Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Low inner diameter requirement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

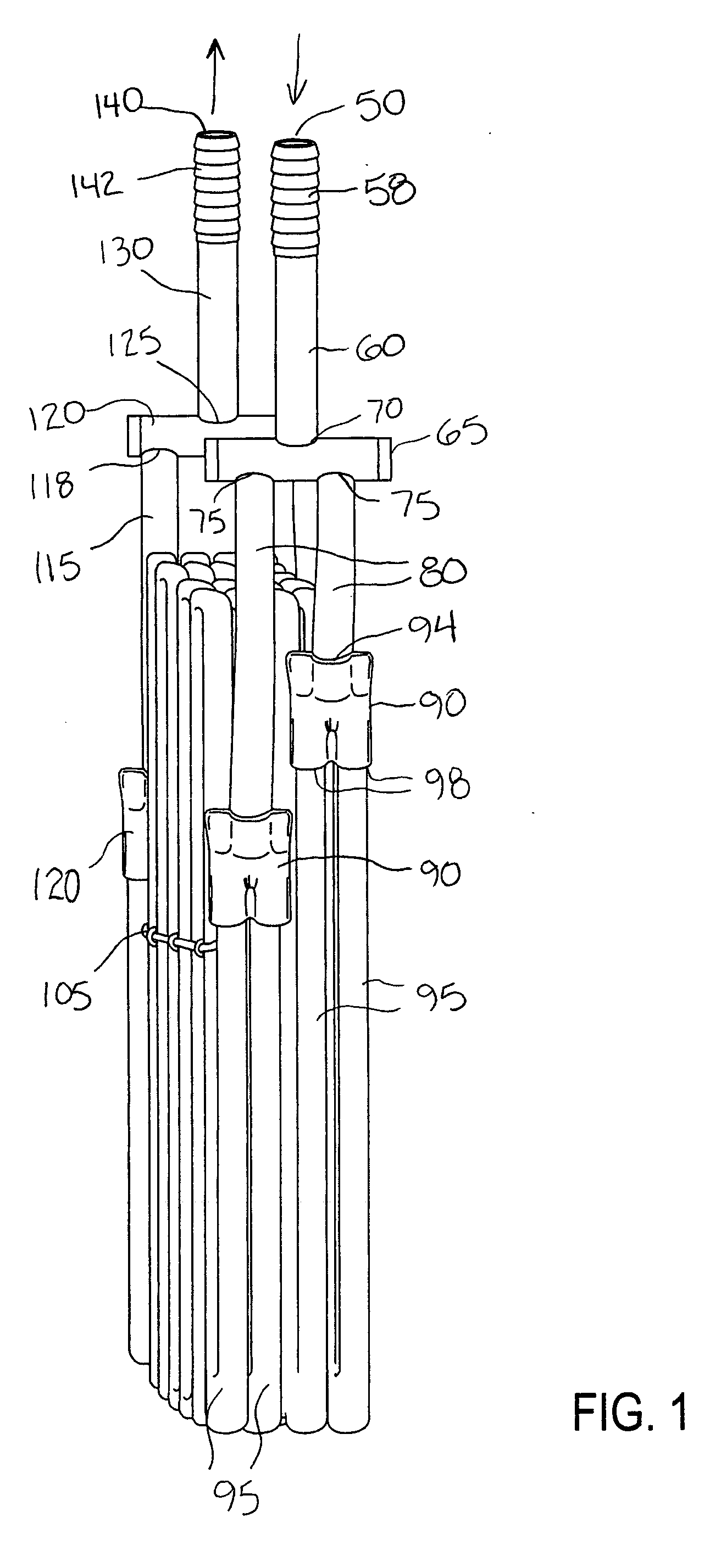

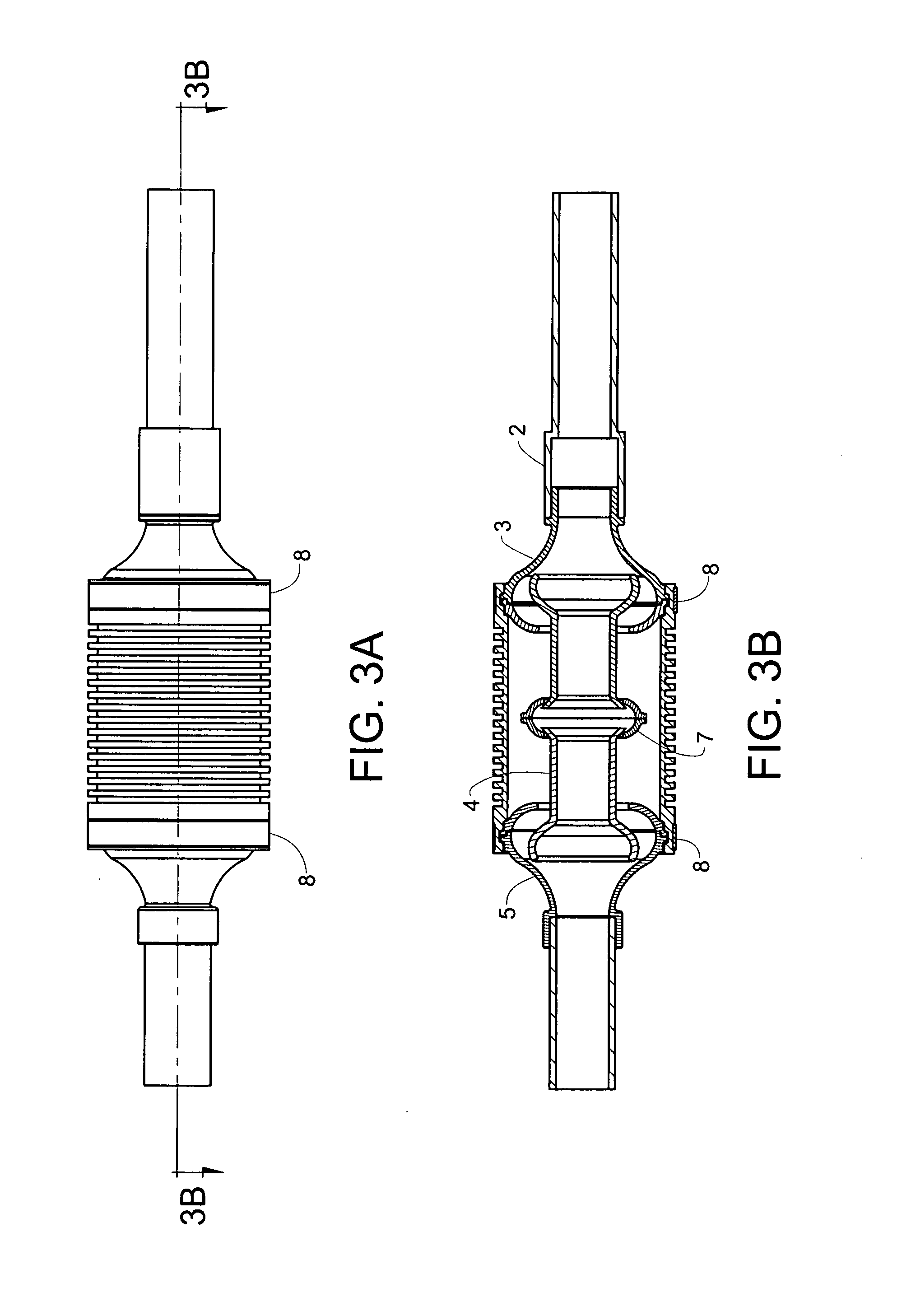

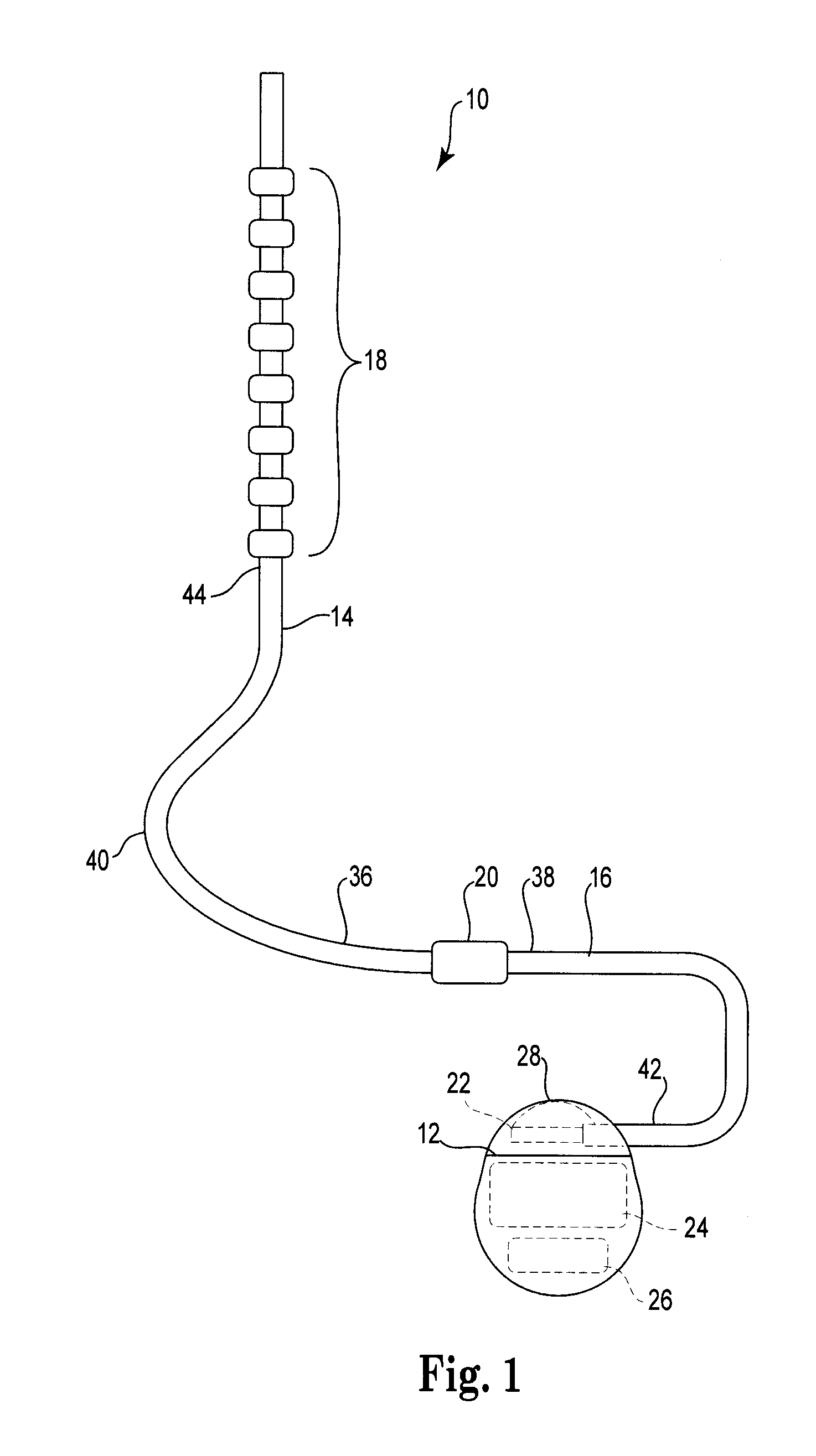

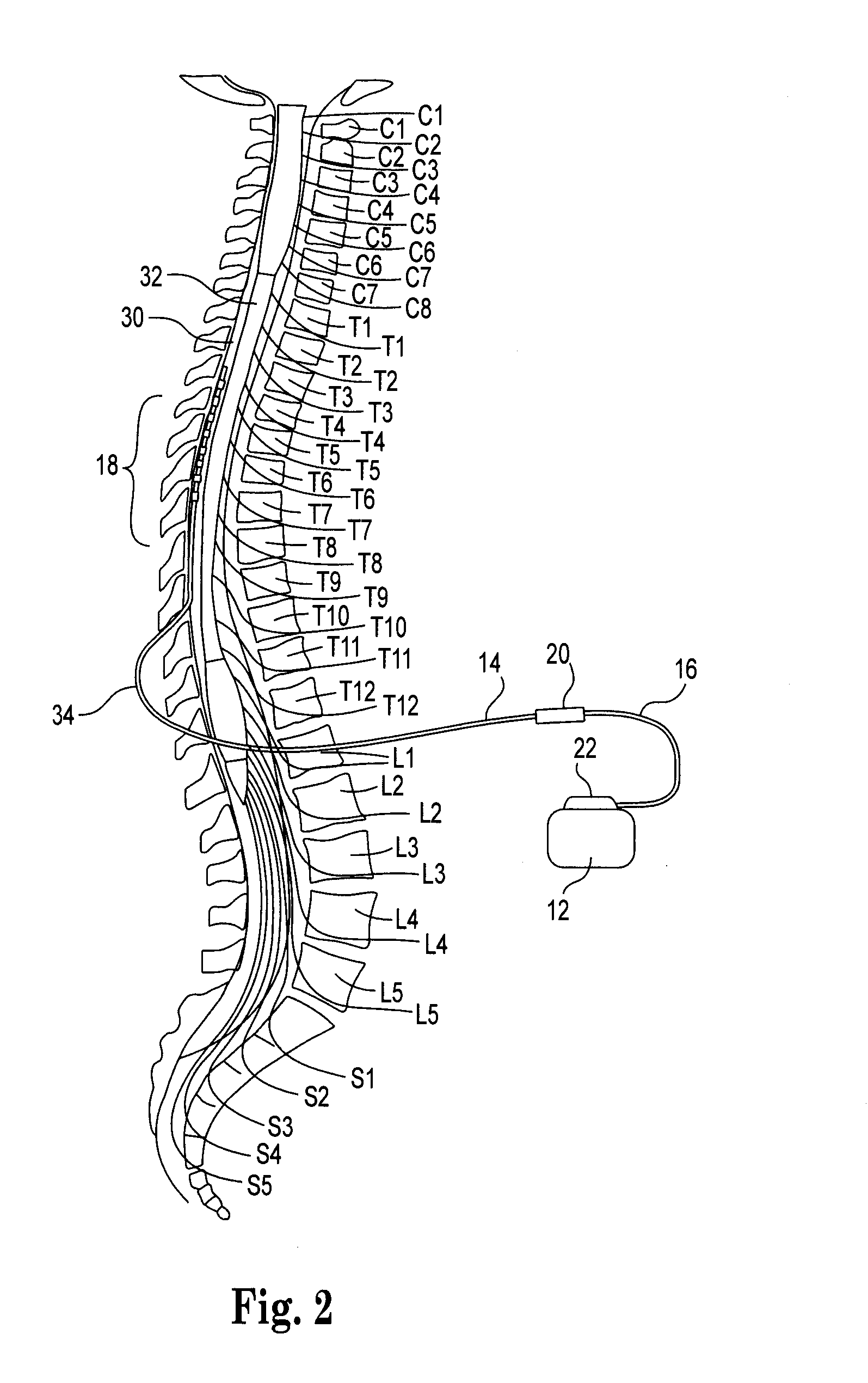

Medical instrument with controlled torque transmission

InactiveUS7780611B2Easy accessLow inner diameter requirementGuide wiresDiagnostic recording/measuringControl mannerTorque transmission

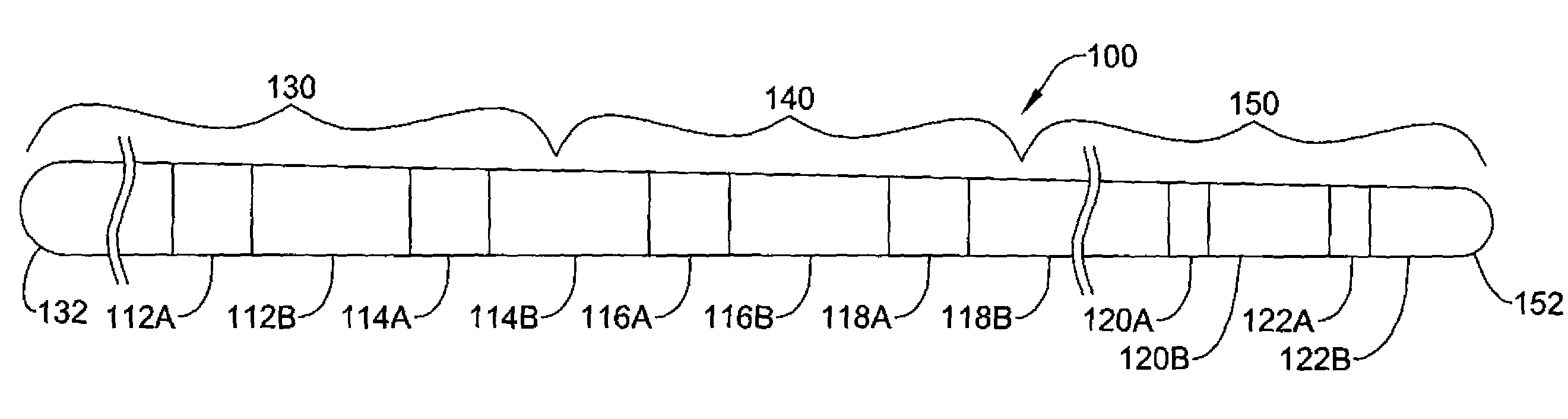

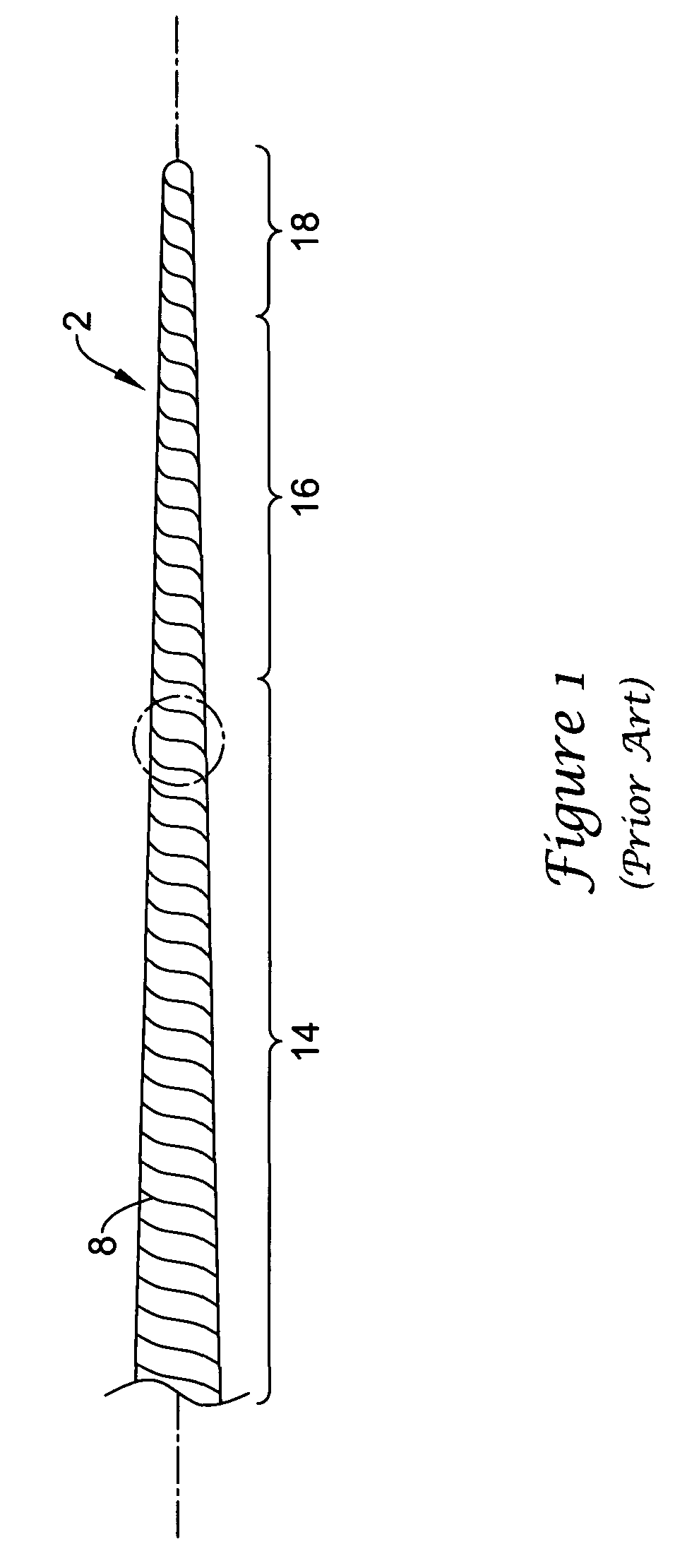

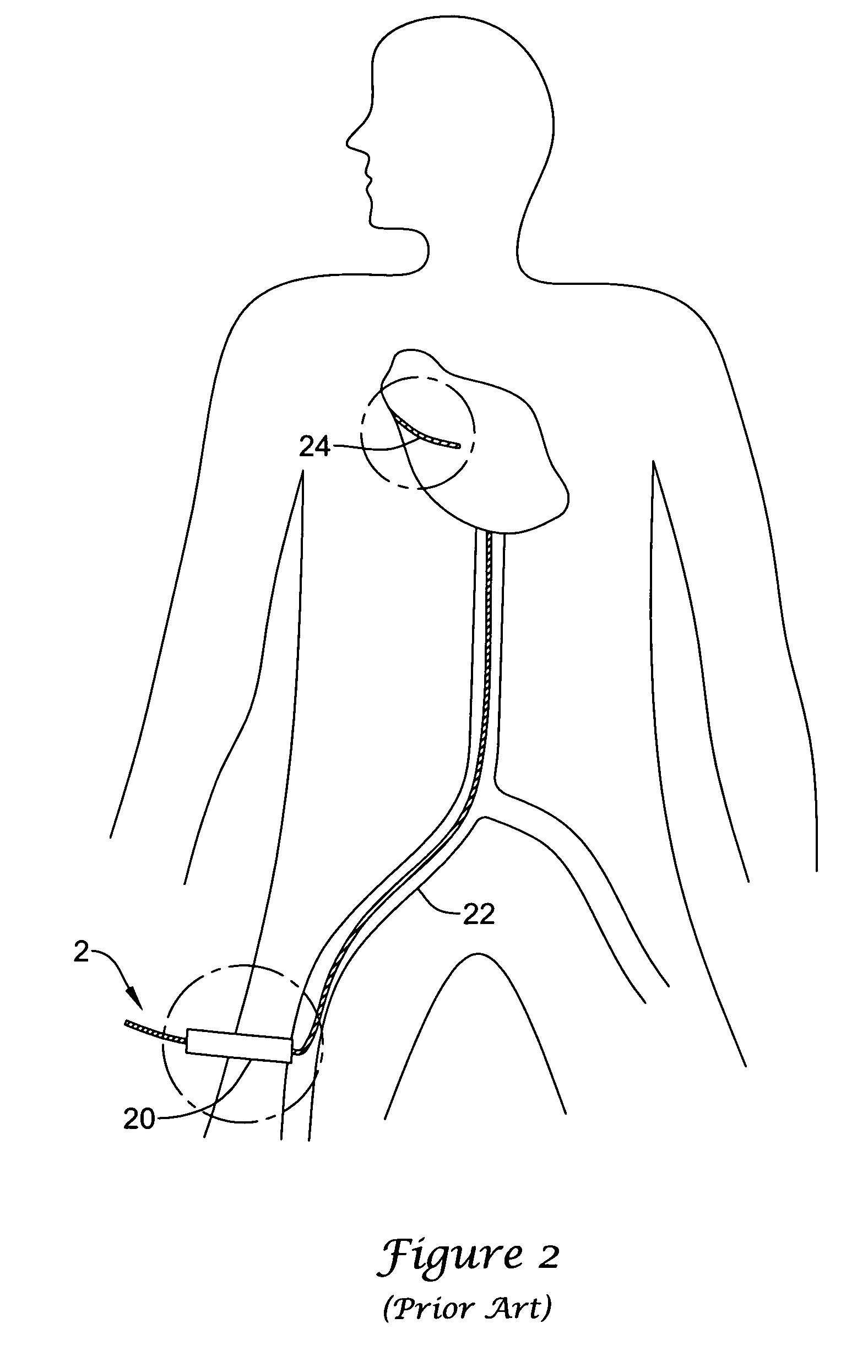

A medical instrument such as a guidewire that is designed to have controlled torque transmission along its length. Specially treated areas are placed in selected and equal areas along the entire length of the elongated shaft of the medical instrument, and are separated from one another by untreated areas. This process ensures that any torque is transmitted distally, in a smooth manner, regardless of the guidewire position, thus resulting in a substantial reduction in whipping. In one embodiment, a stainless steel guidewire is utilized, and is subjected to annealing heat treatment in selected areas. This annealing process creates a mandrel that has repeated temper properties along its length. Torque applied at one end of this mandrel is transmitted to the opposite end in an even and controlled manner, even when the mandrel is formed into a loop.

Owner:BOSTON SCI SCIMED INC

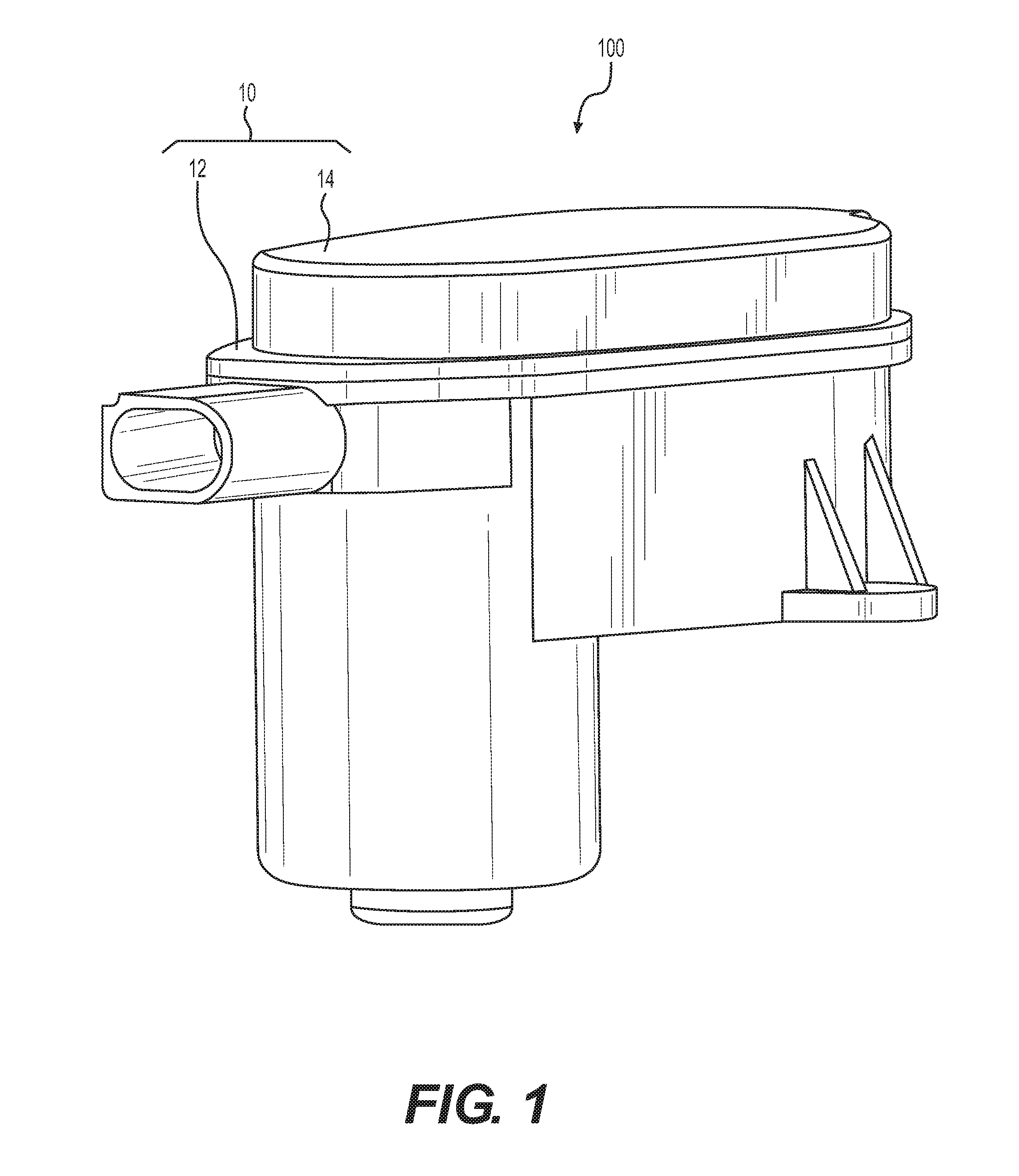

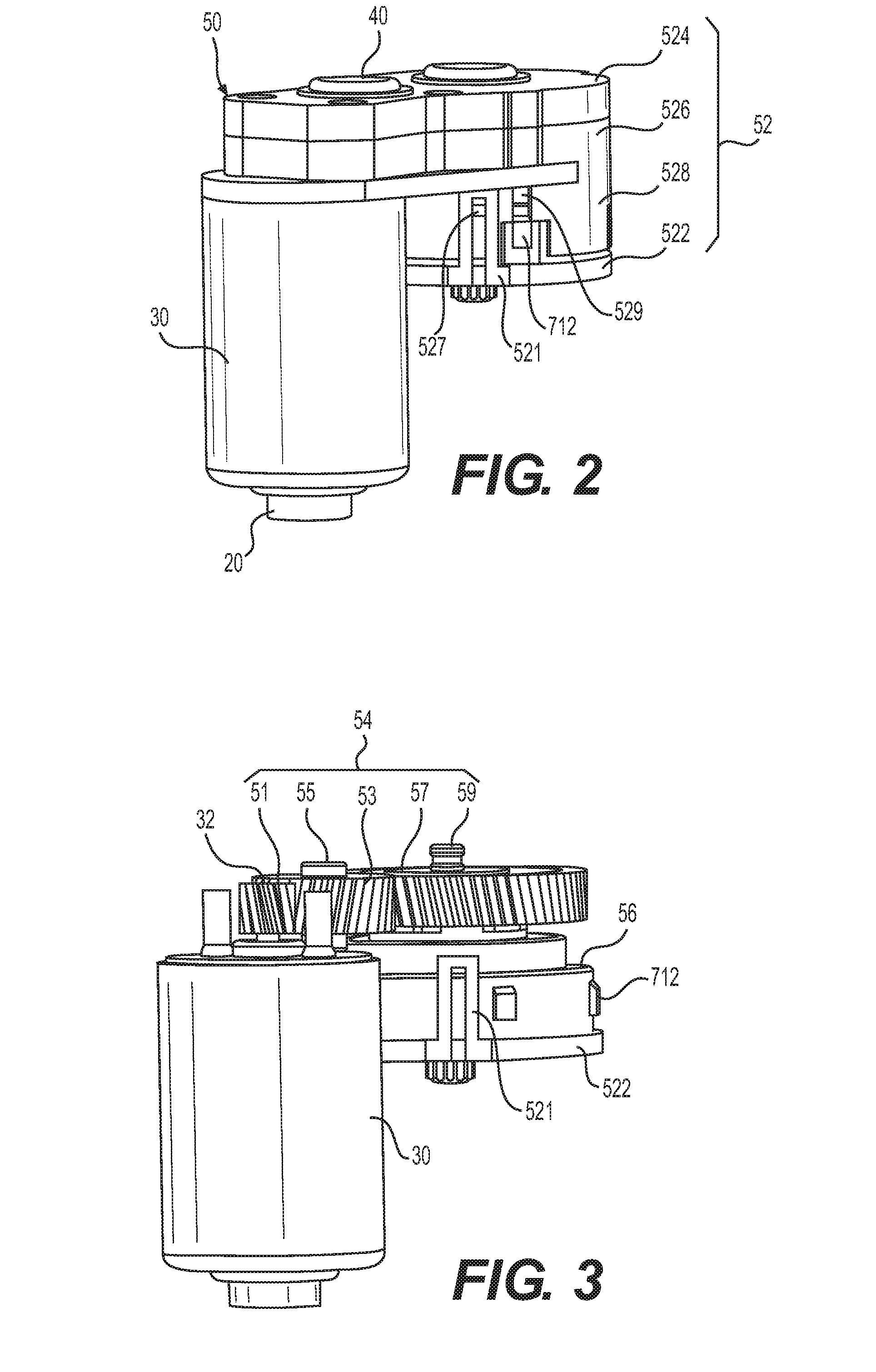

Actuator for Electric Park Brake System and Self-locking Mechanism Thereof

InactiveUS20160223040A1Improve efficiencyLow inner diameter requirementBrake actuating mechanismsSlack adjustersElectric parking brakeLocking mechanism

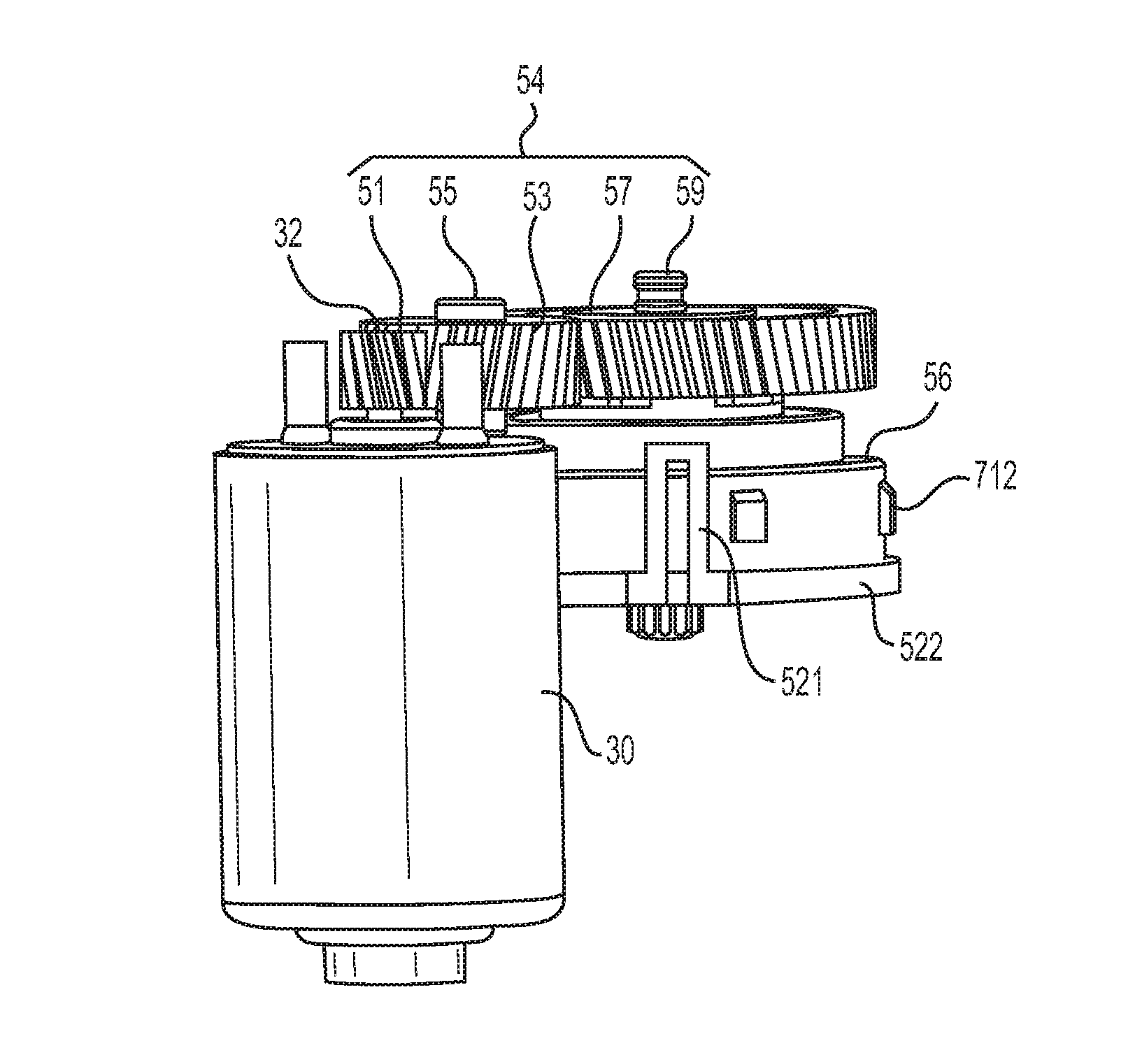

An actuator for an electric parking brake system includes a motor, an output member, and a speed reduction device. The speed reduction device includes a transmission mechanism and a self-locking mechanism. The self-locking mechanism includes a fixed member, first and second rotating bodies, and a spring. The second rotating body transmits torque to the output member via a planetary gear mechanism. The spring prevents the brake from driving the motor.

Owner:JOHNSON ELECTRIC SA

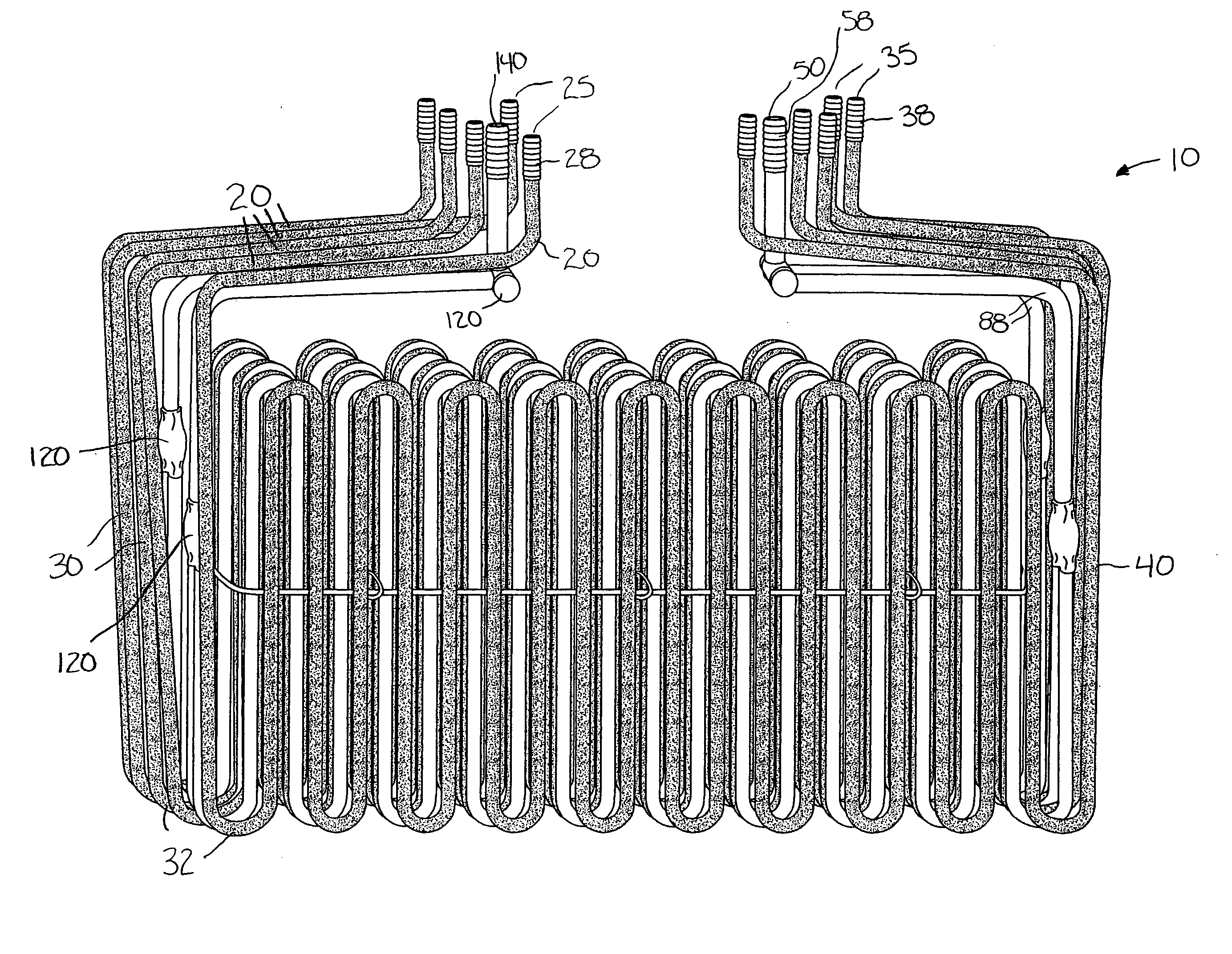

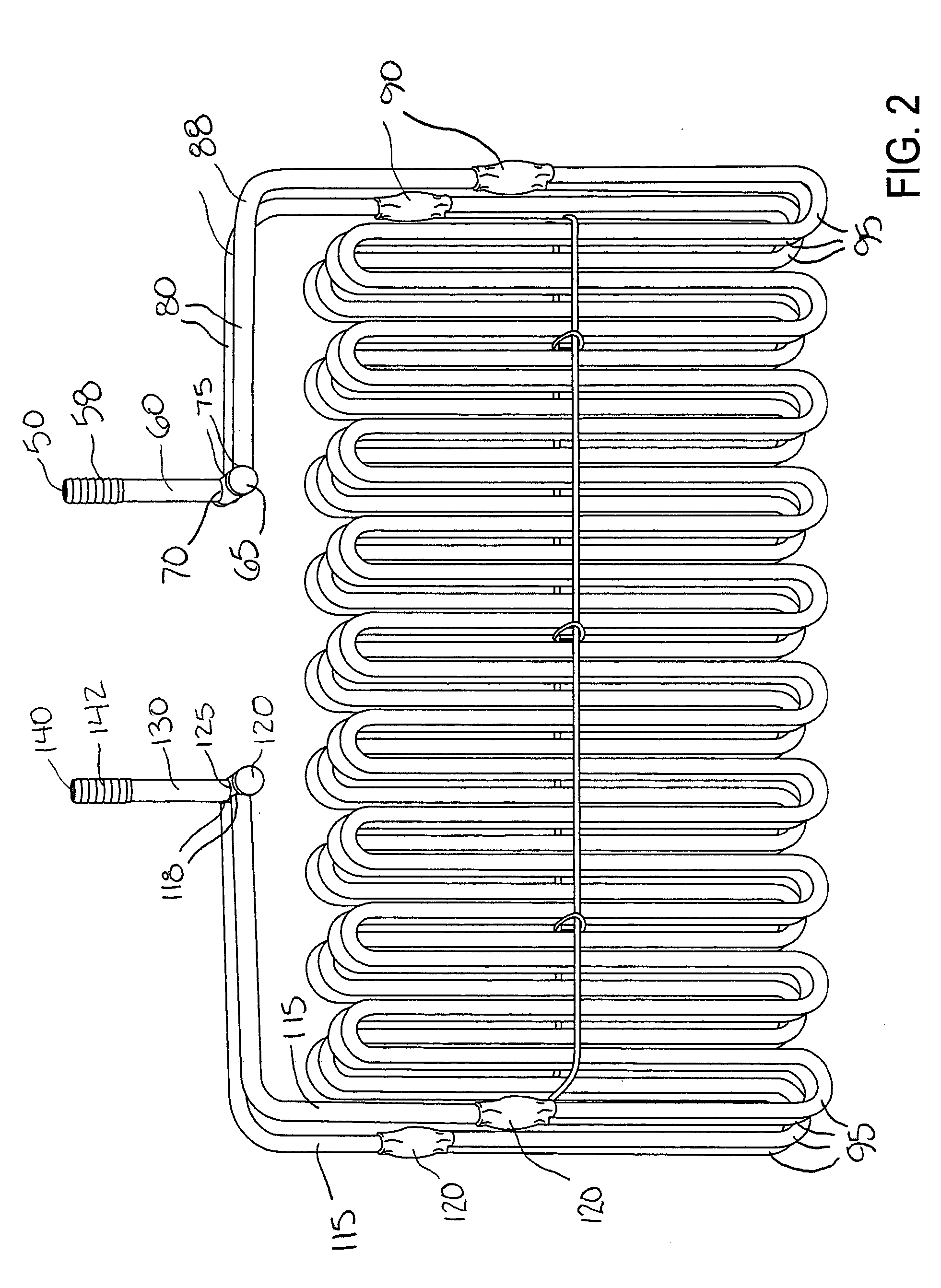

Cold plate for beer dispensing tower

ActiveUS20050028964A1Low inner diameter requirementMore consistent and efficient beer chilling apparatusDomestic cooling apparatusAir heatersLine tubingEngineering

A cold plate for a beverage chilling apparatus comprising a plurality of beverage conducting tubes sinuously arranged within a cast aluminum jacket. Interleaved between the beer conducting tubes are coolant conducting lines arranged in heat exchanging relation. The coolant lines are derived from a main coolant line pumping coolant to the cold plate, where a coolant inlet is divided into two separate smaller intermediate coolant segments at a first stage. Each intermediate glycol segment is then subdivided at a second stage into four heat exchanging coolant lines. At each subdivision of the coolant fluid conducting system, a pair of smaller lines equal distance from a feed line and having a smaller diameter than the feed line are incorporated using a two-for-one splitter so that each stage doubles the number of lines from the previous stage.

Owner:CLELAND SALES CORP

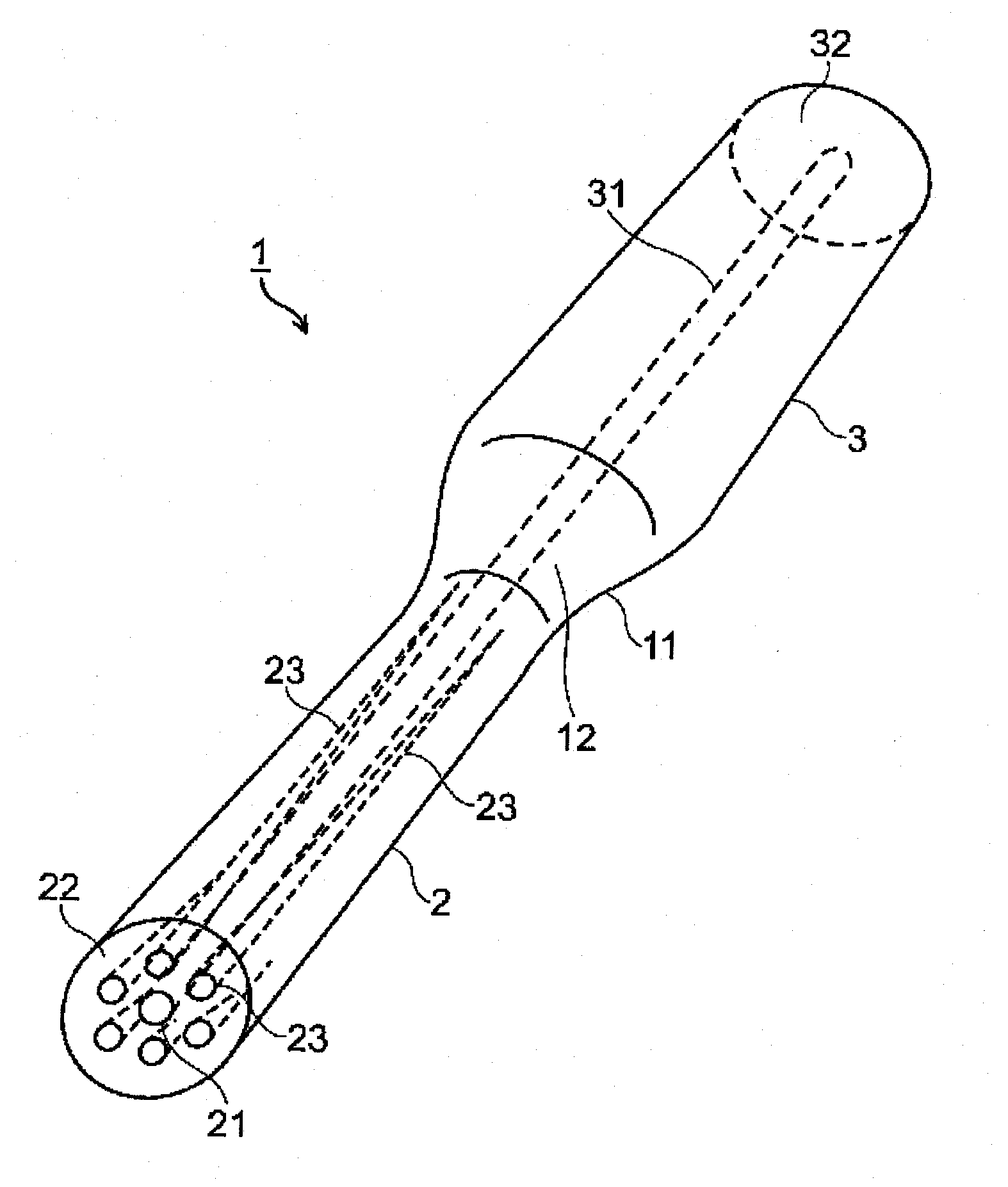

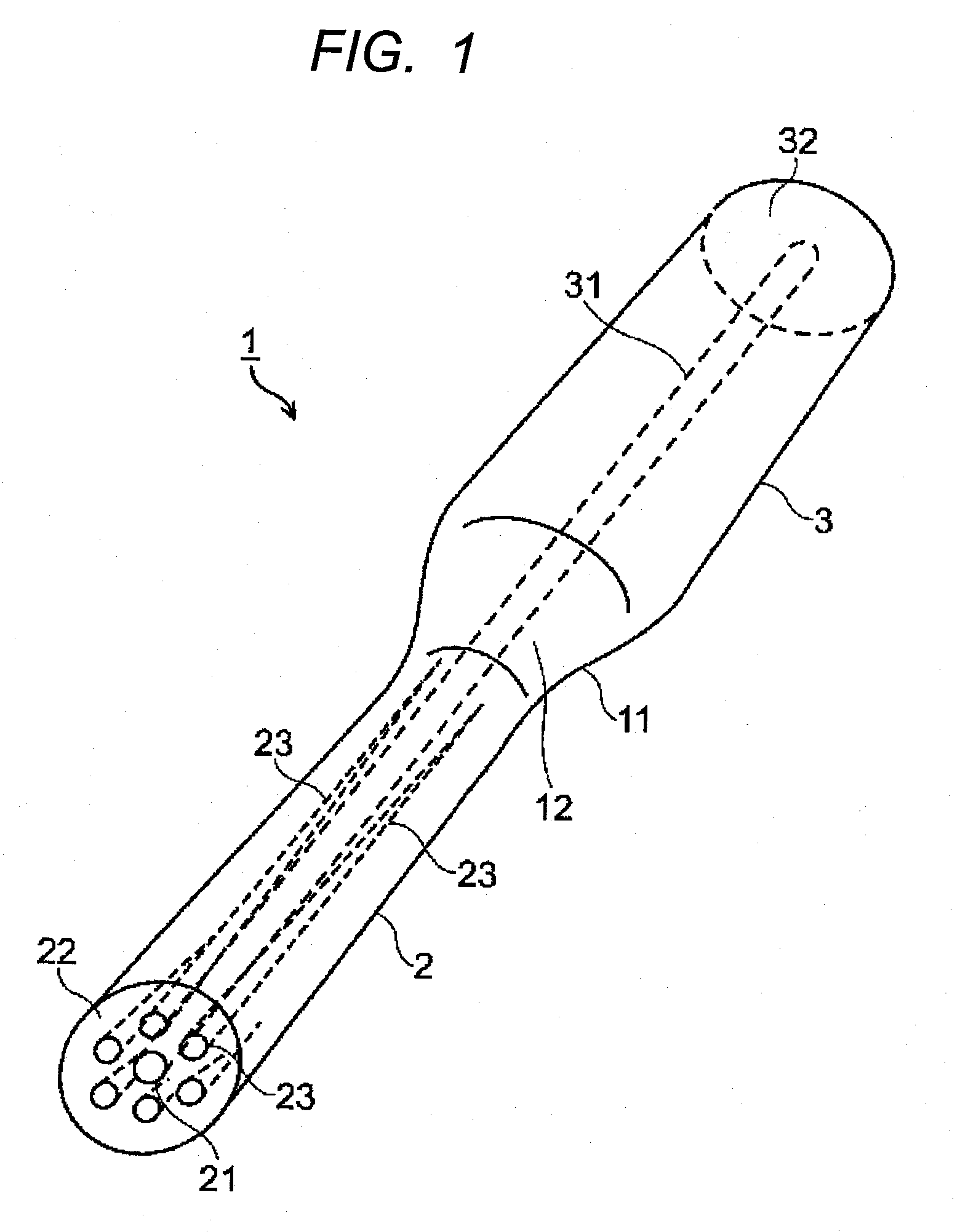

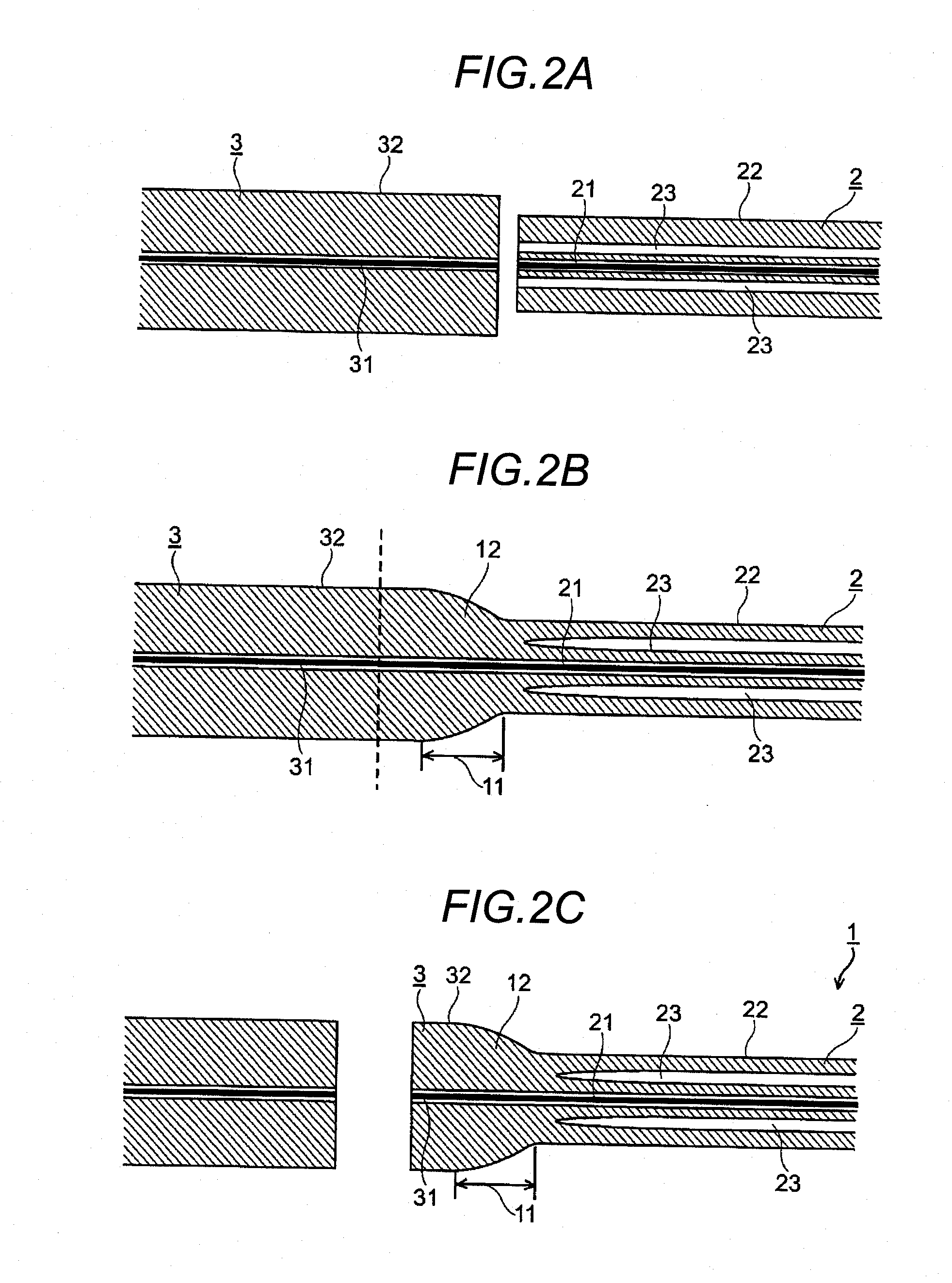

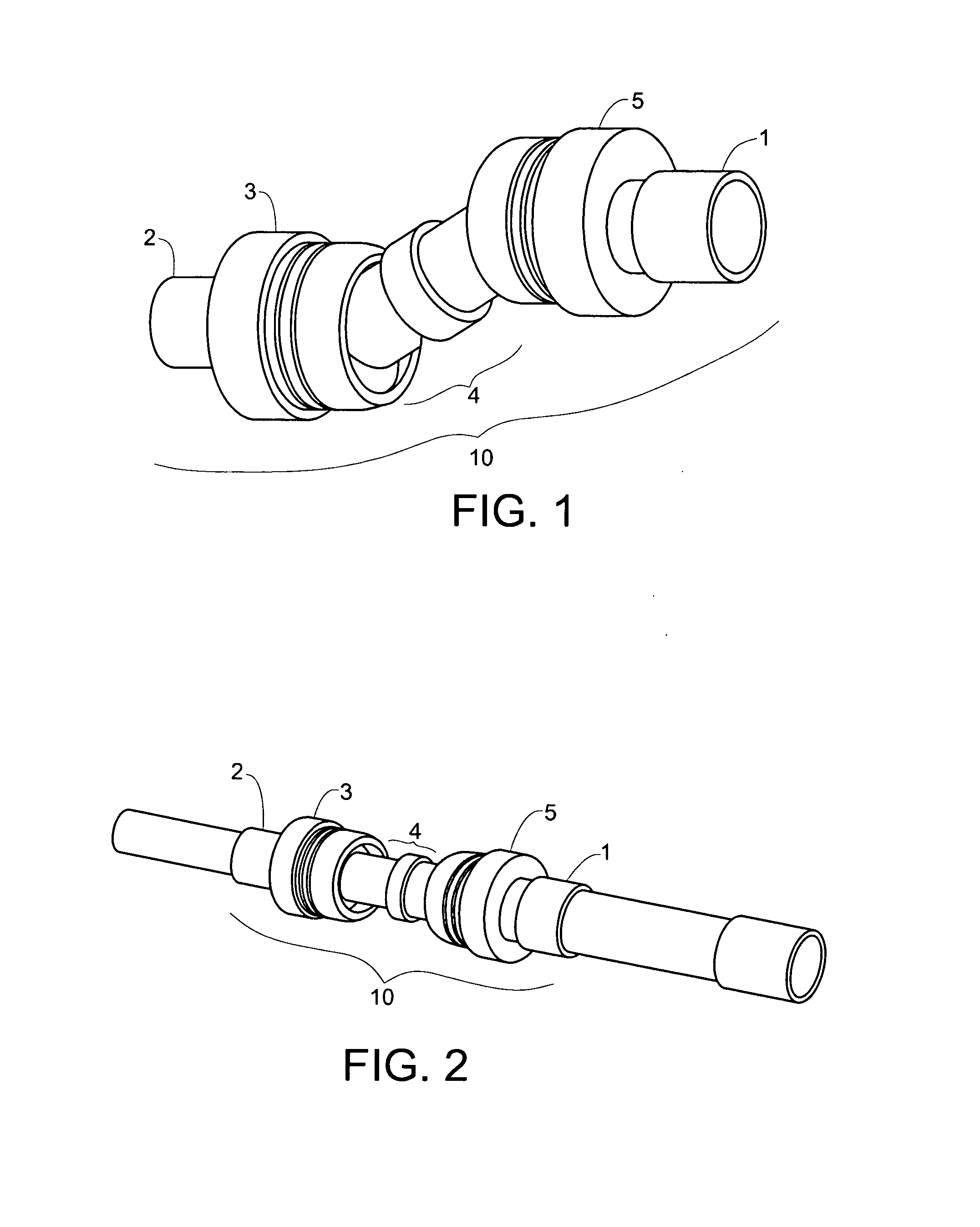

Optical fiber and method of manufacturing the same, end part processing method of optical fiber and optical fiber with ferrule

InactiveUS20110142402A1Slow splicingLow inner diameter requirementOptical articlesCoupling light guidesGeneral purposeEngineering

An optical fiber that permits, even when the cladding outer diameter thereof is smaller than 125 μm, an eased splicing with other optical fiber using a general-purpose ferrule, is provided. The optical fiber comprises: a first optical fiber having a first core and a first cladding having a cladding outer diameter smaller than 125 μm, wherein the first cladding has a plurality of air holes that extend longitudinally along the axis of the first core; a second optical fiber having a second core to be spliced to the first core, and a second cladding having a cladding outer diameter larger than the outer diameter of the first cladding, wherein the second cladding is to be spliced to the first cladding; and a fusion splice formed between the end of the first optical fiber and the end of the second optical fiber by fusion.

Owner:HITACHI METALS LTD

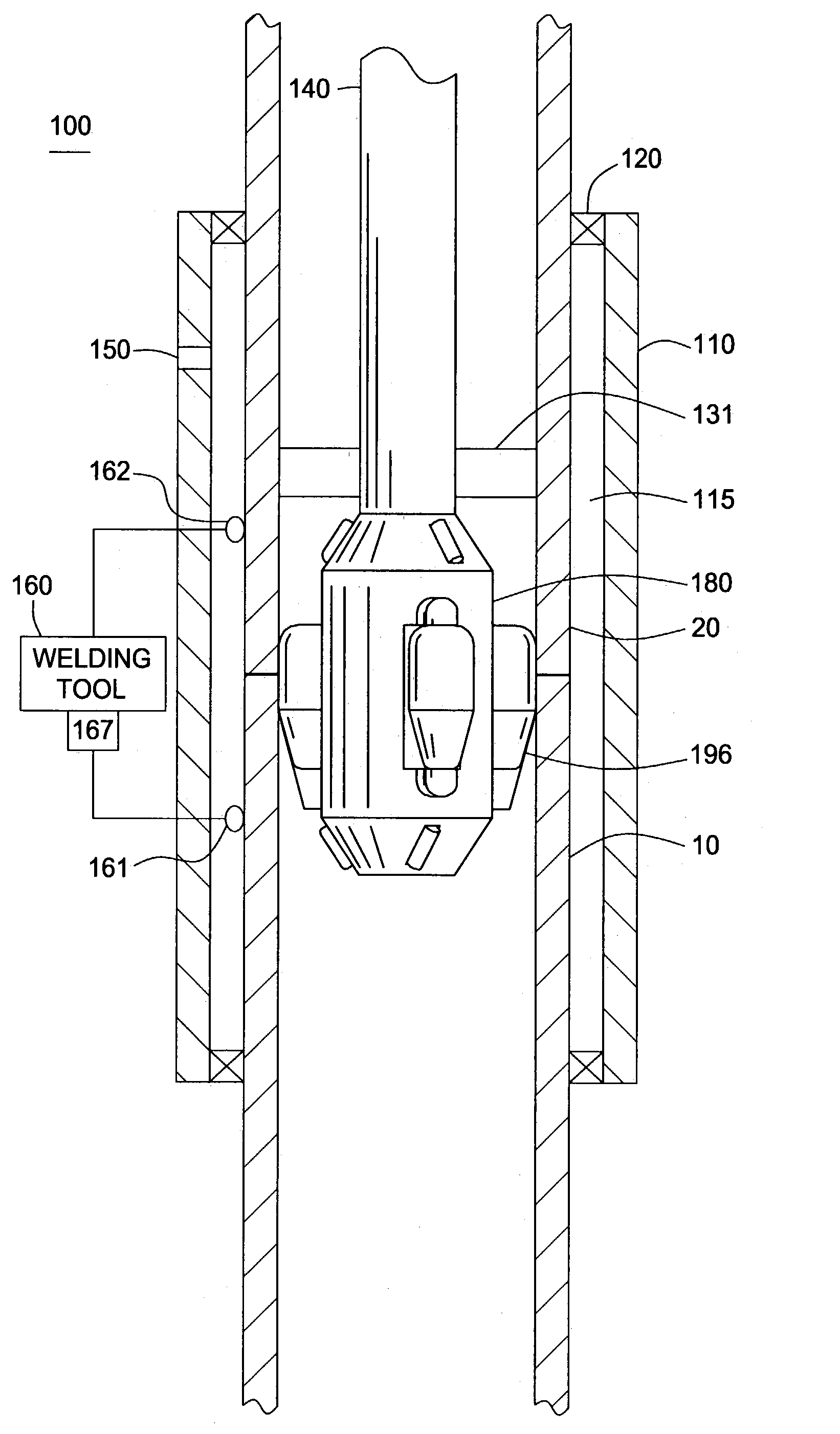

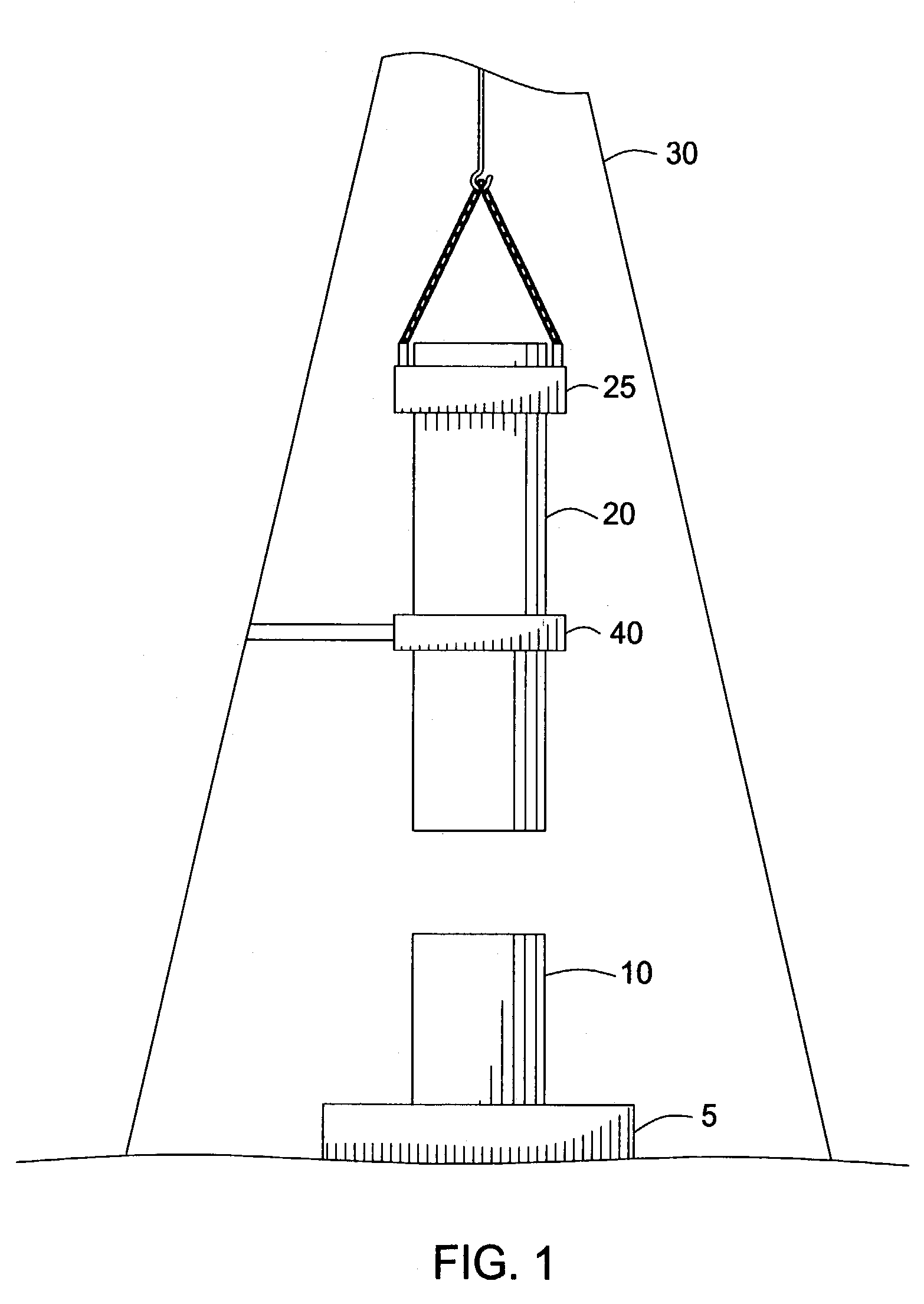

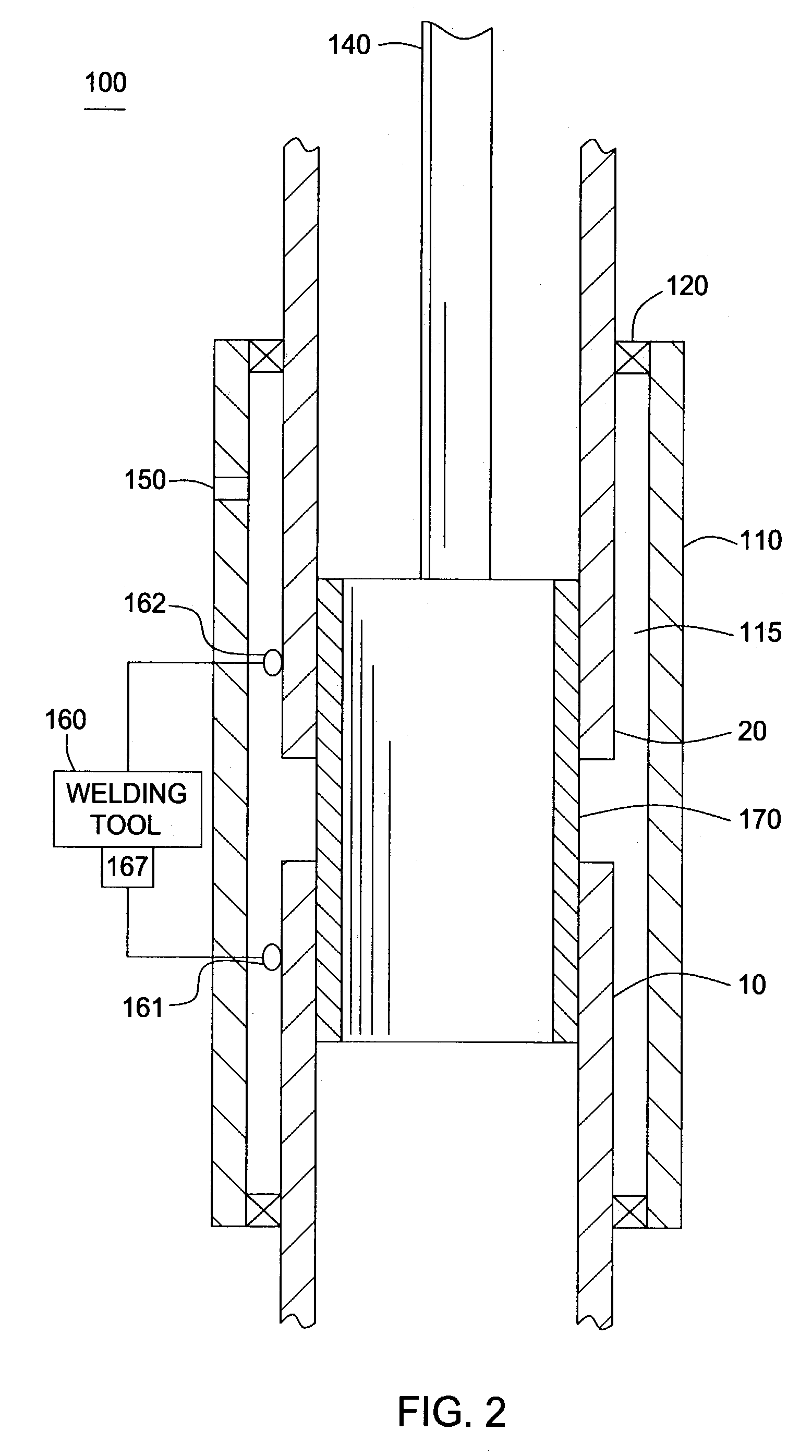

Method of mitigating inner diameter reduction of welded joints

ActiveUS7168606B2Reduced inner diameter flashLow inner diameter requirementDrilling rodsWelding/cutting auxillary devicesEngineering% diameter reduction

Aspects of the present invention provide methods and apparatus for connecting two tubulars using a welding process with reduced inner diameter flash. The method includes connecting an end of a first expandable tubular to an end of a second expandable tubular using a welding process and reducing an inner diameter flash using a flash reducing device. In one embodiment, the flash reducing device is a plug disposed in the bore of the two tubulars. In another embodiment, the flash reducing device is a roller member. In a further embodiment, the flash reducing device is a rotating cutting member.

Owner:WEATHERFORD TECH HLDG LLC

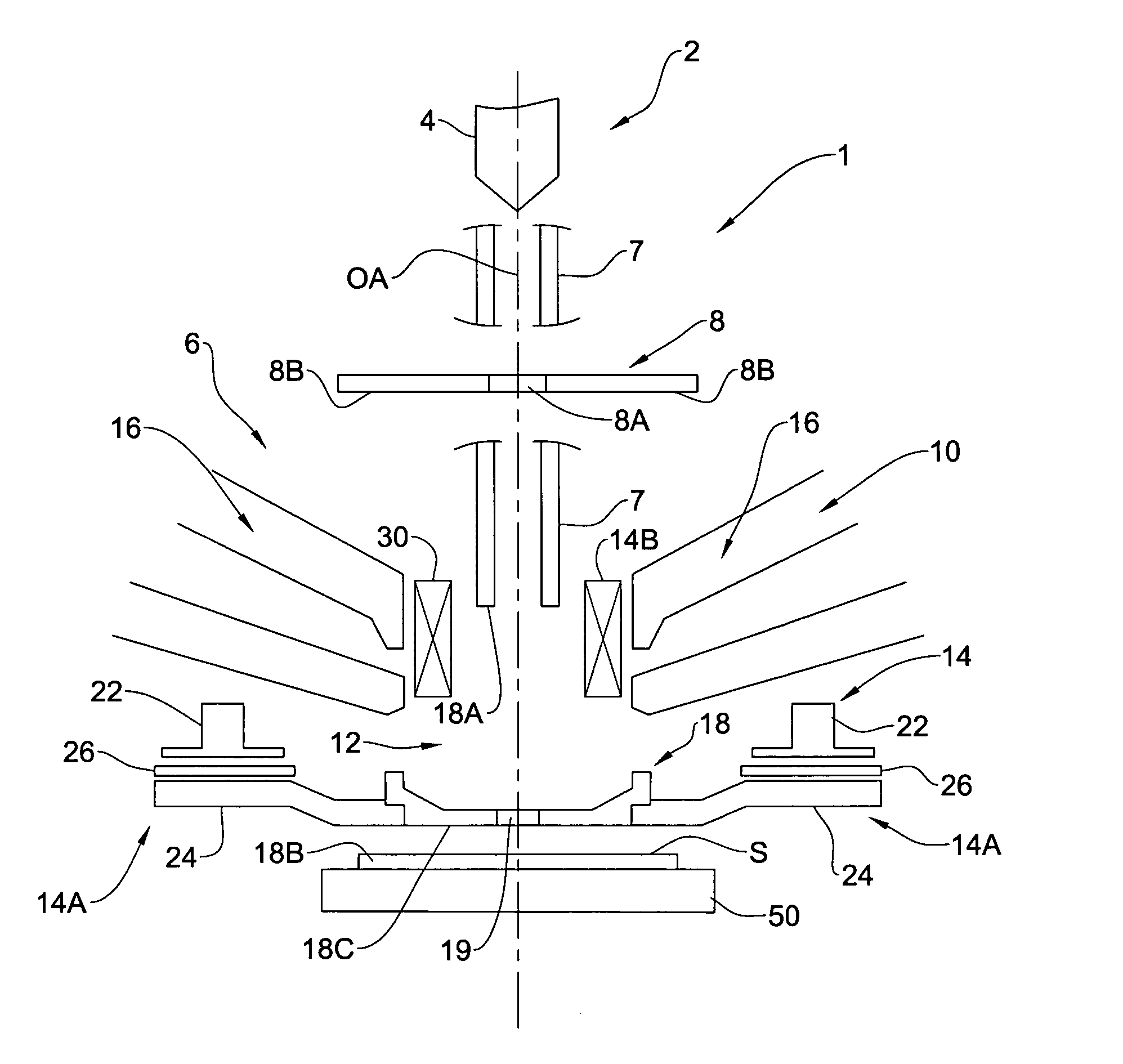

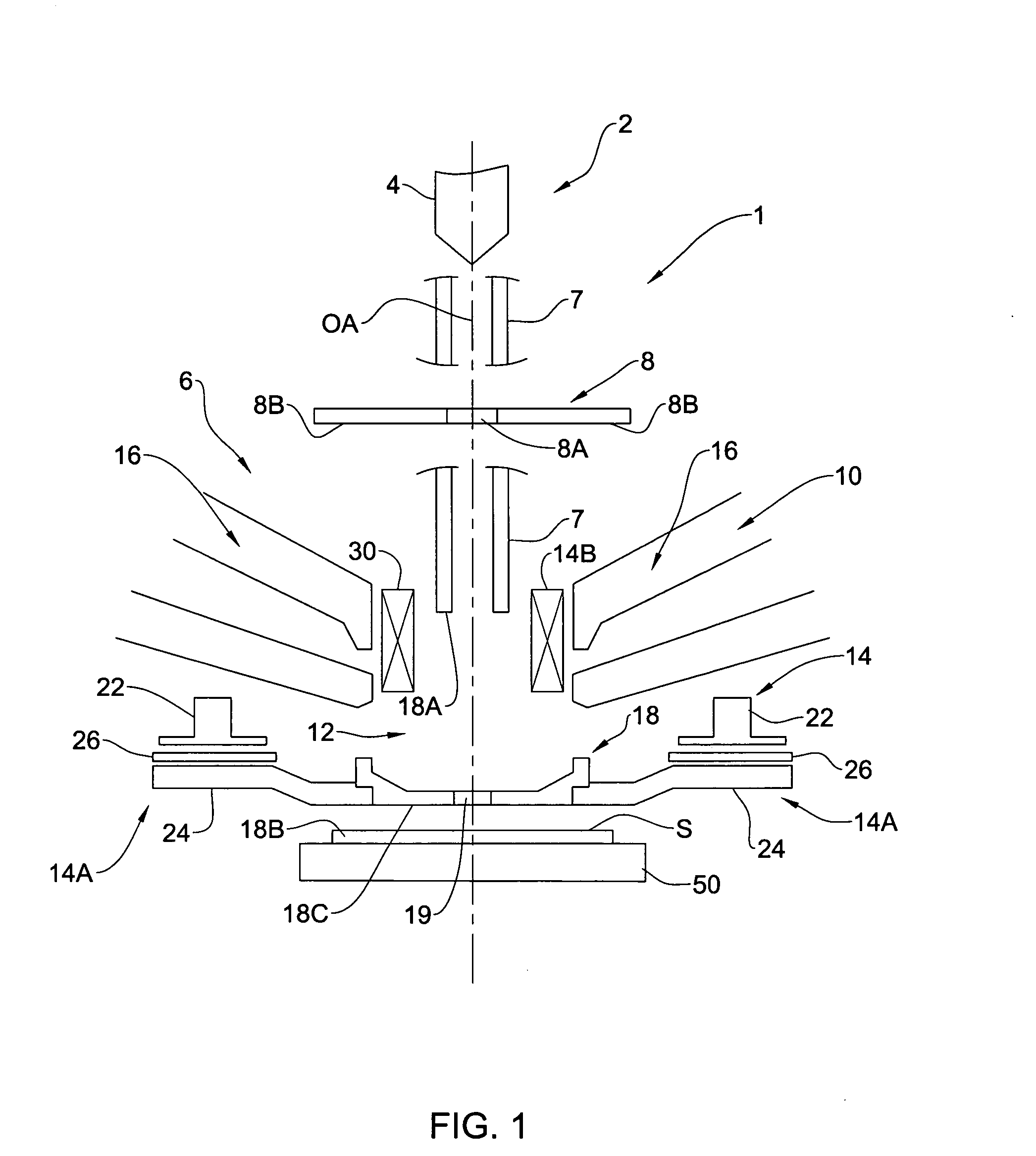

Beam directing system and method for use in a charged particle beam column

ActiveUS20060016988A1Low inner diameter requirementIncrease effective voltageThermometer detailsStability-of-path spectrometersLight beamMolecular physics

A method and system are presented for directing a charged particle beam towards and away from a sample. The system comprises a lens arrangement having an electrode formed with a beam opening for a charged particle beam passage therethrough; and a magnetic deflector. The magnetic deflector has a magnetic circuit formed by a core part for carrying excitation coils and a polepieces part. The polepieces of the magnetic deflector are in electrical communication with the electrode of the lens arrangement and are electrically insulated from the other part of the magnetic circuit.

Owner:APPL MATERIALS ISRAEL LTD

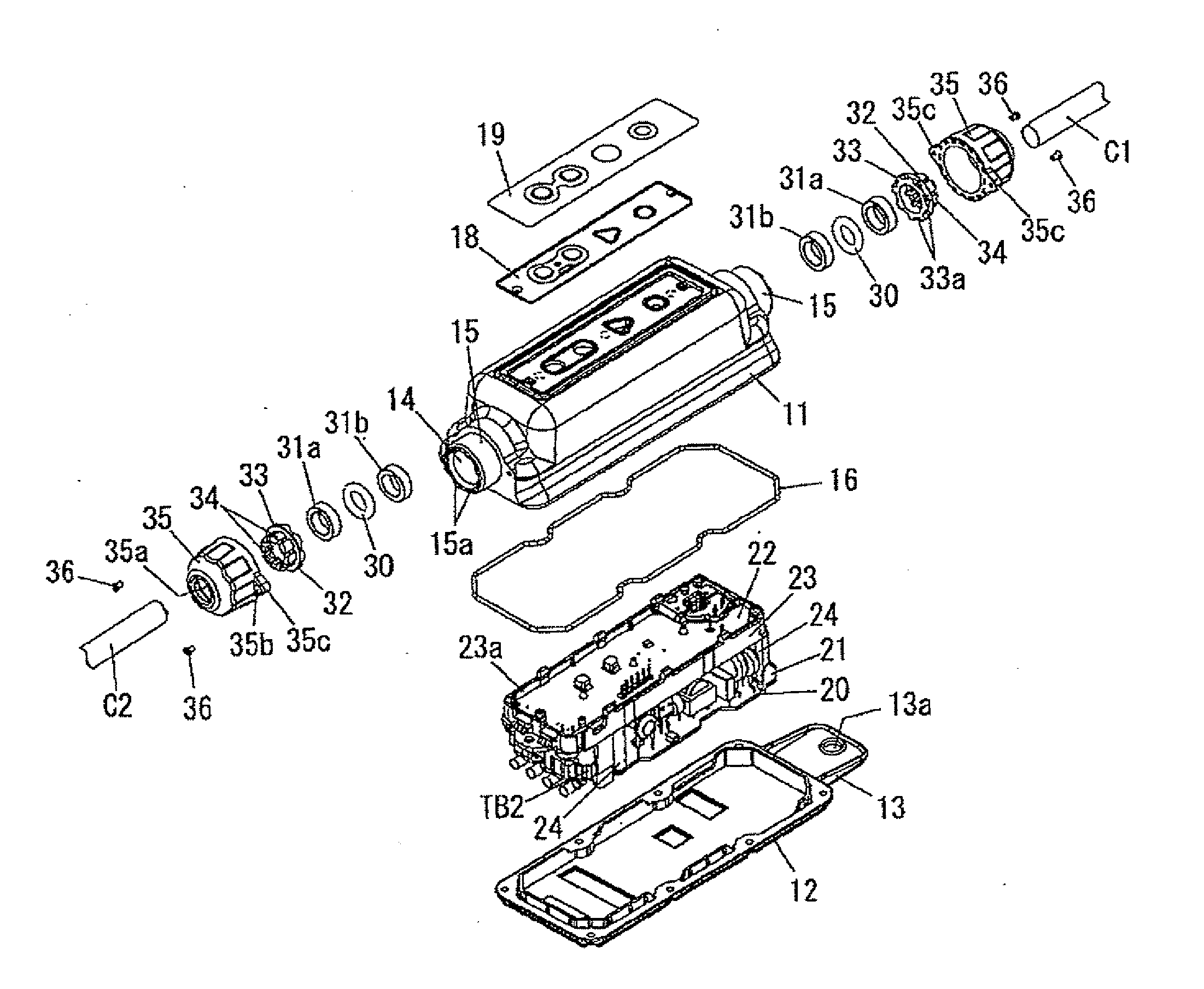

Power supply control device

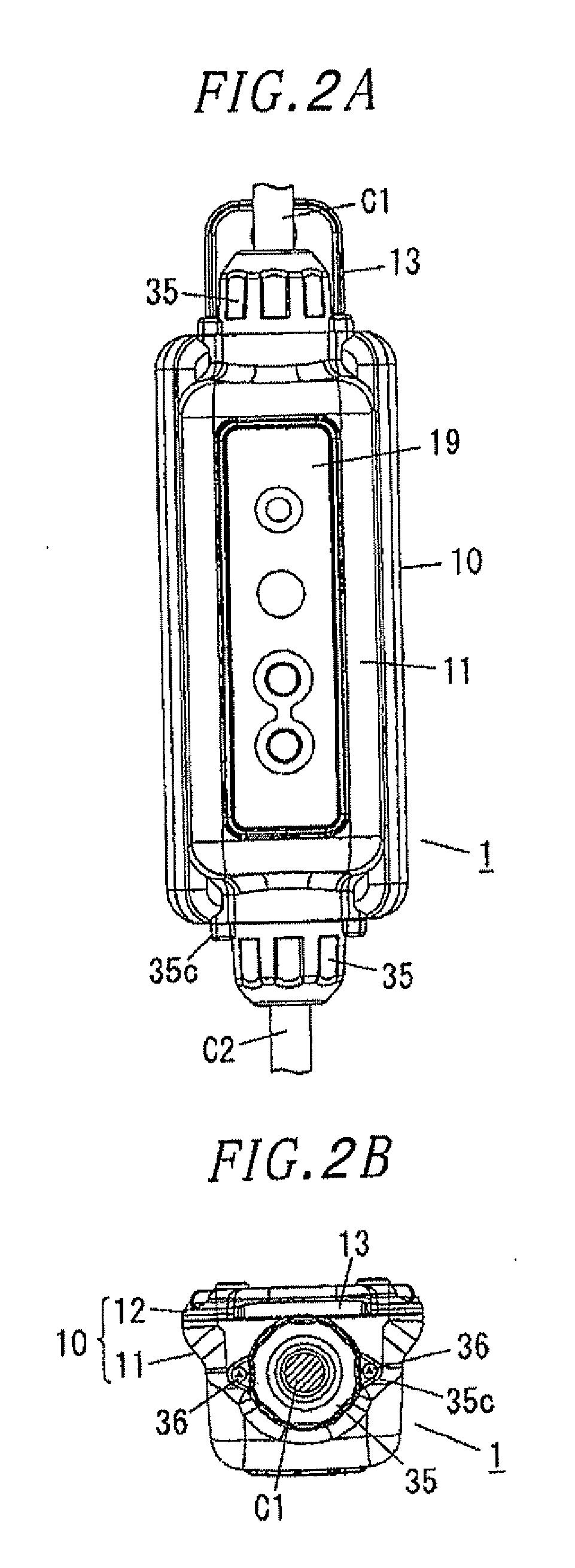

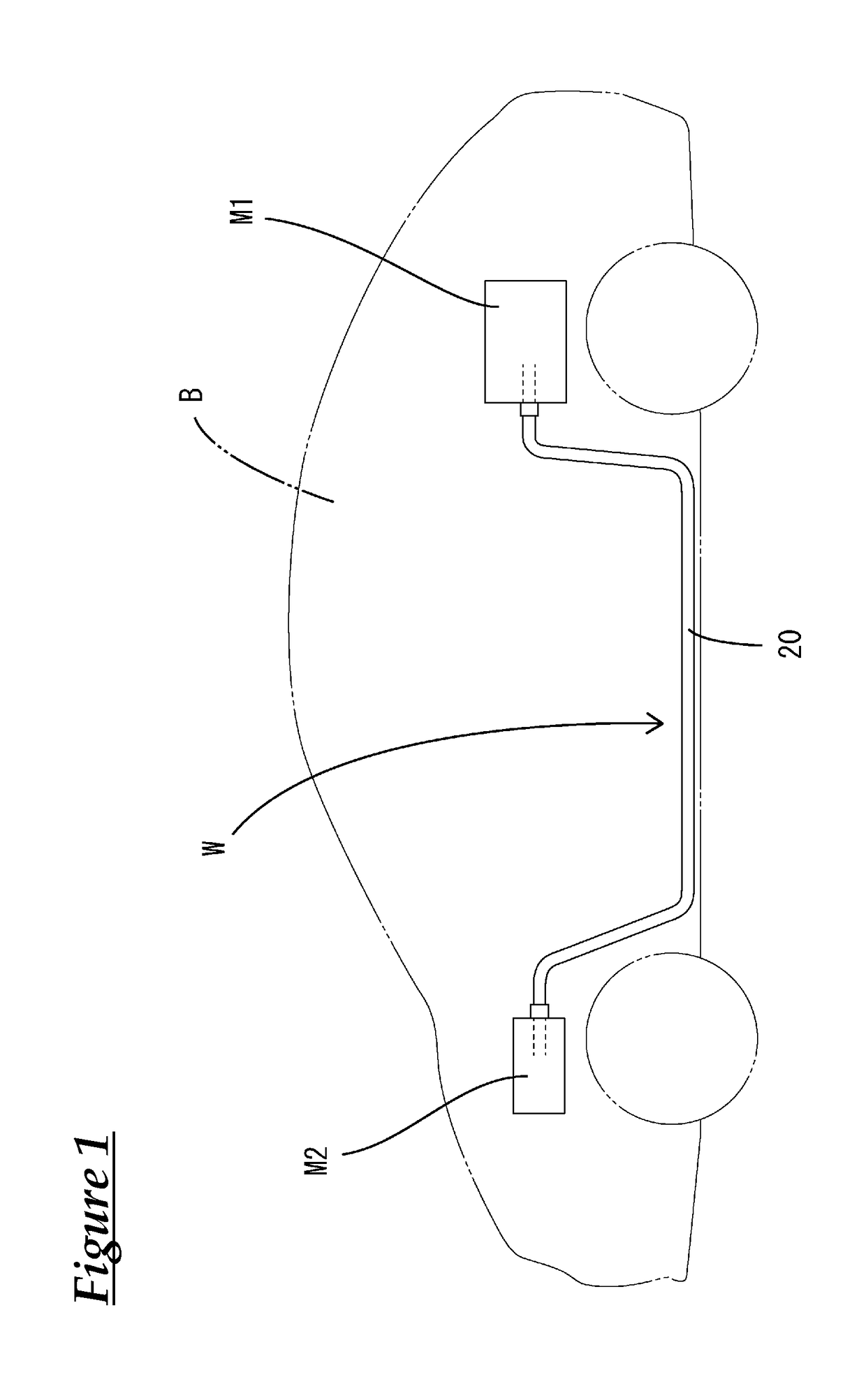

InactiveUS20120048617A1Avoid tensionLow inner diameter requirementCharging stationsElectric devicesElectric vehicleEngineering

A power supply control device includes a body part in which a circuit block is accommodated; a first cable drawn outside from the body part to be connected to a charge circuit of an electric vehicle; a second cable drawn outside from the body part to be connected to a power source; and a sealing member sealing a gap between each of the cables and a corresponding cable passing port of the body part. The power supply control device further includes an outer restriction member provided at each of the cables on an outer side than the sealing member to prevent the corresponding cable from being bent.

Owner:PANASONIC CORP

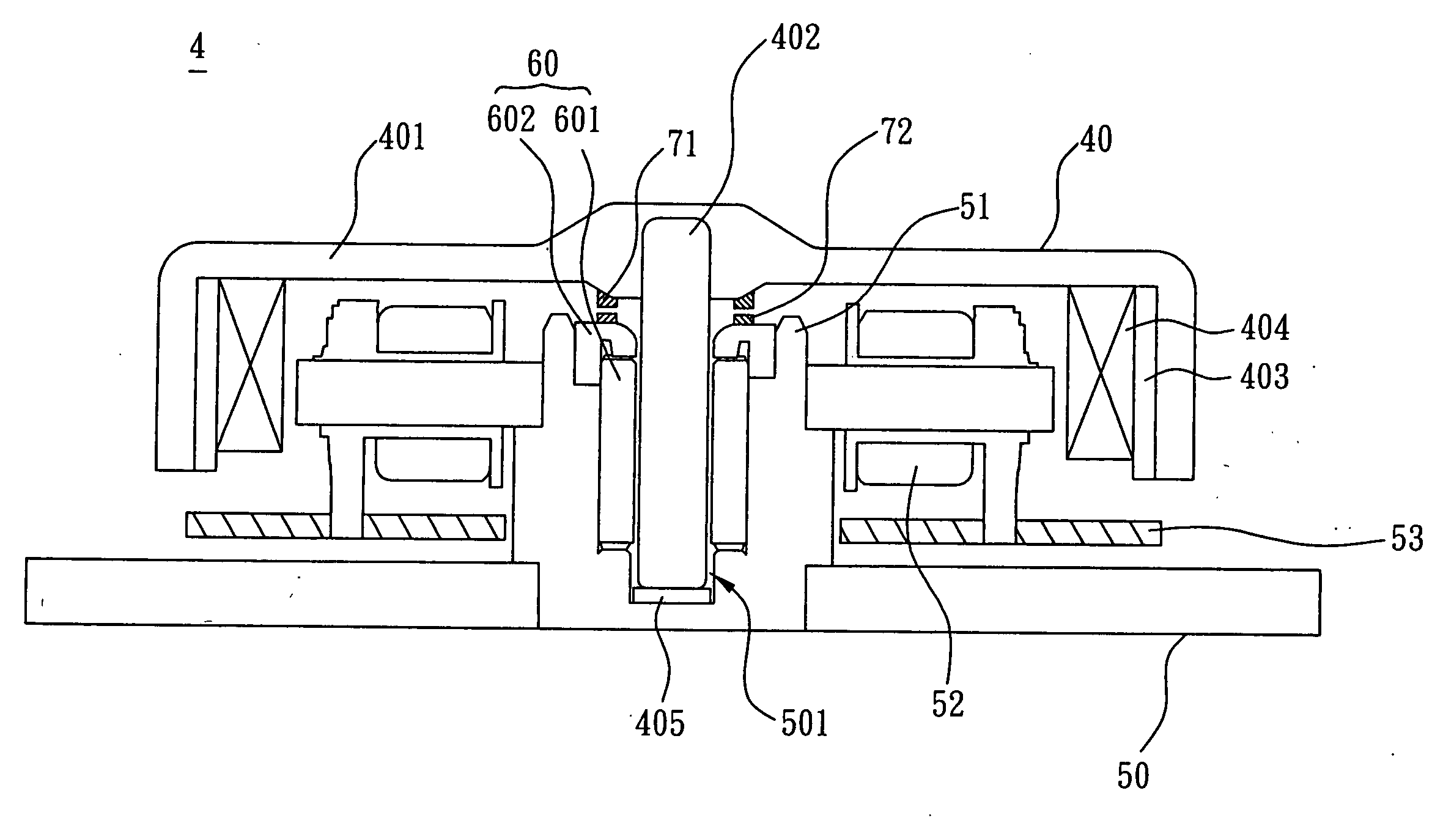

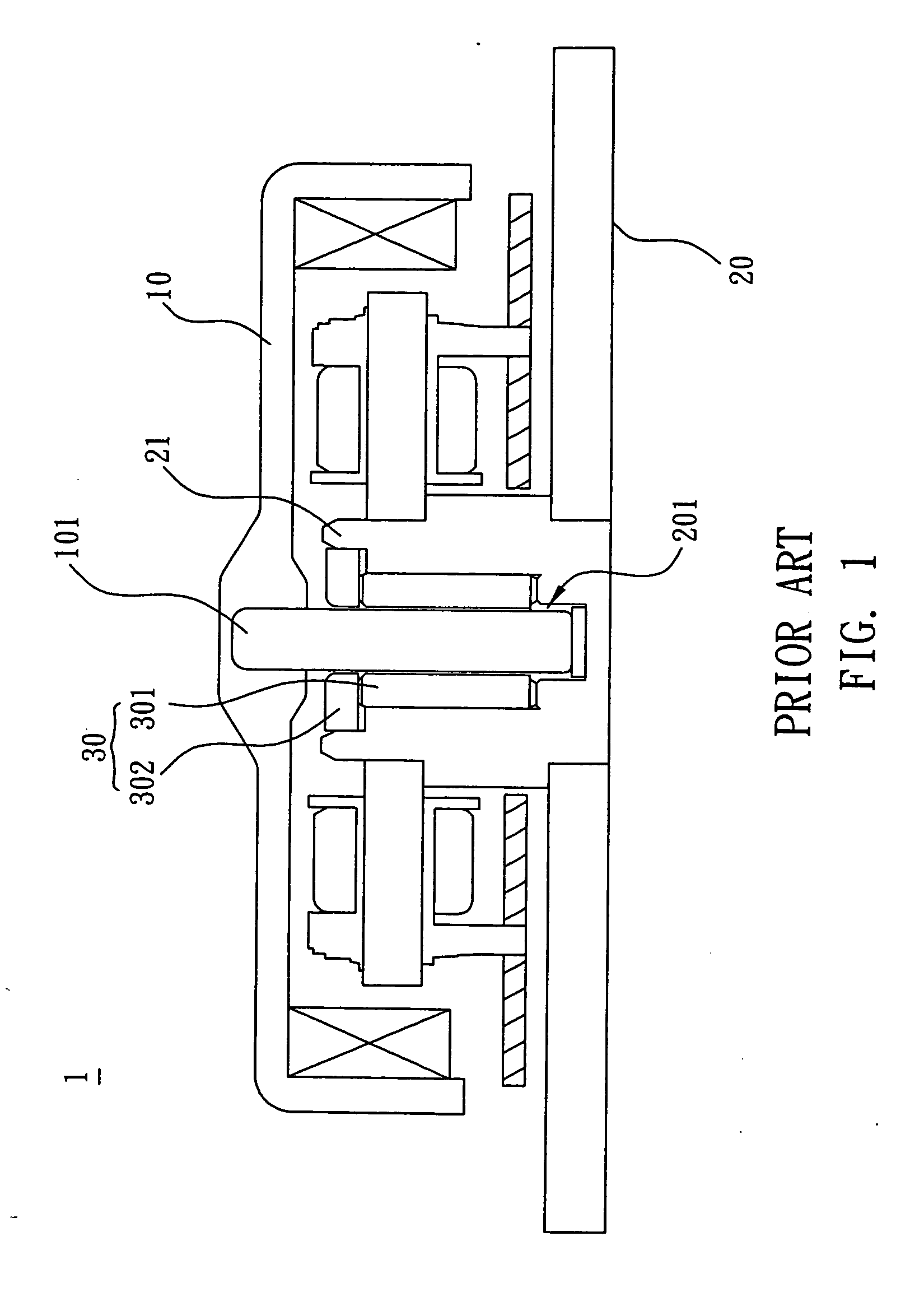

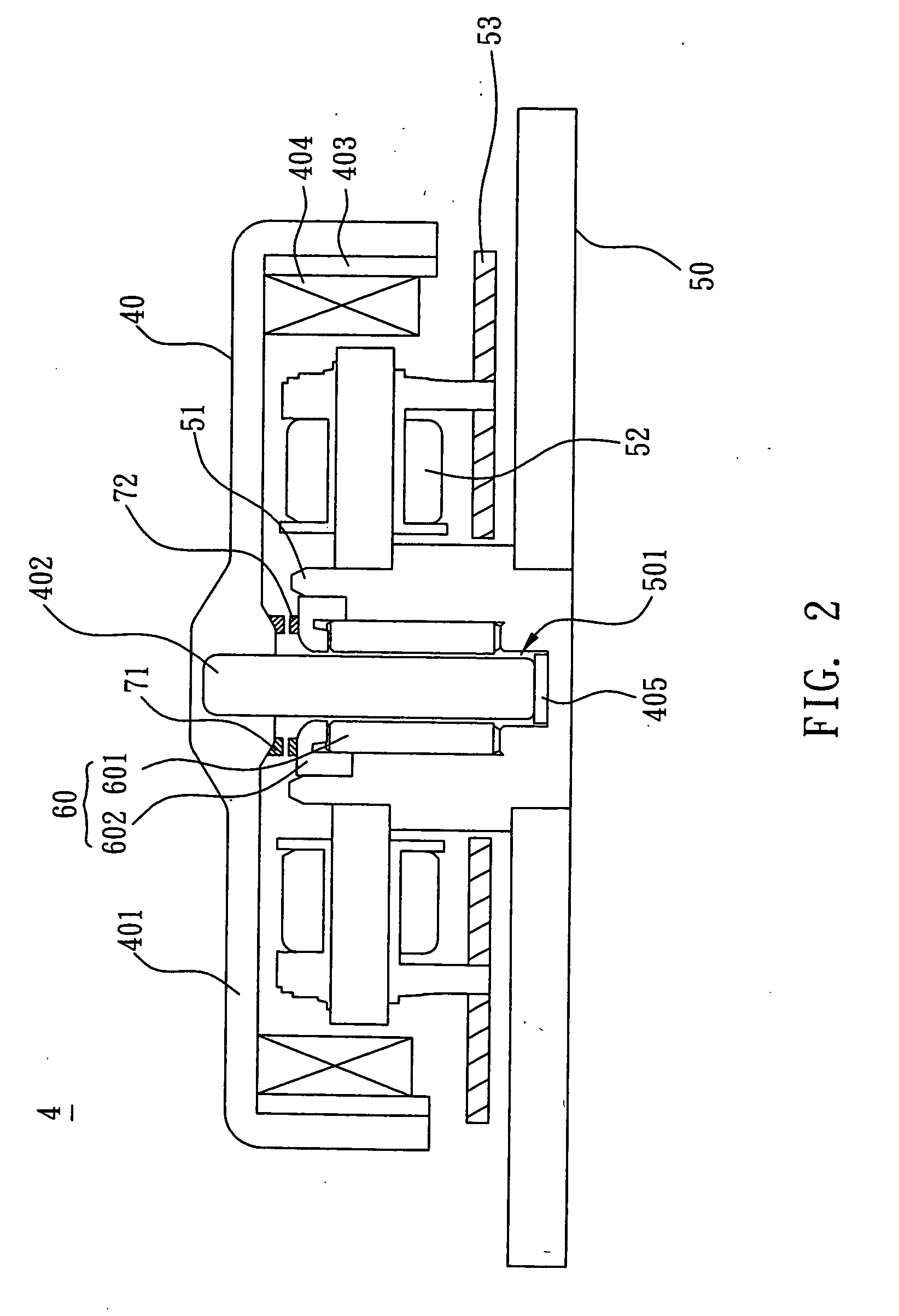

Motor and bearing structure thereof

InactiveUS20070076990A1Alleviate radial shrinkingReduce gap errorSliding contact bearingsBearing unit rigid supportEngineeringElectric motor

A bearing structure coupled to a shaft includes a bearing and a cover element. The cover element is held to the bearing and covers at least one portion of one end of the bearing. The cover element has a turning portion, which has a groove. A motor comprises a rotor structure, a stator structure and a bearing structure. The rotor structure has a hub and a shaft connecting to the hub. The stator structure has a hole, and the shaft is disposed in the hole. The bearing structure has a bearing and a cover element. The bearing is disposed in the shaft hole and coupled to the shaft. The cover element is held to the bearing and covers at least one portion of one end of the bearing. The cover element comprises a turning portion.

Owner:DELTA ELECTRONICS INC

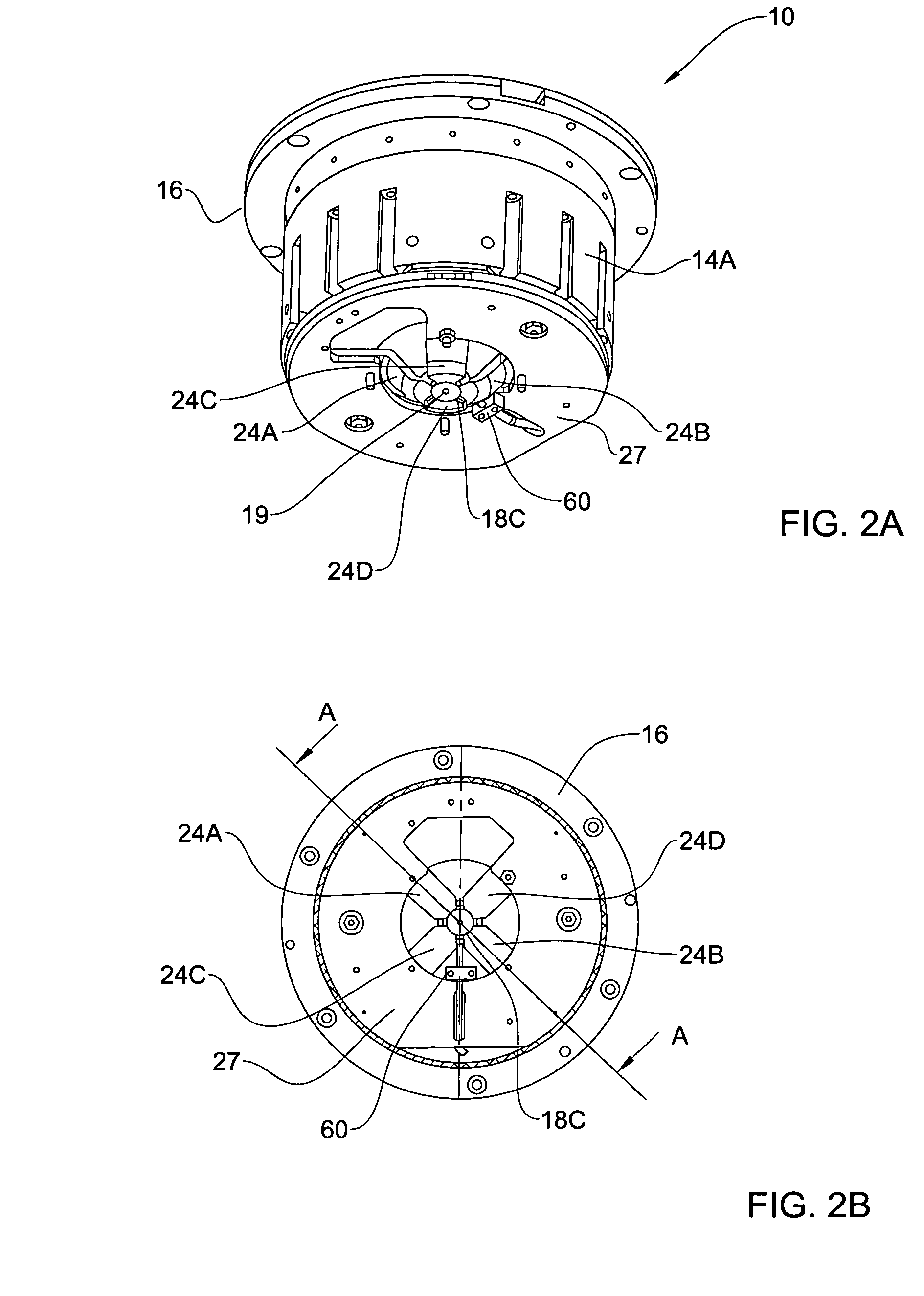

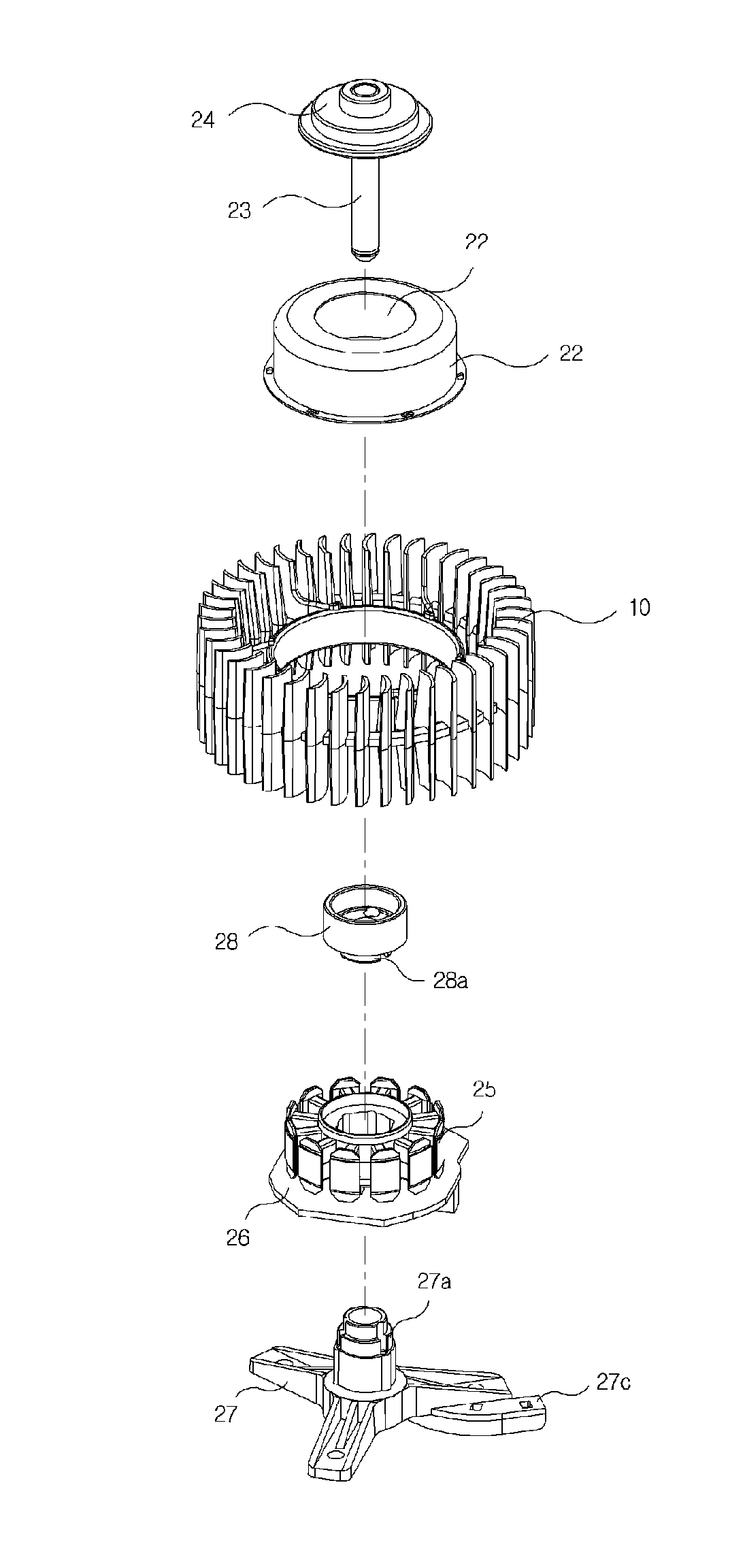

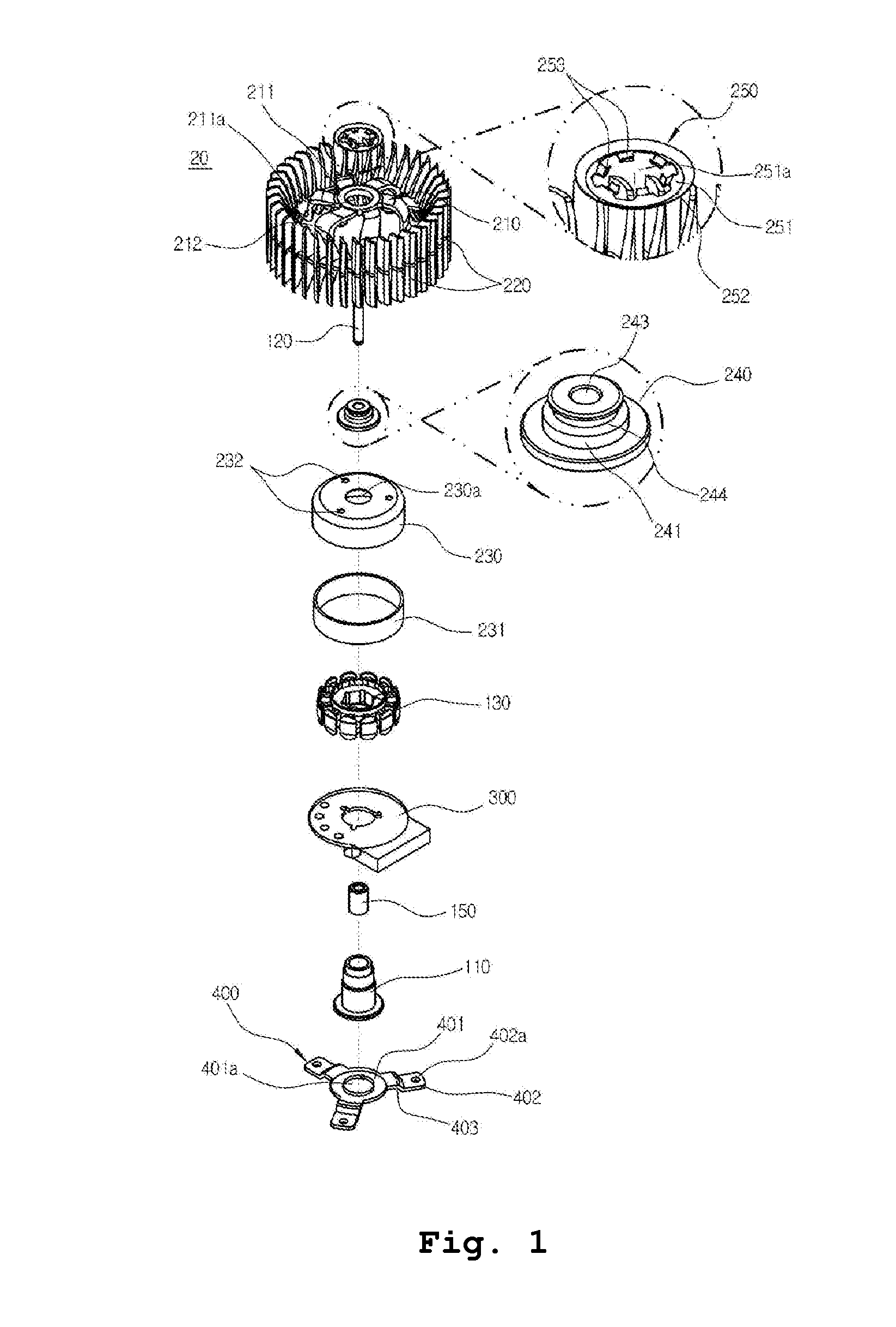

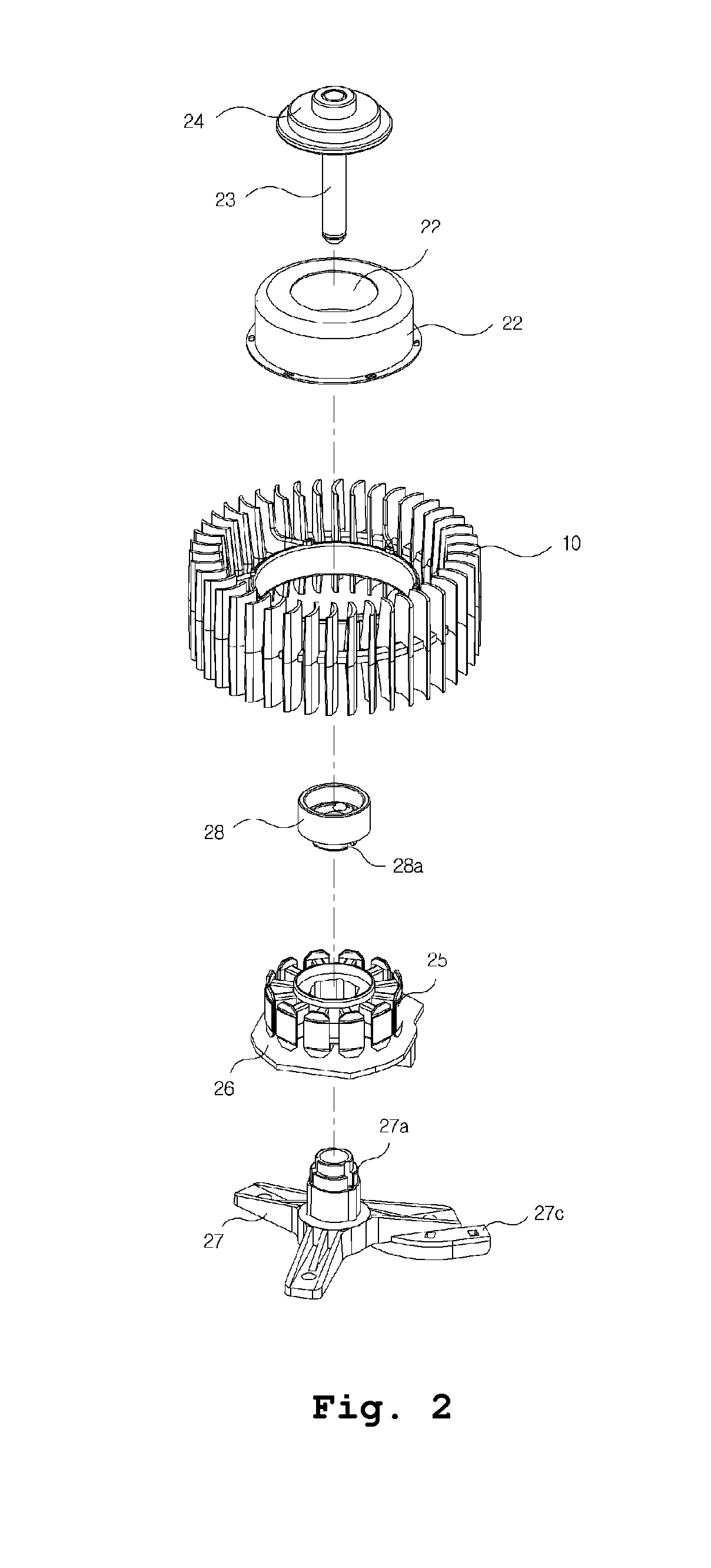

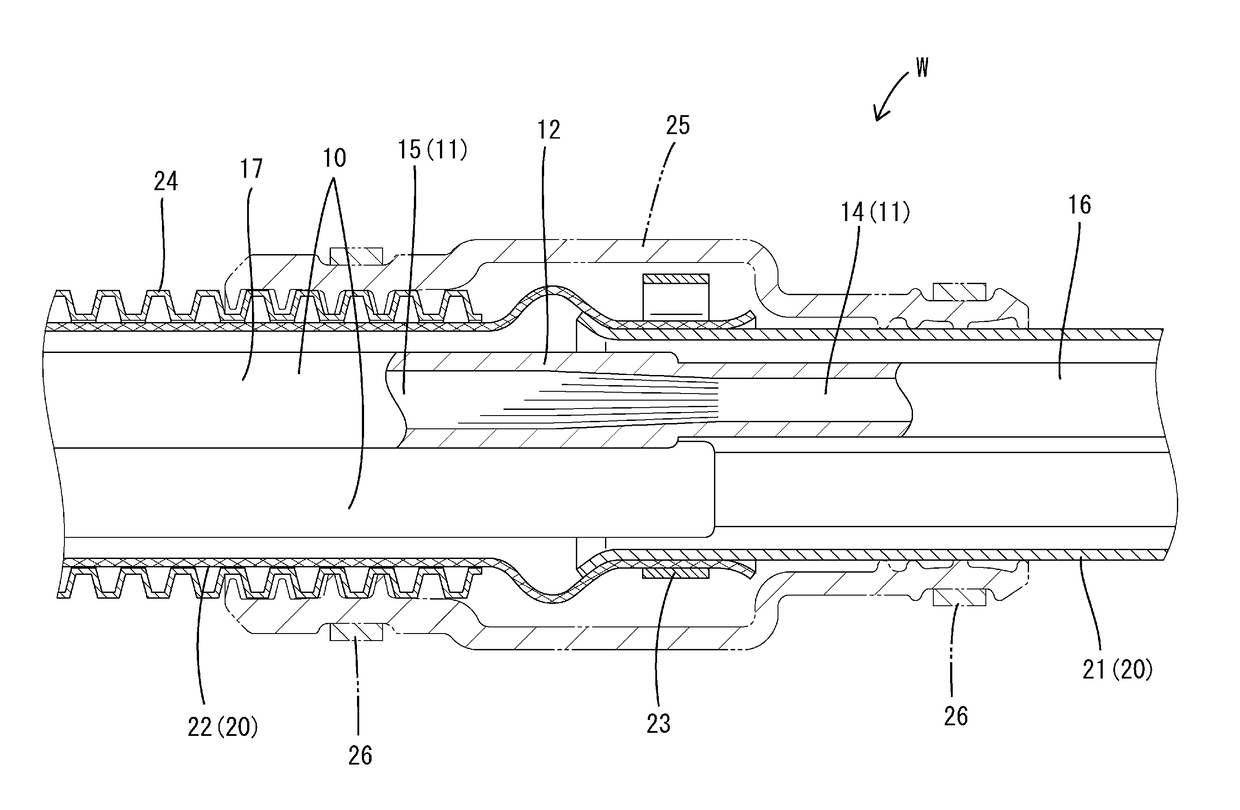

BLDC motor for a hairdryer

ActiveUS20120212087A1Improve ease of useHigh strengthMagnetic circuit rotating partsManufacturing dynamo-electric machinesBall bearingEngineering

Provided is a BLDC motor for a hair dryer, which includes high strength plastic parts integrated through injection molding. Thus, the number of parts is decreased to thereby decrease manufacturing costs and the weight of the BLDC motor. Furthermore, a sirocco fan installed in the BLDC motor is directly coupled to an outer circumferential surface of a rotor housing so as to optimize an assembling structure of the sirocco fan, thereby stabilizing the rotation thereof. Accordingly, vibration and noise due to rotation can be reduced, and an amount of introduced air can be maximized. To this end, the BLDC motor includes a rotor housing including permanent magnets on an inner surface thereof, and a shaft hole in a central portion thereof to receive a shaft, wherein a sirocco fan for blowing air is coupled to an outer portion of the rotor housing, a rotor frame coupling the shaft to the rotor housing to integrally rotate them, a stator core around which a coil is wound to interact with a magnetic field formed on the permanent magnets, thereby generating torque, a PCB coupled to a lower portion of the stator core by a screw, a base bracket including a support protrusion on an upper outer portion thereof to support the stator core, and a bearing housing coupled to an upper portion of the base bracket to support a ball bearing, and including a removal prevention protrusion in a lower outer portion thereof to prevent removal of the stator core.

Owner:JMW

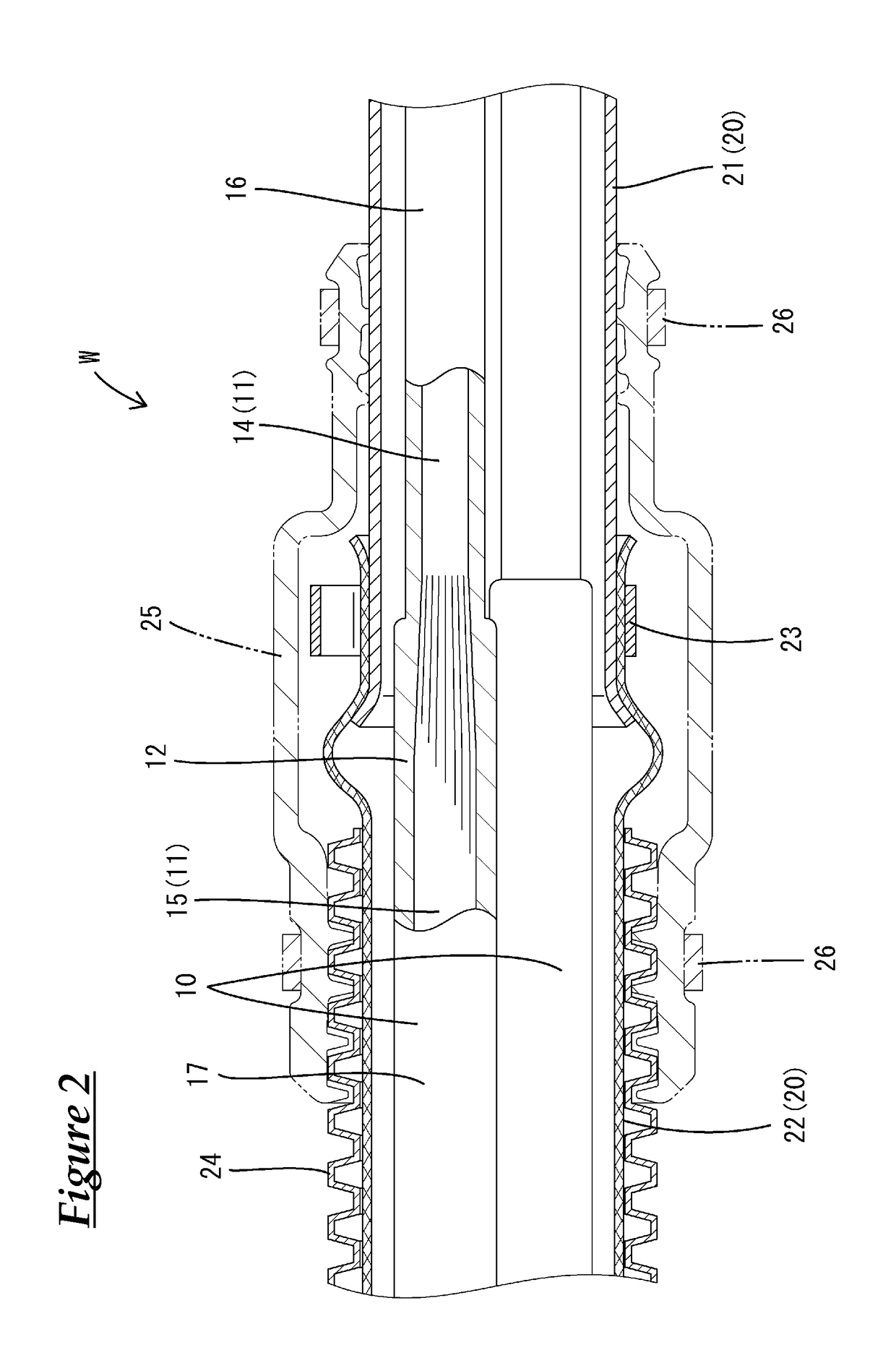

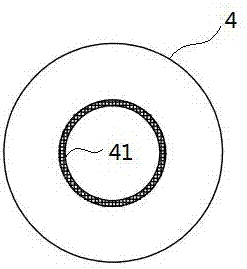

Shielded conduction path

ActiveUS20170148546A1Reduced cross sectionIncrease flexibilityMagnetic/electric field screeningInsulated cablesElectrical conductorEngineering

An electric wire and a shielding member configured to electrically shield the electric wire by enclosing an outer circumference thereof. A core wire of the electric wire has a single-core portion which is formed by applying pressure to a portion of a conductor obtained by twisting a plurality of strands together to reduce their cross section. This causes the strands to be brought into intimate contact with each other and form a single body, and a stranded wire portion in which the strands remain in a twisted-together state with no pressure having been applied thereto. The shielding member has a first shielding portion enclosing a portion of the electric wire where the core wire constitutes the single-core portion, and a second shielding portion enclosing a portion of the electric wire where the core wire constitutes the stranded wire portion. The second shielding portion has higher flexibility than the first shielding portion.

Owner:SUMITOMO WIRING SYST LTD

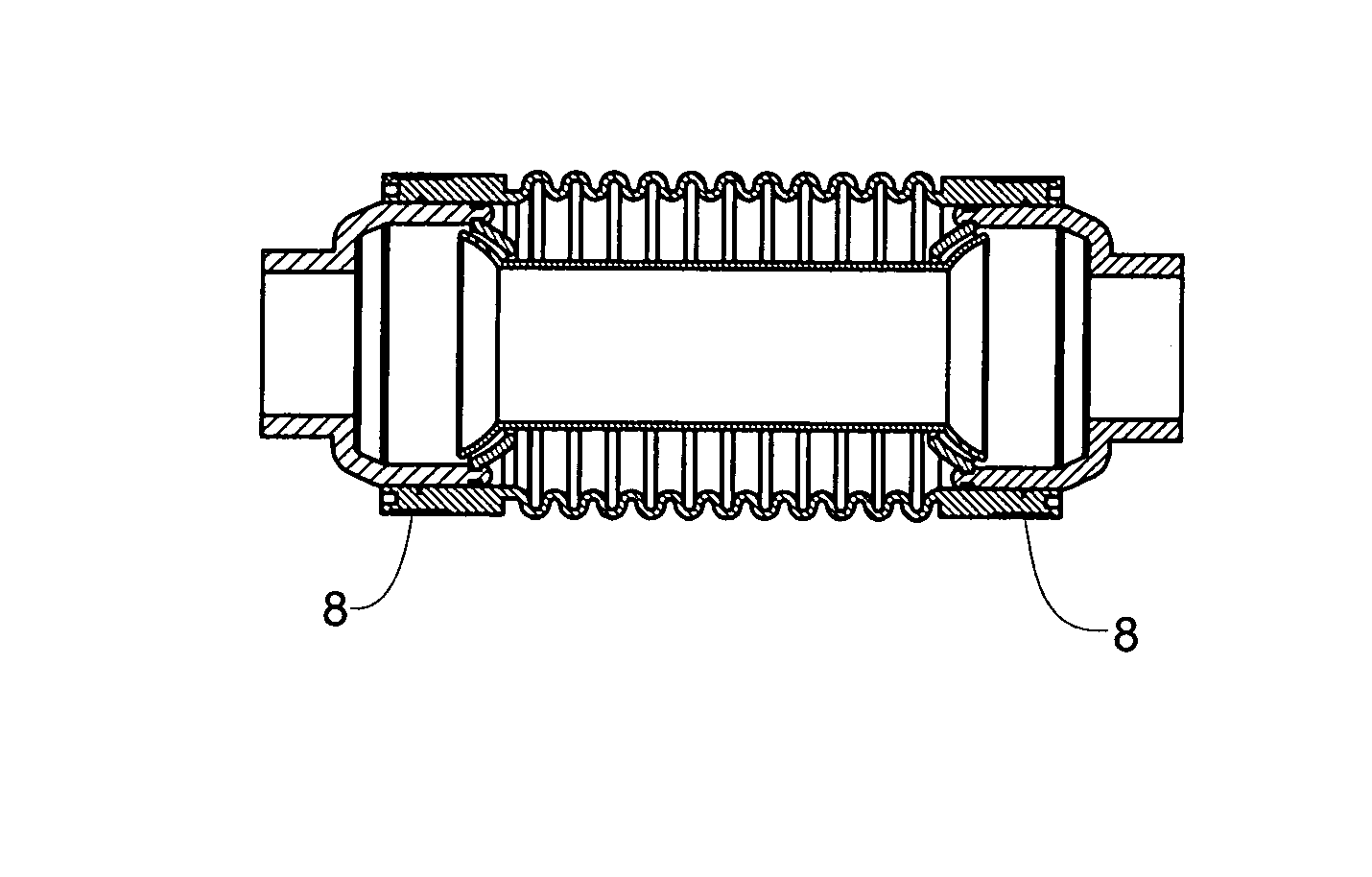

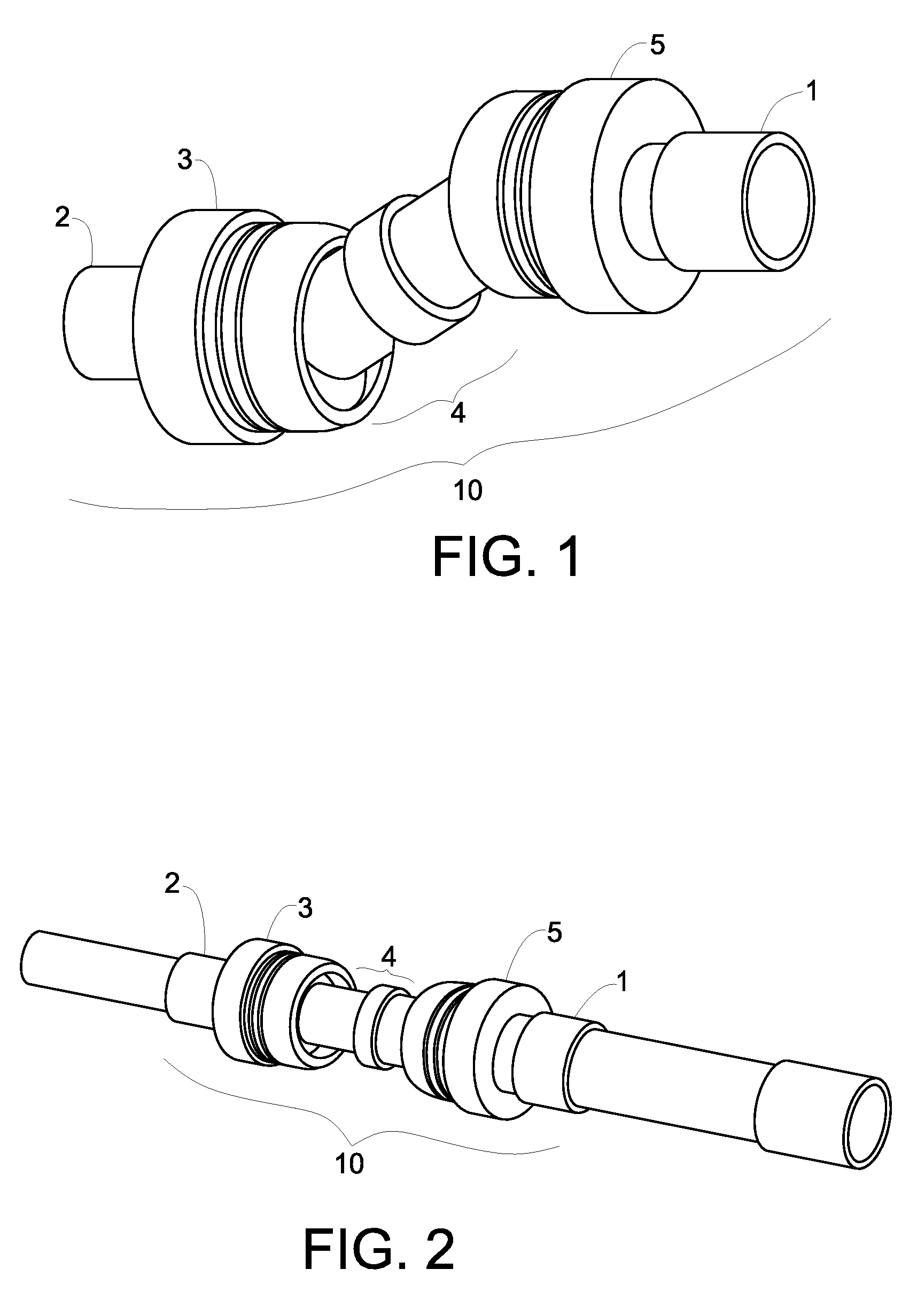

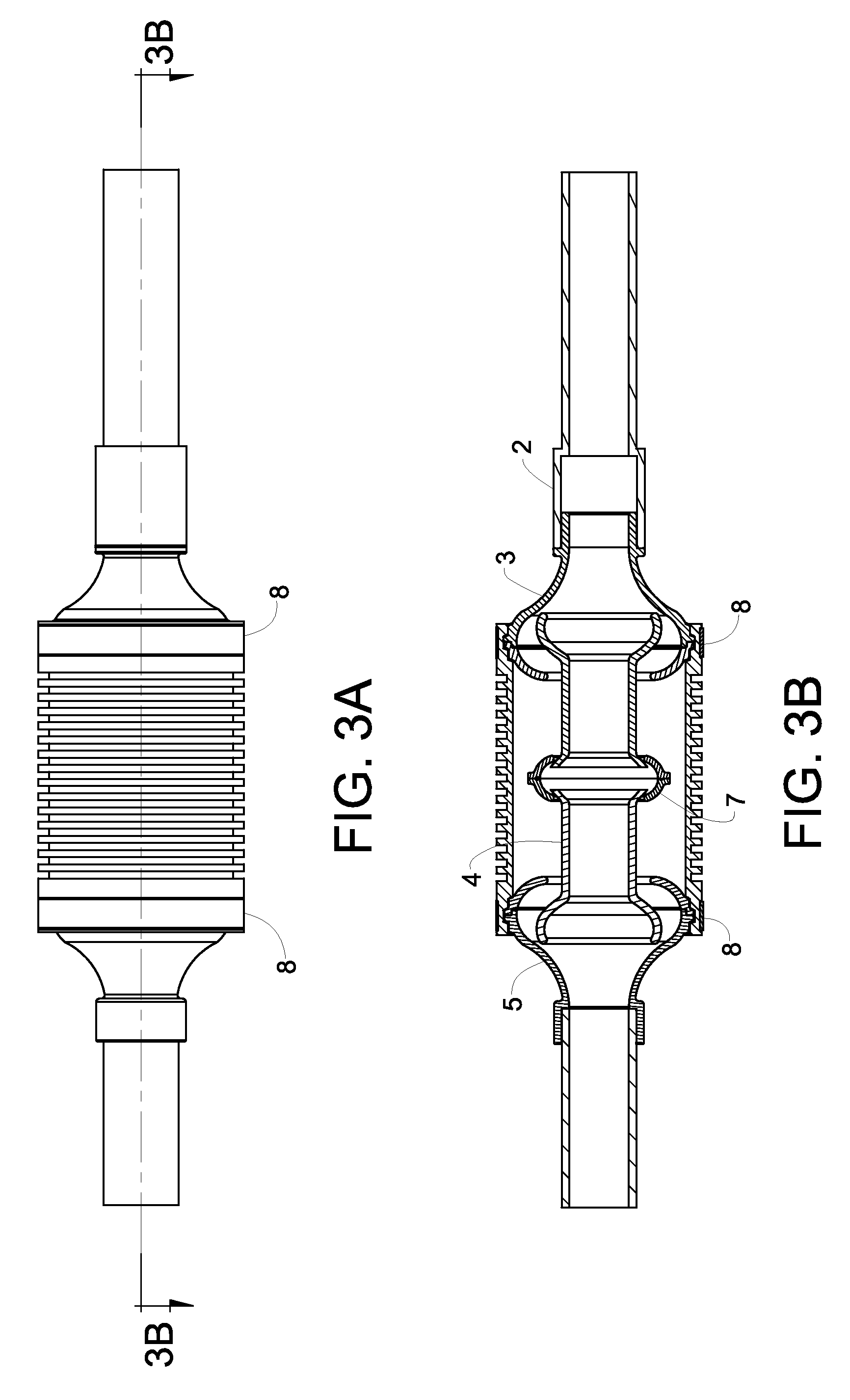

Non-metallic expansion/deflection coupling modules

ActiveUS20140035276A1Large range of motionLow inner diameter requirementSleeve/socket jointsPipeline expansion-compensationCouplingComputer module

An improved device for coupling rigid non-metallic conduits is disclosed. The claimed device is capable of allowing movement in an axial direction due to expansion and contraction and can also compensate for angular or parallel deflection of the conduits.

Owner:THOMAS & BETTS INT INC

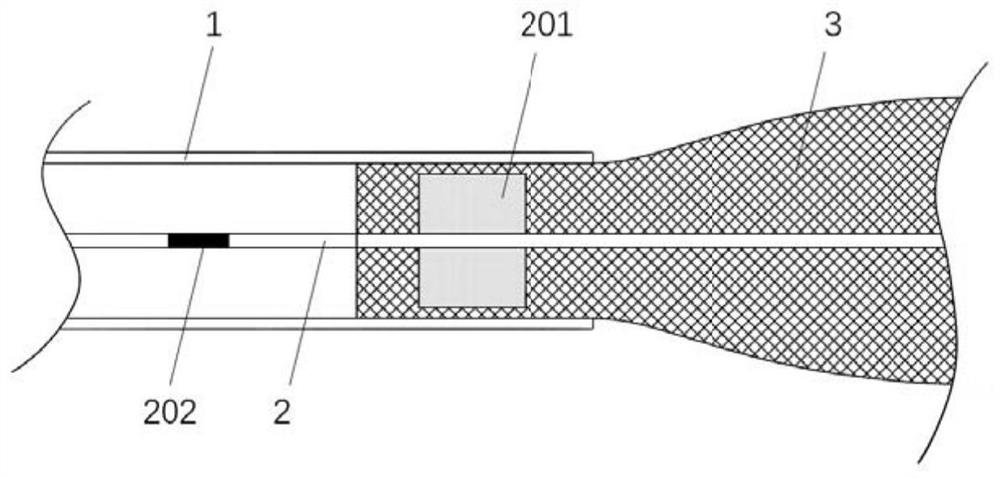

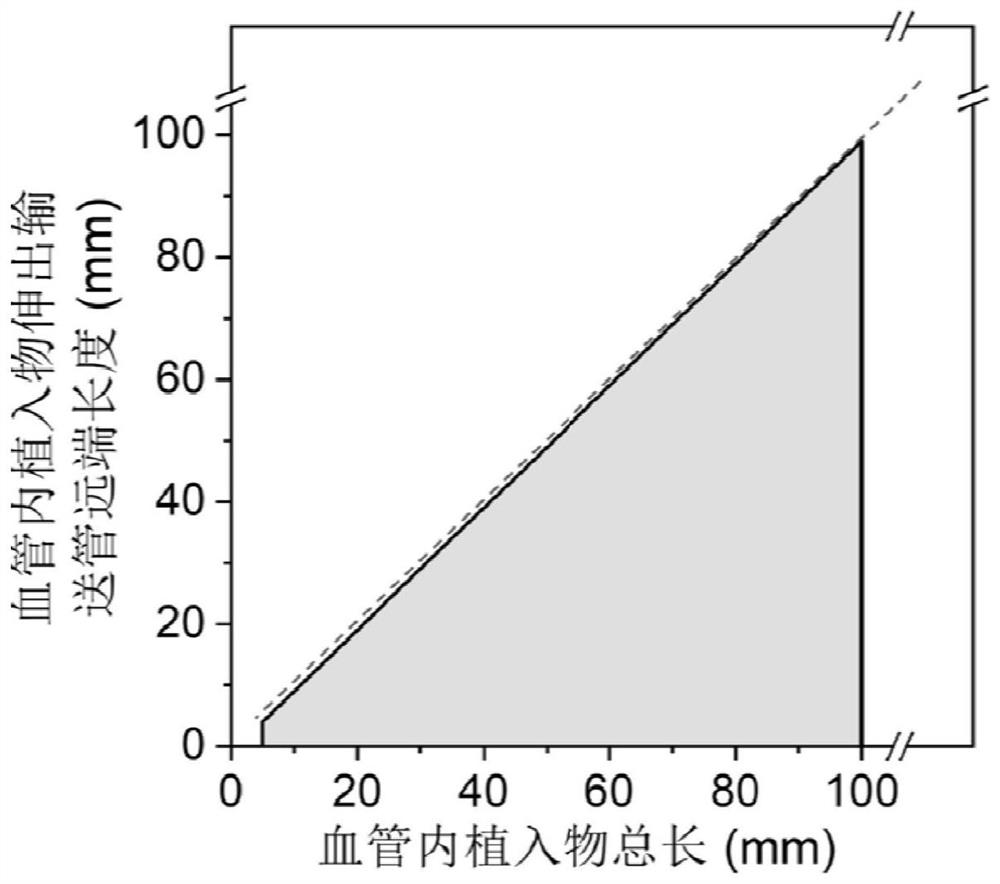

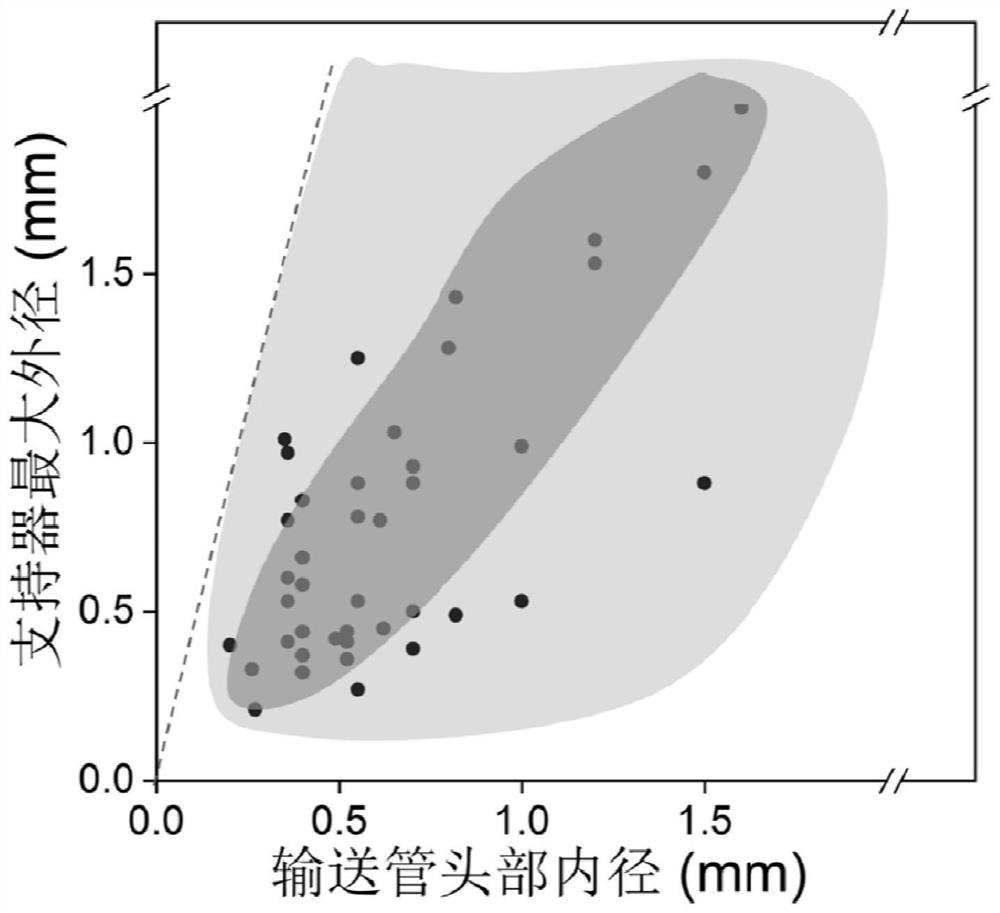

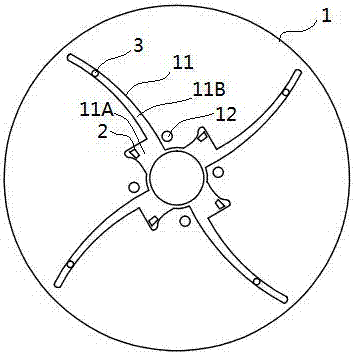

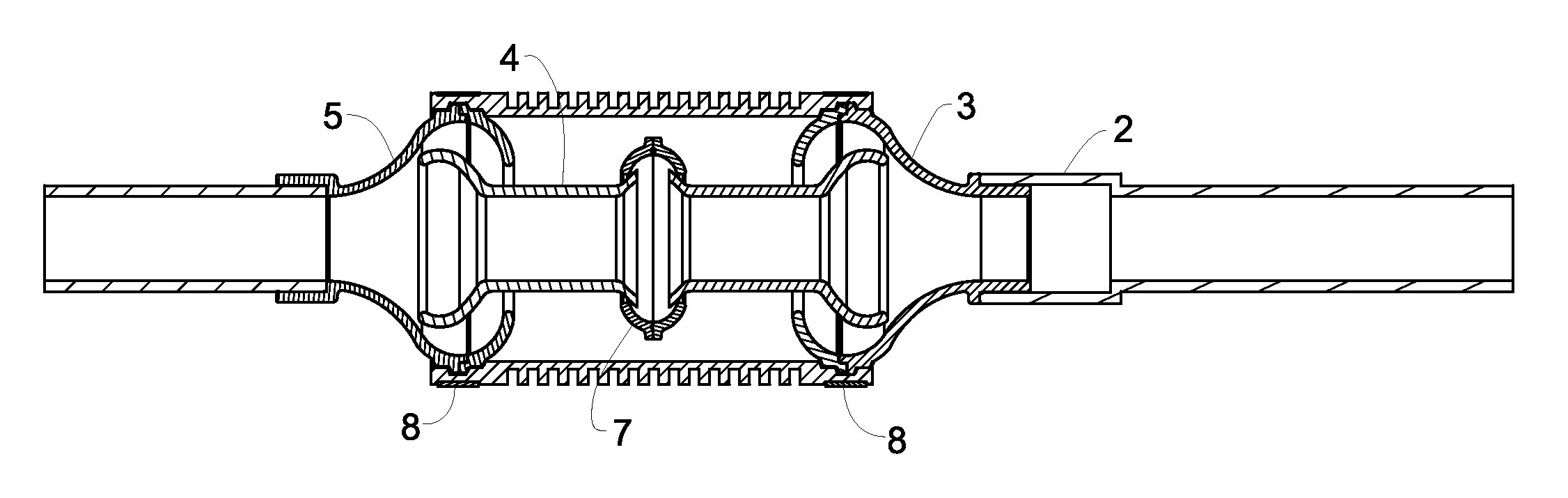

Endovascular implant fixation retention structure and endovascular implant delivery system

The invention provides an endovascular implant fixing and maintaining structure and an endovascular implant conveying system. The endovascular implant fixing and maintaining structure is used for fixing, maintaining and separating an implant in the endovascular implant conveying process. The endovascular implant delivery system comprises a delivery tube, a guide wire penetrating through the delivery tube, and a holder connected to the guide wire. In the initial stage of conveying, the guide wire and the conveying pipe are kept relatively fixed, and the holder is located at the head of the conveying pipe and plays a role in fixing an implant; in the later stage of conveying, the guide wire and the conveying pipe move relatively, the holder extends out of the head of the conveying pipe, and the implant is released. When the length of the implant extending out of the far end of the conveying pipe does not exceed a certain value, the implant can be recovered to the adjusting position in the conveying pipe through the guide wire to be released again. According to the endovascular implant delivery system, the flexibility is good, the success rate is high, the repeated withdrawing and re-releasing functions are achieved, and the endovascular implant delivery system can adapt to various microcatheters.

Owner:JIANGSU NOWYON MEDICAL CO LTD

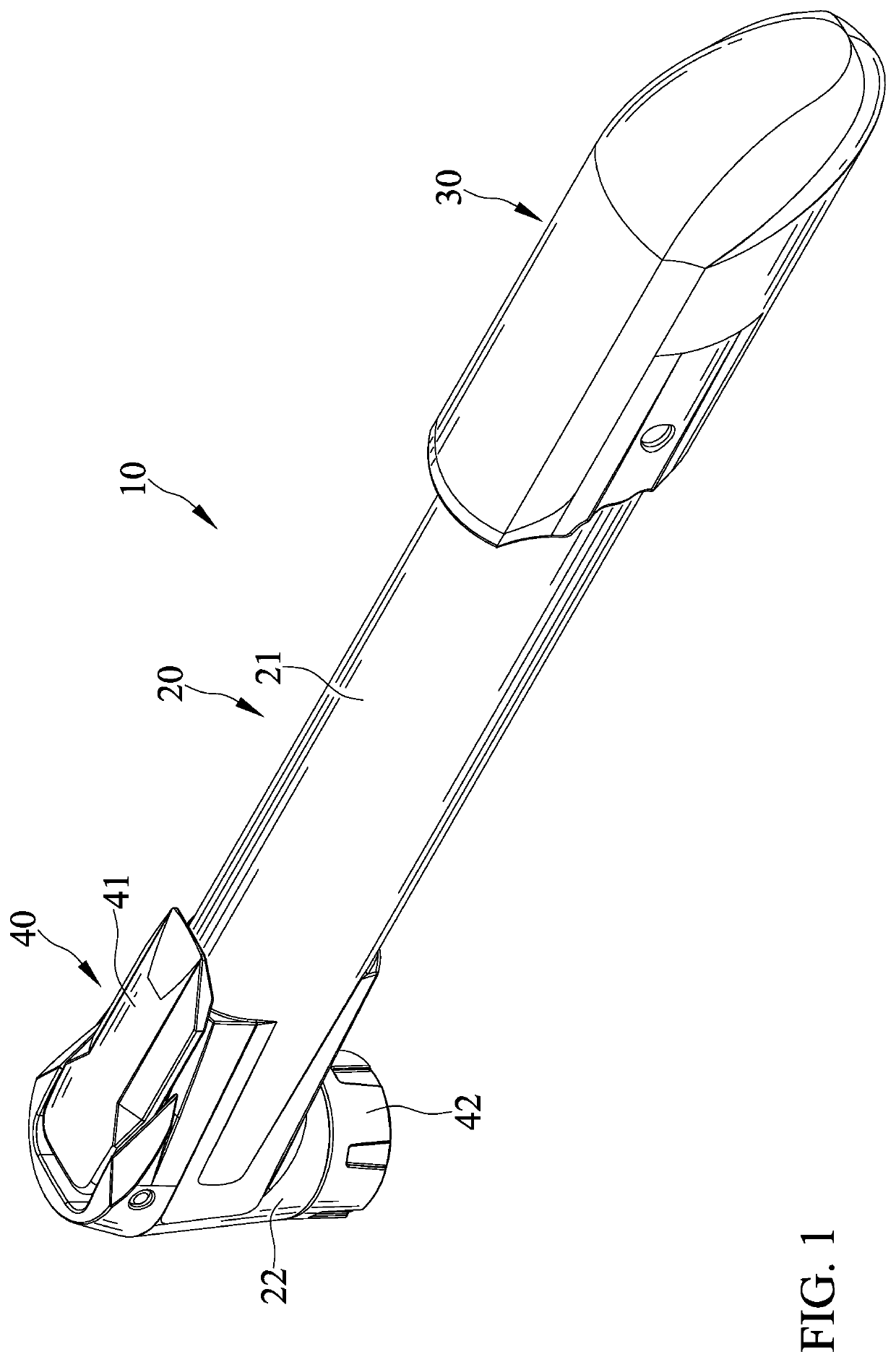

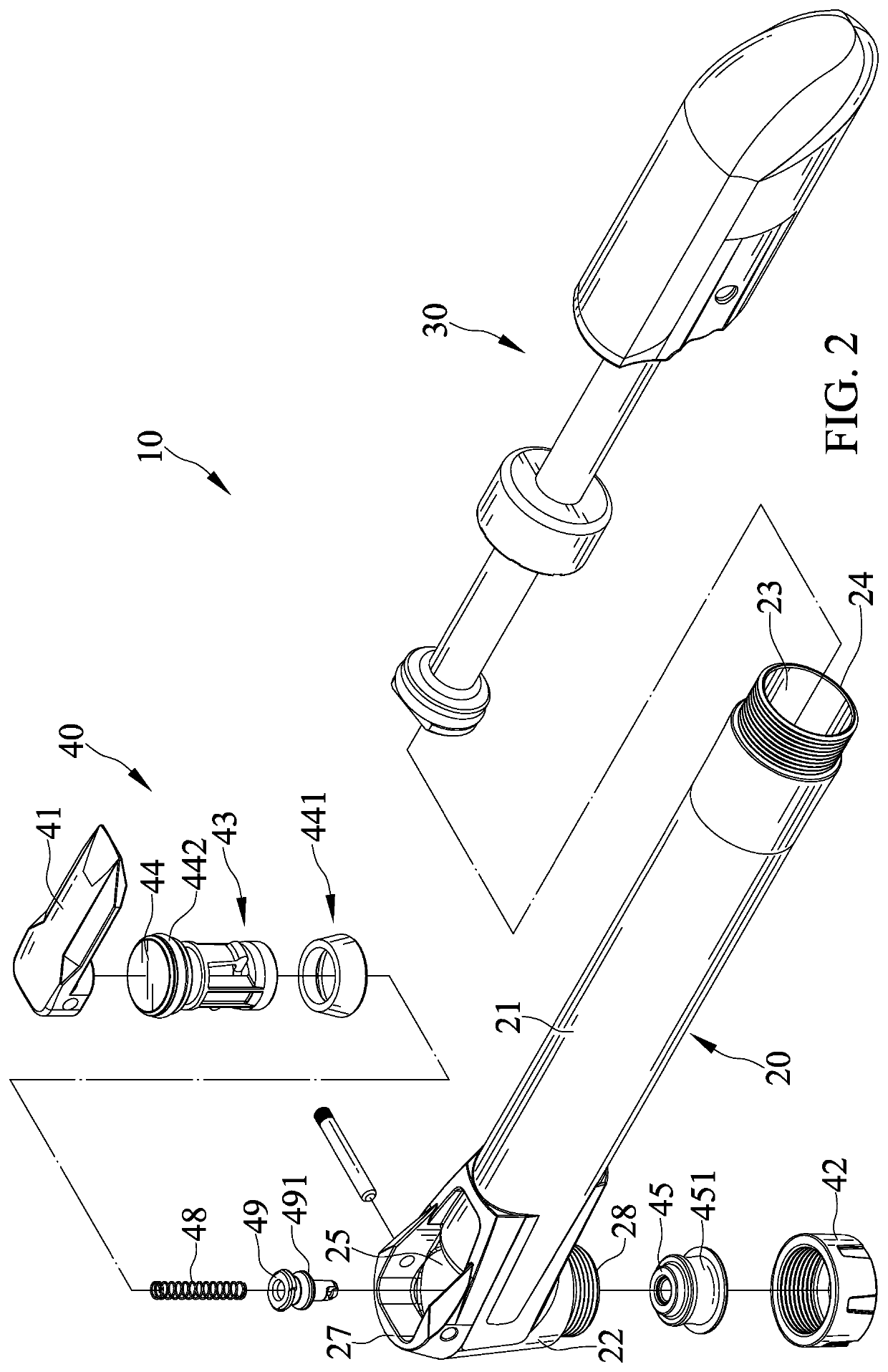

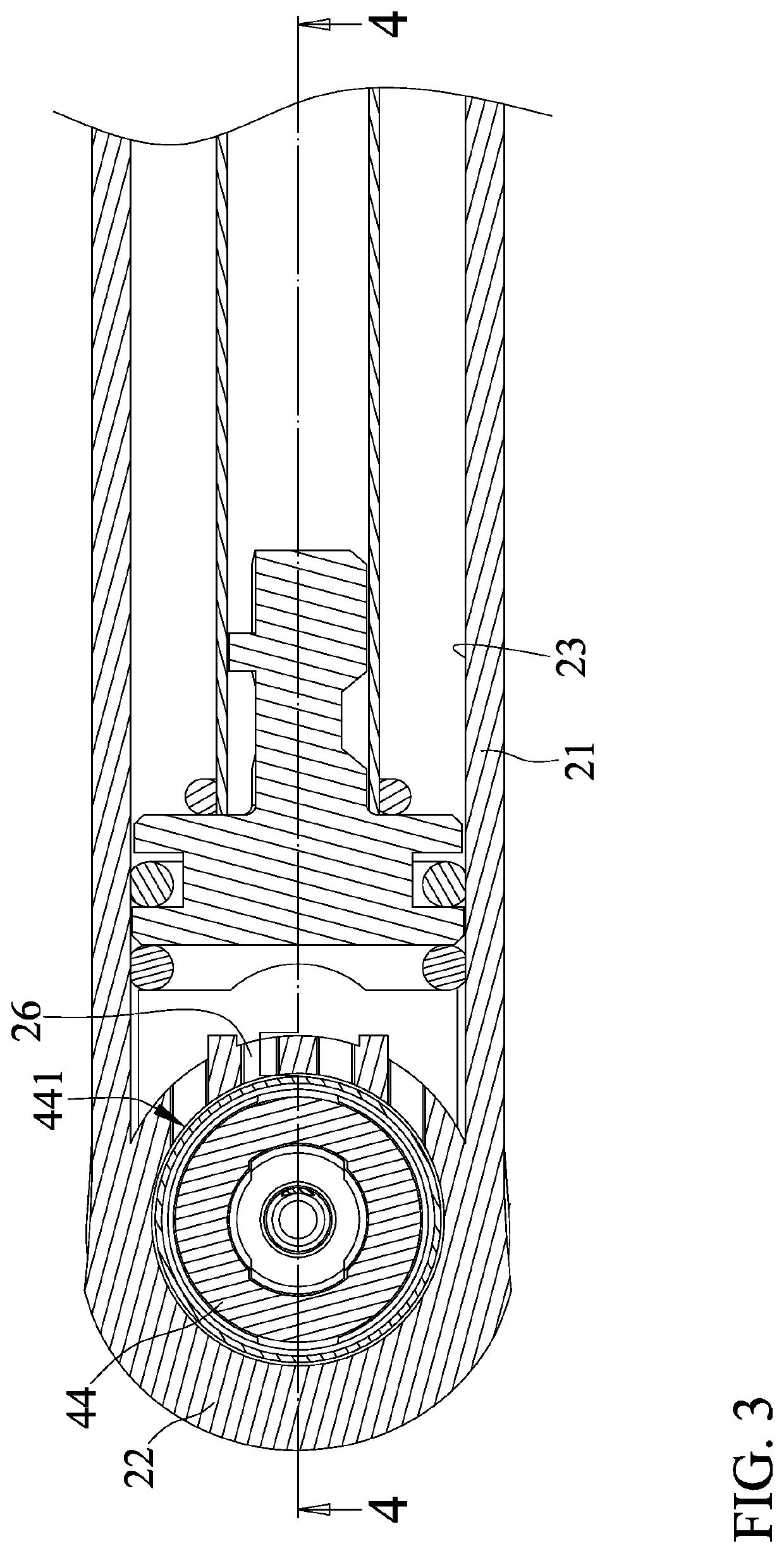

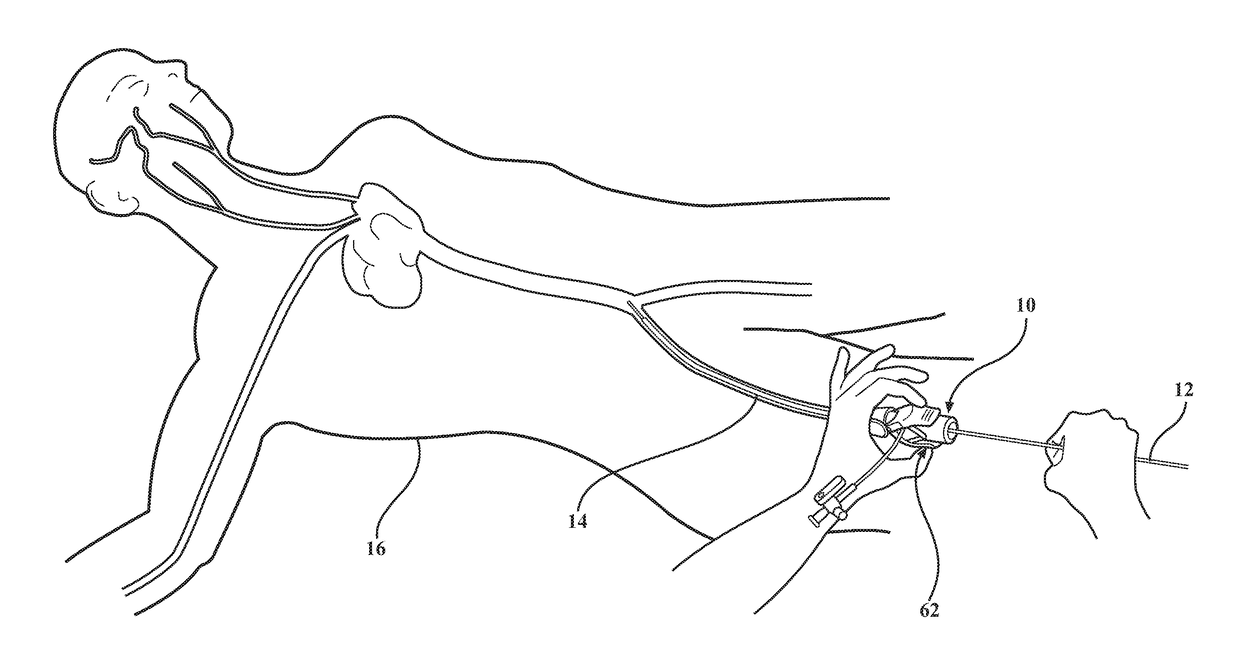

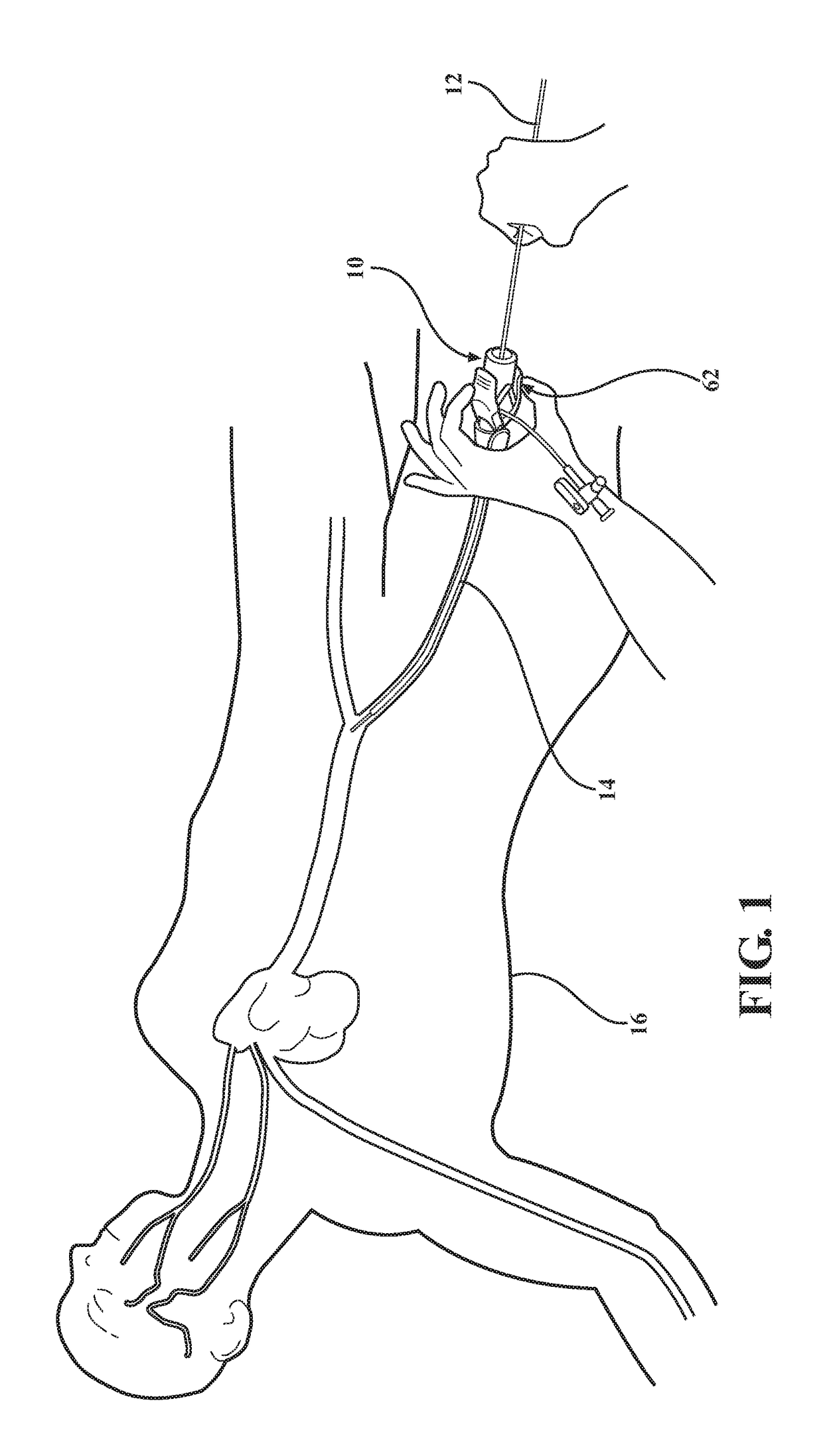

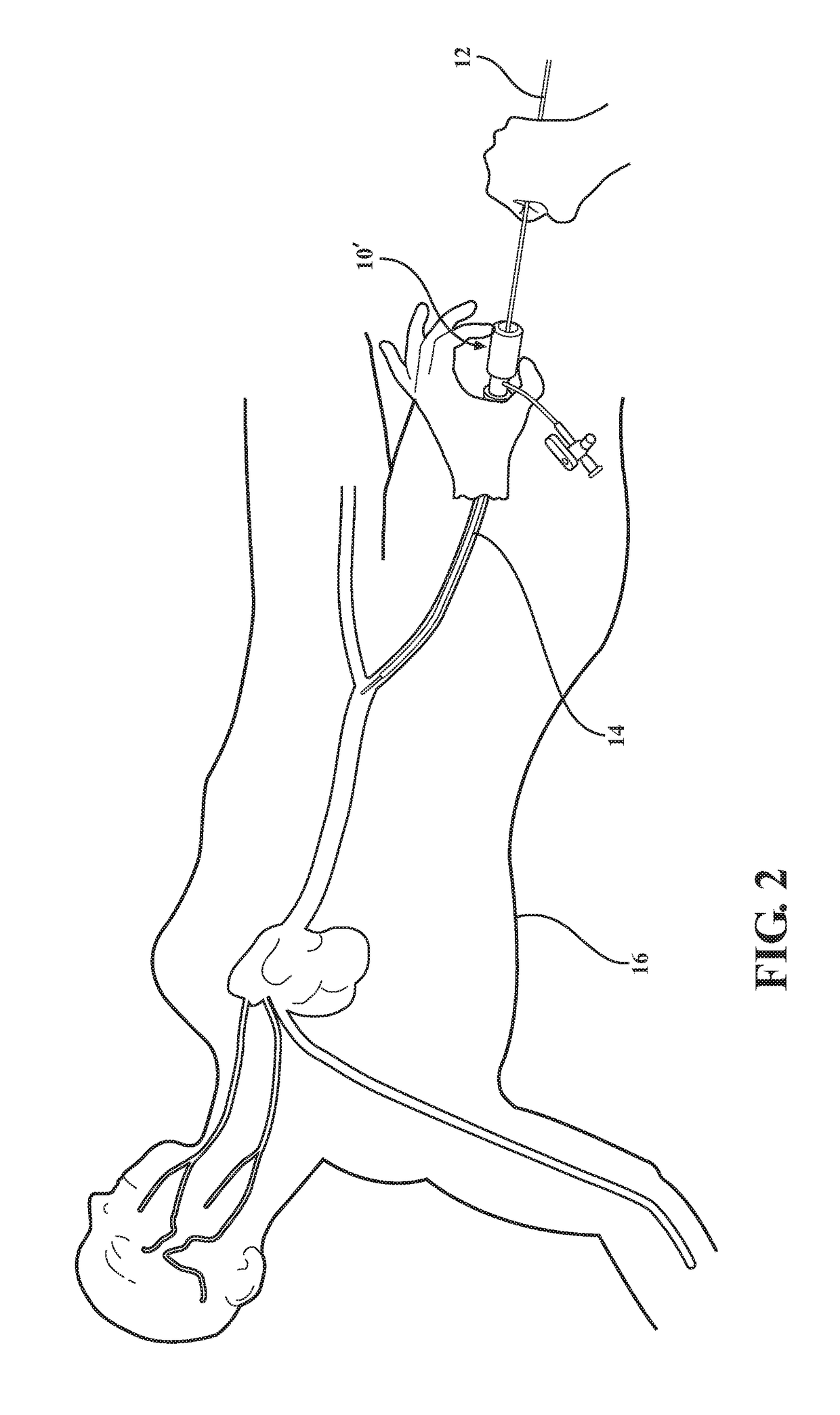

Variable Extension Combined Spinal/Epidural Needle Set and Method For Its Use

InactiveUS20080183151A1Low inner diameter requirementEasy to operateCannulasInfusion syringesEpidural needlesBiomedical engineering

Owner:MARSH RONALD W +1

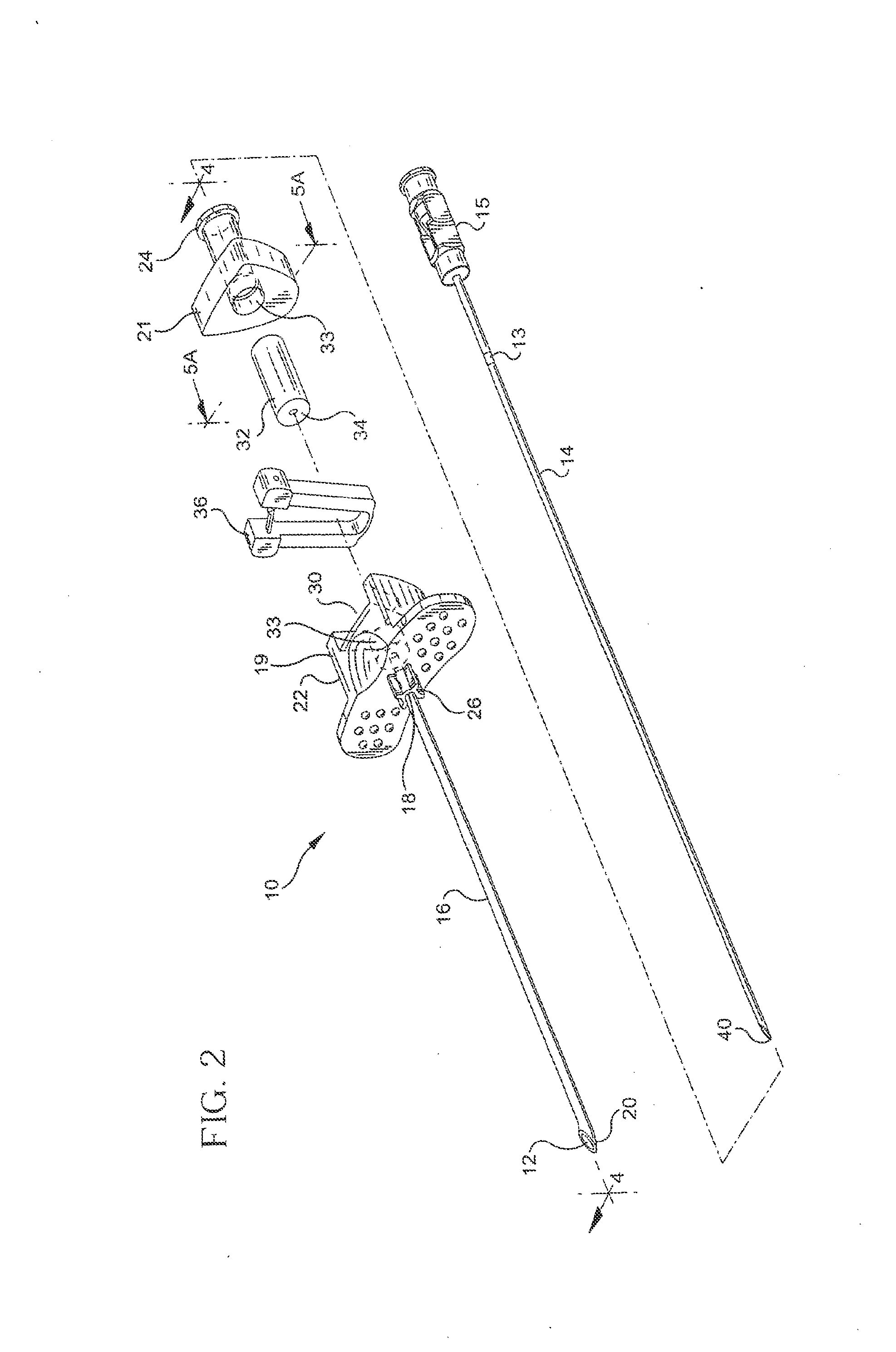

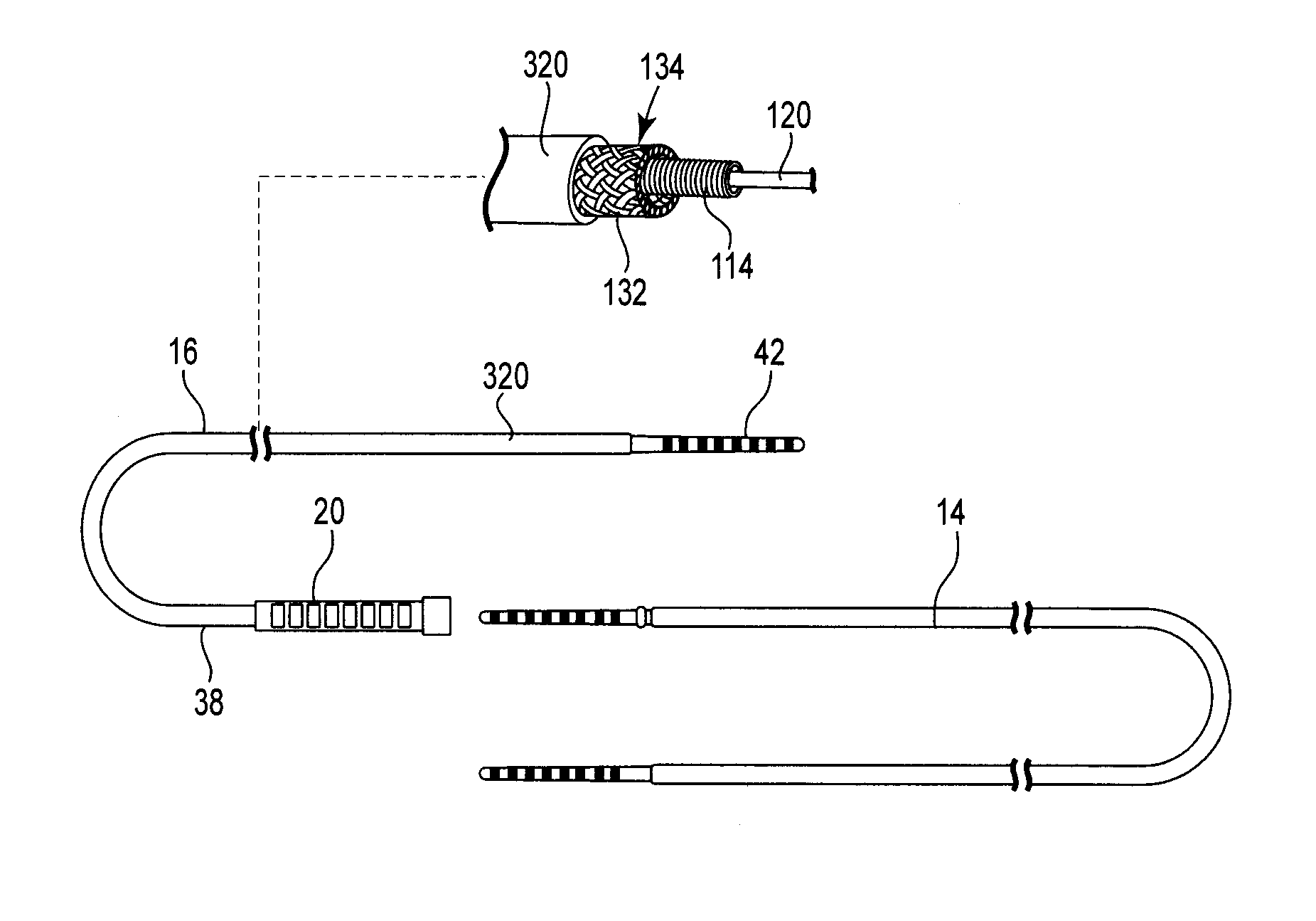

Implantable lead with braided conductors

ActiveUS20120232625A1Low inner diameter requirementReduce the overall diameterSpinal electrodesInsulated cablesBiomedical engineeringLiving body

A therapy delivery element adapted to be implanted into a living body. The therapy delivery element includes an electrode portion with a plurality of electrodes. At least one elongated lead body is attached to the electrode portion. The elongated lead body includes a stylet coil having a stylet coil lumen. The stylet coil extends within the elongated lead body and along at least a portion of the electrode portion. A conductor assembly with a plurality of insulated electrical conductors is braided to extending around the stylet coil and to electrically couple to one or more of the electrodes. The conductor assembly includes an inner lumen with a diameter greater than an outside diameter of the stylet coil. Axial elongation of the elongated lead body reduces the inner diameter of the conductor assembly. A low durometer insulator extends around the conductor assembly. A stylet sized to slide freely within the stylet coil lumen is provided for use during implantation of the therapy delivery element into the living body.

Owner:CIRTEC MEDICAL CORP

Automatic chuck for bundling strip cutting machine

ActiveCN107381136AImprove work efficiencyImprove efficiencyWebs handlingEngineeringOperational safety

The invention provides an automatic chuck for a bundling strip cutting machine, and the automatic chuck is efficient, safe and firm in clamping. The automatic chuck comprises a chuck body. A plurality of tracks which radiate outwards along the center are arranged on the end face of the chuck body. Each track comprises an avoiding notch and a sliding rail from interior to exterior, wherein the avoiding notch is internally provided with an ejector claw ejecting outwards from the center when the chuck works, the sliding rail is internally provided with a clamping arm conducting tight clamping towards the center from the outside when the chuck works. A drive mechanism of each ejector claw and a drive mechanism of each clamping arm are independent of each other. When the automatic chuck works, the clamping arms can be used for rapidly and efficiently clamping the periphery of a cloth roll, the ejector claws are used for ejecting the inner circumferential wall of a paper tube of the cloth roll, and the clamping arms and the ejector claws are driven by air cylinders; and the whole cloth roll fixing process is fast and efficient, clamping is firm, the situation that the human hand gets close to the chuck for operation is not needed, and safety and reliability are achieved.

Owner:肇庆市祥丰利机械实业有限公司

Non-metallic expansion/deflection coupling modules

ActiveUS20120280487A1Large range of motionLow inner diameter requirementPipeline expansion-compensationAdjustable jointsCouplingComputer module

An improved device for coupling rigid non-metallic conduits is disclosed. The claimed device is capable of allowing movement in an axial direction due to expansion and contraction and can also compensate for angular or parallel deflection of the conduits.

Owner:THOMAS & BETTS INT INC

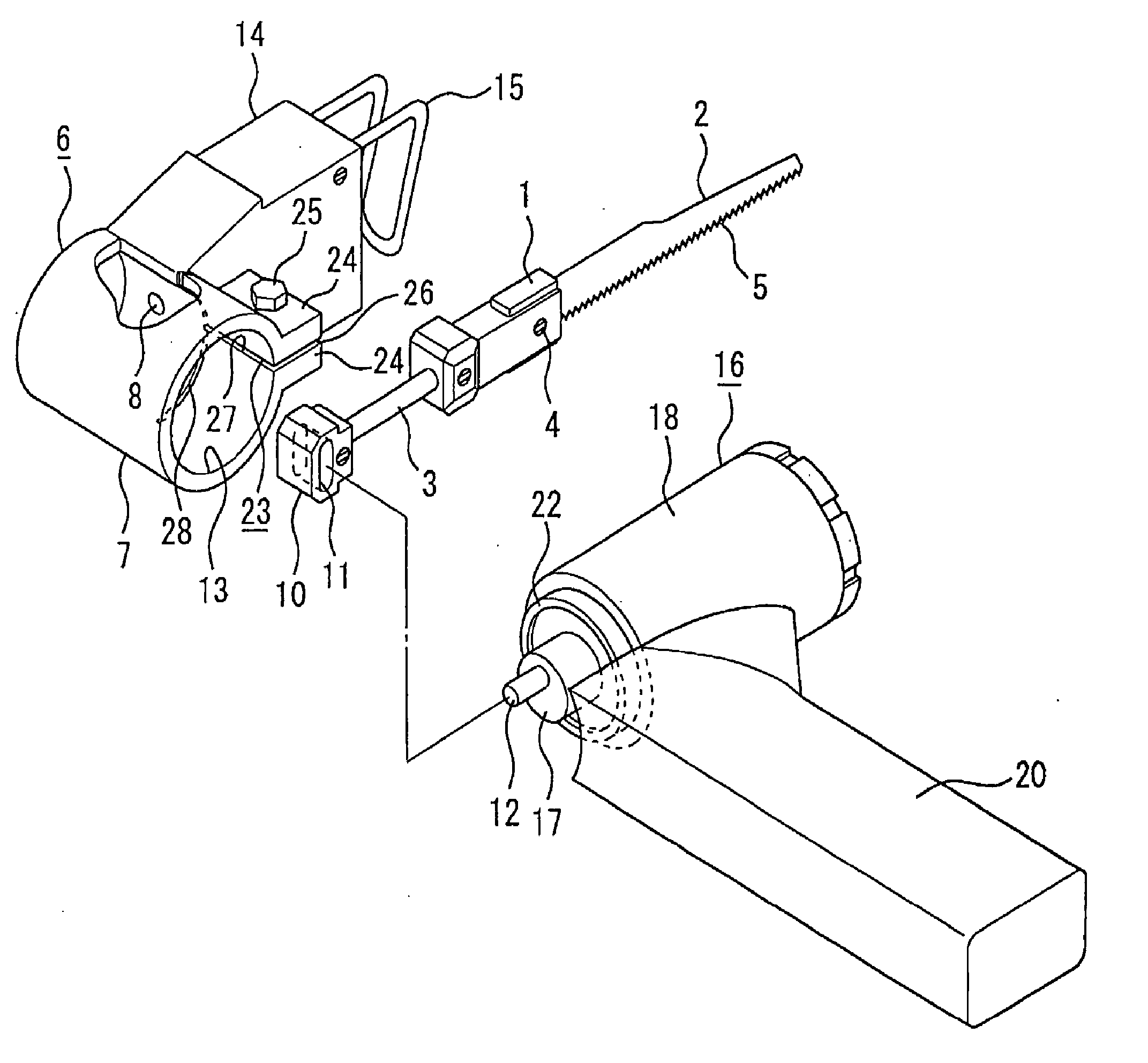

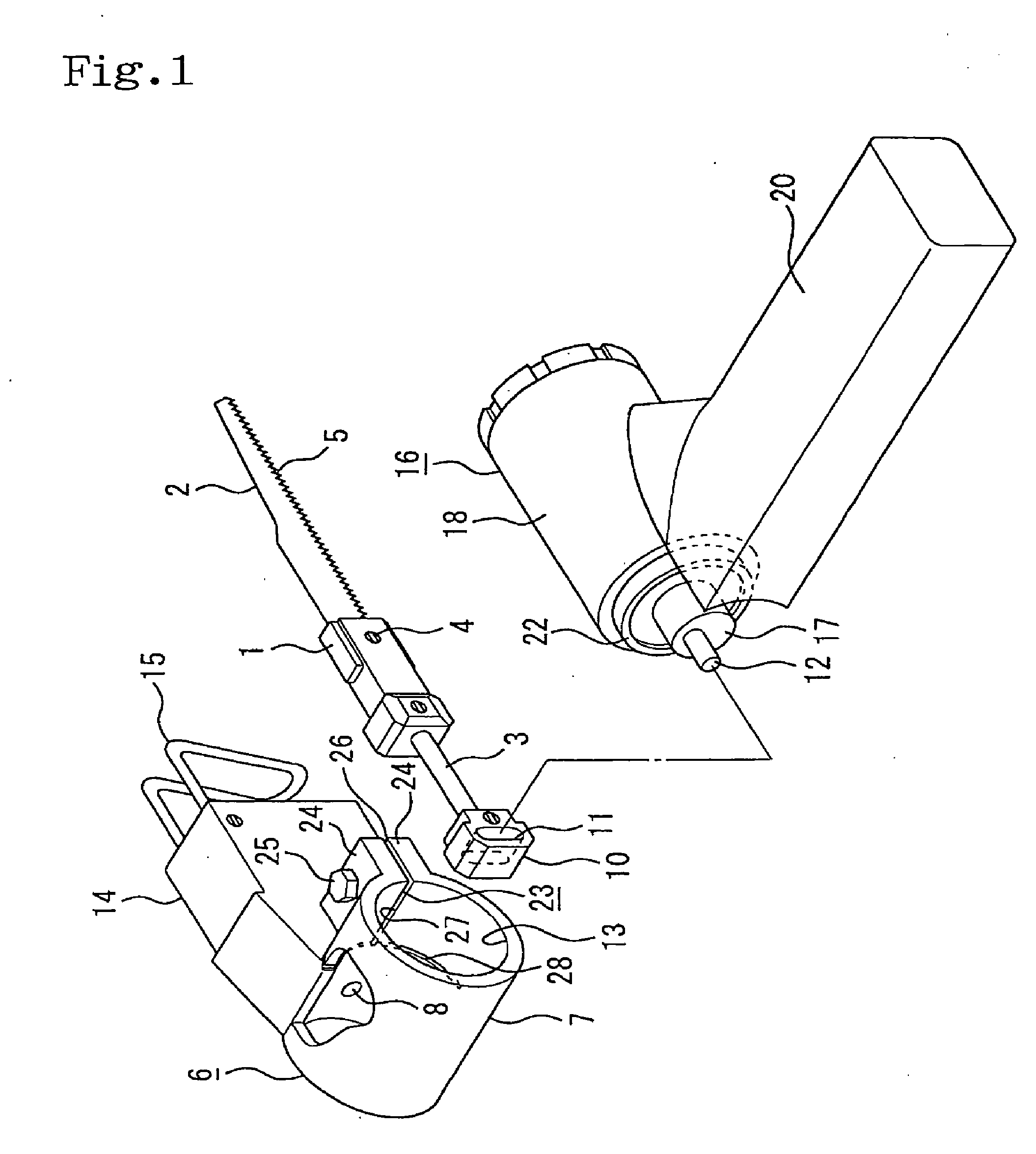

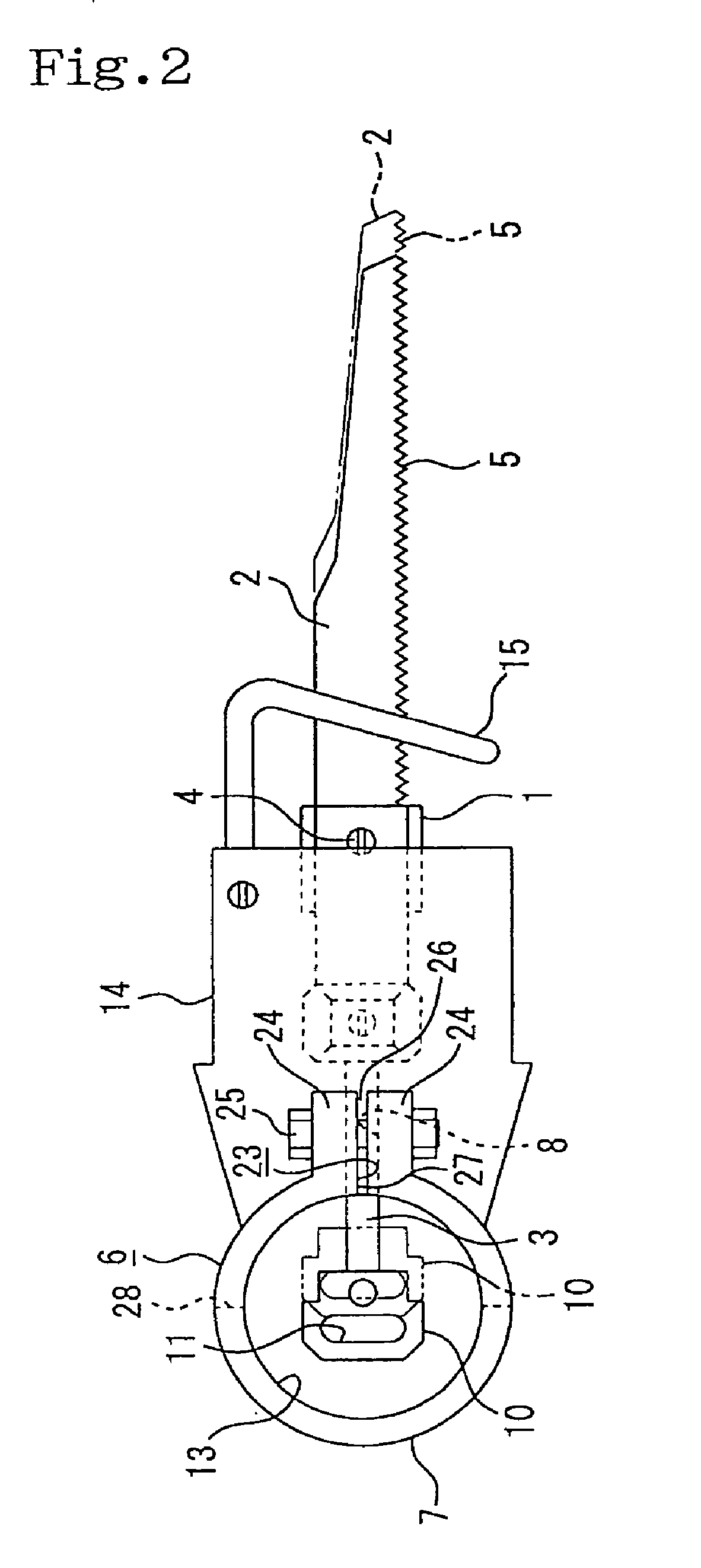

Automatic saw

InactiveUS20060179667A1Low inner diameter requirementCut evenlyMetal sawing devicesGang saw millsReciprocating motionPneumatic motor

An automatic saw includes a serrated blade, a blade holder connected to the serrated blade at one end thereof, a plunger arranged at the other end of the blade holder and arranged inside a housing as slidable in the housing, an engagement piece secured to the plunger inside the housing having an engagement elongated hole formed at a side surface of the engagement piece, the engagement hole extending in a direction perpendicular to an extending direction of an axis of the plunger, an air motor rotatable of a crank shaft inserted in and engaged with the engagement hole via a side opening formed in the housing, and a motor housing covering the motor rotatably coupled to the side opening. The rotational force of the crank shaft according to operation of the air motor is converted to back and forth reciprocal movement of the serrated blade via the engagement hole and the engagement piece.

Owner:S P ARI

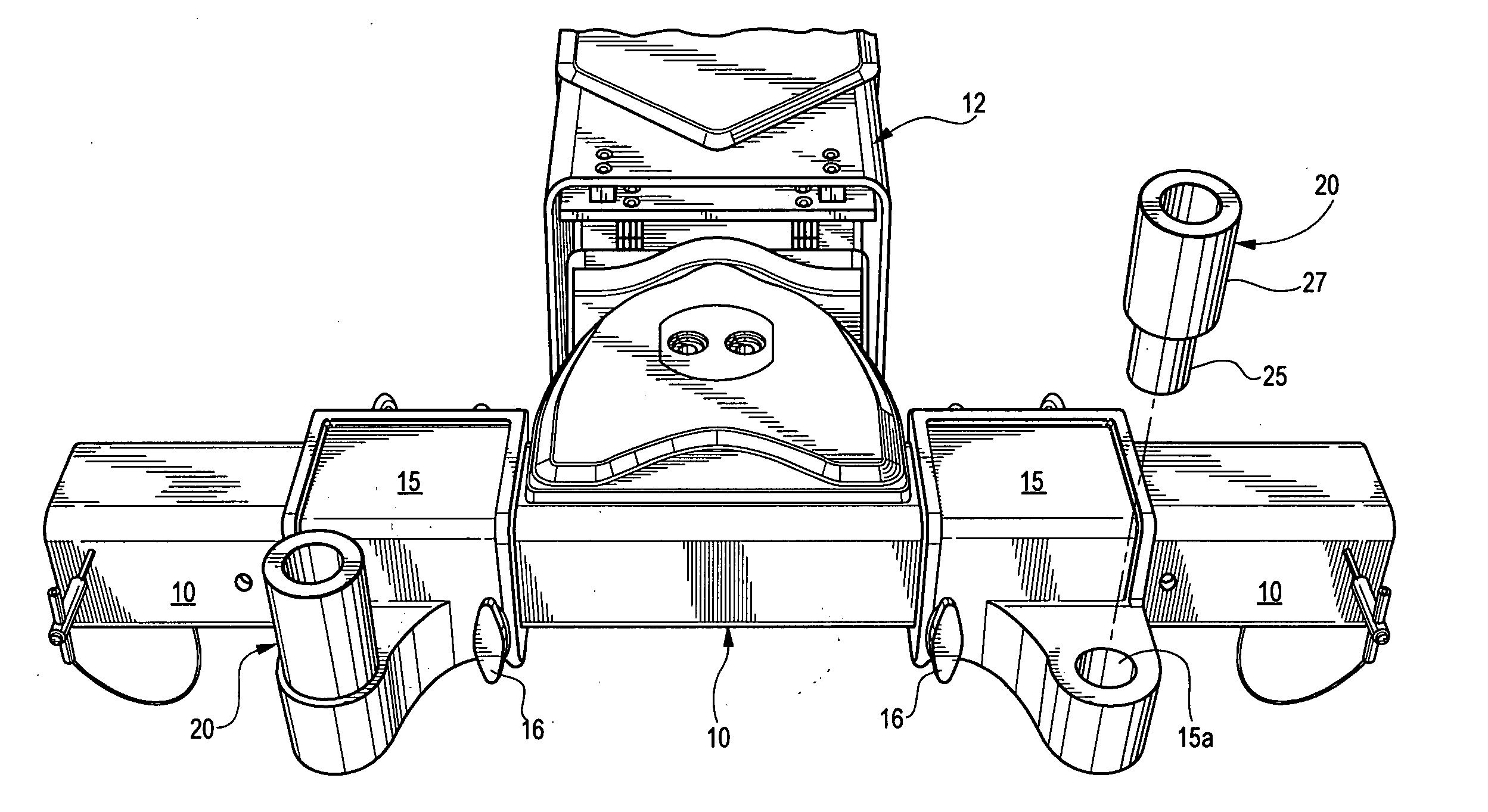

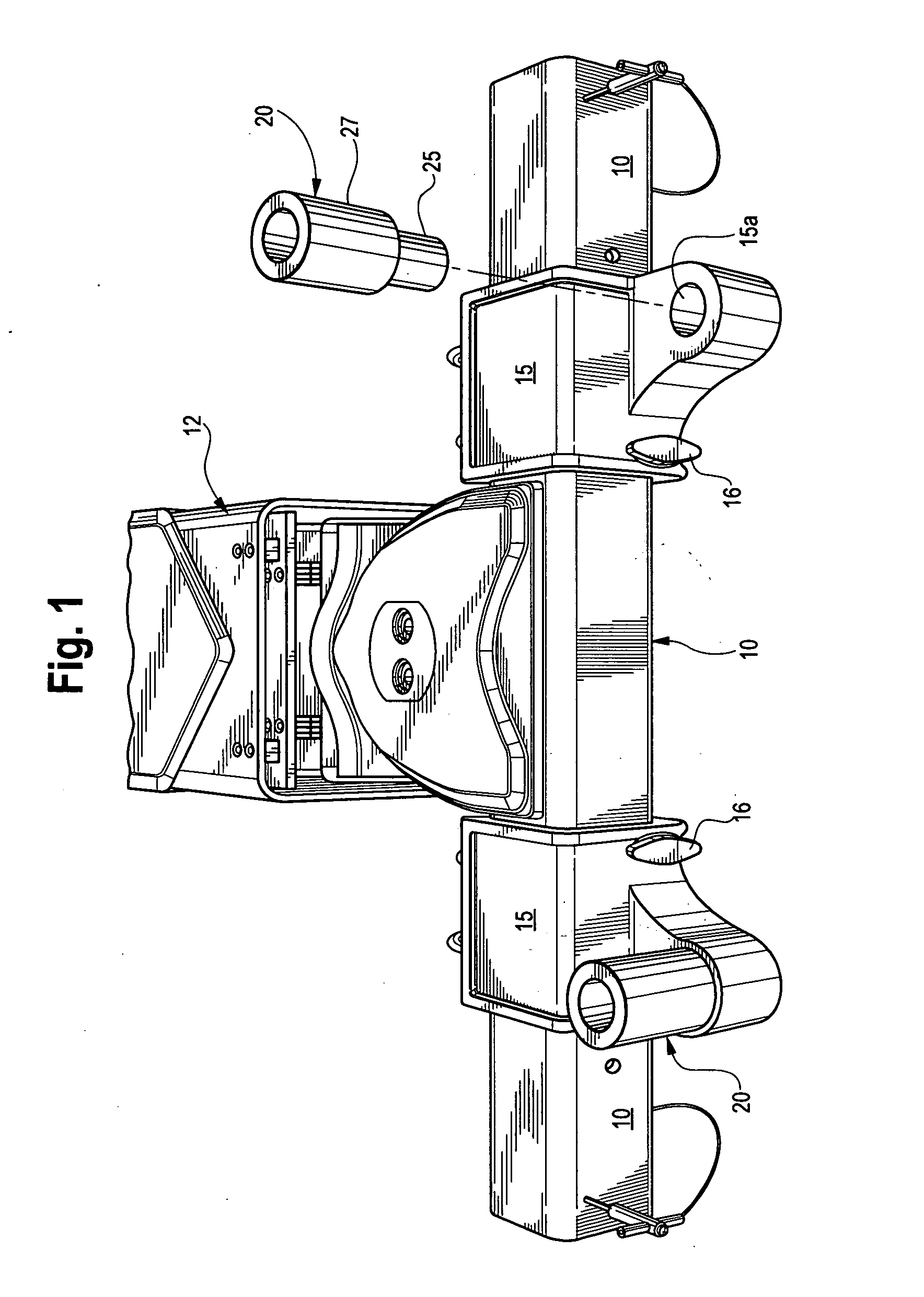

Heavy duty lift adaptor for vehicle towing

InactiveUS20060018744A1Low inner diameter requirementConnection securityItem transportation vehiclesSalvaging damaged vehiclesTruckHeavy duty

Lift adaptors for the hook-up and towing of heavy vehicles such as trucks, buses and trailer-tractors in a damage-free fashion, avoiding the need for pre-picking. The lift adaptors may be connected to receivers slidable over the underlift crossbar of heavy-duty, underlift-type tow vehicles. A movable boom may be used to locate the crossbar in a proper position beneath the towed vehicle, enabling engagement to the lift adaptors. The lift adaptors may be connected to the same receivers that may also be connected to forks, for example.

Owner:MILLER IND TOWING EQUIP INC

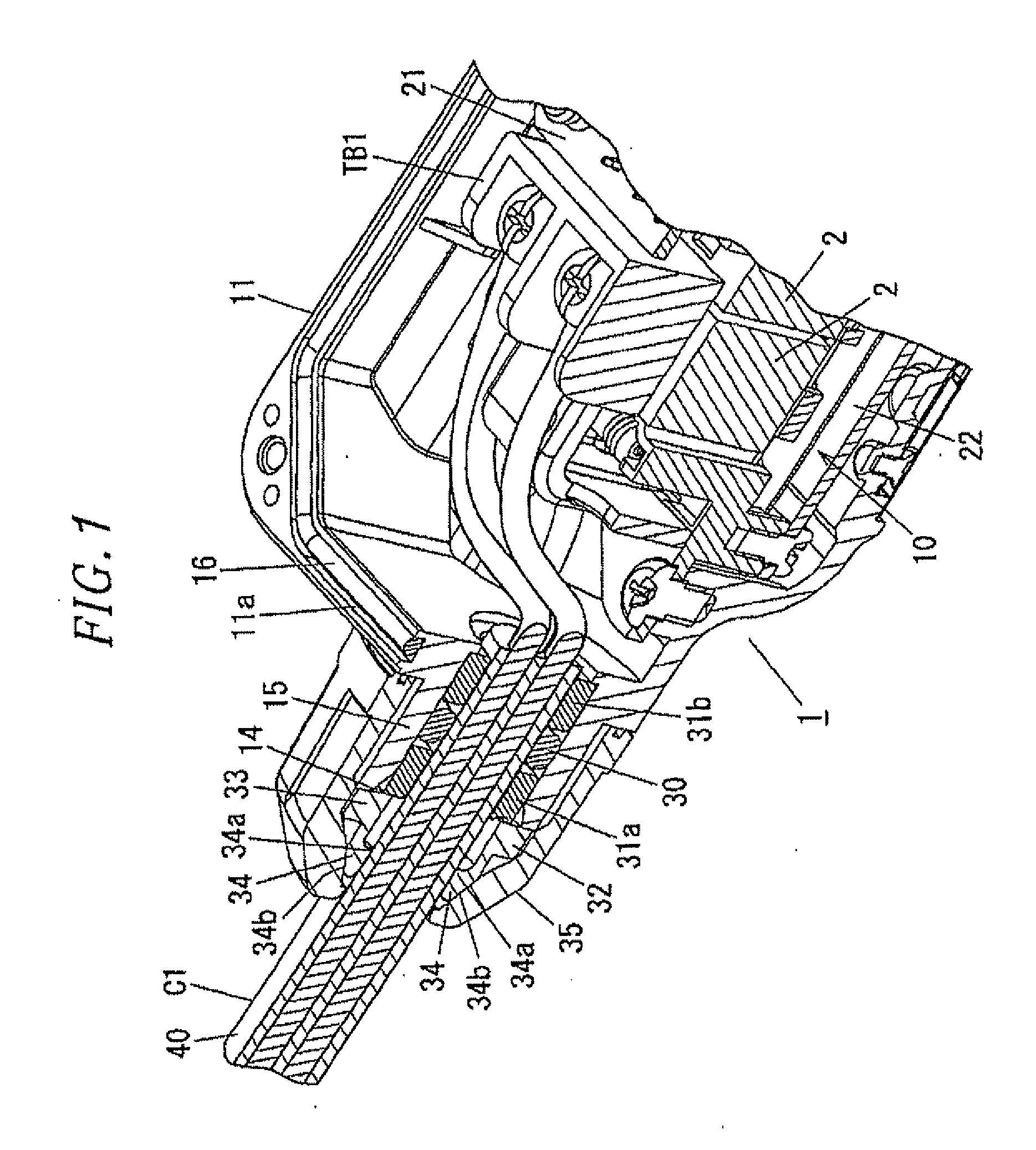

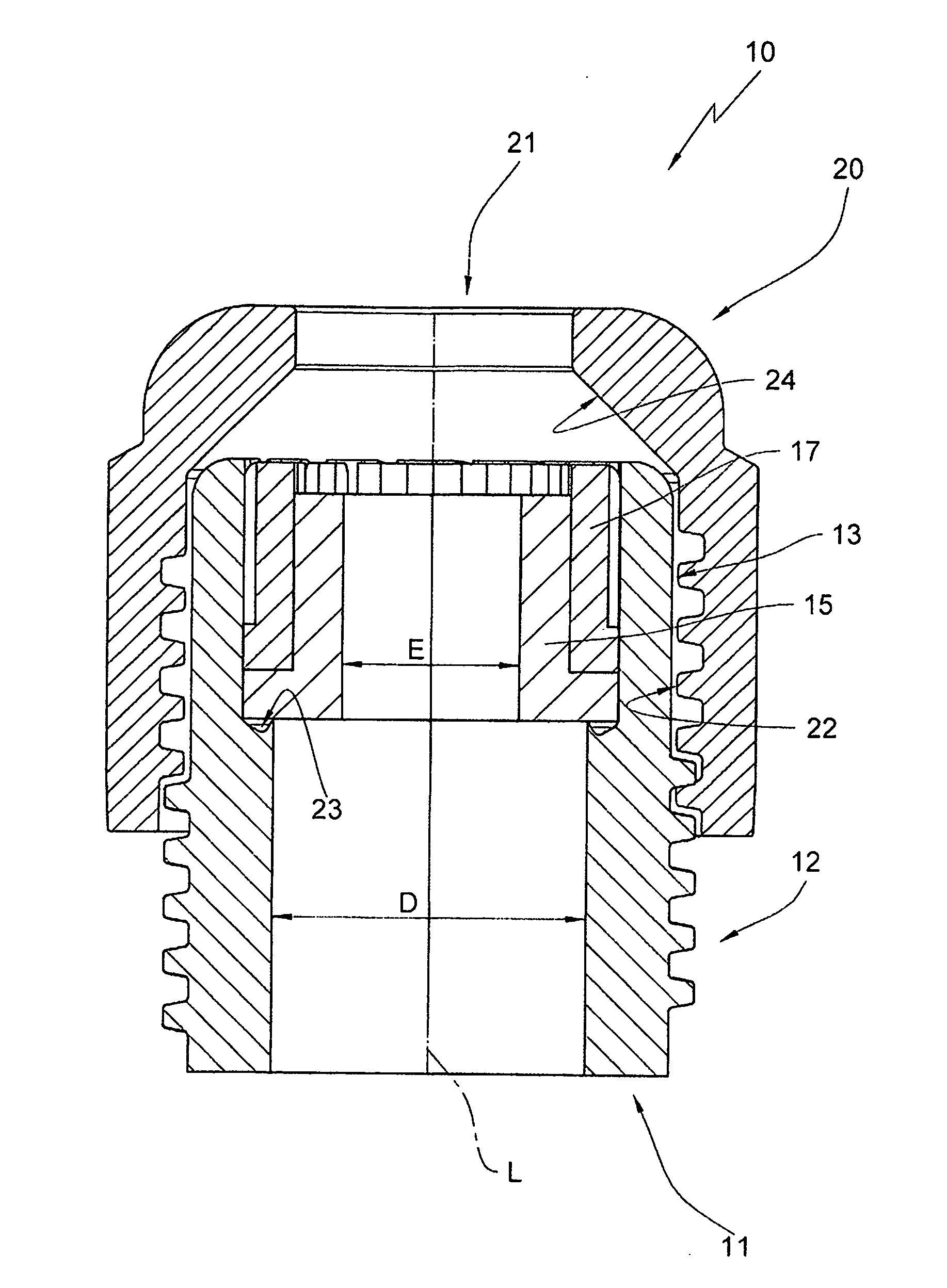

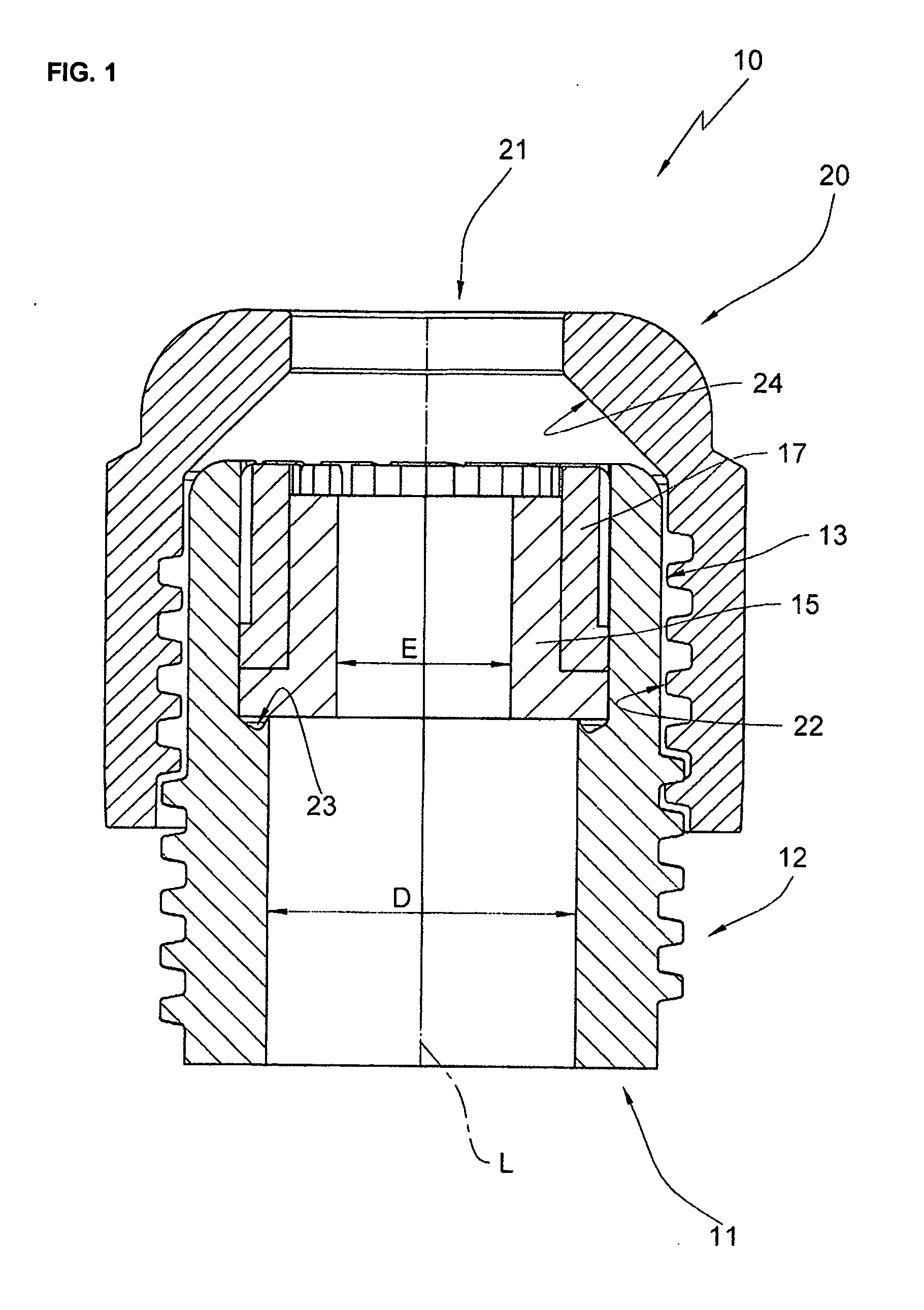

Device for fixating cables with pull relief

InactiveUS20120118631A1Low inner diameter requirementImprove toleranceCable junctionsCable terminationsEngineeringScrew thread

A device for fixating cables with pull relief, including a sleeve component including an outer thread in a first axial portion and a second axial portion that is formed by crush lamellas which are pressed against an outer circumferential surface of a cable that is being fixated. The crush lamellas are pressed against the outer circumferential surface of the cable by a cap nut that is threaded onto the outer thread and provided with a cable pass through opening. The sleeve component is provided with an insert on an inner circumference of its second axial portion that is formed by the crush lamellas, wherein the insert reduces the inner diameter of the sleeve component.

Owner:LUMBERG CONNECT

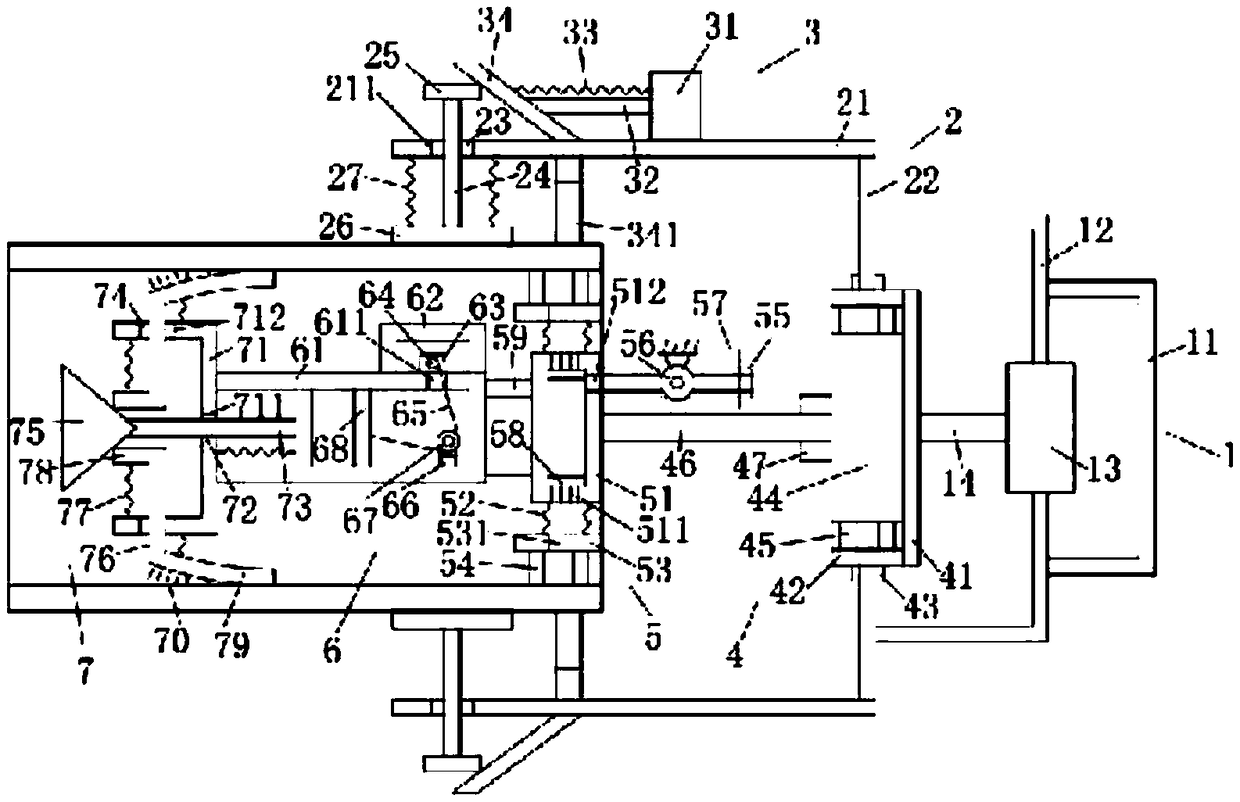

Novel efficient pipeline machining clearing equipment in field of environmental protection

The invention provides novel efficient pipeline machining clearing equipment in the field of environmental protection. The novel efficient pipeline machining clearing equipment comprises a first motordevice, a fixing device arranged on the first motor device, a first electric cylinder device arranged on the fixing device, a second electric cylinder device, a first clearing device arranged on thesecond electric cylinder device, a second motor device arranged on the left side of the first clearing device, and a second clearing device arranged on the second motor device. According to the novelefficient pipeline machining clearing equipment, a pipeline can be fully cleared, the clearing effect is good, the pipeline can be cleared comprehensively and thoroughly, the requirement for the innerdiameter of the pipeline is low, the novel efficient pipeline machining clearing equipment can adapt to the pipelines with the different inner diameters, thus the application range is wide, the clearing efficiency is high, operation is easy, the manual labor intensity is small, the cleaning way is diversified, the using demands of the novel efficient pipeline machining clearing equipment can be met, and the novel efficient pipeline machining clearing equipment is suitable for being applied and popularized.

Owner:马骏

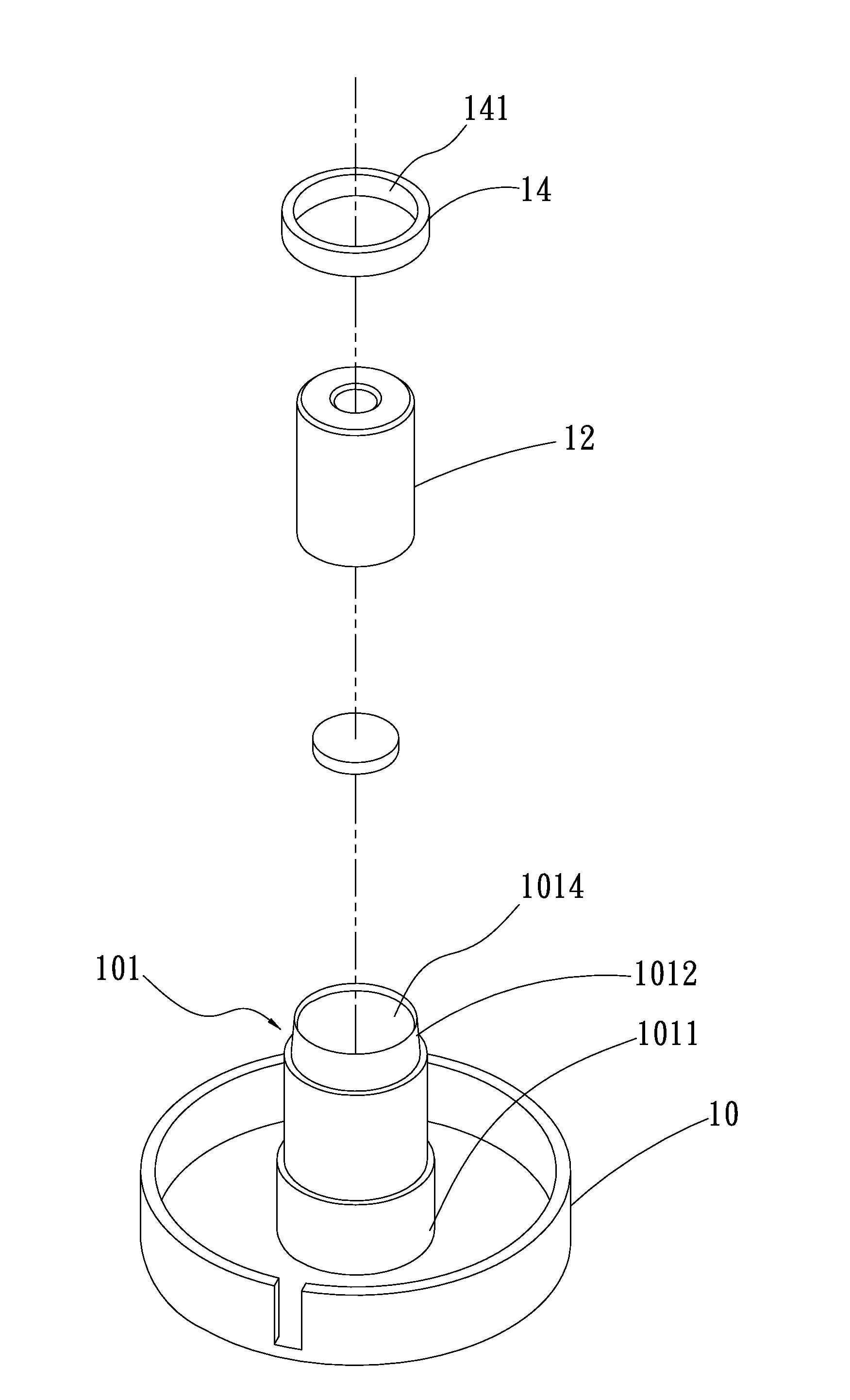

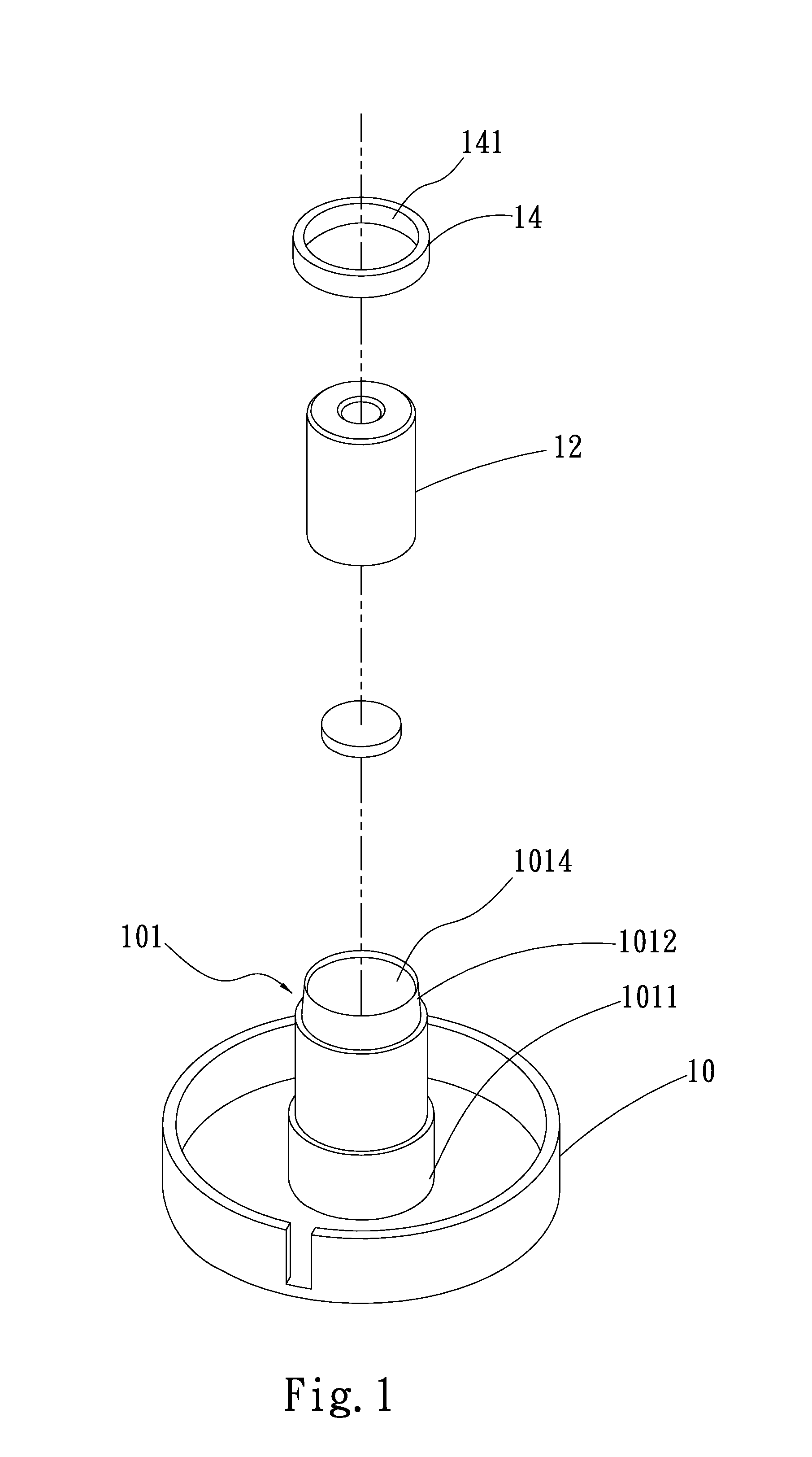

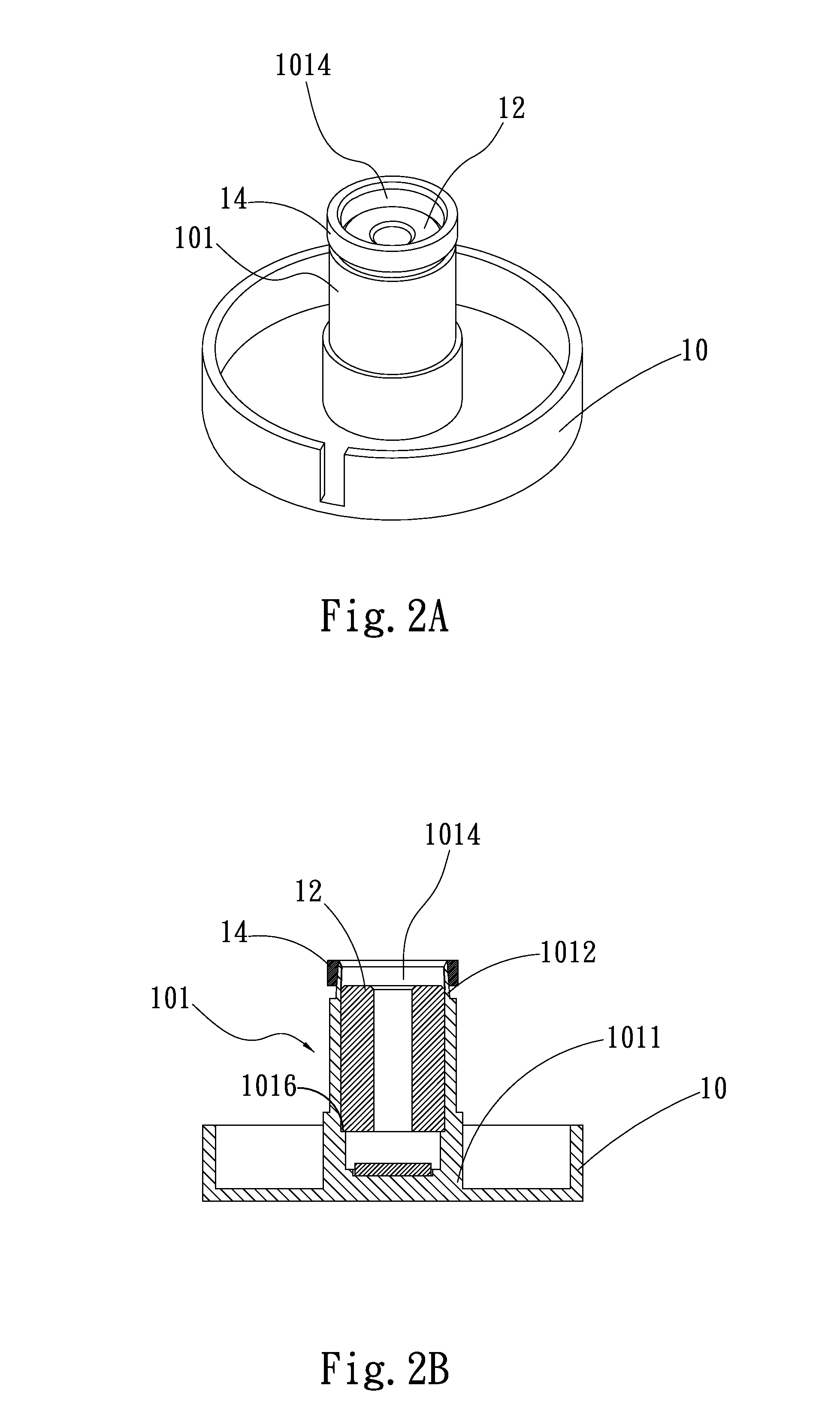

Fan bearing retaining structure

ActiveUS20130309086A1Improve fitting accuracyImproved fitting allowancePump componentsEngine componentsEngineeringMechanical engineering

A fan bearing retaining structure includes a base and a ring member. The base has a bearing cup projected from one side thereof, and the bearing cup internally defines an axial bore for receiving a bearing therein. The ring member is fitted around an outer side of the bearing cup and defines an opening, such that an inner side of the opening tightly contacts with the outer side of the bearing cup to apply a radially inward compression toward the axial bore. With these arrangements, a portion of the axial bore corresponding to the ring member fitted around the bearing cup has a reduced inner diameter to thereby effectively retain the bearing in the bearing cup, enabling a fan to be manufactured at reduced cost.

Owner:ASIA VITAL COMPONENTS SHENZHEN CO LTD

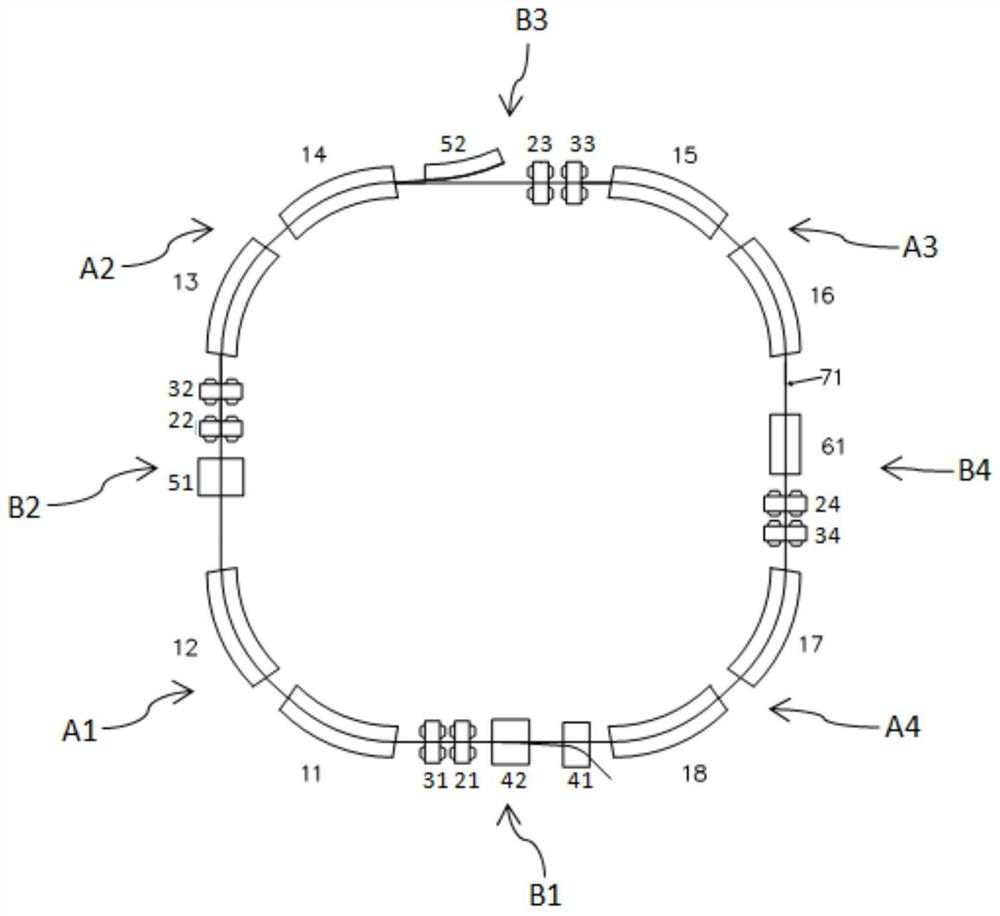

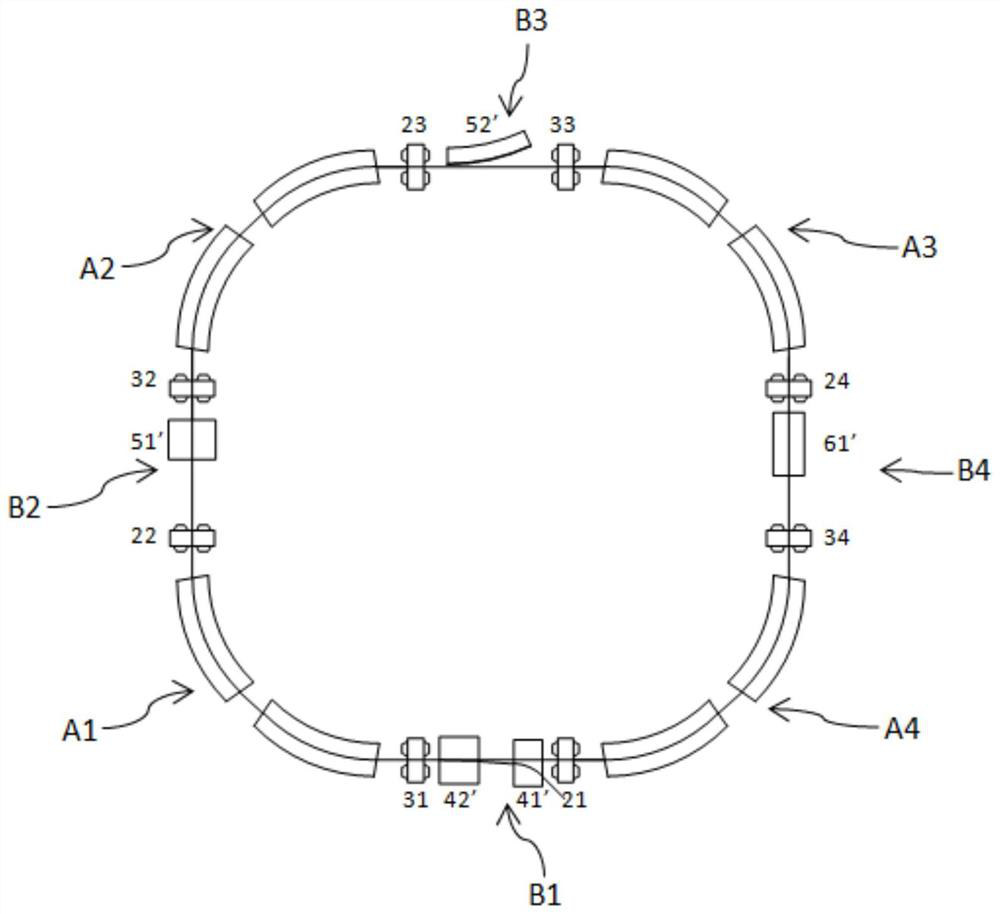

Ultrahigh-dose-rate medical proton synchrotron

PendingCN113382530ALow inner diameter requirementHigh instantaneous dose rateMagnetic resonance acceleratorsX-ray/gamma-ray/particle-irradiation therapyDoses rateNuclear engineering

The invention relates to an ultrahigh-dose-rate medical proton synchrotron which comprises four deflection dipolar magnet sets sequentially connected to form an annular structure. Each deflection dipolar magnet set is composed of at least two deflection dipolar magnets, the sum of deflection angles of the deflection dipolar magnets is 90 degrees, and four linear joints are connected between the adjacent deflection dipolar magnet sets. Each straight section comprises a horizontal focusing quadrupole magnet and a horizontal defocusing quadrupole magnet, protons are injected into the ultrahigh-dose-rate medical proton synchrotron through the injection cutting magnet and the injection impact magnet, and energy is increased under the action of the high-frequency acceleration device. Under the action of the leading-out impact magnet, the proton enters the leading-out cutting magnet and is led out from the ultrahigh-dose-rate medical proton synchrotron, and the cycle frequency is as high as 25Hz. According to the ultrahigh-dose-rate medical proton synchrotron, 25Hz fast circulation and fast leading-out are realized, and the requirements of small beam envelope function, low requirement on the inner diameter of a vacuum chamber and the like are met.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

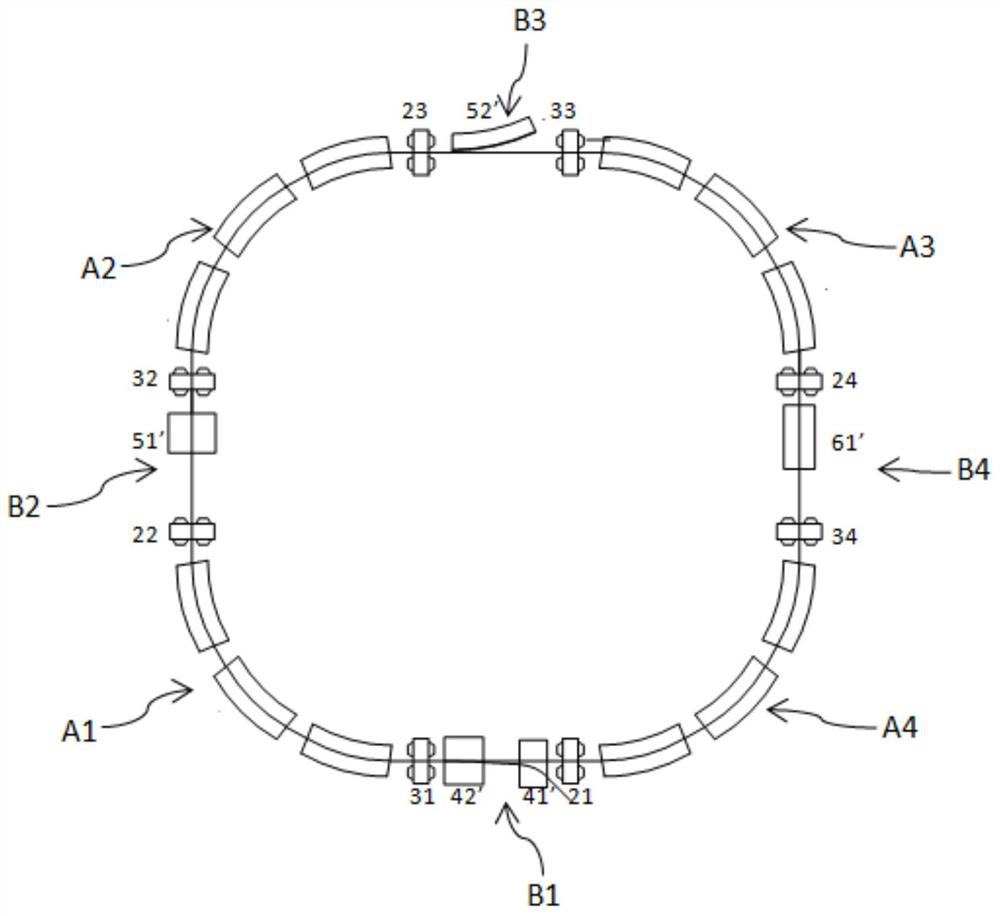

Graft anchor devices, systems and methods

Owner:ABIOMED

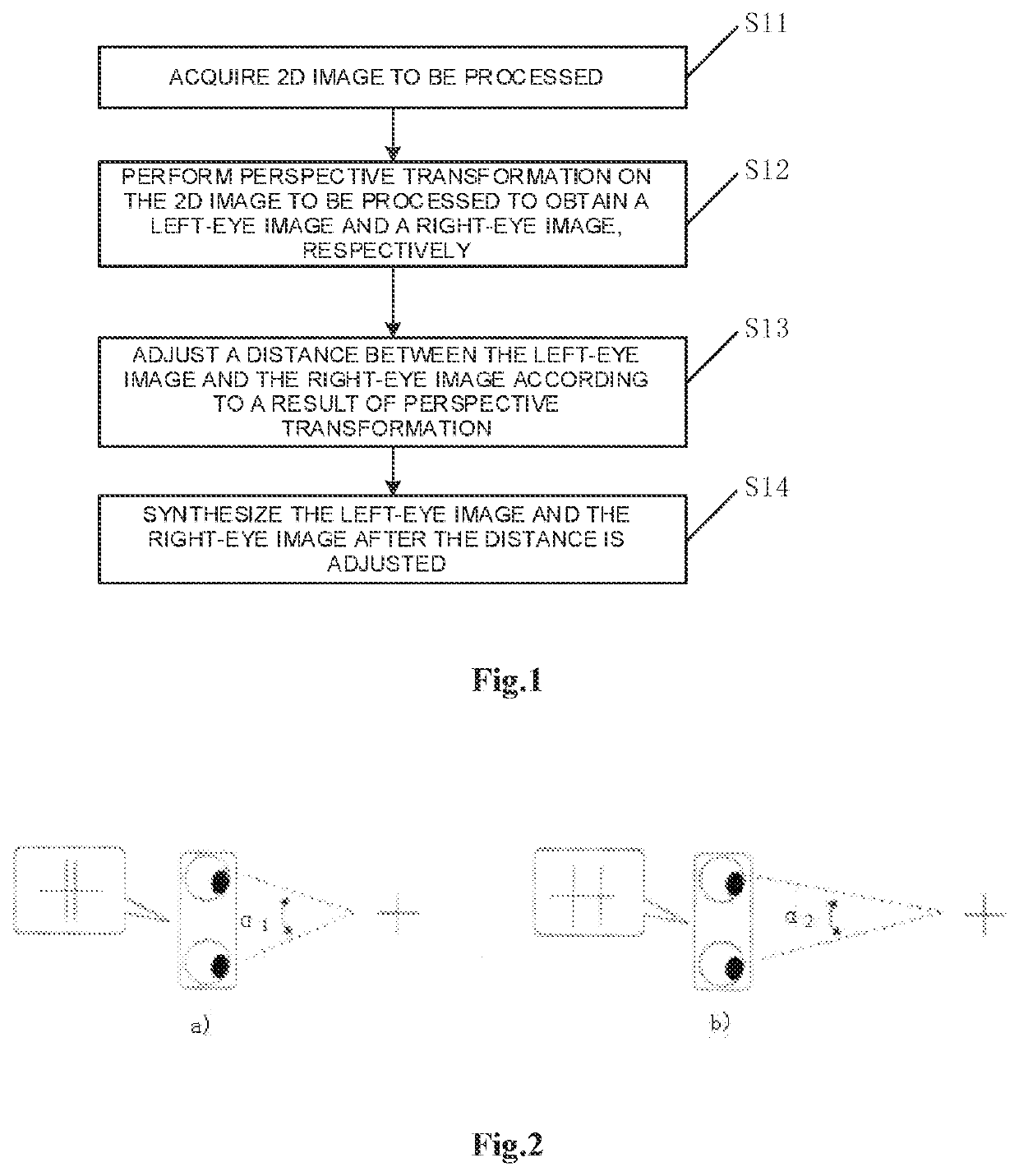

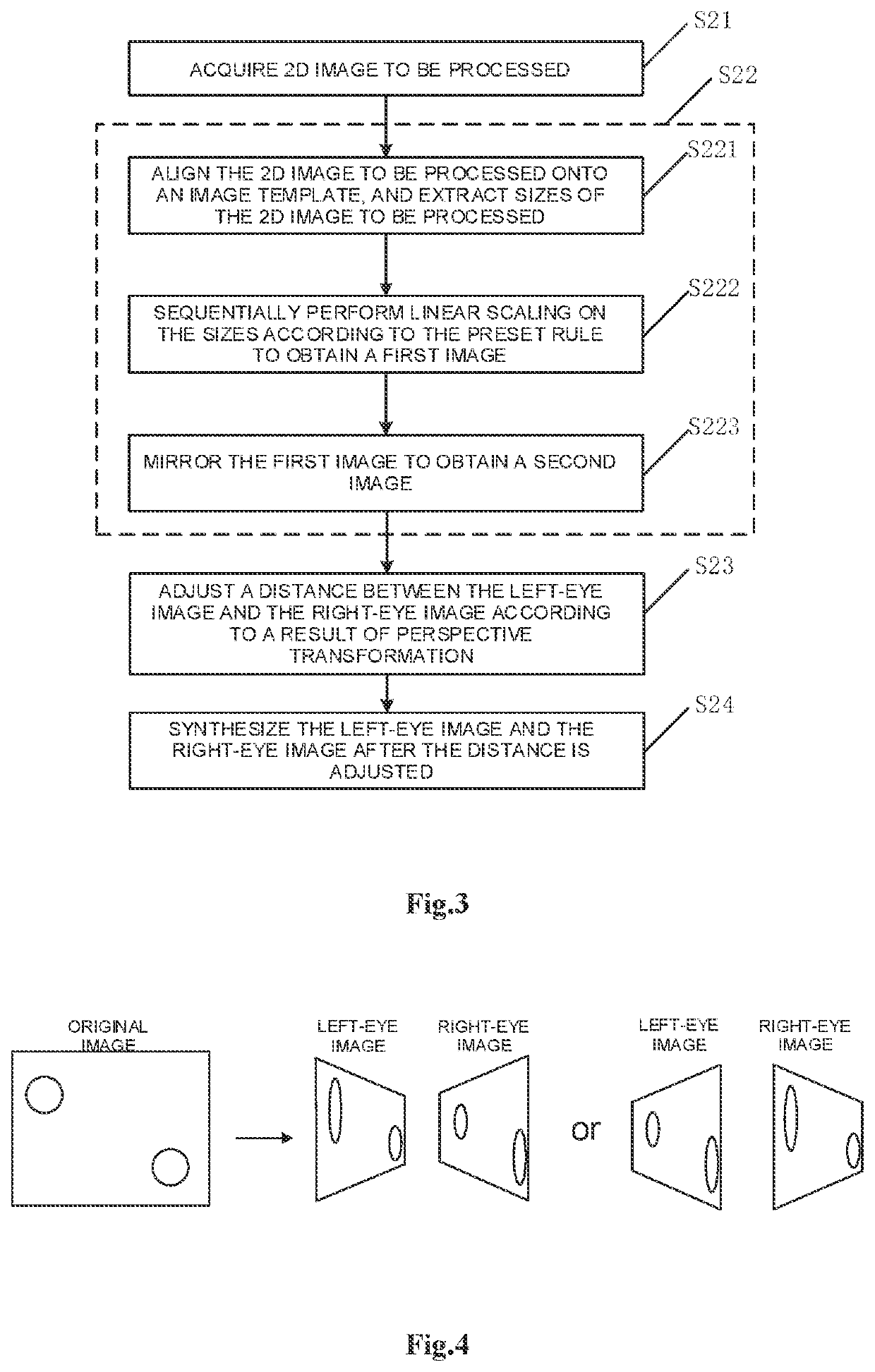

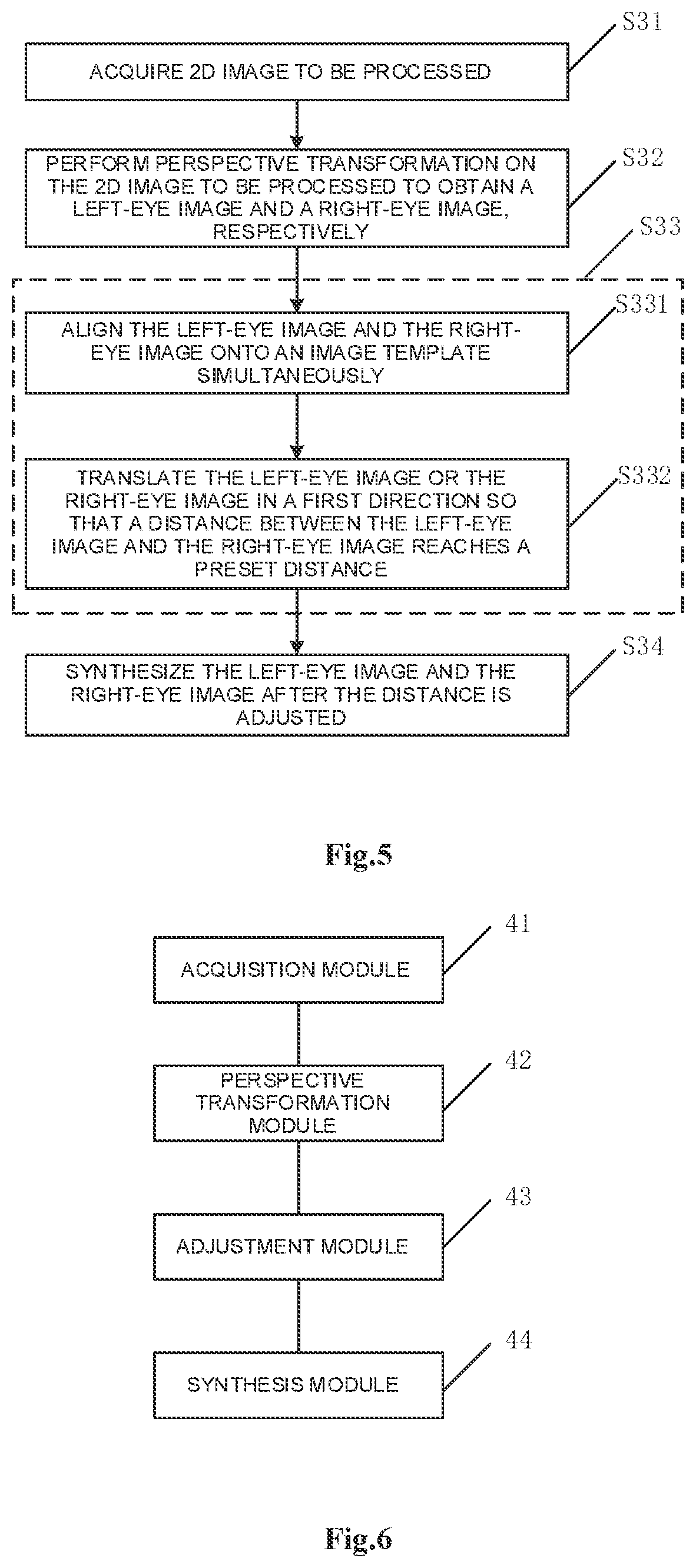

Method and Device for Converting 2D Image into 3D Image and 3D Imaging System

ActiveUS20210127107A1Lower the volumeIncrease the scope of applicationTelevision system detailsGeometric image transformation3d imageImaging quality

The present disclosure discloses a method and a device for converting two-dimensional (2D) images into three-dimensional (3D) images and a 3D imaging system, wherein the method comprises the following steps: acquiring 2D image to be processed; performing perspective transformation on the 2D image to obtain a left-eye image and a right-eye image respectively; adjusting a distance between the left-eye image and the right-eye image according to the result of perspective transformation; and synthesizing the left-eye image and the right-eye image after the distance adjustment. In embodiments of the present disclosure, binocular parallax images are created by performing perspective transformation on the 2D image to be processed; the distance between the left-eye image and the right-eye image after perspective transformation is adjusted to form binocular parallax and create a convergence angle, so that the images observed by naked eyes are located at different depths, thus different stereoscopic effects may be seen. The image transformation is performed on the 2D image without involving the resolution and definition of the image, so that the image quality of the 3D imaged image is the same as that of the original 2D image and the 3D imaging effect is not affected.

Owner:STSIVITA MEDIKAL TECH KO LTD

Inflation Pump

An inflation pump including a body having a cylinder and a head integrally formed with the cylinder. The cylinder includes a pressurizing space. The head includes a through-hole extending along a longitudinal axis. An intercommunication passage is disposed between and intercommunicates with the through-hole and the pressurizing space. A pressurizing unit is slidably received in the pressurizing space and is reciprocally slidable relative to the body. A nozzle unit includes a pressing device disposed in the through-hole. The pressing device includes a push seat having a check ring. The check ring includes an inner side abutting against the push seat and an outer side abutting against a portion of an inner periphery of the through-hole. The portion of the inner periphery of the through-hole is located between the intercommunication passage and the coupling end. The check ring permits air to flow only from the intercommunication passage towards the coupling end.

Owner:WU SCOTT

Medical valve with a variable diameter seal

ActiveUS20180256876A1Improve performanceImprove reliabilitySurgeryEndoscopesCompression memberFlange

A medical valve assembly includes a tube extending between a first and second tube end along an axis, and a plunger plate extends radially from the second tube end. A valve housing surrounds the tube and includes a radially inwardly extending flange. A compression member is biased against the plunger plate and compresses an elastomeric seal from a non-compressed condition to a compressed condition to establish a sealed condition of the medical valve assembly. An inner surface of the elastomeric seal in the non-compressed condition has a plurality of planar portions and a plurality of radiused portions, with adjacent planar portions interconnected with one of the radiused portions to improve a closure of the elastomeric seal during compression. The inner surface preferably includes three planar portions and three radiused portions to define a generally triangular-shaped inner surface as viewed in cross section in the non-compressed condition.

Owner:FREUDENBERG MEDICAL

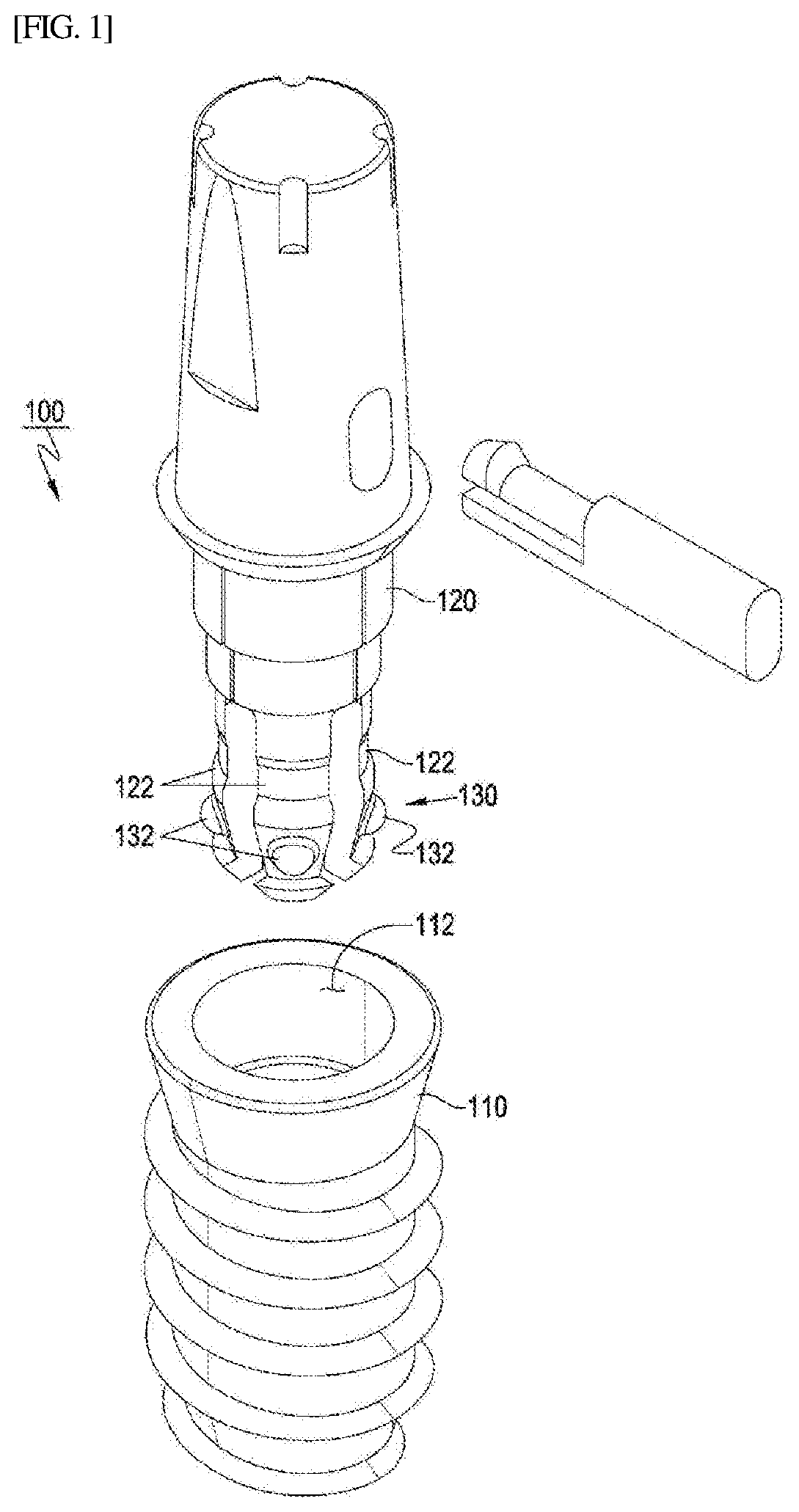

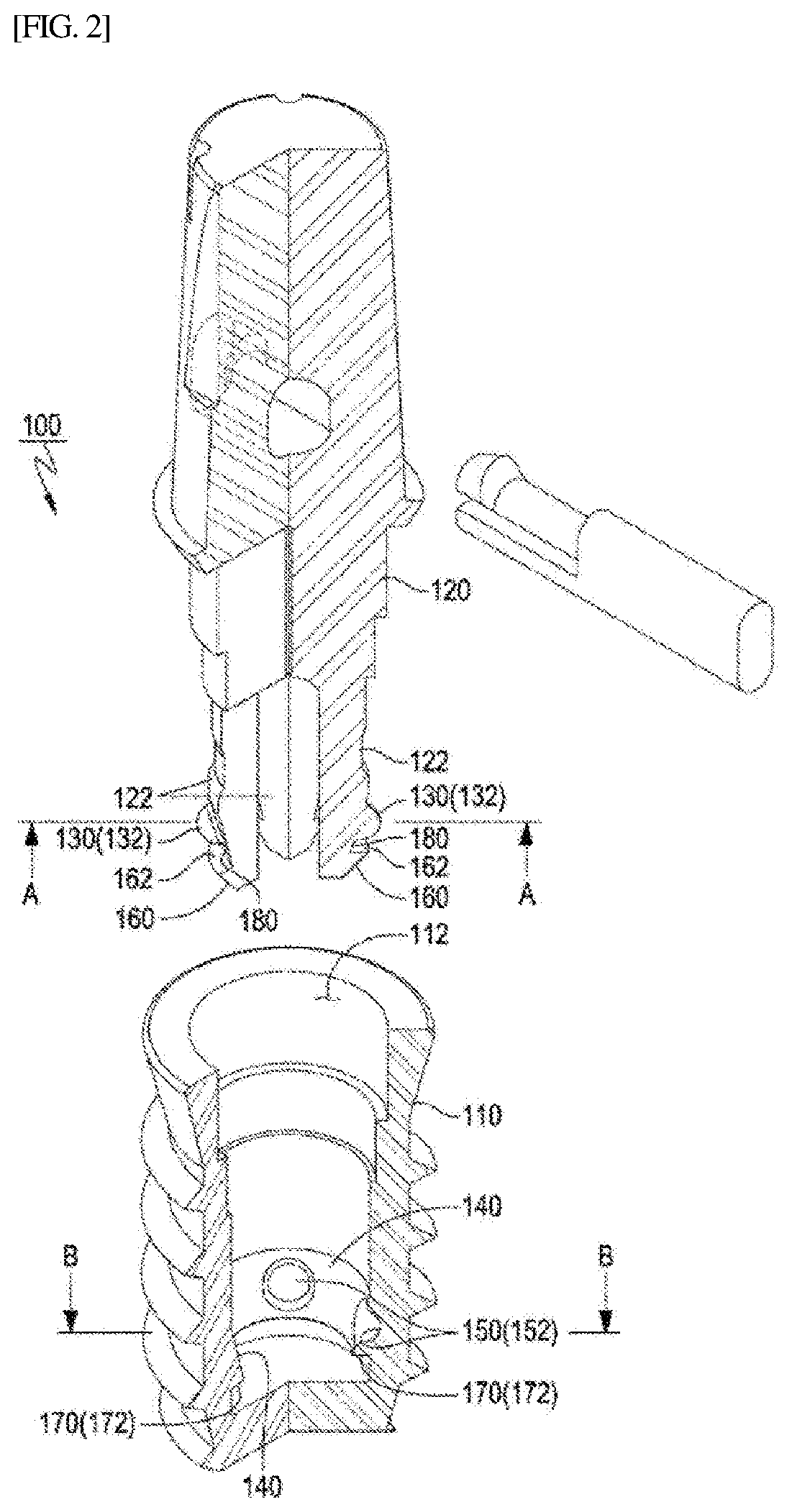

Dental implants

InactiveUS20200315749A1Easy to separateLow inner diameter requirementDental implantsDentistryMechanical engineering

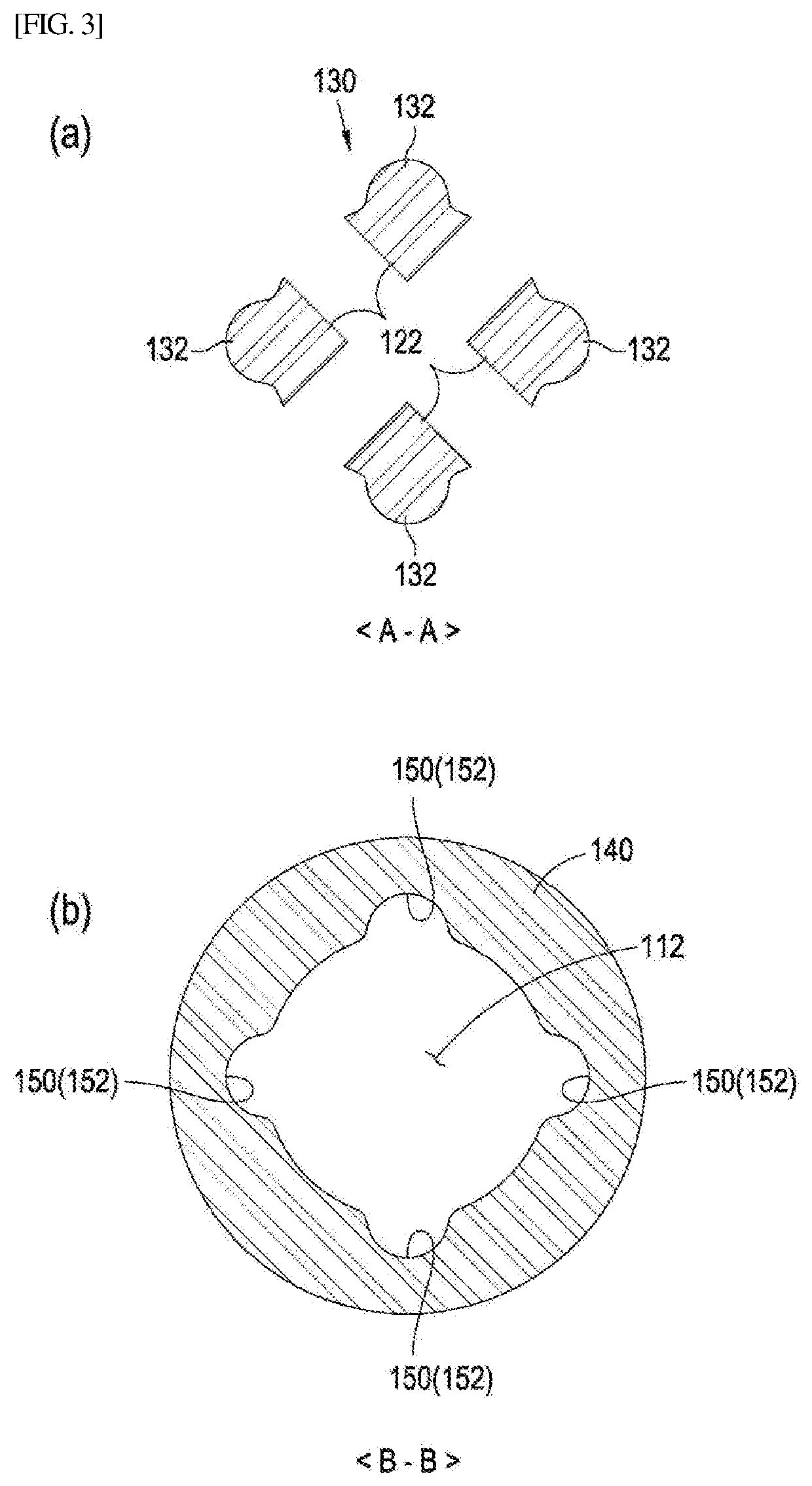

The present invention provides a dental implant comprising: a first coupling part 150 is provided on an inner surface of the axial hole of the fixture, the first coupling part comprising a coupling recess depressed outward, in a predetermined location on the inner surface of the axial hole, and a first corresponding coupling part provided on an outer circumferential surface of the coupling leg 122 to be complementarily coupled to the first coupling part 150, the first corresponding coupling part comprising a coupling protrusion, wherein, in a state in which the abutment is fitted into the fixture by complementary coupling between the first coupling part and the first corresponding coupling part; when a rotation force applied to the abutment has less than a predetermined level, the abutment is prevented from rotating relative to the fixture in a circumferential direction, and when the rotation force applied to the abutment is equal to or greater than the predetermined level, the coupling leg of the abutment is elastically bendable radially inwardly toward a central axis and the abutment is rotated in the circumferential direction, allowing the coupling protrusion of the first corresponding coupling part to be released from the coupling recess of the first coupling part, so that the fixture and the abutment are decoupled from each other.

Owner:LIEBHERR VERZAHNTECHNIK GMBH

Exhaust throttling tooling for oil filling pipe assembly

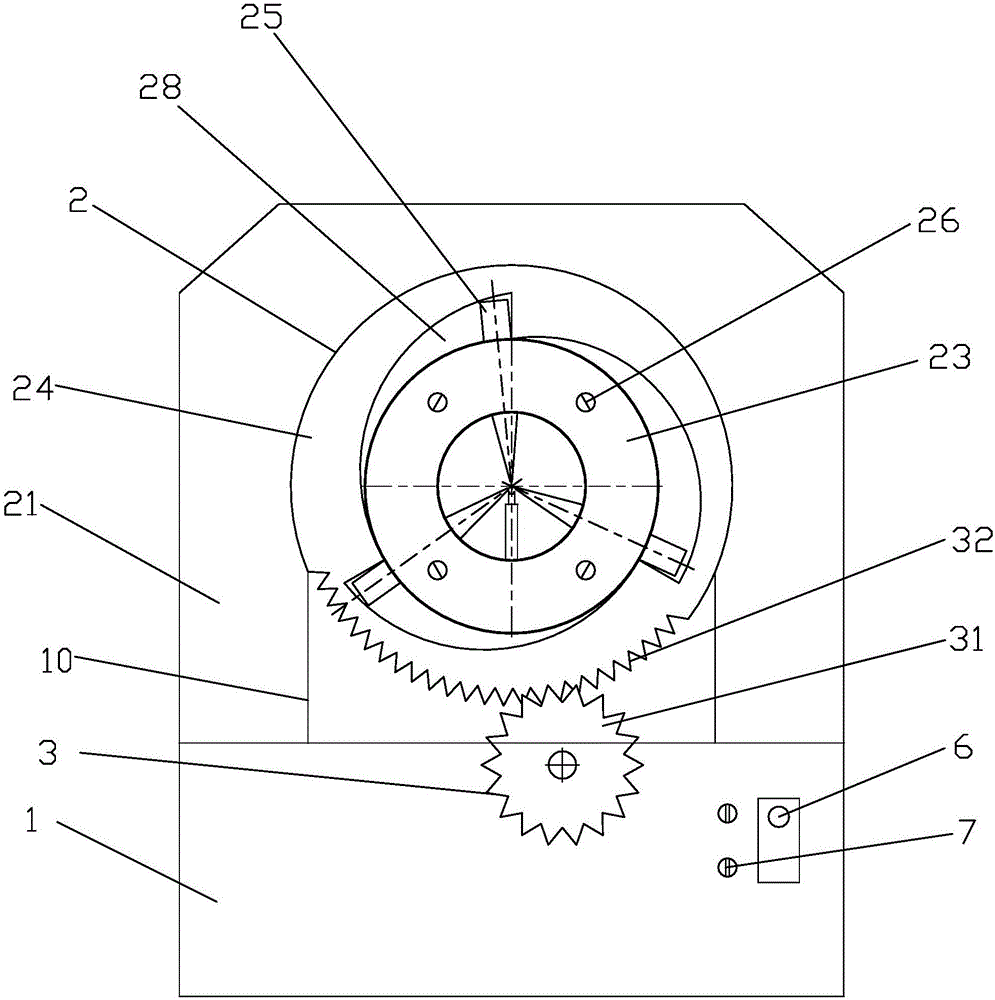

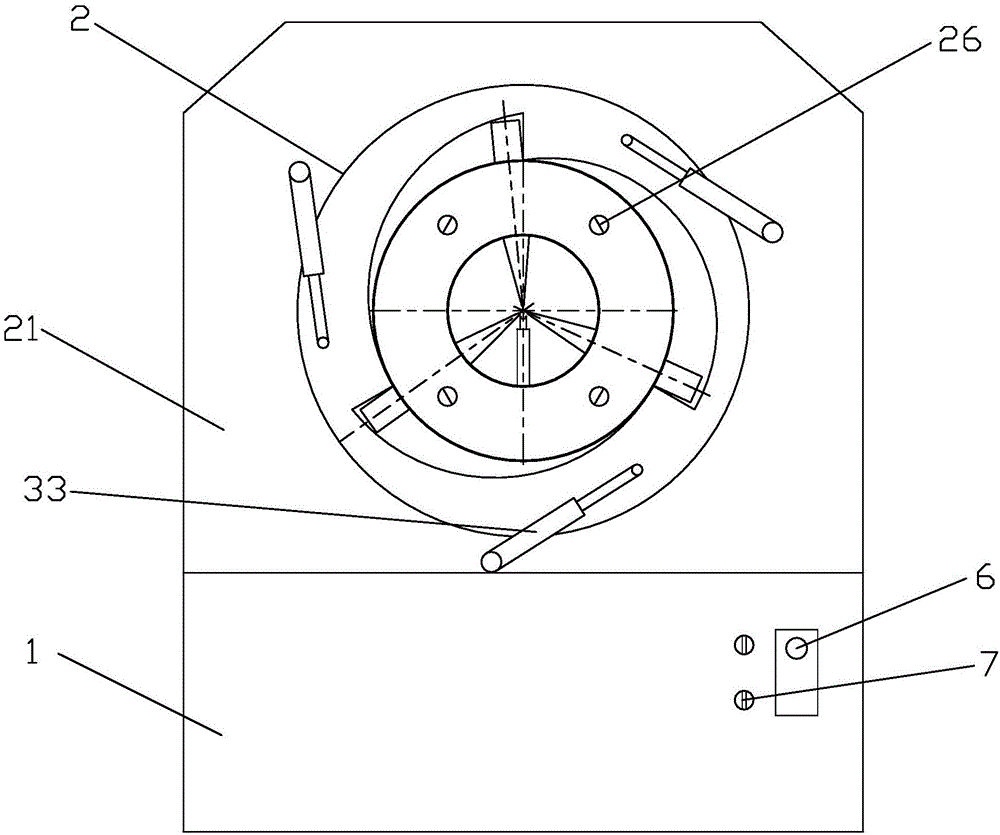

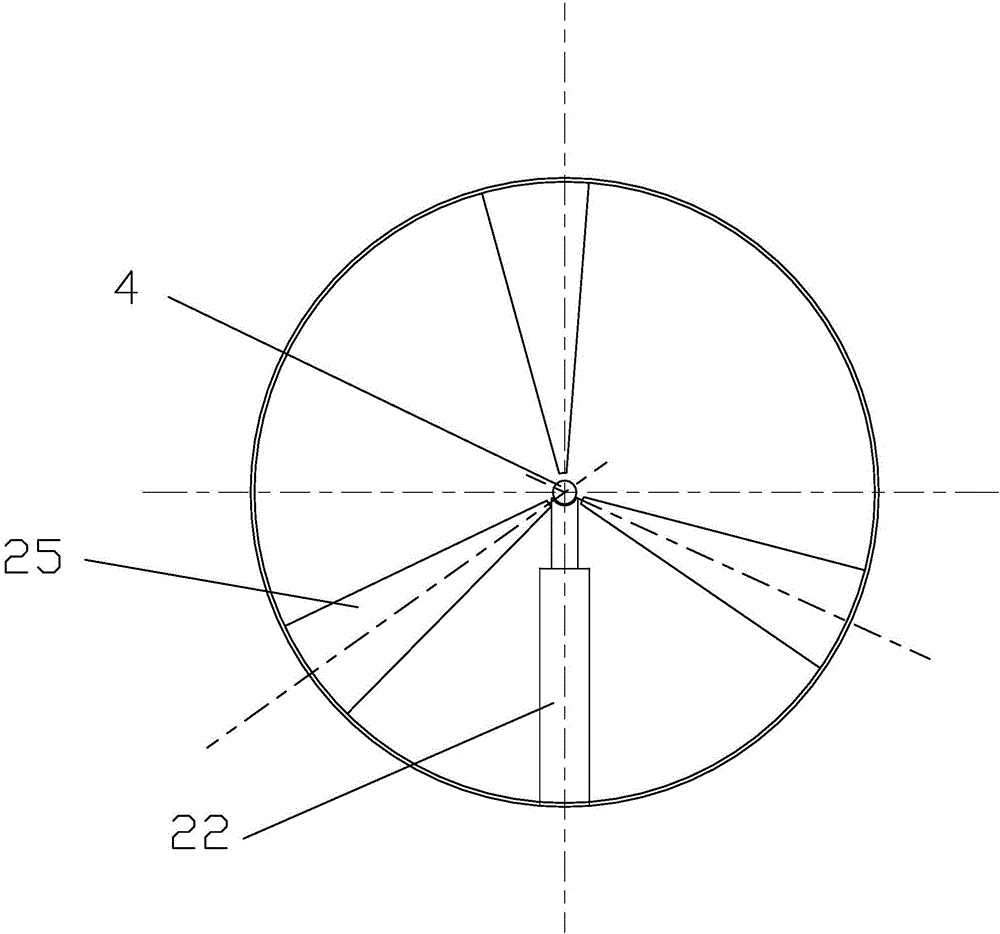

The invention discloses an exhaust throttling tooling for an oil filling pipe assembly, and provides the exhaust throttling tooling for the oil filling pipe assembly, which is simple in structure, facilitates the control over the inner diameter of an exhaust pipe and is enabled to reach reliable discharge standards. The exhaust throttling tooling comprises a machine body, a clamp component and a driving component; the clamp component is arranged on the machine body and comprises a vertical plate, a supporting seat, an inner circular sleeve, an outer circular sleeve and at least two thimbles; the outer circular sleeve is movably arranged in a circular groove through the driving component; the inner circular sleeve is fixedly arranged in the circular groove; penetrating holes which are in one-to-one correspondence to the thimbles are formed in the inner circular sleeve; arc slideways which are in one-to-one correspondence to the thimbles are arranged in sleeve holes of the outer circular sleeve; at least two thimbles are uniformly distributed on the inner circular sleeve; and one end of each thimble is positioned in a through hole, and the other end of each thimble is positioned in the corresponding slideway, so that when the outer circular sleeve rotates, the thimbles slide in the corresponding penetration holes. According to the exhaust throttling tooling disclosed by the invention, in the process of filling fuel oil into an oil tank, steam exhausted by an exhaust pipe of the oil filling pipe assembly is controlled, so that the pollution to the environment is reduced.

Owner:YANGZHOU LIANGCHENG AUTO PARTS

Liquid delivery pump

ActiveUS20160369793A1Avoid deformationIncrease supplyPositive displacement pump componentsPiston pumpsPump chamberEngineering

A plunger seal is mounted on the pump head, has a through hole for allowing penetration of the plunger, and holds the outer circumferential surface of the plunger and also seals an opening of the pump chamber A backup ring is mounted on the pump head by being interposed between the plunger seal and the tip end surface of the pump body. The backup ring has a through hole, for allowing penetration of the plunger, formed in a manner not allowing the plunger seal to enter a gap to the outer circumferential surface of the plunger, and also has a liquid passage element for allowing the cleaning liquid in the cleaning space to reach the plunger seal through the through hole.

Owner:SHIMADZU CORP

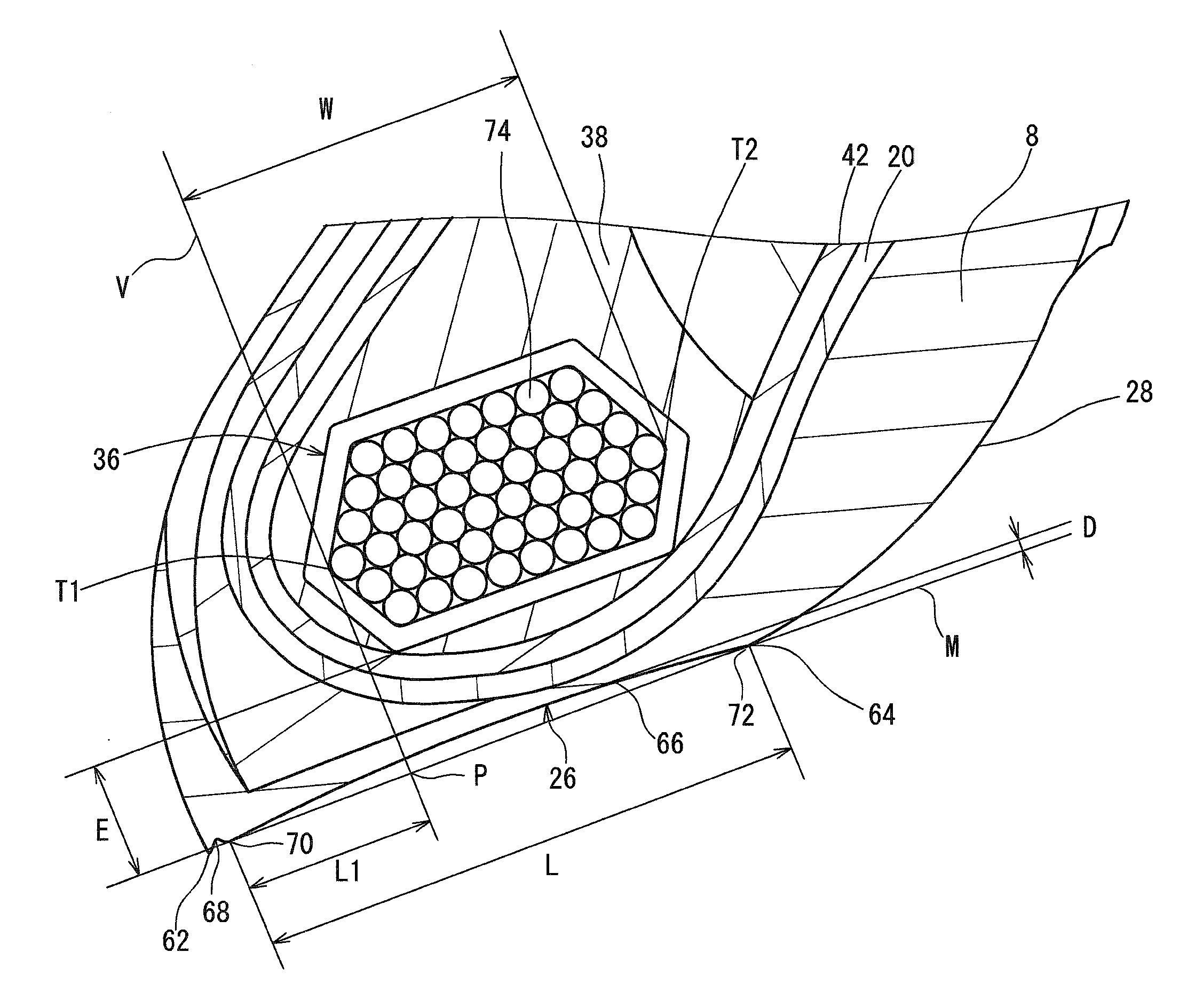

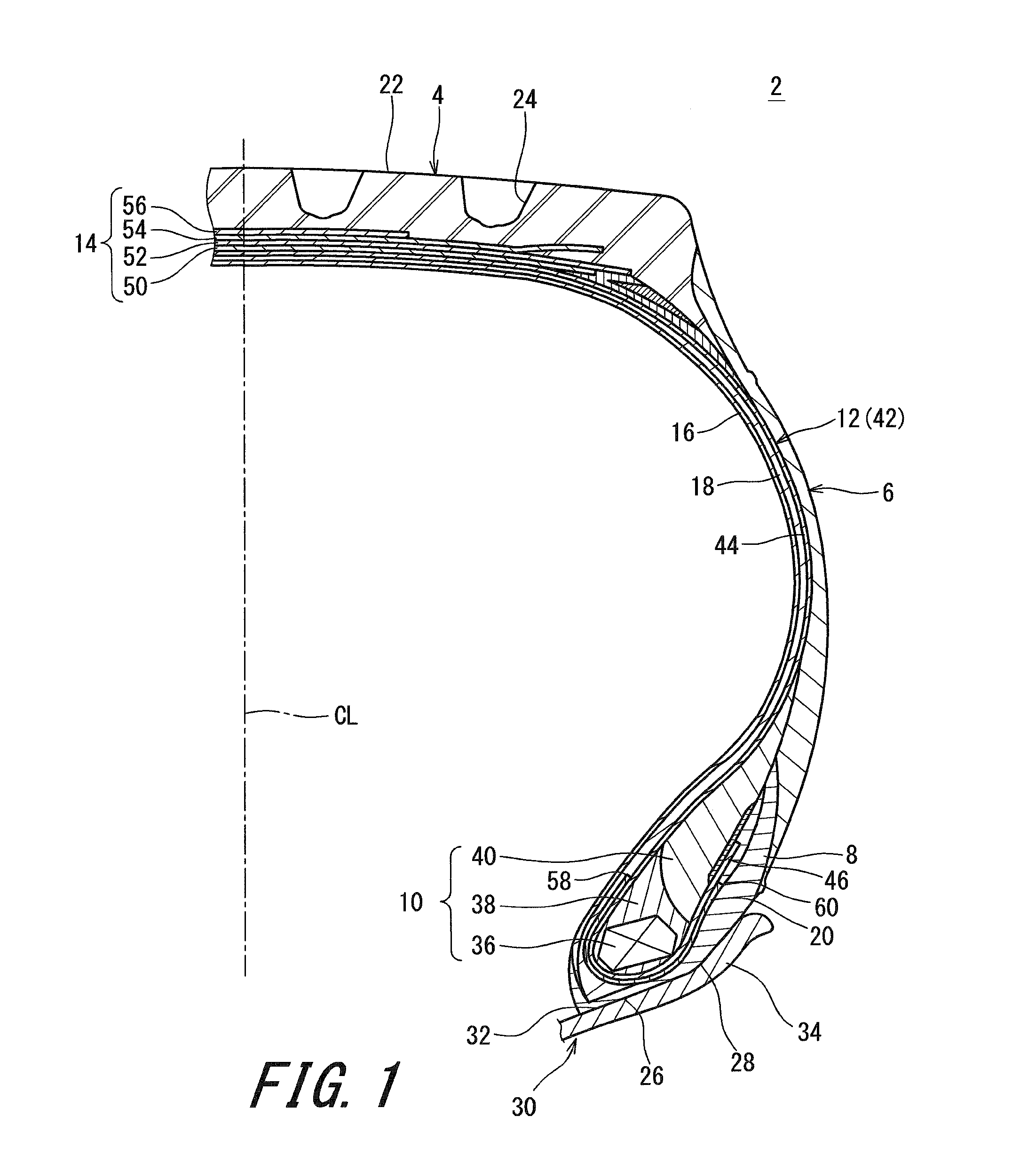

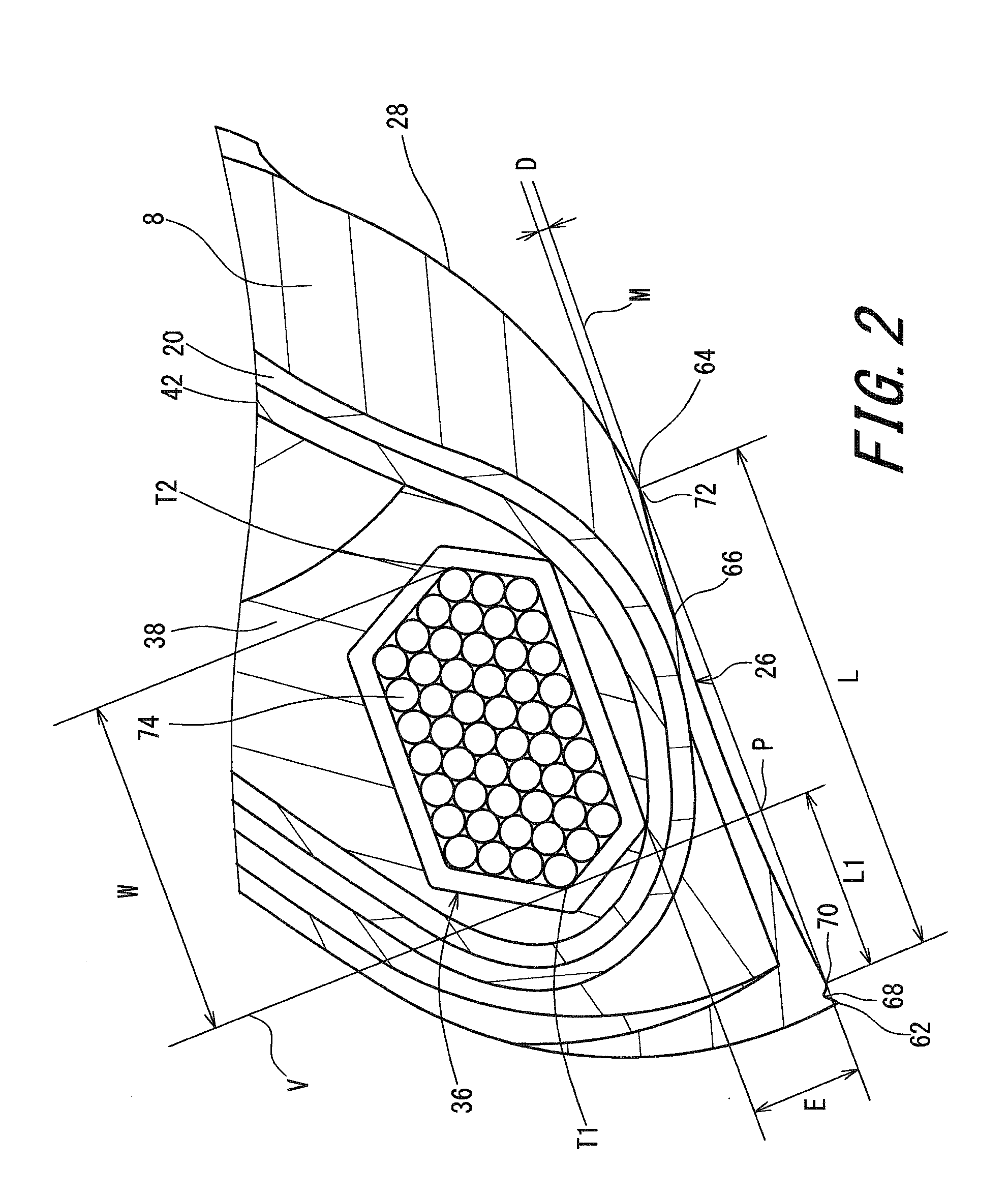

Pneumatic tire

InactiveUS20170043628A1Wave is obstructedIncreasing the thicknessHeavy duty tyresHeavy duty vehicleMechanical engineeringComposite material

A tire 2 of the present invention includes a pair of fillers 20 turned up around beads 10. Each filler 20 has multiple cords made of steel and aligned with each other. In the tire 2, an outer surface of a chafer 8 has a bottom surface 26 that contacts with a seat surface of a rim 30. When a reference line M represents a straight line that contacts with the bottom surface 26 in a cross-section obtained by cutting the tire at the plane perpendicular to the circumferential direction, the bottom surface 26 has a depression 66 that is shaped so as to project radially outward of the reference line M. A ratio (D / L) of a maximum depth D of the depression 66 to a width L of the depression 66 is greater than or equal to 0.007 and not greater than 0.060.

Owner:SUMITOMO RUBBER IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com