Rotational structure for butted panels

A technology of rotating structure and docking surface, used in pivot connections, furniture connectors, tables, etc., can solve problems such as damage to folding tables, panel depressions, and connecting crossbars that cannot be limited, so as to avoid axial drift. The effect of moving, improving the firmness and improving the structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

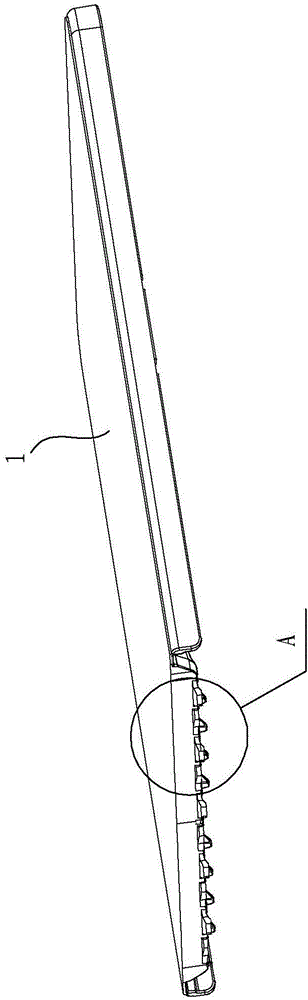

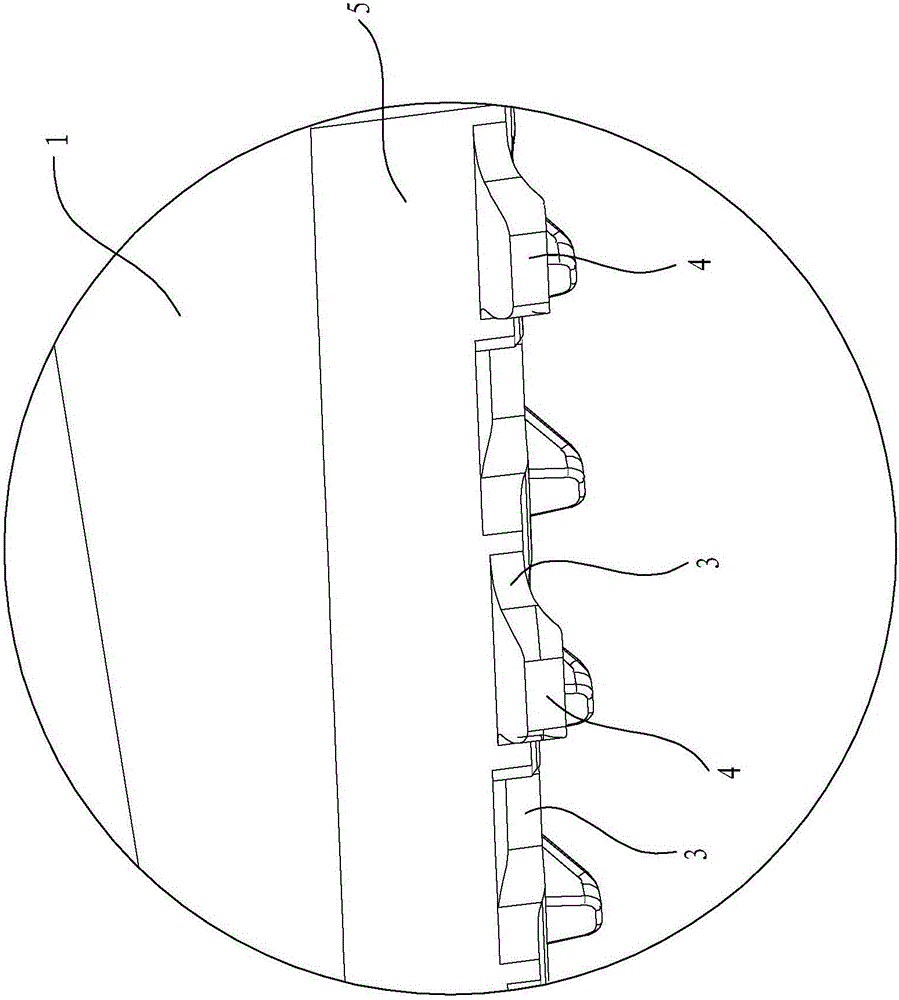

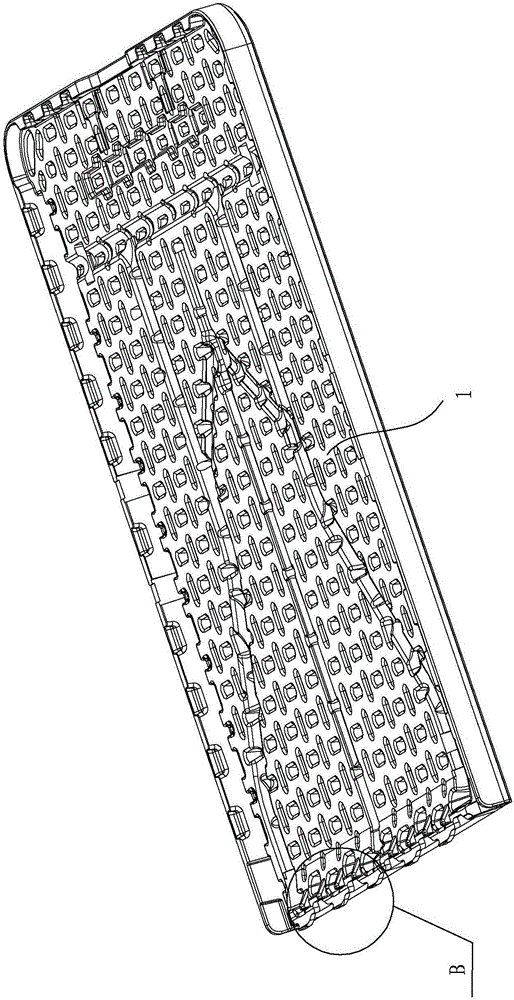

[0031] Such as Figure 1 to Figure 8 As shown, the rotating structure of the docking panels in this embodiment includes a first panel 1 and a second panel 2 that are docked with each other, and the first panel 1 and the second panel 2 are connected through a connecting cross bar 10, and the connecting cross bar 10 adopts a round tube and It is arranged below the junction of the first panel 1 and the second panel 2 . Wherein, an upper butt joint plane 5 that cooperates with each other is formed on the upper side of the butt surface of the first panel 1 and the second panel 2, and recesses distributed at intervals are all formed on the lower side of the butt joint surface of the first panel 1 and the second panel 2. Groove 3 and bump 4. In the docking state of the first panel 1 and the second panel 2, the upper docking plane 5 of the docking s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com