Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Play the role of axial limit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

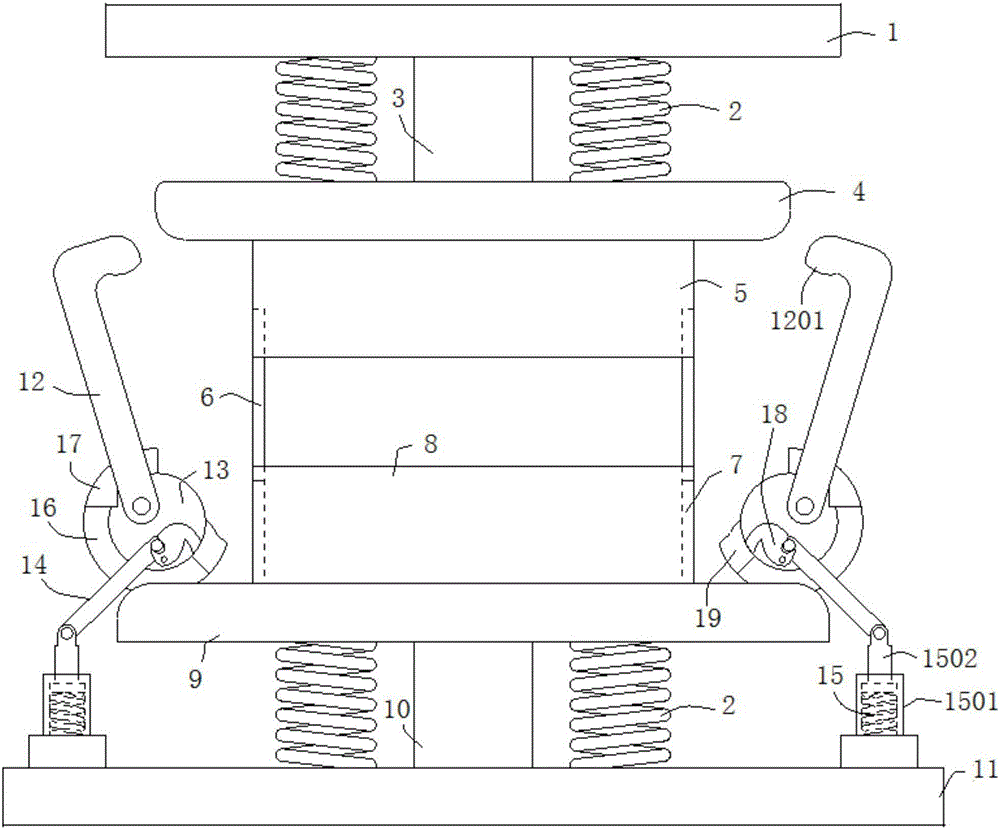

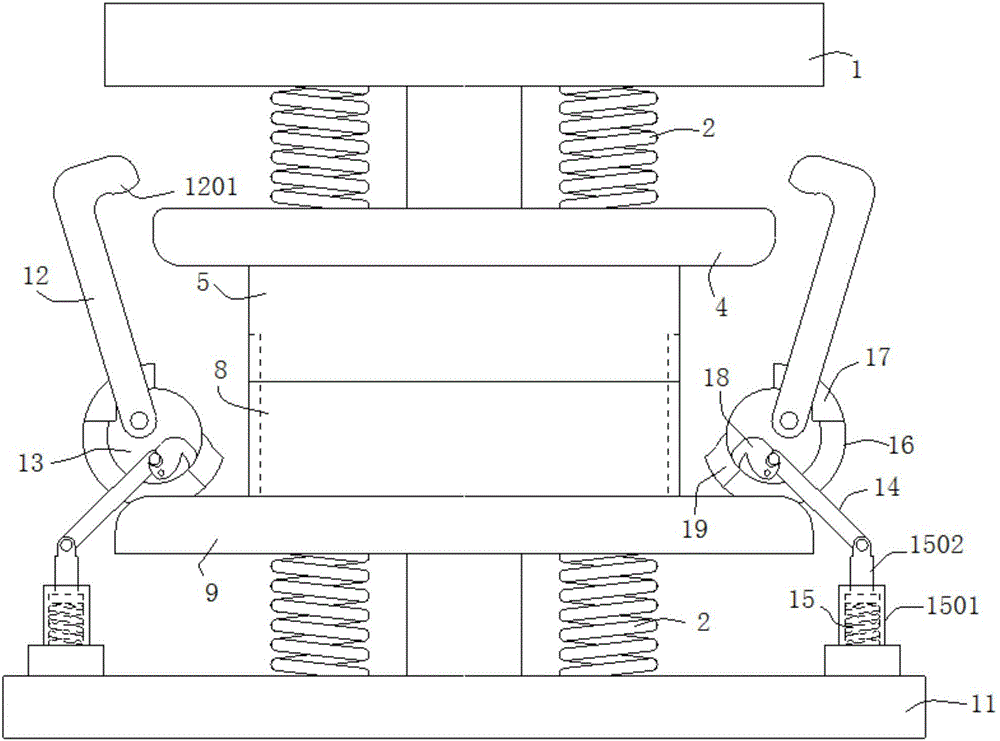

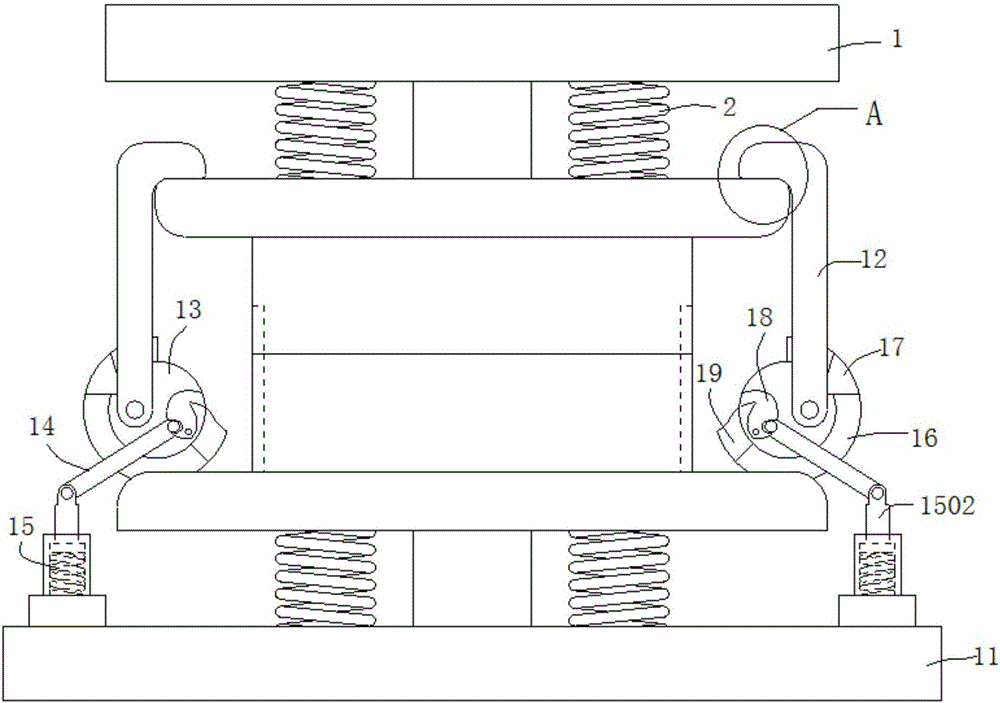

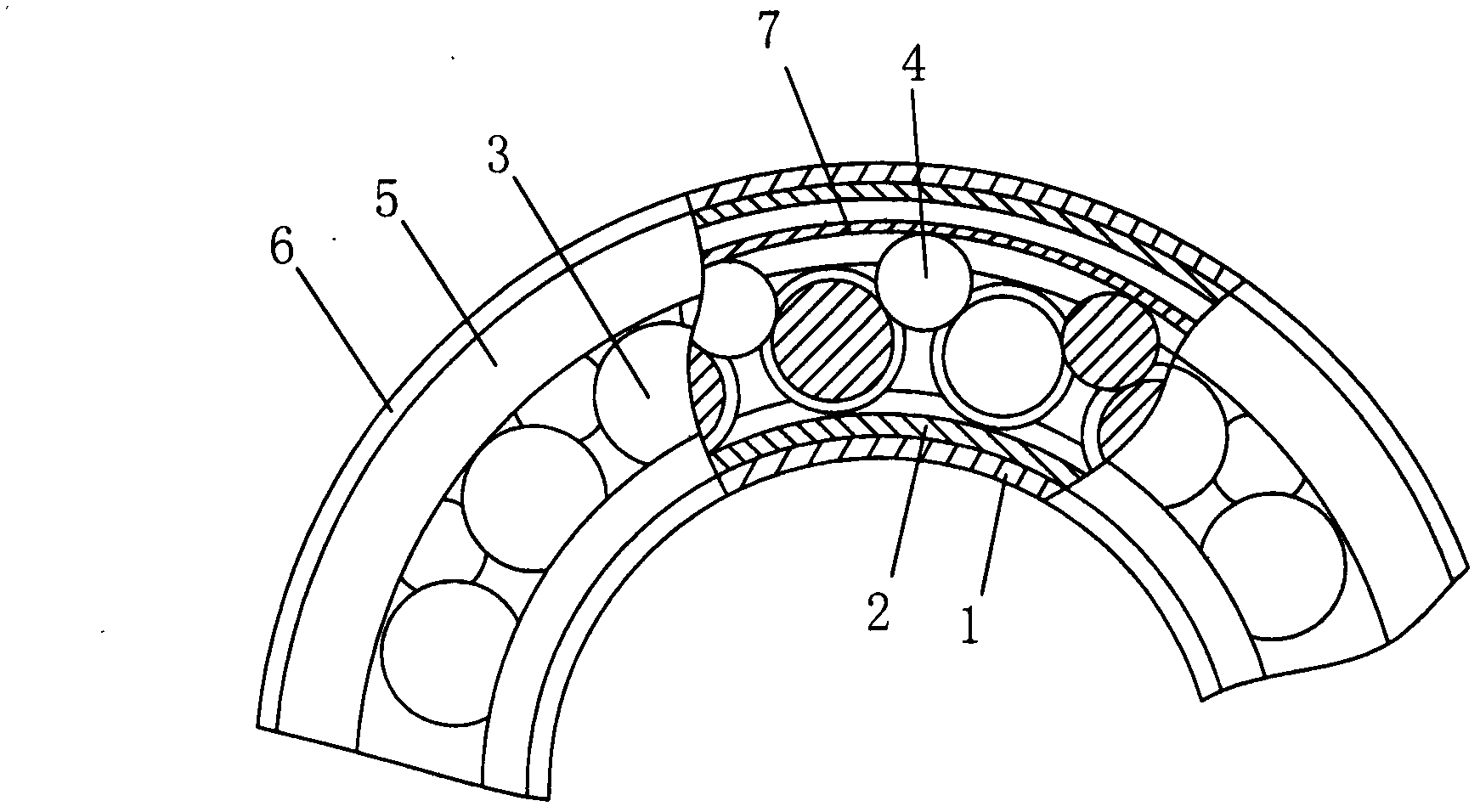

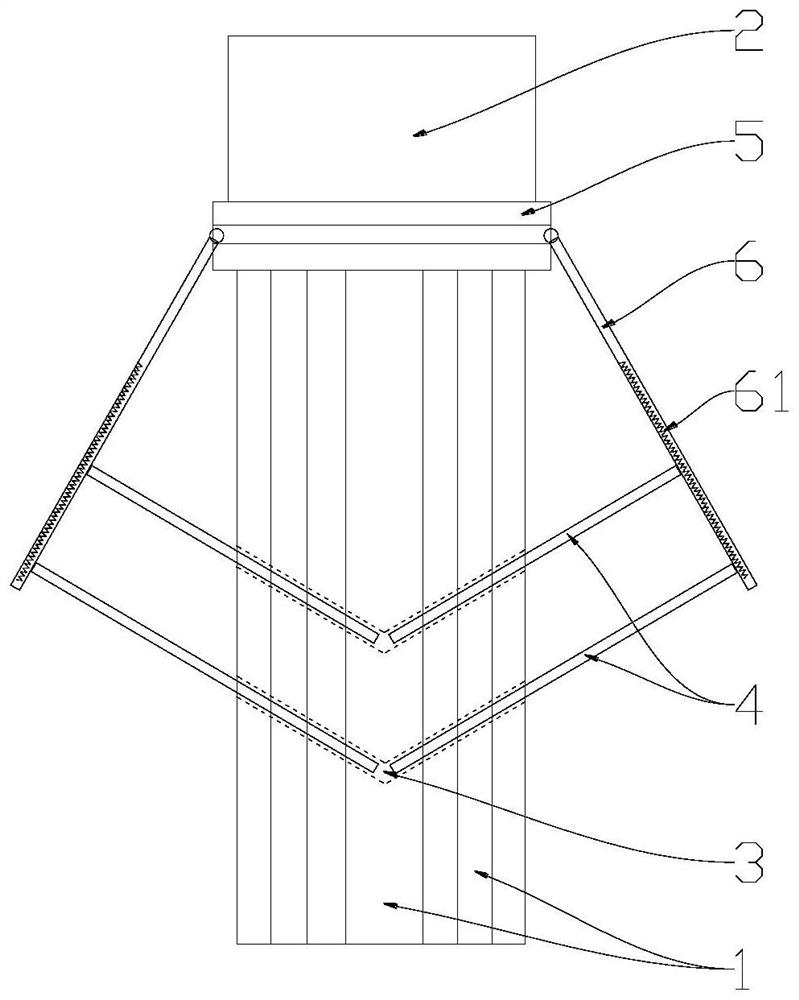

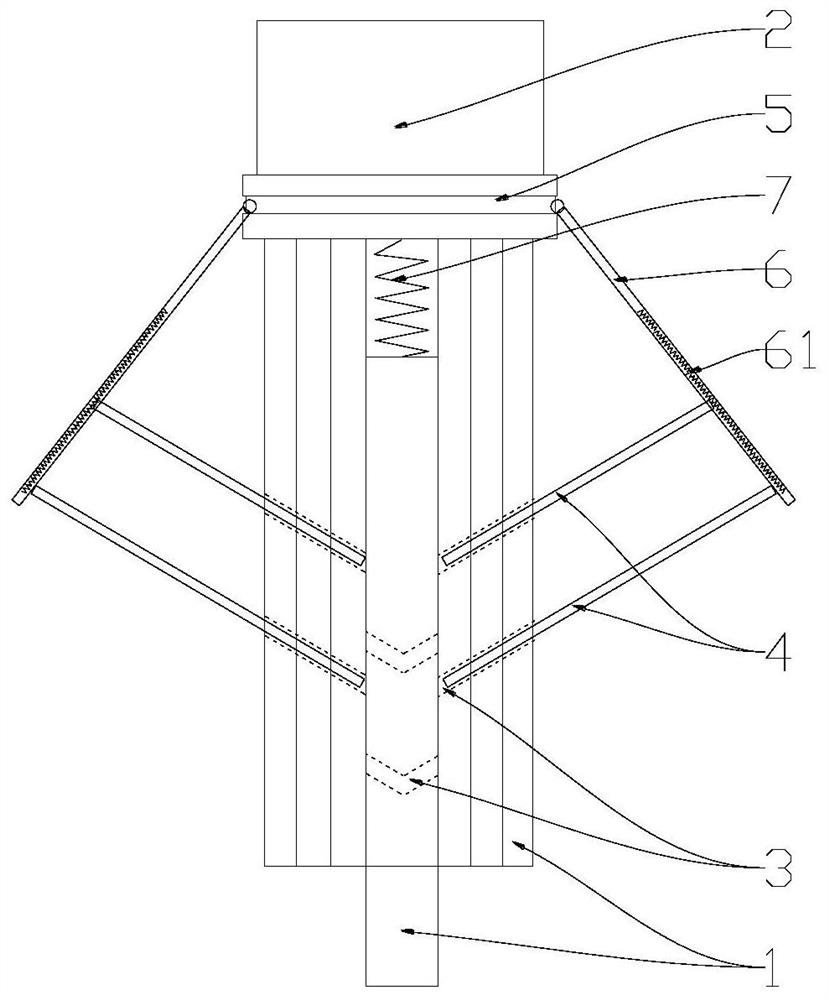

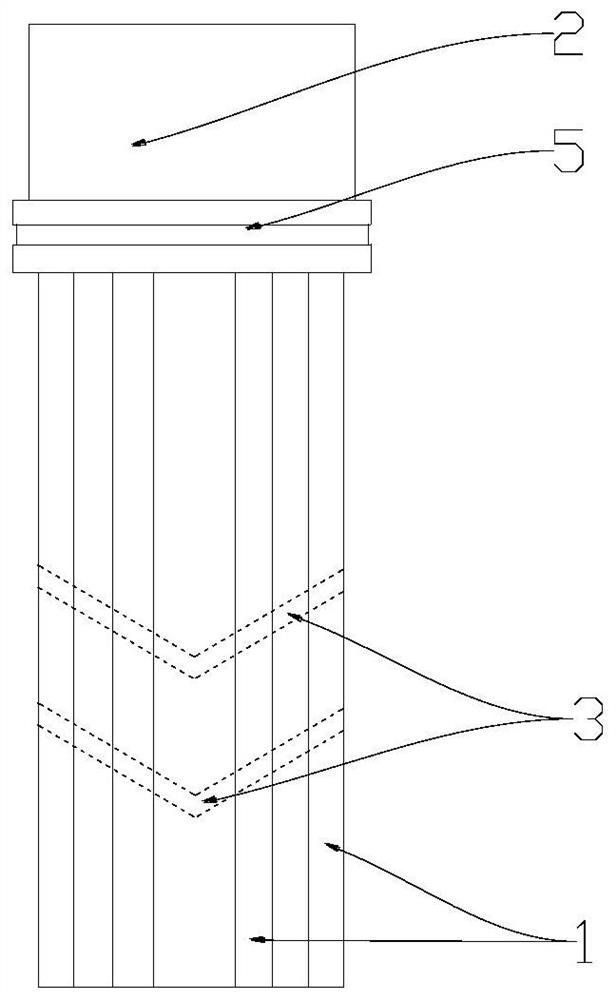

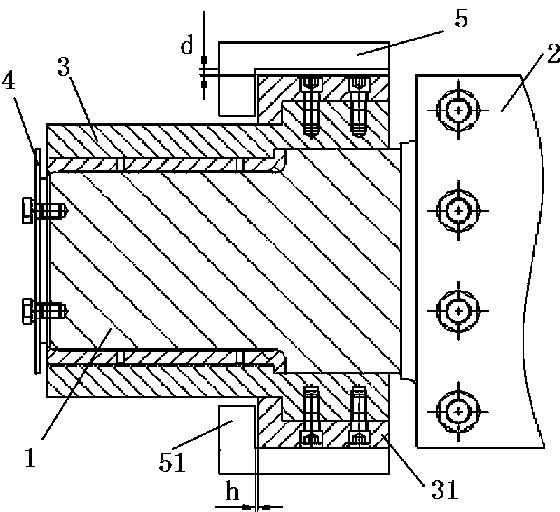

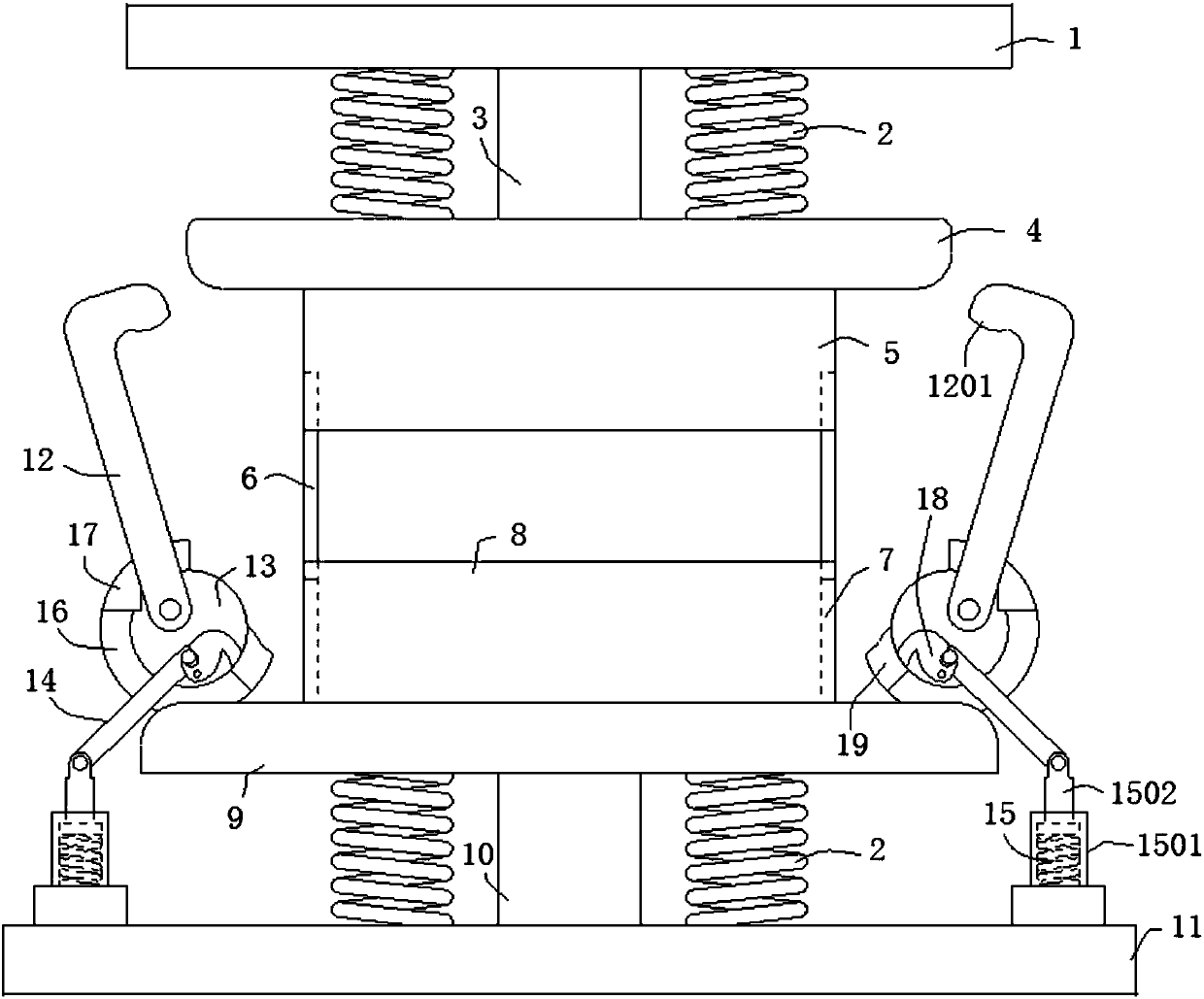

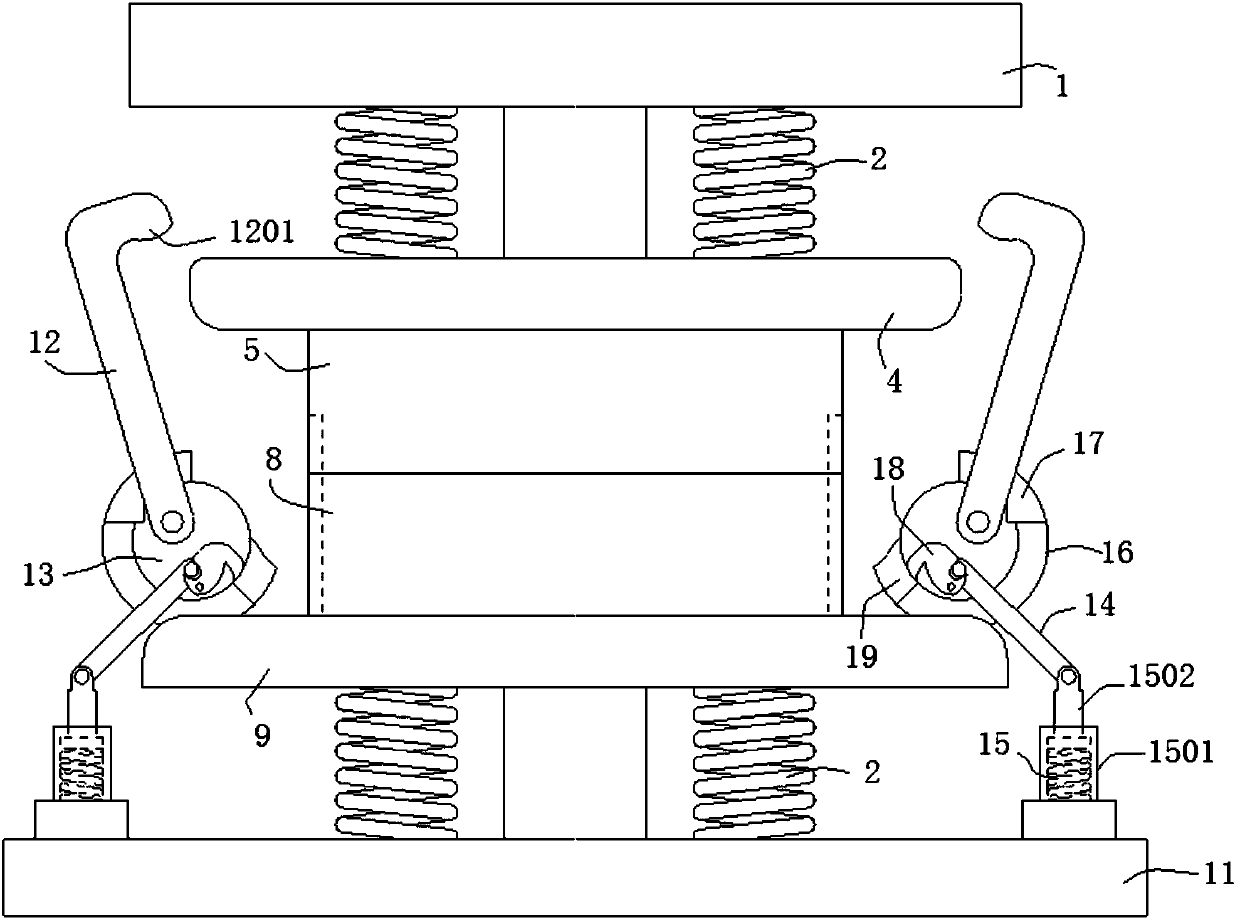

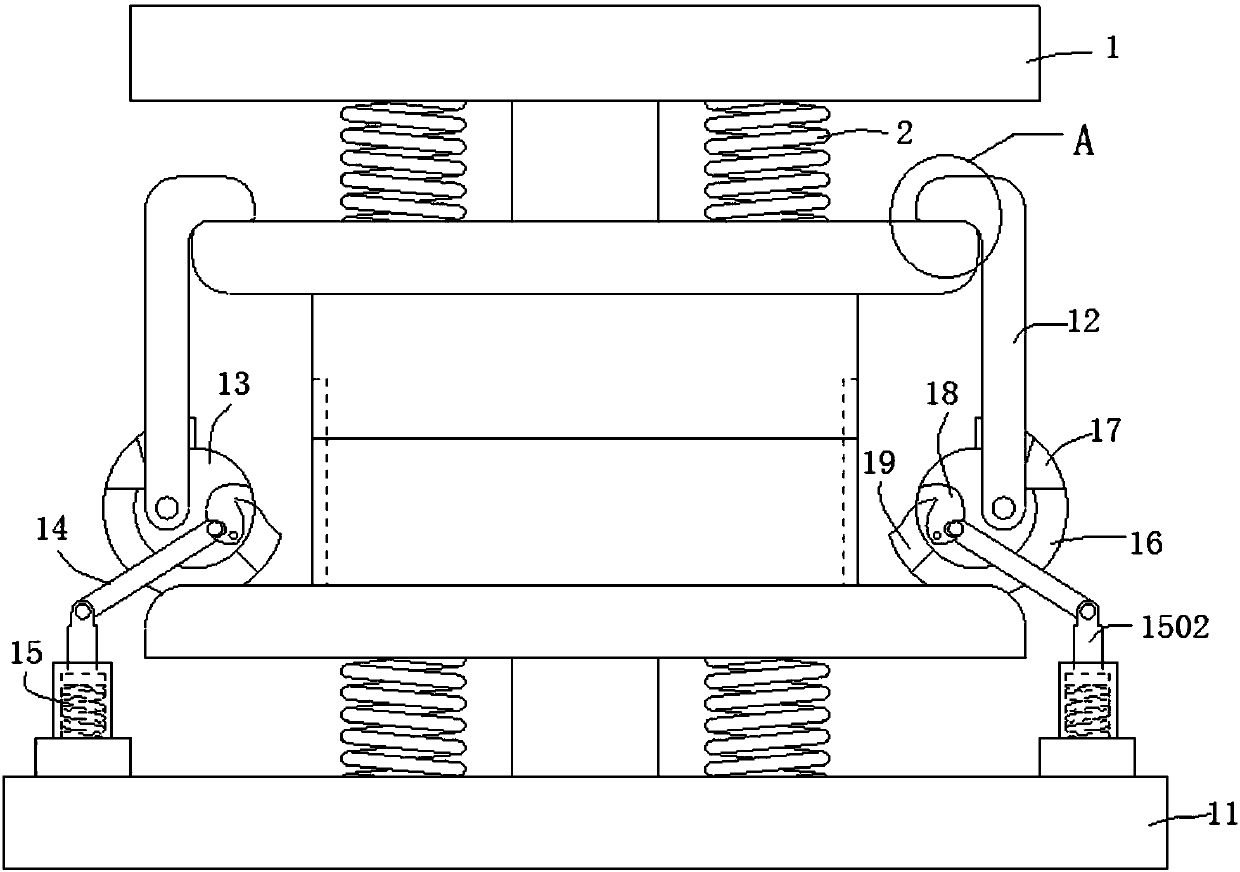

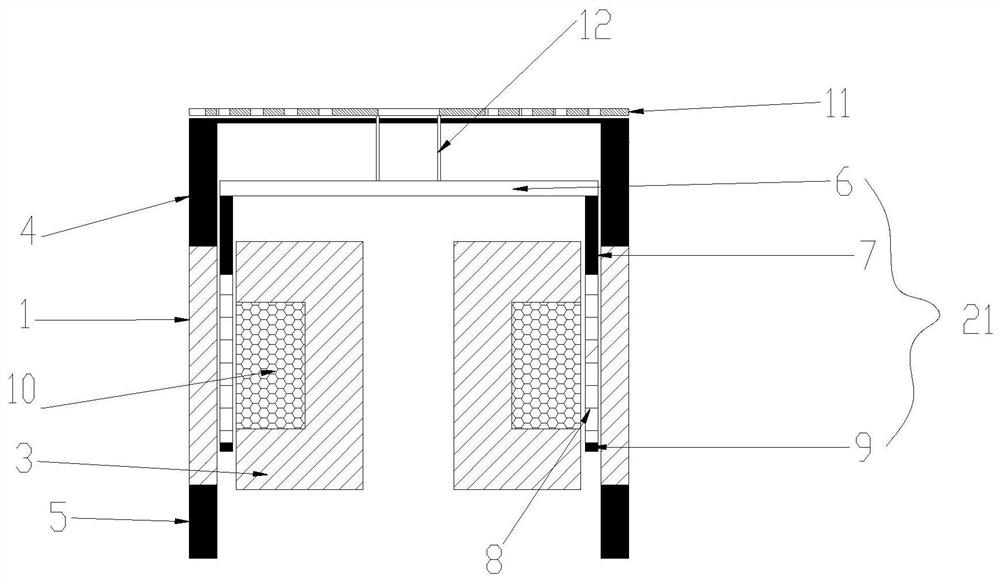

Automatic closed forging forming die

ActiveCN106623722APrevent savingImprove processing pass rateForging/hammering/pressing machinesAutomatic controlEngineering

The invention discloses an automatic closed forging forming die, and belongs to the technical field of metal press machining. The die comprises a rigid die base, a floating female die, and automatic die locking devices symmetrically arranged on the two sides of a lower female die base. The two sides of the upper end face of an upper female die base are symmetrically provided with clamping grooves. Each automatic die locking device comprises a swinging lock rod and a power mechanism driving the swinging lock rod to swing. Lock heads clamped to the clamping grooves in a matched mode are arranged on the tops of the swinging lock rods. During combination of an upper female die and a lower female die, the power mechanisms drive the swinging lock rods to swing in the direction close to the upper female die till the lock heads make contact with the clamping grooves to be clamped; During opening of the upper female die and the lower female die, the power mechanisms drive the swinging lock rods to swing in the direction away from the upper female die till the lock heads get away from the clamping grooves to be reset. The die clamping pressure can be increased, and automatic control over locking and unlocking of the upper and lower female dies of a die locking device is achieved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

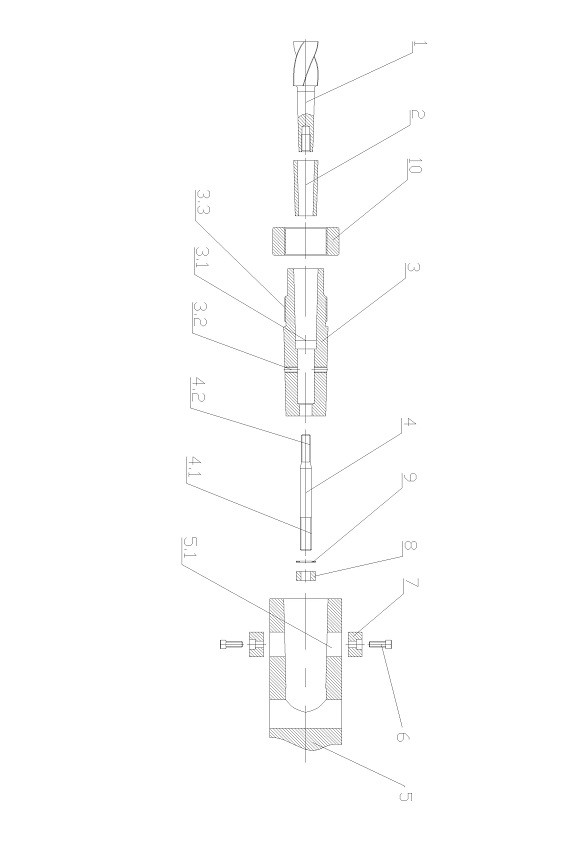

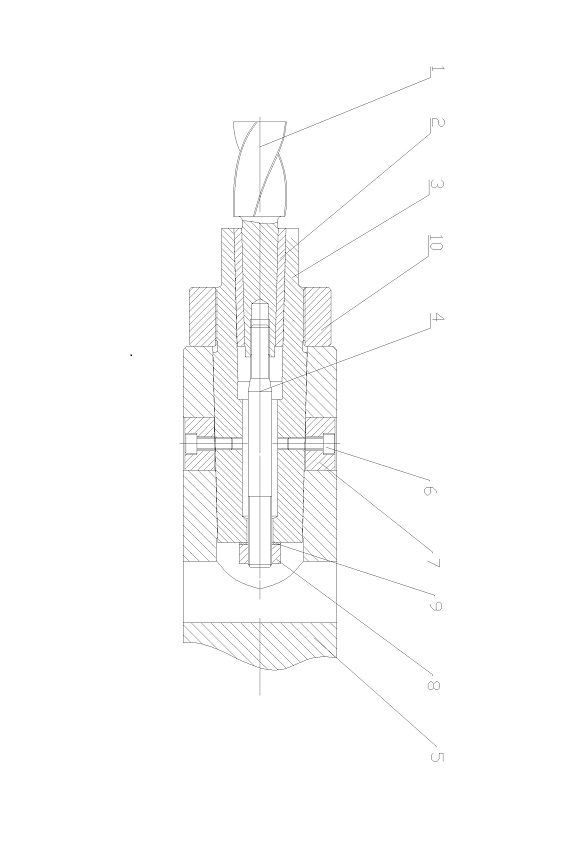

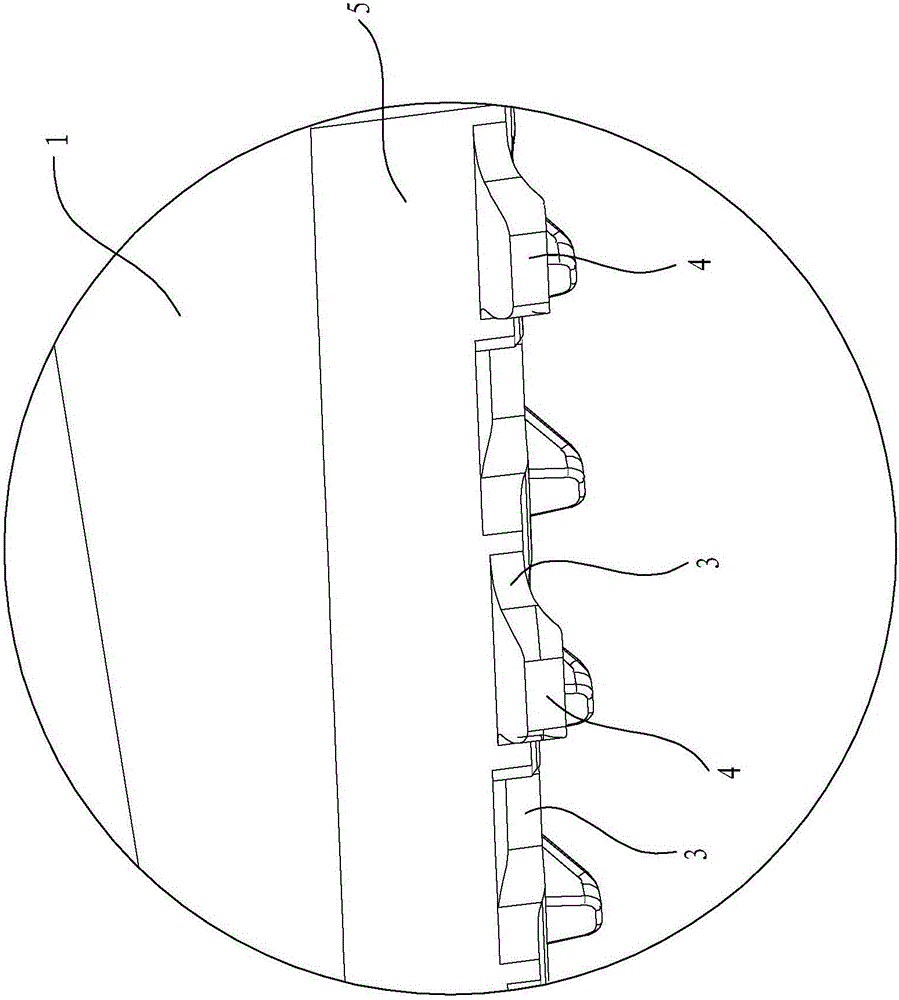

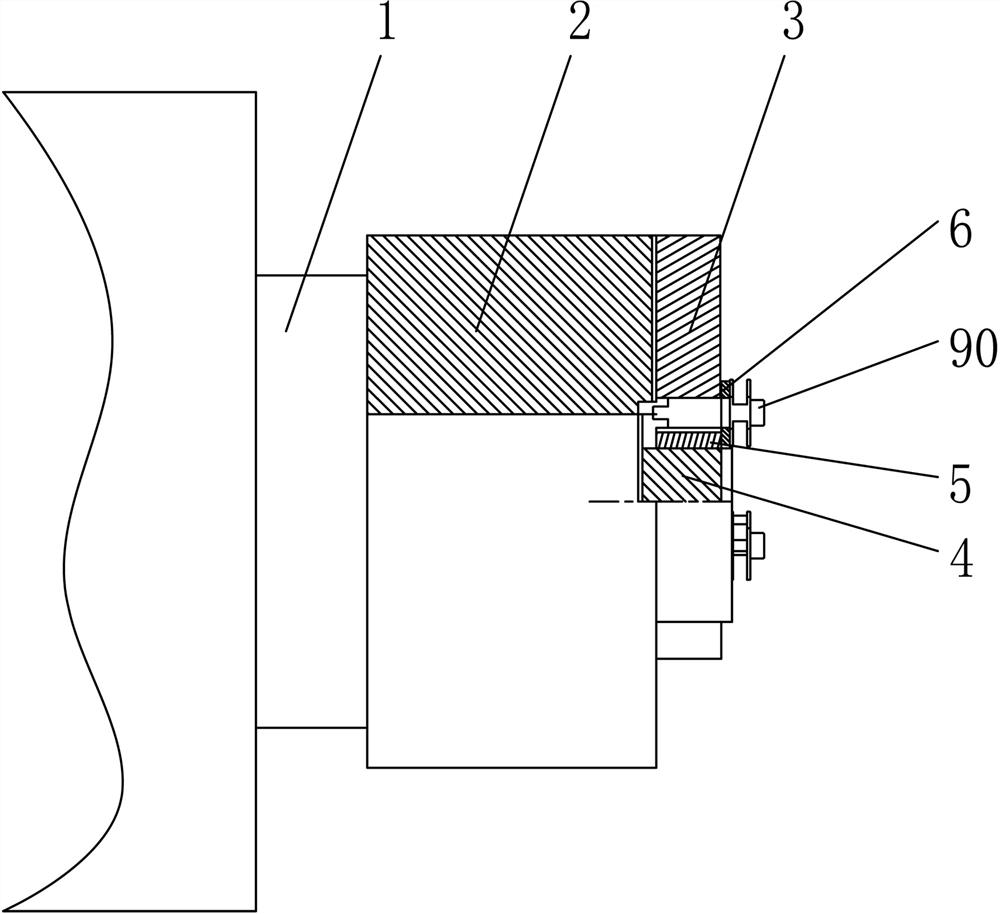

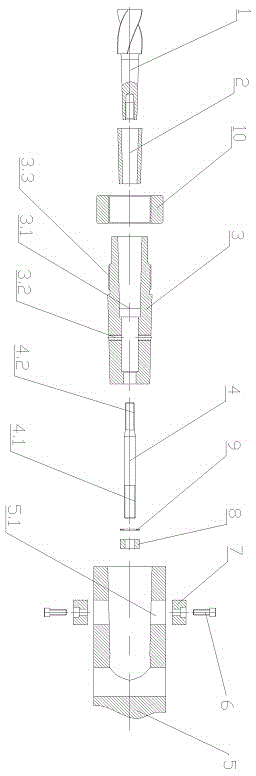

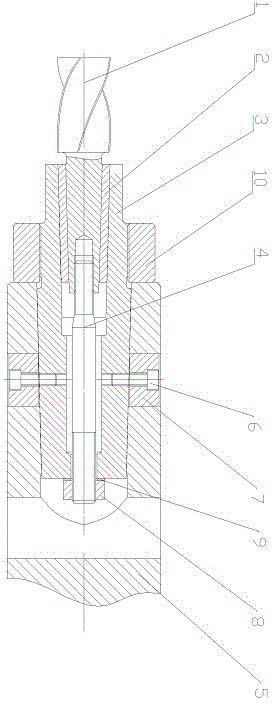

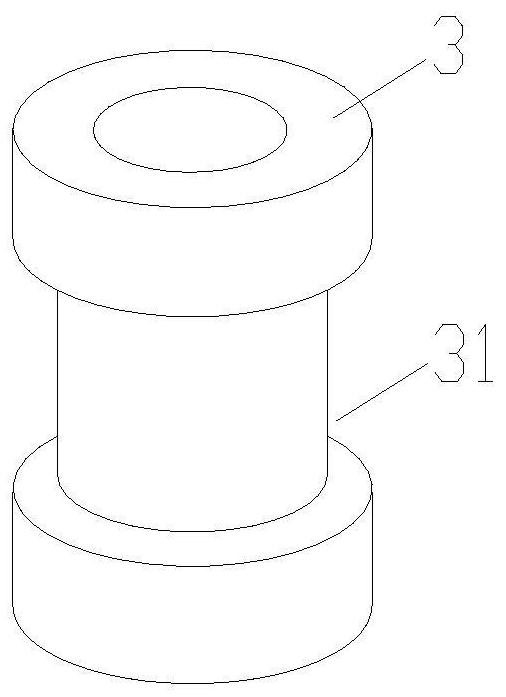

Tool positioning-clamping mechanism for milling machine

InactiveCN102581668ASmooth rotationNot easy to fall offPositioning apparatusMetal-working holdersEngineeringMachine

The invention discloses a tool positioning-clamping mechanism for a milling machine, which comprises a tool (1), a tool shank (3) and a pull bar (4). The tool shank (3) is partially contained in a machine spindle (5) and fixed to the same, the tool shank (3) is provided with a center hole (3.1), the tool (1) is nested into the center hole (3.1), the pull bar (4) is contained in the center hole (3.1), one end of the pull bar (4) is connected with the tool shank (3) and axially limited, the other end of the pull bar (4) is fixedly connected with the tool (1), and accordingly the tool (1) is fixedly connected with the machine spindle (5). The connection way is higher in connection rigidity than the original Morse taper connection way, connection is more stable, and clamping is better. When the machine spindle is in high-speed rotation, the tool is more stable in rotation and less apt to fall from the spindle, and safety factor is higher.

Owner:宁波远达船机配件有限公司

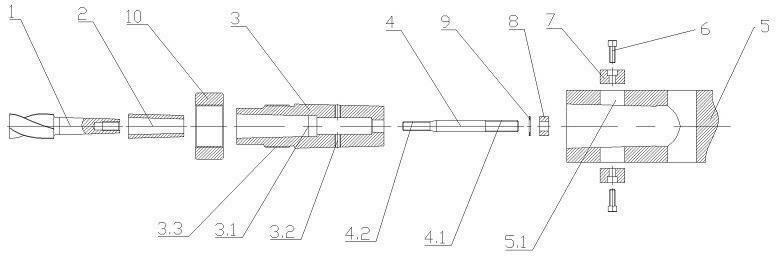

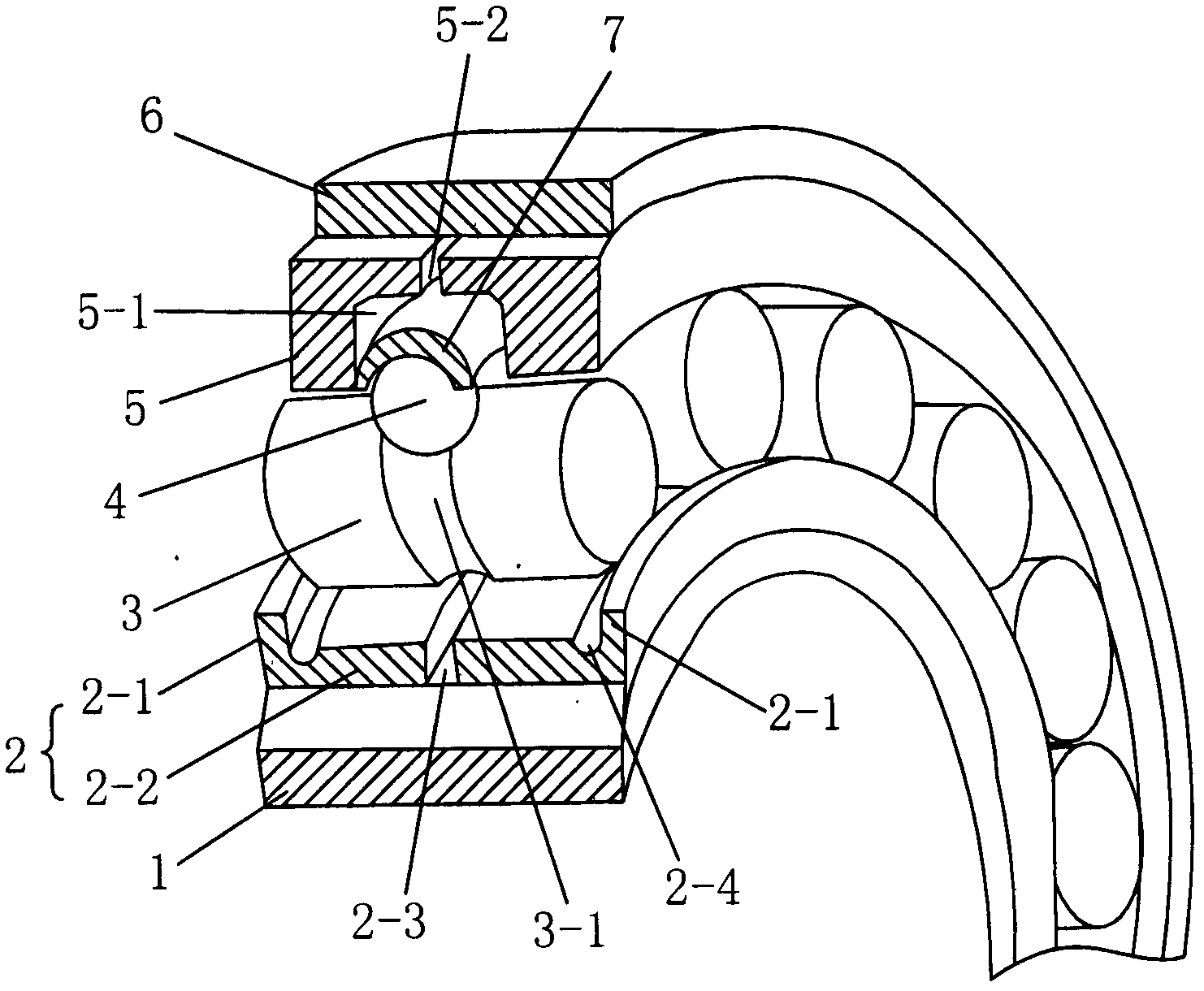

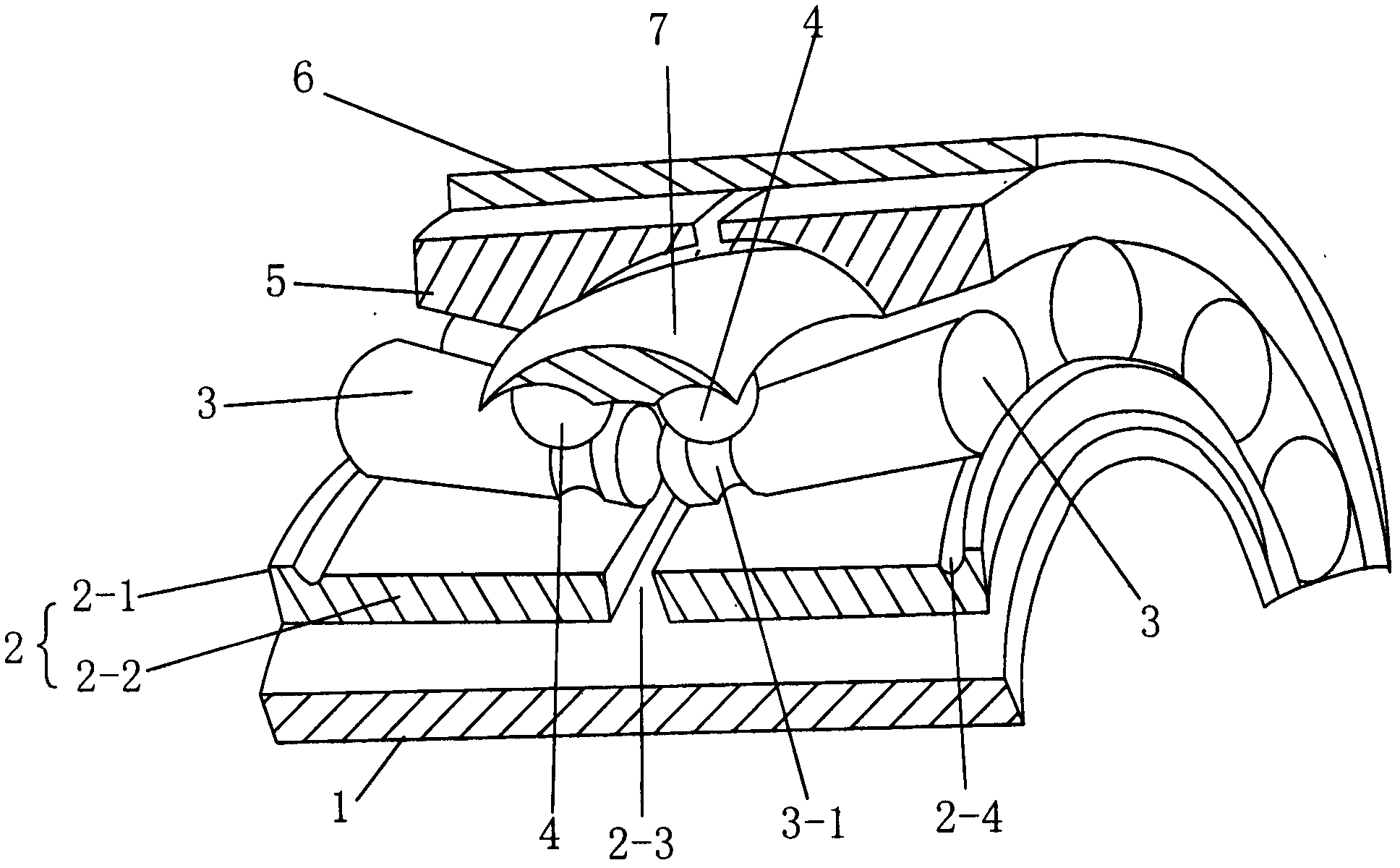

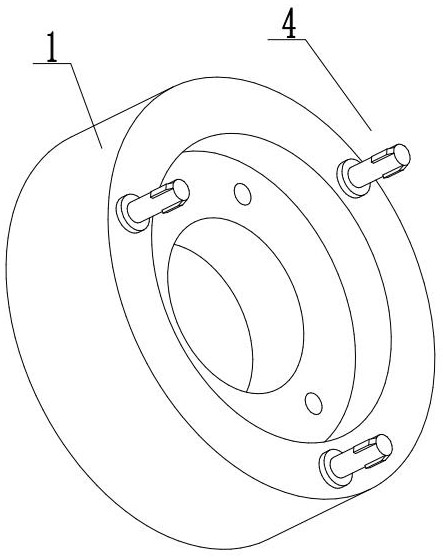

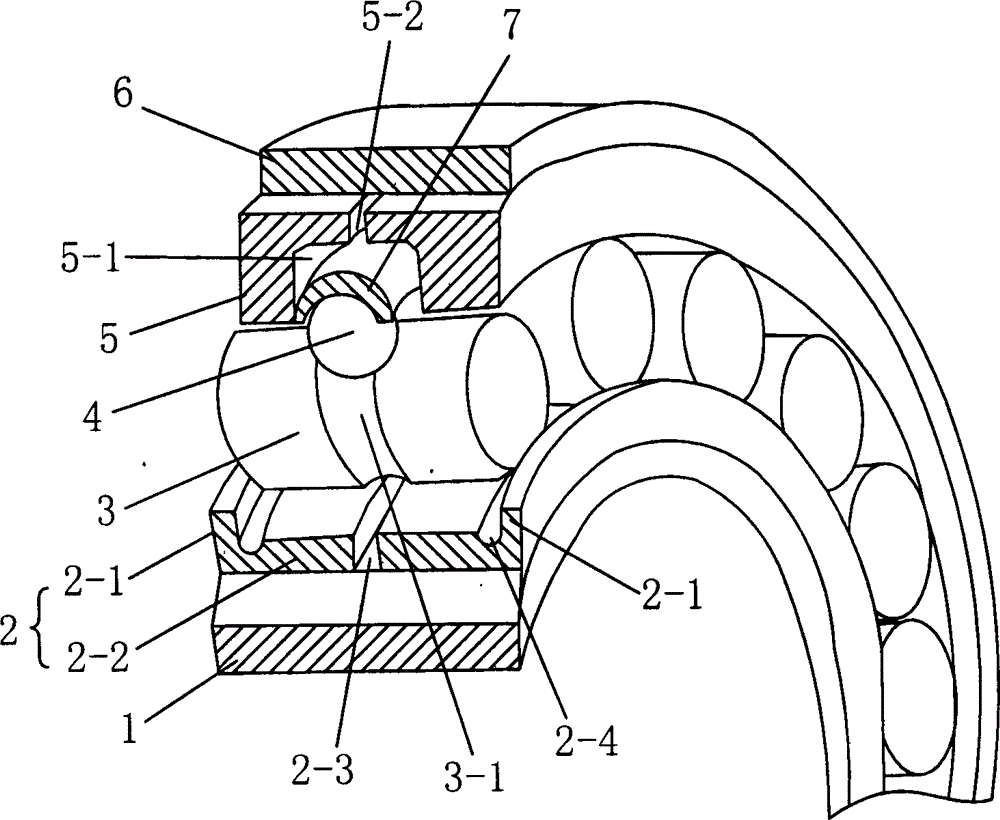

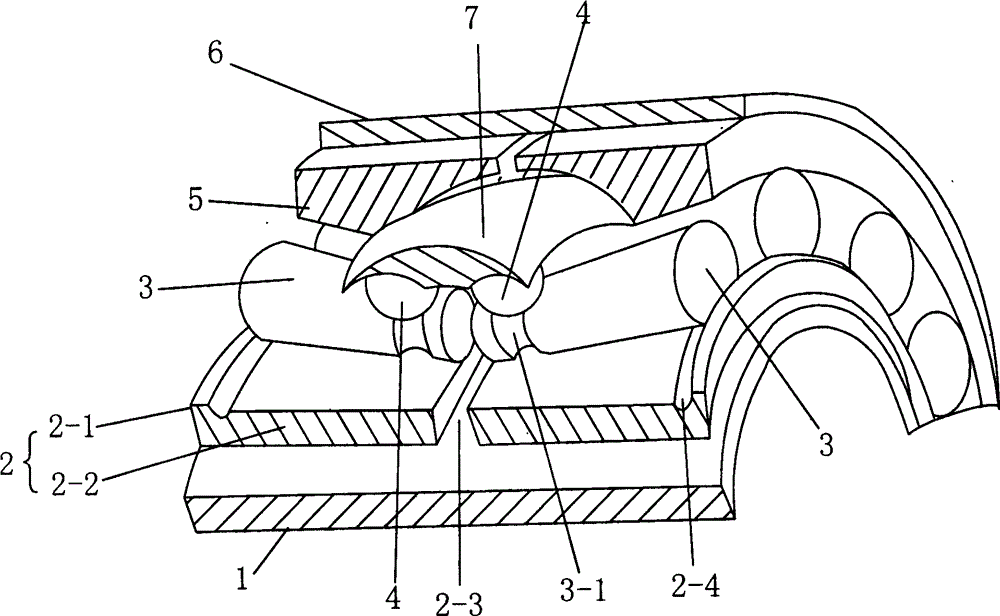

Bearing

ActiveCN102494018AAvoid power lossGood axial and radial load capacityRoller bearingsBall and roller bearingsFlangingAxial symmetry

Owner:卢雨

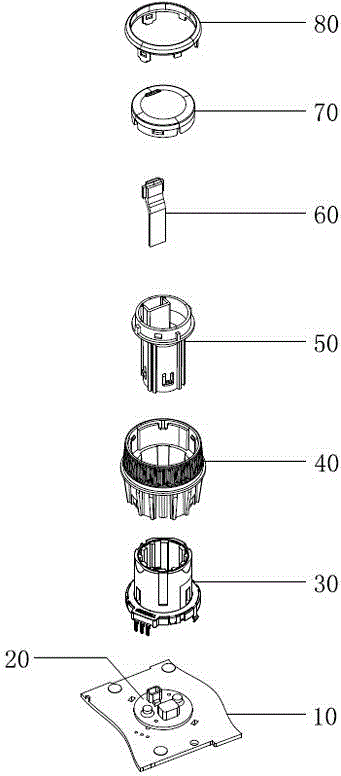

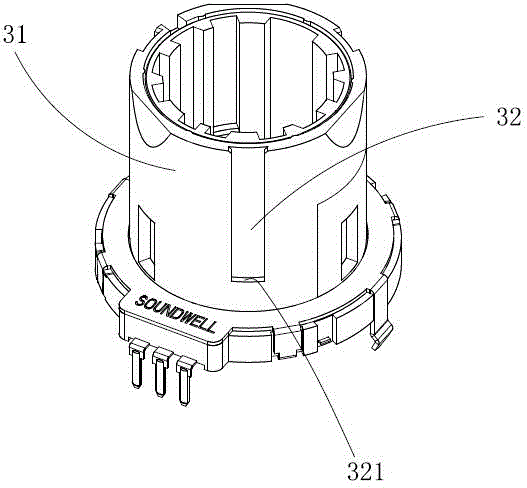

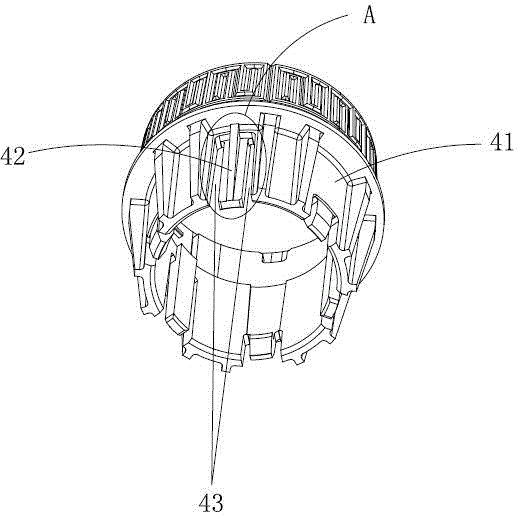

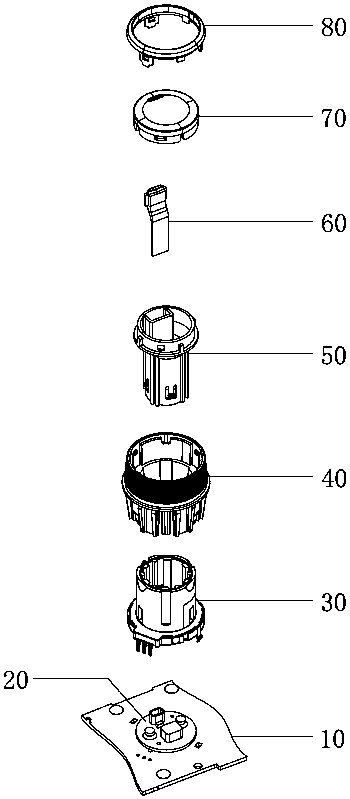

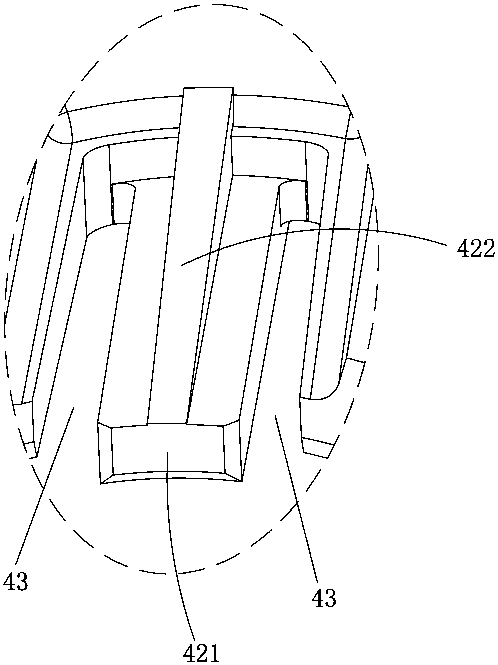

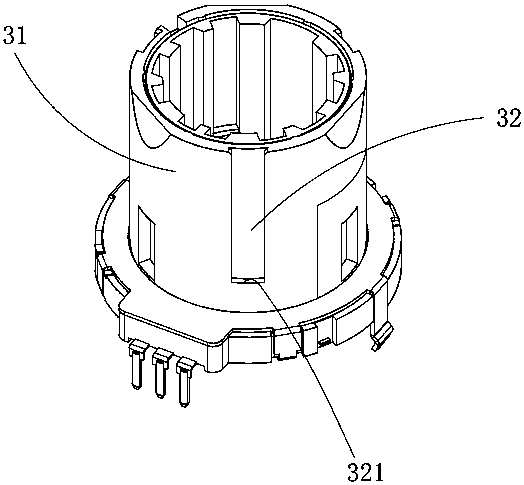

Automobile interior decorative parts turn button structure having crumpling function

ActiveCN106206132ACrushing achievedPlay the role of axial limitElectric switchesKey pressingAxial force

The invention relates to an automobile interior decorative parts turn button structure having a crumpling function. The automobile interior decorative parts turn button structure comprises a PCB board, a hollow encoder, a turn button, a press key support rack, a press key cap and a decoration ring, wherein the turn button sleeves a hollow rotating shaft of the hollow encoder, and three elastic arms are designed on a lower part of the turn button and are enabled to match with three guiding grooves on the hollow encoder. End faces of the elastic arms of the turn button are abutted against a limiting face of a bottom part of a middle guiding groove, and the turn button can be axially limited. An inner side of a bottom part of each of the elastic arms of the turn button is chamfered; when axial force within a certain limit is acts on the turn button, the three elastic arms can easily expand outward, and the turn button is enabled to crumple. When the axial force acting on the turn button exceeds the certain limit, the three elastic arms of the turn button expand outward, the whole turn button slides downward along the hollow encoder / potentiometer, the turn button is enabled to crumple about 3 mm, and safety of passengers can be protected.

Owner:HUIZHOU DESAY SV AUTOMOTIVE

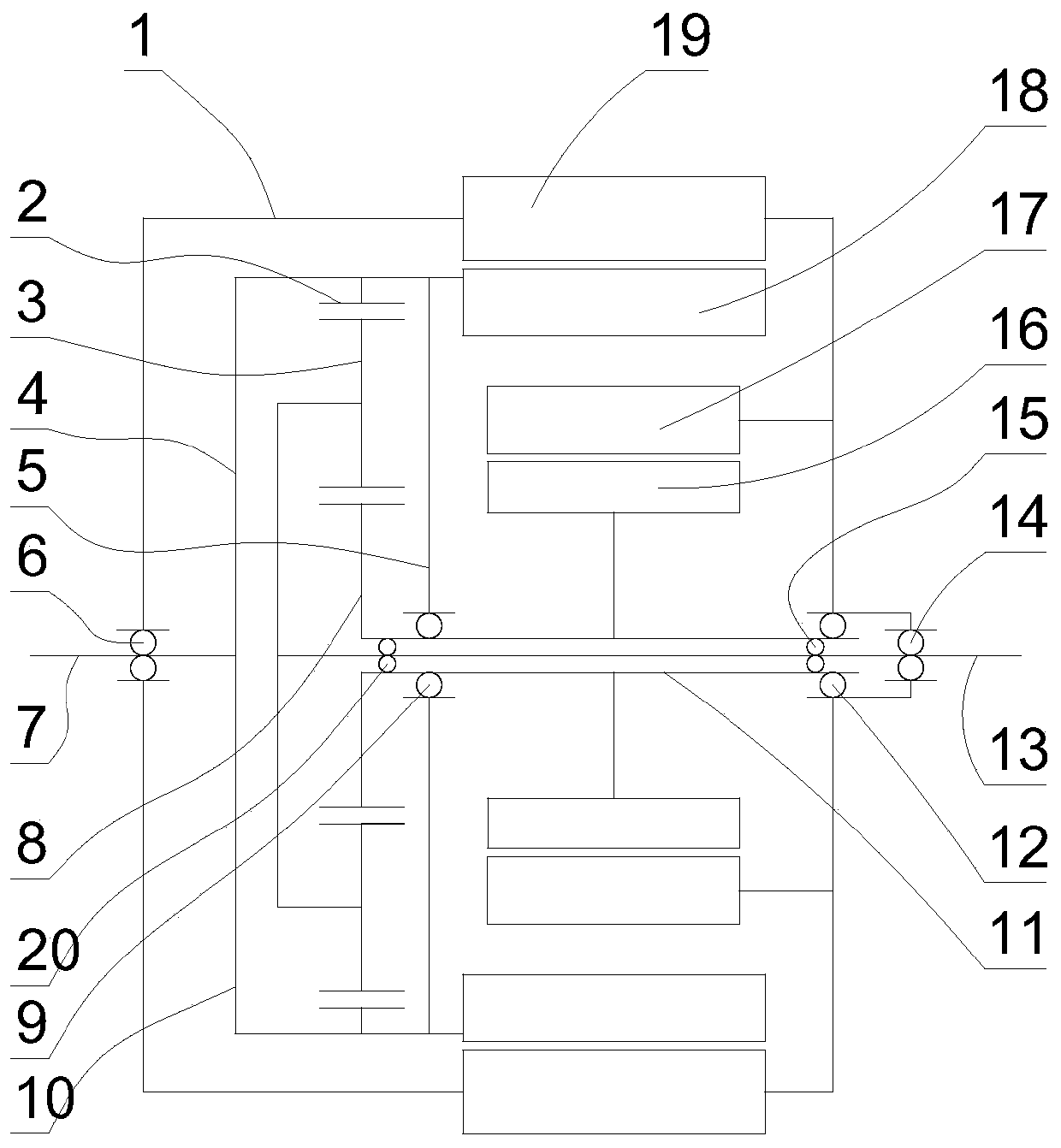

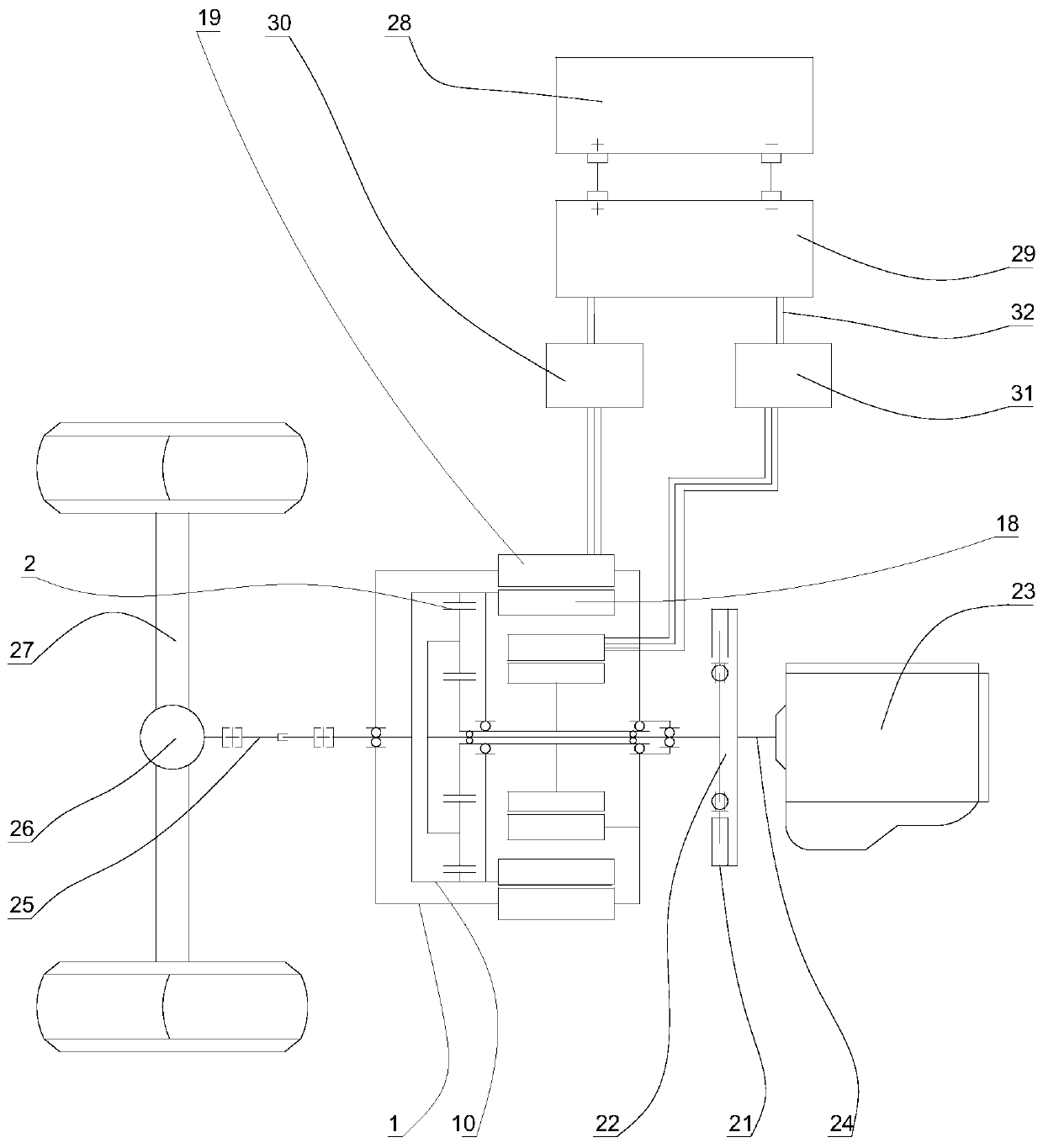

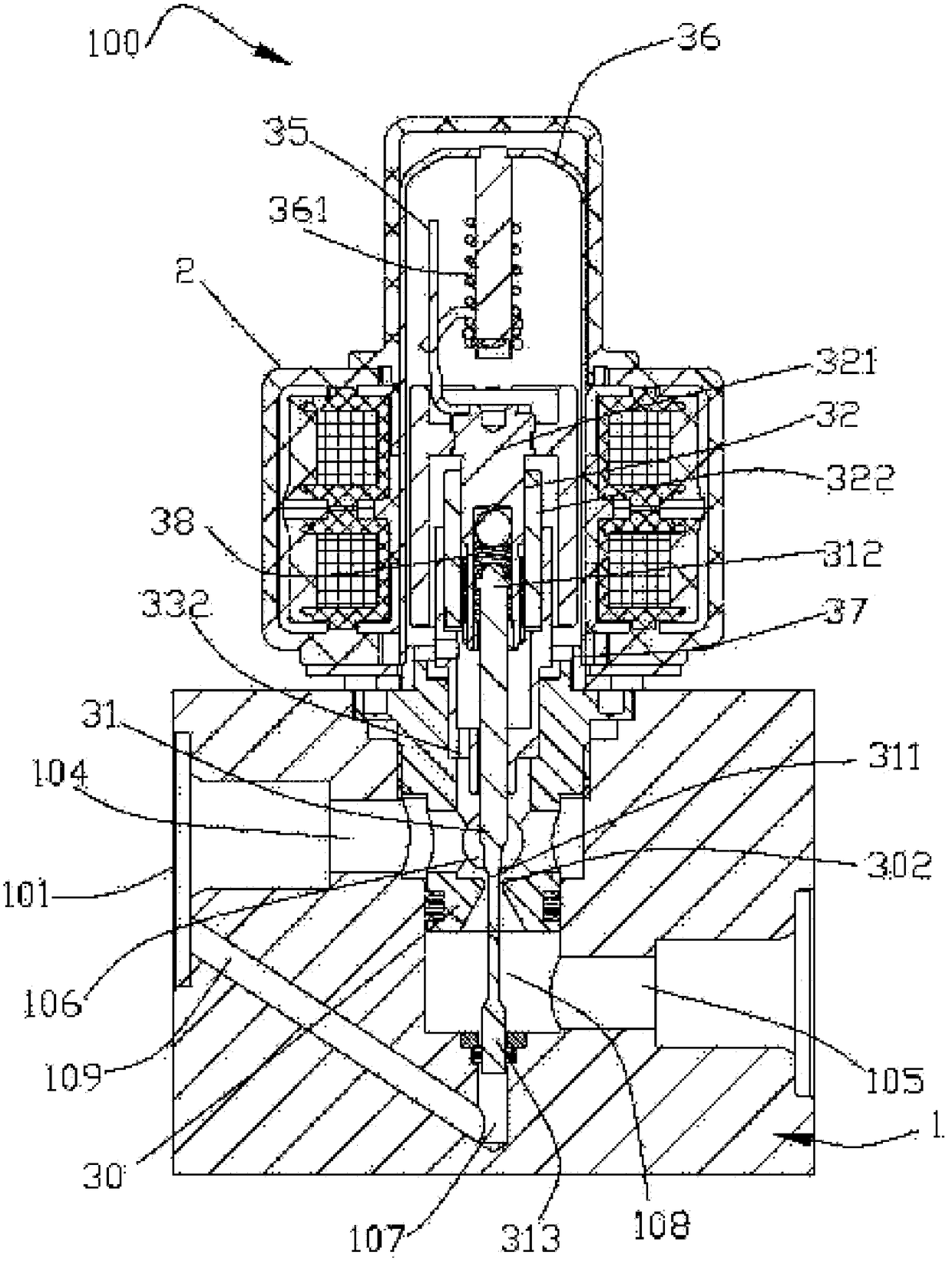

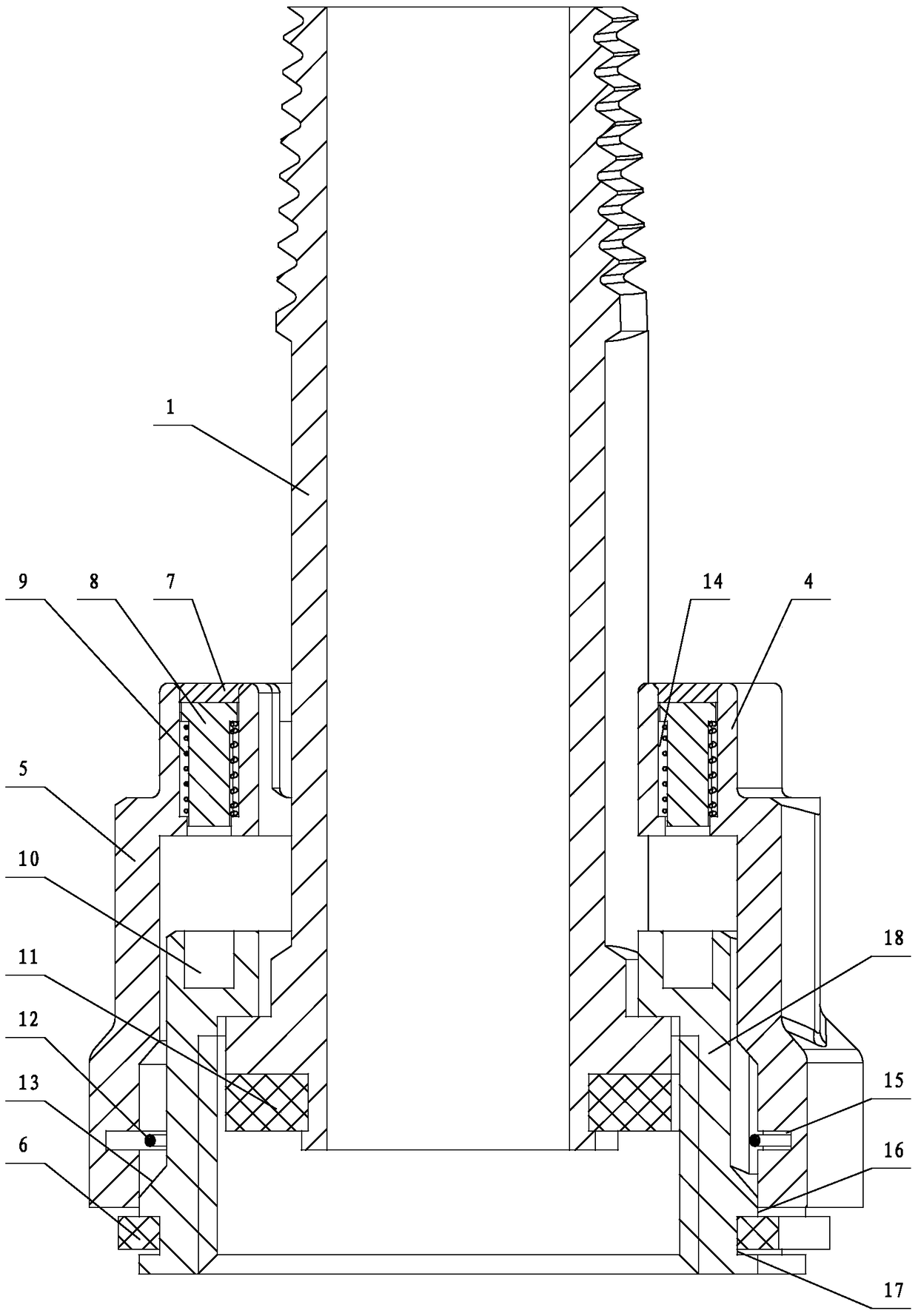

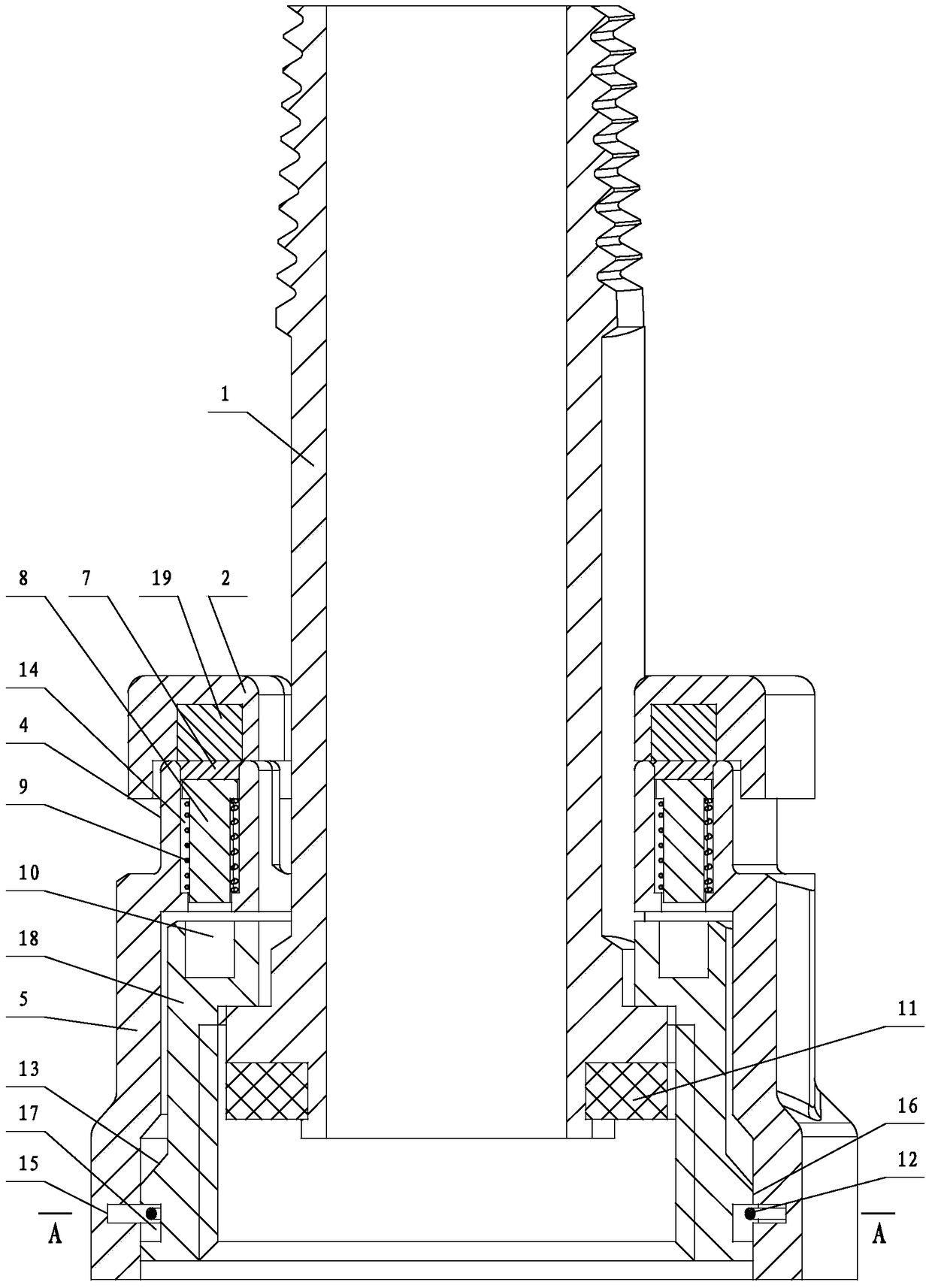

Dual-motor nested electric stepless speed change mechanical-electrical integrated system

PendingCN111409440AReduce axial sizeCompact structureGas pressure propulsion mountingMagnetic circuit stationary partsElectric machineDrive motor

The invention discloses a dual-motor nested electric stepless speed change mechanical-electrical integrated system. The integrated system comprises a shell, a gear ring, a planet wheel, a planet carrier, a supporting arm, a rear bearing, an oil seal, a rear output shaft, a rear hollow shaft inner supporting bearing, a supporting arm bearing, a gear ring frame, a hollow shaft, a hollow shaft outersupporting bearing, a front output shaft, a front bearing, an oil seal, a front hollow shaft inner supporting bearing, an ISG motor rotor, an ISG motor stator, a main drive motor rotor and a main drive motor stator, wherein the main drive motor stator and the main drive motor rotor form a main drive motor, and the ISG motor rotor and the ISG motor stator form an ISG motor, the ISG motor rotor is arranged in a cylindrical ISG motor stator, the ISG motor stator is arranged in a cylindrical main drive motor rotor, and the main drive motor stator and the ISG motor stator are fixed to the shell. The integrated system has advantages of compact structure, high power density and high system efficiency.

Owner:南京清研海易新能源动力有限责任公司

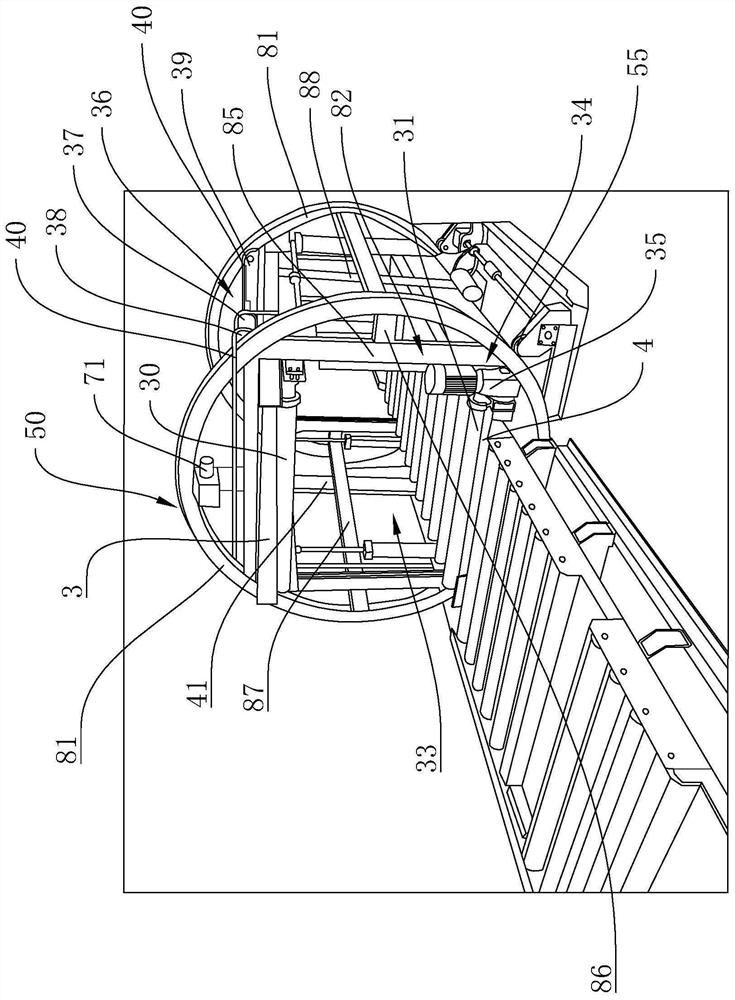

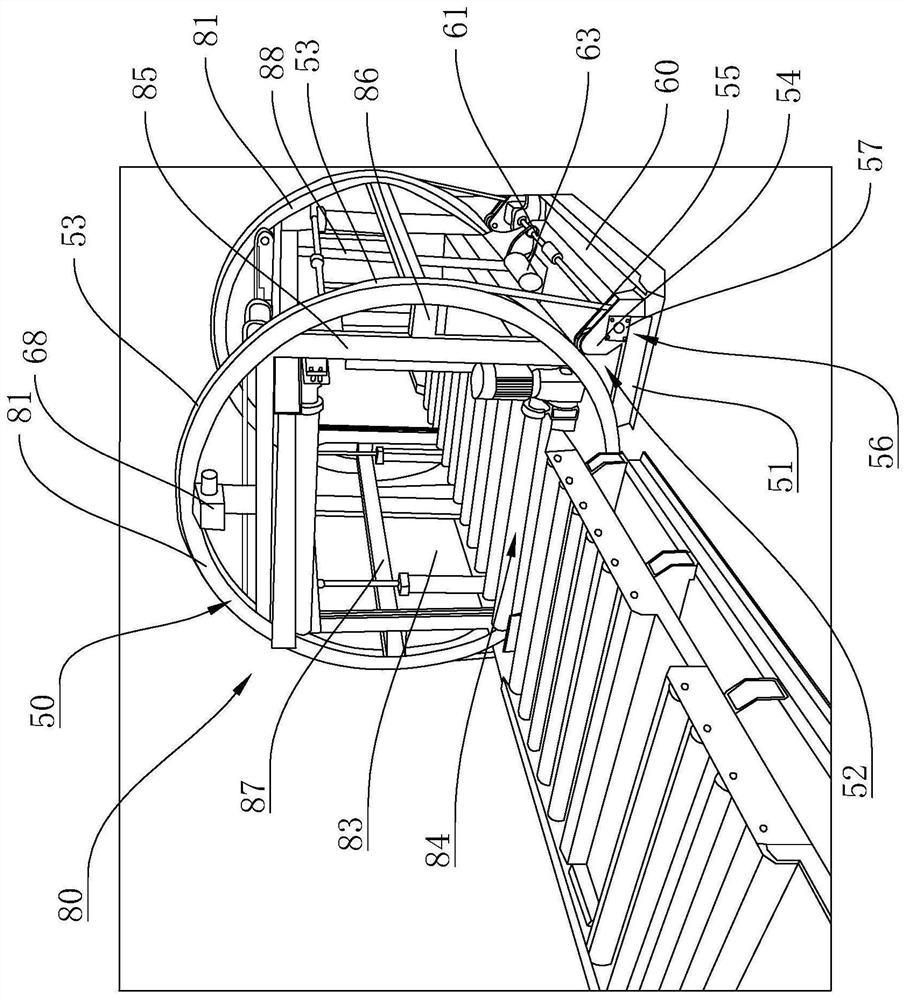

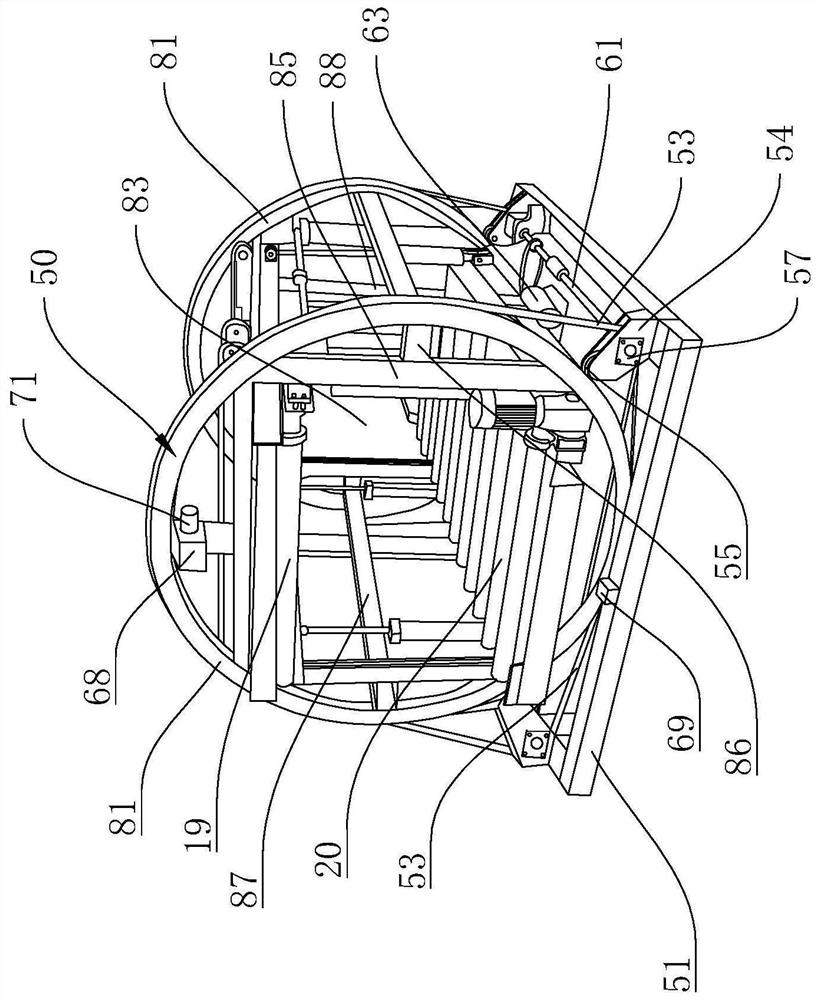

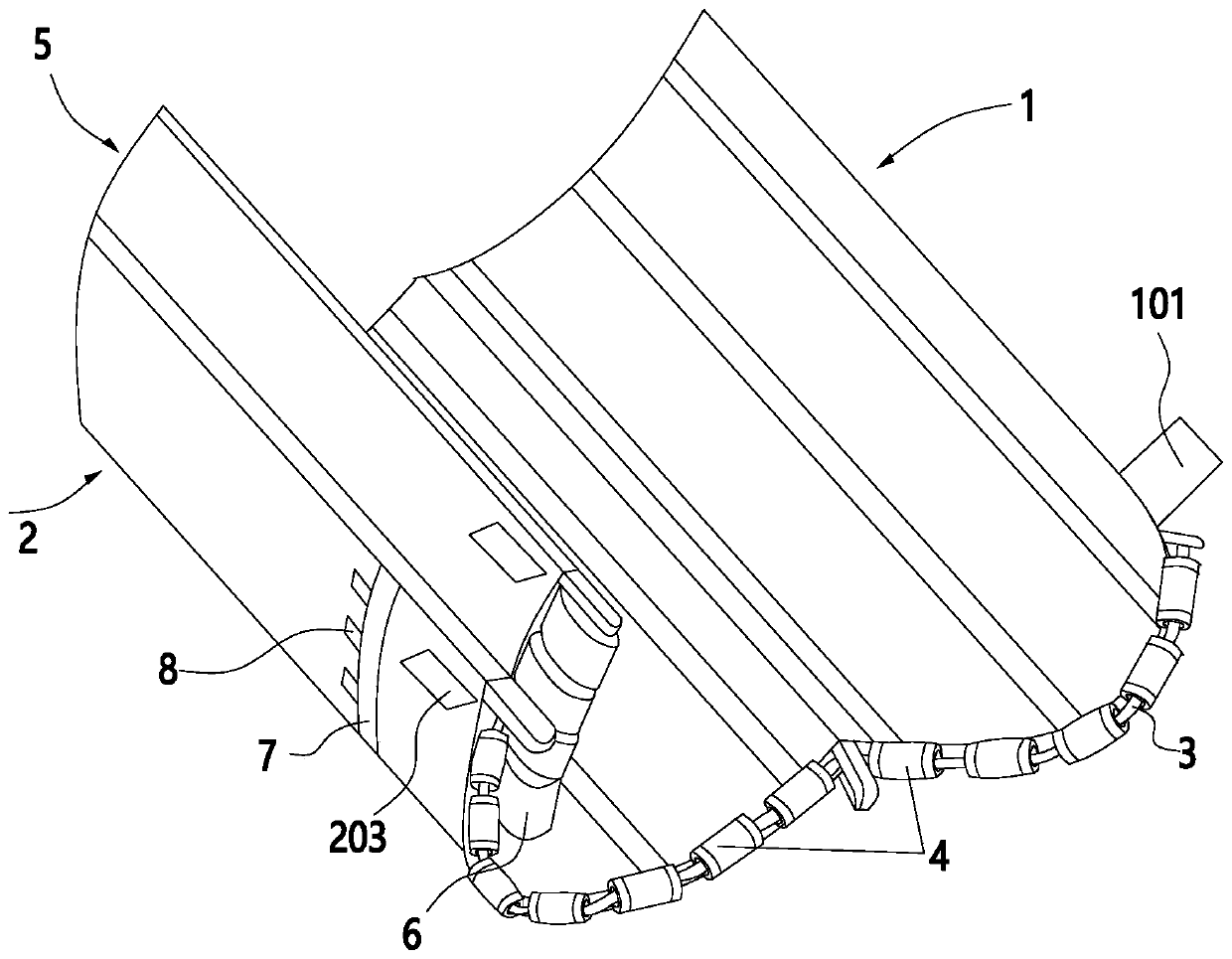

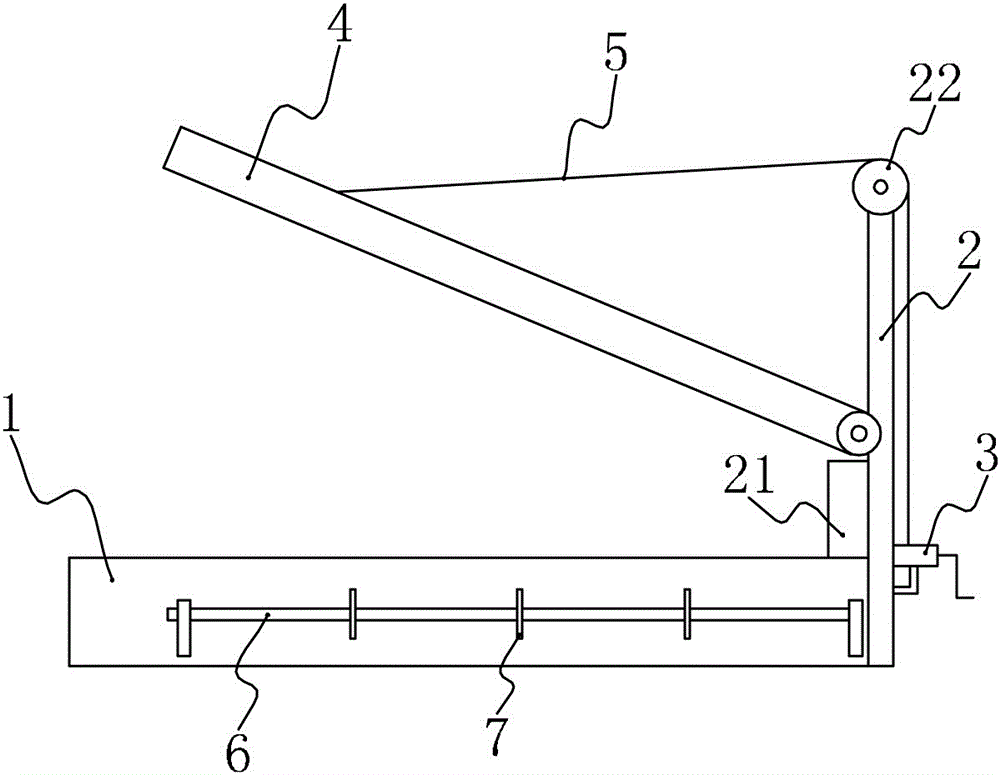

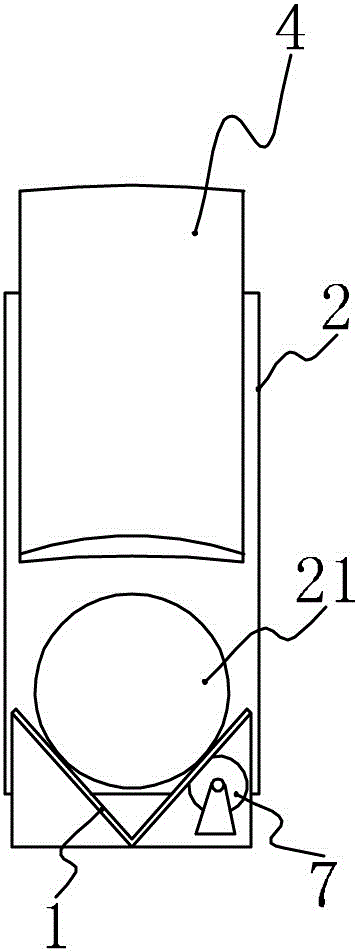

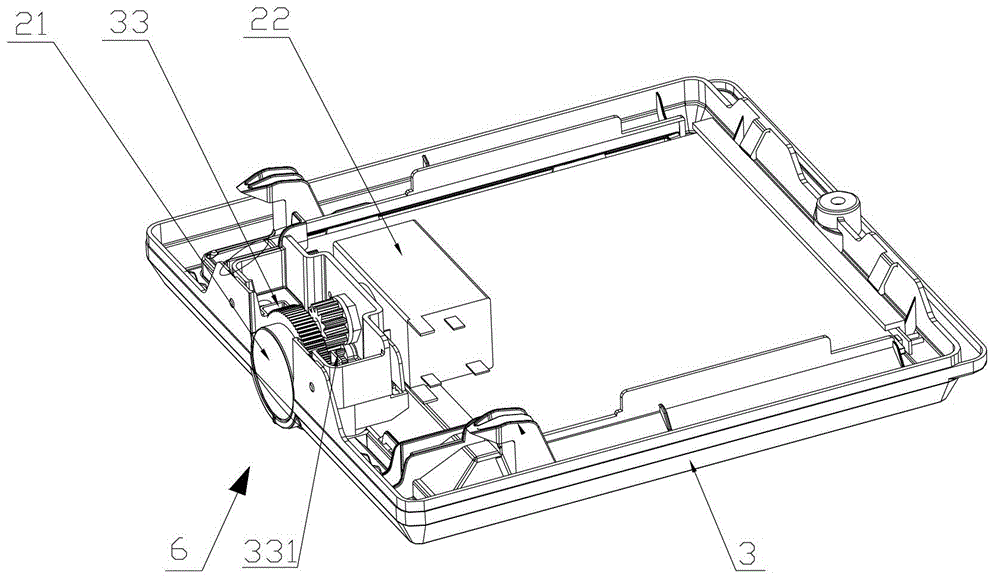

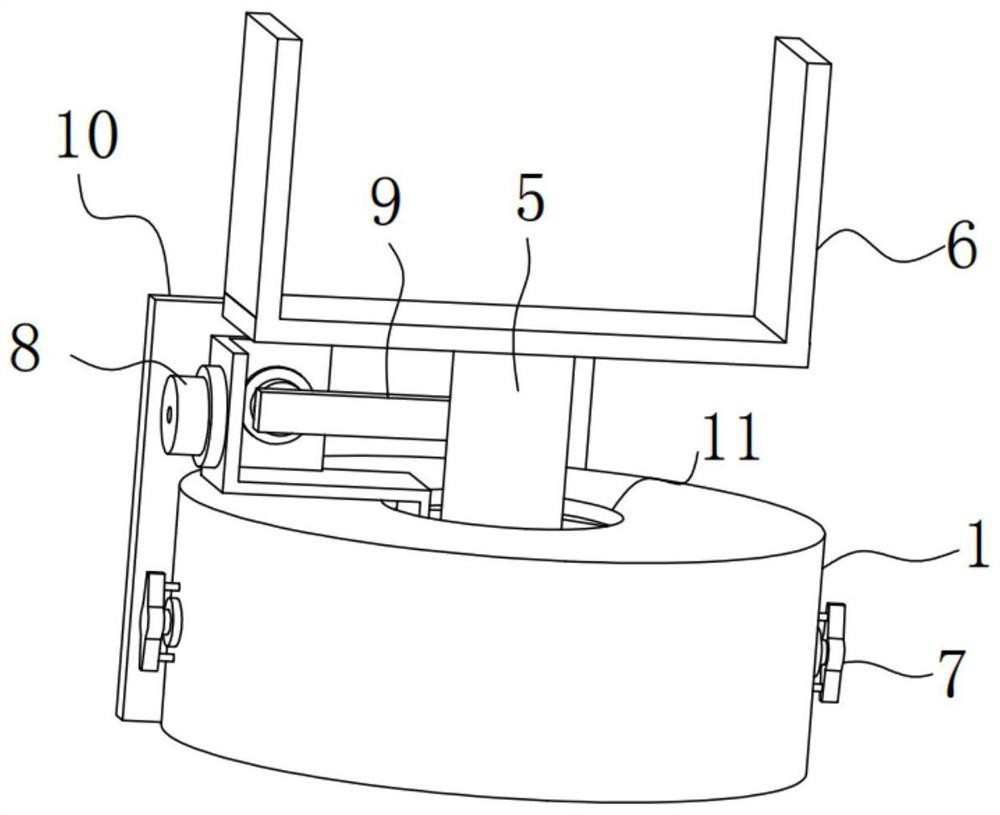

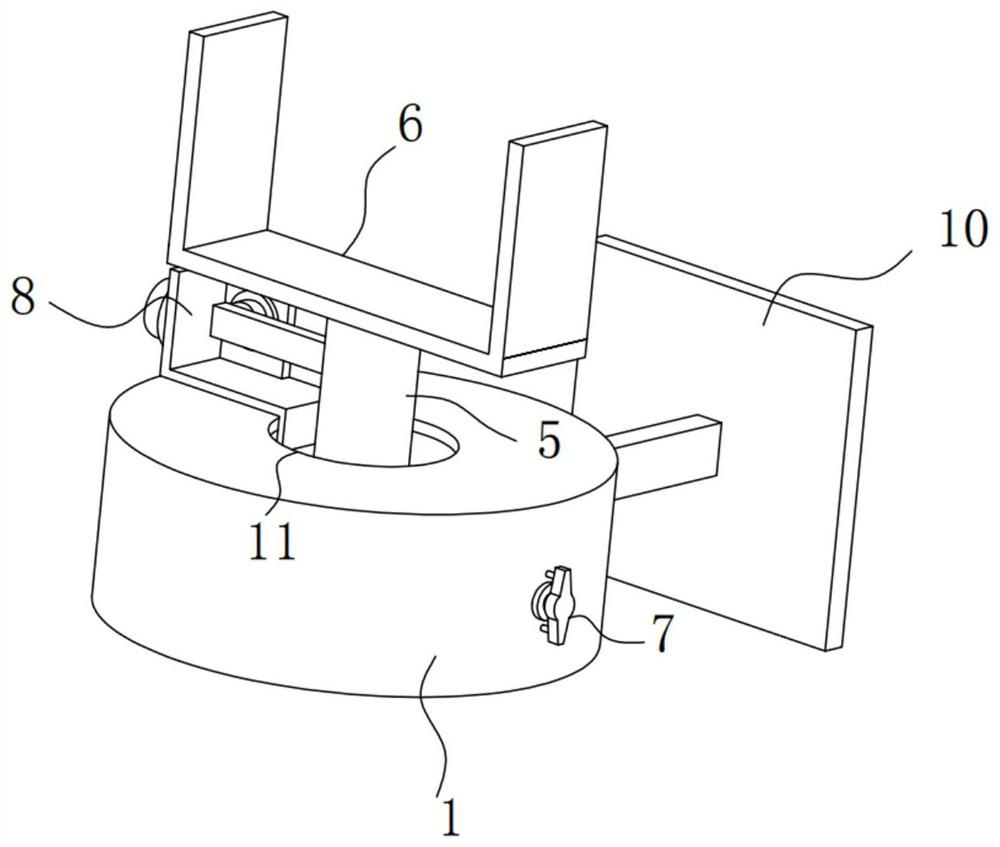

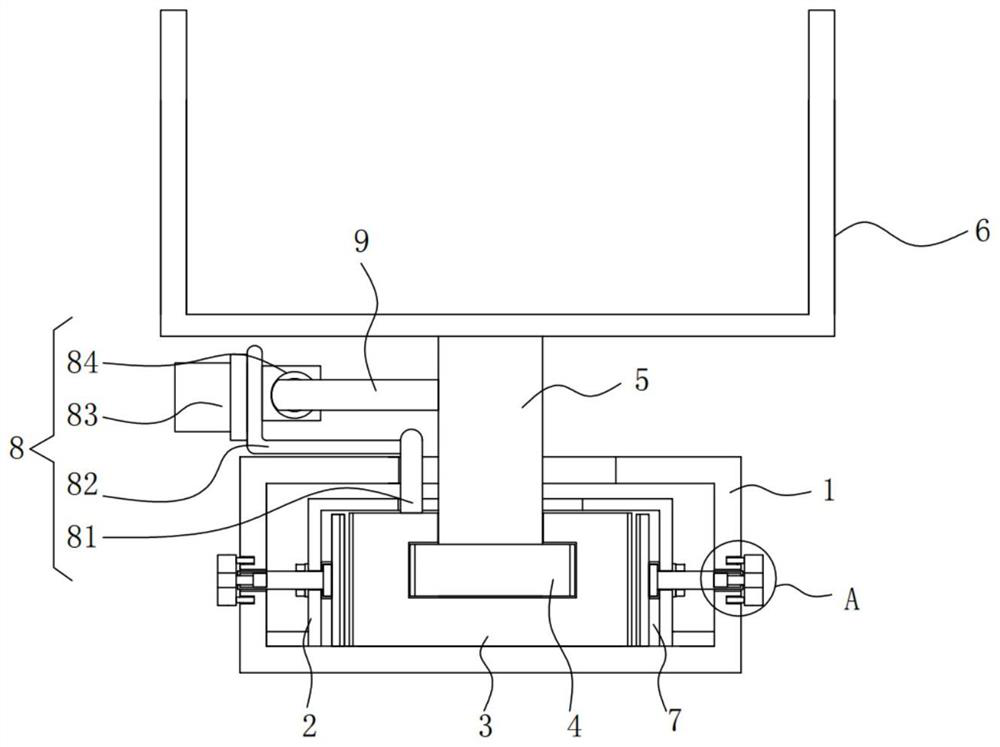

Plate turnover machine

The invention belongs to the technical field of plate turnover machines, and particularly relates to a plate turnover machine. The plate turnover machine comprises a base, a rotating support is arranged on the base, a horizontal rotating mechanism is arranged between the rotating support and the base, the rotating support comprises two symmetrically-arranged supporting rings, a rectangular supporting frame is arranged in each supporting ring, and an upper pedestal and a lower pedestal are arranged between the two supporting rings. By arranging the horizontal rotating mechanism and a turnover clamping mechanism, a plate located in a feeding channel can be clamped firstly, an upper conveying table is always in a horizontal state in the lifting process, it is ensured that angle deflection cannot occur, the clamping precision is high, the horizontal rotating mechanism is started after the plate is clamped, the rotating support is driven to turn over through the horizontal rotating mechanism, 180-degree turning over of plates is achieved, manual conveying and turning over of the plates are not needed, the automation degree and the working efficiency are high, and the labor intensity of workers is greatly reduced.

Owner:ZHEJIANG MOBILE ELECTRIC

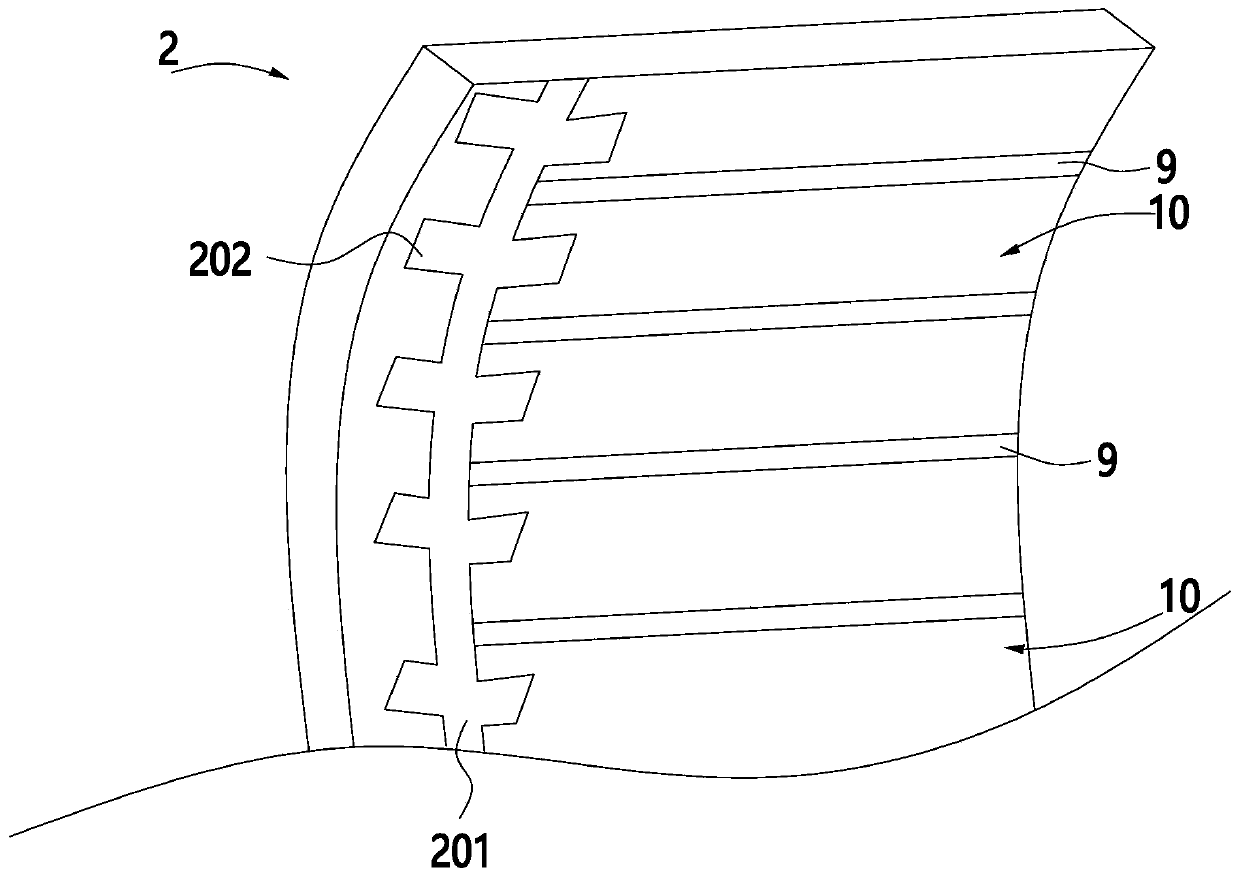

Rotational structure for butted panels

InactiveCN106063638AImprove firmnessImprove structural strengthFurniture joining partsPivotal connectionsEngineeringUltimate tensile strength

A rotational structure for butted panels comprises a first panel and a second panel which are connected through a connecting cross bar, wherein grooves and bulges, which are distributed at intervals, are formed in the lower side part of the butted surfaces of the first panel and the second panel; the lower surfaces of the bulges are upwardly concave arc surfaces; when the first panel and the second panel are butted with each other, the bulges on the first panel are embedded into the grooves of the second panels, and the bulges on the second panels are embedded into the grooves of the first panel; besides, the arc surfaces of the bulges fit the outer peripheral surface of the connecting cross bar; the bulges on the first panel and the bulges on the second panel are respectively arranged on the left side and the right side of the connecting cross bar in a holding manner. The rotational structure has the following advantages: the butting parts of the first panel and the second panel are partially superposed, so that the firmness of a butting structure can be favorably improved, and particularly, as the bulges on the first panel and the bulges on the second panel are respectively arranged on the left side and the right side of the connecting cross bar in a holding manner, the structural strength of the panel butting parts can be further improved.

Owner:YIXIANG BLOW MOLDING FURNITURE (NINGBO) CO LTD

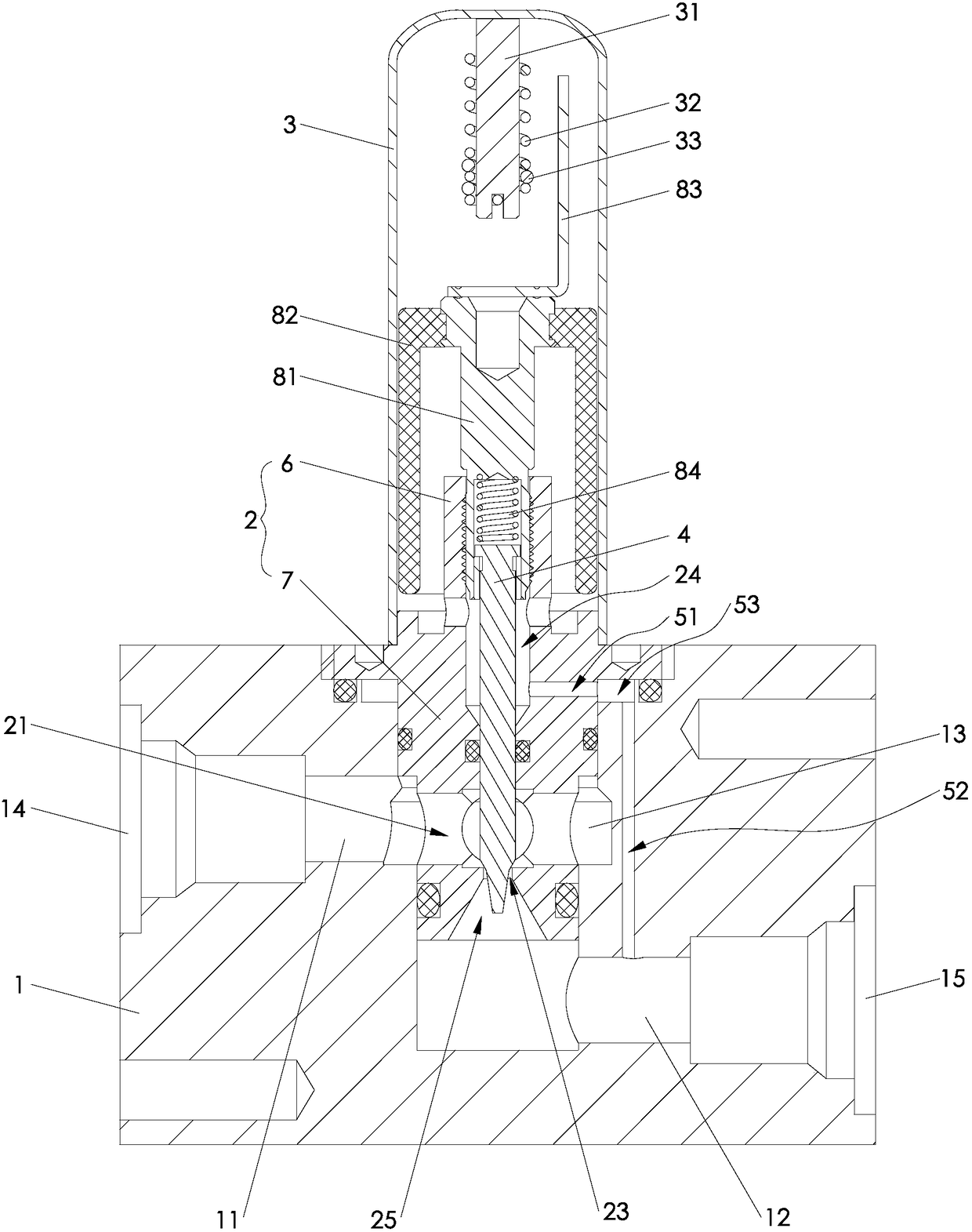

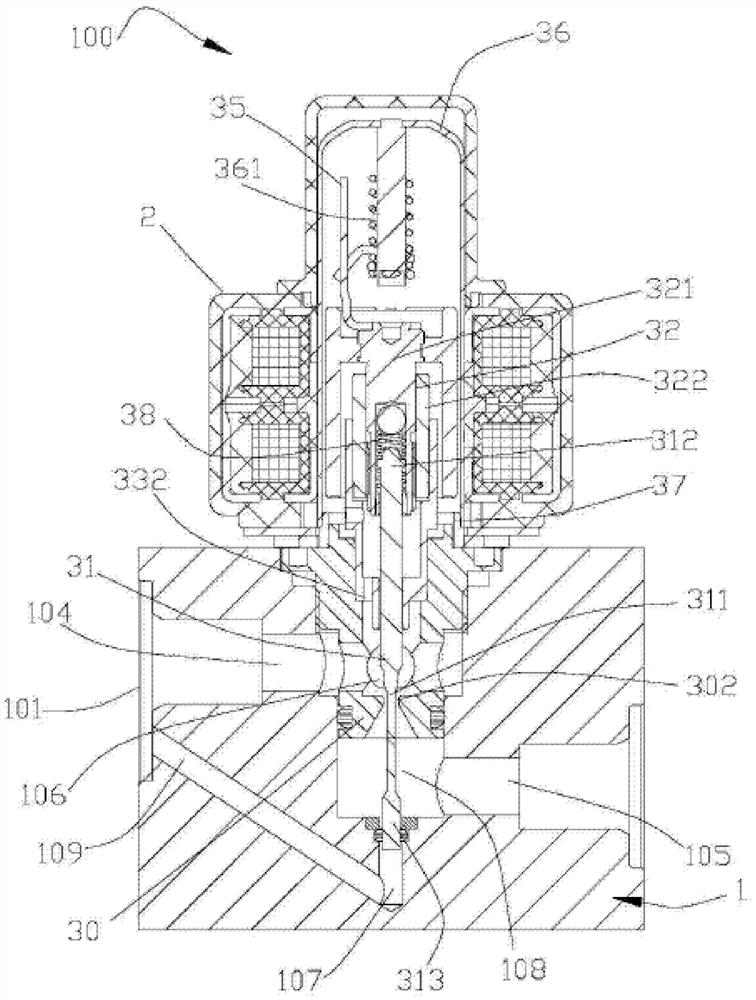

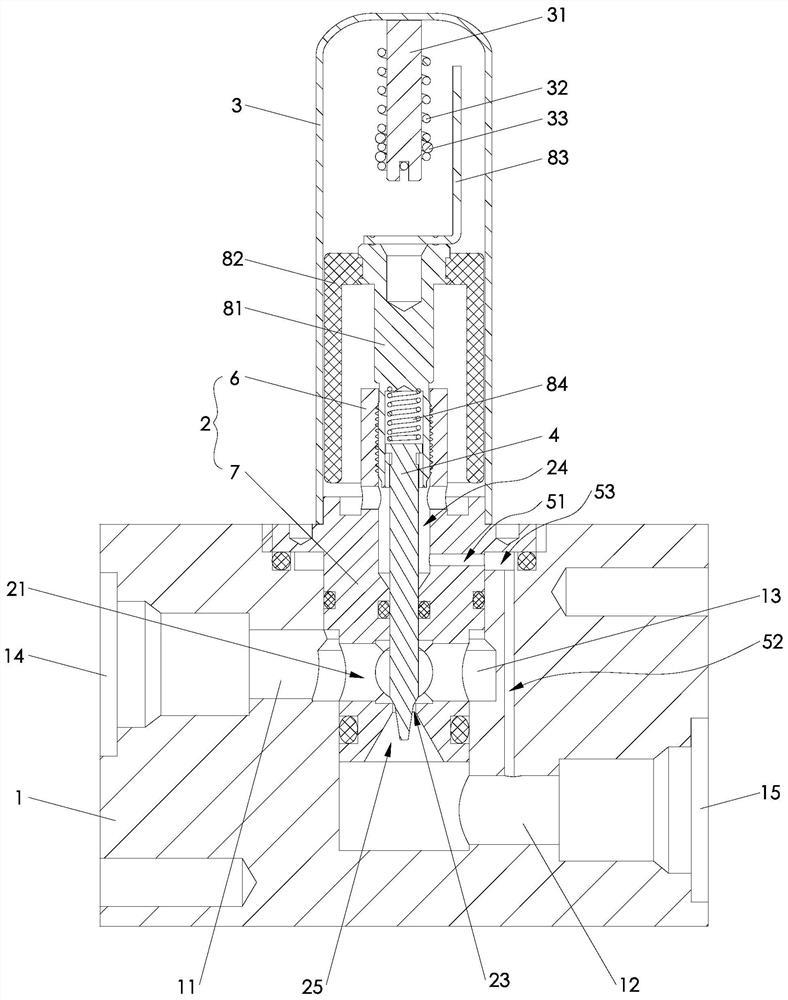

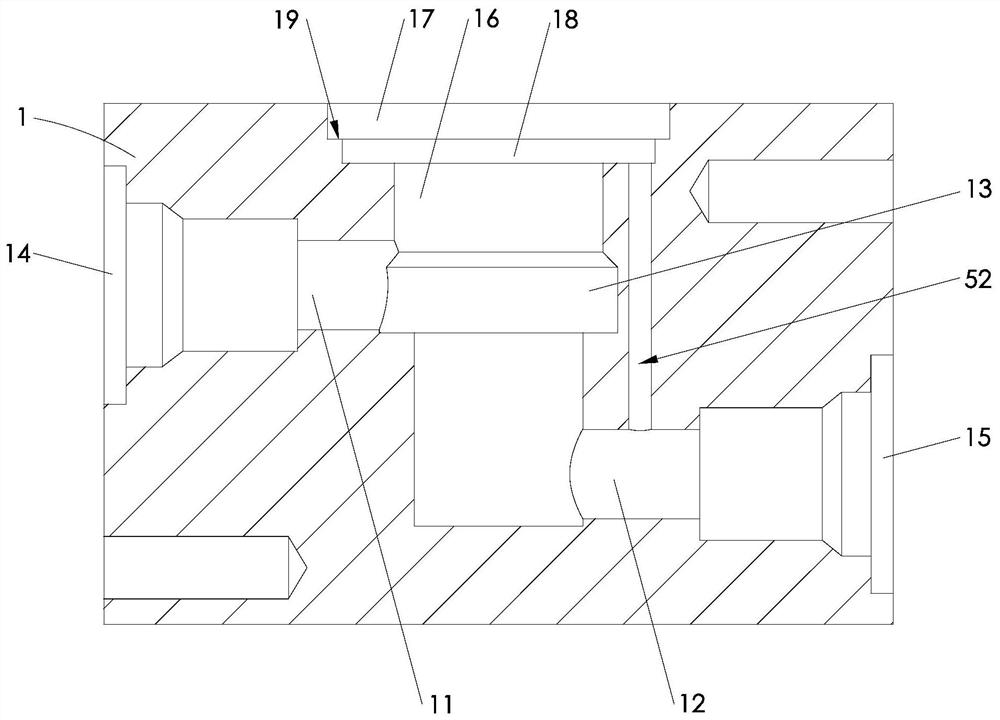

Electronic expansion valve

ActiveCN108662169AEliminate differential pressure resistanceImprove stabilityEfficient regulation technologiesFluid circulation arrangementEngineeringPressure difference

The invention discloses an electronic expansion valve, and belongs to the technical field of expansion valves. The electronic expansion valve comprises a valve seat and a sleeve, wherein the valve seat is arranged on a valve body, and the sleeve is fixed on the valve seat; a first channel and a second channel are formed in the valve body, and the valve seat is provided with a circulation channel located between the first channel and the second channel and a valve port; a valve needle and a rotor assembly used for driving the valve needle to move back and forth are arranged in the sleeve, a guide hole matched with the valve needle is formed in the valve seat, and the valve needle is opened or closed when the valve needle moves back and forth along the guide hole; and an upper valve cavity communicating with the interior of the sleeve is arranged on one side of the valve seat, a lower valve cavity communicating with the second channel is arranged on other side of the valve seat, and a balance hole for communicating the upper valve cavity with the lower valve cavity is formed between the upper valve cavity and the lower valve cavity. According to the electronic expansion valve, the balance hole for communicating the upper valve cavity with the lower valve cavity is formed; and under the action of the balance hole, the pressure in the upper valve cavity and the pressure in the lower valve cavity are consistent, and the pressure difference formed by the upper valve cavity and the first channel on the valve needle and the pressure difference formed by the first channel and the lower valve cavity on the valve needle are counteracted by each other.

Owner:DUNAN ENVIRONMENT TECH

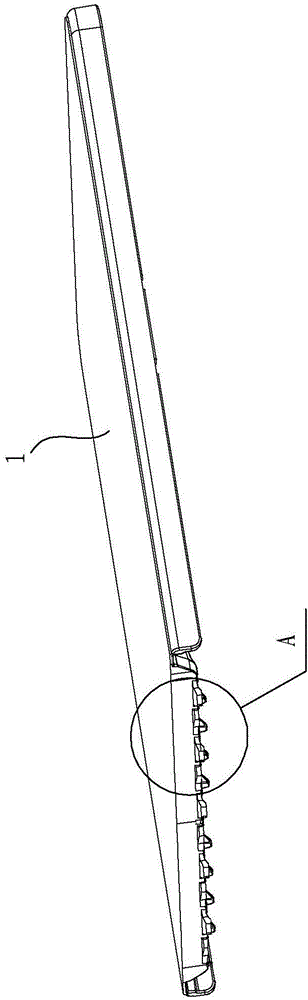

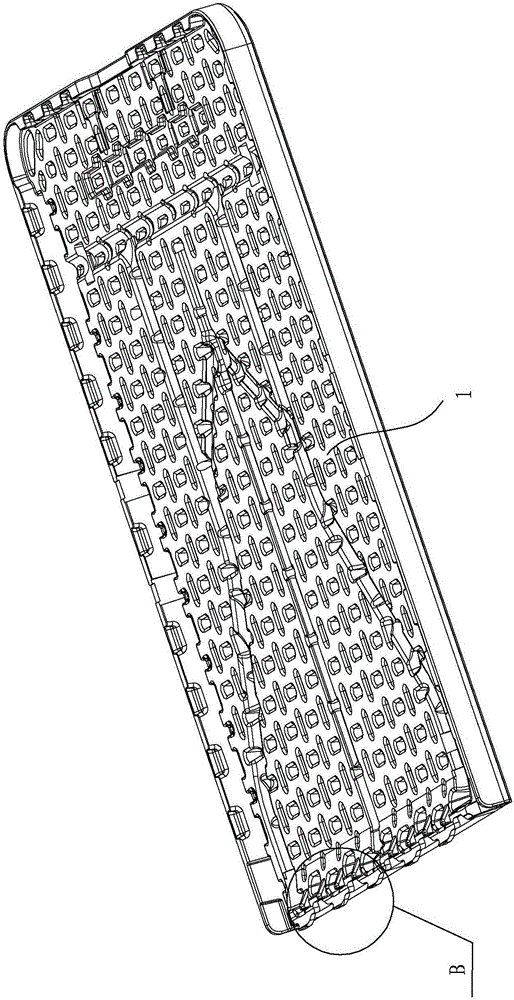

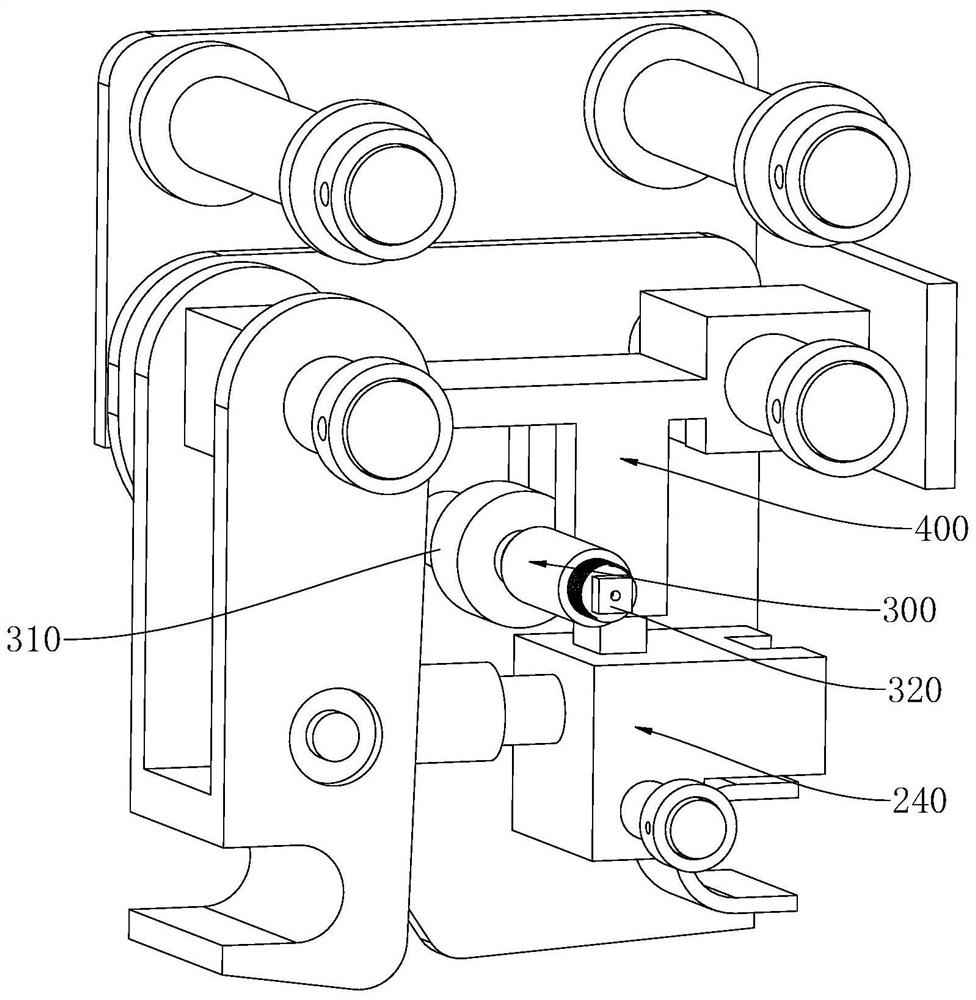

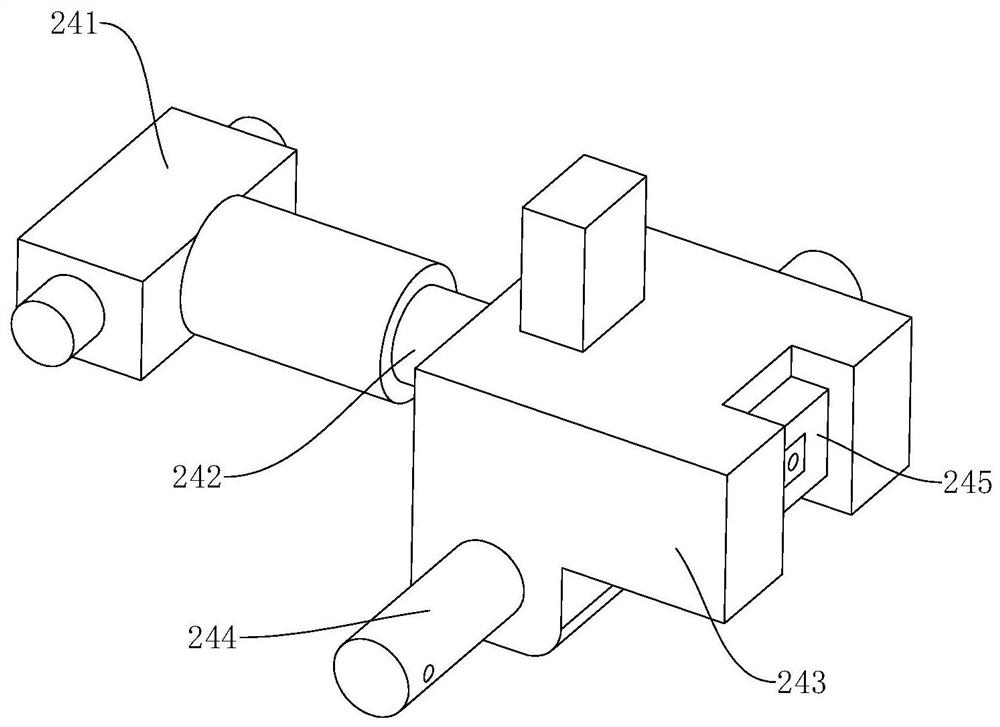

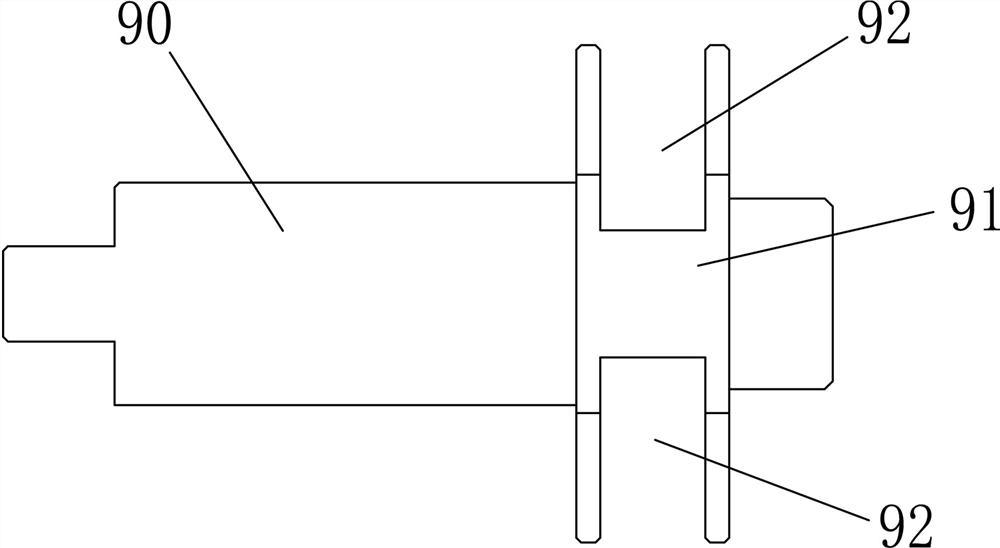

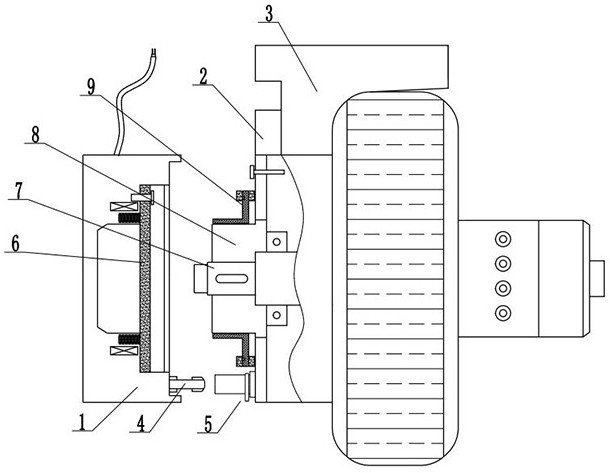

Engine bearing bush mounting and dismounting tool

ActiveCN112975338APrevent radial deformationPrevent radial displacementMetal working apparatusEngineeringMechanical engineering

The invention discloses an engine bearing bush mounting and dismounting tool, and belongs to the field of engine assembly. The engine bearing bush mounting and dismounting tool comprises a tool body. The two ends of the tool body are a dismounting end and a mounting end respectively, and the mounting end sequentially comprises a guide journal and a bearing bush matching journal in the direction away from the dismounting end. The diameter of the guide journal is larger than that of the bearing bush matching journal, the bearing bush matching journal is used for sleeving two half bushes of a bearing bush, and a step surface between the guide journal and the bearing bush matching journal is a bearing bush thrust surface. A guide ring can be hooped on the peripheries of the two half bushes and can provide radial limiting for the bearing bush in the mounting process, so that the two half bushes are prevented from radial deformation or radial displacement. In addition, the guide ring can axially move along the guide journal in the press-fitting process so as to play an axial limiting role in mounting of the bearing bush and determine the press-in amount of the bearing bush pressed into a bearing seat. The engine bearing bush mounting and dismounting tool is simple in structure and low in manufacturing cost, and the assembly precision is easy to guarantee.

Owner:FAW JIEFANG AUTOMOTIVE CO

Capacity-expandable cable pipe-penetrating protector

InactiveCN111355189AImprove general performanceReduce economic costsApparatus for laying cablesStructural engineeringElectric cables

The invention discloses a capacity-expandable cable pipe-penetrating protector, and belongs to the technical field of cable protectors. The capacity-expandable cable pipe-penetrating protector comprises a pipe penetrating protector body, the pipe penetrating protector body comprises a first half pipe body and a second half pipe body, which are oppositely arranged and can move relatively. Semicircular bearings are arranged in front of the first half pipe body and the second half pipe body; a plurality of first rollers penetrate through the bearings, a capacity-expandable structure is arrangedbetween the first half pipe body and the second half pipe body, the pipe-penetrating protector further comprises a limiting locking piece for locking the pipe-penetrating protector at a certain position, and the pipe-penetrating protector in the scheme is high in universality, wide in application range and high in installation efficiency.

Owner:NINGHAI COUNTY POWER SUPPLY BUREAU +1

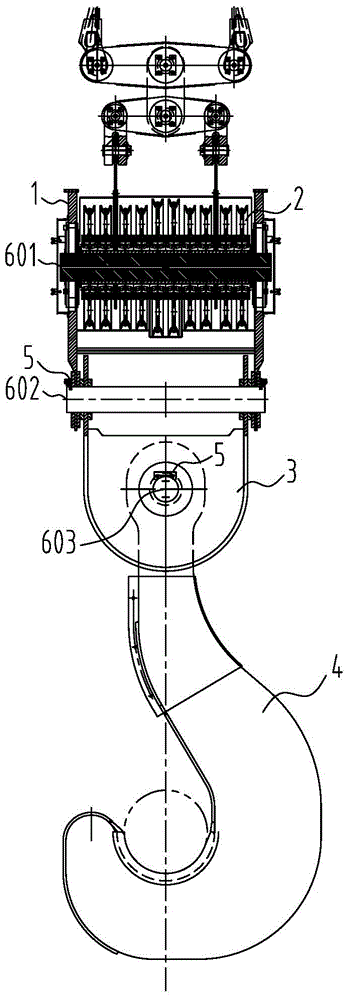

Metallurgical bridge crane

InactiveCN105197802APlay the role of axial limitLimit axial movementTrolley cranesSafety gearEngineeringPulley

The invention discloses a metallurgical bridge crane. The metallurgical bridge crane comprises a cross beam, movable pulley blocks, lifting forks, lifting hooks and a plurality of pin shafts used for hinging two parts. The two parts comprise the first part and the second part which is at least partially located inside the first part so as to be hinged to the first part through the pin shafts. The two ends of each pin shaft extend out of the first part. Grooves are formed in the positions, close to the two ends, of each pin shaft. Baffles used for preventing the pin shafts from being disengaged from the two parts are inserted in the grooves, and the baffles are fixed to the first part. Indicating rods are fixedly arranged at the ends of the pin shafts. By the adoption of the metallurgical bridge crane, the parts can be prevented from being disengaged, and safety accidents are avoided.

Owner:BAOSHAN IRON & STEEL CO LTD

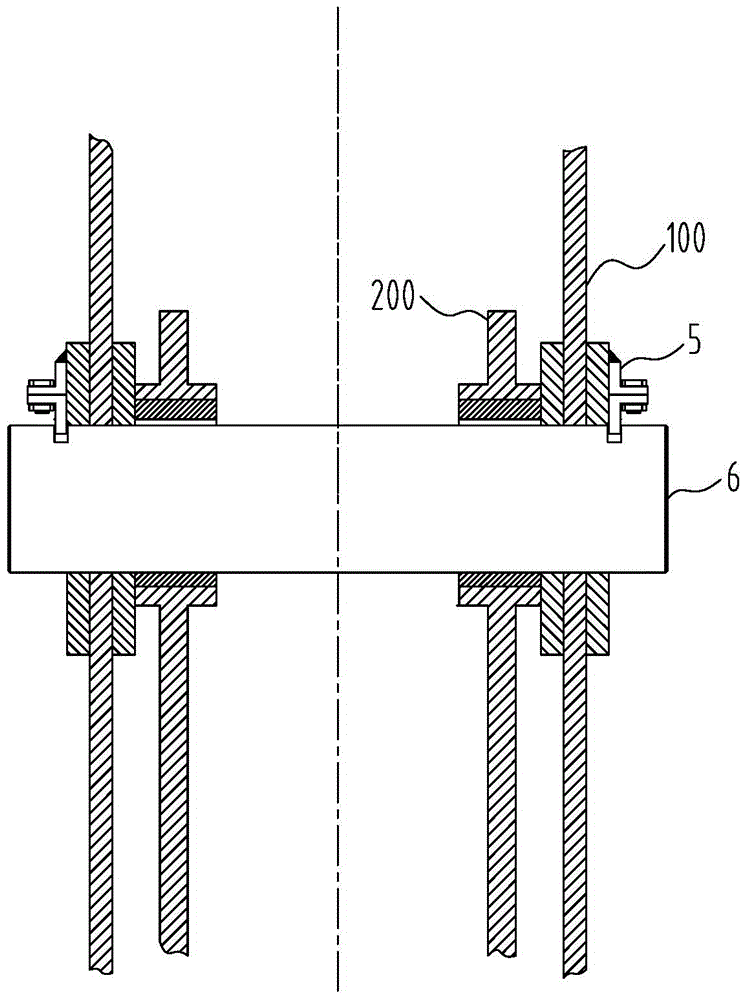

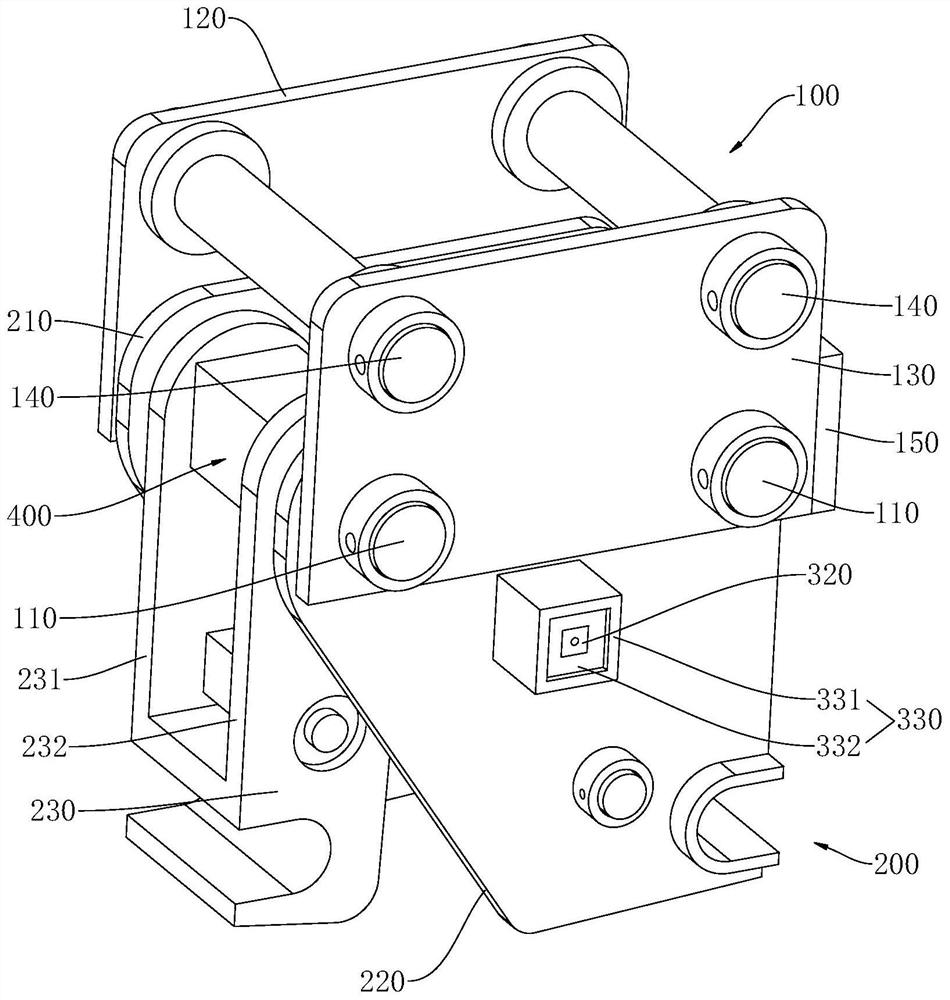

Adjustable excavator connector and excavator

ActiveCN112900517AMeet installation needsPosition does not changeMechanical machines/dredgersExcavatorScrew thread

The invention provides an adjustable excavator connector and an excavator. The adjustable excavator connector comprises a bucket rod connecting module, an accessory connecting module, an opening adjusting mechanism and a middle retainer, wherein the bucket rod connecting module comprises at least two connecting pins, the accessory connecting module comprises a first supporting piece and a second supporting piece, the first supporting piece and the second supporting piece are arranged in parallel and are connected to the connecting pins in a sliding mode, the opening adjusting mechanism comprises a double-end stud, the thread directions of the two ends of the double-end stud are opposite, one end of the double-end stud is connected with the first supporting piece, the other end of the double-end stud is connected with the second supporting piece, the middle retainer is located between the first supporting piece and the second supporting piece and fixedly connected with the bucket rod connecting module, and the middle retainer is connected with the double-end stud to axially limit the double-end stud. According to the adjustable excavator connector and the excavator, the installation requirements of accessories with different opening sizes can be met by adjusting the opening sizes, and centering can be achieved in the adjusting process.

Owner:SANY HEAVY MACHINERY

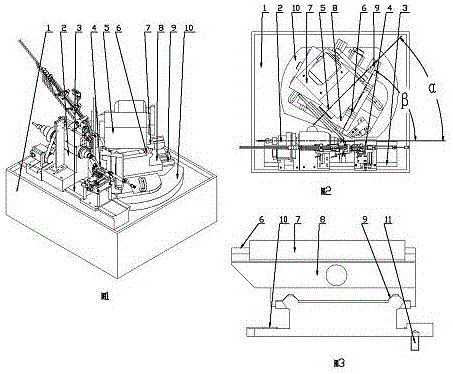

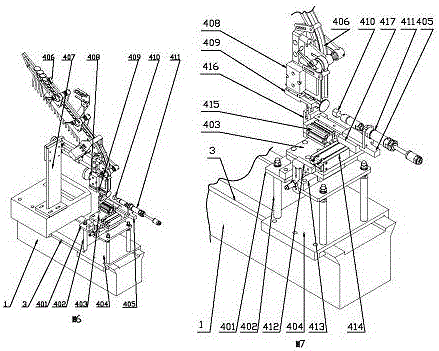

Special grinding machine for valve cone surface

ActiveCN104128863BRealize automatic clampingAchieve relaxationGrinding carriagesRevolution surface grinding machinesEngineeringGrinding wheel

Owner:江苏吉斯特科技有限公司

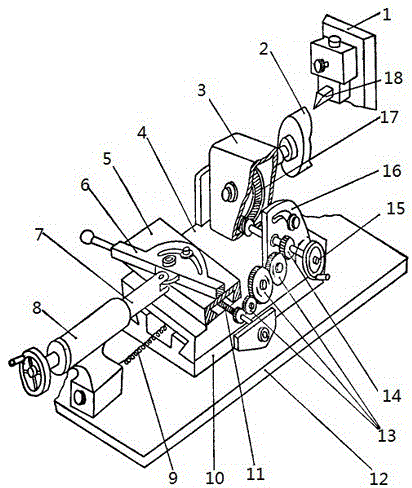

Device used for machining end face cam

The invention discloses a device used for machining an end face cam. By means of the device, the position of a working table can be adjusted. The device comprises a worm shaft driven through power. The worm shaft drives a worm wheel shaft to rotate through a worm and a worm wheel. The worm wheel shaft is sued for driving the end face cam to rotate. A driving gear is arranged on the worm shaft and drives a transverse lead screw to rotate through driven gears which are sequentially meshed with one another. The transverse lead screw is connected with a nut in a threaded manner. The nut is fixed to the bottom of a transverse slide plate which is guided in the transverse direction through a slide block on the upper portion of a vertical slide plate. The vertical slide plate is arranged on a vertical guide rail. A limiting block abutting against the side face of a longitudinal slide plate is fixed to the end of the transverse lead screw. A guide column is fixed to the upper portion of the transverse slide plate and located in an arc-shaped groove of an inclined ruler. The arc top of the arc-shaped groove faces one side of the end face cam. The inclined ruler is located on the upper portion of the transverse slide plate. The side, away from the end face cam, of the inclined ruler is hinged to one end of a threaded rod which is connected to a horizontal base in a threaded manner. A handle is arranged at the other end of the threaded rod.

Owner:重庆市合川区均恒金属加工厂

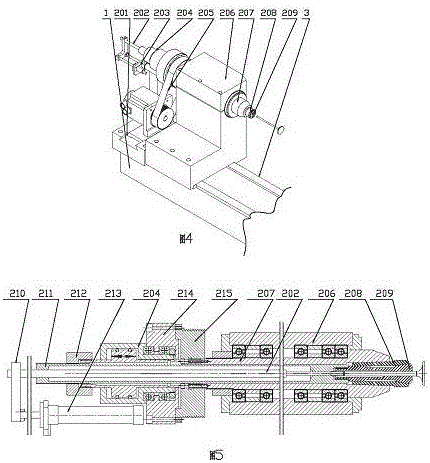

Machining method for grooving of shaft workpiece

ActiveCN112091297AImprove processing efficiencyEasy to operateMilling equipment detailsChucksStructural engineeringProduct processing

The invention discloses a machining method for the grooving of a shaft workpiece. A machining device comprises a main shaft; the main shaft is provided with a hydraulic three-jaw clamping disc; the hydraulic three-jaw clamping disc is connected with three clamping jaws; the hydraulic three-jaw clamping disc is coaxially and fixedly connected with a fixing base; the fixing base is provided with mounting grooves corresponding to the three clamping jaws in a one-to-one mode; a pressing cushion block is arranged in each of the mounting grooves; and the fixing base is further fixedly connected witha directional limiting block. According to the machining method for the grooving of the shaft workpiece, the hydraulic three-jaw clamping disc and as corresponding tool clamp are used for clamping shaft workpieces to be machined, and the grooving of the three shaft workpieces can be machined every time clamping is conducted, so that the machining efficiency is greatly improved; and during machining, the hydraulic three-jaw clamping disc is driven by the main shaft to rotate, and cutters only need to conduct corresponding feeding movement, so that the machining precision is high, the machiningefficiency is greatly improved, and the consistency of product processing is good.

Owner:QIJING MACHINERY

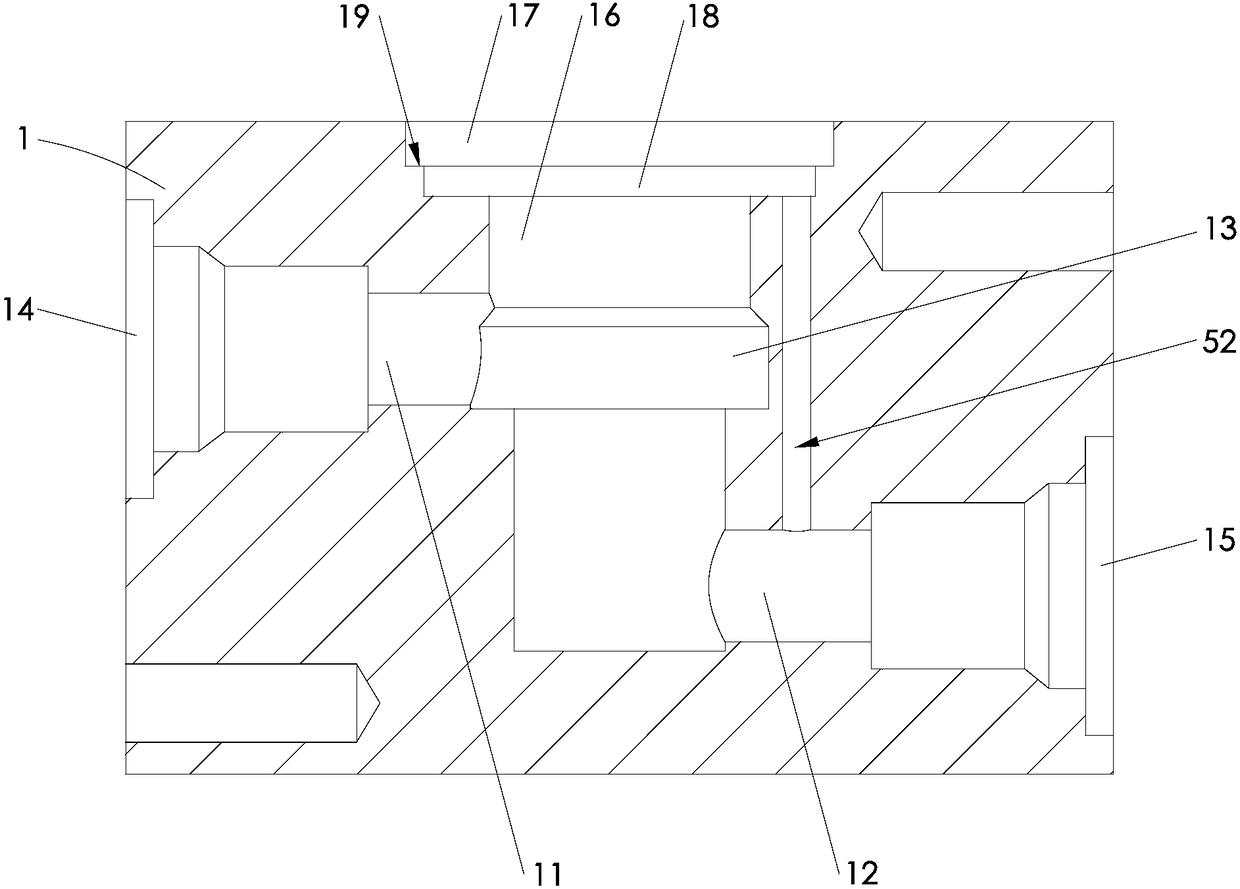

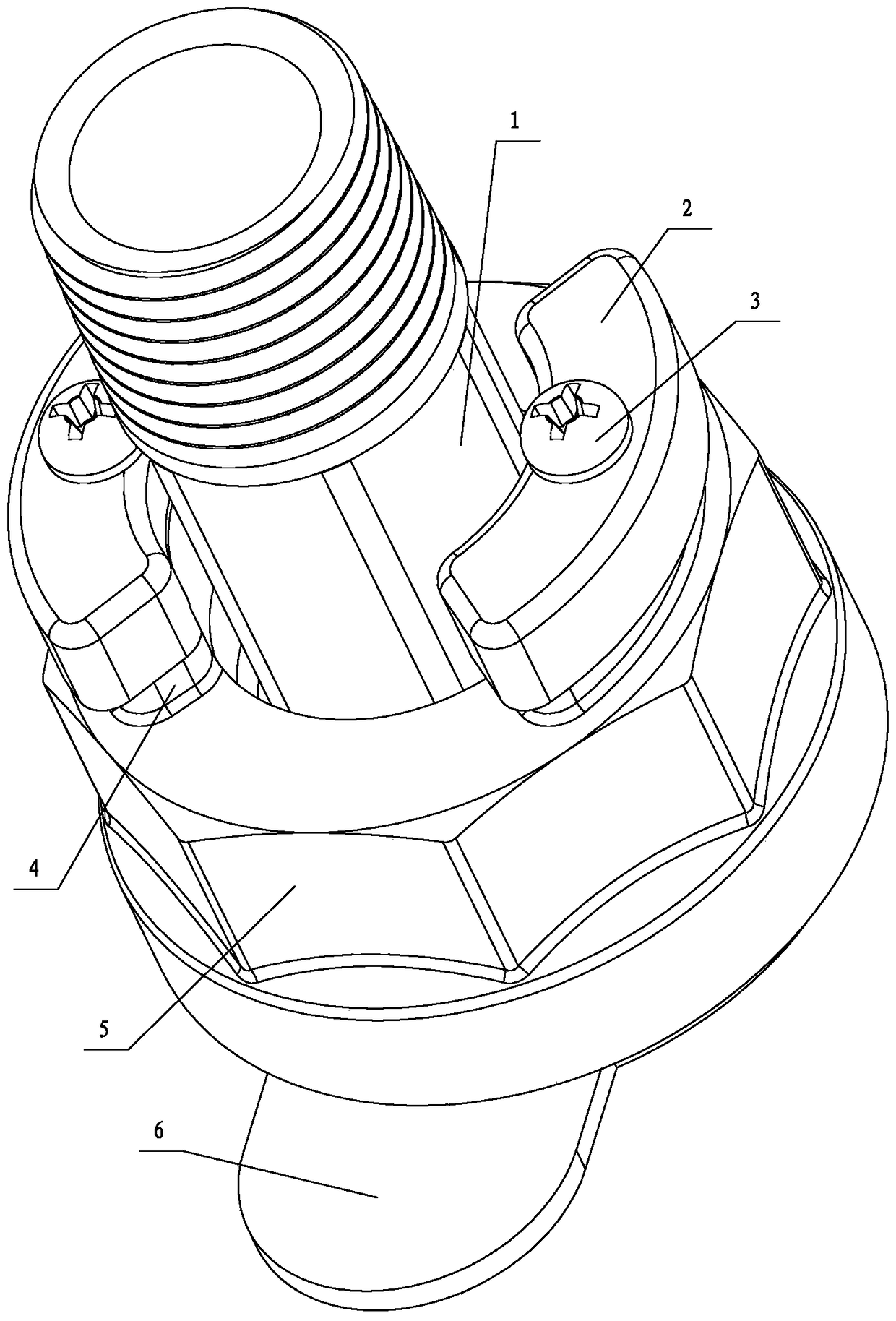

Anti-disassembly gas meter connector

ActiveCN105258754BPlay the function of anti-disassemblyPlay the effect of anti-demolitionVolume meteringEngineeringNon magnetic

The present invention discloses an anti-disassembly gas meter connector. The anti-disassembly gas meter connector comprises a connecting tube (1), a nut inner lining (18), an anti-disassembly outer sleeve (5), anti-disassembly caps (2) prepared by non-magnetic materials, anti-disassembly magnets (19), and limiting magnets (8); the limiting magnets (8) are slidably connected in the top end of the anti-disassembly outer sleeve (5); each anti-disassembly magnet (19) is embedded in the corresponding anti-disassembly cap (2) and positioned over the corresponding limiting magnet (8); the anti-disassembly caps (2) are threaded to the anti-disassembly outer sleeve (5); and the top of the nut inner lining (18) is provided with limiting holes (10) which are used for accommodating the limiting magnets (8) and connected with the limiting magnets (8) when the limiting magnets (8) downwardly slide to the lowest position. By adoption of the structure, the connector has an anti-disassembly function, the connector can also be reused on the premise that the anti-disassembly outer sleeve is not destroyed, and use cost is largely reduced.

Owner:NINGBO XINJIE GAS APPLIANCE INDAL

Multi-size screwdriver bit

The invention discloses a multi-size screwdriver bit. At least two layers of screwdriver bit rods are sleeved with each other, and the screwdriver bit rods with different sizes correspond to screws with different specifications; the screwdriver bit rod located on the inner layer can slide in the axial direction; the connecting end of the screwdriver bit rod on the outermost layer is fixedly connected to a power rod; limiting holes are correspondingly formed in the side walls of all layers of screwdriver bit rods in a penetrating mode; when the limiting holes are aligned, limiting rods can be axially inserted, and the axial limiting effect on all layers of screwdriver bit rods is achieved; according to different insertion depths of the limiting rods, the screwdriver bit rods with different sizes can be moved out in the axial direction, and the screwdriver bit rods closer to the outer side can be moved out when the lengths of the limiting rods pulled out outwards are longer; and when the screwdriver bit rods with proper sizes are moved out, all layers of screwdriver bit rods synchronously rotate in the circumferential direction and are matched with screw heads for screwing operation. The multi-size screwdriver bit can be applied to screws with different specifications, and the size application range of the screwdriver bit is widened.

Owner:SHANDONG YINGXIN COMP TECH CO LTD

Tool positioning-clamping mechanism for milling machine

InactiveCN102581668BSmooth rotationNot easy to fall offPositioning apparatusMetal-working holdersEngineeringMachine

Owner:宁波远达船机配件有限公司

Bearing seat balance structure

InactiveCN104314992AStable supportPlay the role of axial limitBearing unit rigid supportEngineeringSurface plate

The invention discloses a bearing seat balance structure. The structure comprises a rotating shaft which is internally rotationally connected with a bearing seat, wherein the rotating shaft protrudes out of the bearing seat to form a balance section; a balance sleeve is connected onto the balance section; an end surface plate capable of limiting the balance sleeve in the axial direction is fixed on the end surface of the balance section through screws; an annular balance sleeve seat is arranged on the balance sleeve in the radial direction; the balance sleeve seat comprises an annular boss which extends inwardly and is located between the balance sleeve and the end surface plate; a gap of 10 mm is reserved between the balance sleeve seat and the balance sleeve; a gap of 5 mm is reserved between the annular boss and the balance sleeve. As the rotating shaft protrudes out of the bearing seat to form the balance section, load on the two sides of the bearing seat can be balanced and the problem of abrasion caused by uneven stress is solved.

Owner:重庆红旗缸盖制造有限公司

A Knob Structure of Automotive Interior Parts with Crushing Function

ActiveCN106206132BCrushing achievedPlay the role of axial limitElectric switchesKey pressingOccupant safety

Owner:HUIZHOU DESAY SV AUTOMOTIVE

A self-closing forging forming die

ActiveCN106623722BPrevent savingImprove processing pass rateForging/hammering/pressing machinesAutomatic controlMachining

The invention discloses an automatic closed forging forming die, and belongs to the technical field of metal press machining. The die comprises a rigid die base, a floating female die, and automatic die locking devices symmetrically arranged on the two sides of a lower female die base. The two sides of the upper end face of an upper female die base are symmetrically provided with clamping grooves. Each automatic die locking device comprises a swinging lock rod and a power mechanism driving the swinging lock rod to swing. Lock heads clamped to the clamping grooves in a matched mode are arranged on the tops of the swinging lock rods. During combination of an upper female die and a lower female die, the power mechanisms drive the swinging lock rods to swing in the direction close to the upper female die till the lock heads make contact with the clamping grooves to be clamped; During opening of the upper female die and the lower female die, the power mechanisms drive the swinging lock rods to swing in the direction away from the upper female die till the lock heads get away from the clamping grooves to be reset. The die clamping pressure can be increased, and automatic control over locking and unlocking of the upper and lower female dies of a die locking device is achieved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

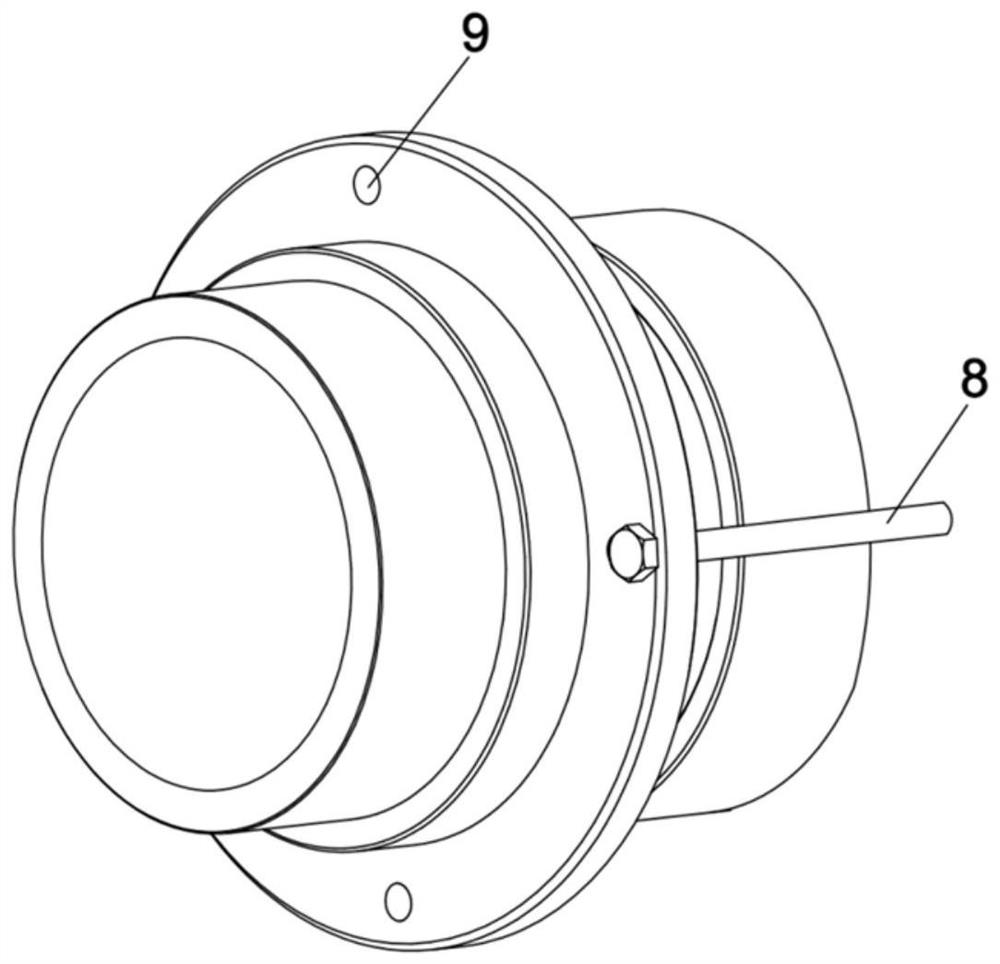

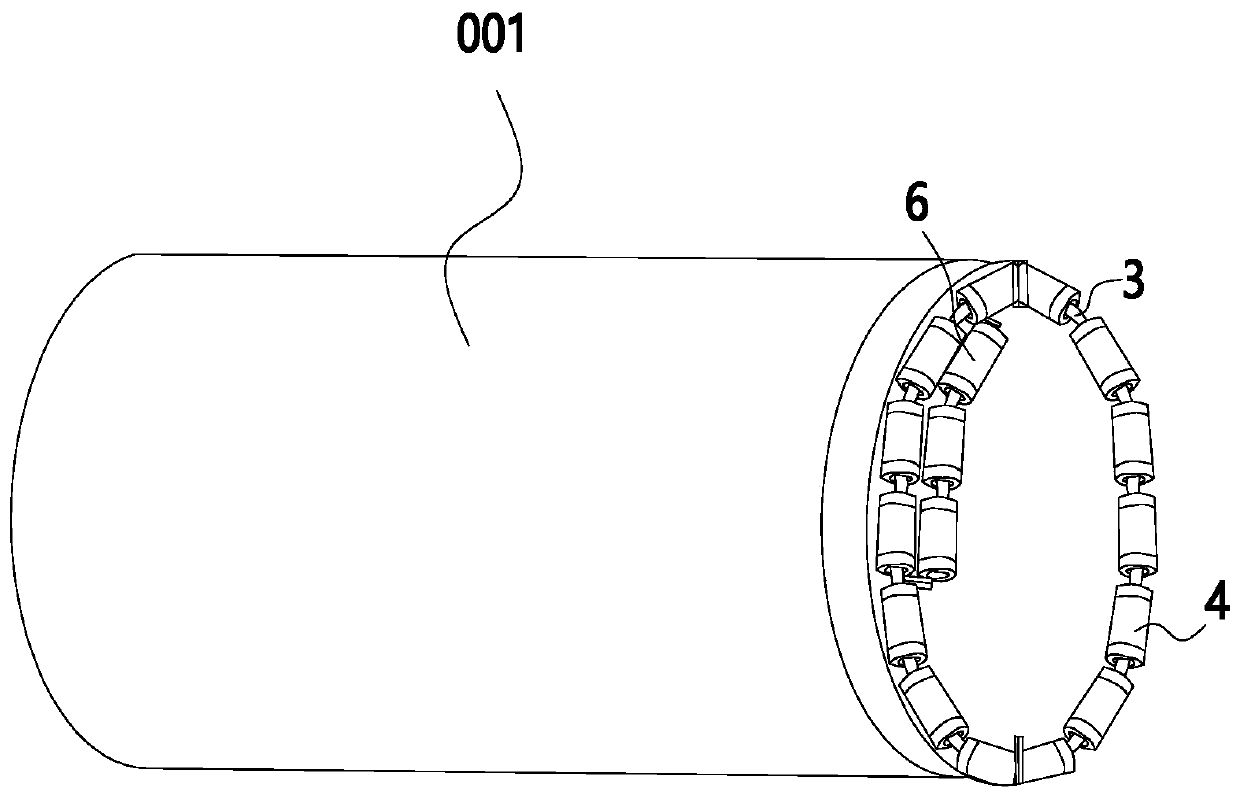

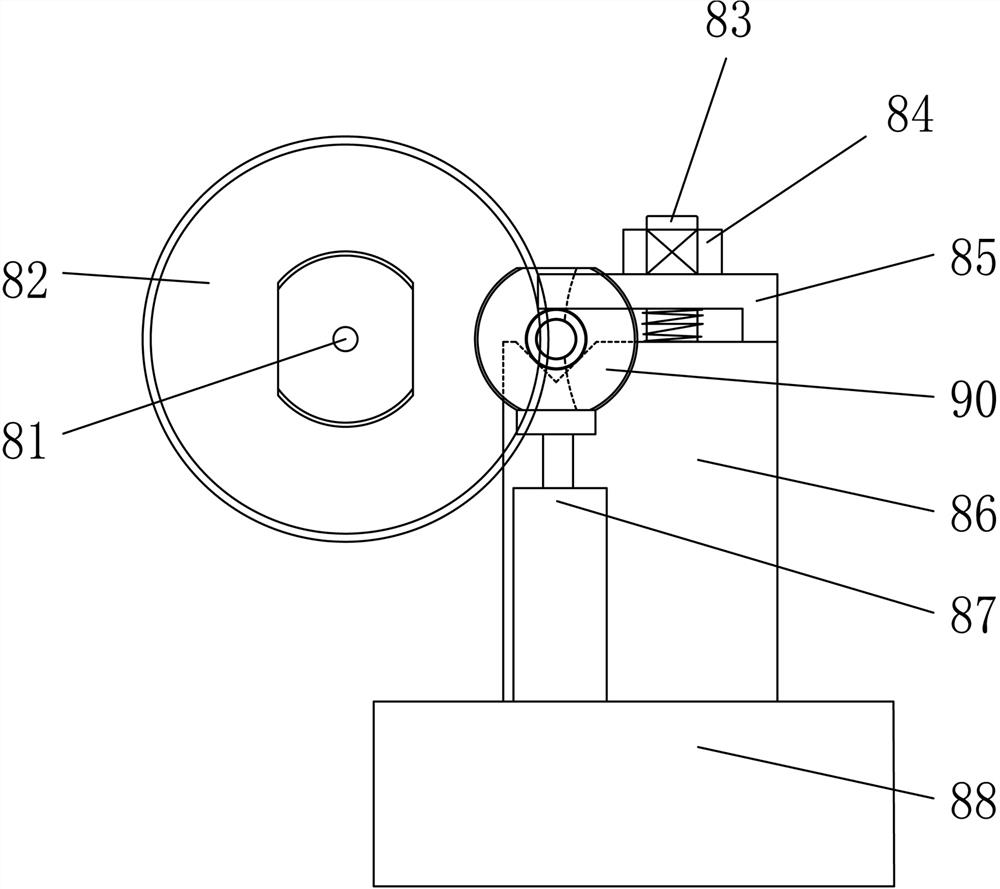

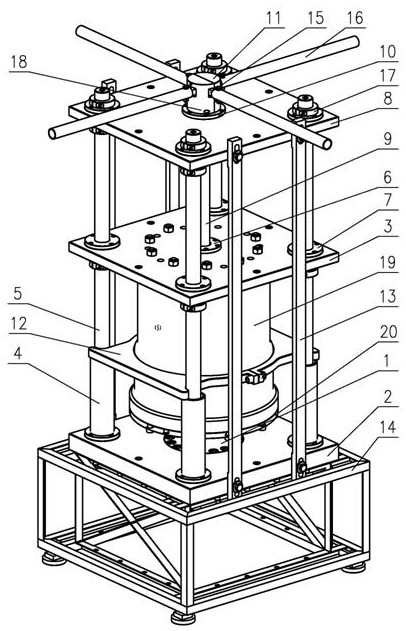

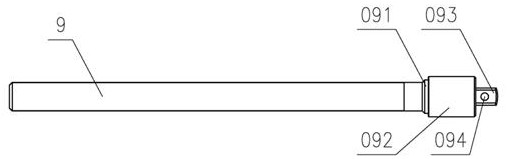

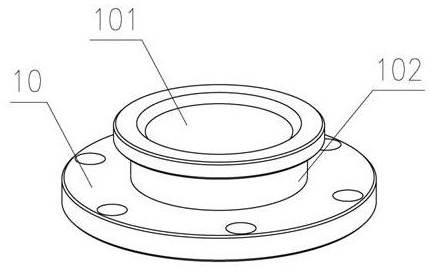

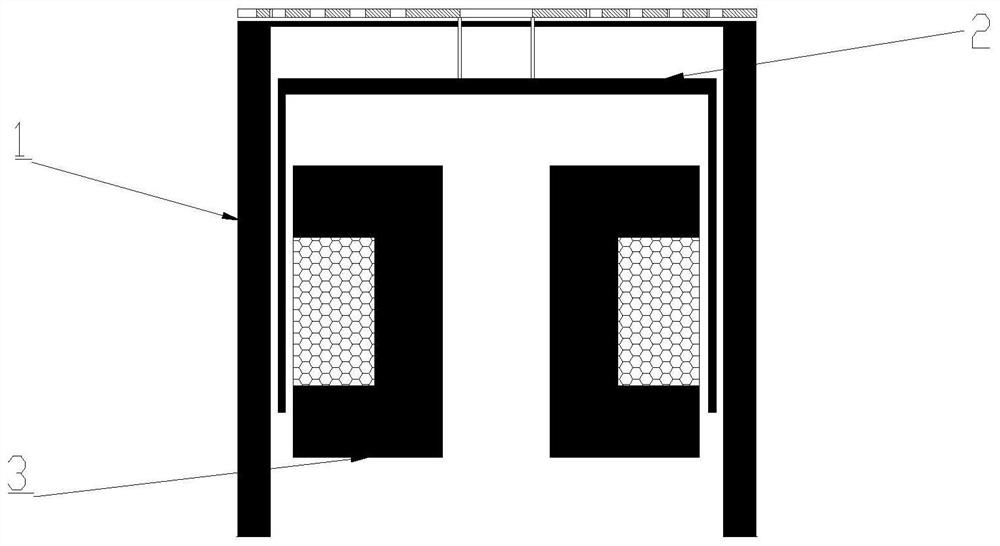

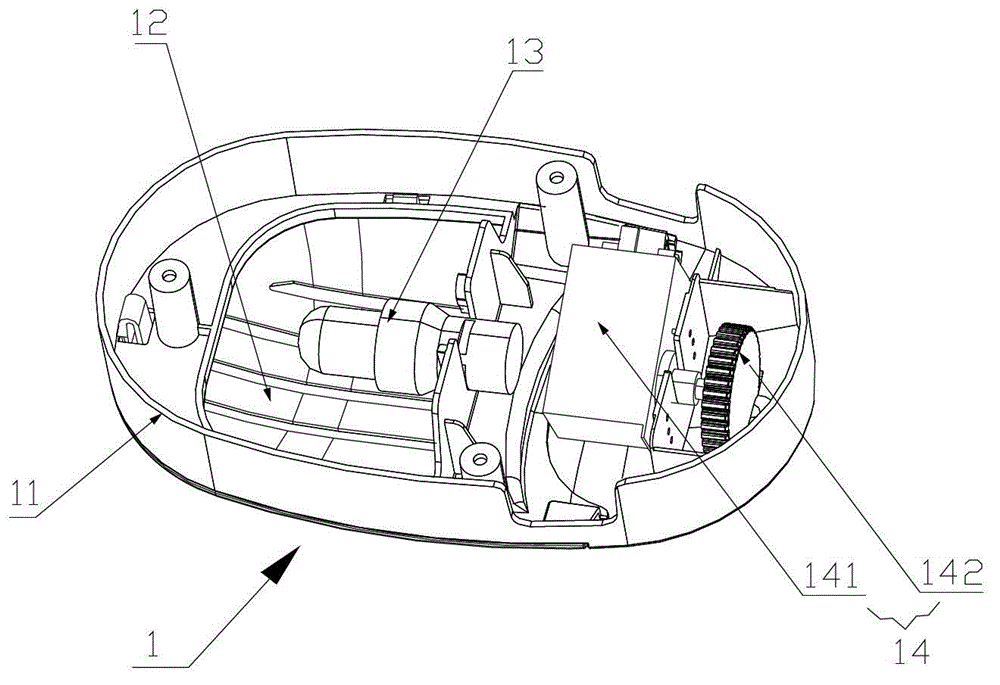

Disassembling and assembling tool for rotor of hub motor

InactiveCN114421721AEasy to lockEasy to loosenManufacturing dynamo-electric machinesMetal-working hand toolsClassical mechanicsElectric machinery

A hub motor rotor dismounting tool is characterized in that a base plate is mounted on a base, and a sliding guide mechanism and a rotating mechanism are mounted on the base plate; a base is arranged in the center of the bottom plate; a sliding plate is mounted at the top of the rotor; a guide sleeve is arranged on the bottom plate; the lower part of the guide rail is arranged in the guide sleeve; the upper part of the guide rail penetrates through the sliding plate; the lead screw seat is arranged in the center of the sliding plate; the lower part of the lead screw is movably connected with the lead screw seat; the upper part of the screw penetrates through the center of the top plate; the top cover is arranged at the upper end of the lead screw; a connecting plate is arranged in the top cover, and the free end of the connecting plate is sleeved with a sleeve. The device is high in self-locking performance, the disassembly and assembly efficiency is improved, the guide rail and the lead screw are positioned in a high-precision mode, and the disassembly and assembly process is stable and safe.

Owner:河北瑞兆激光再制造技术股份有限公司

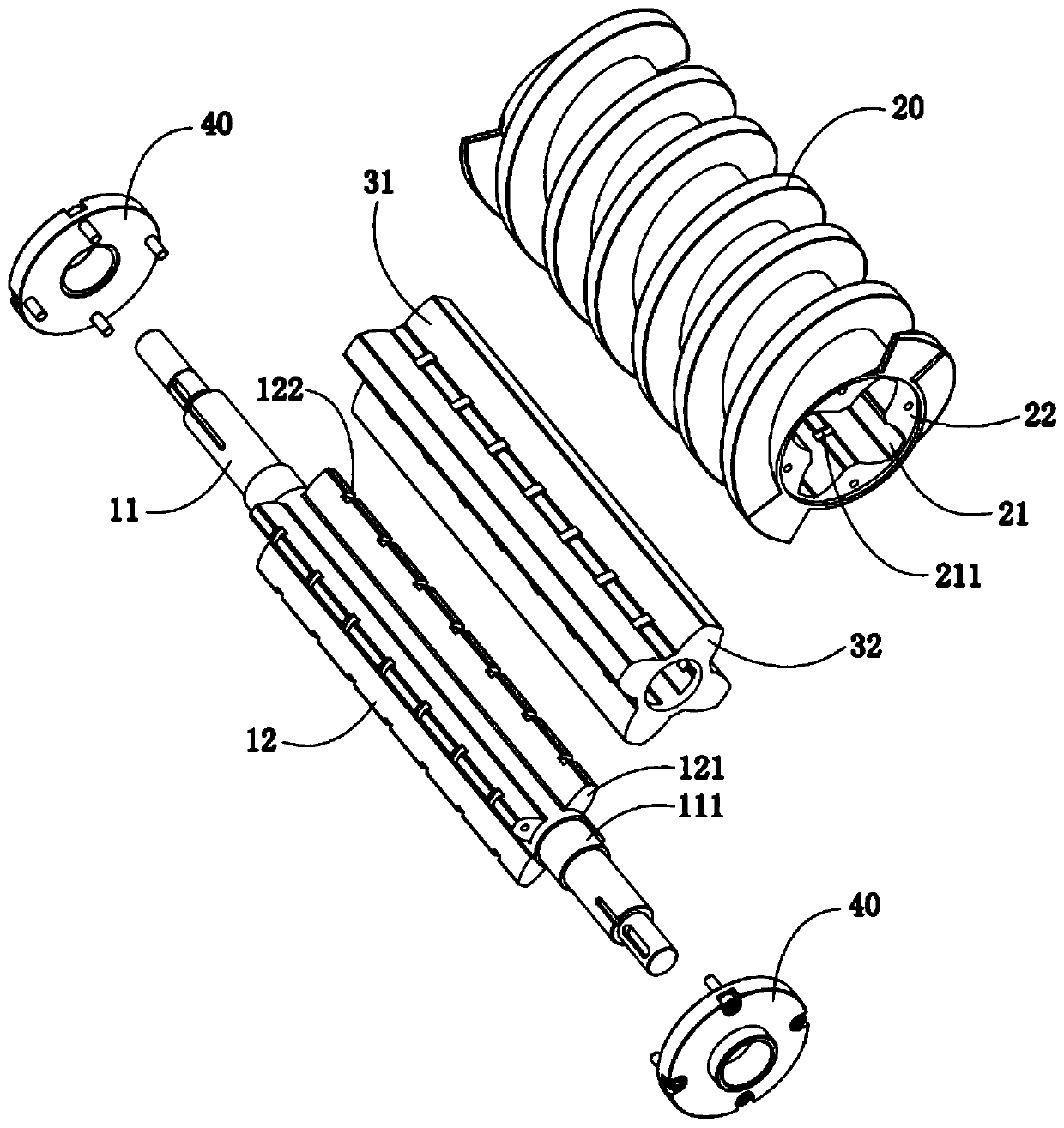

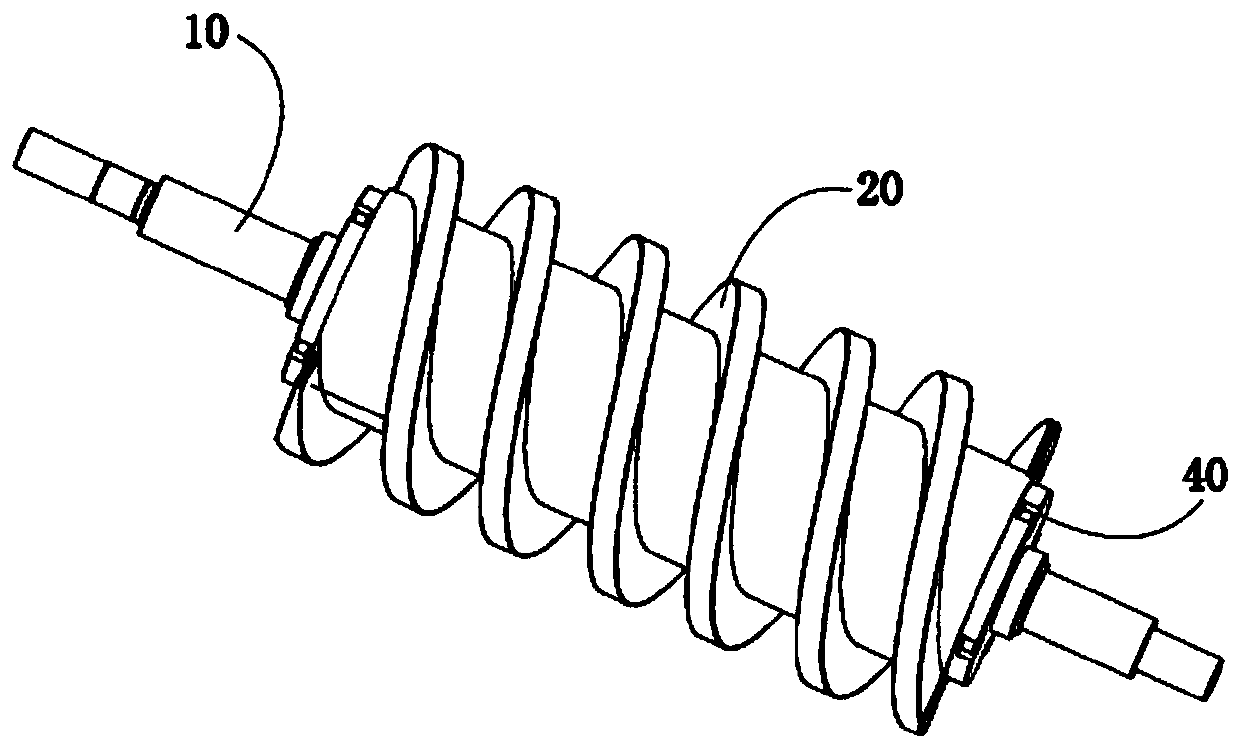

Moving magnet type reciprocating linear oscillation motor of low-temperature refrigerator

PendingCN113659786ASimple structureLow costReciprocating/oscillating/vibrating magnetic circuit partsWindingsElectric machineryEngineering

The invention provides a moving magnet type reciprocating linear oscillation motor of a low-temperature refrigerator, which comprises an inner stator, an outer stator and a rotor, wherein the outer stator is provided with an elastic limiting mechanism; a circle of groove is formed in the outer diameter of the inner stator, and a coil winding is arranged in the groove; the rotor comprises a rotor support and magnetic steel installed on the rotor support, the rotor support is composed of an upper magnetic steel supporting plate, a magnetic steel connecting ring and a lower magnetic steel short gasket, the magnetic steel supporting plate is fixedly installed on the upper end face of the magnetic steel connecting ring, and the magnetic steel supporting plate is connected with the elastic limiting mechanism through a connecting piece. And the magnetic steel is made of a plurality of magnets with ceramic tile structures. The motor has the advantages that 1, the structure of the outer stator is simplified, a special outer stator winding groove is omitted, the cost is reduced, and the winding process is simpler and more convenient; and 2, the coil does not occupy radial space, so that the diameter of the magnetic steel can be made as large as possible, the magnetic energy is stronger, the thrust of the motor is larger, and the motor is suitable for high-power compressors and refrigerators.

Owner:上海超立安科技有限责任公司

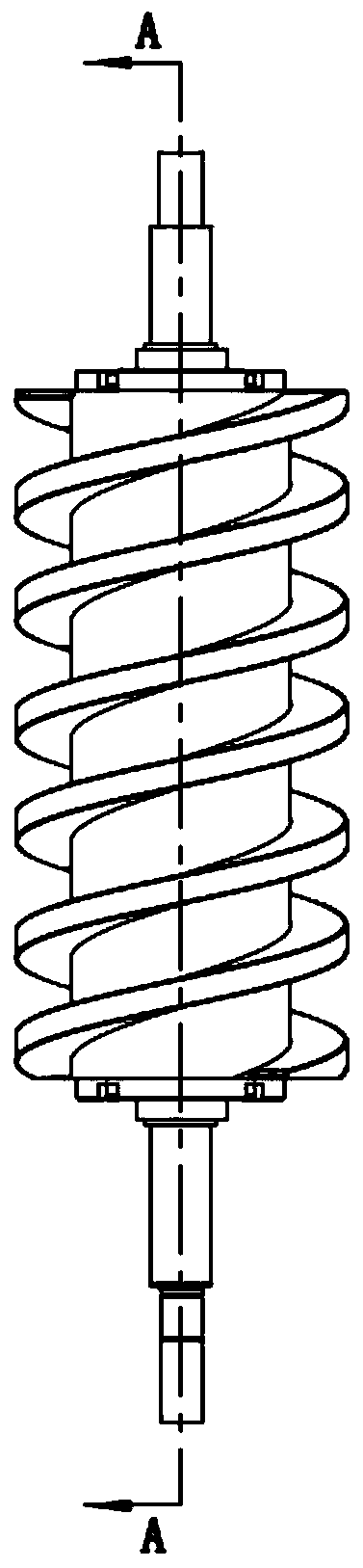

Compound screw

PendingCN111075897AMake noiseReduce noiseGearingGear vibration/noise dampingStructural engineeringMechanical engineering

The invention discloses a compound screw comprising a core shaft and a spiral shaft sleeve arranged on the core shaft in a sleeving manner. The core shaft comprises a body part and a connection part arranged on the middle portion of the body part. The connection part comprises multiple first protrusions arranged in the circumferential direction of the body part. Multiple first notches formed in the length direction of the first protrusion are formed in the outer side face of each first protrusion. The spiral shaft sleeve is provided with a shaft hole in clearance fit with the connection part.A buffer rubber sleeve is arranged between the shaft hole and the connection part in a filling manner. The buffer rubber sleeve comprises a main rubber sleeve matched with the peripheral face of the connection part and the inner side face of the shaft hole and two side rubber sleeves arranged at the two ends of the main rubber sleeve correspondingly and matched with the end faces of the connectionpart. The buffer rubber sleeve of the compound screw can absorb impact and vibration which are generated by movement, a buffering and noise reduction effect is achieved, and the transmission efficiency and the structure reliability are improved.

Owner:SHENZHEN SHENGSHI ELEVATOR CO LTD

An electronic expansion valve

ActiveCN108662169BEliminate differential pressure resistanceImprove stabilityEfficient regulation technologiesRefrigeration componentsElectronic expansion valveVALVE PORT

The invention discloses an electronic expansion valve, belonging to the technical field of expansion valves, comprising a valve seat and a casing arranged on a valve body, the casing is fixed on the valve seat, and a first channel and a second channel are arranged on the valve body. The valve seat is provided with a flow channel and a valve port between the first channel and the second channel, and a valve needle and a rotor assembly for driving the valve needle to move back and forth are arranged in the casing, and a valve seat is provided with a matching valve needle. When the valve needle moves back and forth along the guide hole, it opens or closes the valve port. One side of the valve seat is provided with an upper valve chamber connected to the inside of the casing, and the other side is provided with a lower valve chamber connected with the second channel. , There is a communicating balance hole between the upper valve cavity and the lower valve cavity. The electronic expansion valve provided by the present invention is provided with a balance hole communicating with the upper valve cavity and the lower valve cavity. Through the function of the balance hole, the pressure in the upper valve cavity is consistent with the pressure in the lower valve cavity, and the pressure difference formed by the upper valve cavity and the first channel on the valve needle is the same as the pressure formed by the first channel and the lower valve cavity on the valve needle. The differential forces cancel each other out.

Owner:DUNAN ENVIRONMENT TECH

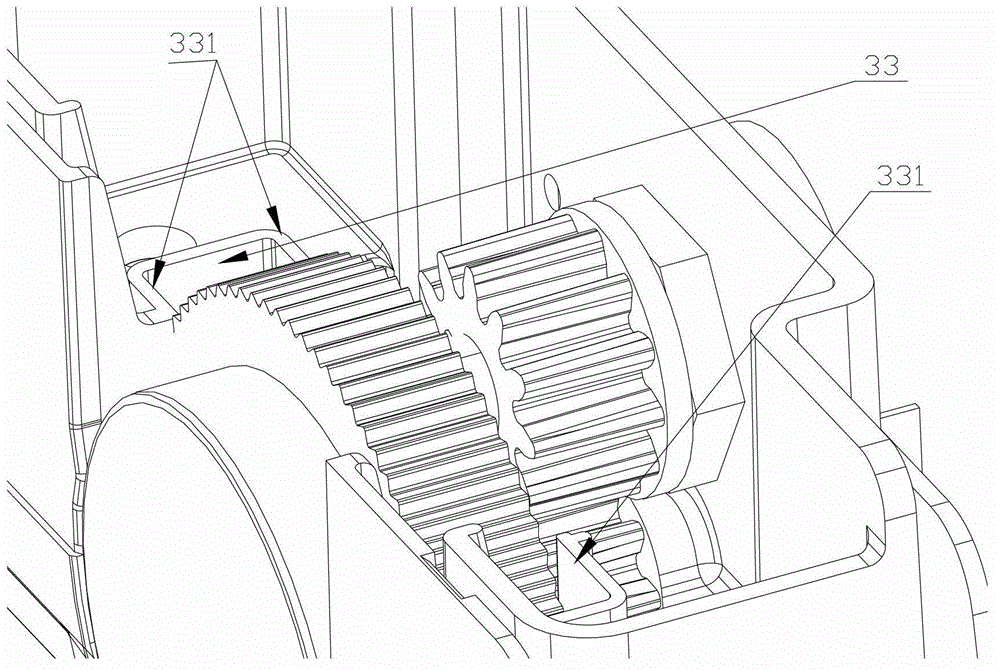

Round tube segmenting machine

The invention provides a round tube segmenting machine. A base is provided with a round tube fixing device and a segmenting device. The round tube fixing device comprises a limiting groove formed in the axial direction of a round tube. One end of the limiting groove is provided with a vertical supporting plate. The face, opposite to the limiting groove, of the supporting plate is provided with a round limiting boss. The other face of the supporting plate is provided with a hinge wheel. A pressing plate is hinged to the portion, located above the limiting boss, of the supporting plate. A stay wire is fixed to the pressing plate. The stay wire penetrates through a fixed pulley located at the upper portion of the supporting plate. The tail end of the stay wire is wound around the hinge wheel. The segmenting device comprises a horizontal rotary shaft. The rotary shaft is in key connection with cutting wheels. Cutting grooves are formed in the groove wall of the limiting groove. The effective cutting edges of the cutting wheels penetrate through the cutting grooves. The round tube can be effectively fixed through the round tube fixing device, and the round tube can be segmented through the segmenting device. The round tube is manually rotated, the round tube can be segmented under the condition that the cutting wheels are not moved, the section is smooth, and cutting accuracy is high.

Owner:ERA PIPELINE (CHONGQING) CO LTD

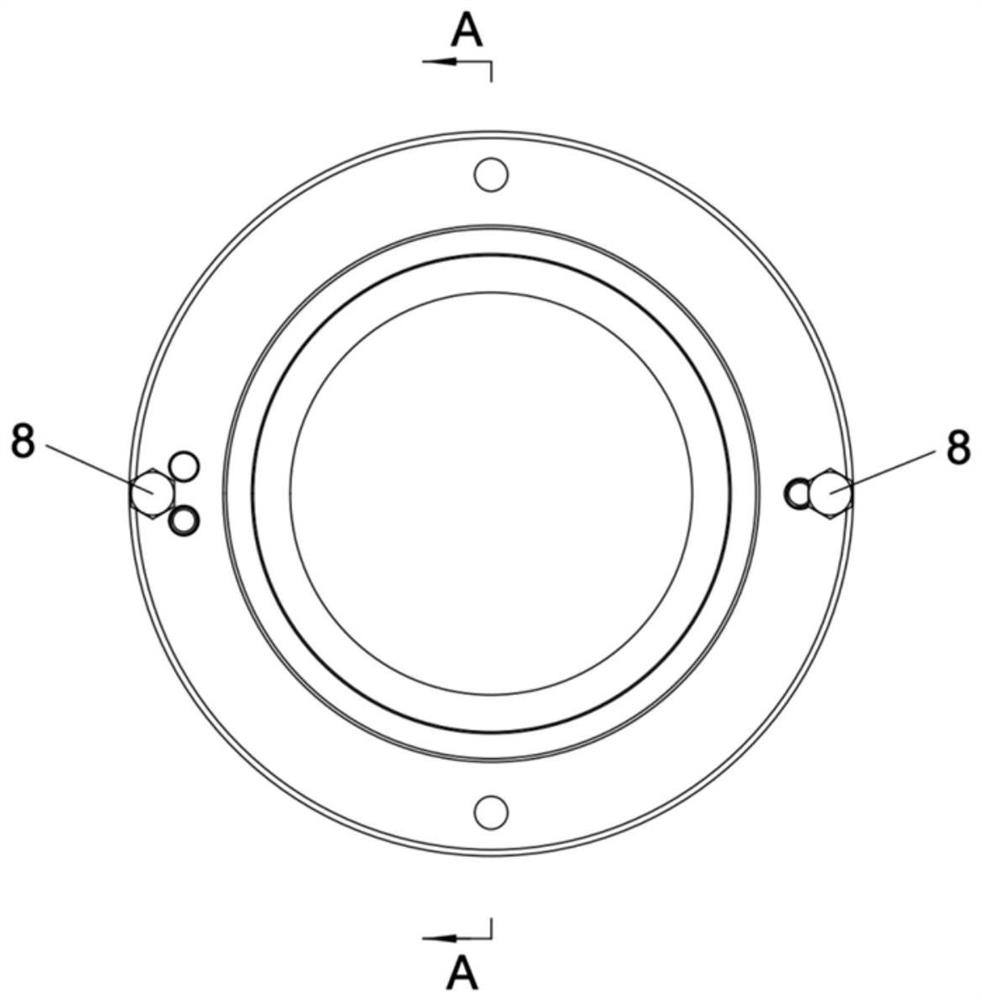

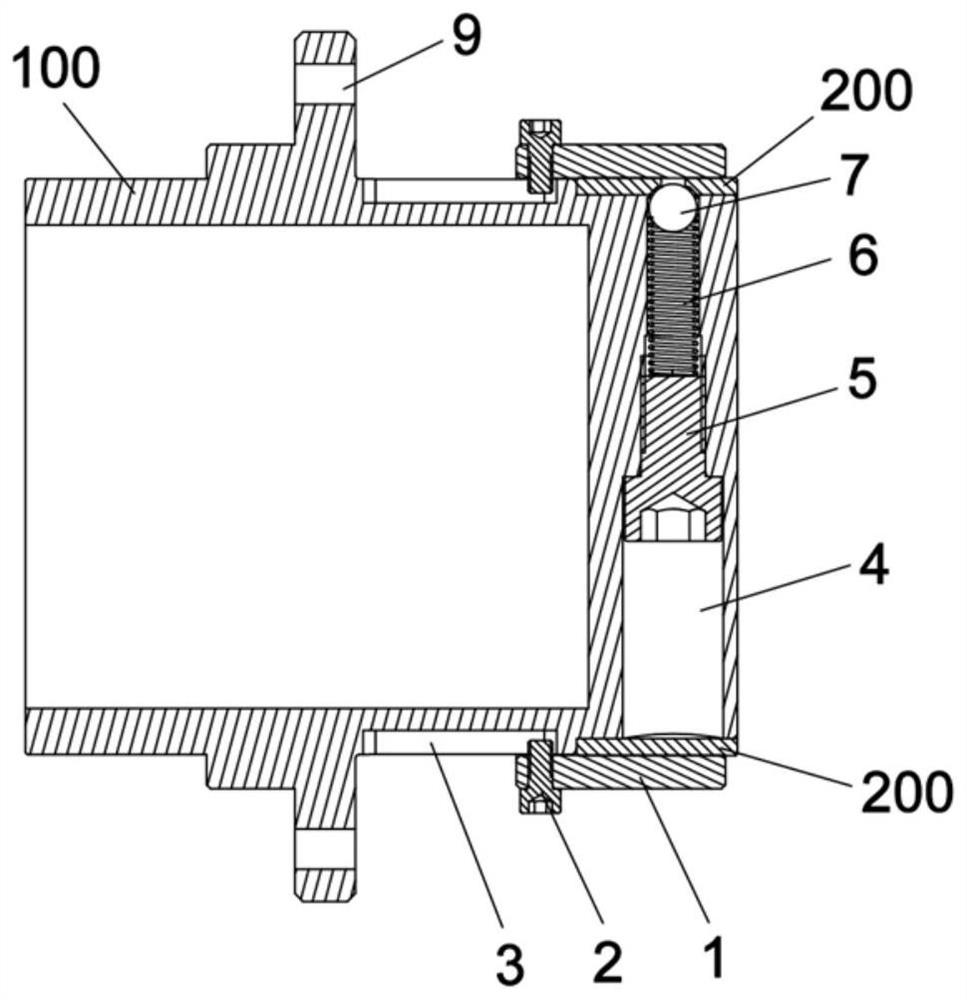

Wet brake convenient to disassemble and assemble

ActiveCN114576292APrevent disengagementSolve the inconvenience of disassemblyBraking elementsDrive shaftGear wheel

The invention discloses a wet brake convenient to disassemble and assemble, and relates to the technical field of wet brakes, the wet brake convenient to disassemble and assemble comprises a main body coil, an outer brake disc, a reduction gearbox, an inner brake disc, a transmission shaft, a transmission gear and a friction plate, the outer brake disc is installed on the reduction gearbox, the inner brake disc is installed in the main body coil, and the transmission gear is connected to the transmission shaft; the wet brake further comprises an inserting part and a locking mechanism, a straight rod is arranged in the inserting part, the surface of the straight rod is connected with a first limiting block, the locking mechanism comprises a fixed shell and a rotating shell, the rotating shell is rotationally connected into the fixed shell, and the first limiting block is connected with the rotating shell. A first through hole and a second through hole which are communicated with each other are formed in the rotating shell, the diameter of the first through hole is larger than that of the second through hole, a second limiting groove connected with the first limiting block in an inserted mode is formed in the inner wall of the second through hole, the length of the first limiting block is not larger than that of the second through hole, and a step is arranged between the first through hole and the second through hole. The disassembly and assembly are convenient.

Owner:江苏凯途液压传动机械科技有限公司

Refrigerator, refrigerator lighting module and temperature controller component of refrigerator lighting module

InactiveCN103335487AAvoid axial collision and shakingImprove reliabilityLighting and heating apparatusLighting arrangementEngineeringFlange

The invention provides a refrigerator, a refrigerator lighting module and a temperature controller component of the refrigerator lighting module. The temperature controller component comprises a rotary knob and a temperature controller connected with the rotary knob, a drive gear is coaxially arranged with the rotary knob, a driven gear is coaxially arranged with the temperature controller, the drive gear and the driven gear are meshed with each other, and a first flange is arranged in the circumference direction of the end surface on one side, far from the temperature controller, of the drive gear, and is arranged in the radial direction of the drive gear in a protruding manner to limit the driven gear to axially move toward the rotary knob. In the temperature controller component, the rotary knob and the temperature controller are respectively provided with the drive gear and the driven gear that are coaxially arranged with the rotary knob and the temperature controller, then through the meshed connection of the drive gear and the driven gear, the structure requirement when the refrigerator lighting module becomes thin can be met, and meanwhile, the first flange of the drive gear can prevent the driven gear from axial movement, so that the axial shake of the gears is avoided, and the connection reliability is ensured.

Owner:HAIER GRP CORP +1

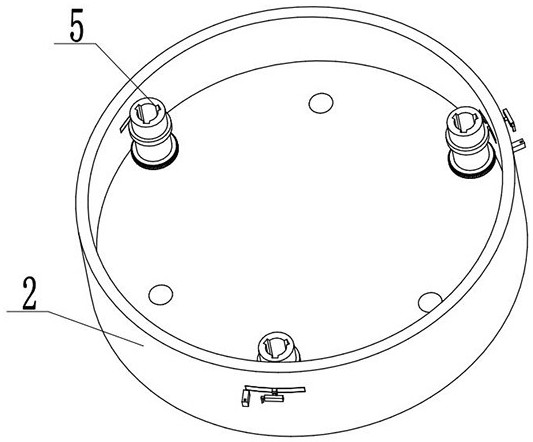

Anti-peeping device for video monitoring

ActiveCN114087490AEasy to usePrevent peepingClosed circuit television systemsStands/trestlesVideo monitoringLocking mechanism

The invention provides an anti-peeping device for video monitoring. The anti-peeping device comprises a mounting cover; a positioning cover fixed in the mounting cover, wherein the positioning cover comprises a circular cover body, and fixing nuts are fixedly arranged on the two sides of the circular cover body; a rotating piece, wherein the rotating piece is arranged in the circular cover body, a connecting piece is arranged on the rotating piece, a connecting arm and two locking mechanisms are fixedly connected to the top of the connecting piece, and the two locking mechanisms are arranged on the two sides of the positioning cover respectively. According to the anti-peeping device for video monitoring provided by the invention, the monitoring equipment is positioned through a positioning piece, and the two locking mechanisms are matched to lock the rotating block connected with the positioning piece, so that an effect of axially limiting the monitoring equipment can be achieved, illegal persons can be prevented from adjusting the angle of the monitoring equipment to peep, and the use of the monitoring equipment is safer.

Owner:北京首融汇科技发展有限公司

Bearing

ActiveCN102494018BEasy to assembleAvoid power lossRoller bearingsBall and roller bearingsFlangingEngineering

Owner:卢雨

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com