Method for protecting crystallizer by nitrogen to reduce loss

A nitrogen protection and crystallizer technology, applied in the field of nitrogen protection crystallizer, can solve the problems of high crystallizer use cost, not too straight nozzle angle, blocked cooling water, etc., to improve quality and casting efficiency, smooth surface of tube billet, The effect of reducing the number of mold changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

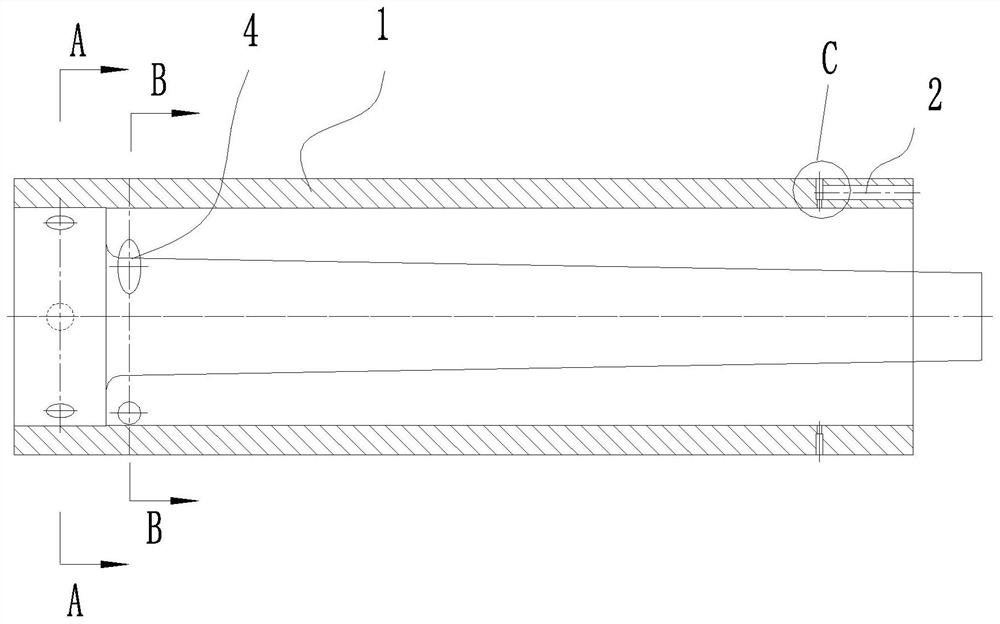

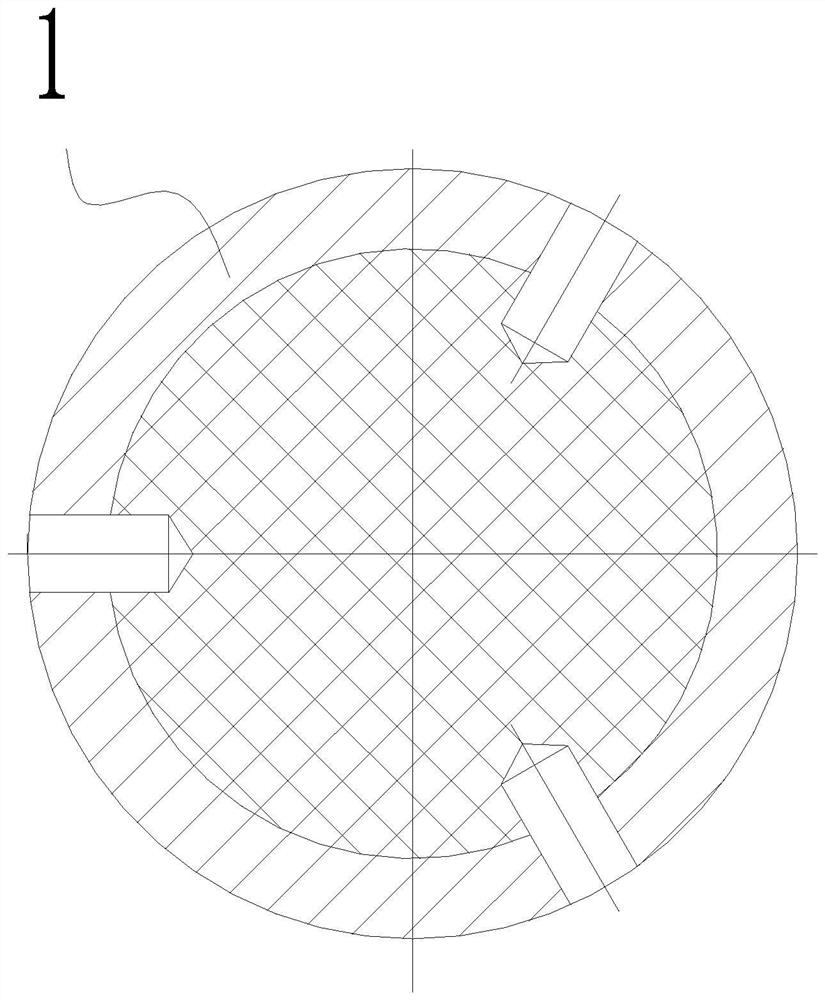

[0020] The following describes in detail the embodiments of the present invention, examples of which are illustrated in the accompanying drawings, wherein the same or similar reference numerals refer to the same or similar elements or elements having the same or similar functions throughout.

[0021] The orientations shown in the drawings should not be construed as limiting the specific protection scope of the present invention, but only for reference and understanding of the preferred embodiments. The product components shown in the drawings may be changed in position or increased in number or simplified in structure.

[0022] The "connection" described in the description and the mutual "connection" relationship of the components shown in the accompanying drawings can be understood as a fixed connection or a detachable connection or an integral connection; it can be directly connected or connected through an intermediate medium. Those of ordinary skill in the art can understan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com