Electric heating full-vacuum heat preservation kettle

An all-vacuum, electric heating technology, applied in water-boiling utensils, cooking utensil lids, cooking utensils shells/sleeves, etc., can solve the problems of reducing the effect of heat preservation, scalding users, low heating efficiency, etc., to enhance the effect of heat preservation , The effect of improving thermal insulation performance and improving heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

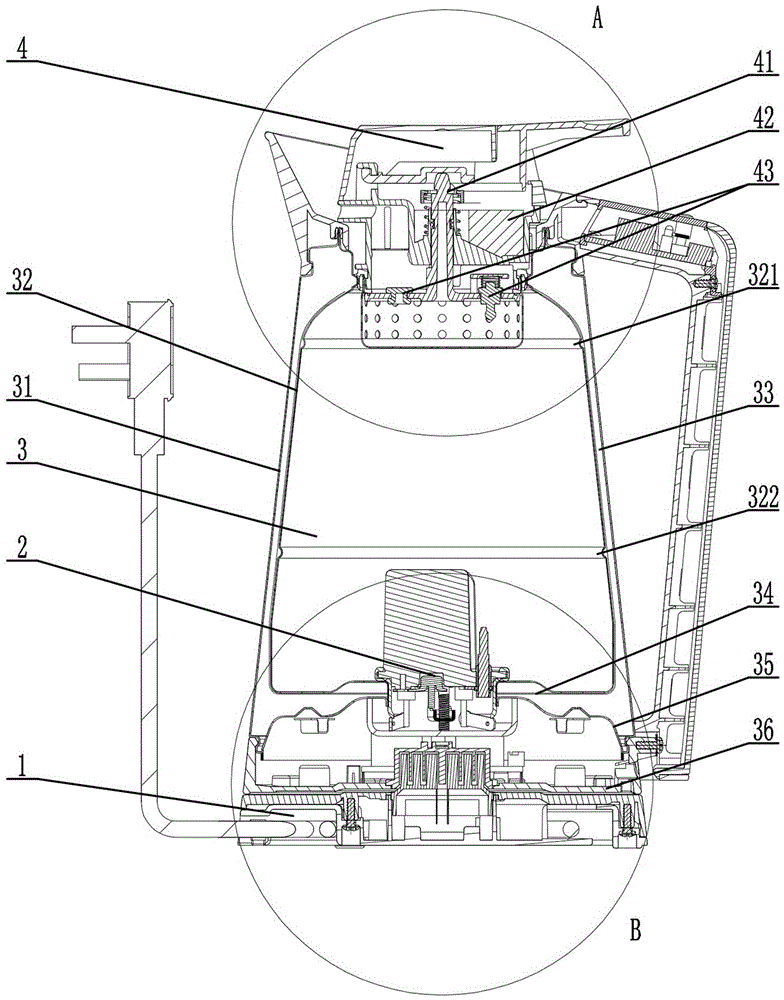

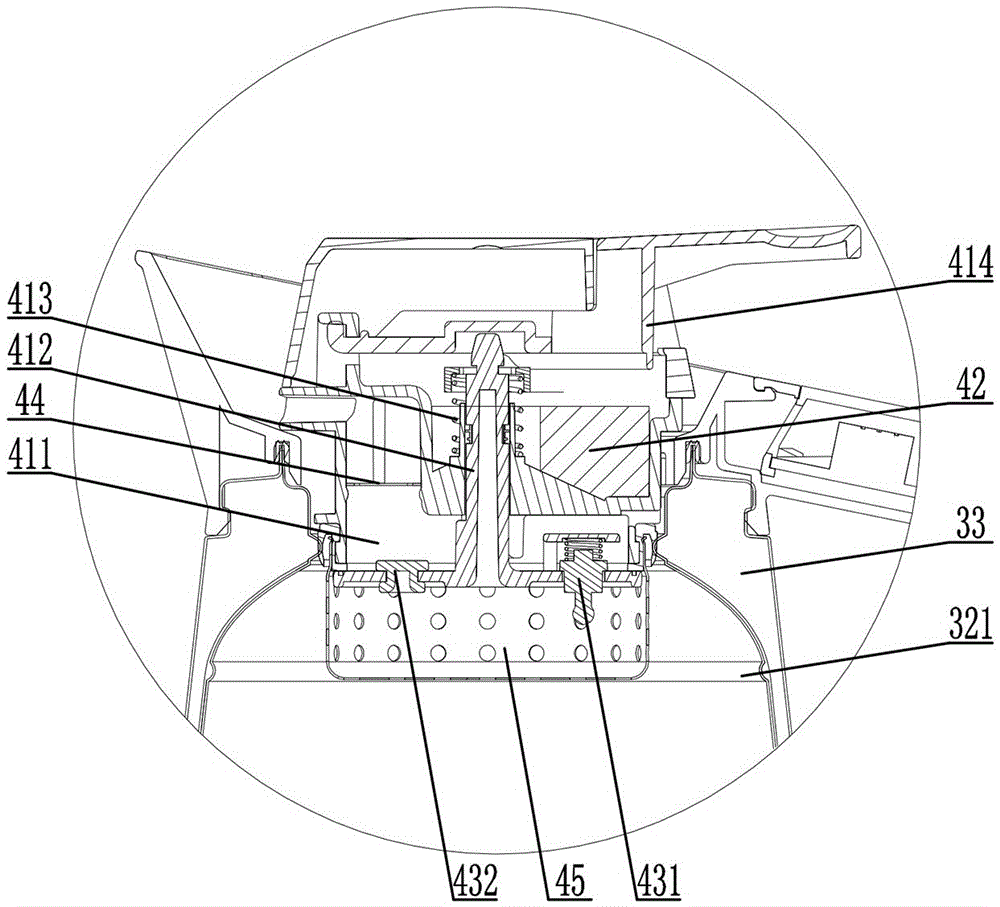

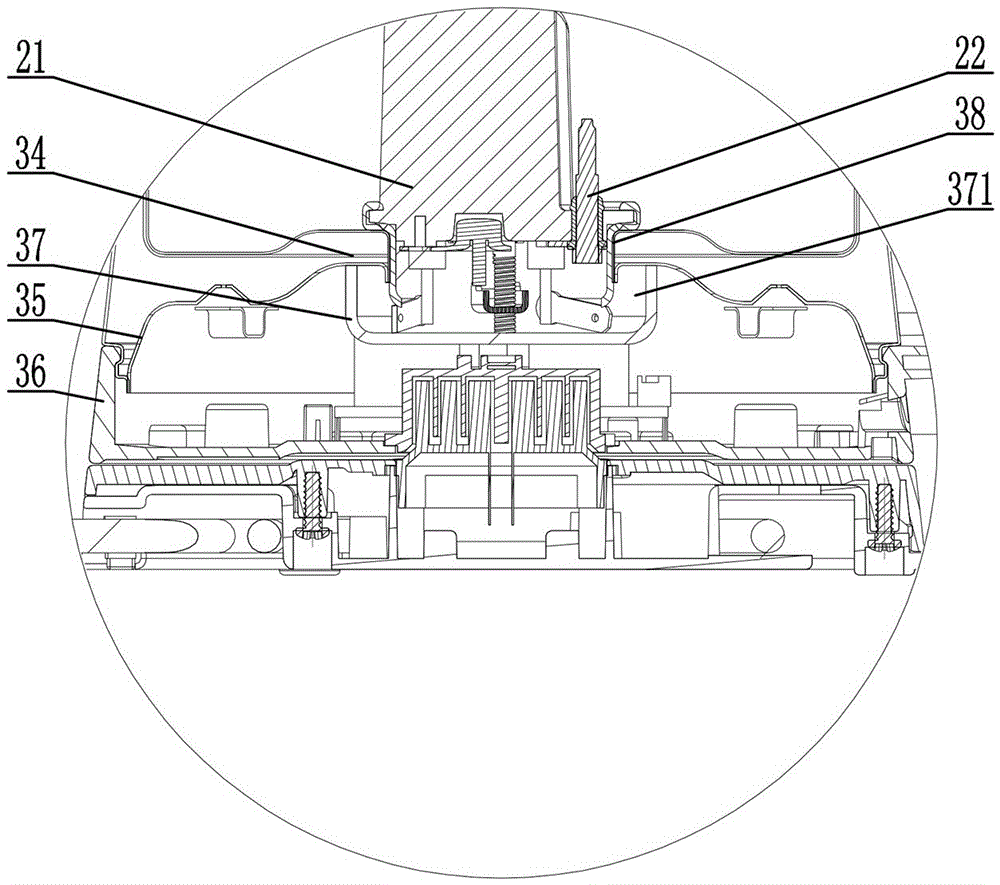

[0027] Such as Figure 1 to Figure 6 As shown, an electric heating full vacuum insulation kettle includes a lid 4, a body 3, a base 1, and a heating assembly 2. The body 3 includes a shell 31 and an inner tank 32. The top of the inner tank 32 is connected to the outer shell 31 top is connected, the kettle body 3 also includes a kettle body bottom 35 and a kettle body bottom 36, the lower end of the shell 31 is connected with the outer edge of the kettle body bottom 35, and the lower end of the inner tank 32 is bent inward Folding is connected with the inner edge of the bottom 35 of the kettle body and forms a heating hole 38. A vacuum layer 33 is formed between the inner tank 32, the shell 31 and the bottom 35 of the kettle body. The bottom 36 of the kettle body and the shell 31 The lower ends are connected, one end of the heating assembly 2 extends into the inner container 32 through the heating hole 38, and the other end of the heating assembly 2 is located in the space form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com