Plate turnover machine

A technology of turning machine and rotating bracket, which is applied in the field of turning machine, which can solve the problems of angle deflection, low degree of automation and work efficiency, and poor clamping accuracy, so as to avoid excessive turning angle, high degree of automation and work efficiency , the effect of improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

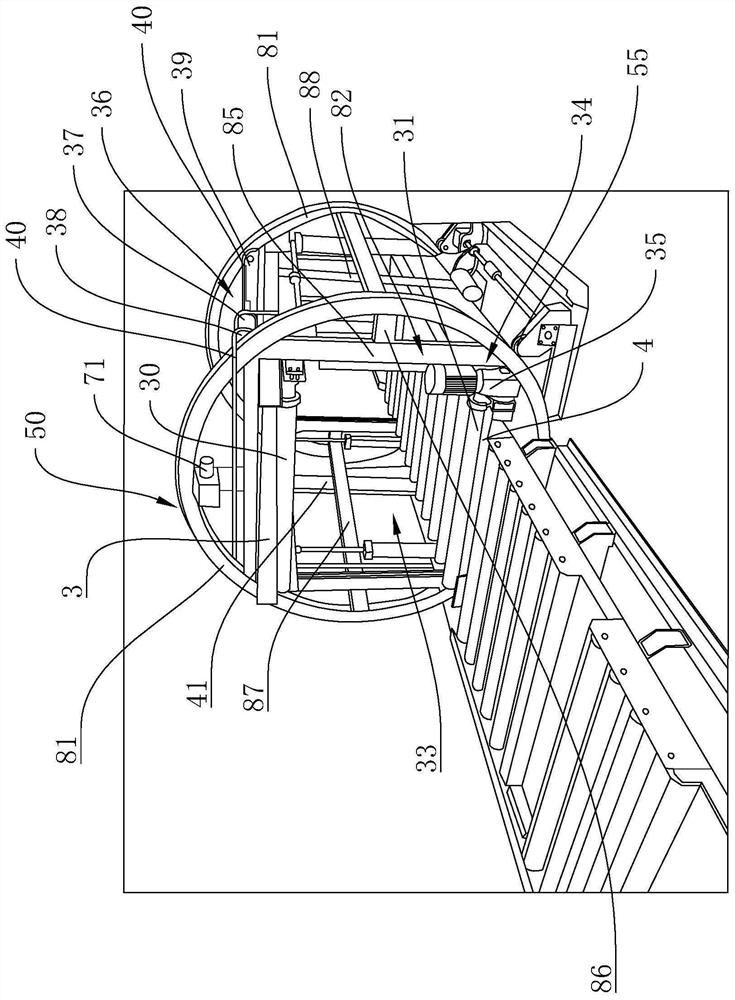

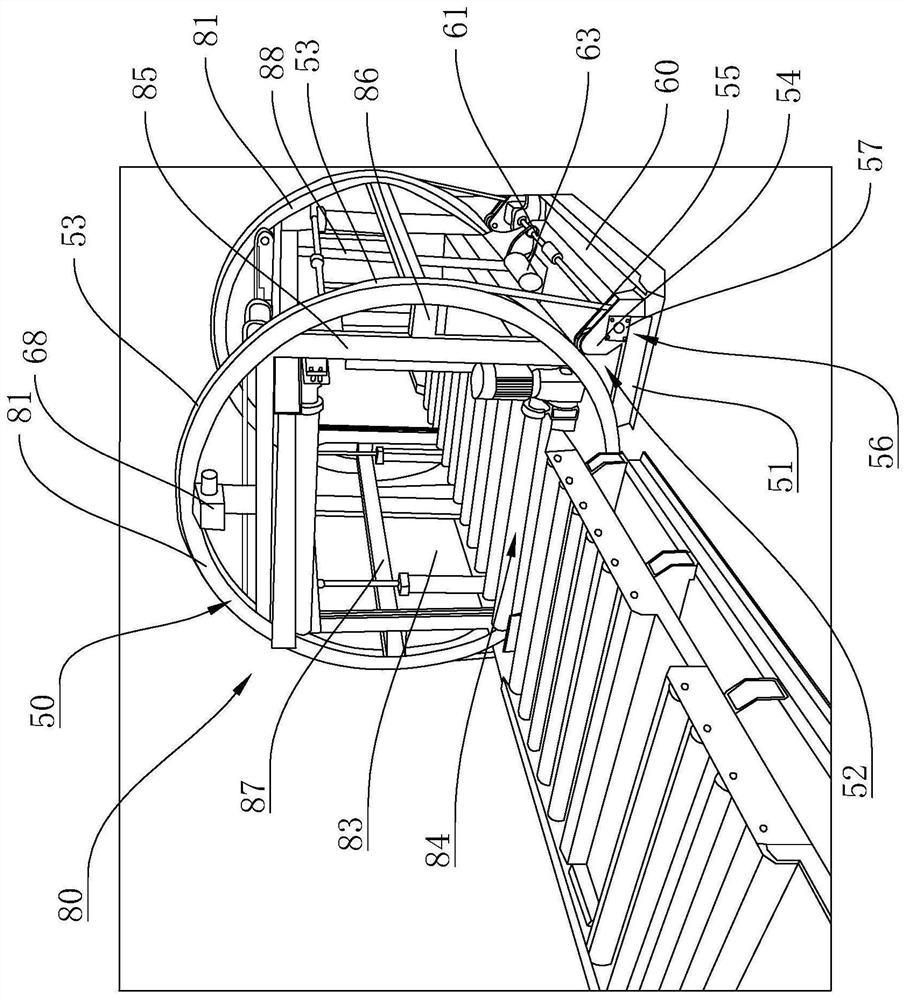

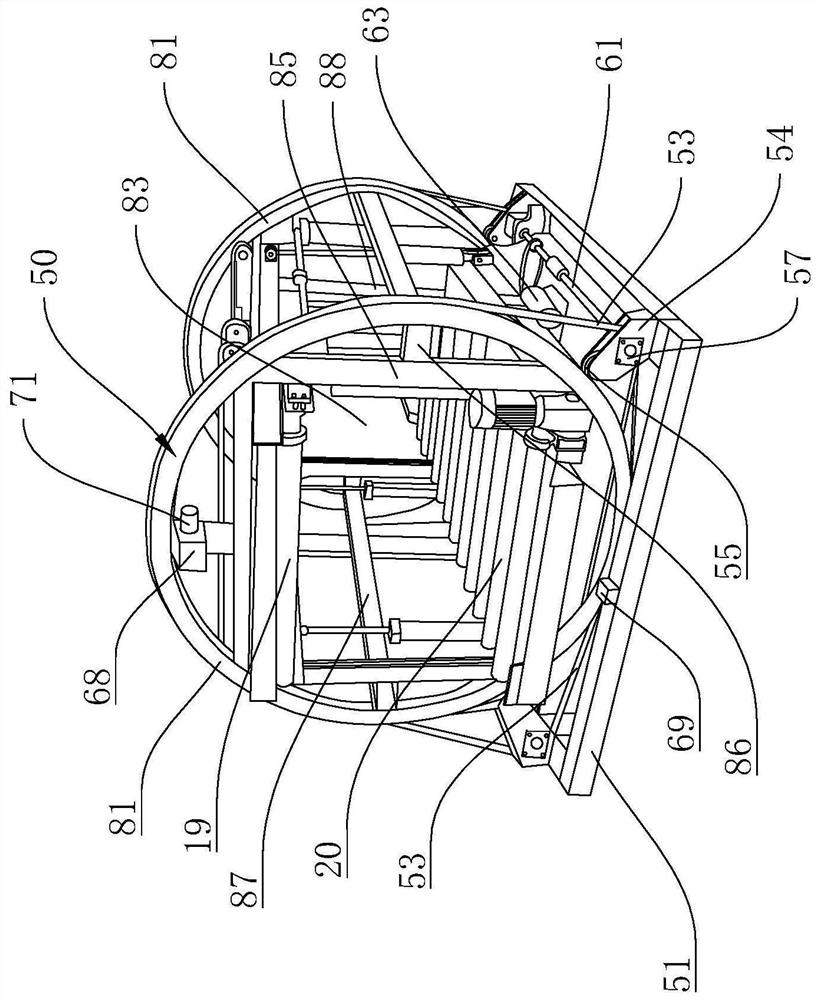

[0031] Such as Figure 1-7 As shown, a turning machine includes a base 51, a rotating bracket 50 is provided on the base 51, a horizontal rotating mechanism 80 is provided between the rotating bracket 50 and the base 51, and the rotating bracket 50 includes two symmetrically arranged support rings 81, each Each support ring 81 is provided with a rectangular support frame 82, an upper pedestal 3 and a lower pedestal 4 are arranged between the two support rings 81, and the upper pedestal 3 and the lower pedestal 4 are respectively fixed on both sides of the upper end of the two rectangular support frames 82 and On both sides of the lower end, an upper conveying platform 30 and a lower conveying platform 31 are respectively arranged on the upper pedestal 3 and the lower pedestal 4, and a feeding channel 83 is formed between the upper conveying platform 30 and the lower co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com