Spinning machine and method for operating the same in case of failure of an external power supply

An external power supply, spinning machine technology, applied in spinning machine, open-end spinning machine, continuous winding spinning machine, etc., can solve the problems of time-consuming, low spinning efficiency, etc., and achieve the effect of preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

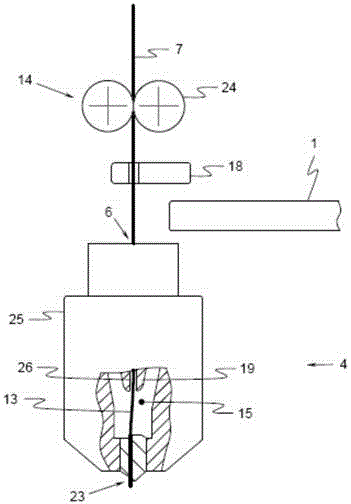

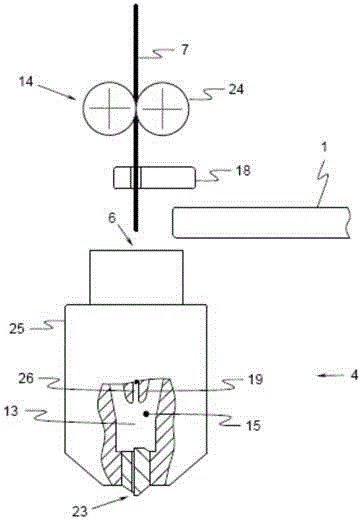

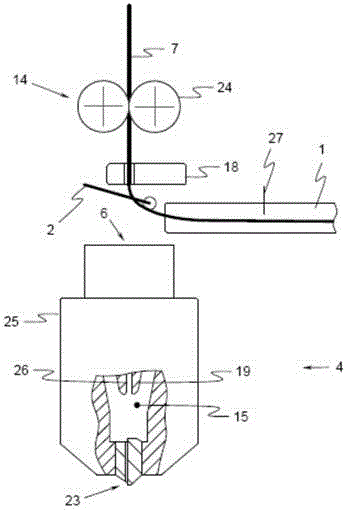

[0036] figure 1 The basic structure of the spinning machine of the present invention, such as a rotor or an air-jet spinning machine, is shown.

[0037] Spinning machines generally comprise a plurality of spinning units 3 arranged adjacently and / or in tandem (for clarity, image 3 Only three are shown). Each spinning unit 3 is supplied with fiber composite material 13 during the spinning operation, for example via a corresponding spinning pot 21 . The fiber composite material 13 is withdrawn from each spinning pot 21 by a conveying device 5 and then supplied to the spinning station 4 in which the fiber composite material 13 is rotated so that the desired yarn 7 is produced. Yarn 7 is wound up to by winding device 8 then figure 2 and image 3 The bobbin 20 is shown in more detail.

[0038] In the event of failure or failure of the external power source 10 (such as the public grid or a dedicated spinning mill grid), yarn production will be forced to stop. In order to be a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com