Mouth ring fixed connection structure of multistage centrifugal pump and quick detaching method for mouth ring fixed connection structure

A technology for centrifugal pumps and mouth rings, which is applied to components, pumps, and pump elements of pumping devices for elastic fluids, and can solve the problem of difficulty in accommodating cylindrical pins and screws at the same time, limited axial size of the mouth ring of the pump body, and inability to Achieve accuracy and other issues, achieve the effect of improving connection accuracy and strength, dispersing stress, and improving positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings.

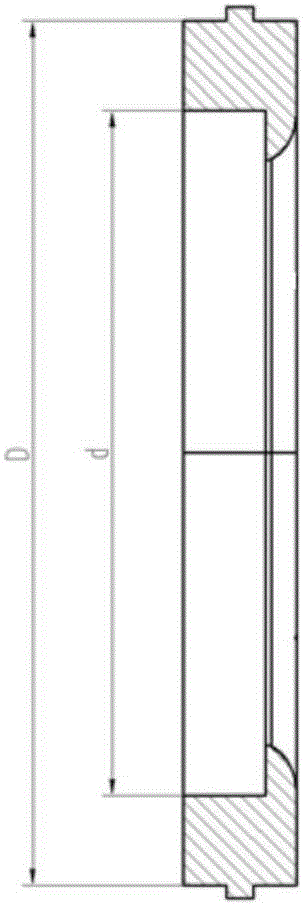

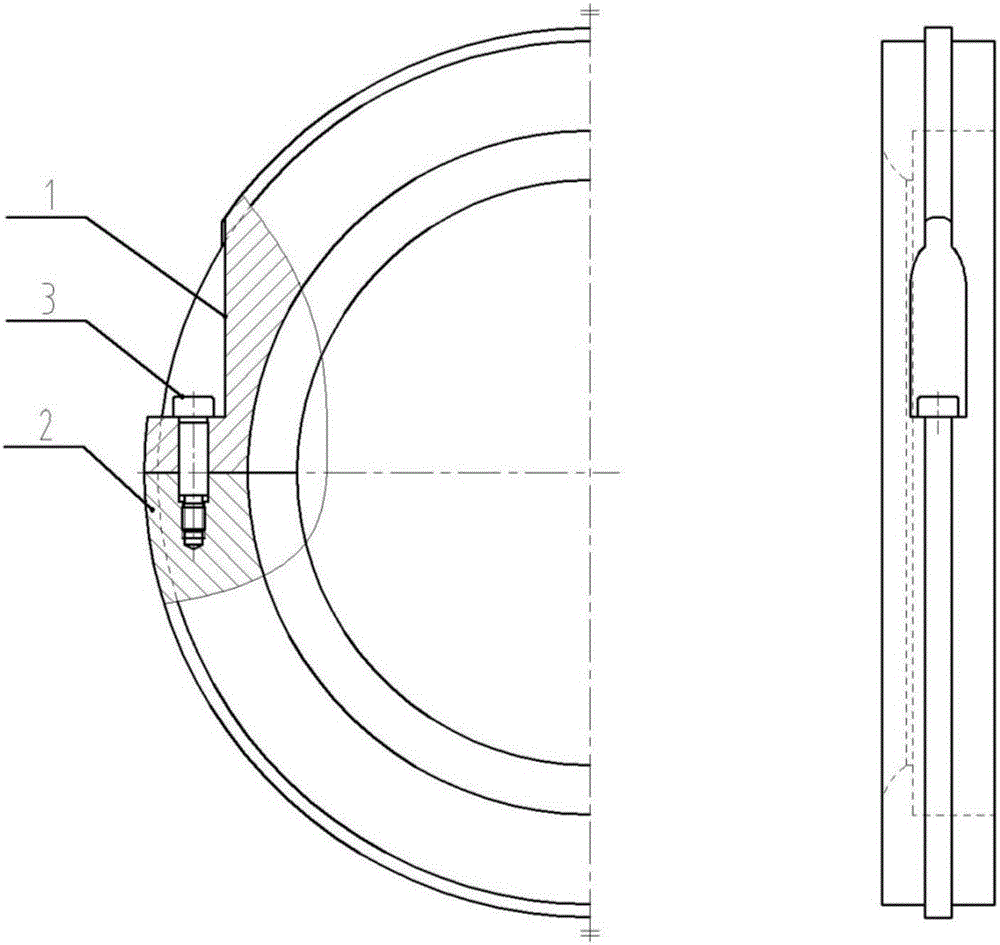

[0038] A multi-stage centrifugal pump mouth ring fixed connection structure, including the pump body upper mouth ring and the pump body lower mouth ring, the connection between the pump body upper mouth ring 1 and the pump body lower mouth ring 2 is provided with a connection hole, the connection hole Inner connection shoulder screw 3. A gap is provided on the upper mouth ring 1 of the pump body.

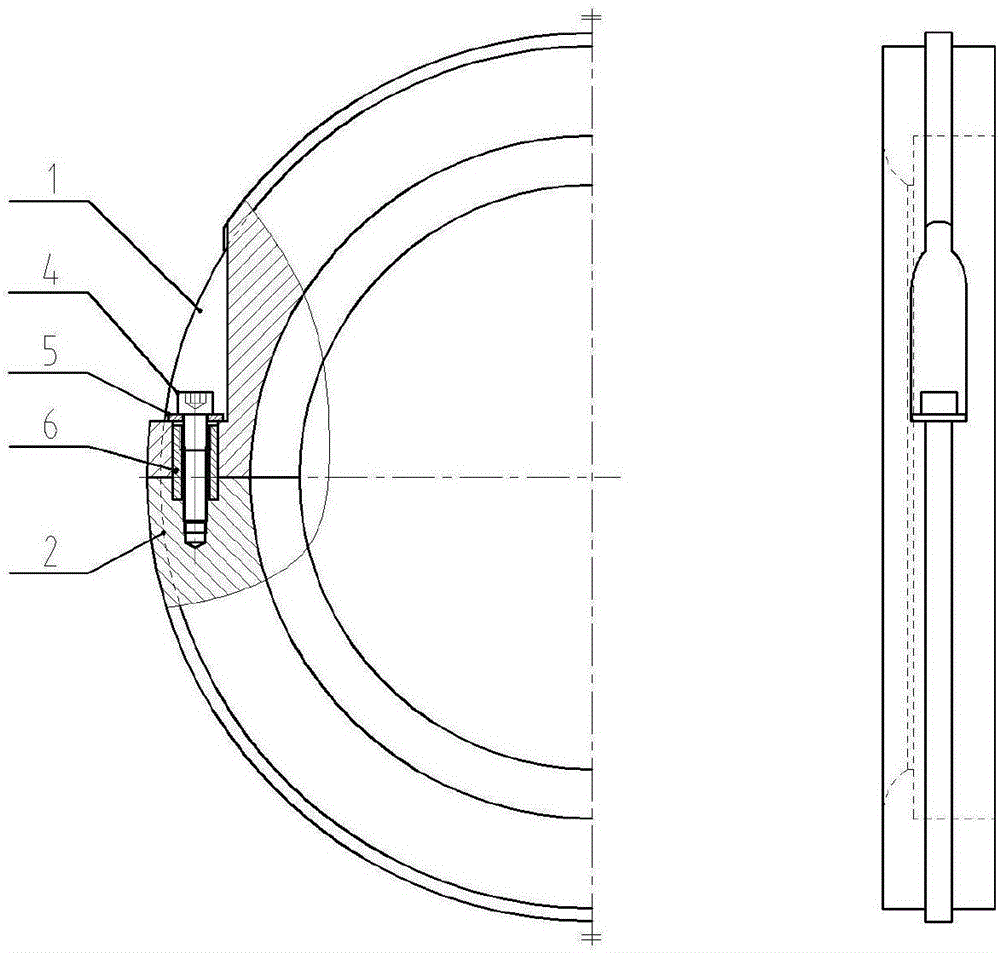

[0039] A connection hole is provided at the joint between the upper mouth ring 1 of the pump body and the lower mouth ring 2 of the pump body, and the hollow cylindrical pin 4 is connected in the connection hole. One end of the screw 5 passes through the hollow cylindrical pin 4 and is connected with the lower mouth ring 2 of the pump body. A flat washer 6 is arranged between the hollow cylindrical pin 4 and the cylindrical head screw 5 . The inner side of the hollow cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com