Friction stir welding process having enhanced corrosion performance

a friction stir welding and corrosion performance technology, applied in the field of structural joints, can solve the problems of difficult to achieve the effect of reducing the number of welding operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030]Embodiments of the present invention are illustrated in the FIGS., like numerals being used to refer to like and corresponding parts of the various drawings.

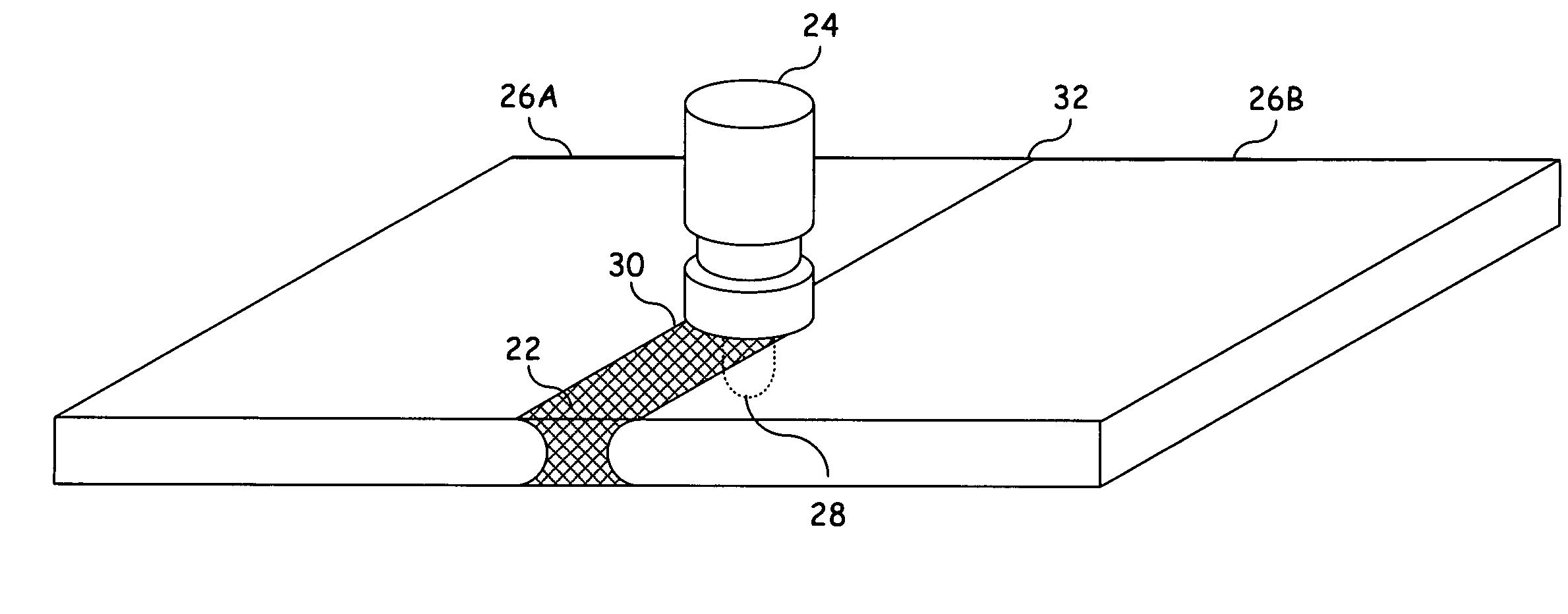

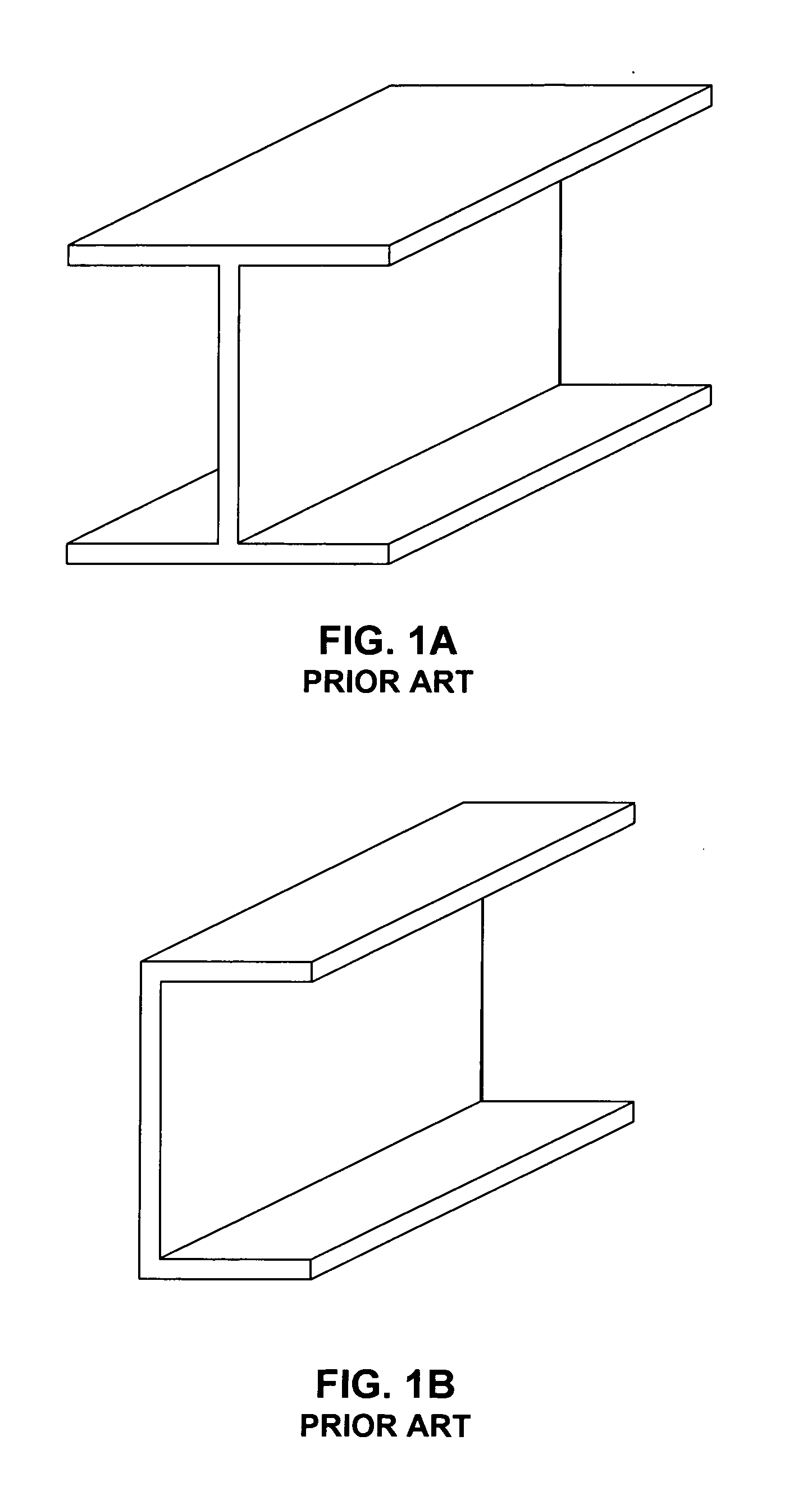

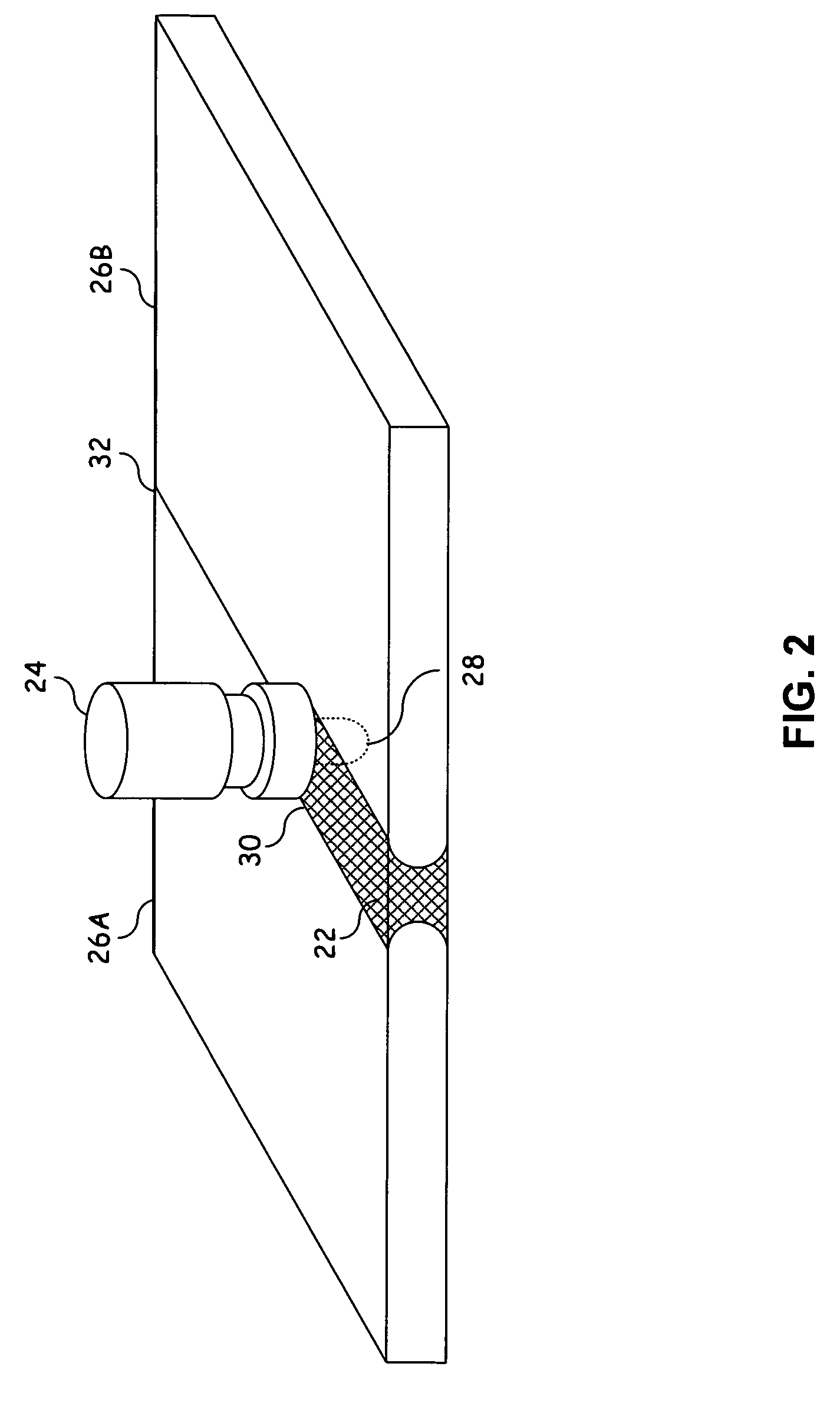

[0031]The present invention provides a means of joining a first structural member and a second structural member that substantially addresses the above identified needs. A three dimensional joint is formed by coupling (joining) a first structural member and a second structural member. This involves first aligning a first structural member to a second structural member. The first structural member has a channel with which to receive a portion of the second structural member. Certain embodiments may place corrosively inert materials within the mating surfaces to prevent or inhibit corrosion or oxidation. Once aligned, the first structural member and second structural member may be friction stir welded at the channel to plasticize the material adjacent to the channel of both the first structural member and the second structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com