Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Reduce paper waste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

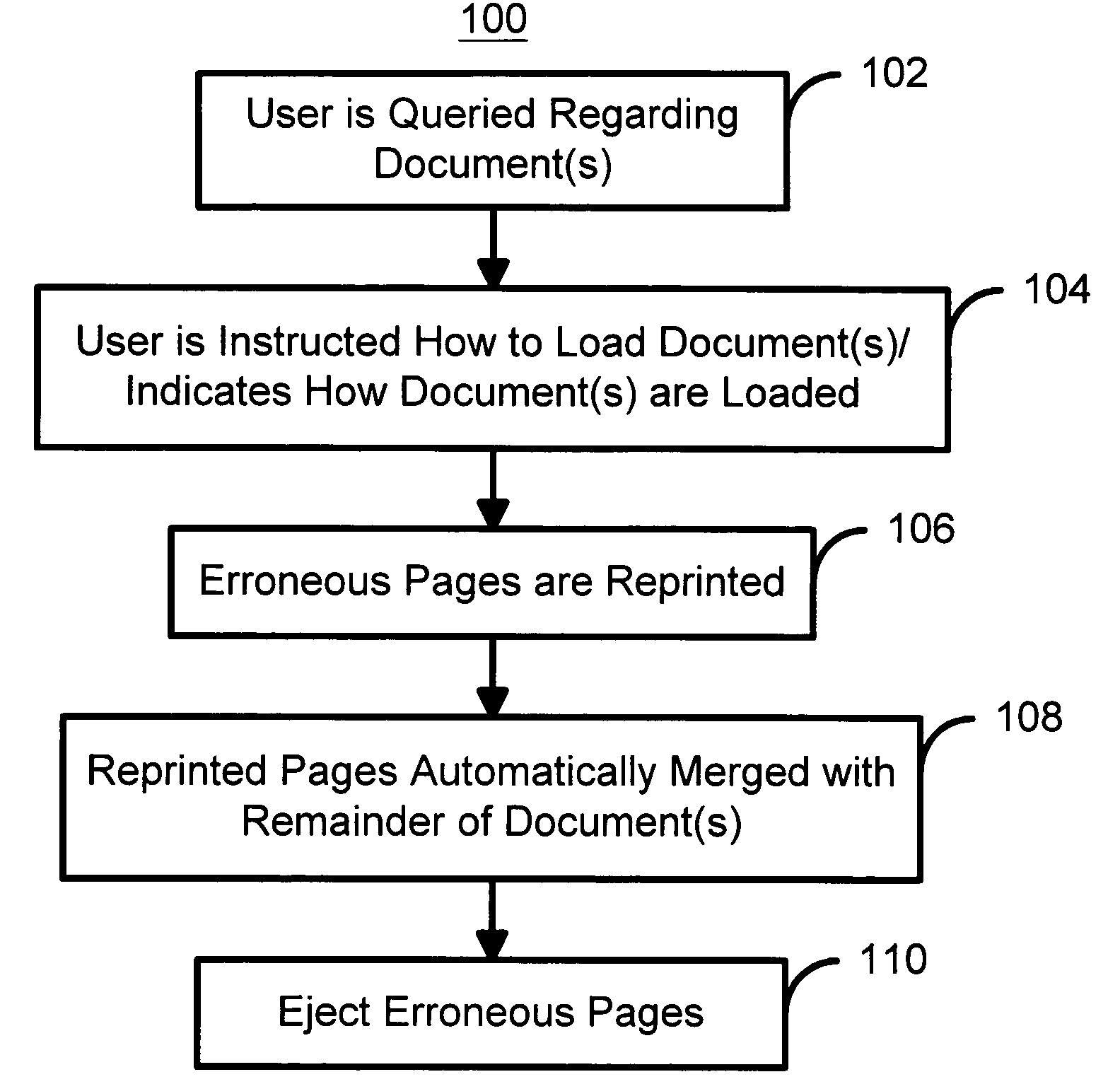

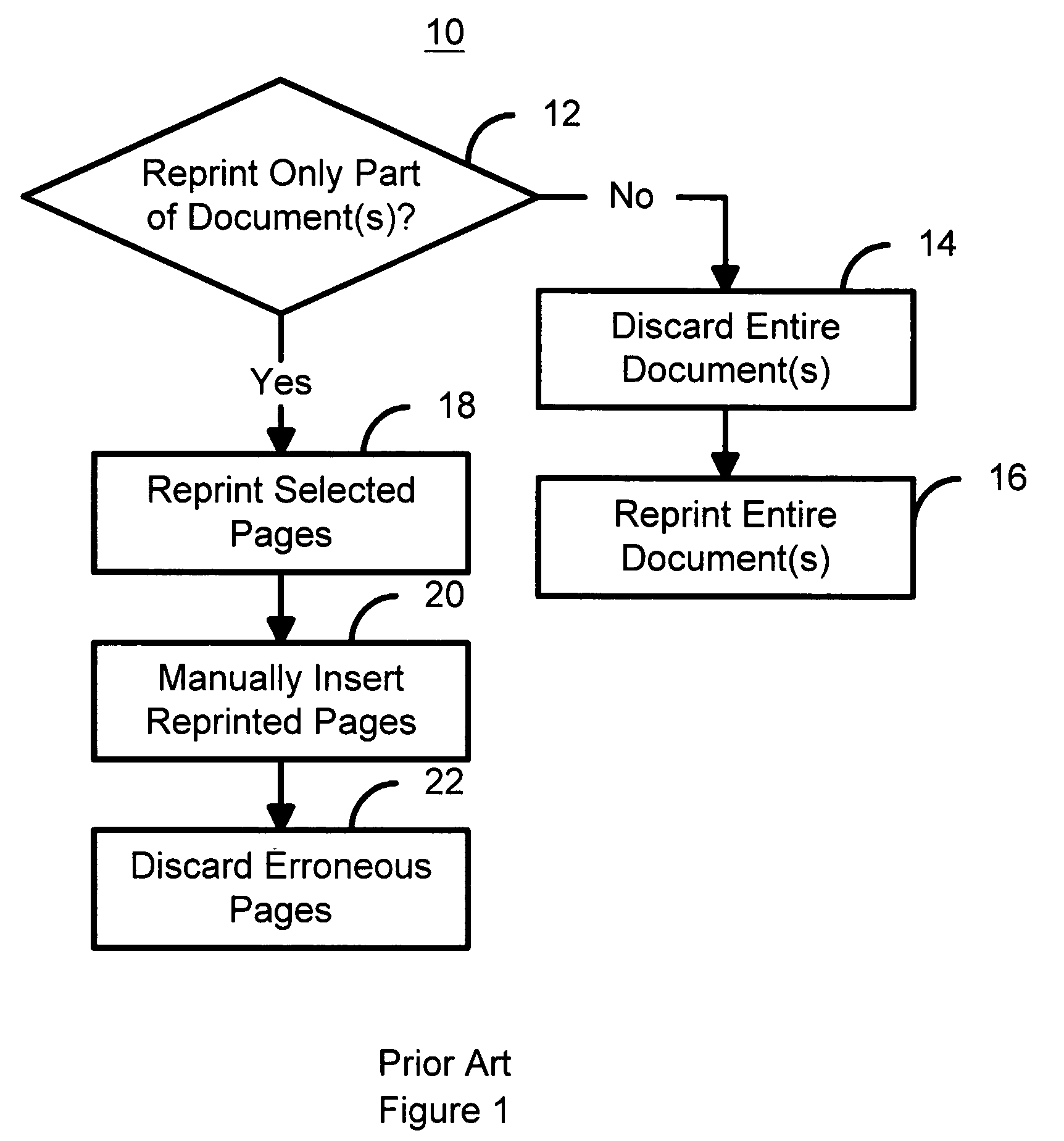

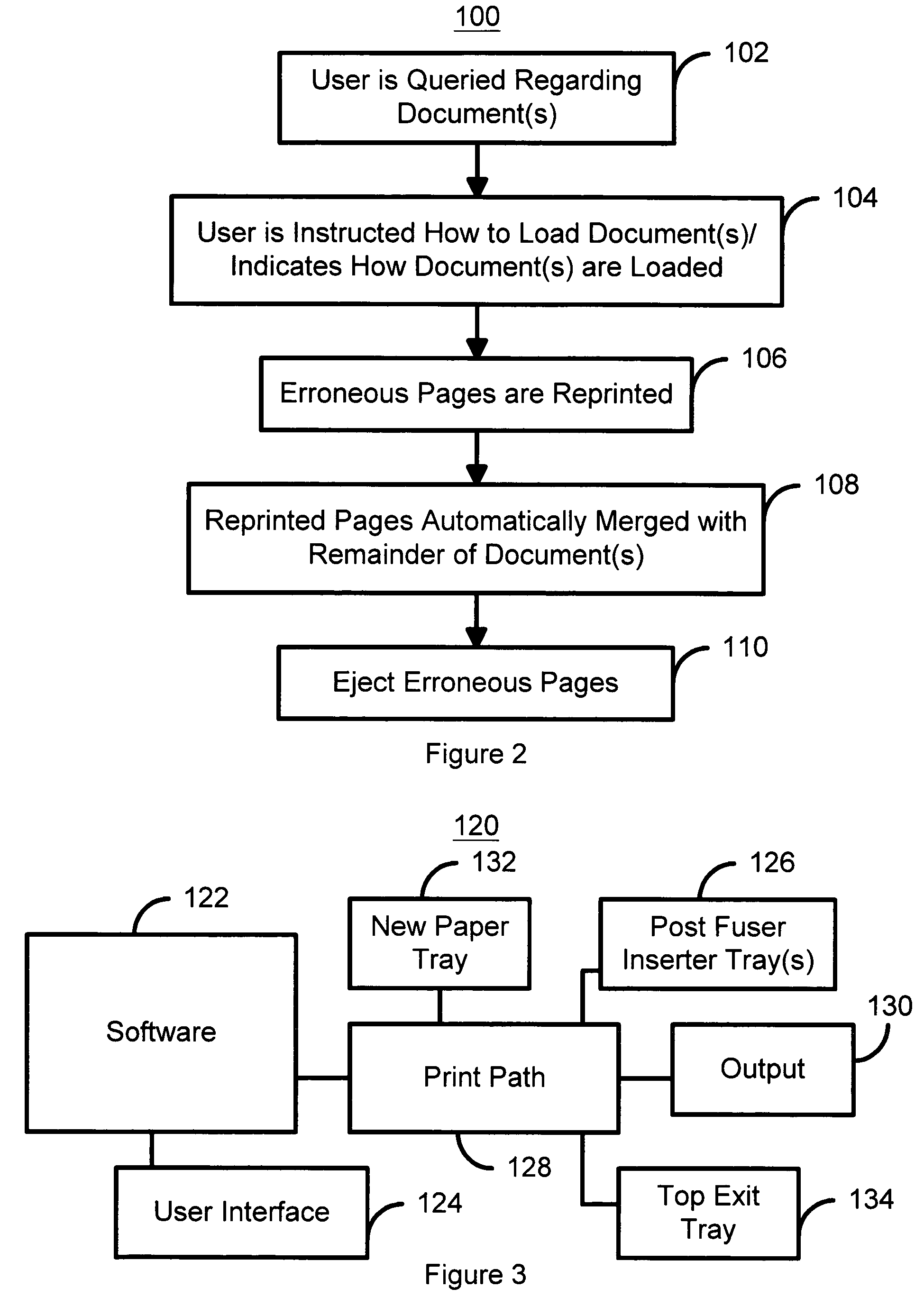

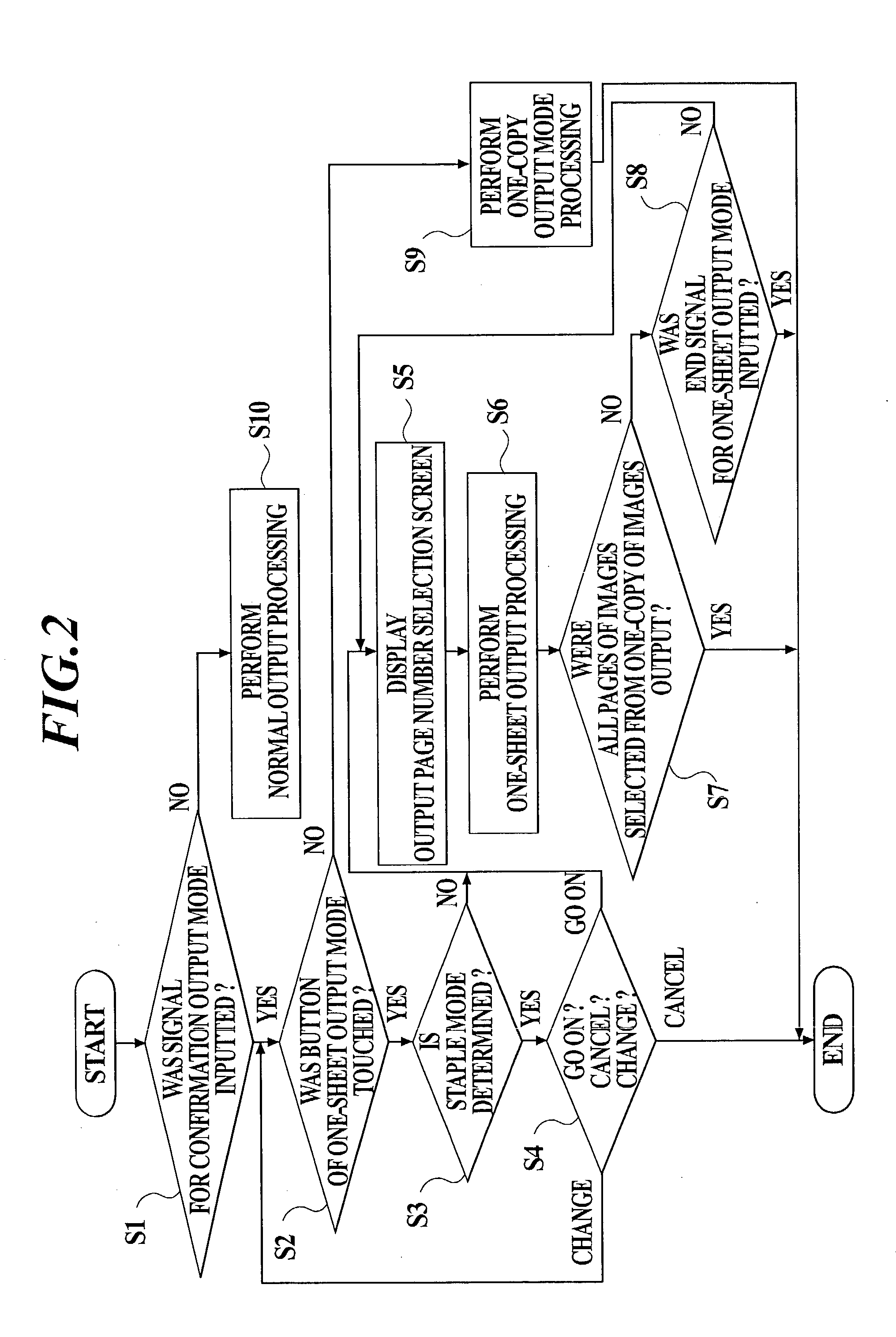

Method and system for reprinting pages

InactiveUS20050168767A1Less paper wasteReduce paper wasteVisual presentationDigital output to print unitsPaper documentDocument preparation

A method and system for reprinting a portion of at least one document is disclosed. The document(s) include a plurality of pages. The method and system include querying a user regarding the portion of the document(s) that includes at least one erroneous page. The method and system also include instructing the user on loading at least a remaining portion of the document(s) or receiving an indication from the user as to how at least the remaining portion of the document(s) are loaded. The method and system also include automatically reprinting the portion of the document(s) to provide at least one reprinted page that is to replace the erroneous page(s). The method and system also include automatically merging the at least one reprinted page with the remaining portion of the document(s).

Owner:INFOPRINT SOLUTIONS COMPANY LLC

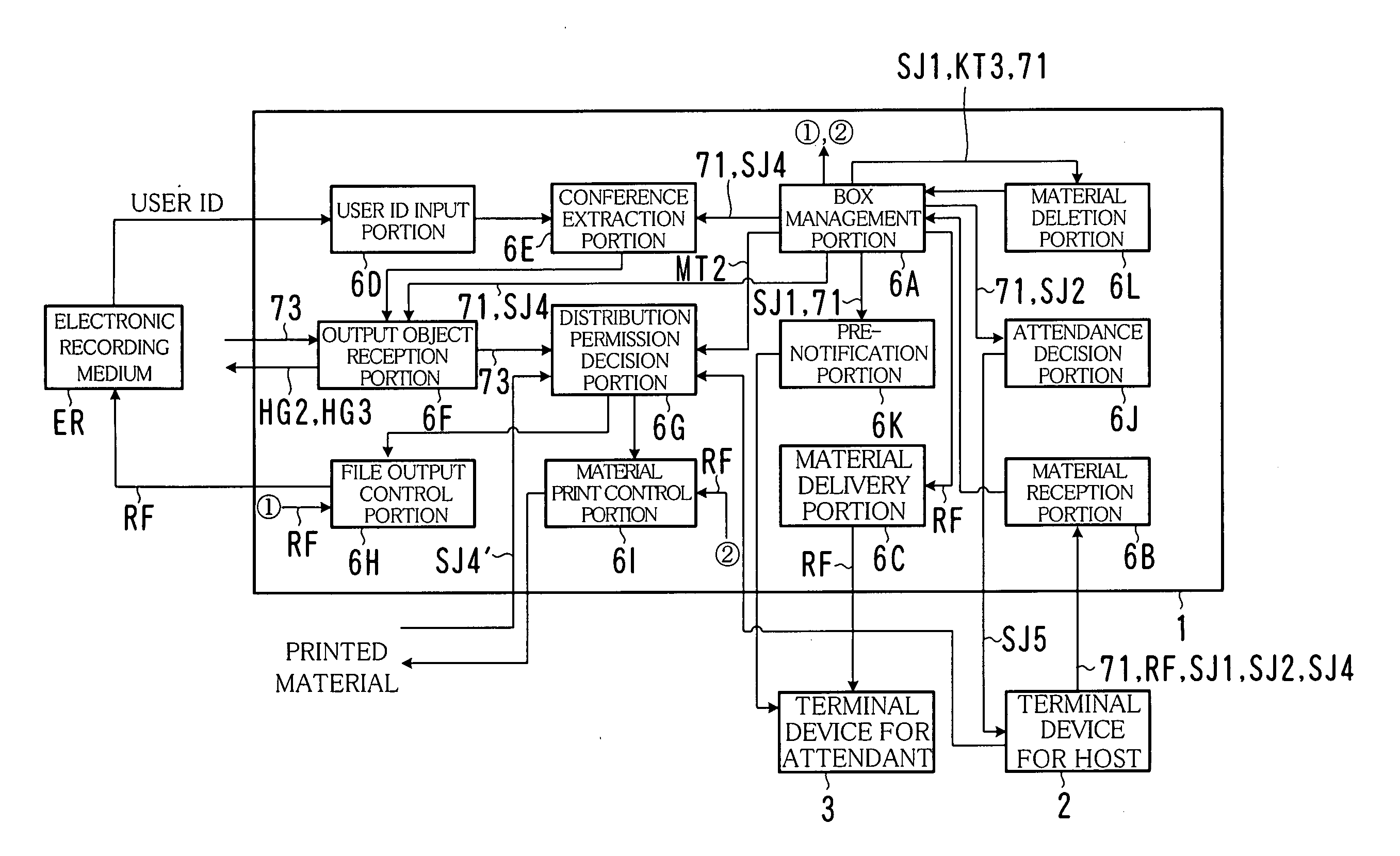

Material distribution system, material distribution method and computer program product

InactiveUS20060053042A1Reduce wasteKeep for a long timeReservationsResourcesUser inputMaterial distribution

A material distribution apparatus includes a storage area for storing materials, a storage area for storing conference schedule information that indicates persons to whom the material is permissible to be distributed, a user ID input portion for entering a user ID of a person who wants the material, a distribution permission decision portion for deciding whether the material is permissible or not to be distributed to the person who wants the material by comparing the entered user ID with the conference schedule information, and a material print control portion for printing the material on paper when it is decided that the material is permissible to be distributed.

Owner:KONICA MINOLTA BUSINESS TECH INC

Method for printing metallic inks

There is disclosed a method for printing metallic inks wherein a fountain solution and a first imprint ink are concurrently deposited onto a printing plate. A foundation metallic ink is then deposited onto the first imprint ink followed by depositing a second imprint ink is then onto the metallic ink. One or more layers of process ink colors can then be deposited onto the second imprint ink. The fountain solution is adjusted to have a pH of from about 3.7 to about 3.9 and the metallic ink is provided to have a tack of from about 14 to about 16.

Owner:WILEN RICHARD

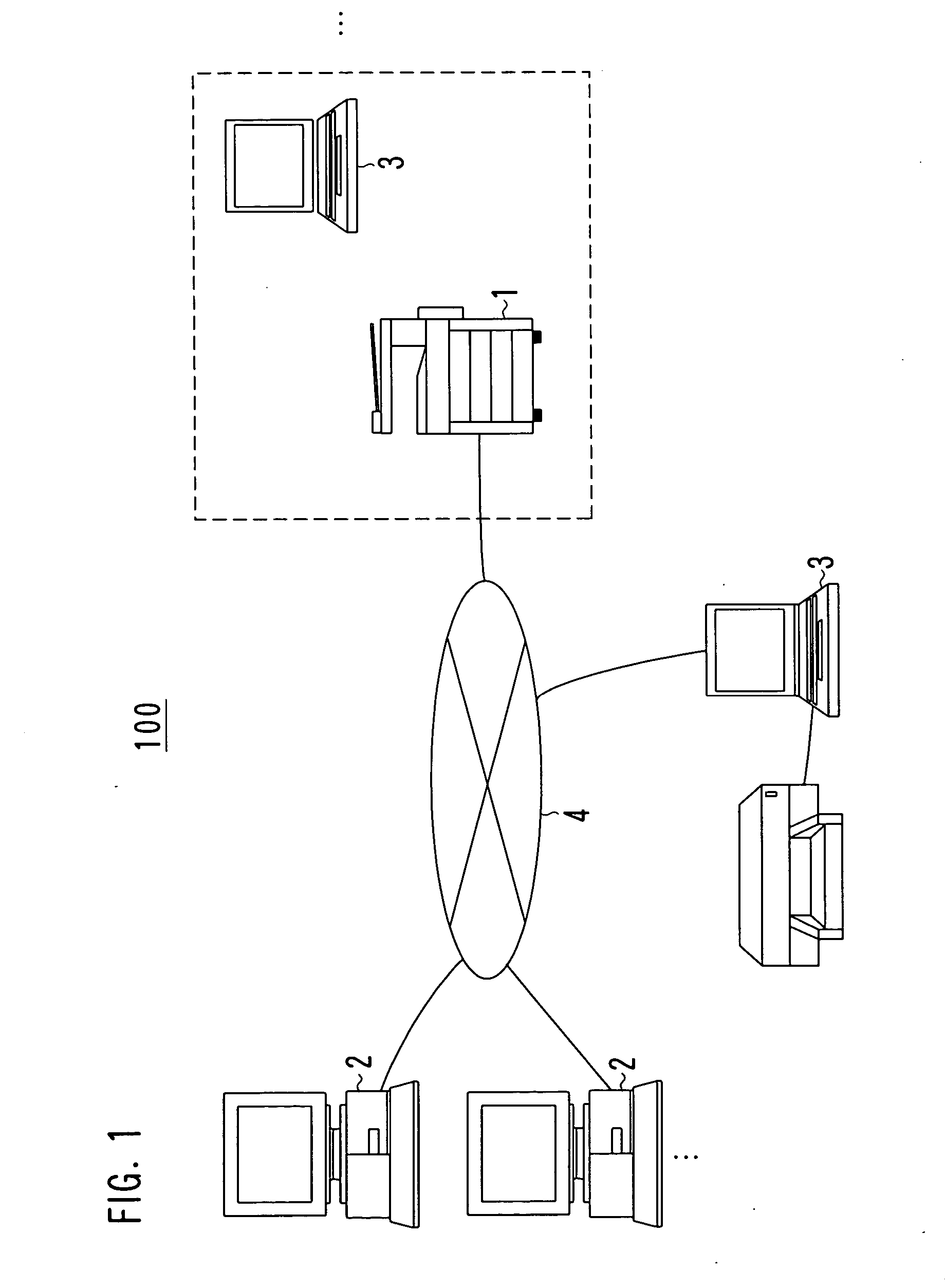

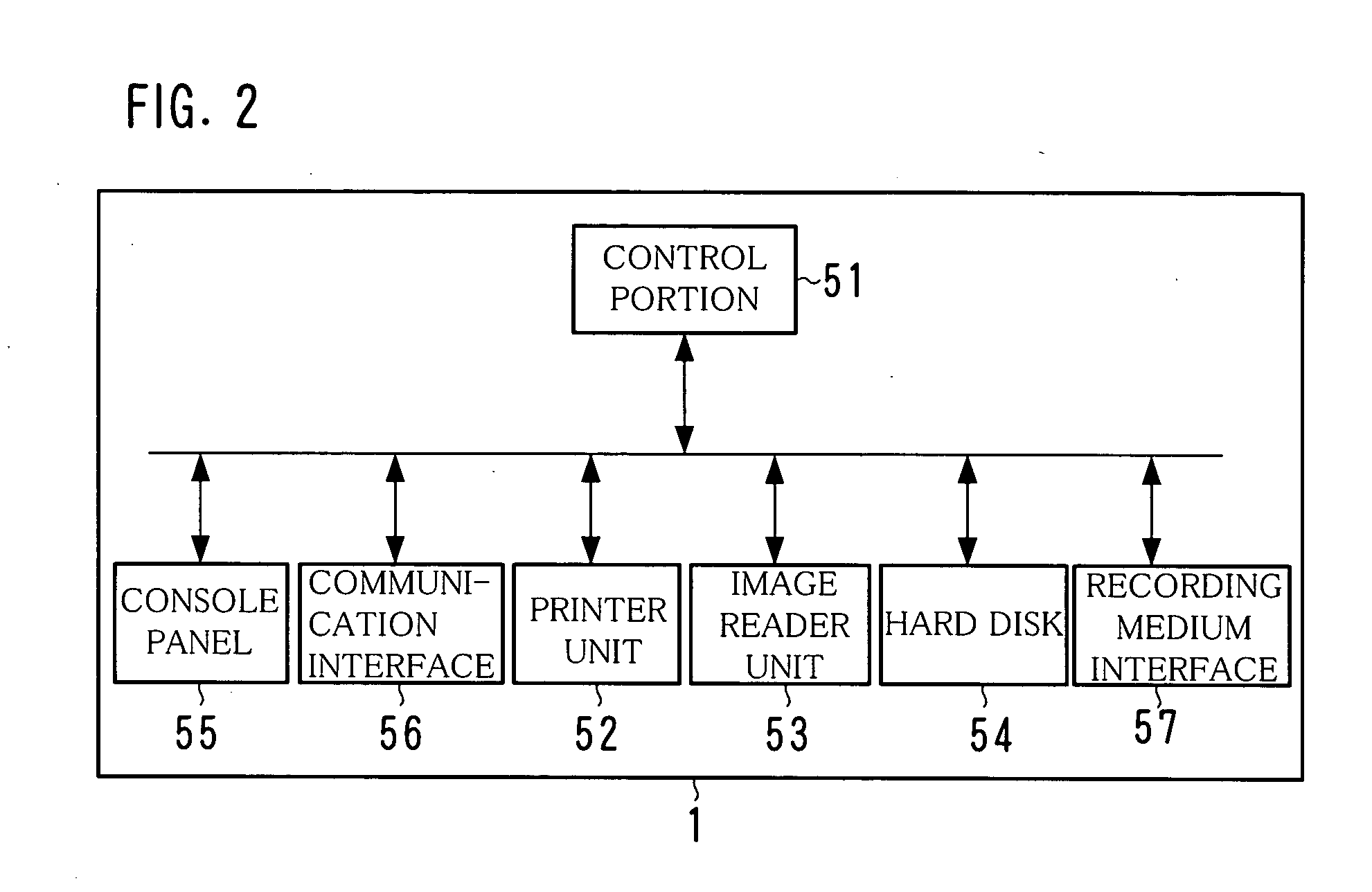

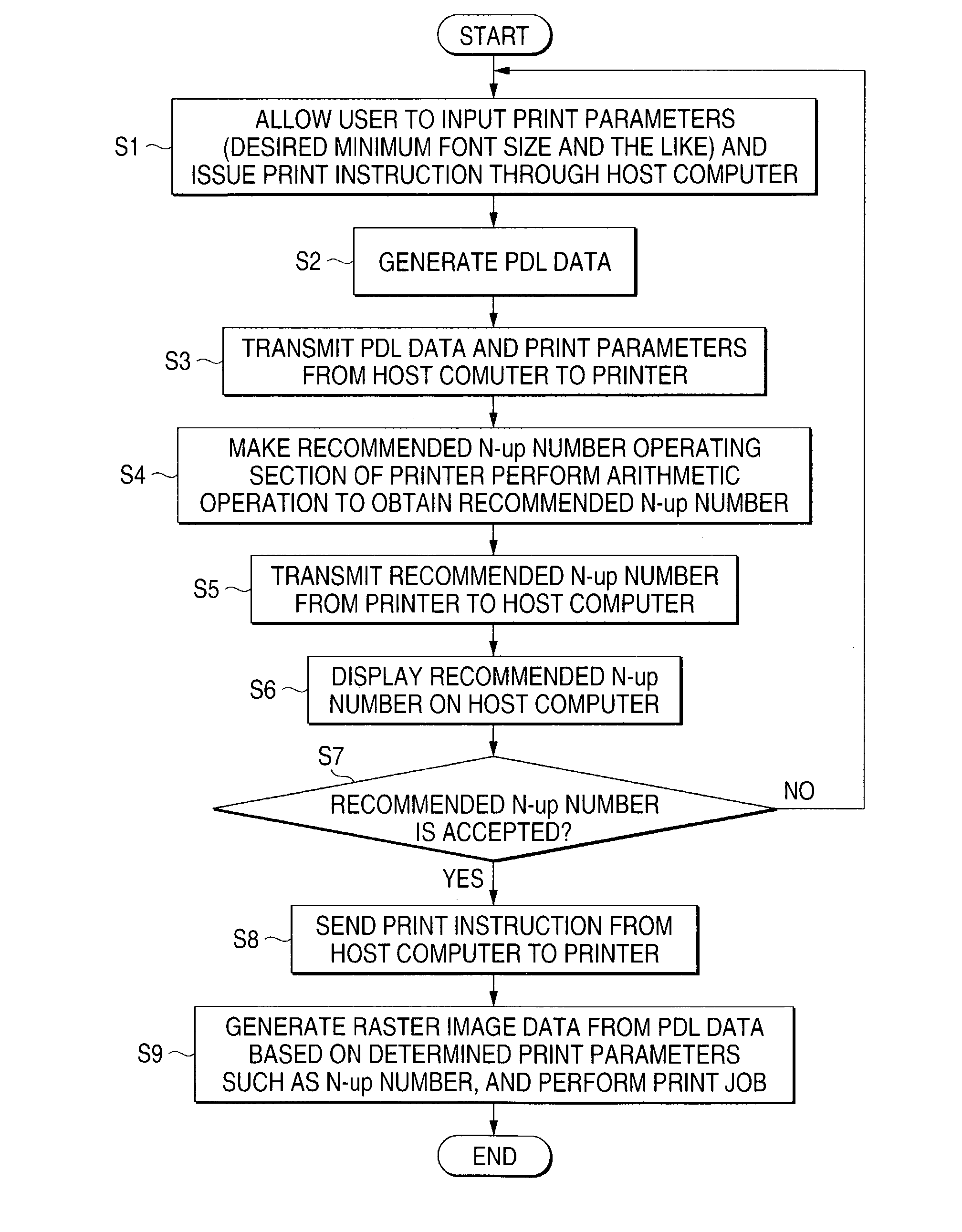

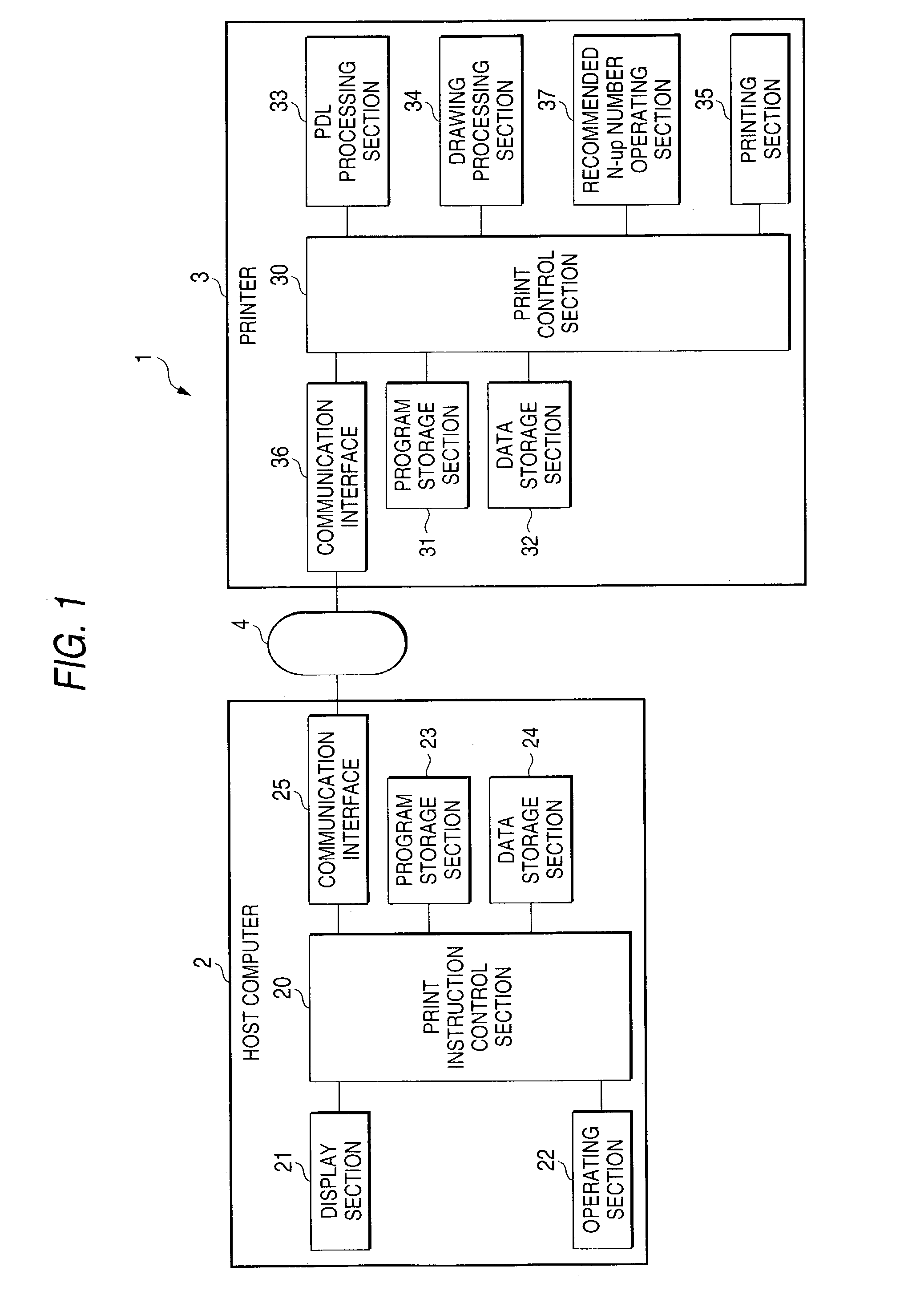

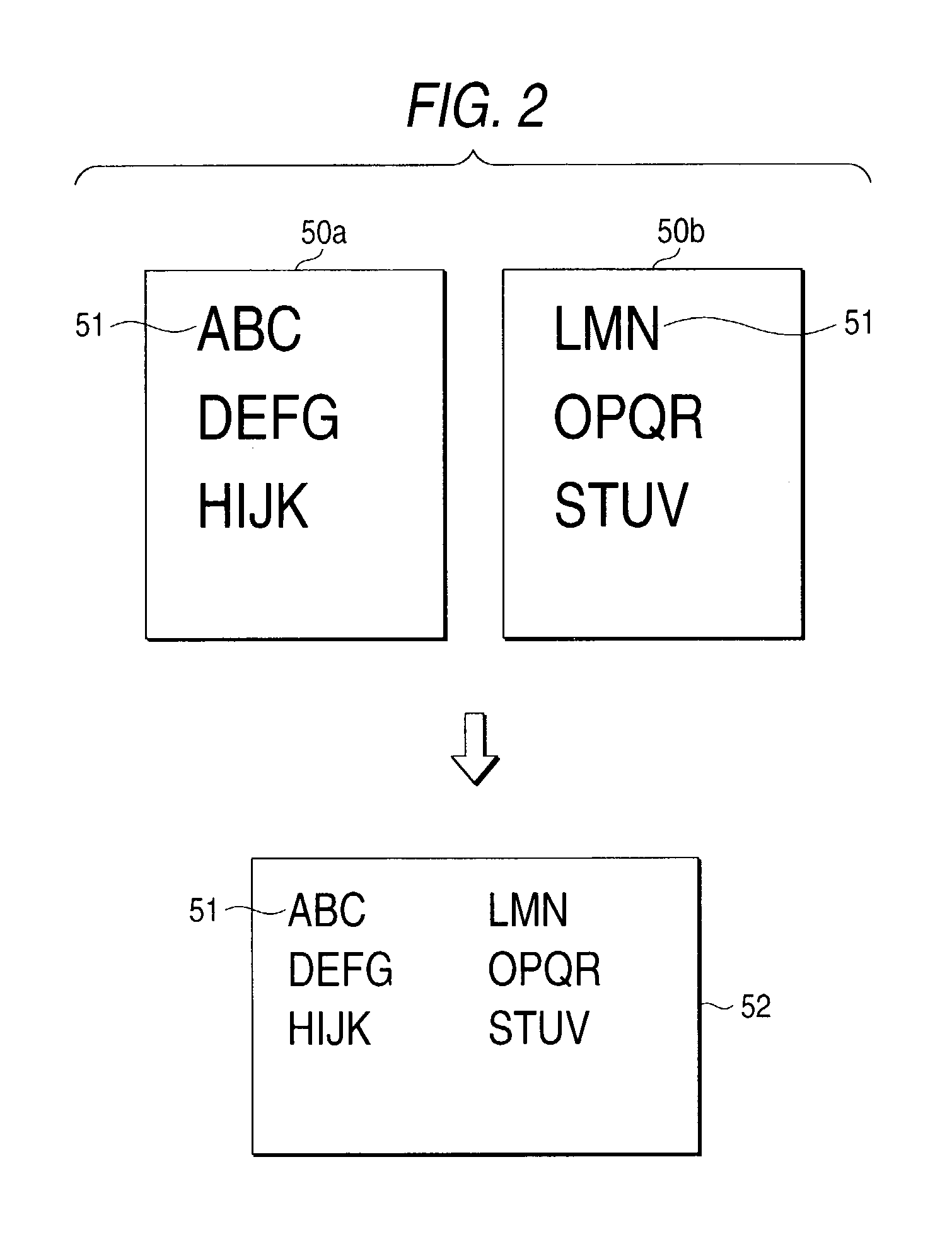

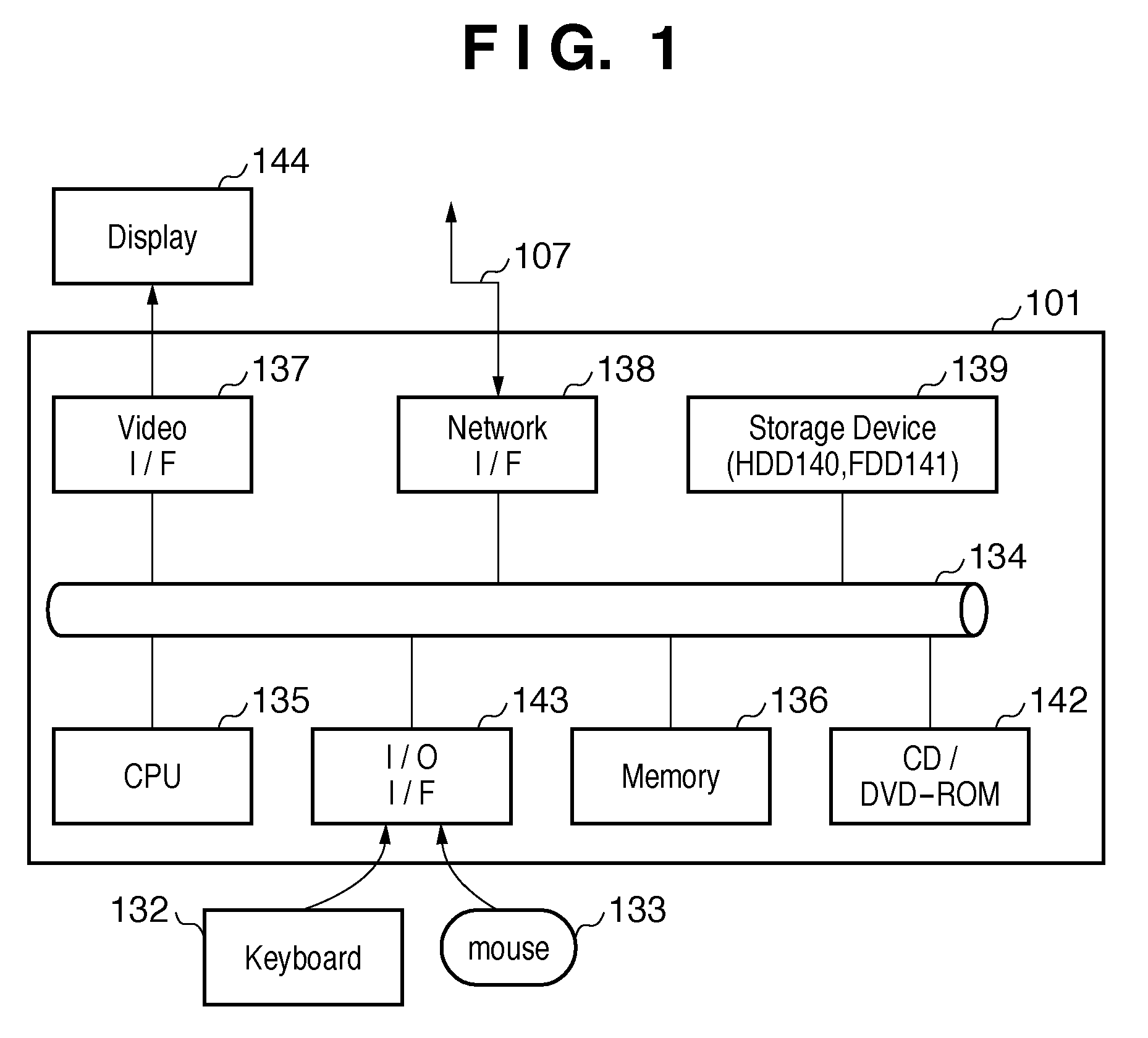

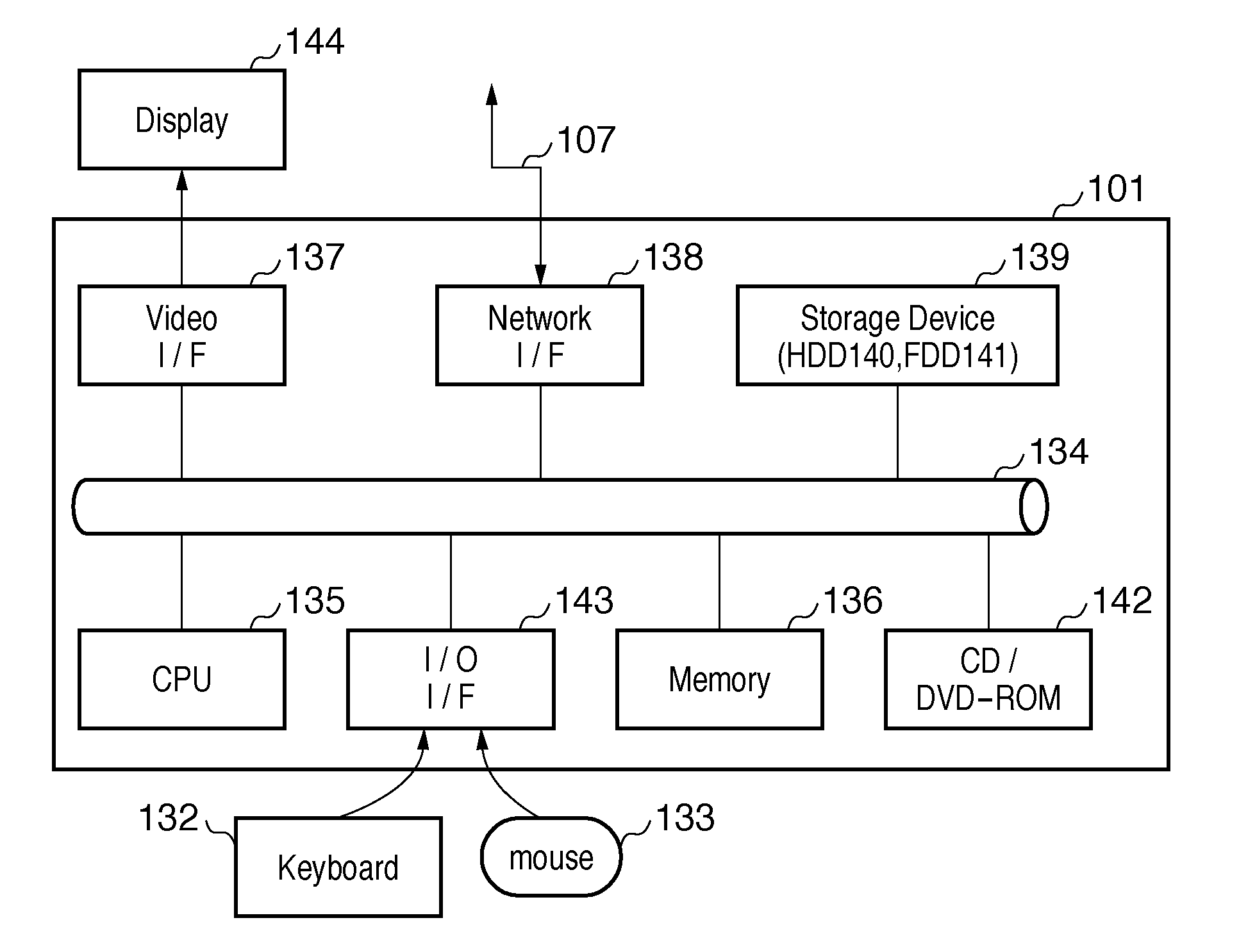

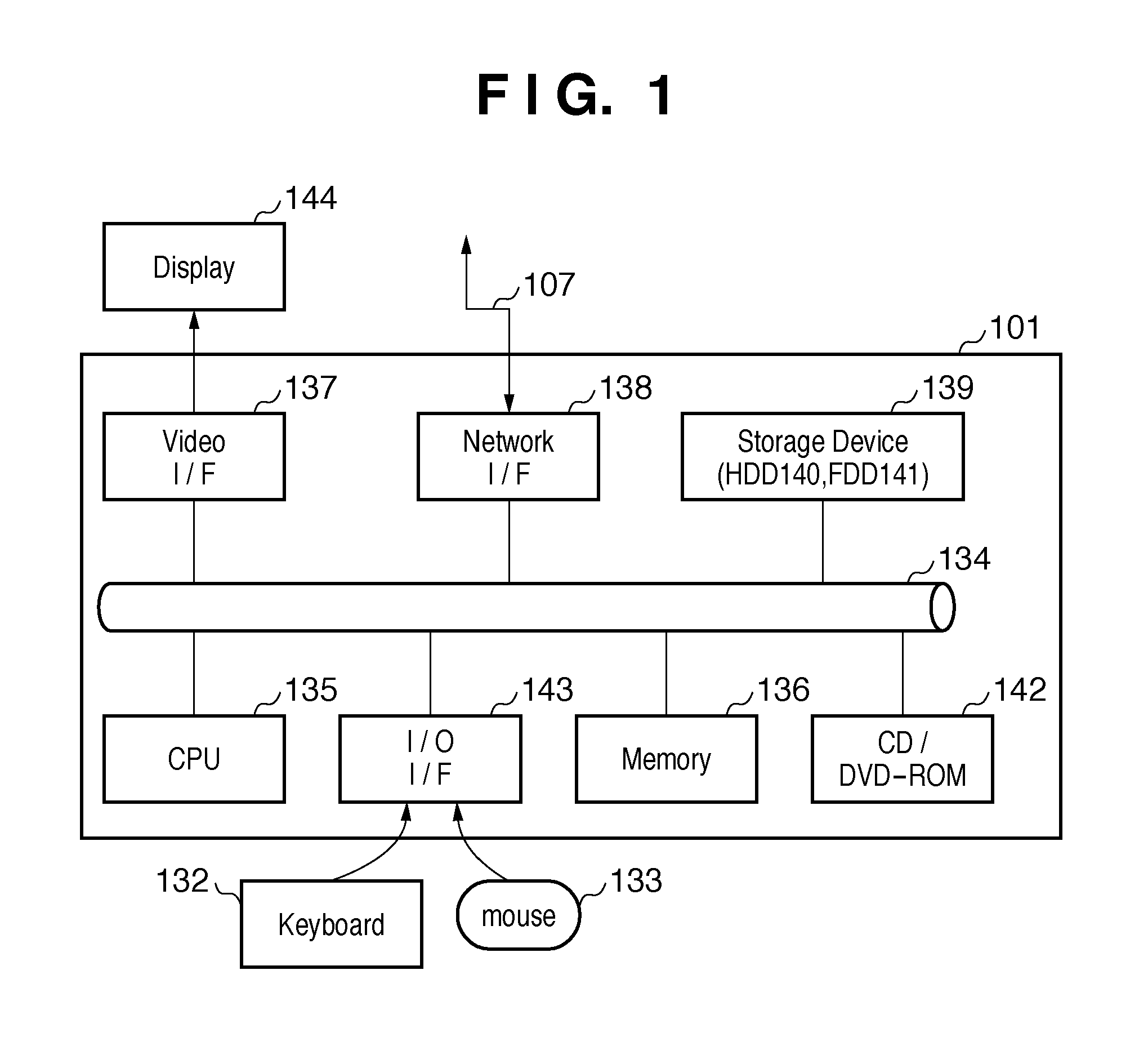

Printing apparatus, print instruction apparatus, image forming apparatus, printing method and a computer-readable recording medium storing a program for inputting a minimum character size for N-up mode printing

InactiveUS7248386B2Small sizeHindering readabilityDigitally marking record carriersDigital computer detailsComputer graphics (images)3D printing

When user specifies a desired minimum font size through a host computer 2, and issues a print instruction to a printer 3, a recommended N-up number operating section 37 of the printer 3 performs an arithmetic operation to obtain a maximum N-up number with which font size not larger than the desired minimum font size are not included. A printing section 35 of the printer 3 prints the obtained N-up number of sheets of original document images on one sheet of paper.

Owner:FUJIFILM BUSINESS INNOVATION CORP

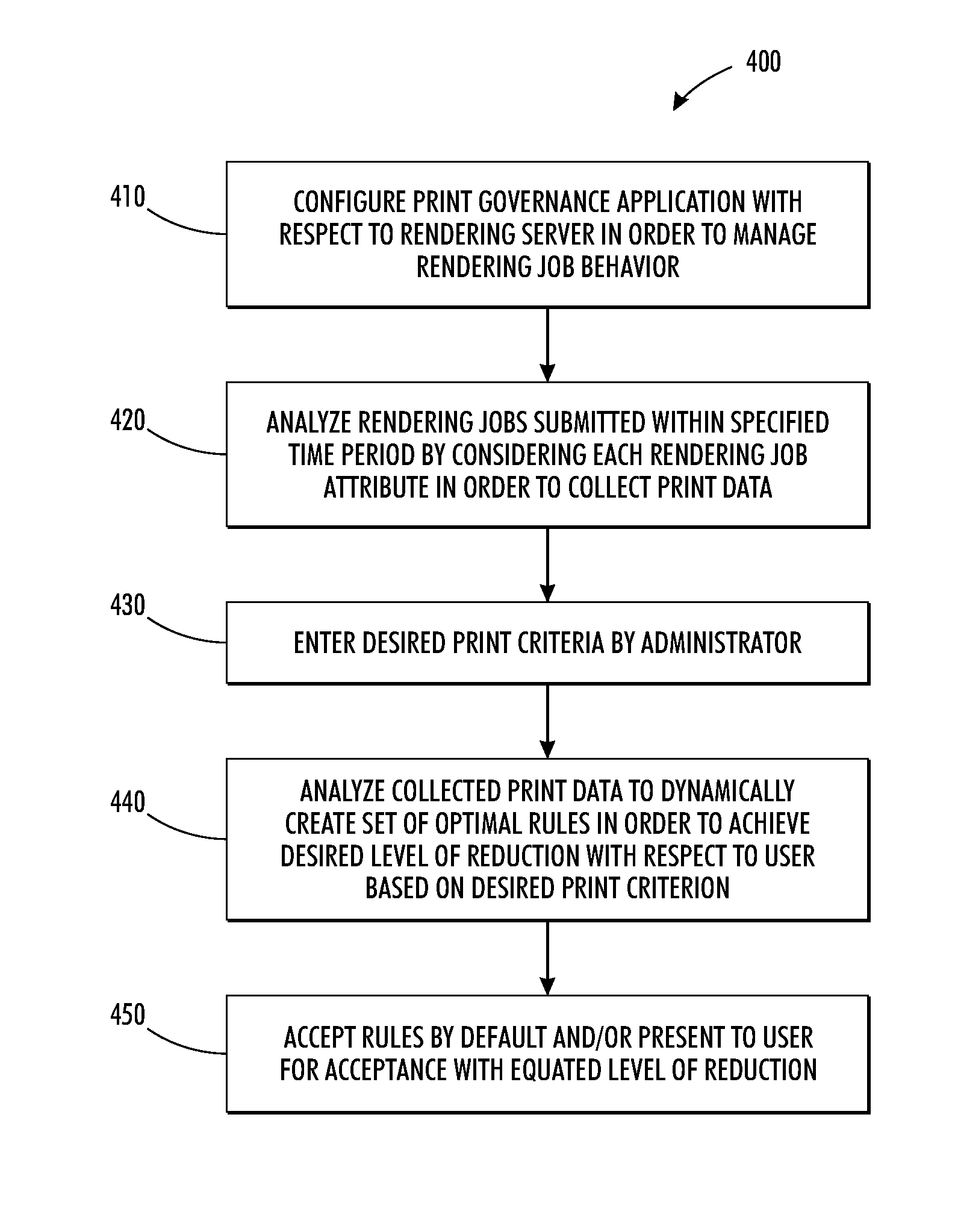

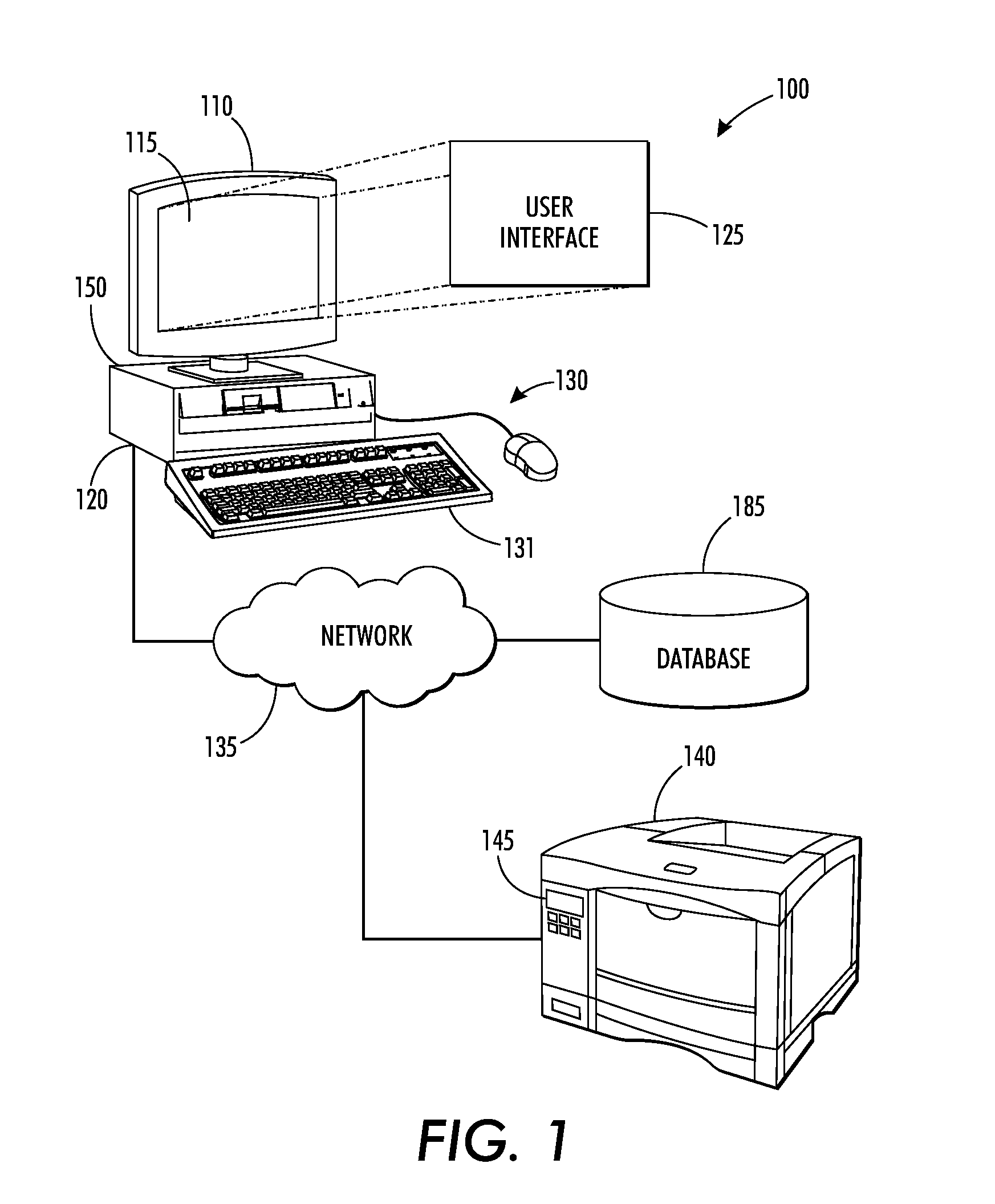

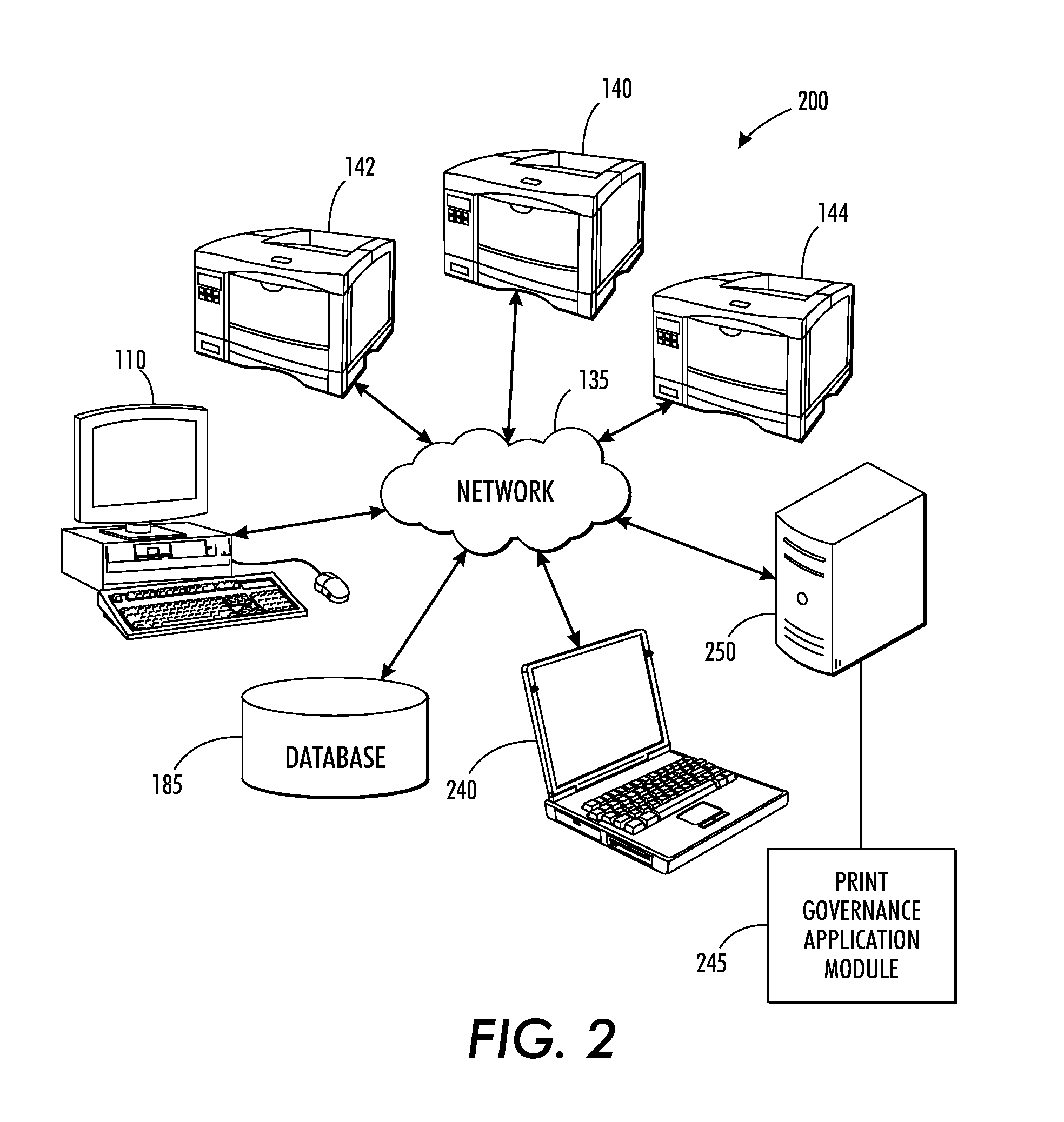

Method and system for automatically recommending rules based on desired print criteria

InactiveUS8619304B2Reduce printingReduce printing costsVisual presentation using printersDigital output to print unitsRule setsRule engine

A method and system for automatically creating and recommending a set of optimal rules based on a desired print criterion. A print governance application can be configured with respect to a rendering server to analyze one or more rendering jobs submitted within a specified time period by considering each rendering job attributes in order to collect a rendering data. A desired print criterion can be entered by an administrator in order to manage the rendering job behavior. The collected rendering data can be analyzed to dynamically create the set of optimal rules by a rules engine in order to achieve a desired level of reduction with respect to each user based on the desired print criterion. The rules can be accepted by default and / or presented to the user for acceptance with an equated level of reduction.

Owner:XEROX CORP

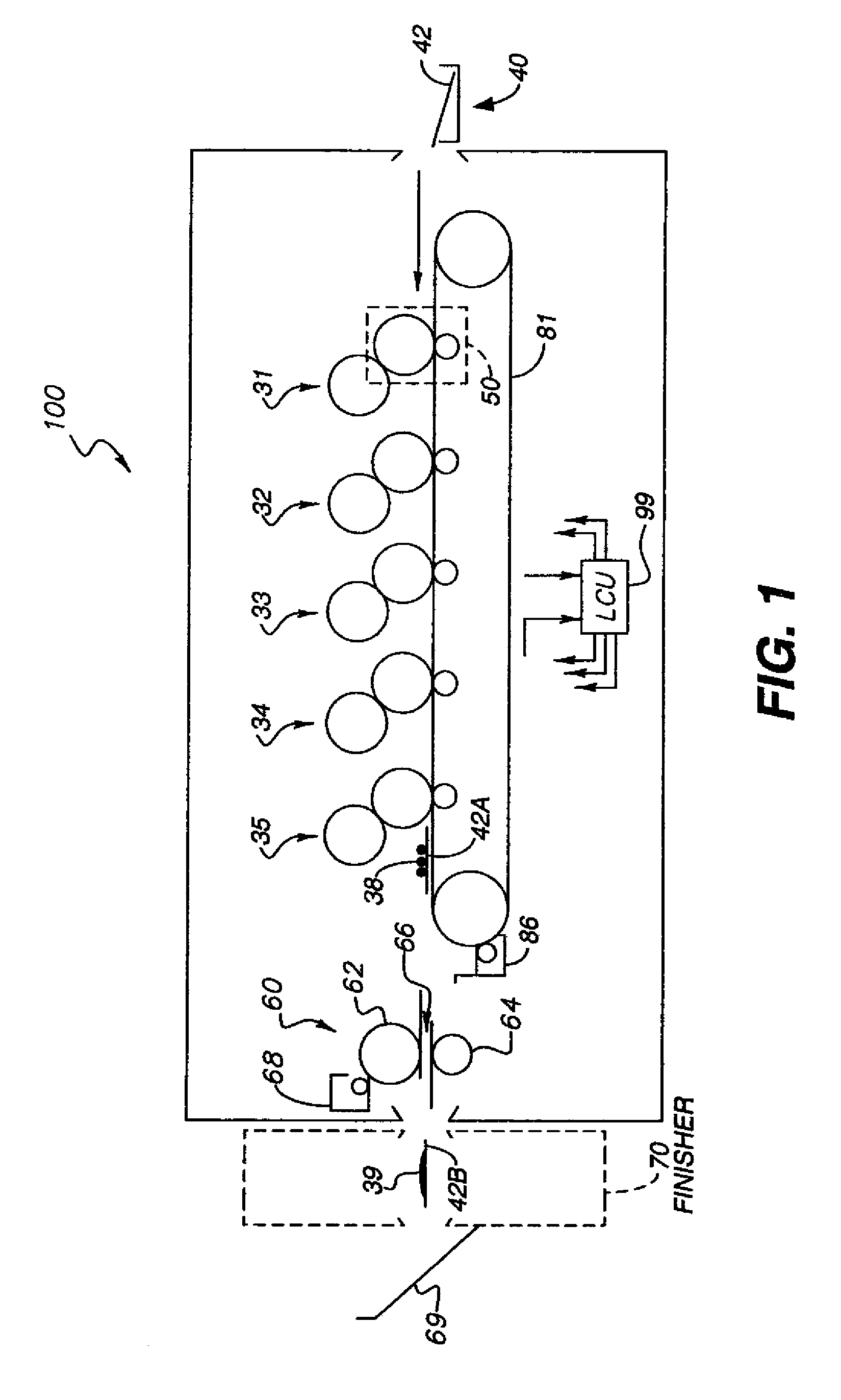

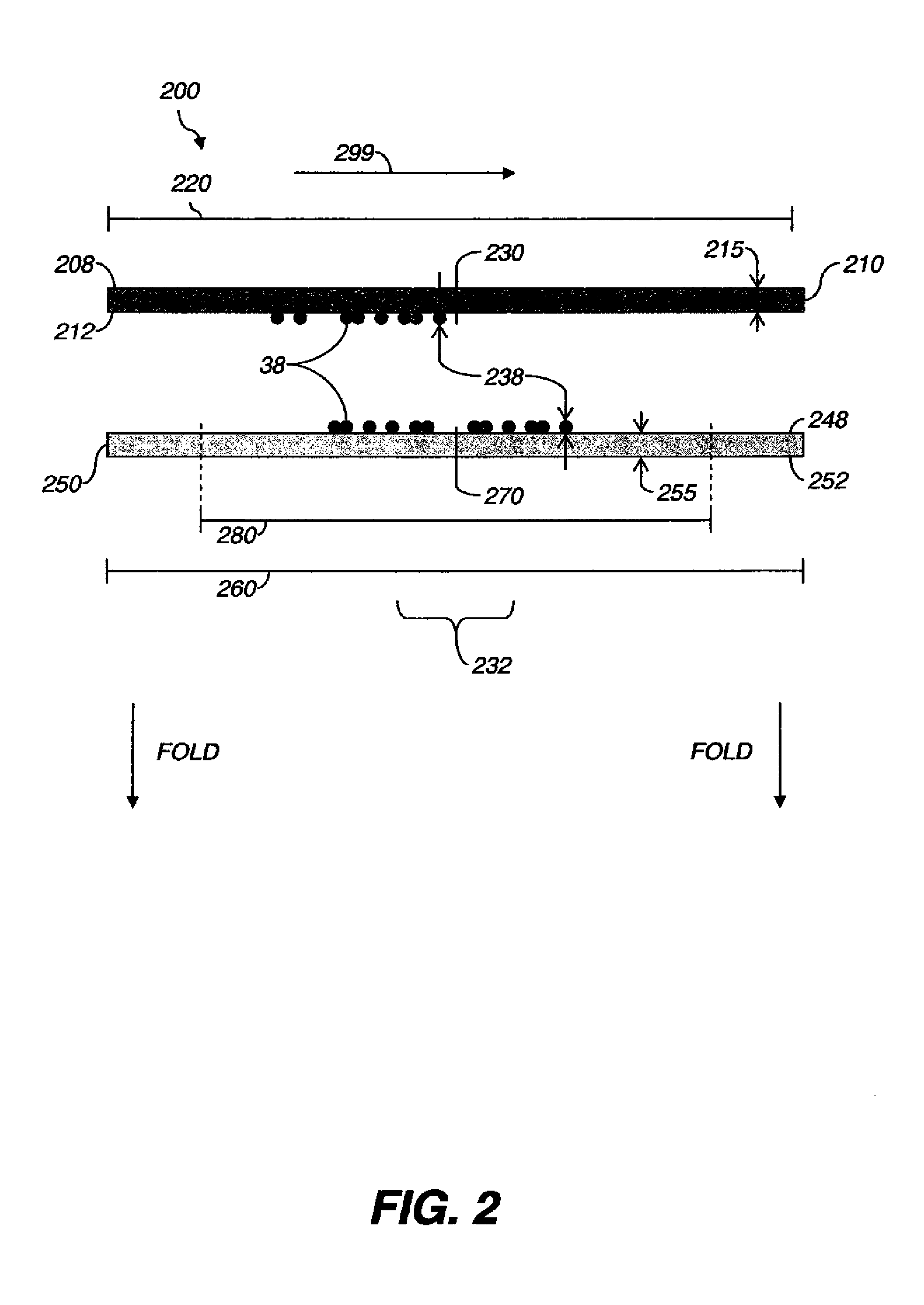

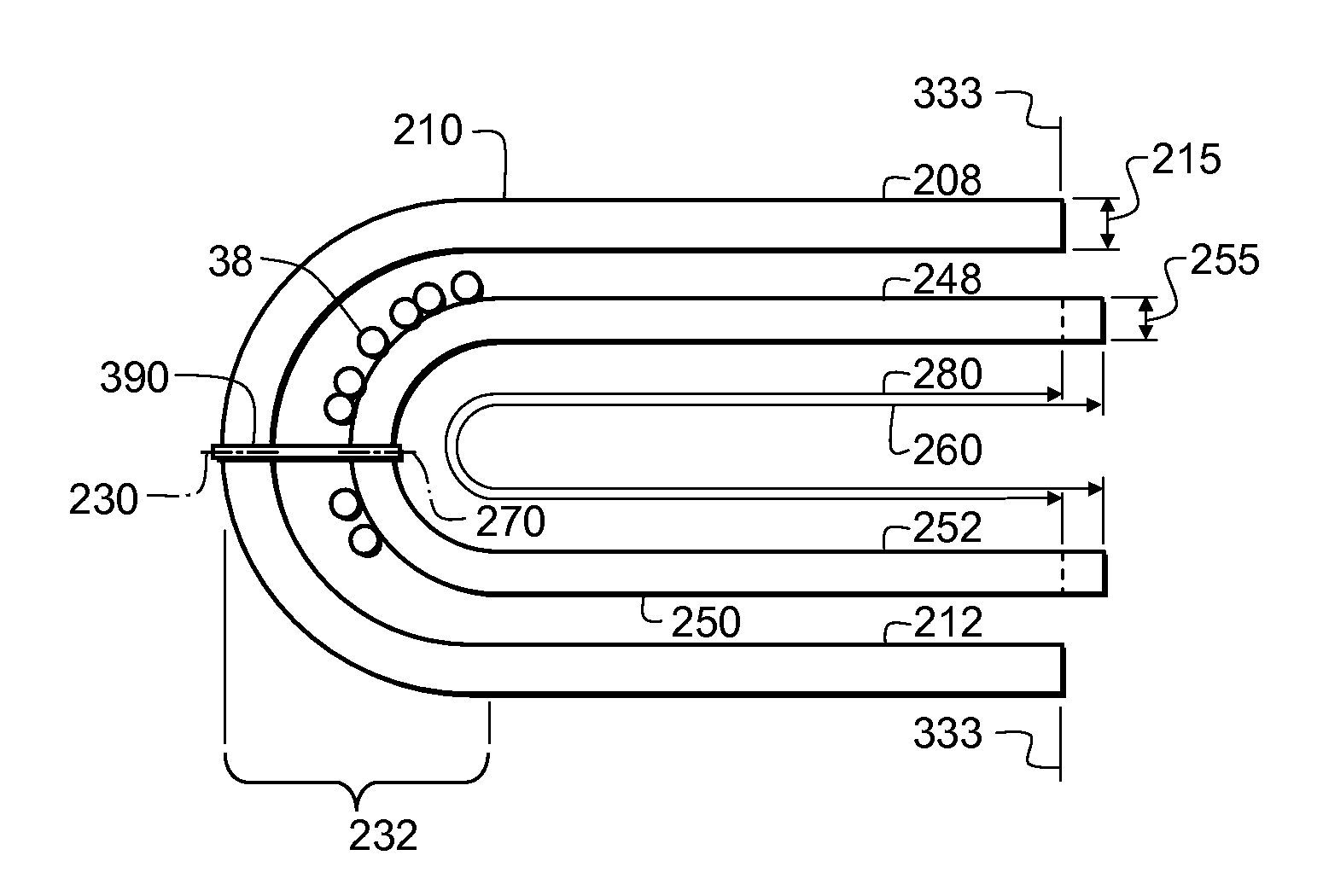

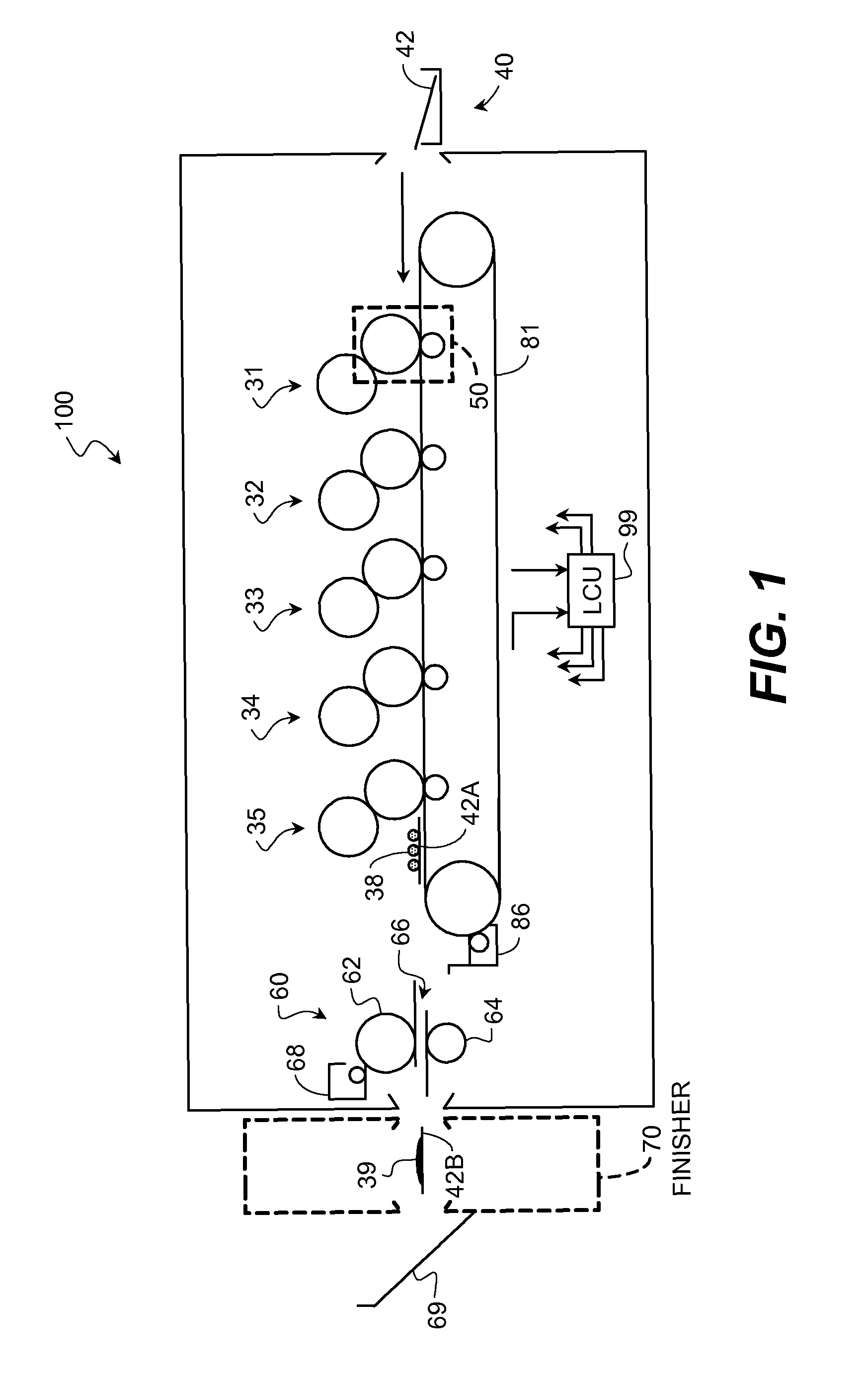

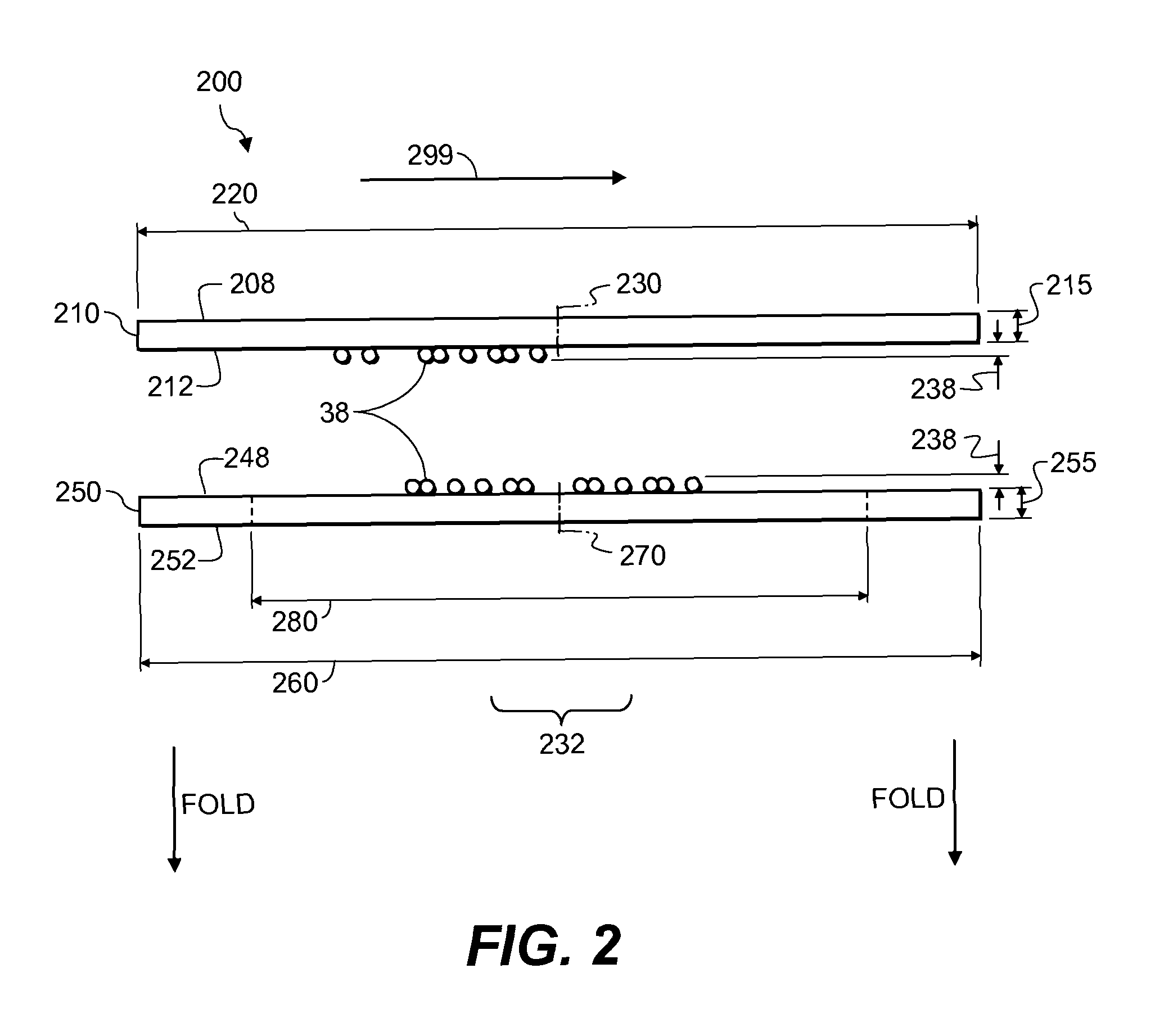

Calculating booklet sheet length using toner thickness

InactiveUS20110266737A1Less audible noiseReduce power consumptionTypewritersFolding thin materialsEngineeringMechanical engineering

A booklet is produced including an outer sheet and an inner sheet folded and nested together. A print image having a thickness is printed where it is between the two sheets when they nest together. A cut length is calculated using the thicknesses of the sheets and the thickness of the print image, so that when the sheets are folded and the inner sheet is nested into the outer sheet, the edges of the inner sheet will not protrude beyond the edges of the outer sheet. The inner sheet is cut to the calculated cut length either before or after printing. The cut inner sheet and the outer sheet are folded and nested together to produce the booklet.

Owner:EASTMAN KODAK CO

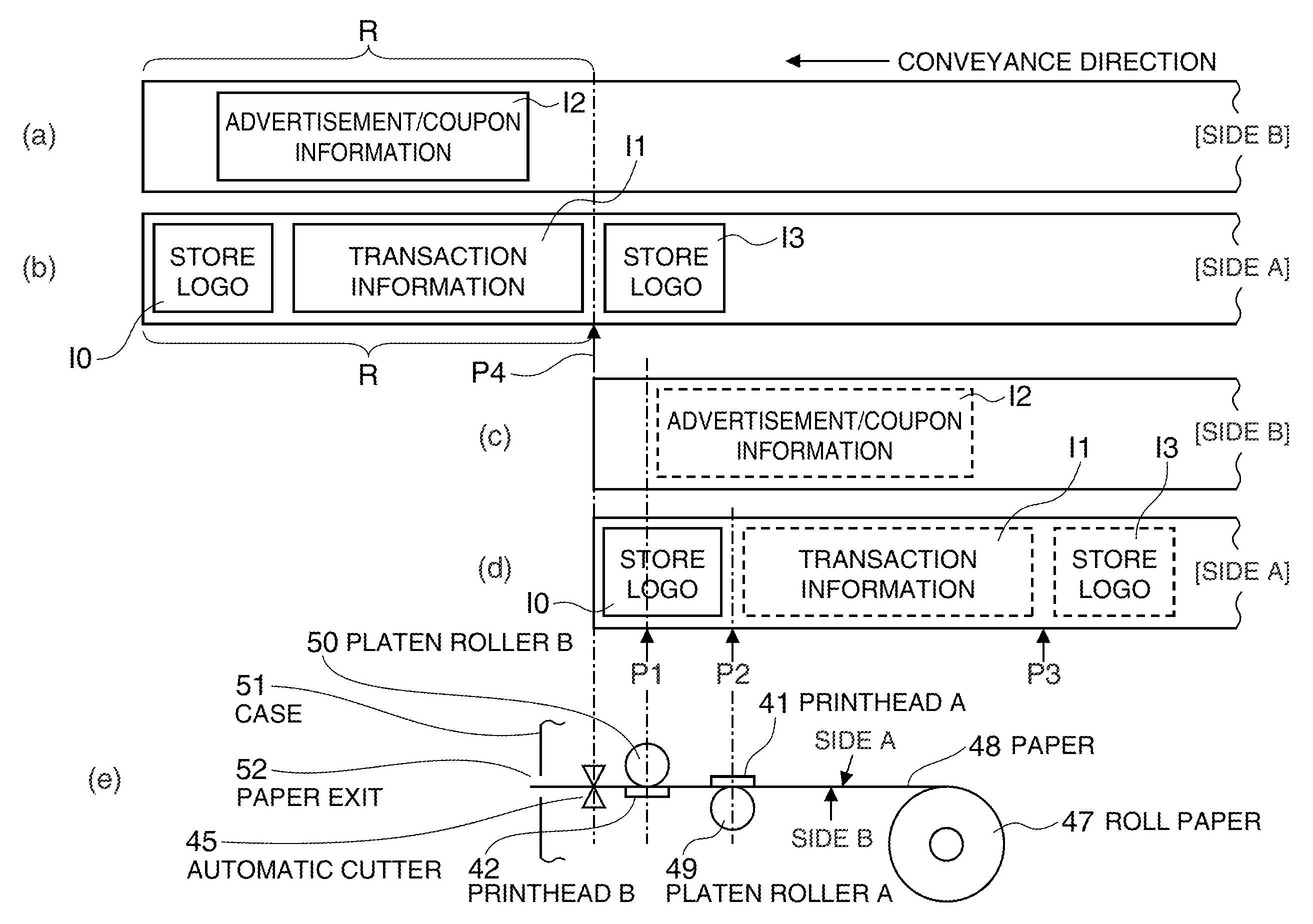

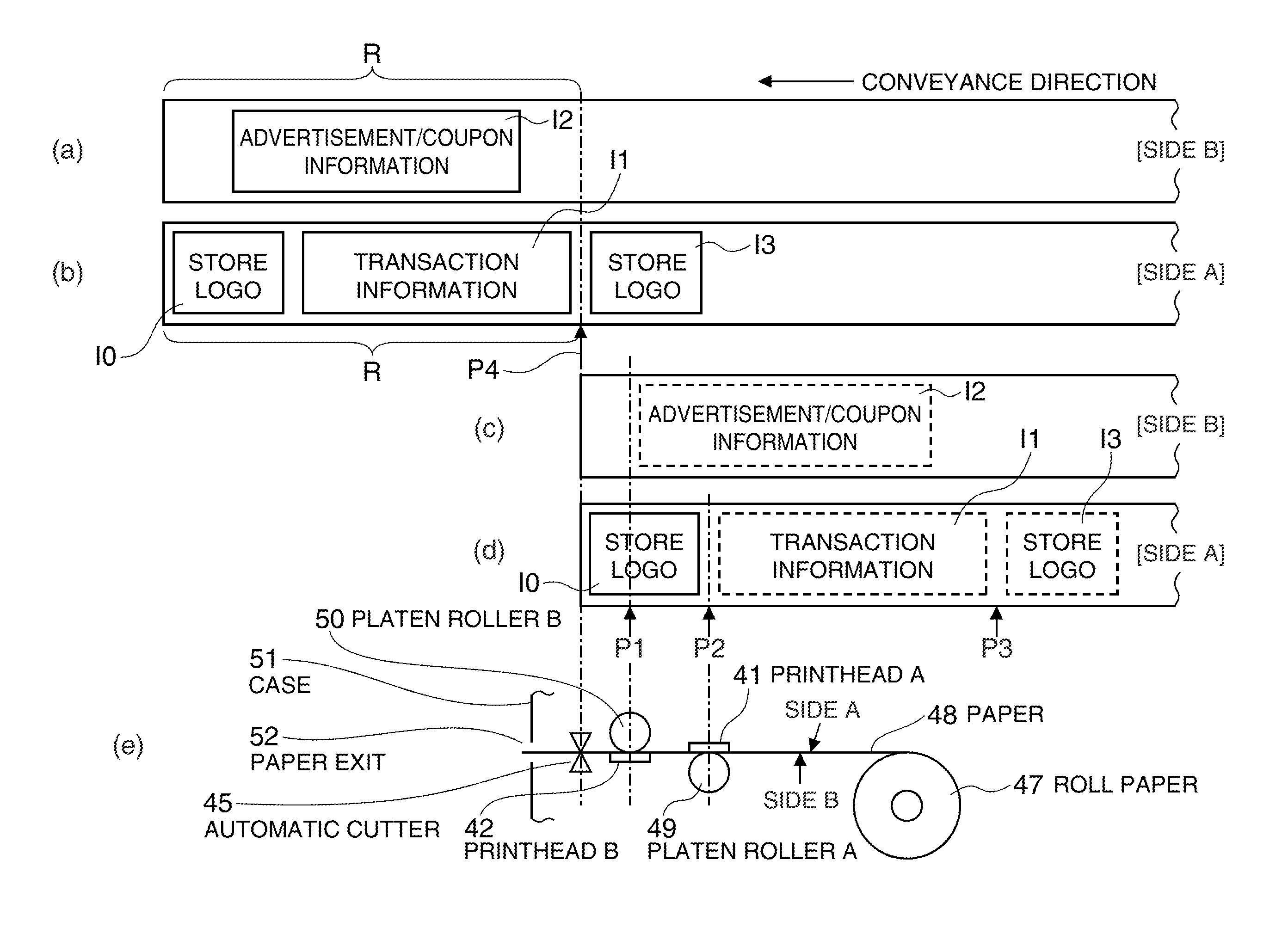

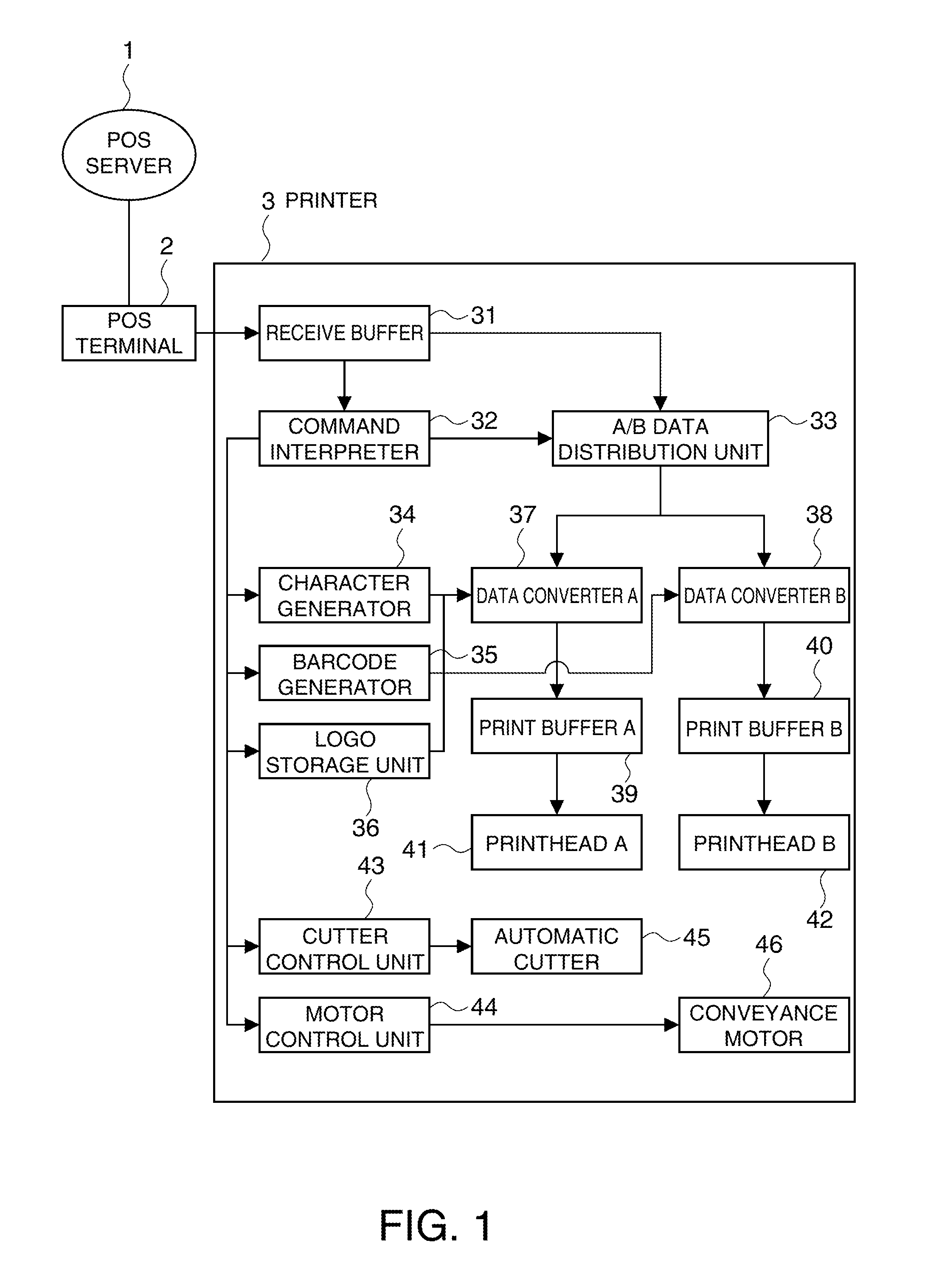

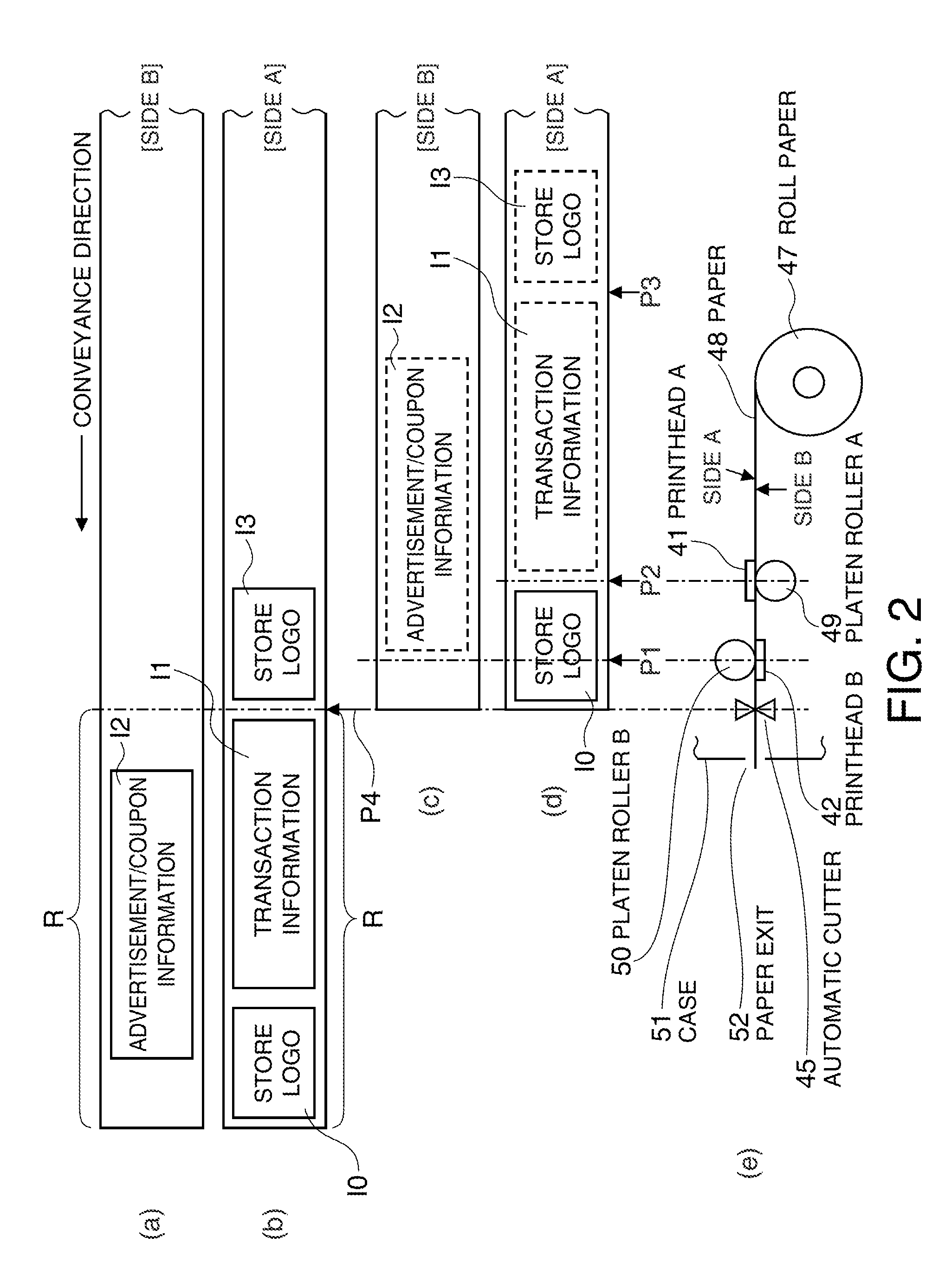

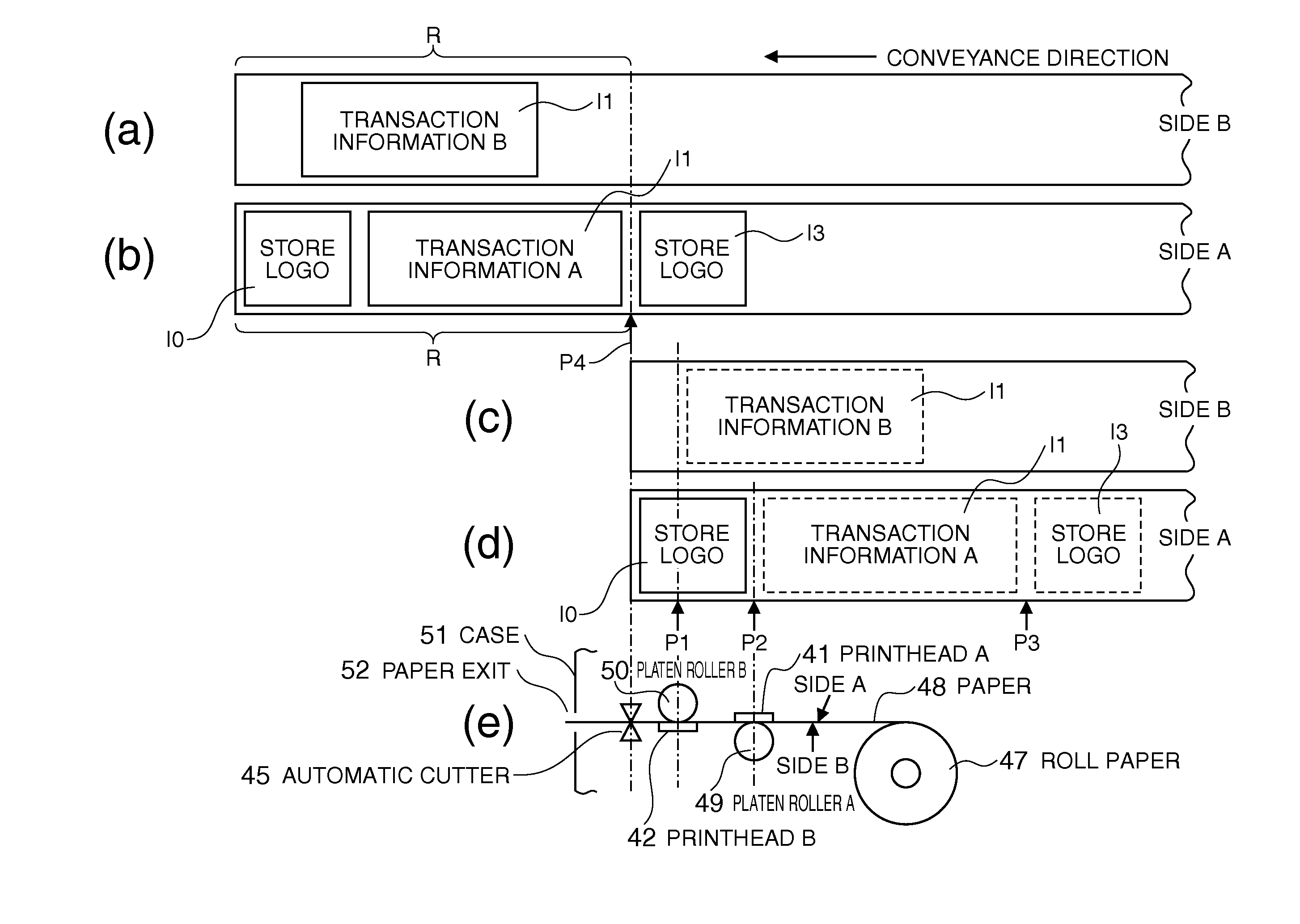

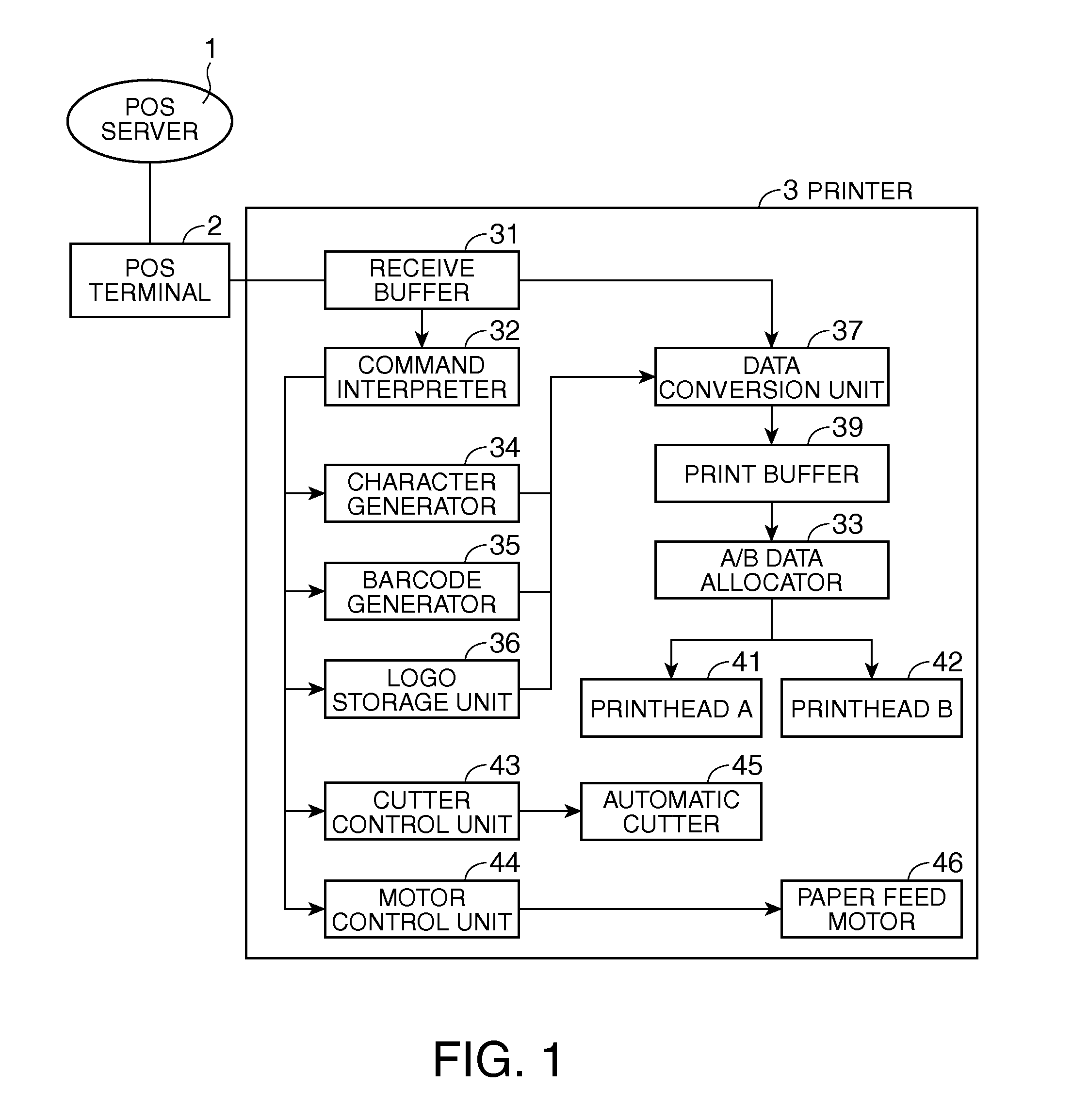

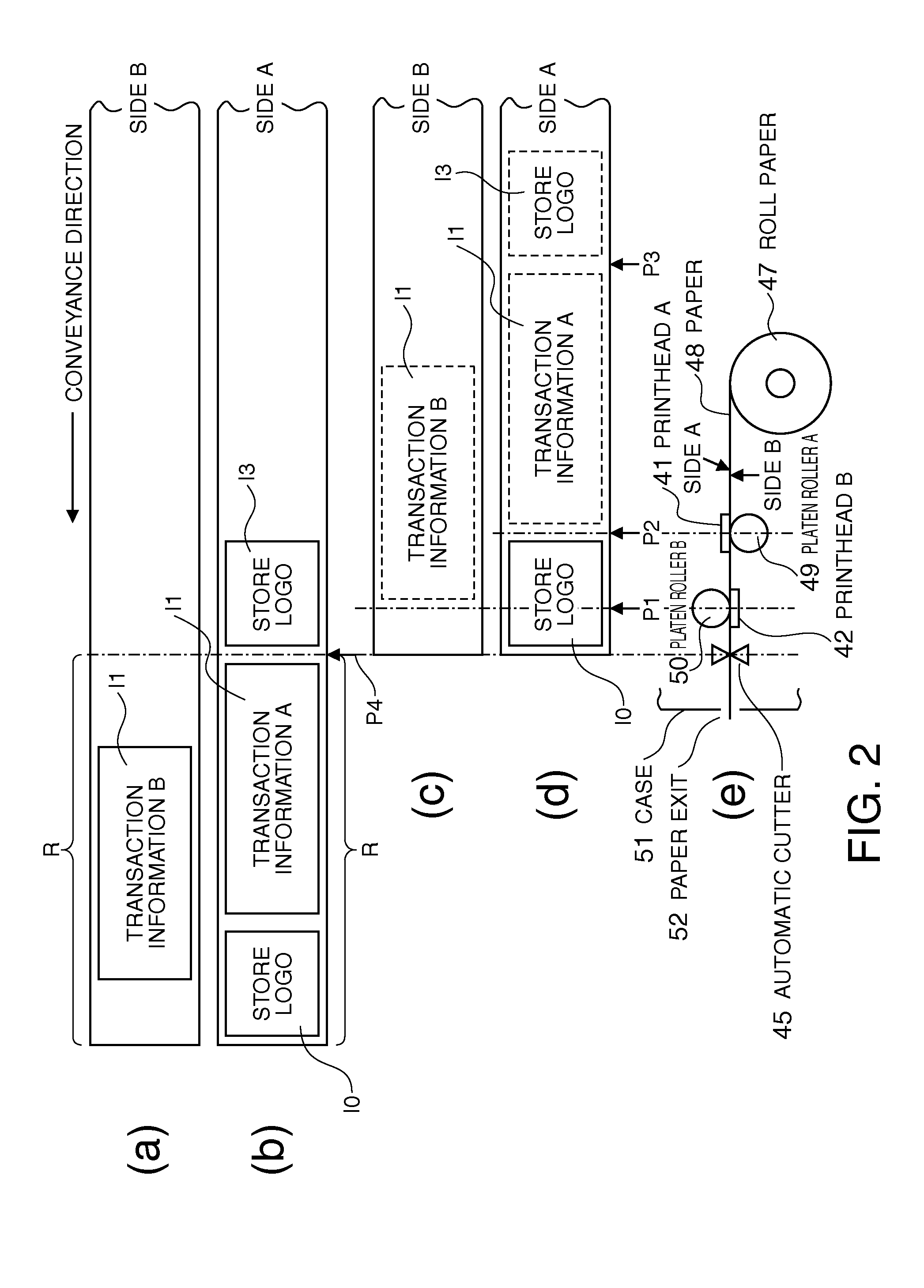

Two-sided receipt printing method, two-sided receipt printing device, and recording medium storing a program executed by a control unit that controls a two-sided receipt printing device

ActiveUS9387693B2Reduce paper wasteTypewritersReceipt giving machinesPulp and paper industryRecording media

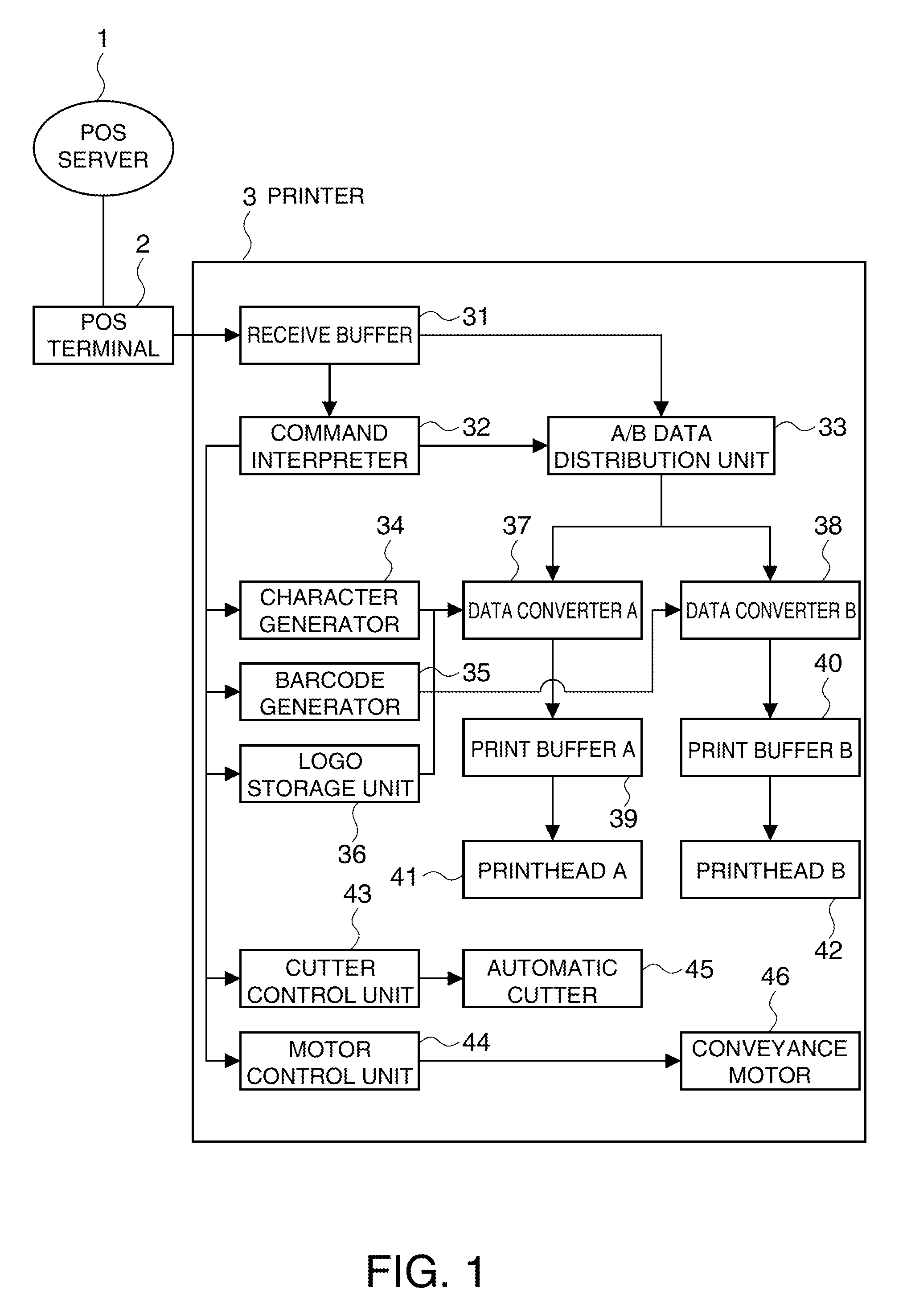

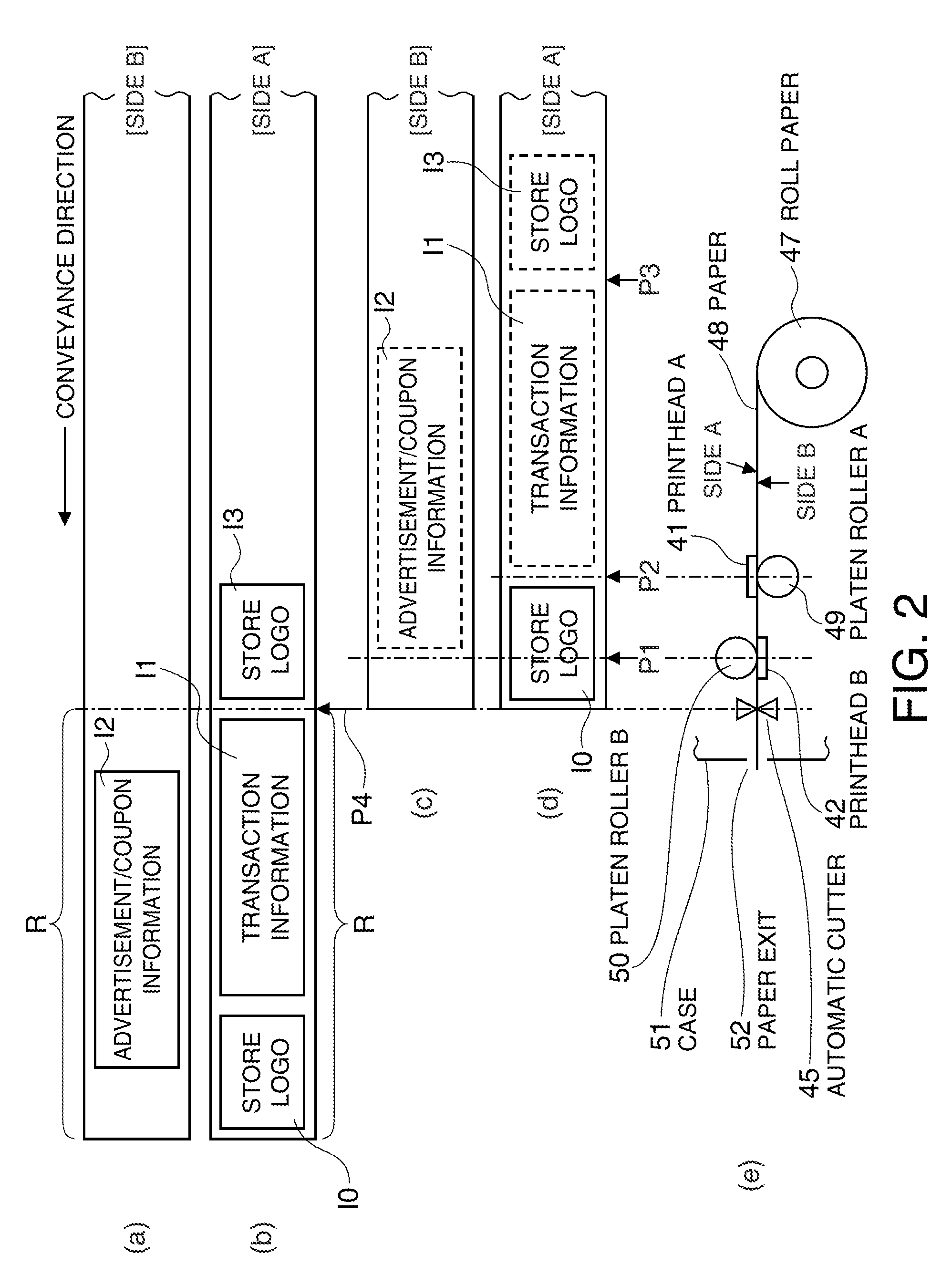

A two-sided receipt printing method that prints on both sides of paper and produces receipts, and can reduce white space at the leading end of receipts without conveying the paper in reverse. A device that produces two-sided receipts has a cutter, a first printhead that prints on one side of the paper, and a second printhead that prints on the other side of the paper disposed at specific intervals along the paper conveyance path from the paper exit. When an end-of-transaction declaration is received, transaction information is printed by the second printhead and non-transaction information is printed by the first printhead. After printing the transaction information, header information of a length that fits between the cutter and the second print data is printed by the second printhead. The cutter then cuts the paper at a position between where the transaction information was printed and where the header information was printed.

Owner:SEIKO EPSON CORP

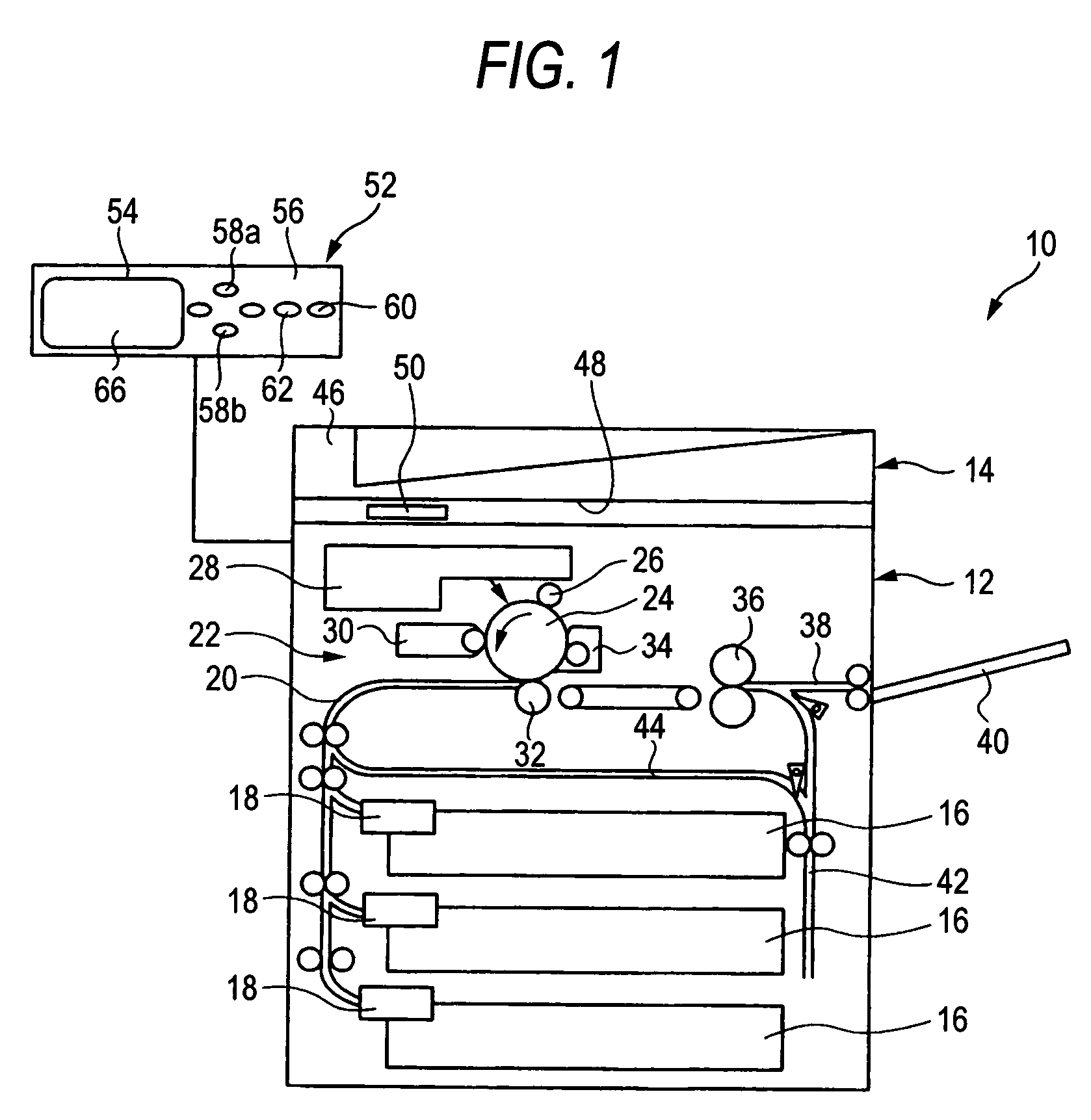

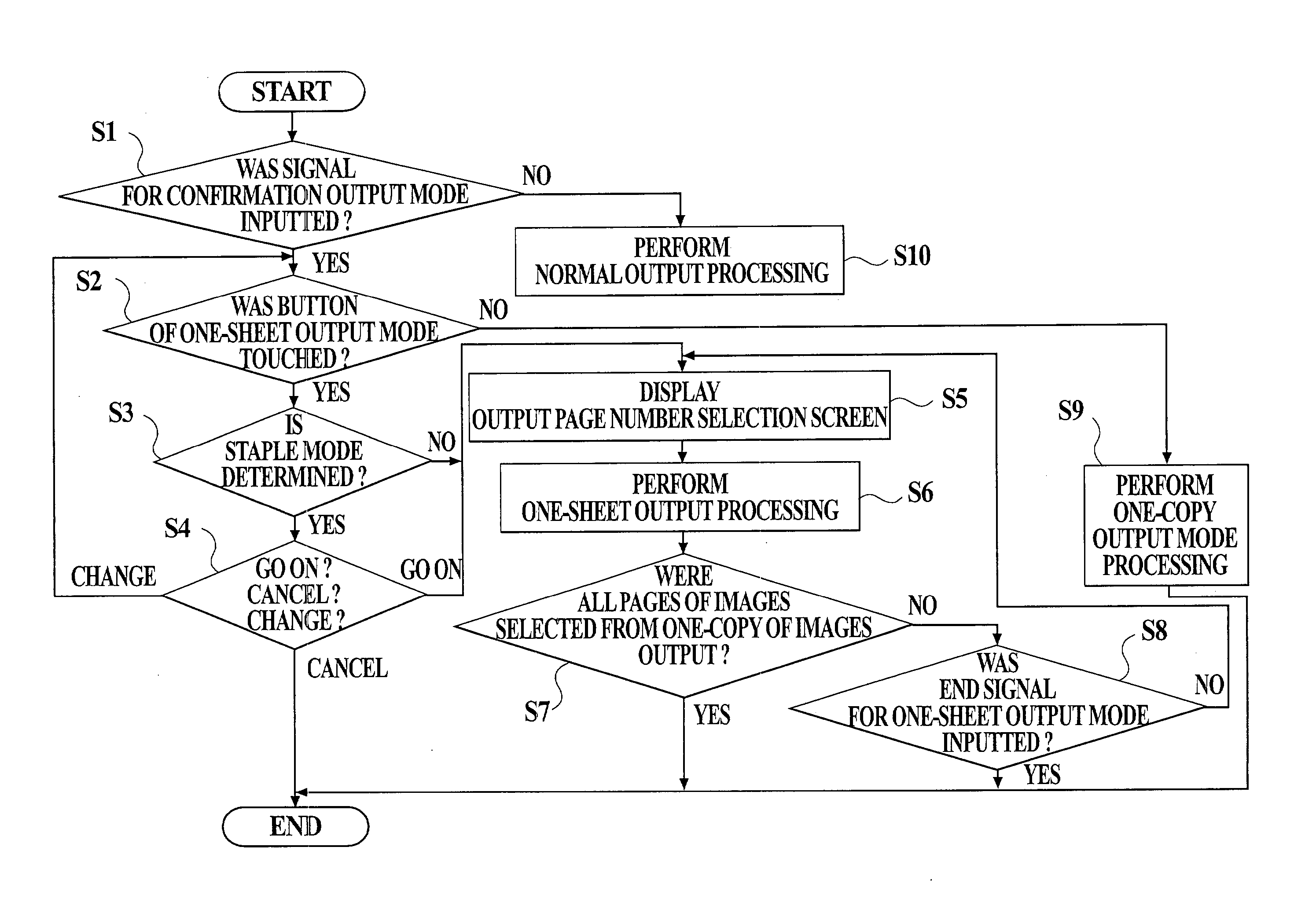

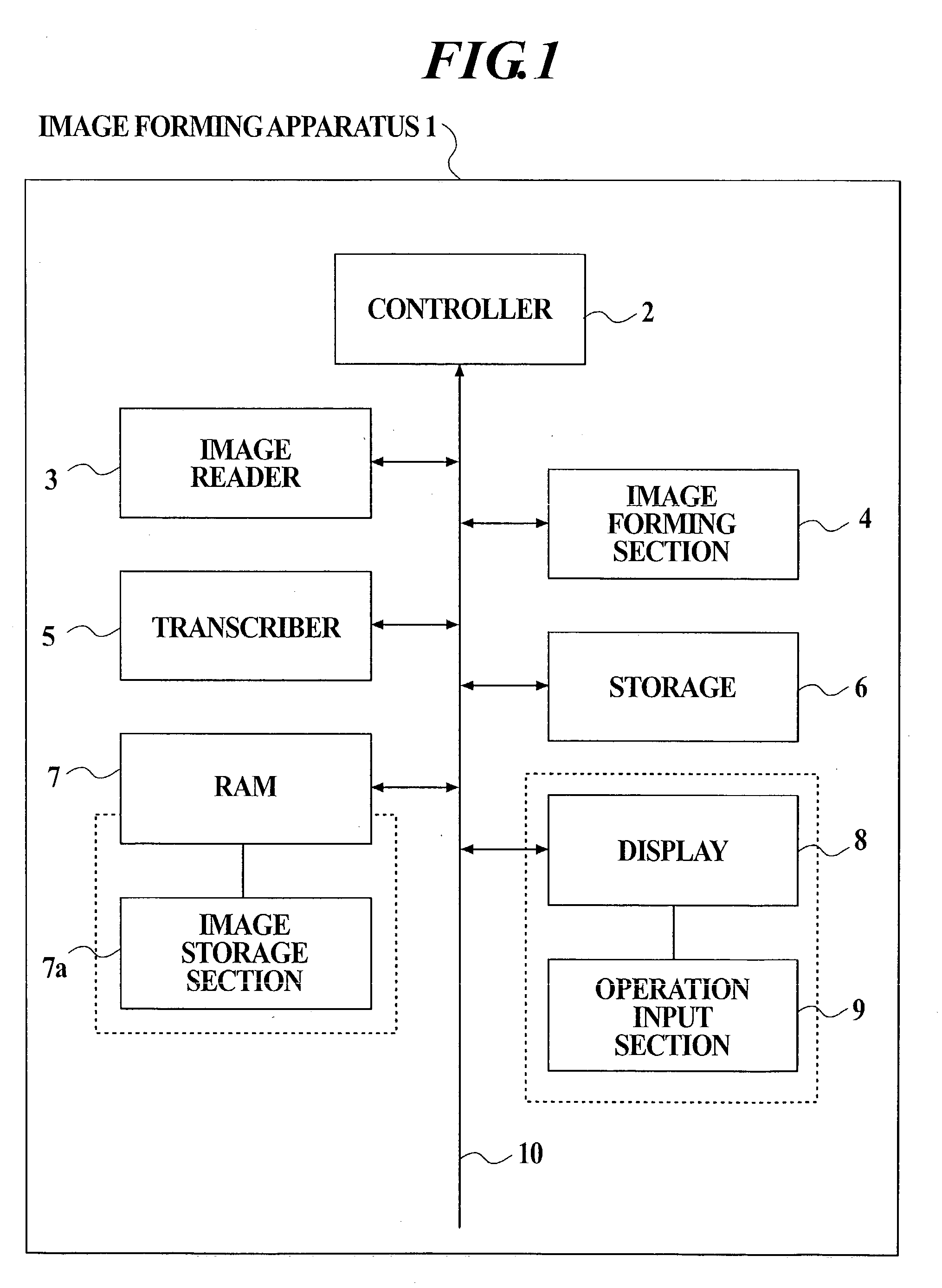

Image forming apparatus

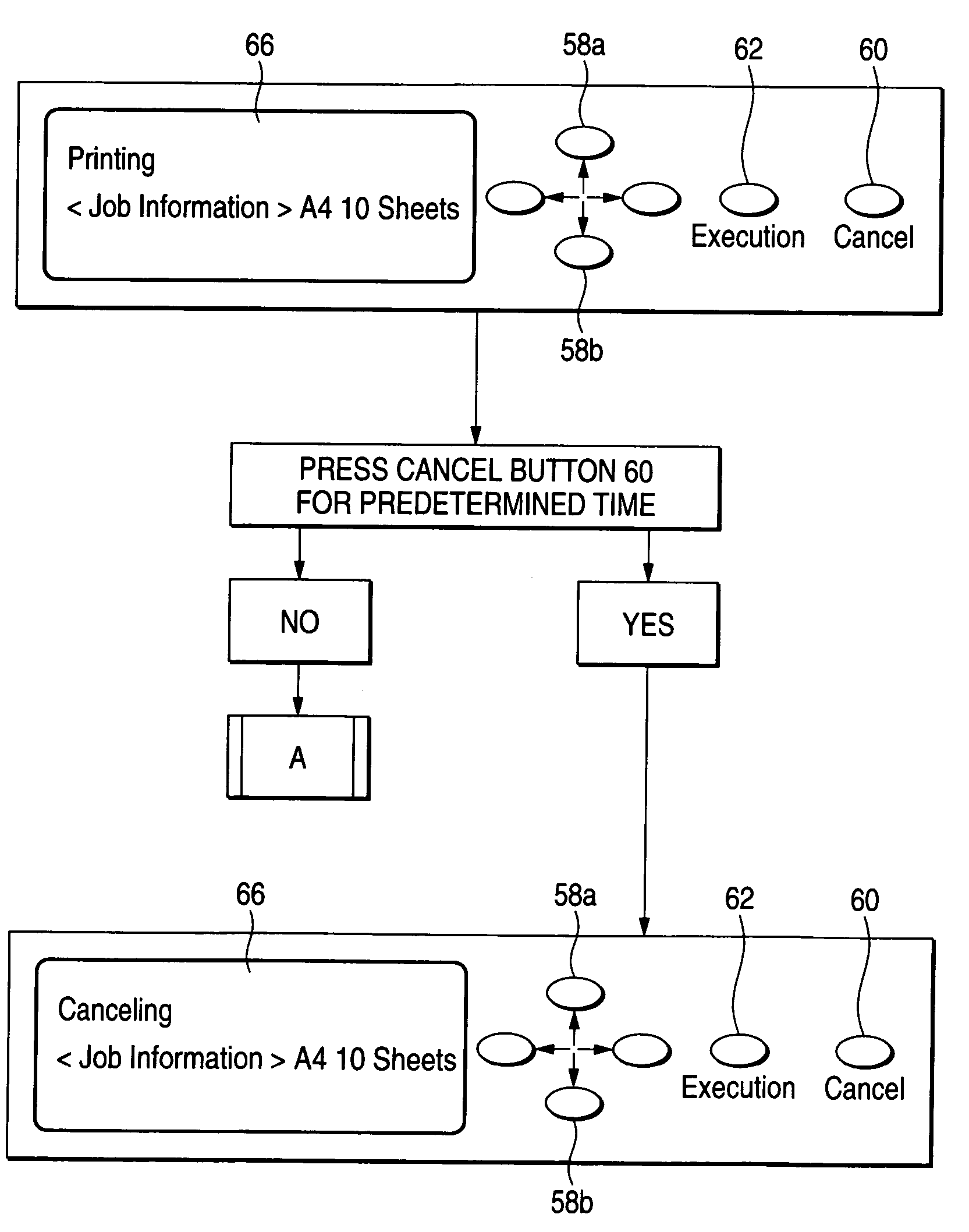

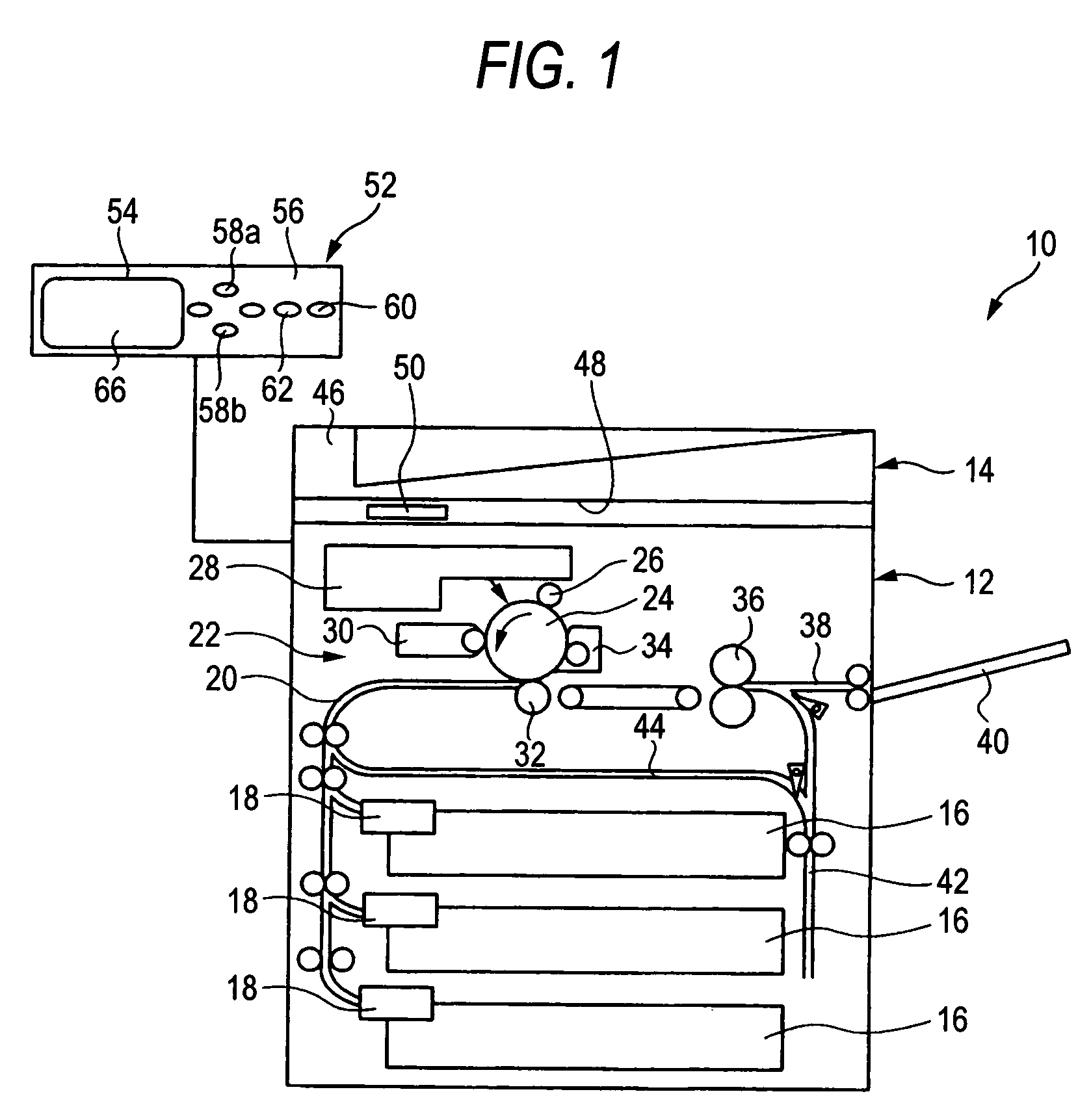

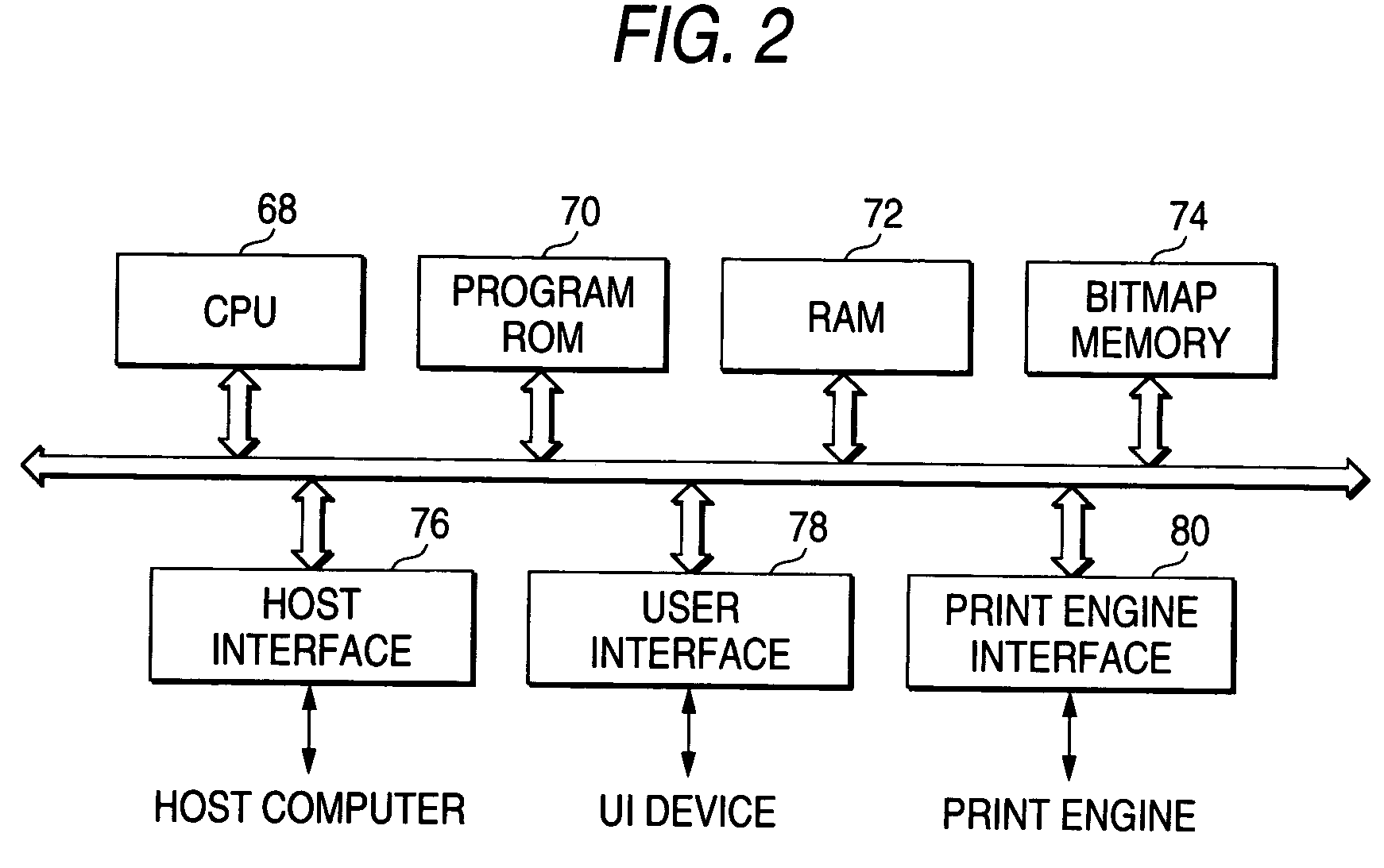

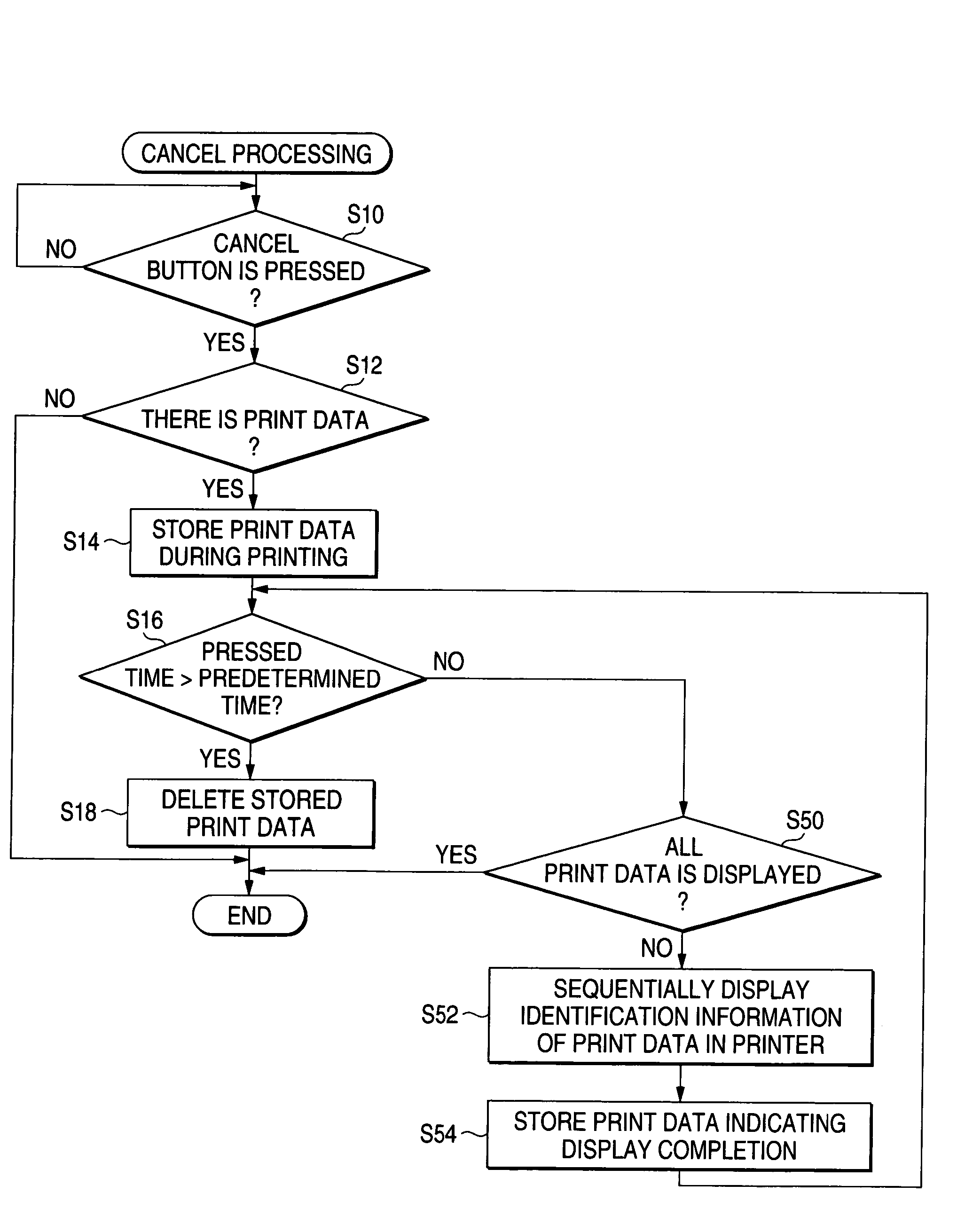

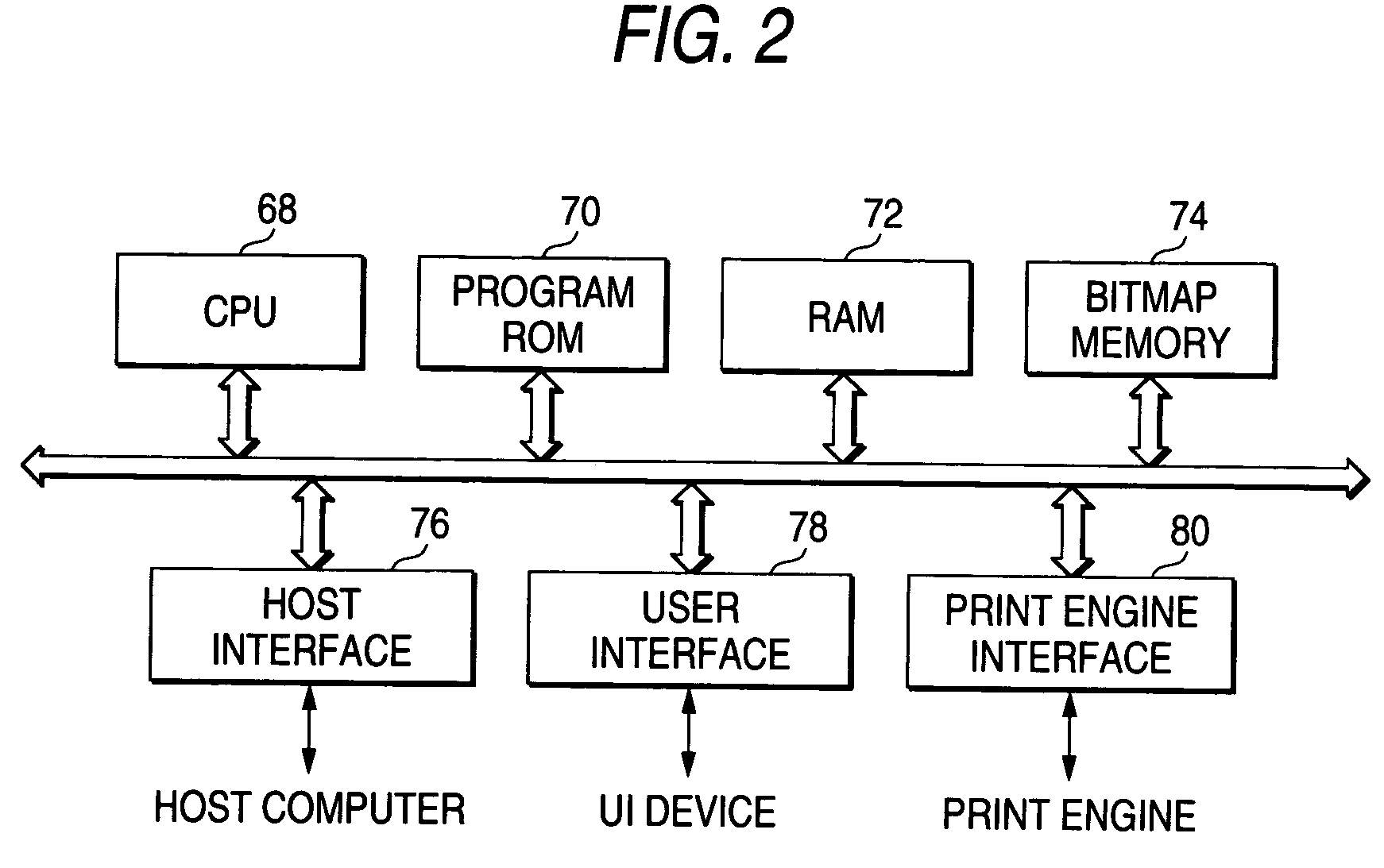

ActiveUS20060061797A1Paper waste can be suppressedReduce paper wasteVisual presentationPictoral communicationData selectionDatabase

An UI device includes a display unit, a cancel button, an execution button, and print data selection buttons. Identification information of print data during printing is displayed on the display unit, and when the cancel button is pressed for a predetermined time, the print data during printing is canceled. Further, when the pressed time is less than the predetermined time, a list of identification information of the print data is shown so that one of print data can be selected with the print data selection buttons and the selection to cancel is determined with the execution button, thereby canceling the print data.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Image forming apparatus with superior print canceling

ActiveUS8253964B2Reduce paper wasteReduce in quantityVisual presentationPictoral communicationComputer hardwareData selection

An UI device includes a display unit, a cancel button, an execution button, and print data selection buttons. Identification information of print data during printing is displayed on the display unit, and when the cancel button is pressed for a predetermined time, the print data during printing is canceled. Further, when the pressed time is less than the predetermined time, a list of identification information of the print data is shown so that one of print data can be selected with the print data selection buttons and the selection to cancel is determined with the execution button, thereby canceling the print data.

Owner:FUJIFILM BUSINESS INNOVATION CORP

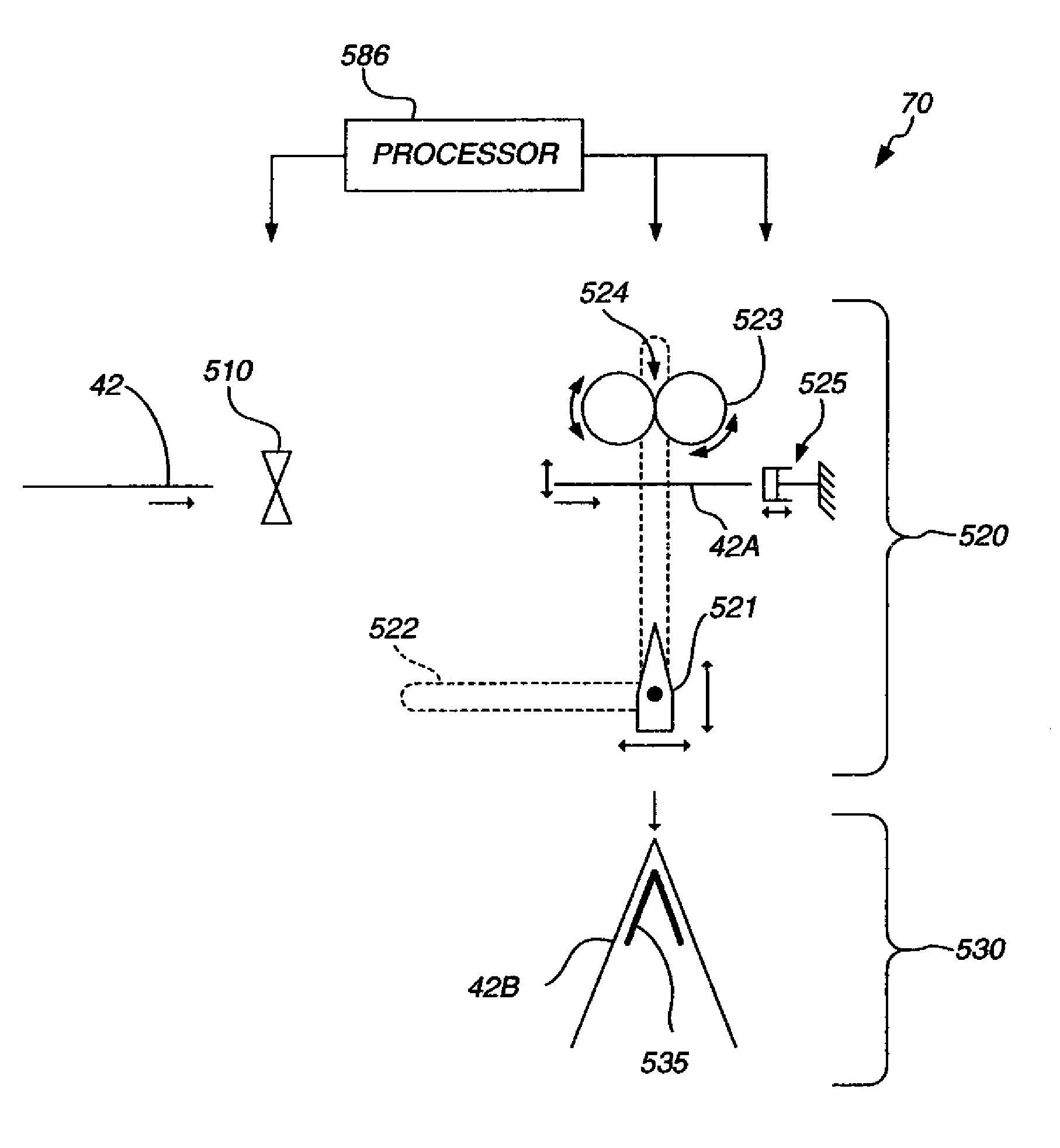

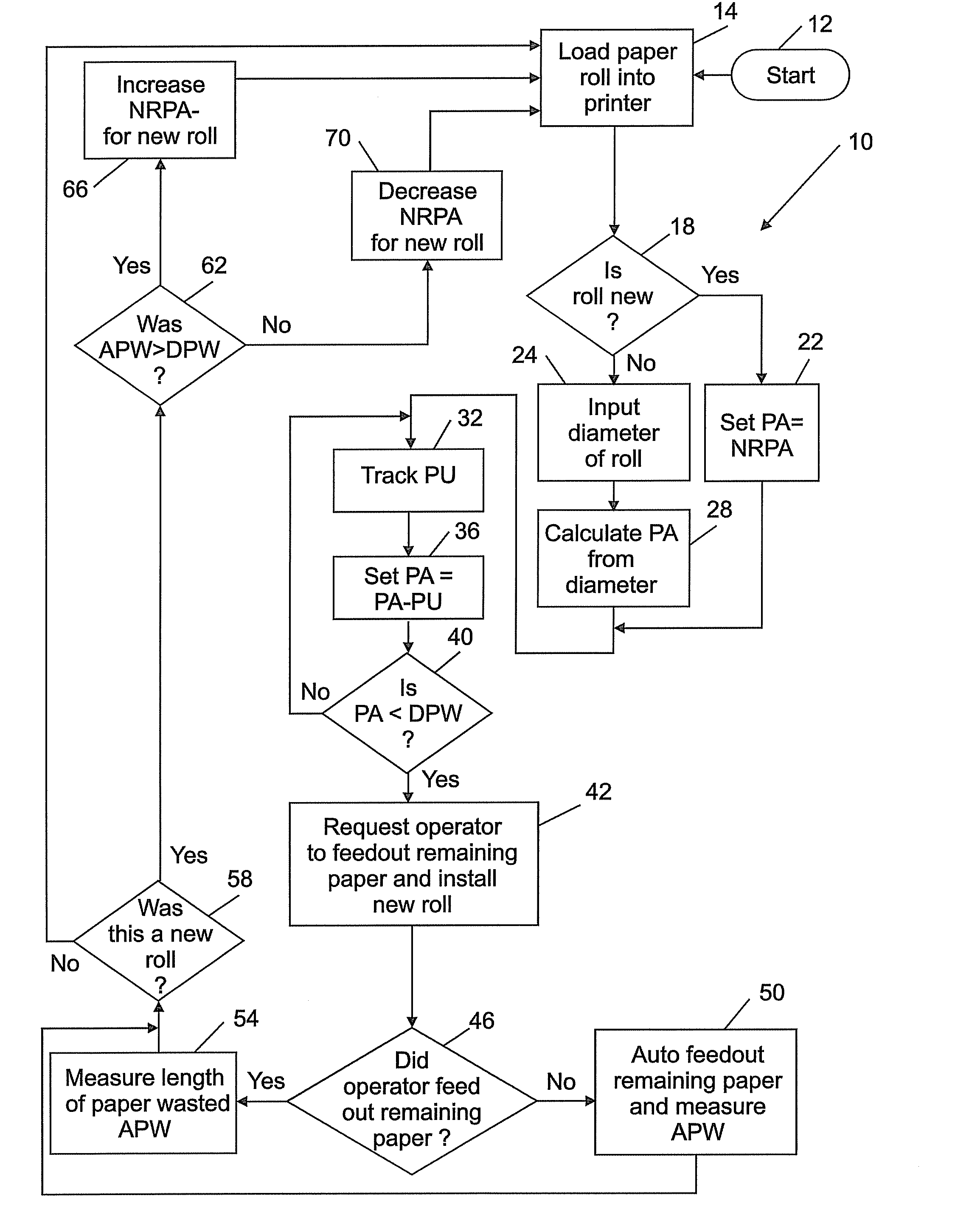

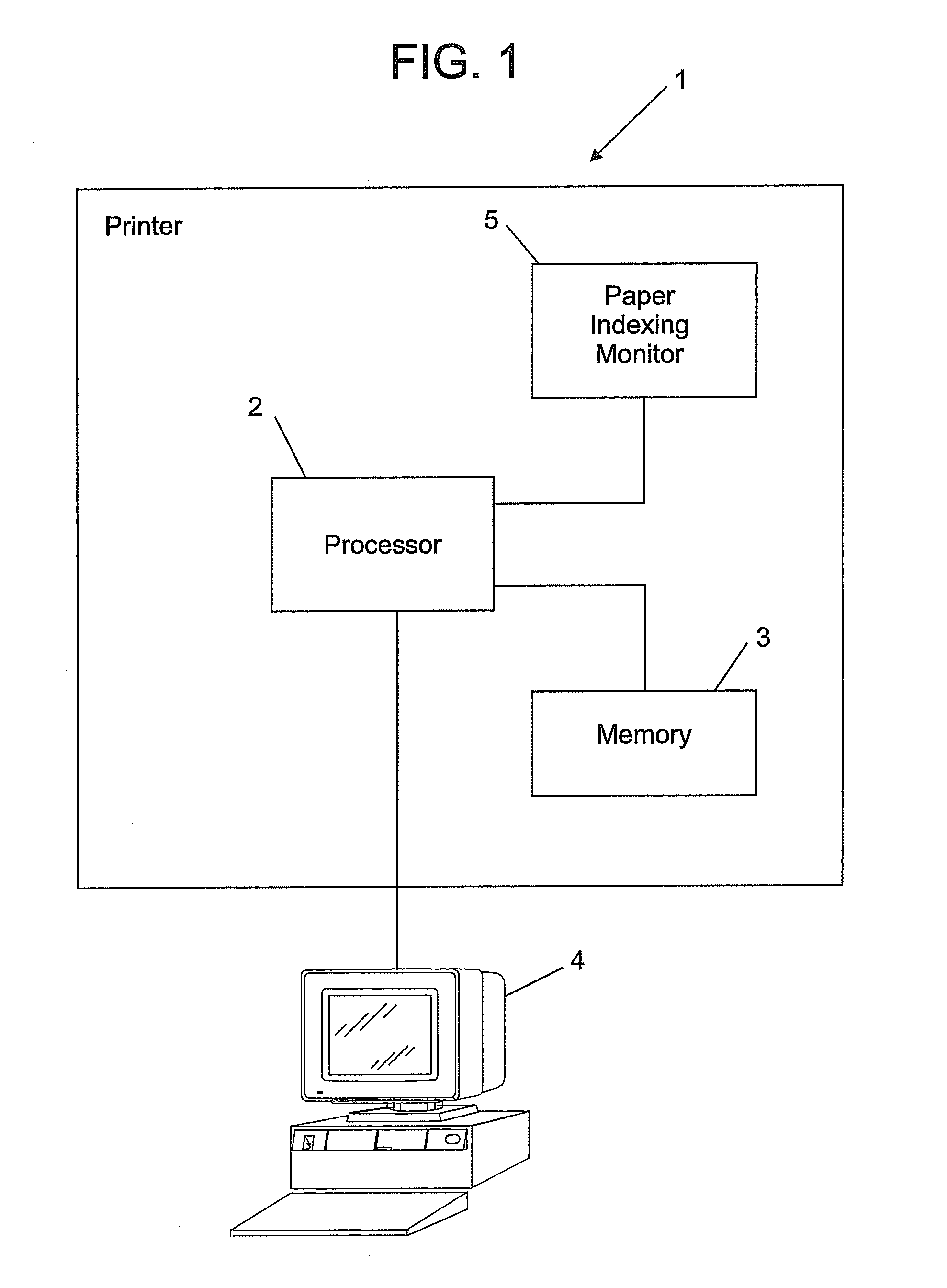

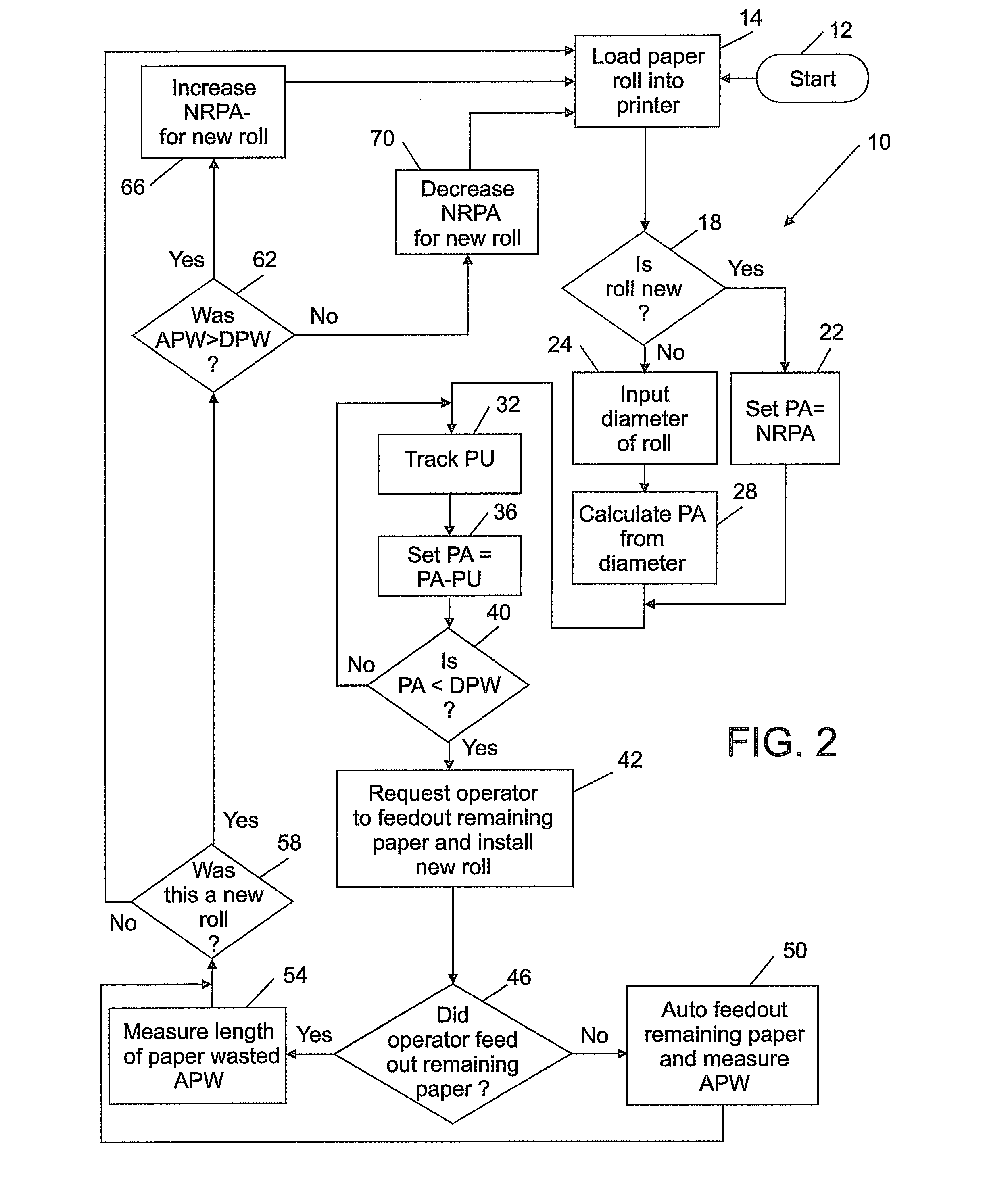

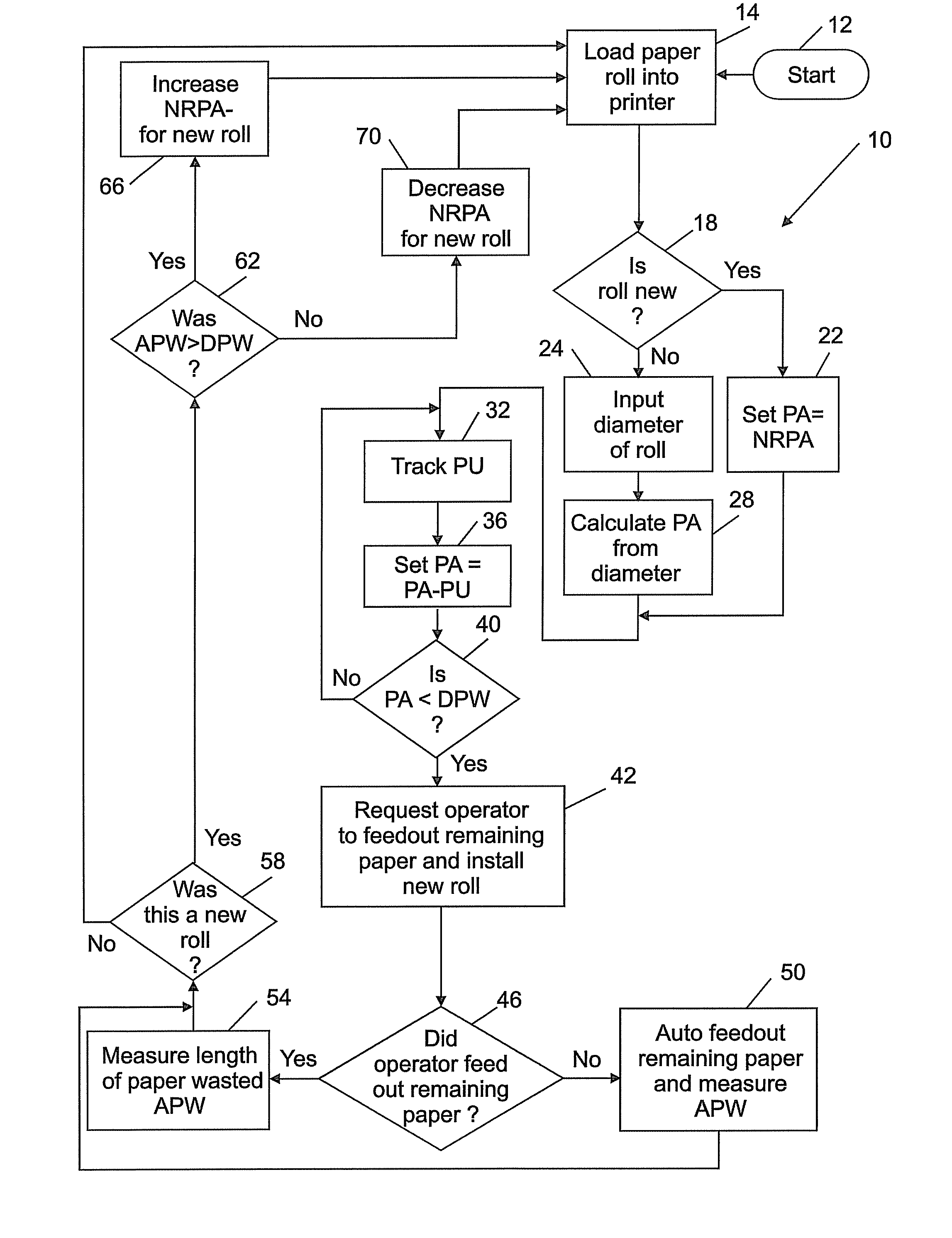

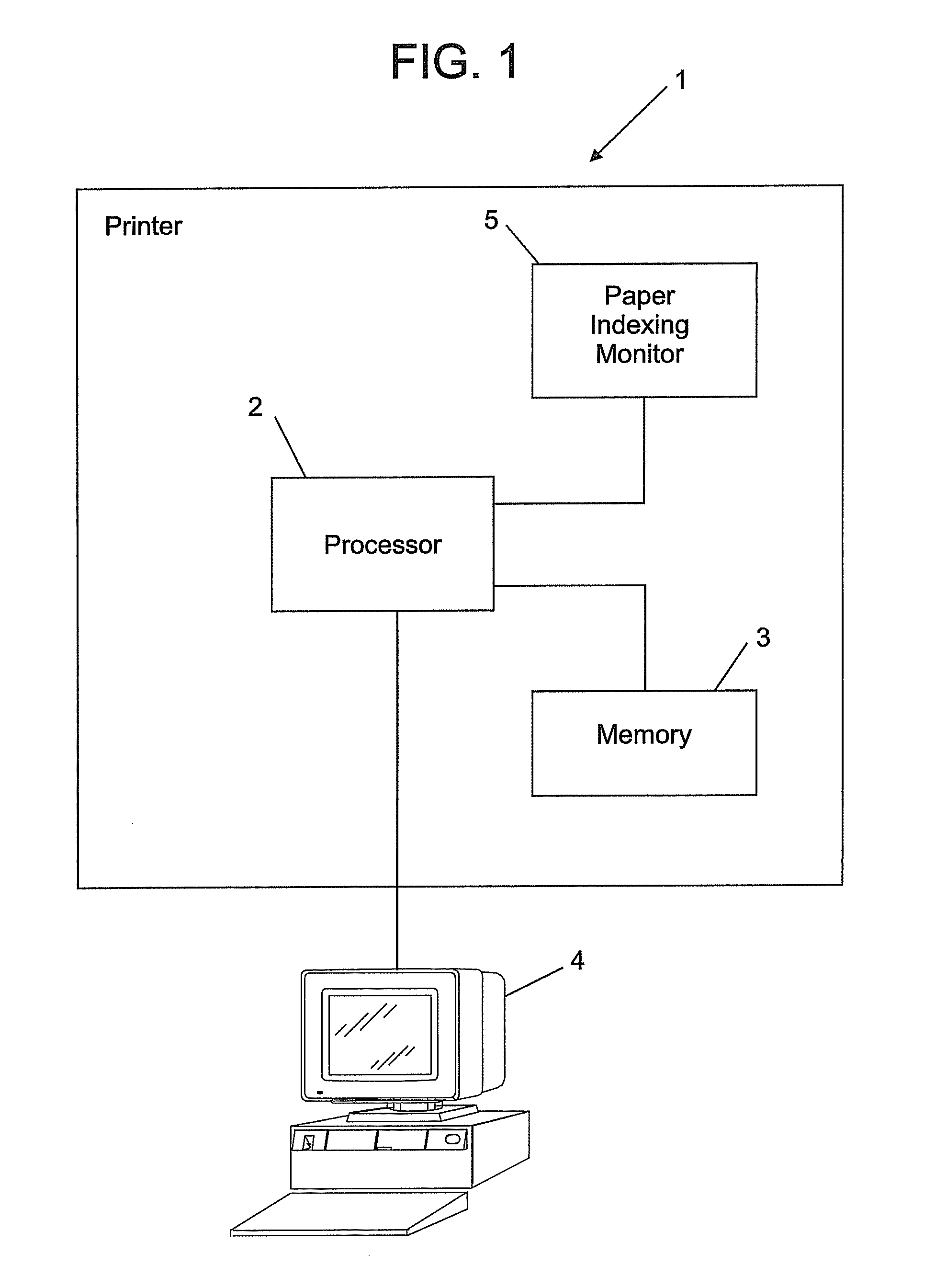

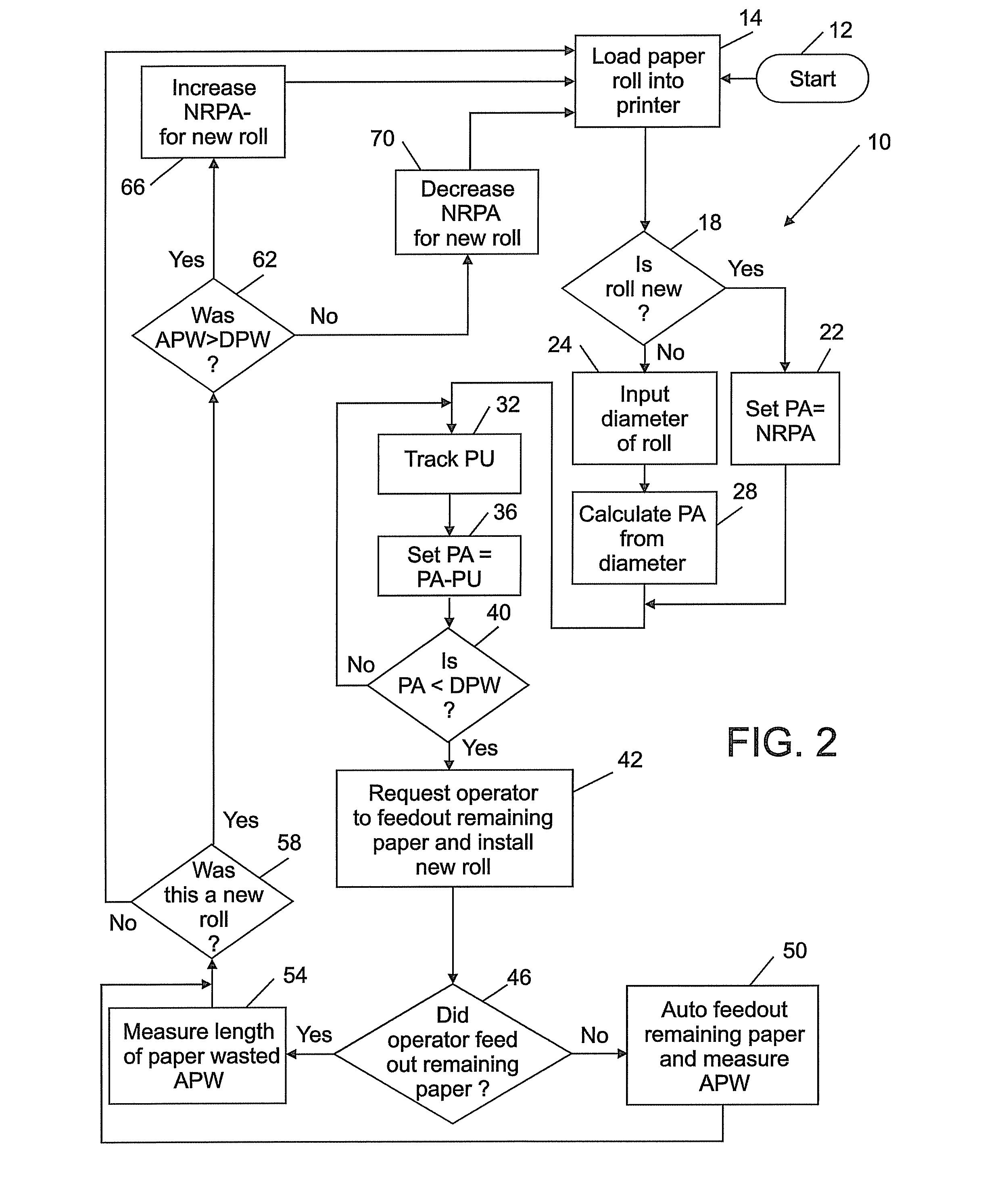

Printer paper waste reduction method and computer program product

InactiveUS20080118295A1Waste paper is reducedReduce paper wasteFilament handlingOther printing apparatusRolling paperComputer printing

Disclosed herein is a method that relates to paper waste reduction with a point of sale printer. The method comprising, establishing a length of paper available (PA) estimate during loading of paper into a point of sale printer and tracking a length of paper used (PU). The method further comprising, continuously updating the PA by subtracting the PU from the PA, and alerting an operator to replenish paper in the printer in response to the PA being less than a desired length of paper wasted (DPW). Additionally, the method updates the new roll paper available (NRPA) to ensure that the difference between actual paper wasted (APW) and the desired length of paper wasted (DPW) is minimal.

Owner:TOSHIBA GLOBAL COMMERCE SOLUTIONS HLDG

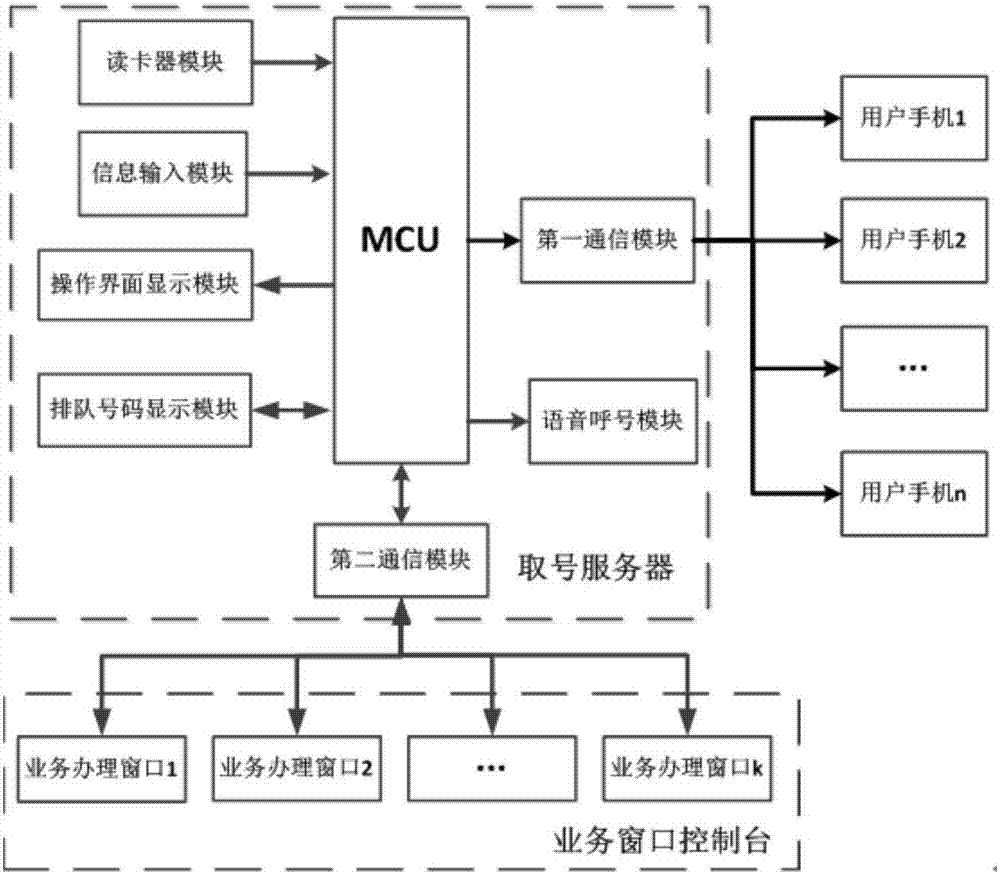

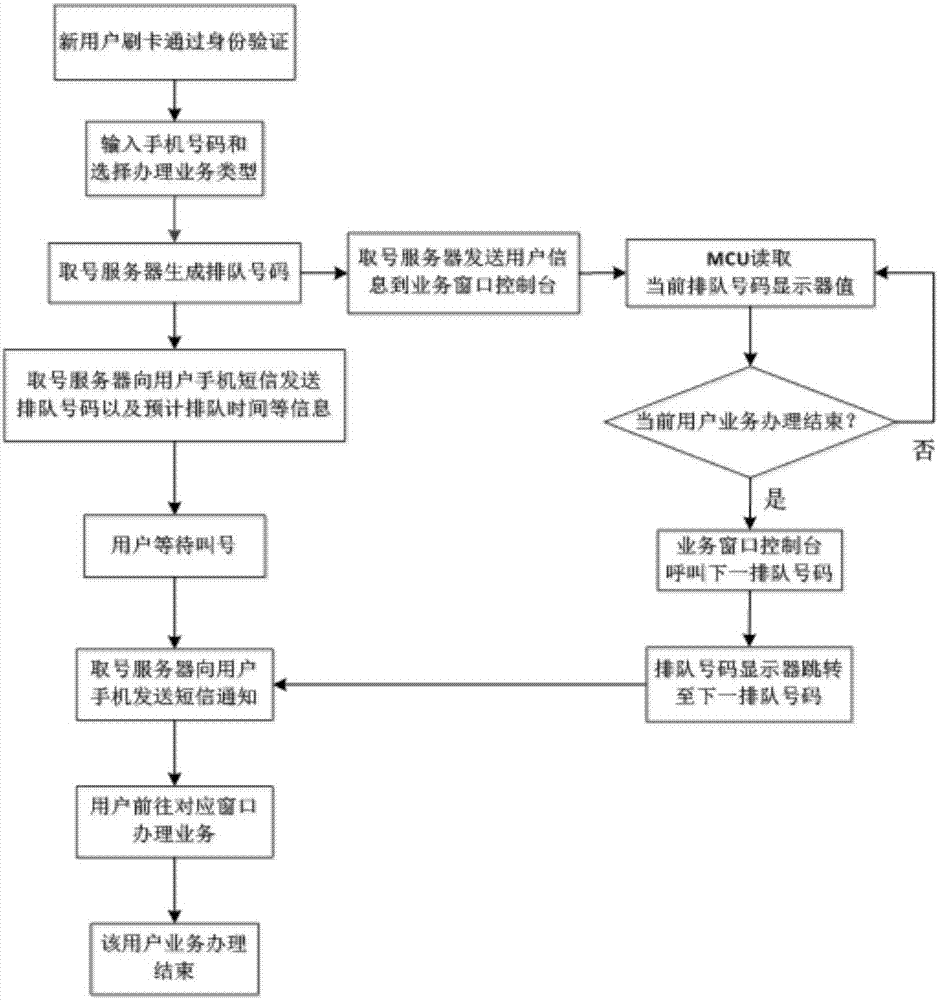

ARM-based bank wireless queuing and informing system and method

InactiveCN107016771AReduce paper wasteImprove work efficiencyChecking apparatusSubstation equipmentSerial portReal-time computing

The invention discloses an ARM-based bank wireless queuing and informing system and method. The system comprises a number taking server, a business window control console and a plurality of user cell phones, wherein the number taking server is communicated with the plurality of user cell phones through a network; the number taking server is communicated with the business window control console through a serial port so as to transmit and receive data. The number taking server comprises an MCU microprocessor, and a card reader module, an information input module, an operation interface display module, a queuing number display module, a first communication module, a second communication module and a language number calling module which are all connected with the MCU microprocessor. According to the system disclosed by the invention, a user can reasonably arrange waiting time according to predicted waiting time and a number calling notification short message, the problem that the waiting time is long during queuing in a bank is relieved, the business handling efficiency is improved, and the problem of missing a called number is avoided; meanwhile, the paper waste generated by a traditional number calling mode is effectively reduced.

Owner:ZHEJIANG UNIV

Two-sided receipt printing method, two-sided receipt printing device, and recording medium storing a program executed by a control unit that controls a two-sided receipt printing device

ActiveUS20120134735A1Reduce paper wasteTypewritersReceipt giving machinesPulp and paper industryPaper sheet

A two-sided receipt printing method that prints on both sides of paper and produces receipts, and can reduce white space at the leading end of receipts without conveying the paper in reverse. A device that produces two-sided receipts has a cutter, a first printhead that prints on one side of the paper, and a second printhead that prints on the other side of the paper disposed at specific intervals along the paper conveyance path from the paper exit. When an end-of-transaction declaration is received, transaction information is printed by the second printhead and non-transaction information is printed by the first printhead. After printing the transaction information, header information of a length that fits between the cutter and the second print data is printed by the second printhead. The cutter then cuts the paper at a position between where the transaction information was printed and where the header information was printed.

Owner:SEIKO EPSON CORP

Printer paper waste reduction method and computer program product

InactiveUS7748918B2Reduce paper wasteReduce the amount requiredFilament handlingOther printing apparatusRolling paperPulp and paper industry

Disclosed herein is a method that relates to paper waste reduction with a point of sale printer. The method comprising, establishing a length of paper available (PA) estimate during loading of paper into a point of sale printer and tracking a length of paper used (PU). The method further comprising, continuously updating the PA by subtracting the PU from the PA, and alerting an operator to replenish paper in the printer in response to the PA being less than a desired length of paper wasted (DPW). Additionally, the method updates the new roll paper available (NRPA) to ensure that the difference between actual paper wasted (APW) and the desired length of paper wasted (DPW) is minimal.

Owner:TOSHIBA GLOBAL COMMERCE SOLUTIONS HLDG

Environment-friendly firework drum body preparation process

The invention discloses an environment-friendly firework drum body preparation process. The firework drum body is composed of the following raw materials of, in parts by weight, 30-60 parts of plant fibers, 3-20 parts of waste paper, 6-15 parts of biological glue, 10-20 parts of filling materials and 5-10 parts of water. According to the environment-friendly firework drum body preparation process,a starch material is adopted to replace polyvinyl alcohol, methanol and other toxic chemical adhesives of a traditional process winding drum, so that the contact skin disease caused by direct contactwith the toxic glue by an operator is avoided, and the working environment of the operator is improved; the plant fibers and the waste paper leftover materials are adopted as raw materials, the wasteof paper is reduced, and the ecological environment is protected; and the firework drum body is integrally formed by adopting high-temperature mould pressing equipment, the structure is firmer, and the setting-off safety is improved.

Owner:张金希

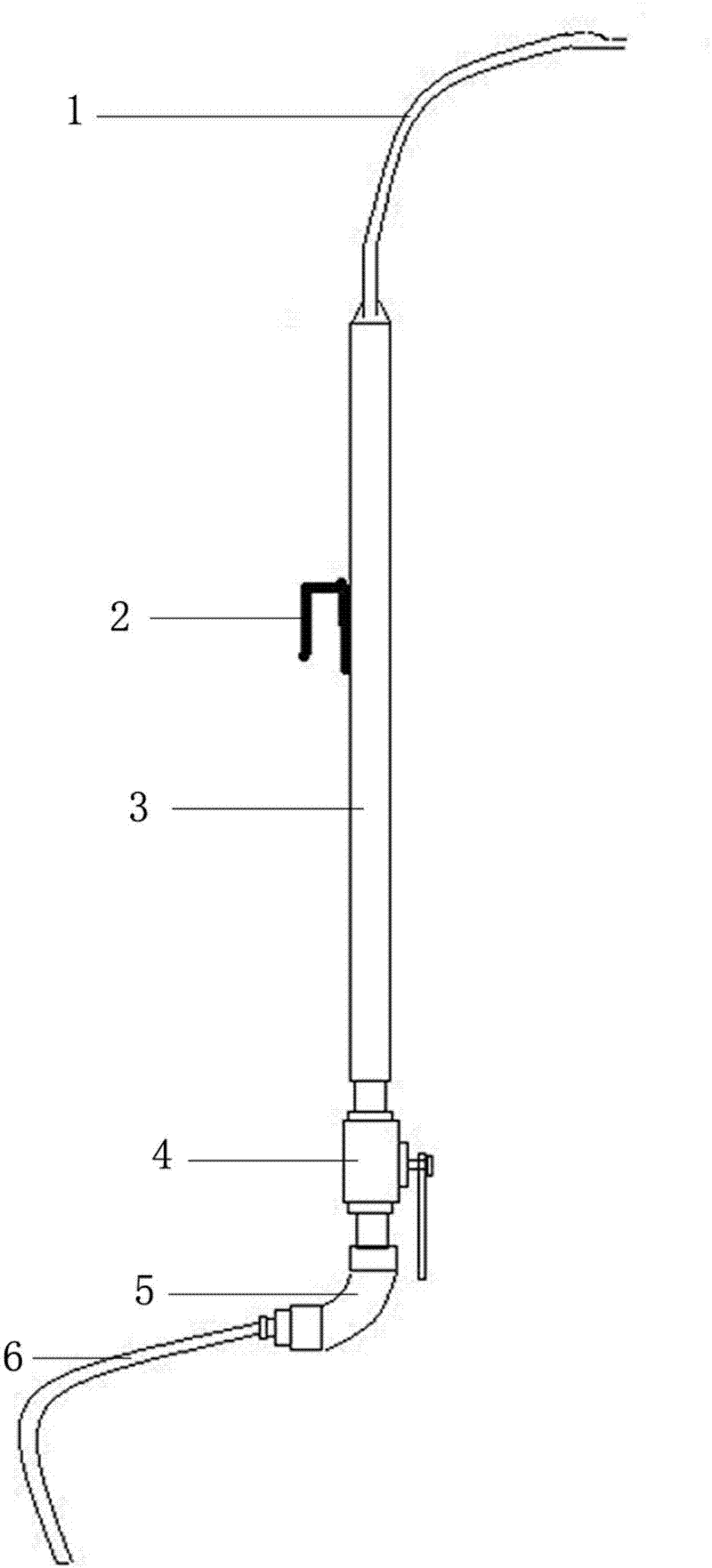

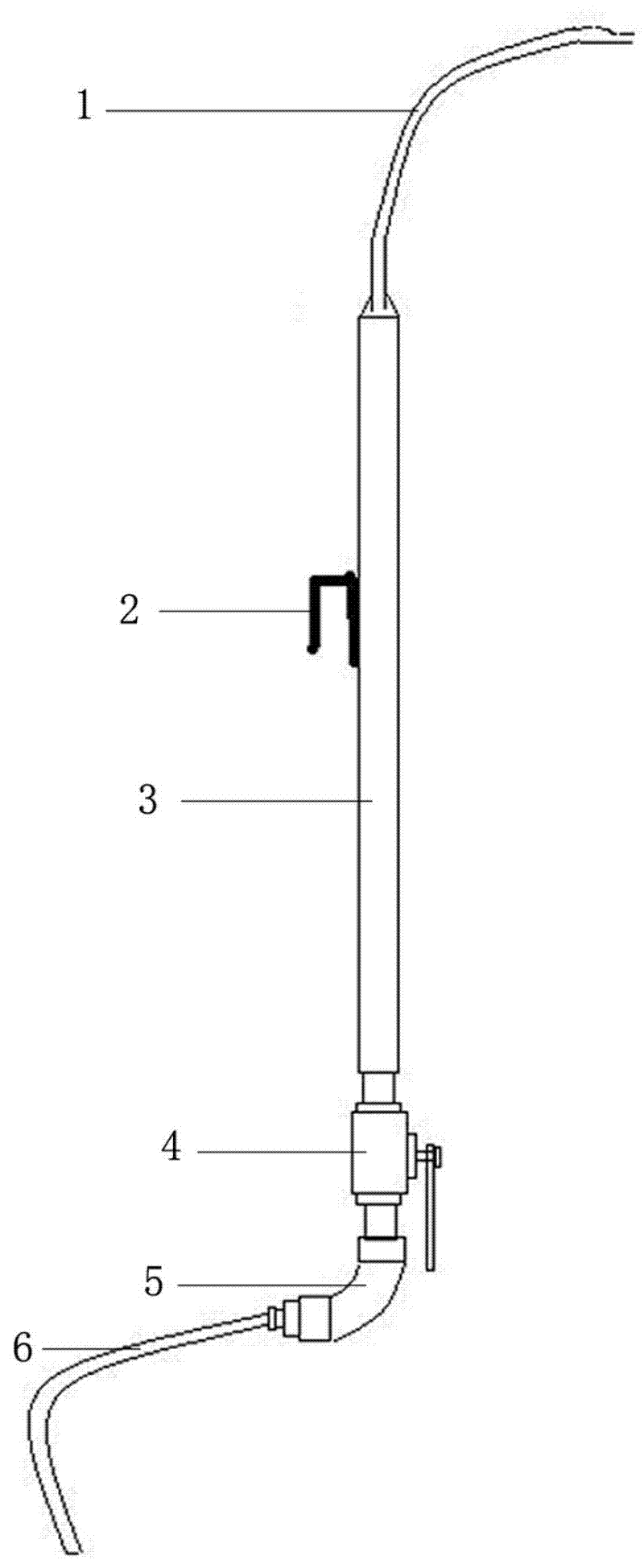

Novel paper leading tool close to vat

ActiveCN102199893AImprove paper threading efficiencyEasy to useDryer sectionSpray nozzleEconomic benefits

The invention provides a novel paper leading tool close to a vat. The tool comprises a hollow rod body, wherein a hand valve and a hollow handle are arranged at the lower end of the hollow rod body; the lower end of the hollow handle is communicated with a compressed air source; a cambered hollow spray nozzle body is arranged at the upper end of the hollow rod body; a nozzle of the hollow spray nozzle body is duckbilled; a hook is arranged at the outer side of the hollow rod body; and the hollow rod body, the hollow spray nozzle body, the hand valve and the hollow handle are all made of stainless steel. The tool has the following beneficial effects: the paper leading efficiency close to the vat can be obviously improved, the broke amount close to the vat is greatly reduced, the productionconsumption is reduced and the potential economic benefits are obvious; and the tool is convenient to use, the potential safety hazards are eliminated and the evaluation given by the operators is good.

Owner:HENAN CIGARETTE IND TOBACCO SLICE

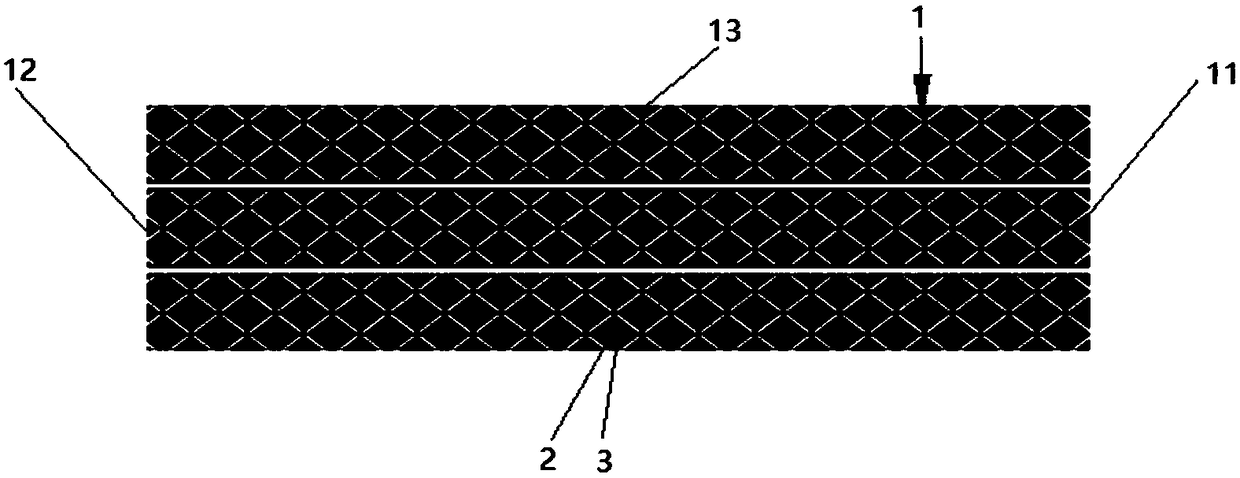

Glue coating method, glue coating part and glue coating machine

InactiveCN108297610AReduce the chance of deformationReduce paper wastePaper-makingBox making operationsPulp and paper industryRejection rate

The invention relates to paper product packaging mechanical automation equipment, in particular to a glue coating method, a glue coating part and a glue coating machine. The glue coating method comprises the steps that the surface of paper is coated with glue in the mode of multiple glue blocks, and the glue blocks are mutually separated in the paper. The paper is coated with the glue in a dispersed mode through the multiple glue blocks, the multiple glue blocks cannot form a film face on the paper, the paper deformation probability is reduced, and the paper rejection rate is reduced. The gluecoating part is provided with a glue coating surface for carrying out glue coating on the paper, and the glue coating surface is provided with multiple glue coating areas which are mutually separated. The mutually-separated glue coating areas on the glue coating surface can achieve dispersed glue coating on the paper, the glue cannot form the film face, the paper deformation probability is reduced, and the paper rejection rate is reduced.

Owner:上海隽韬创意设计发展有限公司

Calculating booklet sheet length using toner thickness

InactiveUS8437687B2Reduce noiseReduce power consumptionMechanical working/deformationTypewritersSheet material

Owner:EASTMAN KODAK CO

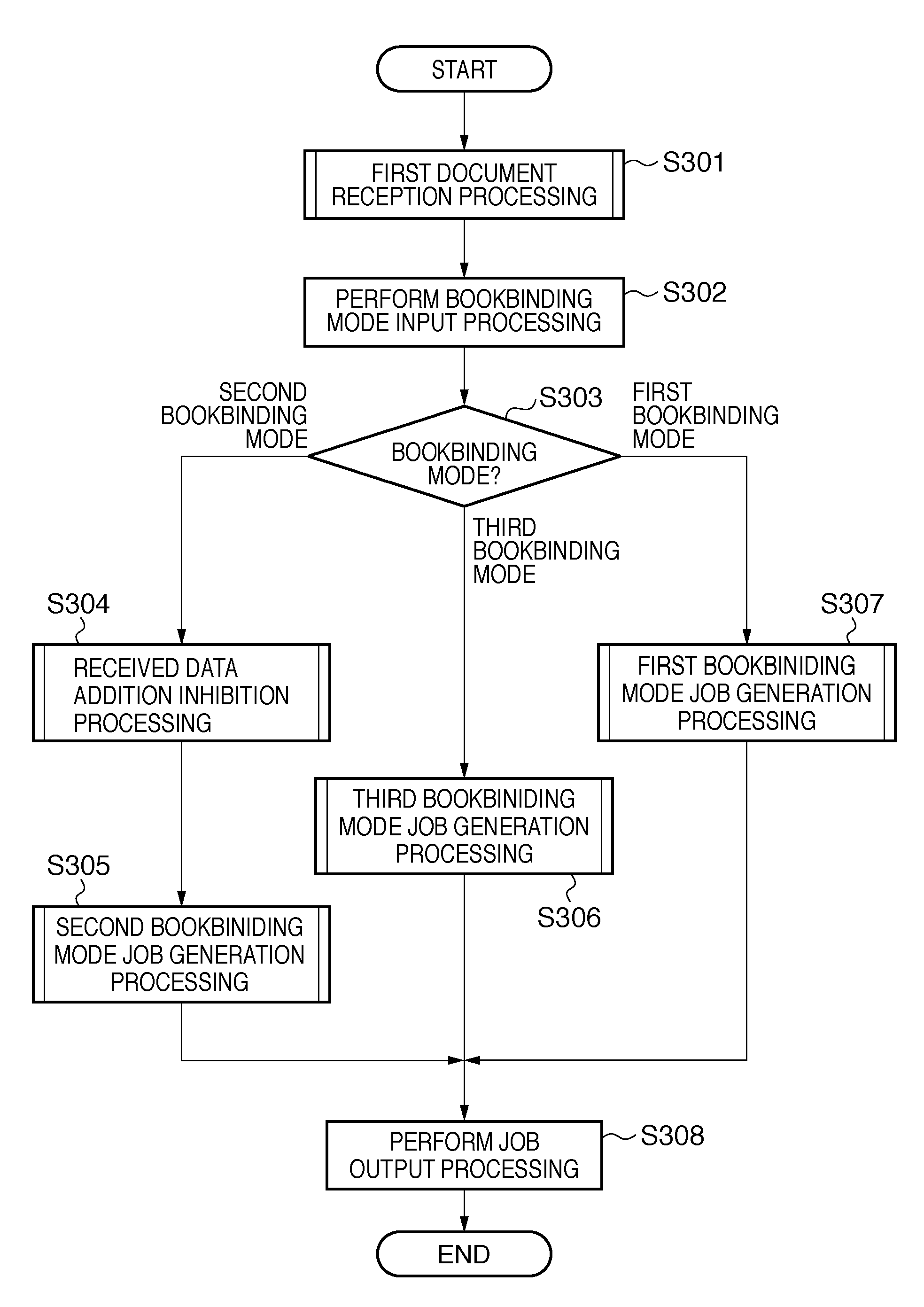

Bookbinding printing system in which a plurality of bound products are generated by a single job

InactiveUS8531708B2Promote generationWaste of paperDigital output to print unitsInformation processingSize determination

Owner:CANON KK

Image forming apparatus and method

InactiveUS20030147093A1Reduce paper wasteEasy to useDigitally marking record carriersDigital computer detailsComputer graphics (images)Image formation

Owner:KONICA CORP

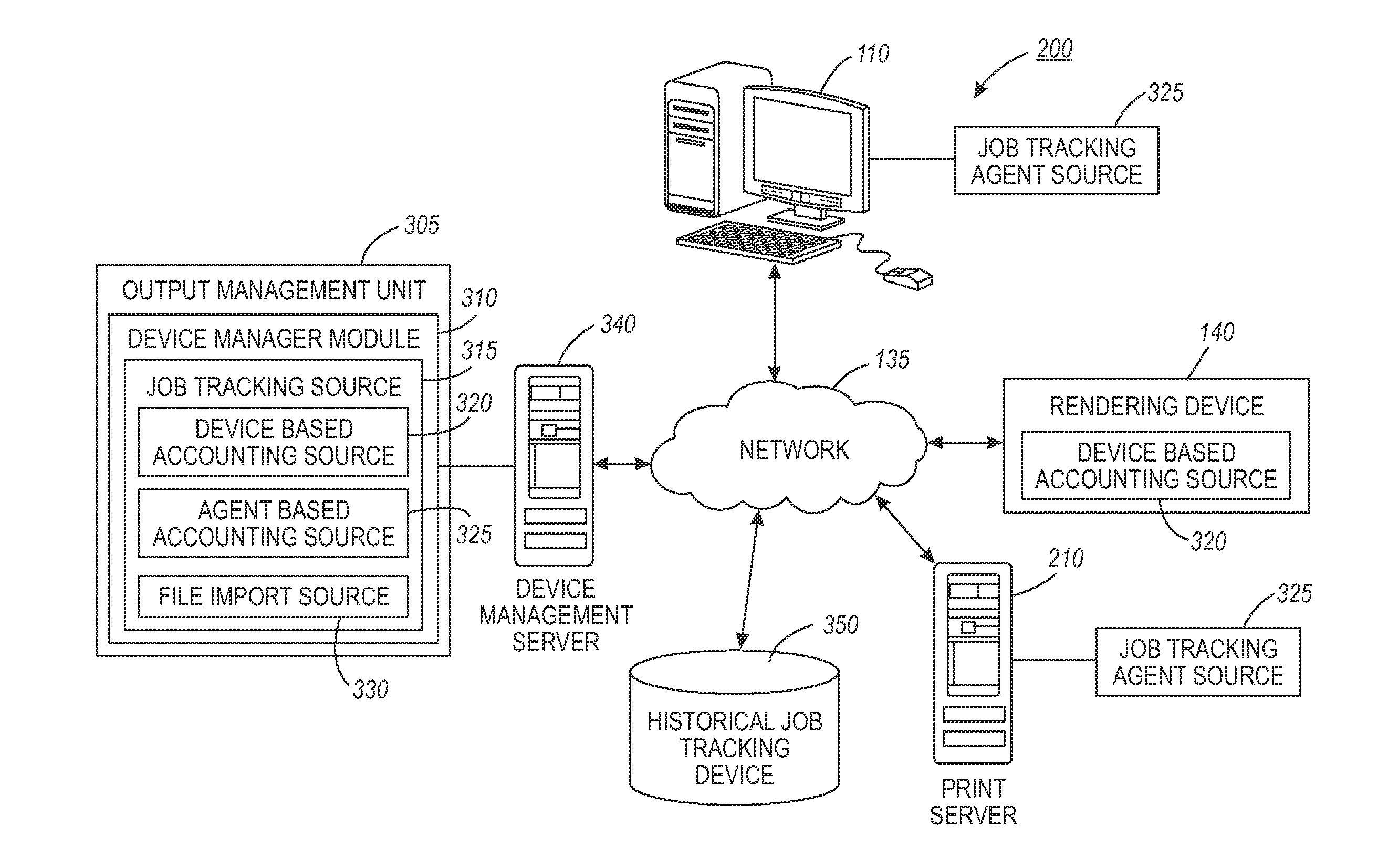

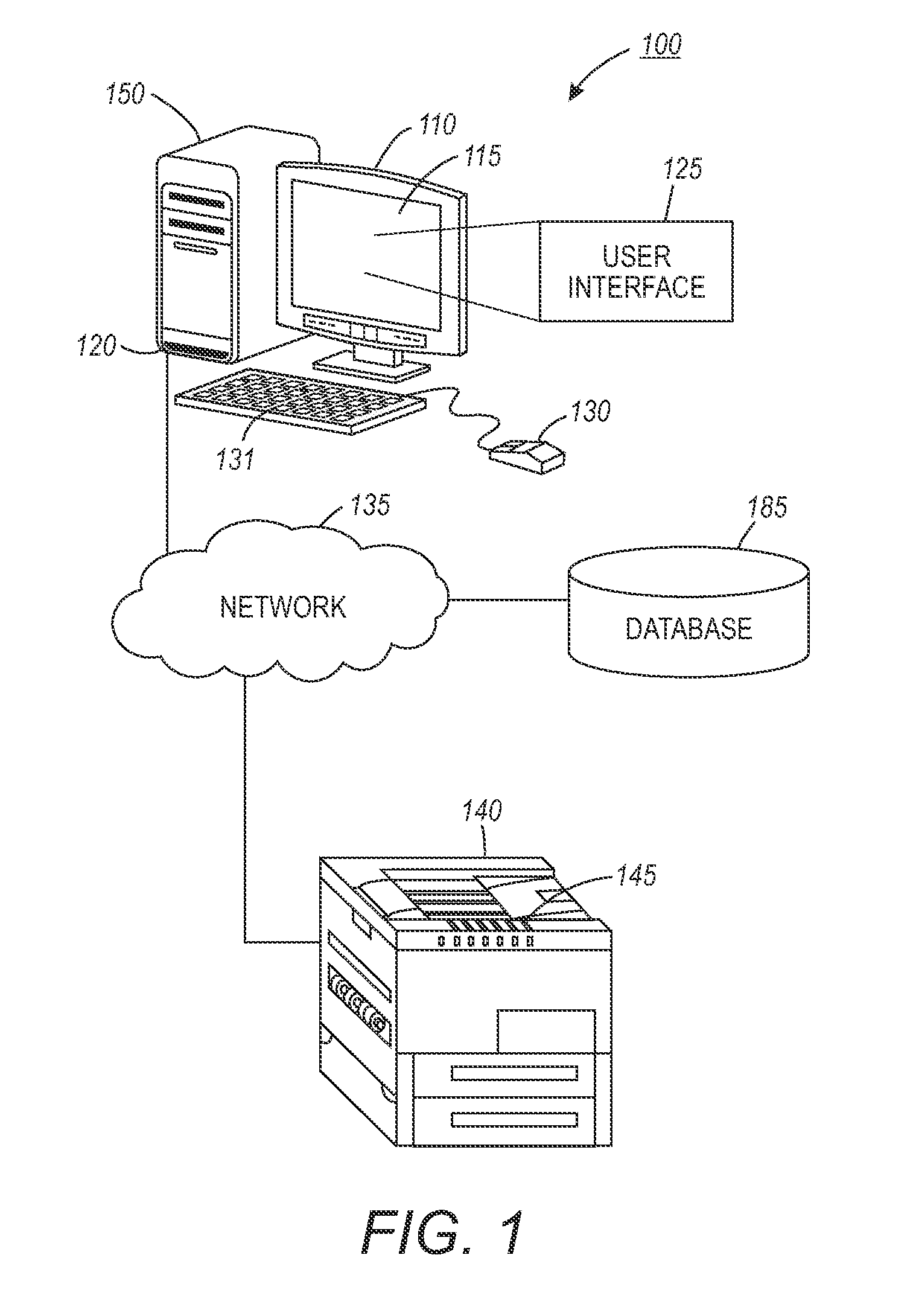

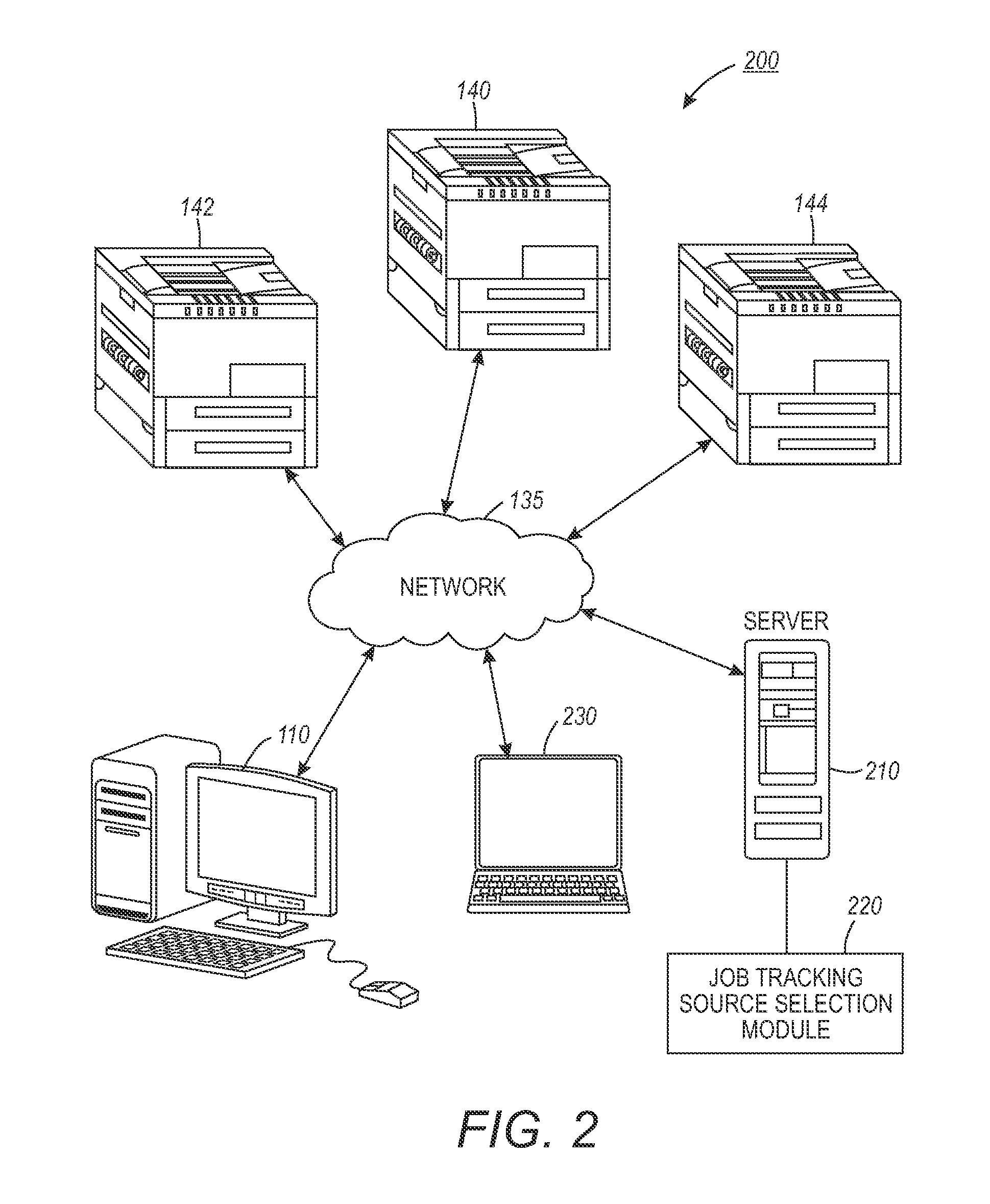

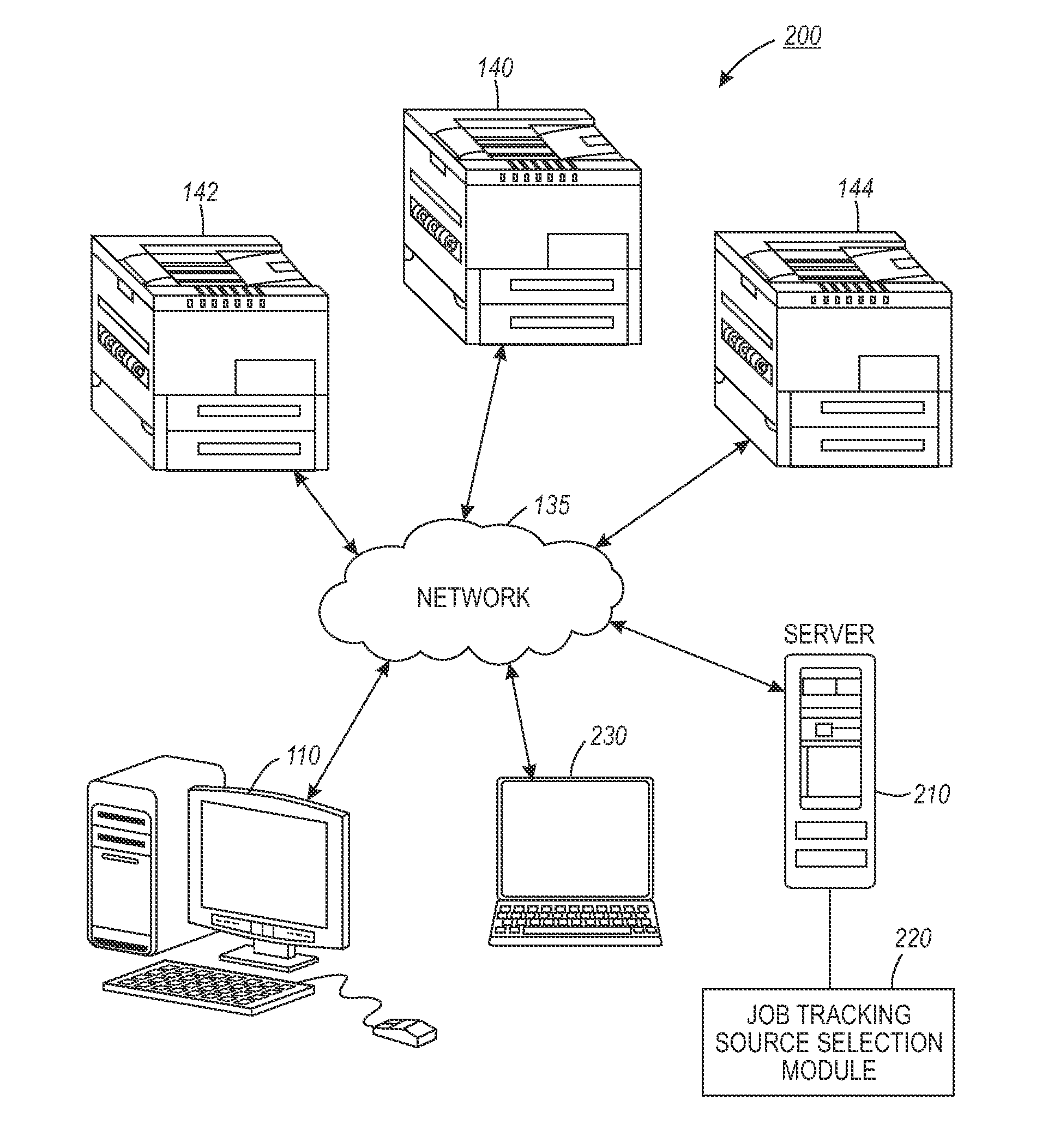

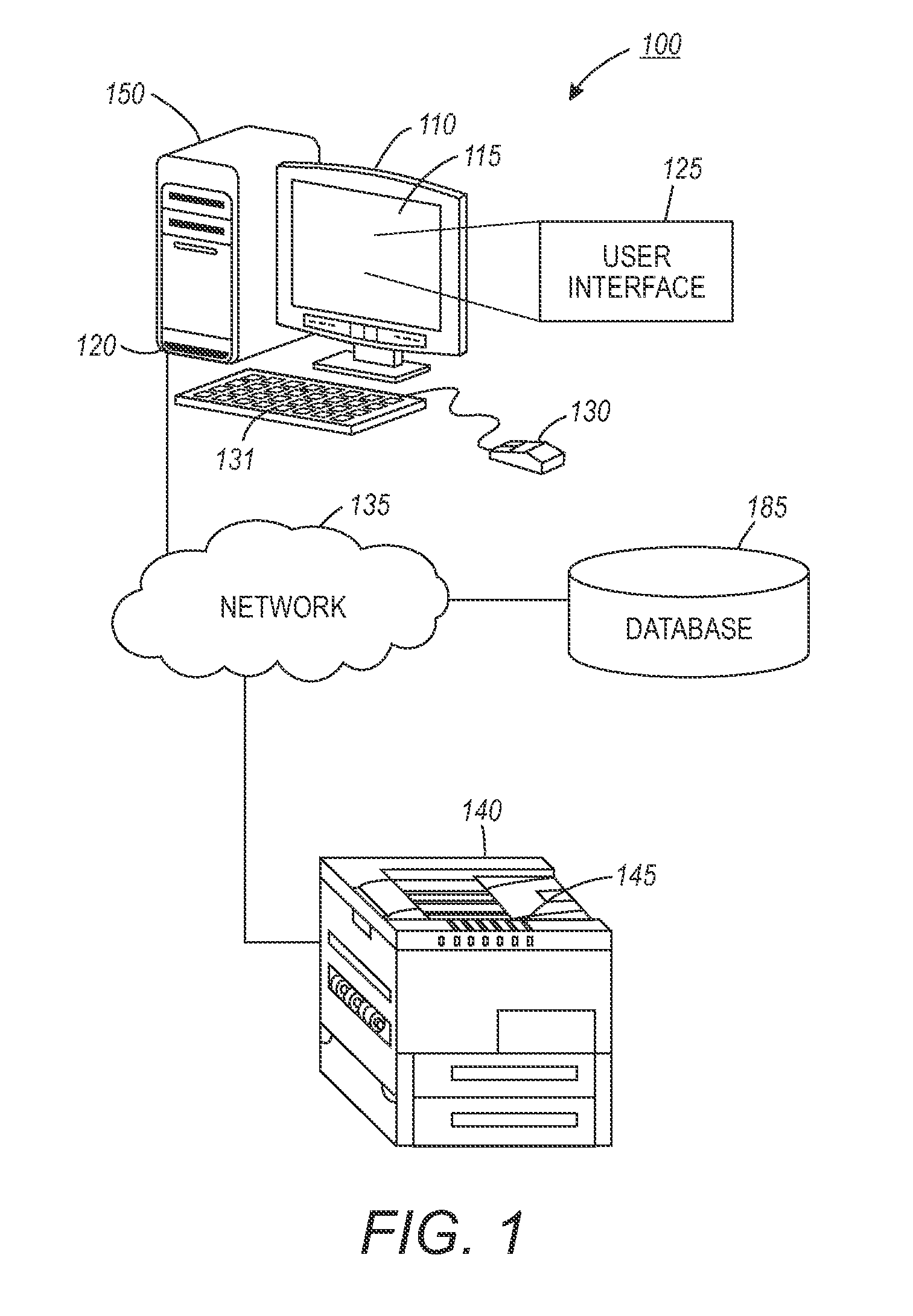

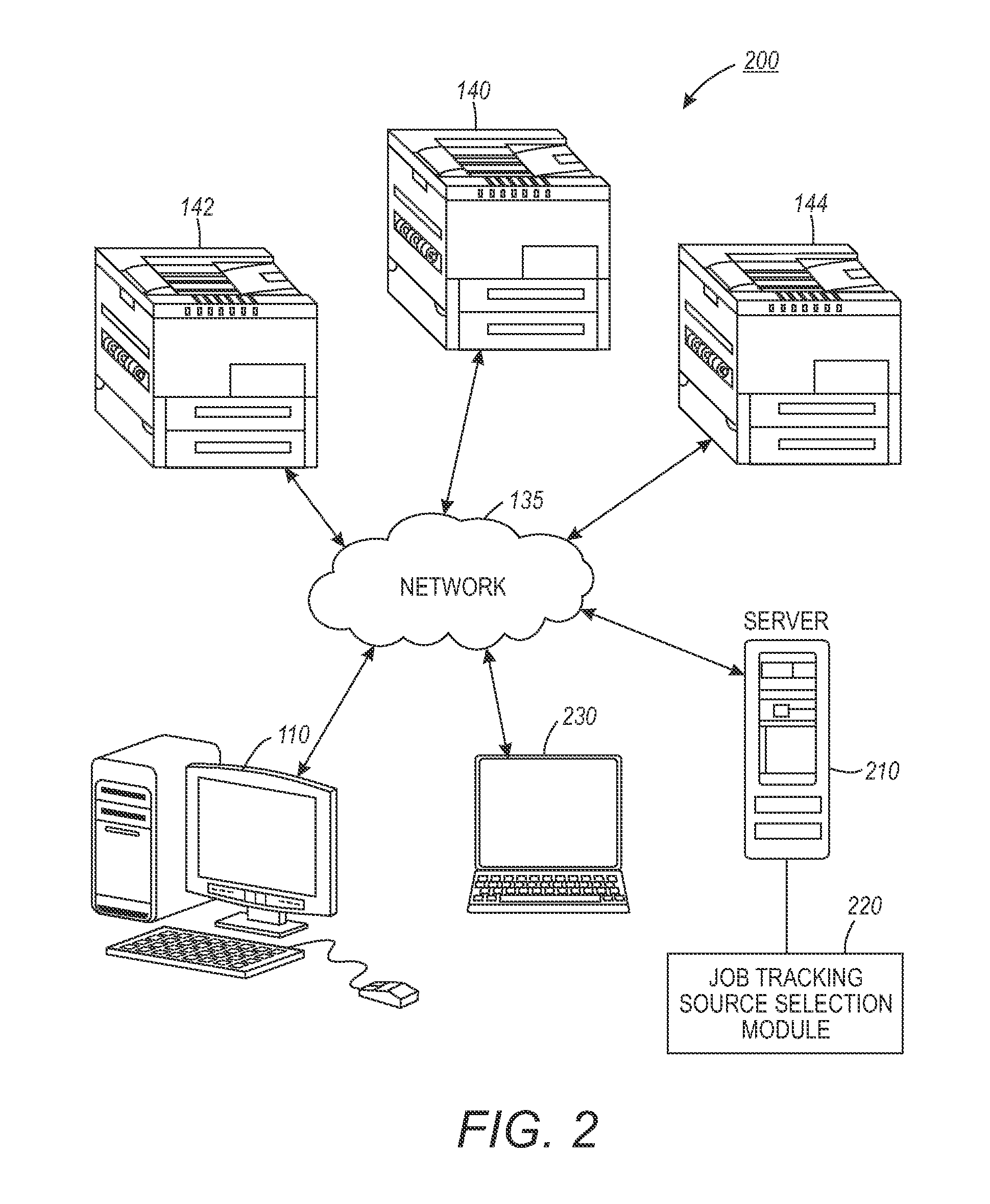

Method, system and processor-readable medium for automatically selecting a job tracking source

InactiveUS20120281250A1Simple methodEffective volumeDigital output to print unitsData sourceWorld Wide Web

A method and system for automatically selecting an accurate job tracking source with respect to each rendering device. An output management solution in association with a device manager can be configured to include a device-based accounting source, a job tracking agent source, and a file import source. The job tracking data sources can be configured by an administrator and can be ranked within the device manager based on an accuracy setting. The device-based accounting source can be selected as the most accurate source upon detection of a built-in job tracking capability with respect to the multi-function device. The job tracking agent source and / or the file import source can be selected as the most accurate source if the built-in job tracking capability is not available. A historical job tracking database can be searched by the device manager in order to detect the job tracking agent source. A flag can be provided if the job tracking agent source is not available to indicate a gap in the job tracking agent coverage.

Owner:XEROX CORP

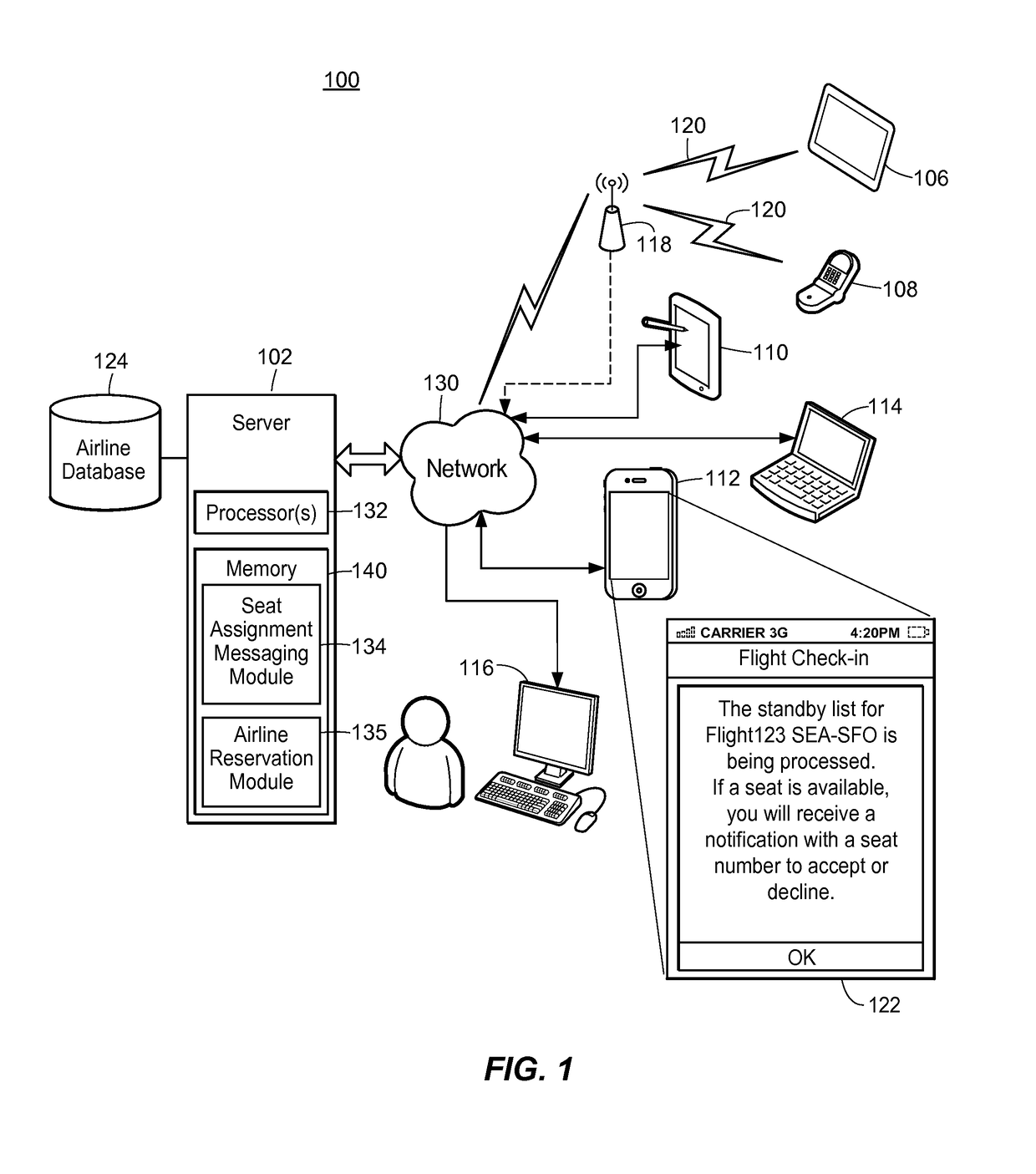

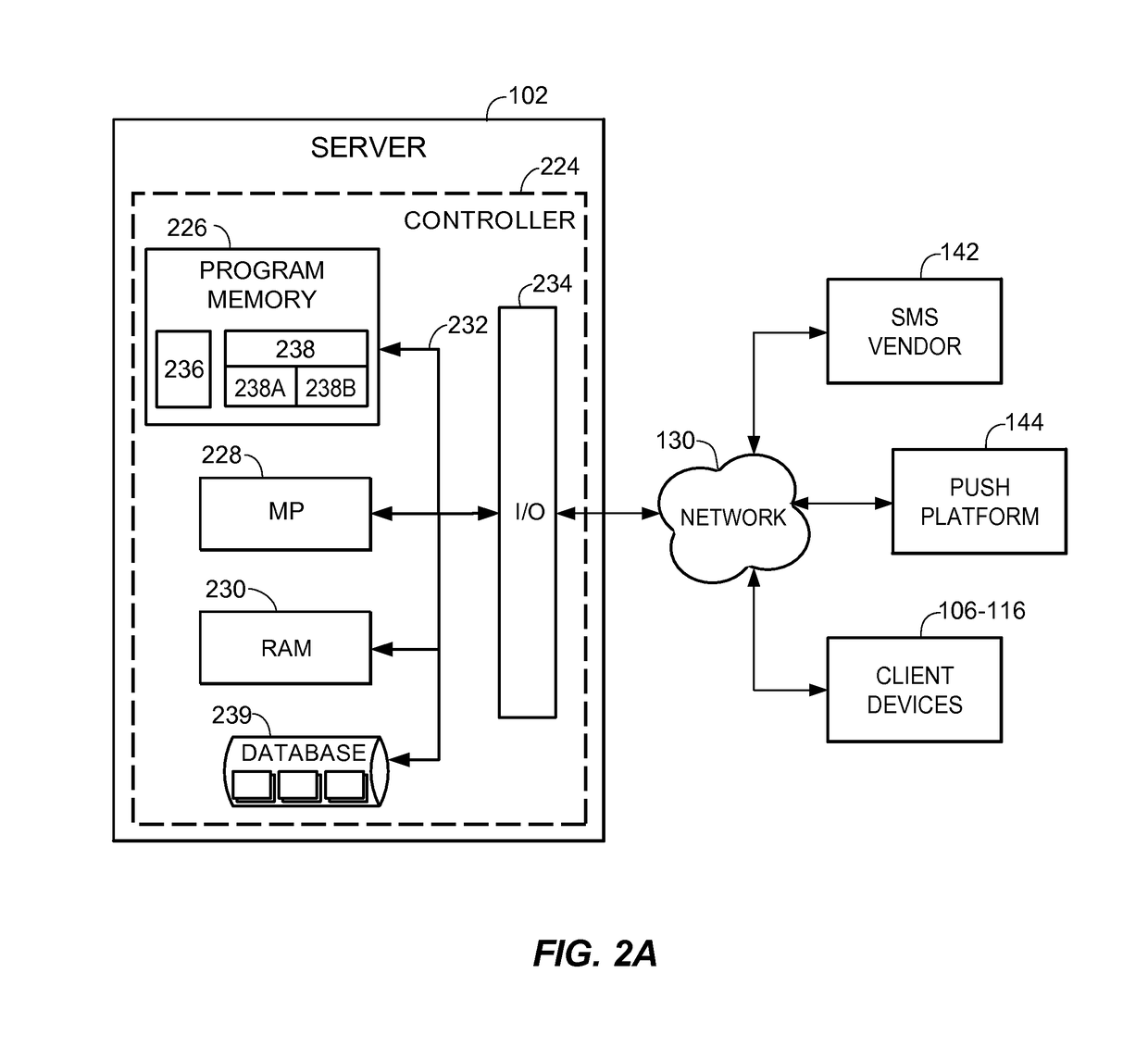

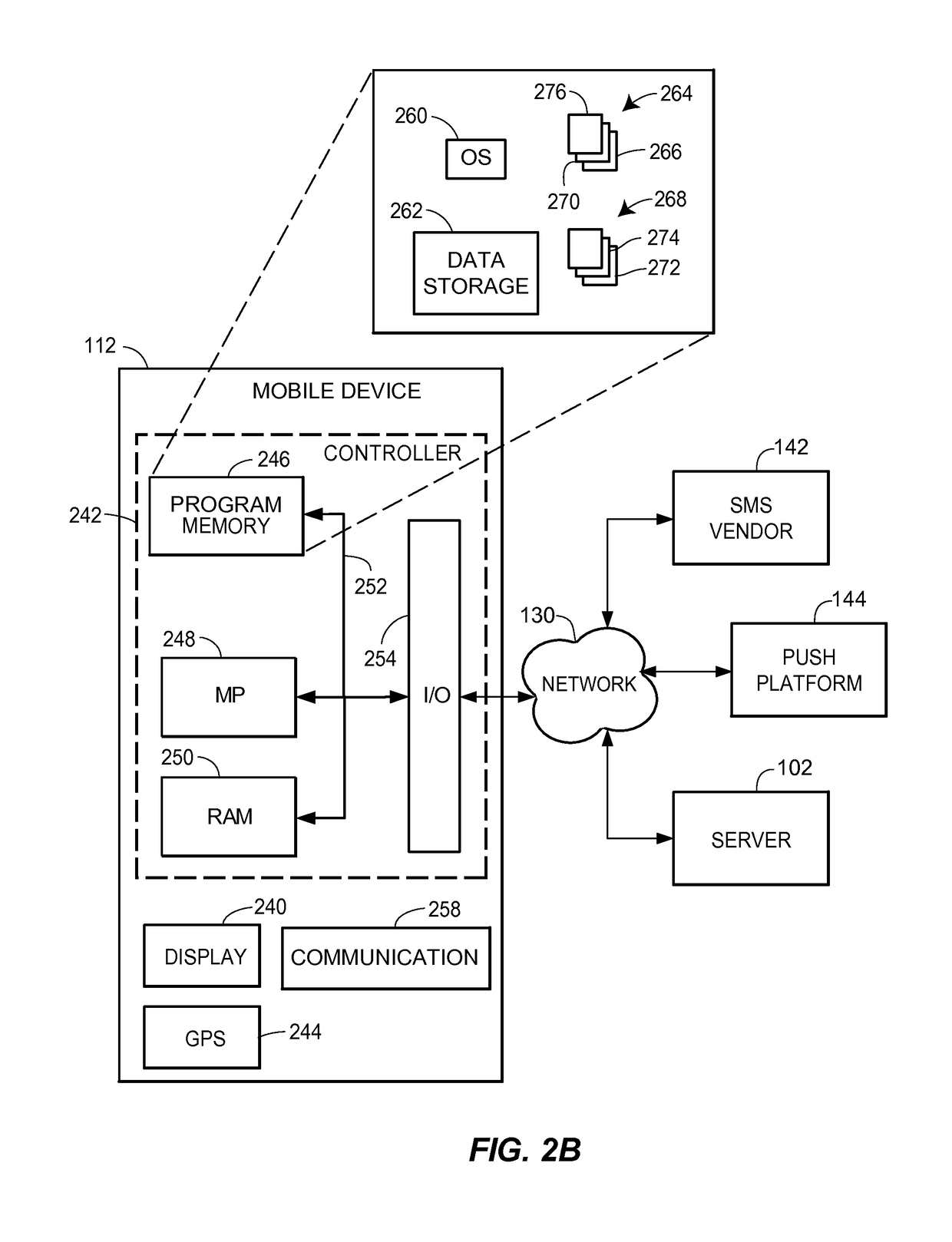

Method and system for automating passenger seat assignment procedures

ActiveUS10185920B2Low costReducing amount of confusion and congestionReservationsTransmissionShort Message ServiceElectronic communication

Owner:UNITED AIR LINES

Double-sided receipt printing method and double-sided receipt printer

ActiveUS20120279406A1Reduce paper wasteReduce white spaceAddressographsPlaten pressesComputer printingPulp and paper industry

Owner:SEIKO EPSON CORP

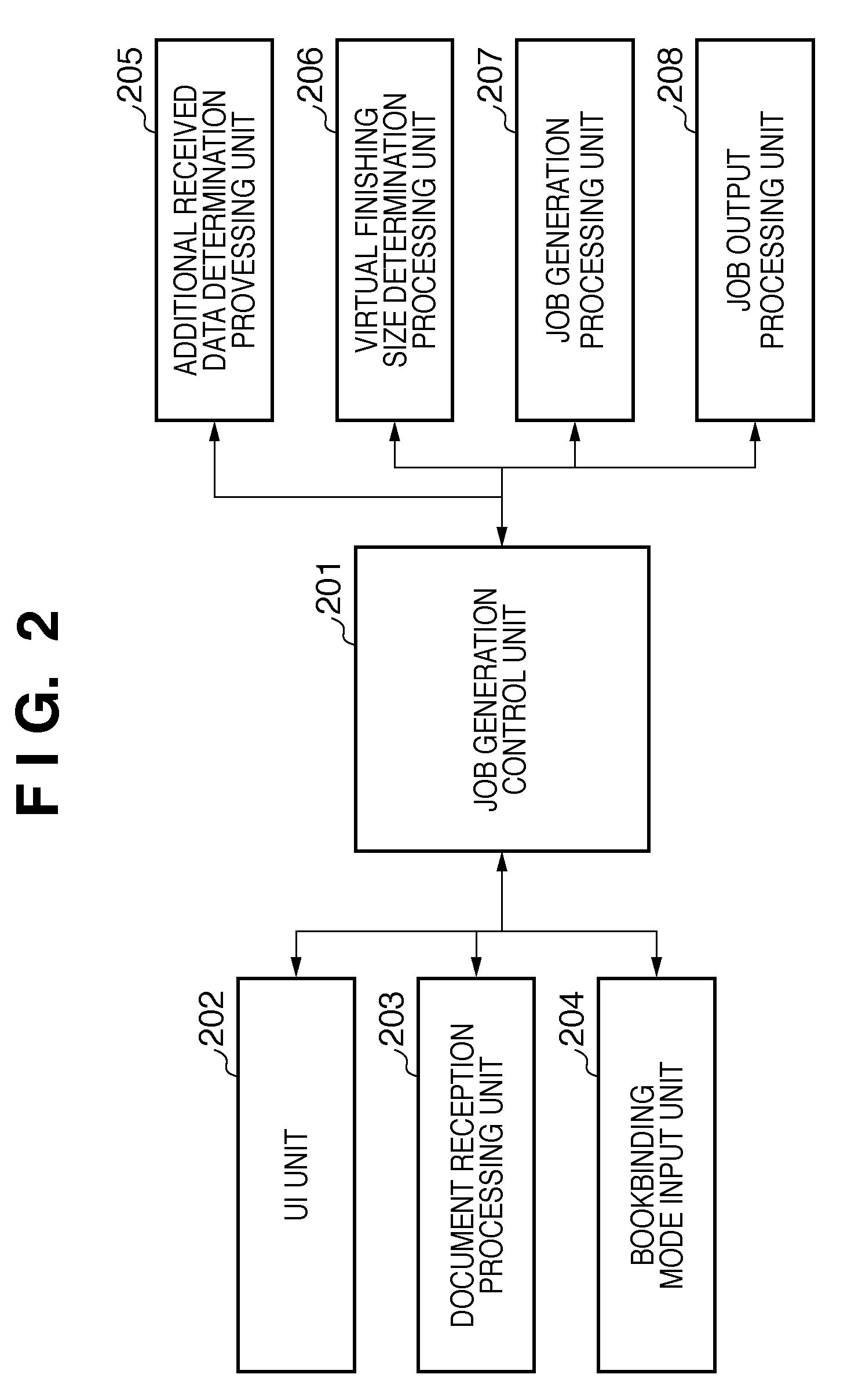

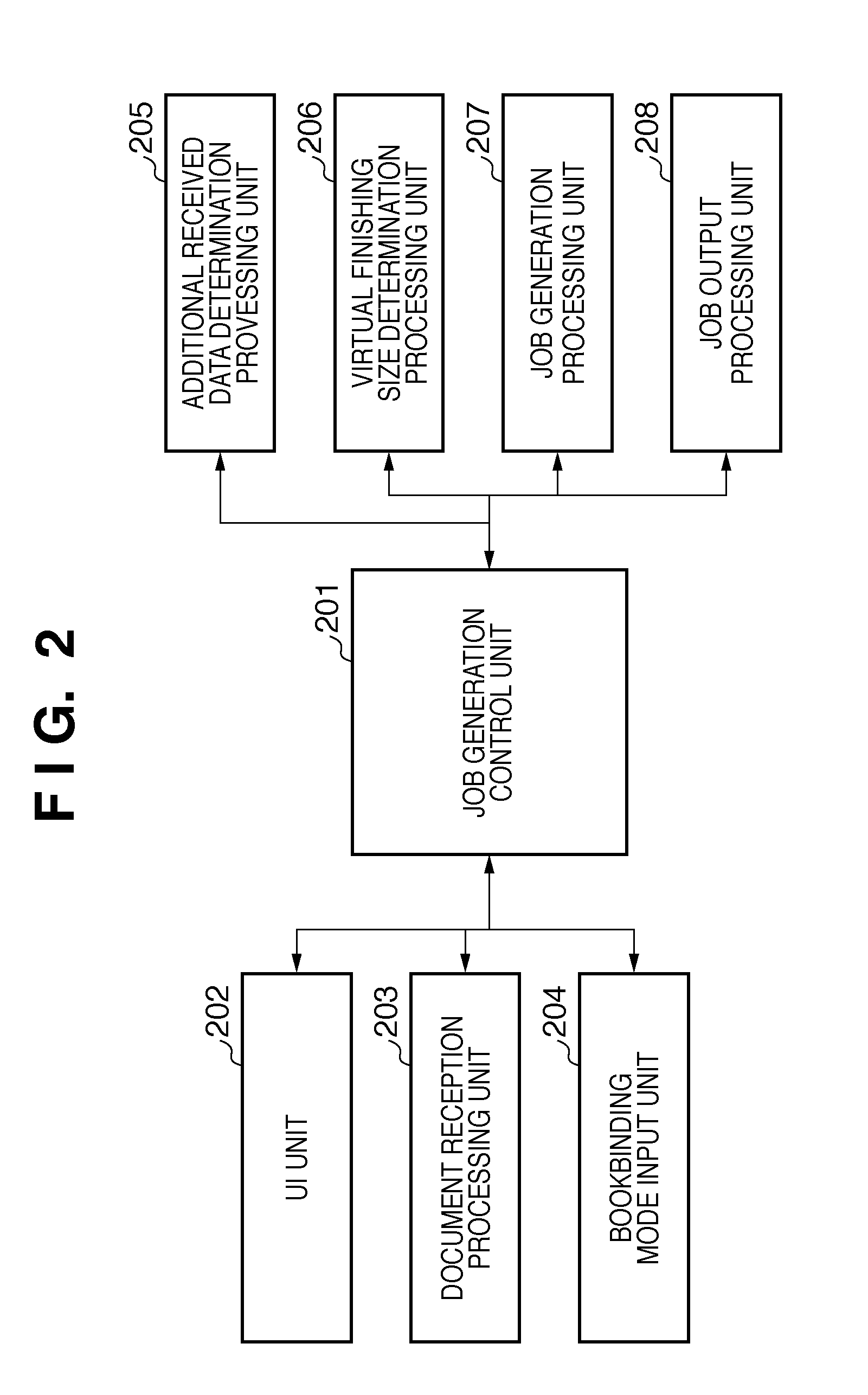

Information Processing Apparatus, Bookbinding Printing Method, and Computer-Readable Medium

InactiveUS20120033252A1Promote generationWaste of paperDigital output to print unitsInformation processingPattern recognition

An information processing apparatus comprises: a data determination unit configured to determine, using first received data as a reference, whether to add another received data to processing in a single job; a size determination unit configured, when the data determination unit determines to add the other received data in a bookbinding mode in which a plurality of bound products are generated by a single job, to regard, as single tentative image data, a plurality of image data which are generated from different received data and laid out on a single sheet of paper, and to determine whether the single tentative image data fits in the sheet of paper; and a job generation unit configured to generate a job for at least one received data corresponding to image data contained in the single tentative image data determined by the size determination unit to fit in the sheet of paper.

Owner:CANON KK

Method, system and processor-readable medium for automatically selecting a job tracking source

InactiveUS8922811B2Simple methodEffective volumeVisual presentationPictoral communicationData sourceWorld Wide Web

A method and system for automatically selecting an accurate job tracking source with respect to each rendering device. An output management solution in association with a device manager can be configured to include a device-based accounting source, a job tracking agent source, and a file import source. The job tracking data sources can be configured by an administrator and can be ranked within the device manager based on an accuracy setting. The device-based accounting source can be selected as the most accurate source upon detection of a built-in job tracking capability with respect to the multi-function device. The job tracking agent source and / or the file import source can be selected as the most accurate source if the built-in job tracking capability is not available. A historical job tracking database can be searched by the device manager in order to detect the job tracking agent source.

Owner:XEROX CORP

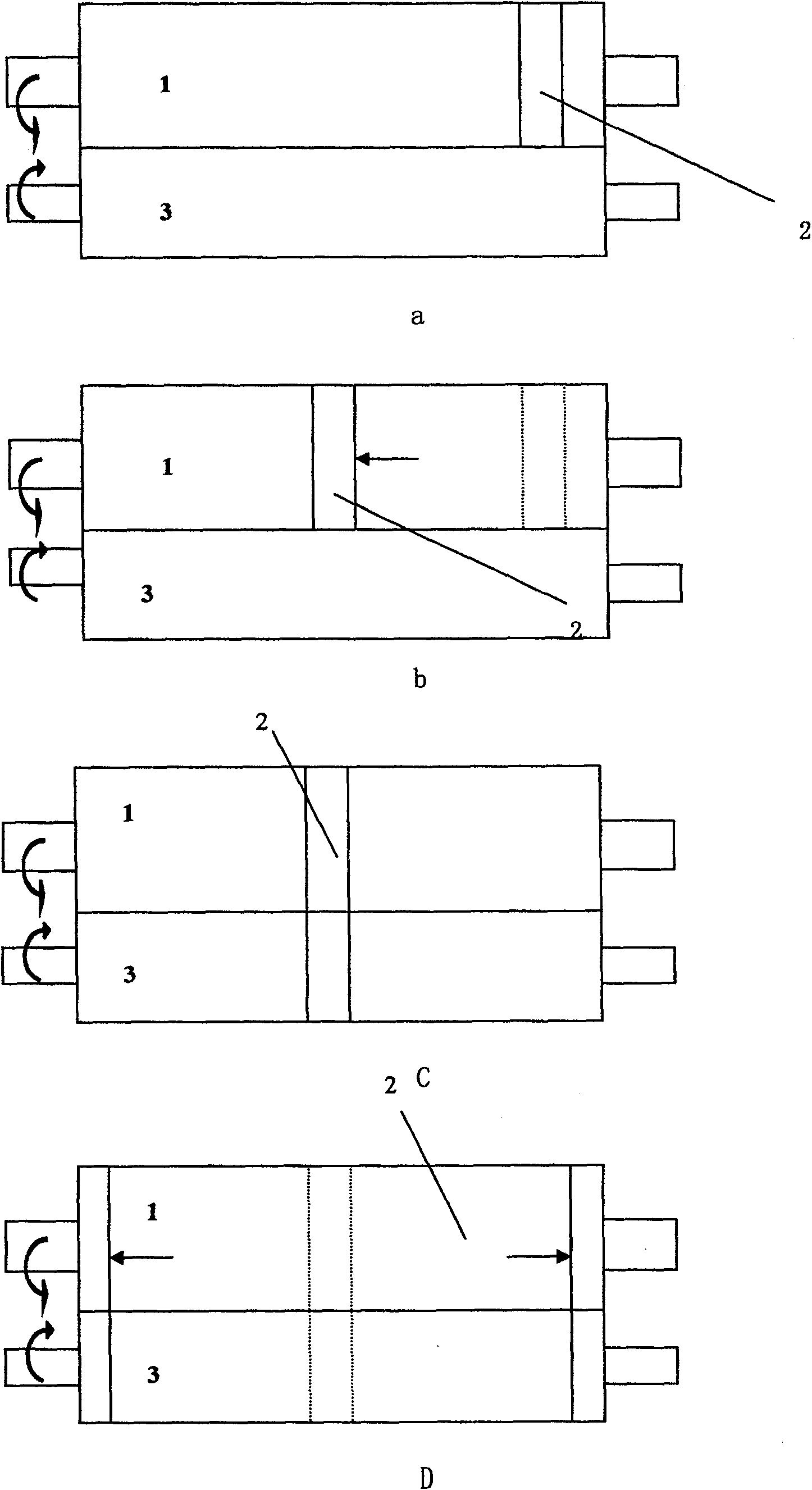

Medium rolling method of coiling part of paper machine

The invention discloses a method for winding in the middle of a paper machine coiling section. Firstly, the paper lug is drawn on the paper lug operation side of the paper roll, and after the paper lug is successfully drawn, it is led to the middle position of the paper roll, and the paper lug is drawn to the middle position of the paper roll. After the ear stays in the middle position, the middle paper ear is then fully widened to both sides of the winding roll. The invention is applied to papermaking, and can realize the winding up of the paper strip from the middle in the take-up section of the paper machine, and then unwinding the whole width. The invention can effectively reduce the dead lines of the bottoming and improve the paper quality. The present invention is easy to operate when coiling and threading, and will not affect the threading time at all.

Owner:GOLD EAST PAPER JIANGSU

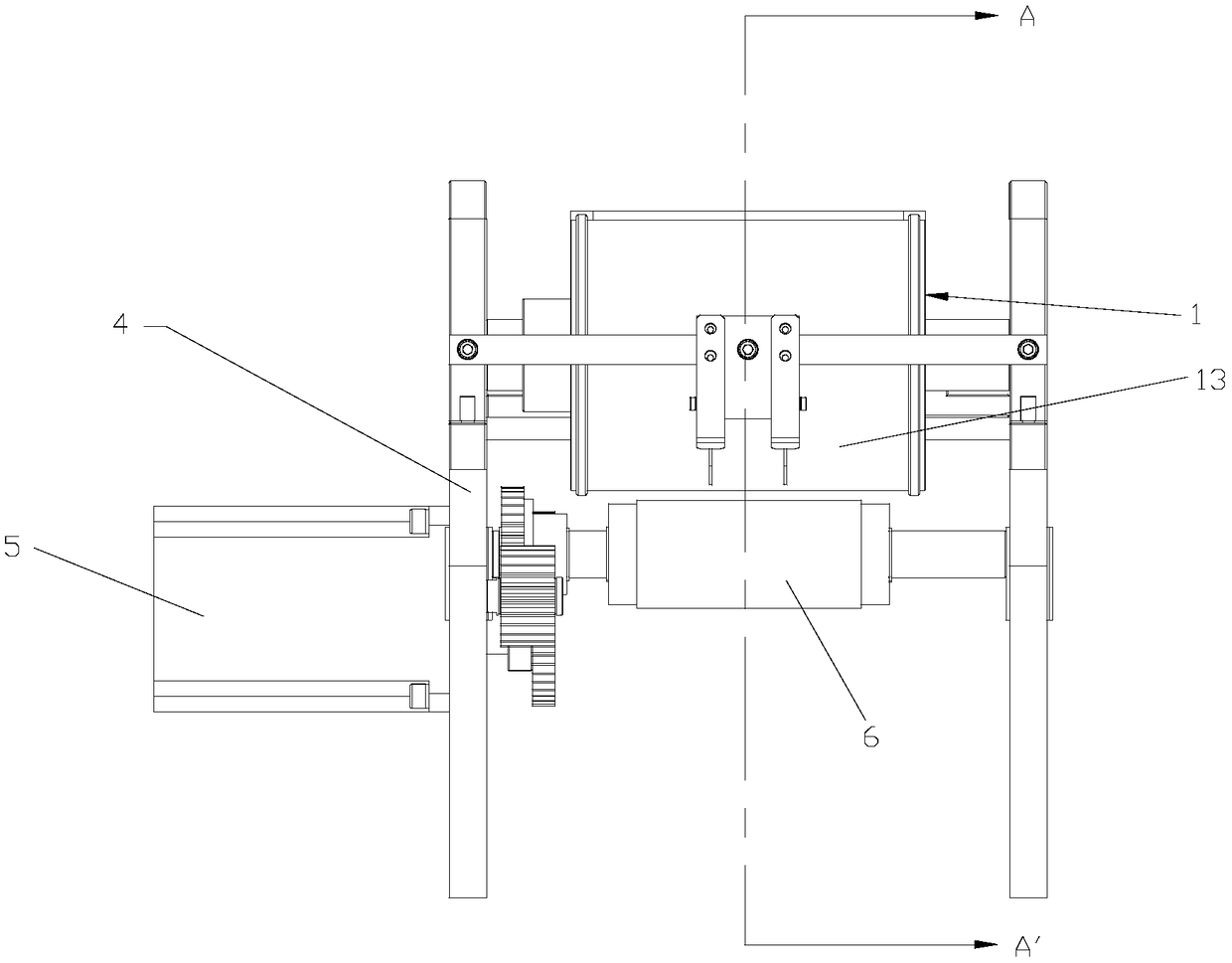

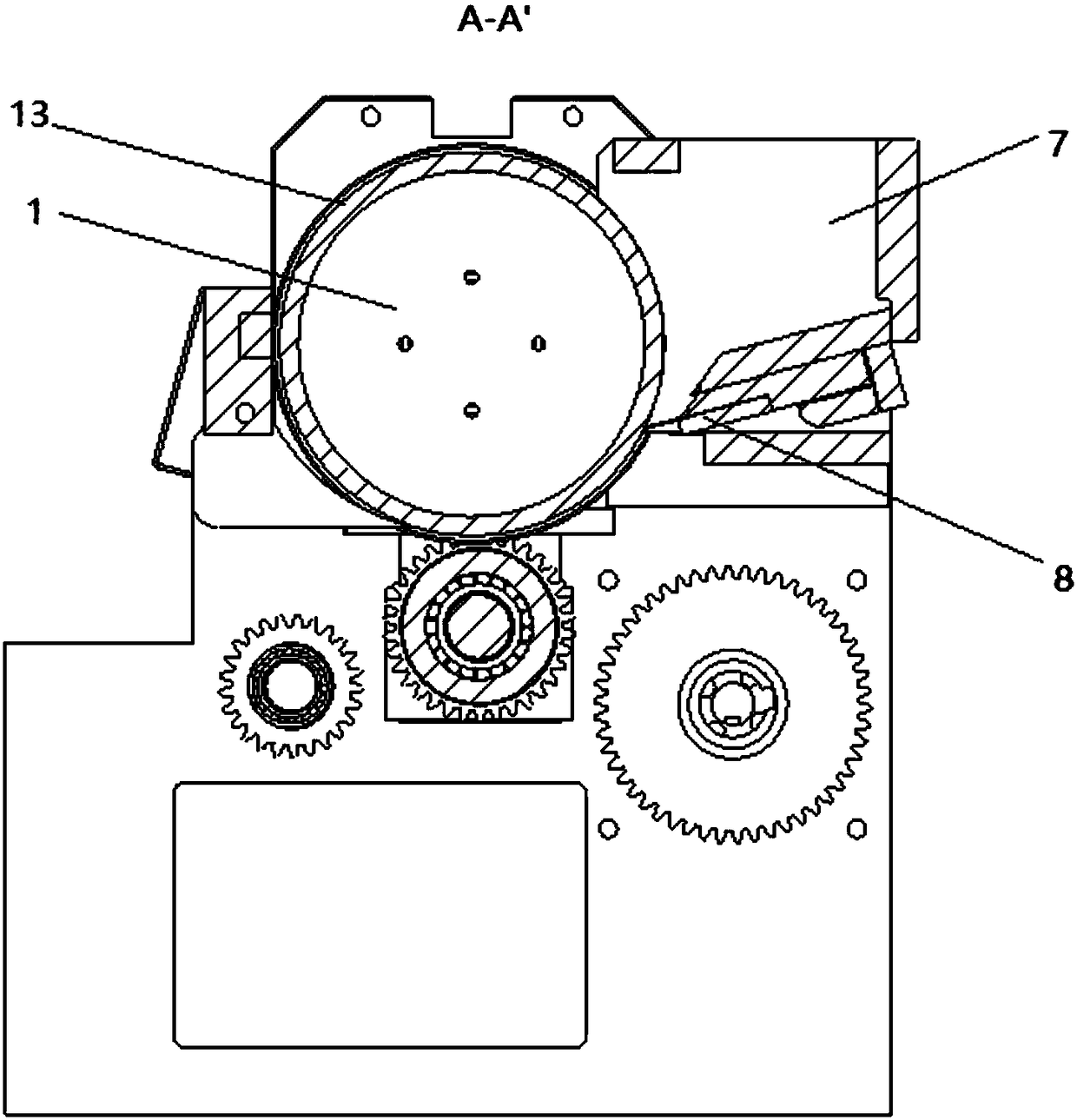

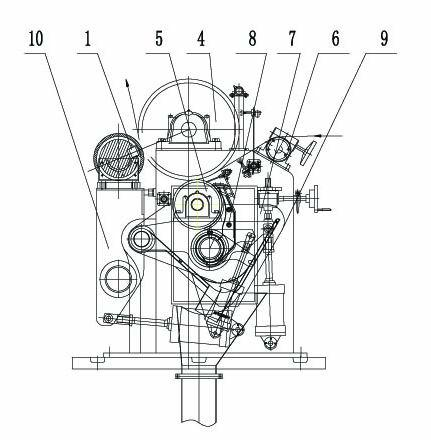

Static-pressure sectional controllable spreader

The invention relates to a static-pressure sectional controllable spreader, which belongs to the technical field of paper making machinery and comprises a static-pressure sectional controllable roll, a backup roll, a feeding roll, an arc-shaped roll, a spreading groove, a flow guide plate, a framework and the like. The backup roll is mounted on the upper portion of the framework by a bearing, the static-pressure sectional controllable roll is mounted on one side of the backup roll, the arc-shaped roll is mounted on the other side of the backup roll, the feeding roll is mounted on the lower portion of the backup roll, the static-pressure controllable roll and the feeding roll are respectively meshed with the backup roll, and the flow guide plate and the spreading groove are mounted on one side of the feeding roll. The static-pressure sectional controllable roll replaces a scraper beam or scraper bar, the static-pressure sectional controllable spreader is supplemented with a control device, precision adjustment is realized, the horizontal spreading quantity can be controlled, paper loss and paper breakage are avoided, the quality of a product is good, the static-pressure sectional controllable spreader is high in production efficiency and convenient in operation, and cost is saved. In addition, the static-pressure sectional controllable spreader solves the problems that in the prior art, paper cannot be dried easily and buckles due to uneven horizontal spreading quantity, damage to parts is severe, and production efficiency and the quality of a paper machine are seriously affected, and paper loss and paper breakage are often caused.

Owner:SHASHI LIGHT IND MACHINERY

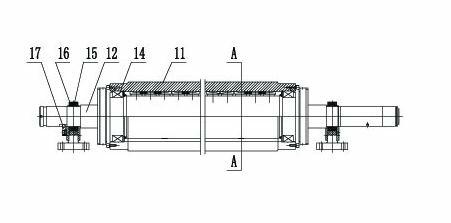

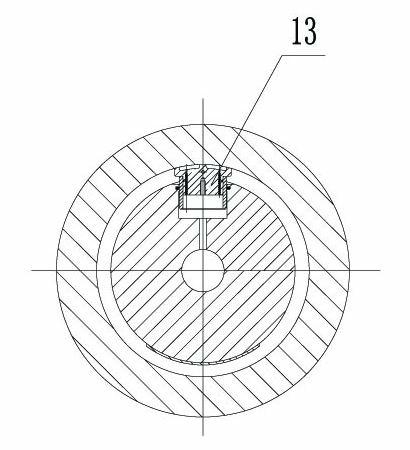

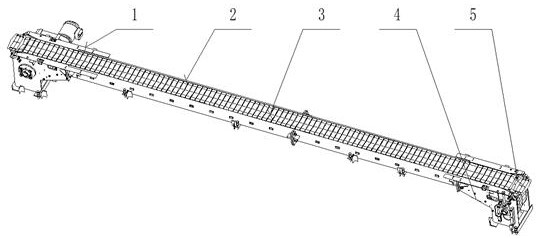

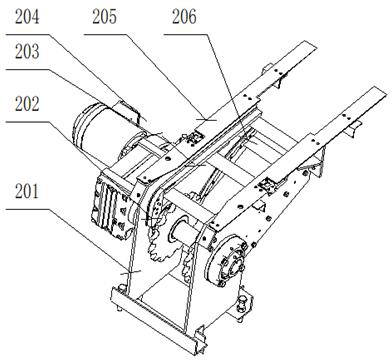

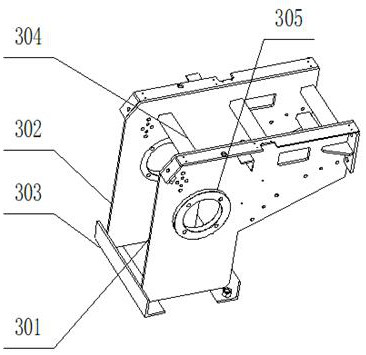

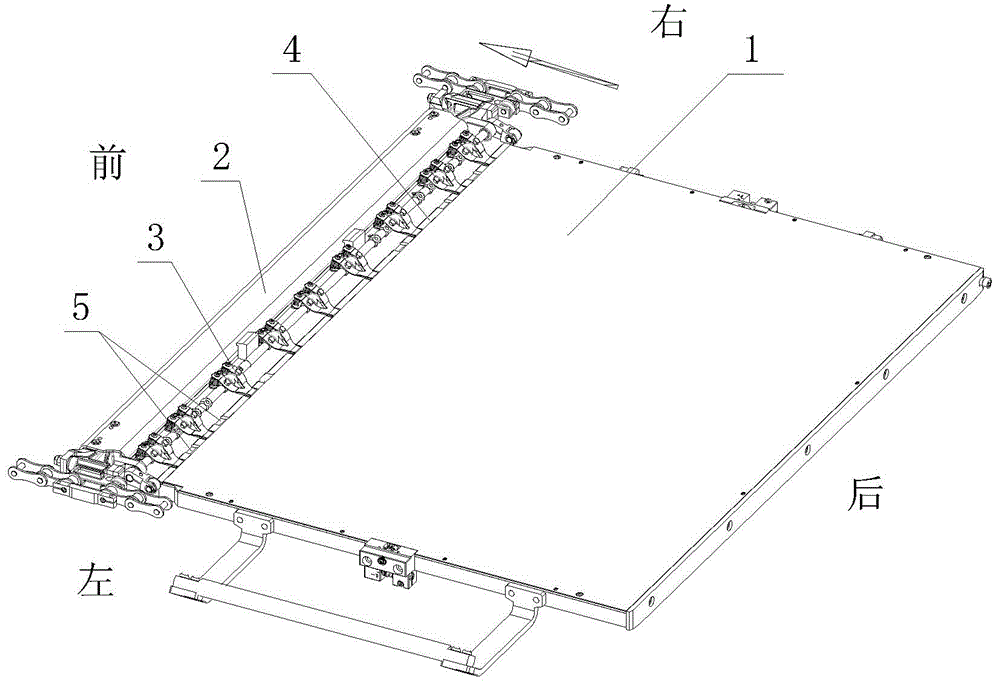

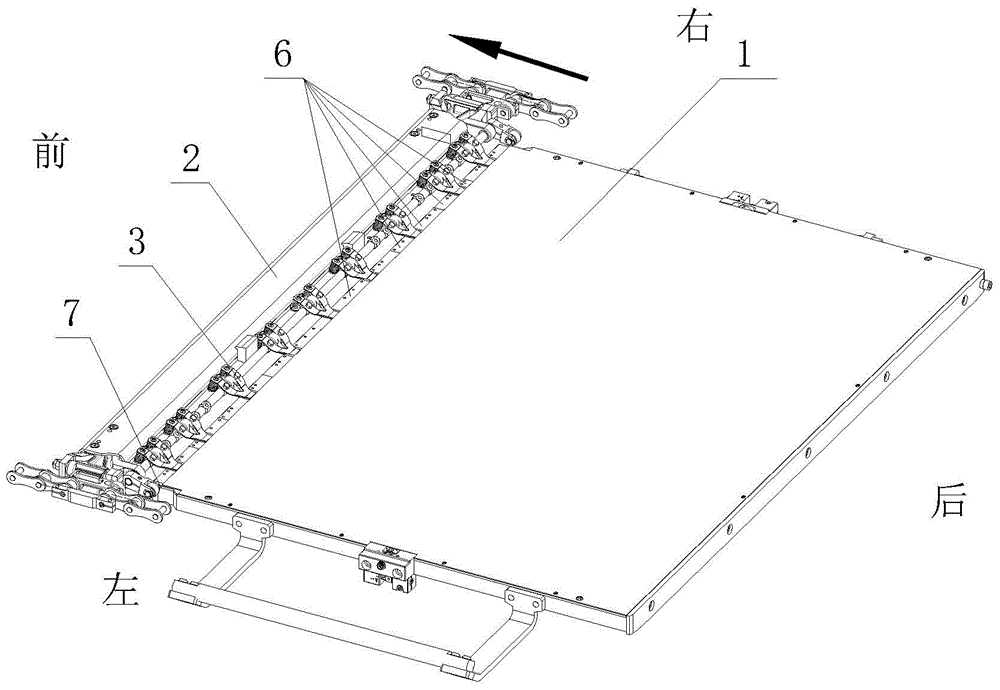

High-speed heavy-load chain scraper conveyor

A high-speed heavy-load chain scraper conveyor comprises a head frame part, a middle frame part, a V-shaped conveying chain, a tail frame part and a transition device. The head frame part comprises a head frame, an arc guide rail block, a head upper guide rail, a driving component, a head cover plate and a head lower arc guide rail; the middle frame part comprises an integrally bent main frame, a connecting plate, a rectangular pipe, an upper guide rail and a lower guide rail; the V-shaped conveying chain comprises a supporting wheel, an outer chain plate, an inner chain plate, a V-shaped panel, a sleeve, a pin shaft and the like; the tailstock part comprises a tail rack, a tensioning device, an arc guide rail block, a tail upper guide rail, a tail cover plate and a tail lower arc guide rail; the transition device comprises a mounting base, a paper passing plate, a mandrel, a sliding bearing and a rubber covered roller. The high-speed heavy-load chain scraper conveyor is simple in structure, high in bending resistance, low in production cost and suitable for batch production.

Owner:中轻长泰(长沙)智能科技股份有限公司

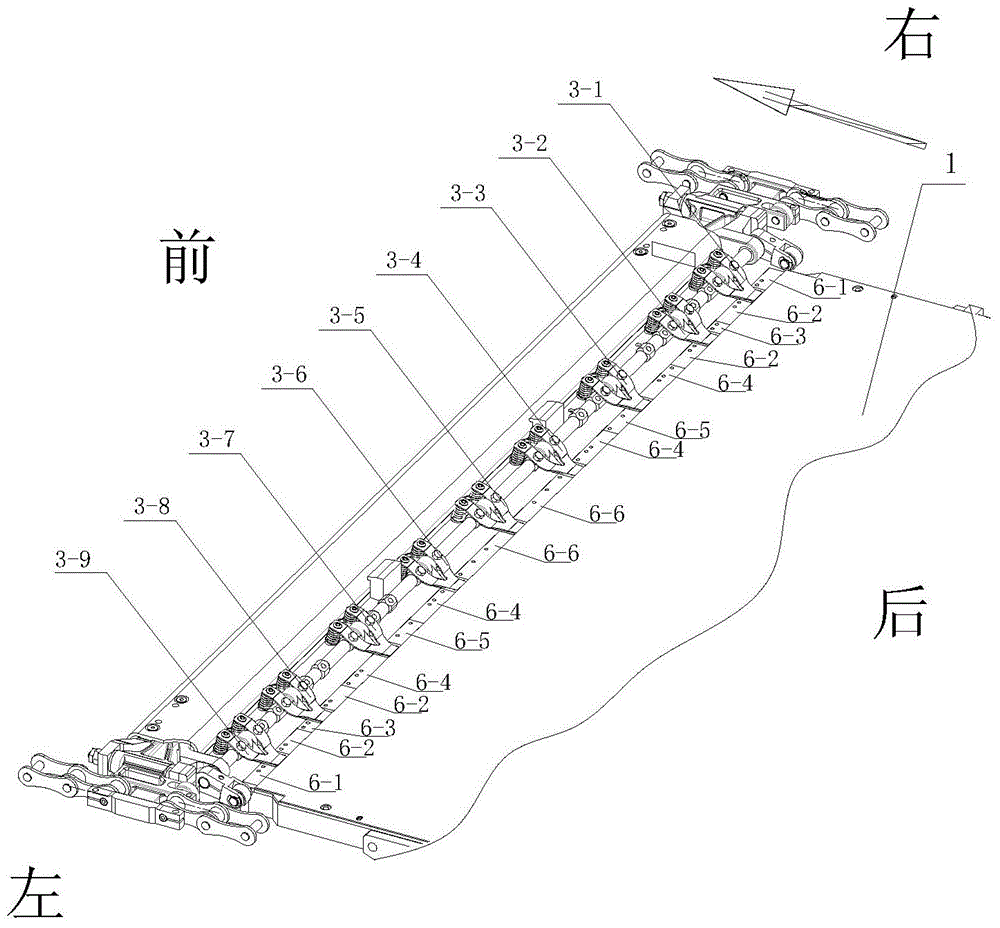

Tooth row cushioning device and working method thereof

Disclosed is a tooth row cushioning device and a working method thereof. The tooth row cushioning device comprises a tooth row and a paper receiving platform. The tooth row cushioning device is characterized in that subplate components filling gaps among tooth pieces of the tooth row are mounted at a paper outgoing end of the paper receiving platform. The working method includes mounting a tooth piece set on a tooth row body; fixing a mounting strip on a paper outgoing side of the paper receiving platform, detachably fixing the subplate components on the mounting strip according to the number of the tooth pieces and position relation, reserving tooth piece gaps, and fully filling the rest portion with cushion blocks; expanding a processing area of a die-cutting plate or a hot-stamping plate to a gripper edge portion supported by the subplate components; placing the tooth pieces of the tooth row on the reserved tooth piece gaps, horizontally and stably placing to-be-processed paper on the paper receiving platform, and enabling the rest portion, of the paper at a gripper edge, apart from the position clamped by the tooth pieces to be supported by the subplate components; completing die cutting of the paper. The tooth row cushioning device and the working method thereof have the advantages that the paper at the gripper edge can be processed, so that paper waste is reduced; the subplate components can be combined according to changing of position and number of the tooth pieces, and high adaptability is realized.

Owner:MASTERWORK GROUP CO LTD

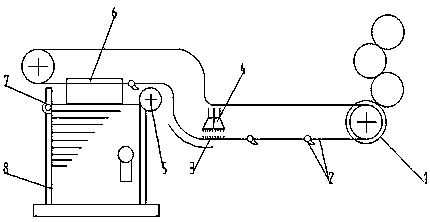

Paper collecting device for lithographic printing machine

InactiveCN107720379ASimple structureReduce paper wastePile receiversArticle deliveryPaper sheetContinuous operation

The invention discloses a paper receiving device of a lithographic printing machine. A cardboard stop is arranged above the left side of the paper table lifting mechanism, a side flush cardboard is provided above the paper table lifting mechanism, and a brake is provided above the right side of the paper table lifting mechanism. The powder spraying device is set on the right side of the lifting mechanism of the paper table. The paper delivery chain and the paper delivery tooth row are set under the powder spraying device. There are two paper delivery rollers, one is set on the right side of the powder spraying device and the other is set on the baffle paper. On the upper left, the two delivery cylinders are connected by the delivery chain and the delivery teeth row. There is a chain guide rail under the delivery chain and the delivery teeth row. There is an impression roller on the upper right of the delivery roller on the right side of the powder spraying device. , There is a rubber cylinder on the upper left of the impression cylinder, and a printing plate cylinder on the upper right of the rubber cylinder. The invention is simple in structure, reasonable and reliable, and can carry out continuous operation without shutting down the cross-cutting machine, thereby ensuring product quality and improving production efficiency.

Owner:李颂

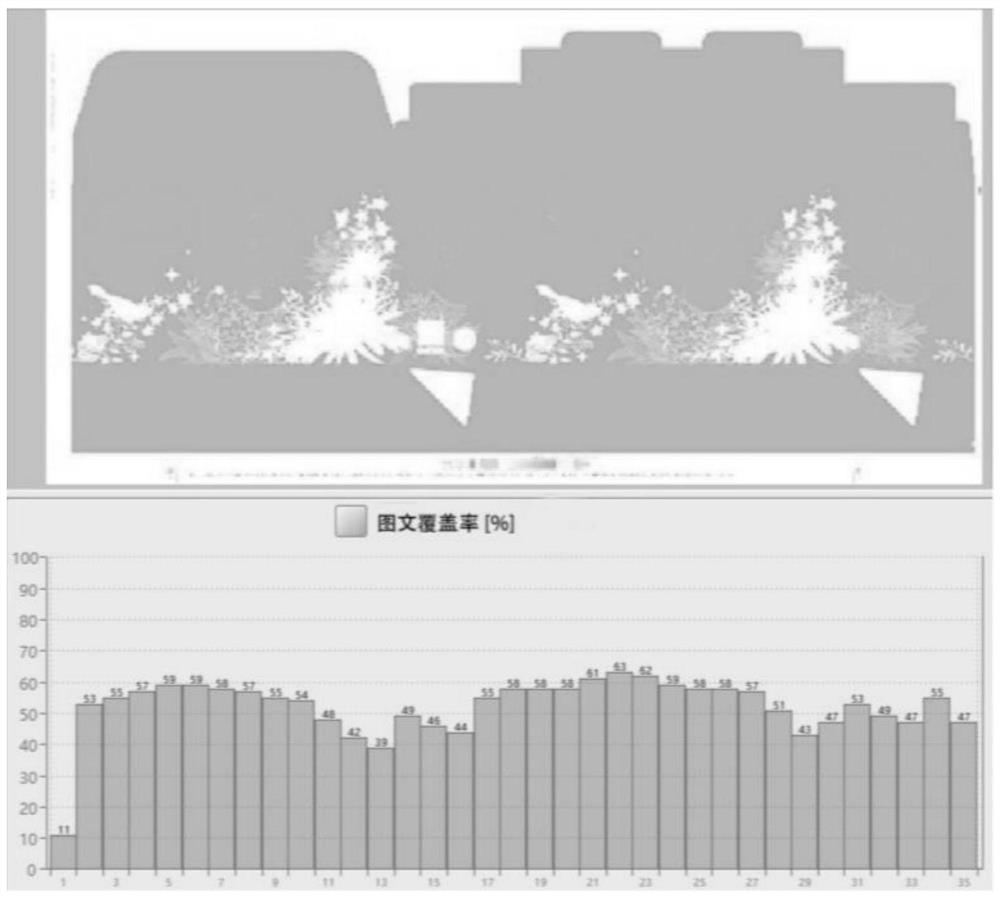

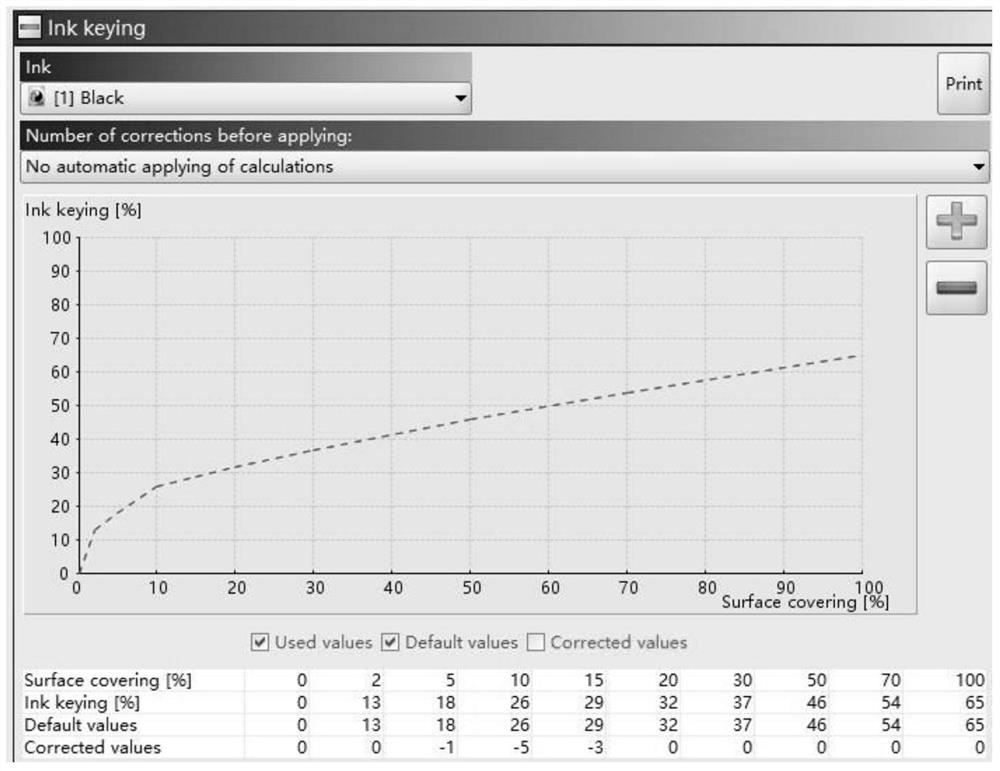

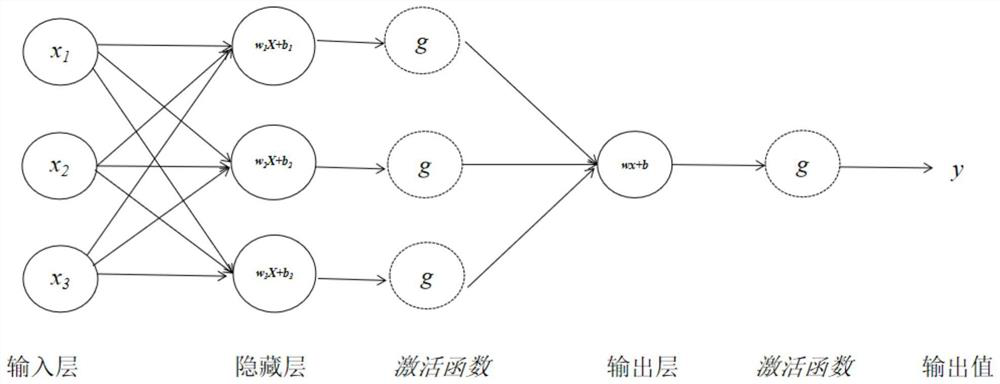

Printing ink presetting method based on artificial neural network algorithm

PendingCN114676819ABoost presetImprove forecast accuracyNeural architecturesNeural learning methodsActivation functionData set

The invention discloses a printing ink presetting method based on an artificial neural network algorithm. The printing ink presetting method comprises the following steps: S1, establishing a three-layer neural network printing ink presetting model; s2, the content of the input layer comprises the average ink coverage rate, the viscosity and fluidity of printing ink and the surface glossiness of a printing stock; s3, the hidden layer is a full connection layer of the input layer; s4, the input of the output layer comes from the calculation result of the hidden layer through the activation function g (z); s5, using empirical data to initialize model parameters; s6, arranging a model training data set; s7, substituting the sorted training data into the established three-layer neural network ink preset model; s8, optimizing the eight model parameters according to the error between the model output y value and the true value Y; and S9, substituting the three parameters corresponding to the new movable part into the optimized model in the step S8 to calculate the corresponding ink tooth opening degree. The device has the beneficial effects that the printing ink presetting accuracy is improved, and the printing quality and efficiency are improved.

Owner:TIANJIN HAISHUN PRINTING & PACKAGING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com