and a plurality of substrate contacts at the first surface and a microelectronic element having a front surface and contacts arranged within a contact-bearing region of the front surface. The contacts of the microelectronic element can face the substrate contacts and can be joined thereto. An underfill can be disposed between the substrate first surface and the contact-bearing region of the front surface of the microelectronic element. The underfill can reinforce the joints between the contacts and the substrate contacts. A joining material can bond the substrate first surface with the front surface of the microelectronic element. The joining material can have a Young's modulus less than 75% of a Young's modulus of the underfill.

Owner:INVENSAS CORP

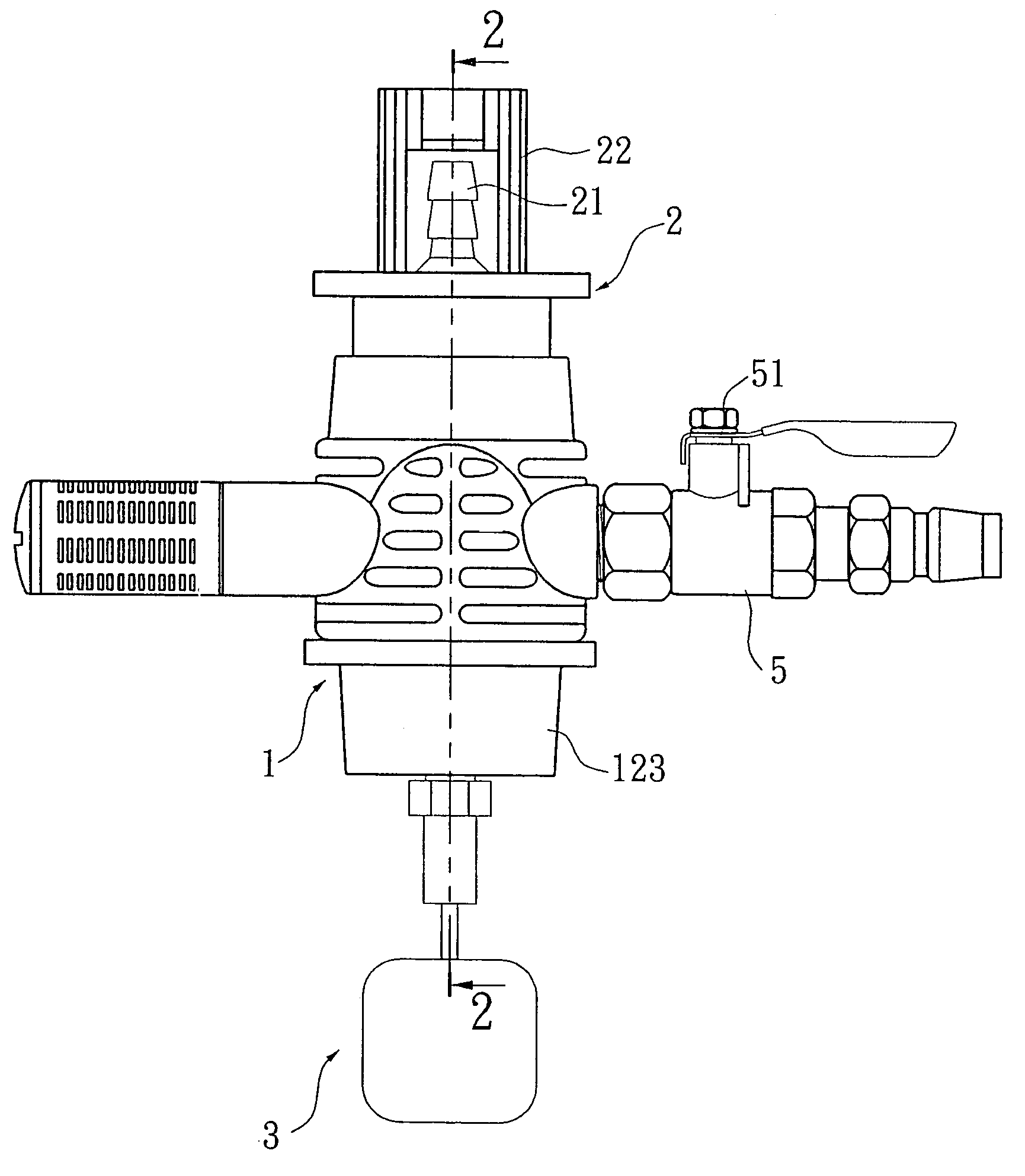

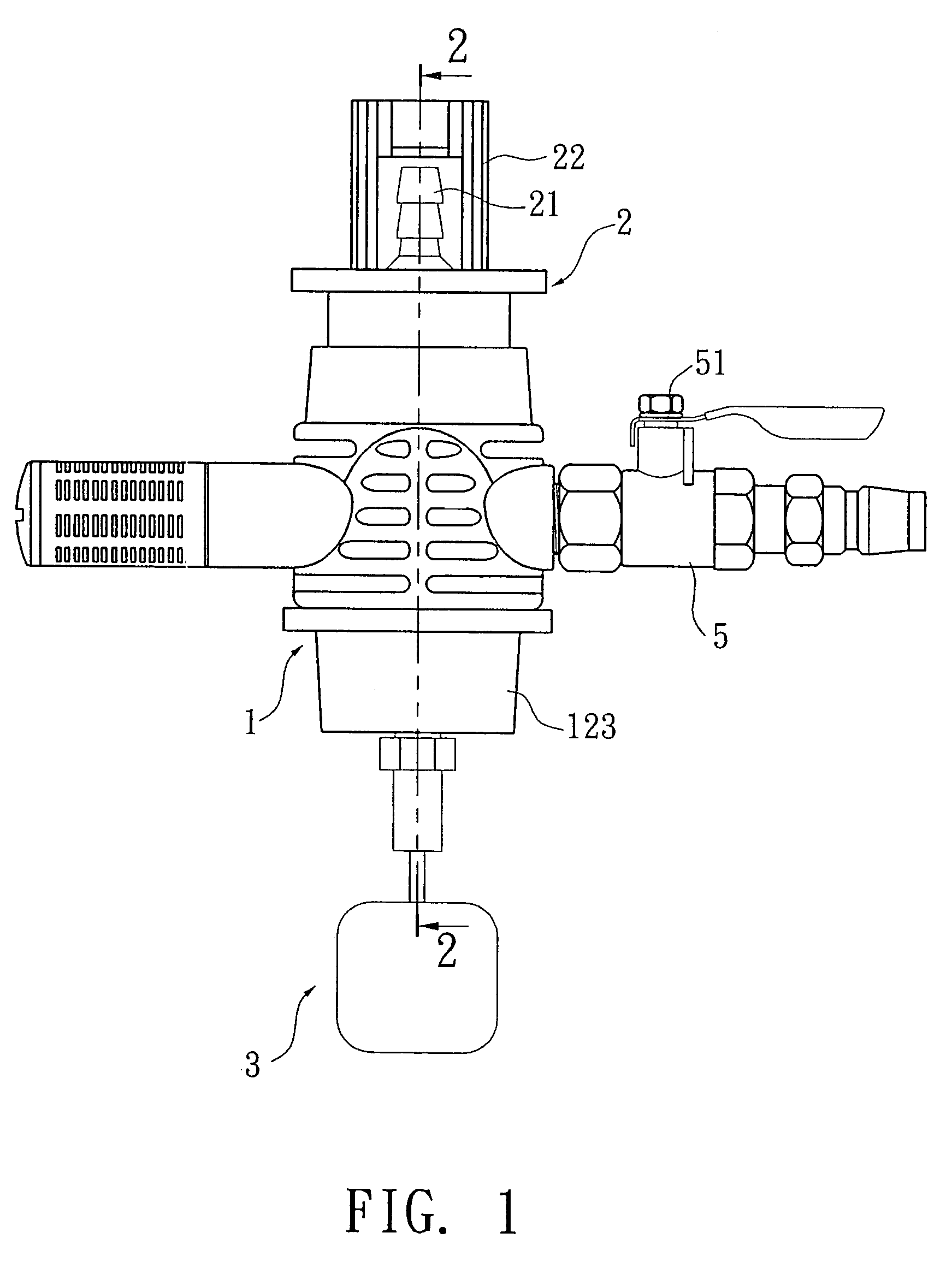

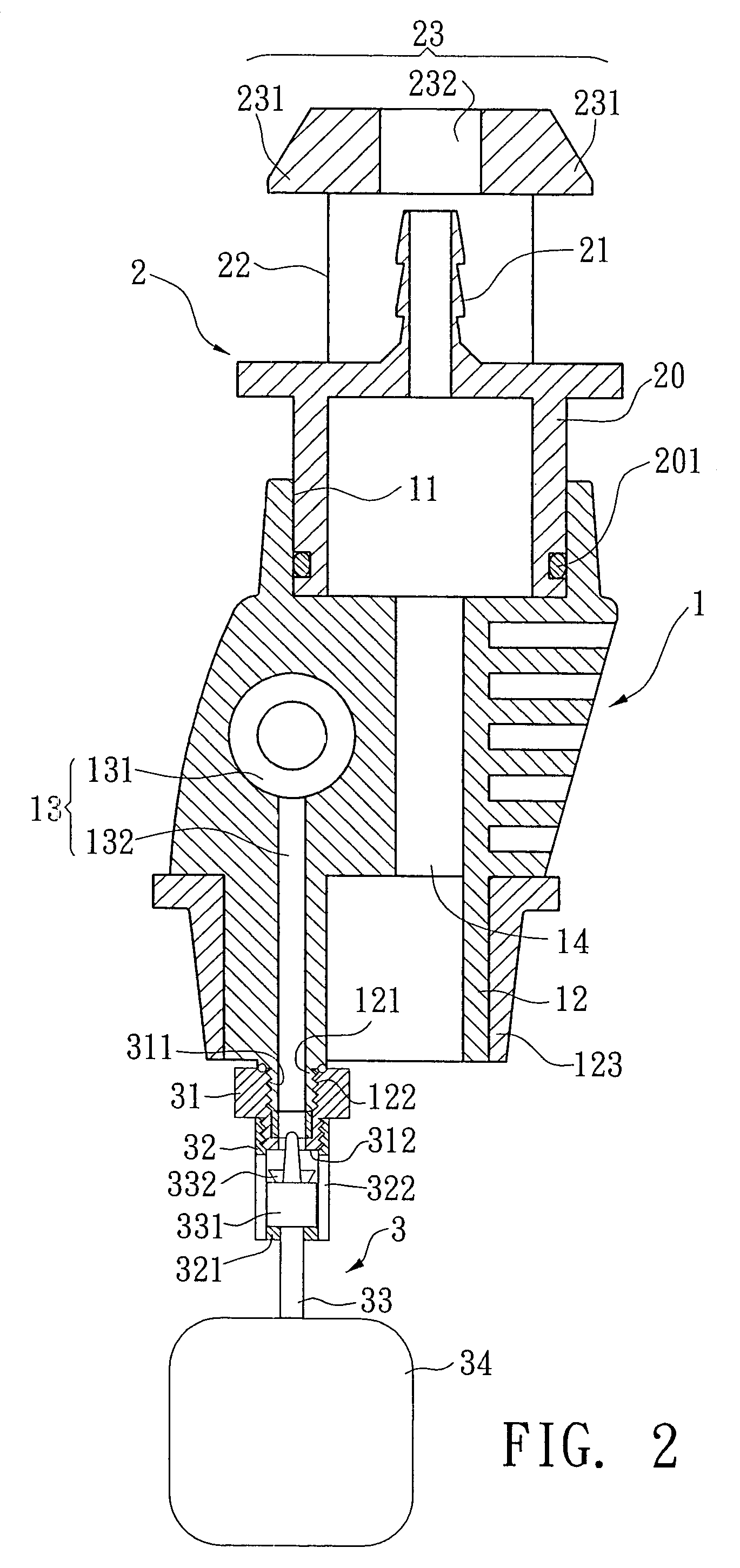

Joint for a fluid pumping apparatus

InactiveUS7104290B2Reinforced jointsSleeve/socket jointsFilling using suctionEngineeringCompressed air

A joint for a fluid pumping apparatus includes a body having a passage defined in the body and extending through the body. A through hole is longitudinally defined in the body and extends through the body. A container is mounted to a lower end of the body, and the passage and the through hole communicate with the interior of the container. A connecting seat in mounted to an upper end of the body and has hollow connector communicating with the through hole in the body. A hose has a first end connected to the hollow connector and a second extending into a pail containing fluid. Consequently, the fluid in the pail can be sucked into the container when a compressed air flows through the passage in the body.

Owner:TSENG TIEN TSAI

Component catch for crash robustness

Systems are disclosed to restrain movement of engine components in the event of a collision. A system may comprise an upper intake manifold; a cam cover; a shear catch located between the upper intake manifold and the cam cover; an upper component of the shear catch is arranged on the upper intake manifold; a lower component of the shear catch is arranged on the cam cover; and the upper component and the lower component are arranged opposite each other such that they engage when the upper intake manifold is subjected to shear forces. Variations to the size, arrangement, and shape of a shear catch are disclosed herein.

Owner:FORD GLOBAL TECH LLC

Method for producing a hollow profile joint and a hollow profile

InactiveUS20110274484A1Easy to controlGood welding performanceMetal rolling stand detailsSoldering apparatusEngineeringHollow core

In a method for producing a joint between a hollow profile made from steel and a component made from an aluminum material, a positive and material joint is produced by a braze welding process in conjunction with a pressing operation. The hollow profile is first pressed on a seating region of the component. Subsequently, a weld layer with an additive is applied by thermal joining, producing a positive and material joint between the hollow profile and the component. The positive joint is facilitated by first forming an end of the hollow profile to be pressed on. Preferably, forming is done by widening the end to be pressed on into the shape of a collar.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com