Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Reduce the "shuttle effect"" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for preparing lithium sulfur battery modified anode

The invention relates to a preparation for a lithium sulfur battery modified anode material. The preparation includes mixing sublimed sulfur and a conductive agent according to a mass ratio of 6:3, adding absolute ethyl alcohol, performing ball milling for 6 hours, drying in a vacuum drying box for 12 hours at the temperature of 50 DEG C to 80 DEG C to obtain a mixture, mixing the mixture and hollow nickel fiber tubes according to a mass ratio of (5-9):1, adding an adhesive, dispersing in a dispersing agent, stirring to obtain slurry, coating the slurry on a metal aluminum foil which is subjected to acetone ultrasonic cleaning, and drying in the vacuum drying box for 12 hours at the temperature of 60 DEG C to obtain the lithium sulfur battery anode material. The preparation for the lithium sulfur battery modified anode material has the advantages that electrochemistry performances of battery cyclicity and the like are improved, and the performances and cyclic service life of the battery can be improved.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Preparation method of positive electrode material of lithium sulfur battery

ActiveCN108172795ASimple preparation processImprove cycle performanceMaterial nanotechnologyCell electrodesDoped grapheneOxygen

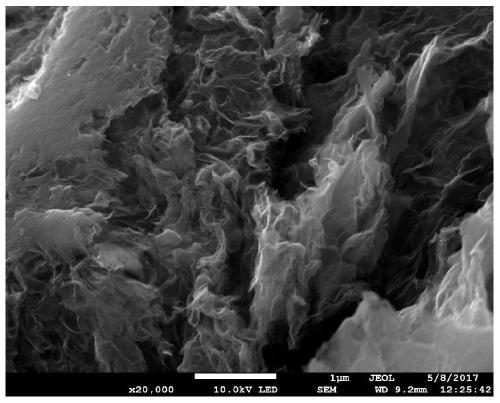

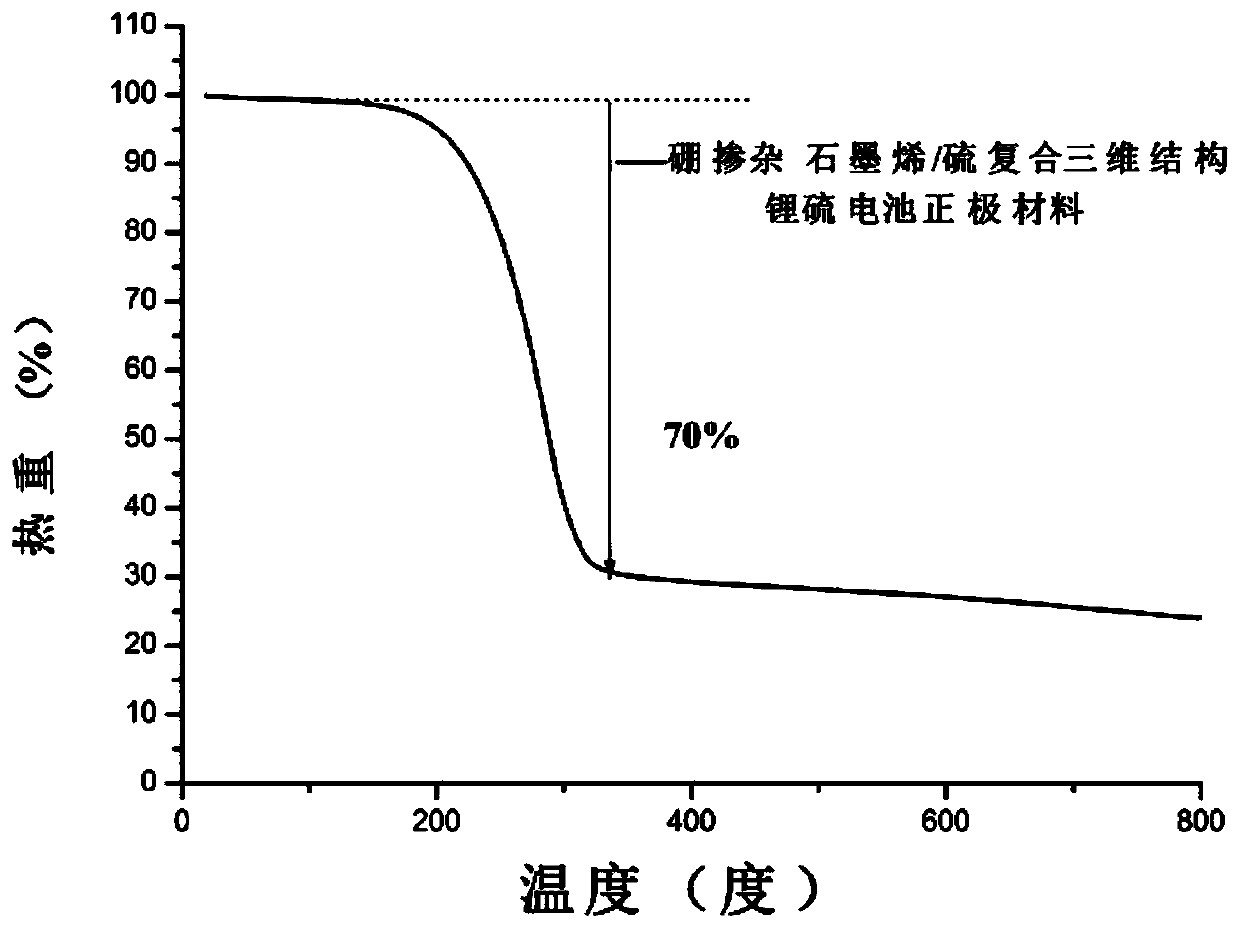

The invention discloses a preparation method of a positive electrode material of a lithium sulfur battery. The preparation method comprises the following steps of putting graphene oxide, nanometer sulfur powder, boric acid and urea into a ball milling tank, performing ball milling and then adding into deionized water to obtain a mixture solution, performing ultrasonic wave dispersion at a normal temperature for 1-3h to obtain a mixed suspension liquid, and carrying out a spray drying process to prepare a boron nitrogen oxygen co-doped graphene / sulfur composite three-dimensional structured positive electrode material of the lithium sulfur battery. The boron nitrogen oxygen co-doped graphene / sulfur compound obtained in the invention has a simple and convenient preparation process; and through the simple spray drying process, the loosening and porous structure is manufactured, a relatively large specific surface area is obtained, and performance for bearing a large amount of elementary nanometer sulfur powder is further achieved, thereby improving the sulfur content of the positive electrode material.

Owner:INT ACAD OF OPTOELECTRONICS AT ZHAOQING SOUTH CHINA NORMAL UNIV

Lithium-sulfur battery composite positive electrode material and preparation method thereof

InactiveCN106532016ASimple methodNo complicated operationsCell electrodesLead zirconate titanateBarium titanate

The invention discloses a lithium-sulfur battery composite positive electrode material. Graphene oxide is used as a matrix of the battery positive electrode material, a graphene / ferroelectric composite material is obtained after the graphene oxide and a ferroelectric material are compounded, and then the graphene / ferroelectric composite material is mixed with nano sulfur according to a mass ratio of 3:7 to prepare the lithium-sulfur battery composite positive electrode material; and the ferroelectric material is one of barium titanate, lead titanate, potassium niobate, strontium titanate, lithium niobate or lead zirconate titanate. According to the lithium-sulfur battery composite positive electrode material disclosed by the invention, excellent electrical conductivity and structural stability of the graphene oxide are utilized, and the graphene oxide is used as an excellent conductive network and the positive electrode matrix, so that electrical conductivity of the positive electrode material is improved; and by utilizing strong adsorption of ferroelectricity of the ferroelectric material on polar polysulfide, dissolution and shuttling of the polysulfide in electrolyte are inhibited, so that loss of active substances is reduced, coulombic efficiency of a lithium-sulfur battery is improved and a cycle life of the lithium-sulfur battery is prolonged.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Sulfur-loaded modified graphene aerogel and preparation method and application thereof

ActiveCN106450209AReduce dissolutionReduce swellingCell electrodesLi-accumulatorsClelands ReagentHigh conductivity

The invention provides a sulfur-loaded modified graphene aerogel and a preparation method and application thereof, and relates to the technical field of battery materials. The sulfur-loaded modified graphene aerogel comprises nitrogenous macromolecular monomers, thiophene monomers, boric acid, graphene oxide, a dispersing agent and dithiothreitol. The advantages of large specific surface area and high conductivity of a graphene aerogel are utilized, a sulfur source is controlled to attach to the surface of the graphene oxide in a form of polythiophene, and the formed elemental sulfur can be uniformly dispersed in a conductive network established by the graphene aerogel, so that loading is stable, dissolving-out of the elemental sulfur during cycling is reduced, the swelling problem of an anode of a lithium sulfur battery is solved, and cycling performance of the lithium sulfur battery can be improved further.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Compound diaphragm for lithium-sulfur battery

InactiveCN106848165AReduce the shuttle effectExtend your lifeCell component detailsChemistryCyclohexanes

The invention provides a compound diaphragm for a lithium-sulfur battery. The diaphragm is prepared by the following steps of: (1) adding MoS2 powder into a hexane solution of n-butyllithium, performing a stirring reaction, performing filtration, and washing the solution with cyclohexane and water to obtain laminar MoS2; and (2) adding graphite oxide and the laminar MoS2 into water for ultrasonic dispersion to form a suspended liquid, then adding the suspended liquid into a suction flask padded with a Celgard diaphragm and filter paper, and drying the suction flask, and tearing off the filter paper to obtain the compound diaphragm for the lithium-sulfur battery. The laminar MoS2 in a laminar MoS2 / graphene oxide layer can form severe chemical absorption on polysulfide formed in the charging and discharging processes, and can effectively prevent the polysulfide from penetrating through the diaphragm to reach a cathode to reduce a shuttle flying effect, so that the service life of the lithium-sulfur battery is prolonged.

Owner:SHENZHEN PEICHENG TECH CO LTD

Ammonia-modified carbon quantum dot and preparation method thereof, and application of ammonia-modified carbon quantum dot in lithium-sulfur battery electrolyte

ActiveCN110518285AImprove cycle performanceDissolution inhibitionLi-accumulatorsSecondary cells servicing/maintenanceModified carbonLithium–sulfur battery

The invention provides an ammonia-modified carbon quantum dot, a preparation method thereof and an application of the ammonia-modified carbon quantum dot in a lithium-sulfur battery electrolyte. An aldehyde compound is placed in an alkaline solution for reaction to obtain a carbon quantum dot, and the obtained carbon quantum dot and ammonia water are subjected to a reflux reaction to obtain an ammonia-modified carbon quantum dot. The ammonia-modified carbon quantum dot is used as an additive to be applied to a lithium-sulfur battery electrolyte, dissolution of polysulfide can be effectively inhibited, a shuttle effect is reduced, and the cycle performance of the lithium-sulfur battery is greatly improved.

Owner:CENT SOUTH UNIV

Preparation method for composite conductive polymer coated with elemental sulfur and applications

ActiveCN105355876AReduce dissolutionReduce swellingCell electrodesSecondary cellsLithium–sulfur batteryConductive polymer

The invention discloses a preparation method for a composite conductive polymer coated with elemental sulfur and applications, and belongs to the electrochemical energy storage field. Concretely, a suspension containing pyrrole, aniline and thiophene monomers and elemental sulfur is employed as a supporting electrolyte, a platinum electrode is employed as an auxiliary electrode, aluminum foil is employed as a working electrode, a saturated calomel electrode is employed as a reference electrode, electrochemical parameters are adjusted, and polymerization of conductive polymer monomers is controlled while aggregation of elemental sulfur can be controlled synchronously. A polypyrrole / polyaniline / polythiophene composite conductive polymer film coated with elemental sulfur can be formed on the surface of the aluminum foil, and elemental sulfur can be bonded with polythiophene through S-S bonds. The composite conductive polymer film coated with elemental sulfur can be used as a positive pole piece of a lithium-sulfur battery directly, and the aluminum foil is employed as a positive pole current collector. The technology omits a combination process of elemental sulfur and a conductive polymer, and omits a later preparation process of introducing bonding agents during the pole piece preparation process. Operation is simple, and the swelling problem of a positive pole of a lithium-sulfur battery can be solved effectively.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Preparation method of graphene/activated carbon microsphere

InactiveCN108383106ALarge specific surface areaGood dispersionHybrid capacitor electrodesCell electrodesMicrosphereCarbonization

The invention discloses a preparation method of a graphene / activated carbon microsphere. The graphene / activated carbon microsphere prepared by the method has the characteristics of spherical structure, large specific surface area and good dispersion, and effectively improves the electrochemical performance of cathode materials. The preparation method of the graphene / activated carbon microsphere includes ultrasonic dispersion, atomization pyrolysis, atomization drying and carbonization, integrates the whole production process, effectively controls the molding of the graphene / activated carbon microsphere, and ensures the material quality. The preparation method has the advantages of simple operation, low cost, energy saving and environmental protection. The prepared graphene / activated carbonmicrosphere has a large specific surface area, not only can be used for electrode materials, and also can be applied to catalyst carriers, water treatment, sewage purification, solvent adsorption andrecovery and other related fields, and has great application prospects.

Owner:HUNAN GUOSHENG GRAPHITE TECH CO LTD

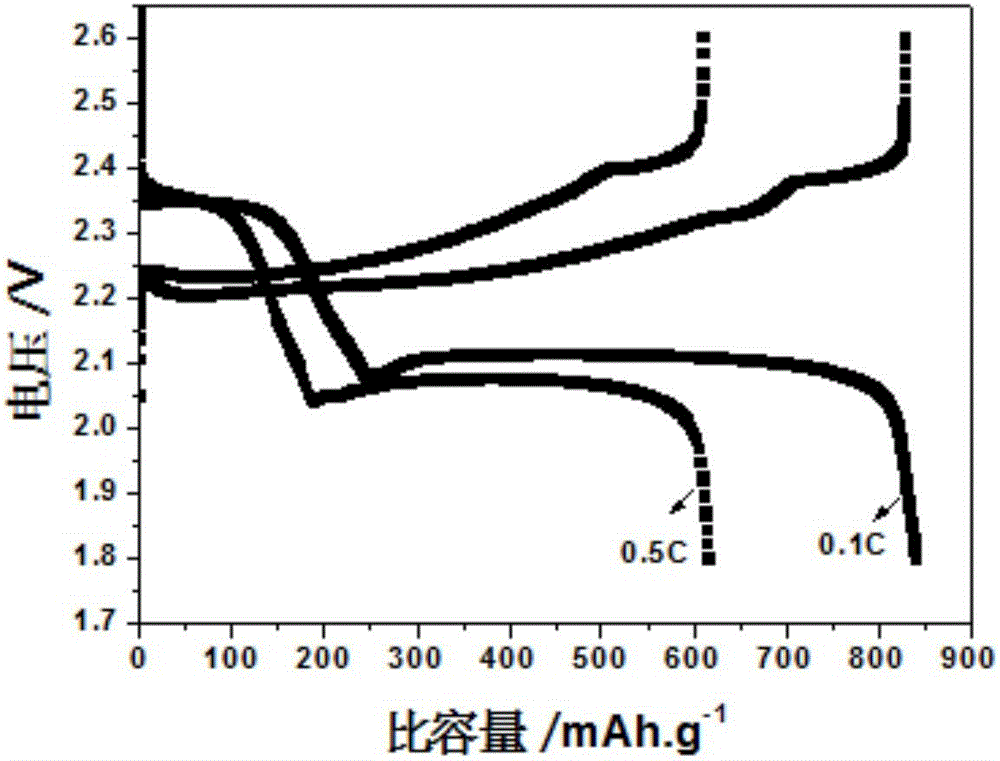

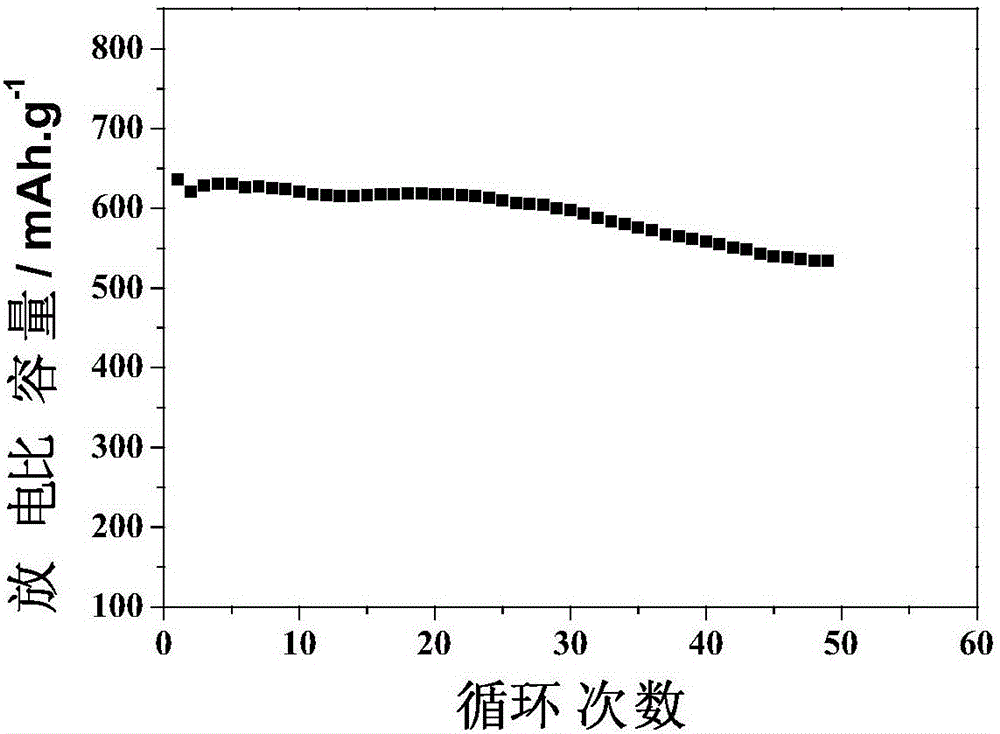

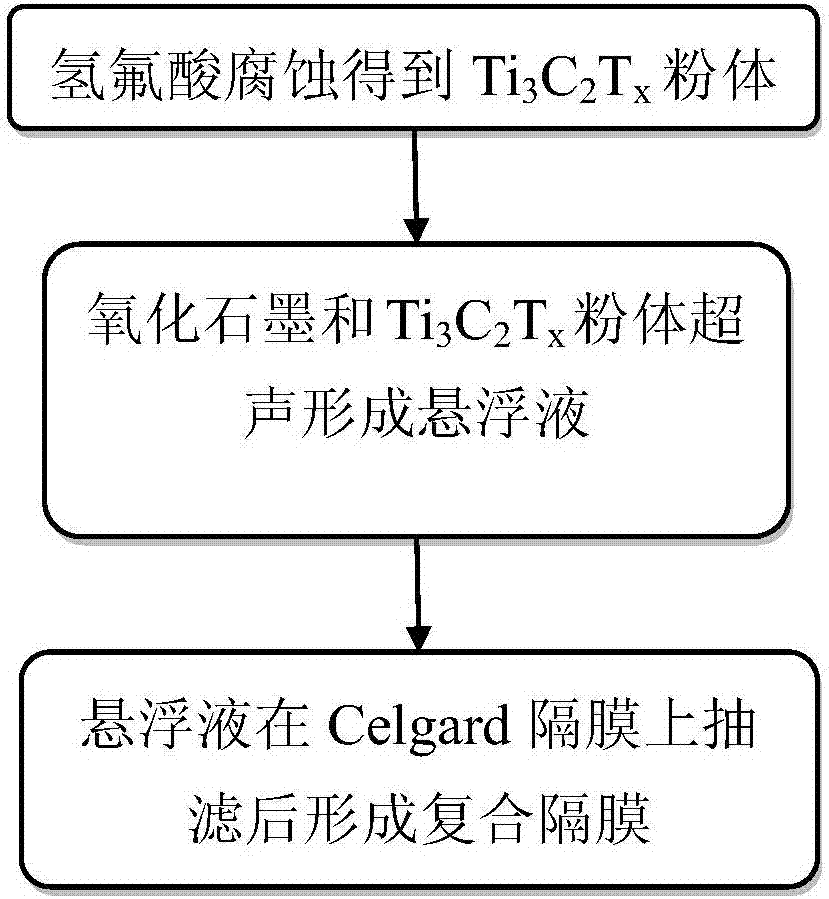

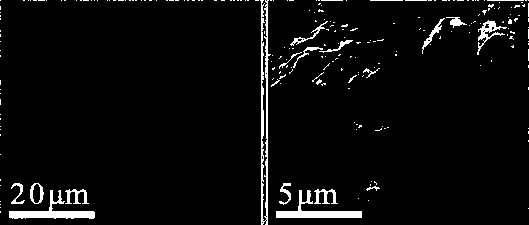

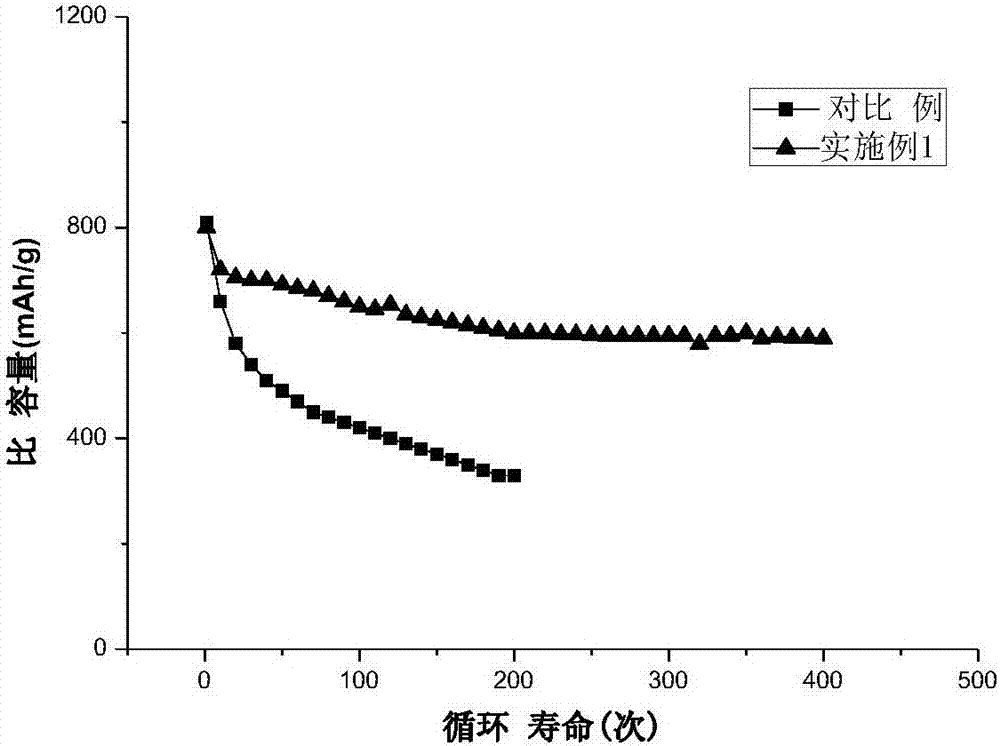

Ti3C2Tx/oxidized graphene/Celgard composite membrane

InactiveCN106972141AReduce the shuttle effectExtend your lifeCell component detailsCharge and dischargeGraphite oxide

The invention provides a Ti3C2Tx / oxidized graphene / Celgard composite membrane. The Ti3C2Tx / oxidized graphene / Celgard composite membrane comprises a Celgard membrane and a Ti3C2Tx / oxidized graphene layer on the surface of the Celgard membrane, wherein the thickness of the Ti3C2Tx / oxidized graphene layer is 1 to 10 microns; and the mass ratio of Ti3C2Tx to oxidized graphene in the Ti3C2Tx / oxidized graphene layer is 1: (0.2 to 1). T on Ti3C2Tx in the Ti3C2Tx / oxidized graphene layer is -F group or -OH group, and is a strongly polar group together with oxygen on the surface of the oxidized graphene, strong chemical adsorption can be formed with a polysulfide formed in the charging and discharging process, the polysulfide can be effectively prevented from passing through the membrane to reach a positive electrode, the occurrence of a shuttle flying effect is reduced, and the service life of a lithium-sulfur battery is prolonged.

Owner:SHENZHEN PEICHENG TECH CO LTD

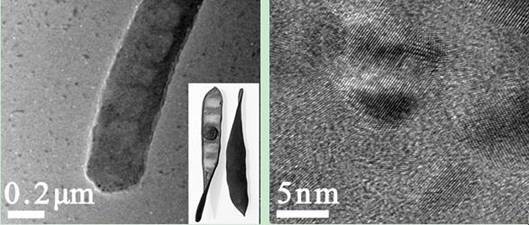

Preparation method of ordered nano-array nitrogen-sulfur double-doped compound carbon rod material and lithium-sulfur battery

ActiveCN109671923AReduce the "shuttle effect"Improve electrochemical performanceMaterial nanotechnologySecondary cellsEnvironmental resistanceSulfur

The invention belongs to the technical field of electrode materials and discloses a preparation method of an ordered nano-array nitrogen-sulfur double-doped compound carbon rod material. The preparation method of the ordered nano-array nitrogen-sulfur double-doped compound carbon rod material comprises the following steps of S1, preparing an ordered nano-array precursor carbon rod; S2, preparing an ordered nano-carbon rod array; S3, preparing the ordered nano-array nitrogen-sulfur double-doped compound carbon rod material. The ordered nano-array nitrogen-sulfur double-doped compound carbon rodmaterial is applied as the anode material of a lithium / sulfur ion battery. The anode material of the lithium / sulfur ion battery prepared from the ordered nano-array nitrogen-sulfur double-doped compound carbon rod material is better in morphology and performance than common carbon materials and can achieve high first discharge specific capacity and a high capacity retention ratio; meanwhile, thepreparation method of the ordered nano-array nitrogen-sulfur double-doped compound carbon rod material is simple, easy to implement, low in cost, green and environmentally friendly and has a good application prospect.

Owner:HUNAN UNIV OF TECH

Ti3C2Tx/PVDF (polyvinylidene fluoride)/Celgard composite membrane

InactiveCN106876637AReduce the shuttle effectExtend your lifeCell component detailsPolyvinylidene fluorideChemistry

The invention provides a Ti3C2Tx / PVDF (polyvinylidene fluoride) / Celgard composite membrane which comprises a commercial Celgard membrane and a Ti3C2Tx / PVDF layer on the surface of the commercial Celgard membrane, wherein the thickness of the Ti3C2Tx / PVDF layer is 1 to 10 mu m; the mass ratio of Ti3C2Tx to PVDF in the Ti3C2Tx / PVDF layer is 1 to (0.01 to 0.1). T on the Ti3C2Tx is an -F group or an -OH group, and any of the -F group and the -OH group is a strong-polar group and can generate strong chemical adsorption for polysulfides produced in charge and discharge processes and effectively prevent the polysulfides from penetrating through the membrane and reaching a negative electrode, thus reducing occurrence of the shuttle flying effect and prolonging the service life of a lithium-sulfur battery.

Owner:SHENZHEN PEICHENG TECH CO LTD

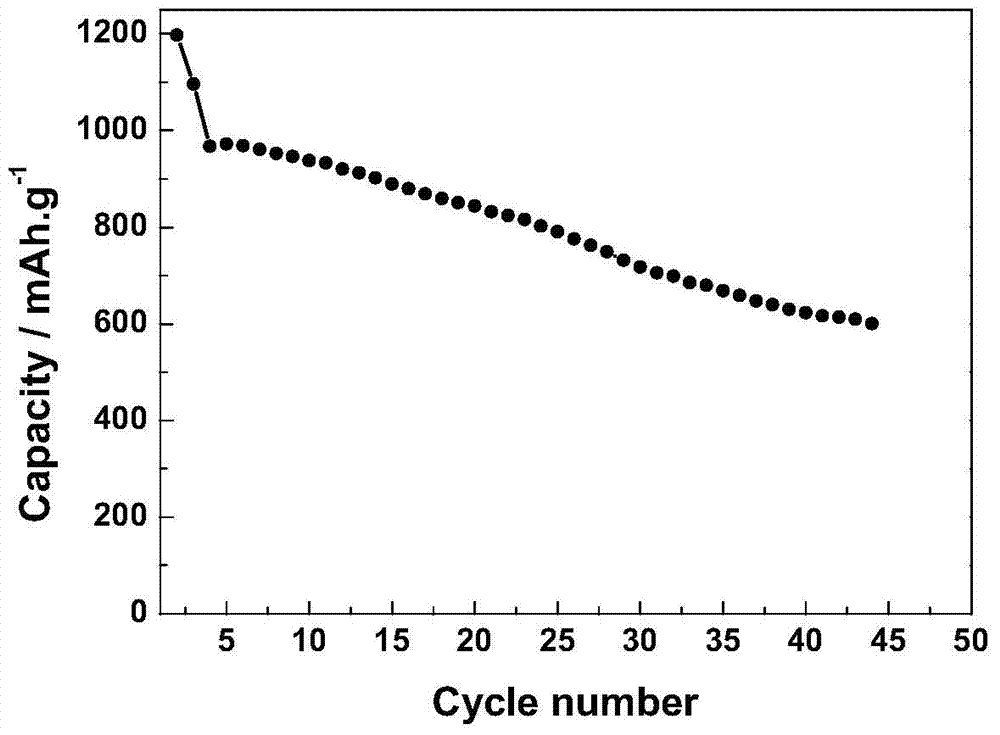

Lithium sulphur battery taking graphene coated carbon nanofiber/sulphur composite material as anode material

InactiveCN108281629AReduce the "shuttle effect"Improve electrochemical performanceNegative electrodesLi-accumulatorsEnvironmental resistanceMetallic lithium

The invention discloses a lithium sulphur battery taking a graphene coated carbon nanofiber / sulphur composite material as an anode material. Carbon nanofiber / sulphur composite microparticle material,acetylene black and PVDF are uniformly mixed in NMP according to a mass ratio of 80:10:10 and an aluminum foil is coated with the mixture, so as to form an anode piece, and a metallic lithium piece taken as a cathode is assembled into a button battery in a glove box; electrolyte adopts 1 M LiTFSI / DOL-DME; the volume ratio is 1:1; a membrane adopts a celgard 2400 microporous membrane. The lithium sulphur battery has high first specific discharge capacity, and is good in capacity retention ratio, the preparation method is simple and practical, the cost is low, and the battery is green and environmentally friendly, and has an excellent application prospect.

Owner:HUNAN GUOSHENG GRAPHITE TECH CO LTD

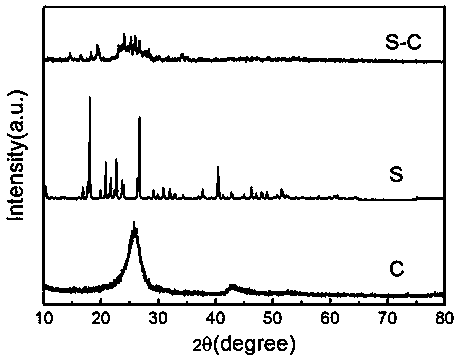

Graphene coated carbon/sulfur composite material and preparation method thereof

The invention discloses a preparation method of a graphene coated carbon / sulfur composite material. The method includes: mixing carbon nanofiber with starch evenly, then adding deionized water, and conducting ultrasonic dispersion to obtain an evenly mixed solution; then subjecting the dispersed mixed solution to atomization by an ultrasonic atomizer to form uniformly dispersed fog beads, then bringing the fog beads into a tube furnace by inert gas for drying spheroidizing treatment and carbonizing treatment in order, thus obtaining carbon microspheres; then mixing the obtained carbon microspheres with elemental sulfur for heat treatment to obtain carbon / sulfur composite microspheres; and finally mixing the obtained carbon / sulfur composite microspheres with a graphene oxide aqueous solution, then adding a reducing agent for reduction so as to obtain the graphene coated carbon / sulfur composite material. The graphene coated carbon / sulfur composite material provided by the invention has high first discharge specific capacity and good capacity retention rate when used as a lithium-sulfur battery cathode material, also has the advantages of simple and feasible preparation method, low cost, and green and environmental protection, thus having good application prospects.

Owner:HUNAN GUOSHENG GRAPHITE TECH CO LTD

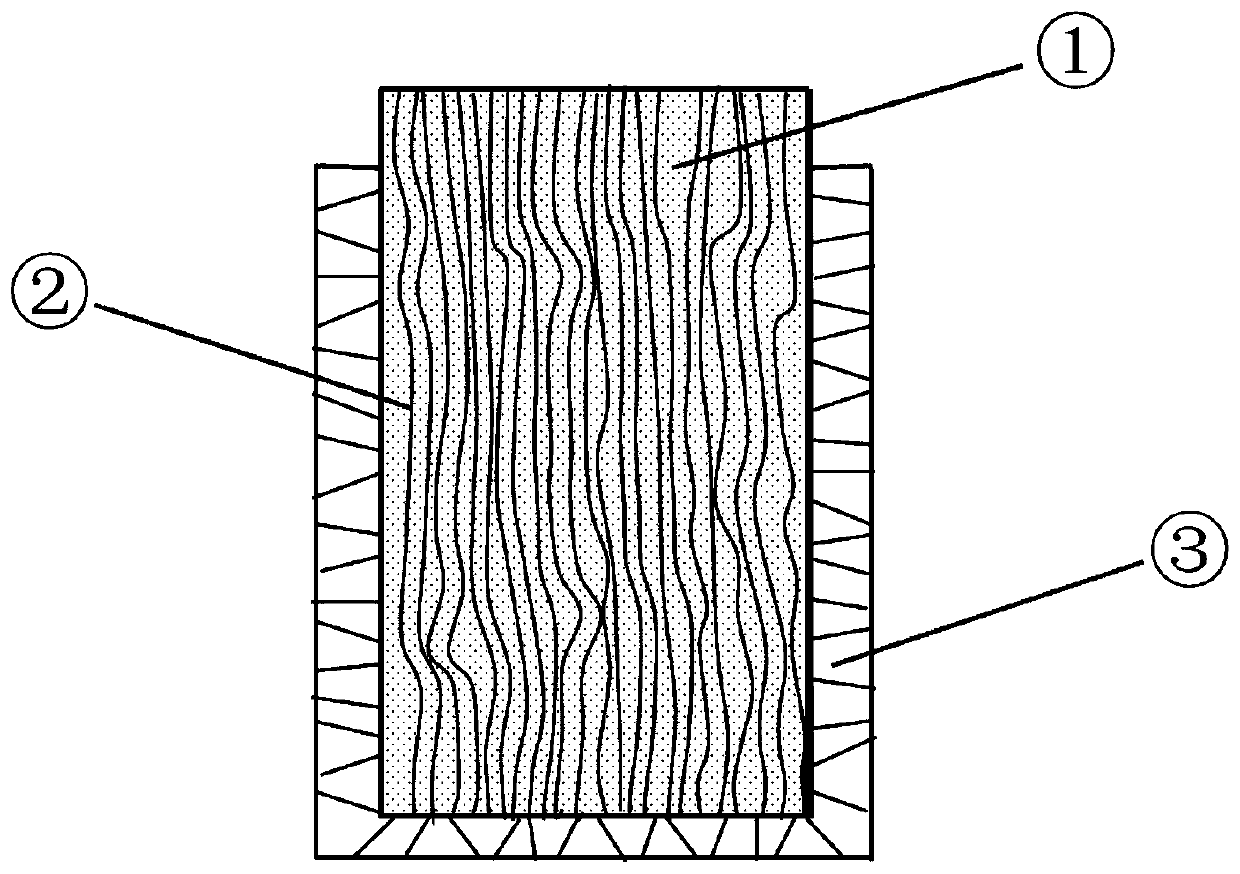

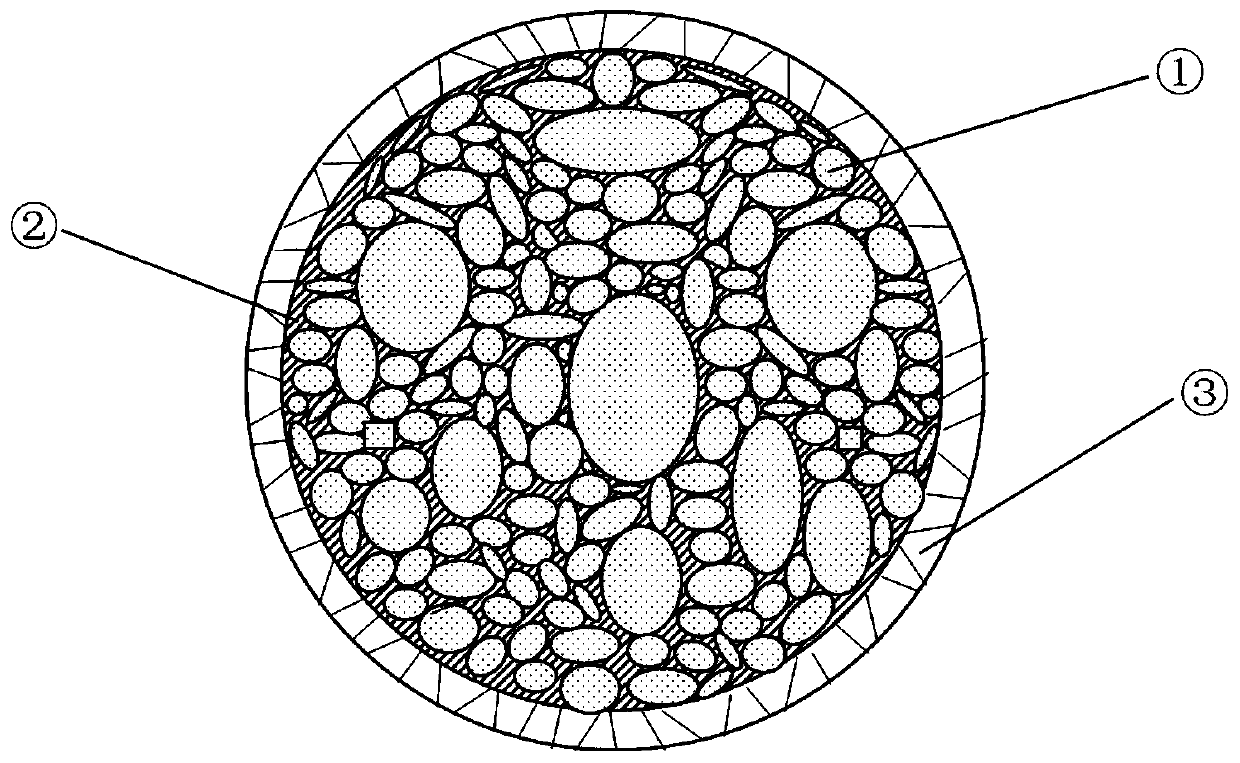

Preparation method and application of sulfur positive electrode of full-wood structure

ActiveCN110165144AExtended service lifeReduce the "shuttle effect"Positive electrodesLi-accumulatorsElectrical batteryLithium–sulfur battery

The invention relates to a preparation method and application of a cylindrical sulfur positive electrode of a full-wood structure, and belongs to the technical field of lithium-sulfur battery positiveelectrode materials. The invention provides the brand-new lithium-sulfur battery positive electrode structure and the preparation method and application thereof in order to overcome the defects thatin the prior art, a lithium-sulfur battery positive electrode can generate large volume strain in the charging and discharging process, a shuttle effect can occur between the positive electrode and the negative electrode, and the like. A porous cylindrical wood block carrier obtained through carbonization treatment is employed, and the porous cylindrical wood block carrier has rich long and thin micro-channels, so the loading capacity of sulfur can be remarkably improved, the volume effect generated in the charging and discharging process can be relieved, and the damages to the electrode structure are reduced; in addition, a carbon material skeleton is used as a conductive network, so that the conductivity of the positive electrode material can be improved, and the cycle stability and ratecapability of the battery are improved; the protective sleeve prepared by the invention can be used as an electrode diaphragm, and also has a certain inhibition effect on the shuttle effect of polysulfide.

Owner:ZHEJIANG UNIV OF TECH

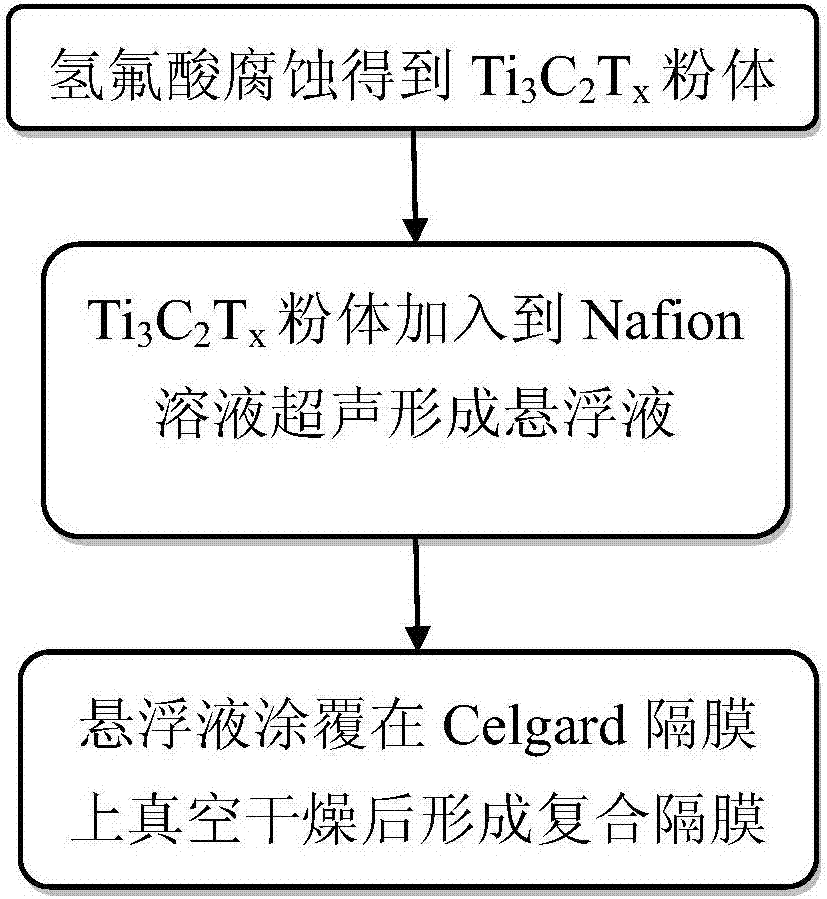

Ti3C2Tx/Nafion/Celgard composite diaphragm

InactiveCN107017376AReduce the shuttle effectExtend your lifeSecondary cell gas removalCell component detailsChemistryChemical adsorption

The invention provides a Ti3C2Tx / Nafion / Celgard composite diaphragm. The composite diaphragm comprises a Celgard diaphragm and a Ti3C2Tx / Nafion layer on the surface of the Celgard diaphragm, wherein the thickness of the Ti3C2Tx / Nafion layer is 1-10 microns, and the mass ratio of Ti3C2Tx to Nafion in the Ti3C2Tx / Nafion layer is (0.05-0.5) to 1. T in Ti3C2Tx in the Ti3C2Tx / Nafion layer represents a -F group or a -OH group, and the -F group or the -OH group and a -F group on a Nafion membrane are strong-polar groups and are capable of generating strong chemical adsorption to polysulfide generated in a charging-discharging process and effectively preventing polysulfide from penetrating the diaphragm to reach a cathode, so that a shuttle effect is reduced, and the service life of a lithium-sulfur battery is prolonged.

Owner:SHENZHEN PEICHENG TECH CO LTD

Preparation method and application of composite conductive polymer-coated elemental sulfur

ActiveCN105355876BReduce dissolutionReduce swellingCell electrodesSecondary cellsSupporting electrolytePolypyrrole

The invention discloses a preparation method for a composite conductive polymer coated with elemental sulfur and applications, and belongs to the electrochemical energy storage field. Concretely, a suspension containing pyrrole, aniline and thiophene monomers and elemental sulfur is employed as a supporting electrolyte, a platinum electrode is employed as an auxiliary electrode, aluminum foil is employed as a working electrode, a saturated calomel electrode is employed as a reference electrode, electrochemical parameters are adjusted, and polymerization of conductive polymer monomers is controlled while aggregation of elemental sulfur can be controlled synchronously. A polypyrrole / polyaniline / polythiophene composite conductive polymer film coated with elemental sulfur can be formed on the surface of the aluminum foil, and elemental sulfur can be bonded with polythiophene through S-S bonds. The composite conductive polymer film coated with elemental sulfur can be used as a positive pole piece of a lithium-sulfur battery directly, and the aluminum foil is employed as a positive pole current collector. The technology omits a combination process of elemental sulfur and a conductive polymer, and omits a later preparation process of introducing bonding agents during the pole piece preparation process. Operation is simple, and the swelling problem of a positive pole of a lithium-sulfur battery can be solved effectively.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

A kind of graphene coated carbon composite material and preparation method thereof

InactiveCN108390024BGood dispersionNo reunionCell electrodesSecondary cellsCarbon compositesElectrolytic agent

The invention discloses a preparation method of a graphene coated carbon composite material. The method adopts sucrose, carbon fiber and graphene as the raw materials, and carries out ultrasonic dispersion, ultrasonic sprayer atomization and carbonization to effectively control the structural morphology of the composite material. The preparation method enables graphene to coat the carbon compositematerial so as to form a core-shell structure conductive network. On the one hand, the conductive network can better provide a channel for migration of ions and electrons, and improves the conductivity of positive electrode materials; and on the other hand, coating of the composite material surface with graphene can further inhibit the dissolution of a reduction product and improve the cycle performance of positive electrode materials. The graphene coated carbon composite material prepared by the method can load more elemental sulfur and hinder the dissolution of a polysulfide in an electrolyte solution when used for preparation of lithium-sulfur batteries, and then can reduce the "shuttle flying effect" of lithium-sulfur batteries, thereby improving the electrochemical performance of positive electrode materials.

Owner:HUNAN GUOSHENG GRAPHITE TECH CO LTD

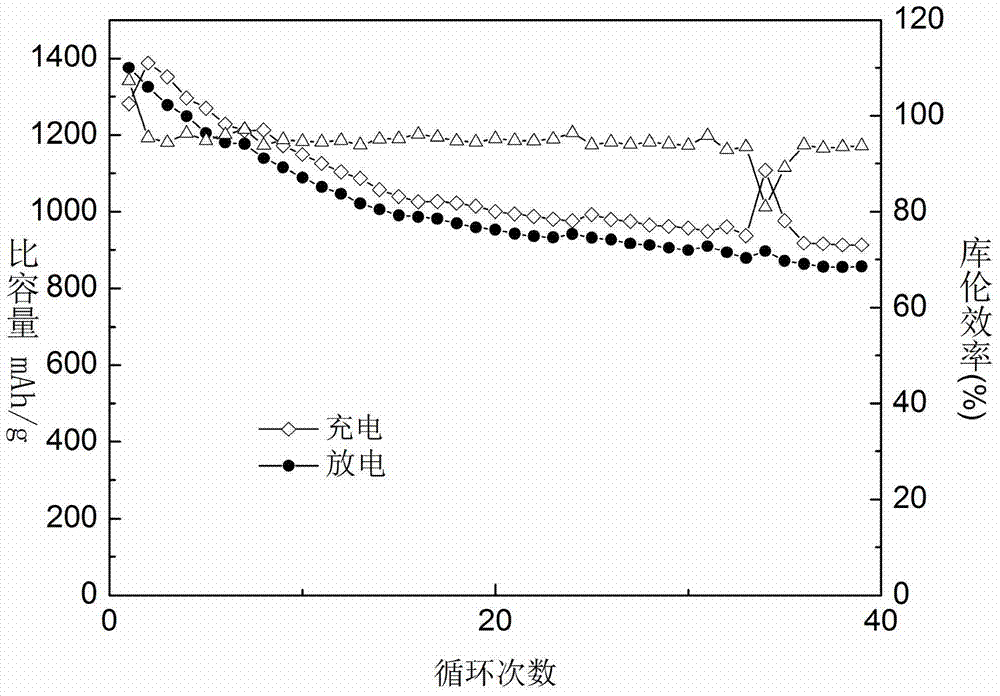

Lithium-sulfur batteries using graphene-coated carbon/sulfur composites as cathode materials

InactiveCN108258220BGood dispersionHinder dissolutionPositive electrodesLi-accumulatorsMetallic lithiumElectrolytic agent

The invention discloses a lithium-sulfur battery using a graphene coated carbon / sulfur composite material as a positive electrode material. The preparation method comprises the following steps: uniformly mixing a carbon / sulfur composite microsphere material, acetylene black and PVDF (Polyvinylidene Fluoride) in NMP (N-Methyl Pyrrolidone) according to a mass ratio of 80:10:10, coating the mixture onto an aluminum foil to prepare a positive pole piece; taking a metal lithium wafer as a negative electrode, and assembling into a button battery in a glove box, wherein the electrolyte is 1 MLiTFSI / DOL-DME, the volume ratio is 1:1, and the diaphragm is a celgard 2400 microporous membrane. The lithium-sulfur battery disclosed by the invention has high first discharging specific capacity, and the capacity retention ratio is excellent. Moreover, the preparation method is simple, feasible, low in cost, green and environmental-friendly, and has excellent application prospects.

Owner:HUNAN GUOSHENG GRAPHITE TECH CO LTD

A kind of ammonia-modified carbon quantum dots and its preparation method and application in lithium-sulfur battery electrolyte

ActiveCN110518285BHigh content of active groupsLow costLi-accumulatorsSecondary cells servicing/maintenanceElectrolytic agentModified carbon

The invention provides an ammonia-modified carbon quantum dot and its preparation method and its application in the electrolyte of lithium-sulfur batteries. The aldehyde compound is placed in an alkaline solution to react to obtain carbon quantum dots, and the obtained carbon quantum dots and ammonia water Reflux reaction to obtain ammonia-modified carbon quantum dots. Applying ammonia-modified carbon quantum dots as an additive to the electrolyte of lithium-sulfur batteries can effectively inhibit the dissolution of polysulfide compounds, reduce the "shuttle effect", and greatly improve the cycle performance of lithium-sulfur batteries.

Owner:CENT SOUTH UNIV

Process for preparing lithium sulfur battery modified anode

The invention relates to a preparation for a lithium sulfur battery modified anode material. The preparation includes mixing sublimed sulfur and a conductive agent according to a mass ratio of 6:3, adding absolute ethyl alcohol, performing ball milling for 6 hours, drying in a vacuum drying box for 12 hours at the temperature of 50 DEG C to 80 DEG C to obtain a mixture, mixing the mixture and hollow nickel fiber tubes according to a mass ratio of (5-9):1, adding an adhesive, dispersing in a dispersing agent, stirring to obtain slurry, coating the slurry on a metal aluminum foil which is subjected to acetone ultrasonic cleaning, and drying in the vacuum drying box for 12 hours at the temperature of 60 DEG C to obtain the lithium sulfur battery anode material. The preparation for the lithium sulfur battery modified anode material has the advantages that electrochemistry performances of battery cyclicity and the like are improved, and the performances and cyclic service life of the battery can be improved.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Lithium-sulfur battery using graphene coated carbon/sulfur composite material as positive electrode material

InactiveCN108258220AGood dispersionHinder dissolutionPositive electrodesLi-accumulatorsMicrosphereButton battery

The invention discloses a lithium-sulfur battery using a graphene coated carbon / sulfur composite material as a positive electrode material. The preparation method comprises the following steps: uniformly mixing a carbon / sulfur composite microsphere material, acetylene black and PVDF (Polyvinylidene Fluoride) in NMP (N-Methyl Pyrrolidone) according to a mass ratio of 80:10:10, coating the mixture onto an aluminum foil to prepare a positive pole piece; taking a metal lithium wafer as a negative electrode, and assembling into a button battery in a glove box, wherein the electrolyte is 1 MLiTFSI / DOL-DME, the volume ratio is 1:1, and the diaphragm is a celgard 2400 microporous membrane. The lithium-sulfur battery disclosed by the invention has high first discharging specific capacity, and the capacity retention ratio is excellent. Moreover, the preparation method is simple, feasible, low in cost, green and environmental-friendly, and has excellent application prospects.

Owner:HUNAN GUOSHENG GRAPHITE TECH CO LTD

Titanium dioxide-coated lithium-sulfur battery positive electrode material and preparation method thereof

ActiveCN105304932BImprove cycle stabilityReduce the "shuttle effect"Non-aqueous electrolyte accumulator electrodesLi-accumulatorsFiberTio2 nanotube

The invention discloses a titanium dioxide-coated lithium sulphur battery anode material and a preparation method thereof, used for solving the technical problem that an existing lithium sulphur battery anode material is low in specific discharge capacity. The technical scheme is that the anode material is prepared from sulphur, a carbon fiber sheet and a titanium dioxide casing. The preparation method comprises the steps of adsorbing a gas sulfur elementary substance by adopting the carbon fiber sheet, then using titanium dioxide to coat a mixture of the carbon fiber sheet and the sulfur elementary substance by adopting a titanium tetrachloride hydrolysis method, drying, cleaning, and drying again to obtain the titanium dioxide-coated lithium sulphur battery anode material. As elementary substance sulfur particles evenly cover the surface of the carbon fiber sheet and are externally coated by TiO2 evenly, the strong adsorption fixing capacity of the microcosmic structure of the carbon fiber sheet and the TiO2 to a polysulfide buffers volume change before and after sulfur lithiation and can limit the polysulfide generated in the charging and discharging processes of a lithium sulphur battery in a TiO2 nanotube, so that the specific discharge capacity and the cycling stability of the lithium sulphur battery are remarkably improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

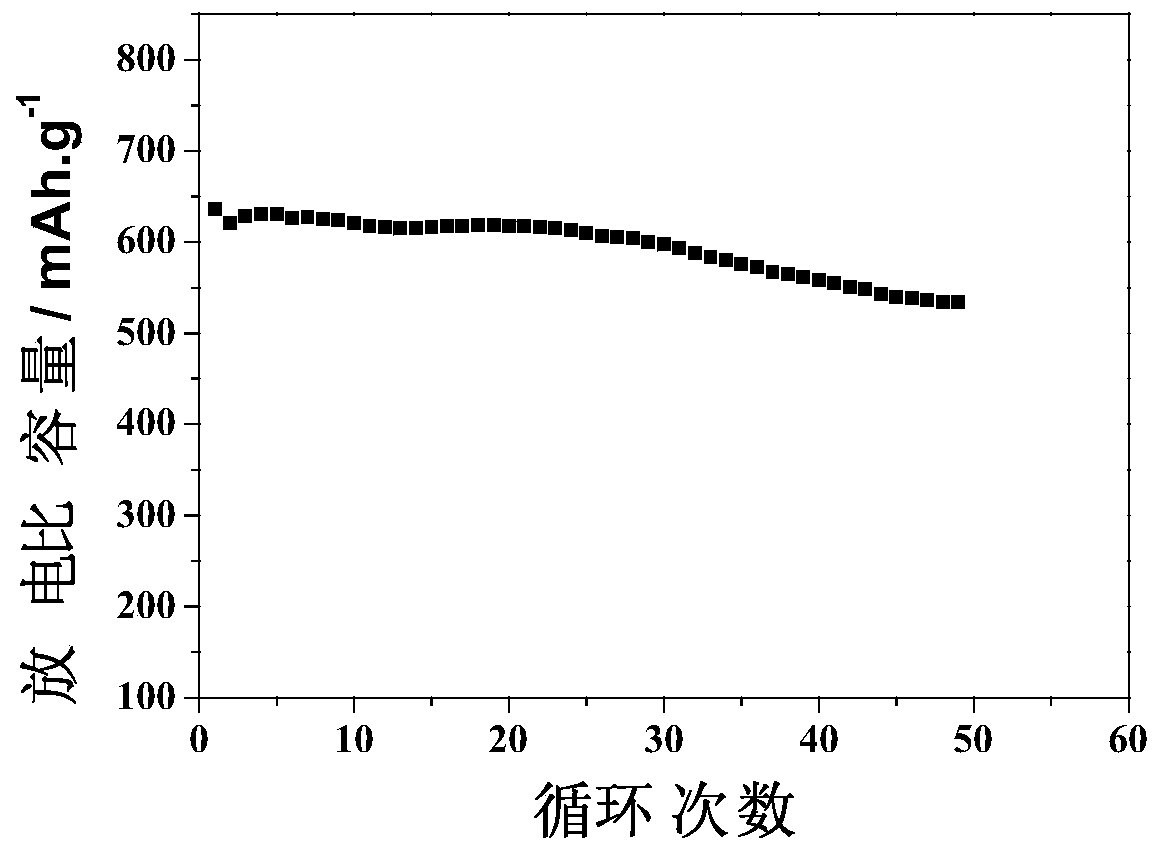

A kind of preparation method of wool spherical carbon/sulfur composite microsphere material and lithium-sulfur battery

The invention discloses a method for preparing carbon / sulfur composite micro-sphere materials in the shapes of woolen yarn balls and a lithium-sulfur battery. Carbon micro-spheres in the shapes of woolen yarn balls can be prepared by the aid of electrostatic spinning processes, and sulfur can be loaded in the carbon micro-spheres to prepare carbon / sulfur composite micro-spheres for positive electrode materials for lithium / sulfur ion batteries. The method for preparing the carbon / sulfur composite micro-spheres includes stirring selected fibrous carbon materials or fibrous carbon precursors andbinders in solvents in a shear-type manner and uniformly dispersing the fibrous carbon materials or the fibrous carbon precursors and the binders in the solvents; carrying out electrostatic spinning treatment to obtain carbon precursor micro-spheres in the shapes of woolen yarn balls; carrying out carbonization treatment to obtain the carbon micro-spheres in the shapes of the woolen yarn balls. The obtained carbon micro-spheres in the shapes of the woolen yarn balls and the elemental sulfur are heated in a tube furnace to obtain the carbon / sulfur composite micro-sphere materials, and the carbon / sulfur composite micro-sphere materials can be used as the positive electrode materials for the lithium-sulfur battery. The method and the lithium-sulfur battery have the advantages that the positive electrode materials prepared from the carbon and composite materials for the lithium / sulfur ion batteries are excellent in morphology and performance as compared with conventional carbon materials and are high in first specific discharge capacity and excellent in capacity retention ratio when used as the positive electrode materials for the lithium-sulfur battery; the method is simple, feasibleand environmentally friendly, is low in cost and has an excellent application prospect.

Owner:HUNAN UNIV OF TECH

A kind of graphene-coated carbon/sulfur composite material and preparation method thereof

The invention discloses a preparation method of a graphene coated carbon / sulfur composite material. The method includes: mixing carbon nanofiber with starch evenly, then adding deionized water, and conducting ultrasonic dispersion to obtain an evenly mixed solution; then subjecting the dispersed mixed solution to atomization by an ultrasonic atomizer to form uniformly dispersed fog beads, then bringing the fog beads into a tube furnace by inert gas for drying spheroidizing treatment and carbonizing treatment in order, thus obtaining carbon microspheres; then mixing the obtained carbon microspheres with elemental sulfur for heat treatment to obtain carbon / sulfur composite microspheres; and finally mixing the obtained carbon / sulfur composite microspheres with a graphene oxide aqueous solution, then adding a reducing agent for reduction so as to obtain the graphene coated carbon / sulfur composite material. The graphene coated carbon / sulfur composite material provided by the invention has high first discharge specific capacity and good capacity retention rate when used as a lithium-sulfur battery cathode material, also has the advantages of simple and feasible preparation method, low cost, and green and environmental protection, thus having good application prospects.

Owner:HUNAN GUOSHENG GRAPHITE TECH CO LTD

A kind of lithium-sulfur battery composite cathode material and preparation method thereof

InactiveCN106532016BSimple methodNo complicated operationsCell electrodesStrontium titanateLead zirconate titanate

The invention discloses a lithium-sulfur battery composite positive electrode material. Graphene oxide is used as a matrix of the battery positive electrode material, a graphene / ferroelectric composite material is obtained after the graphene oxide and a ferroelectric material are compounded, and then the graphene / ferroelectric composite material is mixed with nano sulfur according to a mass ratio of 3:7 to prepare the lithium-sulfur battery composite positive electrode material; and the ferroelectric material is one of barium titanate, lead titanate, potassium niobate, strontium titanate, lithium niobate or lead zirconate titanate. According to the lithium-sulfur battery composite positive electrode material disclosed by the invention, excellent electrical conductivity and structural stability of the graphene oxide are utilized, and the graphene oxide is used as an excellent conductive network and the positive electrode matrix, so that electrical conductivity of the positive electrode material is improved; and by utilizing strong adsorption of ferroelectricity of the ferroelectric material on polar polysulfide, dissolution and shuttling of the polysulfide in electrolyte are inhibited, so that loss of active substances is reduced, coulombic efficiency of a lithium-sulfur battery is improved and a cycle life of the lithium-sulfur battery is prolonged.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

A modified graphene airgel loaded with sulfur and its preparation method and application

ActiveCN106450209BReduce dissolutionReduce swellingCell electrodesLi-accumulatorsCyclic processMonomer

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

A kind of preparation method of lithium-sulfur battery cathode material

ActiveCN108172795BSimple preparation processImprove cycle performanceMaterial nanotechnologyCell electrodesDoped grapheneElectrical battery

The invention discloses a preparation method of a positive electrode material of a lithium sulfur battery. The preparation method comprises the following steps of putting graphene oxide, nanometer sulfur powder, boric acid and urea into a ball milling tank, performing ball milling and then adding into deionized water to obtain a mixture solution, performing ultrasonic wave dispersion at a normal temperature for 1-3h to obtain a mixed suspension liquid, and carrying out a spray drying process to prepare a boron nitrogen oxygen co-doped graphene / sulfur composite three-dimensional structured positive electrode material of the lithium sulfur battery. The boron nitrogen oxygen co-doped graphene / sulfur compound obtained in the invention has a simple and convenient preparation process; and through the simple spray drying process, the loosening and porous structure is manufactured, a relatively large specific surface area is obtained, and performance for bearing a large amount of elementary nanometer sulfur powder is further achieved, thereby improving the sulfur content of the positive electrode material.

Owner:INT ACAD OF OPTOELECTRONICS AT ZHAOQING SOUTH CHINA NORMAL UNIV

A kind of graphene-coated carbon nanofiber/sulfur composite material and preparation method thereof

InactiveCN108417787BReduce the "shuttle effect"Improve electrochemical performanceCell electrodesLi-accumulatorsElectrical batteryMicrosphere

The invention discloses a preparation method of a graphene-coated carbon nanofiber / sulfur composite material. The preparation method comprises the steps of performing uniform mixing on carbon nanofibers and starch, and then adding deionized water and performing ultrasonic dispersion to obtain a uniform mixed solution; next, adopting an electrospinning technique to prepare the obtained mixed solution into carbon microspheres, and next, performing carbonizing treatment in an inert gas atmosphere to obtain spherical carbon microspheres; performing heat treatment on the obtained carbon microspheres and elementary sulfur to obtain carbon / sulfur composite microspheres; and finally, performing mixing on the obtained carbon / sulfur composite microspheres and a graphene oxide water solution and thenadding a reducing agent for reduction, performing stirring to realize complete reaction, and carrying out filtering and drying to obtain the graphene-coated carbon nanofiber / sulfur composite material. When the graphene-coated carbon nanofiber / sulfur composite material is used as the positive electrode material of a lithium-sulfur battery, high initial charging-discharging specific capacity and excellent capacity retention ratio are achieved; and in addition, the preparation method is simple and easy to implement, low in cost, green and environment friendly, and high in application prospect.

Owner:HUNAN GUOSHENG GRAPHITE TECH CO LTD

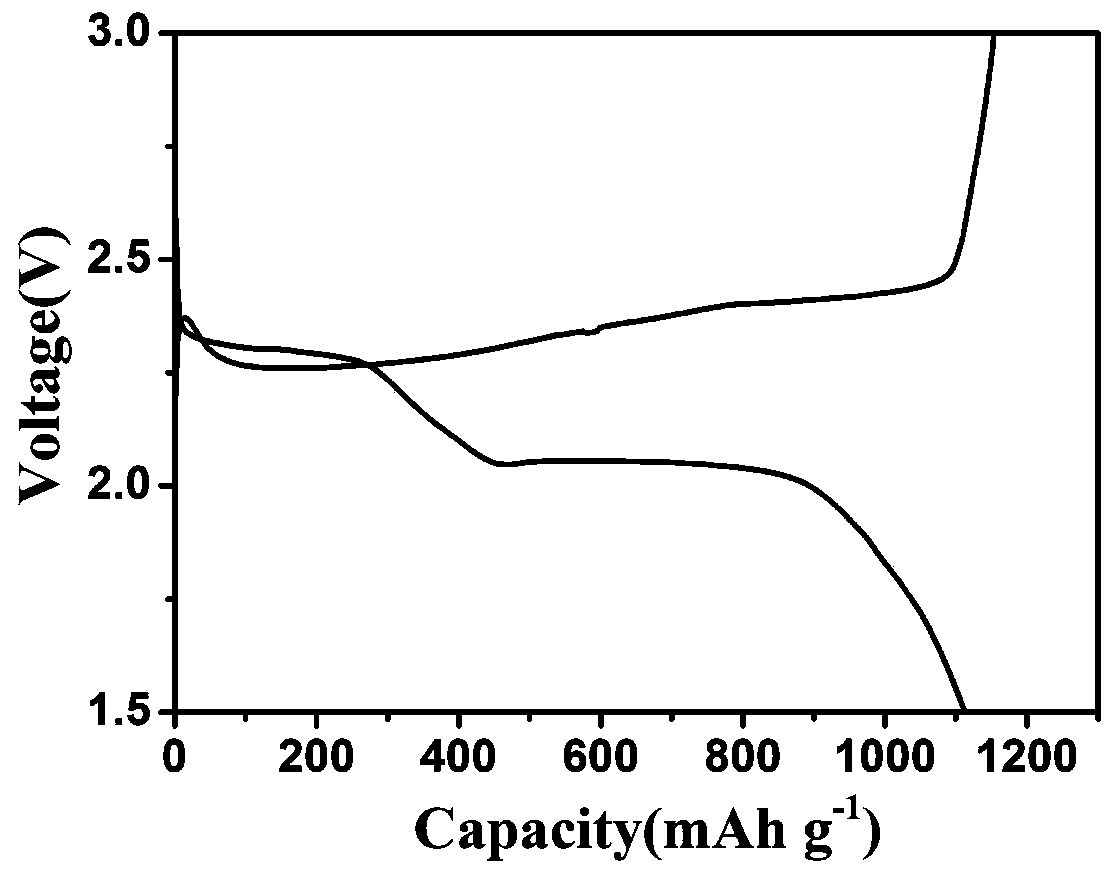

A kind of preparation method of lithium-sulfur battery cathode material

ActiveCN106876685BHighlight substantive featuresWell mixedCell electrodesLi-accumulatorsDoped grapheneSolvent

The invention relates to a method for preparing a cathode material of a lithium-sulfur battery, and relates to an electrode formed by an active material. The method is characterized in that the graphene oxide reduction, boron doping and solvent thermal reaction are completed by one step, and the cathode material of the lithium-sulfur battery with a boron-doped graphene / sulfur composite three-dimensional structure is prepared by a one-step method. The defects that the cathode material of the lithium-sulfur battery has small and uneven sulfur load content, and low active material load and utilization rate, resulting in poor electrochemical performance of the lithium-sulfur battery in the prior art are overcome.

Owner:HEBEI UNIV OF TECH

Preparation method of ordered nano-array nitrogen-sulfur double-doped carbon-sulfur composite carbon rod material and lithium-sulfur battery

ActiveCN109671923BReduce the "shuttle effect"Improve electrochemical performanceMaterial nanotechnologySecondary cellsLithium–sulfur batteryElectrical battery

The invention belongs to the technical field of electrode materials, and discloses a method for preparing an ordered nano-array nitrogen-sulfur double-doped carbon / sulfur composite carbon rod material, comprising the following steps: S1. preparing an ordered nano-array precursor carbon rod; S2. Preparation of ordered nano-carbon rod array; S3. Preparation of ordered nano-array nitrogen-sulfur double-doped carbon / sulfur composite carbon rod material; this ordered nano-array nitrogen-sulfur double-doped carbon / sulfur composite carbon rod material is used for lithium / Cathode materials for sulfur-ion batteries. The lithium / sulfur ion battery positive electrode material made of the carbon / sulfur composite carbon rod material of the present invention has better appearance and performance than conventional carbon materials, and when used as a lithium sulfur battery positive electrode material, it has a high initial discharge specific capacity, The capacity retention rate is good, and the preparation method is simple and easy, low in cost, green and environmentally friendly, and has good application prospects.

Owner:HUNAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com