A Knob Structure of Automotive Interior Parts with Crushing Function

A technology for automotive interior parts and knobs, which is applied to electrical components, electric switches, circuits, etc., can solve the problems of large waste of resources, difficulty in meeting the requirements of customers' collapse force range, and the collapse and fall of knobs, so as to protect the safety of occupants Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

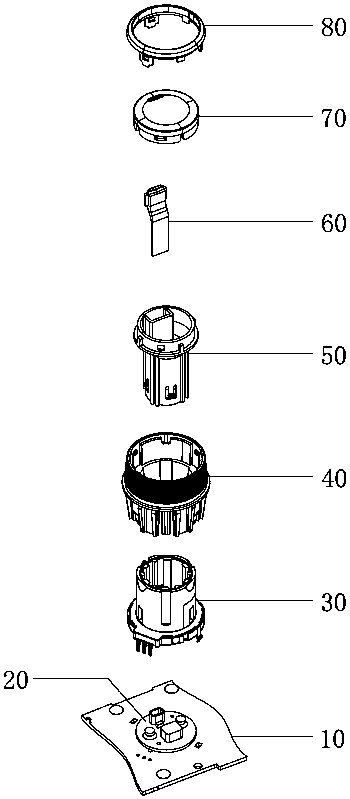

[0012] The knob structure of the automotive interior trim with the collapse function of the present invention will be further described in detail in conjunction with specific embodiments and accompanying drawings.

[0013] See figure 1 , a car interior trim knob structure with a collapse function, which includes a PCB board 10, on which a light touch button 20 is arranged, and a hollow encoder 30 coaxially arranged in sequence is connected to the top of the PCB board 10 , knob 40, button bracket 50, button cap 70 and decorative ring 80, also includes a light guide strip 60 for leading out the light on the PCB board 10, the top of the light guide strip 60 protrudes from the surface of the key cap 70.

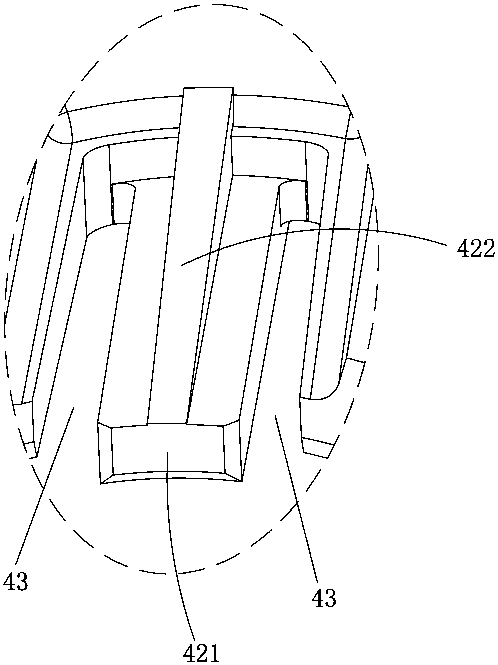

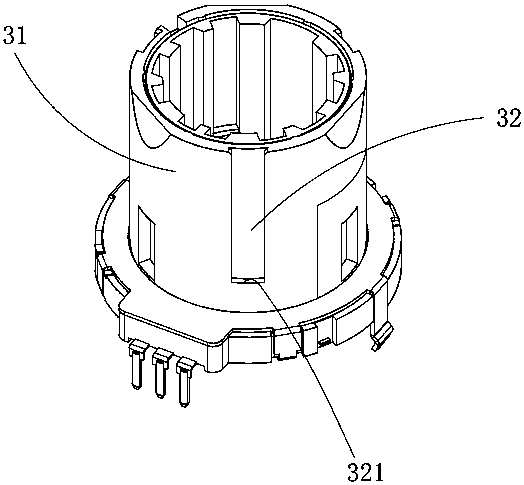

[0014] preferred, see also figure 2 and image 3 , the knob 40 can be fitted on the outside of the hollow rotary shaft 31 of the hollow encoder 30, and extend vertically downward along the top edge of the outer wall of the hollow rotary shaft 31 to form a plurality of parallel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com