Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

60results about How to "Prevent saving" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

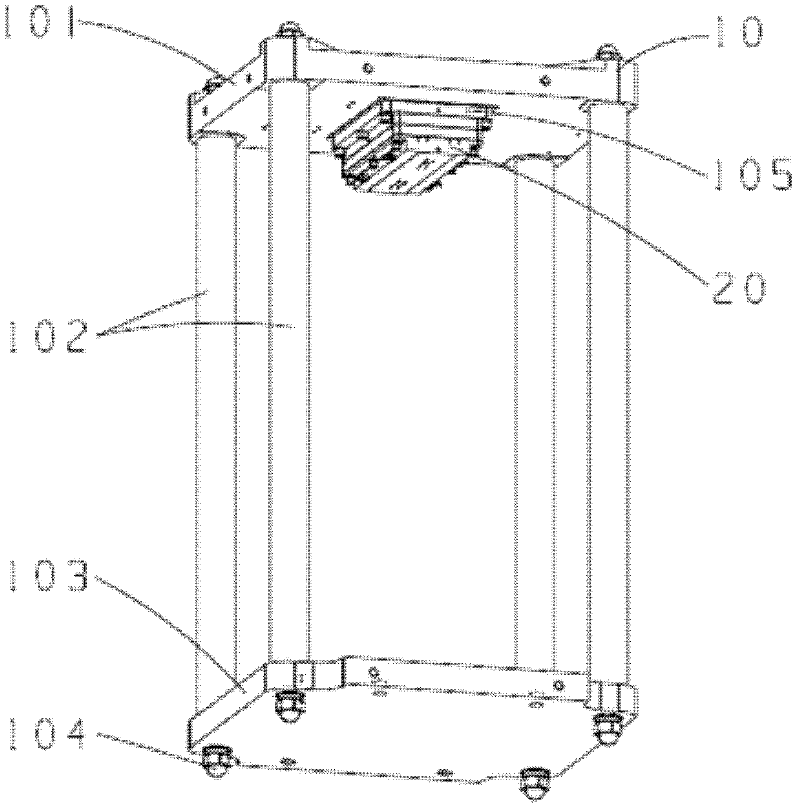

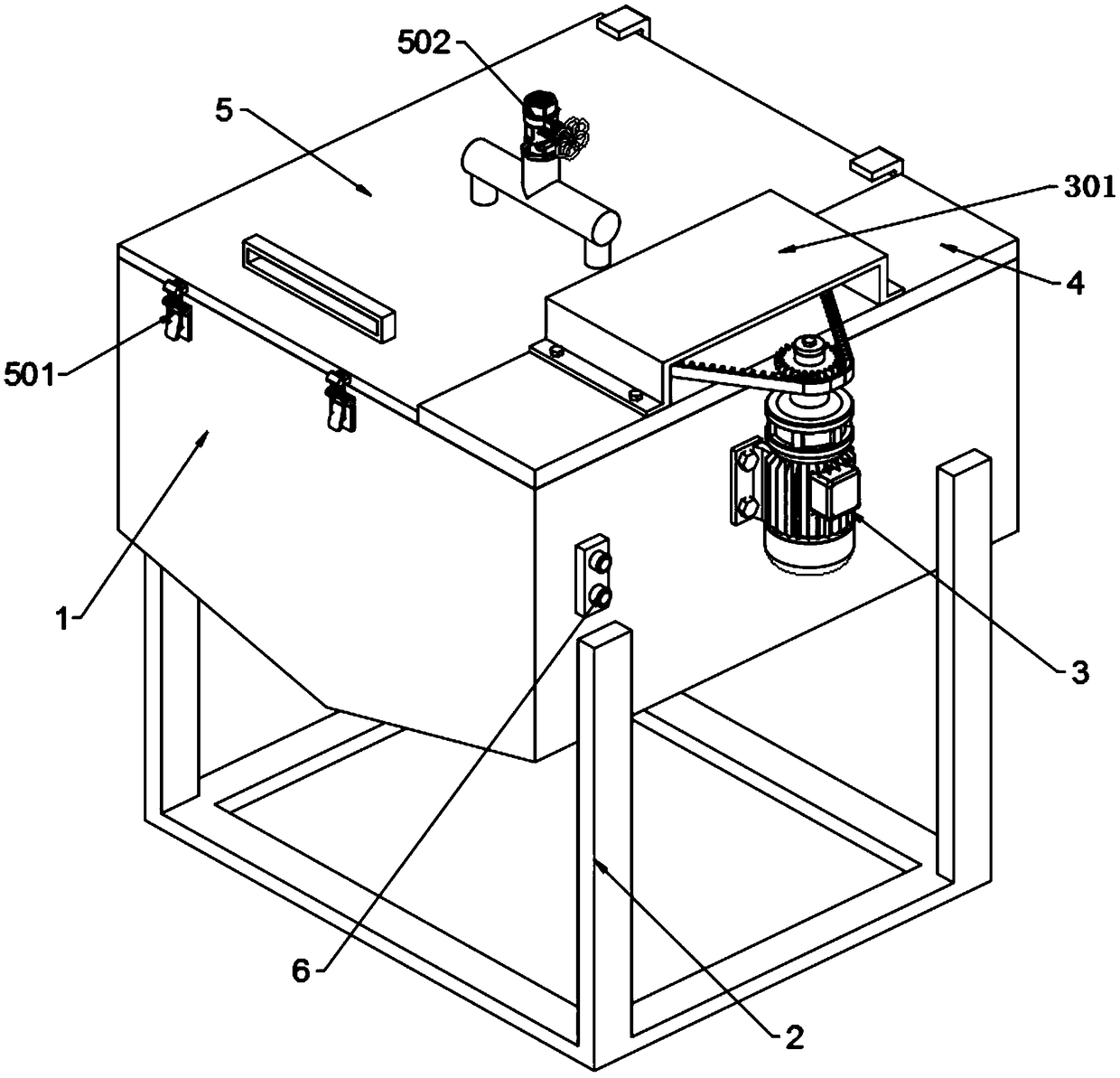

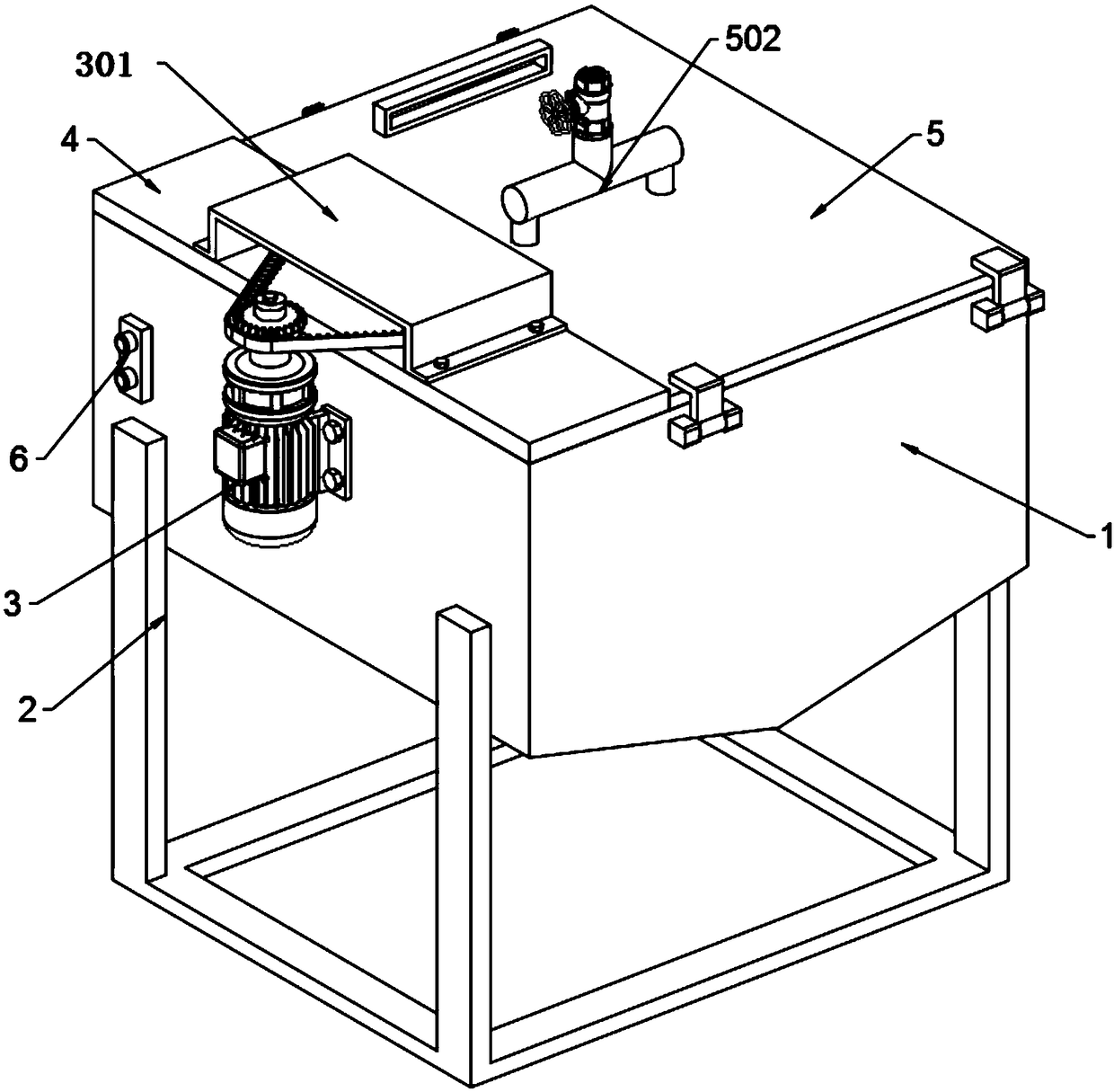

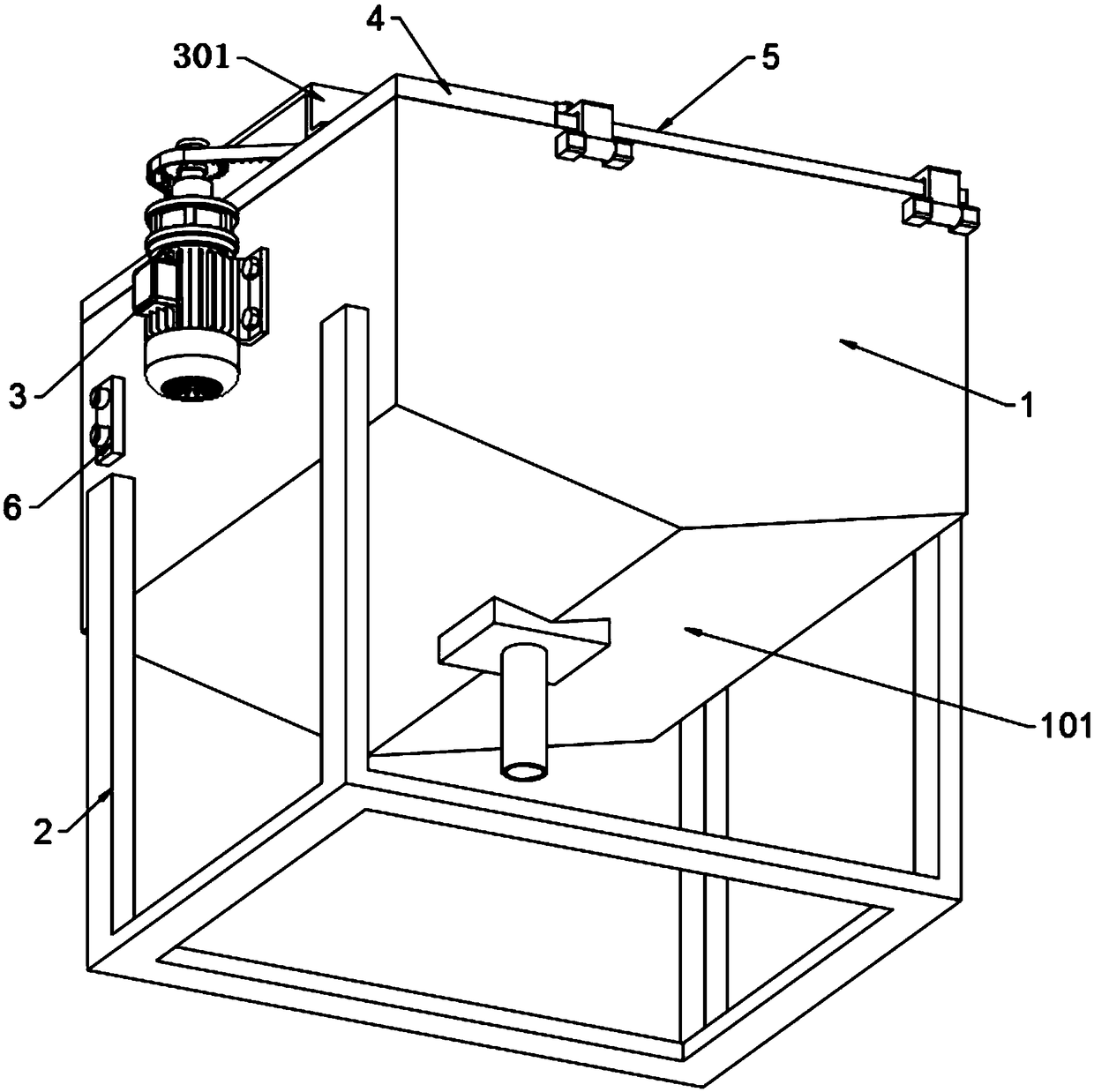

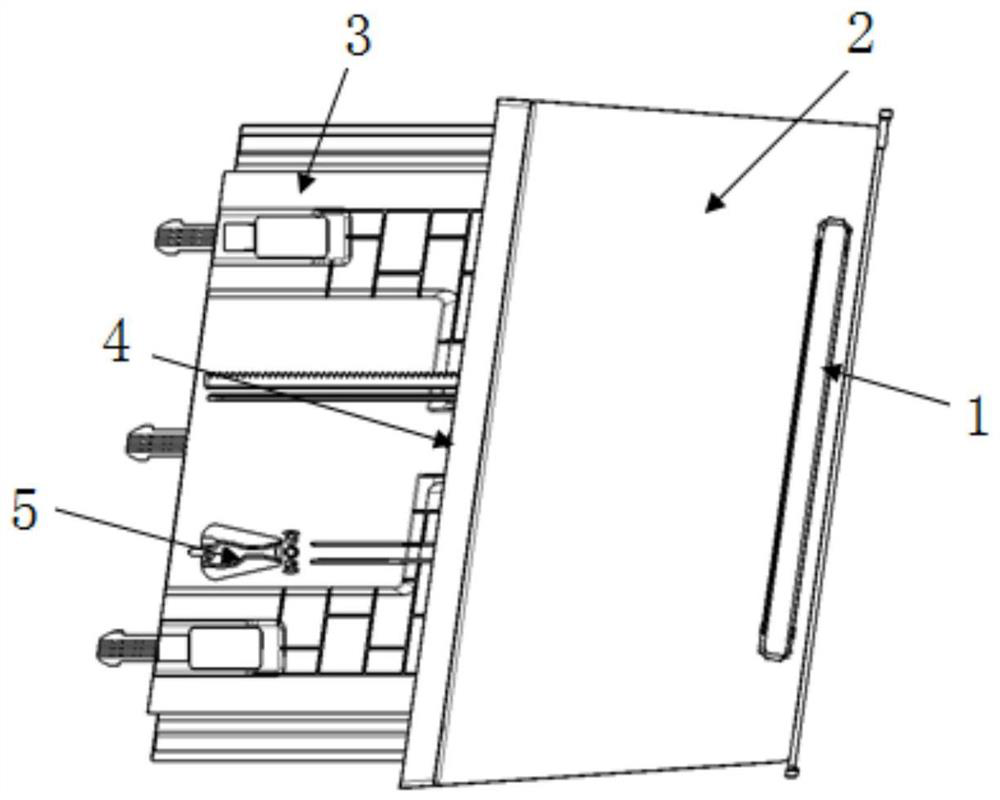

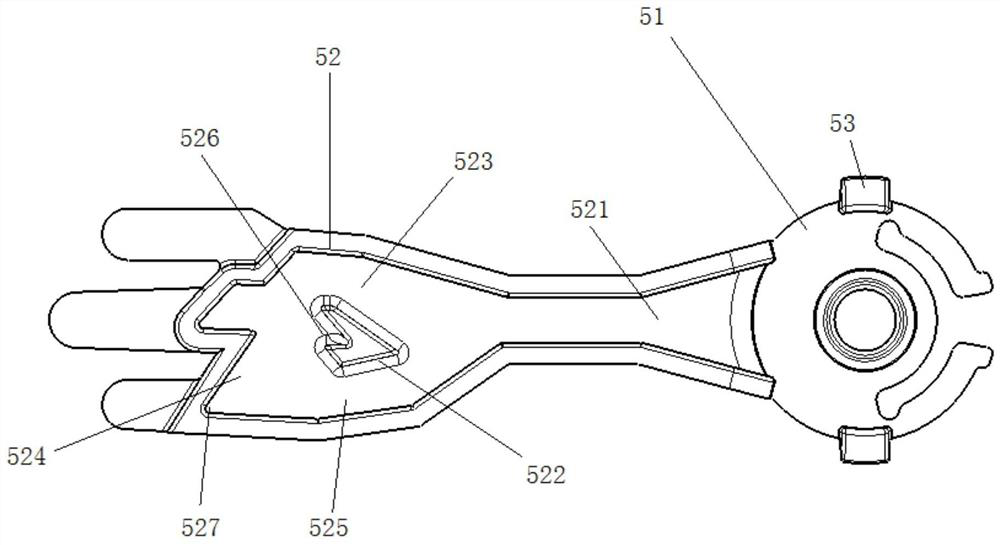

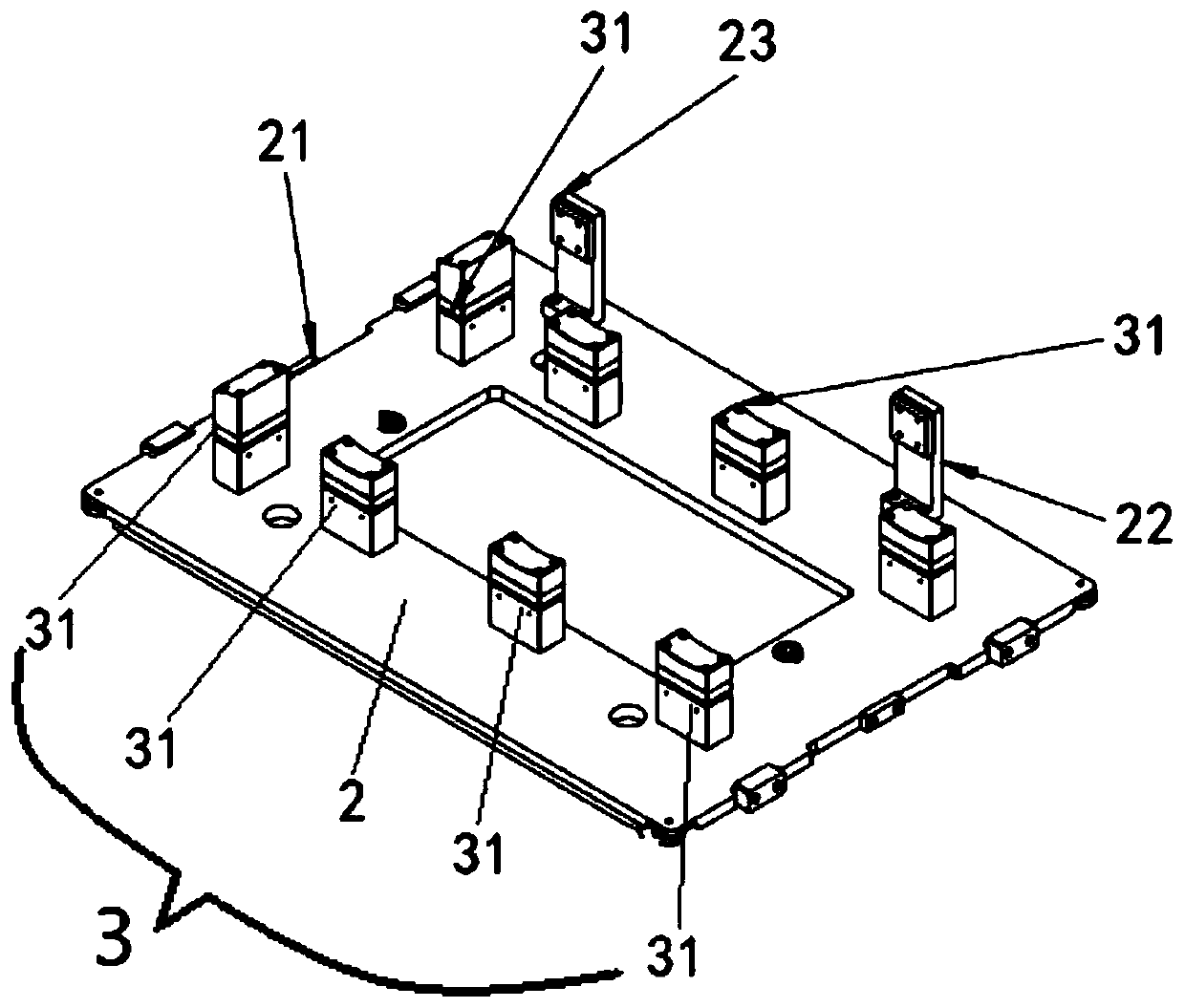

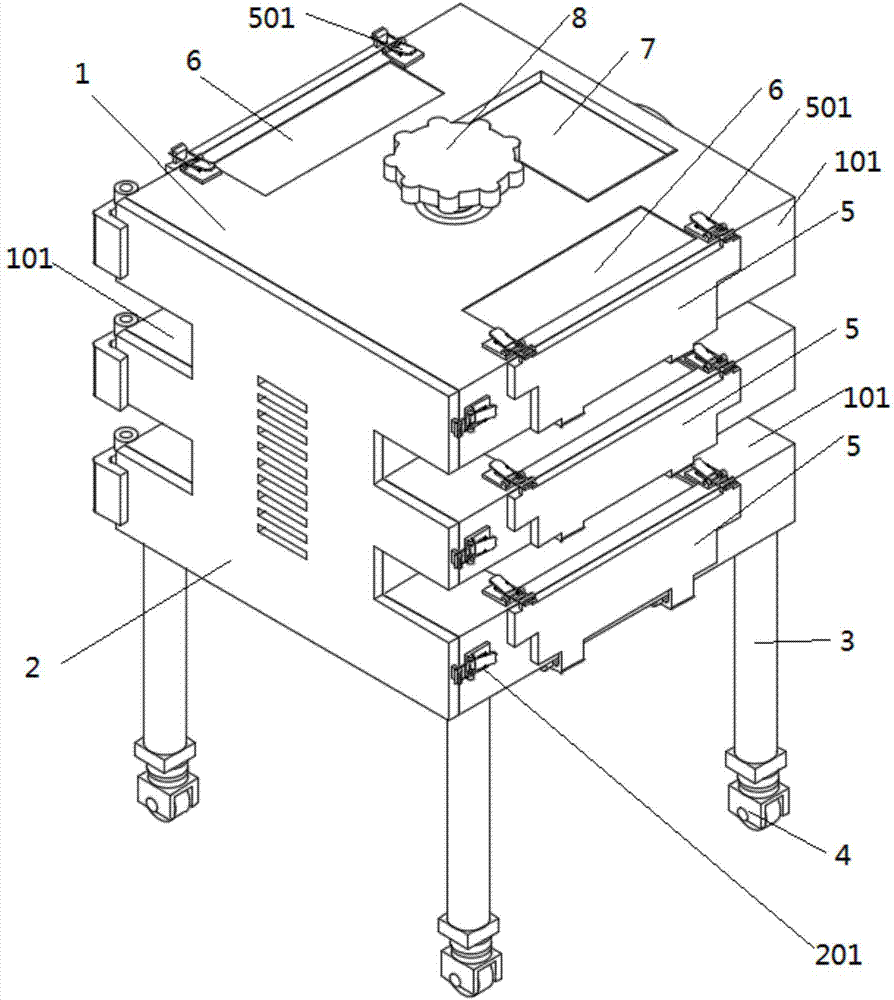

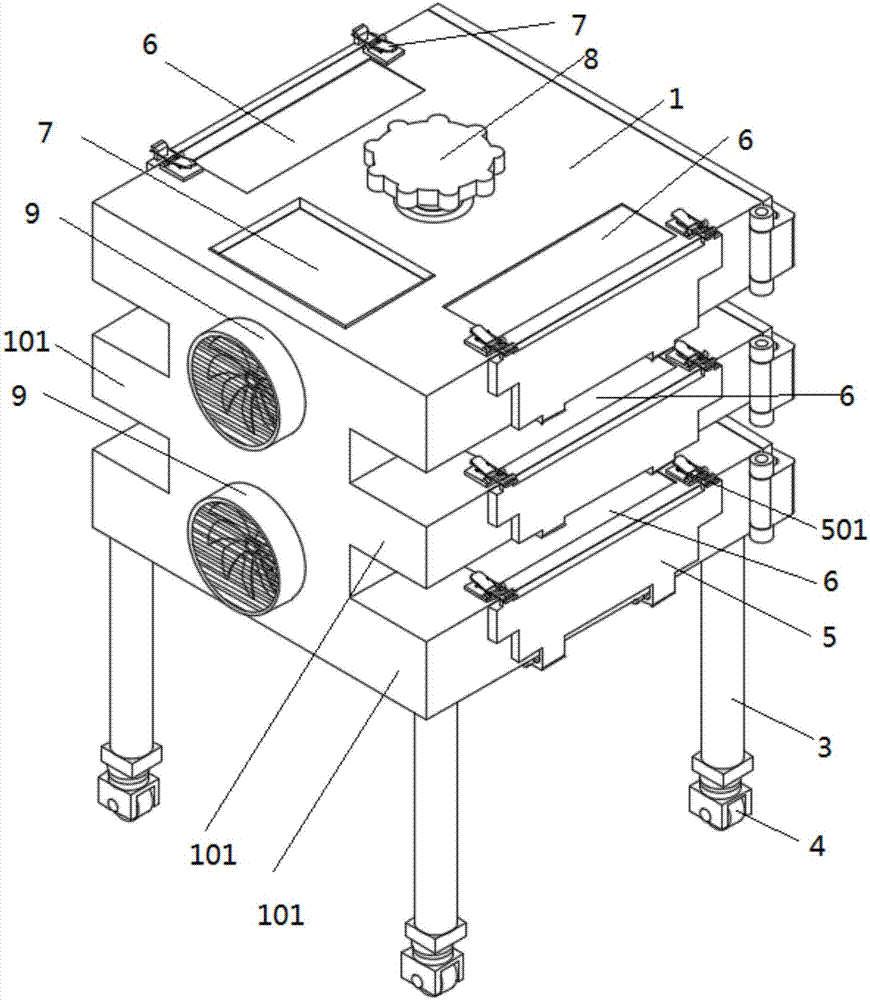

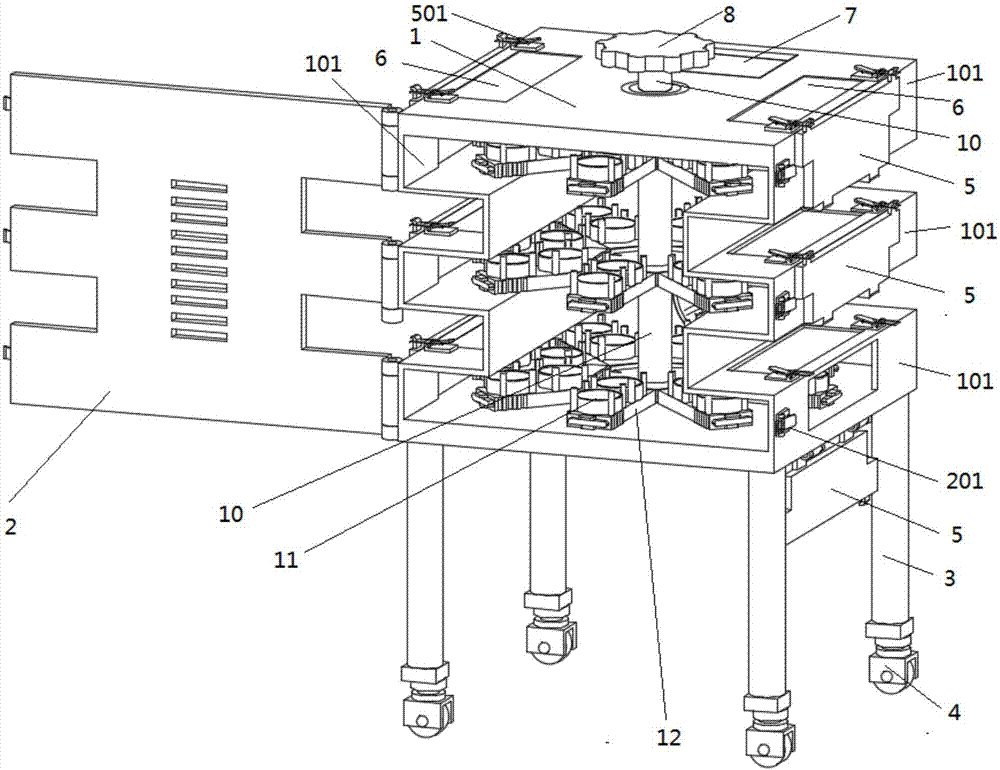

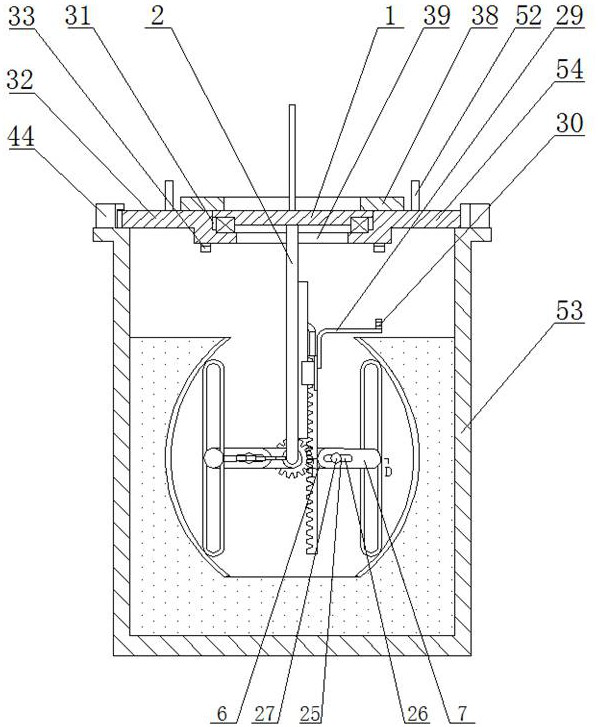

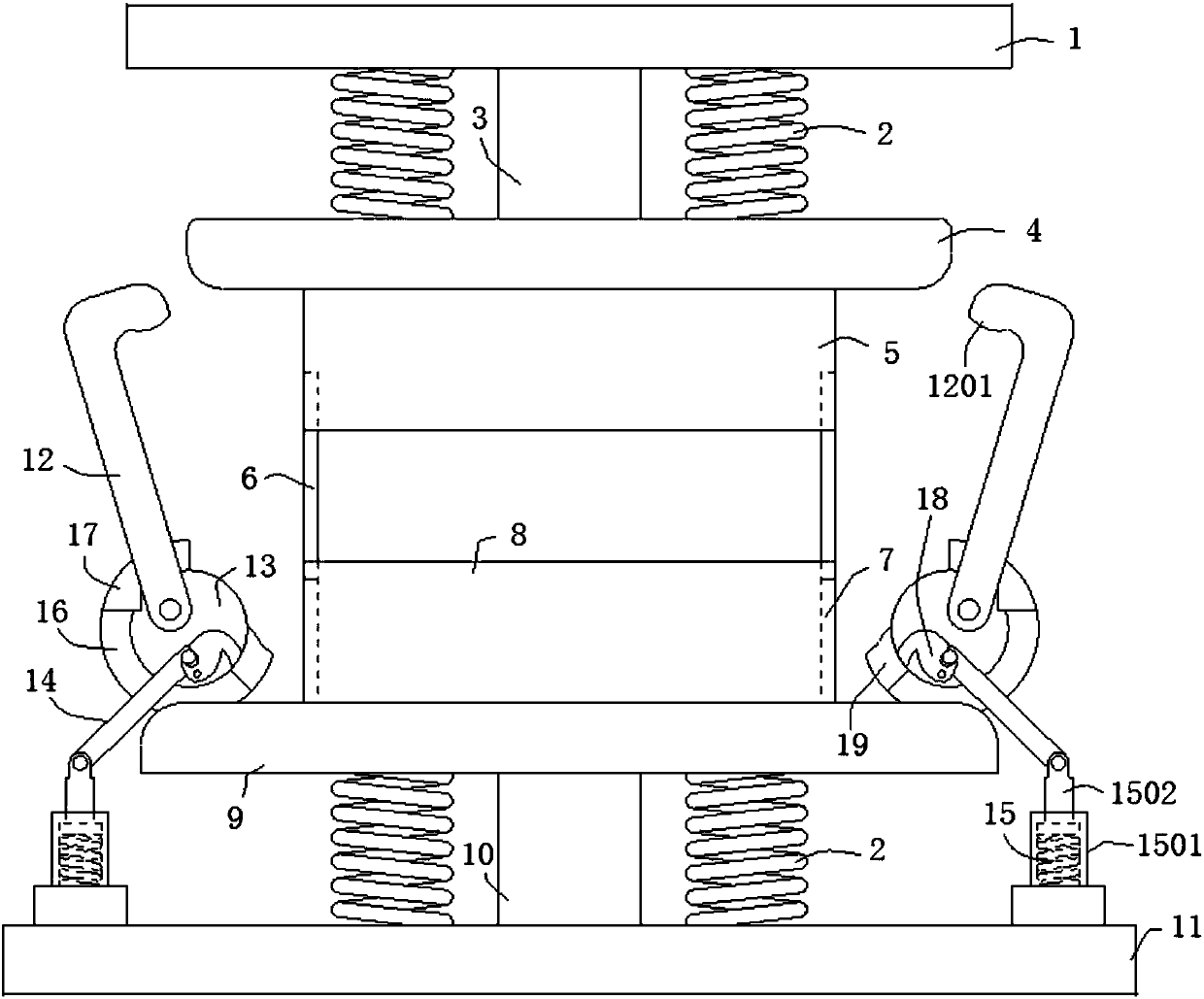

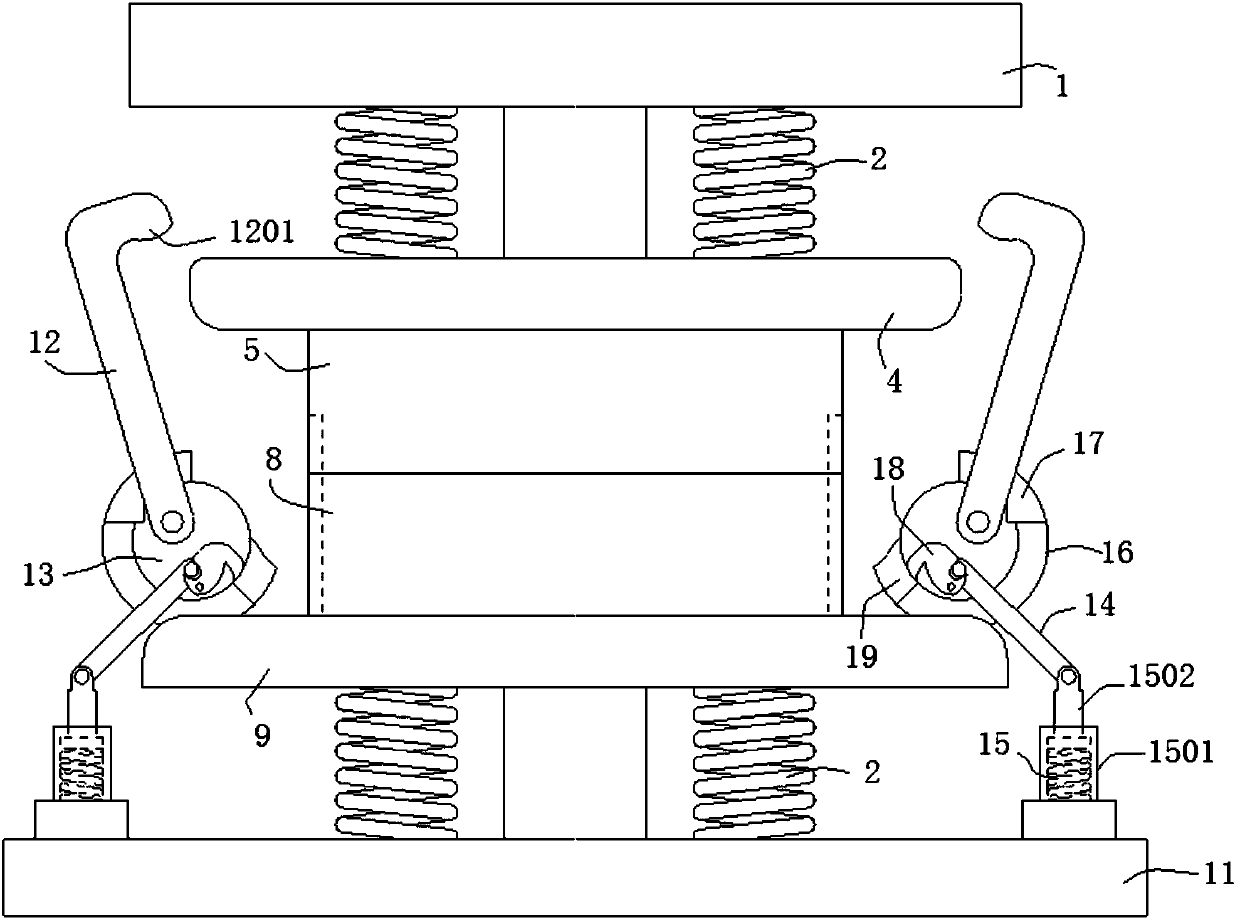

Automatic closed forging forming die

ActiveCN106623722APrevent savingImprove processing pass rateForging/hammering/pressing machinesAutomatic controlEngineering

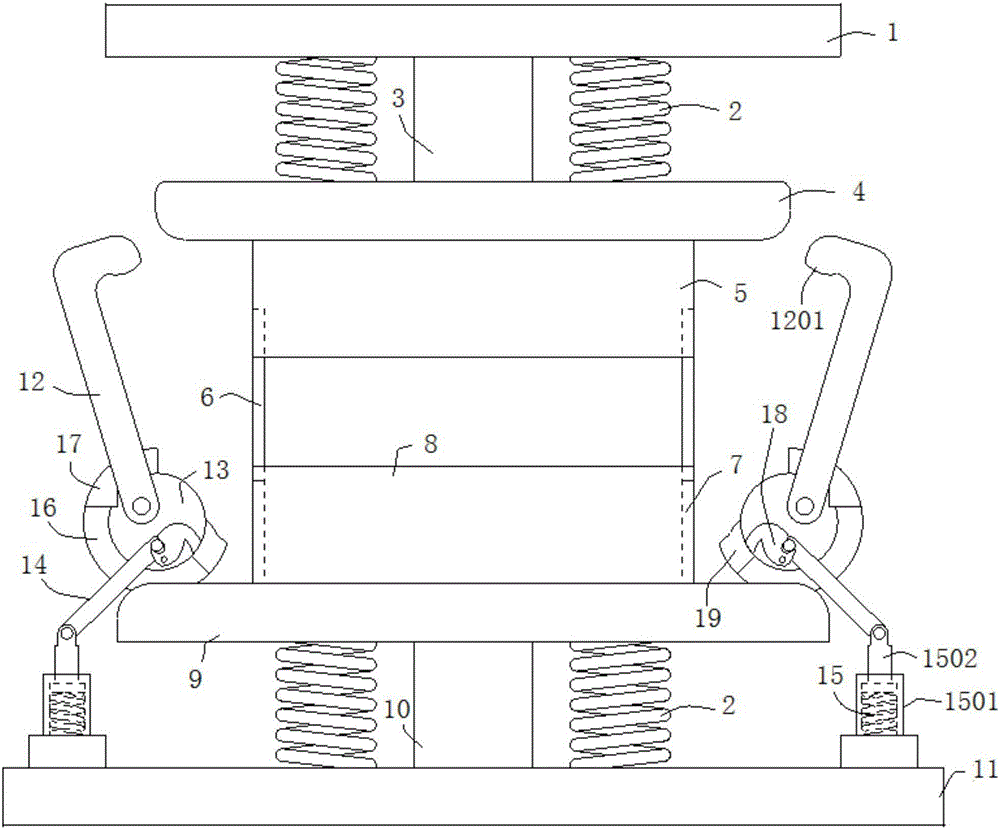

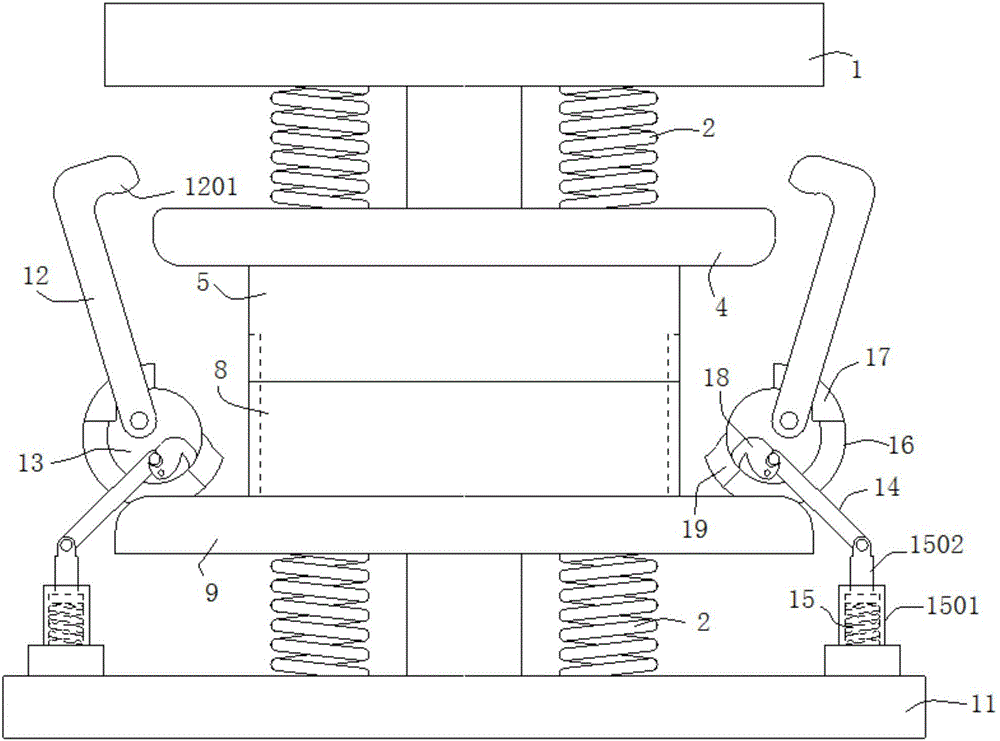

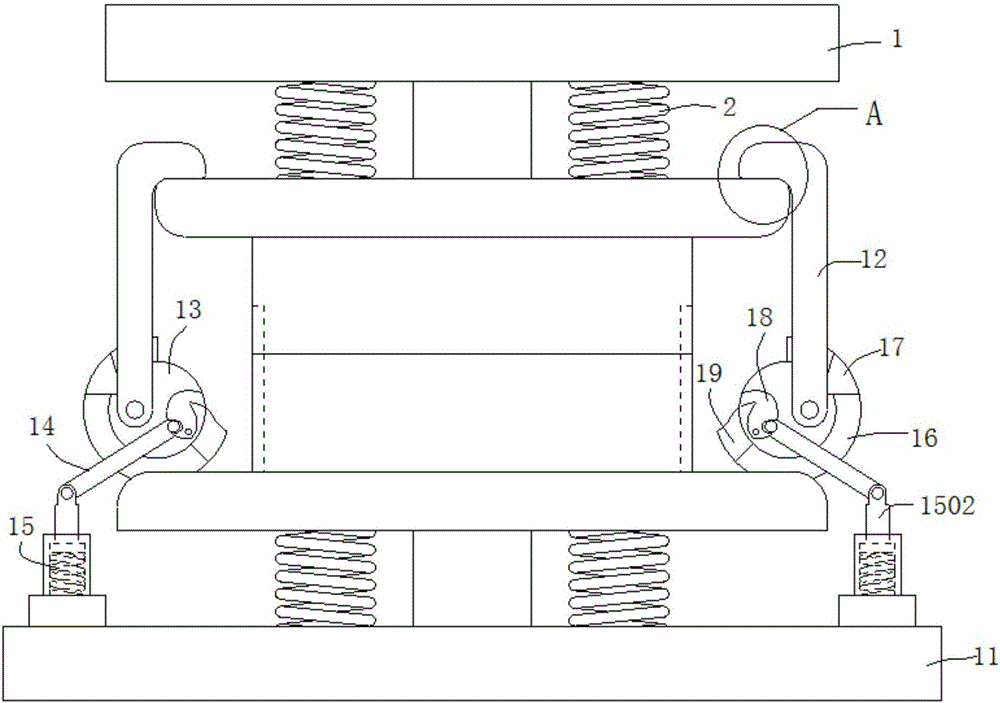

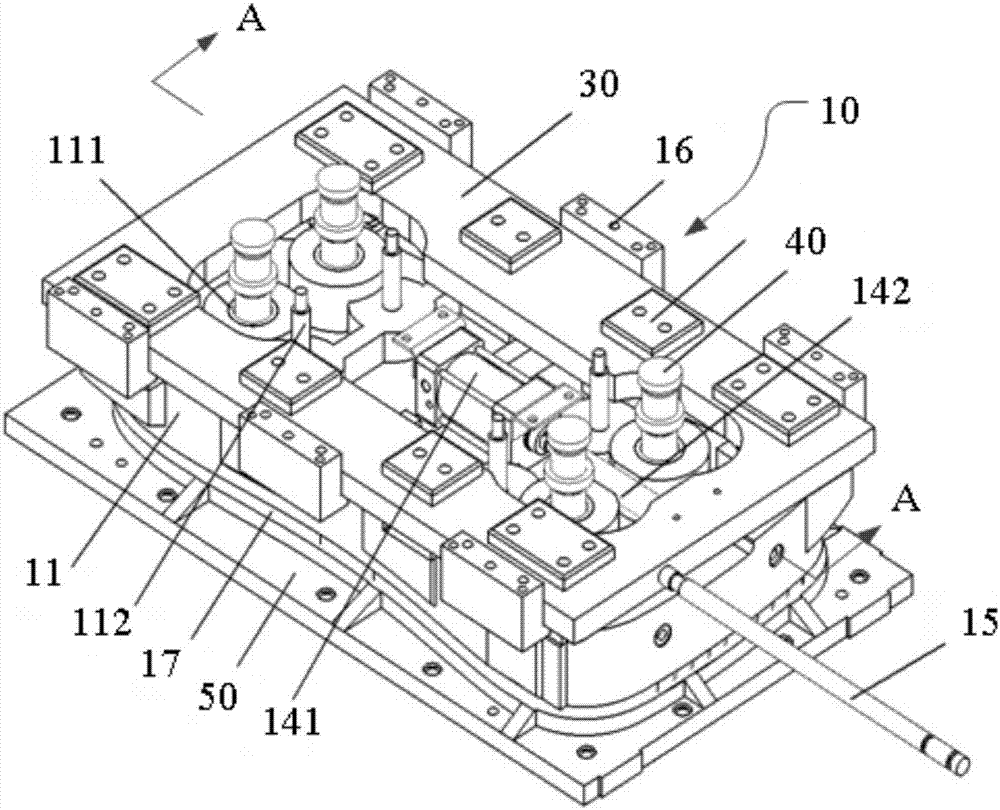

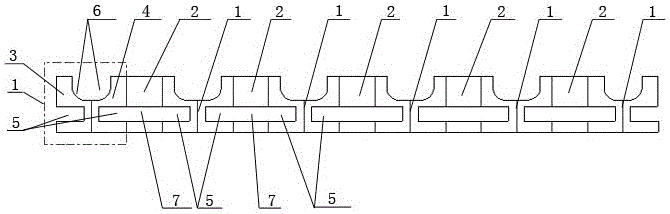

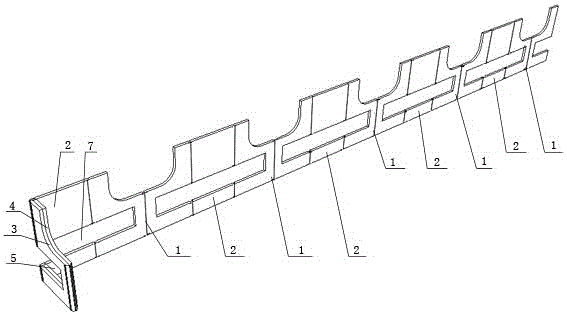

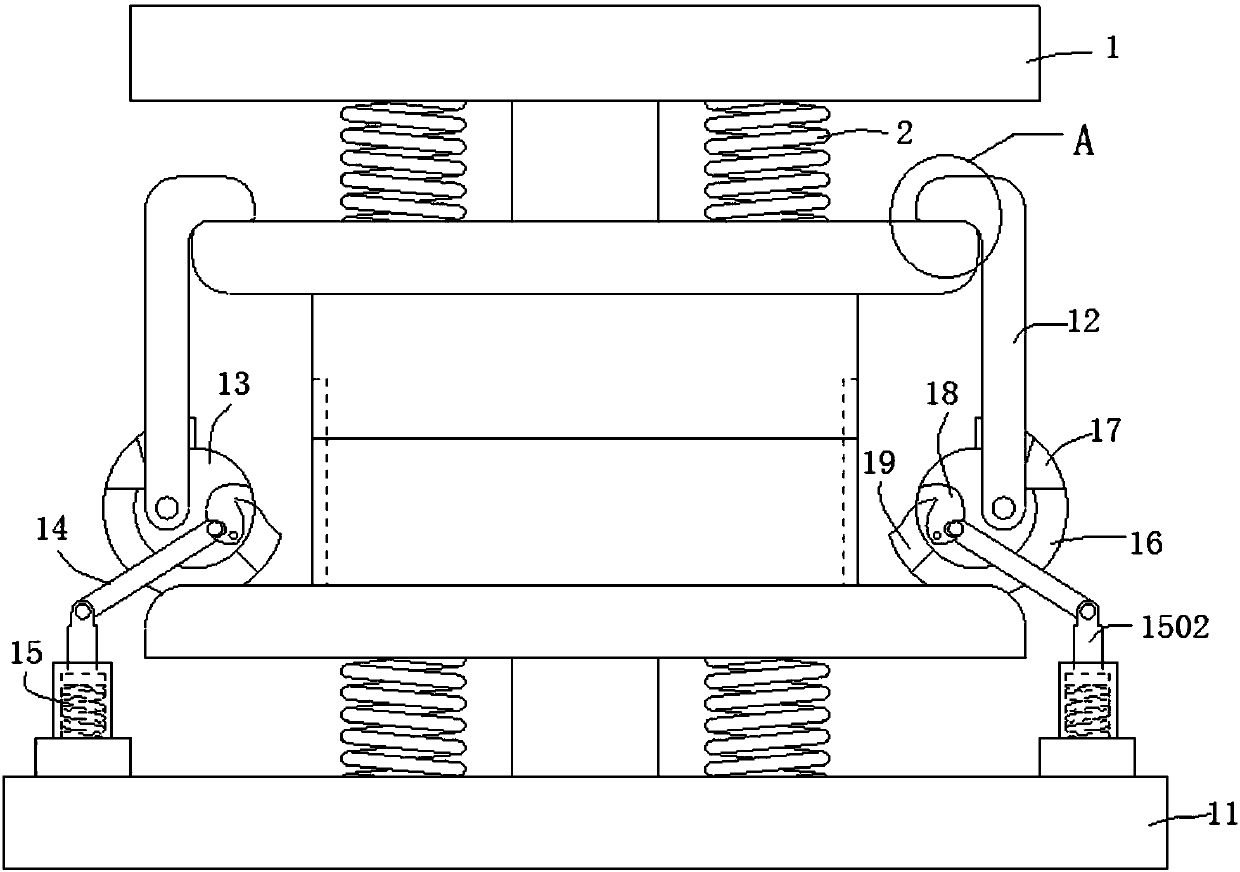

The invention discloses an automatic closed forging forming die, and belongs to the technical field of metal press machining. The die comprises a rigid die base, a floating female die, and automatic die locking devices symmetrically arranged on the two sides of a lower female die base. The two sides of the upper end face of an upper female die base are symmetrically provided with clamping grooves. Each automatic die locking device comprises a swinging lock rod and a power mechanism driving the swinging lock rod to swing. Lock heads clamped to the clamping grooves in a matched mode are arranged on the tops of the swinging lock rods. During combination of an upper female die and a lower female die, the power mechanisms drive the swinging lock rods to swing in the direction close to the upper female die till the lock heads make contact with the clamping grooves to be clamped; During opening of the upper female die and the lower female die, the power mechanisms drive the swinging lock rods to swing in the direction away from the upper female die till the lock heads get away from the clamping grooves to be reset. The die clamping pressure can be increased, and automatic control over locking and unlocking of the upper and lower female dies of a die locking device is achieved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

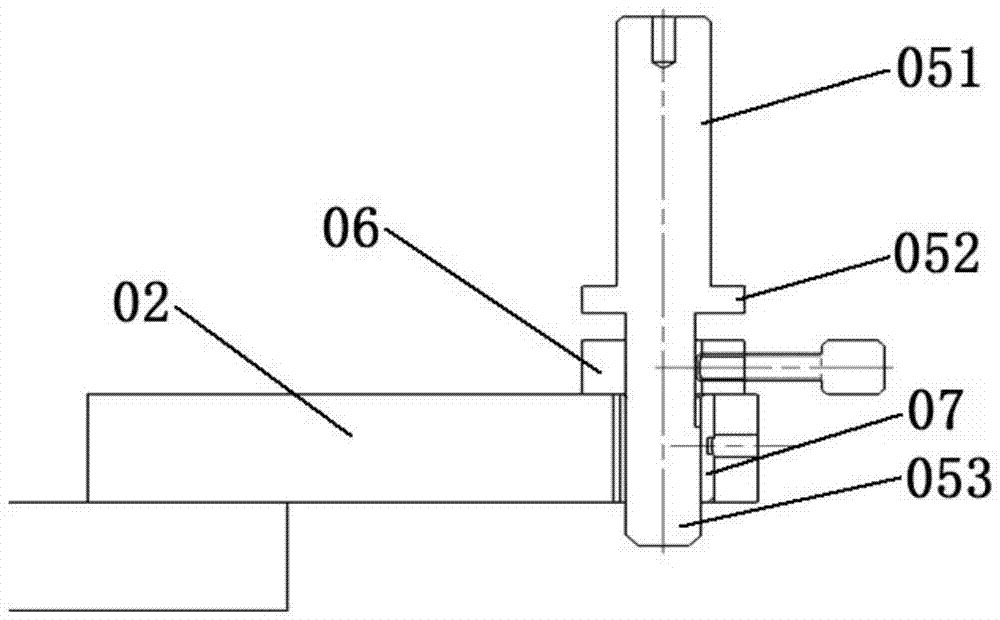

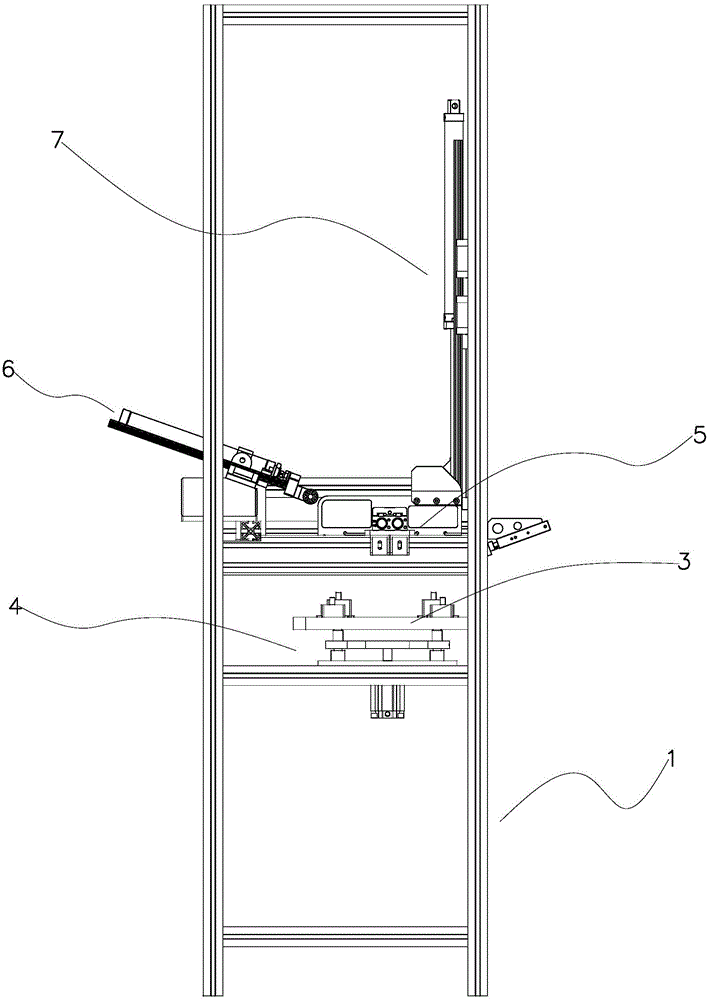

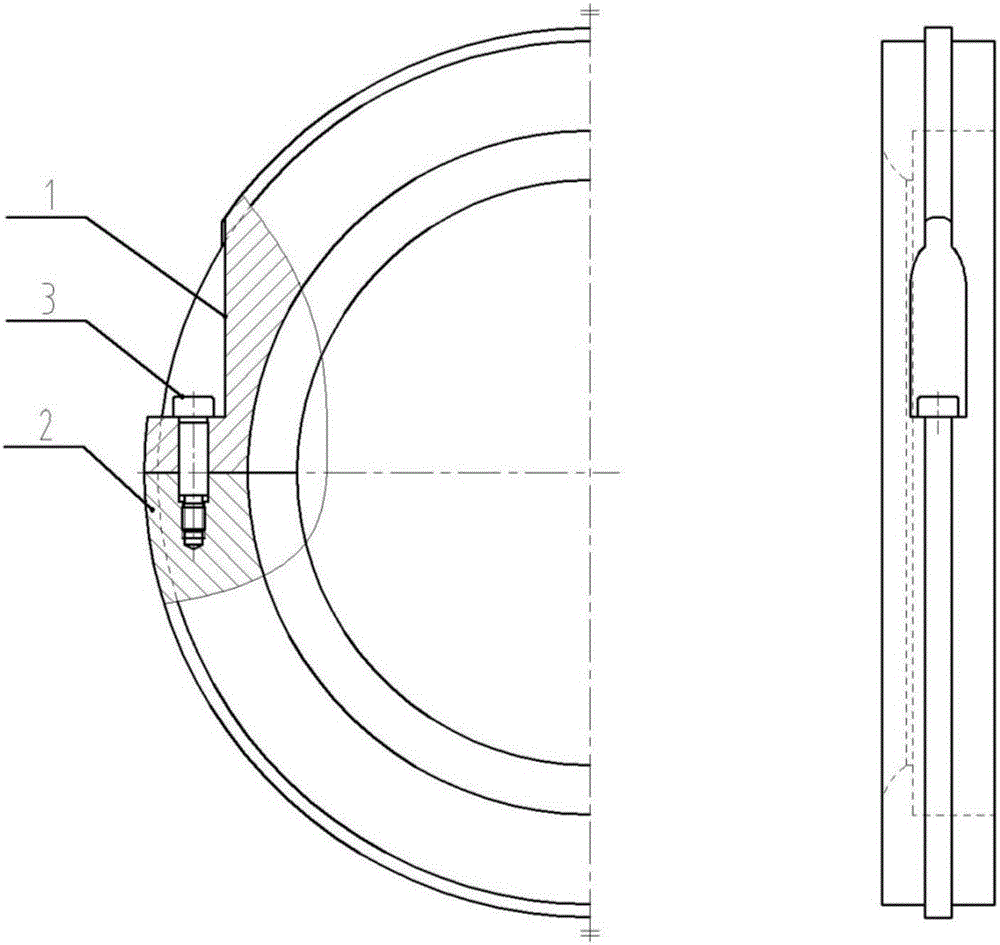

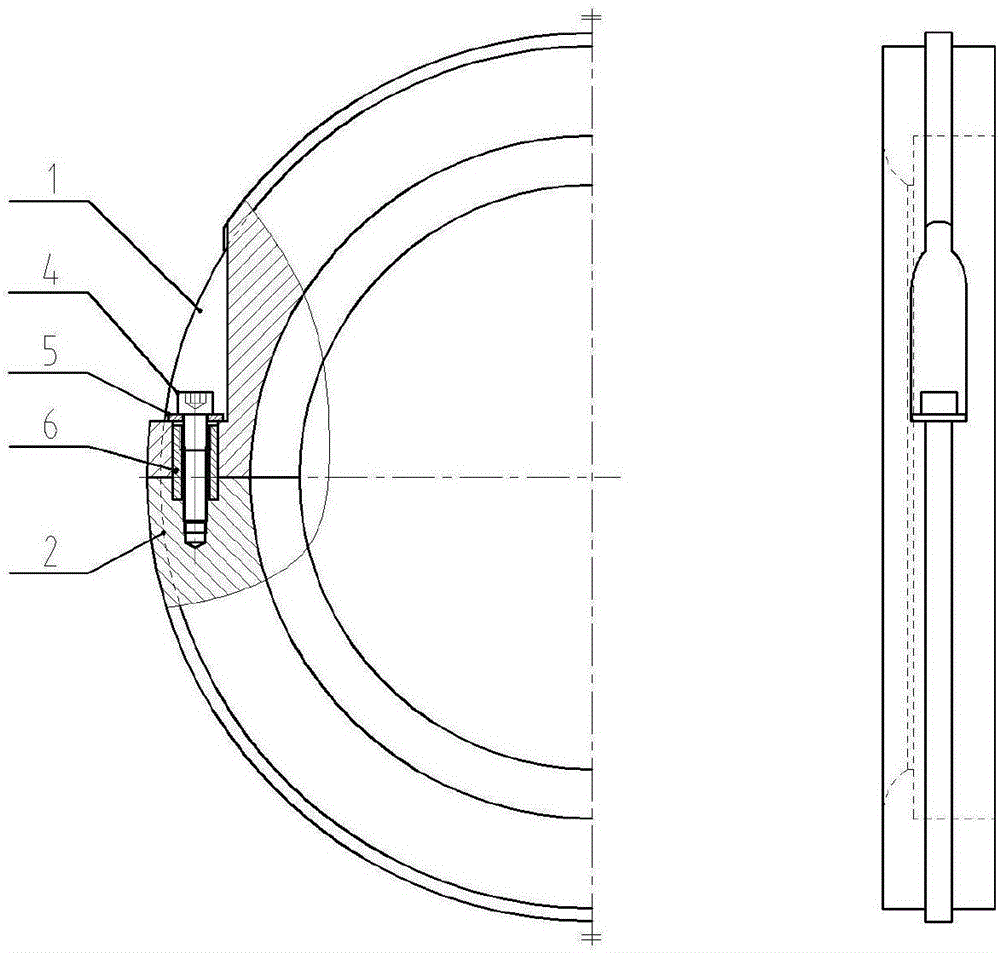

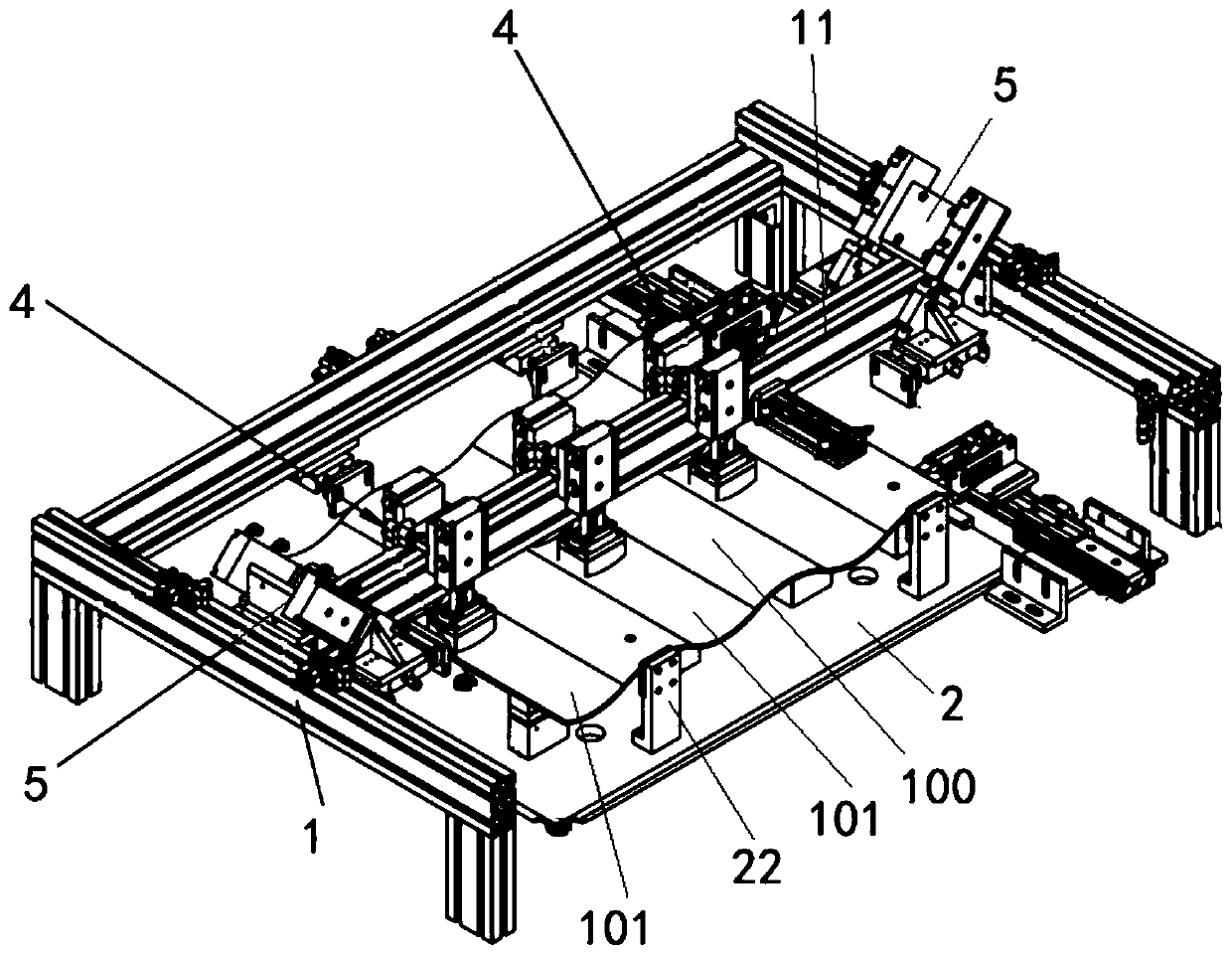

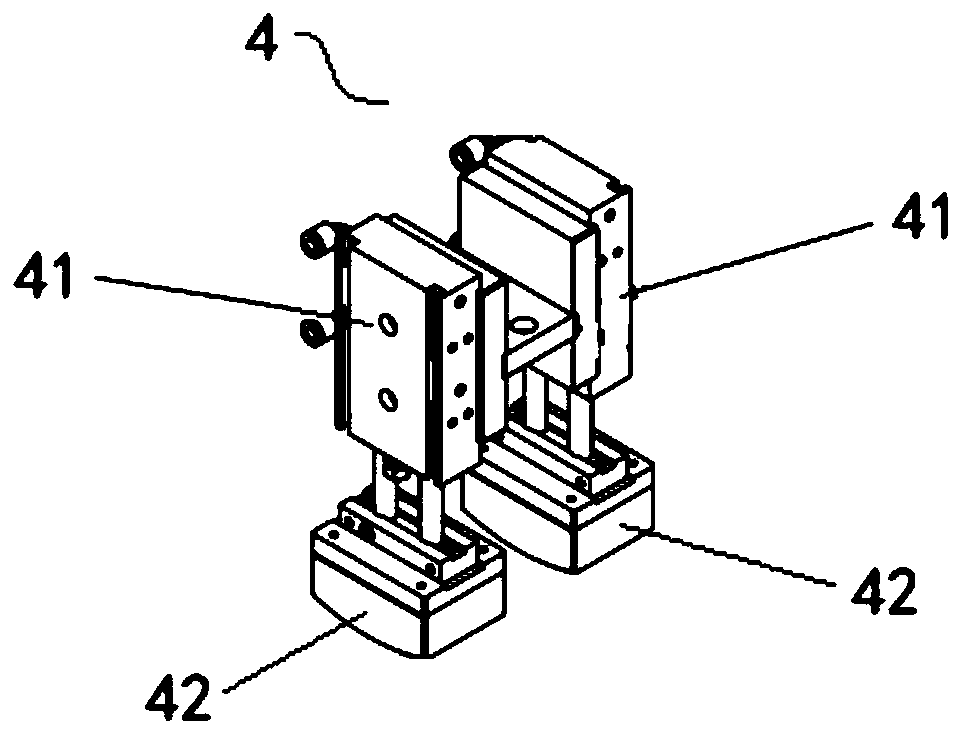

Plane difference detection device of concave molded surface holes

InactiveCN104713446ASimple structureReduce installation difficultyMechanical clearance measurementsEngineeringMechanical engineering

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

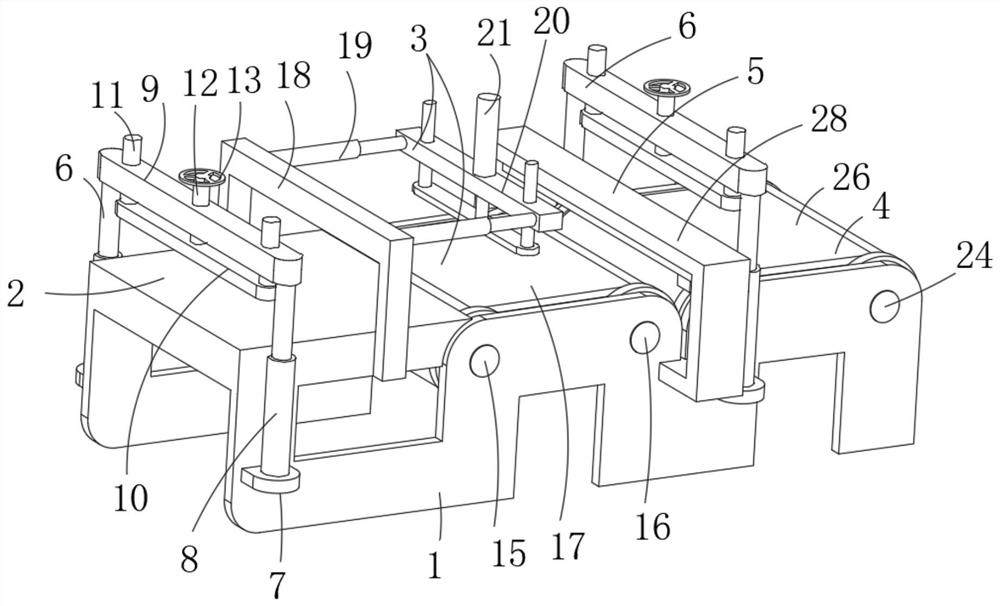

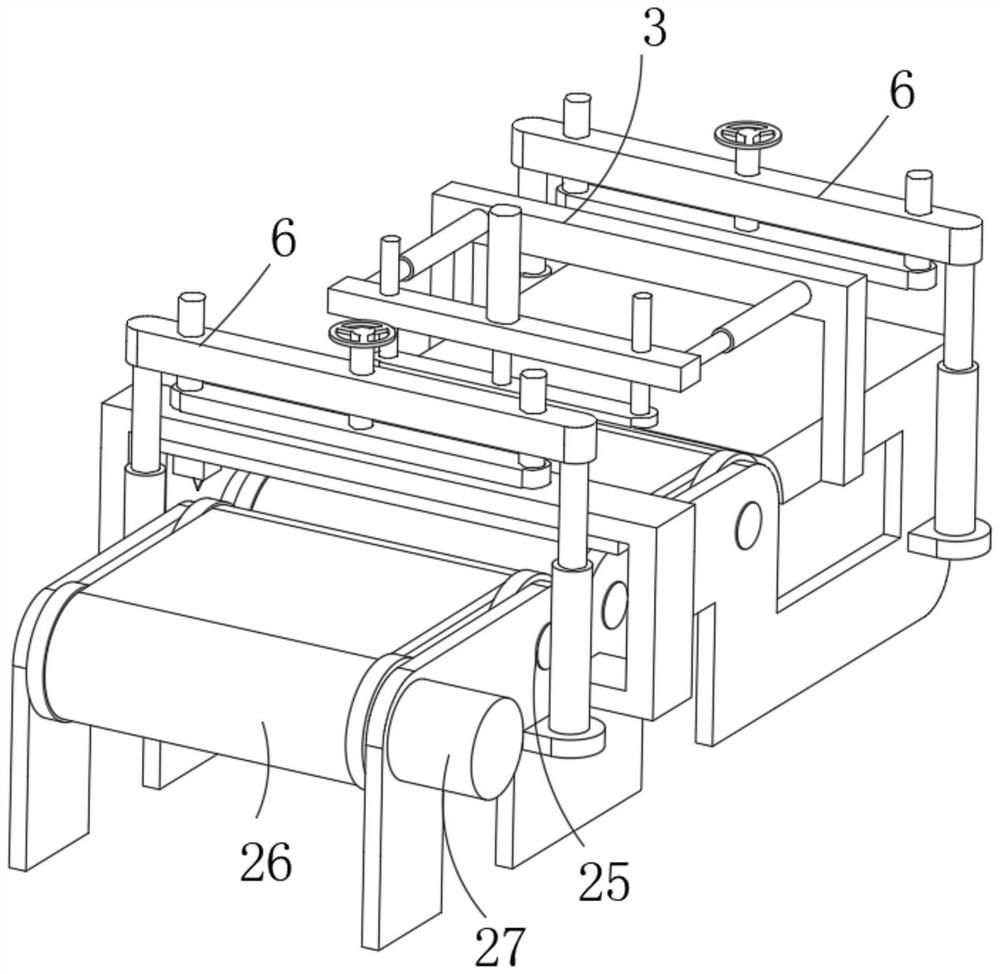

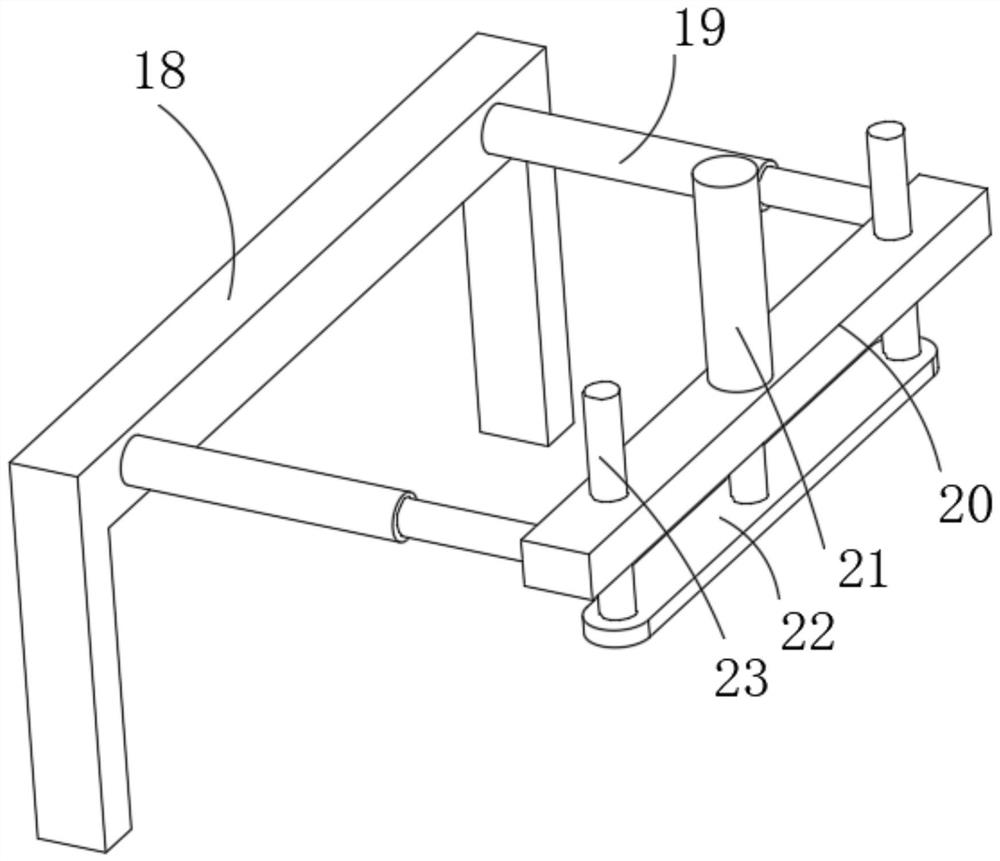

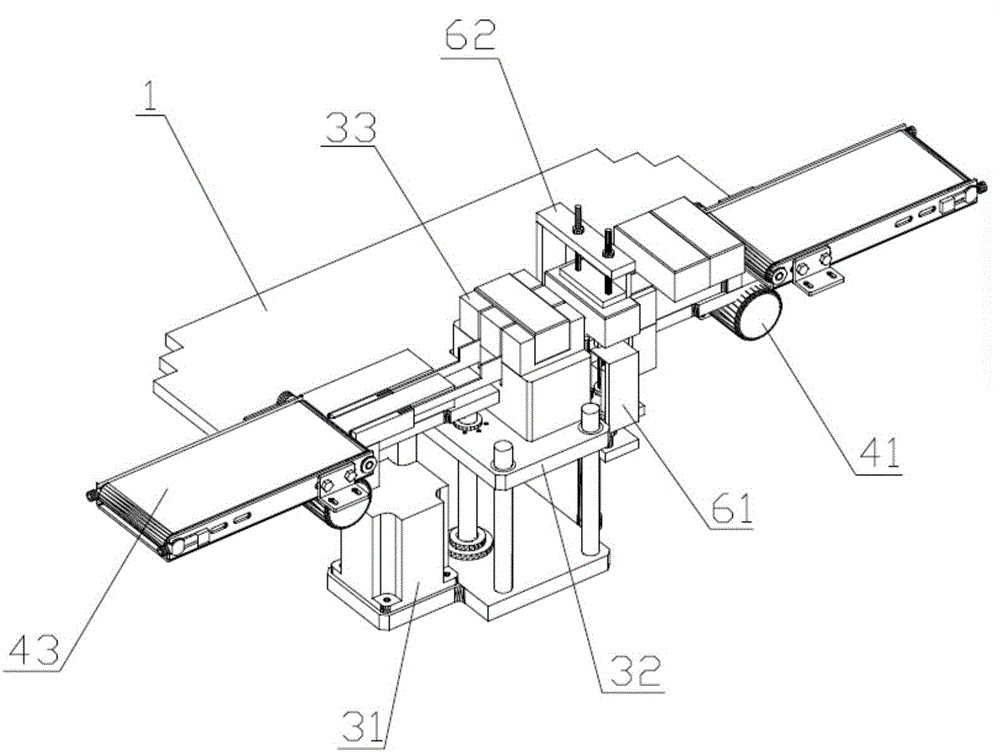

Device for automatically buckling packaging box

ActiveCN106005519ARealize automatic fastening productionIncrease productivityPackagingBuckling - actionFront cover

The invention discloses a device for automatically buckling a packaging box. The device comprises a machine frame, a tool jig, a jacking mechanism, side clamping guide mechanisms, a buckling mechanism and a cover pressing mechanism. A lifting mechanism jacks up the packaging box through the tool jig; the side clamping guide mechanisms clamp the packaging box which is jacked up; then, the lifting mechanism resets; the buckling mechanism conducts rolling on a cover body so that side covers can be buckled on a box body; then, the buckling mechanism resets; finally, the cover body is pressed through the cover pressing mechanism; rolling is conducted on a front cover so that buckle lugs can be buckled on the box body; and therefore the buckling action of the packaging box is automatically completed. The above structure is adopted in the device, automatic production is achieved, the production efficiency is effectively improved, and the labor cost is reduced.

Owner:ZHONGSHAN XINHUI PRECISION TECH CO LTD

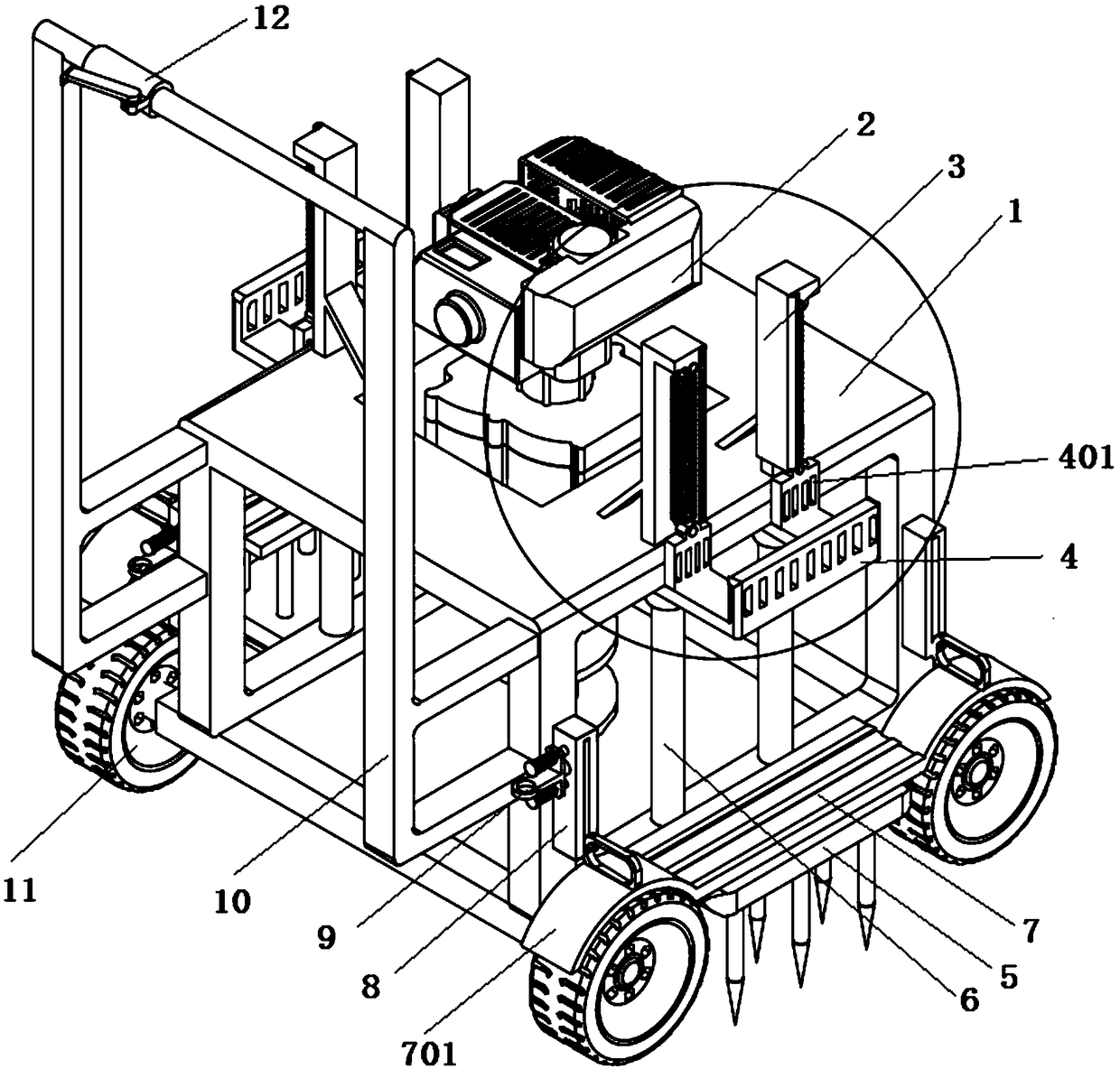

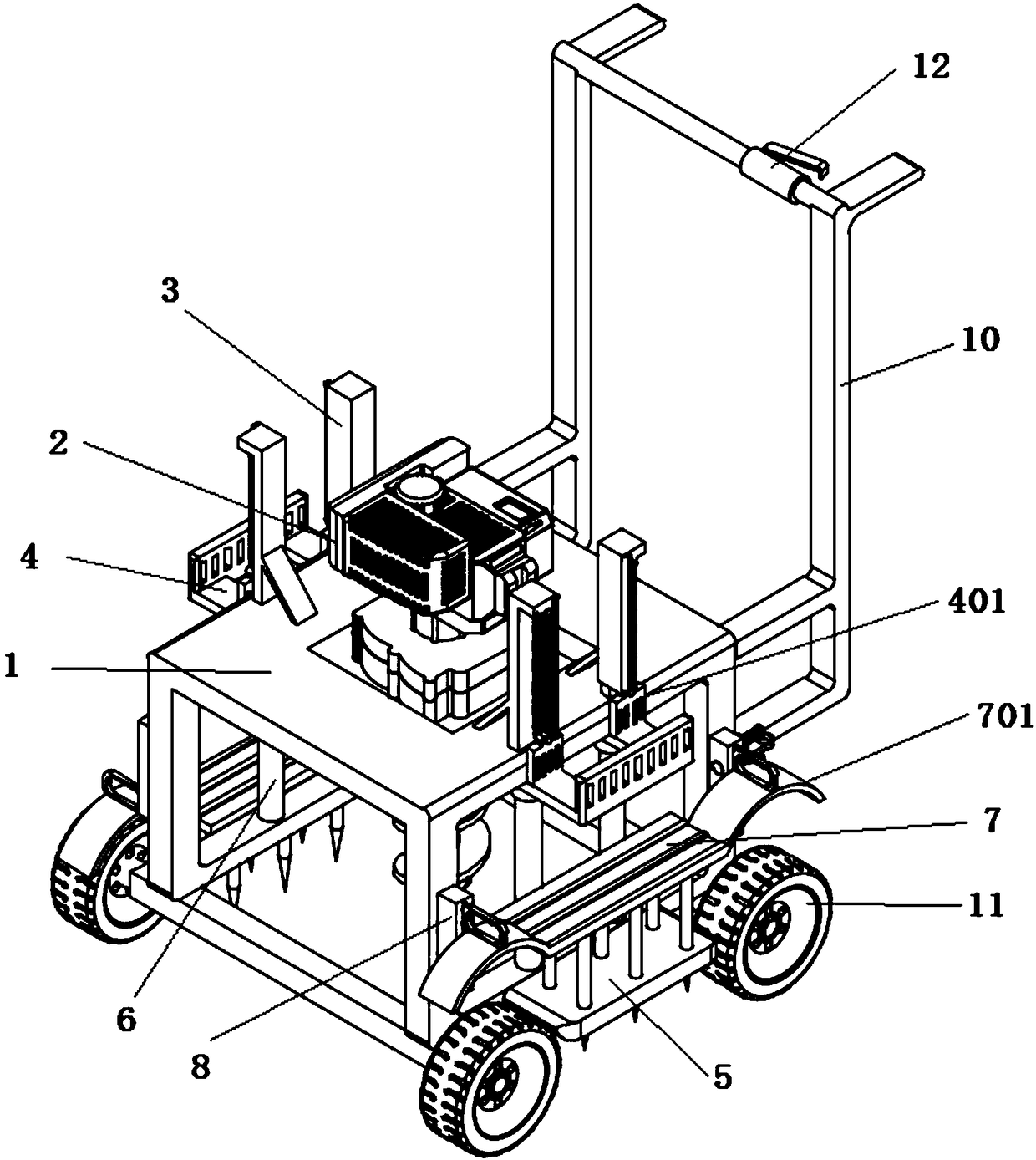

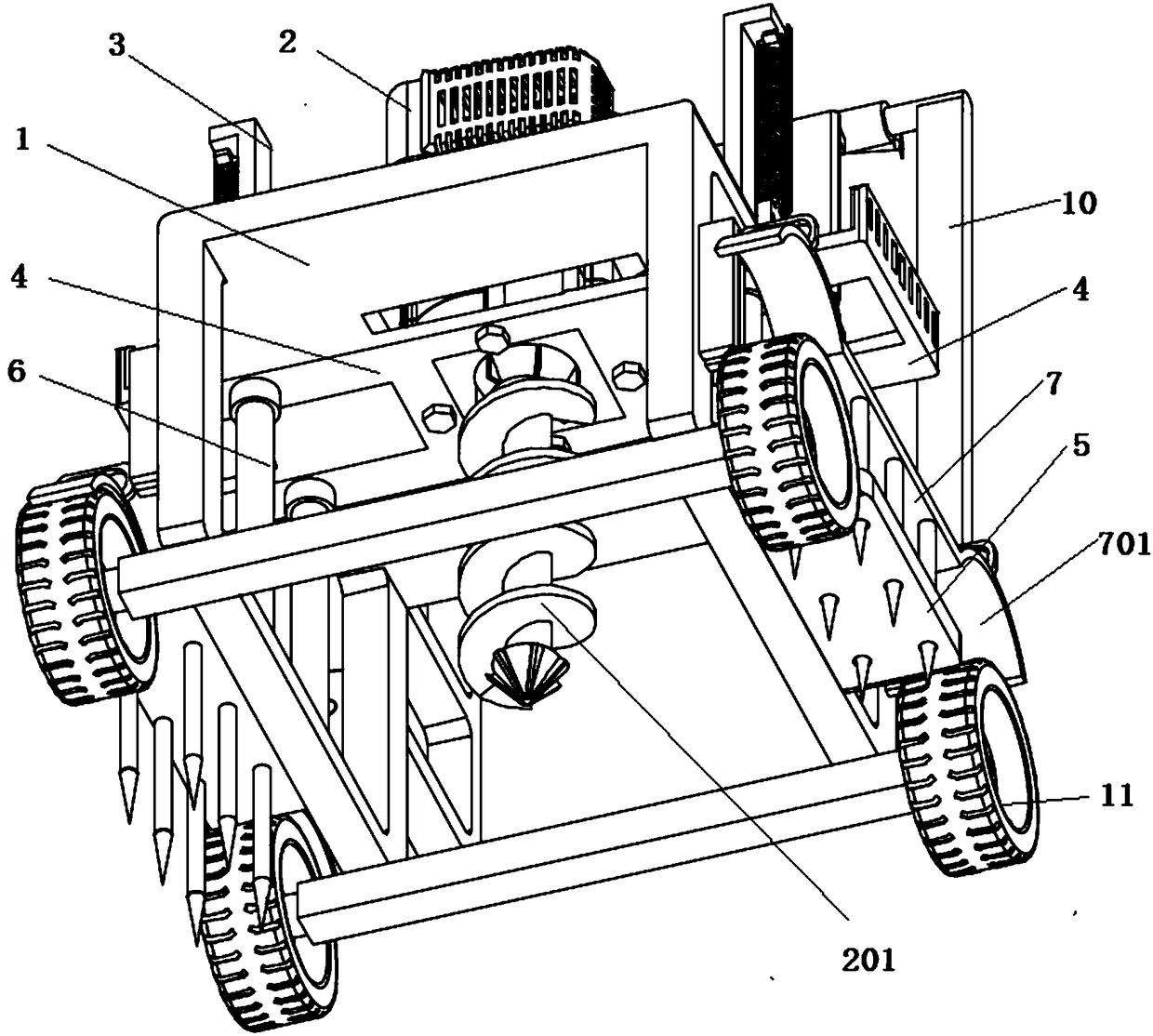

Pit digging equipment for agriculture

InactiveCN108323280AReduce workloadIt is convenient to press down and step on the drilling operationPlantingFurrow making/coveringEngineeringScrew thread

The invention provides pit digging equipment for agriculture. The pit digging equipment comprises a pushing frame, tires and an accelerator clamp, wherein four sliding shaft sleeves are symmetricallyarranged on two support plates of a pedal frame in a penetrated way; two support slide rods are arranged between a support platform and two U-shaped support frames in symmetrical arrangement at the bottom in a supporting way; four sliding shaft sleeves are correspondingly arranged on the four support slide rods in a sleeving way; further, the pedal frame and a gearbox fastened at the top end of the pedal frame through screw threads are glidingly arranged among the four support side rods; a hanging plate is vertically arranged at the top end of each of four support hanging frames in a bent way;a spring hanging ring is hung and welded in the middle position of the bottom of the four hanging plates. Through the arrangement of a positioning pedal, six positioning inserting rods of the positioning pedal pass through an overhead plate and continuously and downwards slide to be finally inserted inside soil at the bottom side of the overhead plate; further, the whole pit digging can be inserted and positioned through the six positioning inserting rods; the forward, backward, leftward and rightward moving during the hole drilling operation of a pit digging equipment body is avoided.

Owner:周玉良

Stamping blanking die with switching mechanism

InactiveCN106890890APrevent savingReduce development costsShaping toolsVehicle componentsSlide plateEngineering

The invention provides a stamping blanking die with a switching mechanism. The stamping blanking die comprises an upper die base, a lower die base, the switching mechanism, a trimming female die and a sliding plate. The lower die base is provided with a trimming male die. The switching mechanism comprises an installation base and an elastic pressing ring. The installation base is connected with the upper die base through a compression spring. The elastic pressing ring is formed by splicing multiple pressing blocks in a strip block shape. The elastic pressing ring is located on the outer ring of the bottom end of the installation base. The trimming female die is fixedly connected with the end face, away from the upper die base, of the installation base, and the sliding plate is in sliding connection with the installation base and located between the installation base and the upper die base. According to the stamping blanking die, no pressing plate structure needs to be designed, the purchasing, machining, lapping-in and assembling machining amount of the whole pressing plate is reduced, the die development cost is reduced, two kinds of side bodies are machined through one die, and machining time and the production cost are saved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Pneumatic hot-press device

ActiveCN102655099APrevent savingImprove alignment accuracySemiconductor/solid-state device manufacturingEngineeringMechanical engineering

The invention discloses a pneumatic hot-press device, comprising a support, wherein a lower thermal press plate is fixed on the support, an upper thermal press plate and a piston cylinder switching plate are respectively arranged above and under the lower thermal press plate, and the upper thermal press plate, the lower thermal press plate and the piston cylinder are sequentially connected through a guide column to form an integrated movement assembly; an upper thermal press head is arranged on the lower surface of the upper thermal press plate; a sliding assembly capable of transversely moving is arranged on the upper surface of the lower thermal press plate, a lower thermal press head is arranged on the sliding assembly, and a fastening assembly is arranged close to the lower thermal press head and is used for locking the lower thermal press head; and the piston cylinder is arranged on the upper surface of the piston cylinder switching plate, an extending shaft of the piston cylinder is connected with the lower surface of the lower thermal press plate, and the lower surface of the piston cylinder switching plate is in contact with a buffering assembly. The pneumatic hot-press device disclosed by the invention has the advantages of balance pressure, quick and uniform heating, high alignment precision and long-term and reliable operation, and is suitable for large-area thermal press stacking between sheets or between sheets and films, or is suitable for complicated work conditions.

Owner:HUAZHONG UNIV OF SCI & TECH

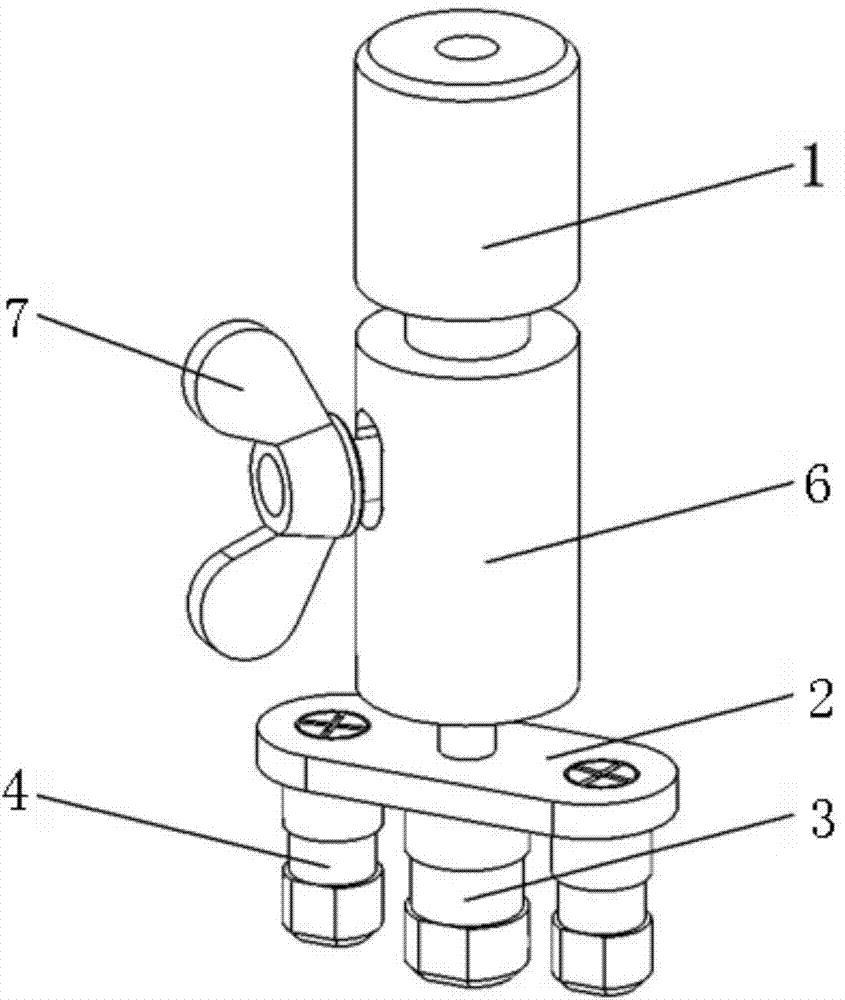

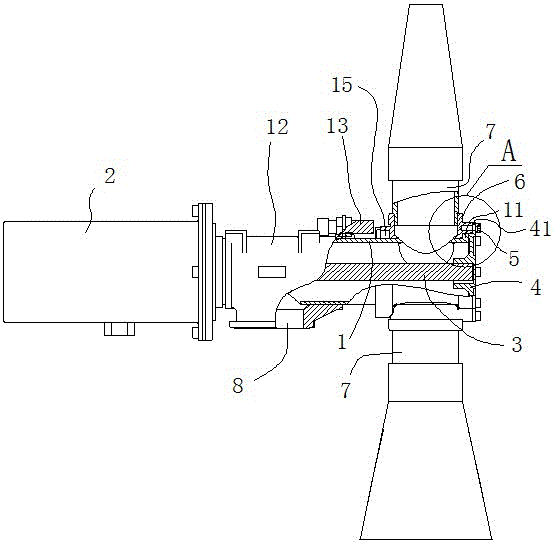

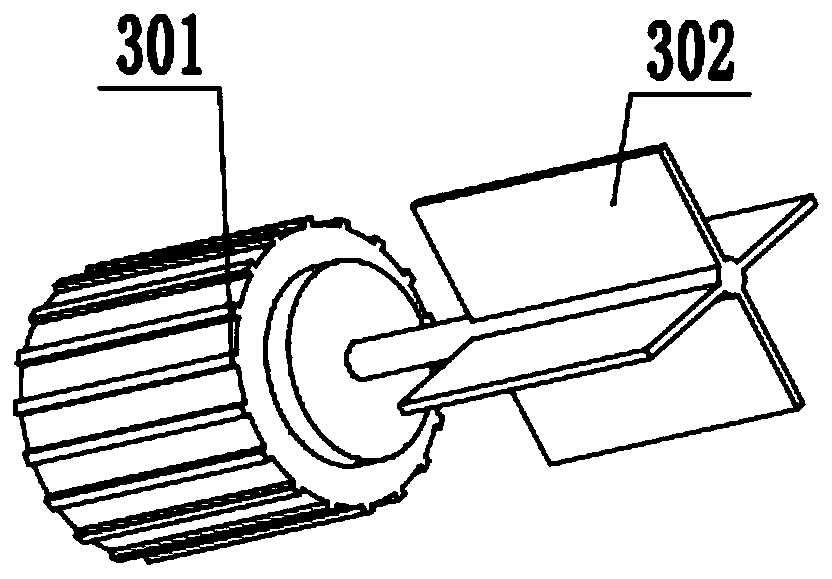

Rotary type multi-nozzle proportional spray head

InactiveCN106493007AShorten the axial lengthPrevent slippageSpray nozzlesLiquid spraying apparatusDrive shaftSpray nozzle

The invention discloses a rotary type multi-nozzle proportional spray head. The rotary type multi-nozzle proportional spray head comprises a water inlet pipe, wherein the rear end of the water inlet pipe is connected with a motor; the motor is in transmission connection with a rotary end cover arranged at the front end port of the water inlet pipe through a transmission shaft arranged in the water inlet pipe; the rotary end cover is provided with a radial extending part; the radial extending part is in transmission connection with a sliding support sleeve arranged on the periphery of the front end part of the water inlet pipe in a sleeving manner through a connecting piece; a plurality of water outlet holes are formed in the pipe wall of the sliding support sleeve; the water outlet holes are connected to nozzles through corresponding guide pipes; a water outlet is formed in the pipe wall of the front end part of the water inlet pipe; the water outlet is communicated with the water outlet hole rotating to the position of the water outlet; a stop step raised along the radial direction is arranged on the port of the water inlet pipe between the radial extending part of the rotary end cover and the sliding support sleeve; and a water inlet is formed in the water inlet pipe between the sliding support sleeve and the motor. According to the rotary type multi-nozzle proportional spray head disclosed by the invention, the external volume can be decreased, the matching precision and processing cost are reduced, and the transmission is smooth and reliable.

Owner:HANGZHOU YUNBO TECH

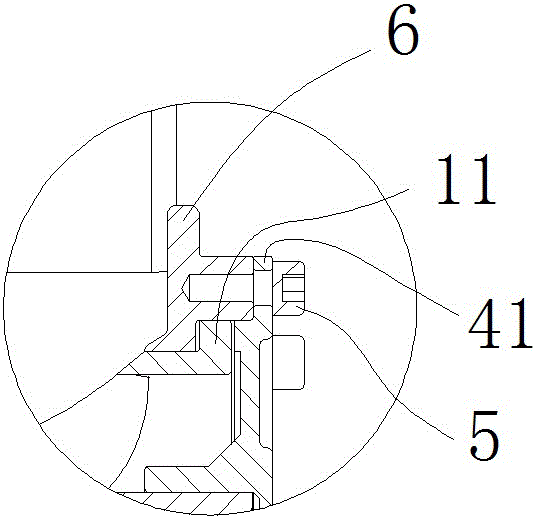

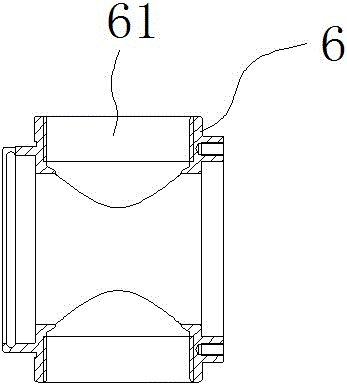

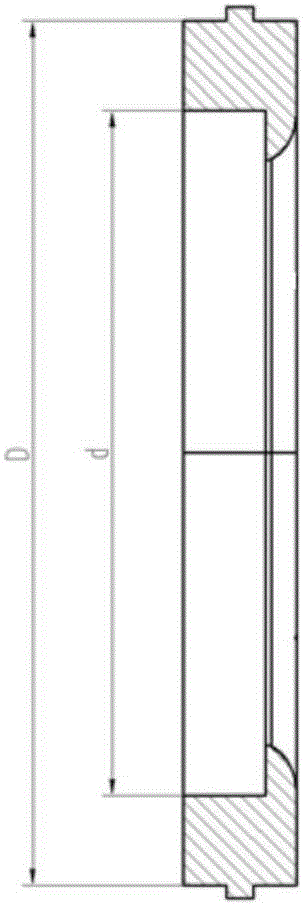

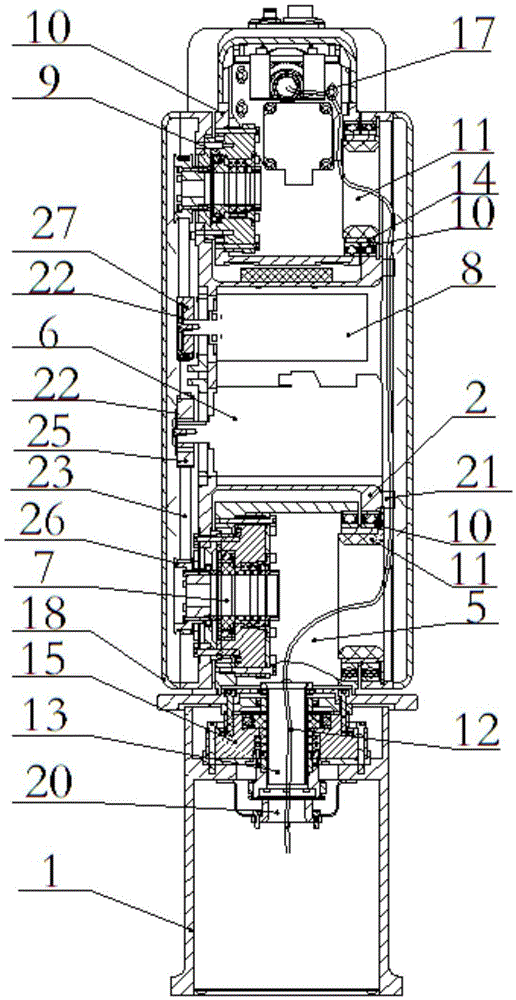

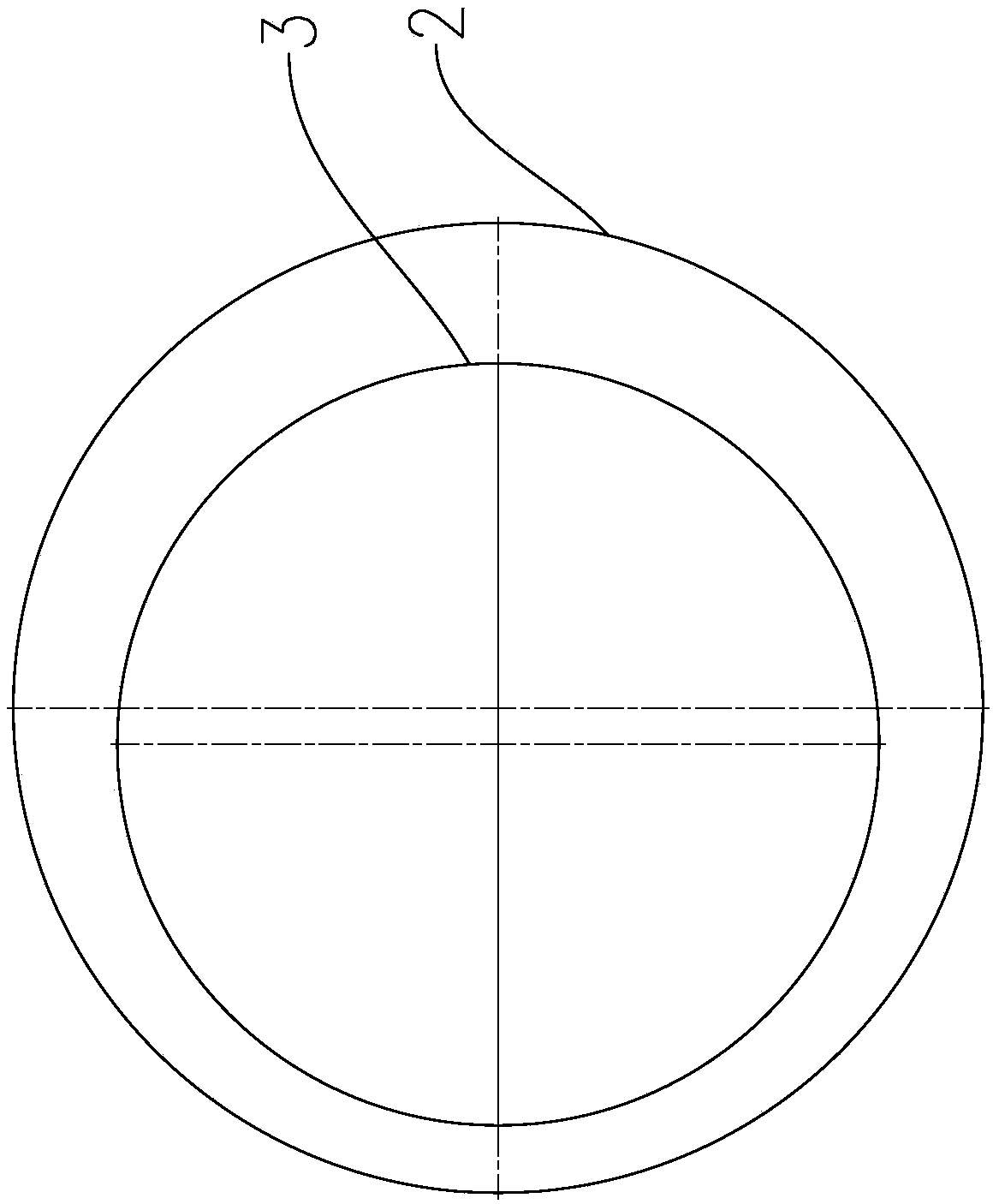

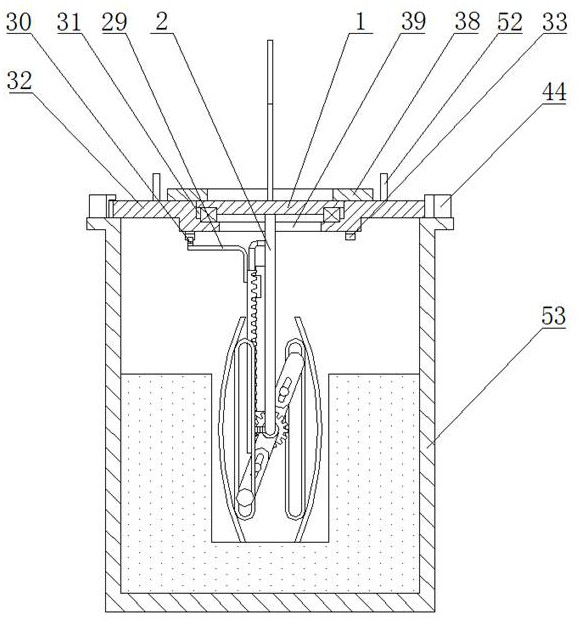

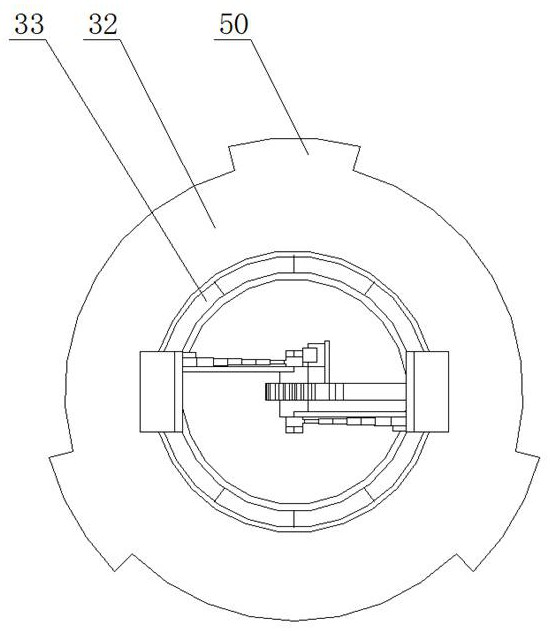

Mouth ring fixed connection structure of multistage centrifugal pump and quick detaching method for mouth ring fixed connection structure

PendingCN106812727AEasy to operateSolve the lack of spacePump componentsRadial flow pumpsEngineeringHydraulic engineering

The invention relates to the technical field of hydraulic engineering design of pump bodies, in particular to a mouth ring fixed connection structure of a multistage centrifugal pump and a quick detaching method for the mouth ring fixed connection structure. The mouth ring fixed connection structure comprises a pump body upper mouth ring and a pump body lower mouth ring and is characterized in that a connecting hole is formed in a connected part of the pump body upper mouth ring and the pump body lower mouth ring; a shoulder screw is connected in the connecting hole; the shoulder screw is used, that is, the upper-half part of the shoulder screw is used for locating and the lower-half part of the shoulder screw is used for connecting. According to the scheme, the problem of insufficient space is solved; a gap is formed in the pump body upper mouth ring and is convenient for operation of mounting a tool; the connecting hole is formed in the connected part of the pump body upper mouth ring and the pump body lower mouth ring; a hollow cylindrical pin is connected in the connecting hole; threads are arranged on the inner side of the hollow cylindrical pin and are connected with an oval fillister head screw; one end of the oval fillister head screw penetrates through the hollow cylindrical pin and is connected with the pump body lower mouth ring; a clearance is further reduced.

Owner:兰州兰泵有限公司

Vibrating screen type edible fungus cleaning device

ActiveCN109198684AImprove cleaning and cleanlinessLow sliding resistanceFood treatmentWater leakageEngineering

The invention provides a vibrating screen type edible fungus cleaning device including a supporting track, a supporting shaft, a positioning ring, a handle, a sliding block, a bearing block fixing plate and a bearing seat, a rectangular top sealing plate is fixedly welded to the right side of the top end of a cleaning box, a box cover is rotationally hinged to the left empty opening of the top sealing plate, the box cover is tightly closed and positioned through two pressing buckles that are symmetrically welded and fixed to the top of the front side wall of the cleaning box, six water spraying pipes are suspended and fixed to the inner wall of the back side of the box cover at equal intervals, five spray heads are vertically downward and threadedly locked to the six water spraying pipes at equal intervals, and the six water spraying pipes are communicated through five middle communicated water guide pipes. By arranging a vibrating screen column, the vibrating screen column can hold the main body member for assembling a vibrating screen cage for performing the vibrating screen washing, and a water leakage port on the bottom plate can ensure that the used cleaning water leaks out toa bottom water collecting cover.

Owner:聊城高新区量子生物医药产业发展有限公司

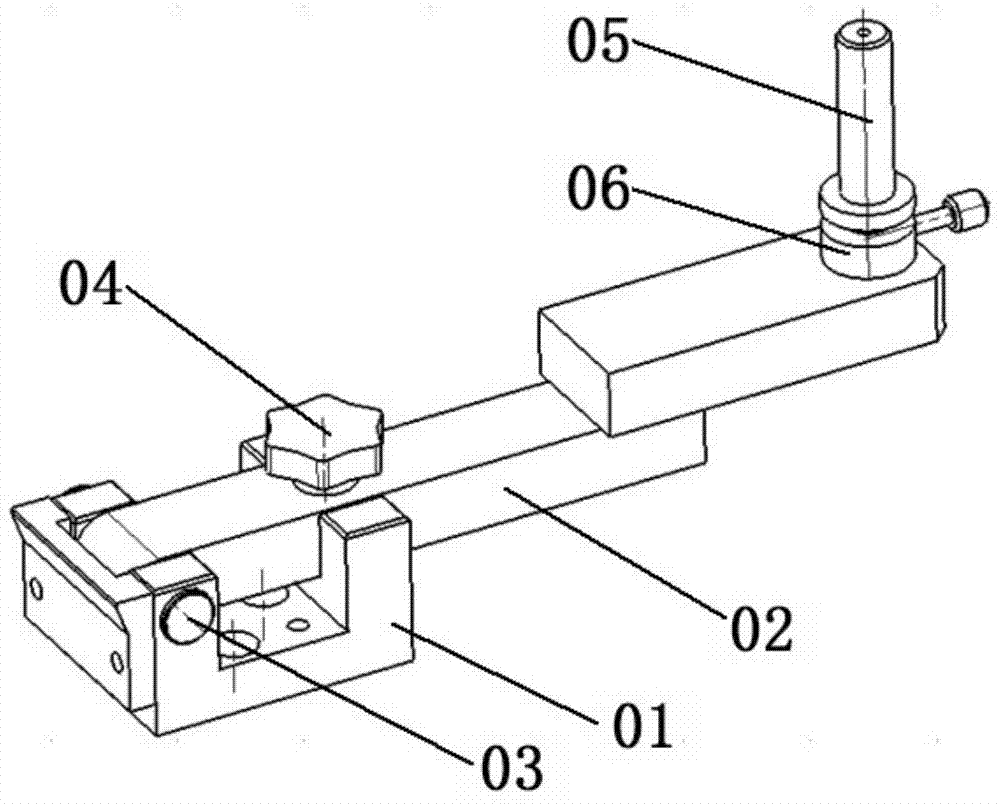

Gauge positioning and clamping device

ActiveCN104015143AGuaranteed stabilityFacilitate the improvement of precisionWork holdersEngineering

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

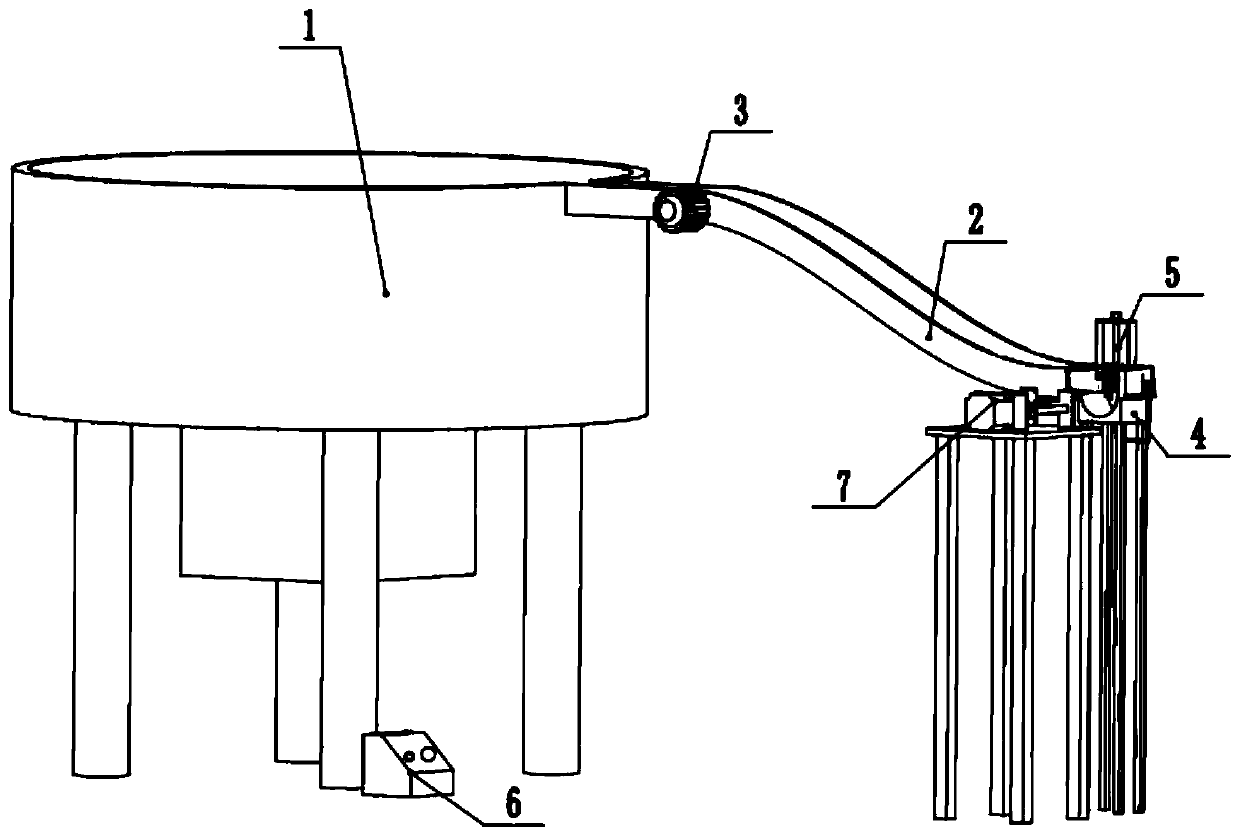

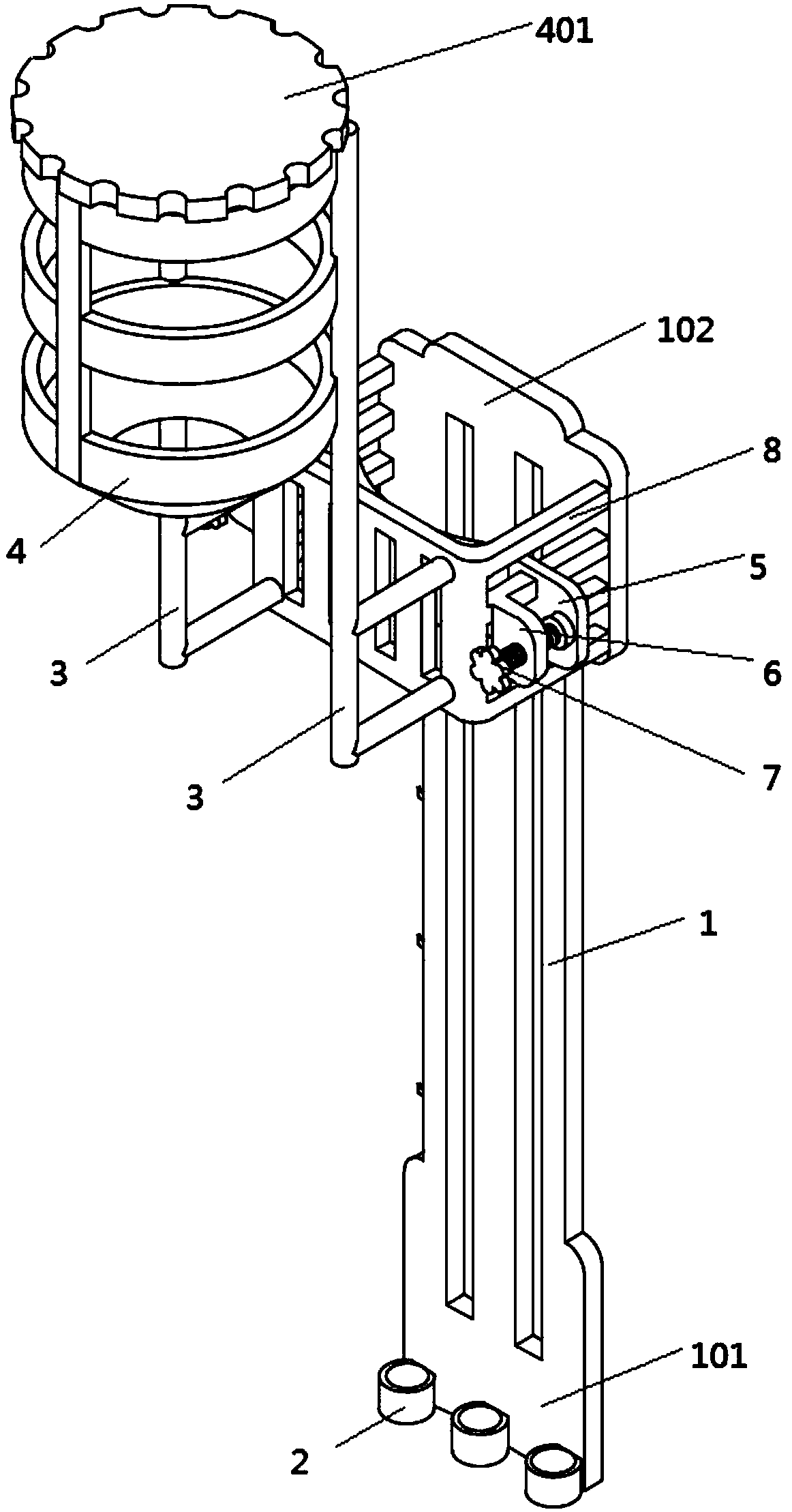

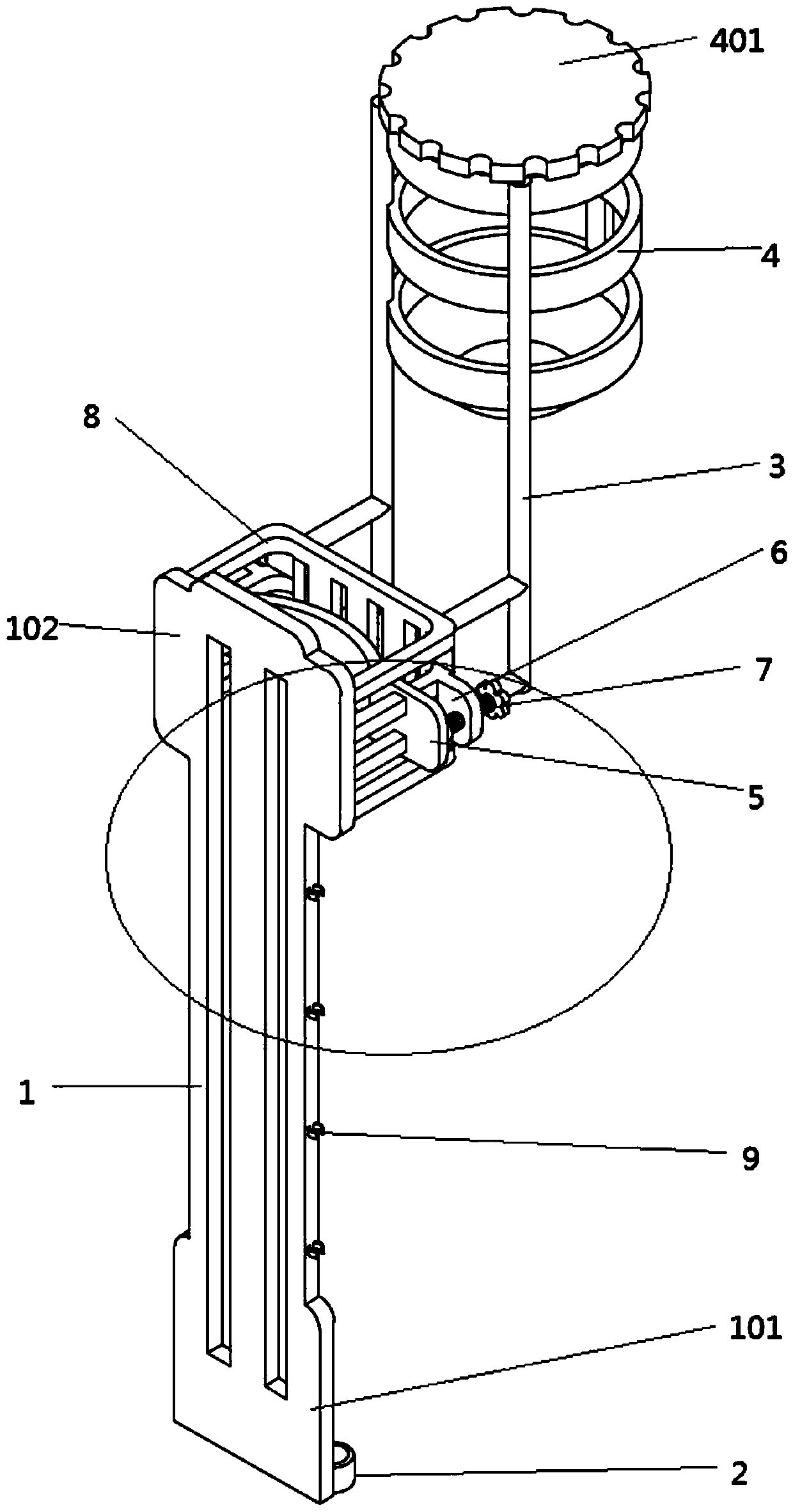

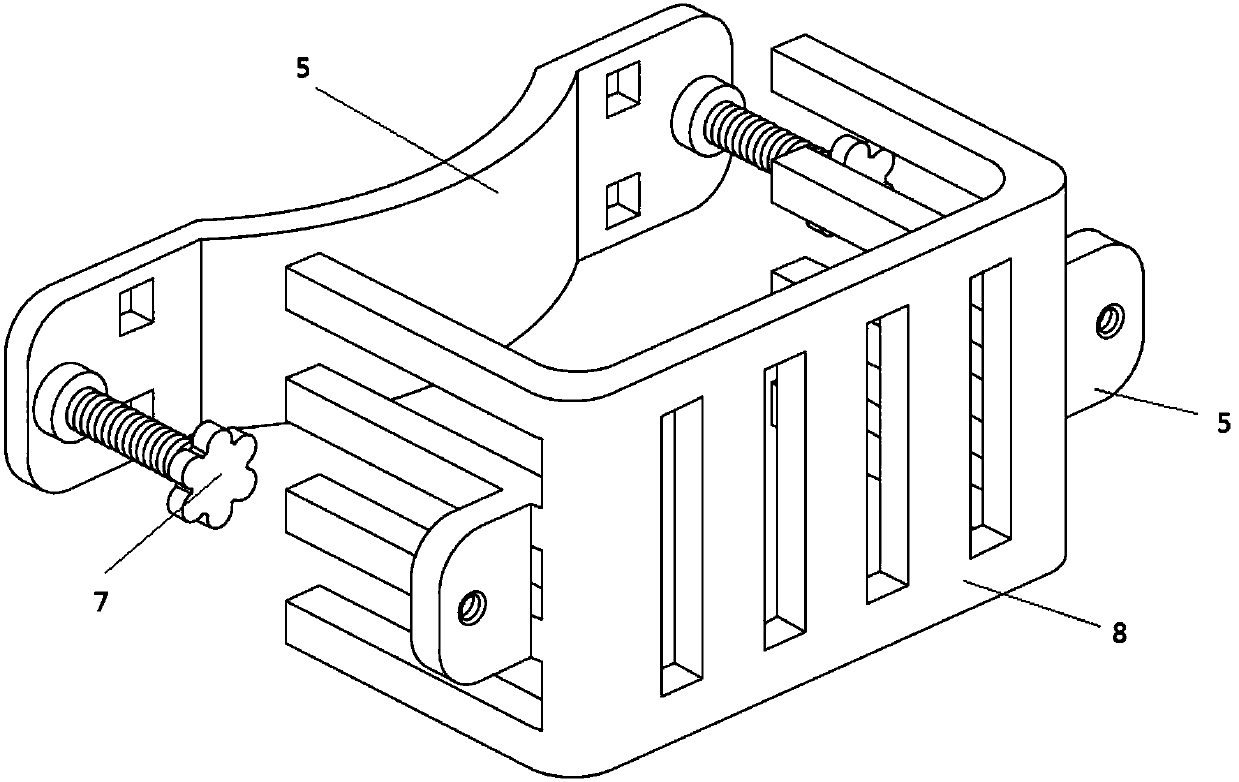

Automatic machining method and device for small PVC short pipes

PendingCN111496915APrevent savingControl footage cutting lengthGrinding carriagesPolishing machinesProcess engineeringAutonomation

The invention discloses an automatic machining method and device for small PVC short pipes, and belong to the field of mechanical automation equipment. The device is composed of a vibration disc, a discharging track, a counting mechanism, a machining base, a positioning hole machining mechanism and a controller, the discharging track is mounted at an outlet of the vibration disc, the counting mechanism is mounted on the discharging track, the machining base is mounted at the tail end of the discharging track, and the positioning hole machining mechanism is mounted on the controller. Accordingto the device, automatic intermittent feeding, automatic positioning hole machining, automatic discharging, pressing and discharging of the short pipes can be achieved through the same power source, cost is saved through sequential linkage, and the failure rate is reduced.

Owner:田桂涛

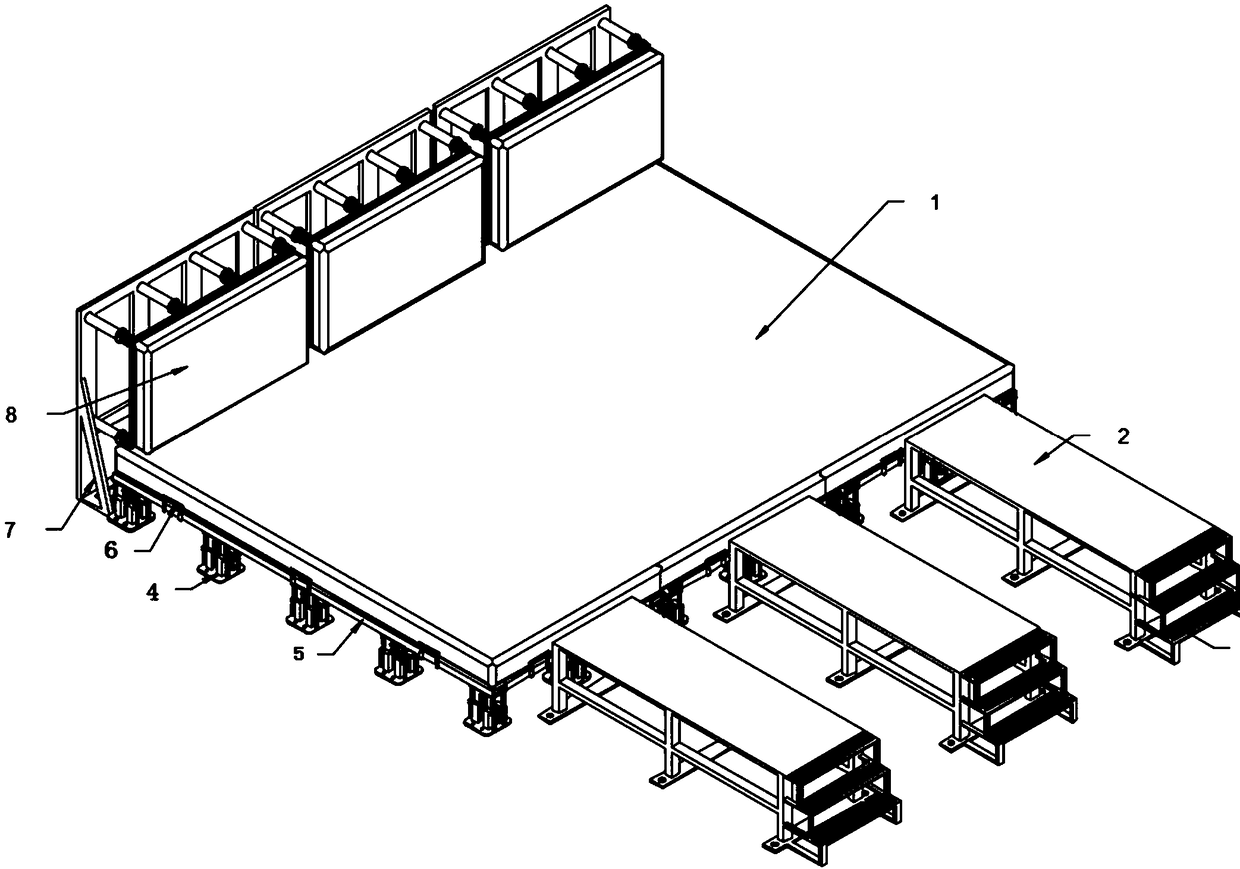

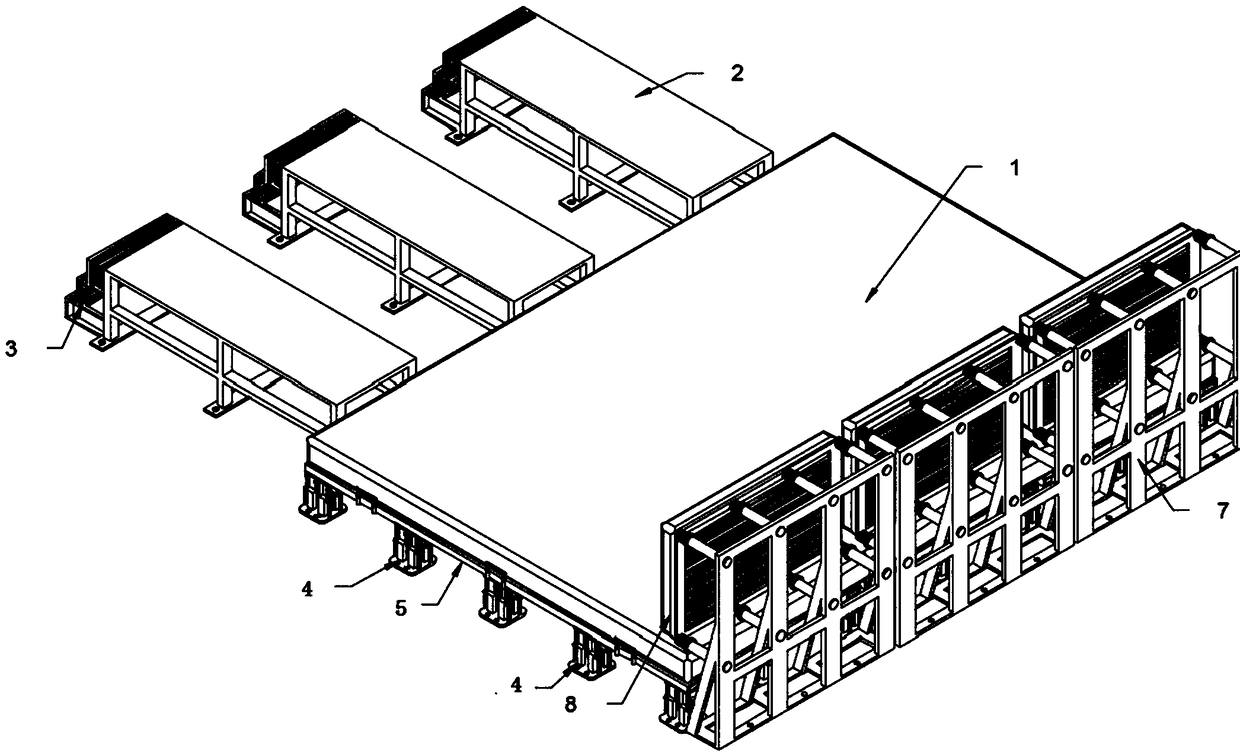

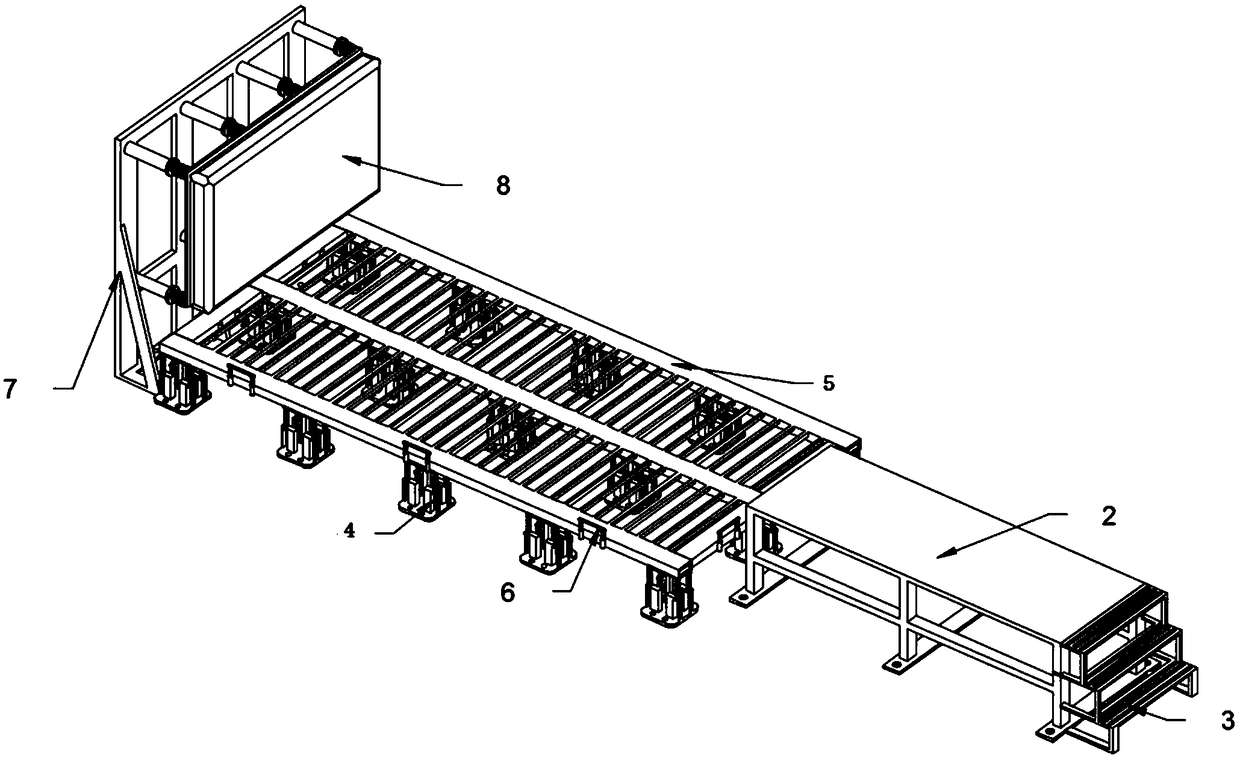

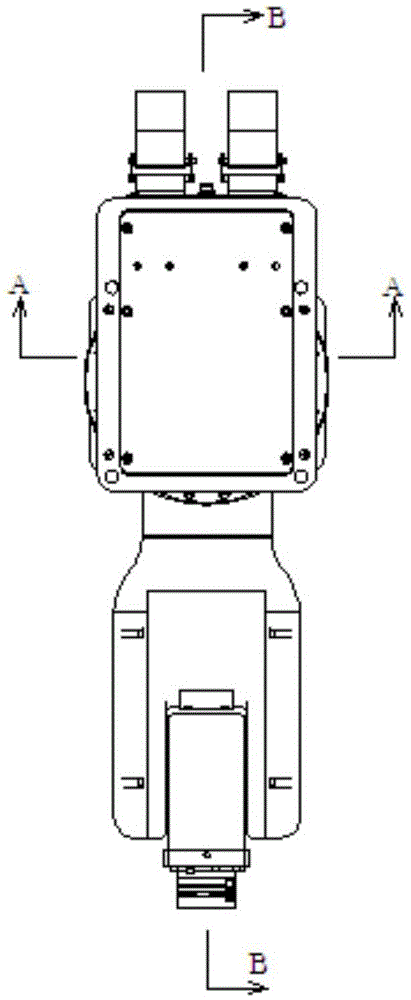

Sports and Kungfu flyer practicing device capable of preventing people from falling damage

InactiveCN108837456ARun-up convenienceGuaranteed training effectJumping apparatusBraced frameFixed frame

The invention provides a sports and Kungfu flyer practicing device capable of preventing people from falling damage. The sports and Kungfu flyer practicing device comprises supporting sliding sleeves,buffer cushions, buffer cushion fixing frameworks and sliding supporting shafts, wherein each supporting bed frame is formed by welding and combining of three supporting square pipes which are horizontally arrayed in a spaced manner and four horizontal connecting square pipes which are connected to two ends of the three supporting square pipes; a row of horizontal connecting square rods are connected to the inner part of every two interval empty grooves between the three supporting square pipes in an arraying manner; each supporting top frame is formed by jointly combining and welding of a rectangular positioning frame at the bottom of the supporting top frame, a supporting framework which is vertically supported to the top end of a rear side fixing plate of the rectangular positioning frame and four reinforcing and supporting plates which are obliquely connected between the supporting framework and the rectangular positioning frame in the arraying manner; every two supporting slidingsleeves are arranged on each of four vertical supporting plates of each supporting frame in a spaced manner in an up-and-down supporting manner. According to the sports and Kungfu flyer practicing device disclosed by the invention, blocking frames are arranged, and the blocking frames which are arranged in a square along the three supporting bed frames can limit and enclose a high jump cushion, so that the phenomenon that the high jump cushion moves from left to right at the top ends of the supporting bed frames can be avoided.

Owner:宋成梅

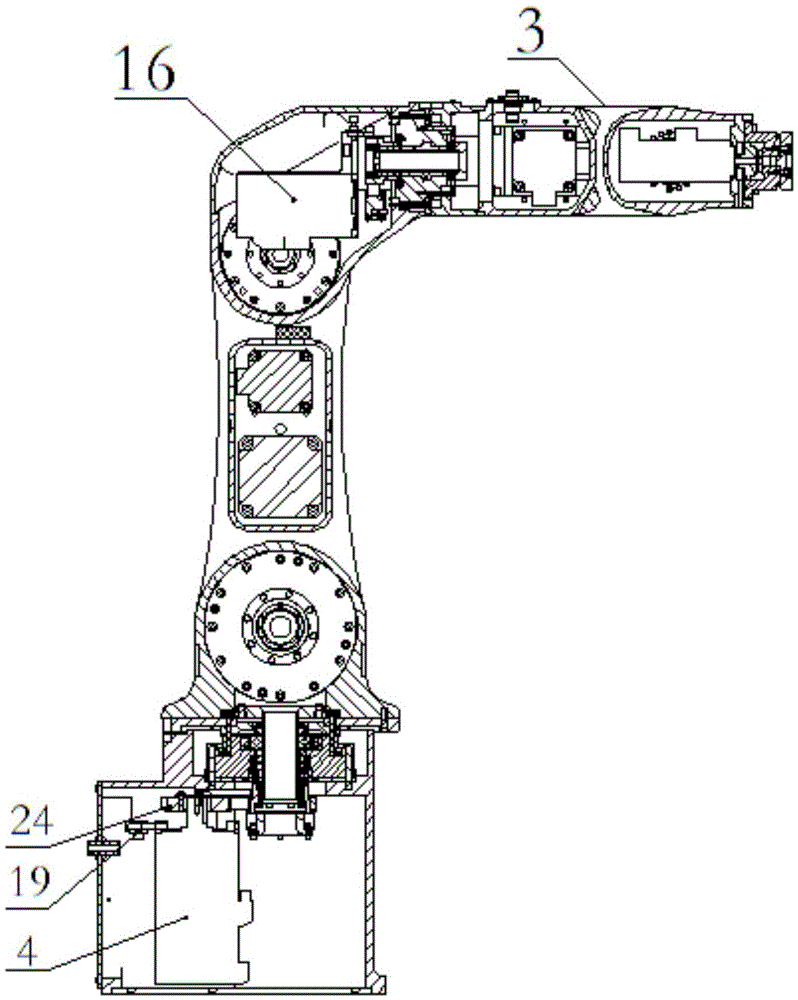

Small-load industrial robot

ActiveCN105619382ACompact structureReduce volumeProgramme-controlled manipulatorArmsReducerControl theory

The invention relates to a small-load industrial robot which comprises a base, a big arm and a small arm. A second servo motor and a third servo motor are mounted in the big arm side by side, bearings are mounted in the other side of the big arm which is provided with a second speed reducer and a third speed reducer, supporting sleeves are mounted on inner rings of the bearings, and cables penetrate through the supporting sleeves to be protected. The second servo motor and the third servo motor are mounted in the big arm side by side, so that the internal structure of the big arm is compact, and the robot is small in size, compact in structure and low in weight. The bearings are mounted in the other side of the big arm which is provided with the second speed reducer and the third speed reducer, so that the requirements for the high precision and the high speed of the robot are met; meanwhile, the bearing capacity of the robot is greatly improved, and stability of the robot is substantially improved. The supporting sleeves are mounted on the inner rings of the bearings, and the cables penetrate through the supporting sleeves to be protected, so that abrasion of the cables is substantially lowered, and the internal structure compactness of the robot is further improved.

Owner:CHONQING HUASHU ROBOT CO LTD

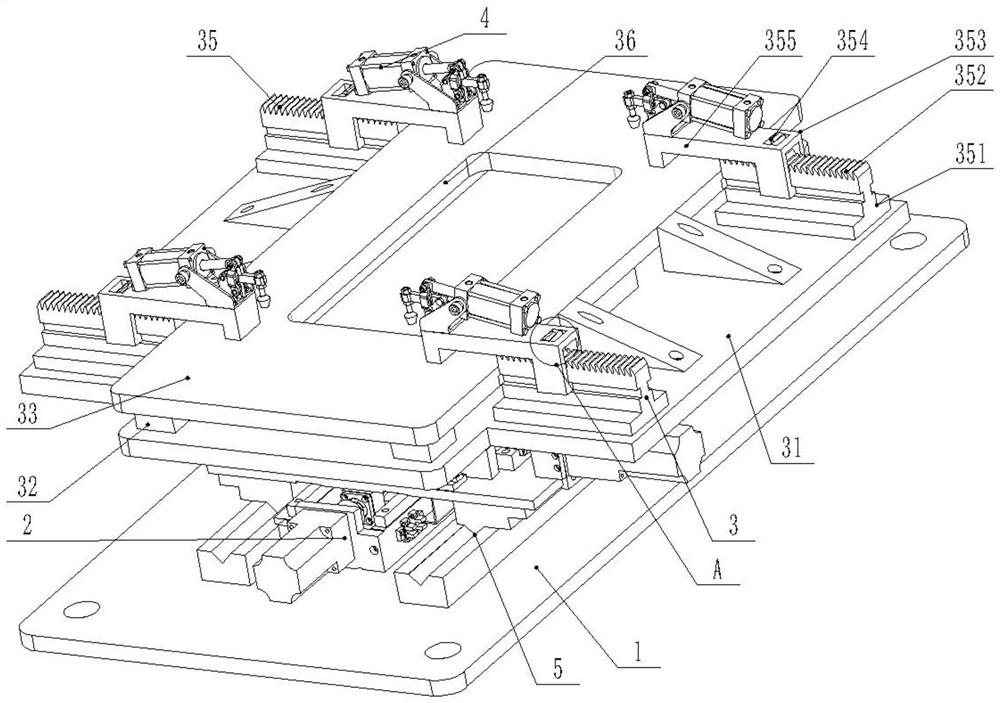

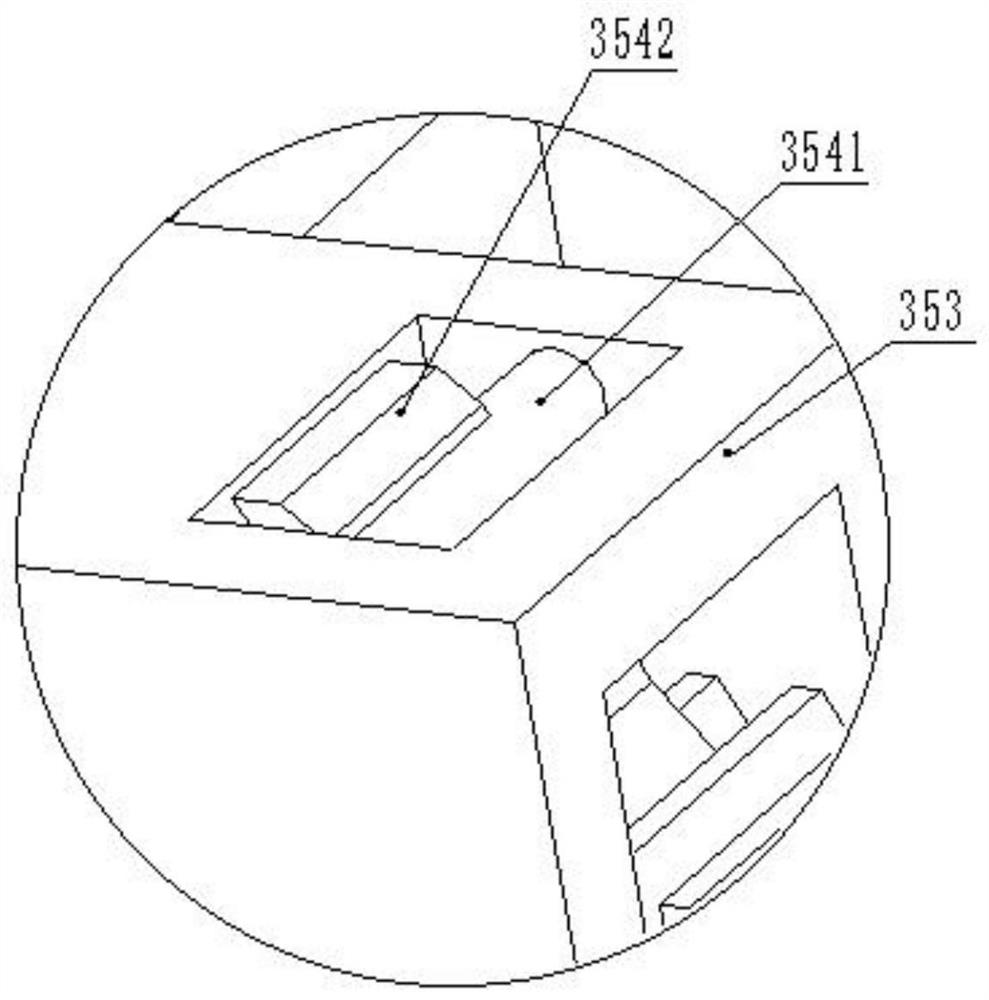

Copper bar machining clamp

ActiveCN112355688AGuaranteed normal processingPrevent savingWork clamping meansMetal working apparatusMachiningManufacturing engineering

The invention relates to a copper bar machining clamp, and belongs to the technical field of copper bar machining equipment. A horizontal adjusting mechanism is installed on a base, a clamping limiting mechanism used for limiting a copper bar in the horizontal direction is installed on the horizontal adjusting mechanism, and a pressing mechanism used for pressing the copper bar is arranged on theclamping limiting mechanism. According to the copper bar machining clamp, the position of the copper bar can be adaptively adjusted by arranging the horizontal adjusting mechanism, and the adjustmentof a machining hole position is carried out under the condition that a machining center is not changed; the clamping limiting mechanism is arranged, the copper bars of different types are horizontallylimited and fixed through the clamping limiting mechanism, and the single clamp is used for machining the copper bars of multiple types; the pressing mechanism is arranged, the copper bars are pressed through the pressing mechanism, and the copper bars are prevented from moving; and the pressing mechanism is installed on the clamping limiting mechanism, the limiting end of the clamping limiting mechanism and the pressing end of the pressing mechanism move relatively, and then the fixing stability is guaranteed.

Owner:中色创新研究院(天津)有限公司

Wearable multifunctional infusion rack body

The invention provides a wearable multifunctional infusion rack body. The wearable multifunctional infusion rack body comprises an infusion bottle rack, a bottle rack top cover, a clamping plate, positioning lug plates, locking bolts and infusion pipe clamping rings; each positioning lug plate is supported outwards and welded to two square supporting rods in the middles of the left and right sidesof the positioning lug plate, and threaded holes run through and are formed in the middles of the two positioning lug plates; two square sliding holes symmetrically run through and are formed in supporting lug plates at the left and right sides of the clamping plate, the four square sliding holes correspondingly and slidingly sleeve the four square supporting rods in the middles of the left and right sides of the positioning lug plates, and then the clamping plate is slidingly arranged in an arm sleeve; the locking bolts penetrate through the middle threaded holes of the two positioning lug plates through screw threads and are rotatably connected with the left and right supporting lug plates of the clamping plate through two rotation bases. According to the wearable multifunctional infusion rack body, through arrangement of the clamping plate, the clamping plate can be pushed and abut against the upper arm under tight threaded topping of the two locking bolts, and then the main infusion rack is effectively fixed.

Owner:HUBEI POLYTECHNIC INST

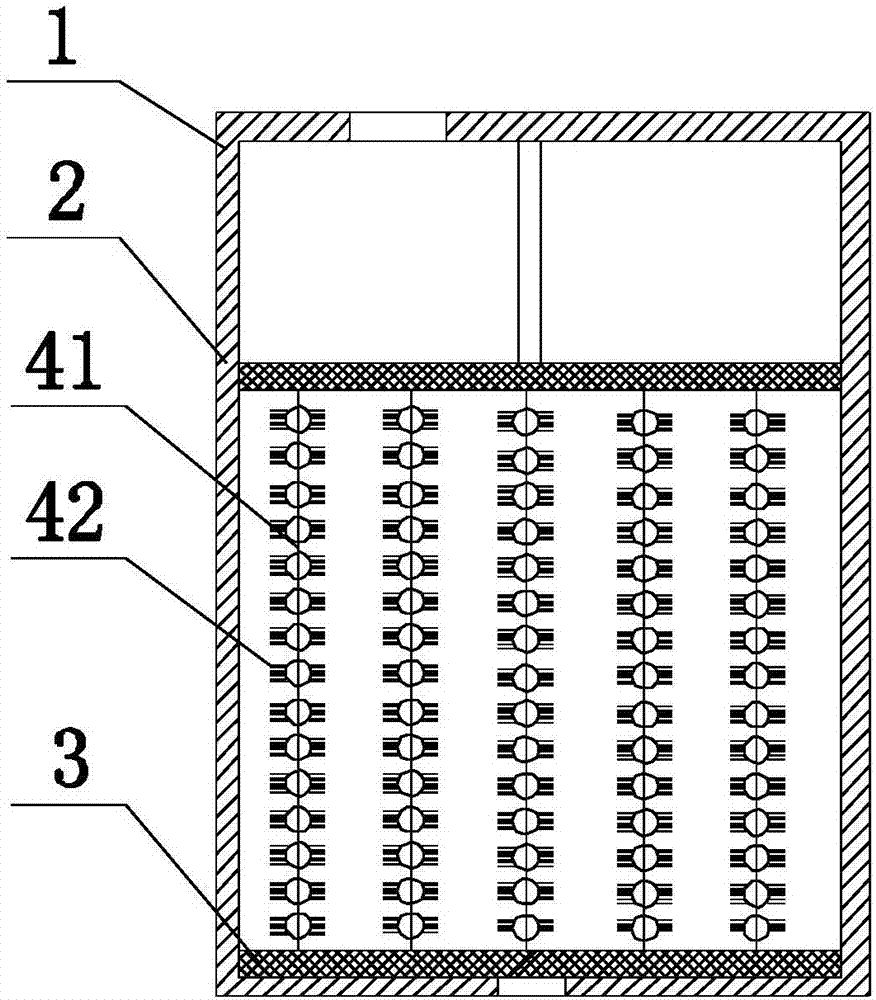

Comet filler filtering equipment

InactiveCN107362595ASimple structural designStructural design is optimized and reasonableLoose filtering material filtersGravity filtersFilter materialFilter effect

The invention discloses comet filler filtering equipment. A filter chamber is arranged in a filter cartridge, the filter chamber has a vertically arranged columnar structure, an upper pressure plate and a lower pressure plate are horizontally arranged in the filter cavity, a first filter hole is formed in the upper pressure plate and a second filter hole is formed in the lower pressure plate, a driving mechanism is connected to the upper pressure plate and the lower pressure plate for driving the upper pressure plate and the lower pressure plate to move relatively, and filter units is located between the upper pressure plate and the lower pressure plate and two ends of the filter unit are separately connected to the upper pressure plate and the lower pressure plate. According to the comet filler filtering equipment of an optimization design, the upper pressure plate and the lower pressure plate press the filter units together during filtration to form a filter structure. A plurality of comet type filter bodies are connected together through a connecting line to prevent movement of the comet type filter bodies between the upper pressure plate and the lower pressure plate, filter materials in filter positions are uniform. In addition, during back washing, the distance from the upper pressure plate to the lower pressure plate is increased to provide a flushing space for the filter materials, so that the filter effect is improved greatly and the back washing is facilitated.

Owner:HEFEI SANFAN WATER TREATMENT EQUIP

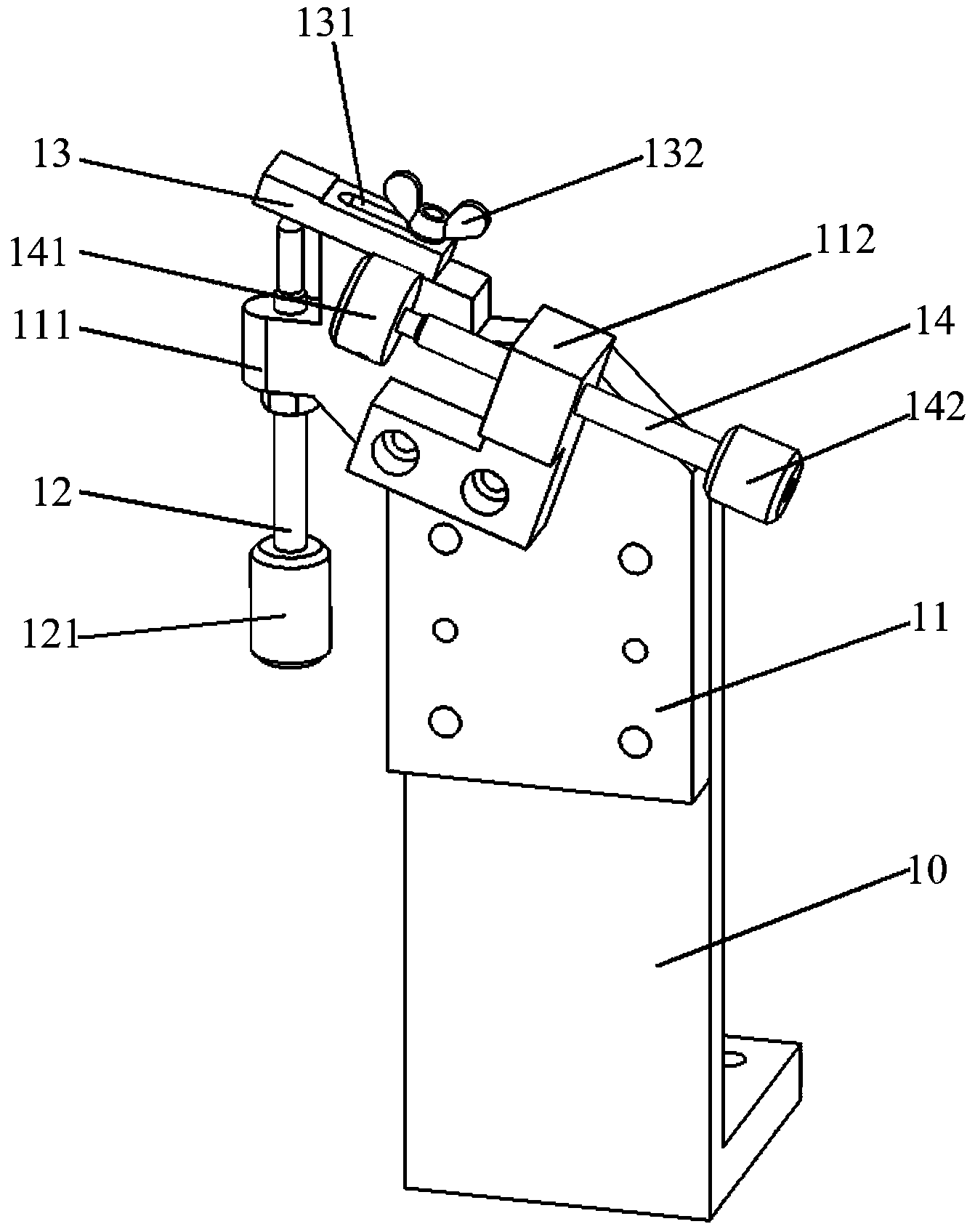

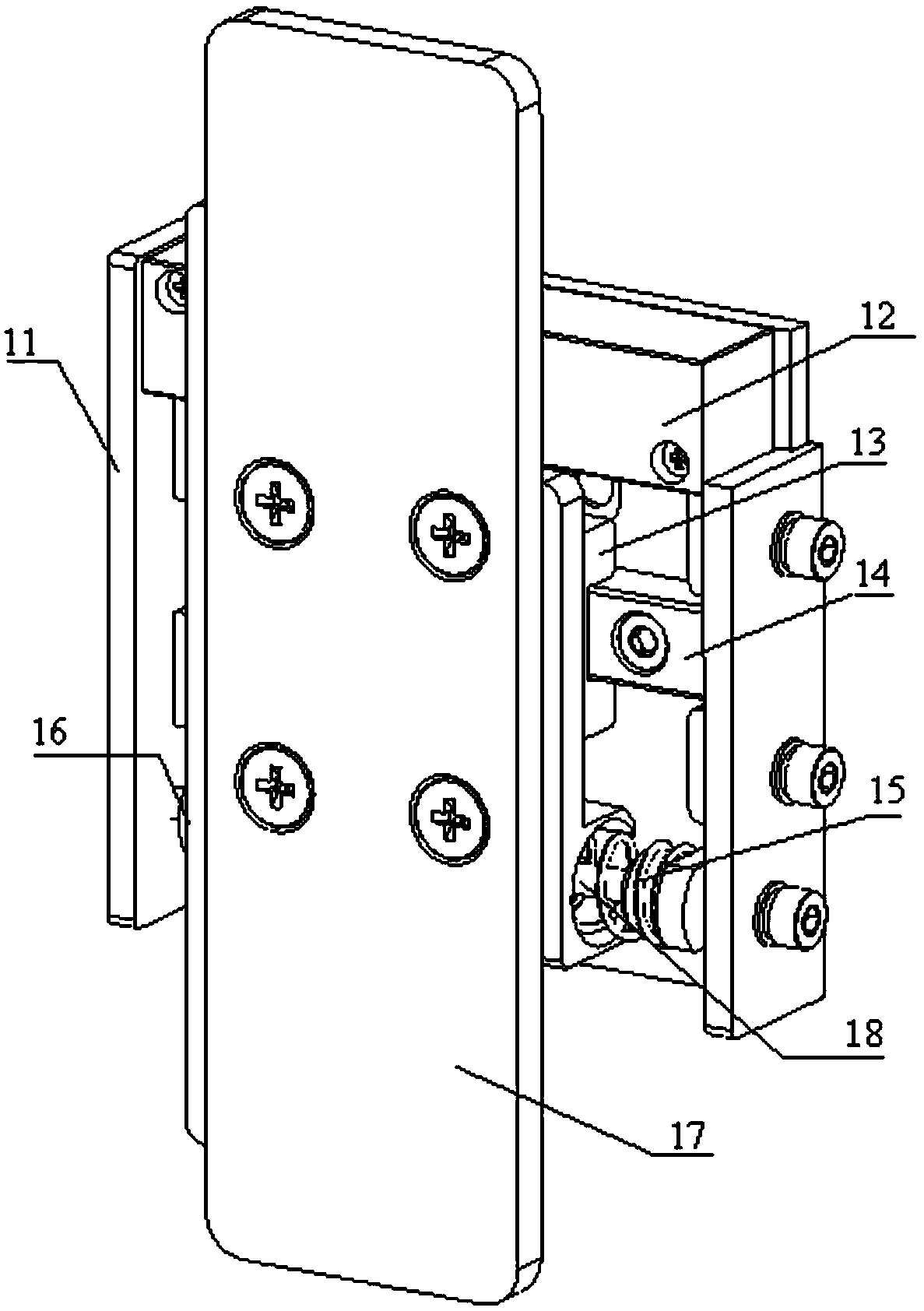

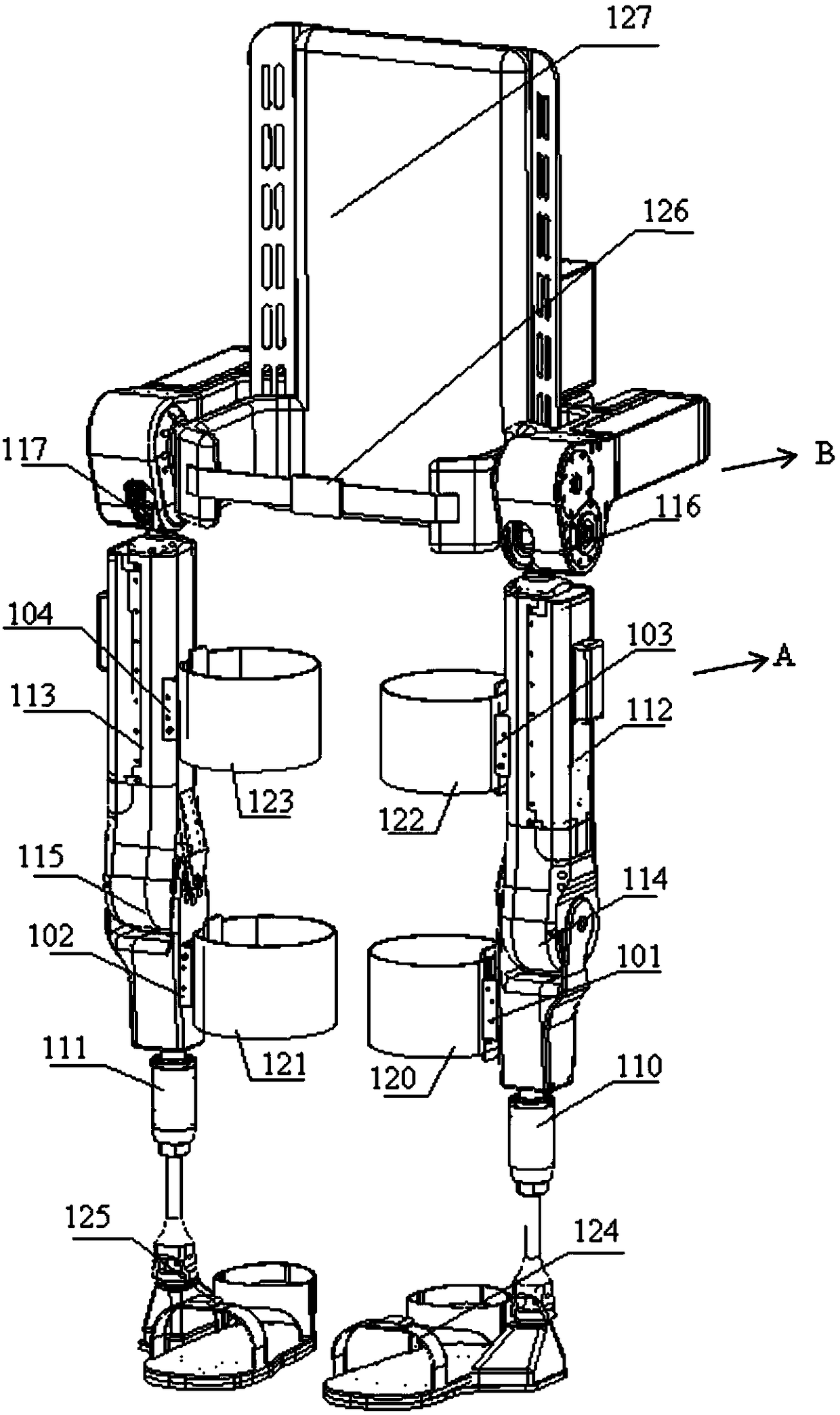

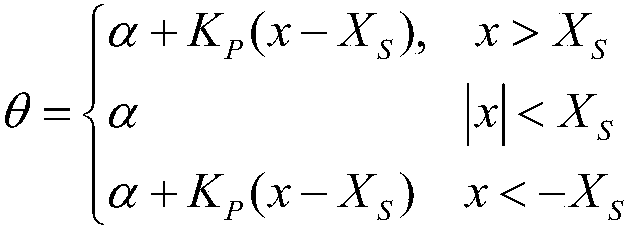

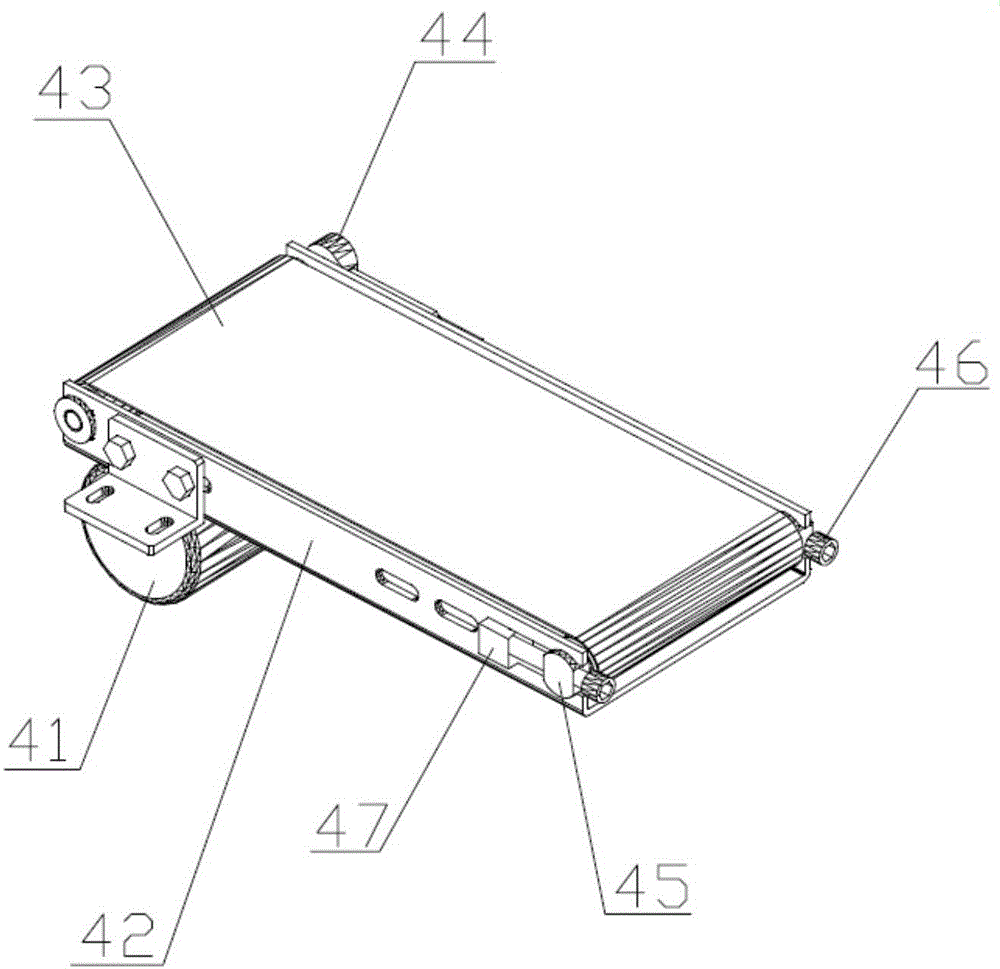

Lower limb exoskeleton robot system and follow-up angle detecting device and control method thereof

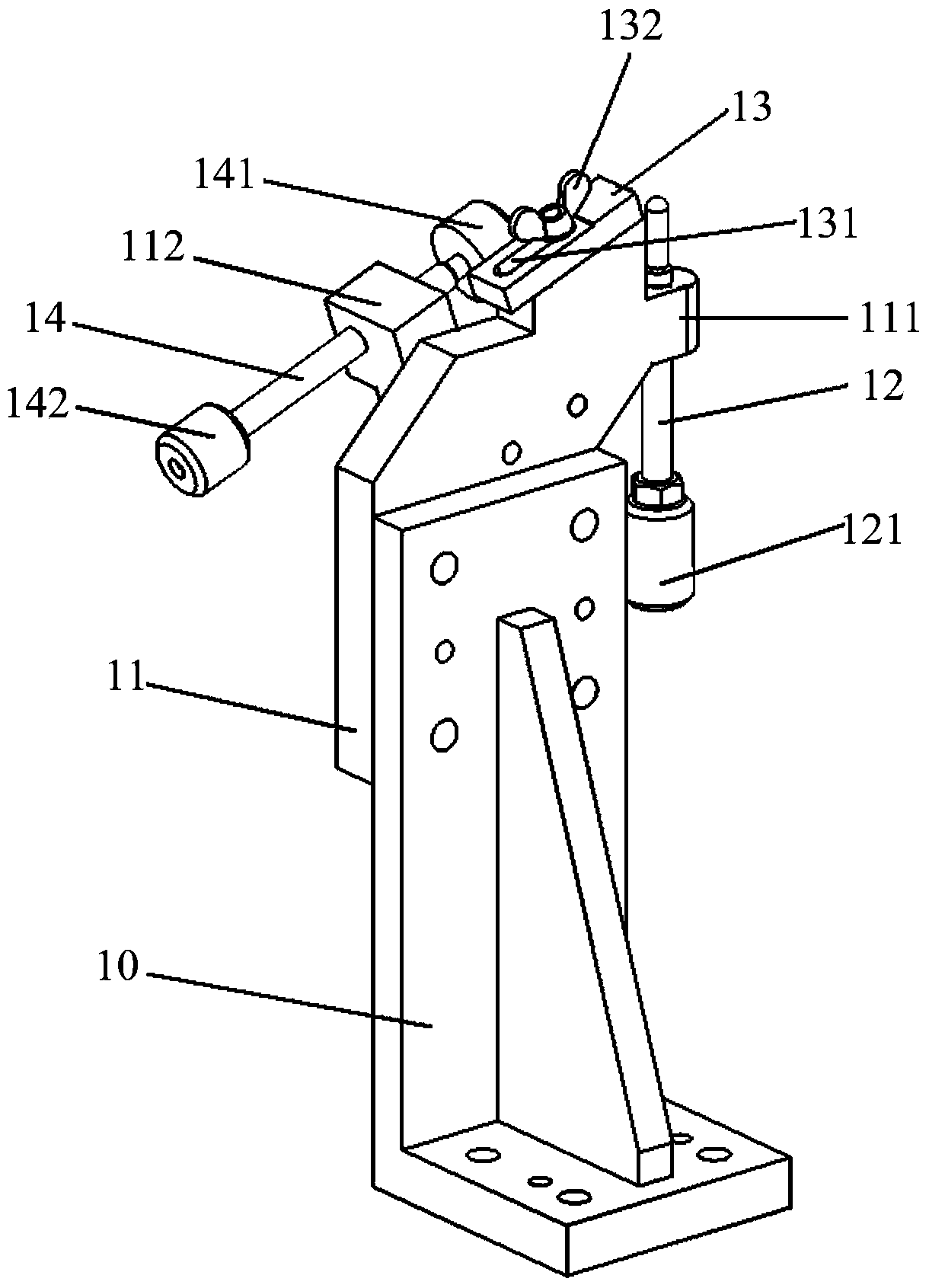

ActiveCN109048868AEasy to connectSimple structureProgramme-controlled manipulatorExoskeleton robotEngineering

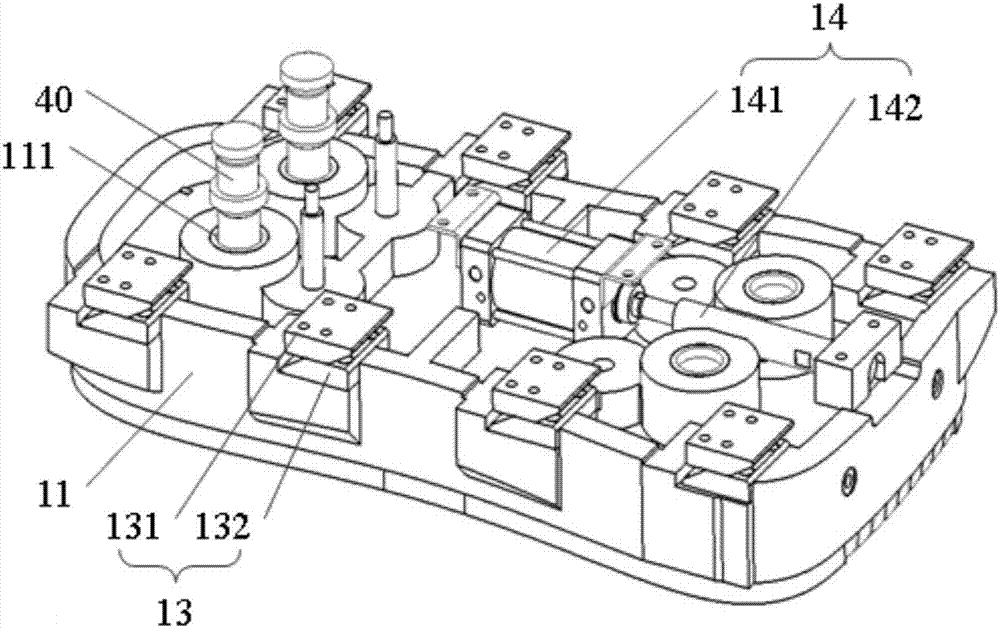

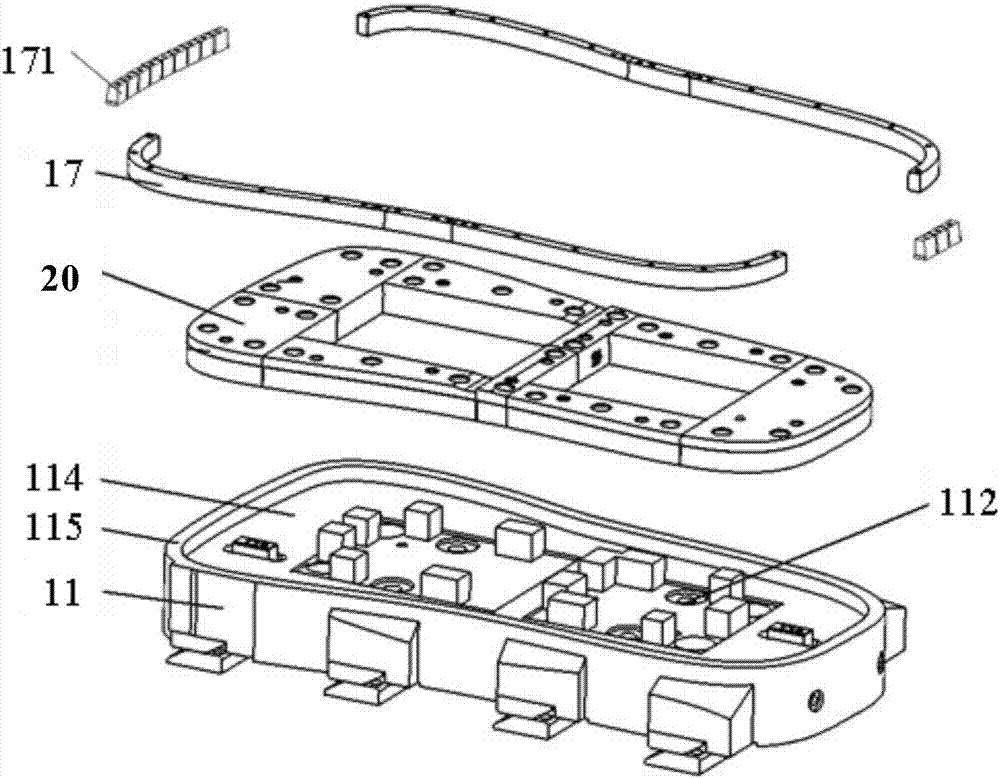

The invention provides a lower limb exoskeleton robot system and a follow-up angle detecting device and a control method thereof, and belongs to the technical field of rehabilitation medical instruments. The device comprises a shell 11, linear displacement sensors 12, sliders 13 and guide rails 14, wherein the guide rails 14 are fixedly arranged on the shell 11, the shell 11 is used for being fixed onto the lower limbs of a lower limb exoskeleton robot, the sliders 13 are used for being fixed onto tying bands of the lower limb exoskeleton robot and slide on the guide rails 14 under the actionof external force, the guide rails 14 extend in the tangent direction of the tying bands, and the linear displacement sensors 12 are used for detecting the displacement of the sliders 13. The device is simple in structure and high in reliability. As the connecting mode of the sliders and the lower limb exoskeleton robot is simple, disassembly and change are facilitated. The device does not have special requirements on the structure of the exoskeleton robot, so that the device has the advantages of wide applying range and low cost.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS +1

Sliding cover structure capable of being locked when being opened and capable of being automatically closed when being pressed

PendingCN111608481ASmooth conversionPrevent savingPassenger spaceBuilding locksEngineeringStructural engineering

The invention relates to a sliding cover structure capable of being locked when being opened and capable of being automatically closed when being pressed. The sliding cover structure comprises a sliding cover support, a sliding cover body capable of linearly sliding on the sliding cover support back and forth, a springback piece arranged between the sliding cover support and the sliding cover body, and a locking and unlocking piece arranged on the sliding cover support. A lug boss capable of being clamped into the locking and unlocking piece is further arranged on the sliding cover body; whenthe lug boss moves along a sliding direction of the sliding cover body until the locking and unlocking piece is opened maximally, the lug boss is locked by the locking and unlocking piece, and the sliding cover body is locked; and when the lug boss continuously moves along an opening direction, the lug boss is unlocked in the locking and unlocking piece, and is sprang back along with the sliding cover body under the action of the springback piece so as to be automatically closed. Compared with the prior art, the sliding cover structure capable of being locked when being opened and capable of being automatically closed when being pressed provided by the invention has a low requirement on an operation space of a sliding cover handle and is convenient to use since the sliding cover structurecan be locked and unlocked through simple pressing.

Owner:SHANGHAI HUAGU VEHICLE IND CO LTD

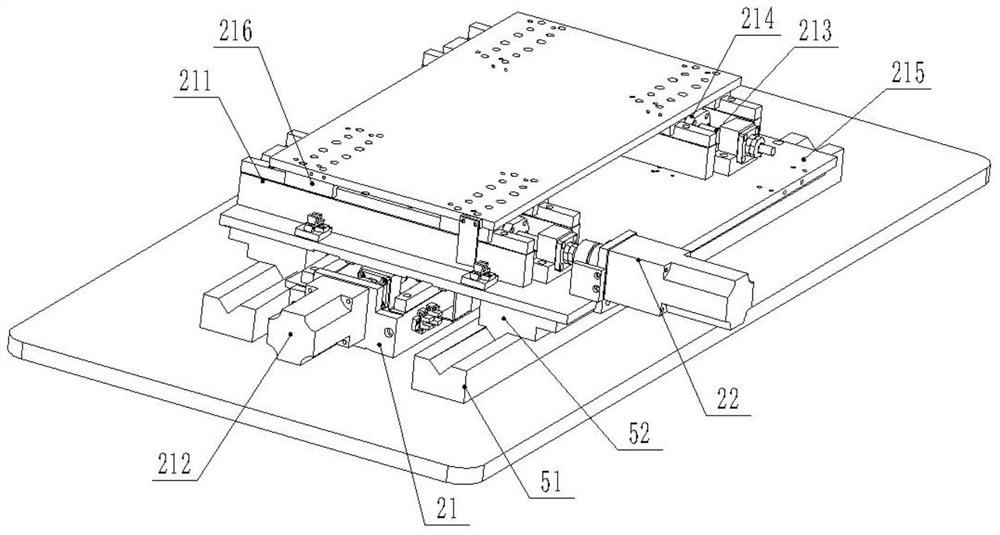

Curved surface workpiece rubberizing equipment and workpiece positioning device thereof

Owner:DONGJUN NEW ENERGY CO LTD

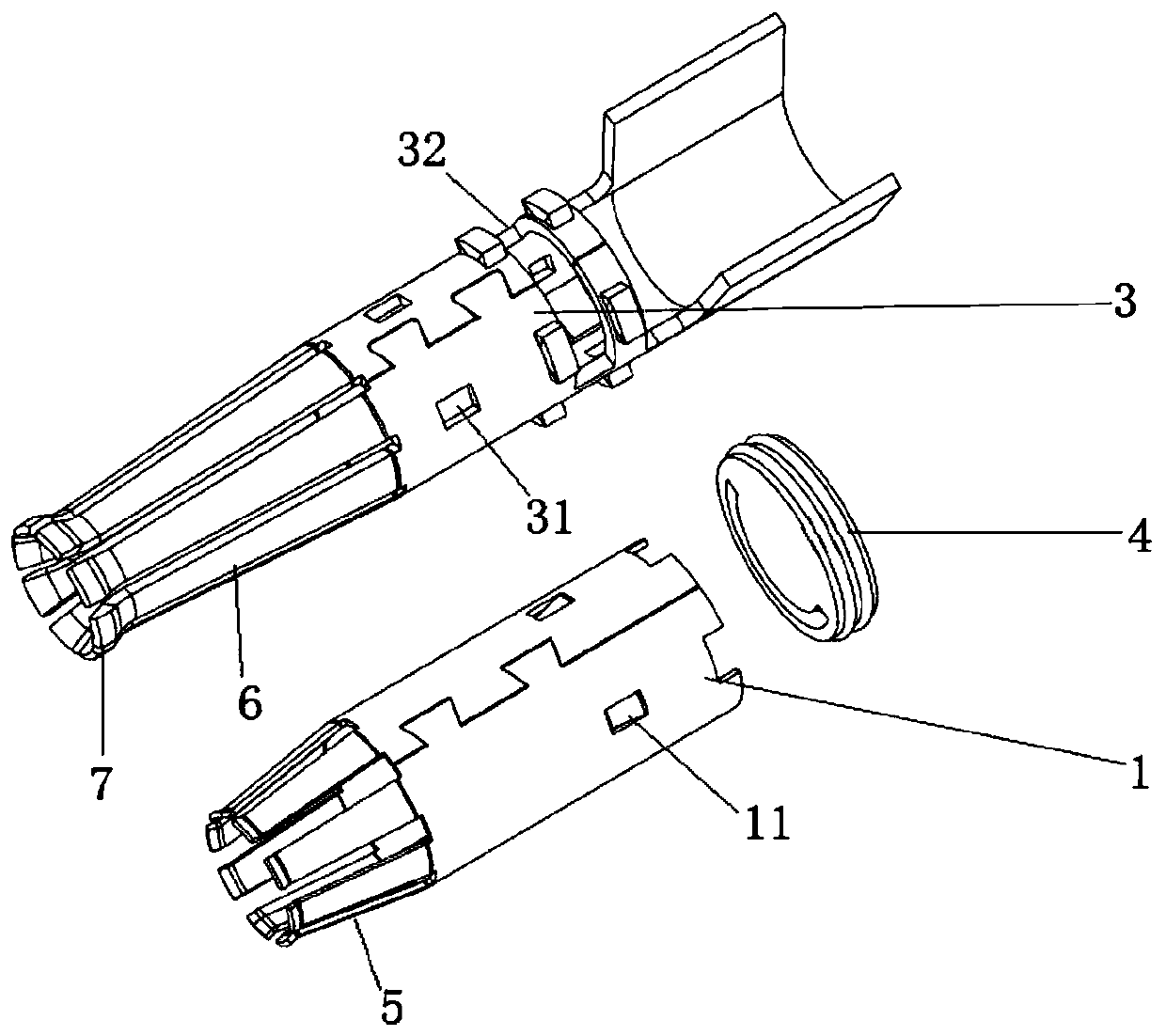

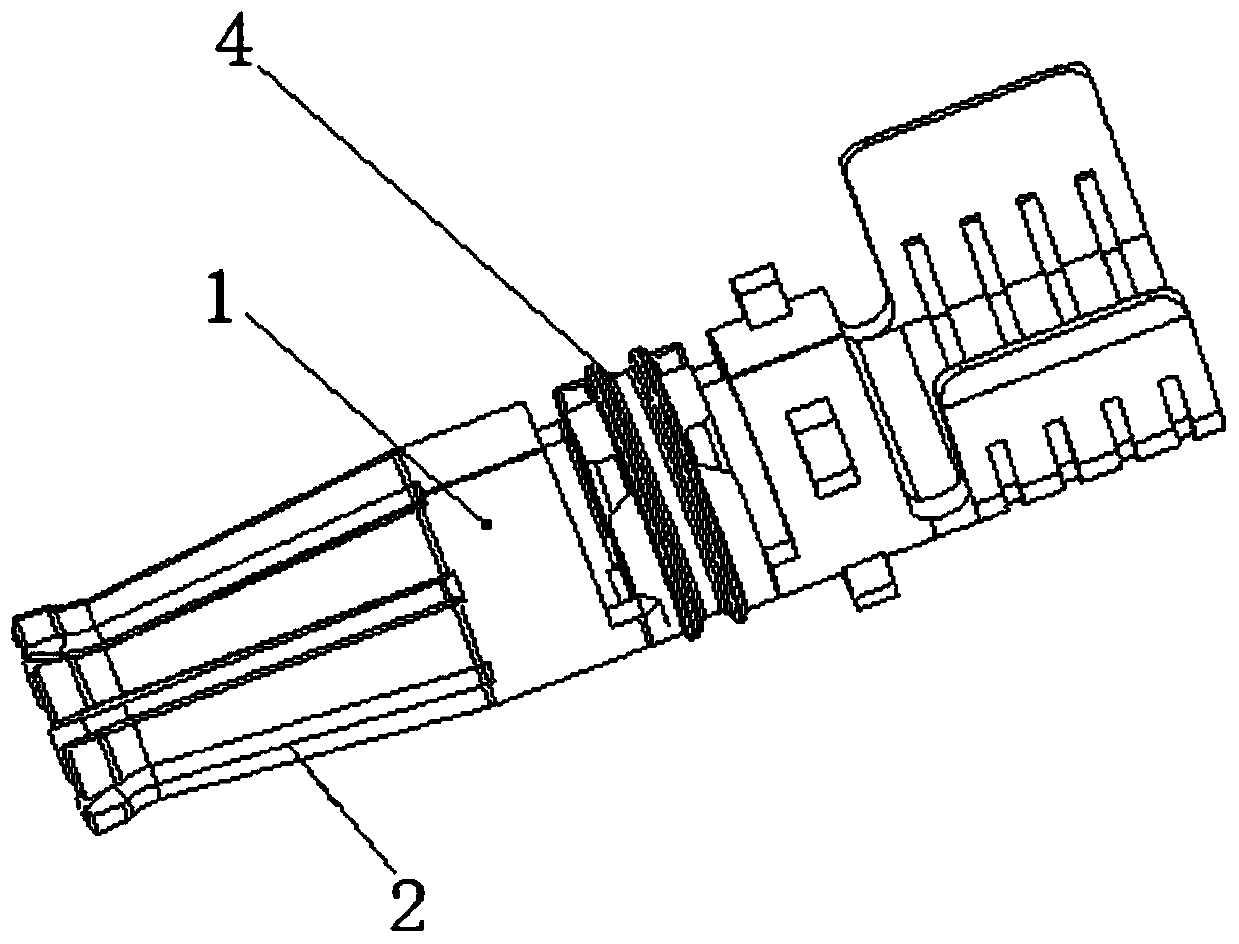

Waterproof terminal of connector

PendingCN110165461AReduce dosageSolve the defect that unilateral sealing cannot be realizedCoupling contact membersCouplings bases/casesRubber matEngineering

The invention belongs to the technical field of connectors and specifically relates to a waterproof terminal of a connector. A front end of a terminal body is connected with a contact arm, and the contact arm is of a conical structure defined by a plurality of strip-shaped bodies, wherein the diameter of the opening end of the conical structure is less than that of the bottom end of the conical structure, and a gap is reserved between every two adjacent strip-shaped bodies. The terminal body is provided with an annular groove used for installing a rubber mat, and the annular groove is providedwith an anti-skid structure to prevent the rubber mat from sliding. The terminal is low in cost and good in sealing performance.

Owner:SHENZHEN CHOGORI TECH CO LTD

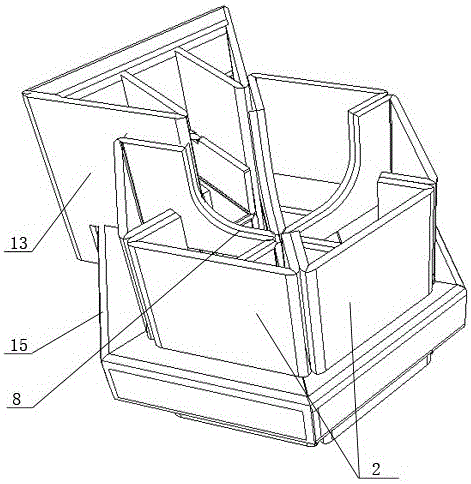

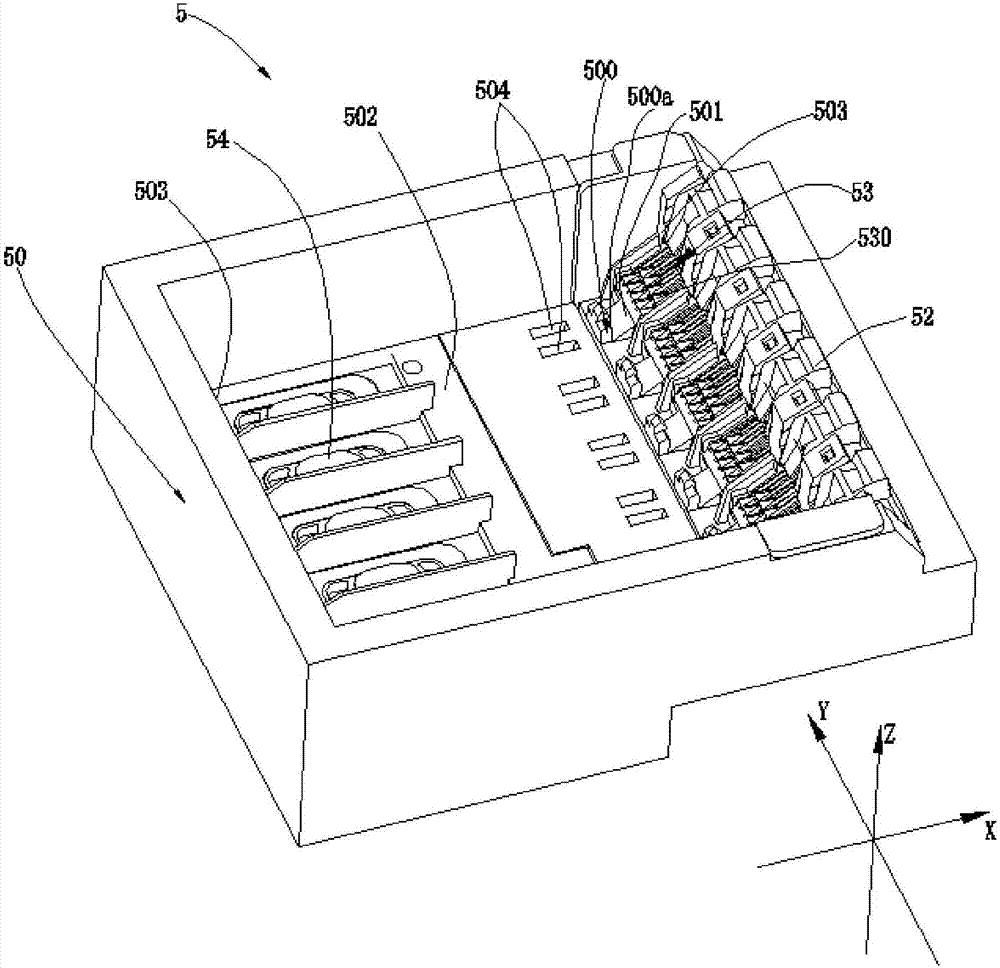

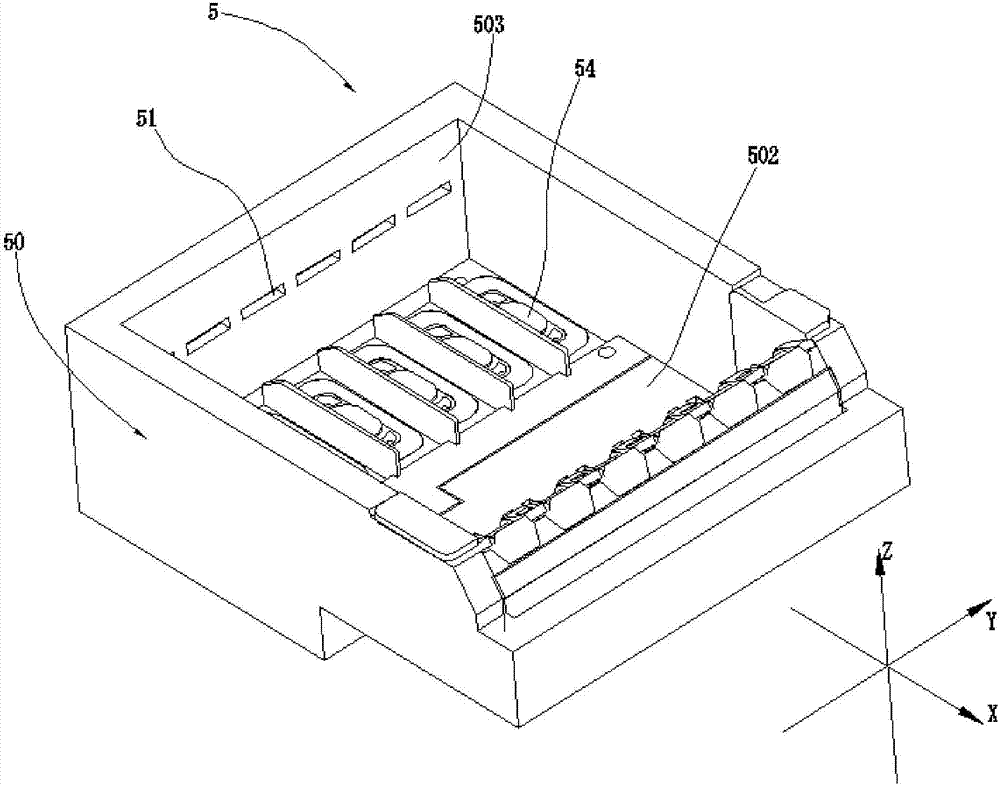

Buffering combination for packaging soybean milk machine

InactiveCN106516332AReduce occupancyCompact structurePackaging vehiclesContainers for machinesEngineeringMechanical engineering

A buffering combination for packaging a soybean milk machine comprises a first buffering body and a second buffering body, wherein the first buffering body is formed by sequentially connecting six supporting plates and five side plates alternately; each supporting plate is formed by connecting a supporting plate I and a supporting II; a notch is formed in the side edge, relative to the connecting line of each supporting plate I and the corresponding supporting plate II, of each supporting plate I; an arc-shaped gap is formed in each supporting plate I; grooves are formed in the side plates; two ends of each groove communicate with the notches of two supporting plates I which are connected to two side edges of each side plate; the first buffering body can be folded to form a hexagonal prism structure which is provided with an empty groove, so that a buffering fixing chamber of the soybean milk machine can be formed in the first buffering body; the second buffering body is inserted and fixed into the empty groove of the first buffering body. The buffering combination is used for buffering to protect a soybean milk machine product and supporting products thereof during the transferring process.

Owner:ZHENGZHOU ELECTRIC POWER COLLEGE

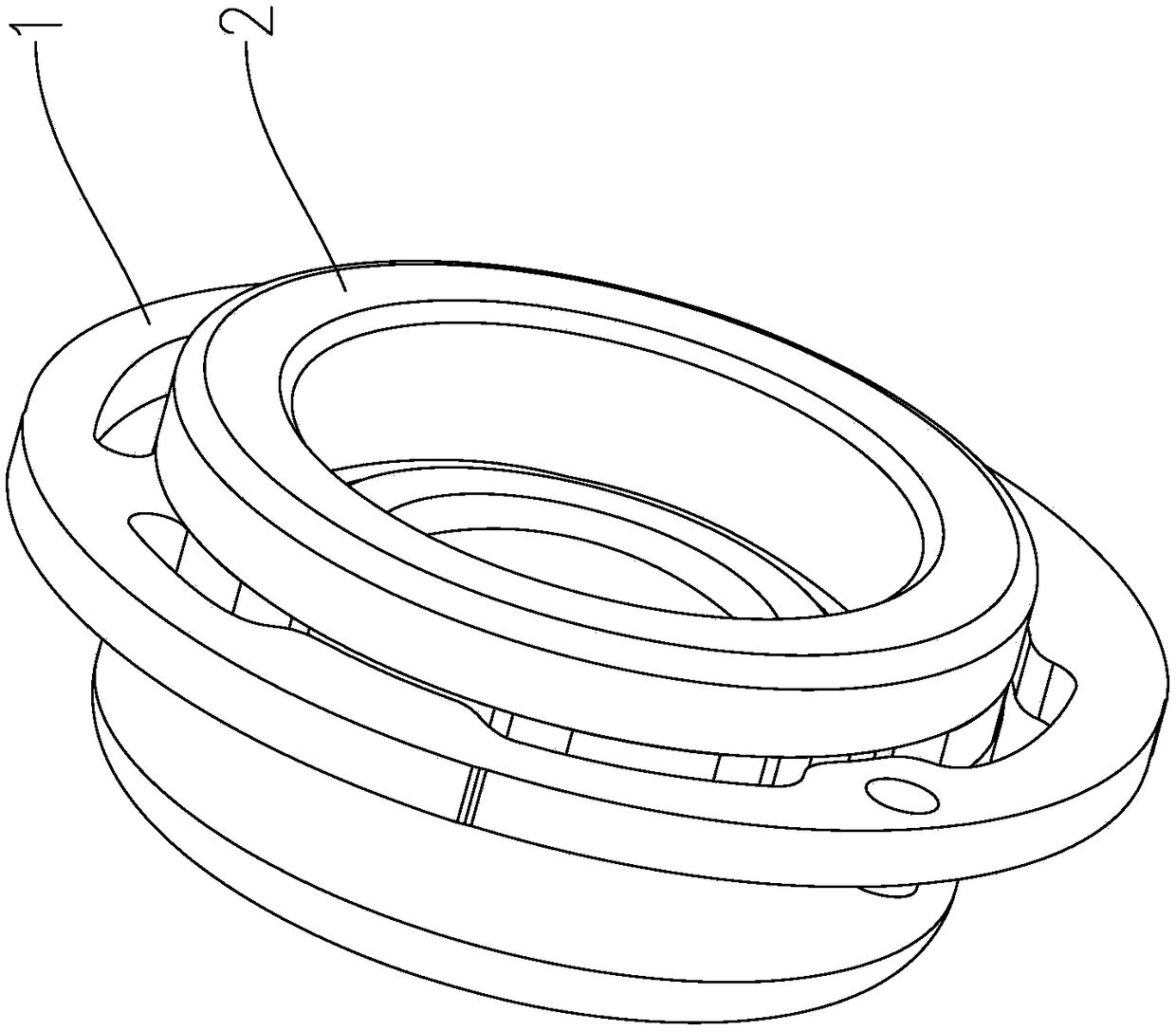

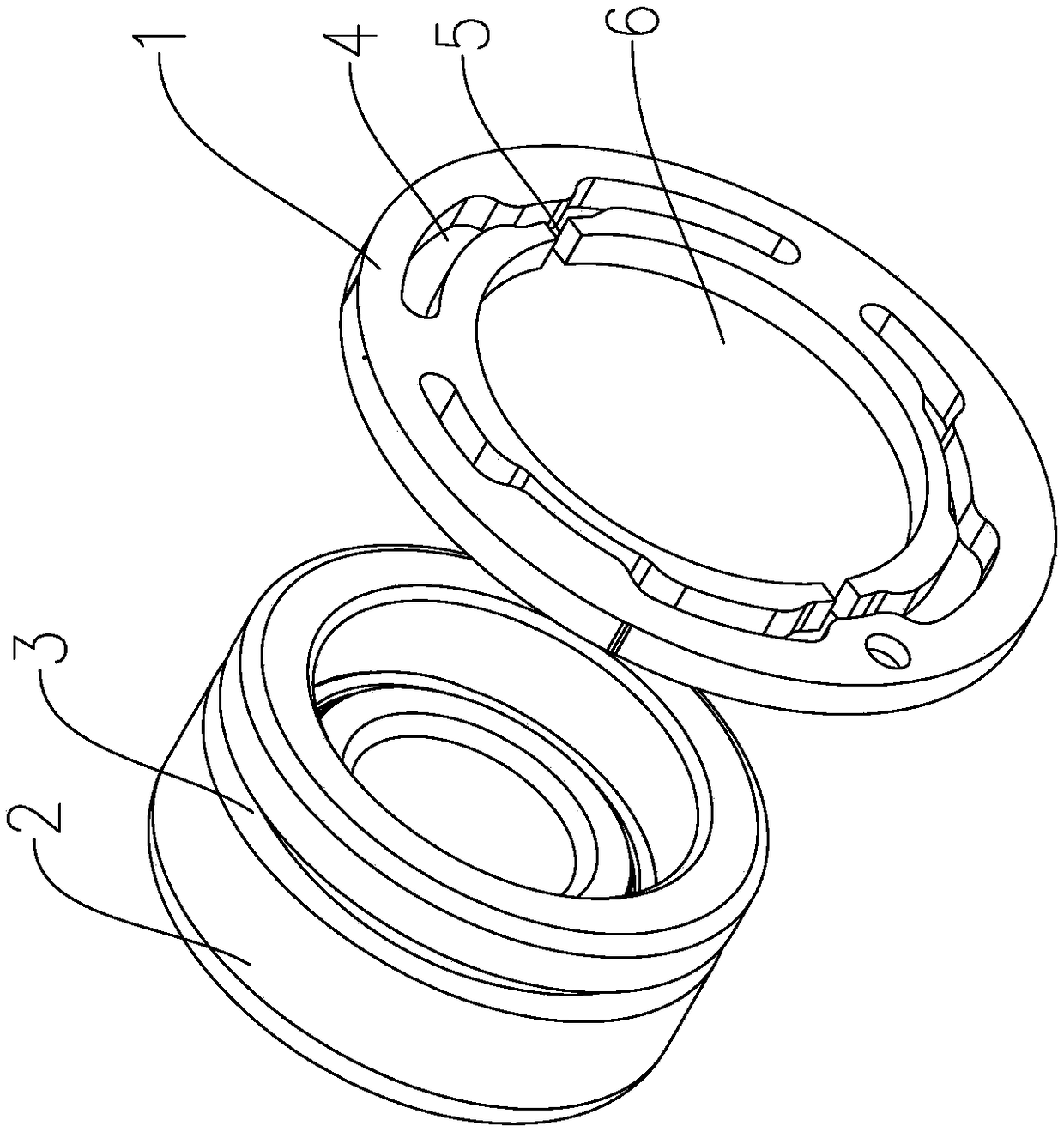

Elastic supporting bearing structure

PendingCN108189905AImprove mesh stabilityPrevent savingNon-rotating vibration suppressionMechanical steering gearsElectric power steeringBall bearing

The invention relates to a bearing structure, particularly to an elastic supporting bearing structure, and belongs to the technical field of the bearing structure. The elastic supporting bearing structure comprises a floating elastic block and a ball bearing; a locking slot is arranged on the surface of an outer circumference of the ball bearing, the floating elastic block is embedded in the locking slot of the ball bearing; an installing cavity is arranged in the center of the floating elastic block, and at least one elastic slot is arranged on the floating elastic block; a pressing slot is arranged between the installing cavity and the elastic slot, the pressing slot is connected with the installing cavity and the elastic slot. The elastic supporting bearing structure is simple, compactand reasonable in structure, low in manufacturing cost, and high in product stability; the transferred vibration can be completely absorbed by using the floating elastic block, the worm movement in crowd is prevented, the noise happening is reduced, the meshing stability of an electric power steering machine of an automobile is improved, and the service life is prolonged.

Owner:WUXING HUAYANG ROLLING BEARING JIANGSU LITTLESWAN GROUP

Clothing fabric distance adjusting and cutting equipment

InactiveCN112338967APrevent savingSevering textilesMetal working apparatusStructural engineeringMechanical engineering

The invention discloses clothing fabric distance-adjusting cutting equipment. The clothing fabric distance-adjusting cutting equipment comprises a machine frame and a cutting device, wherein a feedingplatform, a feeding device and a discharging device are sequentially arranged at the inner side of the machine frame from left to right, the cutting device is installed between the feeding device andthe discharging device, and clamping devices are installed at the two ends of the machine frame; and each clamping device comprises lug plates, lifting air cylinders, a mounting plate and a clampingplate, the lug plates are fixedly connected to the two side walls of the machine frame, the lifting air cylinders are fixedly connected to the tops of the lug plates, the ends of output shafts of thetwo lifting air cylinders are fixedly connected through each mounting plate, and each clamping plate is arranged at the bottom of each mounting plate. According to the clothing fabric distance-adjusting cutting equipment, the extension amount of extension of feeding air cylinders is controlled according to the length of actually needed fabric, so that feeding is facilitated, the fabric is prevented from wrinkling in the cutting process, the cutting uniformity is guaranteed, the cutting edge of a cutting knife makes good contact with the fabric through the arrangement of a spring, and the cutting effect is better.

Owner:储海霞

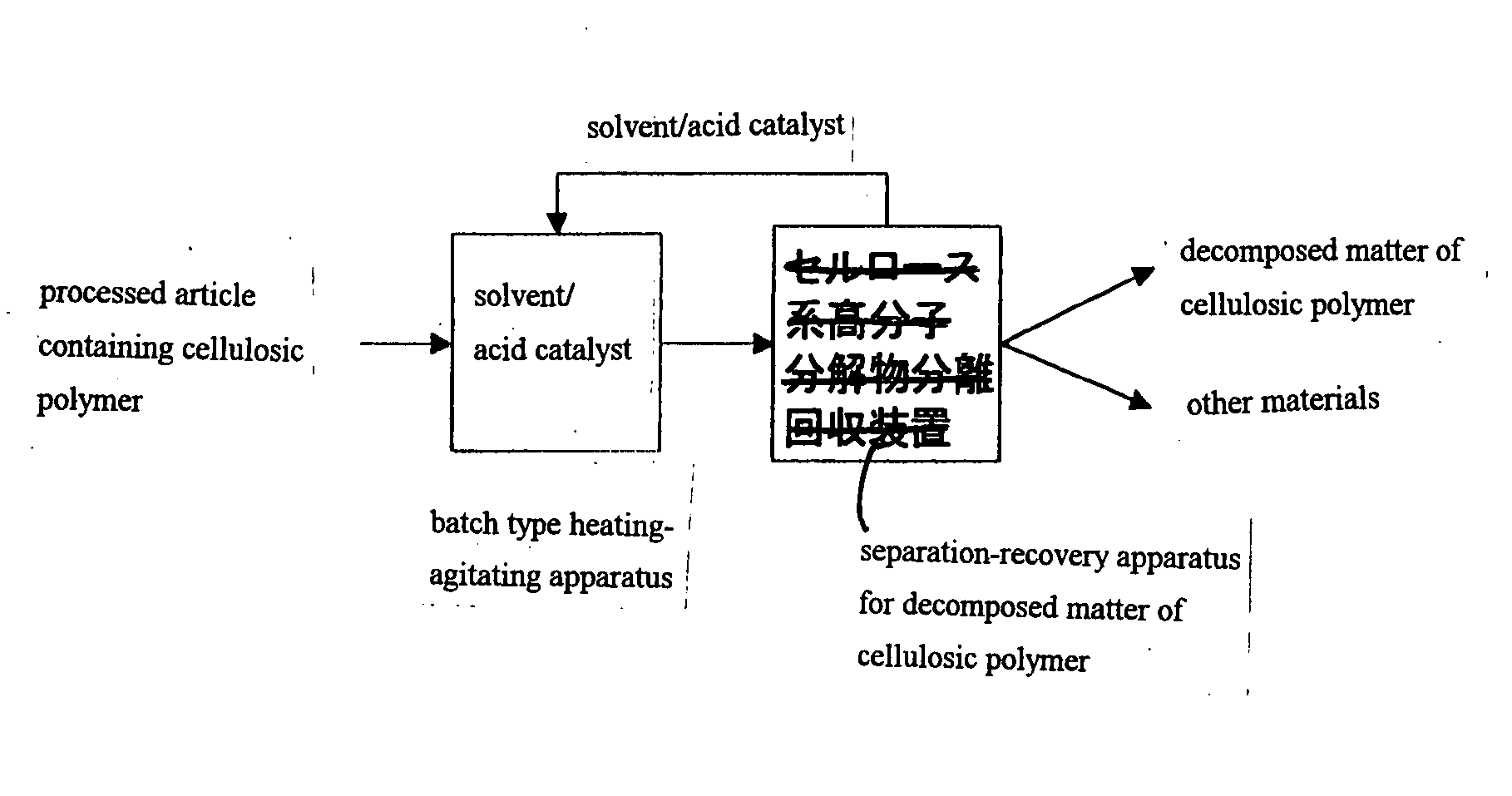

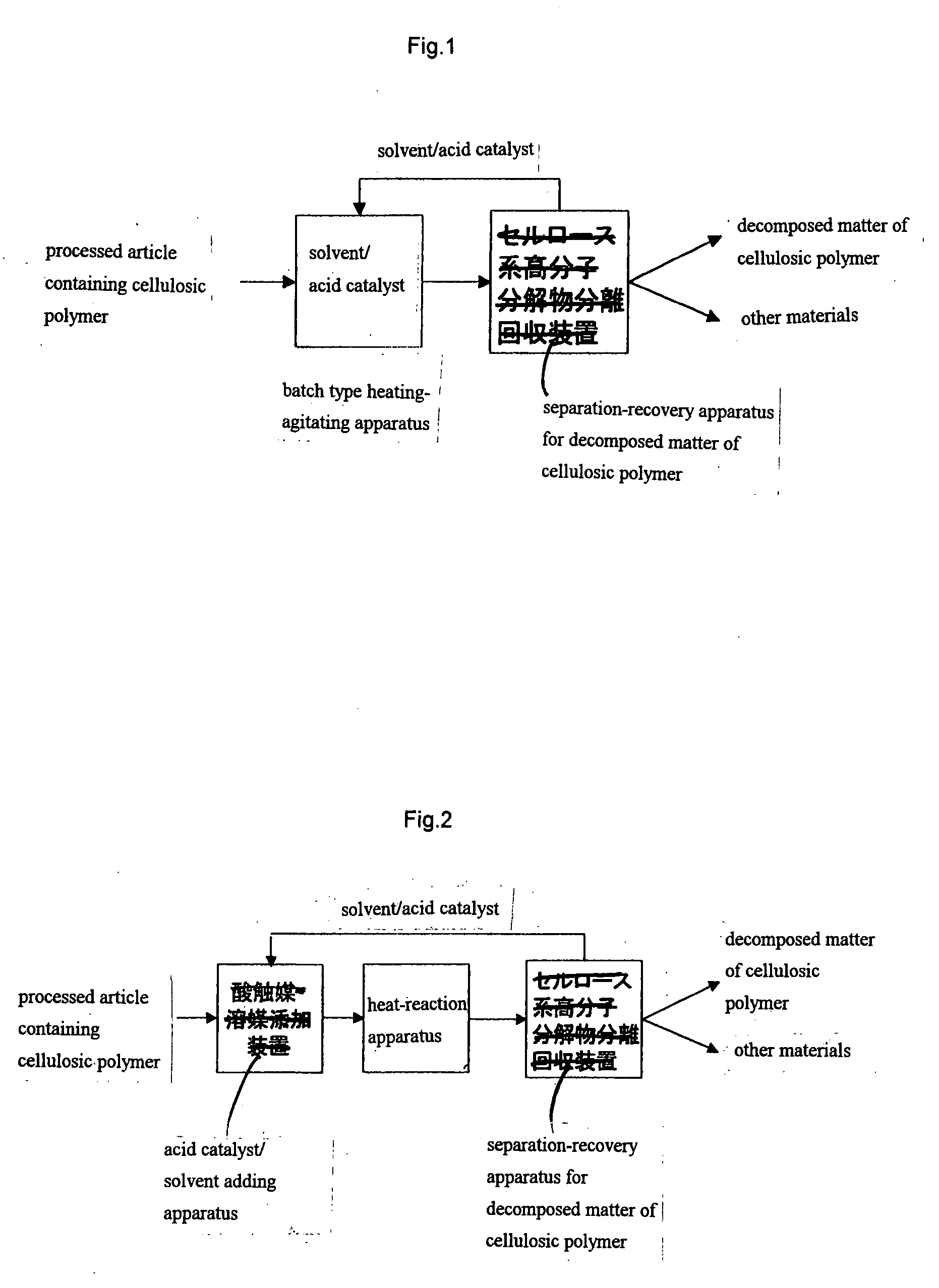

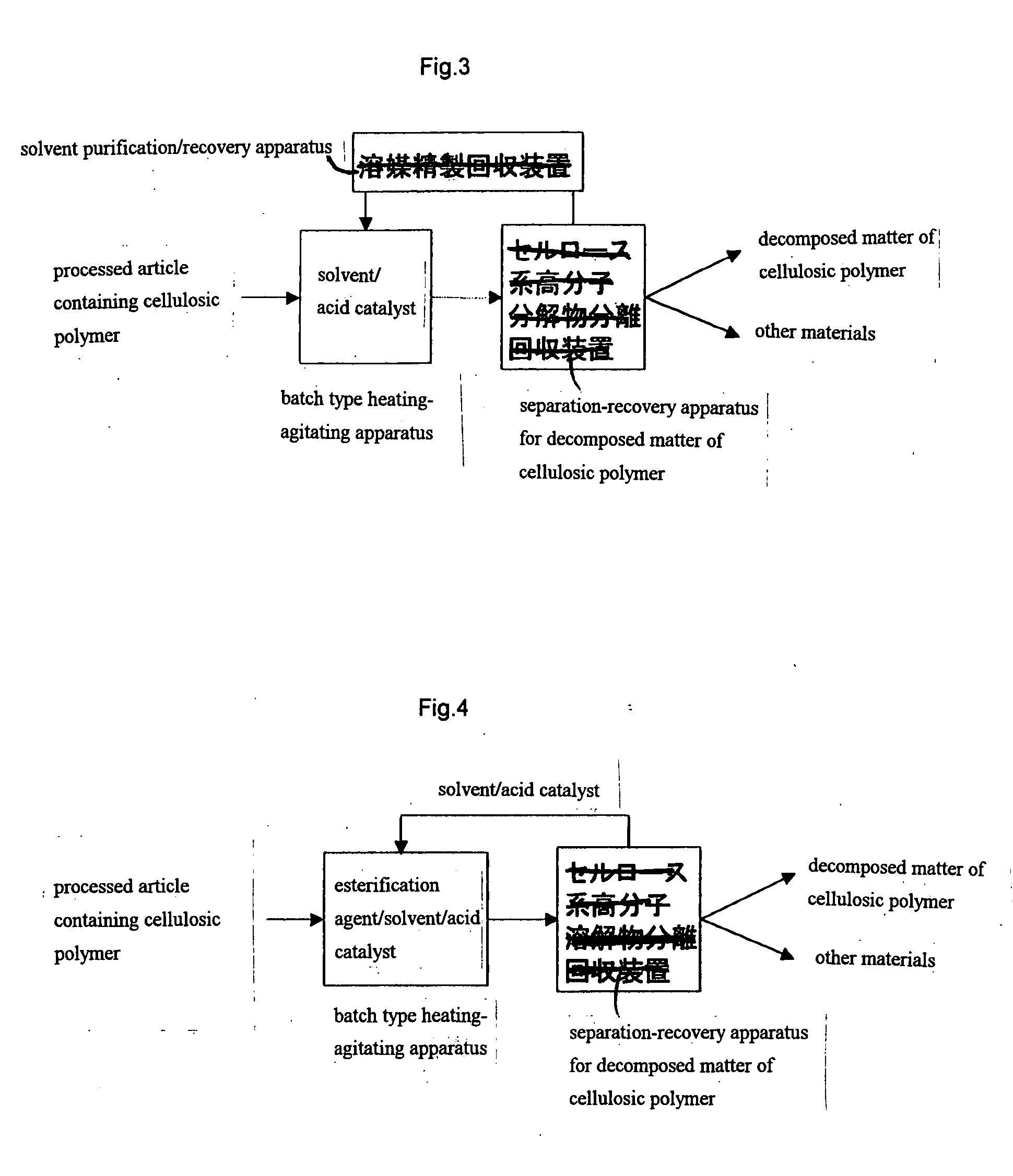

Method for Selective Separation of Cellulosic Polymer and Apparatus Therefor

InactiveUS20080306255A1Simple processSave energySugar derivativesPlastic recyclingPolymer scienceSolvent

A matter to be treated which contains a cellulosic polymer is heated in a solvent in the presence of an acid catalyst, to thereby selectively decompose the cellulosic polymer to a fine powder. Furthermore, a matter to be treated which contains a cellulosic polymer is reacted with an esterification agent in the presence of an acid catalyst, to thereby selectively dissolve or disperse the cellulosic polymer. In either method, the treated matter other than the cellulosic polymer does not change in state but remains solid, so that both can be easily separated by sieving or solid-liquid separation.

Owner:NAT INST OF ADVANCED IND SCI & TECH

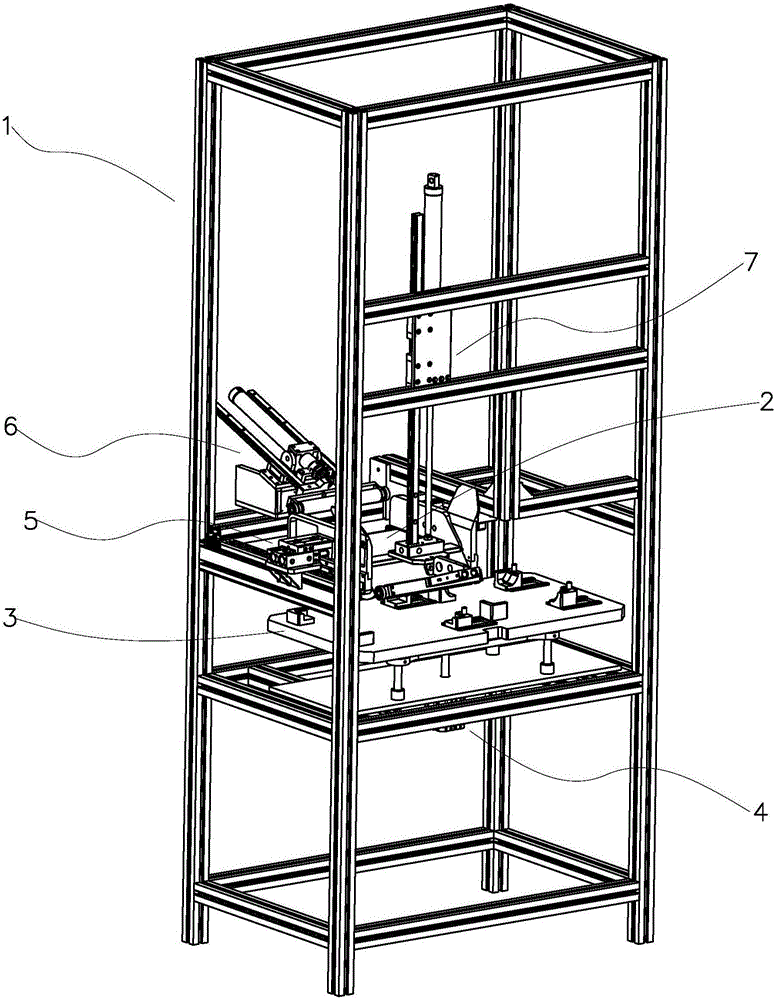

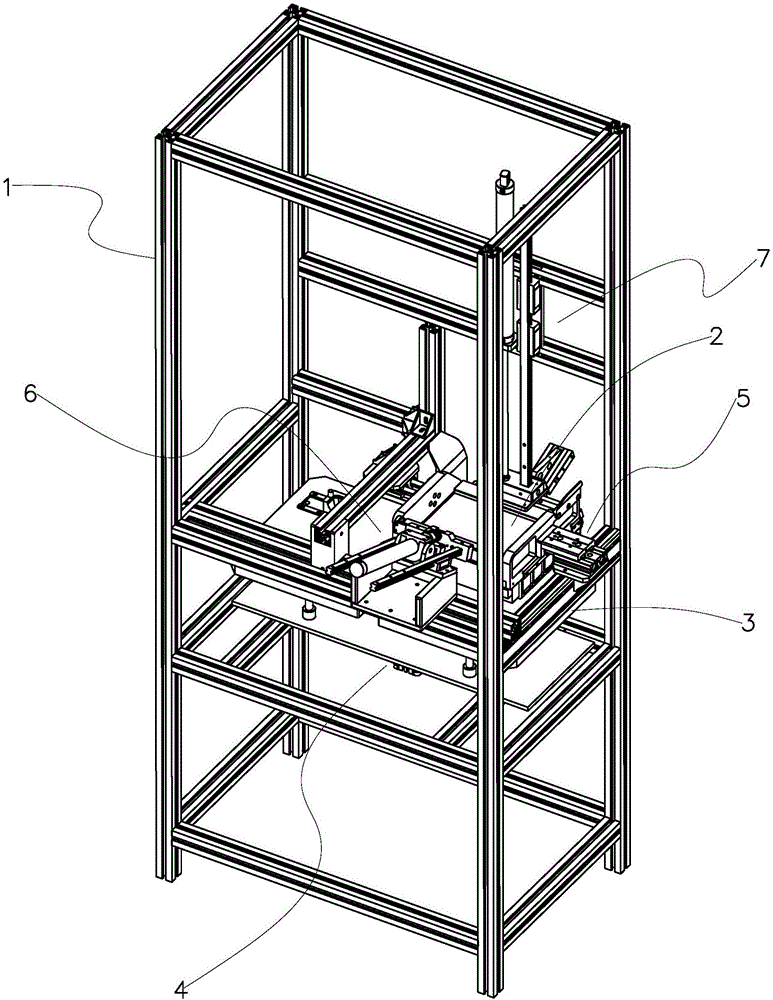

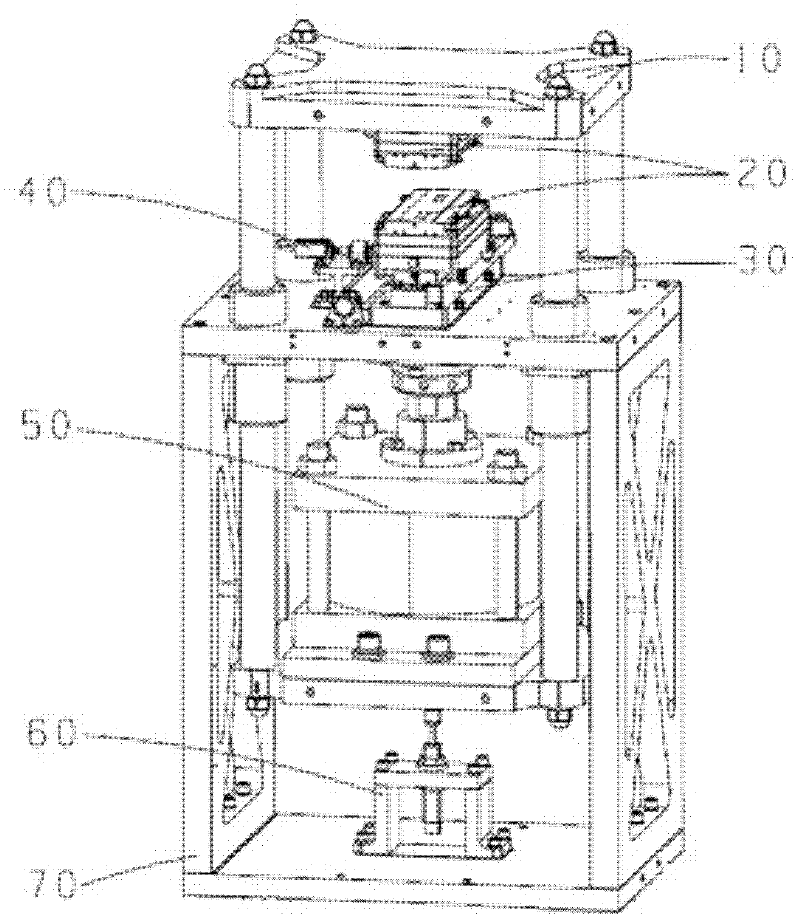

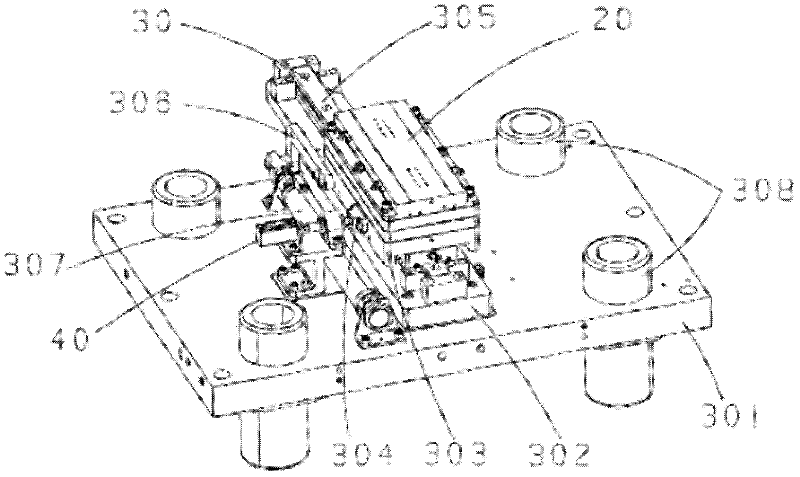

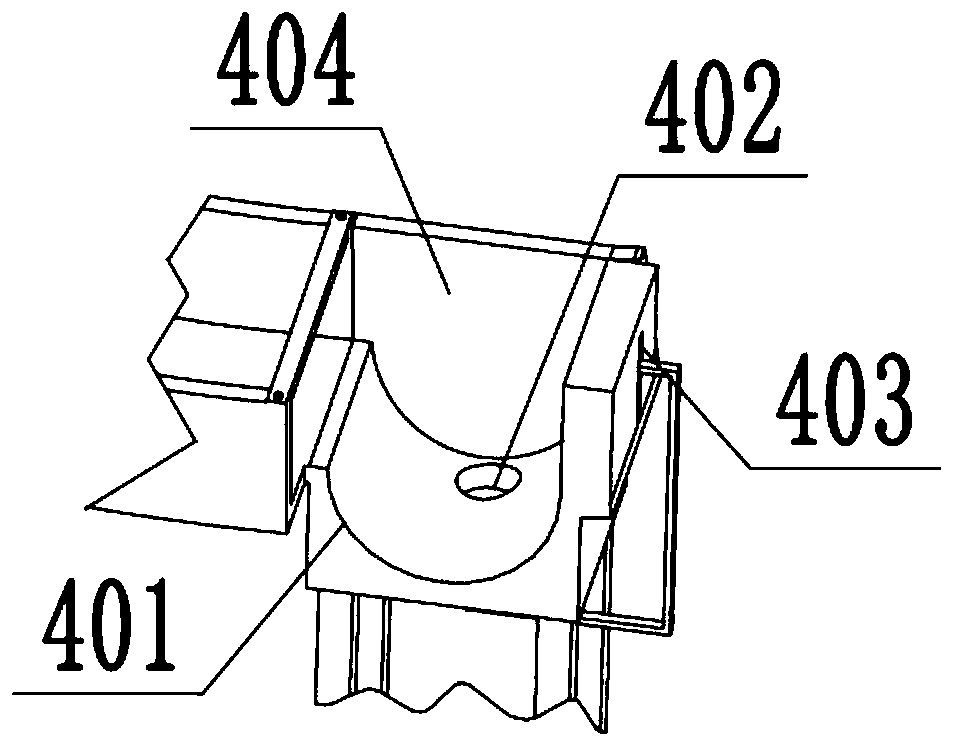

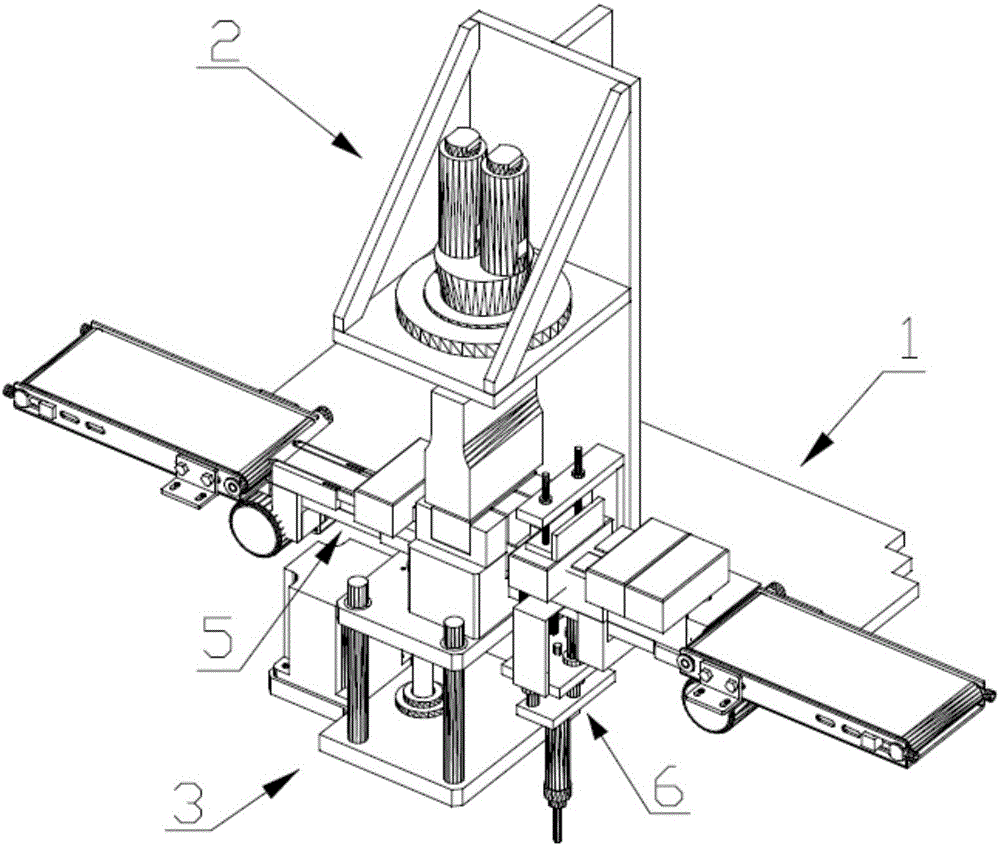

Novel ultrasonic efficient rivet welding machine

The invention relates to the field of ultrasonic rivet welding, in particular to a novel ultrasonic efficient rivet welding machine.The machine comprises a welding mechanism used for ultrasonic welding, a lifting mechanism used for transferring a workpiece to be machined to the welding mechanism and located under the welding mechanism, a supporting mechanism used for pushing the workpiece to be machined to the lifting mechanism, and a pushing mechanism used for discharging the machined workpiece out of the lifting mechanism, wherein the supporting mechanism and the pushing mechanism are located on the two sides of the welding mechanism respectively, the welding mechanism comprises an ultrasonic vibrator and a welding head, the ultrasonic vibrator and the welding head are fastened and connected, the lifting mechanism comprises a servo motor and a lifting table, and the lifting table is provided with a welding jig; welding is finished on the welding mechanism, and the machined workpiece is pushed away from the lifting mechanism by the pushing mechanism while the lifting mechanism descends to restore.By the adoption of the machine, production rate can be effectively increased, and through action cooperation of different mechanisms, time is saved greatly and production efficiency is improved greatly.

Owner:东莞市南方力劲机械有限公司

Mounting support of automotive rear bumper and rear collision beam

The invention discloses a mounting support of an automotive rear bumper and a rear collision beam. The mounting support comprises a vertical stamping part and a horizontal stamping part. The horizontal stamping part is arranged at the lower end of the vertical stamping part and integrated with the vertical stamping part. A bumper mounting nut is arranged on the horizontal stamping part, and a rear collision beam mounting bolt is welded on the vertical stamping part. The mounting support can be used for mounting the automotive rear bumper and the rear collision beam, the strength of the mounting support is improved, and mounting efficiency of the rear collision beam is improved.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Ink boxes and printing device

ActiveCN106926587AImprove assembly reliabilityPrevent savingPrintingMechanical engineeringJoint surface

The invention relates to the technical field of printing, in particular to ink boxes and a printing device. The ink boxes are mounted on a mounting part provided with mounting holes, the joint surface and the positioning surface opposite to the joint surface. Each ink box comprises an ink box main body, a joint part connected with the ink box main body and elastic part connected with the joint part. The joint parts can stretch into the mounting holes and be in positioning fit with the joint part; and the elastic parts can be connected with the positioning surface in an abutting mode to apply acting force on the joint parts toward the directions of the joint parts. After the joint parts and the mounting part are matched, the elastic parts can apply the acting force on the joint parts to enable the joint parts to be in positioning fit with the joint surface on the mounting part, even if the ink boxes are subjected to the acting force from contact pins, the elastic parts can prevent bustle of the joint parts, and matching failure between the joint parts and the mounting holes is prevented, so that it is guaranteed that the joint parts and the mounting part are assembled together more reliably.

Owner:ZHUHAI NINESTAR MANAGEMENT CO LTD

Biopharmaceutical constant temperature incubation device

InactiveCN107964508AEasy to operateSimplify the operation processBioreactor/fermenter combinationsBiological substance pretreatmentsBiopharmaceuticalEngineering

The invention provides a thermostatic culture device for biopharmaceuticals, comprising a support frame, a support plate and a limit stop ring. The bottom of the box body is supported with four support rods, and the bottom of the four support rods supports a roller. The supporting frame is formed by welding and combining eight supporting plates in a circular array, and each supporting plate is sleeved with a rectangular supporting sliding sleeve; the supporting clamp bars are symmetrically combined and supported to form a culture dish placing frame, and The top of each supporting sliding sleeve is arranged to support two culture dish placing racks; the culture dishes are slidably placed inside the above-mentioned culture dish placing racks and are supported against the top of the supporting sliding sleeve. In the arrangement of the support clamp rod of the present invention, the inner side of the support clamp rod is provided with an arc surface section, and then the four support clamp rods form a culture dish placing rack, which is suitable for the sliding assembly of a round cake-shaped culture dish. In addition, the culture dish is assembled by sliding assembly. The operation method placed inside the Petri dish rack is simple and efficient.

Owner:蒋晓伟

Variable-diameter mold for making hollow wheaten food

InactiveCN112493277AIncrease contentImprove qualityDough extruding machinesMechanical engineeringFood item

The invention discloses a variable-diameter mold for making hollow wheaten food. The variable-diameter mold comprises a mold body, a cavity expanding assembly is installed on the upper end face of themold body, the cavity expanding assembly is connected with the mold body through a lock catch assembly, the cavity expanding assembly comprises an upper cover plate, an installation plate is installed in the center of the upper cover plate, and a support is connected to the lower surface of the installation plate; a cavity making mechanism is connected to the lower portion of the support, an adjusting mechanism is installed on the cavity making mechanism, and a driving mechanism is installed on the support; and a clamping jaw is fixedly connected to the driving mechanism, and a gear ring is fixedly connected to the lower surface of the upper cover plate. The invention aims to solve the problems that an existing wheaten food hollow cavity making device cannot enable the size of a cavity indough to be larger than the size of an opening for taking out a mold core from the dough, so that the content of food stuffing is limited, and cavities of various models cannot be made by the same cavity making tool, and cooked wheaten food deforms due to the fact that the cooked wheaten food needs to be taken out of the container to be cooked, are solved.

Owner:YANTAI XIAOMI MASCH TECH CO LTD

A self-closing forging forming die

ActiveCN106623722BPrevent savingImprove processing pass rateForging/hammering/pressing machinesAutomatic controlMachining

The invention discloses an automatic closed forging forming die, and belongs to the technical field of metal press machining. The die comprises a rigid die base, a floating female die, and automatic die locking devices symmetrically arranged on the two sides of a lower female die base. The two sides of the upper end face of an upper female die base are symmetrically provided with clamping grooves. Each automatic die locking device comprises a swinging lock rod and a power mechanism driving the swinging lock rod to swing. Lock heads clamped to the clamping grooves in a matched mode are arranged on the tops of the swinging lock rods. During combination of an upper female die and a lower female die, the power mechanisms drive the swinging lock rods to swing in the direction close to the upper female die till the lock heads make contact with the clamping grooves to be clamped; During opening of the upper female die and the lower female die, the power mechanisms drive the swinging lock rods to swing in the direction away from the upper female die till the lock heads get away from the clamping grooves to be reset. The die clamping pressure can be increased, and automatic control over locking and unlocking of the upper and lower female dies of a die locking device is achieved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com