Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

97results about How to "Minimize waiting time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

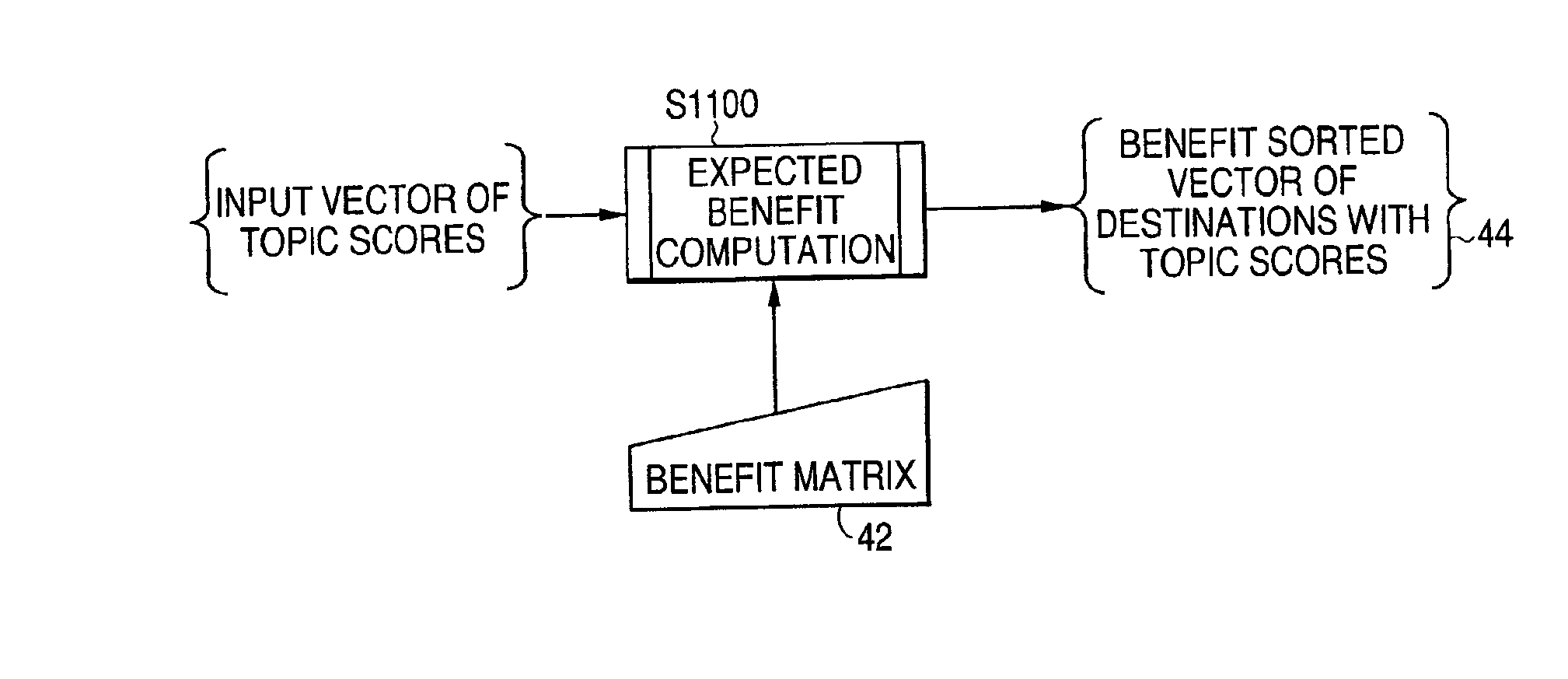

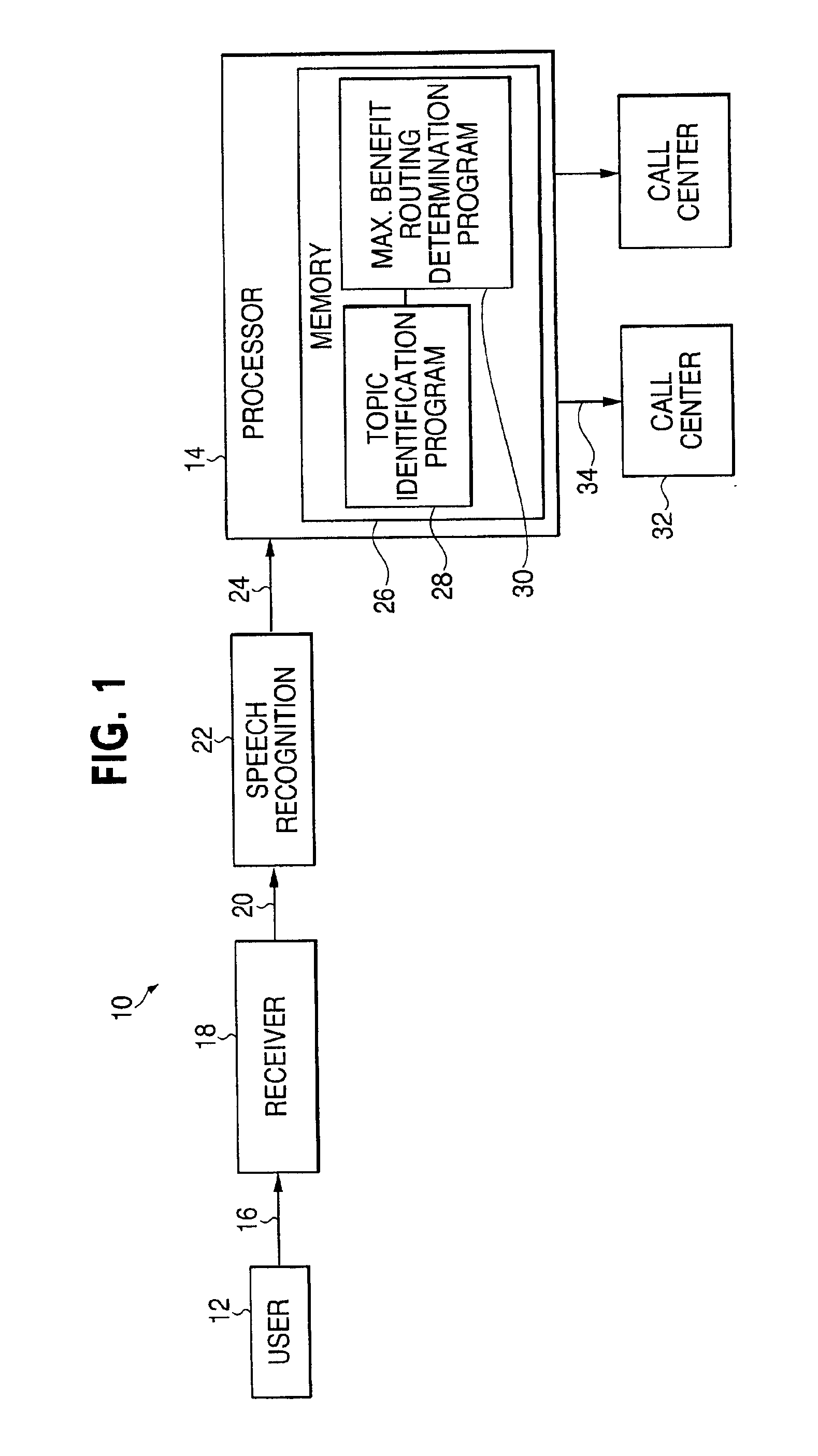

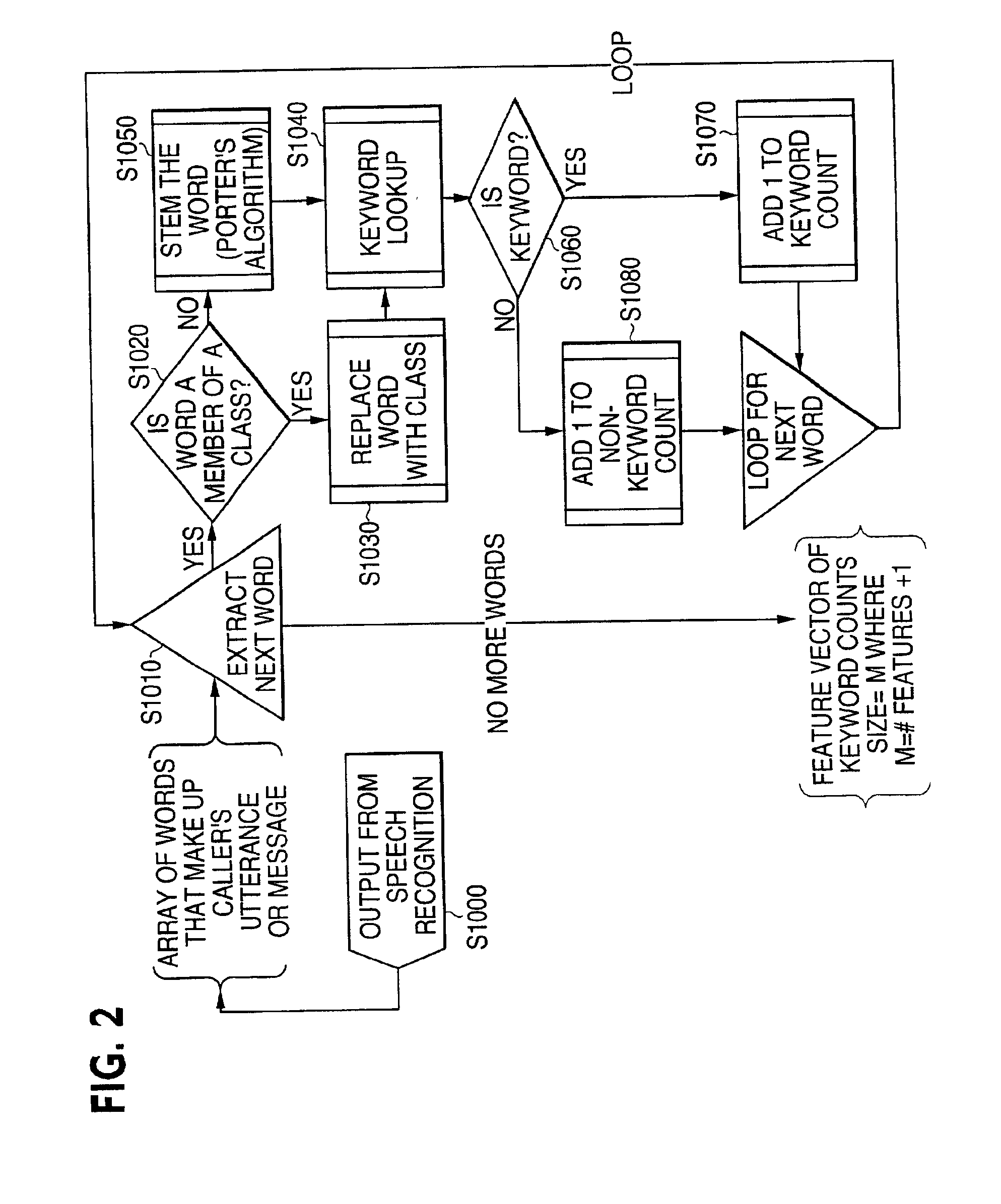

System and method for maximum benefit routing

InactiveUS6895083B1Easy to changeReduce randomnessAutomatic call-answering/message-recording/conversation-recordingSpecial service for subscribersCall routingTelephone call

A system and method for routing telephone calls is based on identifying caller goals, and maximizing the benefit of routing the call to the appropriate call center. The appropriate call center is identified as the call center best equipped to respond to the needs of the caller. The cost or benefit is based on the fastest and least expensive way to answer a query posed by a caller. A probabilistic model of the caller's goals or call topics based on a response to a top-level prompt is used, along with a set of functions associating a utility or benefit with routing those call topics to destinations within the center. Maximum benefit routing allows for the separation of the caller's goals from those of the call center, thereby optimizing use of available resources.

Owner:VERIZON PATENT & LICENSING INC +1

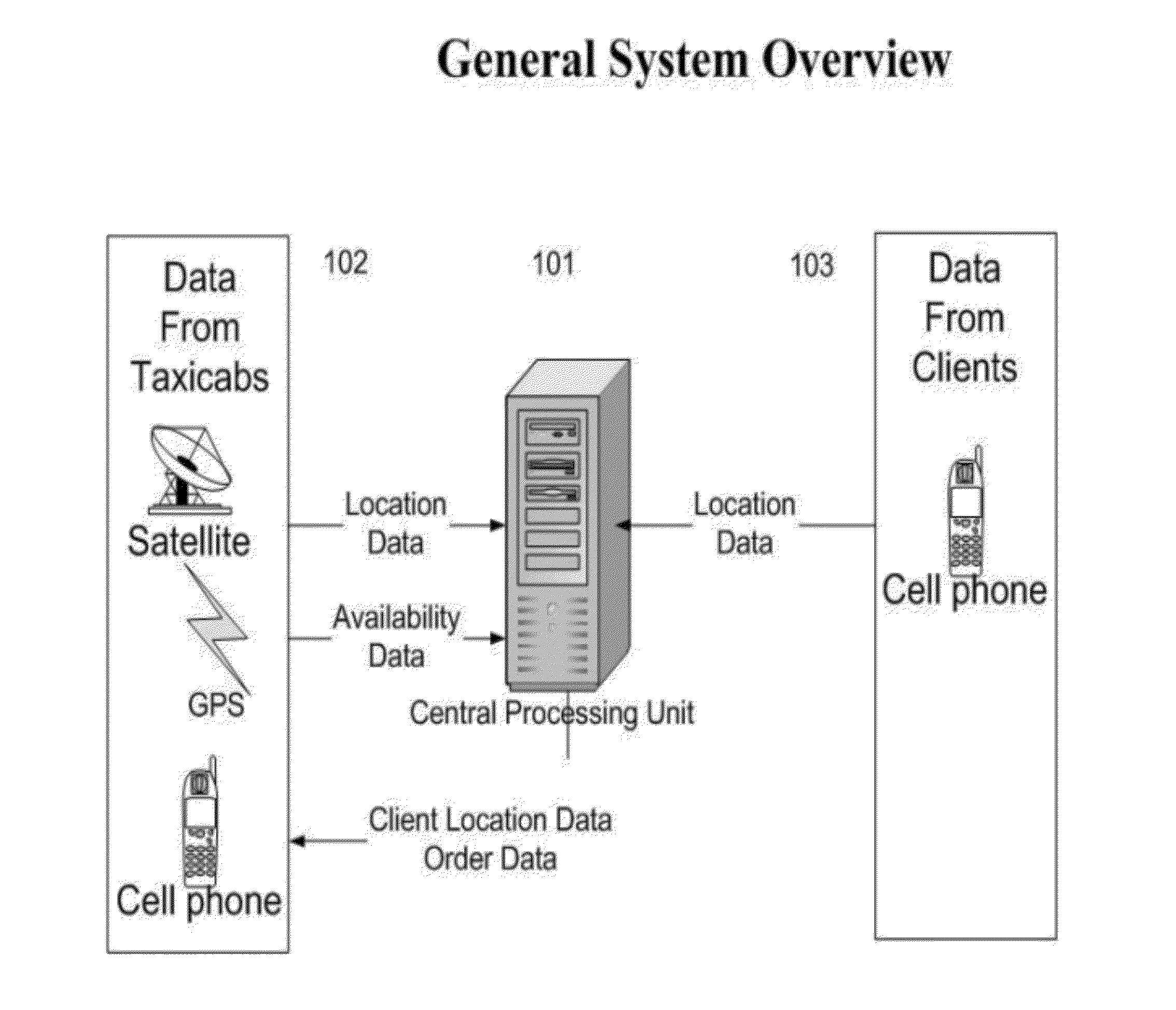

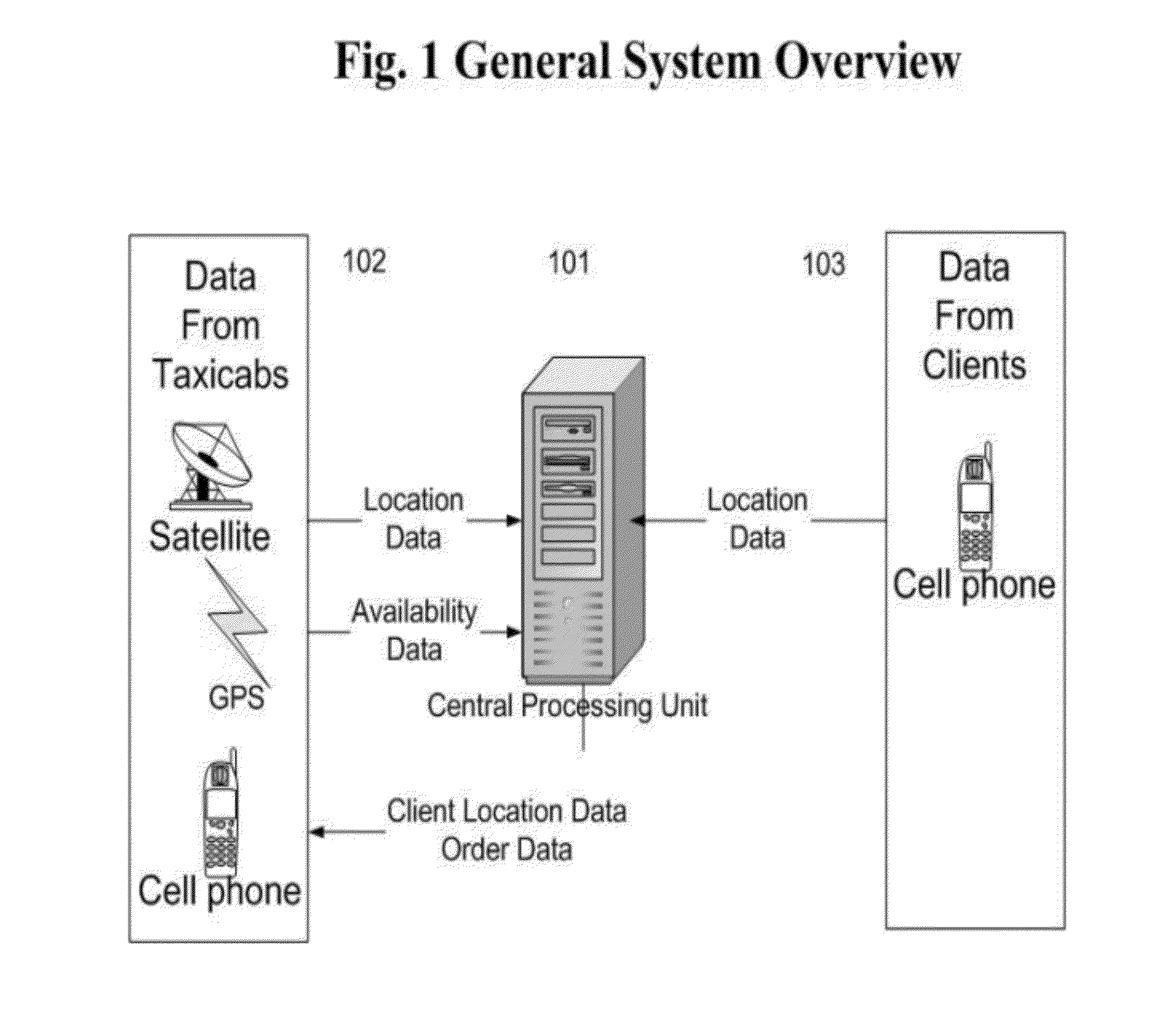

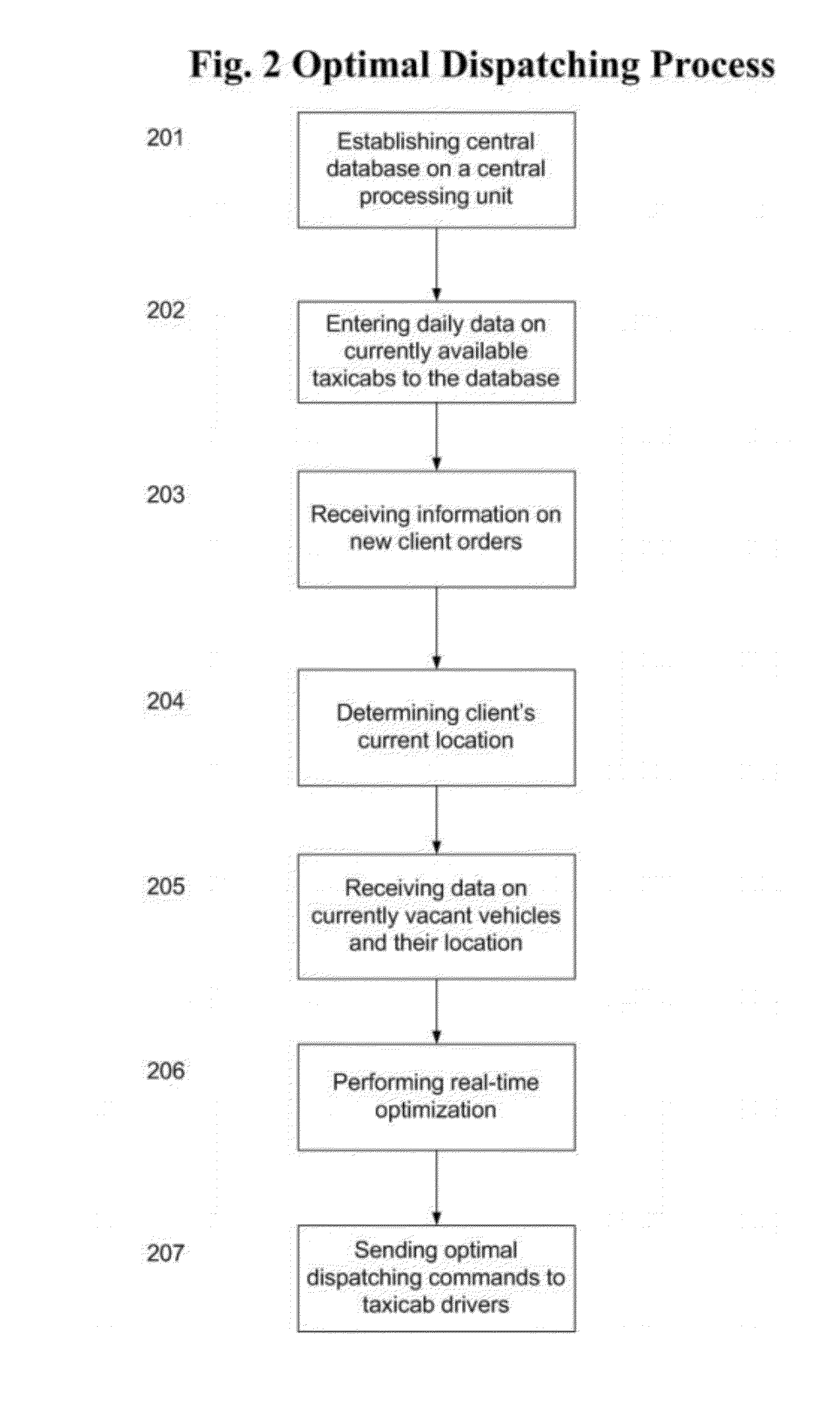

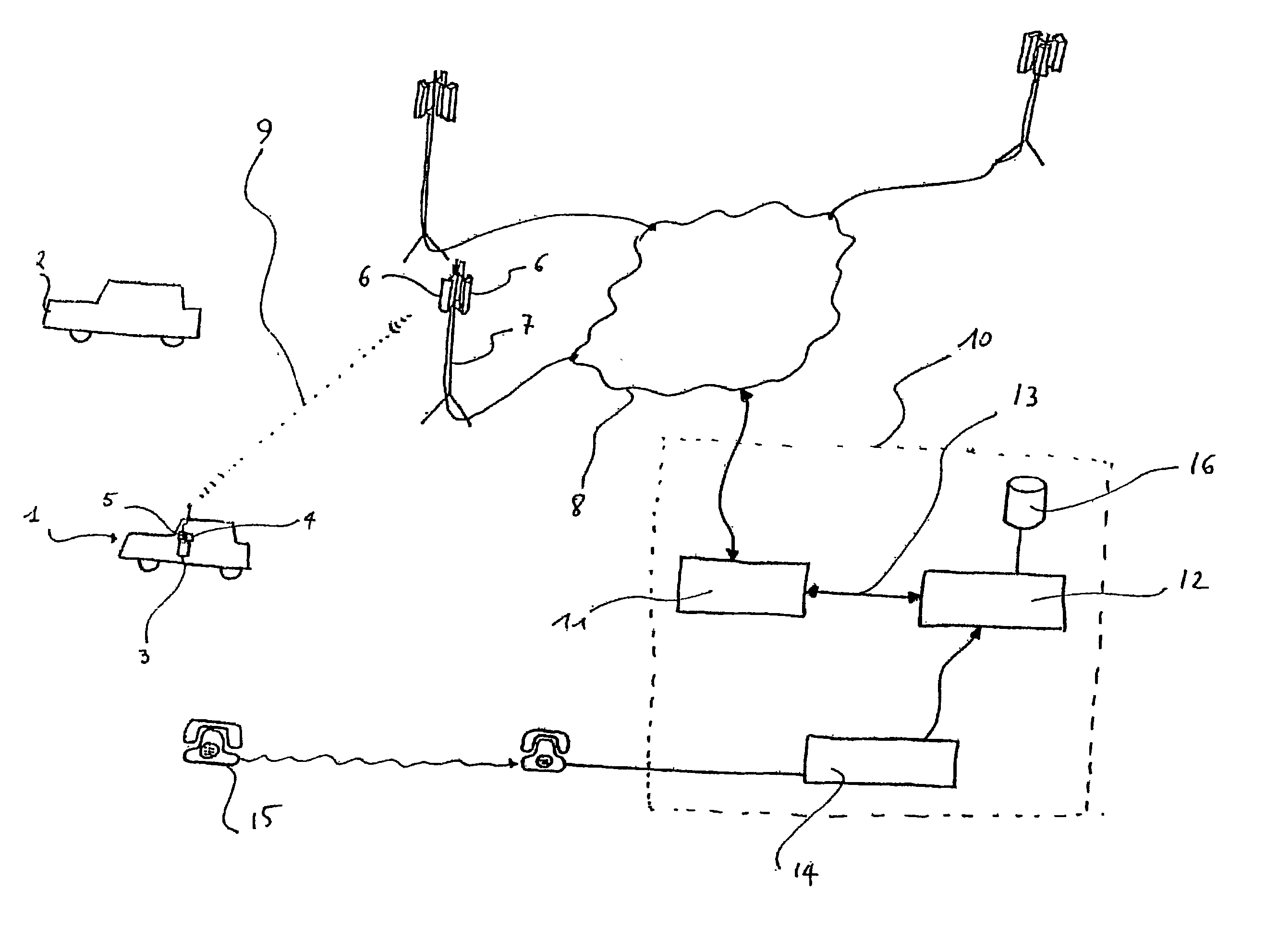

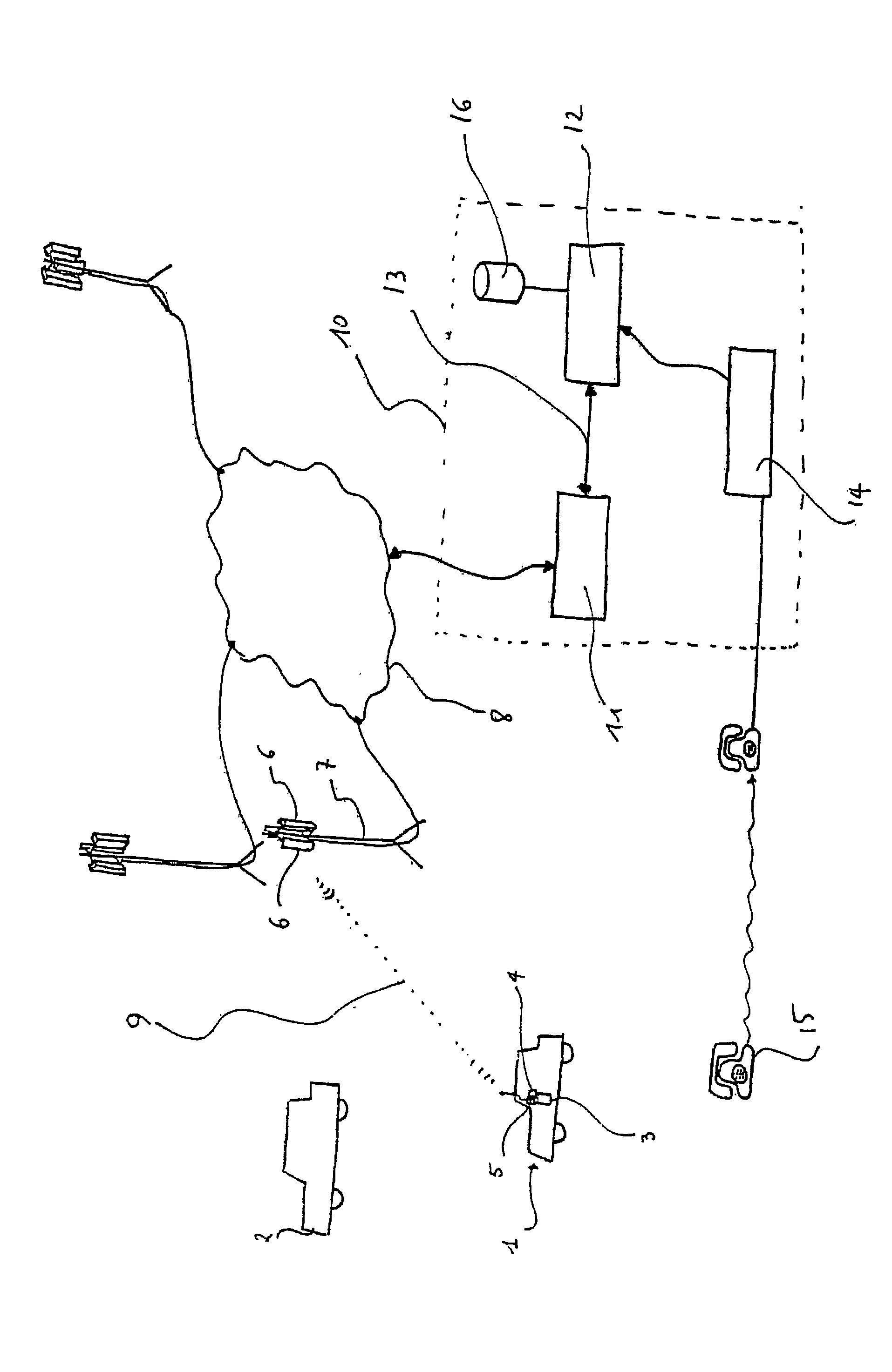

Automatic optimal taxicab mobile location based dispatching system

InactiveUS20120232943A1Improve the level ofMinimize waiting timeRoad vehicles traffic controlForecastingSystem usageComputer science

The invention discloses a method and system for real-time automatic optimal dispatching of a plurality of taxicabs to passenger pick-up locations. The system uses optimization model to optimally dispatch taxicab vehicles in order to minimize total clients waiting time and to maximize taxicab business profitability. The optimization is performed based on the data on currently available taxicabs and their location, and based on the data on new clients orders and clients' pick-up locations, wherein the data on available taxicabs and their locations is obtained by the cell phone / GPS means from taxicab in-car devices and the data on clients' pick-up locations is obtained from clients cell phones / GPS-based devices.

Owner:MYR DAVID

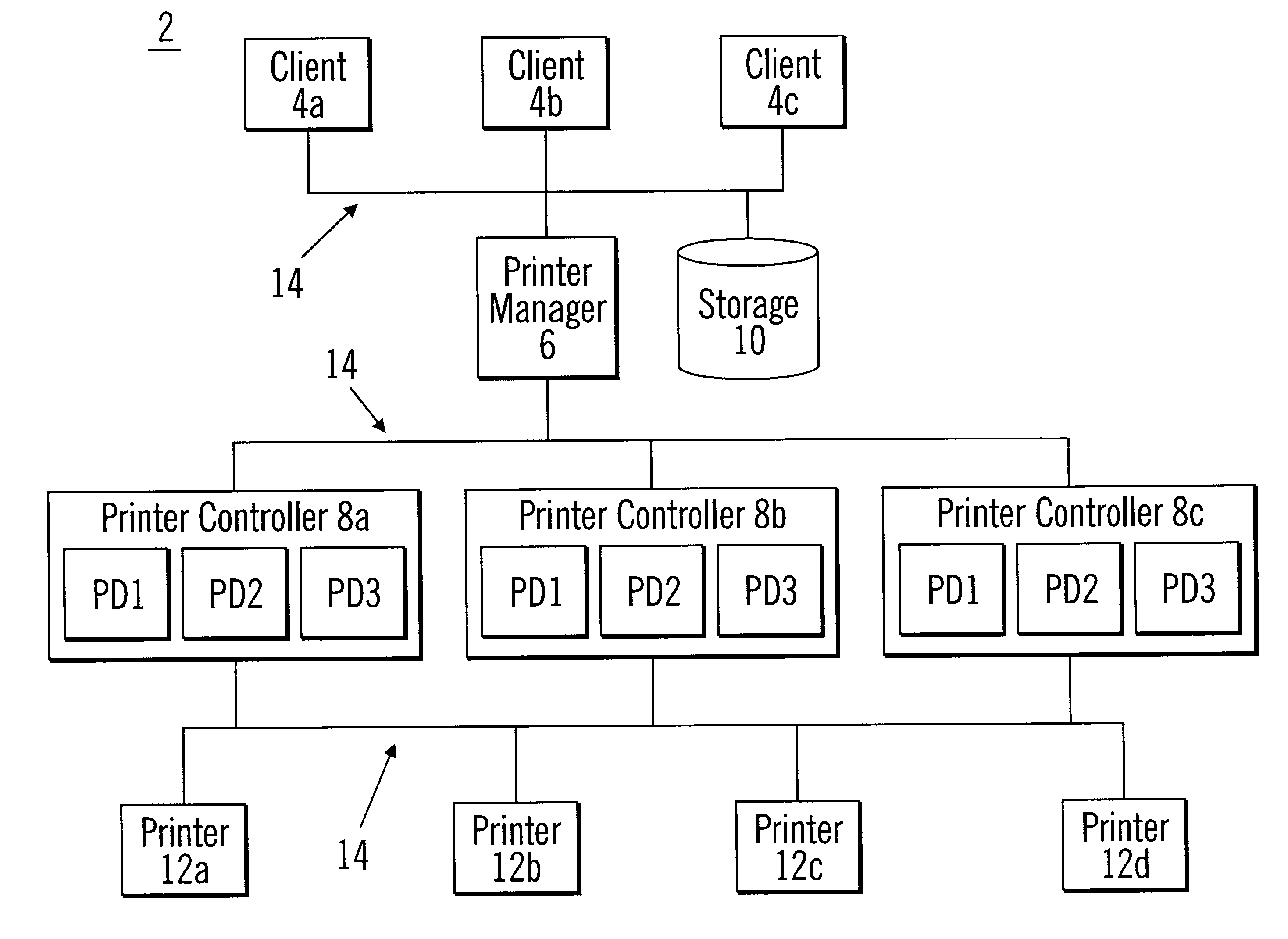

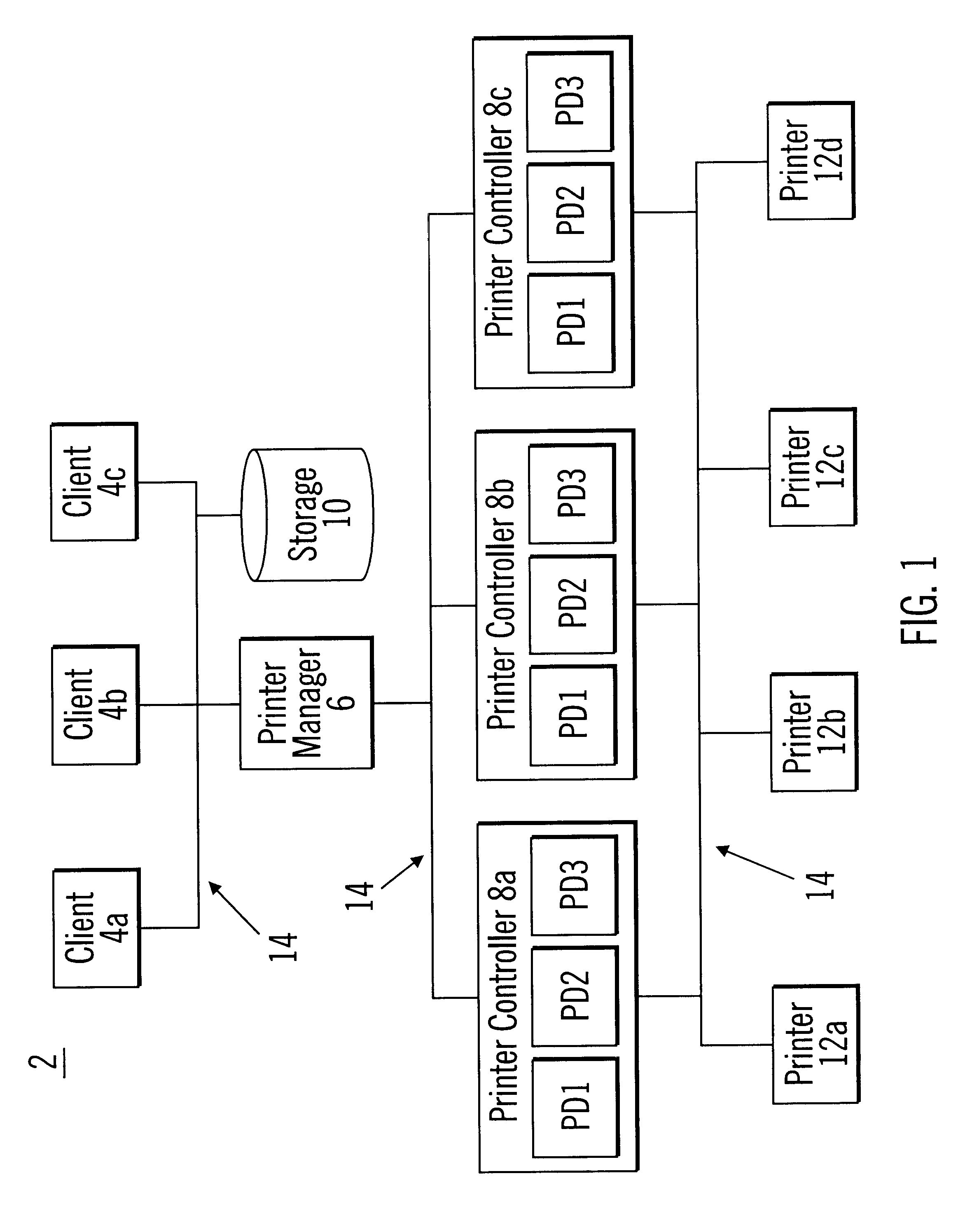

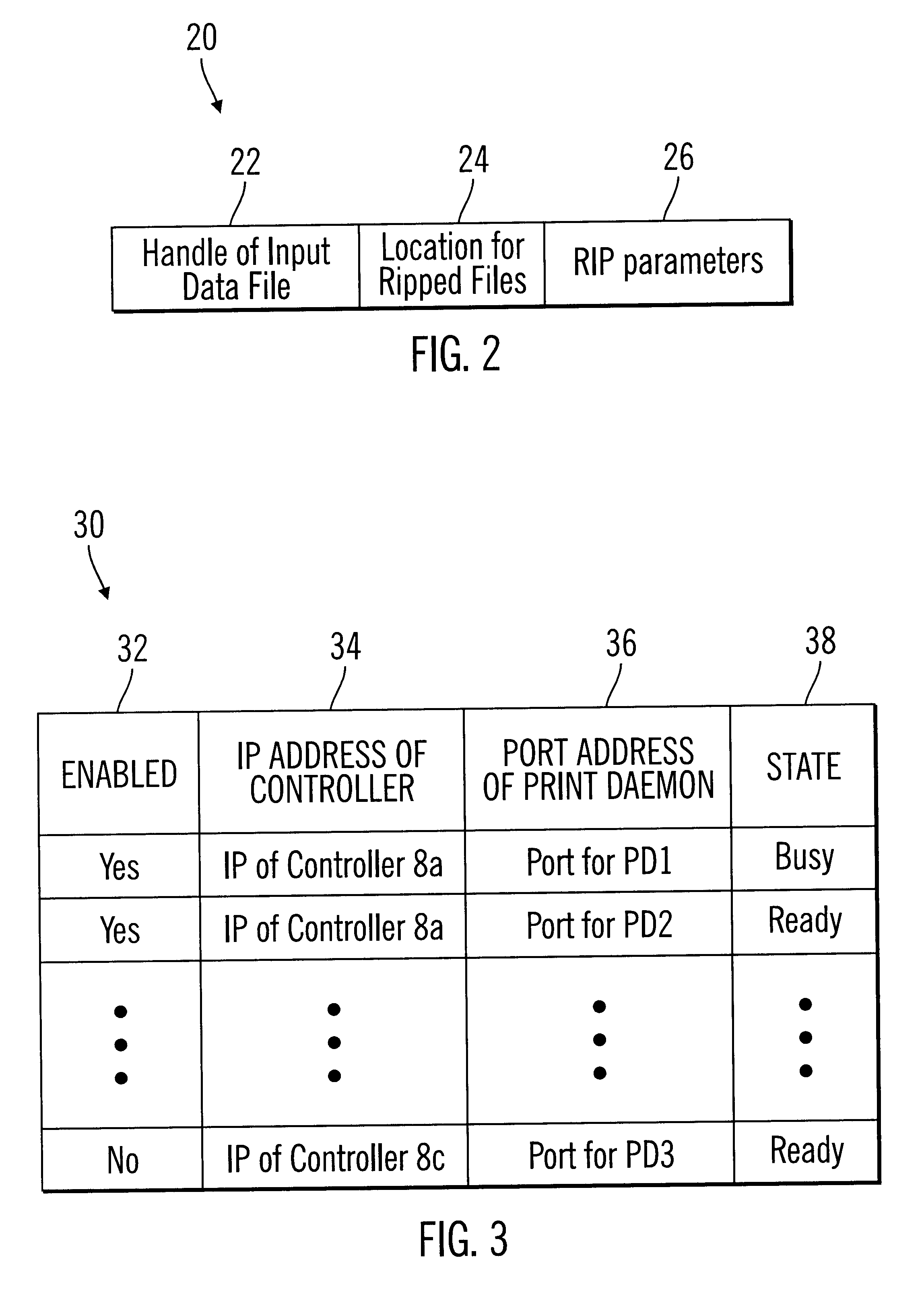

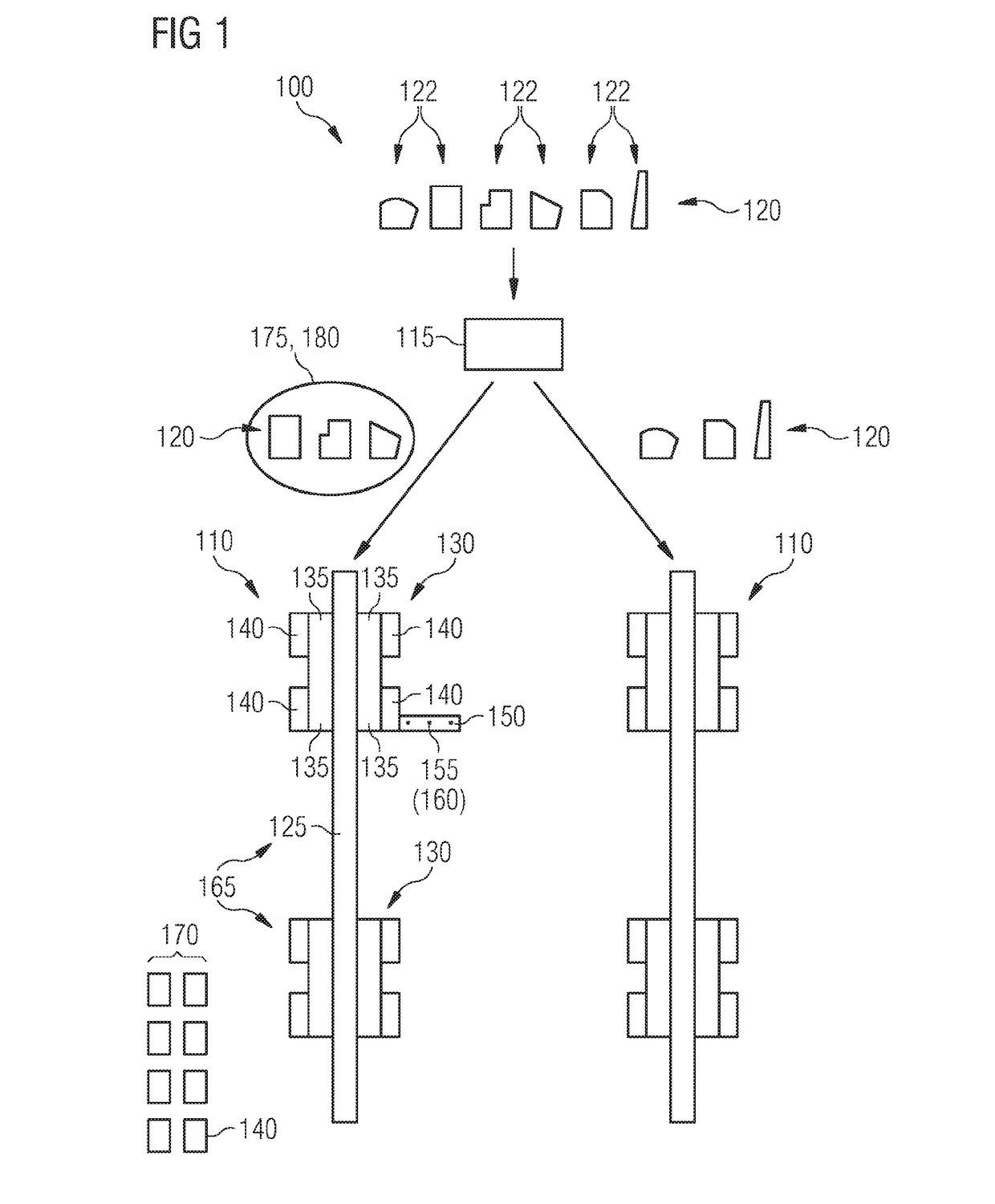

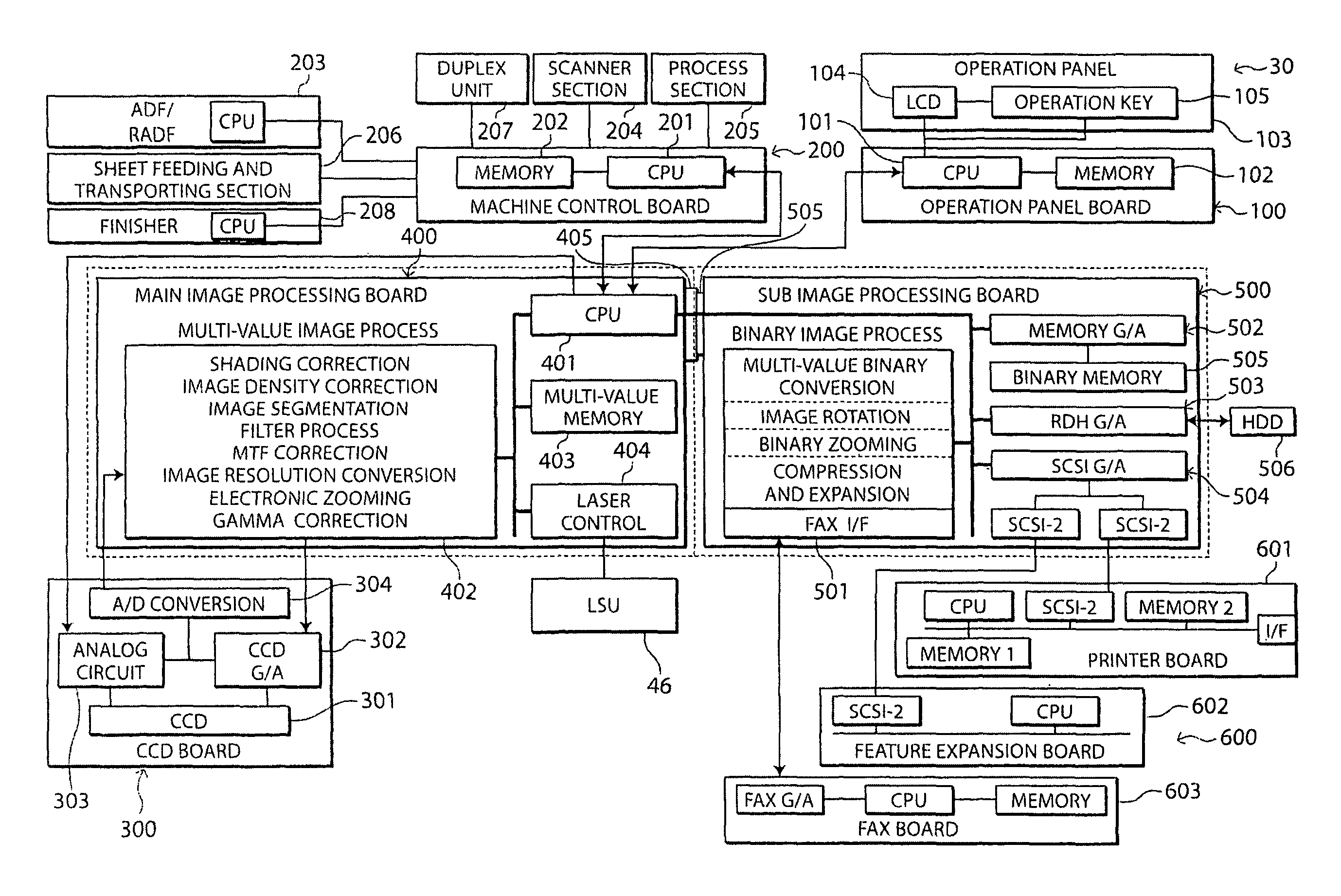

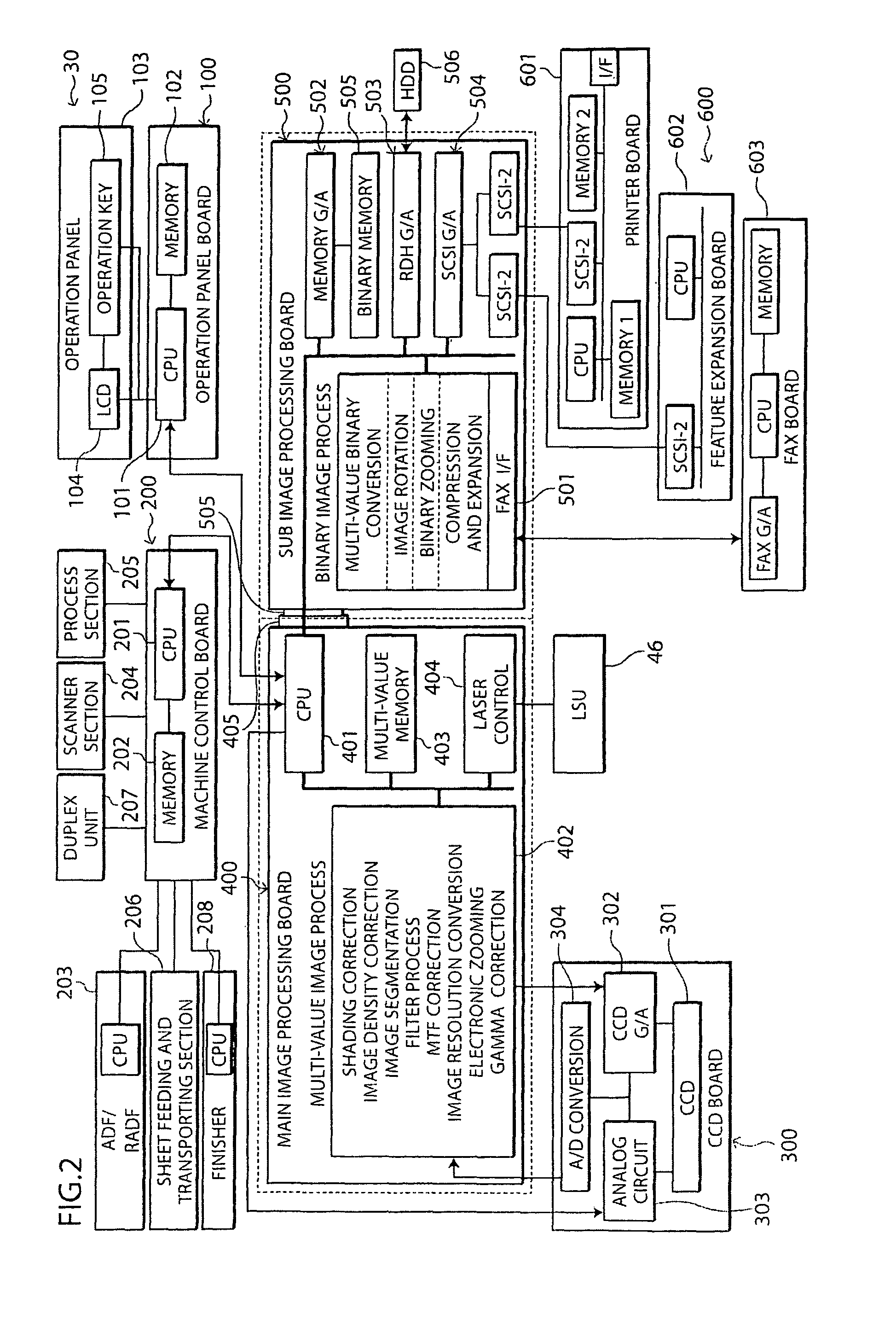

Load balancing for processing a queue of print jobs

InactiveUS6373585B1Maximize useSave consumptionDigital computer detailsVisual presentationData streamData file

A system is provided for processing a print job. A processing unit, such as a server, receives a plurality of print job files. Each print job file is associated with a data file. The print job files are maintained in a queue of print job files. The processing unit selects a print job file in the queue and processes a data structure indicating a plurality of transform processes and the availability of each indicated transform process to process a data file. The processing unit selects an available transform process, such as a RIP process, in response to processing the data structure and indicates in the data structure that the selected transform process is unavailable. The transform process processes the data file associated with the selected print job to generate a printer supported output data stream.

Owner:RICOH KK

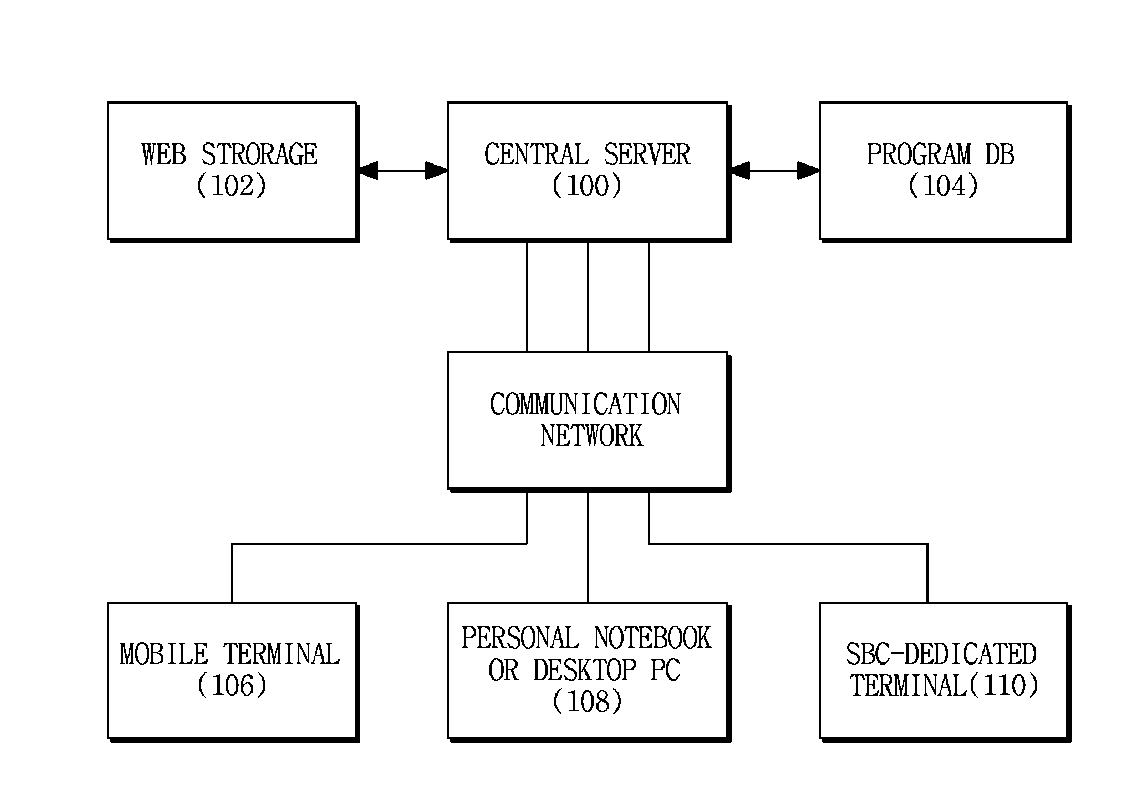

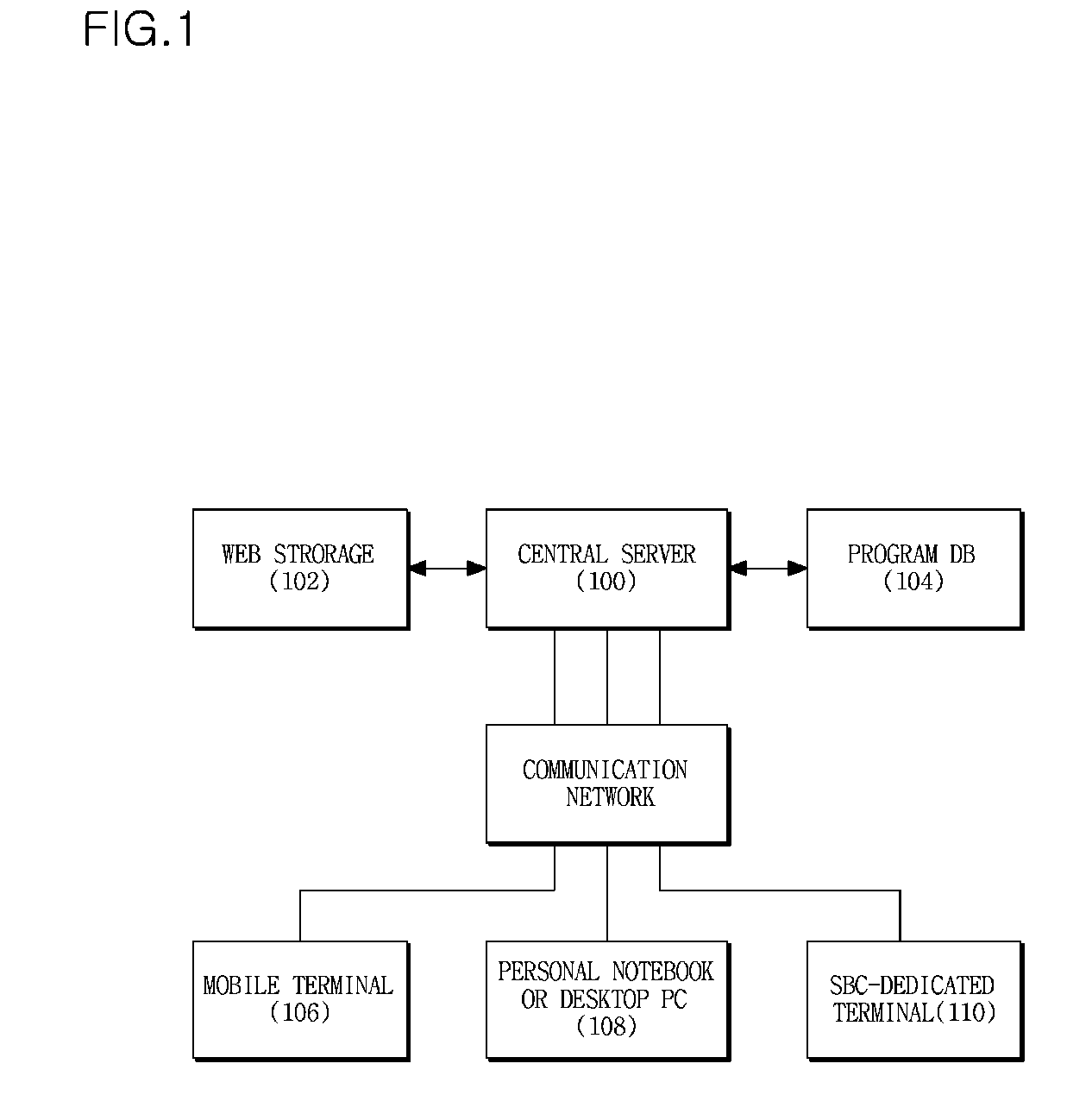

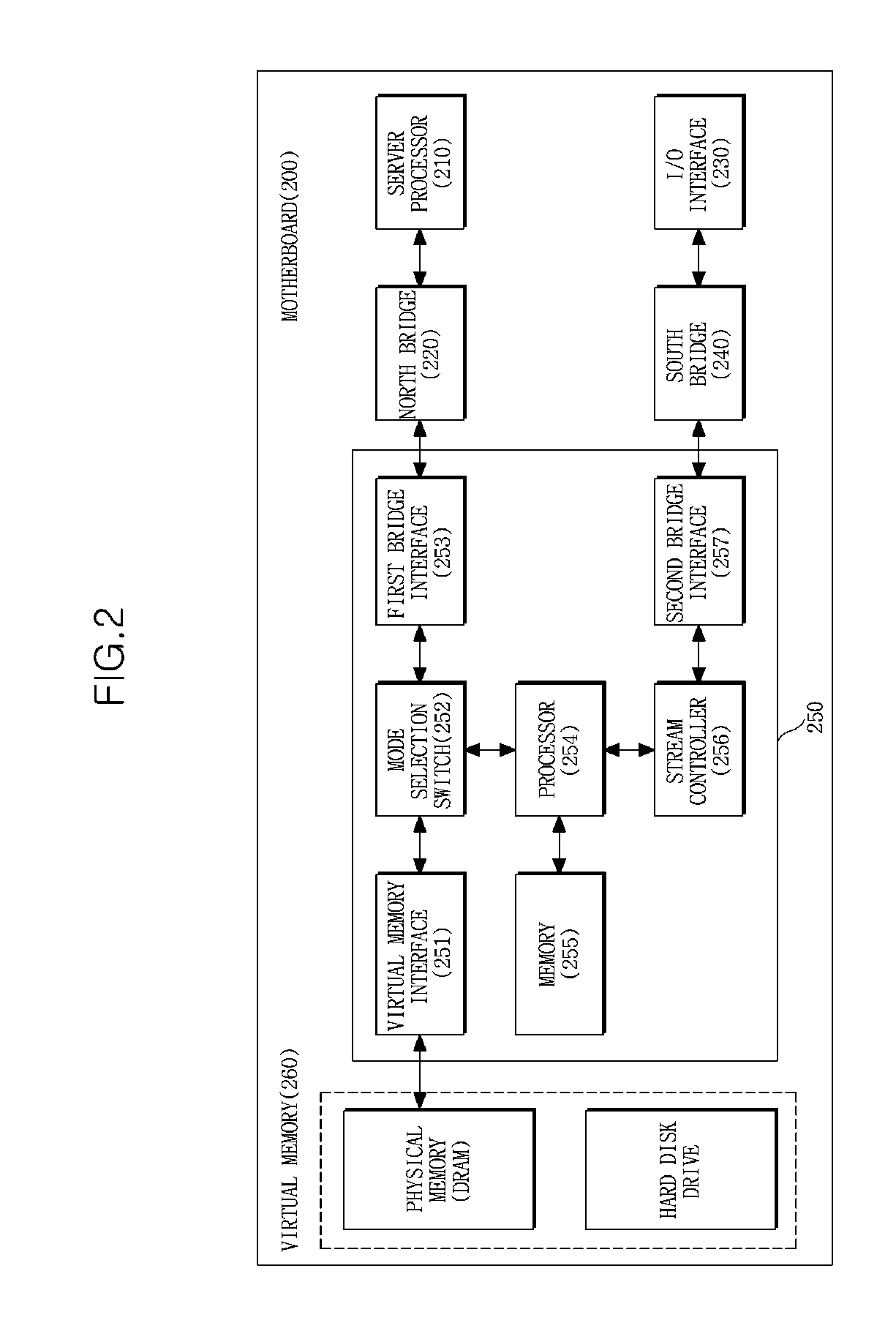

Virtual computing accelerator and program downloading method for server-based virtual computing

InactiveUS20100088448A1Minimize waiting timeReduce loadMultiple digital computer combinationsComponent plug-in assemblagesVirtual memoryClient-side

Provided are a virtual computing accelerator and program downloading method for server-based virtual computing. The virtual computing accelerator divides a program allocated to a virtual memory into groups, such as pages or segments, and downloads the groups of program data in sequence. Here, the groups of program data are downloaded after download sequence is estimated on the basis of statistical data accumulated in a hash table, or only a part that must be first downloaded is downloaded in advance. Thus, a program-execution wait time of a client can be reduced. In addition, only a part of a possibly required program is transferred in advance, and the client can execute the application program using only a small amount of virtual memory.

Owner:INFRANET +1

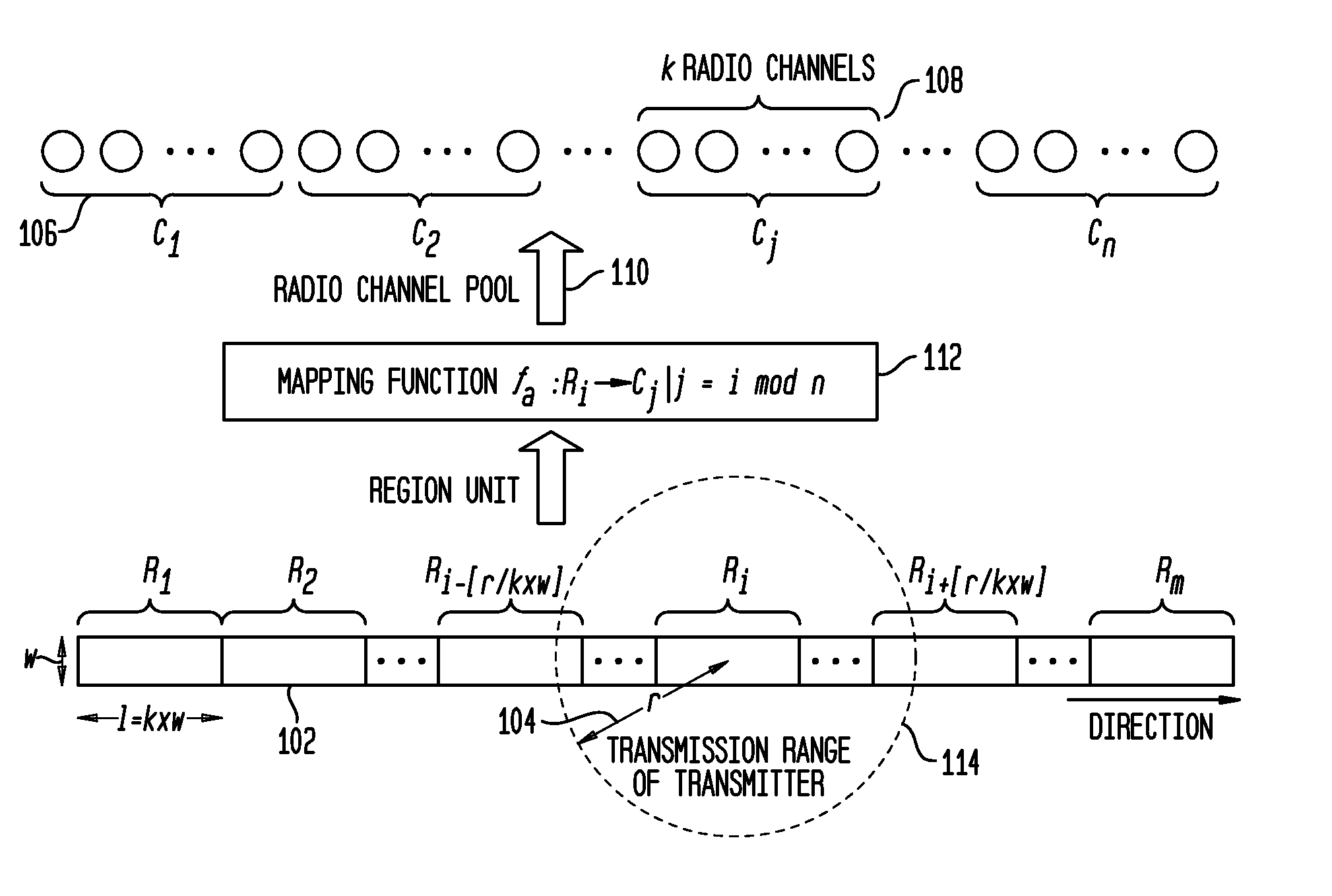

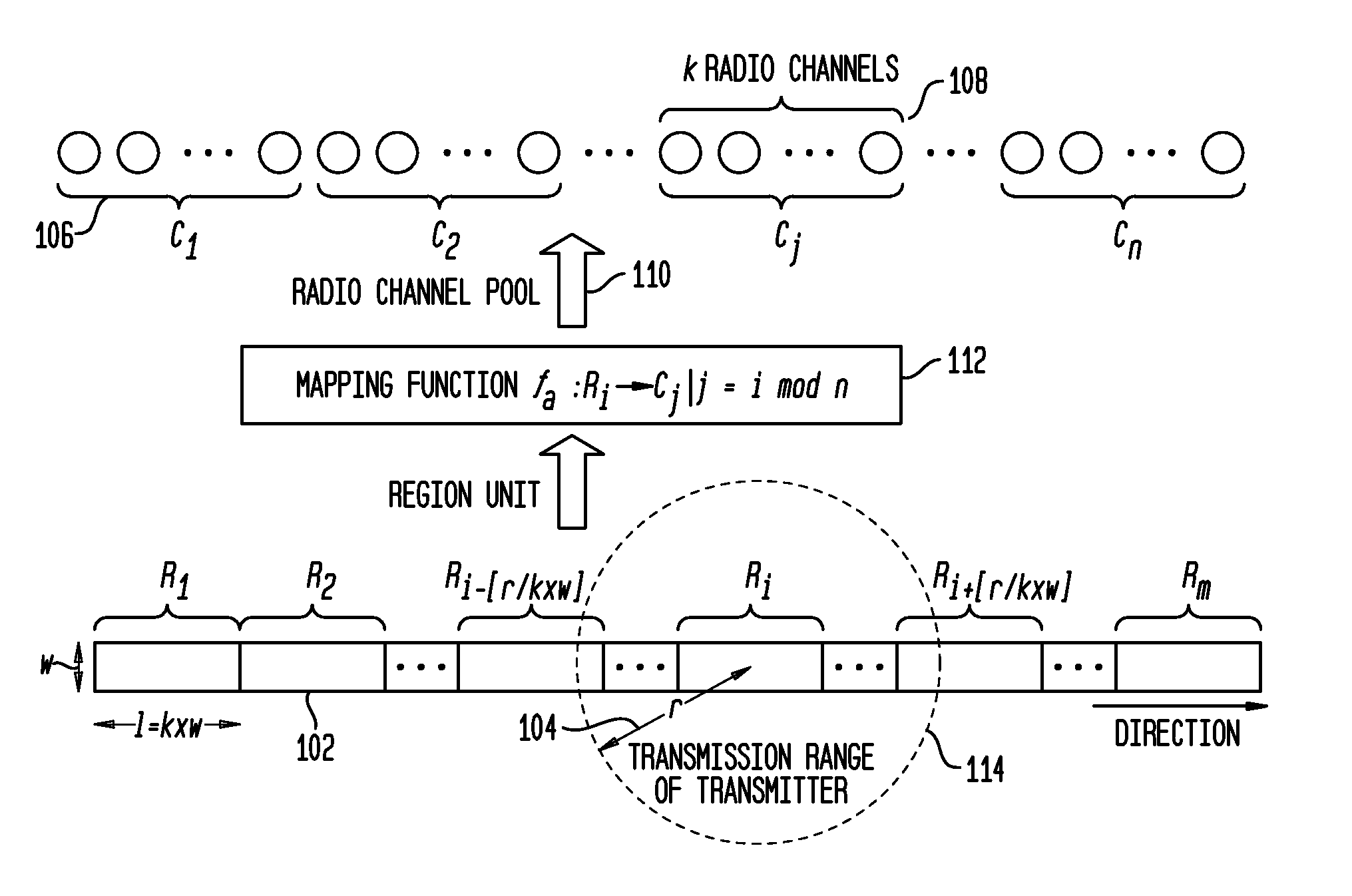

Region-based clustering mechanism for channel access in vehicular ad hoc networks

ActiveUS20120120883A1High data transmission data throughputLower latencyNetwork topologiesWireless commuication servicesTime division multiple accessTelecommunications

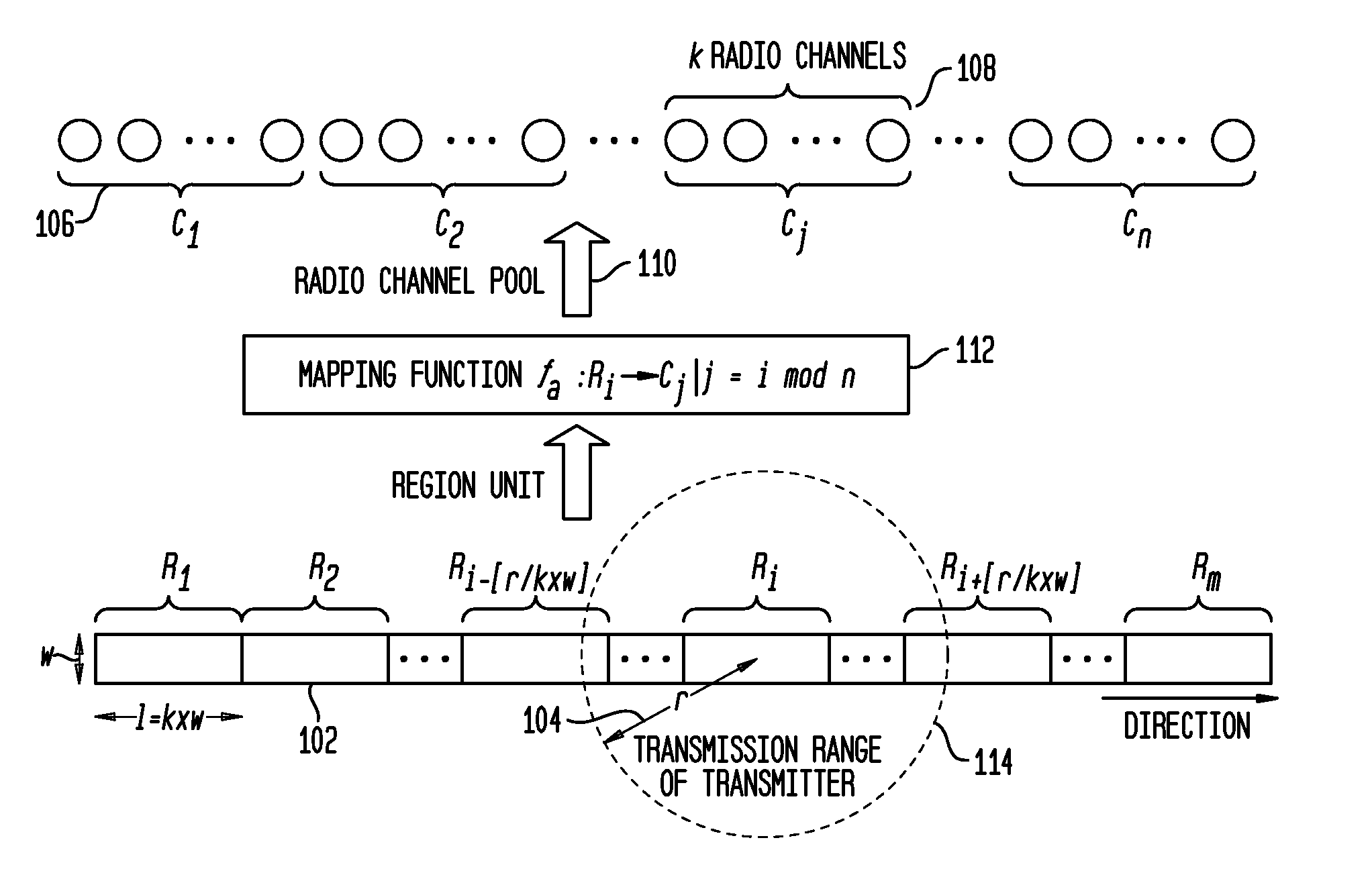

In a Vehicular Ad Hoc Network (VANET) a hybrid method combines SDMA (Space Division Multiple Access) and dynamic TDMA (Time Division Multiple Access) that divides the roadway into regions (whose size is larger than the SDMA unit) where each region is allocated a pool of radio channels based on SDMA and may contain a limited number of vehicles. Vehicles within the same region compete for and access the channels using dynamic TDMA. A channel allocation scheme that maps the pool of channels to the regions such that when a vehicle acquires multiple channels (time slots) in a region, the intervals among the channels are as uniform as possible, thus minimizing the waiting time of the messages to be broadcast by the vehicle, which is critical for safety related applications. This solution is referred to as R-SDMA (Region based SDMA).

Owner:TELCORDIA APPLIED RES CENT TAIWAN

Method for implementing an energy management of a vehicle

InactiveUS20130345945A1Improve energy consumptionThe degree of freedom becomes largerAnalogue computers for vehiclesBatteries circuit arrangementsElectricityElectric drive

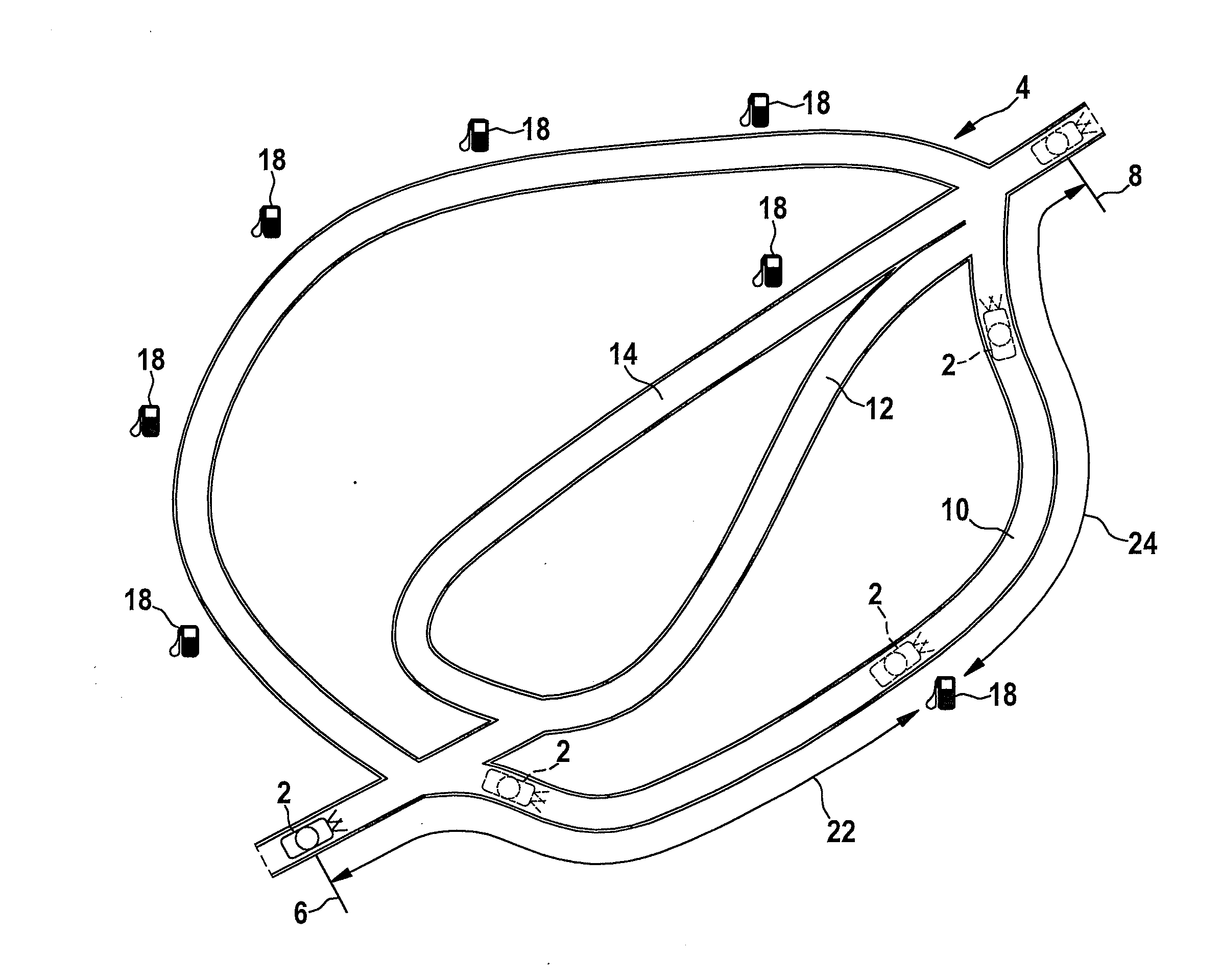

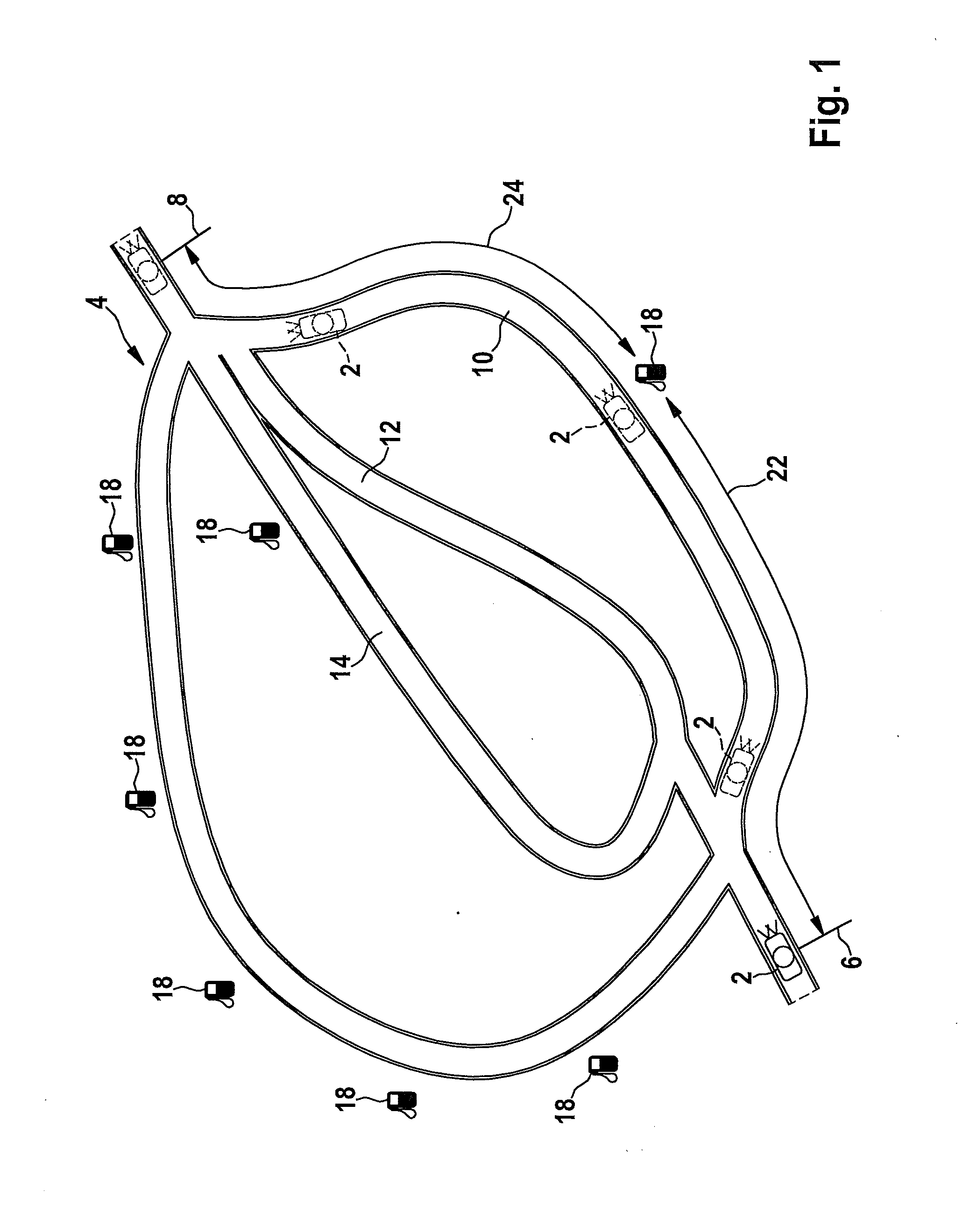

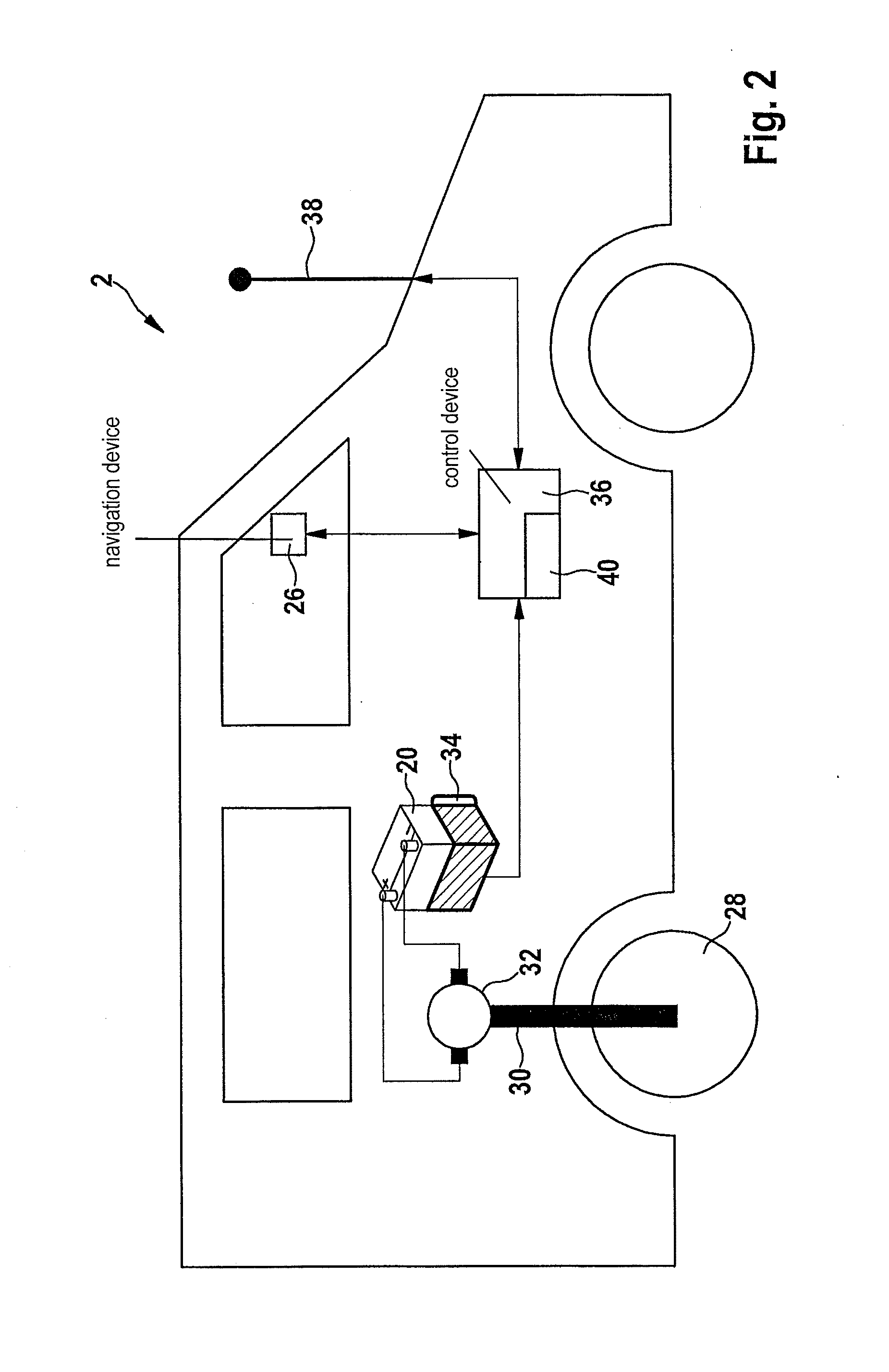

A method for implementing an energy management of a vehicle which is movable via an electric drive, the electric drive being able to be driven by electrical energy stored in an electrical energy store, the method including: inputting a destination; and searching for a route to the destination, on which an available electrical energy source able to be used to recharge the electrical energy store is available within a minimum distance; the minimum distance corresponding to a path along which the vehicle is minimally still able to drive using the energy stored in the electrical energy store.

Owner:ROBERT BOSCH GMBH

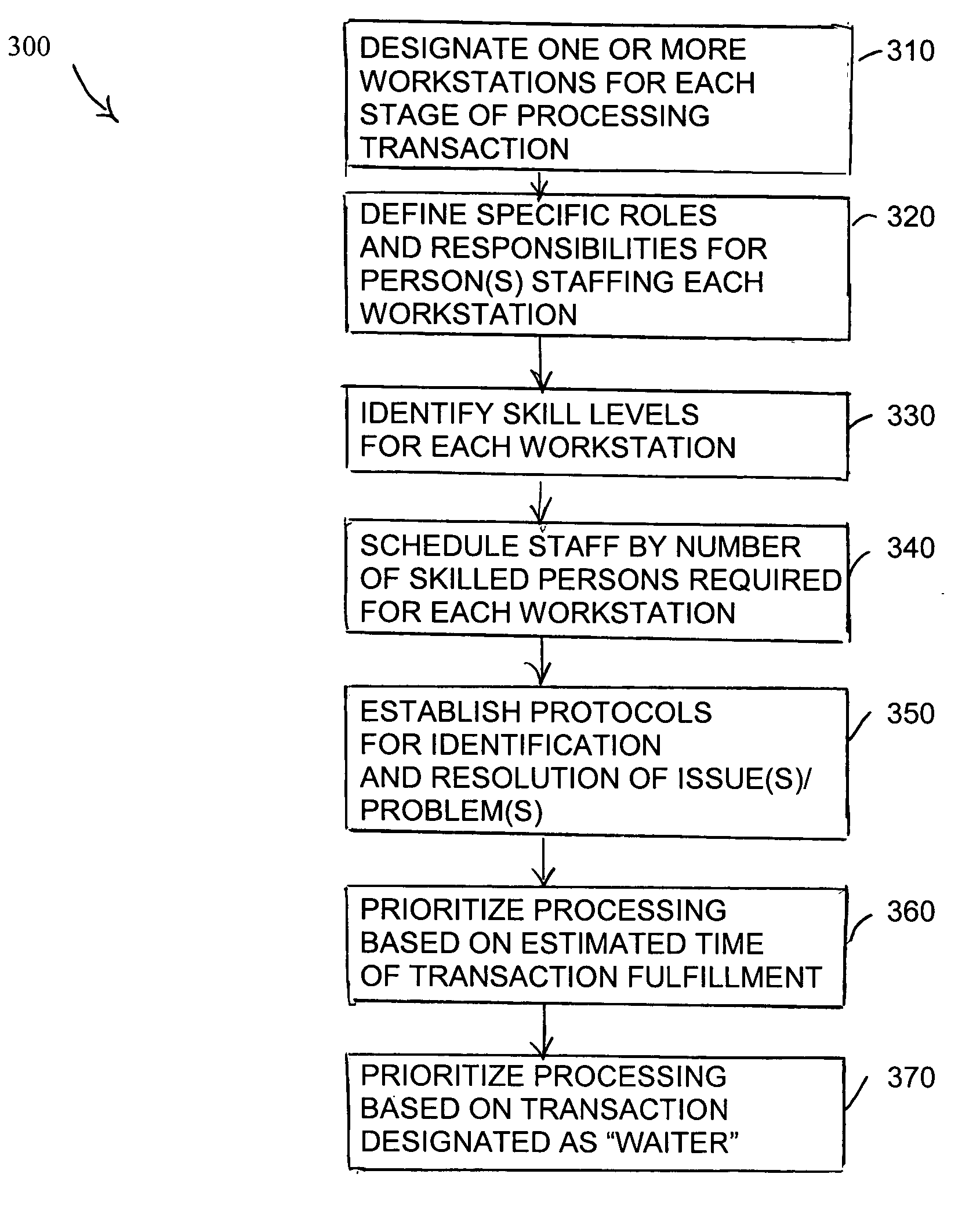

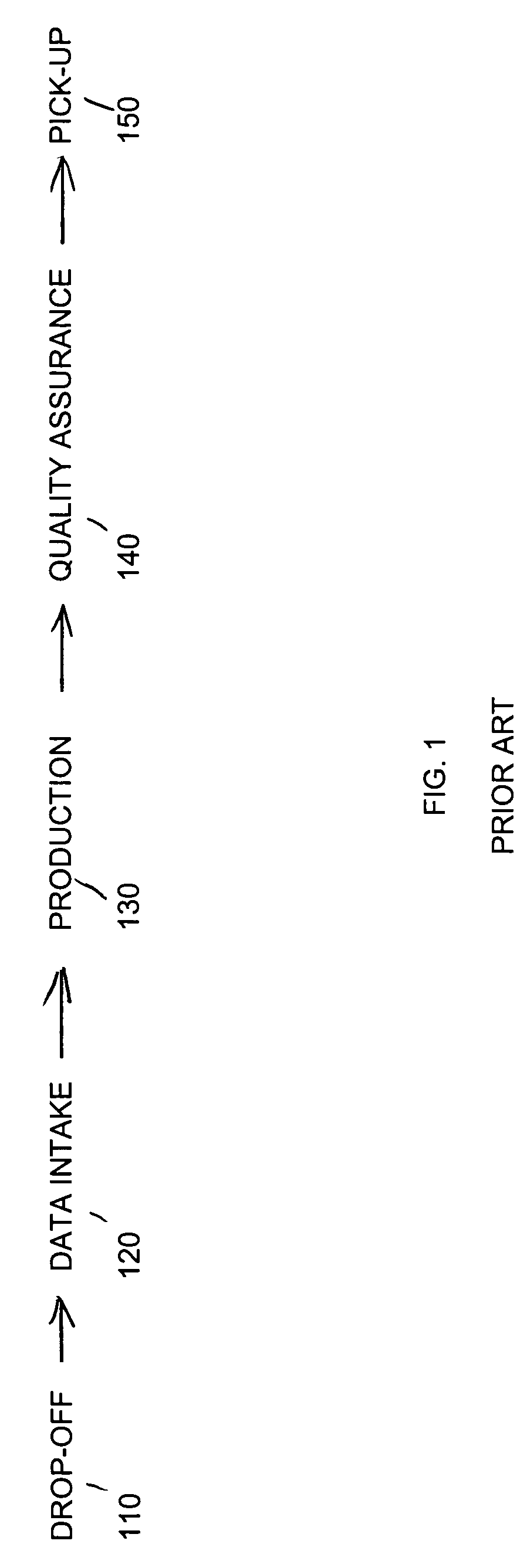

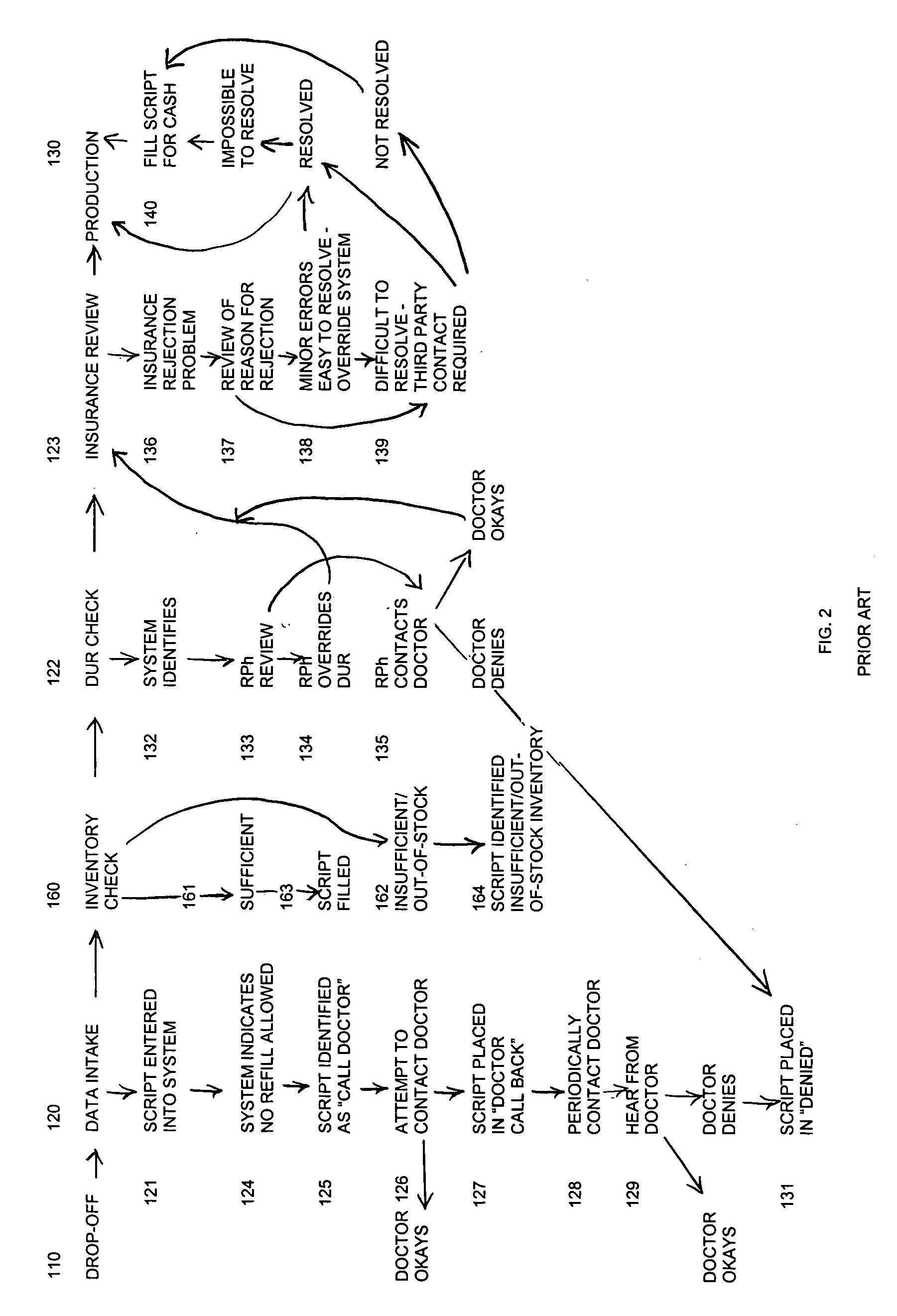

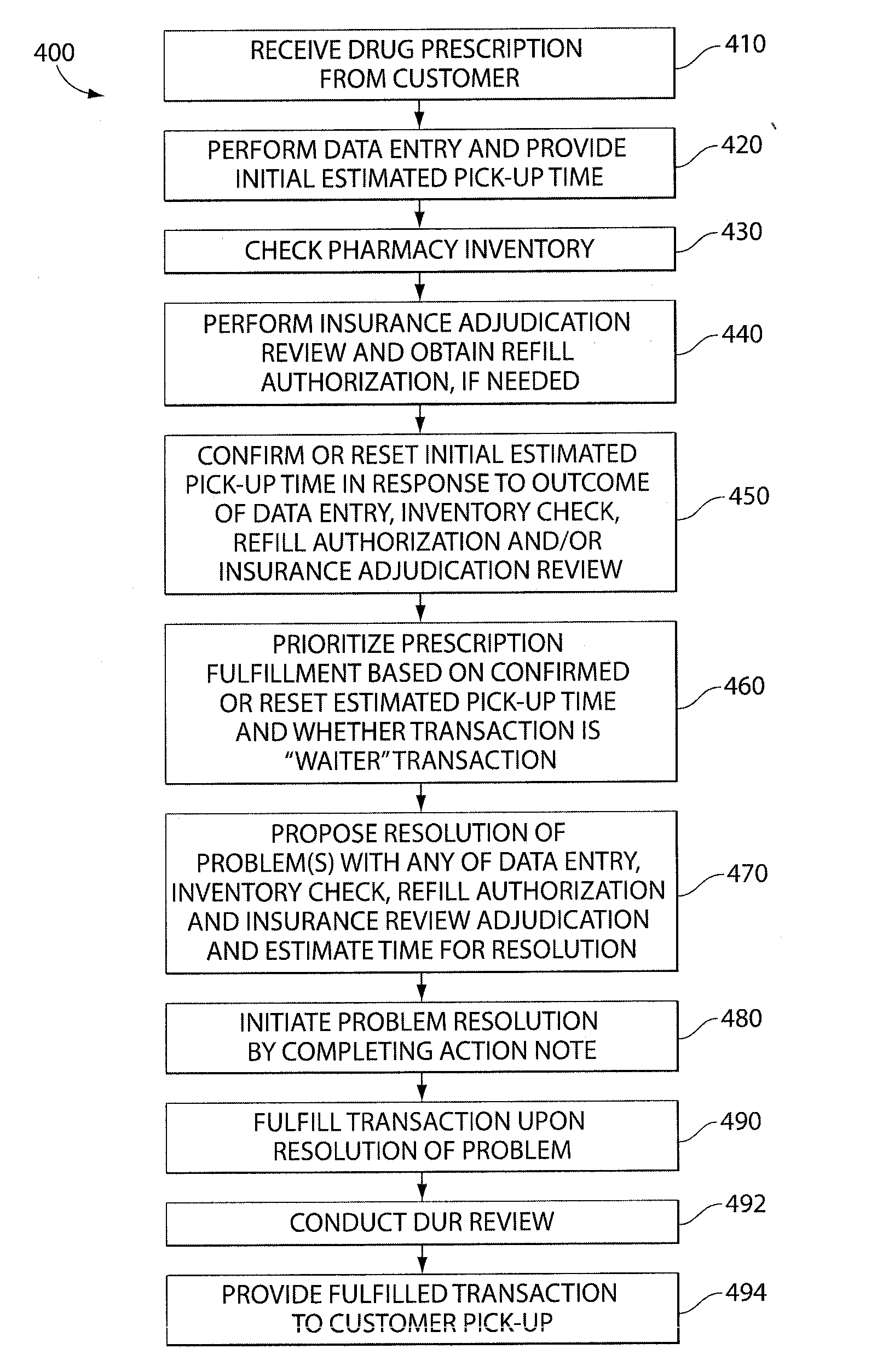

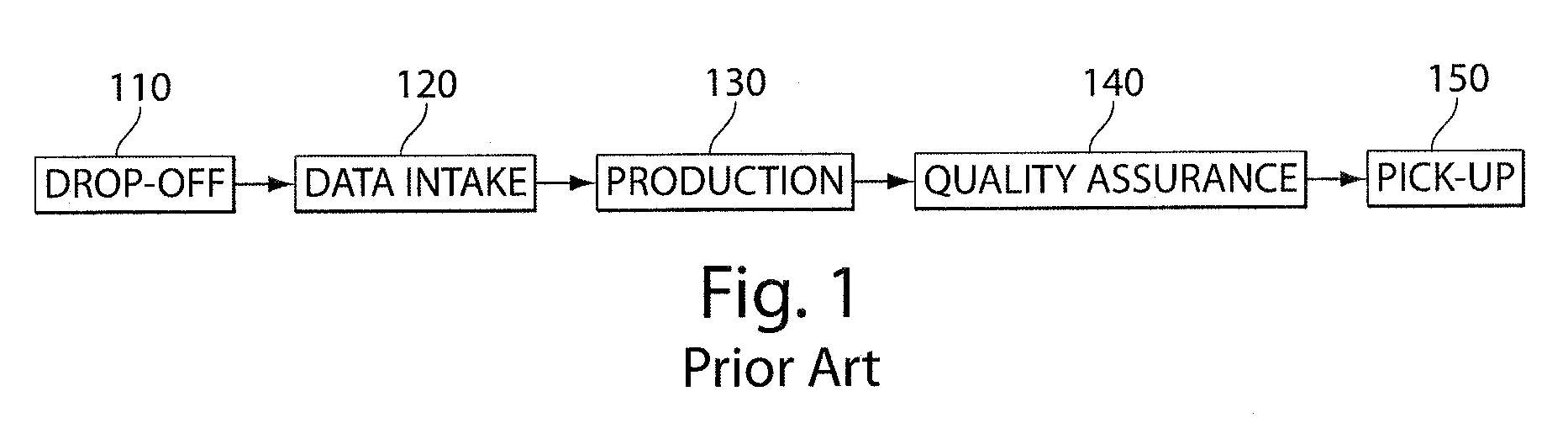

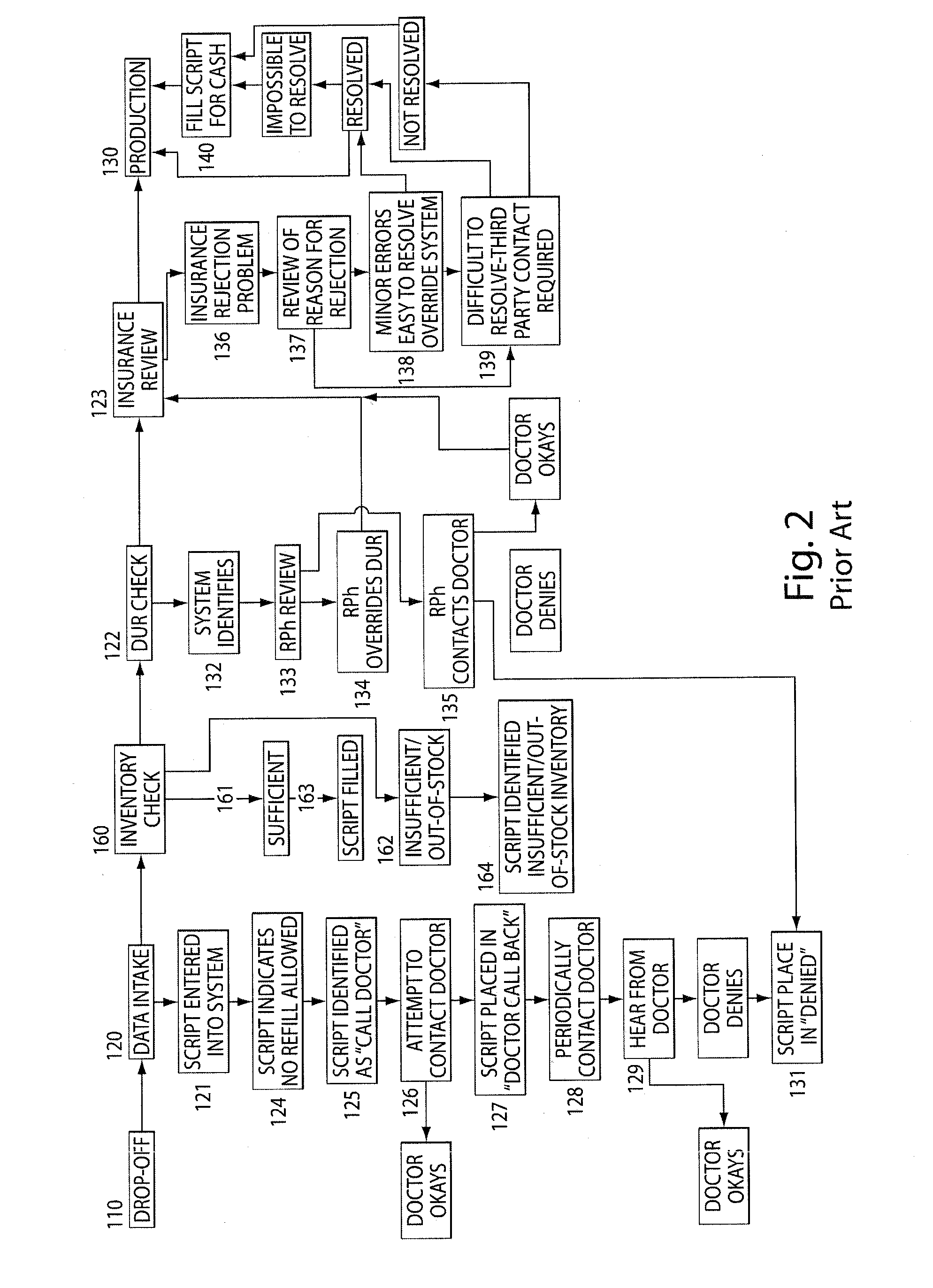

System and methods of providing pharmacy services

ActiveUS20050228766A1Minimize customer wait time customerMinimize customer customer drop-off/pick-up lineDigital data processing detailsDrug and medicationsProgram planningQuality assurance

System and methods for processing a drug prescription transaction are configured to identify and resolve any issue or problem associated with the transaction during one or more early stages of processing. System and methods of processing the transaction handle prescription and customer data entry, pharmacy inventory check, prescription refill authorization check and / or insurance adjudication review well in advance of production and quality assurance stages by identifying and resolving any issue or problem. Prescription fulfillment is prioritized and estimated prescription pick-up times are predicted based on one or more outcomes of such early stage processing. Customers can be provided with realistic and relatively accurate prescription pick up times that a pharmacy can efficiently and consistently meet as a result of fulfillment prioritization. Further, system and methods for determining a staffing schedule for a workflow process requiring different skill levels during different operaton times is provided.

Owner:CVS PHARMACY INC

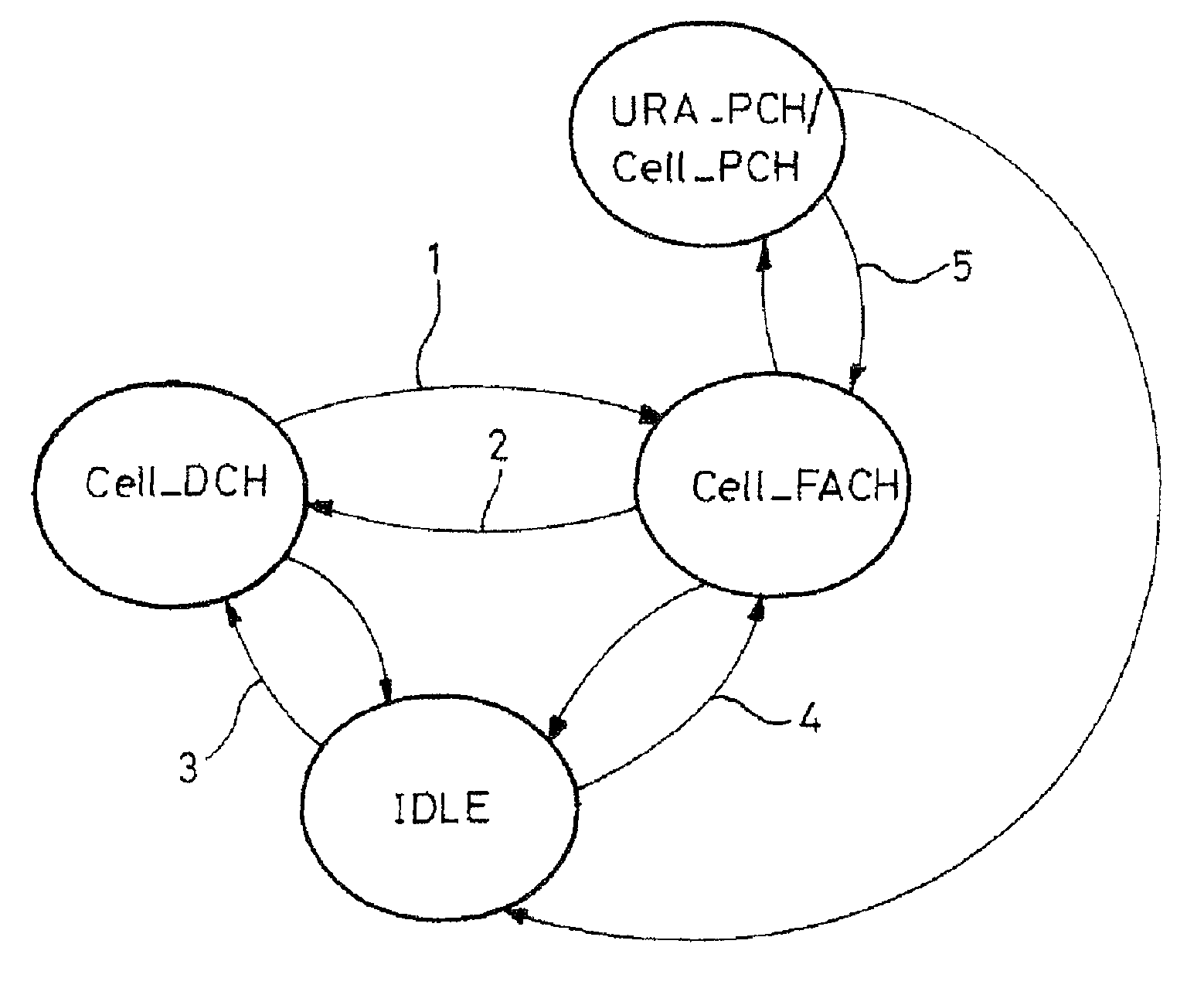

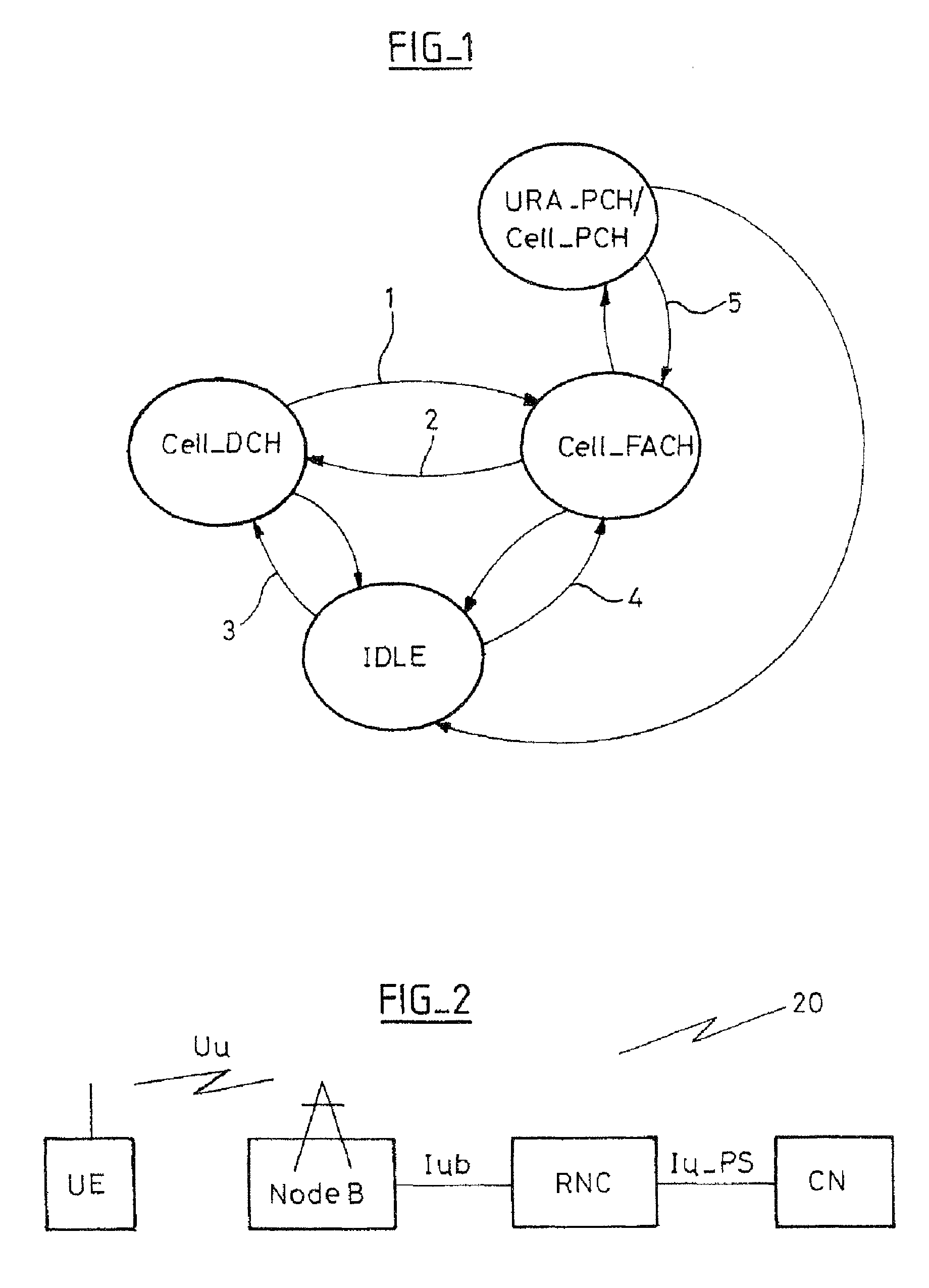

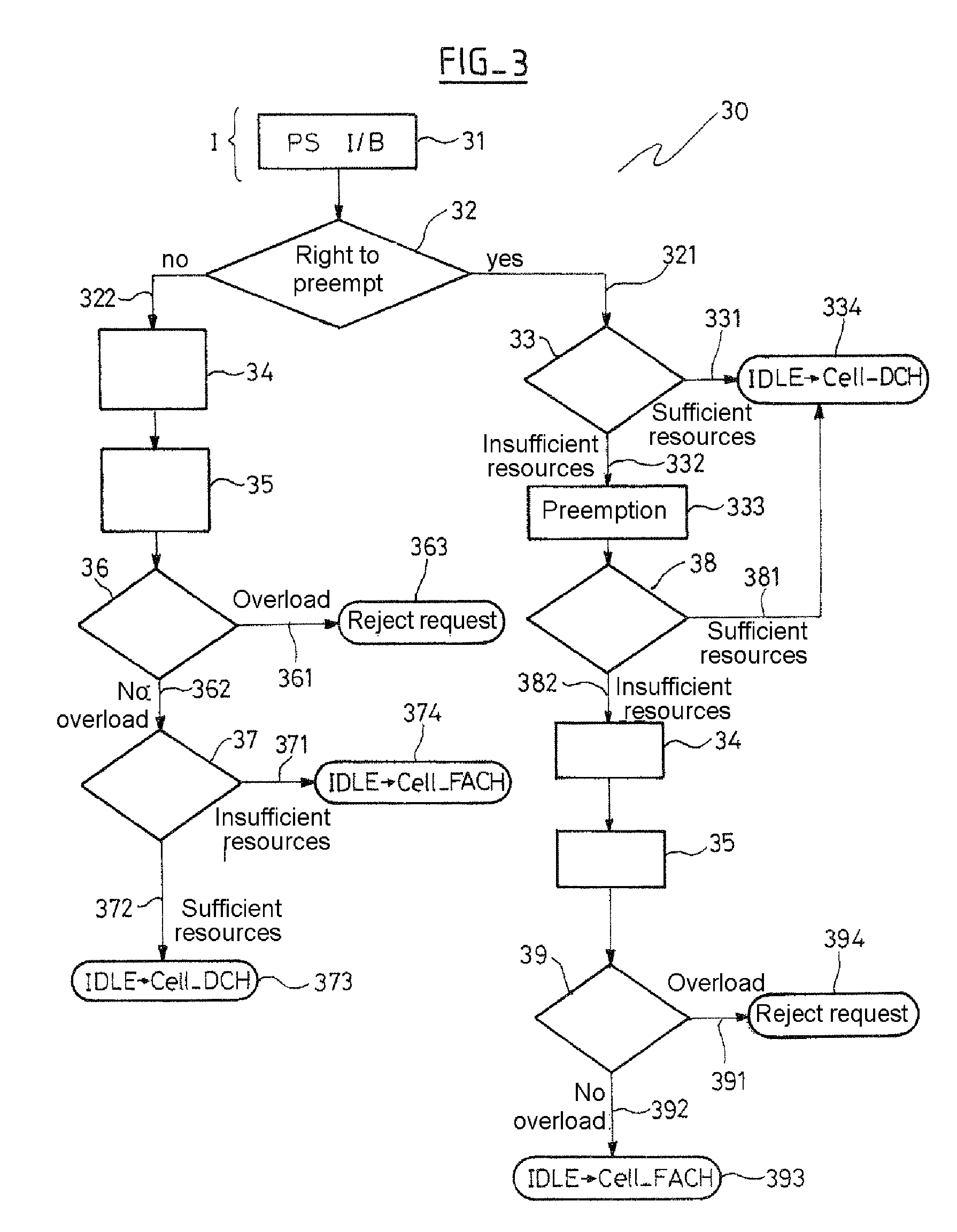

Method and device for management of an overload in a cell of a radio communication network, corresponding uses, computer program and storage means

ActiveUS20070135113A1Simple to implementMinimize waiting timeNetwork traffic/resource managementStore-and-forward switching systemsTelecommunicationsComputer program

The invention concerns a method of managing an overload in a cell of a cellular radio communication network comprising a plurality of user equipments (UE) each of which can switch between a plurality of states including a Cell_DCH state and a Cell_FACH state. According to the invention, this kind of method comprises the following steps, for each request (RAB request) for allocation of radio resources to a given user equipment in an initial state, before sending said request, in which initial state no radio resource is allocated to said user equipment: obtaining for said cell a current rate of successful transitions for the change from the Cell_FACH state to the Cell_DCH state; detecting an overload of the Cell_FACH state by analyzing said current rate of successful transitions; if an overload is detected, rejecting said request; if no overload is detected, accepting said request and switching said user equipment from said initial state to a final state in which at least one radio resource is allocated to said user equipment.

Owner:WSOU INVESTMENTS LLC

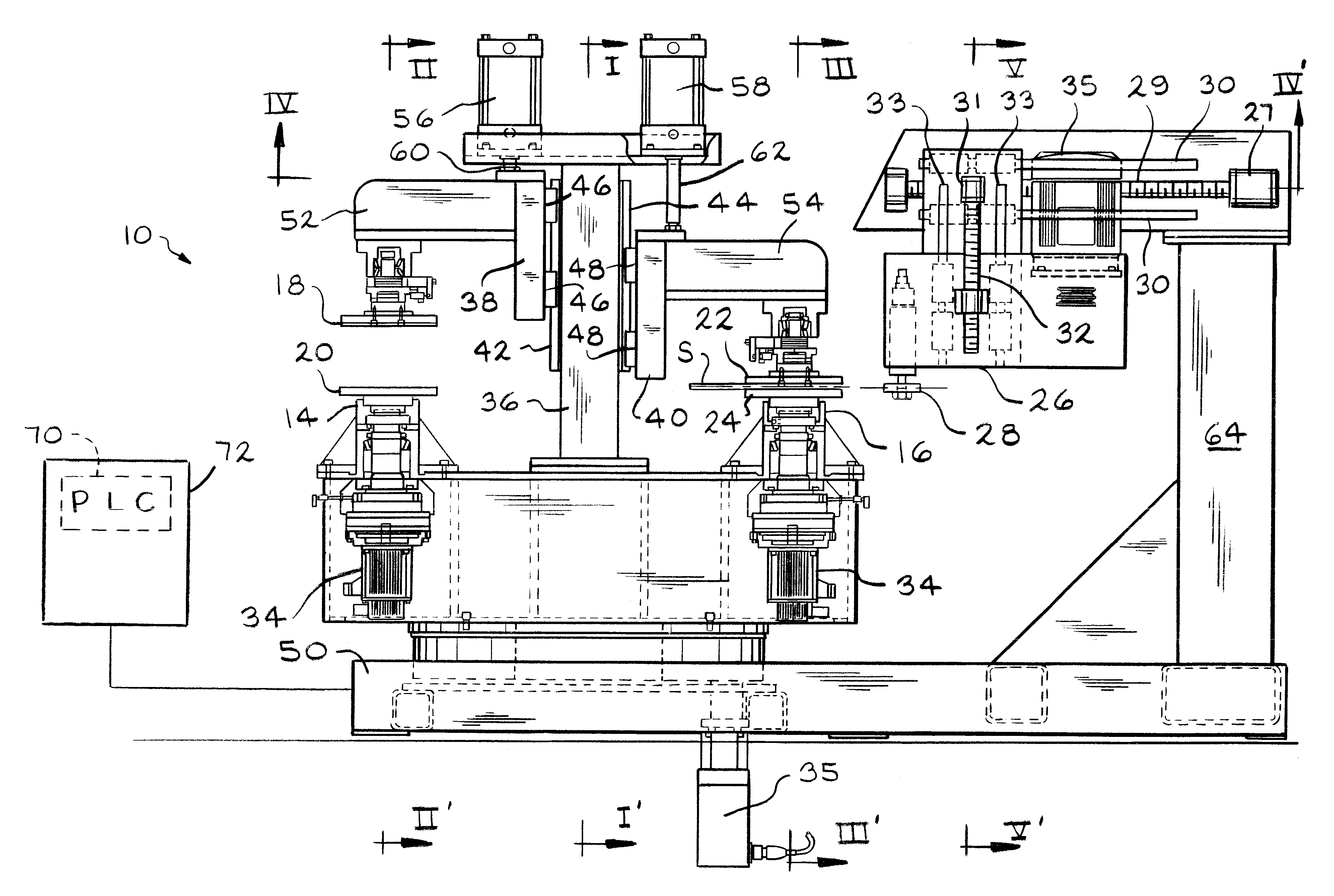

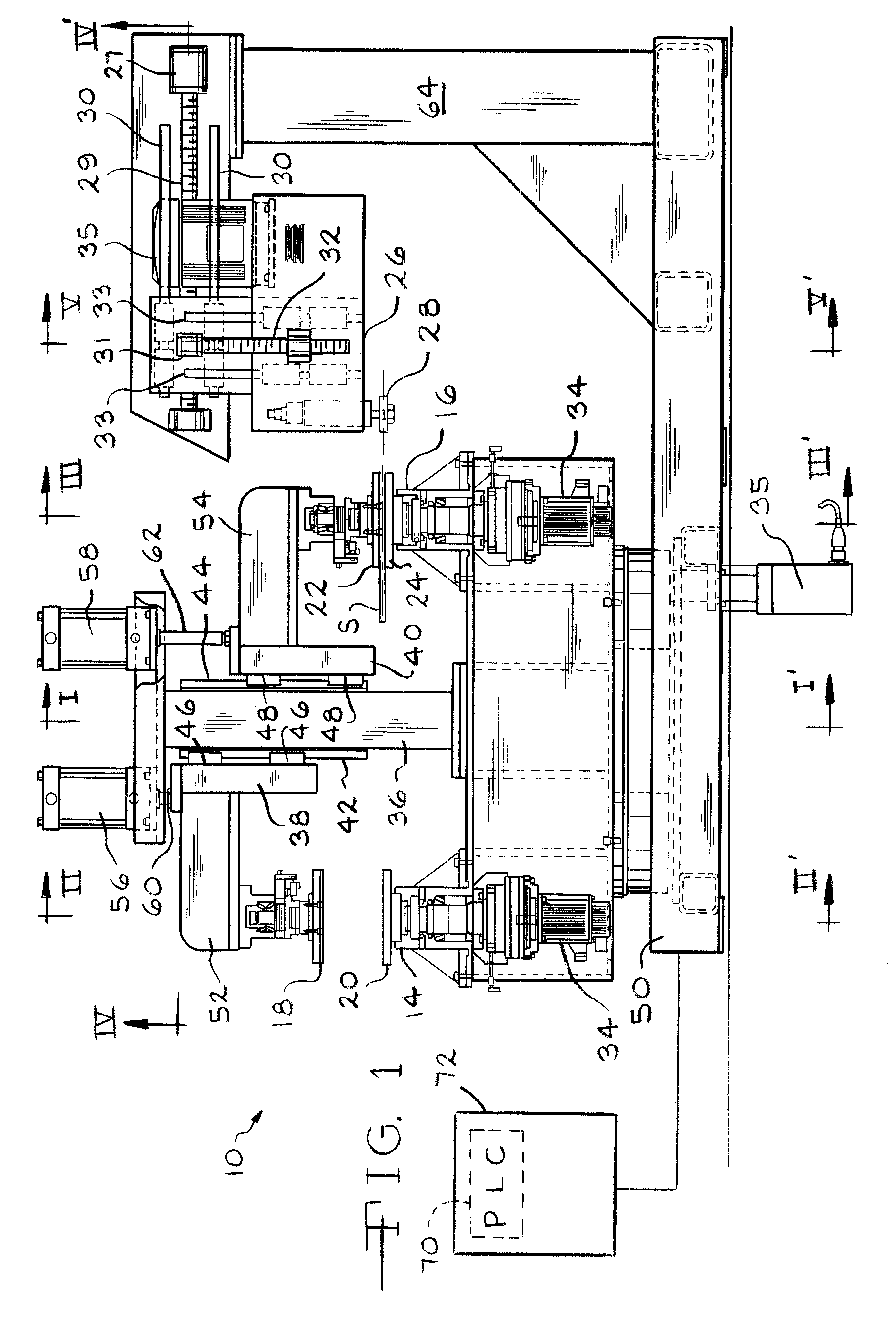

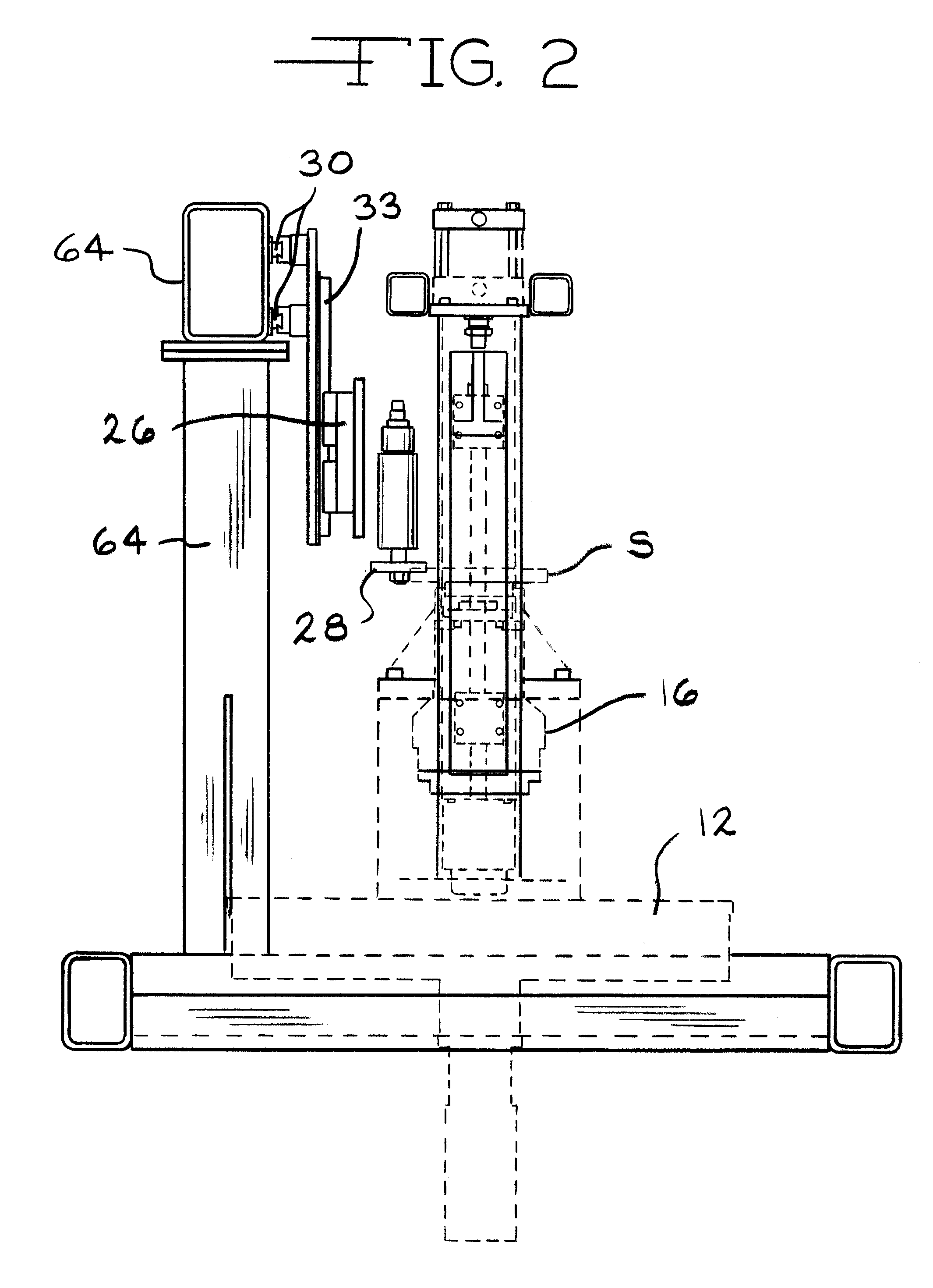

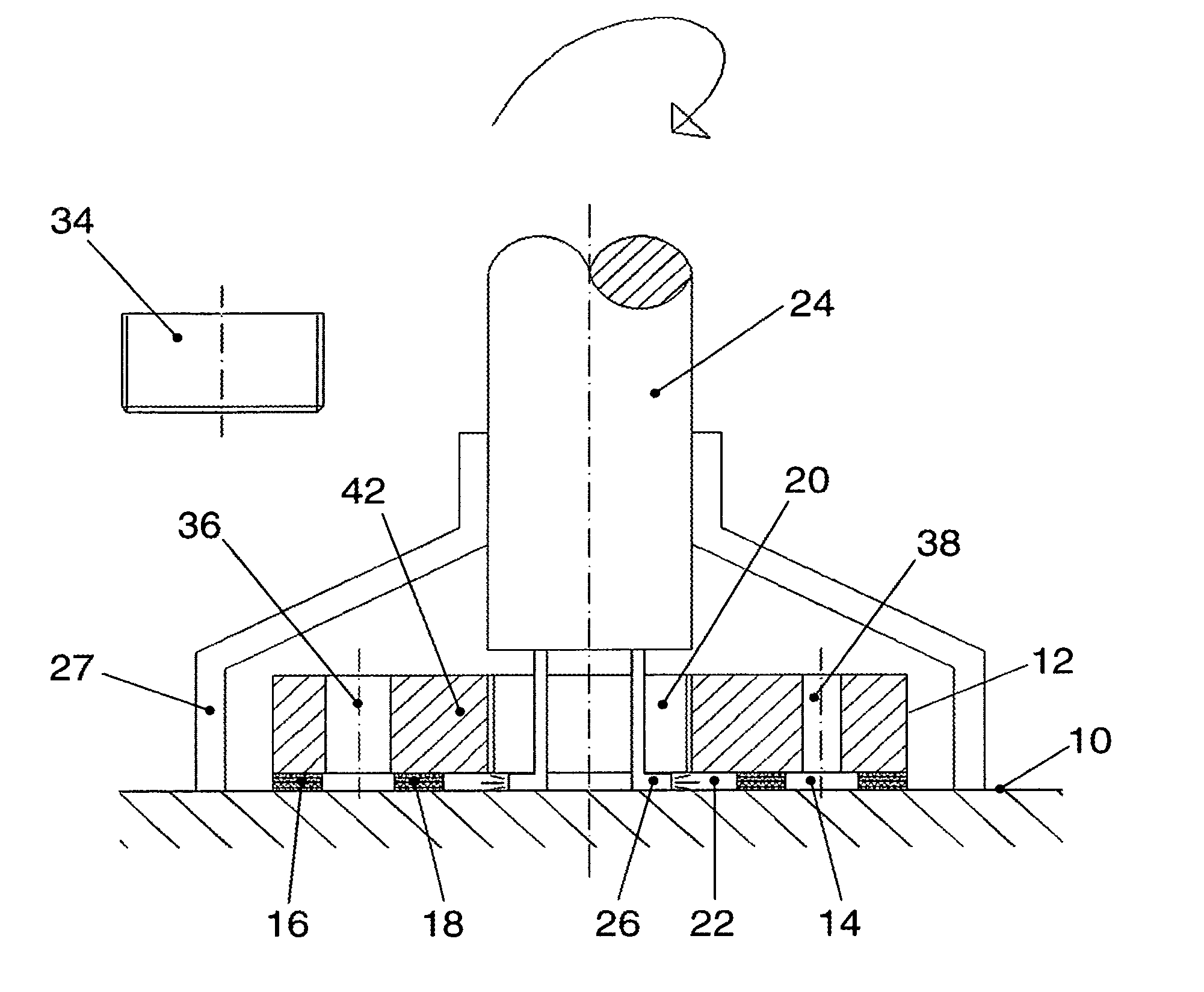

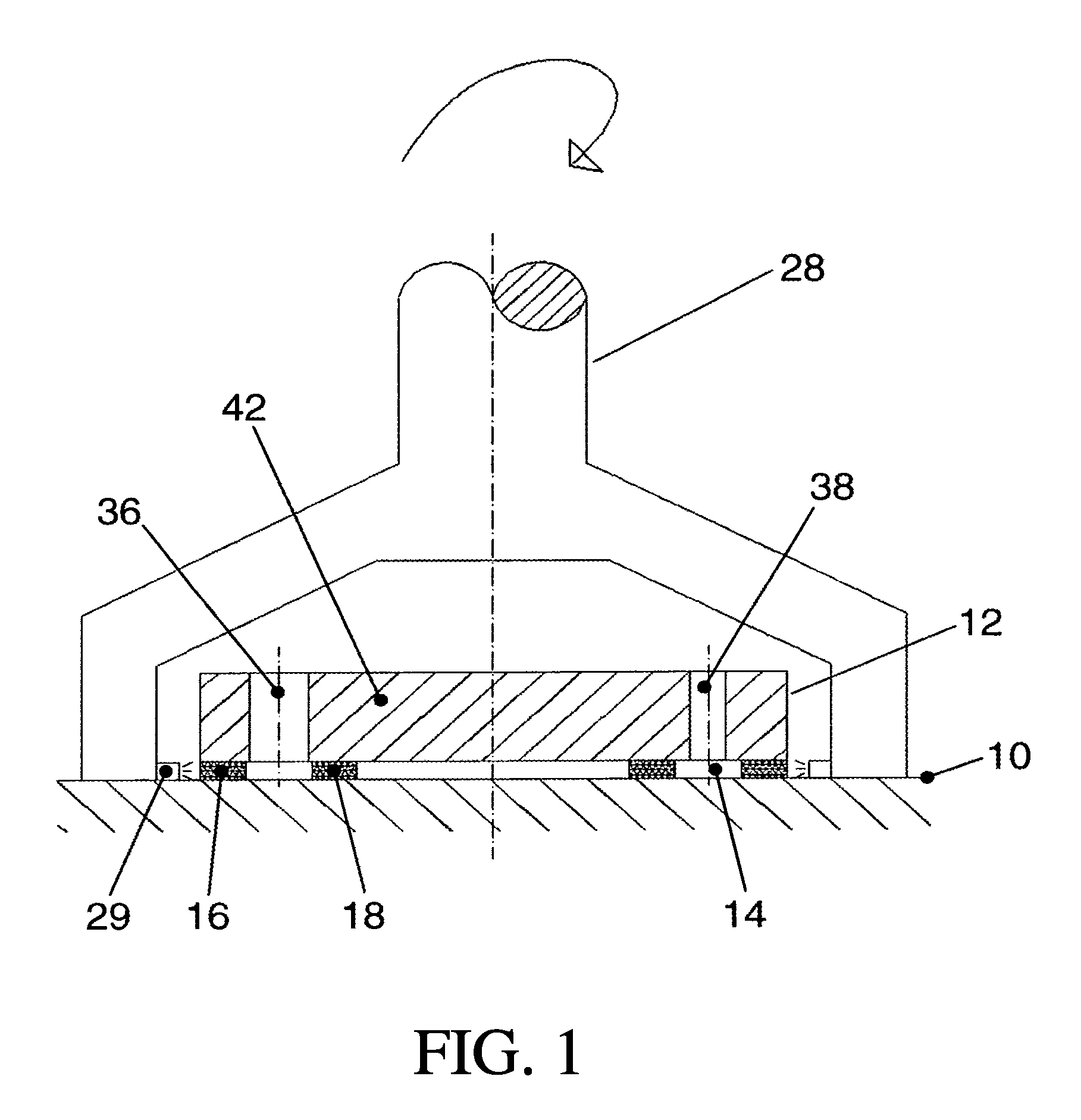

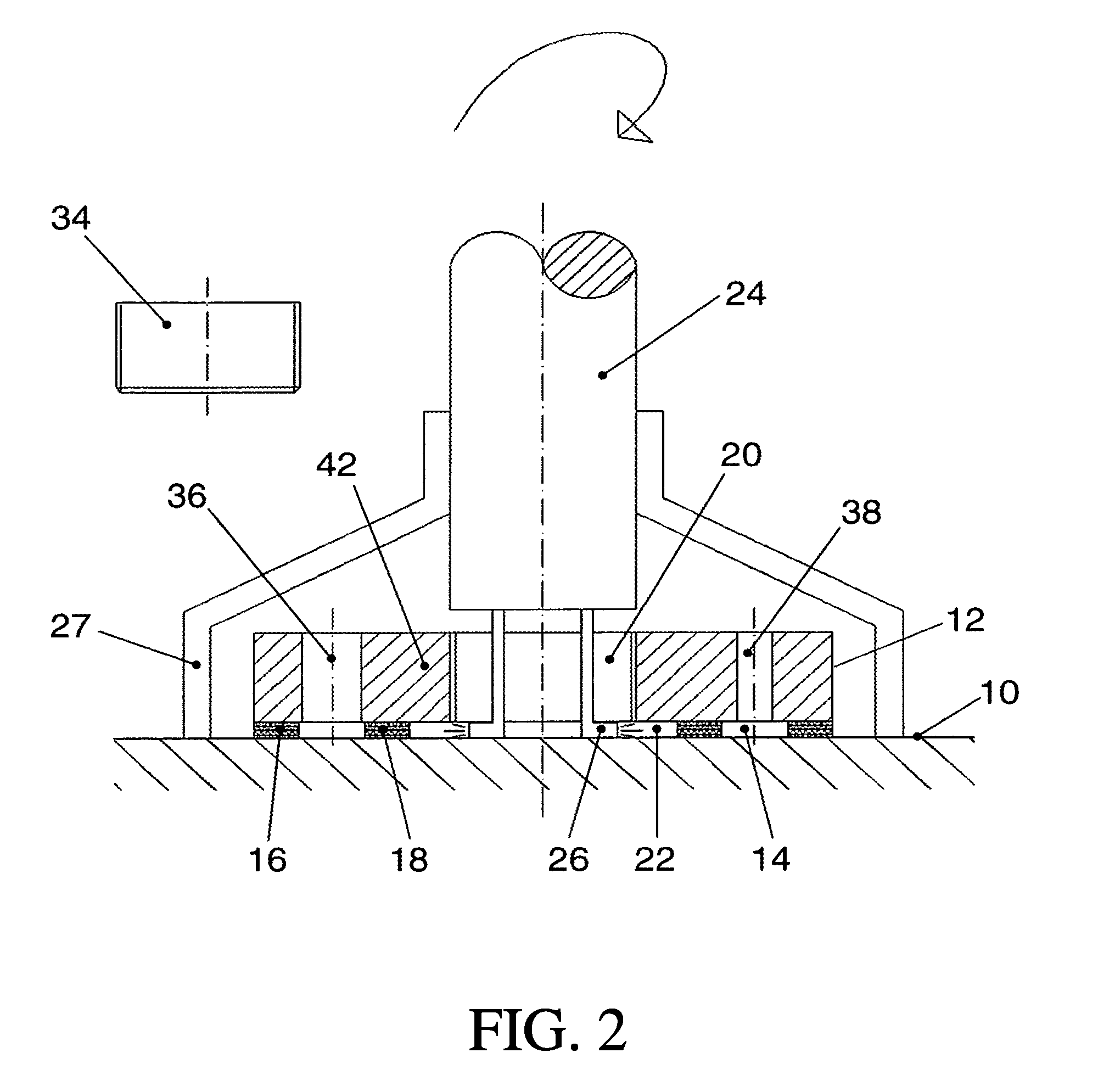

Machine for tooling small parts

InactiveUS6445971B1Reduce outputMinimize waiting timeTool changing apparatusLarge fixed membersGrindEngineering

This machine tool such as CNC edge grinding apparatus is an apparatus for machining small glass parts such as a side view mirror. For small parts, grind time can exceed by a considerable amount the load / unload time. This machine greatly increases the output of the system. It minimizes the waiting time by providing an auxiliary station for simultaneous unloading / loading while grinding. Controls integrate multiple axes, which are part of the holding mechanisms, with the linear axes of the grind head, to grind the part.

Owner:GLASSLINE

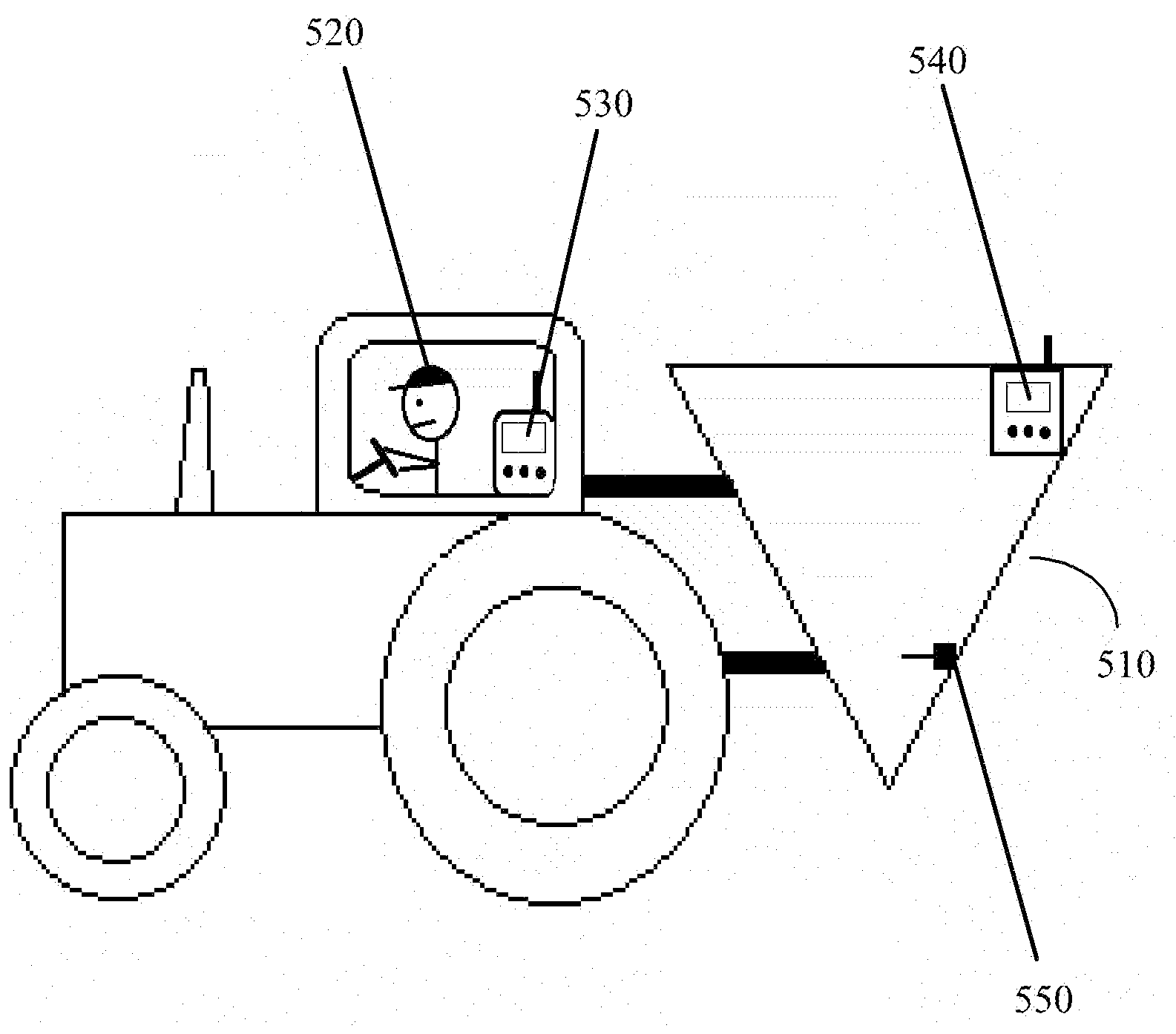

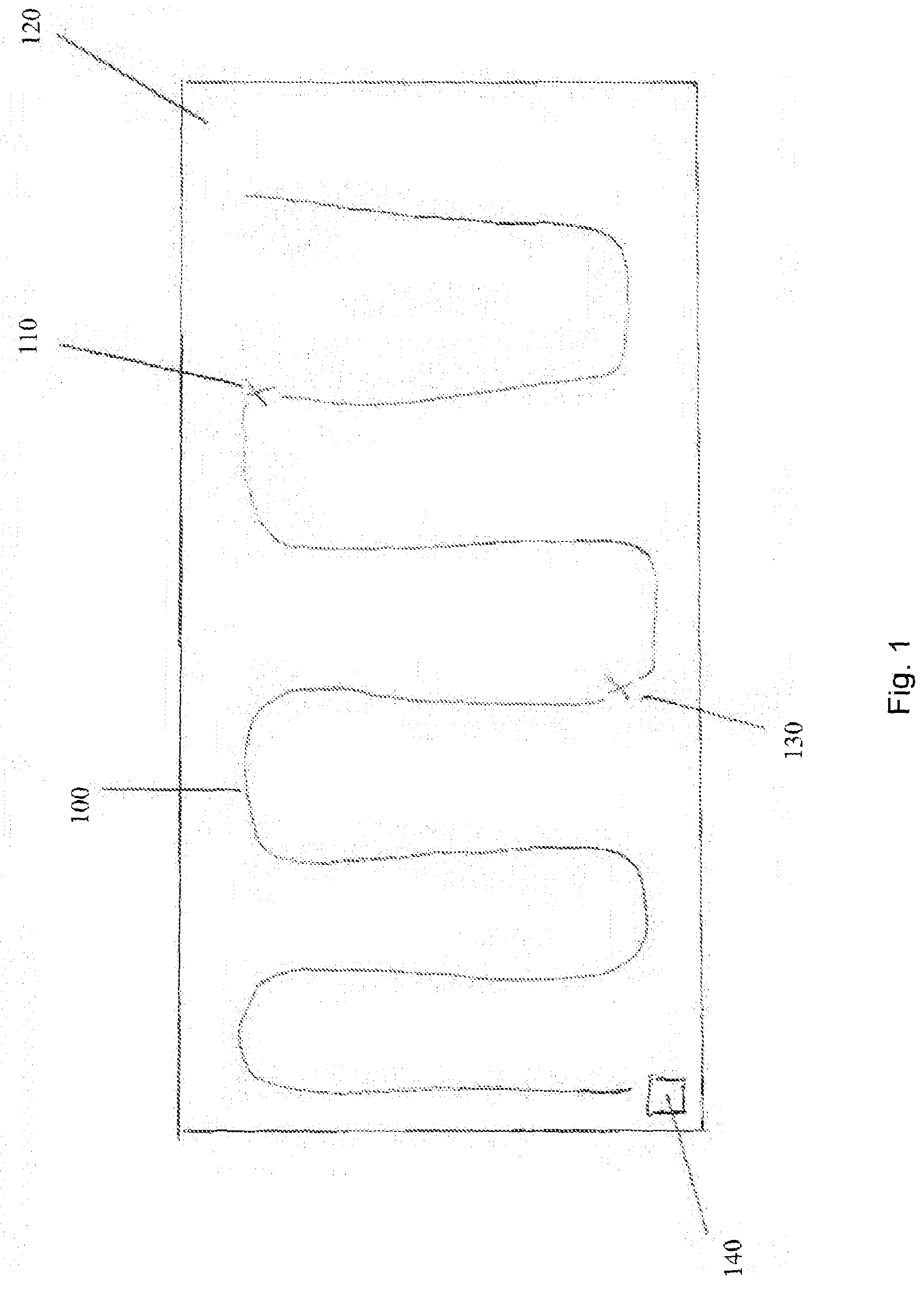

System and method of an agricultural machine to optimise working capacity

ActiveUS20160278277A1Reduction of potential working capacityIncrease costRoad vehicles traffic controlSowingLevel sensorAgricultural engineering

A method and a system in an agricultural machine for the coordination of agricultural machines when refilling substance intended to be disseminated over an agricultural field by generating coordination data indicative of an optimum refill location, comprising a level sensor arranged for generating level data, said level data indicating a volume of a substance in a substance reservoir; a position sensor for generating and storing position data and storing or reading a preplanned route; a communication device arranged for transmitting and receiving data; characterised by: a coordination device generating coordination data, based on said level data, said preplanned route and said position data; and transmitting said generated coordination data via the communication device to a refill vehicle.

Owner:VADERSTAD HLDG

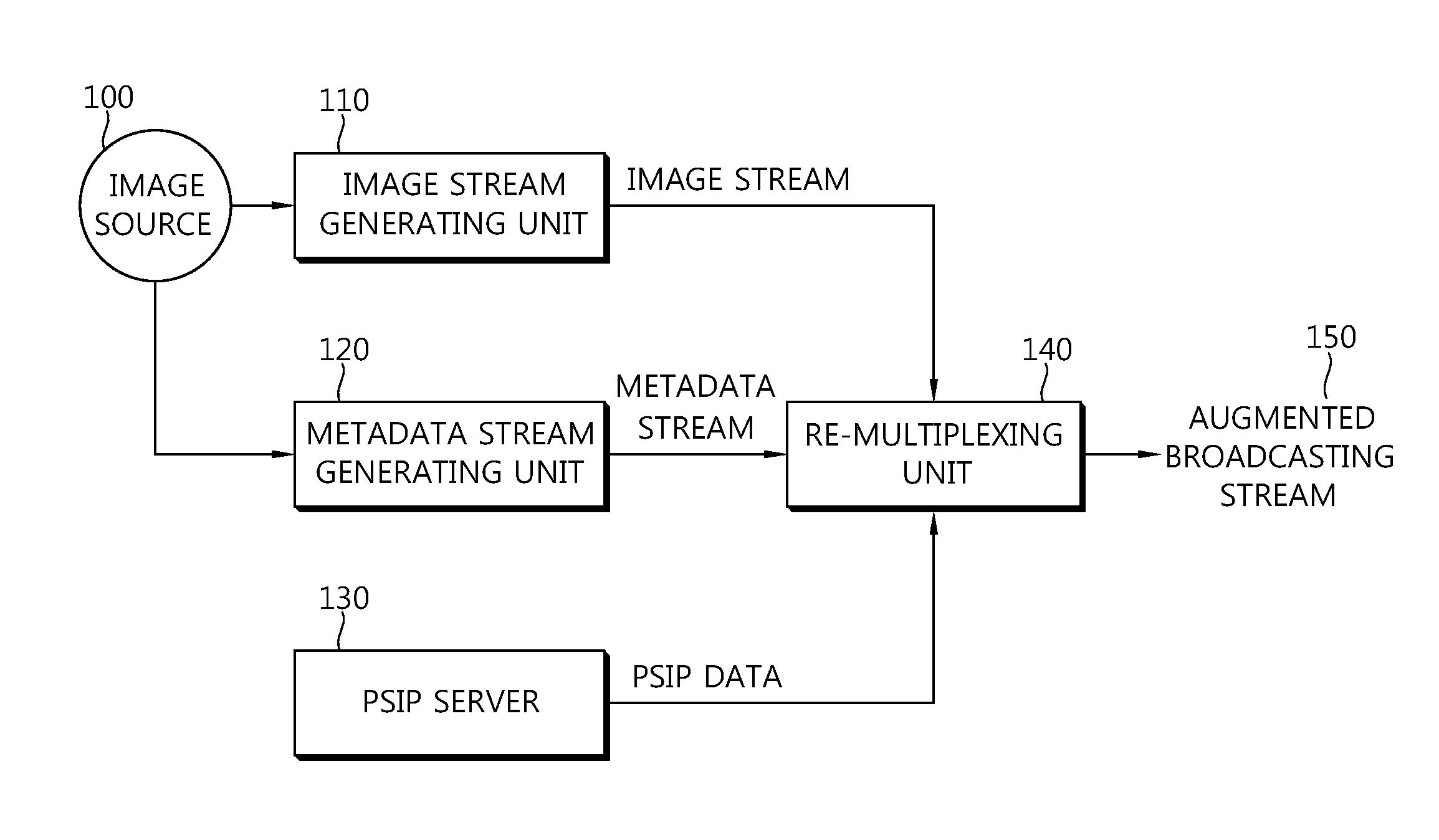

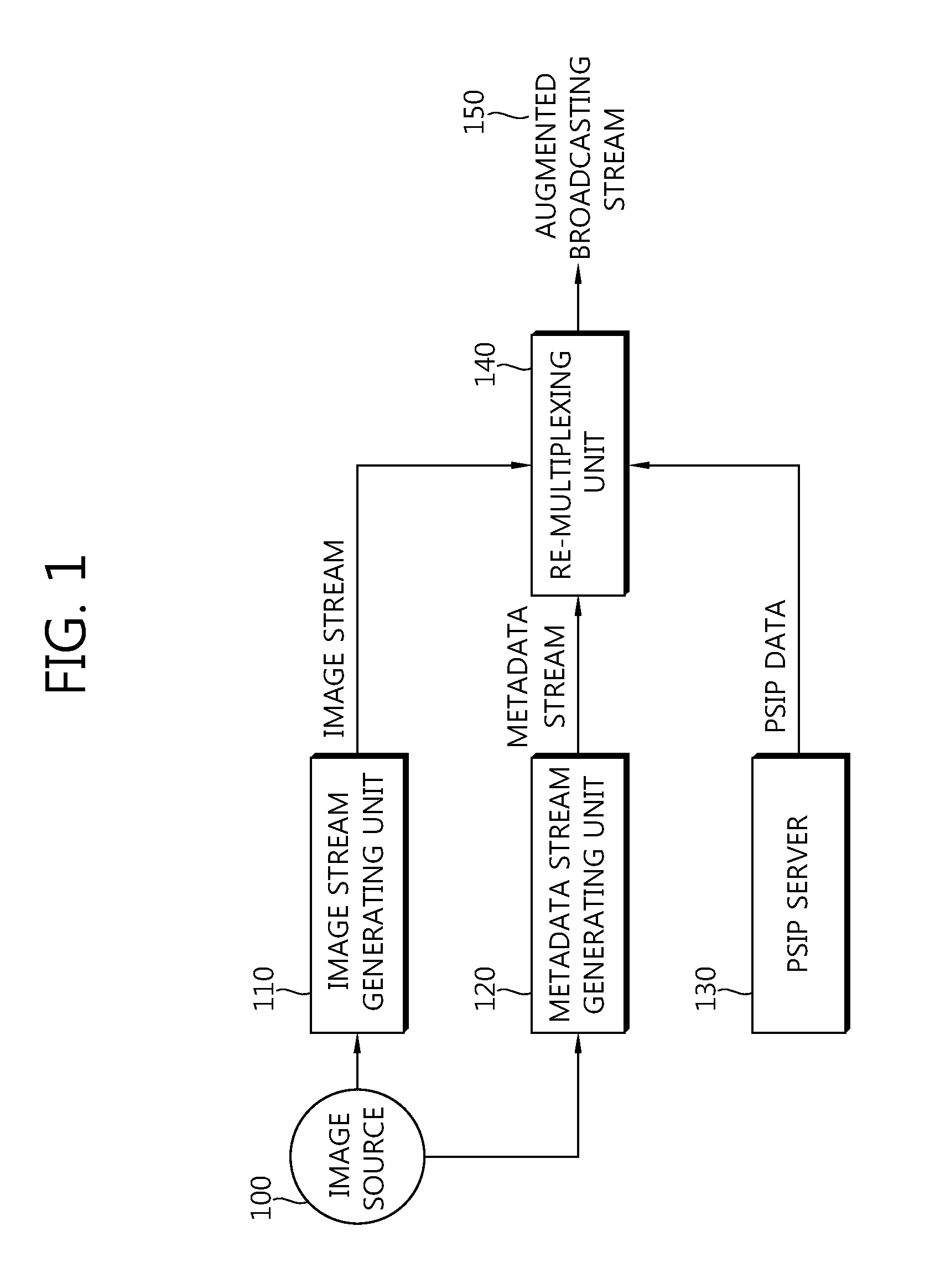

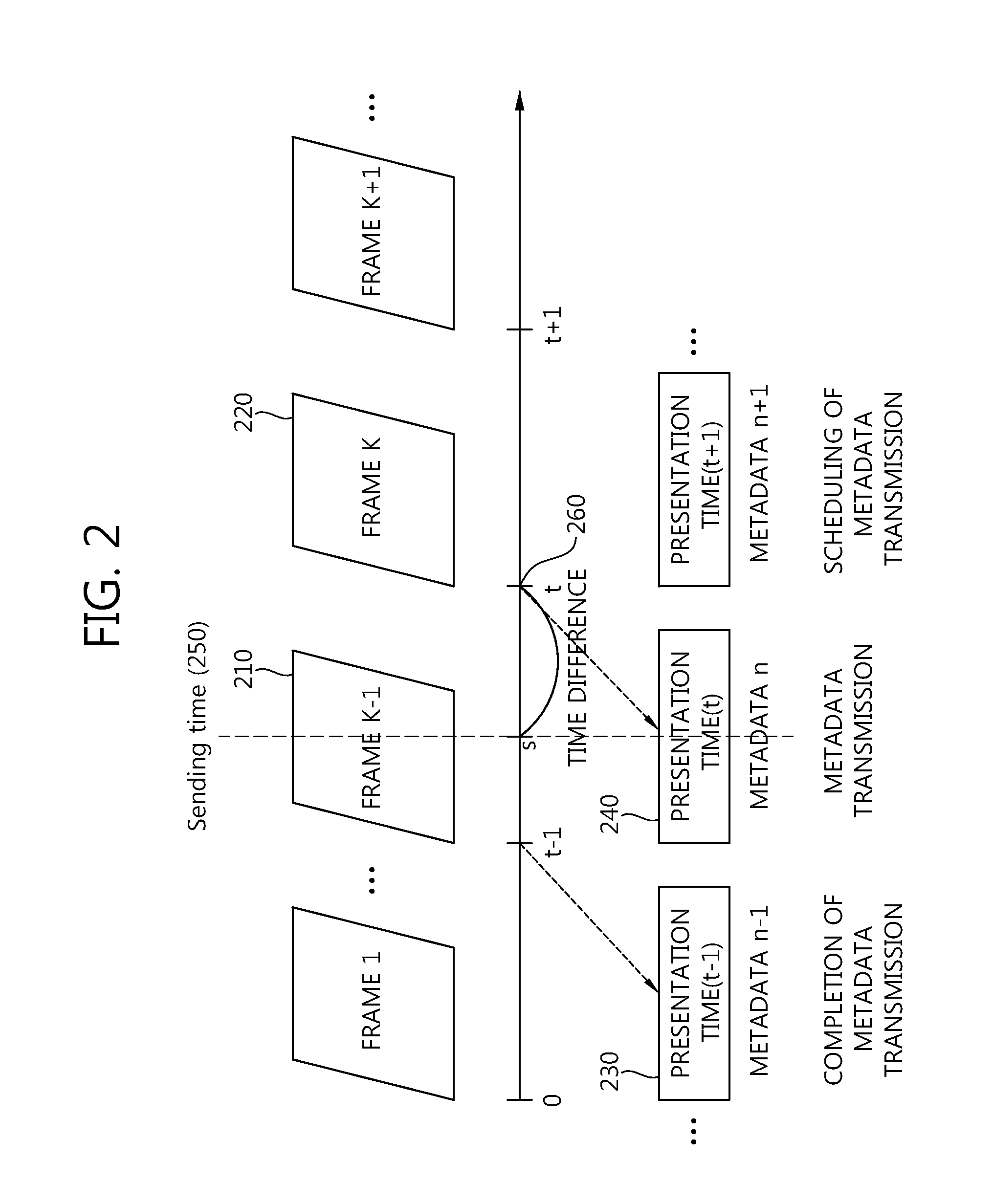

Augmented broadcasting stream transmission device and method, and augmented broadcasting service providing device and method

InactiveUS20130254798A1Quickly arriveEfficient receptionBroadcast information switching/replacementPlural information simultaneous broadcastComputer terminalBroadcasting

An augmented broadcasting stream transmission device and method and an augmented broadcasting service providing device and method capable of ensuring that augmented broadcasting metadata arrive at a receive terminal in a time more rapid as compared to a corresponding video frame by a predetermined time are provided.

Owner:ELECTRONICS & TELECOMM RES INST

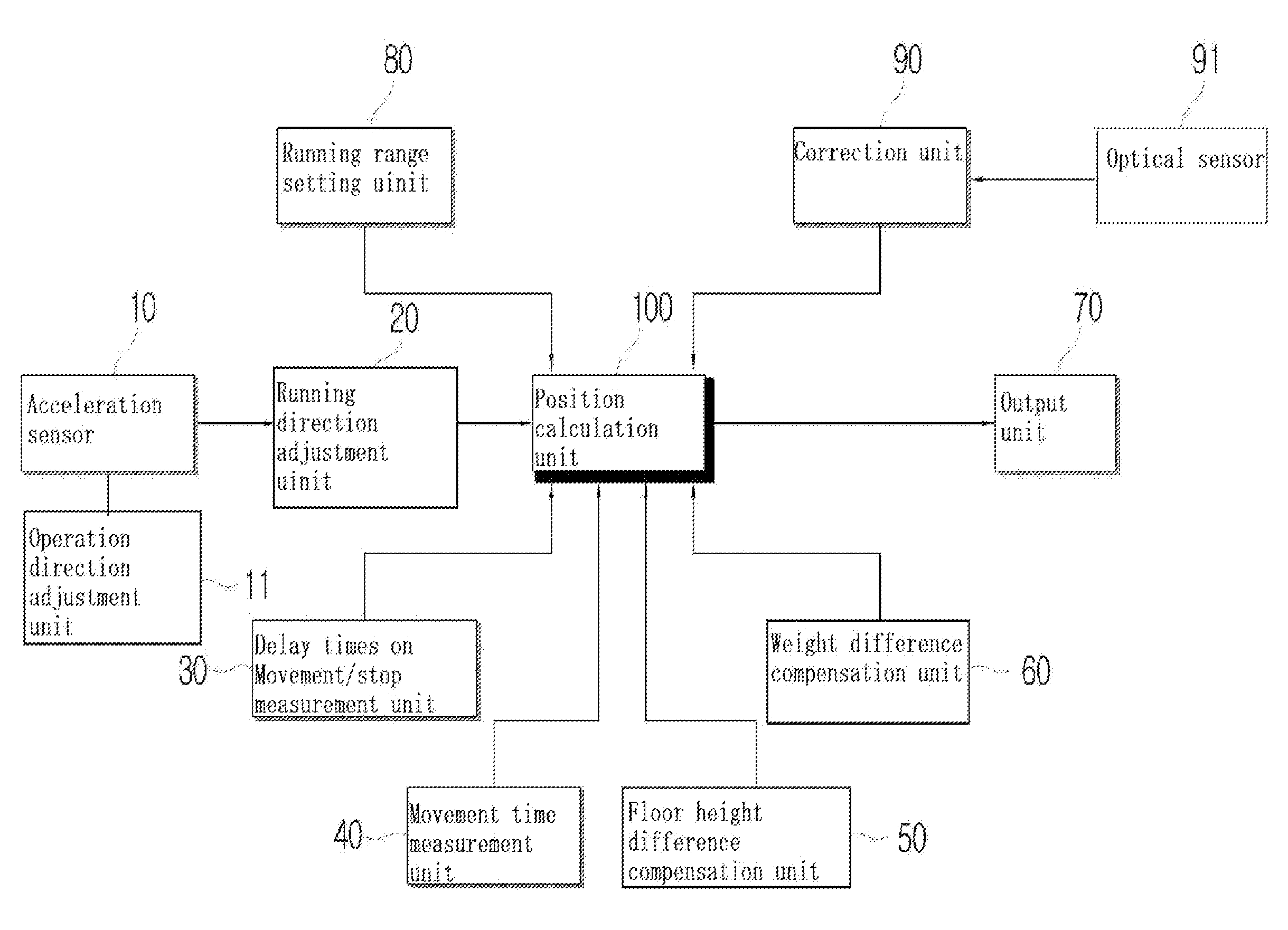

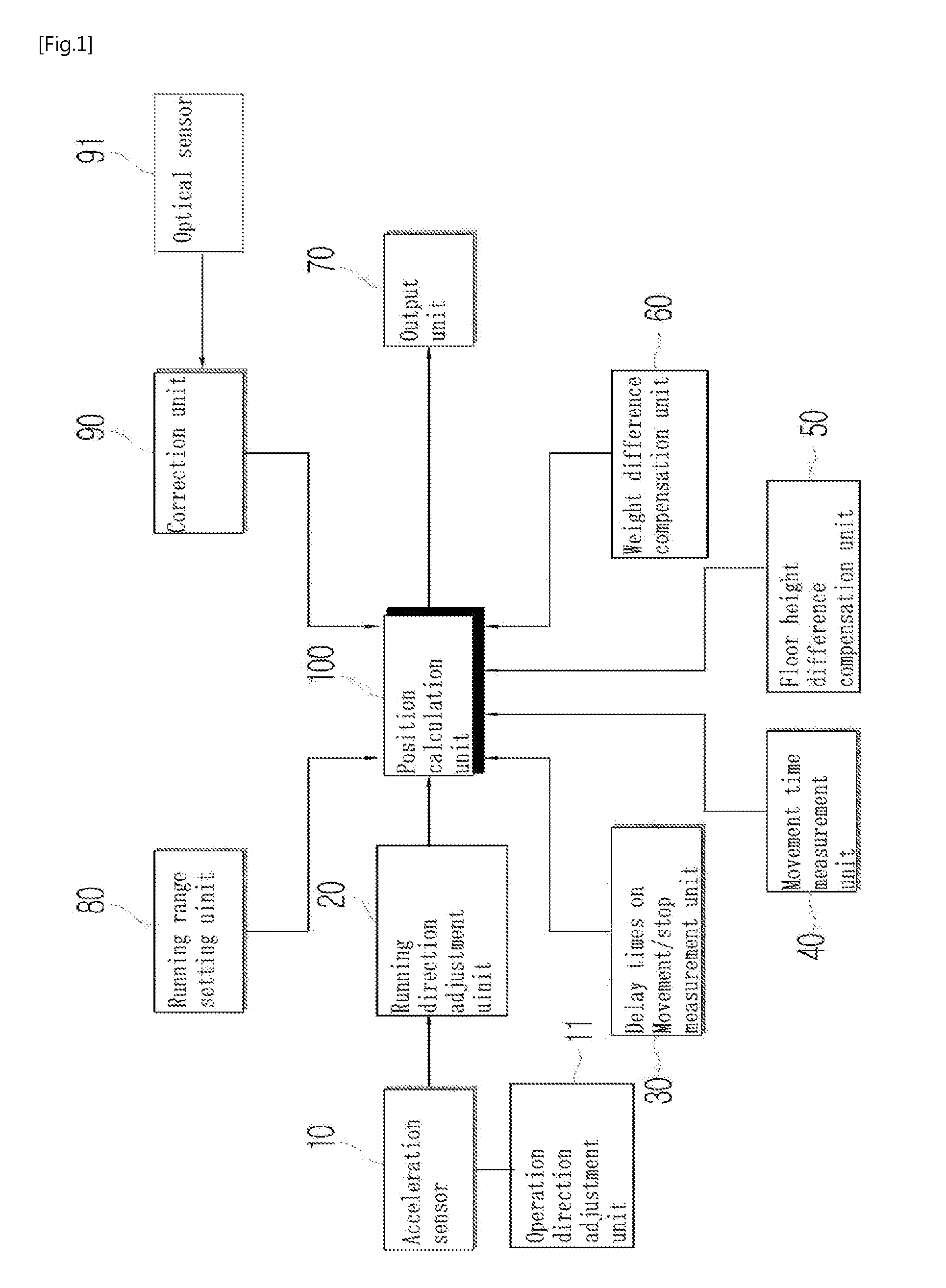

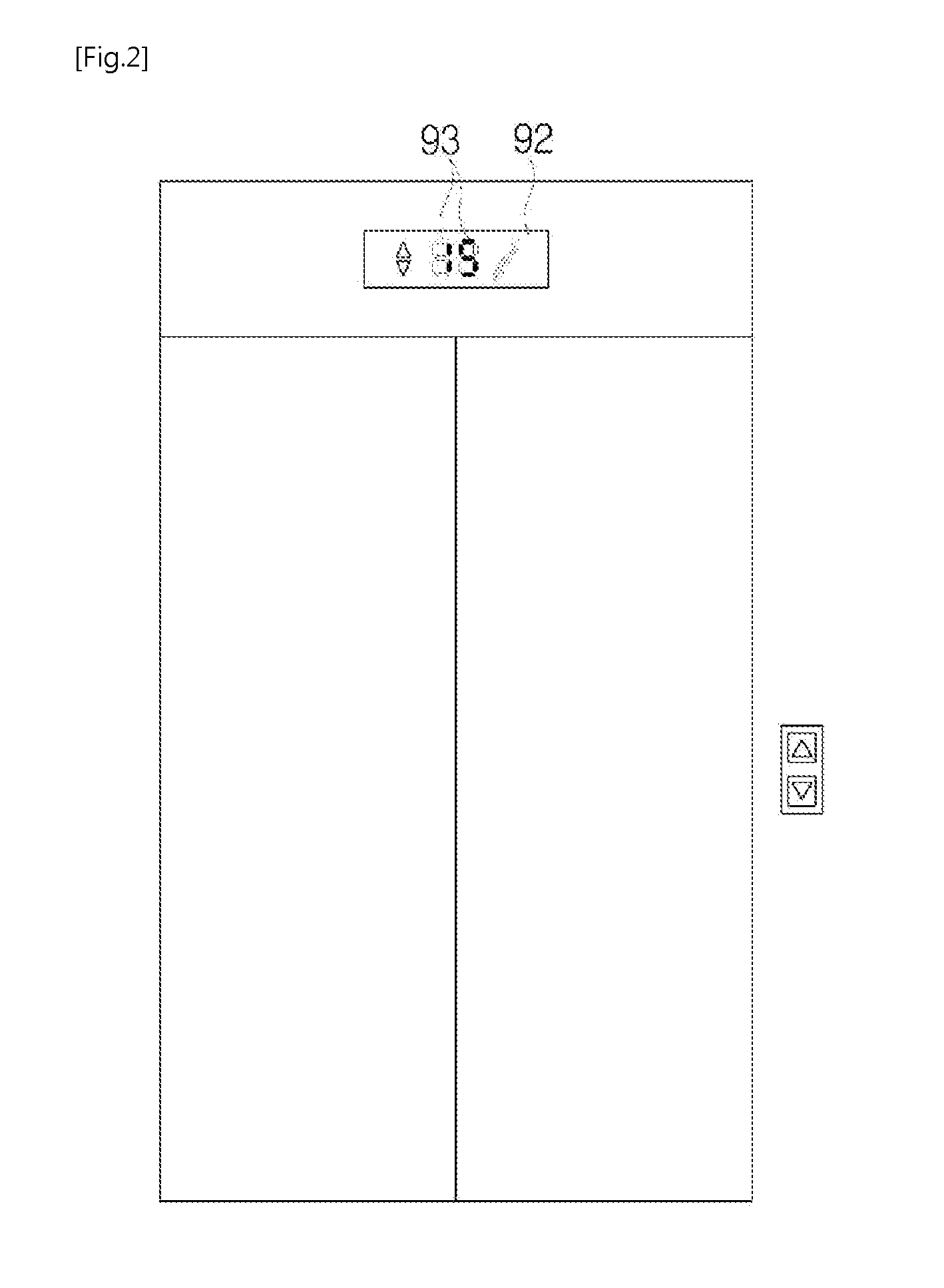

Device for displaying floor information of operating elevator using acceleration sensor

The present invention relates to a device for displaying floor information of an operating elevator, which provides a user with information on the floor where an elevator car is positioned by operating the current position of the elevator car. The device is not electrically connected to an existing elevator driving system, so that the installation procedure of the display device is simple and easy. In addition, it is possible to realize integration even though every elevator employs protocols different from each other.

Owner:CHOI JAE BOO +1

Method and device for management of an overload in a cell of a radio communication network, corresponding uses, computer program and storage means

ActiveUS7853266B2Simple to implement and efficientMinimize waiting timeNetwork traffic/resource managementStore-and-forward switching systemsCellular radioTelecommunications

Owner:WSOU INVESTMENTS LLC

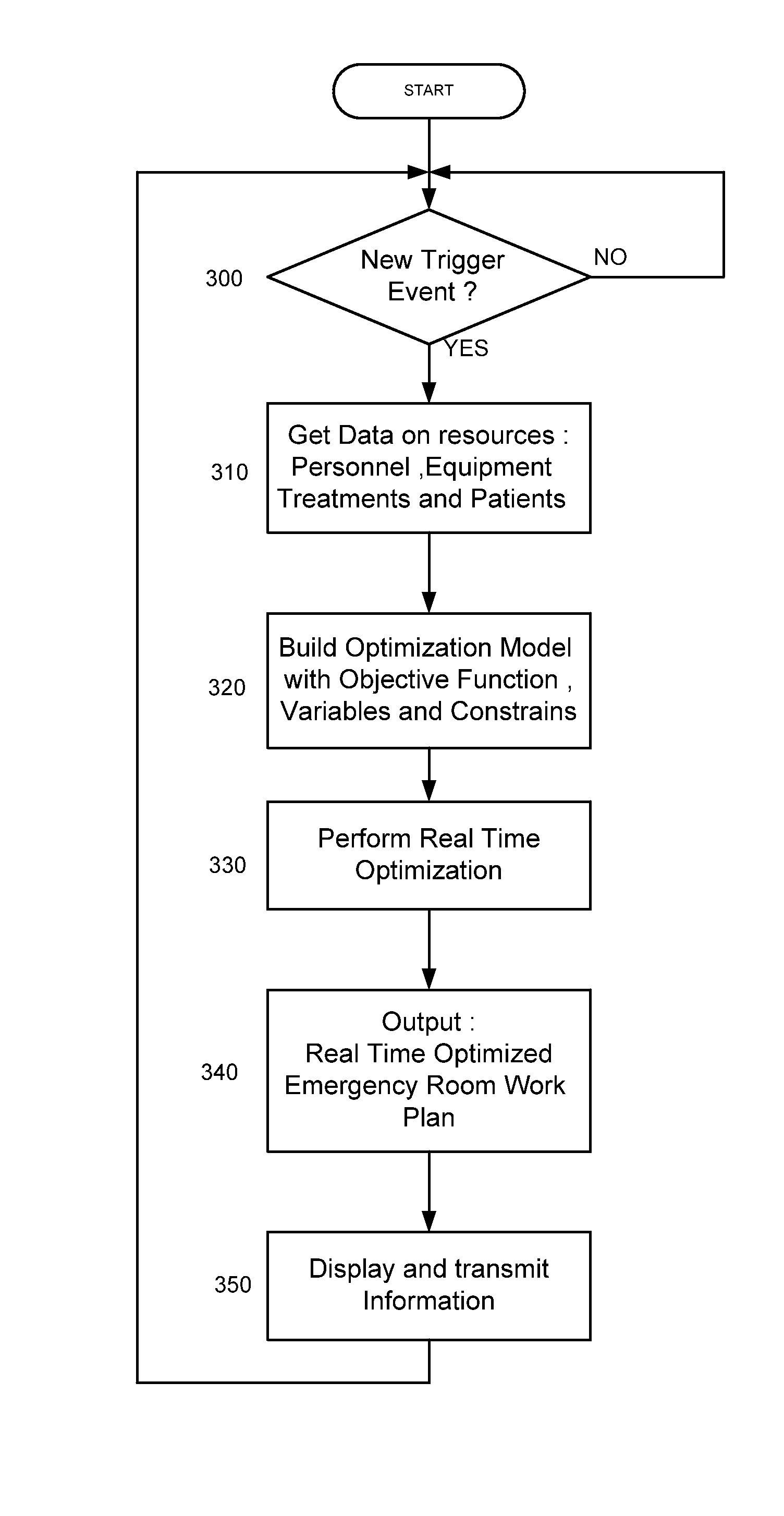

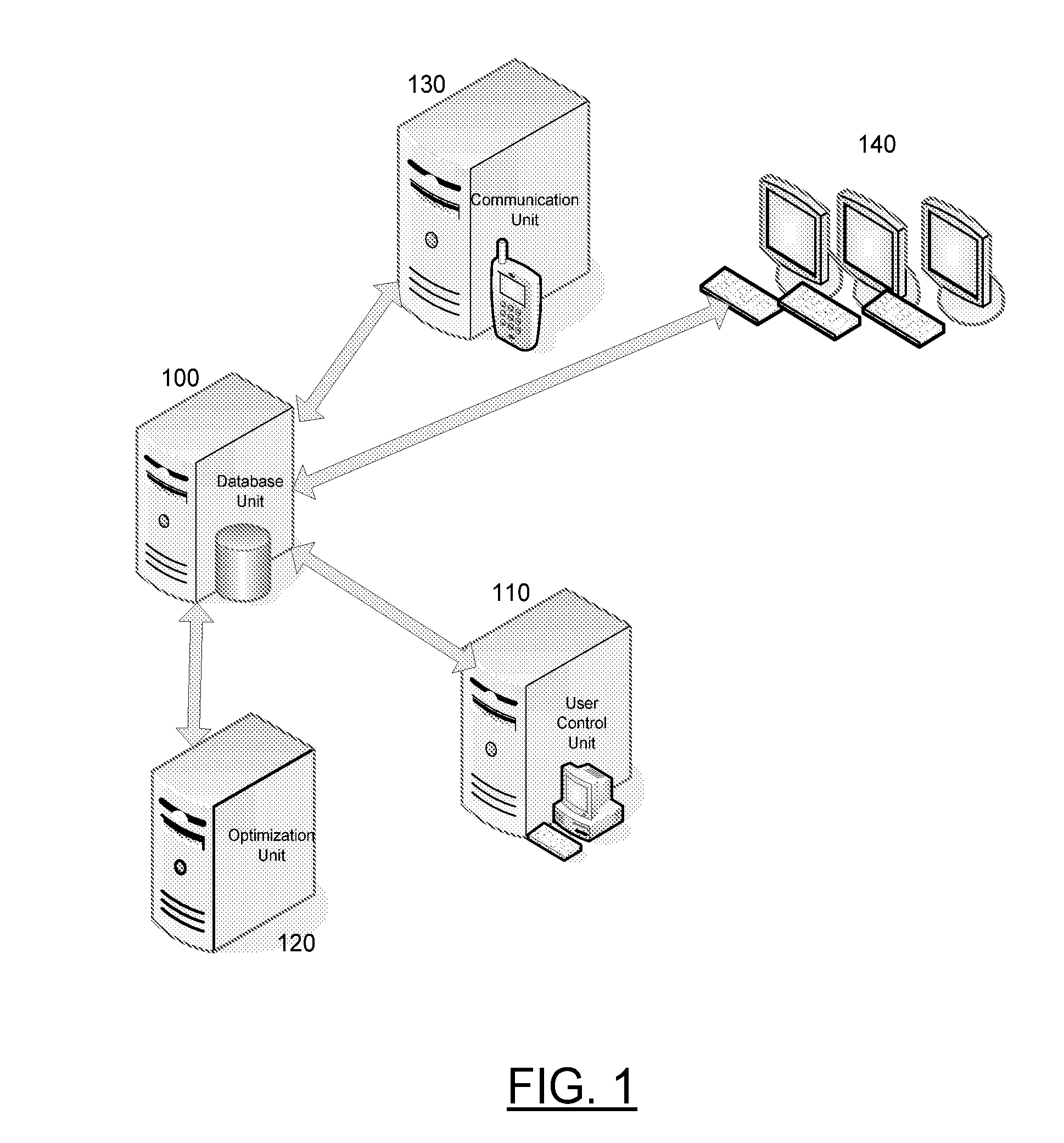

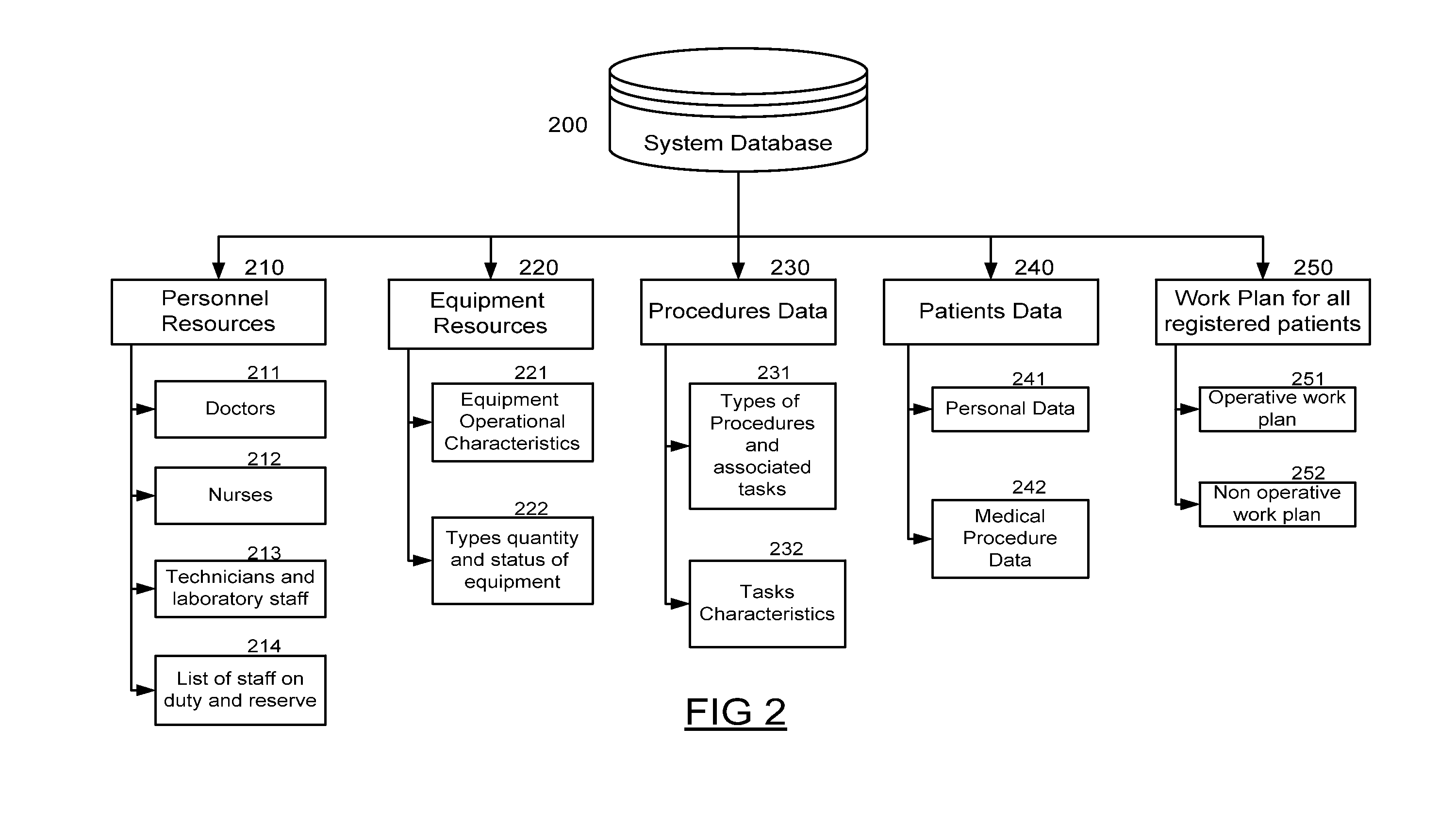

Method and System for Real-Time Automatic Optimization of Emergency Room Resources Management

InactiveUS20120203564A1Minimize waiting timeLow cost of treatmentHealthcare resources and facilitiesResourcesTime informationMultivariable optimization

The invention discloses a computer implemented method and system for real-time optimal management of hospital's Emergency Room resources. The system provides optimal work plan for crewmembers and equipment, taking into consideration relevant variables. It uses multivariable optimization techniques to optimize the defined cost functions, which represent overall patient treatment waiting time and cost. Real-time information is provided to both patients and crewmembers. The work plan is continuously updated according to occurring events.

Owner:MAKOR ISSUES & RIGHTS

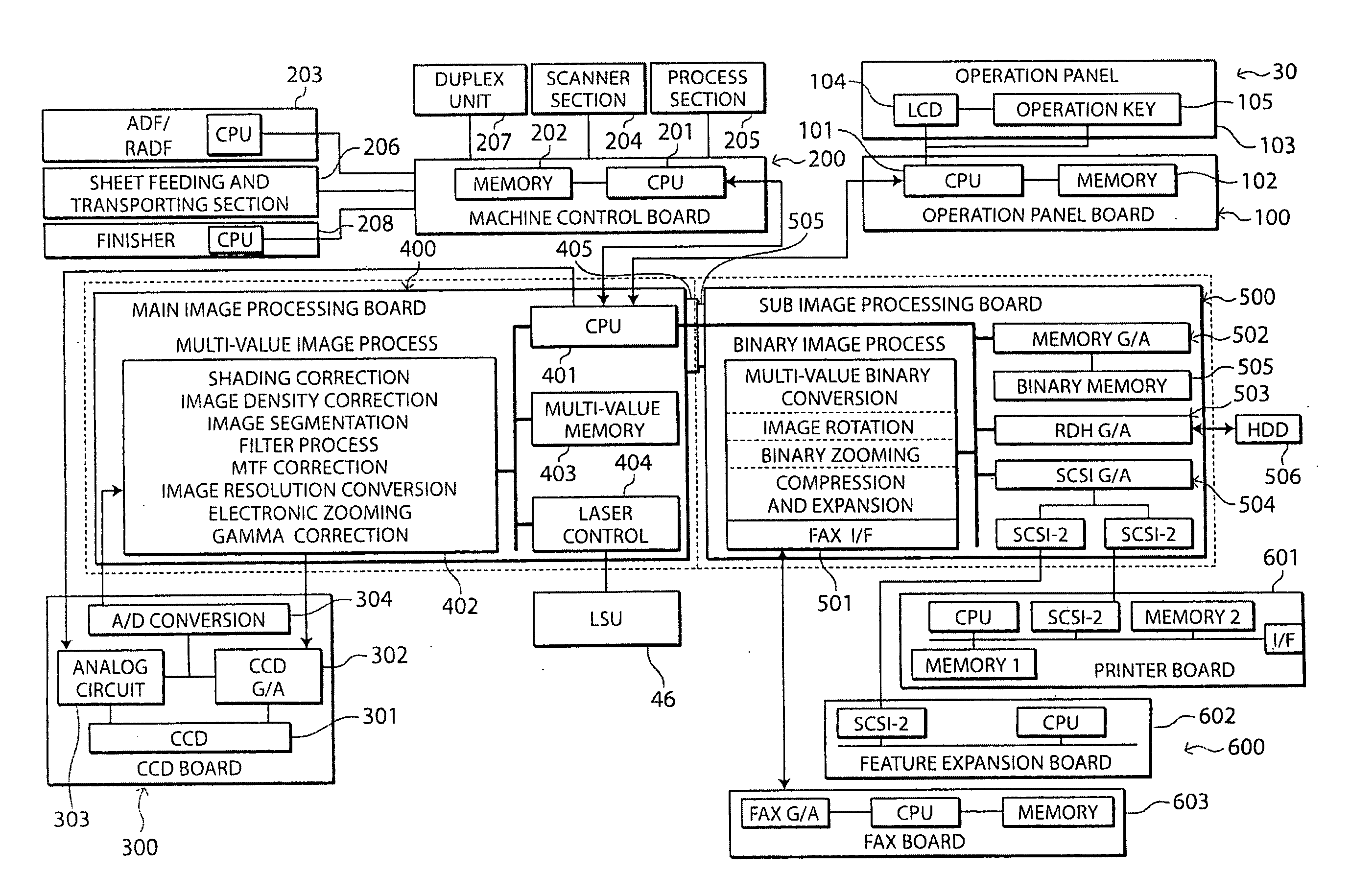

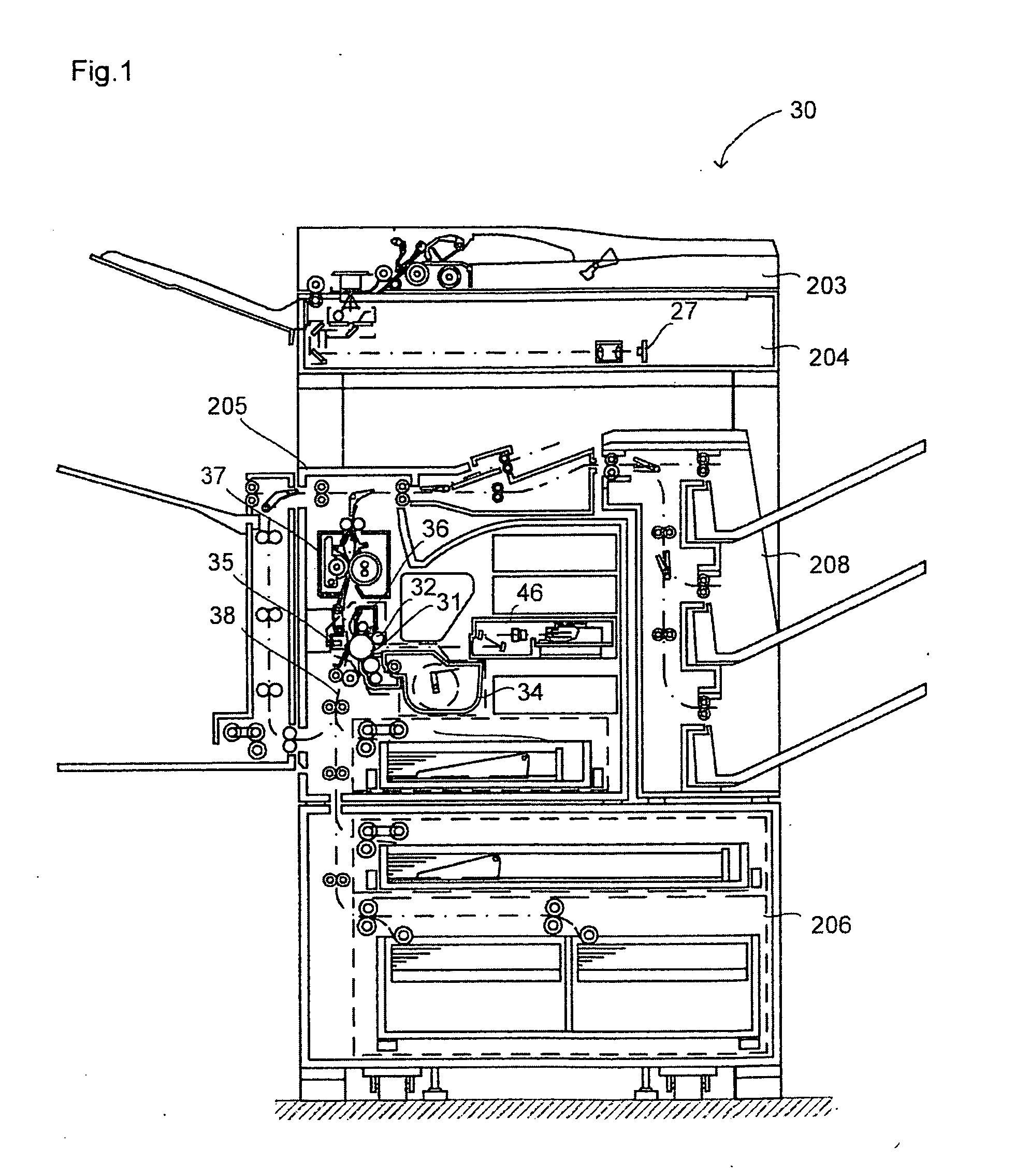

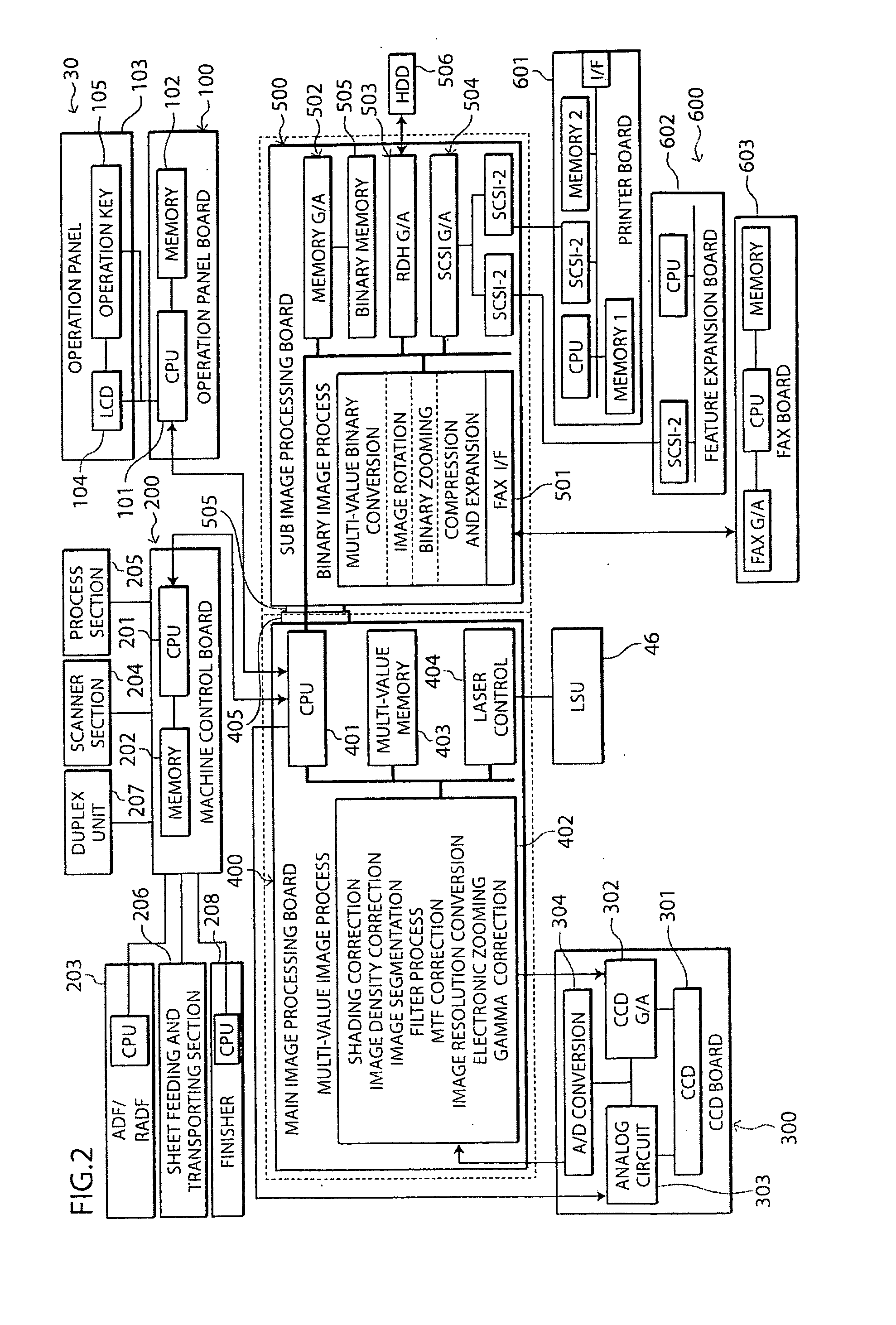

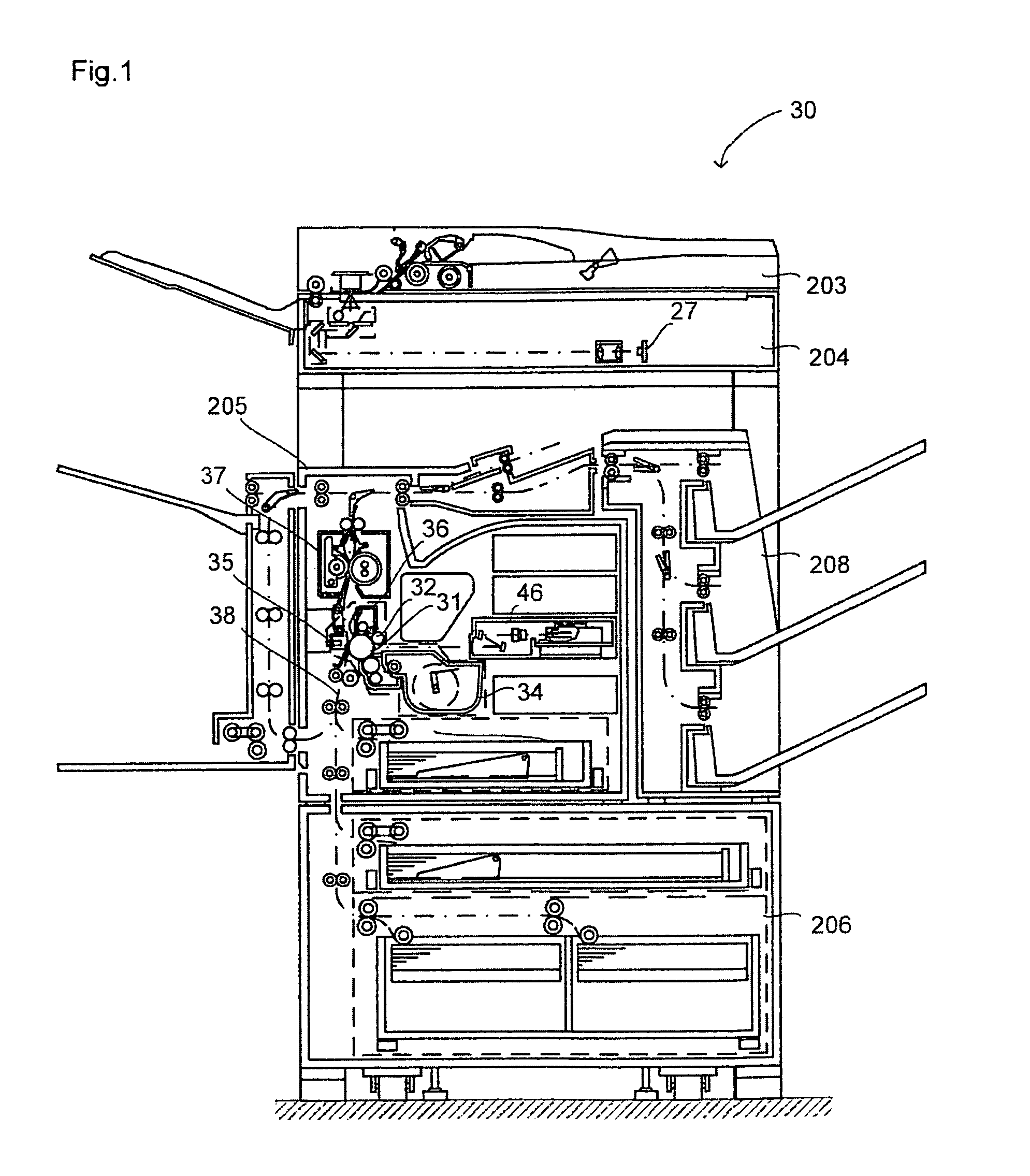

Image output apparatus

ActiveUS20090116058A1Minimize waiting timeElectrographic process apparatusVisual presentationImaging processingOutput device

An image output apparatus including: an image processing section for processing an image; a printing section that prints the image; a display section that displays the image; an instruction section that allows a user to instruct execution of a print job, and execution of a display job; and a job control section that controls the jobs to start the execution of the print job or the display job in response to the instruction, wherein when the job control section receives instructions to start print jobs and / or display jobs, the job control section controls the jobs to register the print jobs and / or the display jobs in a queue and start these jobs in the order, and when an instruction for a display job in the queue is again received from the instruction section, the job control section controls the jobs to move the display job to the forefront of the queue.

Owner:SHARP KK

System and method for visual display of bed status by integration of location information from ambulance transports

InactiveUS20130073302A1Minimize waiting timeMore roomHealthcare resources and facilitiesResourcesPatient roomBed Status

A method and system is disclosed that conveys information to various hospital staff including the housekeeping staff regarding the patient inflow and patient outflow from the hospital vis-a-vis medical transport agencies. By providing the hospital staff with information on “outbounds”, the housekeeping staff can process hospital rooms and beds soon after a previous patient is discharged. The system also tracks the status of “inbound” patients, i.e. patients en route to the hospital by way of a medical transport agency along with the estimated time of arrival (ETA) at the hospital. By providing the nursing staff with information that an ambulance is on the way and how long it will take to arrive at the hospital, housekeeping staff will be informed of the need for a clean patient room before an inbound patient even arrives at the hospital.

Owner:FLEETEYES

Spinning machine and method for operating the same in case of failure of an external power supply

ActiveCN104562328AAvoid damageSlow down the feed rateContinuous wound-up machinesOpen-end spinning machinesYarnEngineering

The invention relates to a method for operating a spinning machine, the spinning machine comprising a plurality of spinning units (3), fibrous composite (13) is transmitted to at least a portion of the spinning units (3) during a spinning process, in a present spinning station (4) of each spinning unit (3), rotation motion is transmitted to the fibrous composite (13), and therefore fibrous composite (13) turns into rotary yarn (7), the yarn (7) is taken off from the respective spinning station (4) through an outlet (6) and is wound up by a winding device (8), the spinning machine is supplied with power by an external power supply (10). The method is characterized in that the the yarn production in the spinning units (3) for producing the yarn (7) is stopped in case of failure or malfunction of the external power supply (10), so that a winding side yarn end is formed in the area of each spinning unit (3), each winding side yarn end is in the respective spinning station (4) or between the outlet (6) of this spinning station (4) and the winding device (8) associated with the spinning station (4), wherein the energy to for the further operation of the spinning machine until the end of yarn production is provided by at least one energy store (9). Furthermore, the invention also relates to a spinning machine which has a controller (11) which is designed to operate the spinning machine according to the above method.

Owner:MASCHINENFABRIK RIETER AG

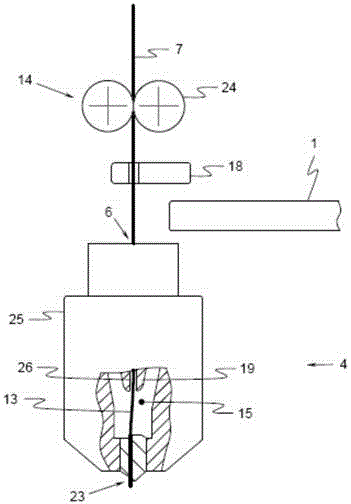

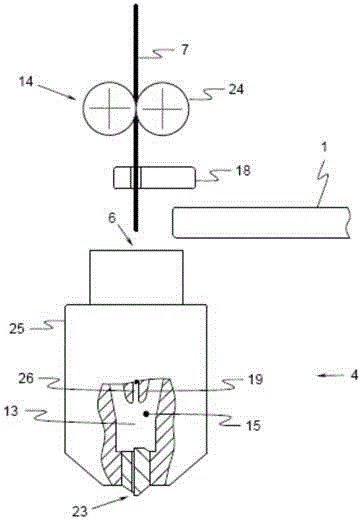

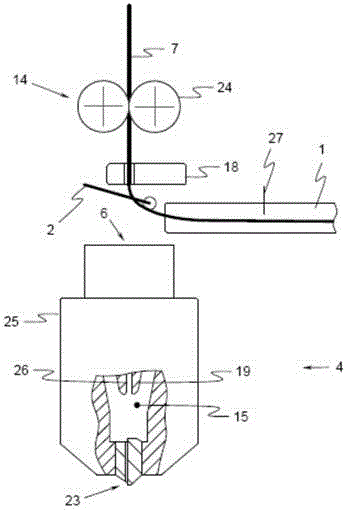

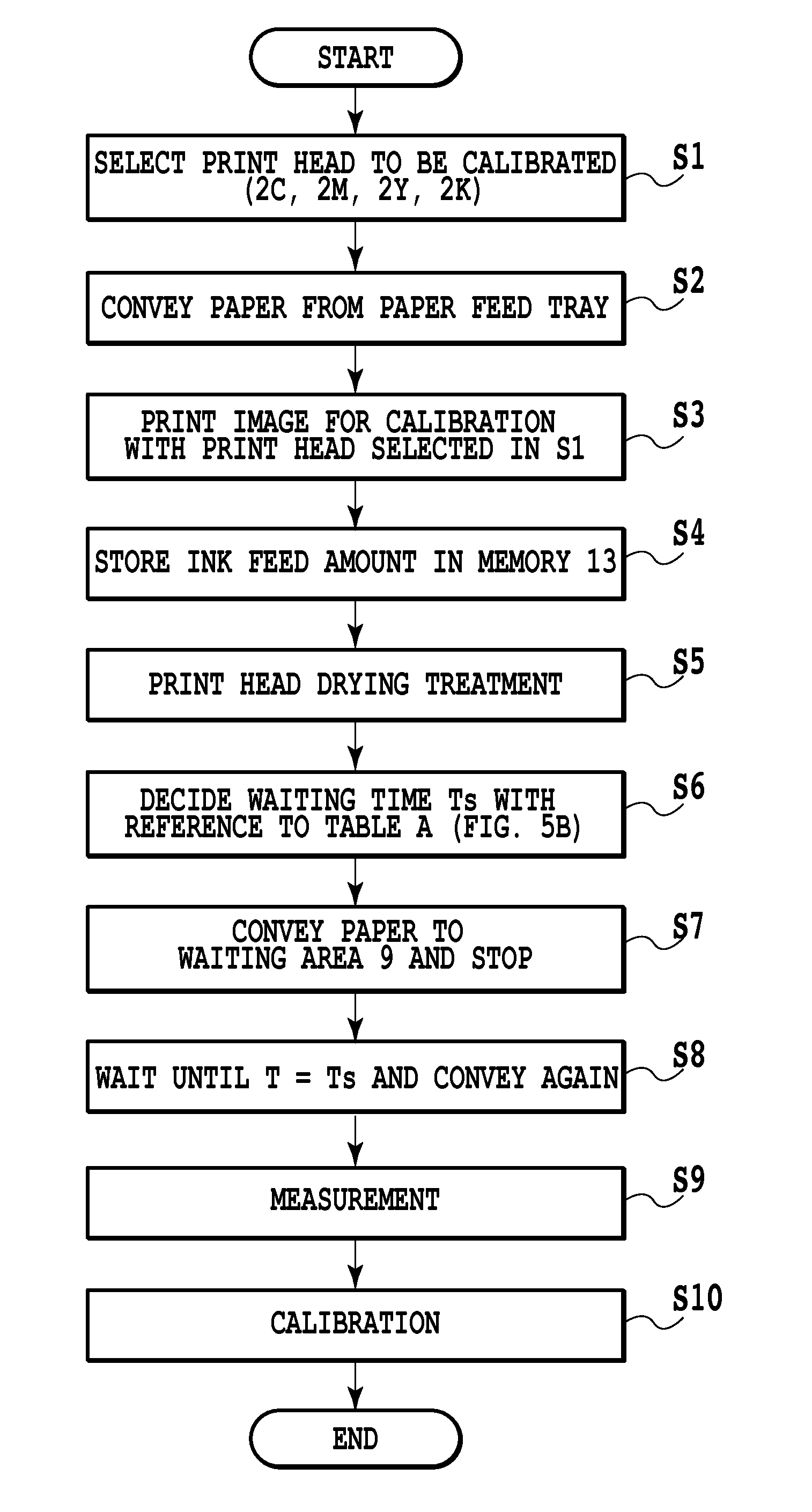

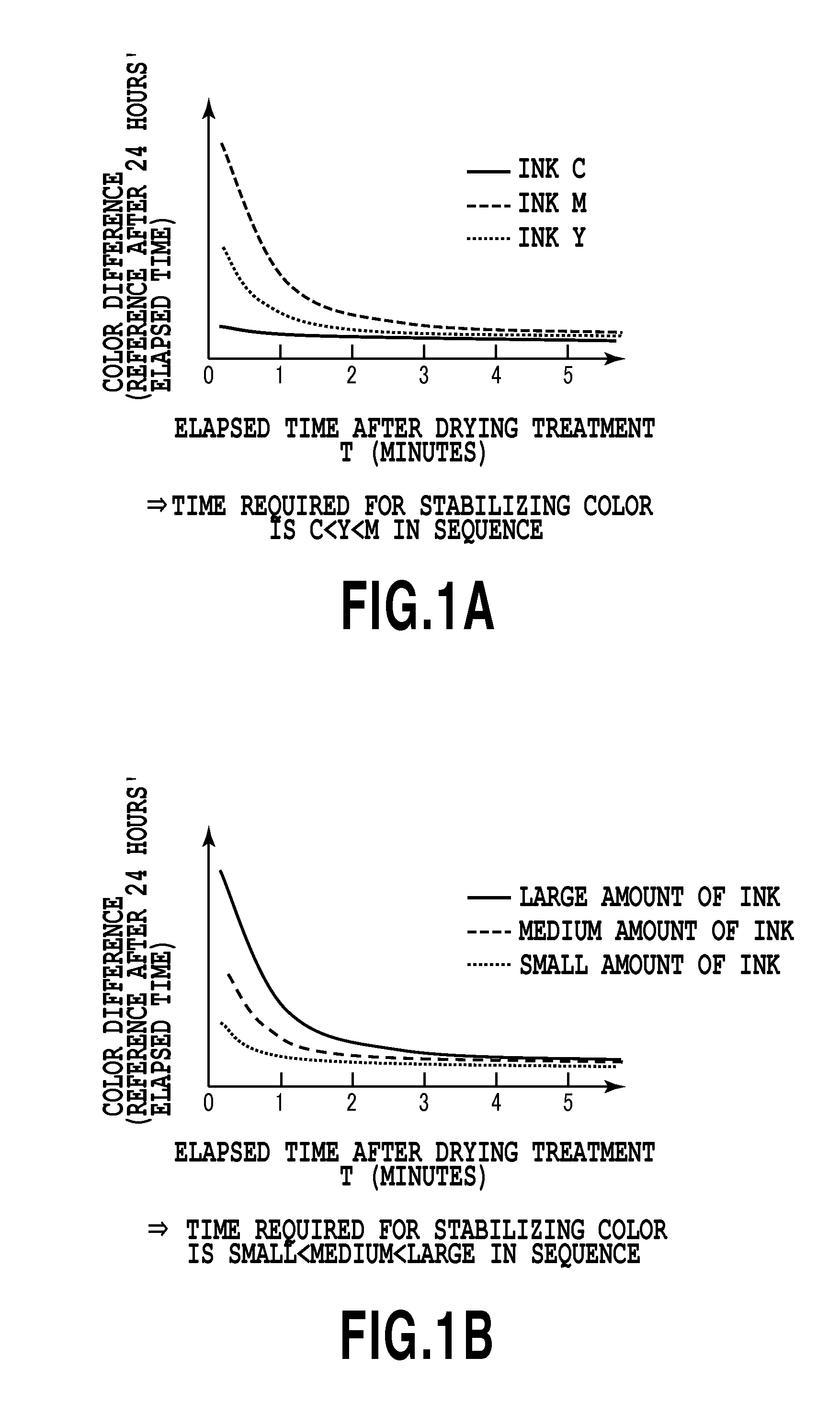

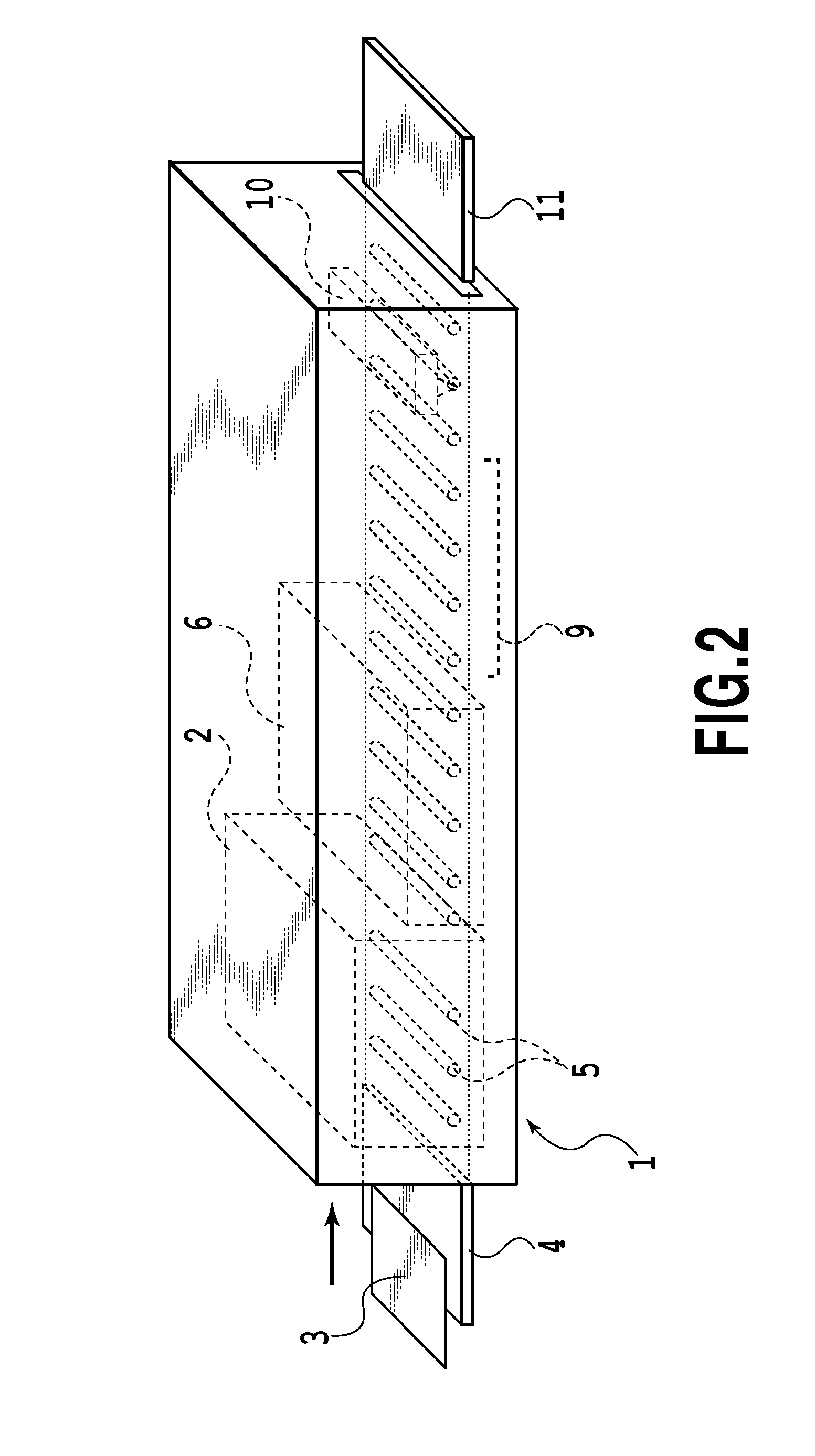

Inkjet printing apparatus and calibration method

ActiveUS8675250B2Minimize waiting timeDigitally marking record carriersDigital computer detailsComputer scienceTime table

A waiting time Ts is decided on the basis of ink type information and ink feed amount information, referring to waiting time table A (Step 6). Along with this, a dried printing paper is carried to and stopped in a waiting area 9 (Step 7), a time period T is measured after stopping, and measurement processing in the next step is delayed until the time period T reaches the waiting time Ts. Then, when the time period T reaches the waiting time Ts, a measuring instrument 10 is used to measure a density of a patch printed on the printing paper (Steps 8 and 9).

Owner:CANON KK

Region-based clustering mechanism for channel access in vehicular Ad Hoc networks

ActiveUS8488545B2Minimize waiting timeImprove data throughputNetwork topologiesWireless commuication servicesTime division multiple accessCode division multiple access

In a Vehicular Ad Hoc Network (VANET) a hybrid method combines SDMA (Space Division Multiple Access) and dynamic TDMA (Time Division Multiple Access) that divides the roadway into regions (whose size is larger than the SDMA unit) where each region is allocated a pool of radio channels based on SDMA and may contain a limited number of vehicles. Vehicles within the same region compete for and access the channels using dynamic TDMA. A channel allocation scheme that maps the pool of channels to the regions such that when a vehicle acquires multiple channels (time slots) in a region, the intervals among the channels are as uniform as possible, thus minimizing the waiting time of the messages to be broadcast by the vehicle, which is critical for safety related applications. This solution is referred to as R-SDMA (Region based SDMA).

Owner:TELCORDIA APPLIED RES CENT TAIWAN

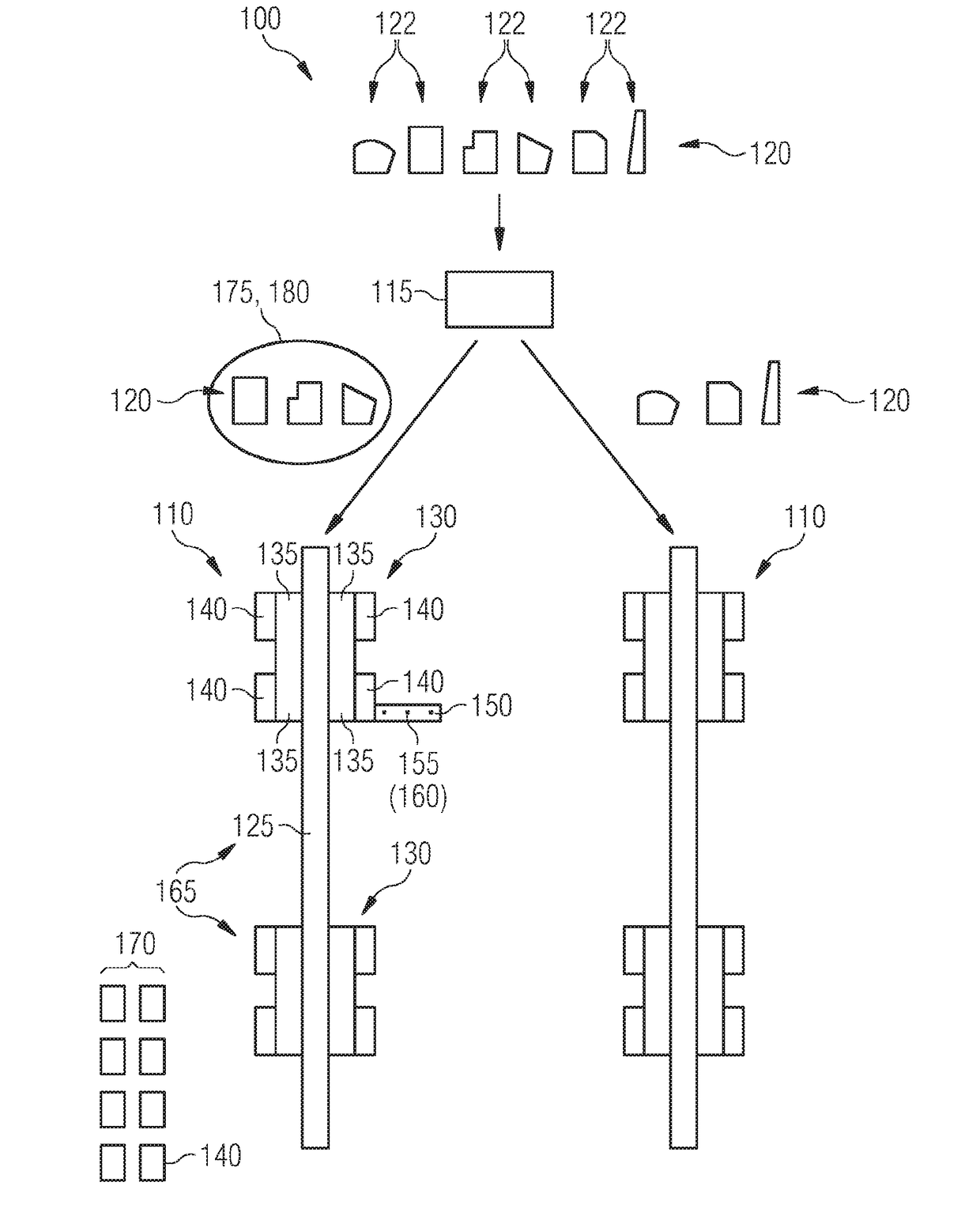

Population of printed circuit boards

ActiveUS20170318716A1Improved cost-saving and resource-savingPromote resultsProgramme controlComputer controlEngineeringPrinted circuit board

To populate printed circuit boards by means of a pickrand-place line, multiple set-ups, each having an associated set-up family, are formed. A number of component types is associated with each set-up and a number of printed circuit board types is associated with each associated setup family, such that a printed circuit board of a printed circuit board type in a set-up family can be populated on the pick-and-place line using components of the component types associated with the set-up. A setting-up table comprising a stock of components of a component type in a set-up can be provided on the pick-and-place line. A method for populating the printed circuit boards includes the steps of recording printed circuit board types, from which printed circuit boards are to be populated with components of associated component types, and associating recorded printed circuit board types with set-up families.

Owner:SIEMENS AG

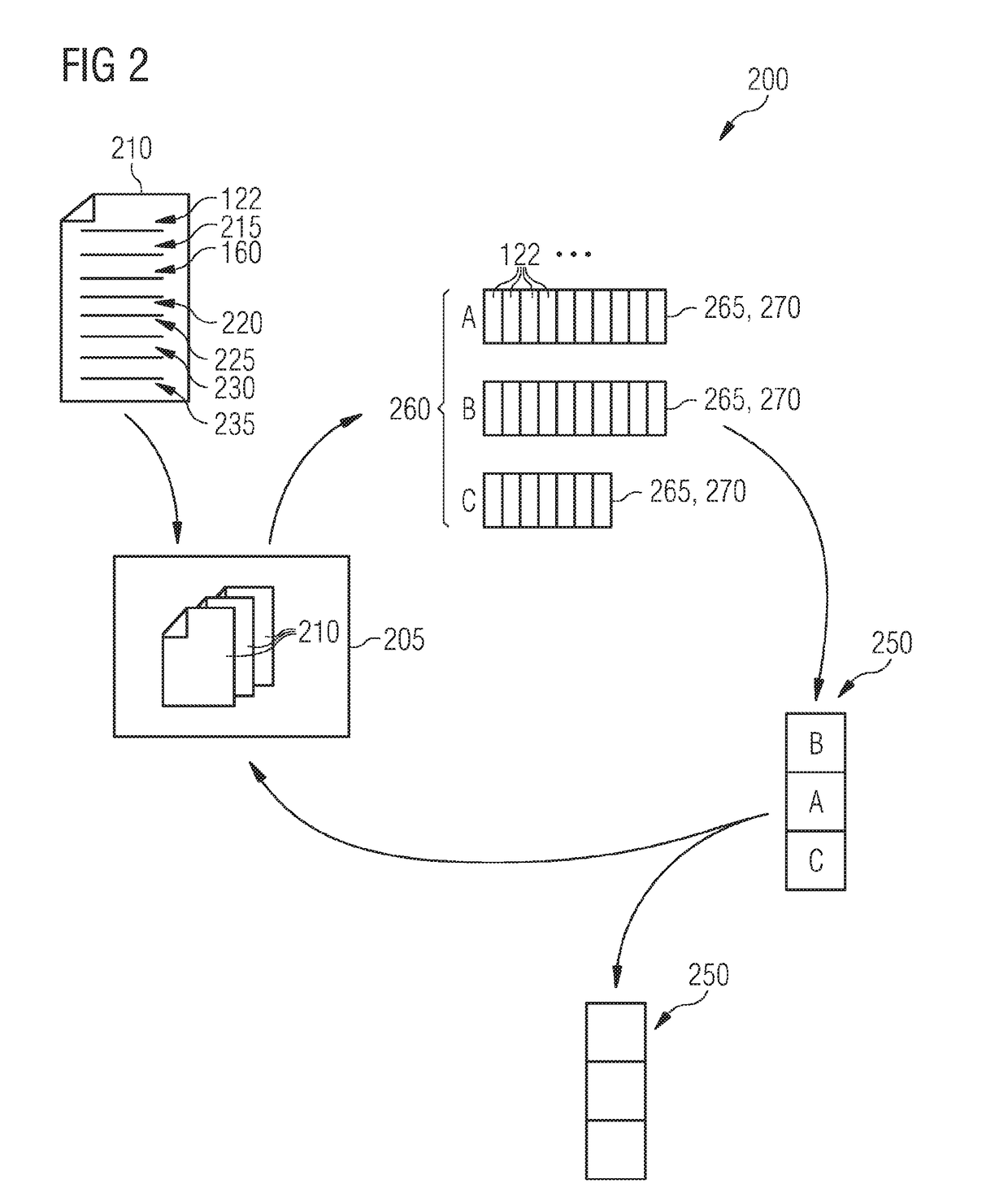

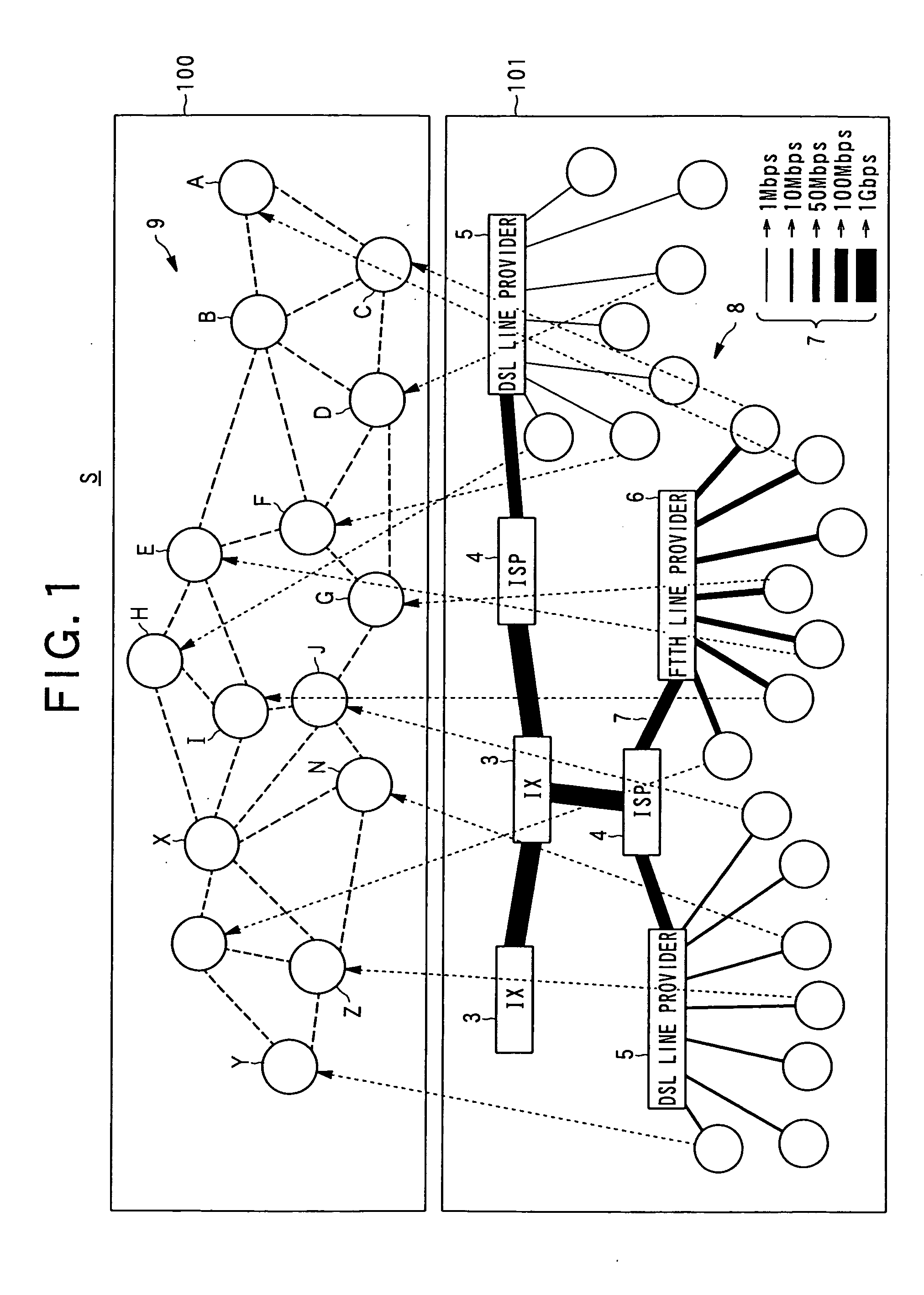

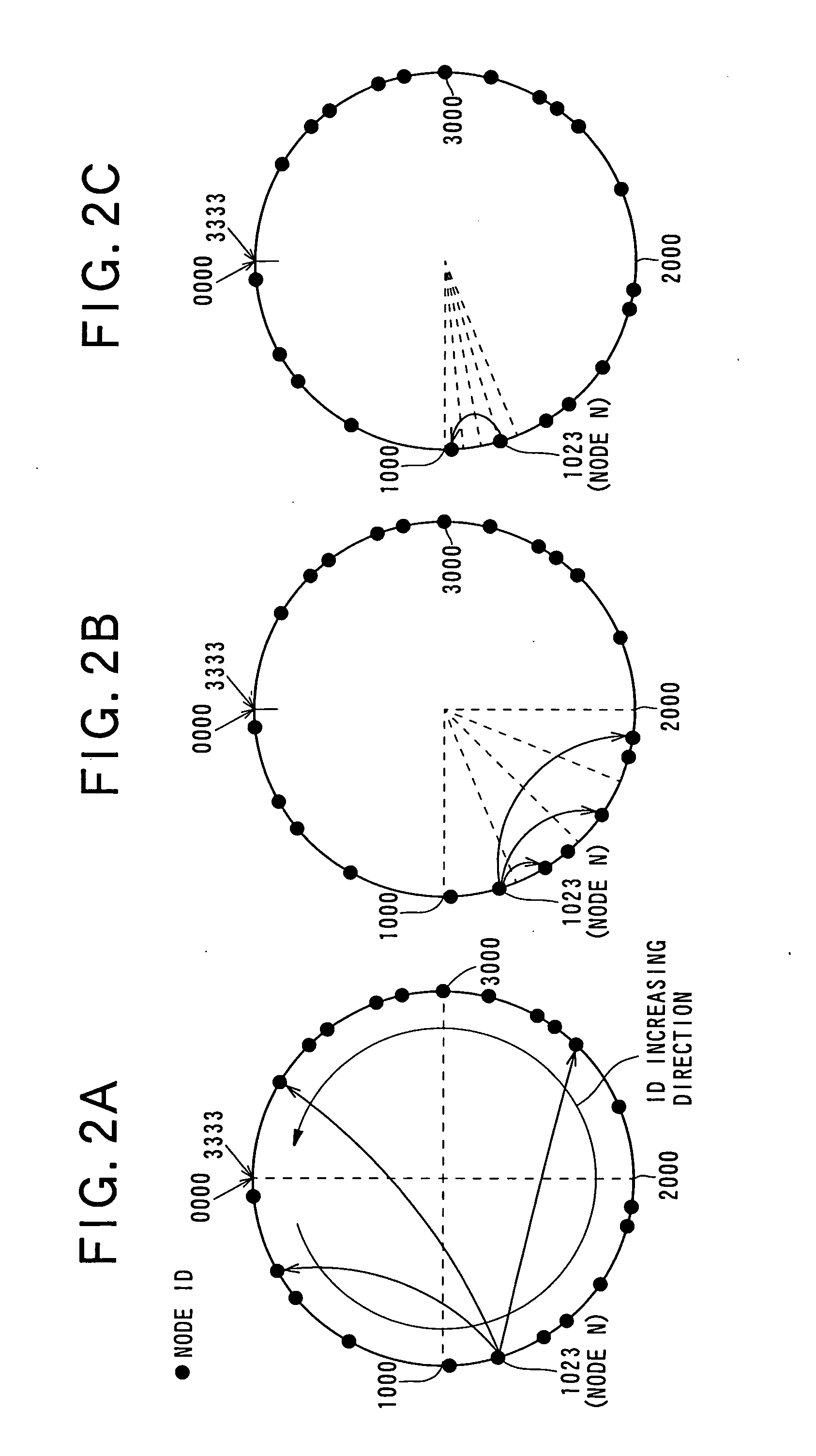

Information delivery system, information delivery method, delivery device, node device, and the like

InactiveUS20080201371A1Minimize waiting timeSuppress load loadDigital data information retrievalTransmissionInformation retrievalInformation delivery

The present invention is to provide for example a node device that receives content catalog information having attribute information and delivered from a delivery device in an information delivery system, the nodes being mutually communicable through a network and divided into a plurality of groups, the node device including:a new content catalog receiving means for receiving new content catalog information, delivered from the delivery device and having attribute information;a new content catalog saving means;a condition information saving means for saving the grouping condition and presentation time information;a group judgment means for judging on the basis of the grouping condition;a presentation time judgment means; anda content catalog presentation setting means for presenting the new content catalog information after the presentation time arrives.

Owner:BROTHER KOGYO KK

Image output apparatus for controlling order of print jobs and display jobs in queue

ActiveUS8243311B2Minimize waiting timeVisual presentationElectrographic process apparatusImaging processingComputer science

An image output apparatus including: an image processing section for processing an image; a printing section that prints the image; a display section that displays the image; an instruction section that allows a user to instruct execution of a print job, and execution of a display job; and a job control section that controls the jobs to start the execution of the print job or the display job in response to the instruction, wherein when the job control section receives instructions to start print jobs and / or display jobs, the job control section controls the jobs to register the print jobs and / or the display jobs in a queue and start these jobs in the order, and when an instruction for a display job in the queue is again received from the instruction section, the job control section controls the jobs to move the display job to the forefront of the queue.

Owner:SHARP KK

Process making it possible to select a taxi from a fleet with a view to allocating it to be undertaken

InactiveUS20030020637A1Precise cuttingHigh densityRoad vehicles traffic controlCellular radioNetwork link

A process making it possible to select a taxi from a fleet of taxis, with a view to allocating it a trip to be undertaken, this selection being a function of the position of the taxis and of the point of departure of the trip. The process is one wherein: the taxis are linked to a control center via a network to which the taxis are connected by a cellular radio link; the position of each taxi is determined by the control center by virtue of the identifying of at least the last cellular radio link antenna via which the taxis was connected to the network.

Owner:GLEIKE

System and Methods of Providing Pharmacy Services

ActiveUS20100256987A1Minimize waiting timeFinanceDigital data processing detailsDispensaryPharmacy medicine

Owner:CVS PHARMACY INC

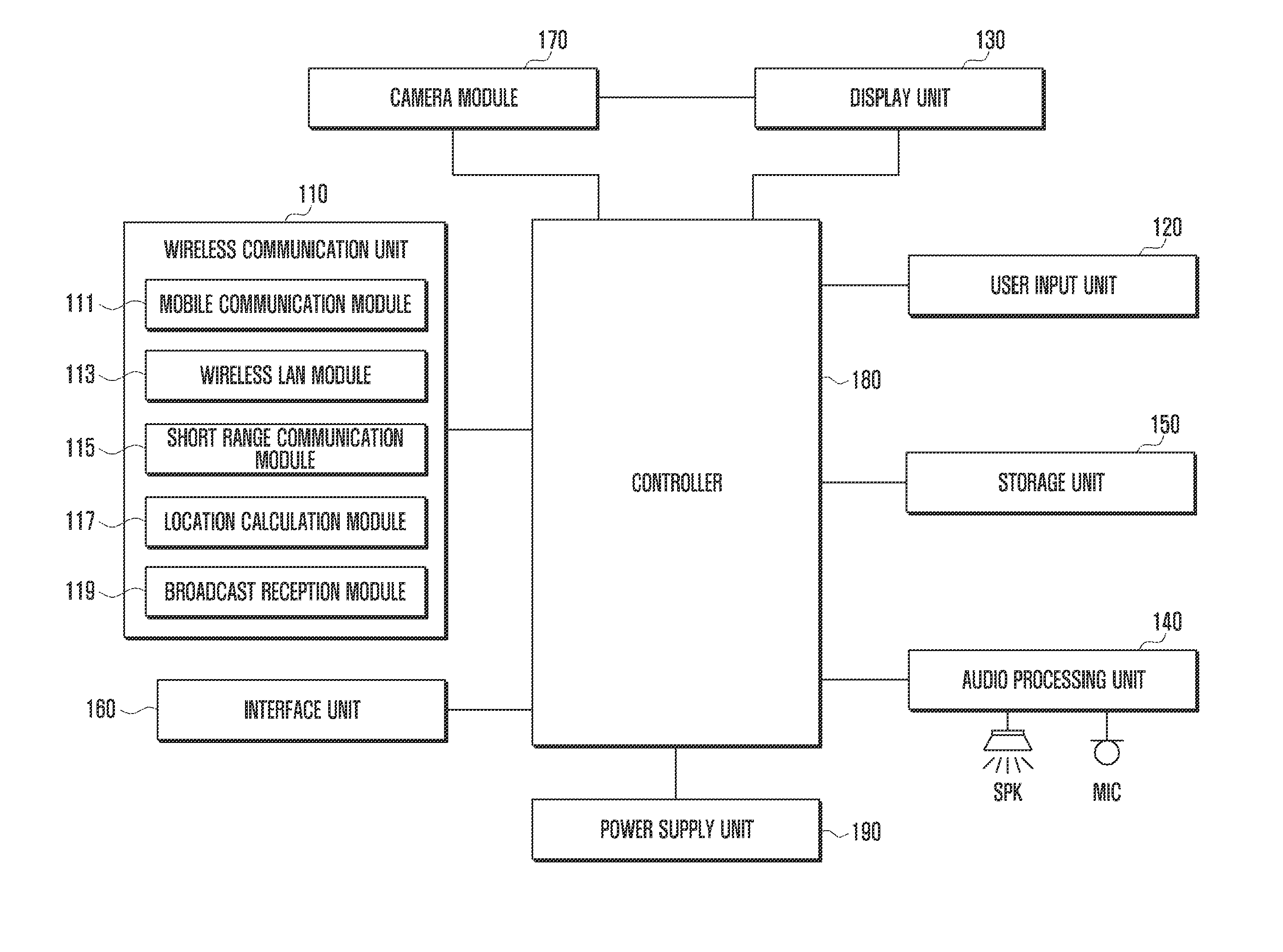

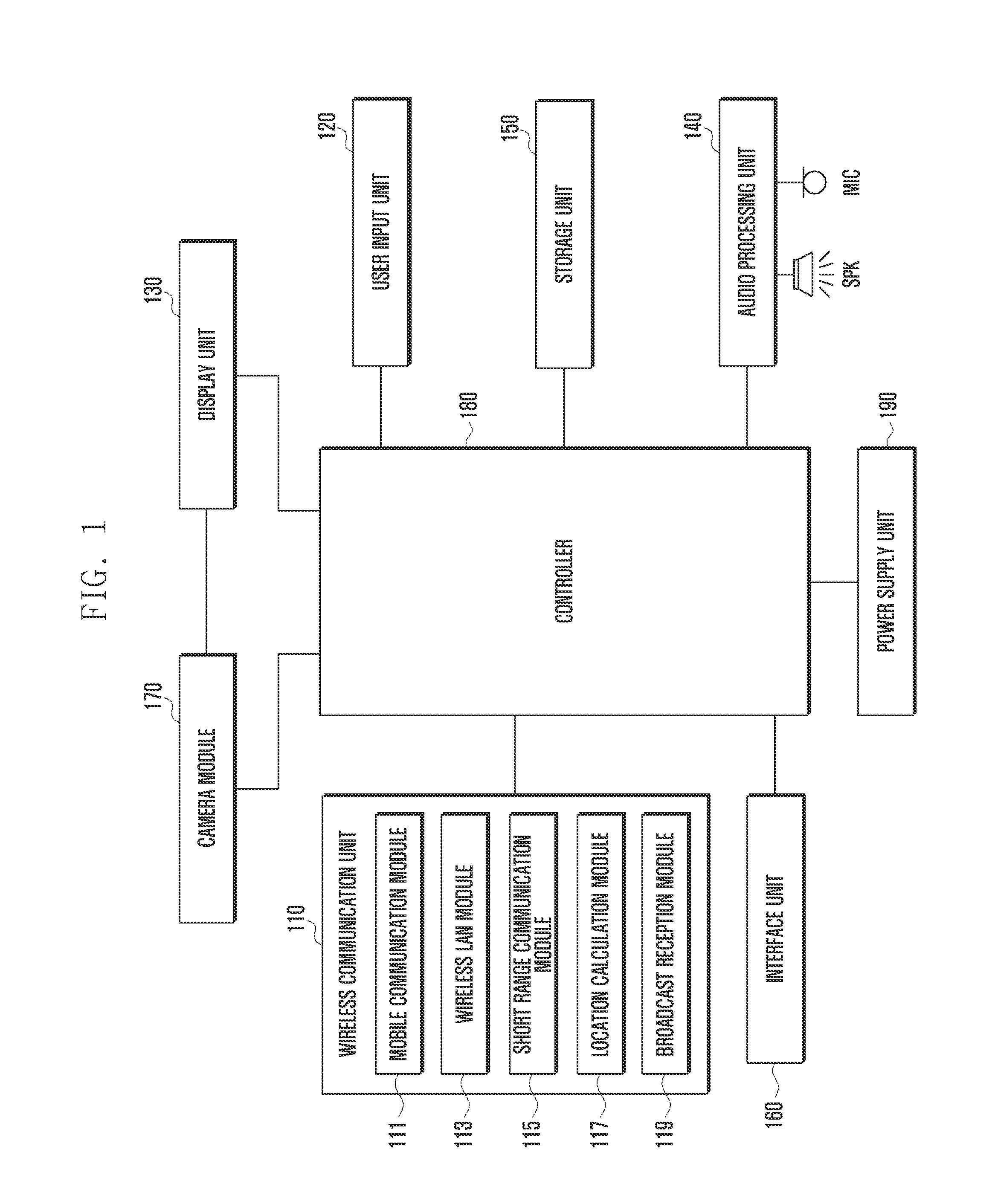

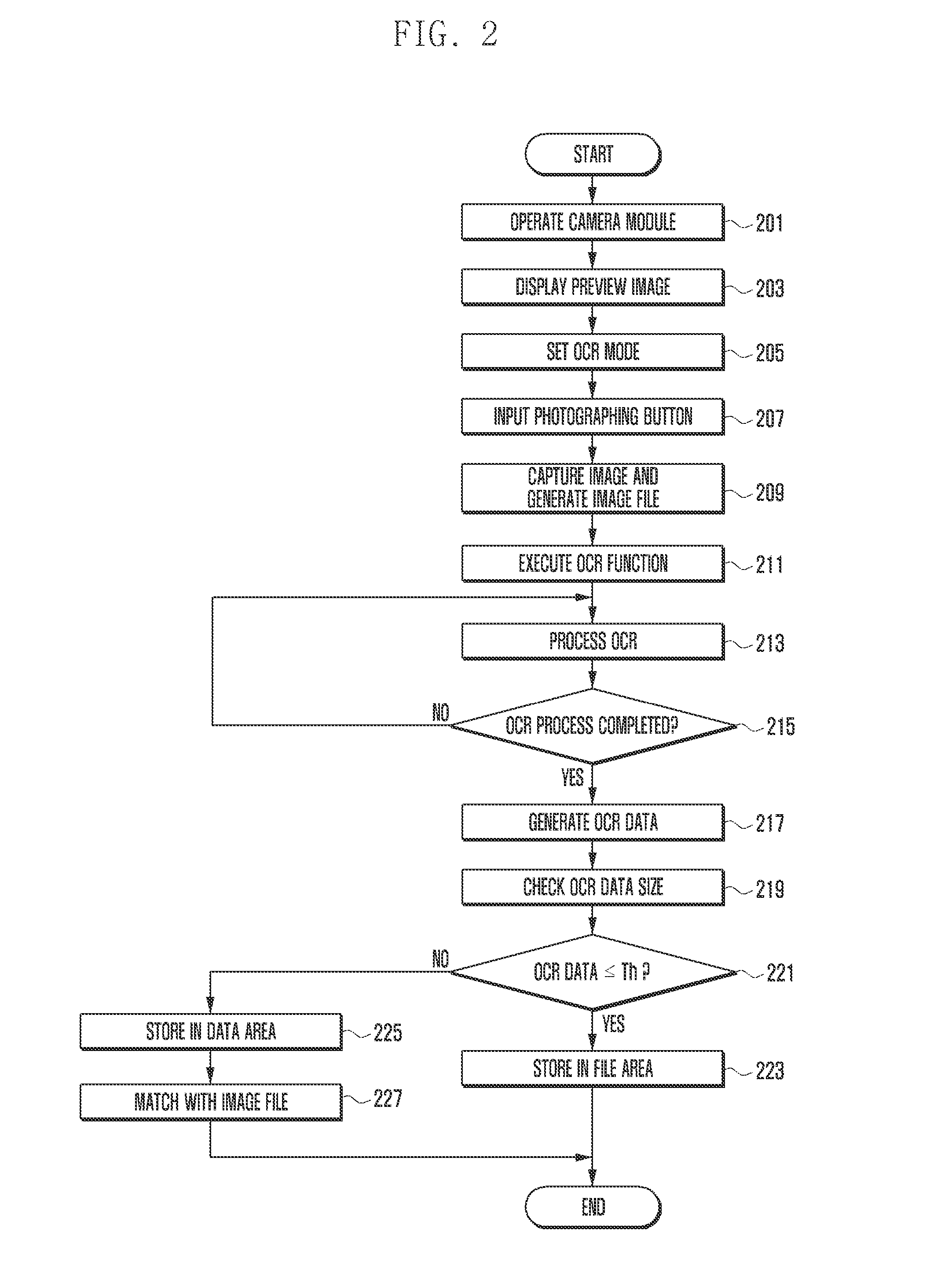

Method and apparatus for processing data using optical character reader

ActiveUS20140056522A1Minimizing drawing timeEasy accessSpecial data processing applicationsCharacter recognitionComputer graphics (images)

A method for processing data by using an optical character reader (OCR) is provided. The method includes obtaining OCR data from each image file of a plurality of image files and storing the obtained OCR data, receiving a search command with respect to an object, extracting the object from the stored OCR data, selecting OCR data which includes the object from among the OCR data, and displaying a list of image files which correspond to the selected OCR data.

Owner:SAMSUNG ELECTRONICS CO LTD

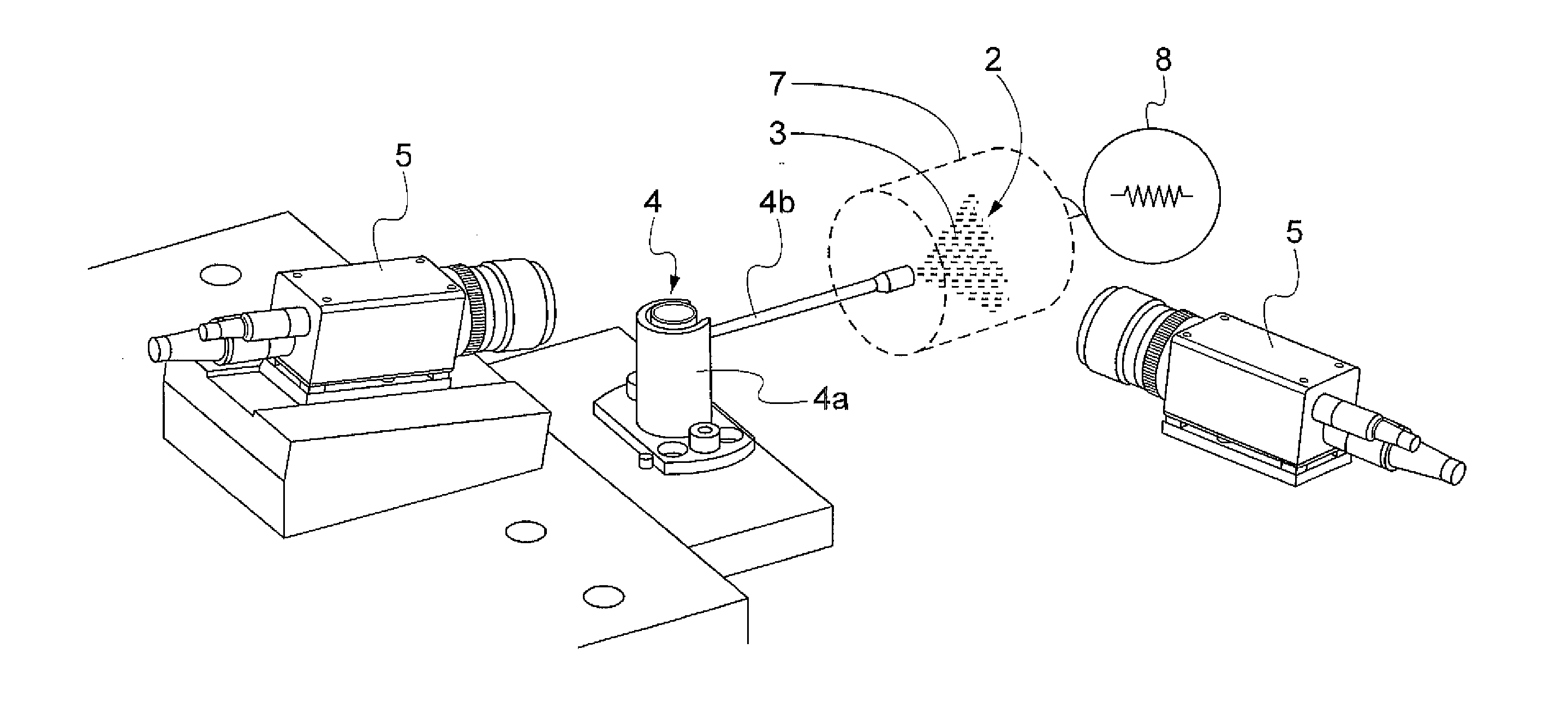

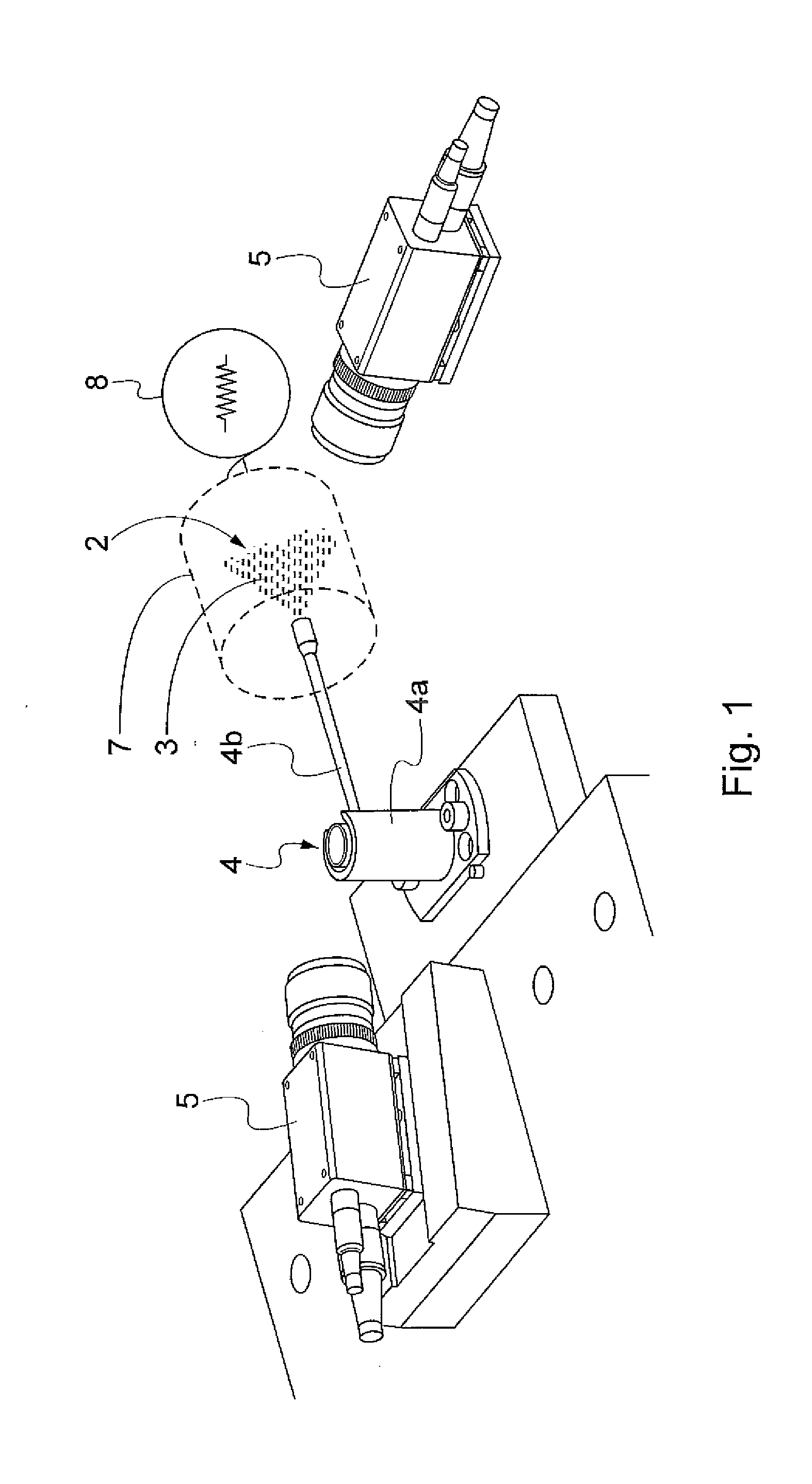

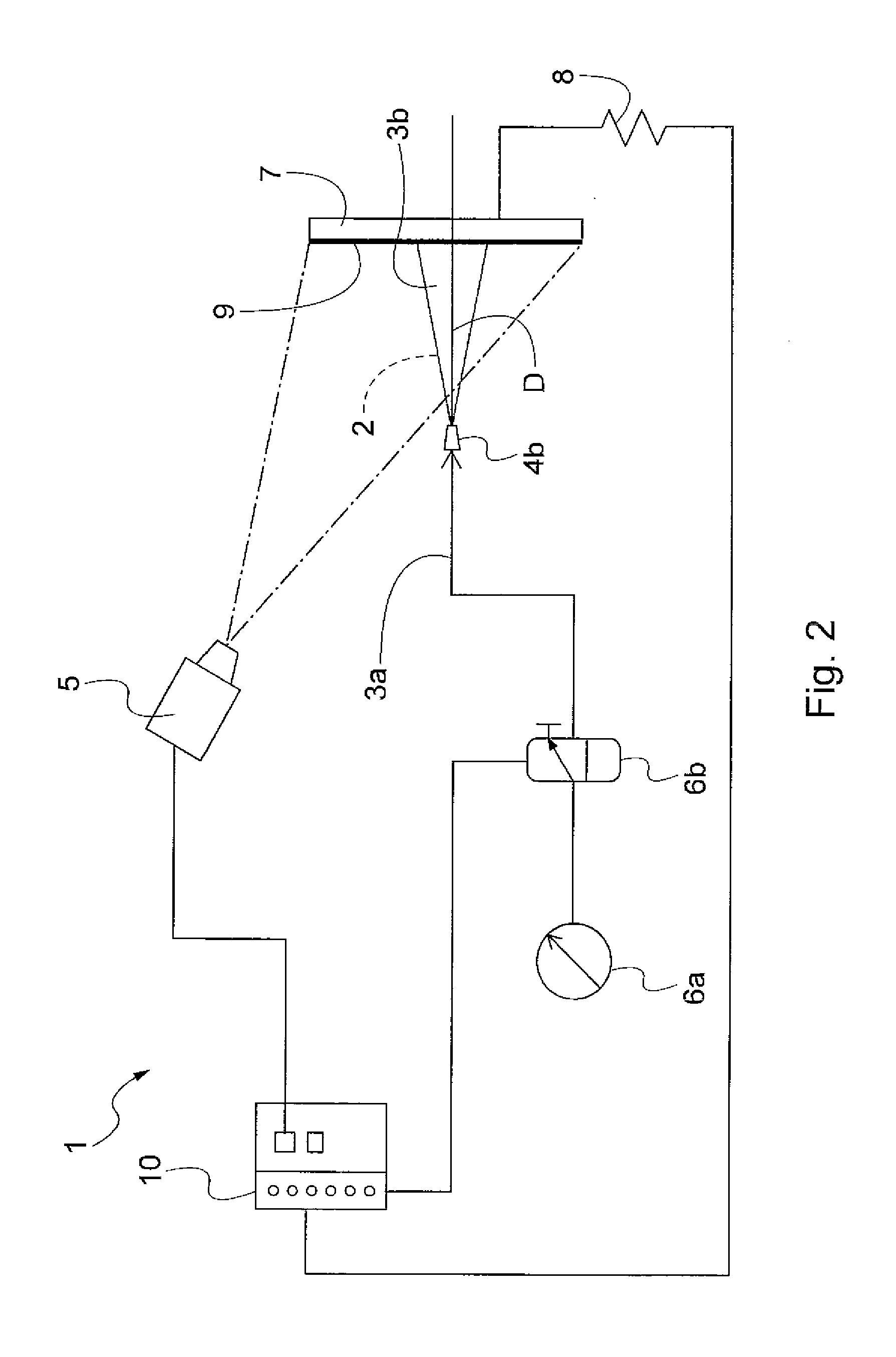

Device for controlling the distribution of fluid ejected from a fluid nebulizing dispenser

InactiveUS20160216108A1Avoid pollutionMinimize waiting timeSpray nozzlesMedical devicesTemperature differenceBiomedical engineering

Disclosed is a device for checking the distribution of fluid ejected from a nebulizing dispenser of fluid, of the type including a discharging nozzle for a nebulized fluid. The device having detecting means for detecting the temperature difference between at least part of the nebulized fluid ejected from the dispenser and a one contrast space, and / or the temperature difference caused by the nebulized fluid ejected from the dispenser to the contrast space. In this case, the contrast space is arranged so as to be at least partially incident to said nebulized fluid.

Owner:INMAN

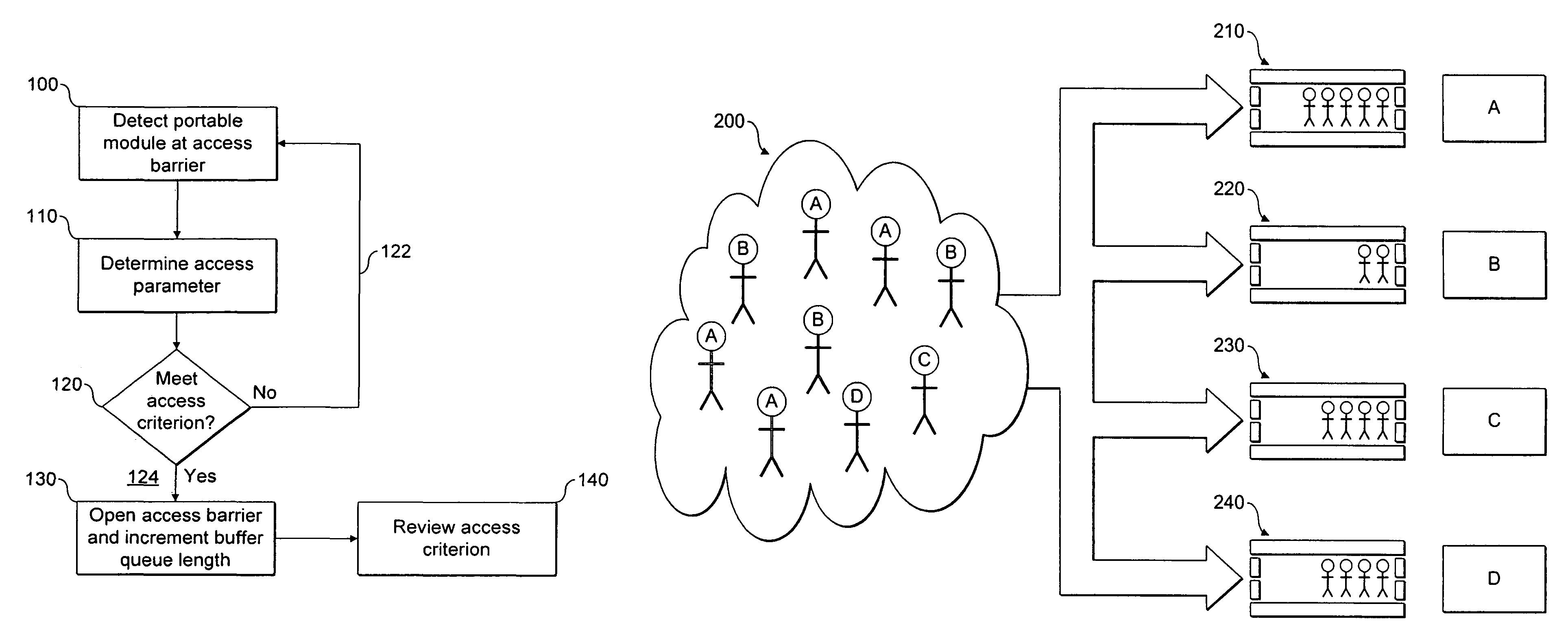

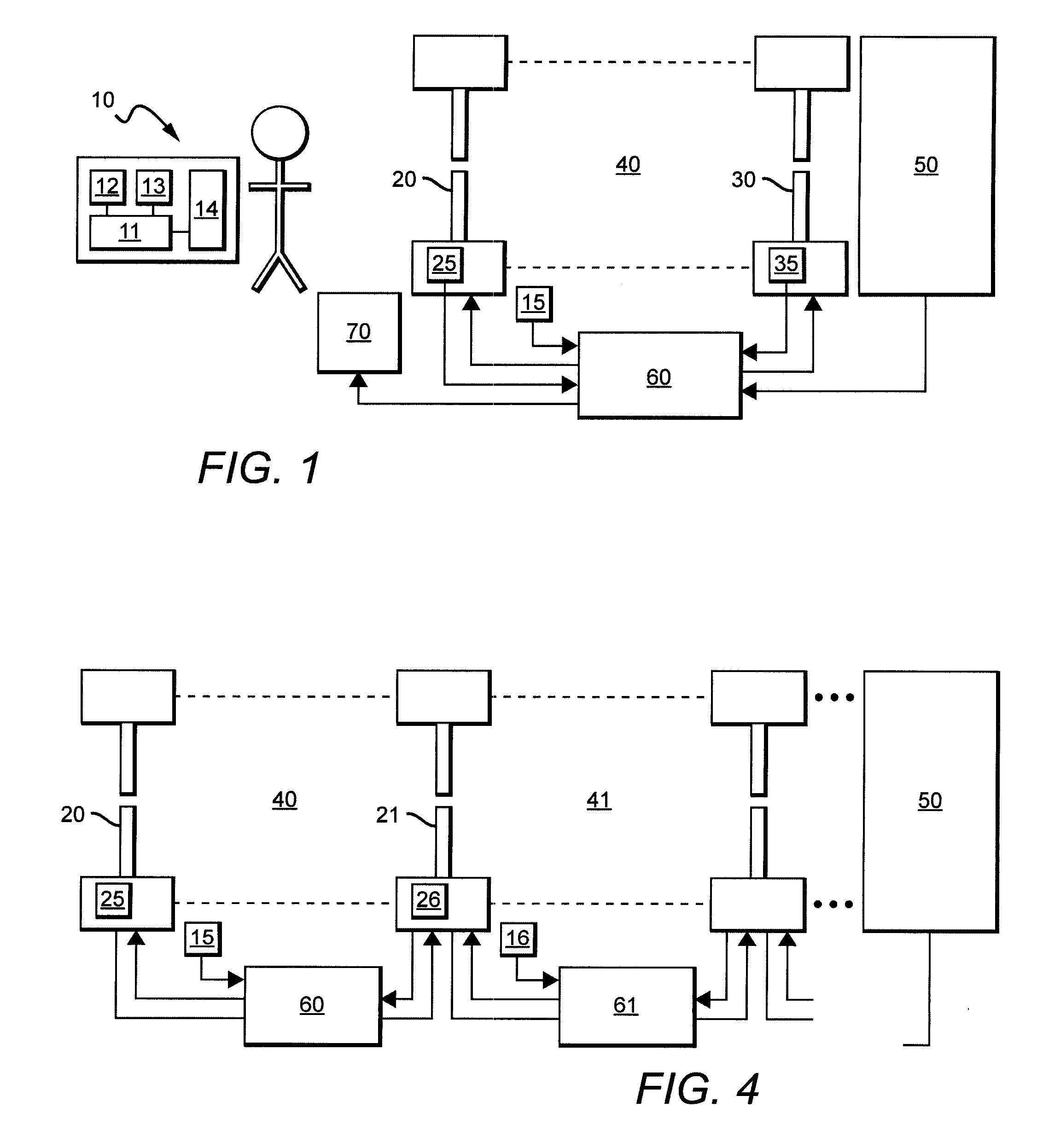

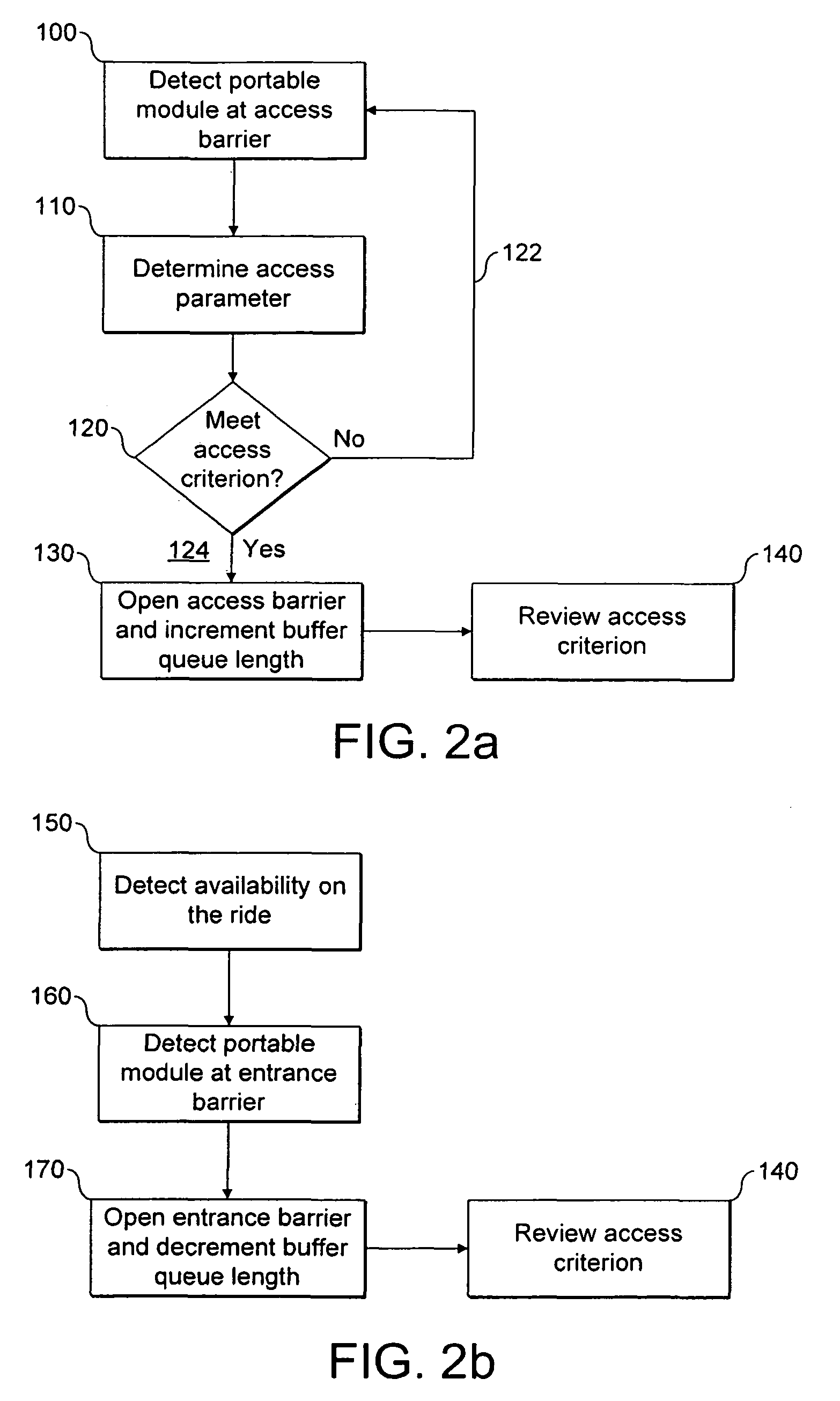

System for regulating access to a resource

ActiveUS8779889B2Reduce complexityLow costElectric signal transmission systemsMultiple keys/algorithms usageClosed stateAccess key

A system for regulating access to a resource by a plurality of users is provided. The system comprises: a plurality of portable access keys, each being provided to one of the users and having an associated variable access parameter; an access barrier, having an open state allowing passage through and a closed state denying access to the resource, and defining an access queue; a sensor that determines an access queue characteristic related to a number of users in the access queue; a controller, which sets an access criterion based on the determined access queue characteristic; and a detector, located at the access barrier and which determines the variable access parameter of a portable access key when it is brought into the vicinity of the detector. The controller sets the access barrier in its open state if the variable access parameter determined by the detector meets the access criterion.

Owner:LO Q

Installation system for quickly attaching fastening elements by means of light-curing adhesives

ActiveUS8663417B2Minimize waiting timeUniform curingMechanical working/deformationPicture framesEngineeringLight cure

An installation system for mounting stationary objects, such as towel holders, shelves, lights, or similar furnishing items, on an installation surface, such as a wall or a ceiling, in particular in rooms equipped with tiles, marble slabs, or similar wall coverings, includes one or more fastening elements, a lighting device, and / or an adhering and connecting agent, wherein the adhering and connecting agent is a light-curing adhesive. The one or more fastening elements can be fastened by introducing an adhering and connecting agent into an adhesive space formed by the installation surface and components of the fastening element. The fastening element has at least one at least partially transparent component for irradiating the adhering and connecting agent.

Owner:TESA NIE WIEDER BOHREN GMBH

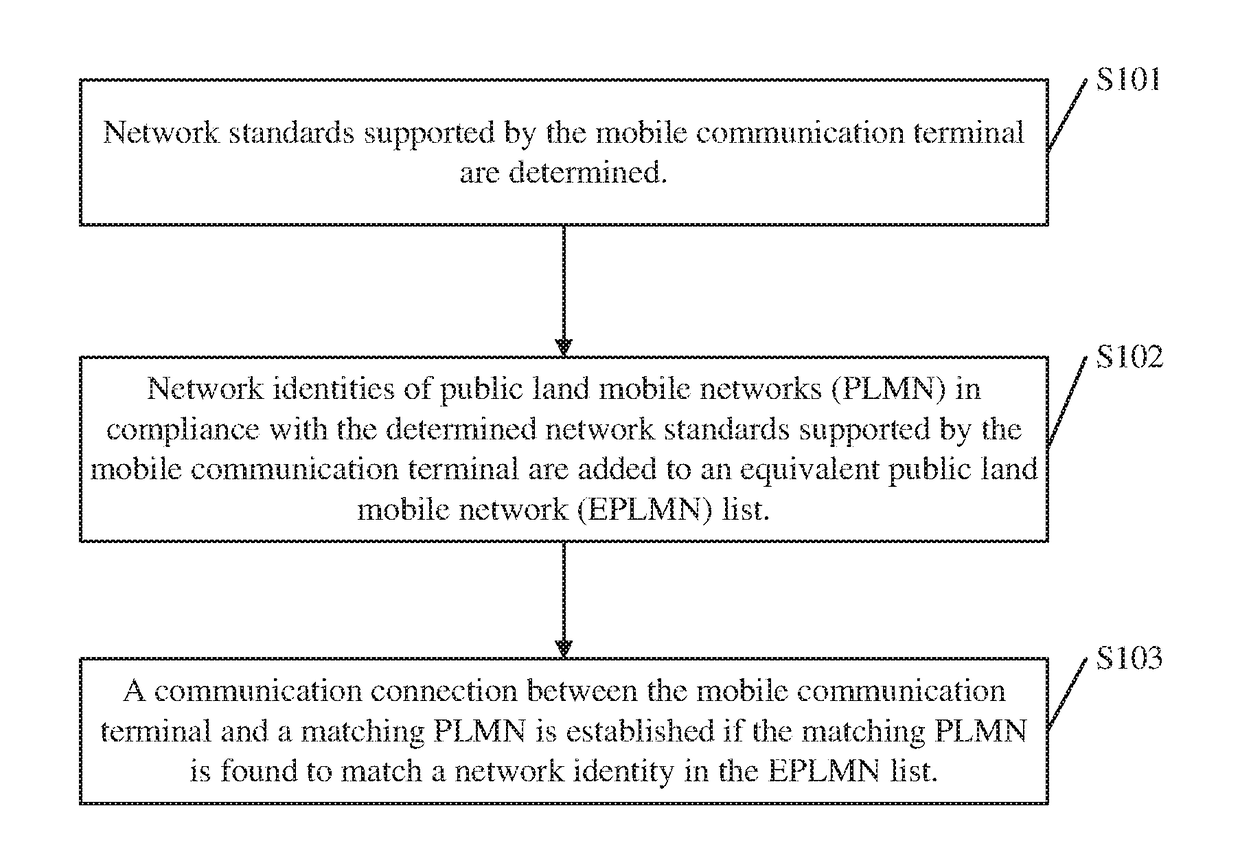

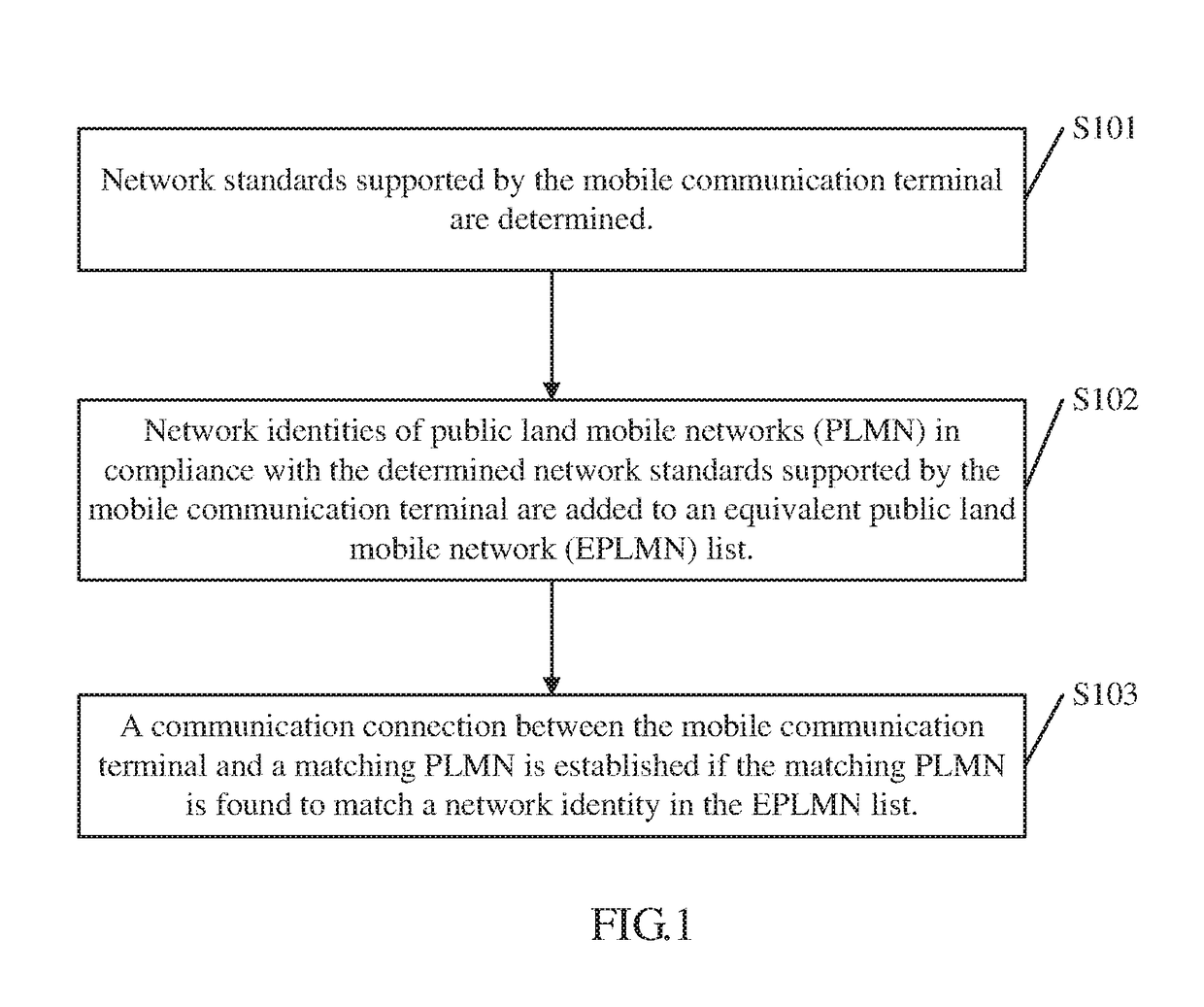

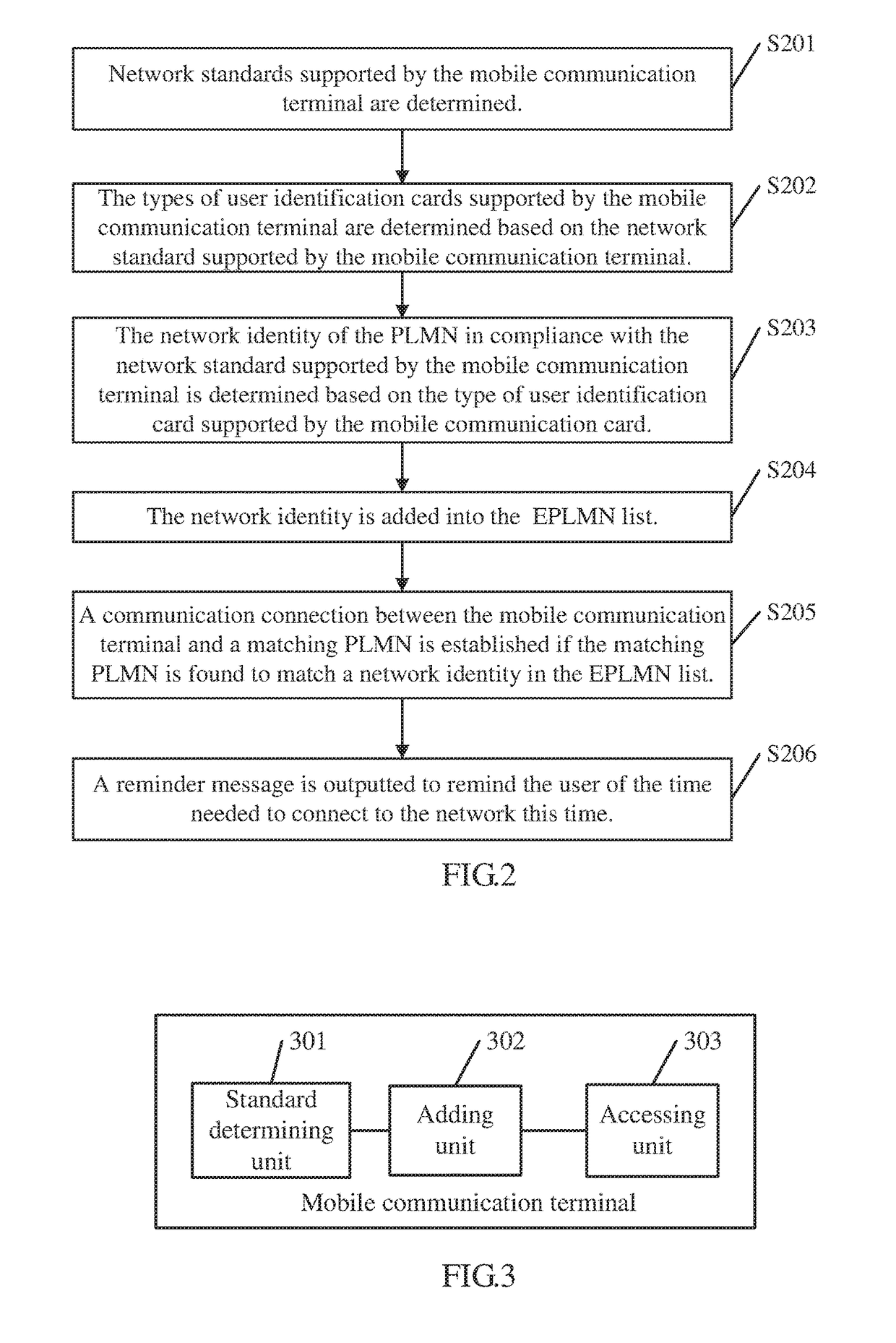

Network access method and mobile communications terminal

ActiveUS20170223618A1Shorten the timeImprove communication experienceAssess restrictionWireless commuication servicesTelecommunicationsAccess method

Disclosed in the embodiments of the present invention are a network access method and a mobile communications terminal, comprising: determining a network standard supported by a mobile communications terminal; adding to an equivalent public land mobile network (EPLMN) the network identifier of a public land mobile network (PLMN) of the determined network standard supported by said mobile communications terminal; if a PLMN matching the network identifier of said EPLMN is discovered by searching, then establishing a communications connection between said mobile communications terminal and said matching PLMN.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

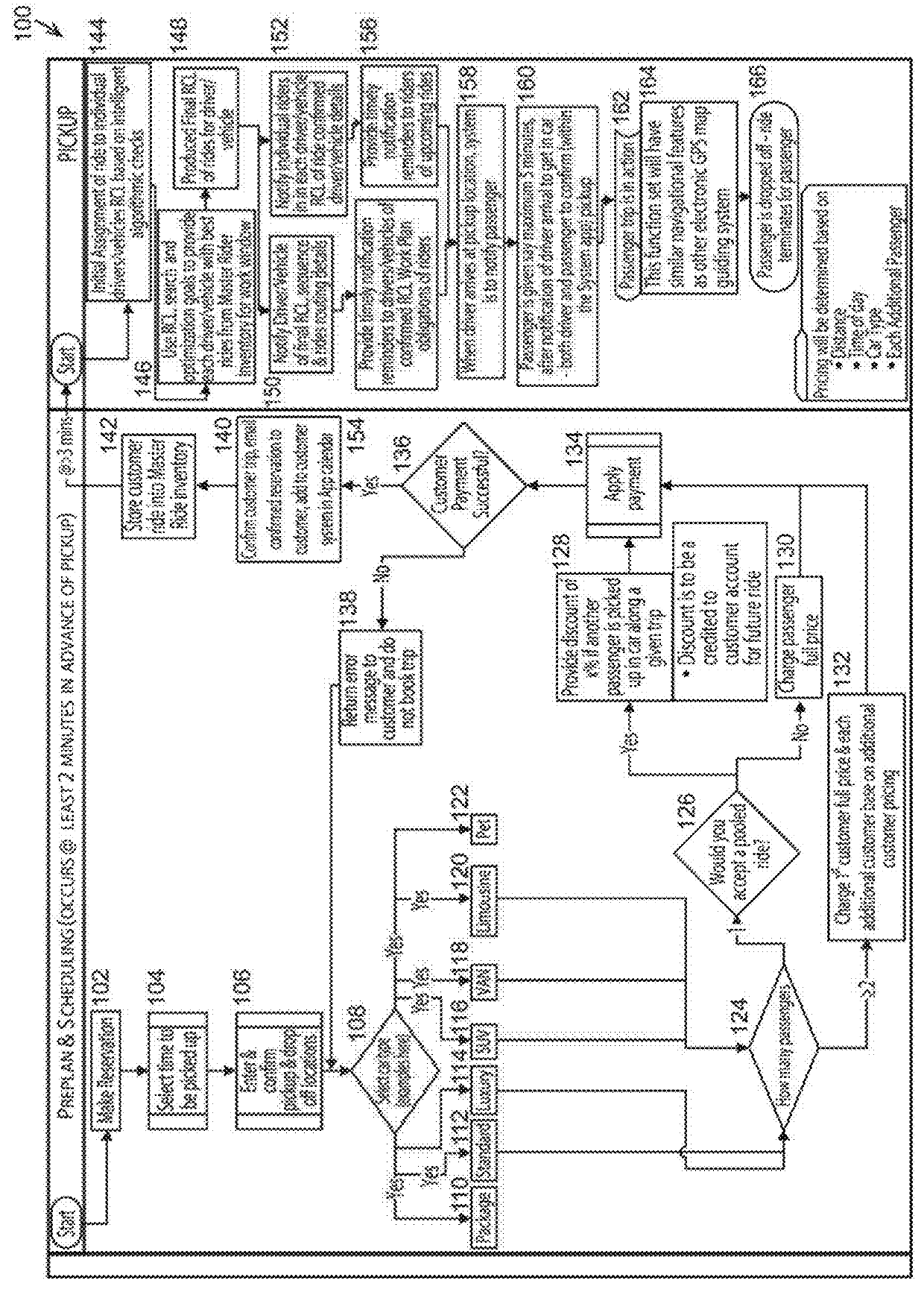

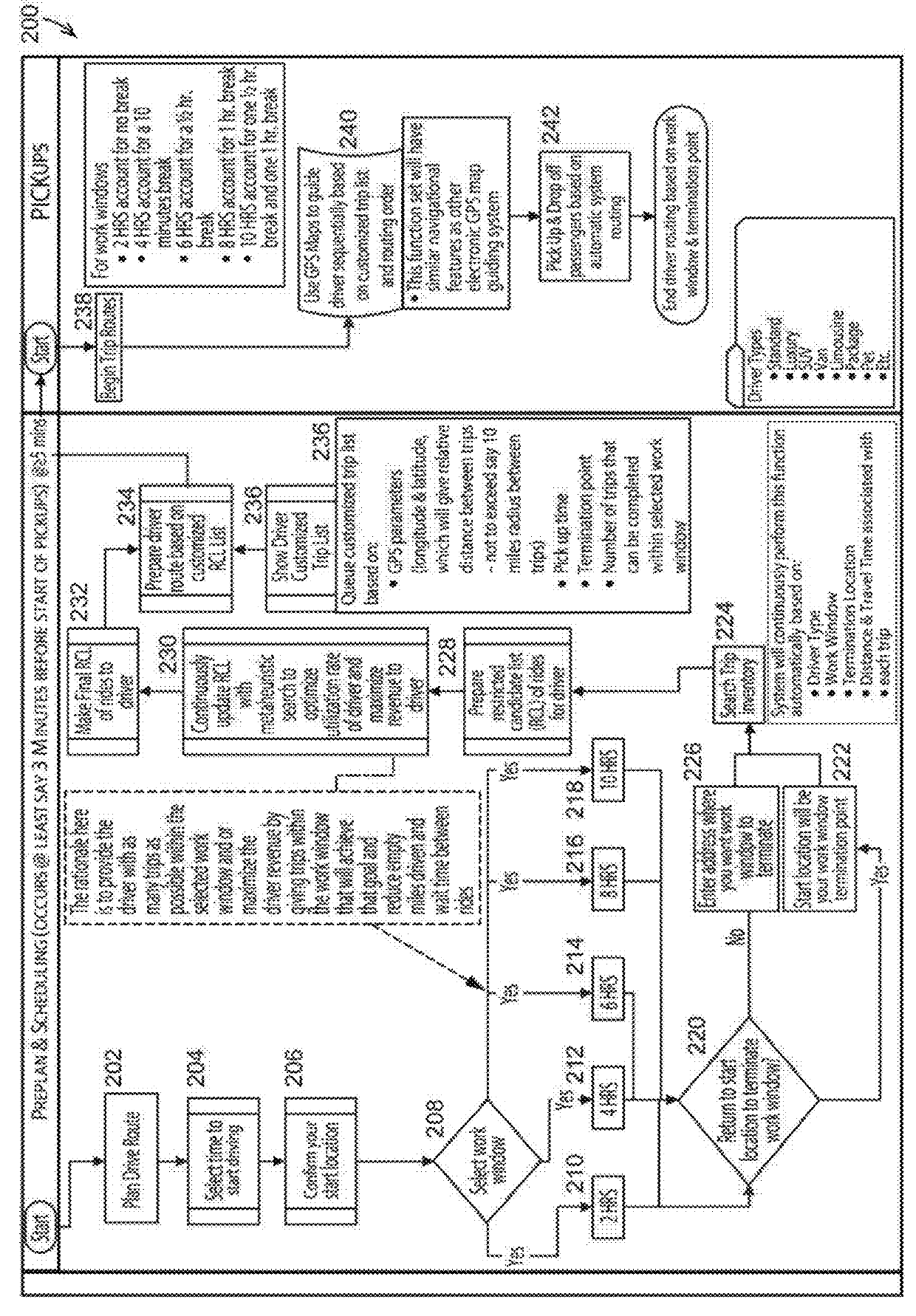

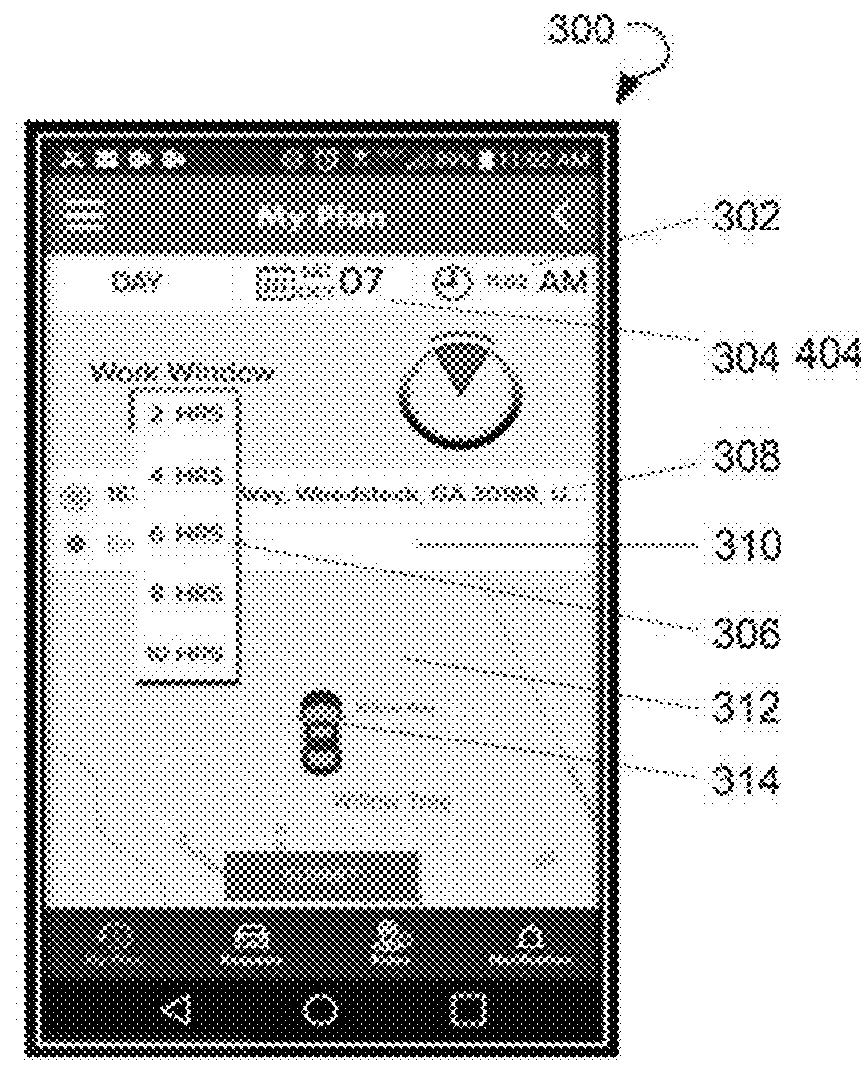

Systems and methods for routing vehicles and scheduling vehicle rides

InactiveUS20180276586A1Minimize waiting timeMinimize the uncertainty for each driverAutonomous decision making processRegistering/indicating working of vehiclesGraphical user interfaceStart time

The disclosure relates to systems and methods for routing vehicles and scheduling vehicle rides. In a system embodiment, a computer processor operable to execute computer-executable instructions, and a memory comprising computer-executable instructions can be provided. The computer-executable instructions can be operable to, prior to a predefined cutoff time and based at least in part on the start time and the end time for a first driver, generate a sequenced list of vehicle rides; determine, prior to the predefined cutoff time, a revenue potential for each hour increment between the start time and the end time; modify, based at least in part on implementation of a metaheuristic algorithm, and after the predefined cutoff time, the sequenced list; and output, via a graphical user interface, the modified sequenced list to the first driver, wherein the graphical user interface comprises a list of optimized vehicle rides.

Owner:ZYLECK TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com