Disassembling and assembling tool for rotor of hub motor

A hub motor and rotor technology, applied in the direction of electromechanical devices, manufacturing tools, manufacturing motor generators, etc., can solve the problems of low disassembly and assembly efficiency, collision between rotor and stator, large footprint of horizontal structure, etc., to achieve the disassembly process Stable and safe, improve the efficiency of disassembly and assembly, and move smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

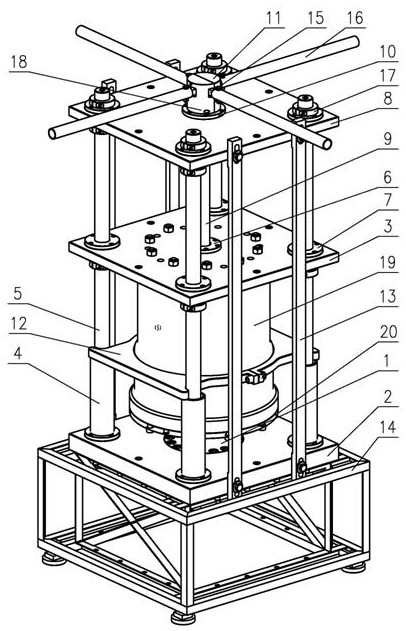

[0023] Such as Figure 1-5 As shown, the in-wheel motor rotor dismounting tool includes a base 14 on which a bottom plate 2 is mounted, and a sliding guide mechanism and a rotating mechanism are mounted on the bottom plate 2 .

[0024] A base 1 is arranged in the center of the bottom plate 2, and the stator 20 is fixedly installed on the base 1 through connecting pieces such as bolts.

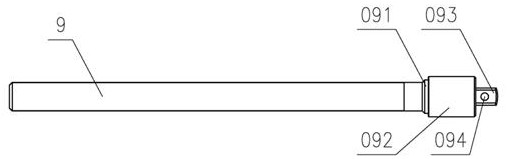

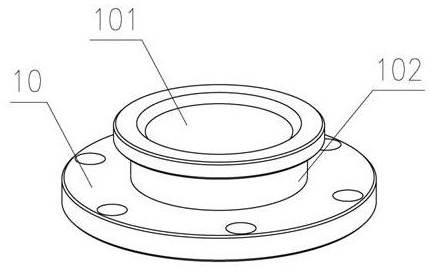

[0025] The sliding guide mechanism includes a slide plate 3, a top plate 8, a guide rail 5 and a guide sleeve 4; the rotor 19 is placed on the stator 20, and the slide plate 3 is installed on the top of the rotor 19. The bottom plate 2 is provided with a guide sleeve 4, and the lower part of the guide rail 5 is placed in the guide sleeve 4; the upper part of the guide rail 5 passes through the slide plate 3 and is connected with the top plate 8. The rotating mechanism includes a lead screw 9, a top cover 11 and a lead screw seat 6; the lead screw seat 6 is arranged at the central position of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com