Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Large insulation area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

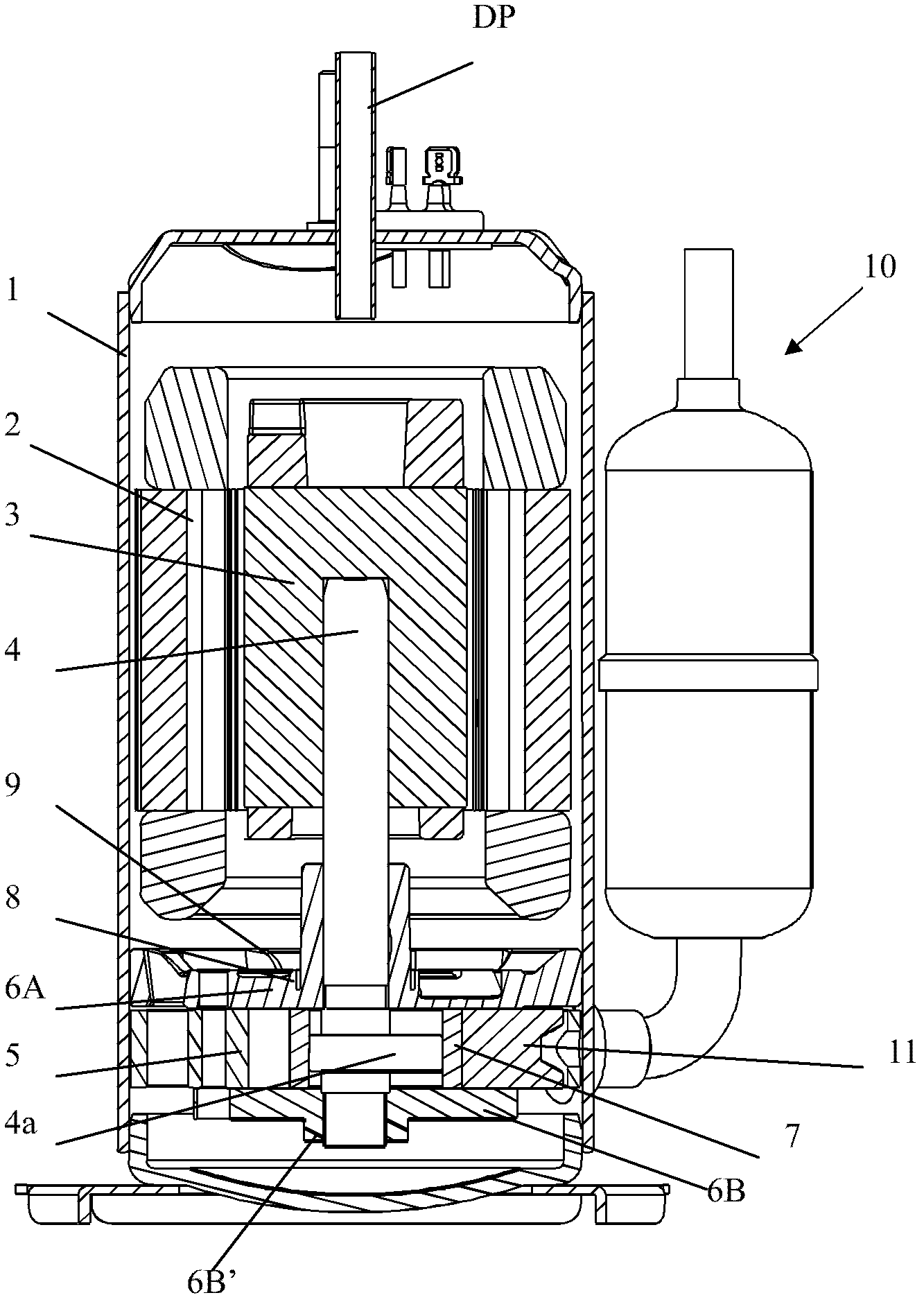

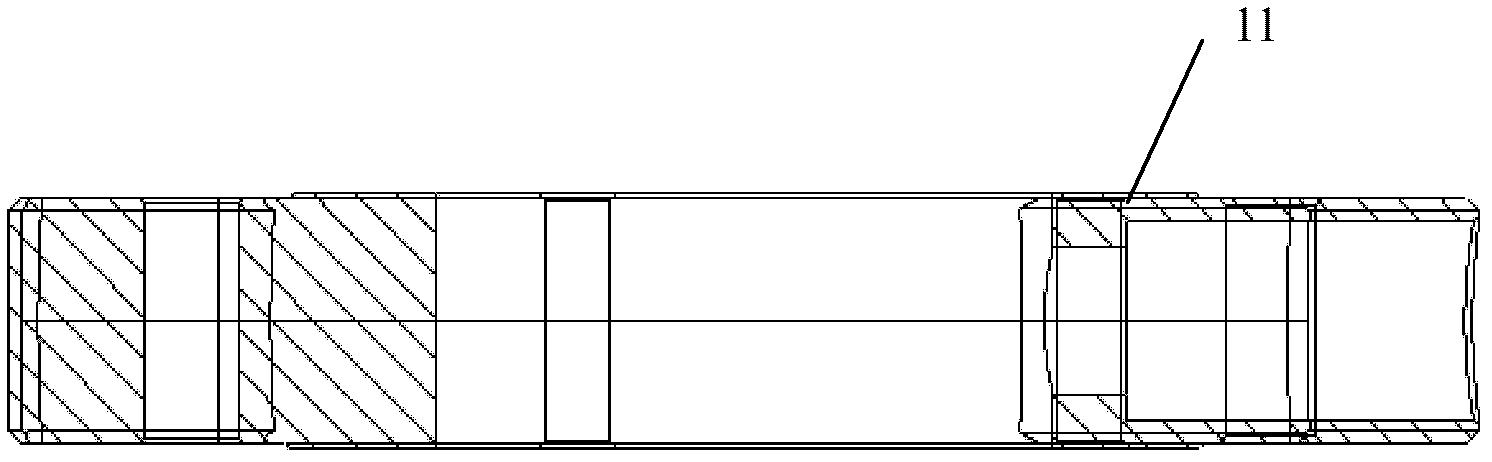

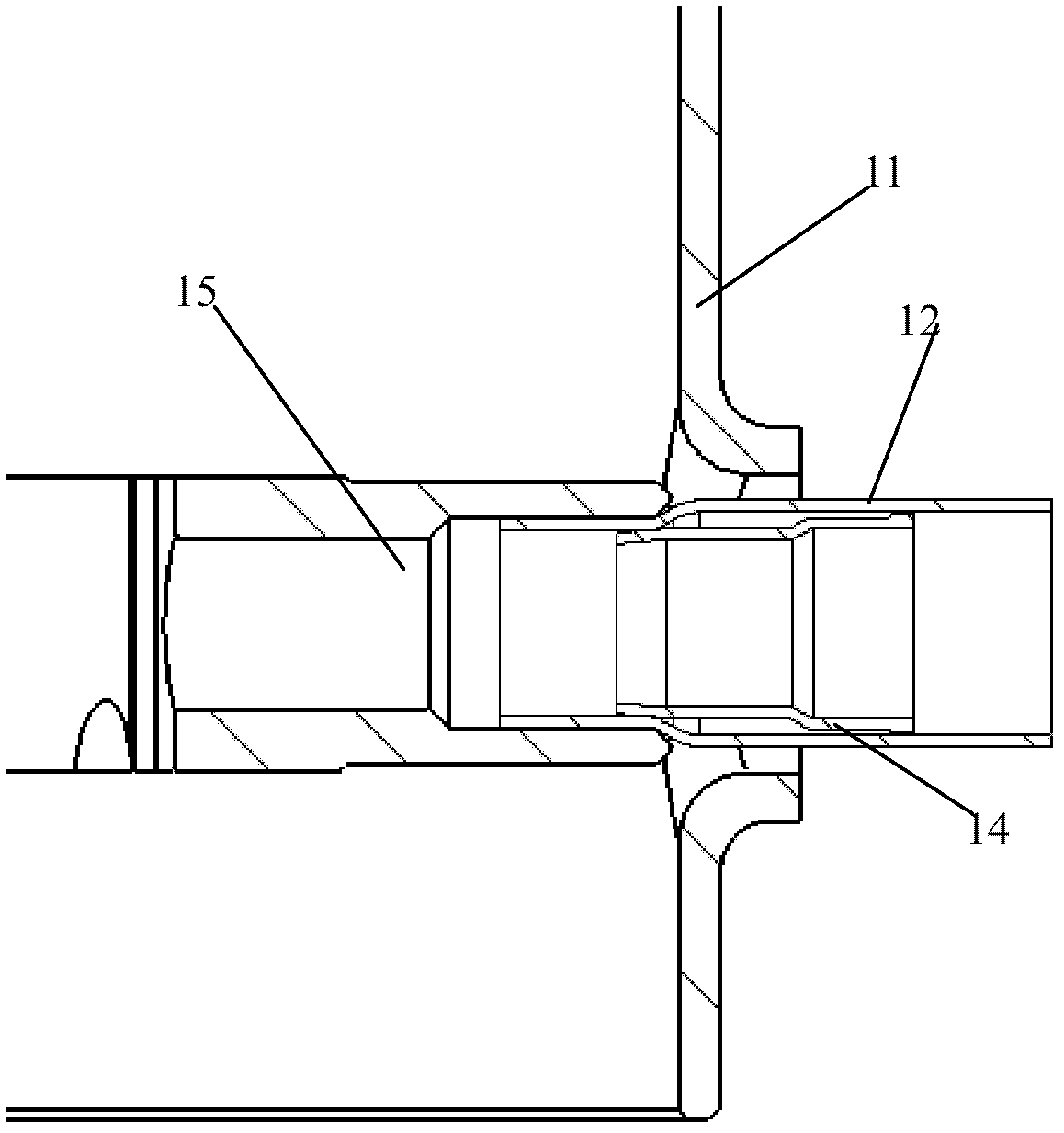

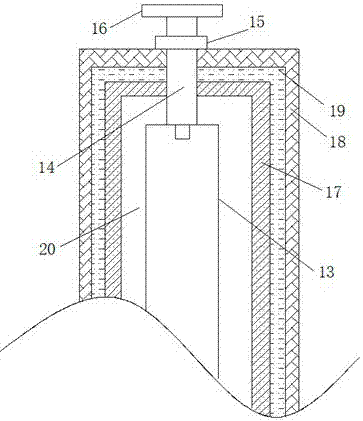

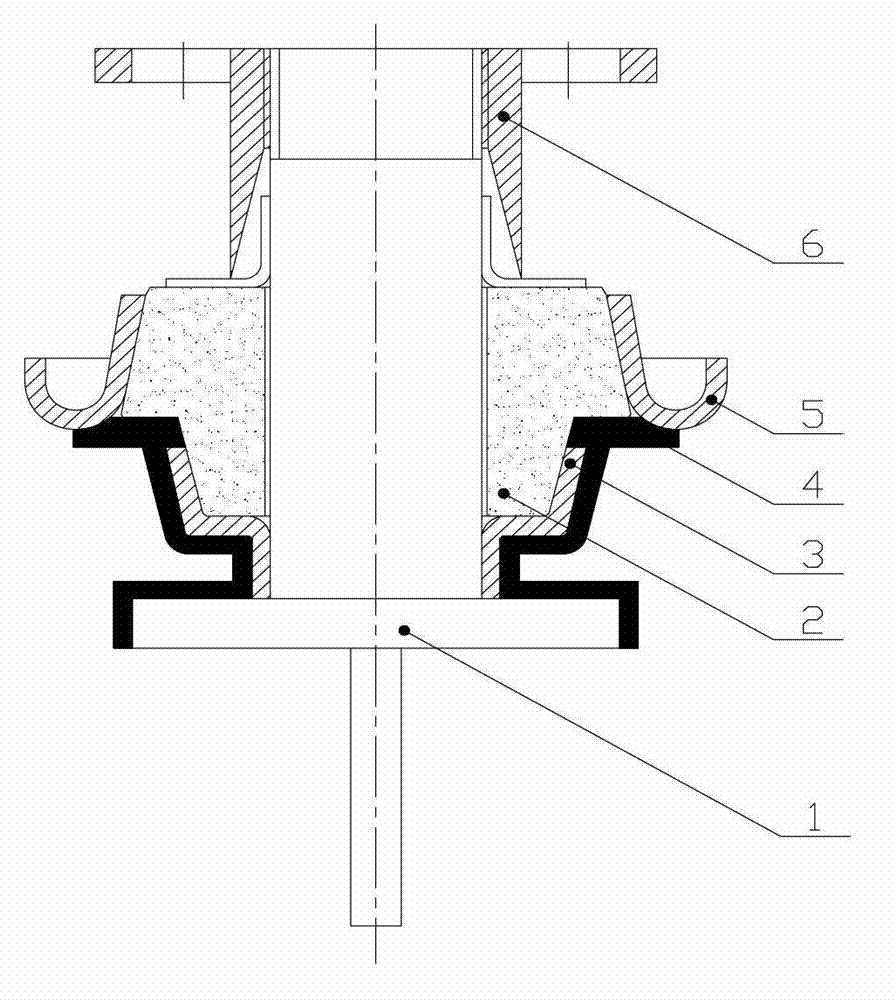

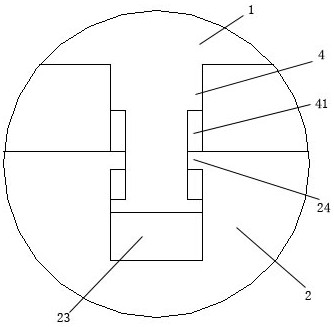

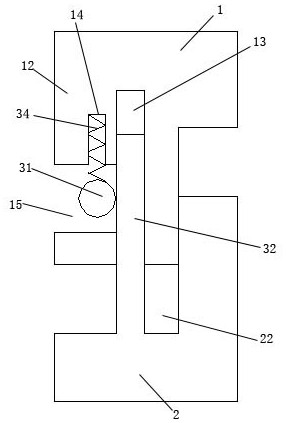

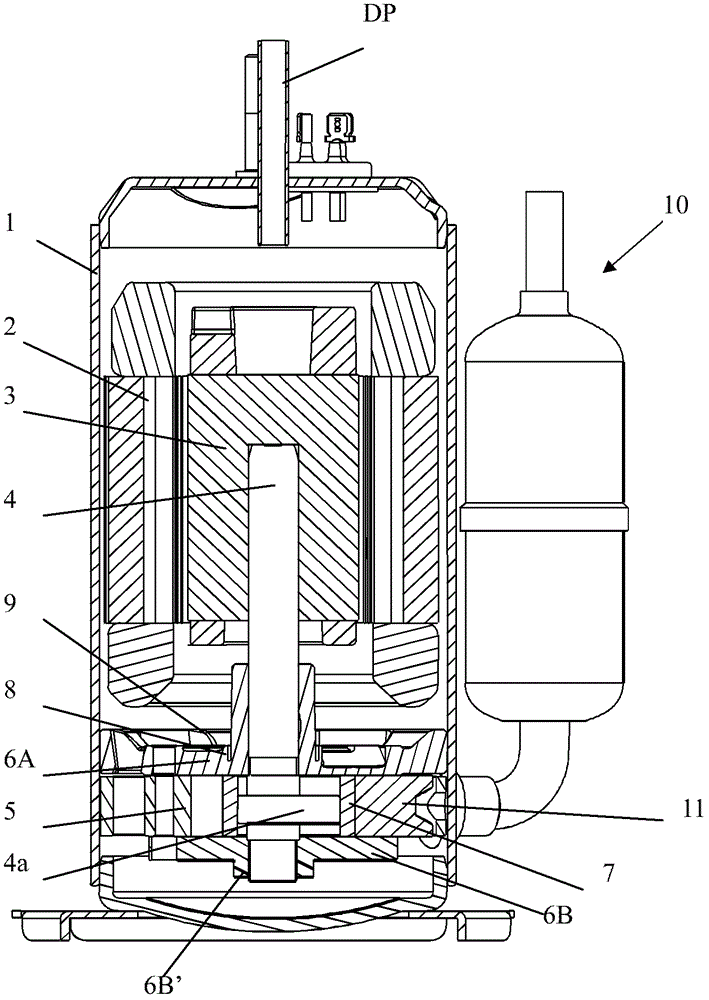

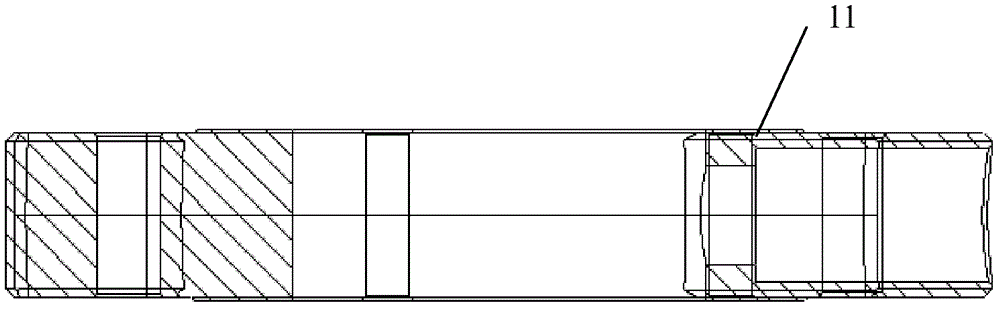

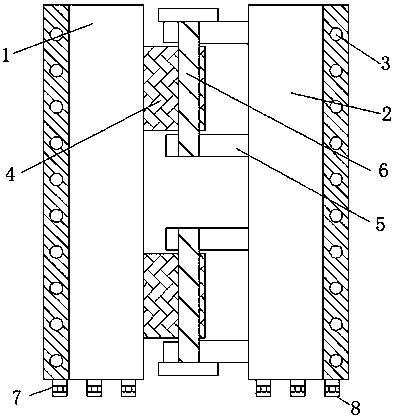

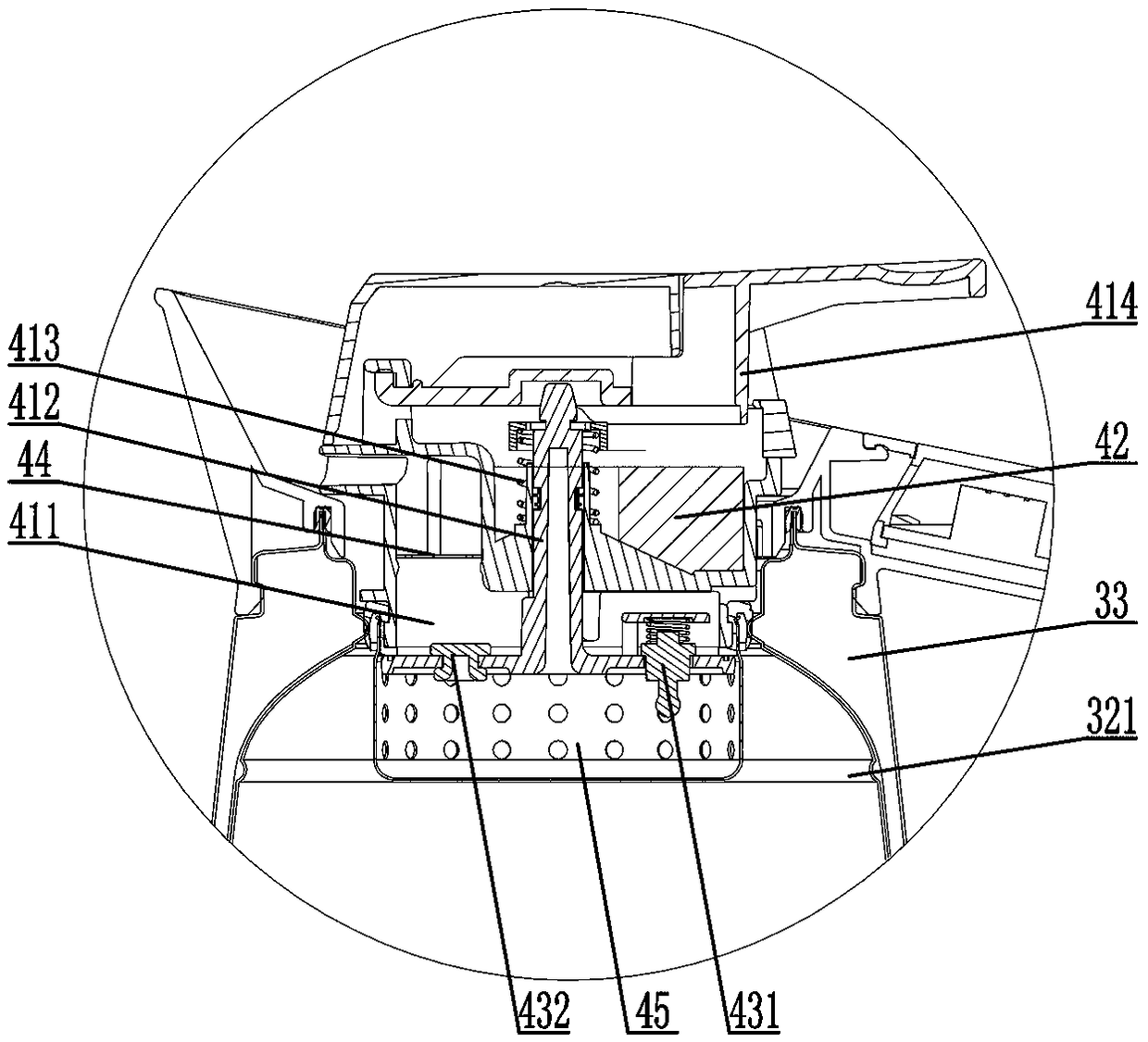

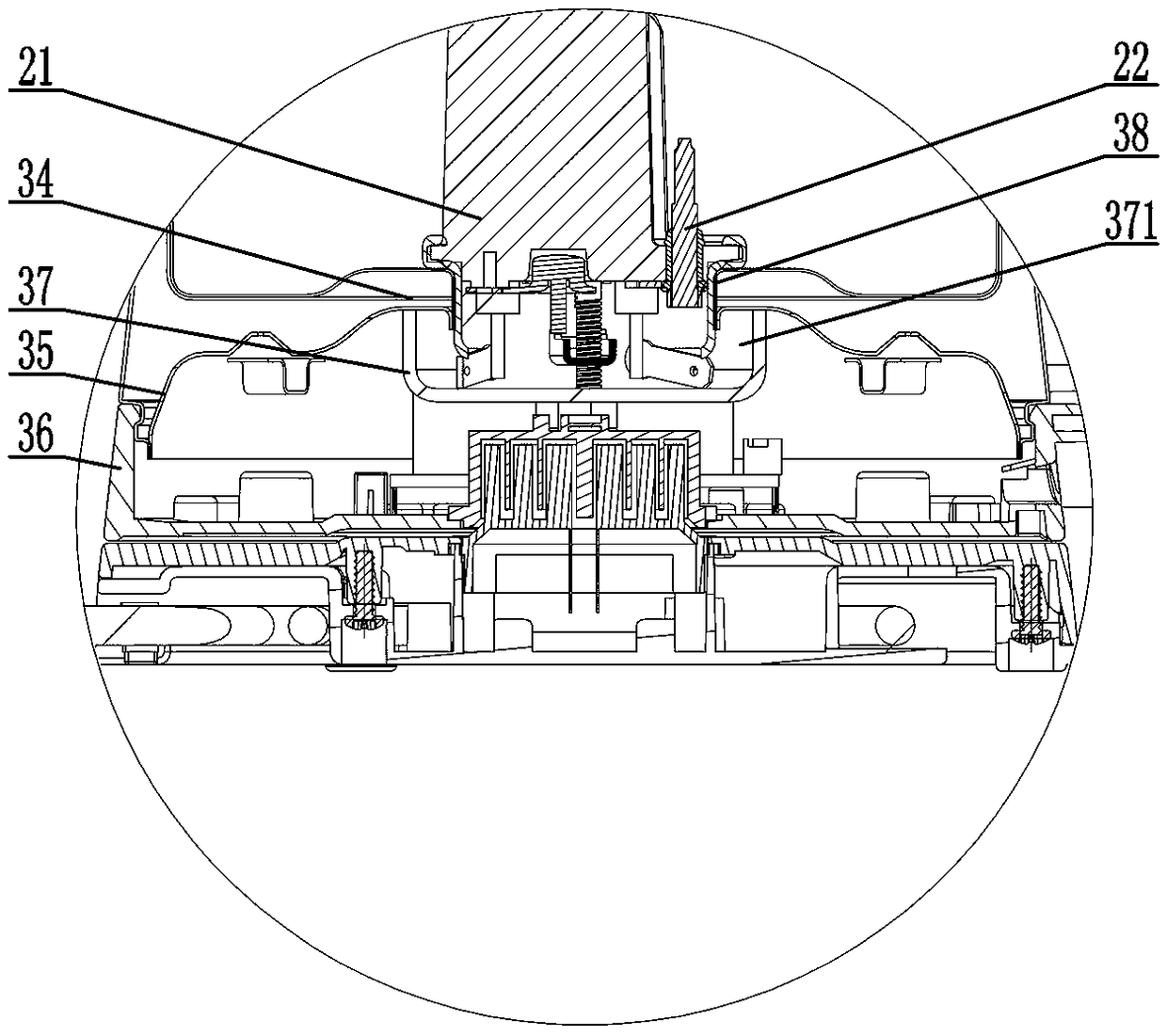

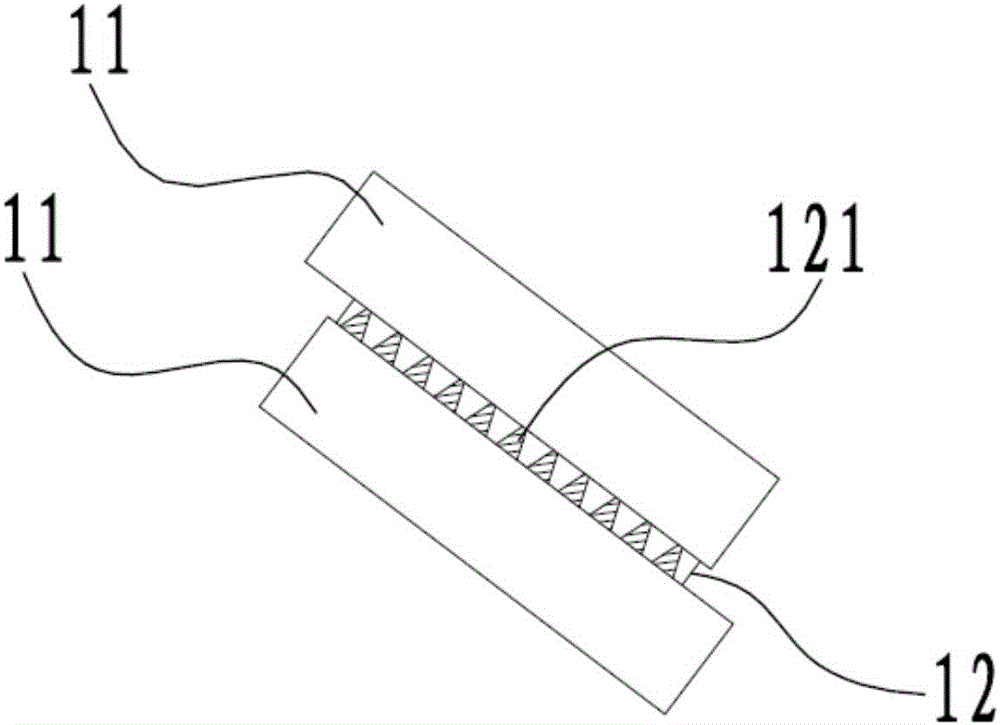

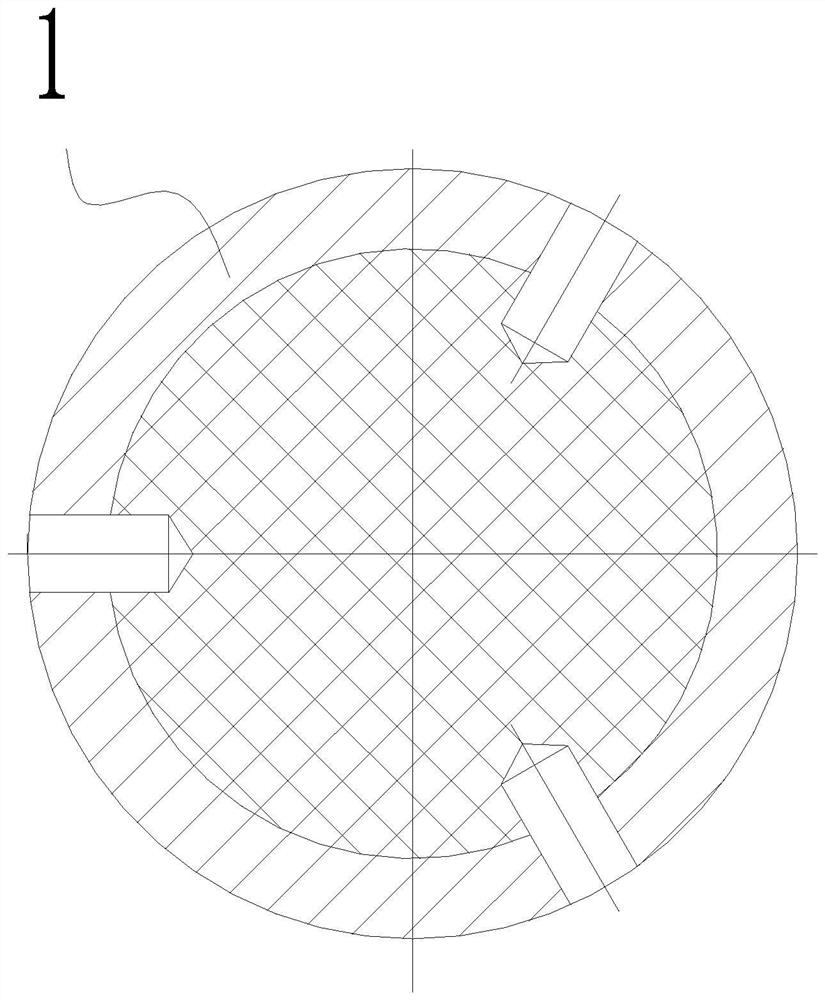

Suction opening structure of compressor

InactiveCN102828956ALimited axial freedomReduce adverse effectsRotary/oscillating piston pump componentsLiquid fuel engine componentsLiquid storage tankEngineering

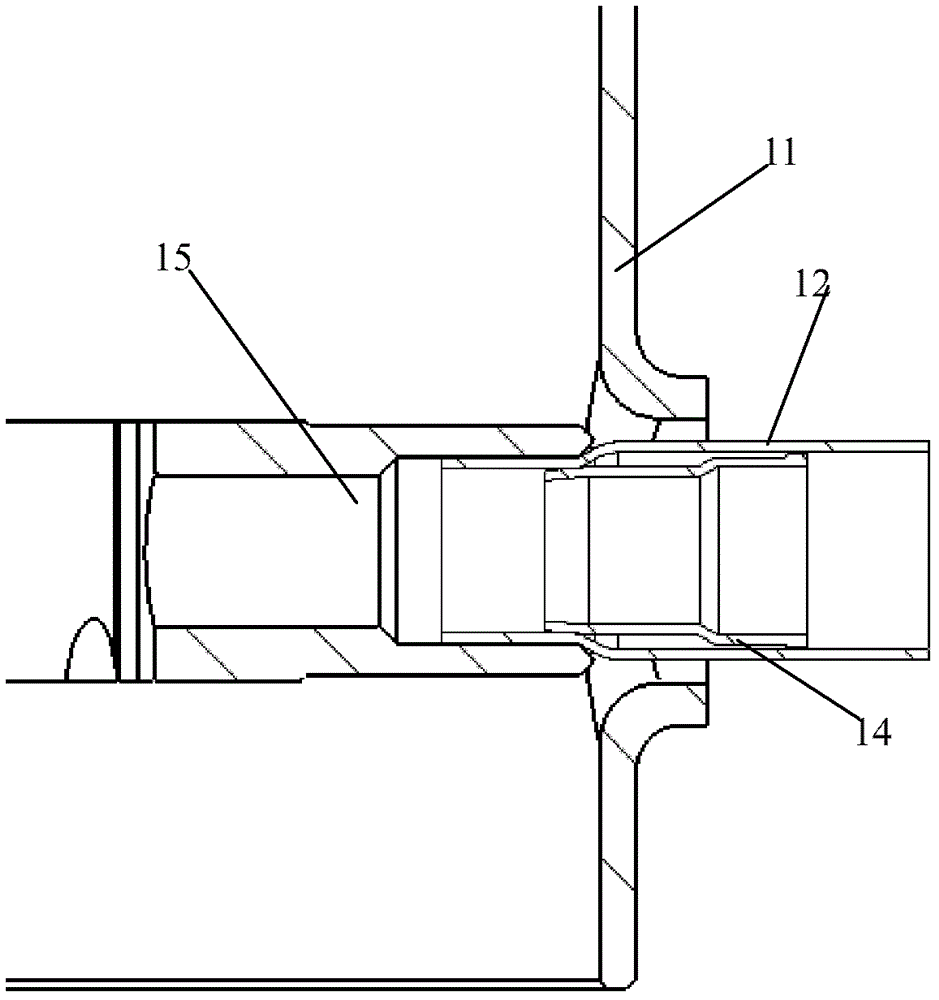

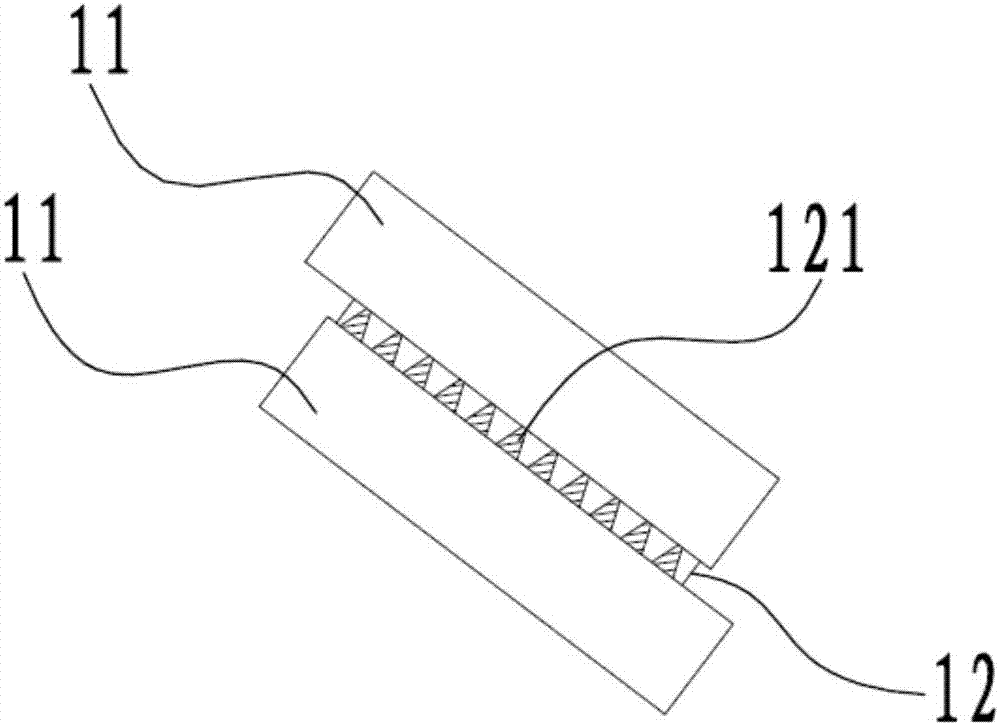

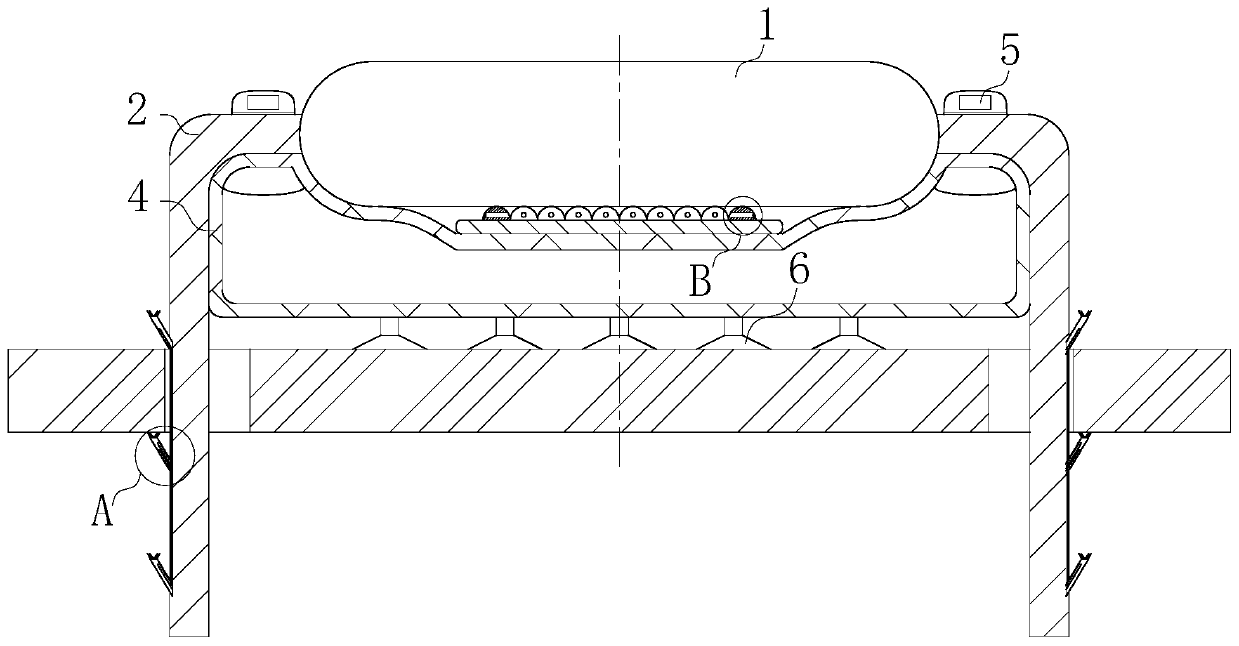

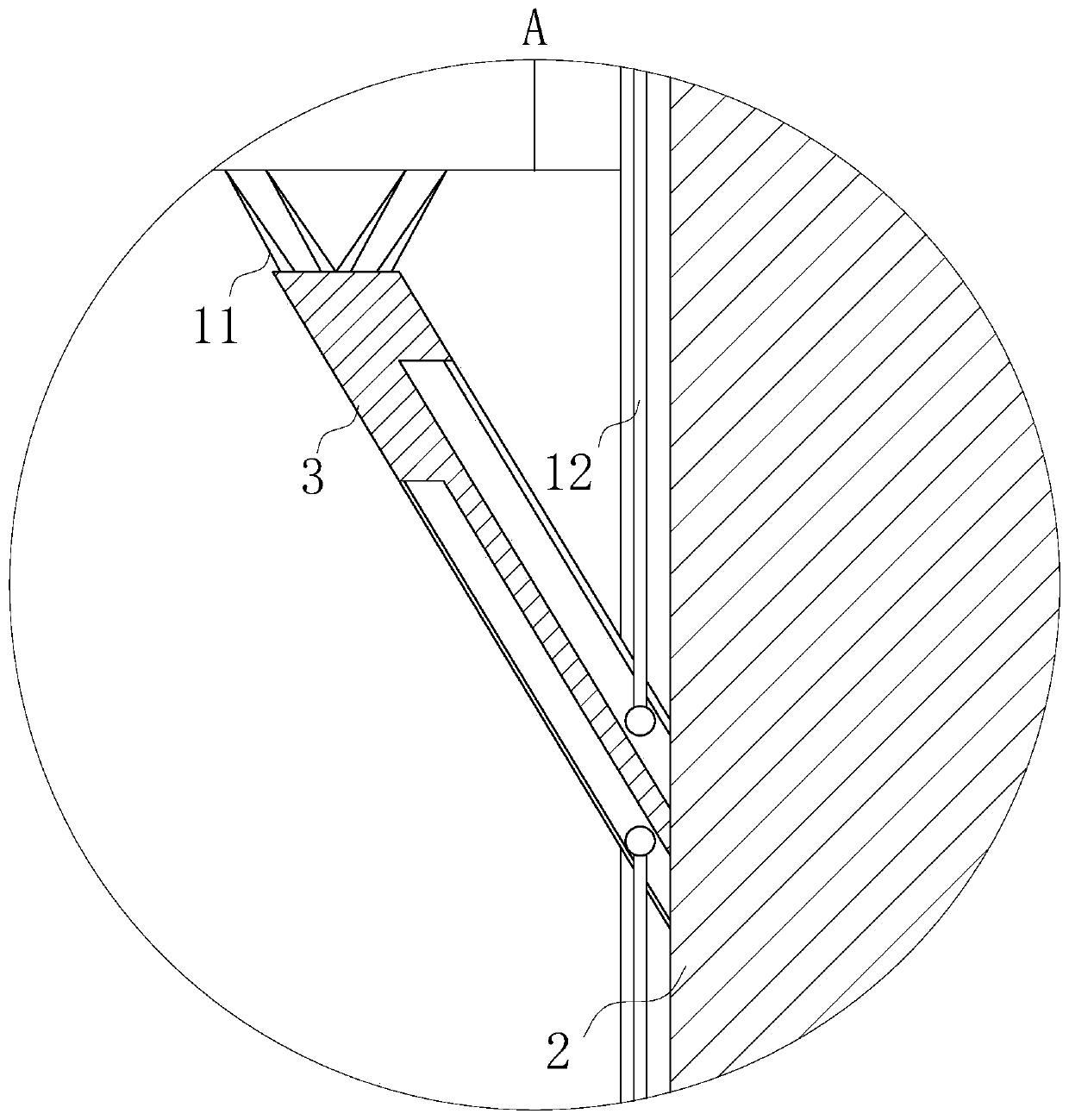

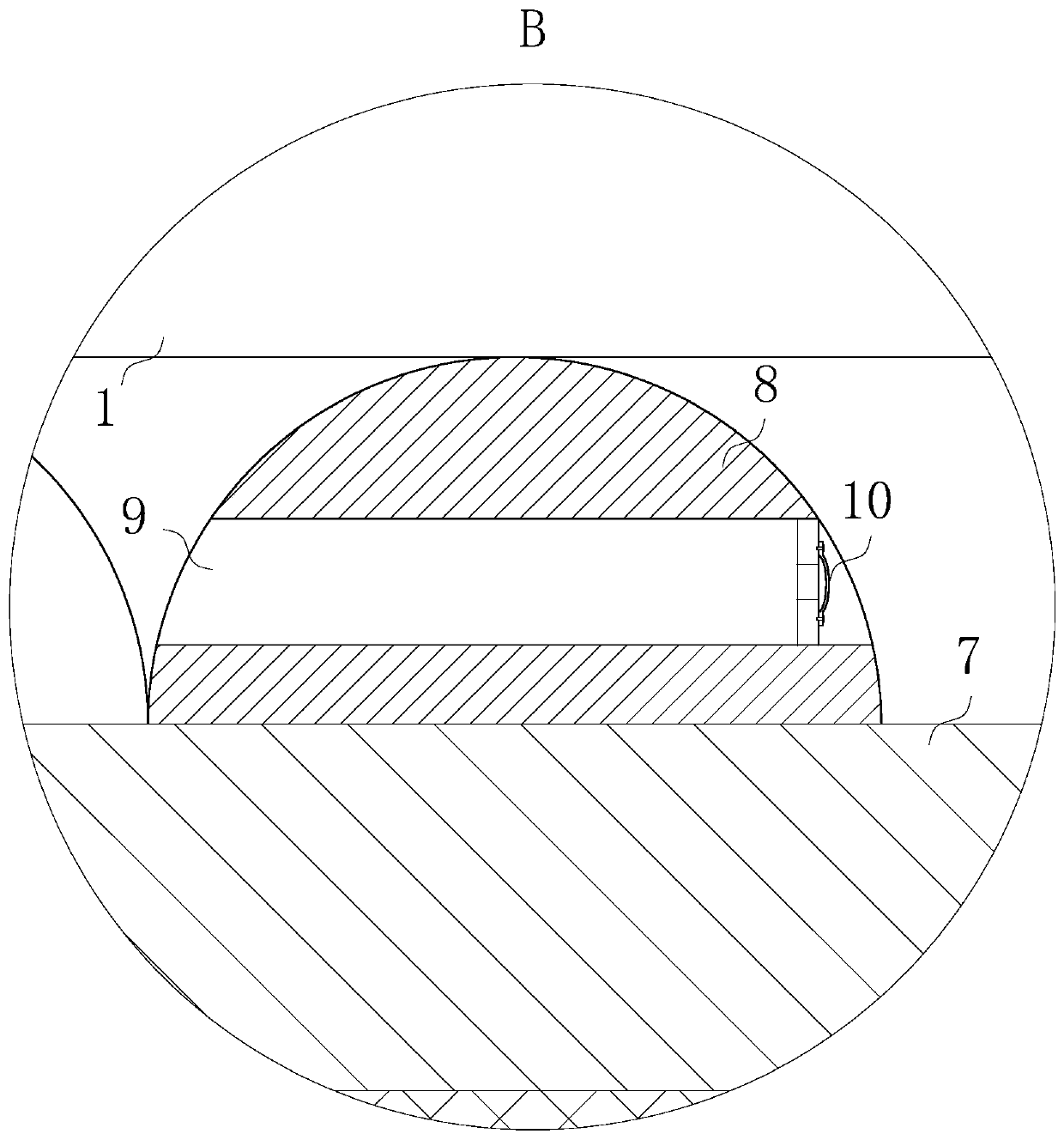

The invention discloses a suction opening structure of a compressor. The suction opening structure comprises a suction pipe which is fixedly connected with a suction port of a cylinder, a heat-insulation ceramic tube which is fixedly arranged inside the suction pipe, and a liquid storage tank's exhaust pipe which is fixedly connected with the suction pipe. A taper surface is formed on the external end portion of the heat-insulation ceramic tube. A bell mouth which fits with the taper surface is formed on the end portion of the liquid storage tank's exhaust pipe. The heat-insulation ceramic tube fits with the liquid storage tank's exhaust pipe through the taper surface. An assembly operator can conveniently perform total freedom degree of contact between the liquid storage tank's exhaust pipe and the end portion of the heat-insulation ceramic tube. Fitting allowance is easy to guarantee. In addition, axial freedom degree of the heat-insulation ceramic tube is restricted, and adverse influence of shock during the operation process of the compressor on the heat insulation ceramic is relatively reduced. Simultaneously, it is ensured that dimensions of the housing and subsidiary parts are not changed. In this case, as the end portion of the heat-insulation ceramic tube extends into the inside of an exhaust pipe, the length of the heat-insulation ceramic tube is relatively increased, heat insulation area is increased, and inhalation efficiency is more effectively raised.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

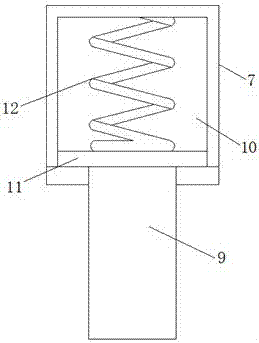

Multilayer composite vacuum heat-insulating plate

ActiveCN107989210AEasy to fixPromote withdrawalClimate change adaptationInsulation improvementMechanical engineeringEngineering

Owner:CHUZHOU YINXING NEW MATERIAL TECH CO LTD

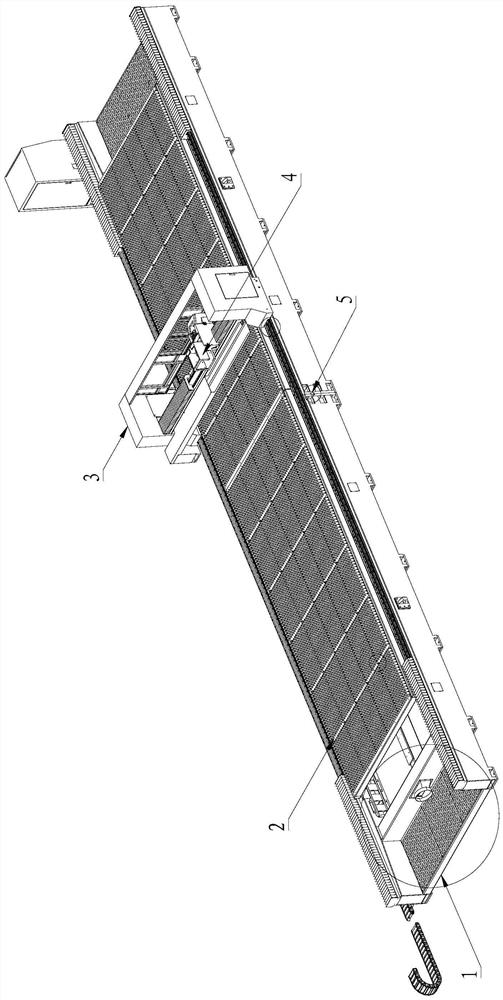

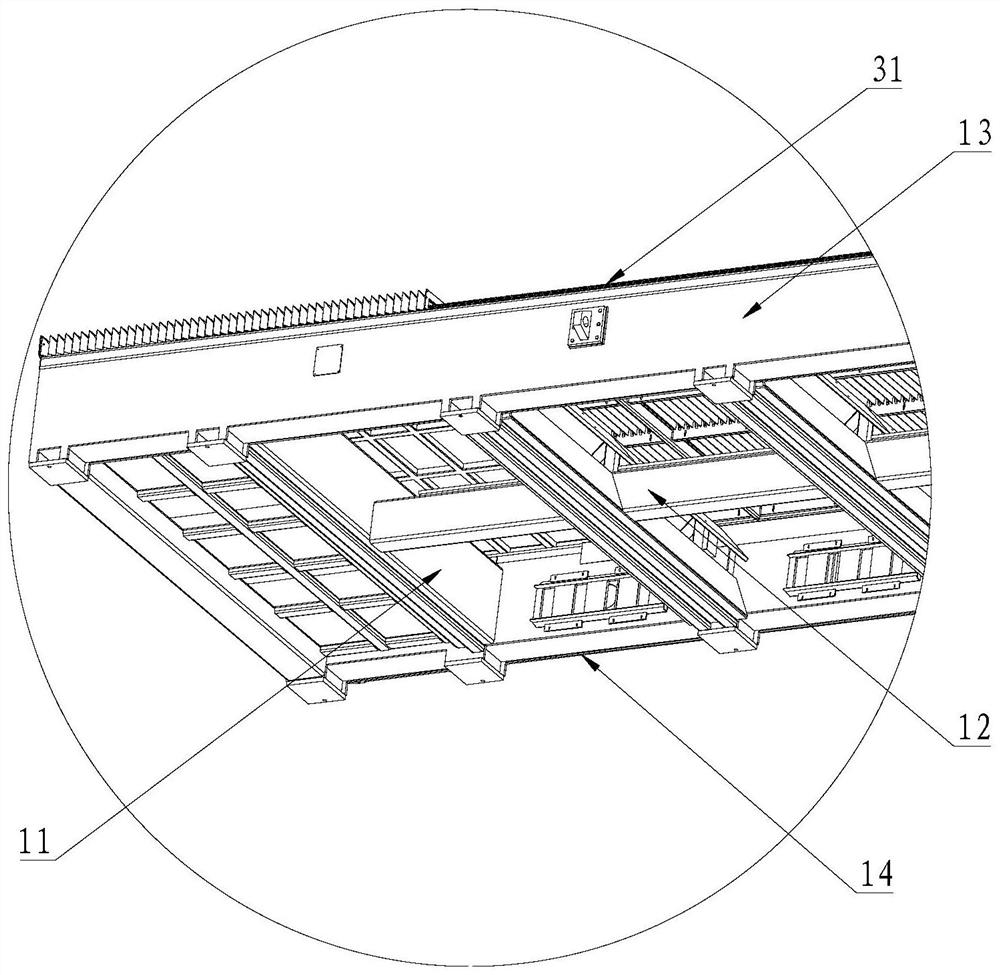

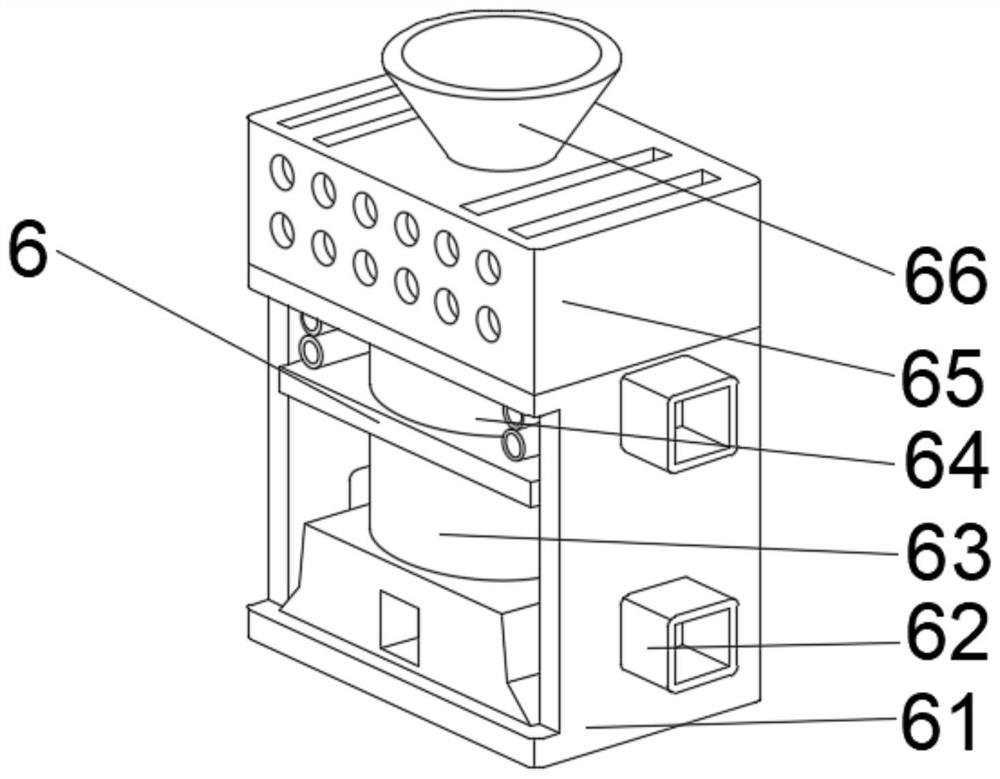

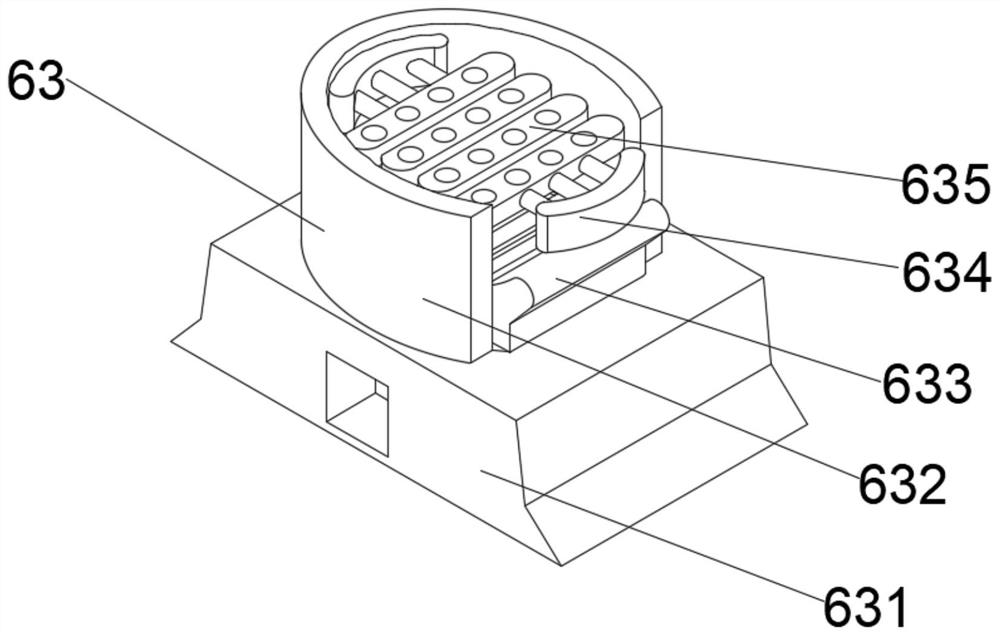

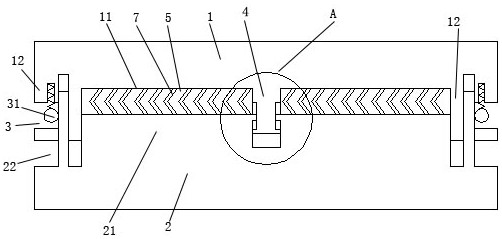

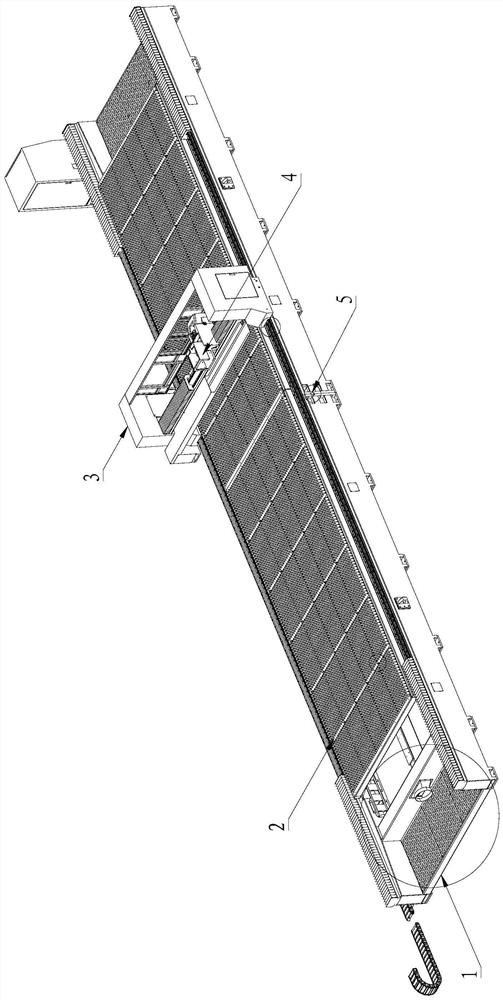

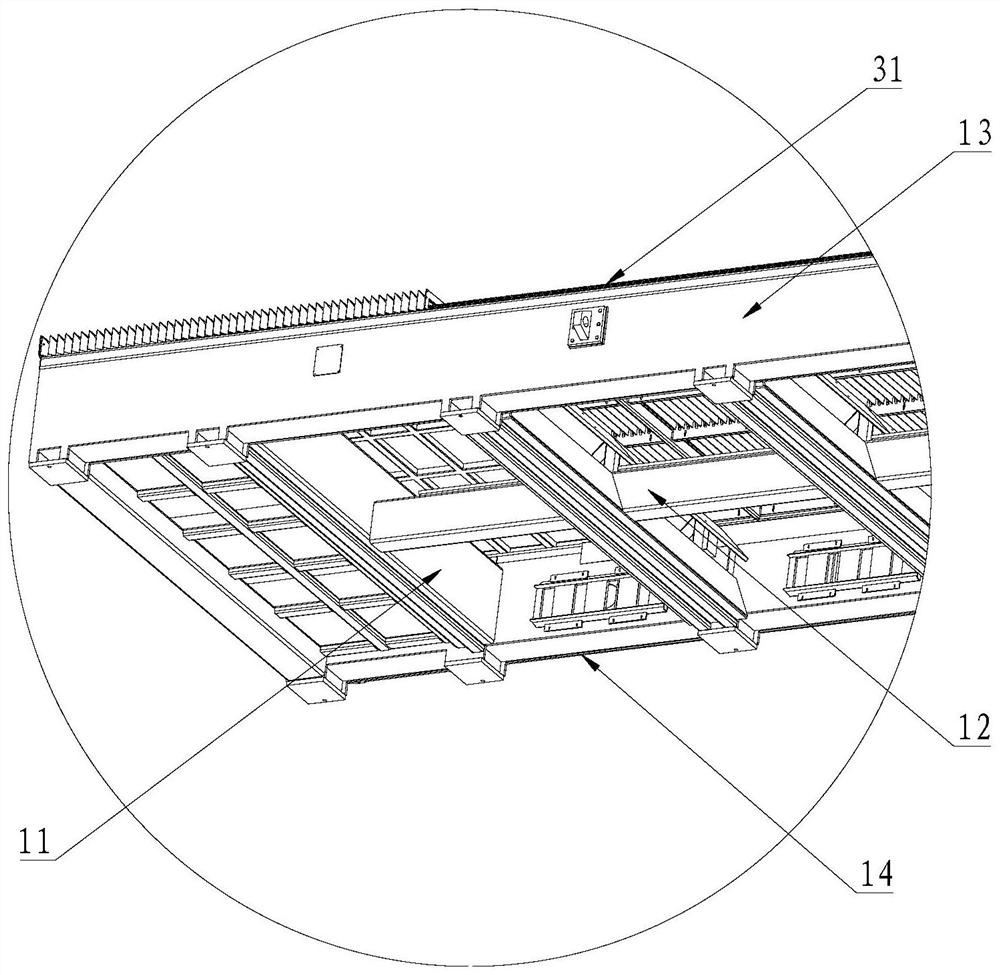

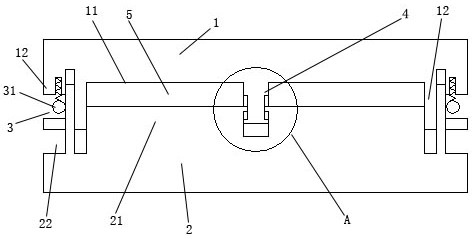

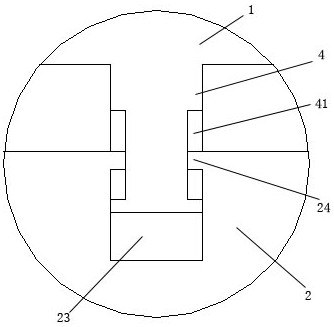

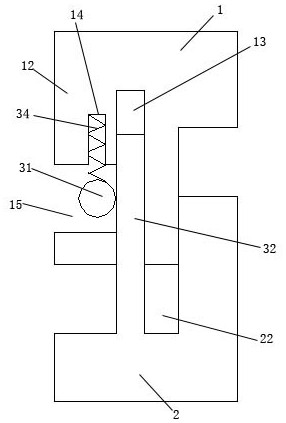

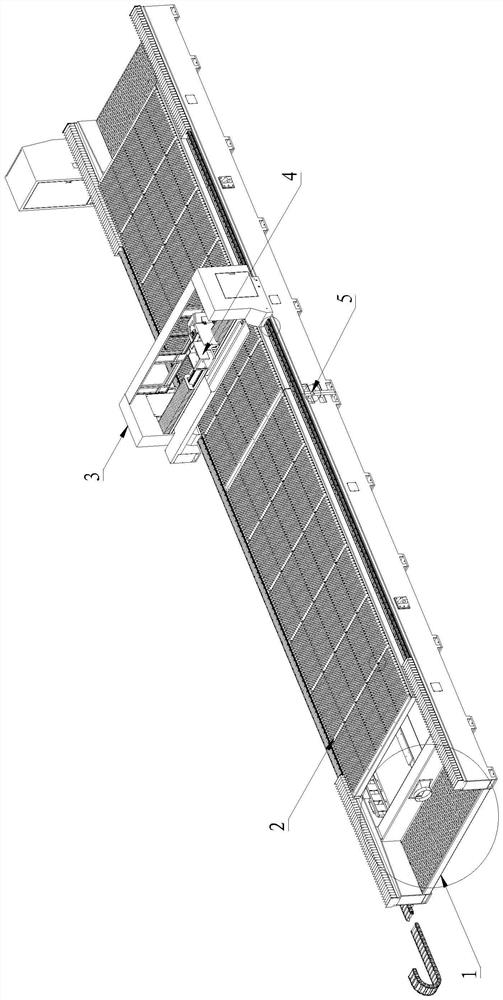

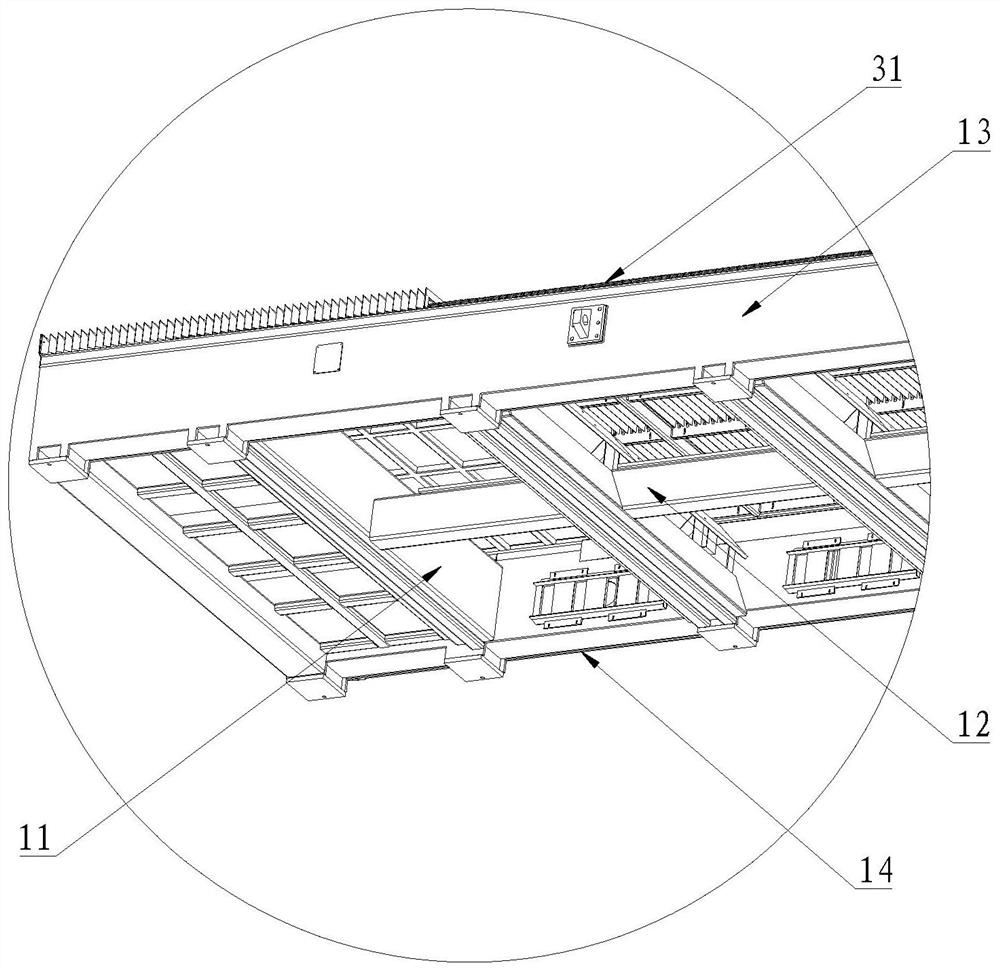

Large-breadth laser cutting machine

ActiveCN112059433AEasy to install, remove and replaceGuaranteed horizontal accuracyLaser beam welding apparatusPhysicsElectric machinery

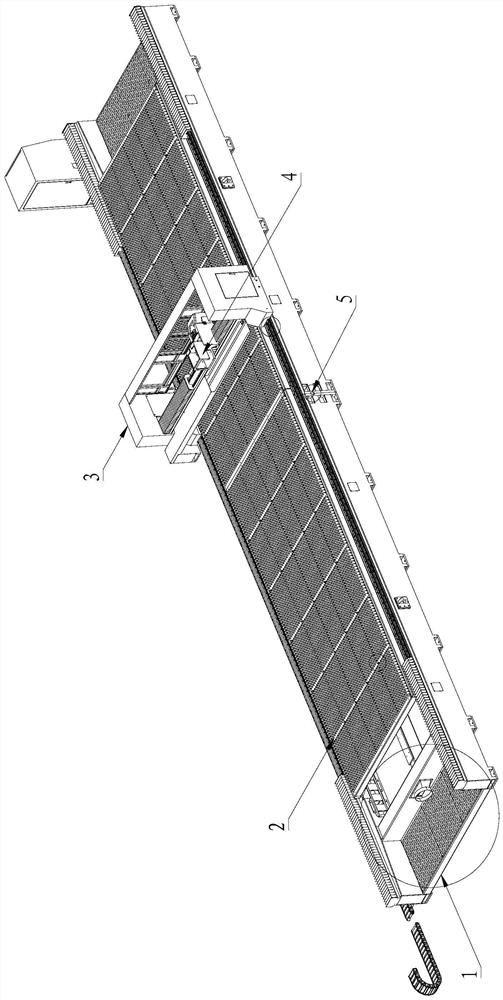

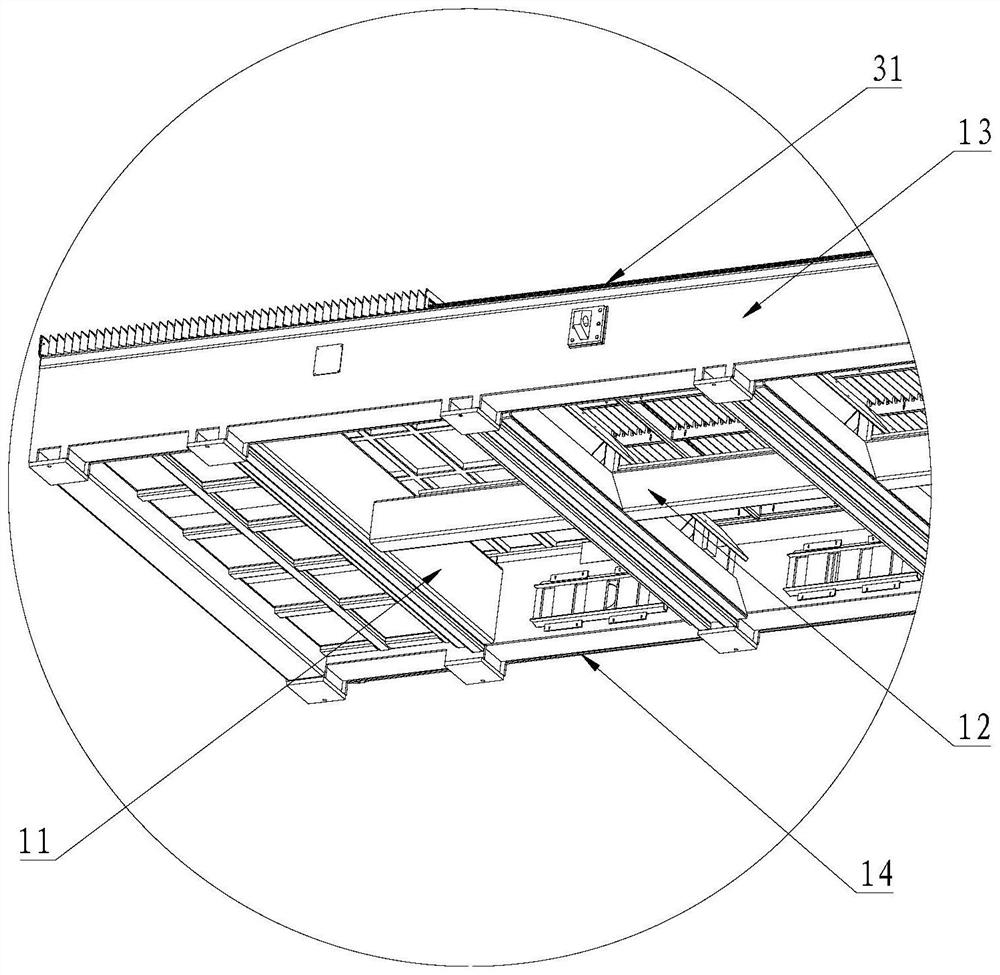

The invention relates to the technical field of laser cutting equipment, in particular to a large-breadth laser cutting machine which comprises a machine tool, and a material supporting mechanism, a gantry mechanism, a cutting mechanism, position adjusting mechanisms, a heat insulation mechanism and a dust removal mechanism respectively arranged on the machine tool. The rack comprises a main crossbeam, a main longitudinal beam, a first boundary beam and a second boundary beam; the material supporting mechanism comprises a first material frame and a second material frame; the gantry mechanismcomprises a first rack, a gantry, a first motor, a second rack and a guide rail; the cutting mechanism comprises a moving frame, a second motor and a laser cutting machine, the moving frame is slidably connected with the guide rail, the second motor is arranged on the moving frame, the second motor is connected with the second rack through a gear, and the laser cutting machine is installed on themoving frame; and the two sets of position adjusting mechanisms are symmetrically arranged on the first boundary beam and the second boundary beam. The large-breadth laser cutting machine provided bythe invention can adapt to the cutting machining of large-breadth plates, and is high in precision and good in effect.

Owner:CHINA MACHINERY CNC TECH FUJIAN CO LTD

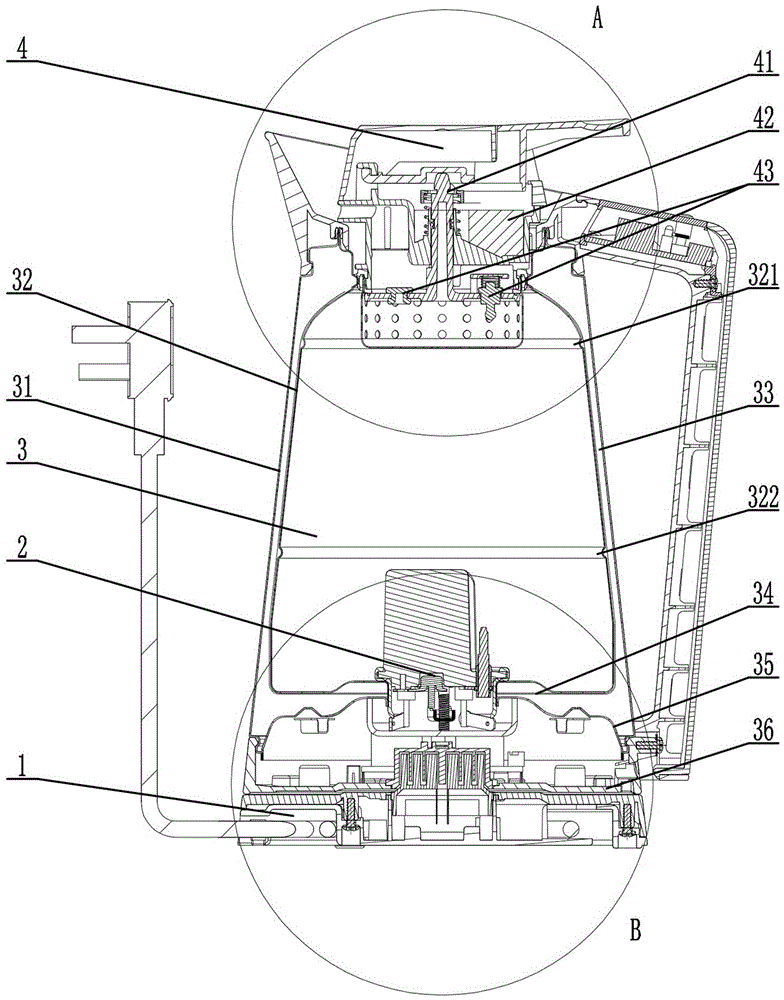

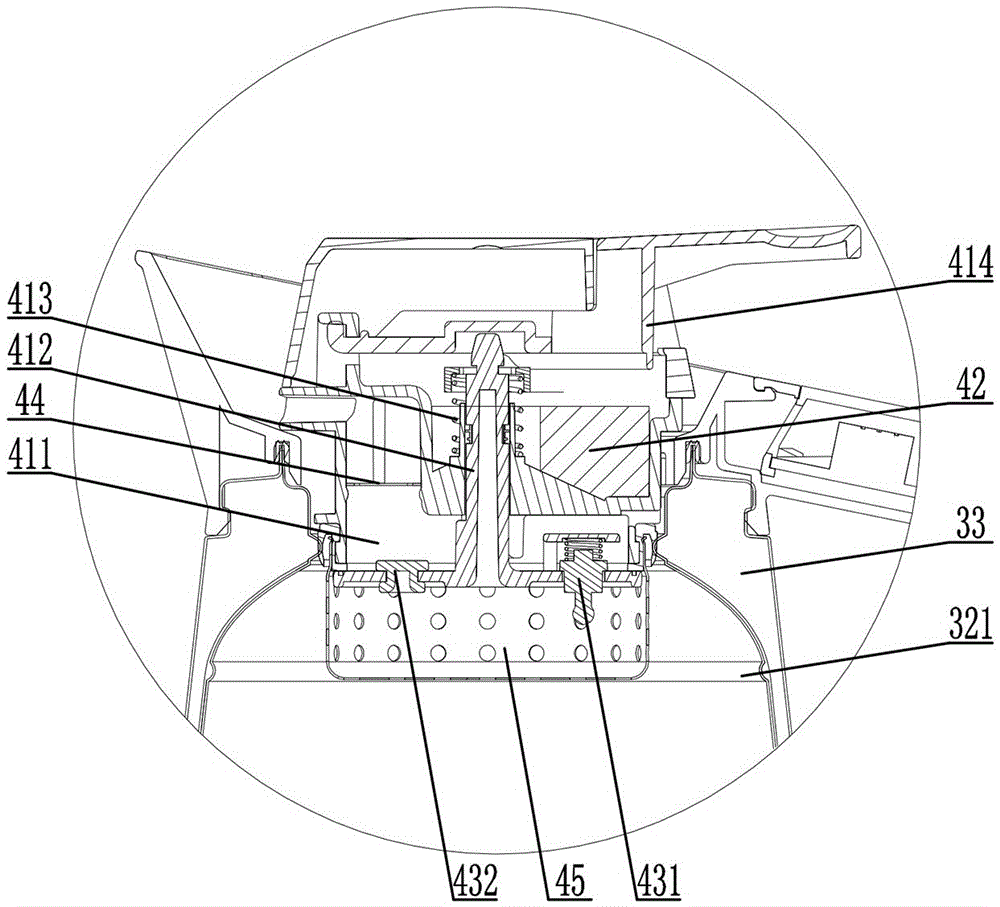

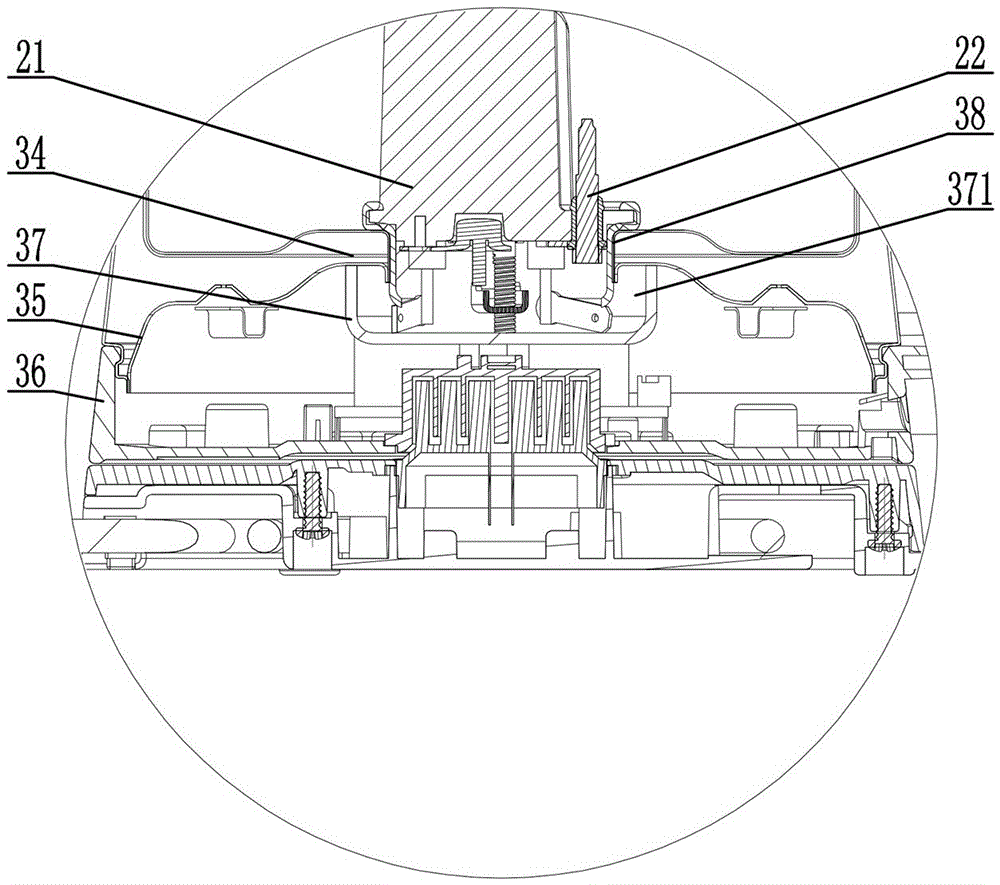

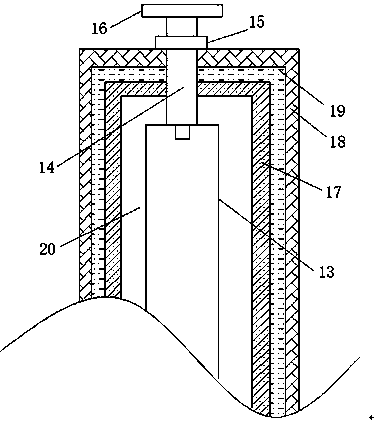

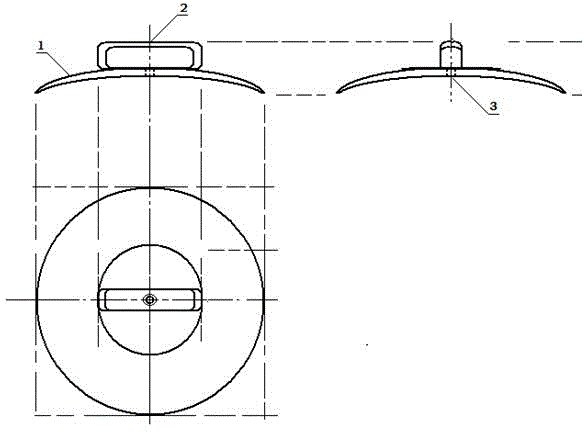

Electric heating full-vacuum heat preservation kettle

ActiveCN106473600ALarge insulation areaProduce anti-scald effectCooking-vessel lids/coversWater-boiling vesselsDirect heatingWater bottle

The invention discloses an electric heating full-vacuum heat preservation kettle which comprises a kettle lid, a kettle body, a base and a heating assembly. The kettle body comprises a shell, an inner container, a kettle body upper bottom and a kettle body lower bottom. The lower end of the shell is connected with the outer edge of the kettle body upper bottom. The lower end of the inner container is bent inwards to be connected with the inner edge of the kettle body upper bottom to form a heating hole. The inner container, the shell and the kettle body upper bottom form a vacuum layer. The kettle body lower bottom and the lower end of the shell are connected. One end of the heating assembly stretches into the inner container through the heating hole, the other end of the heating assembly is located in the space formed by the kettle body and the kettle body lower bottom, a sealing water outlet device is arranged on the kettle lid, and a pressure relief device is arranged on the sealing water outlet device. The vacuum layer can increase the heat preservation performance and generate the anti-scalding effect; due to the fact that only the heating hole into which the heating assembly can stretch is reserved in the bottom of the kettle body, the area of vacuum heat preservation is increased, heat emitted from the bottom is reduced, the heat preservation effect is improved, one end of the heating assembly directly stretches into the inner container to directly heat liquid, and the heating efficiency is greatly improved.

Owner:浙江南龙工贸有限公司

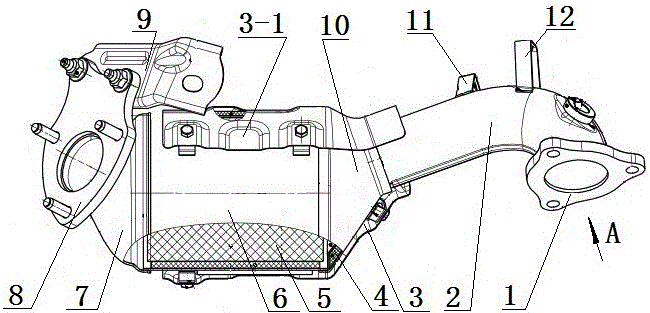

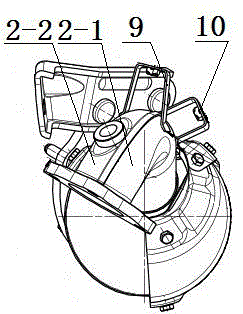

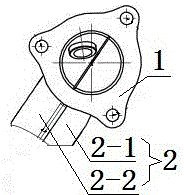

Three-way catalyst assembly

InactiveCN106014561AHigh strengthIncrease stiffnessSilencing apparatusMachines/enginesEngineeringFlange

The invention discloses a three-way catalyst assembly, and relates to the technical field of manufacturing of three-way catalysts. The three-way catalyst assembly comprises a barrel body in which a catalyst assembly is arranged, wherein one end of the barrel body is connected with an air outlet flange through an air outlet end cover; the other end of the barrel body is connected with an air inlet pipe through an air inlet end cover; an air inlet flange is arranged at the front end of the air inlet pipe; the air inlet pipe is formed by assembling and welding an air inlet pipe half shell I and an air inlet pipe half shell II; a plurality of mounting brackets are arranged at a position, located at the joint of the two half shells, on the air inlet pipe; a heat insulation cover is arranged outside the air inlet end cover and the barrel body; a plurality of grooves are formed in the outer surface, positioned on the barrel body section, of the heat insulation cover. Compared with the prior art, the three-way catalyst assembly disclosed by the invention has the advantage that the problem that the air inlet end cone of the three-way catalyst of a conventional turbocharged engine is easy to break can be solved.

Owner:柳州利和排气控制系统有限公司

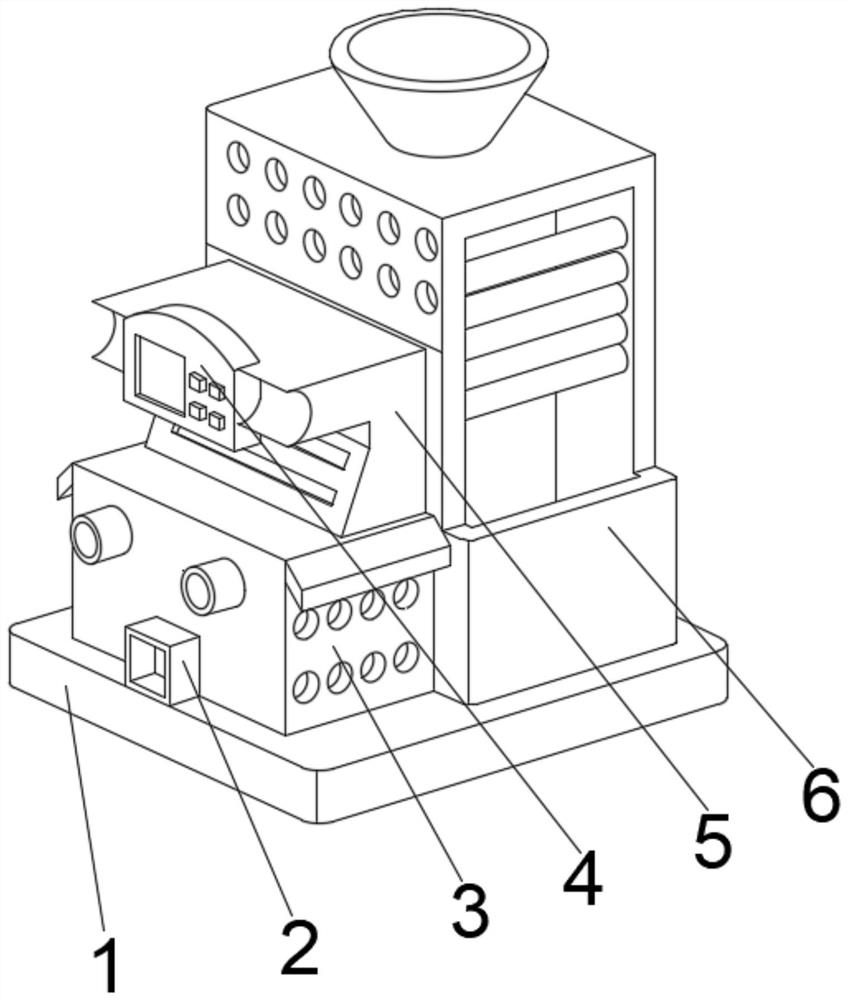

Energy-saving boiler

PendingCN113803702AIncrease profitNot easy to influenceSteam generation heating methodsSteam boilersThermodynamicsEngineering

The invention discloses an energy-saving boiler. The boiler comprises a bottom plate, a heating device is fixedly connected to the right side of the top of the bottom plate, a heating box is fixedly connected to the position, located at the bottom of the outer wall of the left side of the heating device, of the top of the bottom plate, a heat insulation plate is fixedly connected to the right side of the top of the heating box, a control panel is arranged at the top of the outer wall of the left side of the heat insulation plate, and a ventilation opening is formed in the middle of the bottom of the outer wall of the left side of the heating box. The invention relates to the technical field of boilers. According to the energy-saving boiler, heat generated by electrifying of the heating box can be transferred through connection with a preheating mechanism, meanwhile, the heat insulation plate can insulate the influence of the heat, dust generated by traditional heating can be conveniently reduced, the situation that water is scattered in the water adding process is avoided, then the utilization rate of the heat generated by heating can be improved, the boiler has good stability during working, the boiler can be uniformly heated, and the service life of the boilder is effectively prolonged.

Owner:黄涌凯

High-voltage nickel-hydrogen storage battery internal positive post secondary insulation method

ActiveCN102931375AIncrease the insulating areaImprove securityCell component detailsNickelEngineering

The invention relates to a high-voltage nickel-hydrogen storage battery internal positive post secondary insulation method comprising the steps of fixing a lower transitional sleeve and a ceramic sleeve on a post rod through connecting pieces to assemble into a positive post, cleaning and wiping the positive post with acetone, coating HR-8747 high-temperature-resistant sealing insulation glue on the macroaxis surface of the post rod, the upper end face of the macroaxis, a bare part of the lower transitional sleeve, the bottom of a transitional ring, and a bare face of the ceramic sleeve between the transitional ring and the lower transitional sleeve, keeping warm for 2 hours to 3 hours at a temperature between 60 DEG C to 80 DEG C, and taking the positive post out after cooling to form the high-voltage nickel-hydrogen storage battery internal secondary insulation positive post. Before a post of a single battery is welded with a battery shell body, the surface of the positive post in the battery is coated by a layer of the HR-8747 high-temperature-resistant sealing insulation glue so as to form a secondary insulation of the positive post in the battery, to increase the insulation area if the surface of the positive post in the battery, to enlarge the insulation distance between an anode and a cathode of the battery, and to improve safety of the battery.

Owner:TIANJIN SPACE POWER TECH CO LTD

Method for preparing interior trim part of car roof from moxa

ActiveCN104691440AProtectiveHas a health effectLaminationLamination apparatusActivated carbonCarbonization

The invention discloses a method for preparing an interior trim part of a car roof from moxa. The method comprises the following preparation steps: firstly, extracting the moxa and combing downwind to form raw material moxa; adding activated carbon formed by carbonization of elm powder and folium artemisiae argyi into the raw material moxa, hot-pressing by a mold to form a moxa car roof matched with the car roof in shape, wherein the thickness of the moxa car roof is 2-10 mm, and the inner surface of the moxa car roof is corrugated; spraying the back surface of the moxa car roof with a layer of waterproof and moisture-proof heat-insulating aluminum membrane; blending gastrodia elata or natural silk with the moxa to prepare cloth, punching a conical inverted hole in the front surface of the cloth and then covering the front surface of the moxa car roof. The method is simple in process, and the prepared interior trim part of the car roof is good in heat-insulating effect, and can fully absorb odor in the car and send out effective ingredients with sterilization and antivirus functions, thereby preventing bacteria and virus from invading a respiratory tract, preventing influenza virus and playing a role in purifying air.

Owner:河南中鸿电子科技有限公司

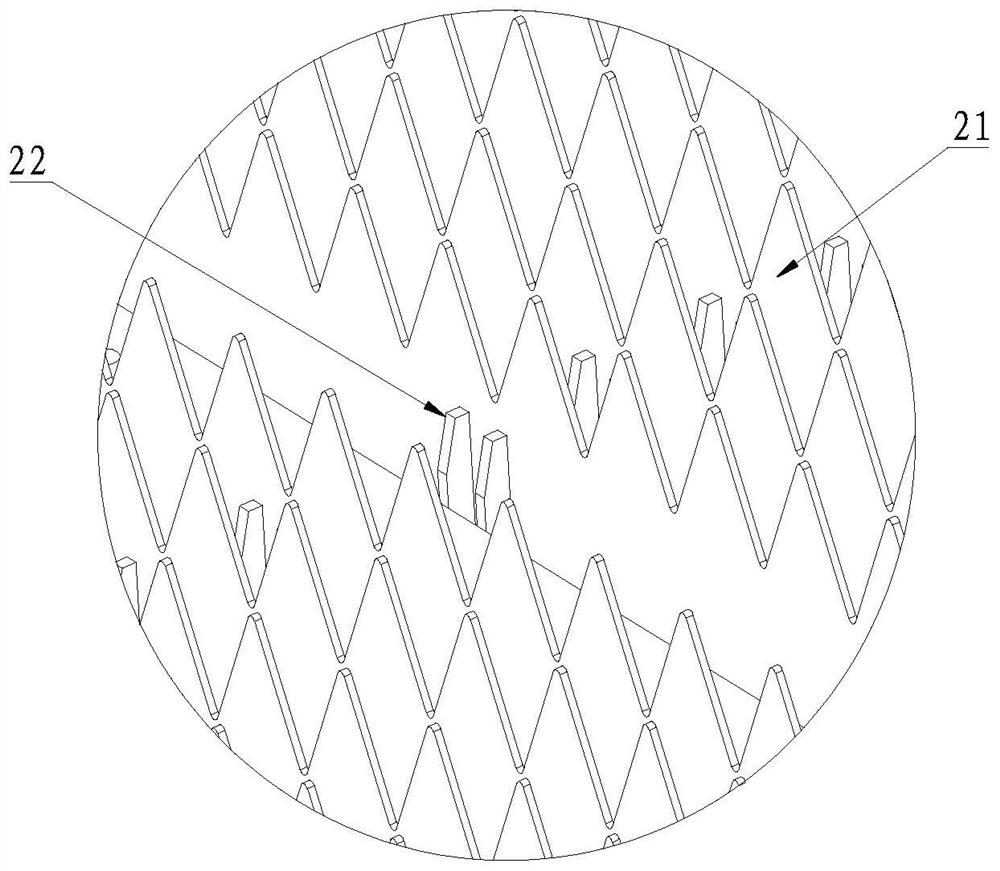

Abutting locking type brick body heat insulation structure

The invention discloses an abutting locking type brick body heat insulation structure. The heat insulation structure comprises an external decorative plate, an internal heat insulation plate, floating assemblies, abutting positioning mechanisms and a heat insulation filler layer. According to the heat insulation structure, rotary abutting screw rods are rotationally connected to the outer ends of clamping rods in an abutting or separating mode, when the rotary abutting screw rods are rotationally connected to the outer ends of the clamping rods in an abutting mode, locking of the clamping rods is formed, in this way, locking of driving gears is formed, then positioning of the whole floating assemblies is formed, the whole structure is more stable, the upper ends and the lower ends of aerogel sheet bodies of the V-shaped structures are fixedly connected to the inner side face of the external decorative plate and the outer side face of the inner heat insulation plate correspondingly, so that the aerogel sheet bodies of the V-shaped structures can be opened, closed and stretched in a mouth opening mode, floating of the inner heat insulation plate is cooperated, the heat insulation effect is improved, and the floating of the internal heat insulation plate is not influenced.

Owner:港泰耐火材料(江苏)有限公司

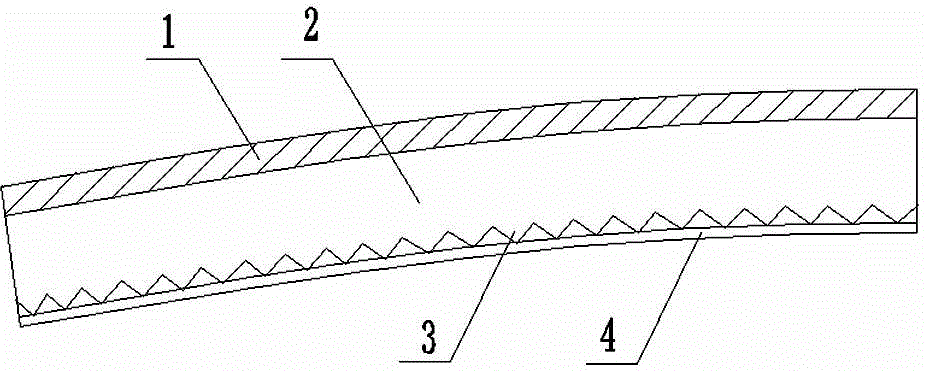

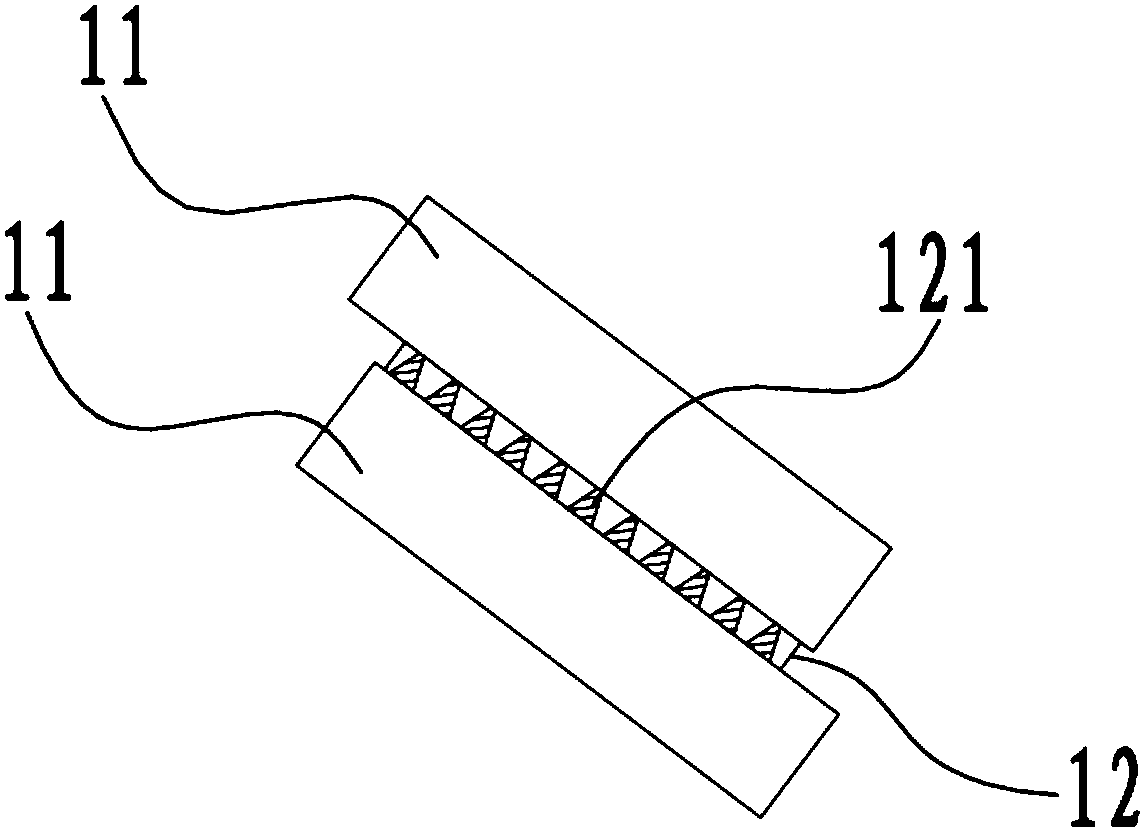

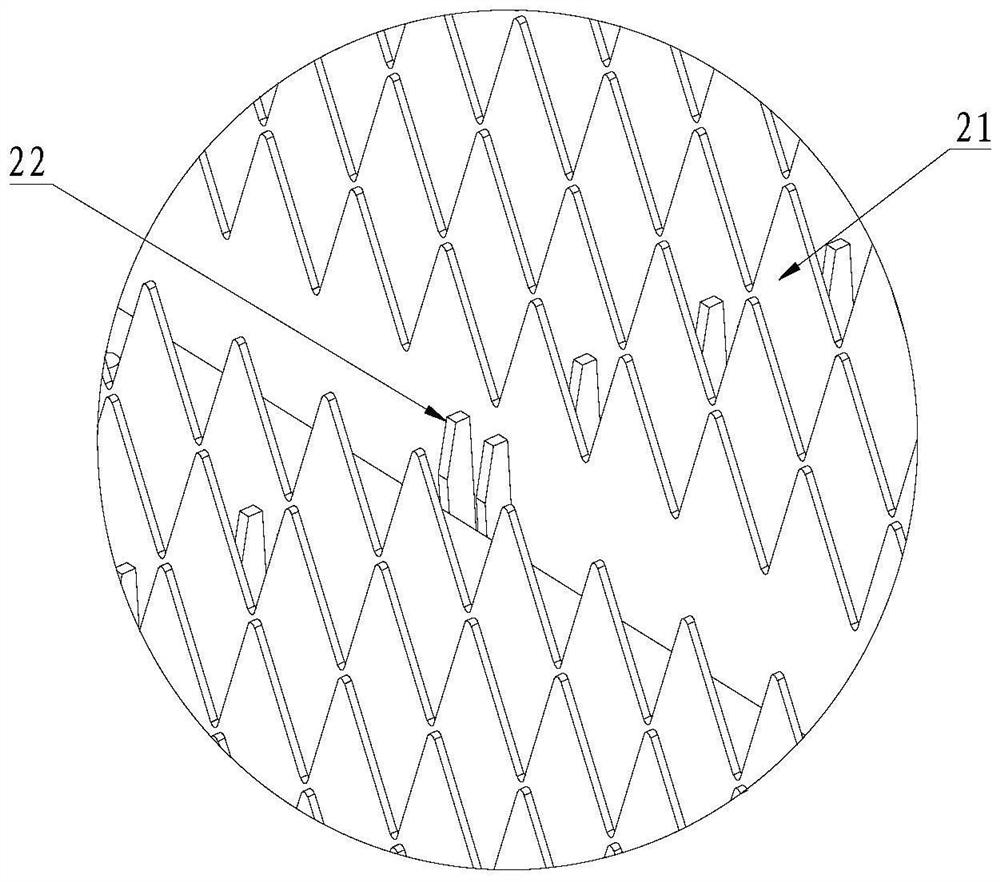

Waterproof and mildew-proof brick with heat preservation plates

The invention discloses a waterproof and mildew-proof brick with heat preservation plates. The brick comprises a brick body, wherein two through holes are formed in the upper surface of the brick body and are longitudinally formed along the upper surface; tooth-shaped structures are arranged on the surfaces of inner holes of the through holes; the heat preservation plates matched with the through holes are tightly embedded into the through holes; a waterproof layer and a mildew-proof layer are arranged on the outer surface of the brick body in sequence from inside to outside. According to the brick disclosed by the invention, the tooth-shaped structures are arranged on the surfaces of the inner holes of the through holes, and the heat preservation plates matched with the through holes are arranged in the through holes, so that the heat preservation area in the brick body is greatly enlarged, loss or increase of heat is greatly reduced, and effects of warming in winter and cooling in summer are achieved; meanwhile, the volumes of the through holes are also enlarged, and the use of coal ash materials is reduced; due to the waterproof and mildew-proof layers, the service life of the brick body can be effectively prolonged, and the waterproof and mildew-proof performance can be improved. The waterproof and mildew-proof brick with the heat preservation plates has the advantages of simple structure, reasonable arrangement, low manufacturing cost and the like.

Owner:杨海蓉

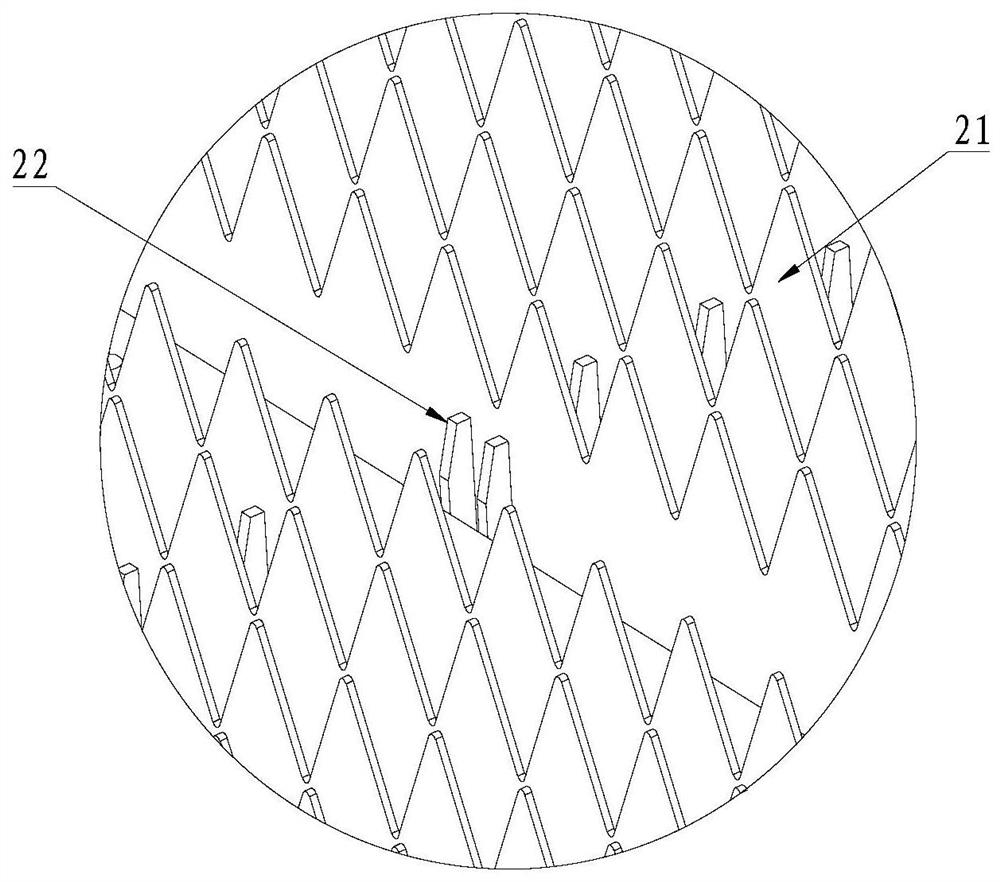

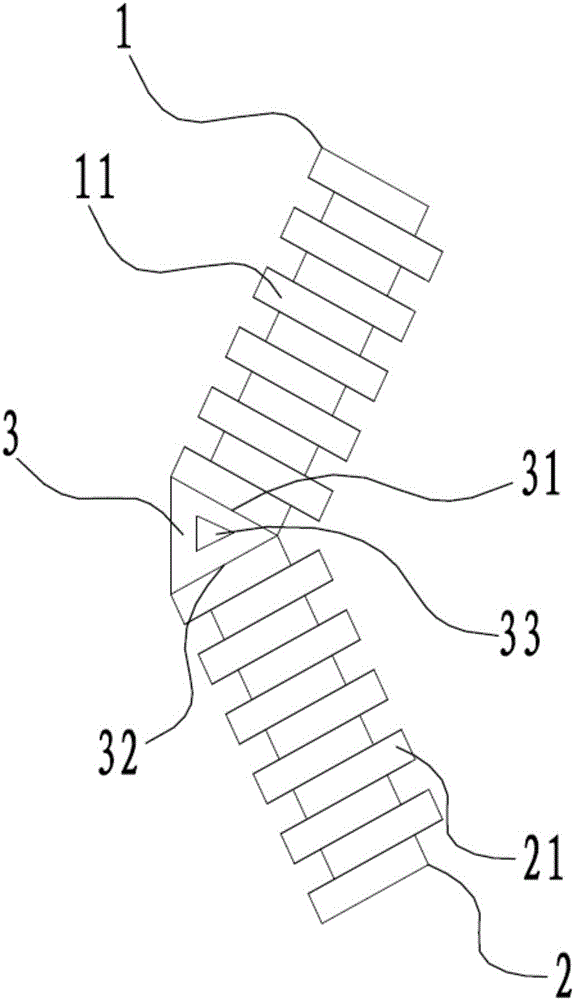

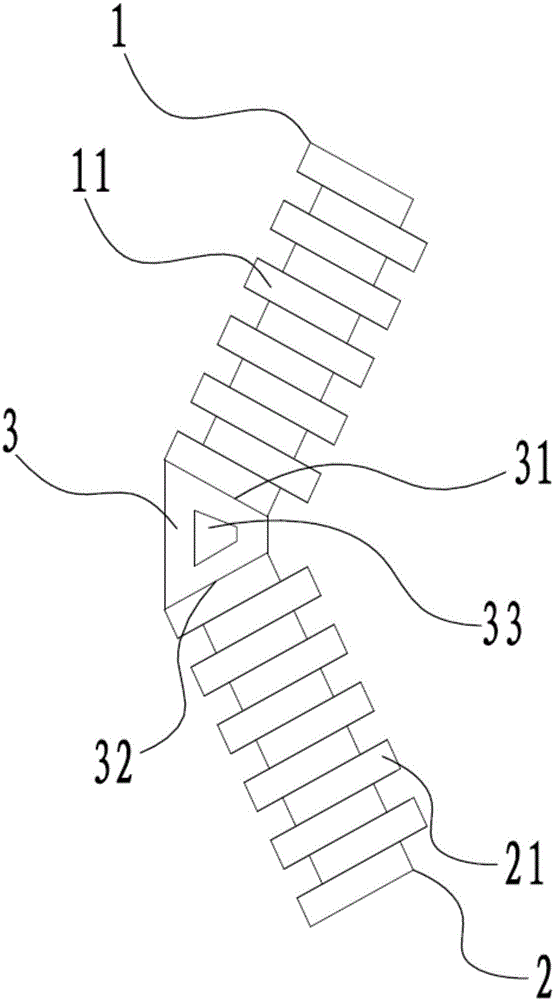

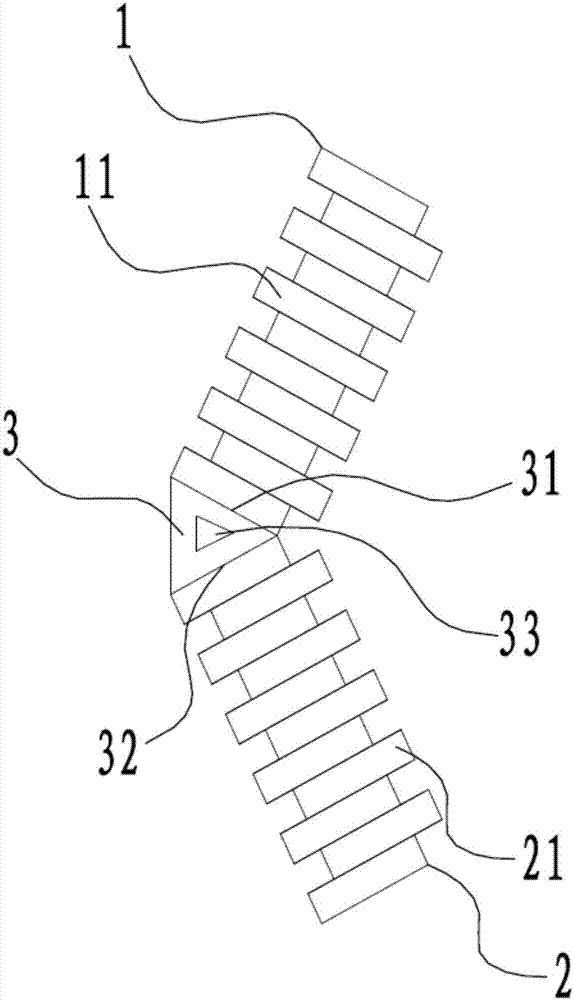

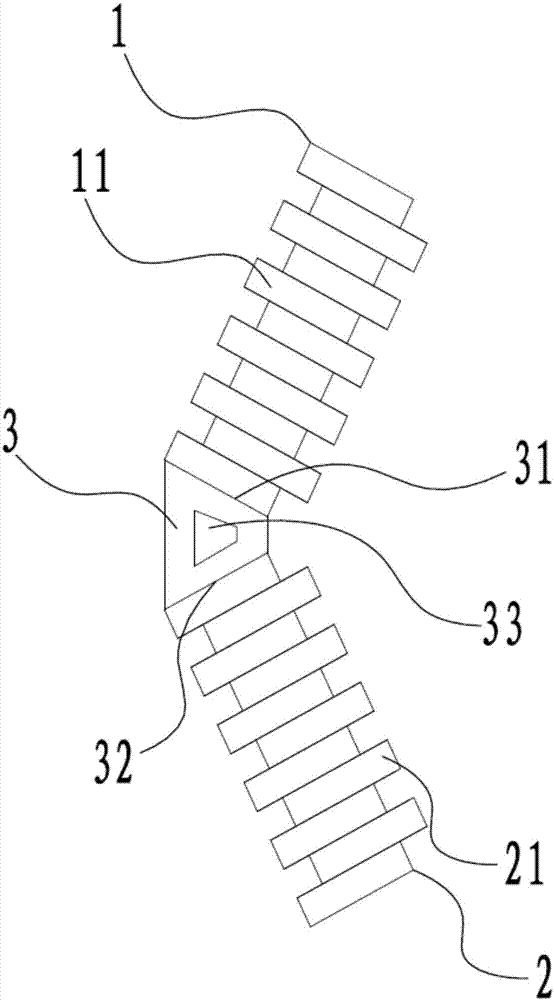

Foam insulation device for building residential pc insulation wall panels and pc insulation wall panels

The invention provides a foam thermal insulation device of a PC thermal insulation wallboard of a residence building. The foam thermal insulation device comprises a plurality of horizontally arranged thermal insulation block sets and a third thermal insulation block. The thermal insulation block sets comprise the first thermal insulation block set and the second thermal insulation block set which are perpendicularly and symmetrically arranged; the first thermal insulation block set and the second thermal insulation block set are arranged by an angle; the first thermal insulation block set comprises a plurality of overlapped first thermal insulation blocks; the second thermal insulation block set comprises a plurality of overlapped second thermal insulation blocks; the third thermal insulation block is arranged between the first thermal insulation block set and the second thermal insulation block set; the third thermal insulation block is provided with a first inclined face and a second inclined face which are symmetric; the first inclined face is fixedly connected with the first thermal insulation block set; the second inclined face is fixedly connected with the second thermal insulation block set; and a cavity is further formed inside the third thermal insulation block. The invention further provides the PC thermal insulation wallboard. Compared with the prior art, the foam thermal insulation device of the PC thermal insulation wallboard of the residence building and the PC thermal insulation wallboard have the excellent thermal insulation performance.

Owner:苏州良浦节能新材料股份有限公司

Compressor suction port structure

InactiveCN102828956BLimited axial freedomReduce adverse effectsRotary/oscillating piston pump componentsLiquid fuel engine componentsLiquid storage tankExhaust pipe

The invention discloses a suction opening structure of a compressor. The suction opening structure comprises a suction pipe which is fixedly connected with a suction port of a cylinder, a heat-insulation ceramic tube which is fixedly arranged inside the suction pipe, and a liquid storage tank's exhaust pipe which is fixedly connected with the suction pipe. A taper surface is formed on the external end portion of the heat-insulation ceramic tube. A bell mouth which fits with the taper surface is formed on the end portion of the liquid storage tank's exhaust pipe. The heat-insulation ceramic tube fits with the liquid storage tank's exhaust pipe through the taper surface. An assembly operator can conveniently perform total freedom degree of contact between the liquid storage tank's exhaust pipe and the end portion of the heat-insulation ceramic tube. Fitting allowance is easy to guarantee. In addition, axial freedom degree of the heat-insulation ceramic tube is restricted, and adverse influence of shock during the operation process of the compressor on the heat insulation ceramic is relatively reduced. Simultaneously, it is ensured that dimensions of the housing and subsidiary parts are not changed. In this case, as the end portion of the heat-insulation ceramic tube extends into the inside of an exhaust pipe, the length of the heat-insulation ceramic tube is relatively increased, heat insulation area is increased, and inhalation efficiency is more effectively raised.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

High-precision large-breadth laser cutting machine

ActiveCN114654110AGuaranteed horizontal accuracyEasy to install and disassembleLaser beam welding apparatusElectric machineDust control

The invention relates to the technical field of laser cutting equipment, in particular to a large-breadth laser cutting machine which comprises a machine tool as well as a material supporting mechanism, a gantry mechanism, a cutting mechanism, a position adjusting mechanism, a heat insulation mechanism and a dust removal mechanism which are respectively arranged on the machine tool, the machine tool comprises a main cross beam, a main longitudinal beam, a first edge beam and a second edge beam. The material supporting mechanism comprises a first material frame and a second material frame; the gantry mechanism comprises a first rack, a gantry frame, a first motor, a second rack and a guide rail; the cutting mechanism comprises a moving frame, a second motor and a laser cutting machine, the moving frame is slidably connected with the guide rail, the second motor is arranged on the moving frame and connected with the second rack through a gear, and the laser cutting machine is installed on the moving frame; and the two groups of position adjusting mechanisms are symmetrically arranged on the first edge beam and the second edge beam. The large-breadth laser cutting machine can adapt to cutting machining of large-breadth plates, and is high in precision and good in effect.

Owner:CHINA MACHINERY CNC TECH FUJIAN CO LTD

A multi-layer composite vacuum heat insulation board

ActiveCN107989210BEasy to fixPromote withdrawalClimate change adaptationSynthetic resin layered productsEngineeringBar pressing

Owner:CHUZHOU YINXING NEW MATERIAL TECH CO LTD

Secondary Insulation Method for Positive Pole of High-voltage Ni-MH Storage Battery

ActiveCN102931375BImprove securityLarge insulation areaCell component detailsEngineeringHigh voltage

The invention relates to a high-voltage nickel-hydrogen storage battery internal positive post secondary insulation method comprising the steps of fixing a lower transitional sleeve and a ceramic sleeve on a post rod through connecting pieces to assemble into a positive post, cleaning and wiping the positive post with acetone, coating HR-8747 high-temperature-resistant sealing insulation glue on the macroaxis surface of the post rod, the upper end face of the macroaxis, a bare part of the lower transitional sleeve, the bottom of a transitional ring, and a bare face of the ceramic sleeve between the transitional ring and the lower transitional sleeve, keeping warm for 2 hours to 3 hours at a temperature between 60 DEG C to 80 DEG C, and taking the positive post out after cooling to form the high-voltage nickel-hydrogen storage battery internal secondary insulation positive post. Before a post of a single battery is welded with a battery shell body, the surface of the positive post in the battery is coated by a layer of the HR-8747 high-temperature-resistant sealing insulation glue so as to form a secondary insulation of the positive post in the battery, to increase the insulation area if the surface of the positive post in the battery, to enlarge the insulation distance between an anode and a cathode of the battery, and to improve safety of the battery.

Owner:TIANJIN SPACE POWER TECH CO LTD

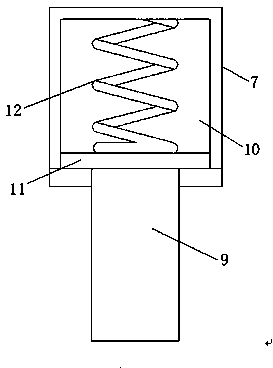

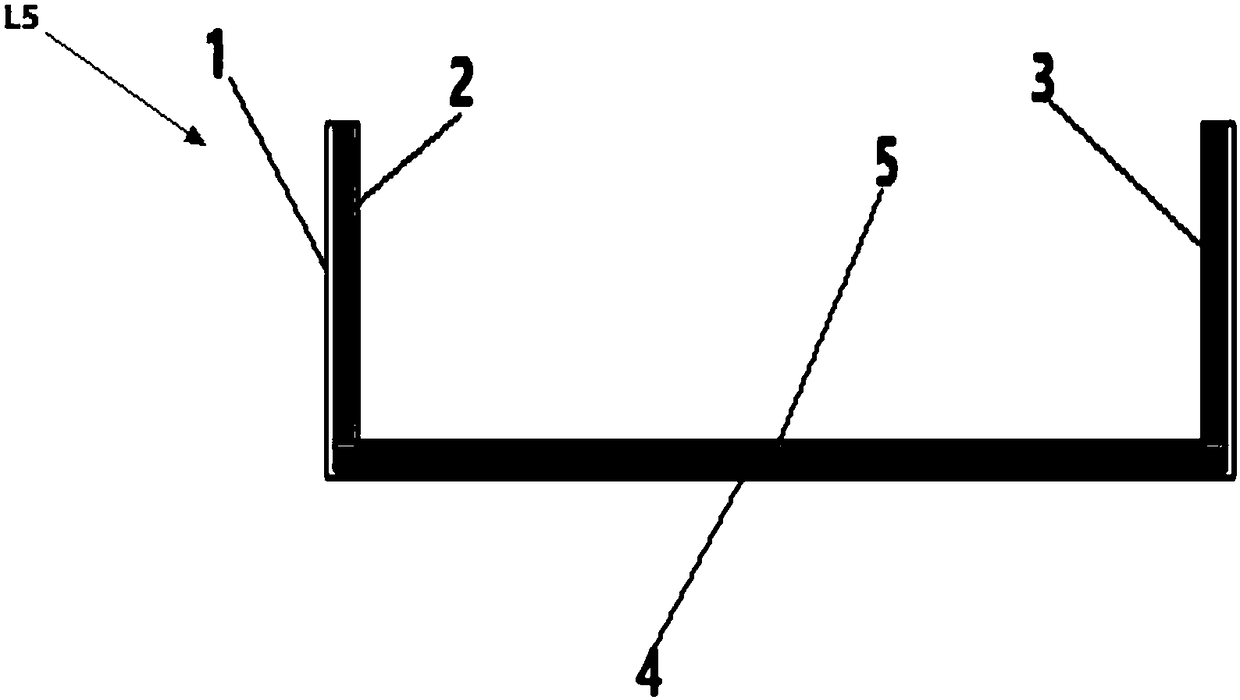

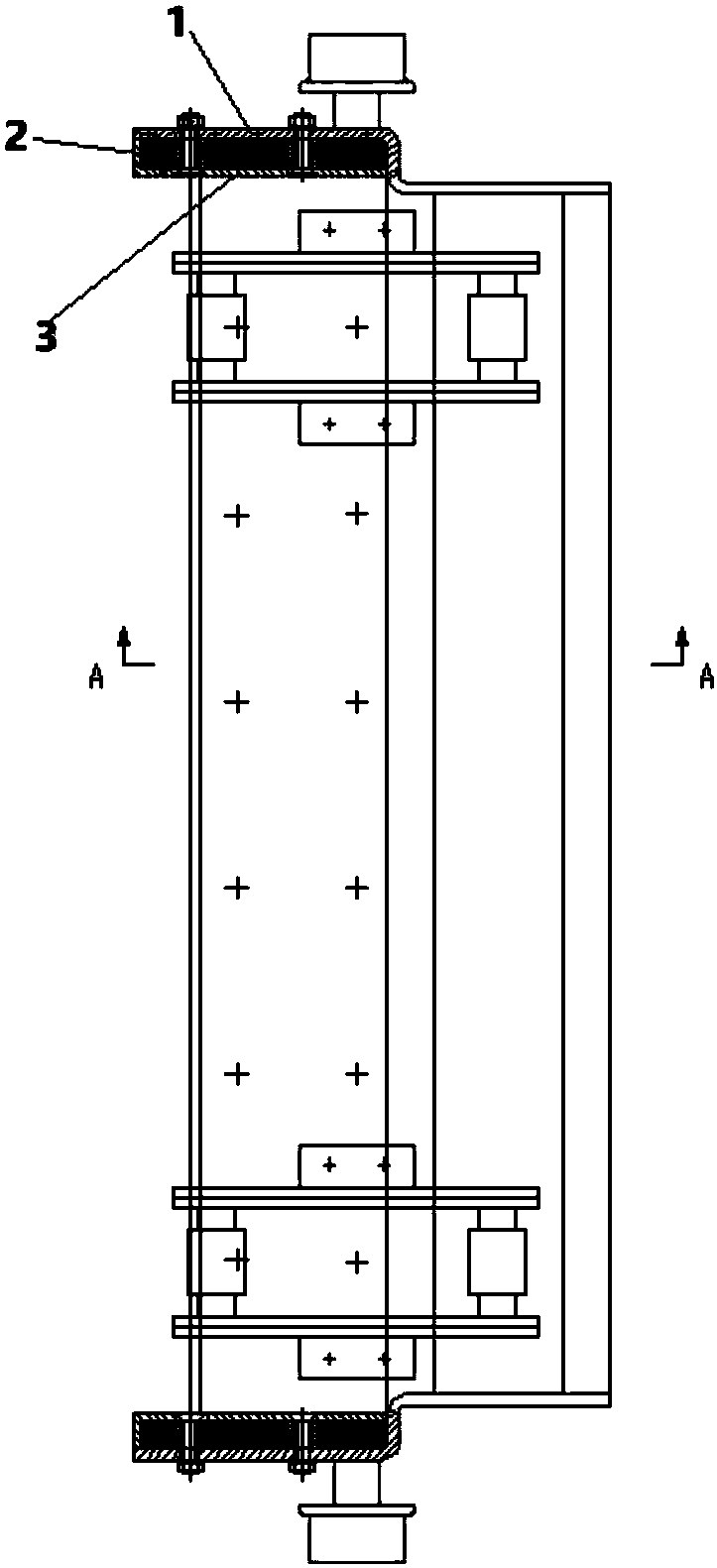

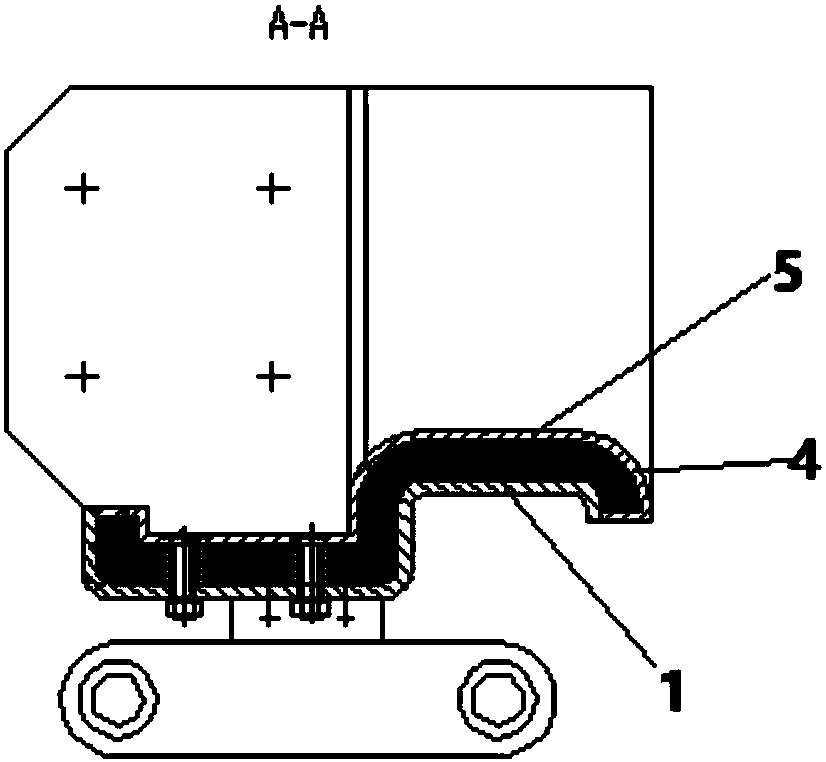

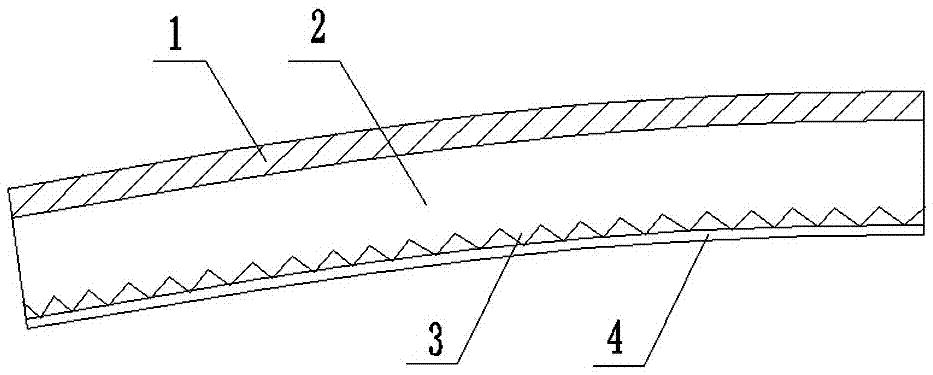

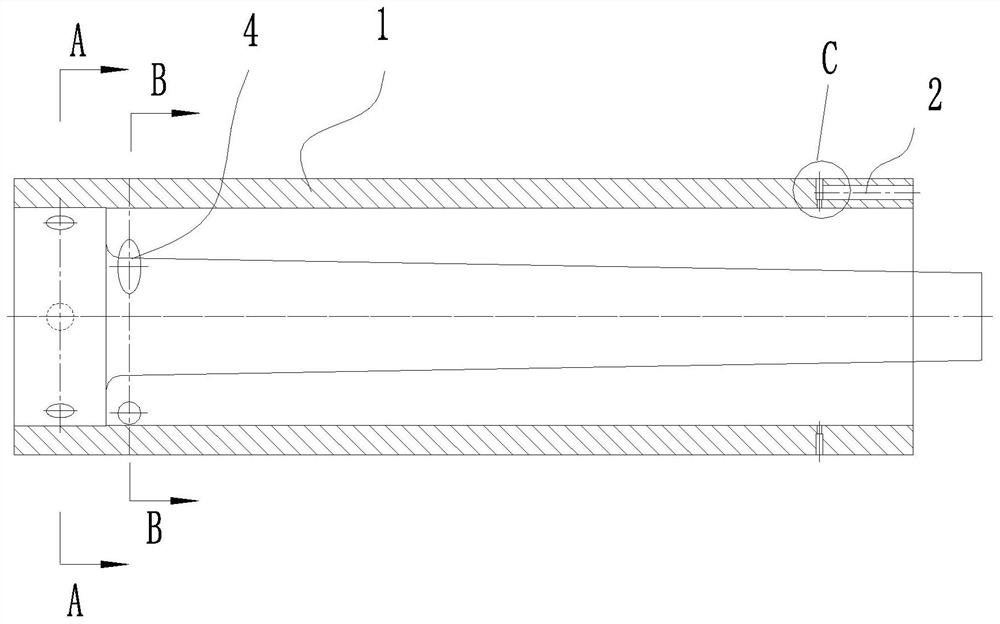

High-temperature plate conveying channel, conveyor and sinter cooling system

PendingCN109205182ADoes not affect operationPlay the role of thermal insulationConveyorsCharge manipulationEngineeringHeat losses

The invention relates to a high-temperature plate conveying channel (L5) which comprises a channel body (1), side thermal insulating material layers (2), side cover plates (3), a bottom thermal insulating material layer (4) and a bottom cover plate (5), wherein the channel body (1) is of a U-shaped or concave structure, and is provided with a bottom surface and two side surfaces; the side thermalinsulating material layers (2) are arranged on the inner surfaces of the side surfaces of the channel body (1); the side cover plates (3) are arranged on the surfaces of the side thermal insulating material layers (2); the bottom thermal insulating material layer (4) is arranged on the surface of the bottom surface of the channel body (1); the bottom cover plate (5) is arranged on the surface of the bottom thermal insulating material layer (4); and the bottom ends of the side cover plates (3) are connected with the bottom cover plate (5). Heat losses of high-temperature materials at the bottomand on the two sides in the conveying process are reduced, material leakage of a conveyor is reduced, and deformation of the conveying channel in the conveying process is reduced, so that the life cycle of the conveying channel is prolonged, and the service life of the conveyor is also prolonged.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

A large format laser cutting machine

ActiveCN112059433BGuaranteed horizontal accuracyEasy to install and disassembleLaser beam welding apparatusGear wheelElectric machinery

The present invention relates to the technical field of laser cutting equipment, in particular to a large-format laser cutting machine, including a machine tool and a racking mechanism, a gantry mechanism, a cutting mechanism, a positioning mechanism, a heat insulation mechanism and a dust removal mechanism respectively arranged on the machine tool ; The frame includes a main beam, a main longitudinal beam, a first side beam and a second side beam; the racking mechanism includes a first rack and a second rack; the gantry mechanism includes a first rack, a gantry frame, a first motor, a second rack and a guide rail; the cutting mechanism includes a moving frame, a second motor and a laser cutting machine, the moving frame is slidably connected with the guide rail, and the second motor is arranged on the moving frame , the second motor is connected to the second rack through a gear, and the laser cutting machine is installed on a moving frame; two sets of positioning mechanisms are symmetrically arranged on the first side beam and the second side beam. The large-format laser cutting machine provided by the invention can be adapted to the cutting processing of large-scale plate materials, and has high precision and good effect.

Owner:CHINA MACHINERY CNC TECH FUJIAN CO LTD

A kind of preparation method of moxa making car roof trim

ActiveCN104691440BEliminate odorPlay a heating roleLaminationLamination apparatusActivated carbonAdditive ingredient

The invention discloses a method for preparing an interior trim part of a car roof from moxa. The method comprises the following preparation steps: firstly, extracting the moxa and combing downwind to form raw material moxa; adding activated carbon formed by carbonization of elm powder and folium artemisiae argyi into the raw material moxa, hot-pressing by a mold to form a moxa car roof matched with the car roof in shape, wherein the thickness of the moxa car roof is 2-10 mm, and the inner surface of the moxa car roof is corrugated; spraying the back surface of the moxa car roof with a layer of waterproof and moisture-proof heat-insulating aluminum membrane; blending gastrodia elata or natural silk with the moxa to prepare cloth, punching a conical inverted hole in the front surface of the cloth and then covering the front surface of the moxa car roof. The method is simple in process, and the prepared interior trim part of the car roof is good in heat-insulating effect, and can fully absorb odor in the car and send out effective ingredients with sterilization and antivirus functions, thereby preventing bacteria and virus from invading a respiratory tract, preventing influenza virus and playing a role in purifying air.

Owner:河南中鸿电子科技有限公司

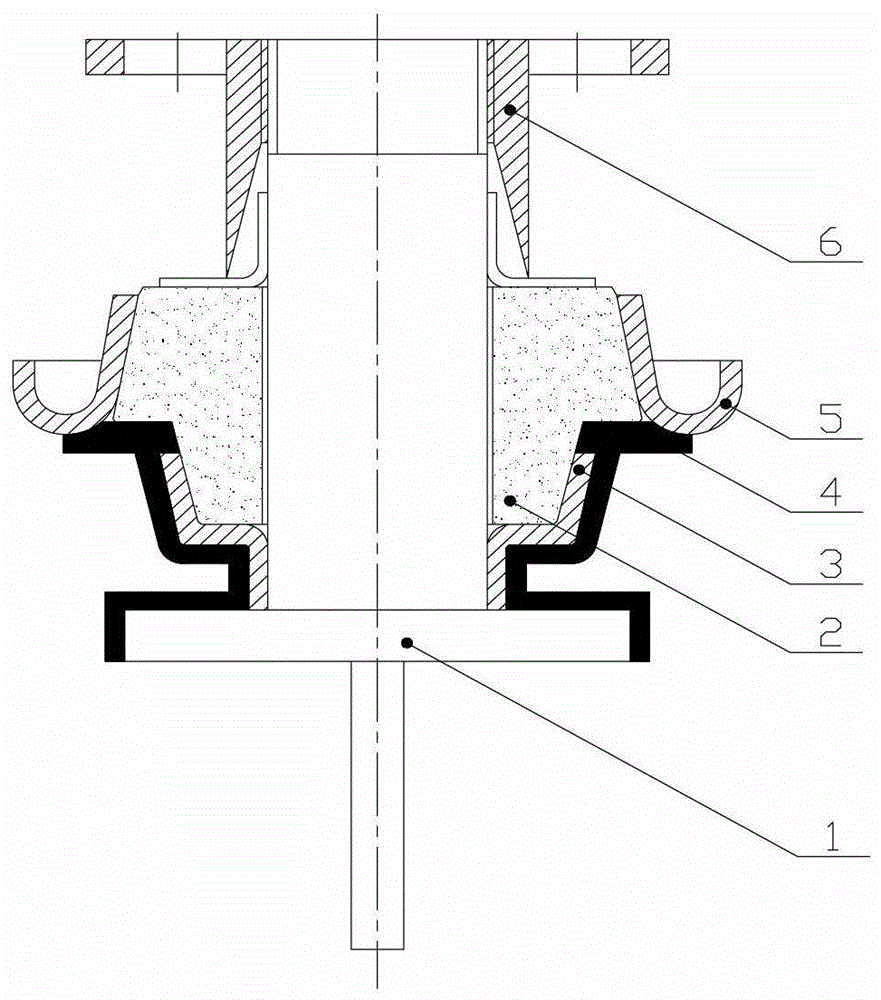

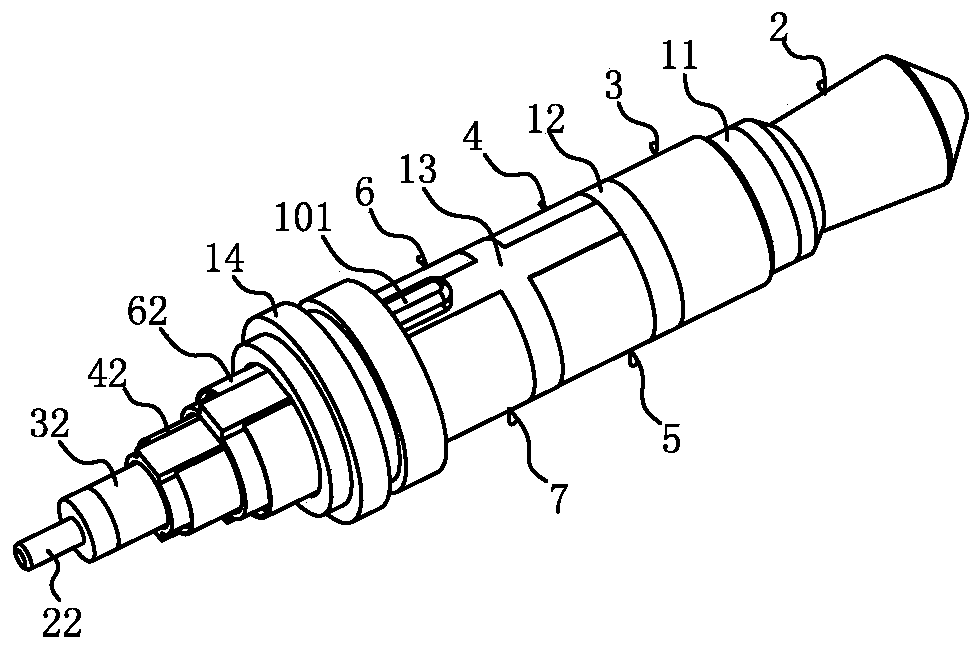

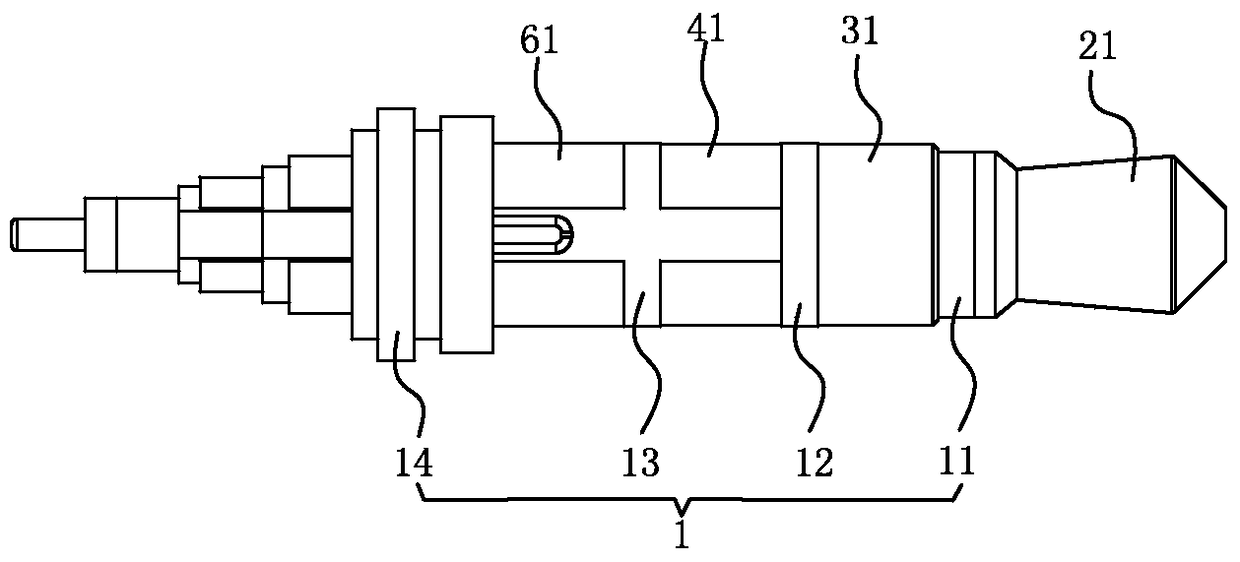

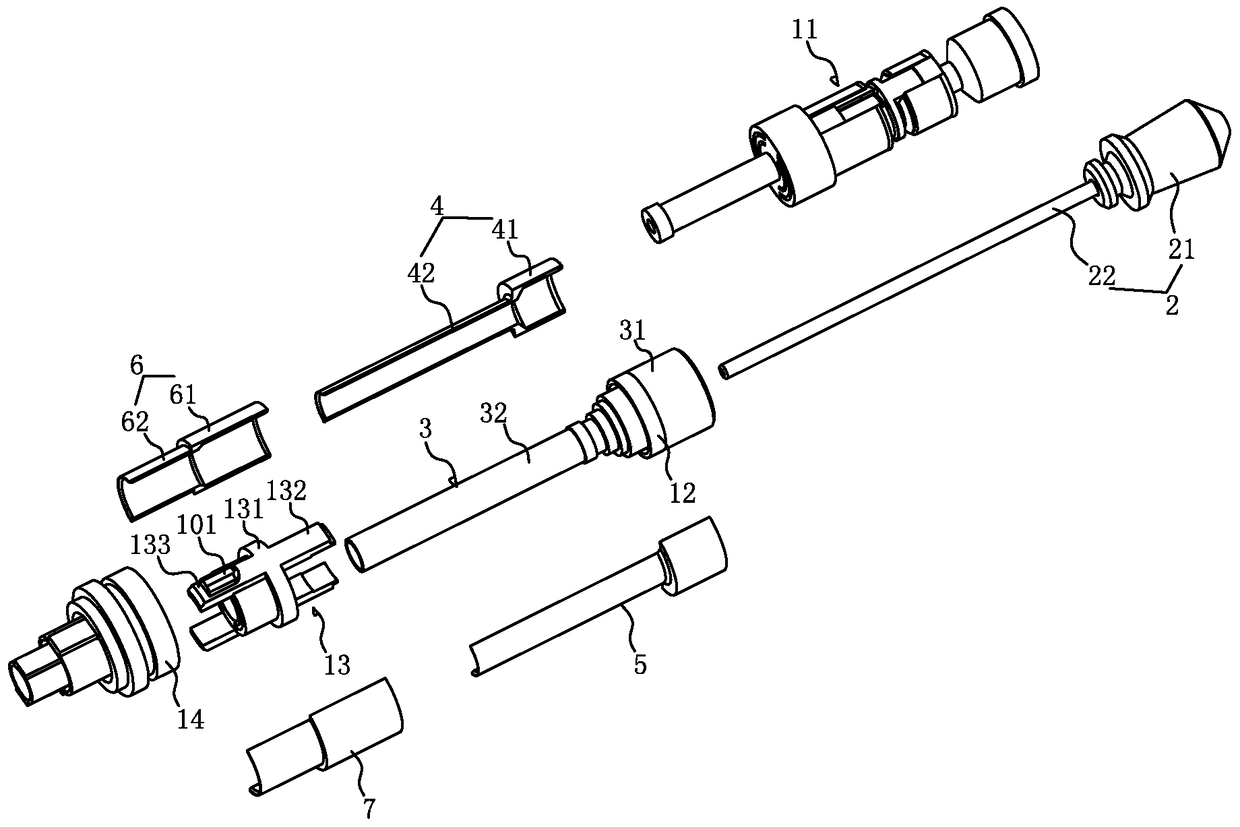

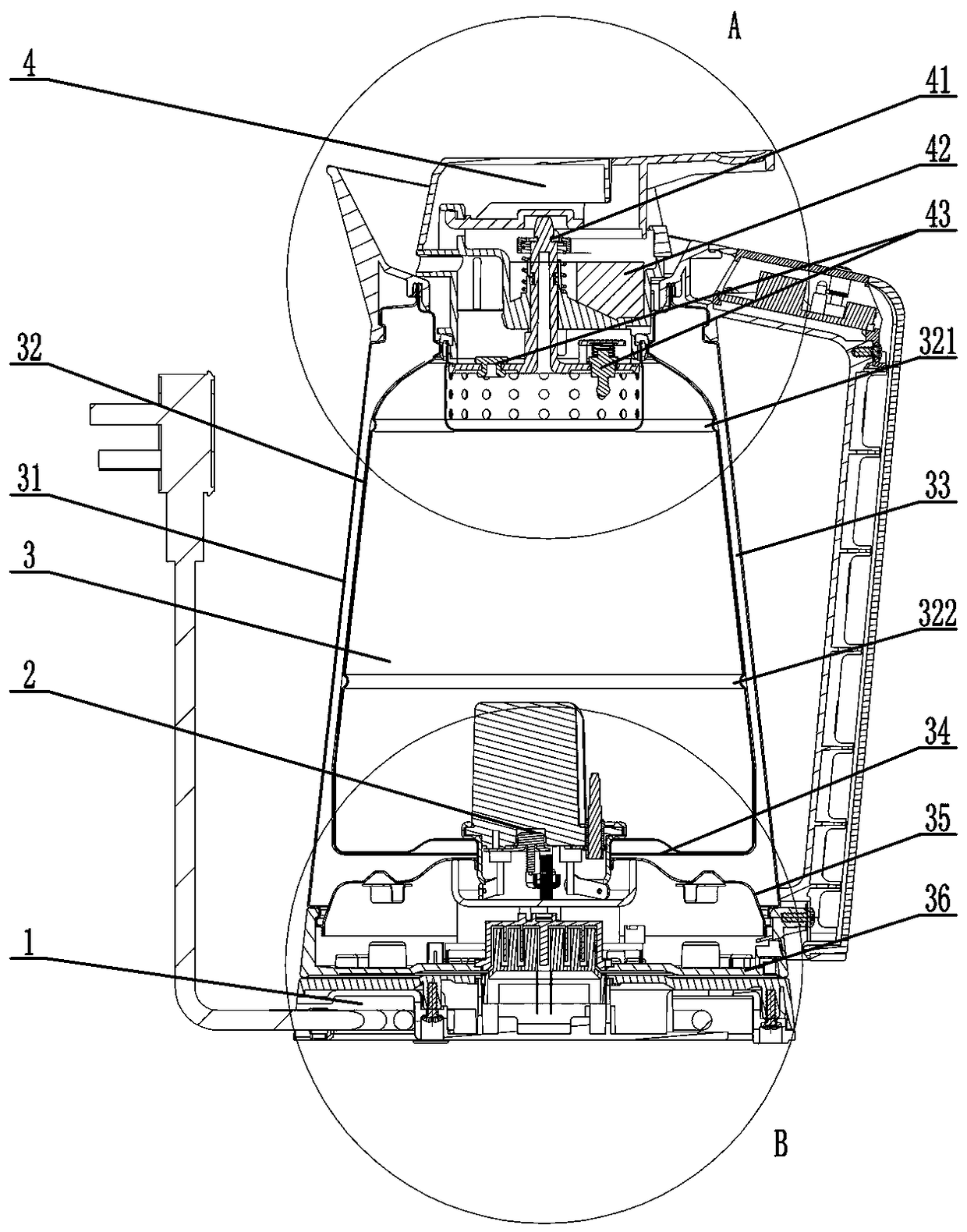

A six-level plug

InactiveCN104733891BLarge insulation areaHigh insulation resistanceSecuring/insulating coupling contact membersCoupling contact membersEngineeringMechanical engineering

A six-level plug. The six-level plug comprises: an insulator assembly (1), and a first-level conductor (2) and a second-level conductor (3) which are mounted at the periphery of the insulator assembly, wherein the first-level conductor is located at a front end of the second-level conductor, and a coaxial stepped distribution is formed; and the six-level plug further comprises third, fourth, fifth and sixth-level conductors (4, 5, 6, 7), wherein the third and fourth-level conductors are provided at the periphery of the insulator assembly symmetrically on the left and right and in parallel, and are located behind the second-level conductor, and the fifth and sixth-level conductors are provided at the periphery of the insulator assembly symmetrically on the left and right and in parallel, and are respectively located behind the third and fourth-level conductors; and the first, second, third, fourth, fifth and sixth-level conductors are all insulated from one another by the insulator assembly. Compared with the existing product, the six-level plug adds one level of conductor, and enhances the insulation among levels.

Owner:DONGGUAN RICH & PRECISION HARDWARE PROD

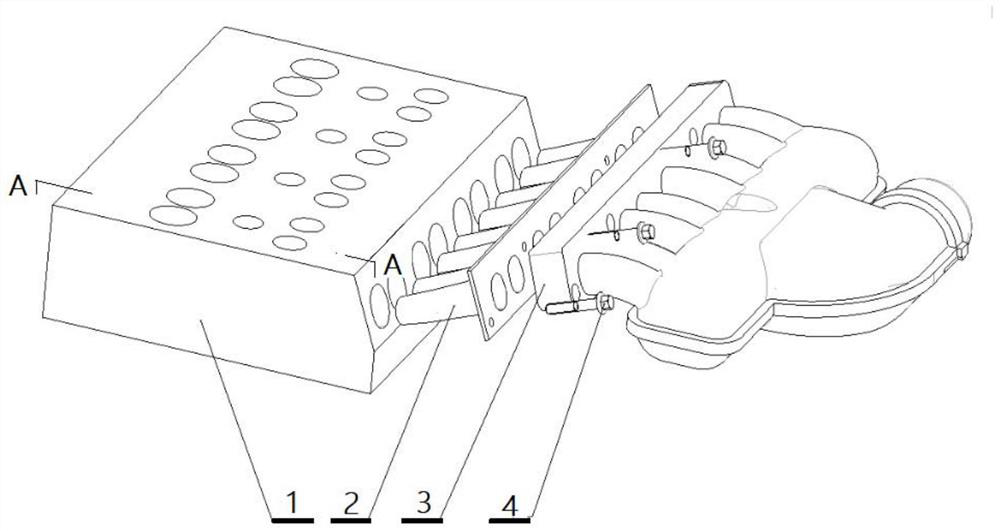

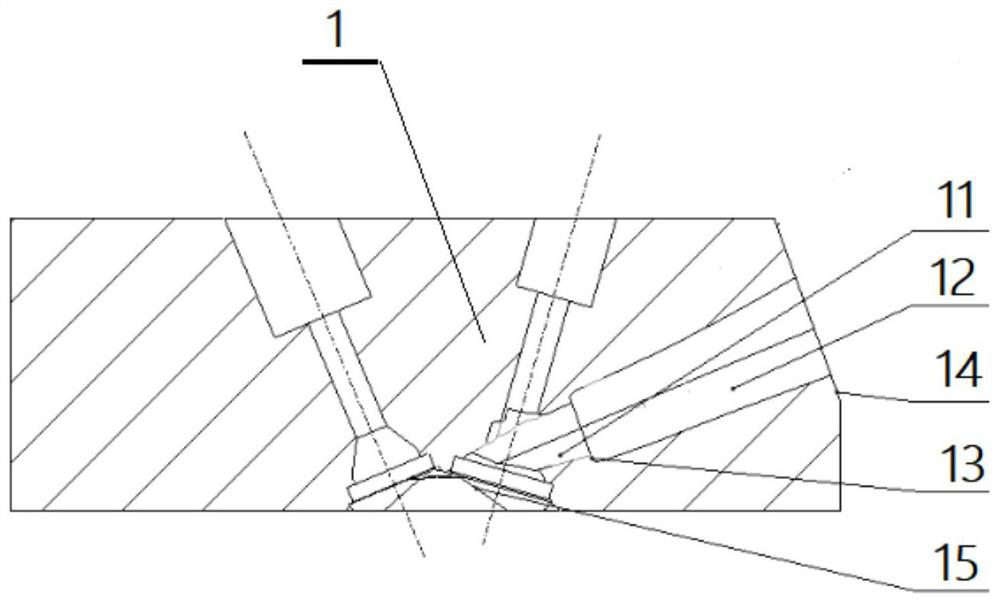

Air inlet channel heat insulation structure on air cylinder cover

InactiveCN114165350AHeat transfer barrierLarge insulation areaCylinder headsCylindersThermodynamicsInlet channel

The invention relates to an air inlet channel heat insulation structure on a cylinder cover, which comprises the cylinder cover and an air inlet manifold, a heat insulation component is arranged between the air inlet manifold and the cylinder cover, and the heat insulation component is fixedly connected with the cylinder cover and the air inlet manifold through a plurality of mounting bolts; the heat insulation component is composed of an installation face and a plurality of air channels vertically arranged on the installation face, and a plurality of bolt holes are further formed in the installation face. A plurality of upper air inlet channels are formed in the air cylinder cover, a heat insulation component matching part is arranged at the air inlet end of each upper air inlet channel, a step is arranged at the position, connected with the corresponding upper air inlet channel, of one end of each heat insulation component matching part, and the other end of each heat insulation component matching part is located on an air inlet flange face of the air cylinder cover. The multiple air channels in the heat insulation component are matched with the multiple heat insulation component matching parts of the air cylinder cover in a one-to-one correspondence mode, and gaps exist between the air channels and the heat insulation component matching parts. The cylinder cover can meet the requirements of different air inlet channels, and heat transfer between the wall face of the air inlet channel of the cylinder cover and air flowing through the wall face is effectively blocked.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Floating type brick body heat insulation structure

InactiveCN113027035AAdjustable thicknessIncreasing the thicknessConstruction materialBrickEngineering

The invention discloses a floating type brick body heat insulation structure. The heat insulation structure comprises an external decorative plate, an internal heat insulation plate and a floating assembly. The heat insulation structure is characterized in that an integrated structure of a traditional heat insulation brick is changed into a mounting structure with the internal heat insulation plate floating on the inner side of the external decorative plate; a driving gear is rotated to drive a floating plate to float up and down, so as to drive the internal heat insulation plate to float up and down, such that a thickness of the entire heat insulation brick is adjusted; in addition, if a heat insulation effect of the heat insulation brick needs to be improved, the internal heat insulation plate can be adjusted to be far away from the external decorative plate, so that the thickness of a heat insulation adjusting gap between an insertion lug on the outer side of the internal heat insulation plate and an insertion groove in the inner side face of the external decorative plate is increased, and an air heat insulation space is increased. The heat insulation structure is flexible to use and adjustable in heat insulation effect.

Owner:港泰耐火材料(江苏)有限公司

An electric heating full vacuum insulation kettle

ActiveCN106473600BLarge insulation areaProduce anti-scald effectCooking-vessel lids/coversWater-boiling vesselsDirect heatingWater bottle

The invention discloses an electric heating full-vacuum heat preservation kettle which comprises a kettle lid, a kettle body, a base and a heating assembly. The kettle body comprises a shell, an inner container, a kettle body upper bottom and a kettle body lower bottom. The lower end of the shell is connected with the outer edge of the kettle body upper bottom. The lower end of the inner container is bent inwards to be connected with the inner edge of the kettle body upper bottom to form a heating hole. The inner container, the shell and the kettle body upper bottom form a vacuum layer. The kettle body lower bottom and the lower end of the shell are connected. One end of the heating assembly stretches into the inner container through the heating hole, the other end of the heating assembly is located in the space formed by the kettle body and the kettle body lower bottom, a sealing water outlet device is arranged on the kettle lid, and a pressure relief device is arranged on the sealing water outlet device. The vacuum layer can increase the heat preservation performance and generate the anti-scalding effect; due to the fact that only the heating hole into which the heating assembly can stretch is reserved in the bottom of the kettle body, the area of vacuum heat preservation is increased, heat emitted from the bottom is reduced, the heat preservation effect is improved, one end of the heating assembly directly stretches into the inner container to directly heat liquid, and the heating efficiency is greatly improved.

Owner:浙江南龙工贸有限公司

Foam thermal insulation device of PC thermal insulation wallboard of residence building and PC thermal insulation wallboard

The invention provides a foam thermal insulation device of a PC thermal insulation wallboard of a residence building. The foam thermal insulation device comprises a plurality of horizontally arranged thermal insulation block sets and a third thermal insulation block. The thermal insulation block sets comprise the first thermal insulation block set and the second thermal insulation block set which are perpendicularly and symmetrically arranged; the first thermal insulation block set and the second thermal insulation block set are arranged by an angle; the first thermal insulation block set comprises a plurality of overlapped first thermal insulation blocks; the second thermal insulation block set comprises a plurality of overlapped second thermal insulation blocks; the third thermal insulation block is arranged between the first thermal insulation block set and the second thermal insulation block set; the third thermal insulation block is provided with a first inclined face and a second inclined face which are symmetric; the first inclined face is fixedly connected with the first thermal insulation block set; the second inclined face is fixedly connected with the second thermal insulation block set; and a cavity is further formed inside the third thermal insulation block. The invention further provides the PC thermal insulation wallboard. Compared with the prior art, the foam thermal insulation device of the PC thermal insulation wallboard of the residence building and the PC thermal insulation wallboard have the excellent thermal insulation performance.

Owner:苏州良浦节能新材料股份有限公司

Anti-scalding handle of pot cover

InactiveCN105615669ALarge insulation areaEasy to install appsCooking-vessel lids/coversStructural engineeringMechanical engineering

The invention provides an anti-scalding handle of a pot cover. The anti-scalding handle is made of rubber, has certain elasticity, is suitable for an arc-shaped pot cover, is firm in use, safe in application, easy to mount and use, and convenient to maintain, and is particularly suitable for the old and weak as well as common children.

Owner:XIAN SHENKE ELECTRONICS RES INST

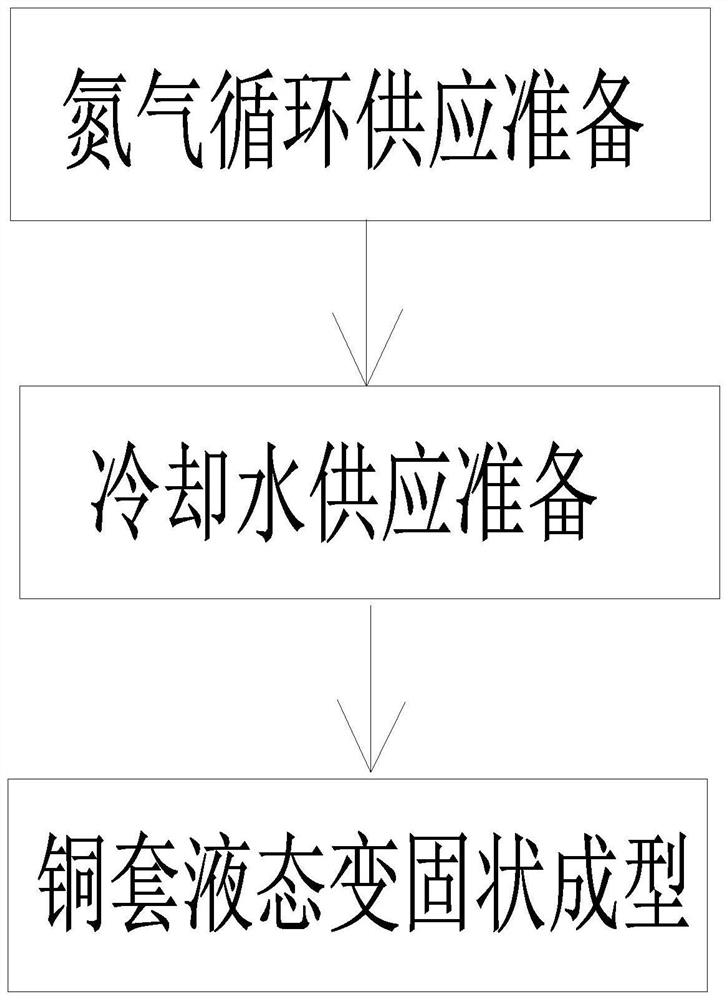

Method for protecting crystallizer by nitrogen to reduce loss

A method for protecting a crystallizer through nitrogen to reduce loss comprises the following steps that a, nitrogen circulation supply preparation is conducted, specifically, a nitrogen circulation groove is formed in the position, away from an end opening, of the crystallizer, nitrogen inlet holes are evenly distributed in the nitrogen circulation groove, and the nitrogen circulation groove is communicated with the nitrogen inlet holes so that nitrogen can be supplied in a circulation mode; b, cooling water supply preparation: transforming a plurality of water inlets and water outlets of the water jacket into smooth water inlets and water outlets with inclination of 45 degrees and rotating shapes, so that the cooling water flows smoothly and uniformly for cooling; c, the copper sleeve is formed in a liquid-to-solid state, high-pressure cooling water is arranged outside the copper sleeve, and high-temperature copper water is arranged inside the copper sleeve; the inner hole of the high-temperature-resistant graphite gasket of the mold body is reduced, so that the heat insulation area of the copper sleeve at the heat insulation end is increased, the sealing and heat insulation effects are realized, and the copper sleeve is effectively protected to reduce the loss of the crystallizer. The method is high in work efficiency, effectively enlarges the heat insulation area of the copper sleeve at the heat preservation end and effectively protects the copper sleeve; and the cooling is smooth and uniform, the surface of the pipe blank is smooth, the cost is saved, and the quality and casting efficiency are improved.

Owner:佛山建投华鸿铜业有限公司

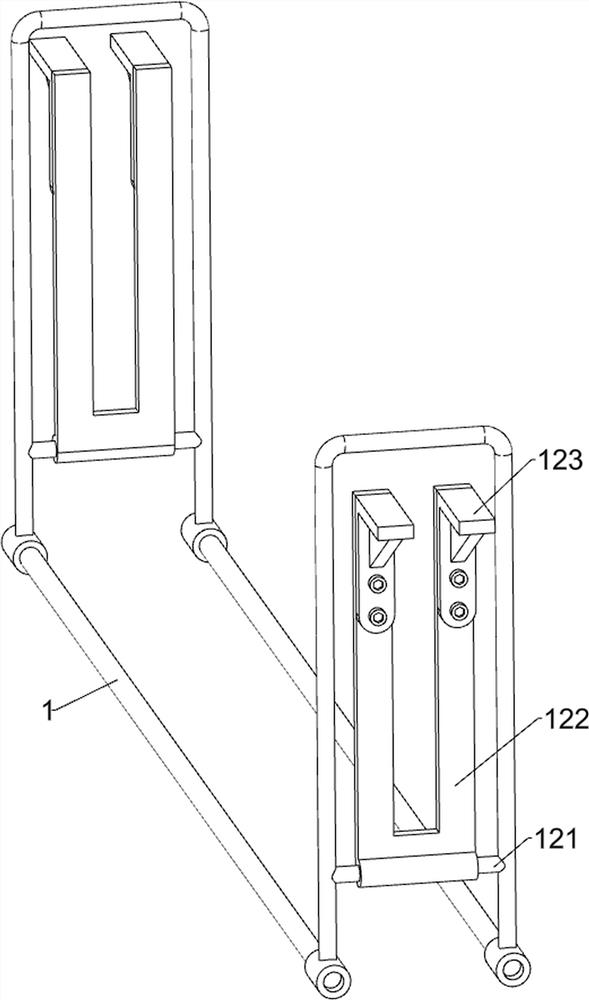

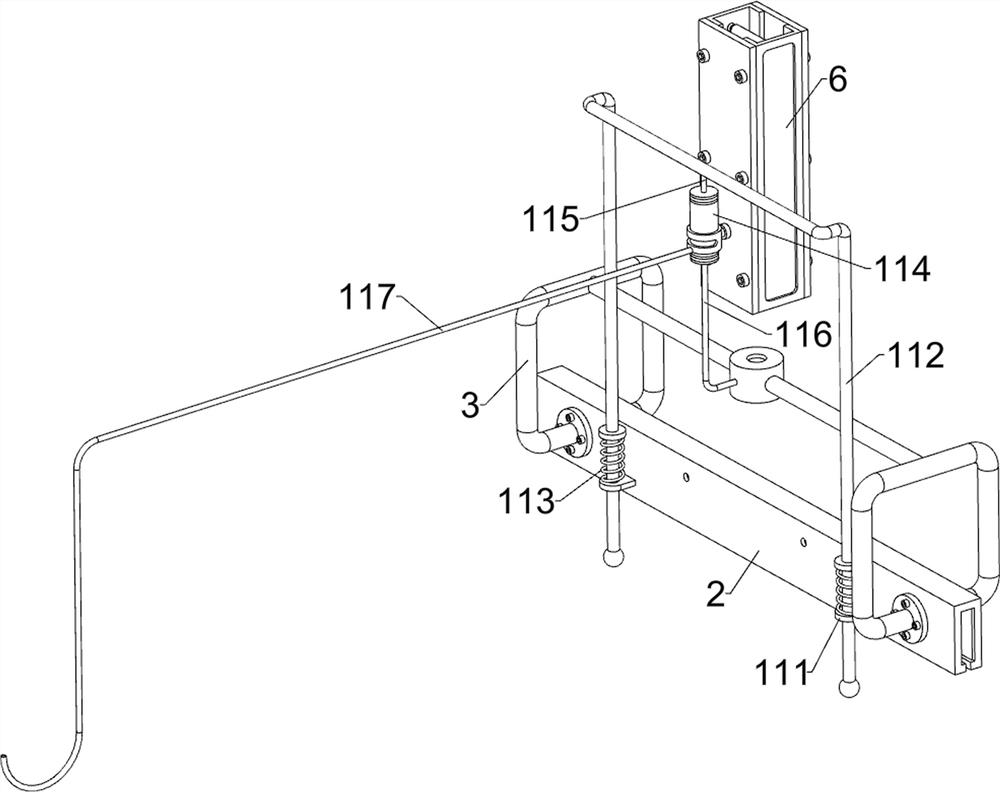

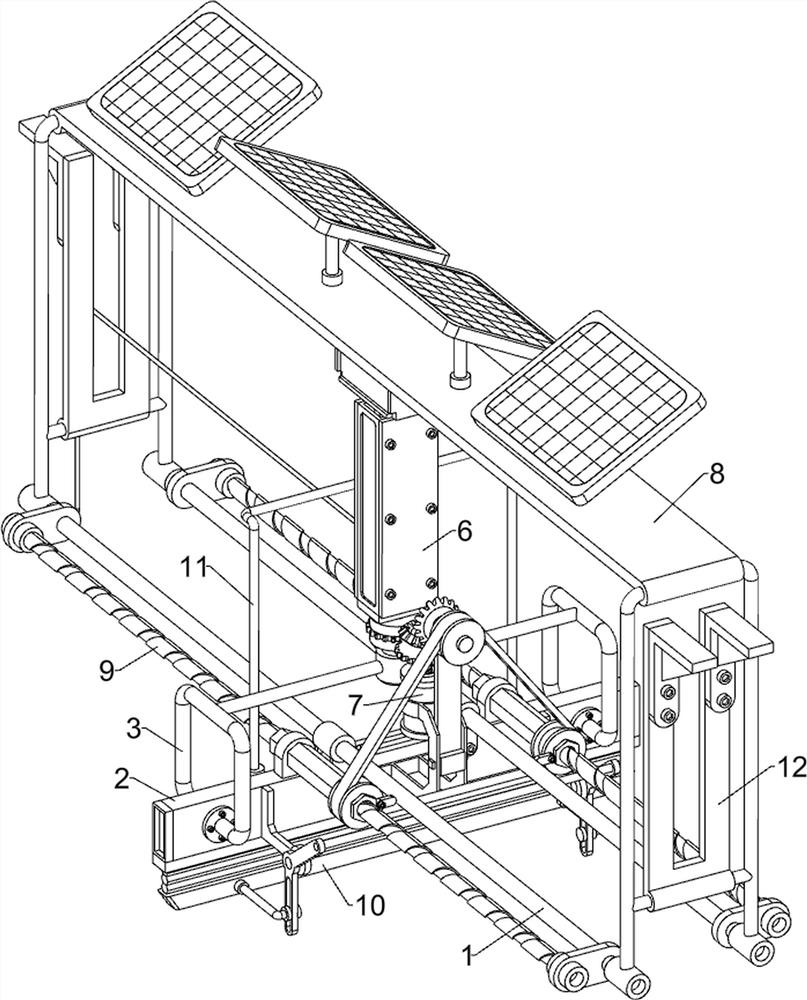

Solar heat preservation device for vegetable cultivation

PendingCN114568182AReduce consumptionSpray evenlyClimate change adaptationGreenhouse cultivationPhotovoltaic solar energyThermodynamics

The invention relates to a heat preservation device for vegetable cultivation, in particular to a solar heat preservation device for vegetable cultivation, which comprises a guide frame, a frame body, an air inlet pipe, a cylinder, a gear ring, a heater, an extraction assembly and a power generation assembly, the lower part of the guide frame is slidably connected with the frame body, the frame body is connected with the air inlet pipe, and the middle upper part of the air inlet pipe is connected with the cylinder; the middle of the cylinder is rotationally connected with a gear ring, the top of the cylinder communicates with a heater, an extraction assembly is arranged between the frame and the gear ring, and a power generation assembly is arranged on the guide frame. The photovoltaic solar panel can absorb solar energy and convert the solar energy into electric energy to be stored in the storage battery, and the storage battery can supply power to the heater and the gear motor, so that the effects of reducing the consumption of electric power resources and preserving heat of vegetables cultivated in the greenhouse by using the solar energy are achieved.

Owner:张岩

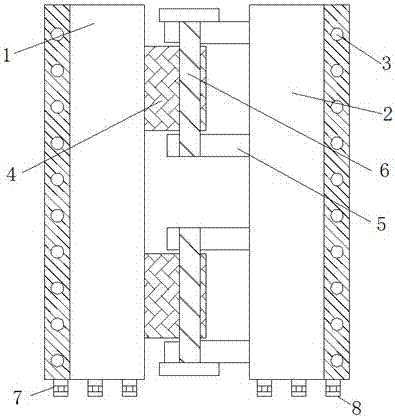

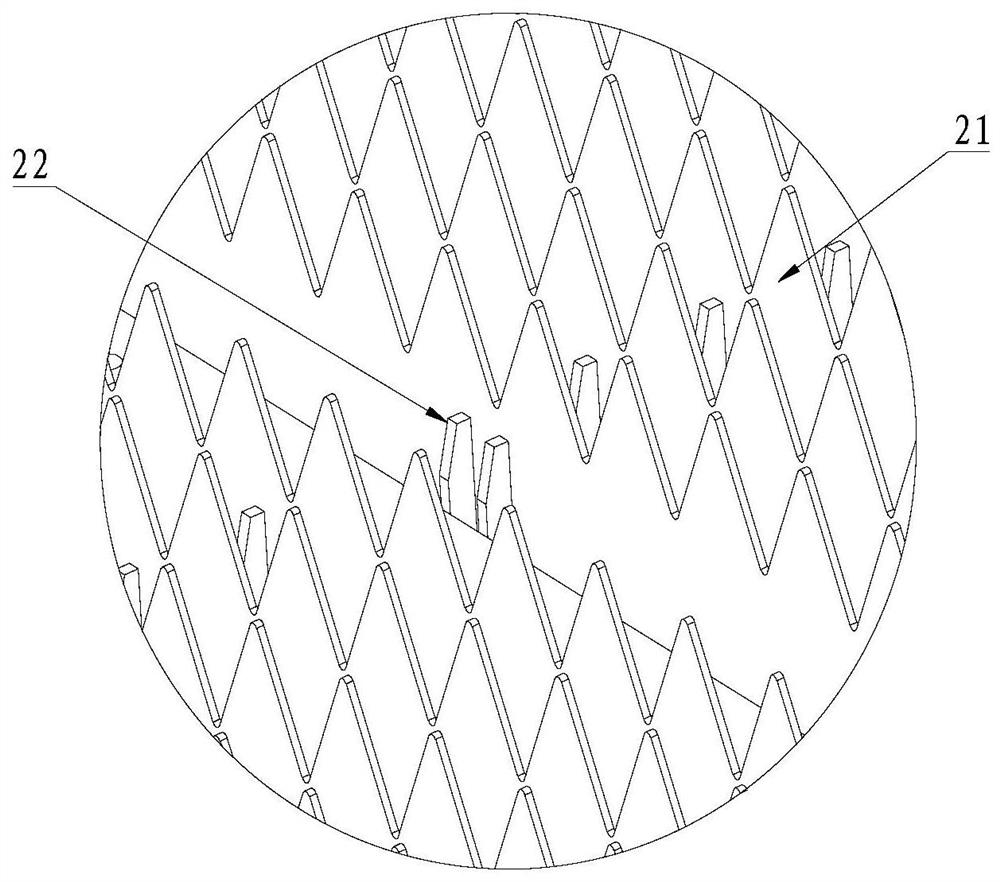

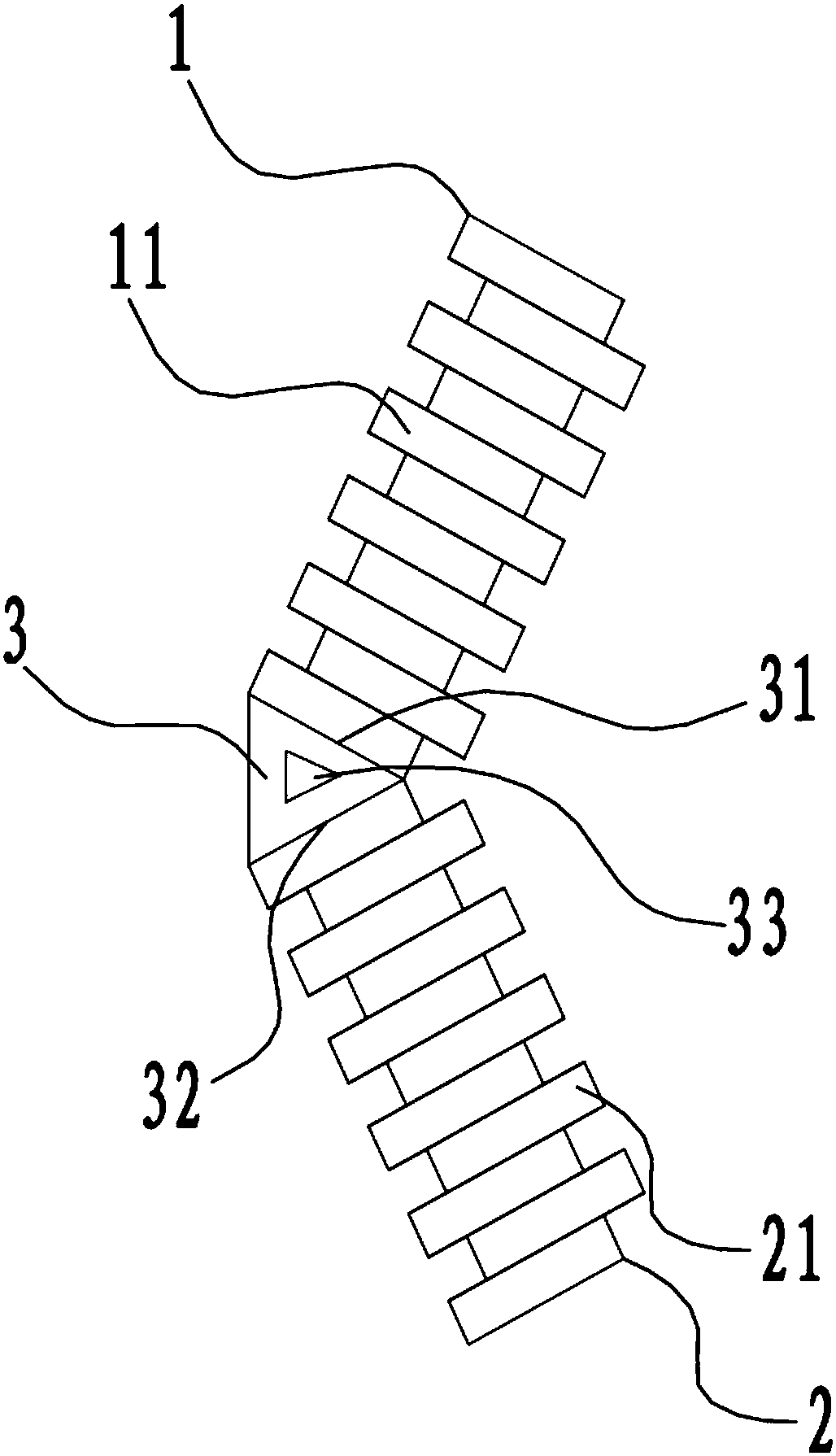

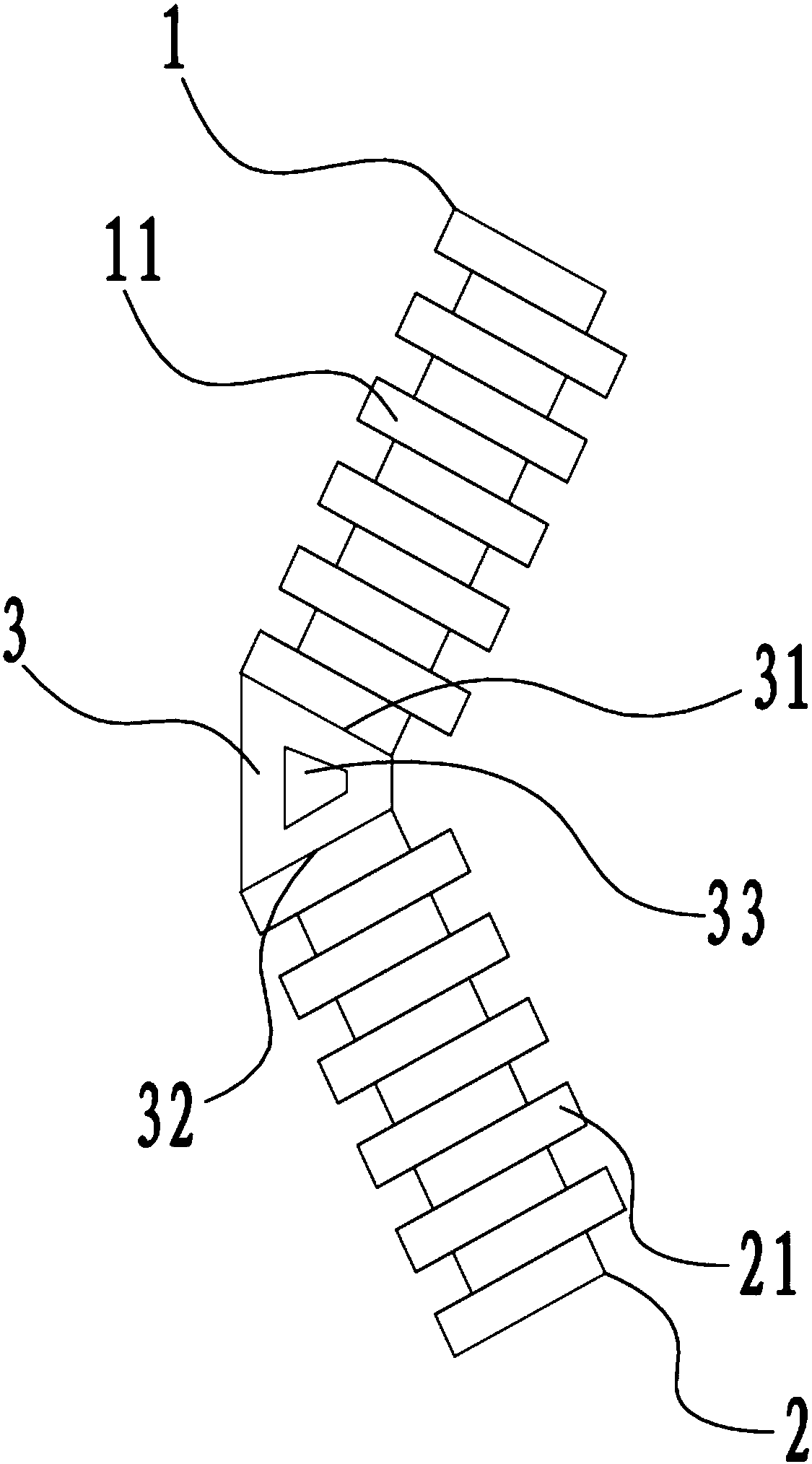

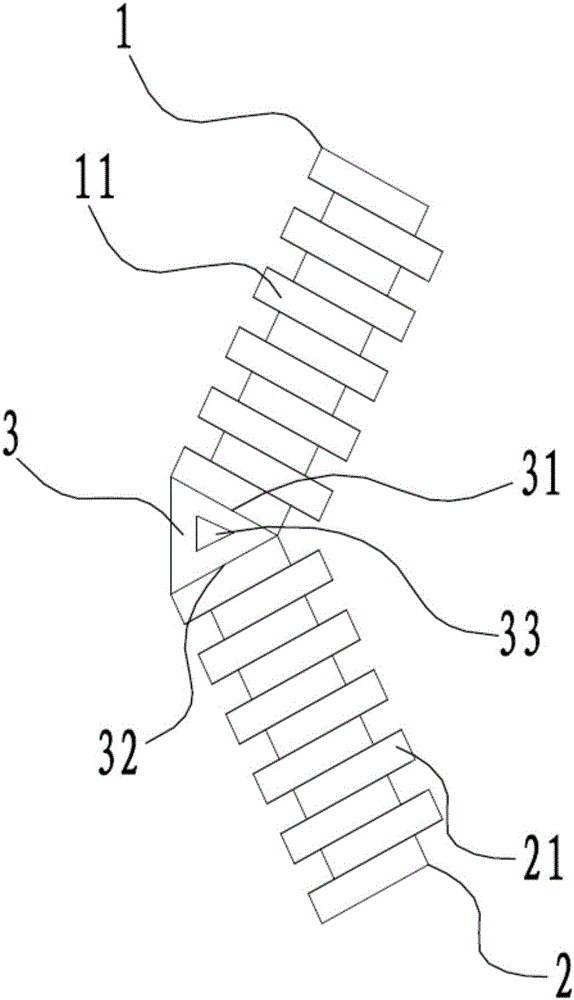

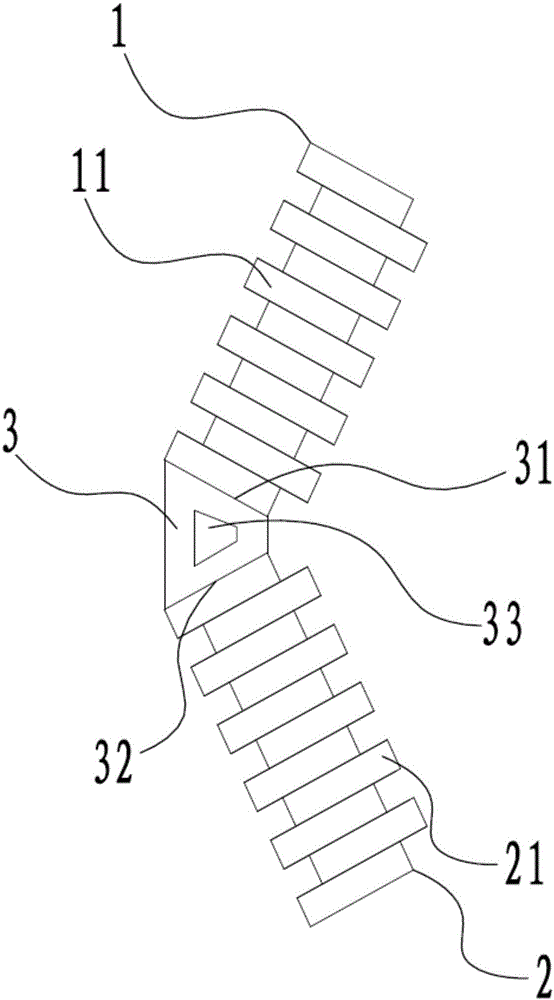

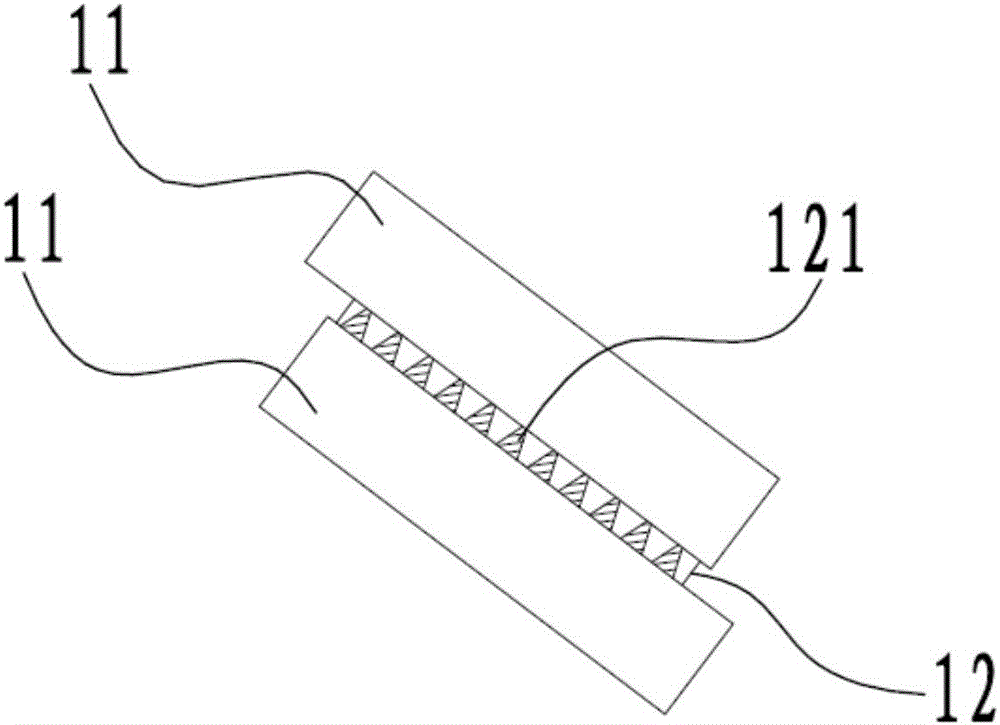

Thermal-insulation device for PC thermal-insulation embedded column of residence building and PC thermal-insulation embedded column

ActiveCN106121066ALarge deformationLarge insulation areaStrutsHeat proofingResidenceThermal insulation

The invention provides a thermal-insulation device for a PC thermal-insulation embedded column of a residence building. The thermal-insulation device comprises a first thermal-insulation block set, a second thermal-insulation block set and a third thermal-insulation block, wherein the first thermal-insulation block set and the second thermal-insulation block set are symmetrically arranged with an included angle. The first thermal-insulation block set comprises a plurality of overlaid first thermal-insulation blocks, and the second thermal-insulation block set comprises a plurality of overlaid second thermal-insulation blocks. The third thermal-insulation block is arranged between the first thermal-insulation block set and the second thermal-insulation block set and provided with a first inclined face and a second inclined face symmetrical with the first inclined face. The first inclined face is fixedly connected with the first thermal-insulation block set, the second inclined face is fixedly connected with the second thermal-insulation block set, and the third thermal-insulation block is further internally provided with a cavity. Meanwhile, the invention provides the PC thermal-insulation embedded column. Compared with the prior art, the thermal-insulation device for the PC thermal-insulation embedded column of the residence building and the PC thermal-insulation embedded column have more excellent thermal insulation performance.

Owner:苏州良浦节能新材料股份有限公司

Large-breadth laser cutting machine convenient for sucking and removing machining chips

ActiveCN114654111AGuaranteed horizontal accuracyEasy to install and disassembleLaser beam welding apparatusElectric machineDust control

The invention relates to the technical field of laser cutting equipment, in particular to a large-breadth laser cutting machine which comprises a machine tool as well as a material supporting mechanism, a gantry mechanism, a cutting mechanism, a position adjusting mechanism, a heat insulation mechanism and a dust removal mechanism which are respectively arranged on the machine tool, the machine tool comprises a main cross beam, a main longitudinal beam, a first edge beam and a second edge beam. The material supporting mechanism comprises a first material frame and a second material frame; the gantry mechanism comprises a first rack, a gantry frame, a first motor, a second rack and a guide rail; the cutting mechanism comprises a moving frame, a second motor and a laser cutting machine, the moving frame is slidably connected with the guide rail, the second motor is arranged on the moving frame and connected with the second rack through a gear, and the laser cutting machine is installed on the moving frame; and the two groups of position adjusting mechanisms are symmetrically arranged on the first edge beam and the second edge beam. The large-breadth laser cutting machine can adapt to cutting machining of large-breadth plates, and is high in precision and good in effect.

Owner:CHINA MACHINERY CNC TECH FUJIAN CO LTD

The thermal insulation device of the pc thermal insulation concealed column of the building and the house and the pc thermal insulation concealed column

ActiveCN106121066BLarge deformationLarge insulation areaStrutsHeat proofingResidenceThermal insulation

The invention provides a thermal-insulation device for a PC thermal-insulation embedded column of a residence building. The thermal-insulation device comprises a first thermal-insulation block set, a second thermal-insulation block set and a third thermal-insulation block, wherein the first thermal-insulation block set and the second thermal-insulation block set are symmetrically arranged with an included angle. The first thermal-insulation block set comprises a plurality of overlaid first thermal-insulation blocks, and the second thermal-insulation block set comprises a plurality of overlaid second thermal-insulation blocks. The third thermal-insulation block is arranged between the first thermal-insulation block set and the second thermal-insulation block set and provided with a first inclined face and a second inclined face symmetrical with the first inclined face. The first inclined face is fixedly connected with the first thermal-insulation block set, the second inclined face is fixedly connected with the second thermal-insulation block set, and the third thermal-insulation block is further internally provided with a cavity. Meanwhile, the invention provides the PC thermal-insulation embedded column. Compared with the prior art, the thermal-insulation device for the PC thermal-insulation embedded column of the residence building and the PC thermal-insulation embedded column have more excellent thermal insulation performance.

Owner:苏州良浦节能新材料股份有限公司

Rectifier diode

ActiveCN110164842AEasy to fixFit tightlySemiconductor/solid-state device detailsSolid-state devicesThermal insulationRectifier diodes

The invention belongs to the technical field of diodes, in particular to a rectifier diode comprising a body and pins which are mounted at the two ends of the body. The vertical sections of the pins penetrate through the through holes on the surface of a circuit board. Inverted pins are fixedly connected on the outer side of the vertical sections of the pins. A pressing capsule is arranged at thebottom of the body and positioned between the two pins. The pressing capsule and the inverted pins are arranged, and the pressing capsule is extruded to deform to the two sides and the pressing capsule is closely fit with the body when the two pins on the body are inserted into the through holes on the circuit board so that thermal insulation of the body can be realized and the stability of conduction can be enhanced; meanwhile, the inverted pins on the pins are clamped at the bottom of the circuit board under the push of the restoring force of the pressing capsule so as to have a good fixingeffect on the pins and improve the stability of connection; meanwhile, the pins are tightly adhered to the circuit board when the pressing capsule pushes the pins outward, thereby improving the stability of conduction.

Owner:泰州镭昇光电科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com