Exhaust throttling tooling for oil filling pipe assembly

A technology of exhaust throttling and oil filling pipe, which is applied in the field of metal oil filling pipe assembly, which can solve the problems such as easy blockage of the inner hole of the exhaust pipe, and achieve the effect of reducing pollution, reducing the inner diameter and less emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

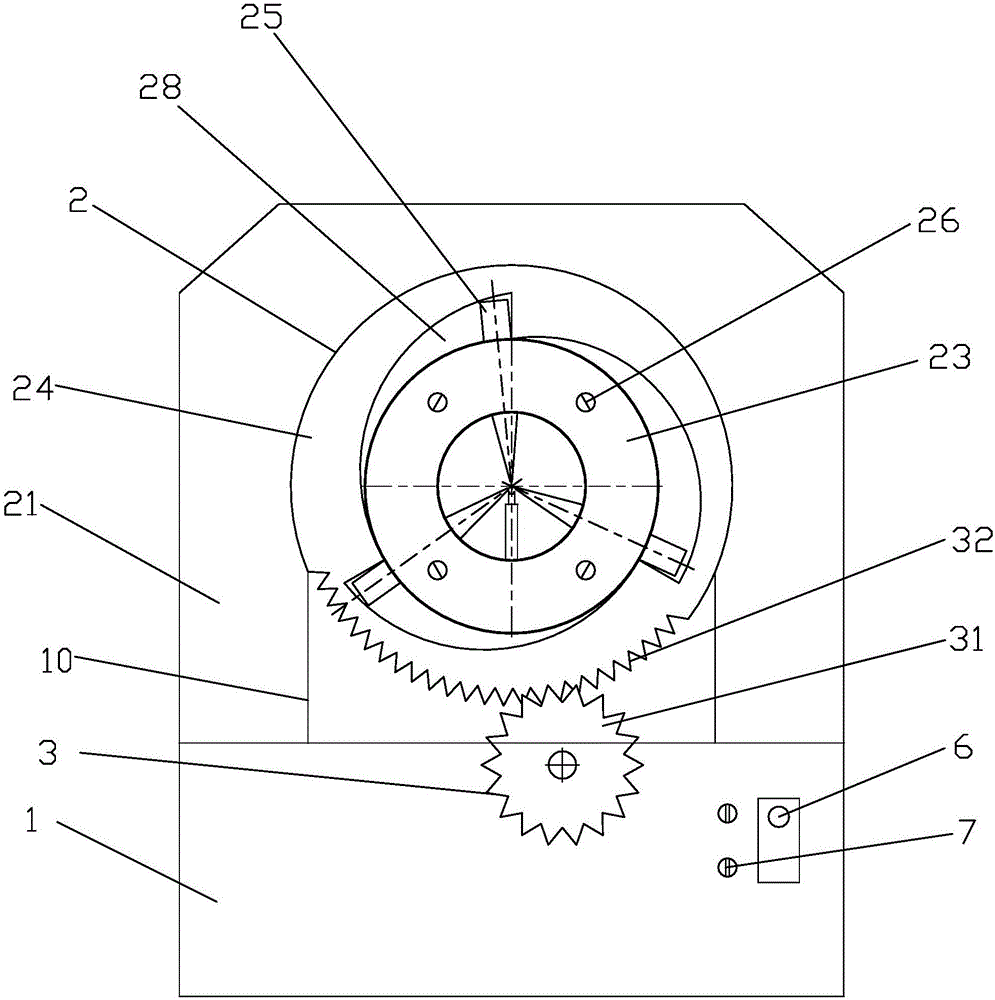

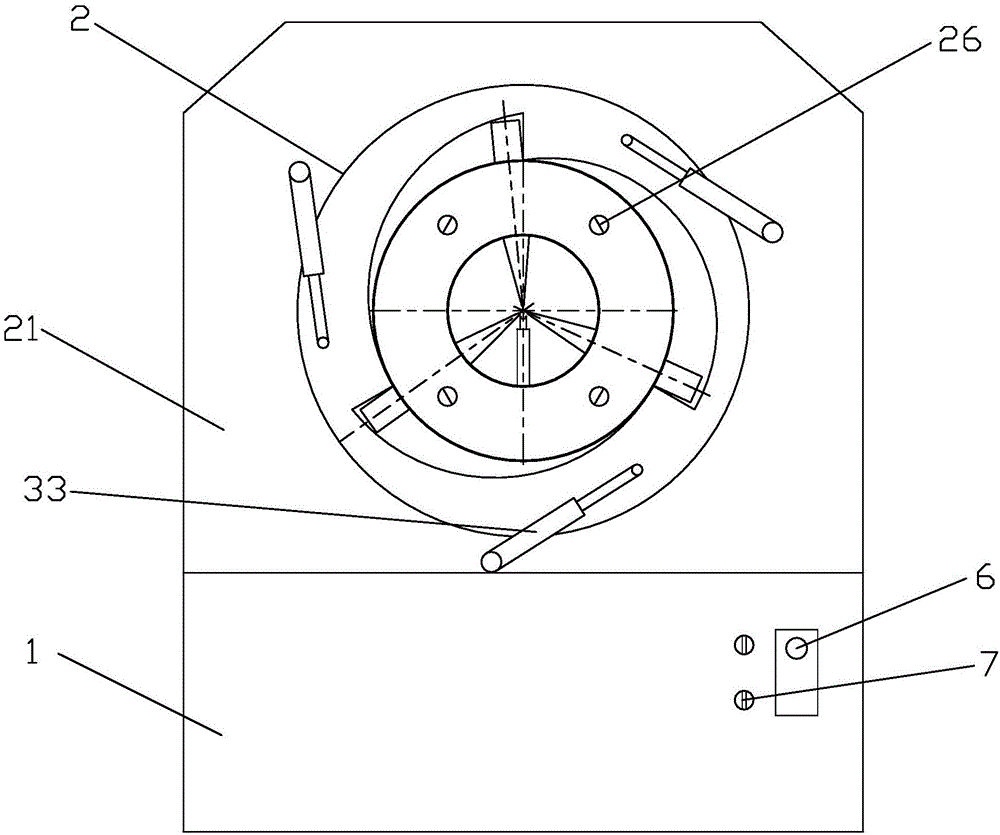

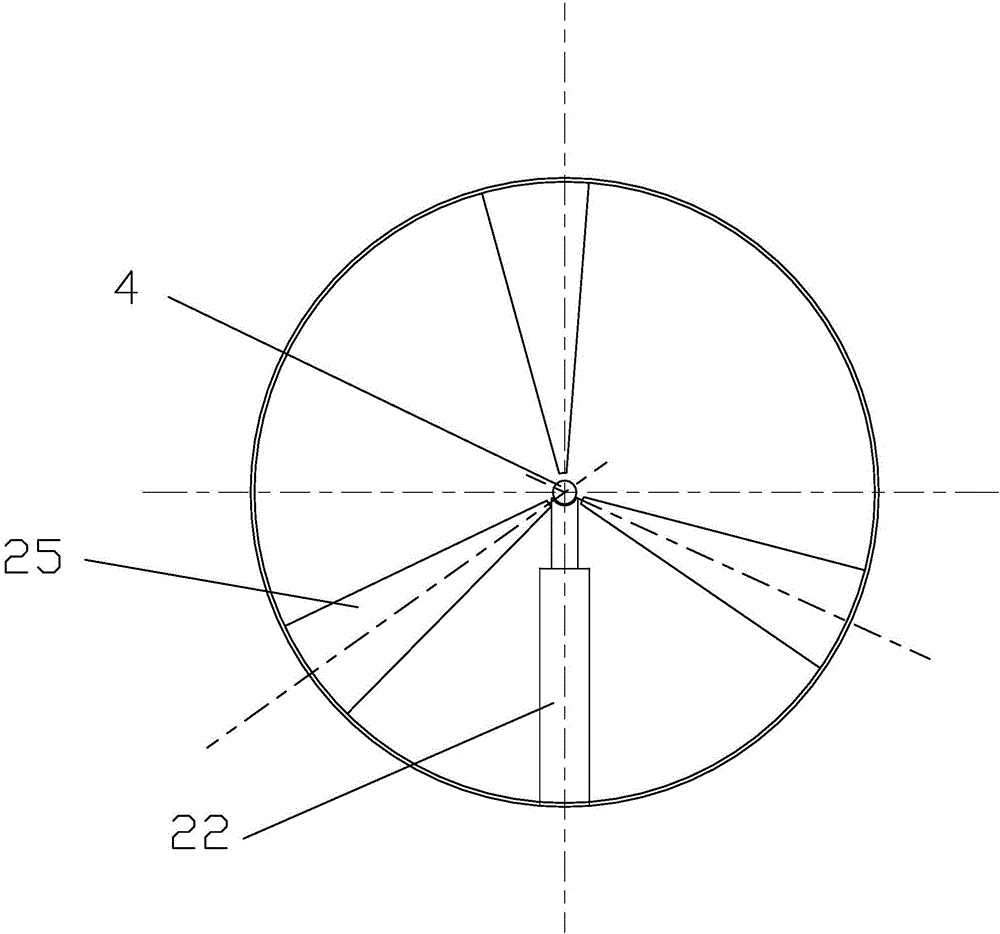

[0033] The present invention as Figure 1-11 As shown, the refueling pipe assembly includes a refueling pipe body and an exhaust pipe 4, one end of the exhaust pipe communicates with the refueling pipe body; , the clamp assembly is arranged on the fuselage, and the clamp assembly includes a vertical plate 21, a support seat 22, an inner sleeve 23, an outer sleeve 24, and at least two thimbles 25 (in applications, it is best to set three, forming Three extrusion points, stable and reliable), the vertical plate 21 has a circular groove 211, the center of the circular groove 211 is provided with a through hole 212, and the support seat is arranged in the through hole for supporting the exhaust pipe 4;

[0034] The outer sleeve 24 is movably arranged in the circular groove 211 through the driving assembly, the inner sleeve 23 is located in the outer sleeve 24, and the sleeve hole of the inner sleeve is concentric with the sleeve hole of the outer sleeve , the inner ring sleeve 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com