Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Large bending stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

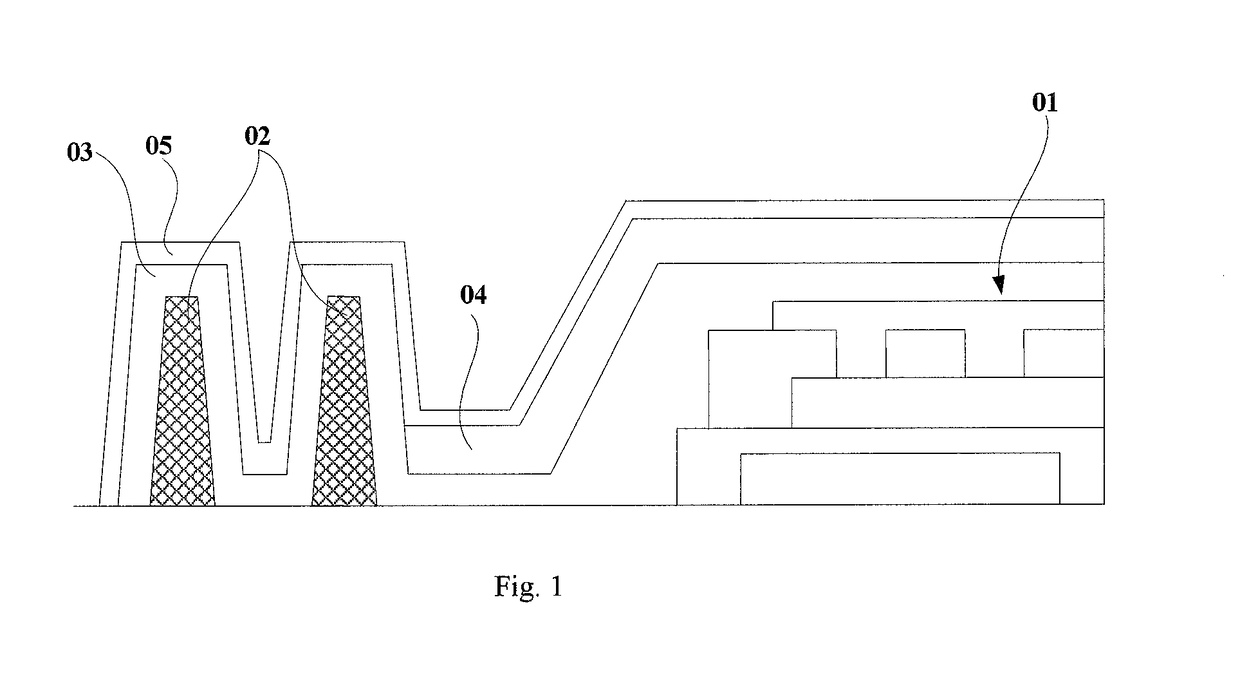

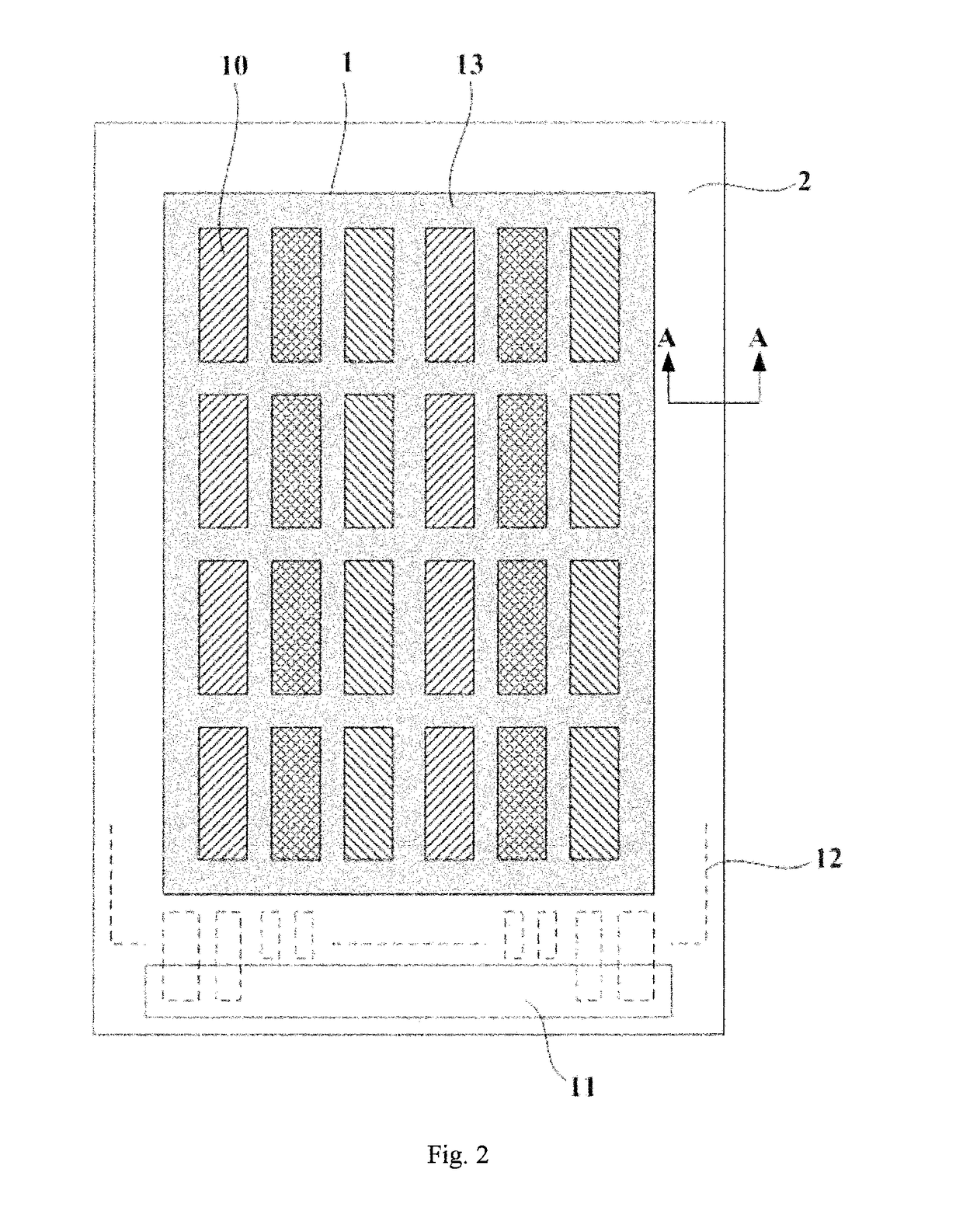

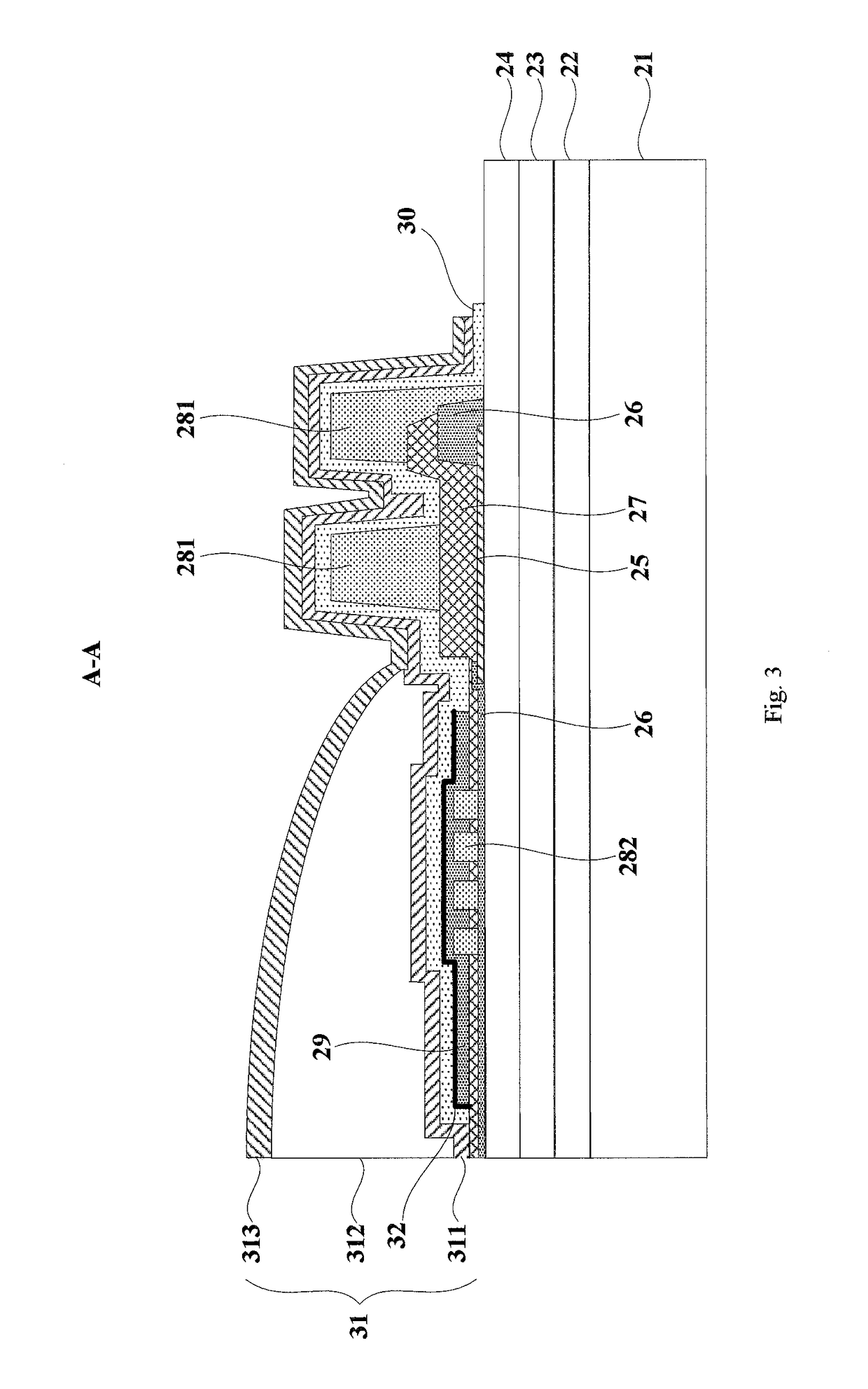

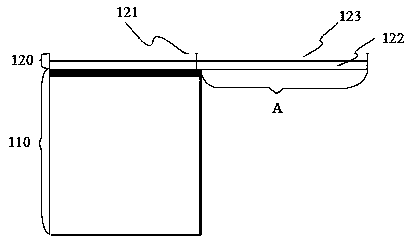

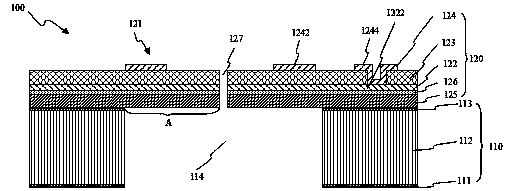

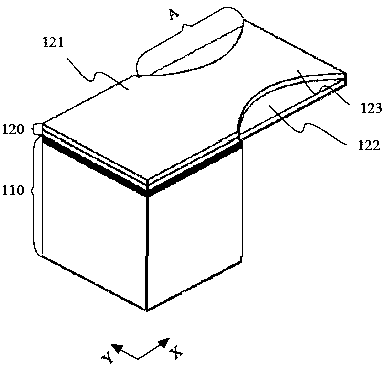

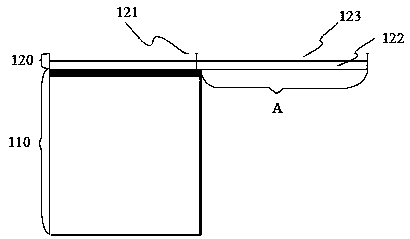

Display panel and method for manufacturing same

PendingCN108898954AImprove stabilityImprove support strengthIdentification meansEngineeringUltimate tensile strength

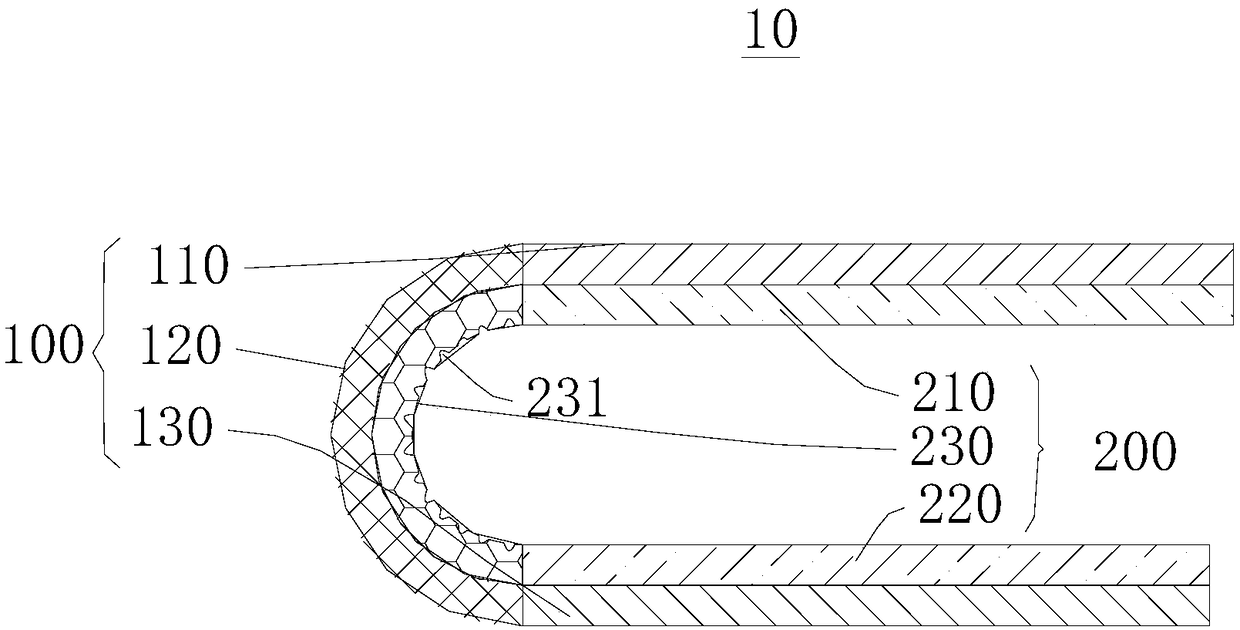

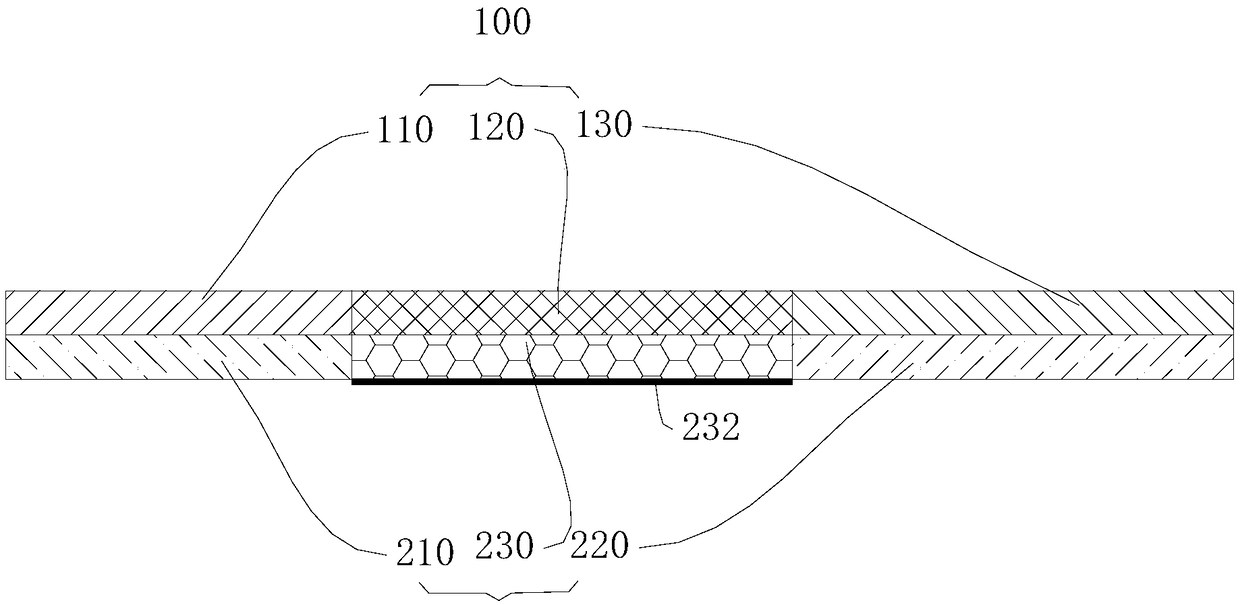

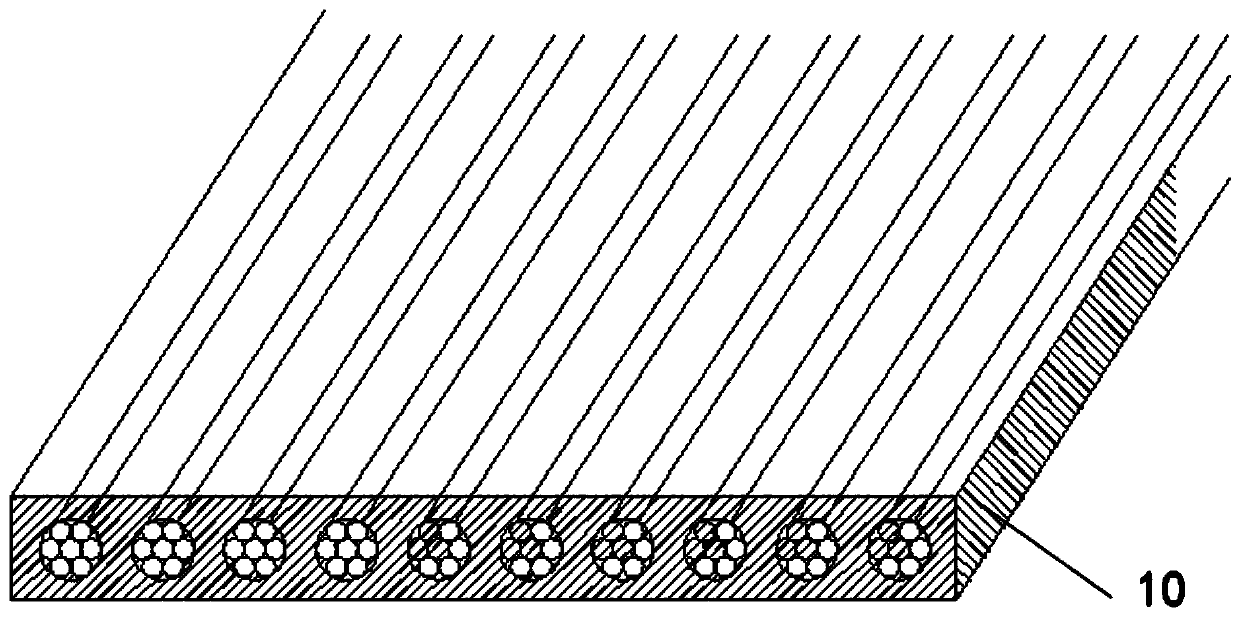

The present application relates to a display panel and a method for manufacturing the display panel. The display panel comprises a flexible screen body and a support film. The flexible screen body comprises a display area, a bending area and an extension area arranged in sequence. The display region and the extension region are not coplanar. The support film is attached to the back surface of theflexible screen body. The support film includes a first curing region and a second curing region spaced apart. The first curing region and the second curing region are positioned opposite to the display region and the extension region, respectively. By curing the first cured region and the second cured region, the support strength and hardness of the support film in the display region and the extension region can be enhanced. At the same time, the bending of the bending region of the flexible screen body is not affected, so the stability of the flexible screen body can be improved.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

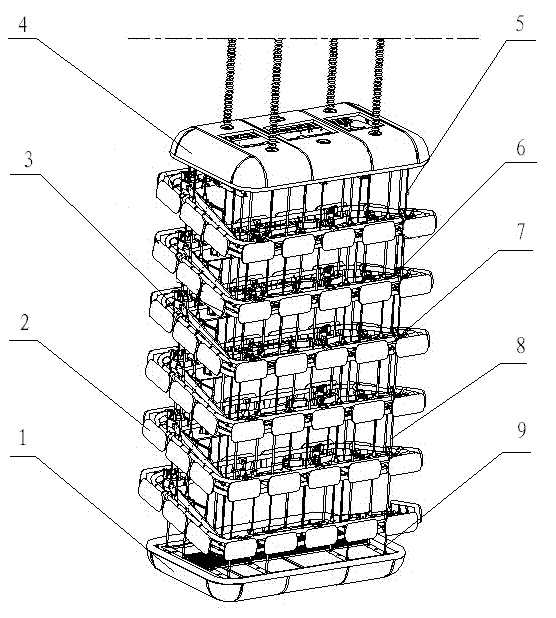

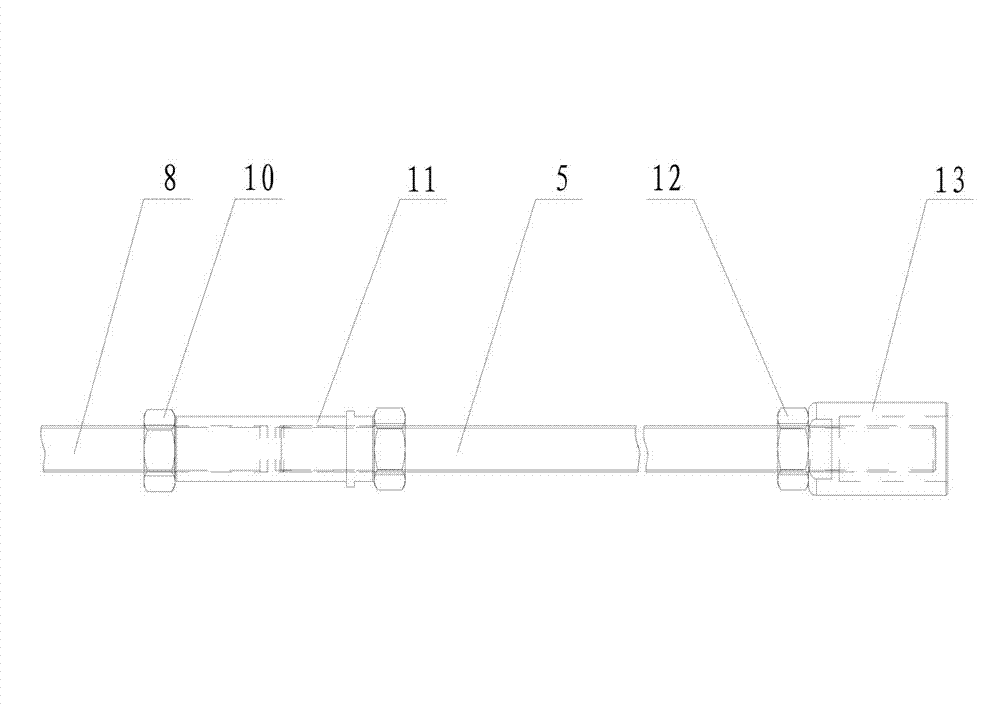

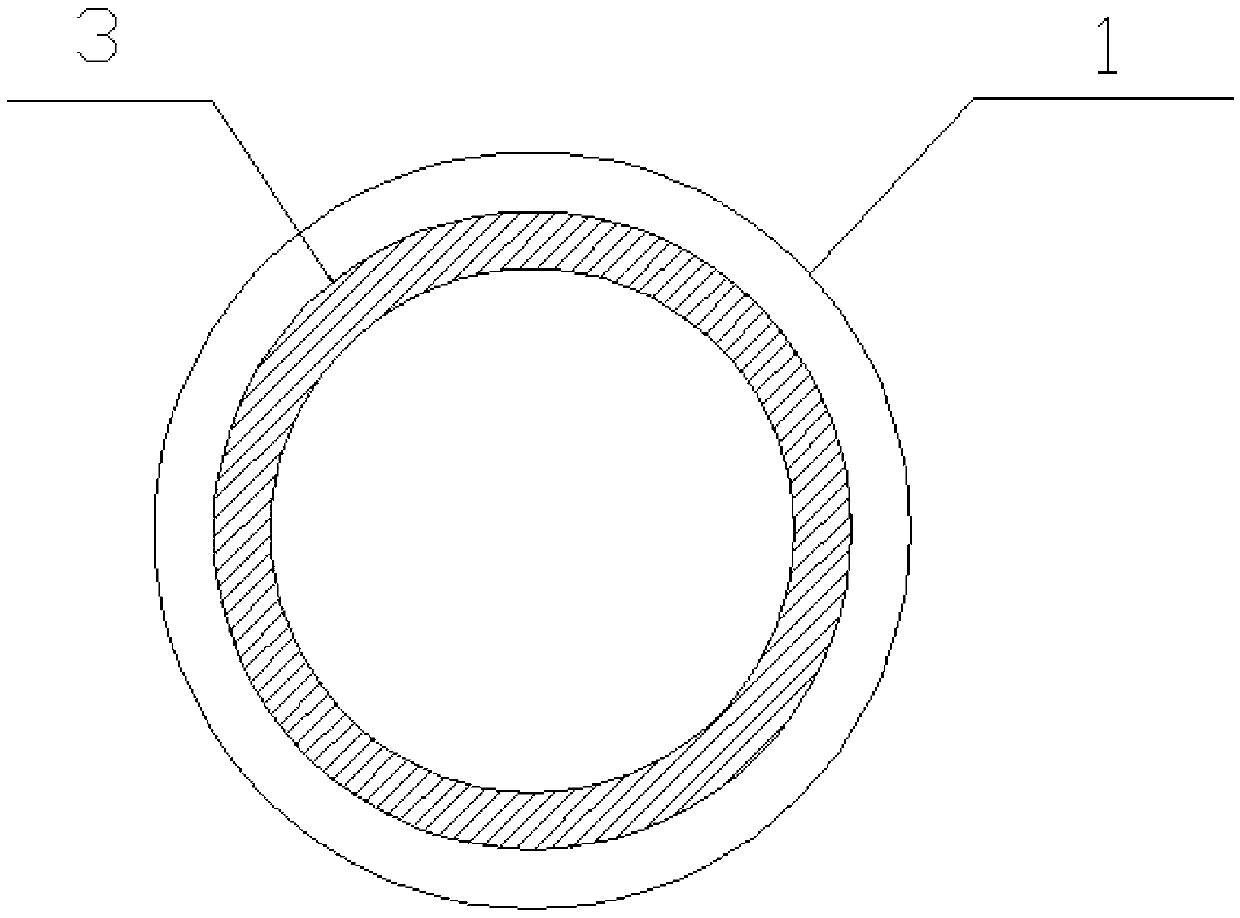

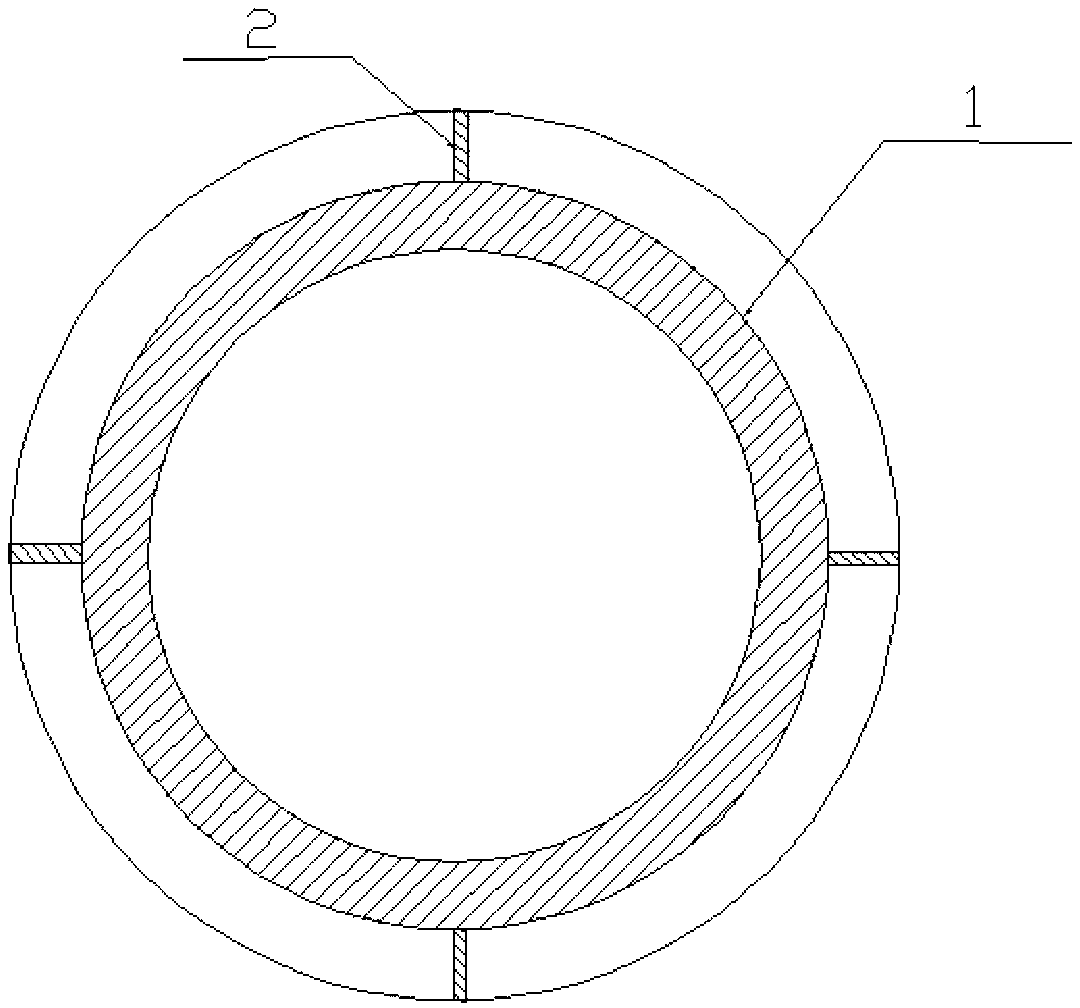

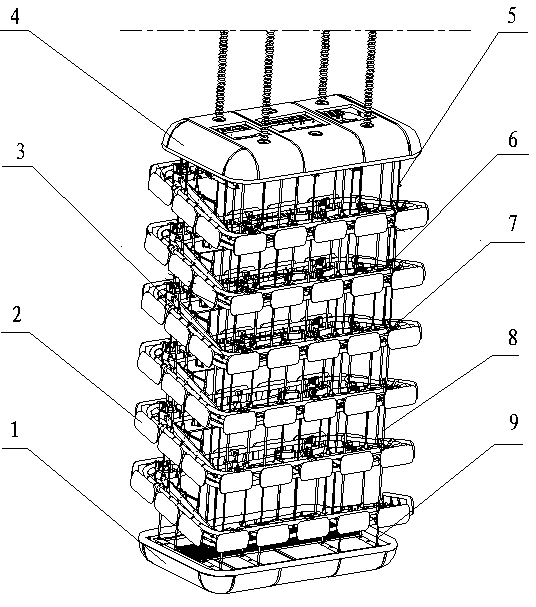

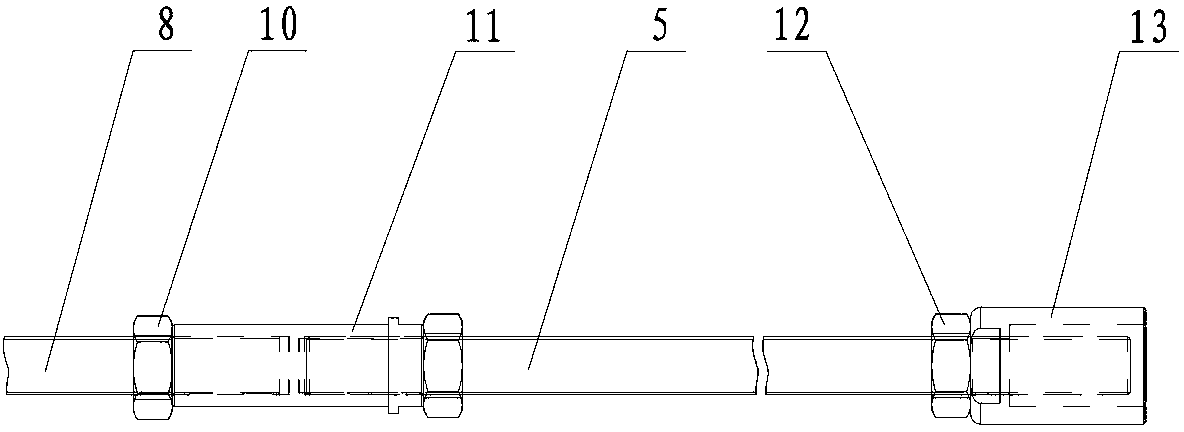

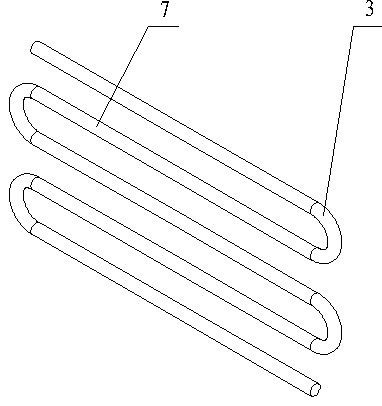

Hanging valve tower for converter valve

ActiveCN102882356AImprove seismic performanceHigh strengthCooling/ventilation/heating modificationsPower conversion systemsGlass fiberEpoxy

The invention discloses a hanging valve tower for a converter valve. The hanging valve tower comprises more than two valve layers arranged up and down at intervals, wherein an interlayer connection structure is connected between every two adjacent valve layers and comprises interlayer threaded sleeves respectively fixed in corresponding positions of each valve layer and arranged at intervals in the circumferential direction; the interlayer threaded sleeves of every two adjacent valve layers mutually correspond in an up-and-down pairwise manner; an interlayer stud is connected between every two interlayer threaded sleeves corresponding up and down; and all the interlayer studs are made from epoxy resin glass fibers. The interlayer studs made of epoxy resin glass fibers has not only high strength and rigidity but also favorable electric insulation performance, can bear very large bending stress, ensures that the valve tower has a certain of flexibility on the basis of relative rigidity, reduces relative sway of the valve layers, and enhances the shock resistance of the valve tower.

Owner:XJ ELECTRIC +1

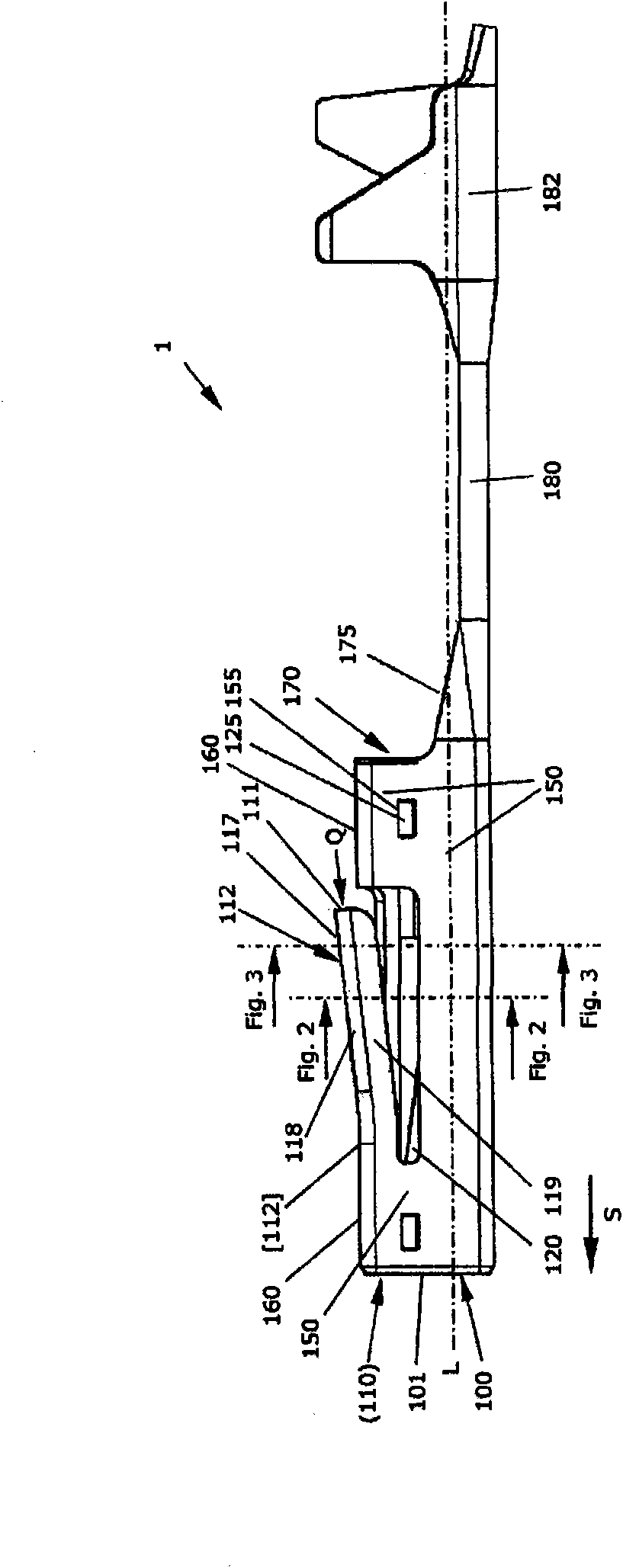

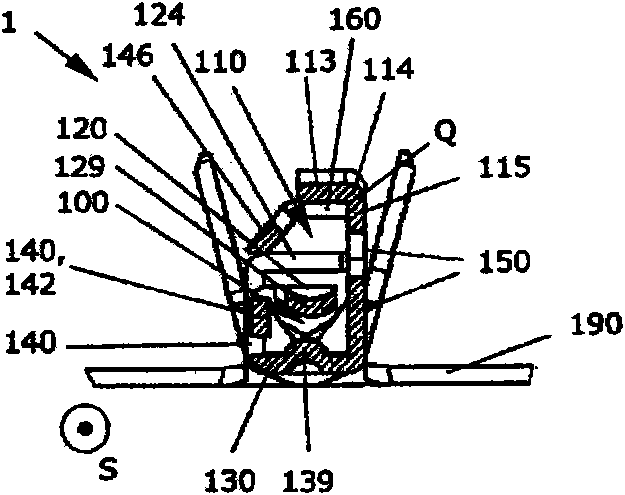

Electrical contact

ActiveCN101790819ACombined continuousLarge bending stressCoupling device detailsMechanical engineeringElectrical contacts

Owner:TE CONNECTIVITY GERMANY GMBH

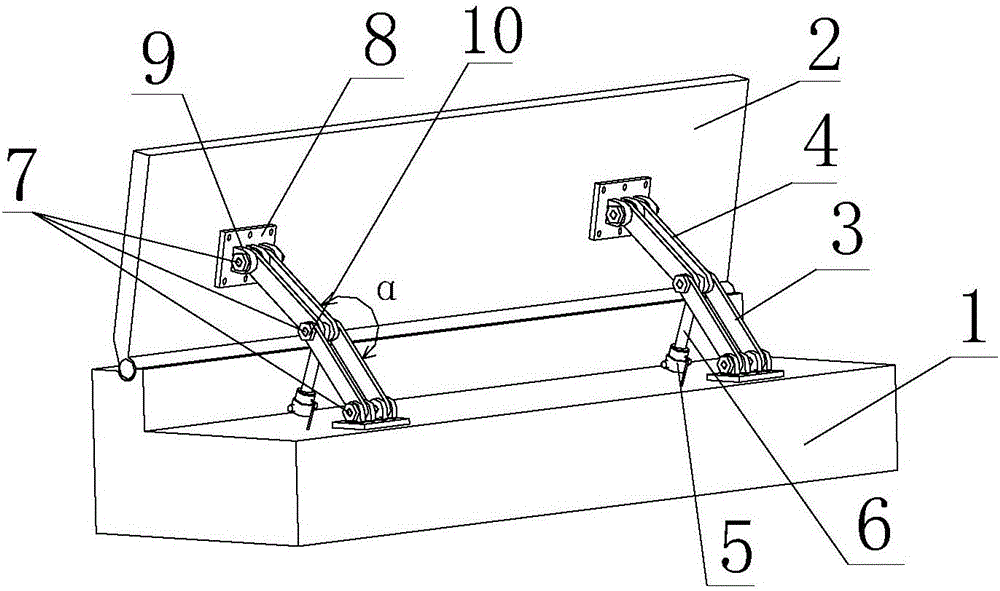

Hydraulic folding dam with mechanical self-locking for forked type rod

The invention discloses a hydraulic folding dam with mechanical self-locking for a forked type rod. The dam comprises a dam base and a door page which is movably connected to the dam base. Two supporting devices are arranged between the dam base and the door page, each of the supporting devices comprises a lower connecting rod connected to the dam base and an upper connecting rod connected to the door page, and the upper connecting rod is movably connected to the lower connecting rod. The dam disclosed by the invention has the advantages that the dam is more compact in structure; compared with a supporting hydraulic cylinder which directly supports the door page, the stroke of the hydraulic cylinder is long; as a mechanical self-locking structure is arranged, two locking hydraulic cylinders are cancelled; all the connecting rods are two-force beams, so that the dam is more reliable in structure and the connecting rods are only subjected to a pressure or tension. Compared with the hydraulic dam in the drawing, the lower connecting rod is subjected to a great bending stress; the supporting devices are double connecting rod structures which are more firm, and in the moving process, inference with the supporting rods of the hydraulic cylinder is avoided; the hydraulic cylinder is directly supported at an upper and lower connecting rod motion pair, so that the supporting force is greatly lowered, the dimension of the hydraulic cylinder is reduced, and the reliability is improved.

Owner:安徽省胜达液压坝科技有限公司 +1

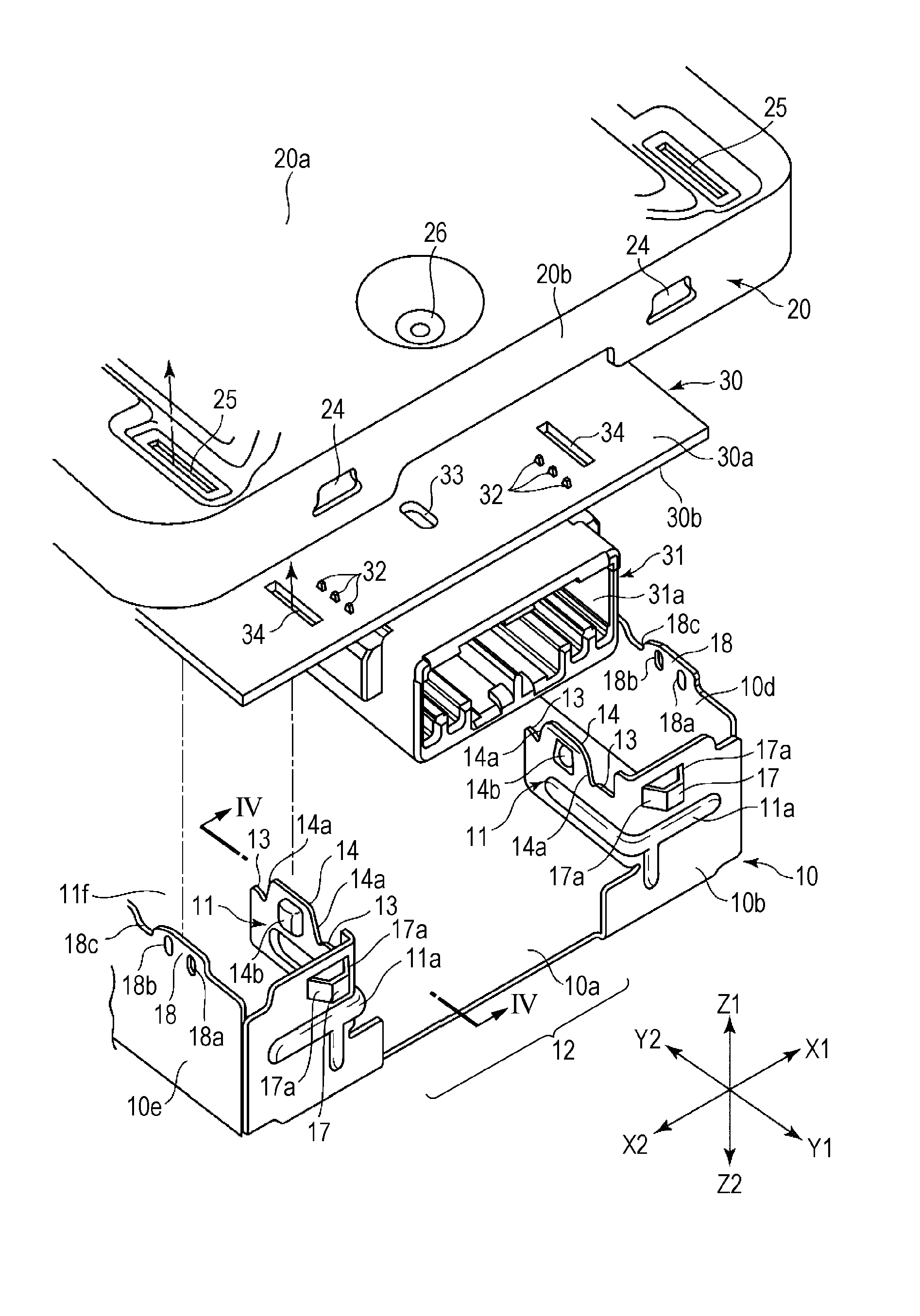

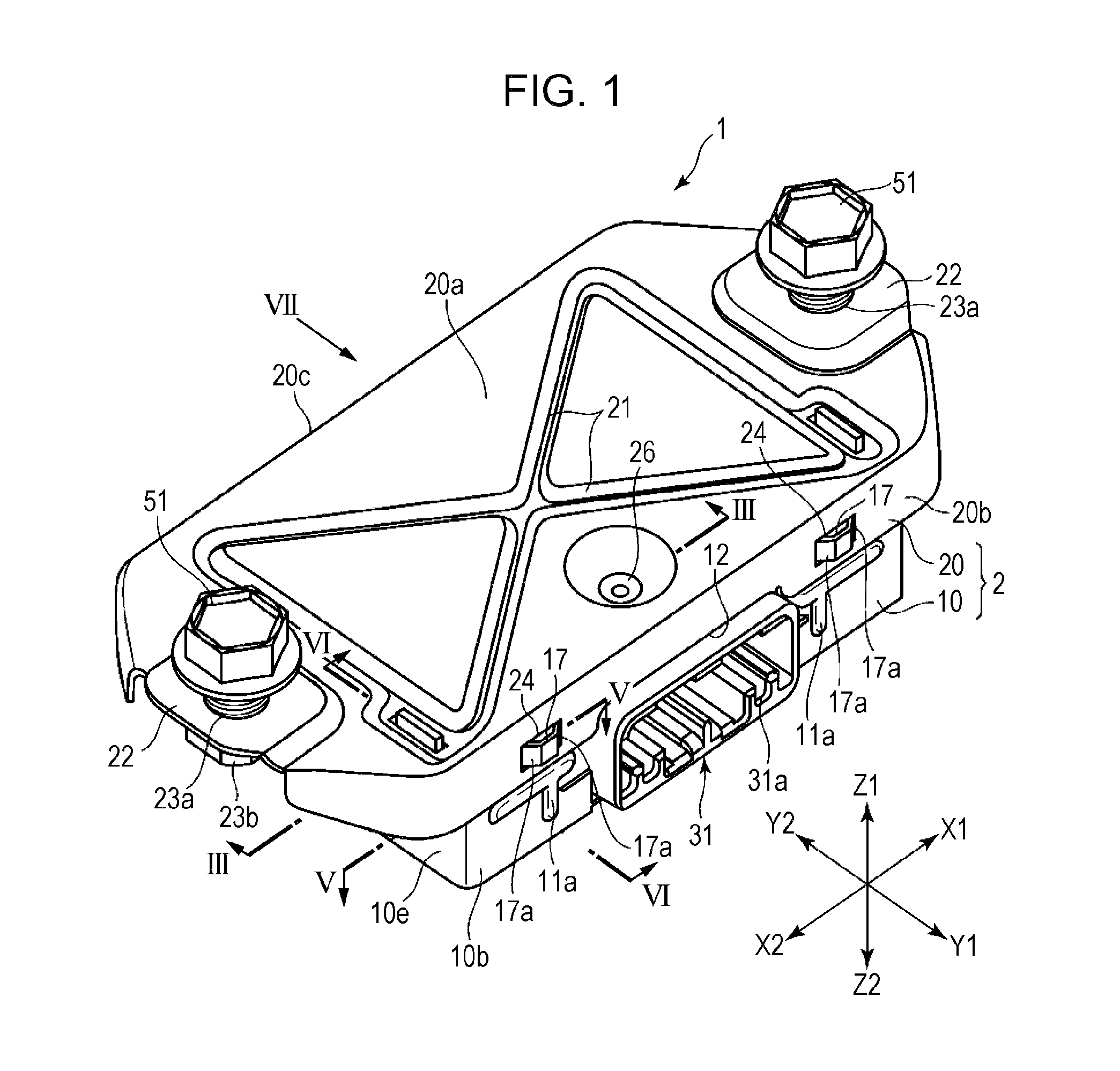

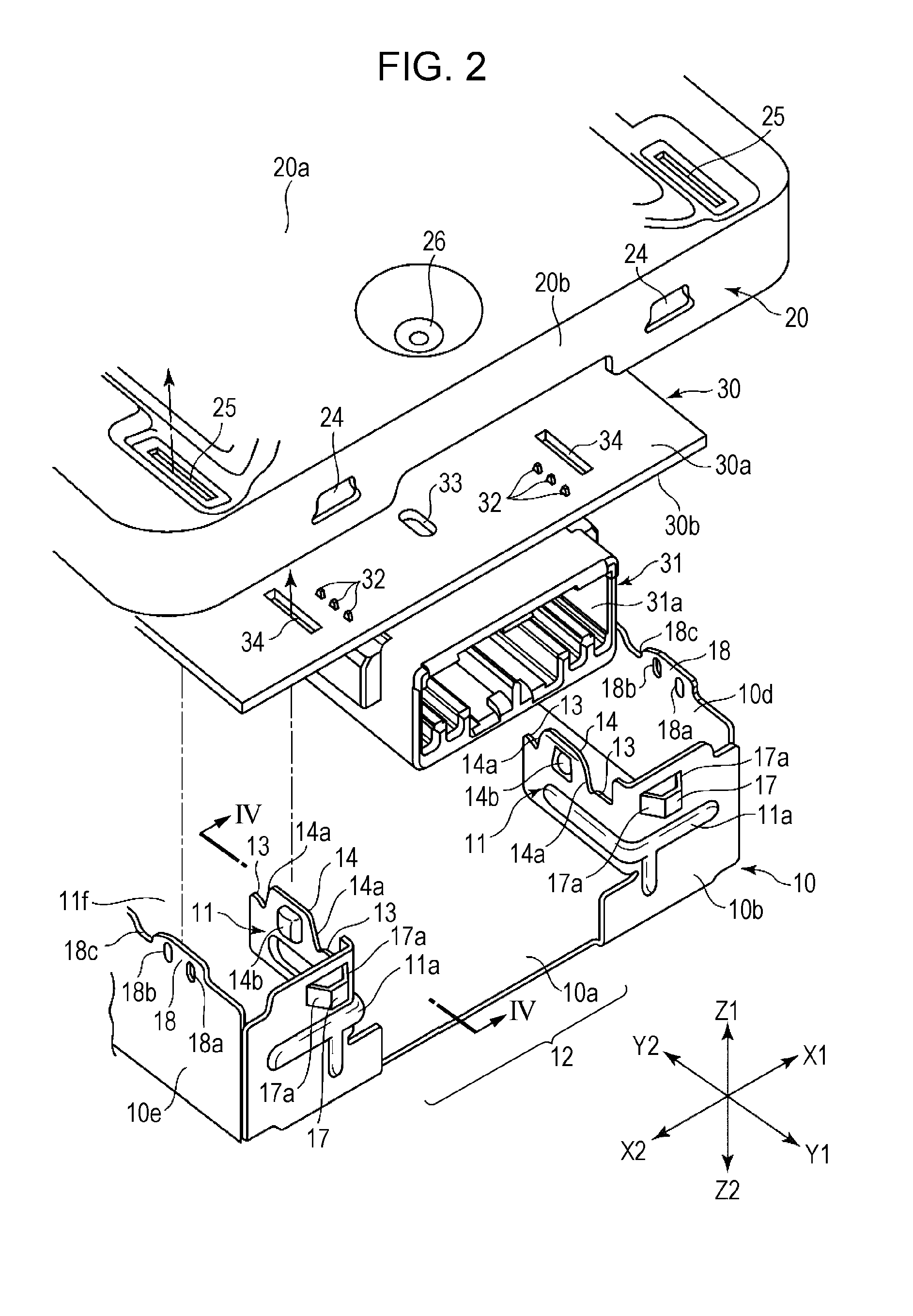

Electronic circuit unit

ActiveUS20160044799A1Easy to solveLarge bending stressCoupling device connectionsCasings with connectors and PCBMetal sheetElectronic circuit

A housing includes a first chassis and a second chassis which are each formed of a metal sheet. Support projections integrally formed with support pieces formed in the first chassis are fitted into support holes of a circuit board on both left and right sides of a connector. A lower surface of the circuit board is supported by receiving portions formed in the support pieces, and part of the circuit board facing the connector is pressed downward by a pressing projection formed in the second chassis.

Owner:ALPINE ELECTRONICS INC

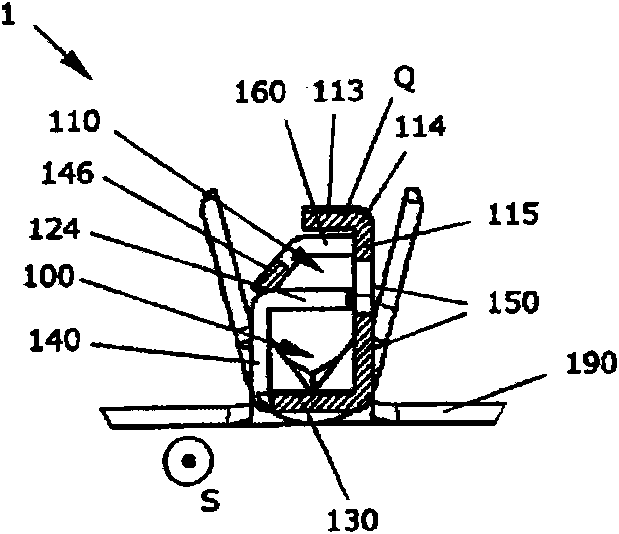

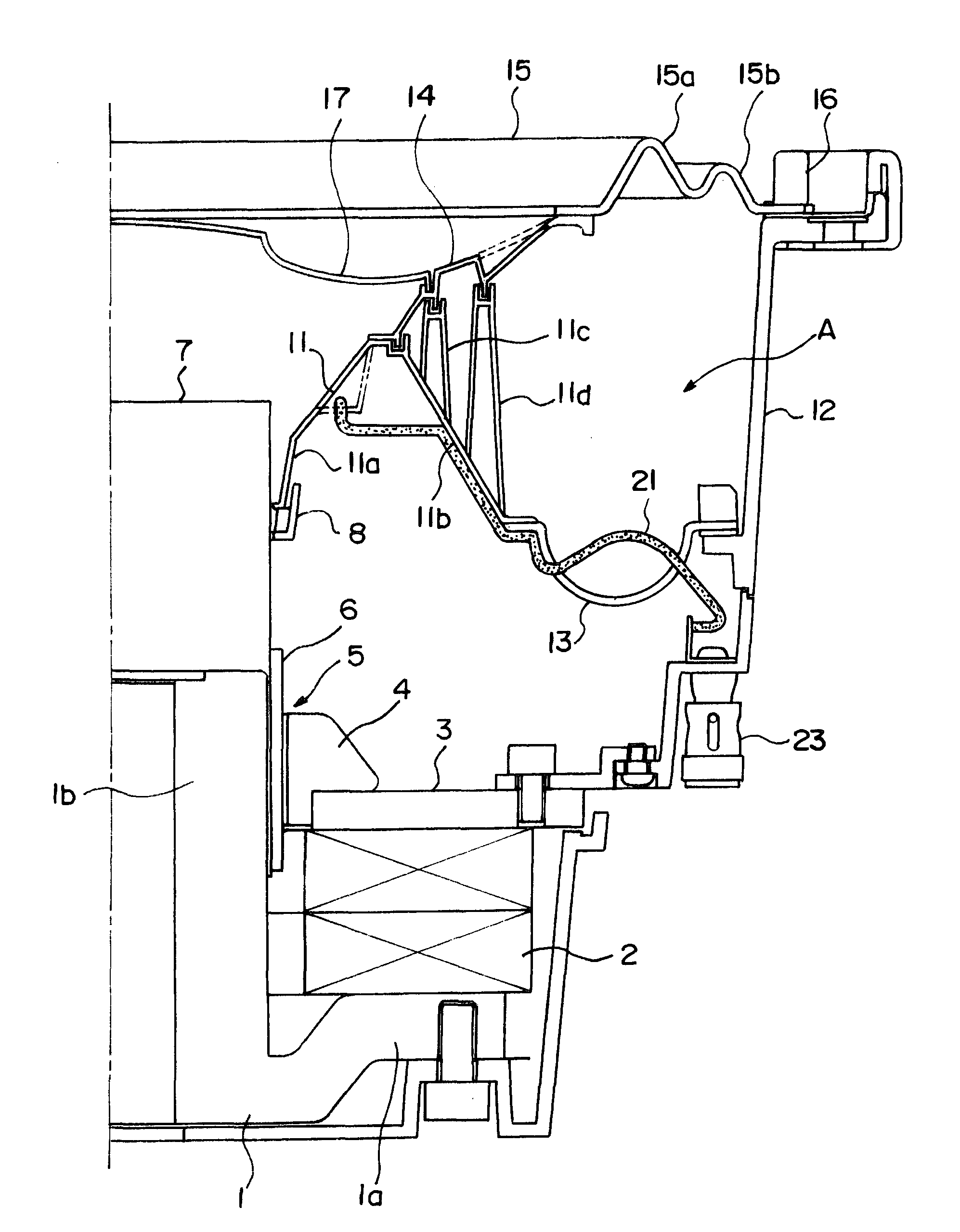

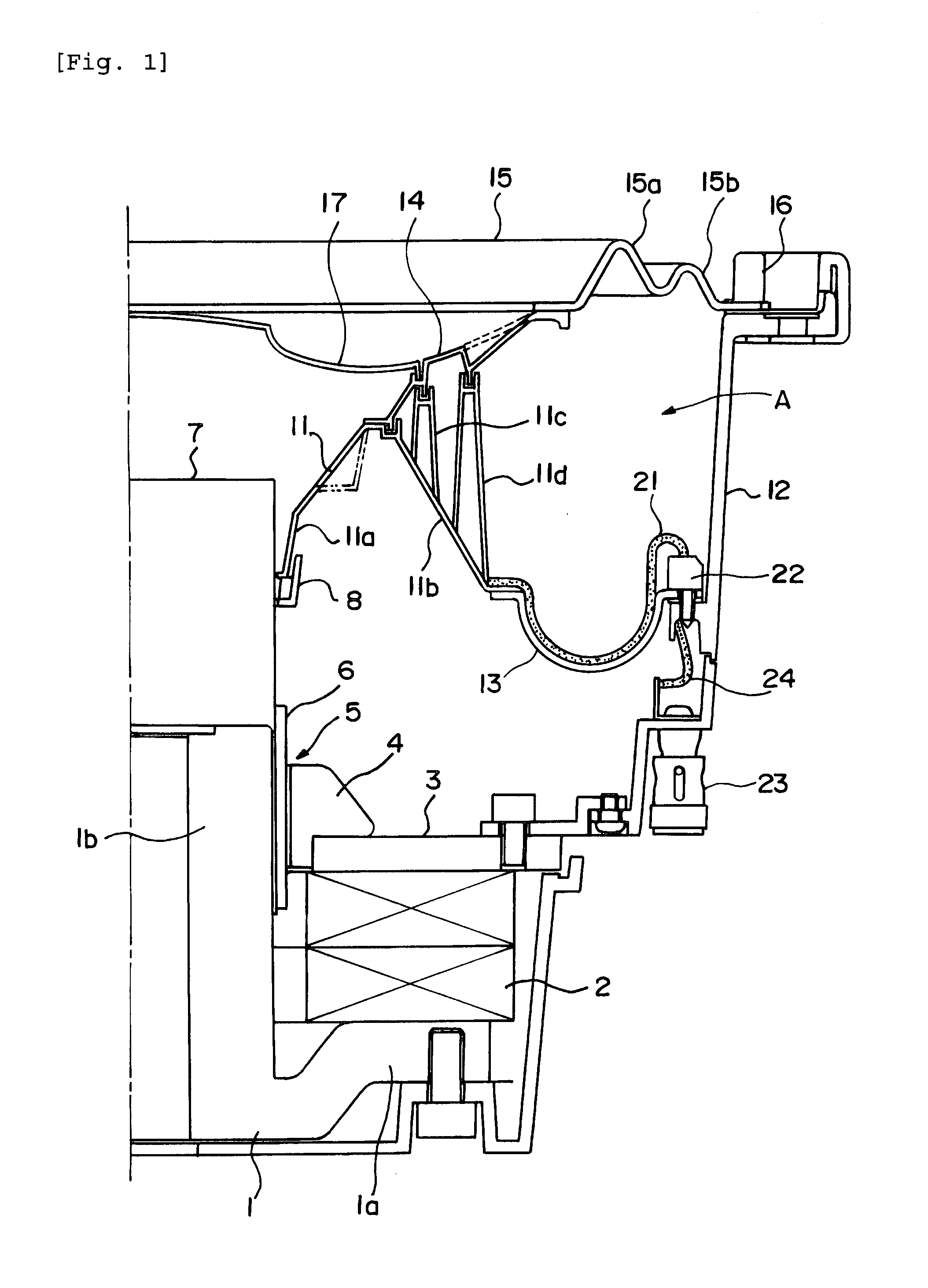

Speaker device

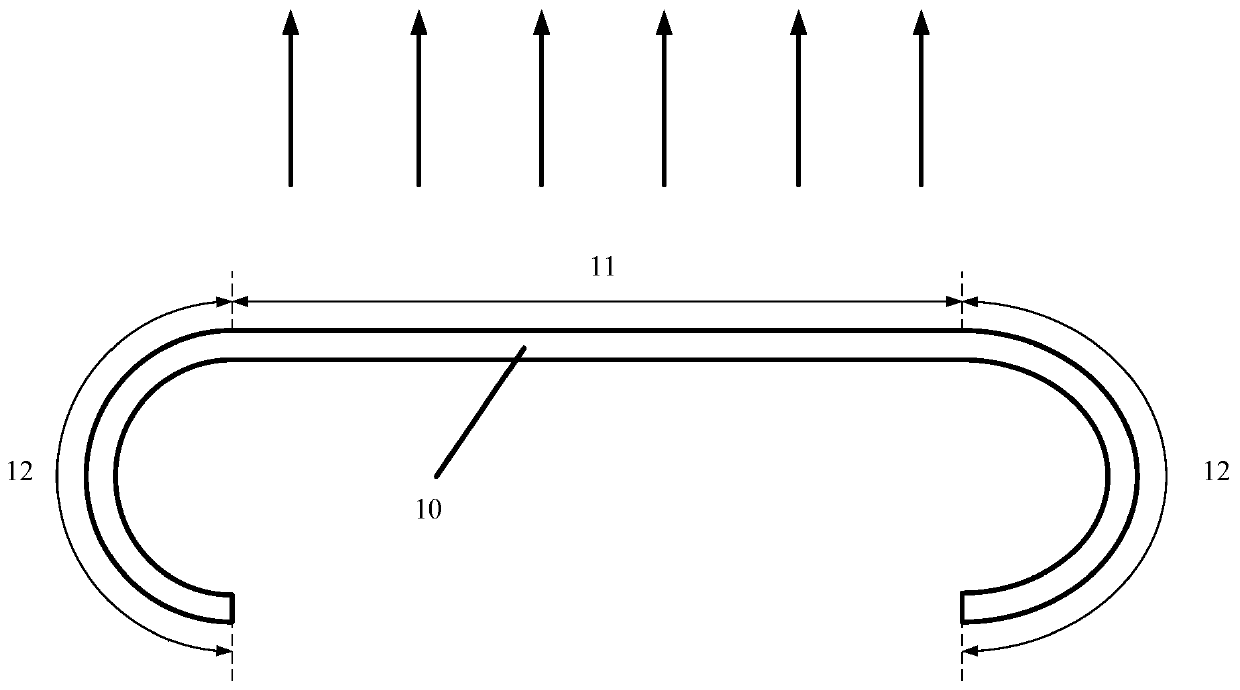

InactiveUS20100092024A1Large bending stressAvoid problemsCircuit lead arrangements/reliefLoudspeakerEngineering

A drive cone 11 and a diaphragm 14 are integrally driven by a voice coil 6 which is movably disposed in a magnetic gap 5. Peripheral edges of the drive cone 11 and diaphragm 14 are supported by a frame 12 through edge portions 13 and 15. A lead wire 21 supplies a drive signal to the voice coil 6. The lead wire 21 is disposed along a surface shape of the edge portion 13 which supports the drive cone 11. The lead wire 21 is mounted along a roll shape of a flexible adhesive utilizing the adhesive.With this structure, the lead wire 21 deforms such as to follow deformation of the edge portion 13 in the drive cone 11 in accordance with vibration of the diaphragm 14. Therefore, it is possible to prevent a bending stress caused by vibration from being transmitted to a portion of the lead wire.

Owner:PIONEER CORP +1

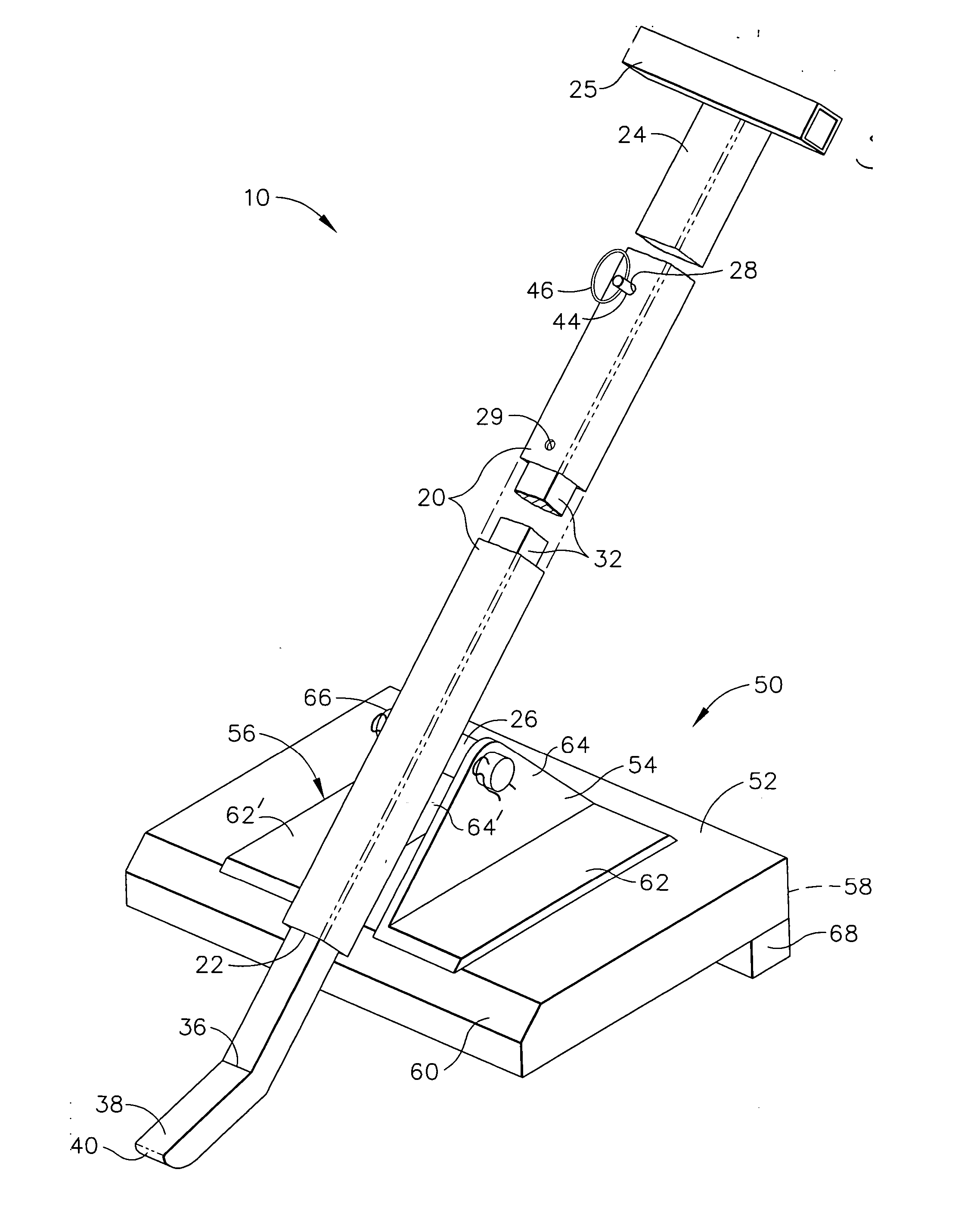

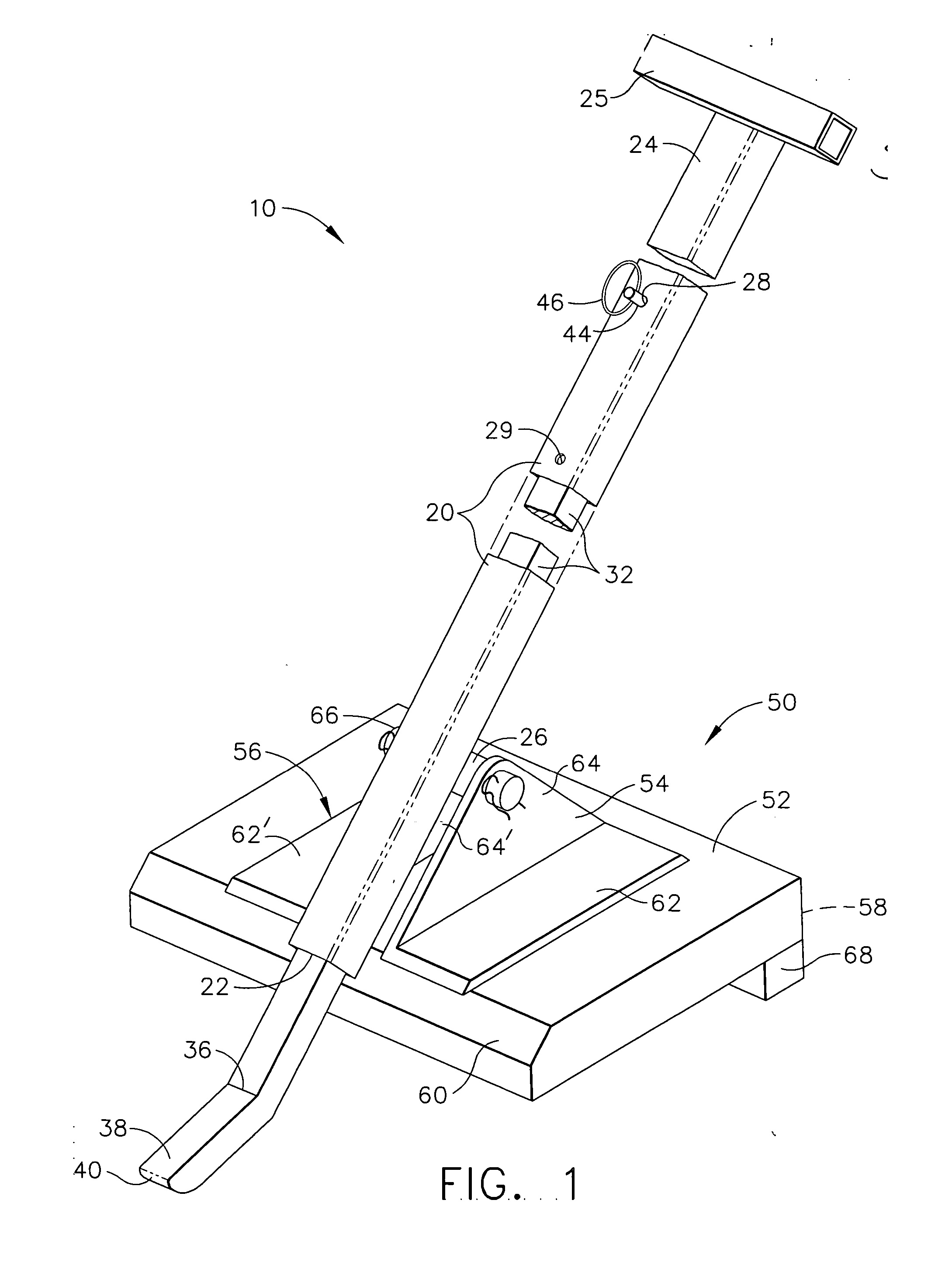

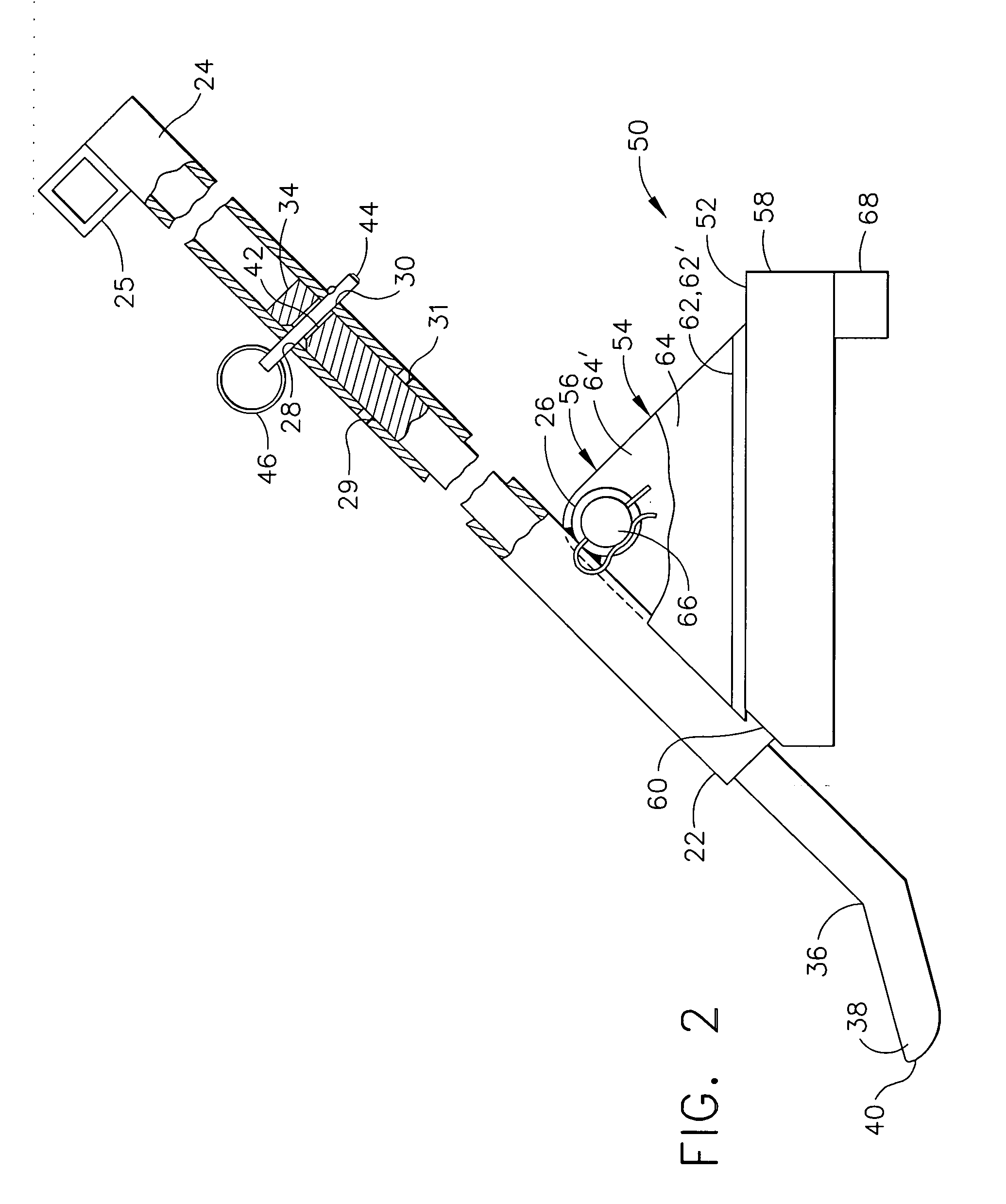

Honeysuckle bush remover

An implement for removing honeysuckle bushes and the like wherein the implement is inserted below the soil surface and the root ball of the bush is leveraged up and out of the soil. The implement may be manually used to break the roots of the bush before ultimate removal.

Owner:GRENNER CHRISTOPHER

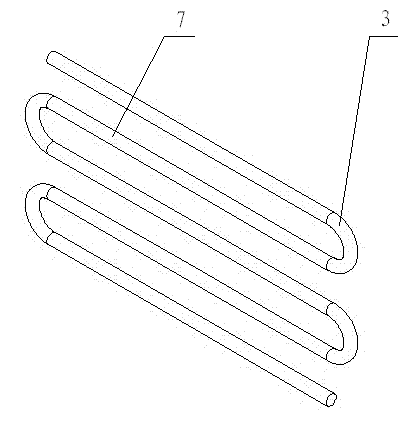

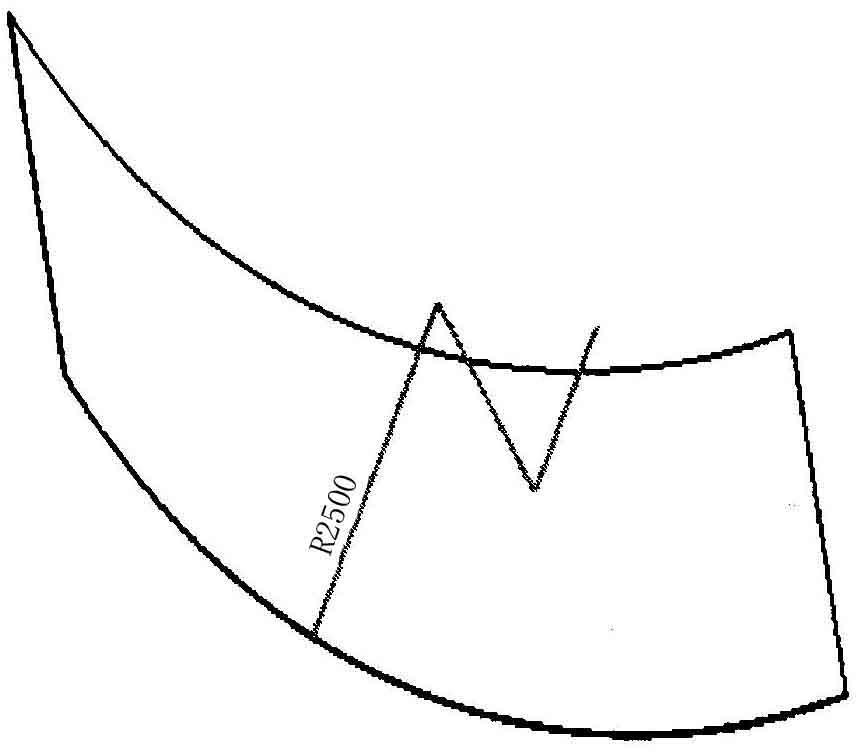

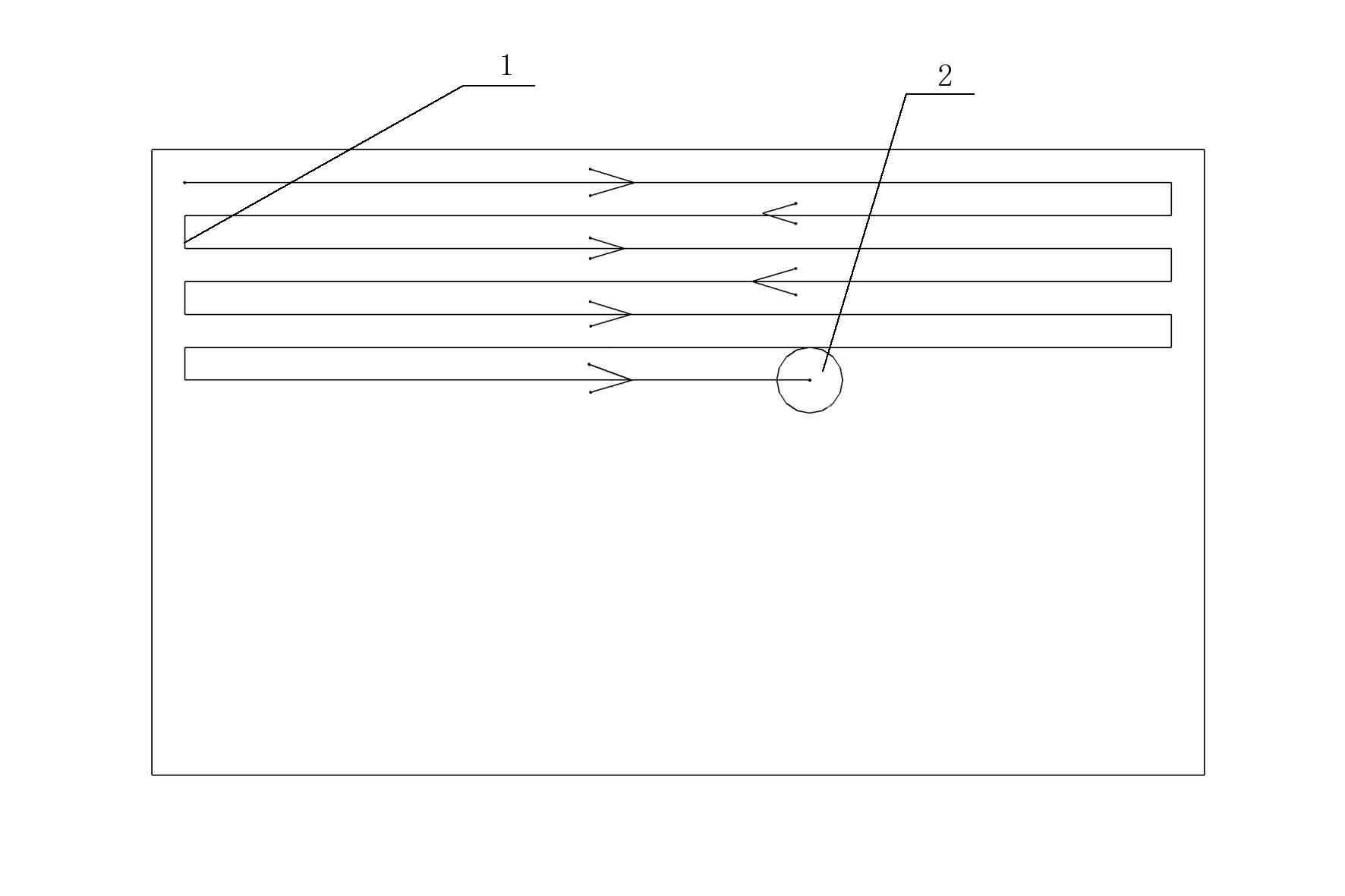

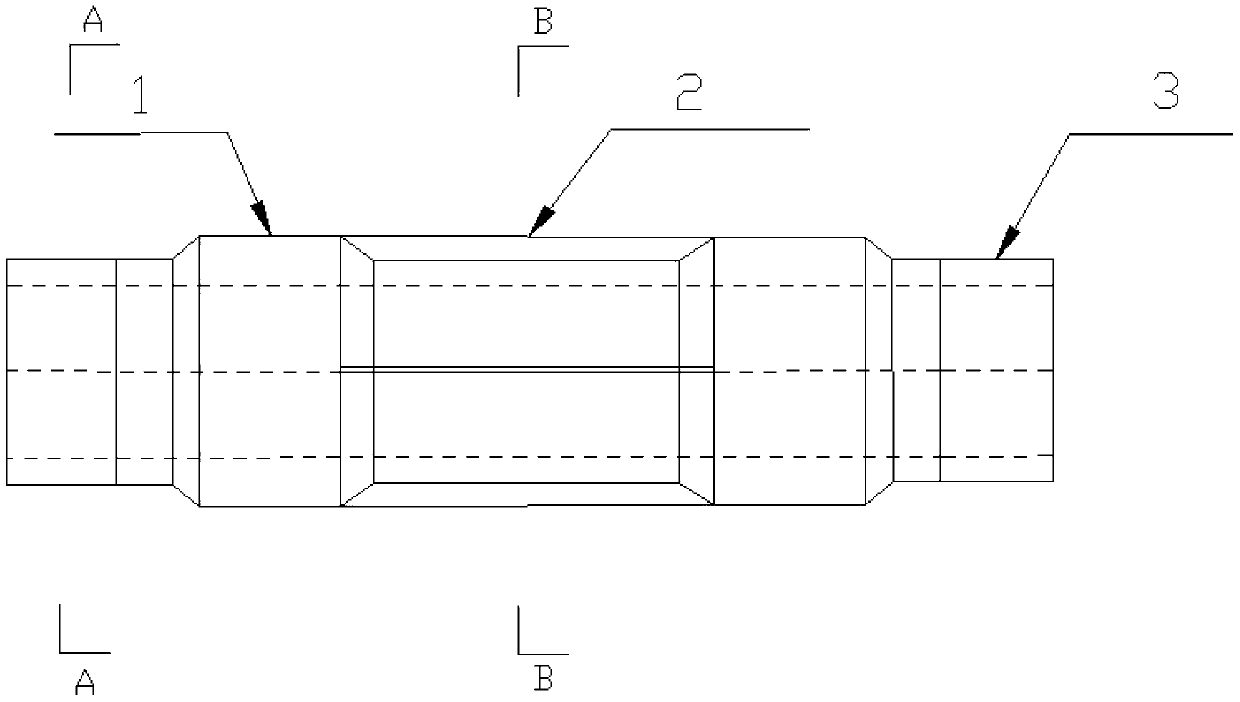

Unfolding and machining method for single-bent thin-walled parts

The invention relates to an unfolding and machining method for single-bent thin-walled parts, which is applicable to thin-walled parts with a curvature radius of more than 1000 mm. The method is characterized by comprising the following steps of: 1) carrying out pre-roll bending on thin-walled parts, wherein the rolled radius of each thin-walled part is 1000 mm larger than the final curvature radius thereof; 2) carrying out unfolding and machining on the thin-walled parts, namely, unfolding the thin-walled parts on a vacuum platform of a numerical control device to be clamped, keeping the machined surfaces of the thin-walled parts horizontal, and machining the thin-walled parts through selecting a high-speed milling numerical control machining mode, wherein the machining path is a longitudinal serpentine milling path; and 3) discharging the parts from the vacuum platform, and placing the parts in a natural state, so that the final technical requirement can be satisfied. The method is not only simple, but also can save a lot of production cost on the premise of ensuring the quality and machining cycle of the parts.

Owner:SHENYANG AIRCRAFT CORP

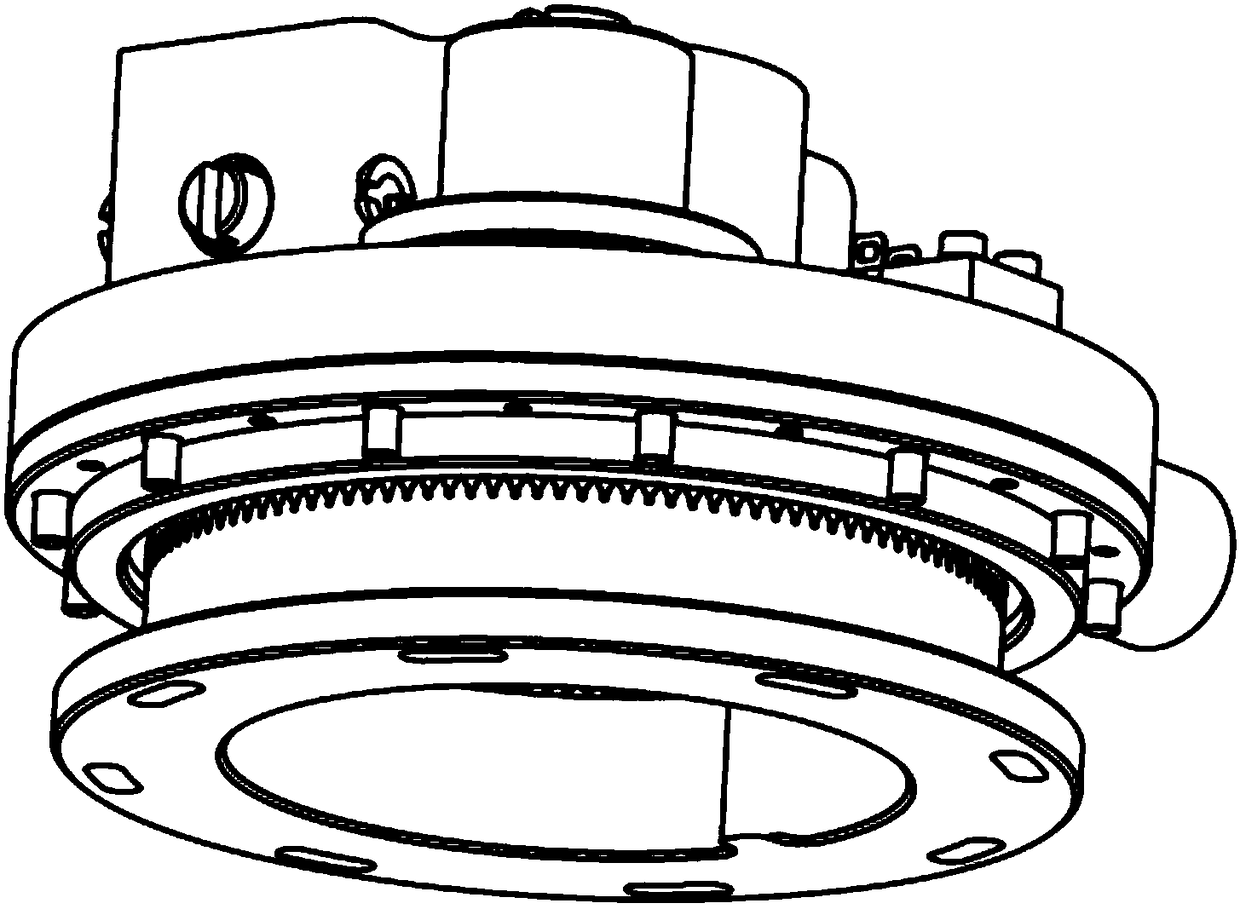

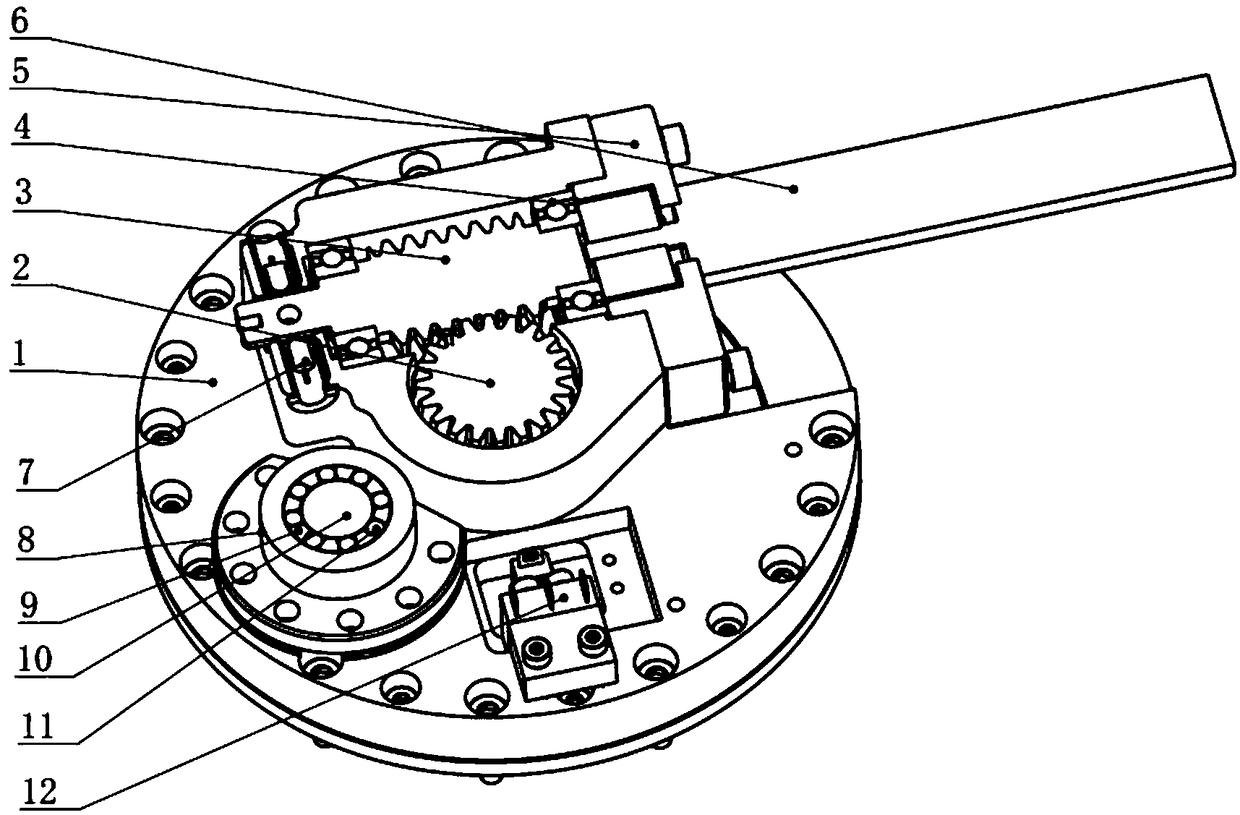

High-precision locking mechanism capable of resisting large impact and vibration

PendingCN109372840AReliable lockingGood self-lockingSecuring devicesStructural associationLocking mechanismEngineering

The invention relates to a locking mechanism capable of resisting large impact and vibration. The locking mechanism is driven by a servo motor, through a worm and gear and threads are transferred to drive a fixed fluted disc to perform a linear movement until the fixed fluted disc and a movable fluted disc (are installed on the carrier) are completely meshed, so that the positioning and locking functions can be realized. The worm and gear is designed to be a worm and gear capable of self-locking, so that the locking mechanism can be reliably locked, the phenomenon that looseness occurs is avoided, a threaded connection mode is adopted for the worm gear and the fluted disc, and can be prevented from being loosened under a certain friction force; meanwhile, the high-precision positioning ofthe fixed fluted disc can be realized under the cooperation of guide dense beads; and the high-precision locking mechanism can achieve high-impact resistance and vibration resistance.

Owner:JIUJIANG PRECISION MEASURING TECH RES INST

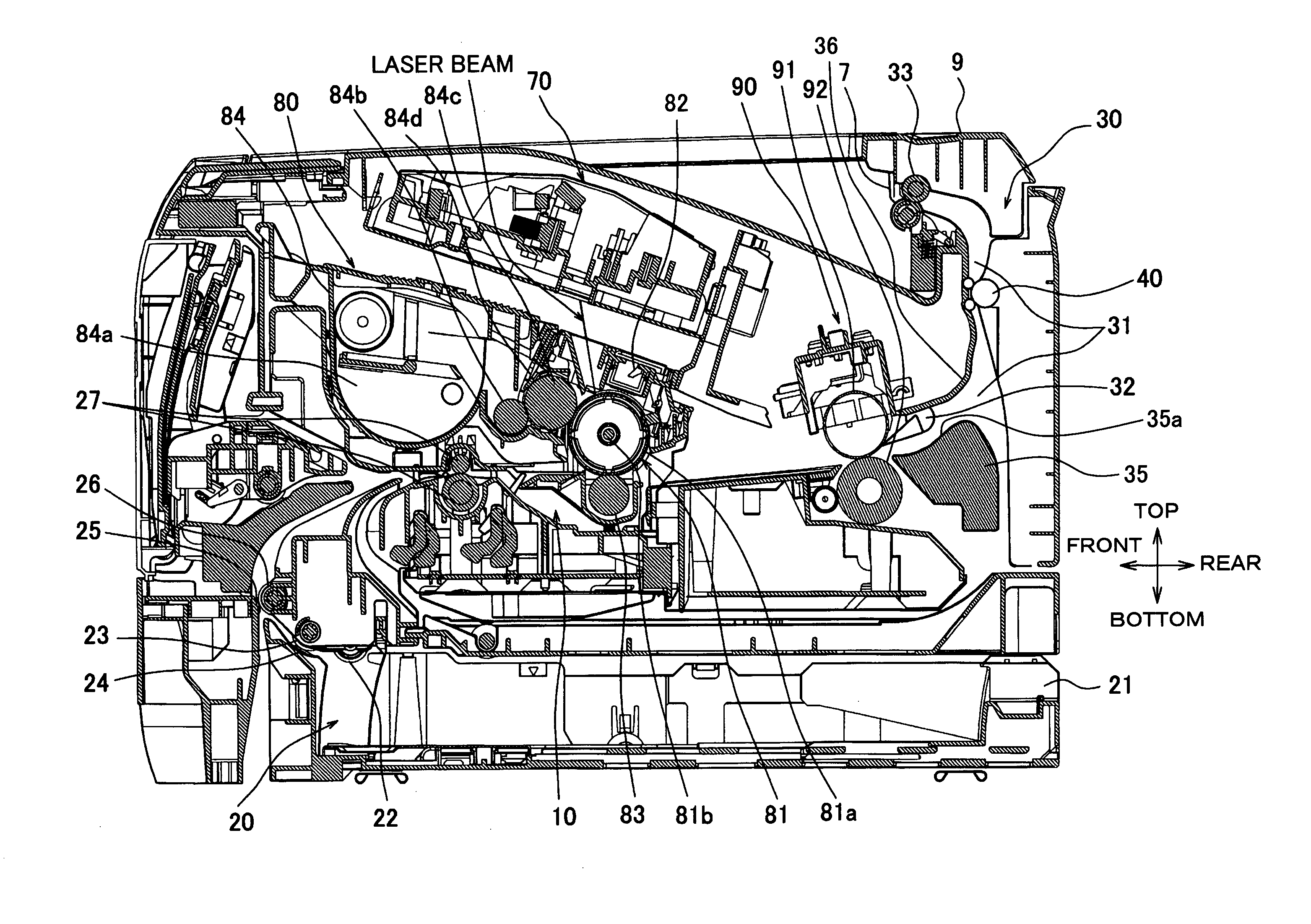

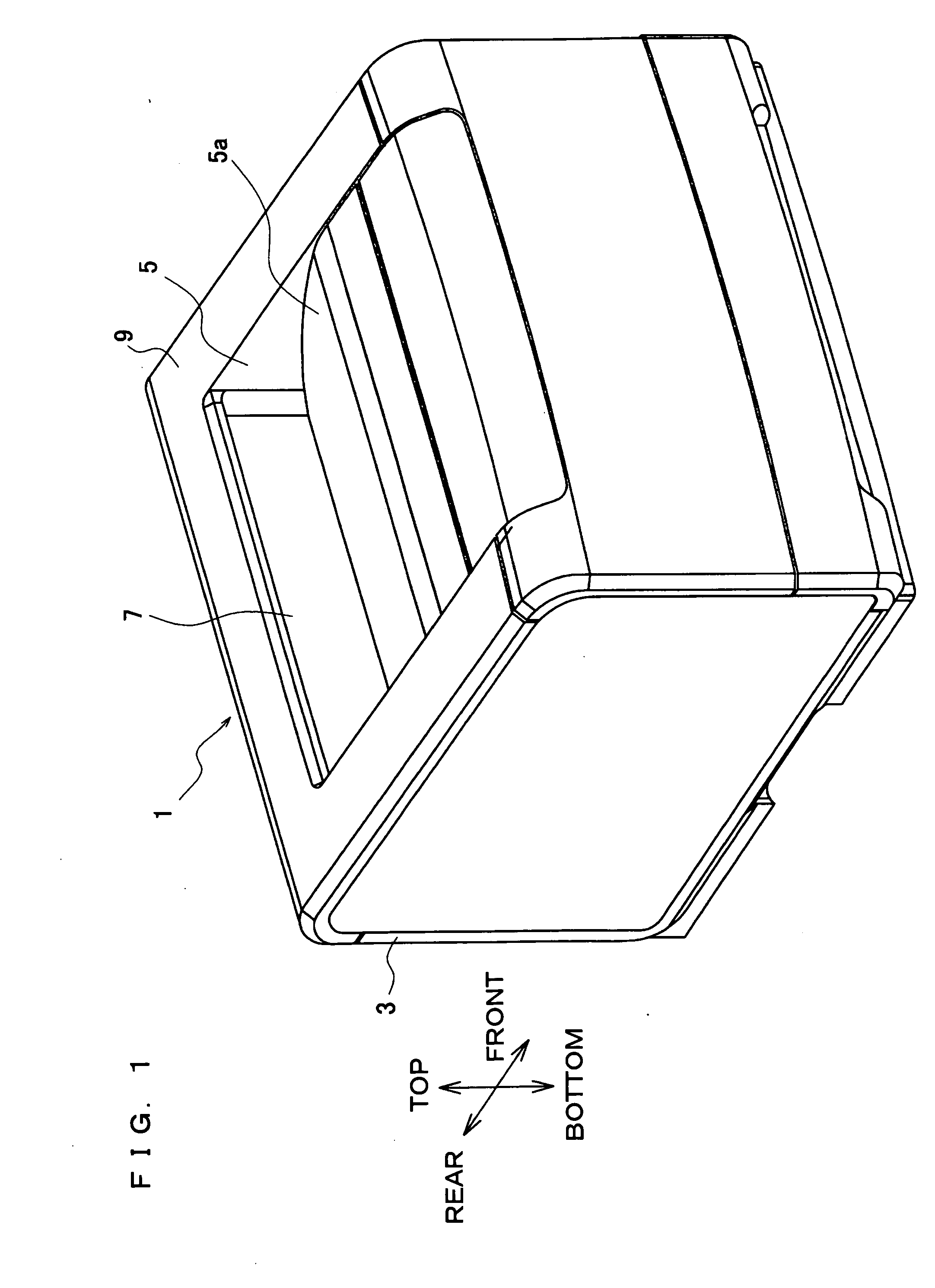

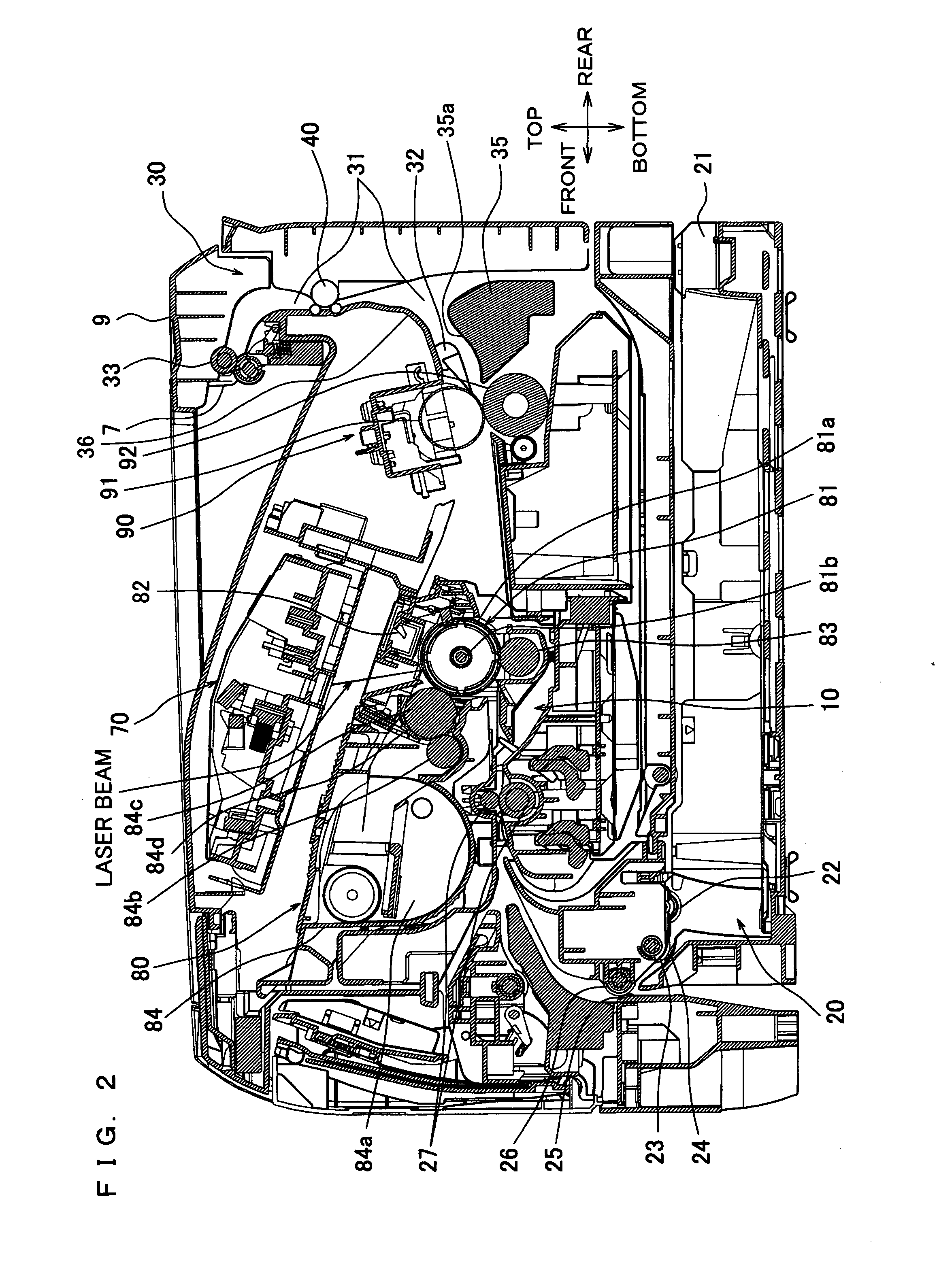

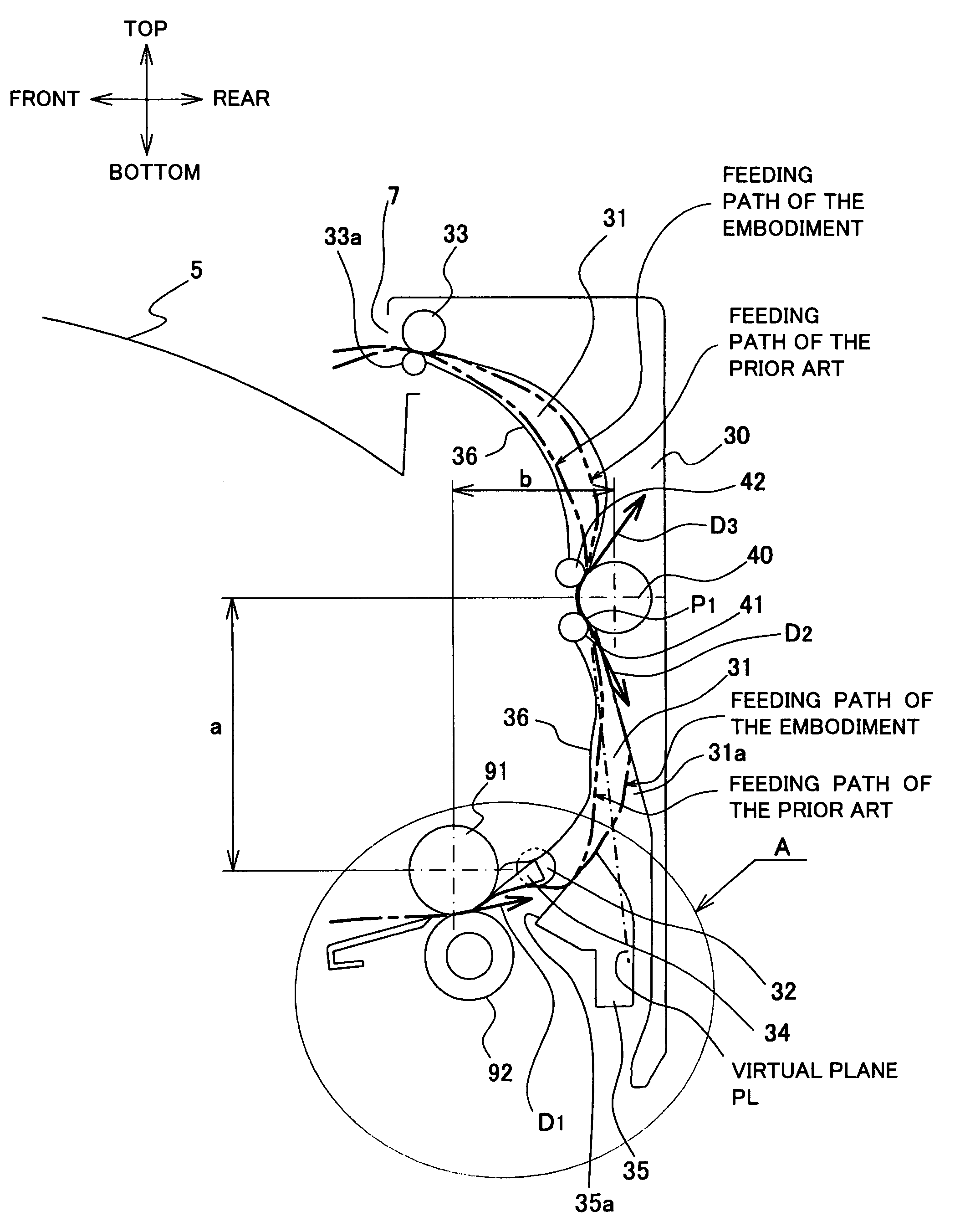

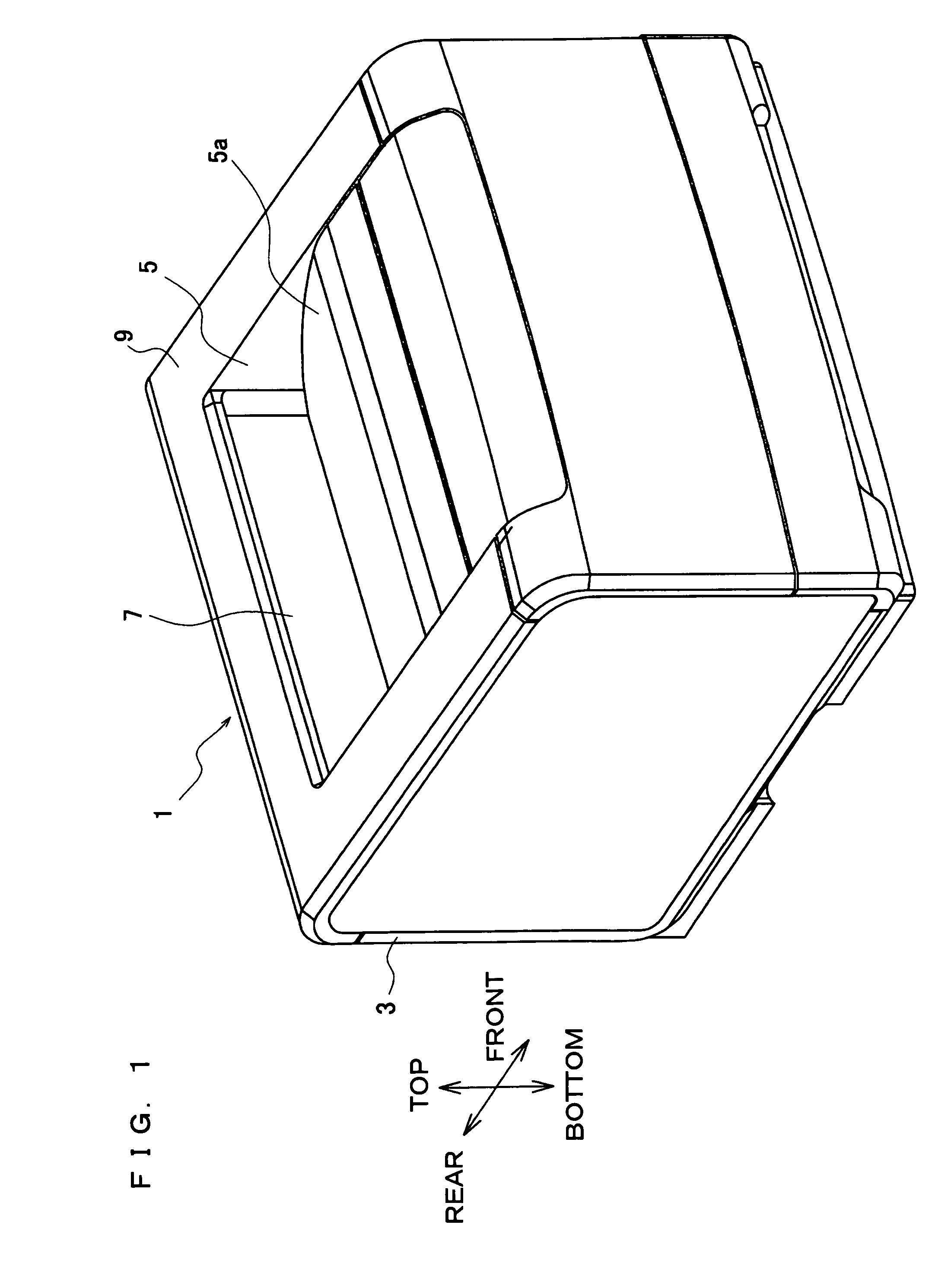

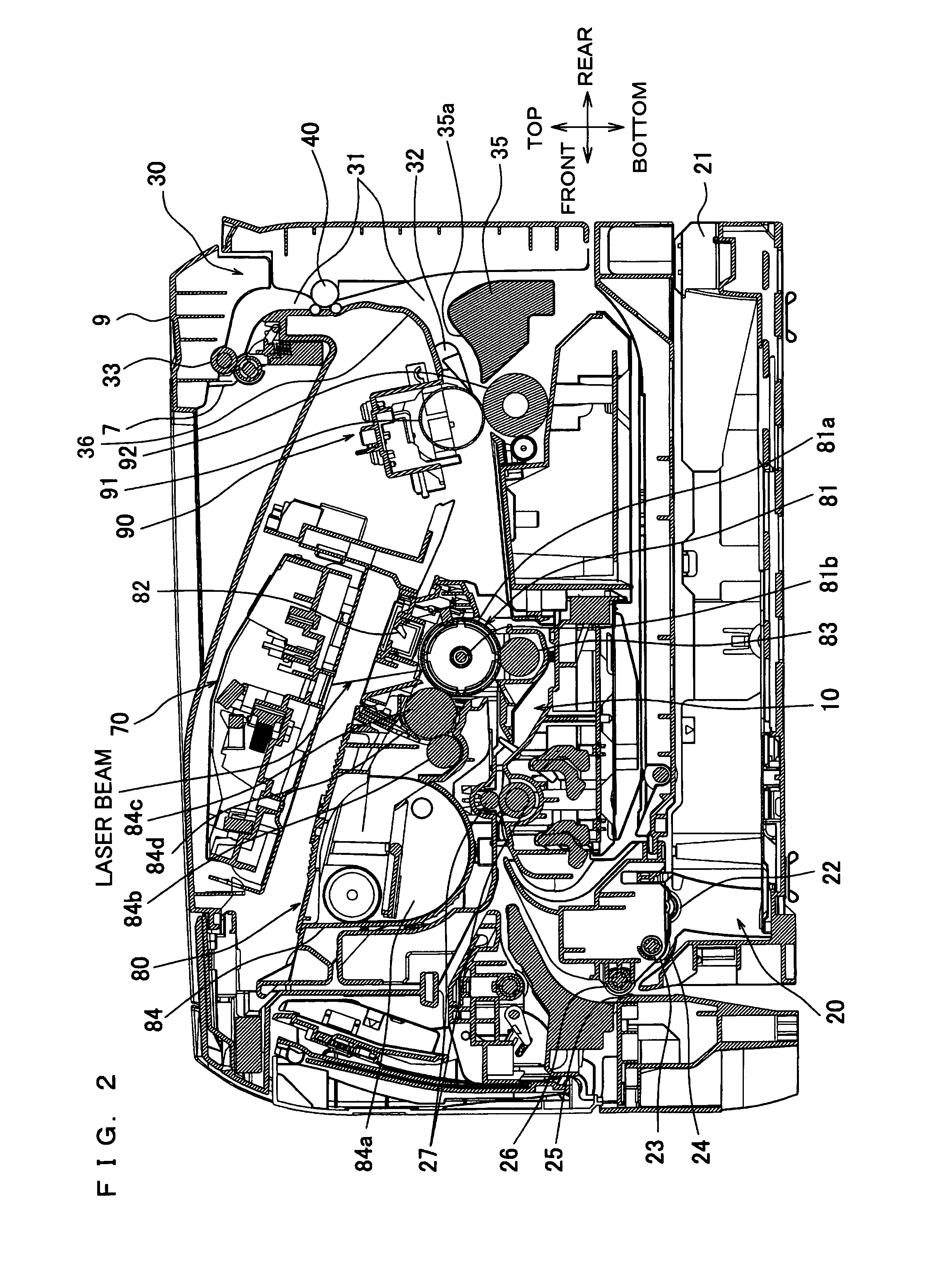

Image forming apparatus

ActiveUS20070070171A1Curl suppressionCurl can be prevented from generatingRecording apparatusElectrographic process apparatusImage formationEngineering

There are described a turning unit that turns the recording medium fed from a fixing unit, which fixes toner transferred to a recording medium and has a heating roller for heating toner, by approximately 90° with respect to a feeding direction of the recording medium, and a discharge roller that discharges the recording medium turned by the turning unit. A circumferential speed of the discharge roller is smaller than a circumferential speed of the heating roller.

Owner:BROTHER KOGYO KK

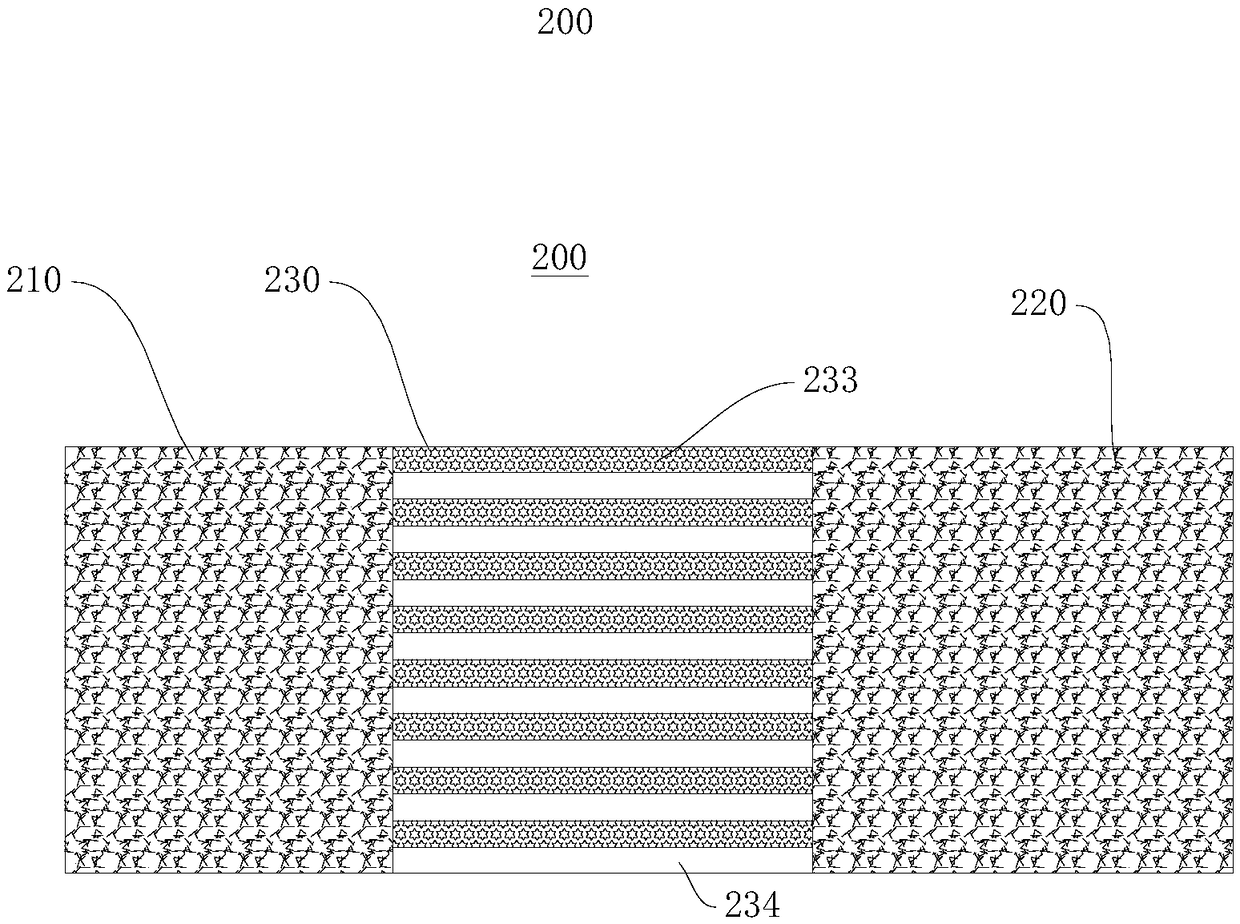

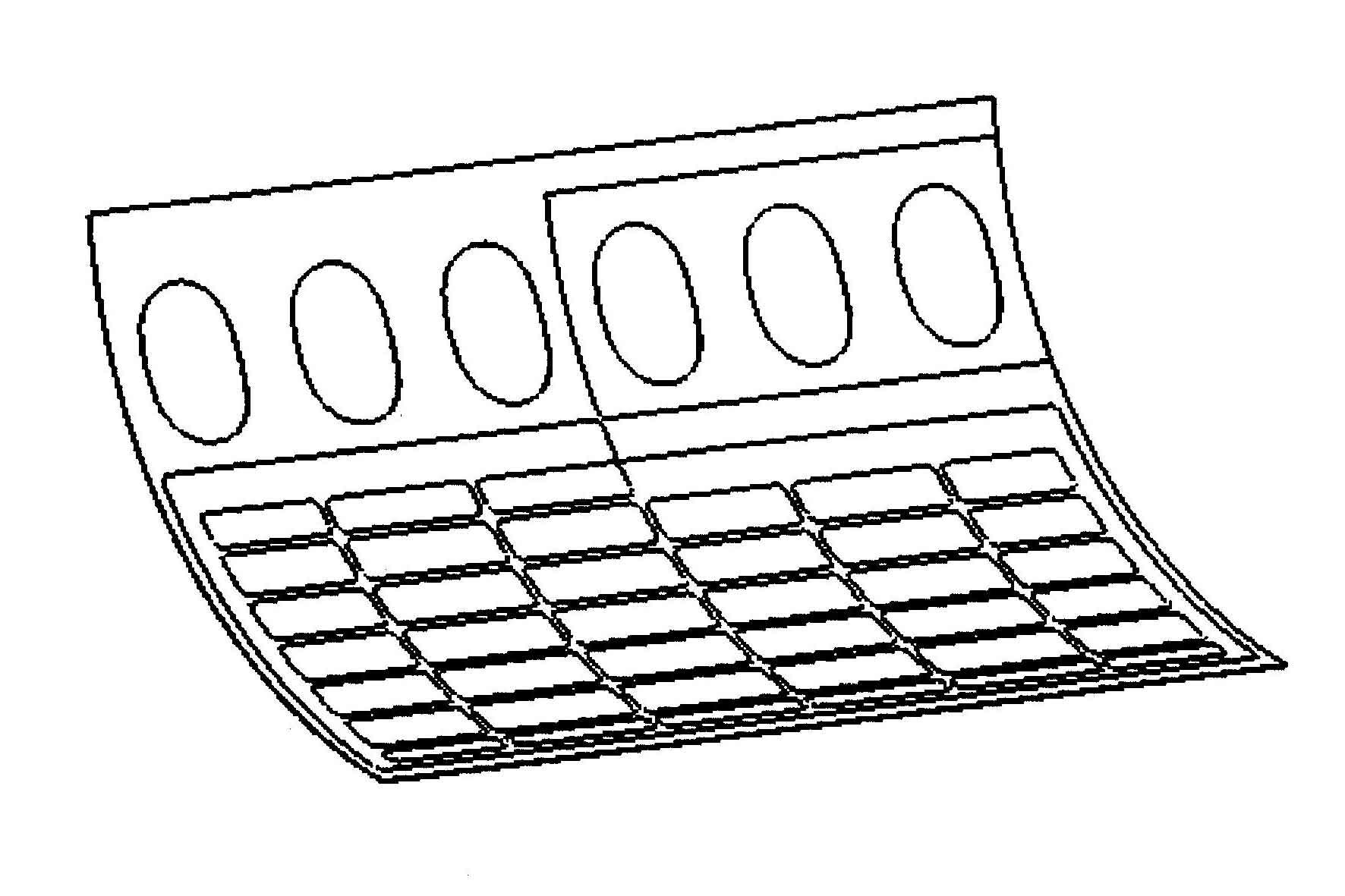

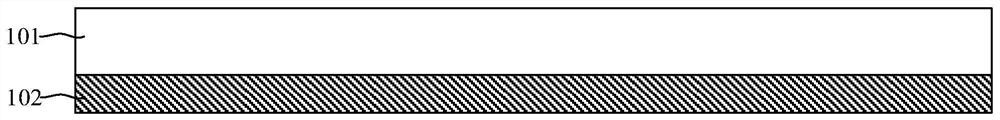

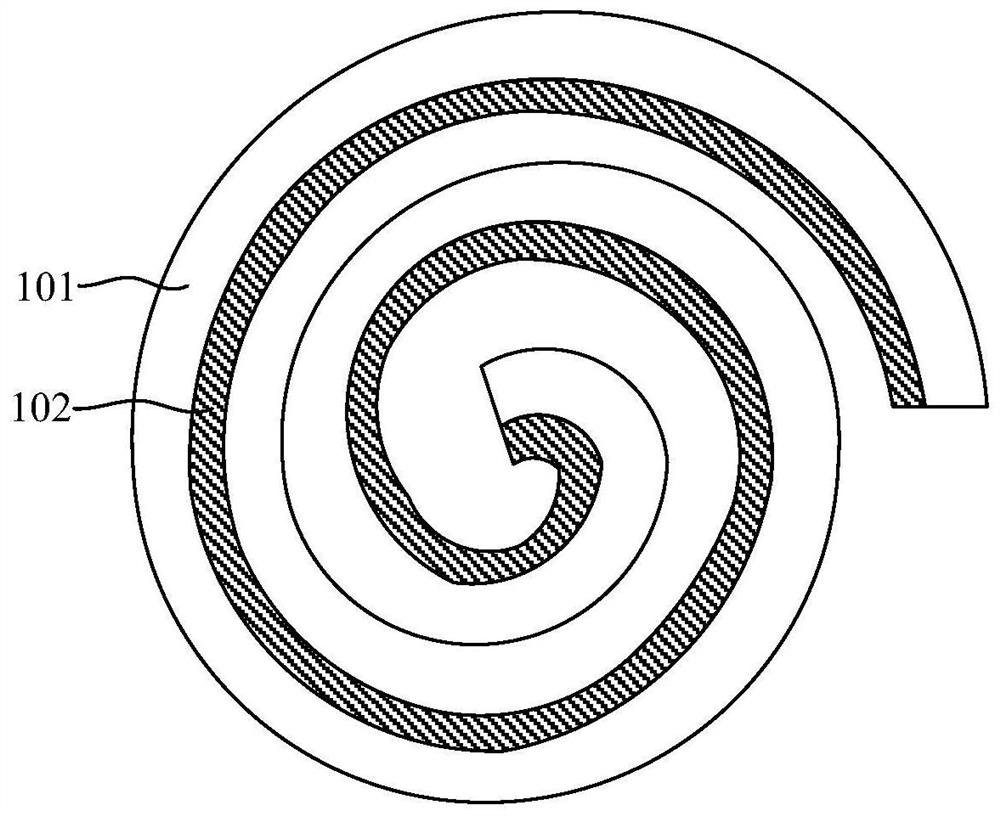

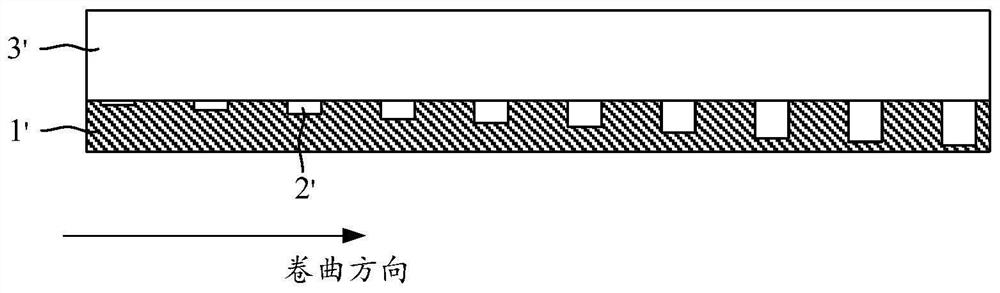

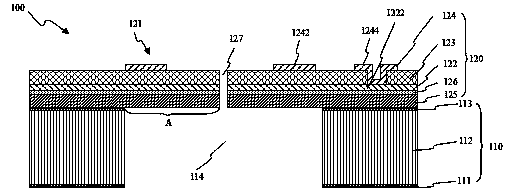

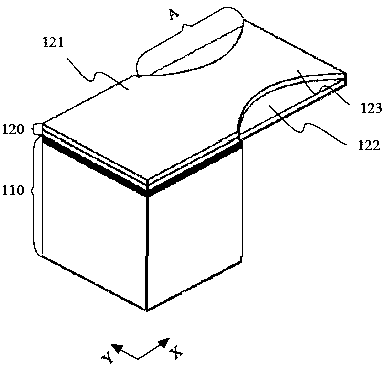

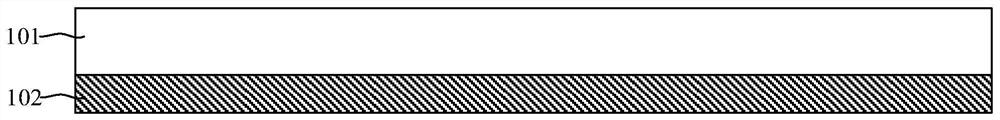

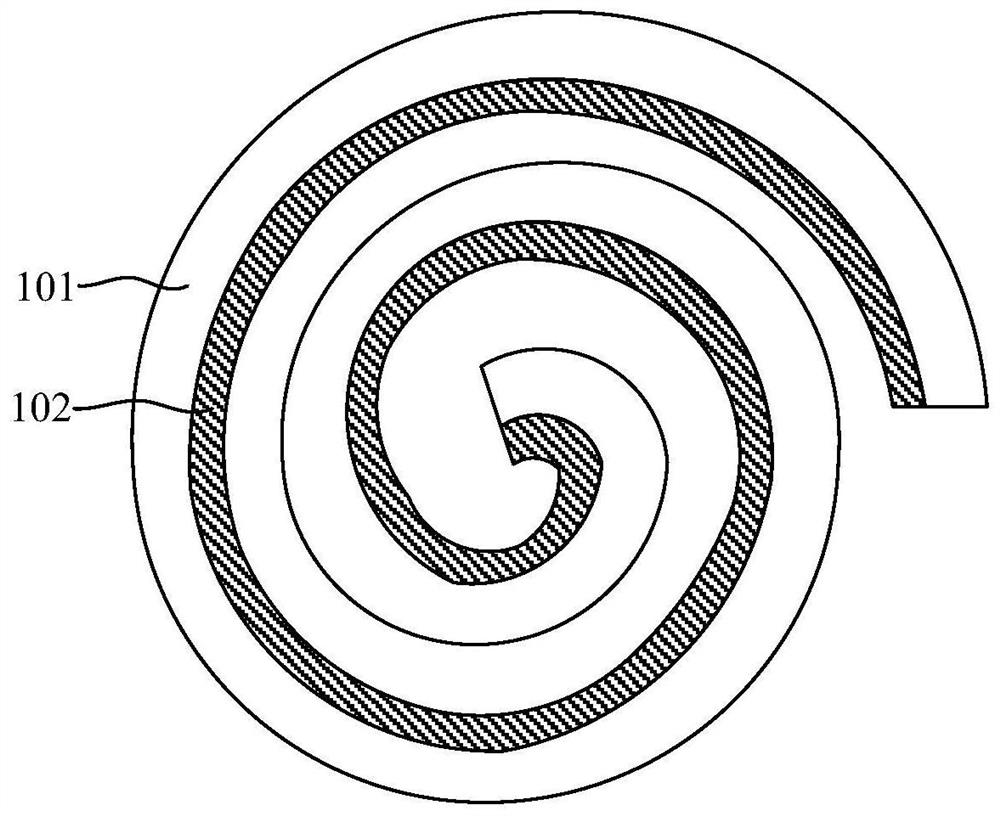

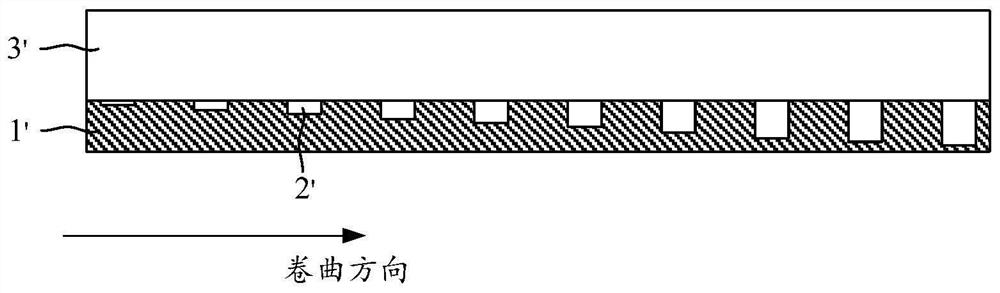

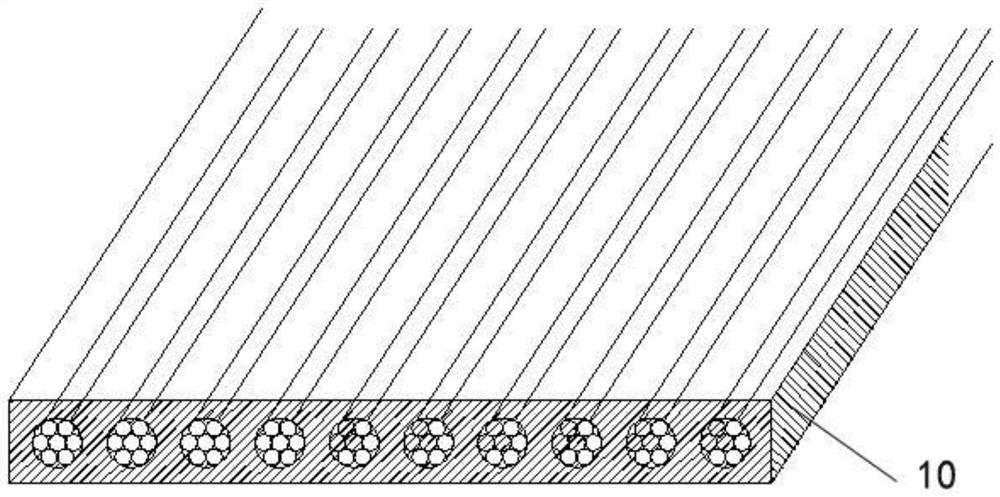

Supporting structure for supporting flexible display screen and flexible display device

The embodiment of the invention provides a supporting structure for supporting a flexible display screen and a flexible display device, and relates to the technical field of display. When the flexible display device is curled, uniform distribution of stress of the flexible display screen is guaranteed, meanwhile, a supporting layer is prevented from being broken, and the flatness of the flexible display screen is improved. The supporting structure comprises a flexible supporting layer, and the flexible supporting layer comprises a first supporting layer and a second supporting layer; the first supporting layer comprises a first surface and a second surface which are oppositely arranged, and the first surface is the surface, facing the flexible display screen, in the first supporting layer; the second supporting layer is located on one side of the second surface of the first supporting layer, the second supporting layer comprises a plurality of supporting parts arranged at intervals, the supporting parts comprise the first supporting parts and the second supporting parts, and the direction, pointing to the second supporting parts, of the first supporting parts is the curling direction of the flexible display screen; and the film thickness of the first supporting part is larger than that of the second supporting part in the direction perpendicular to the plane where the first supporting layer is located.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

Connection method for heat-conducting wire and metal substrate

ActiveCN105728876AReduce usageAchieve seamless connectionSolid state diffusion coatingWelding/cutting media/materialsMolten stateHeat conducting

The invention discloses a connection method for a heat-conducting wire and a metal substrate. By the adoption of the connection method, the problems that the heat-conducting wire is not matched with metal due to heat expansion, so that cracks are generated easily, and consequentially a connector fails and the wettability between molten liquid and the heat-conducting wire is poor are solved. The connection method comprises the steps that the end, to be connected, of the heat-conducting wire is cleaned, and surface coating treatment is conducted on one end of the heat-conducting wire, so that the end of the heat-conducting wire is coated with a coating with the thickness being 0.01 mm-1 mm; solder paste containing expansion particles is fully smeared on the end, to be connected, of the heat-conducting wire, and the heat-conducting wire is placed into a groove, with the diameter being 5 mm-8 mm, in the metal substrate after the solder paste containing the expansion particles is solidified; heating is conducted till the solder paste of the end, to be connected, of the heat-conducting wire is fully molten, and heat preservation is conducted; and cooling is conducted till the indoor temperature is reached. According to the connection method for the heat-conducting wire and the metal substrate, the expansion particles are added into the solder paste so that the size of solder in the molten state can be expanded rapidly, and accordingly air is exhausted, seams in the groove are filled with the solder, seamless connection between the heat-conducting wire and the metal substrate is achieved, and the efficient heat conductivity of the heat-conducting wire can be brought into full play easily.

Owner:SOUTH CHINA UNIV OF TECH

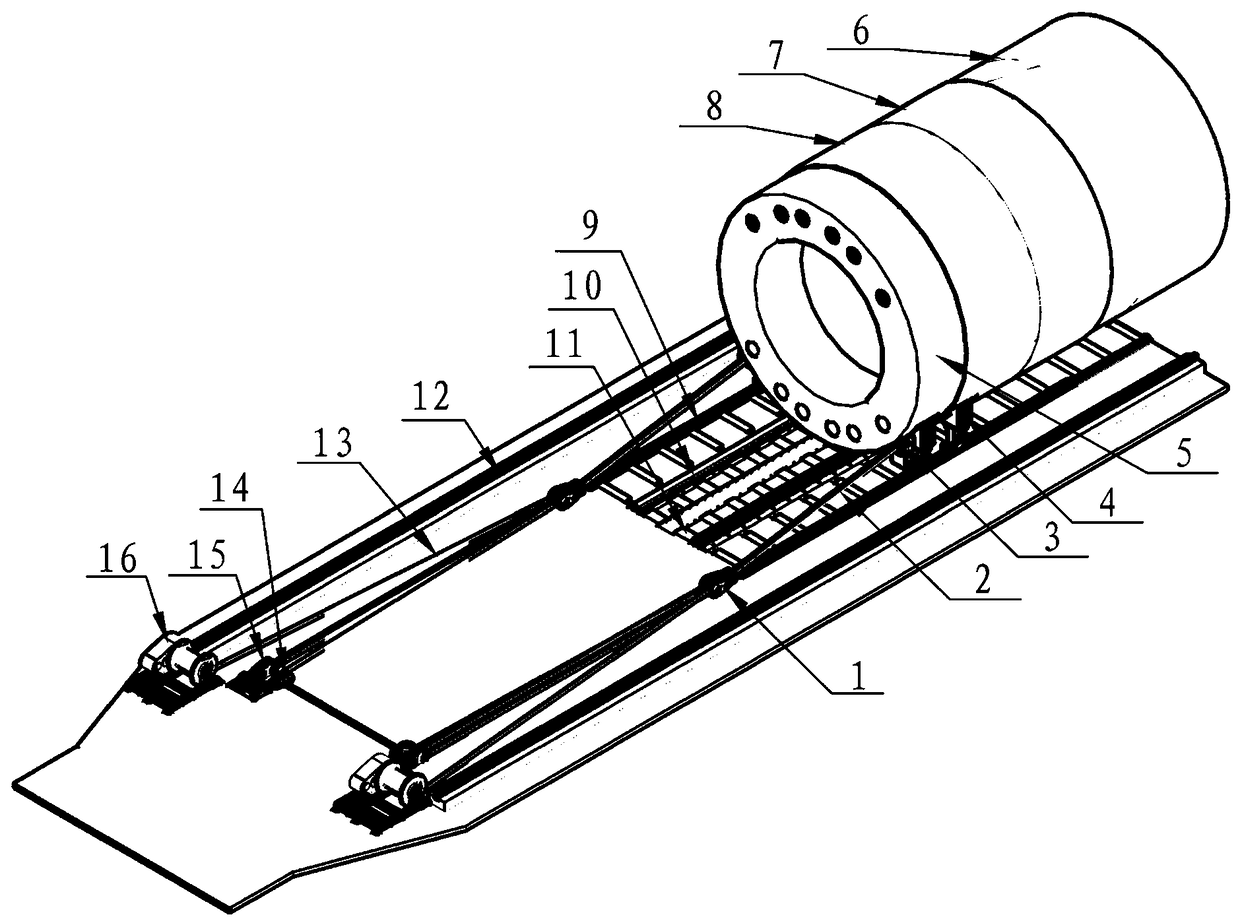

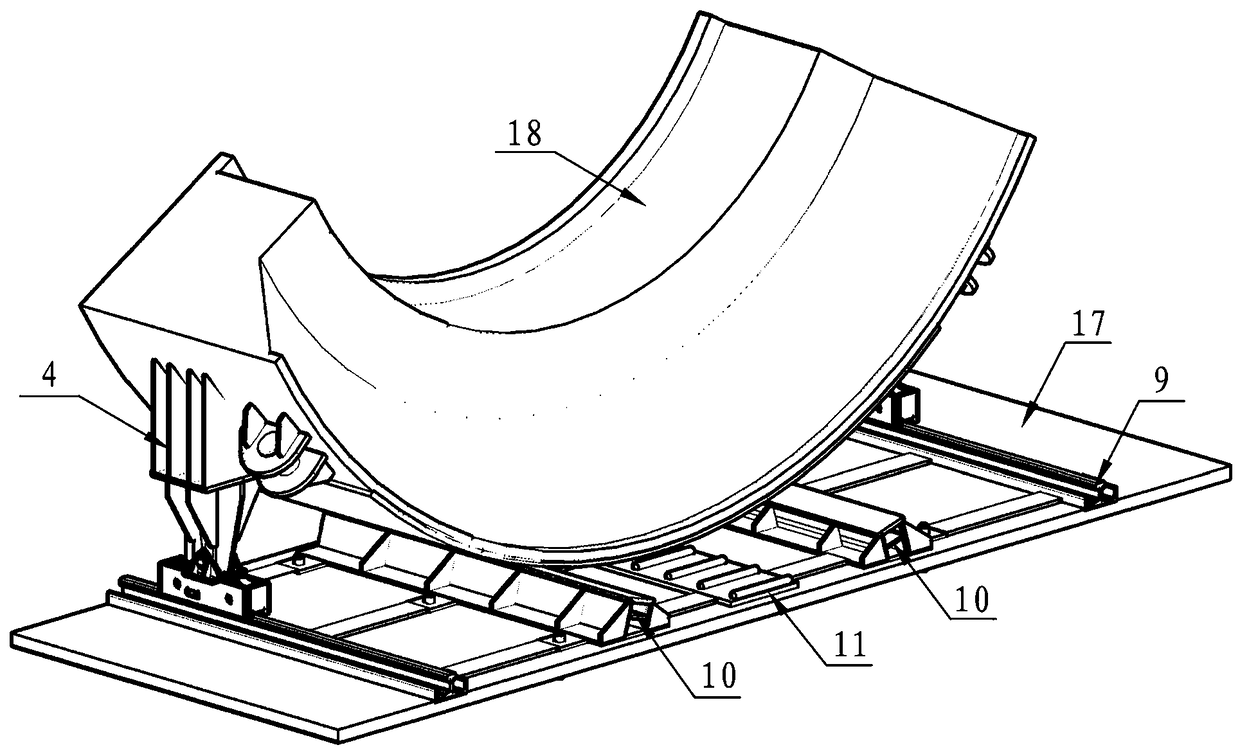

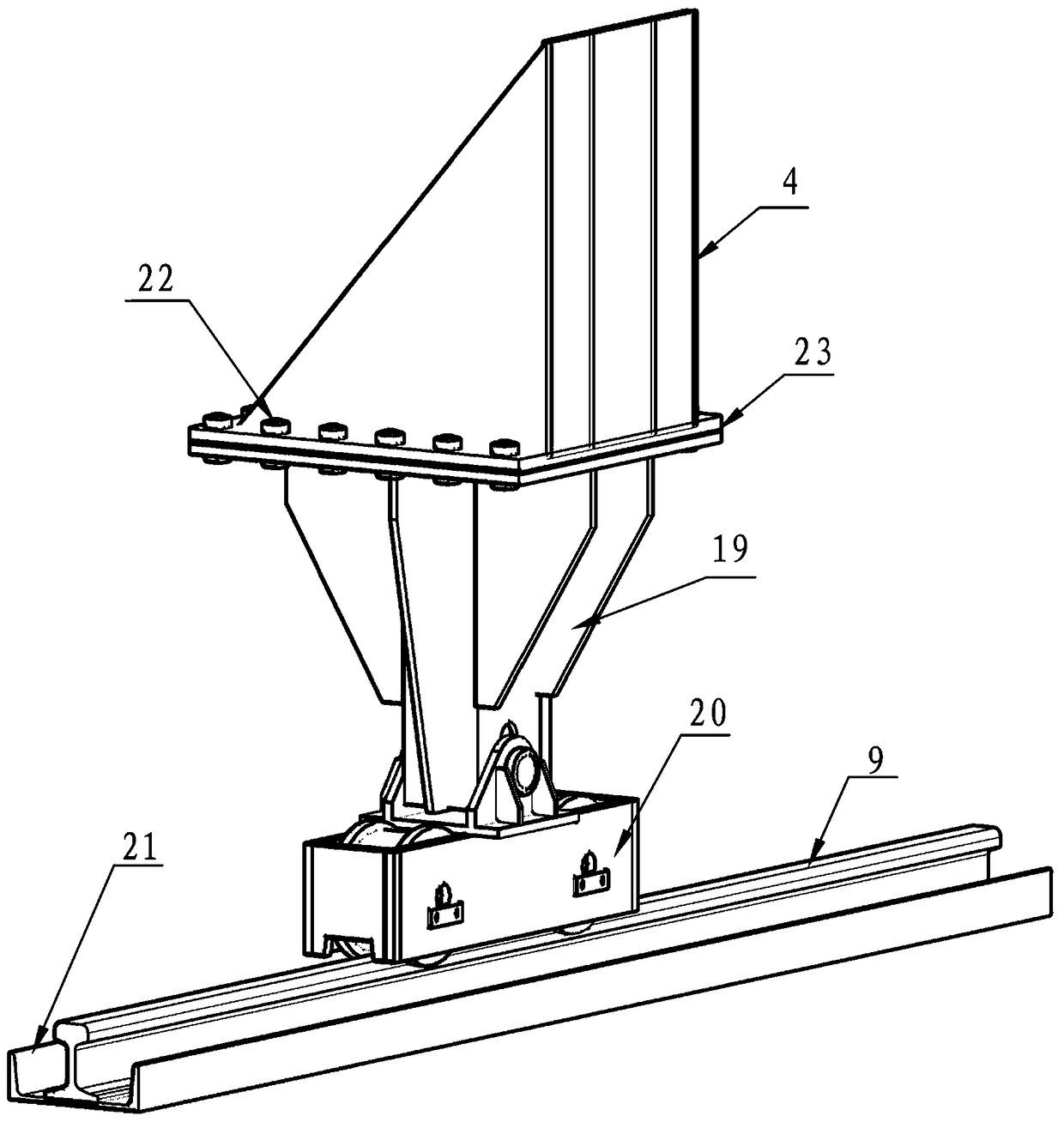

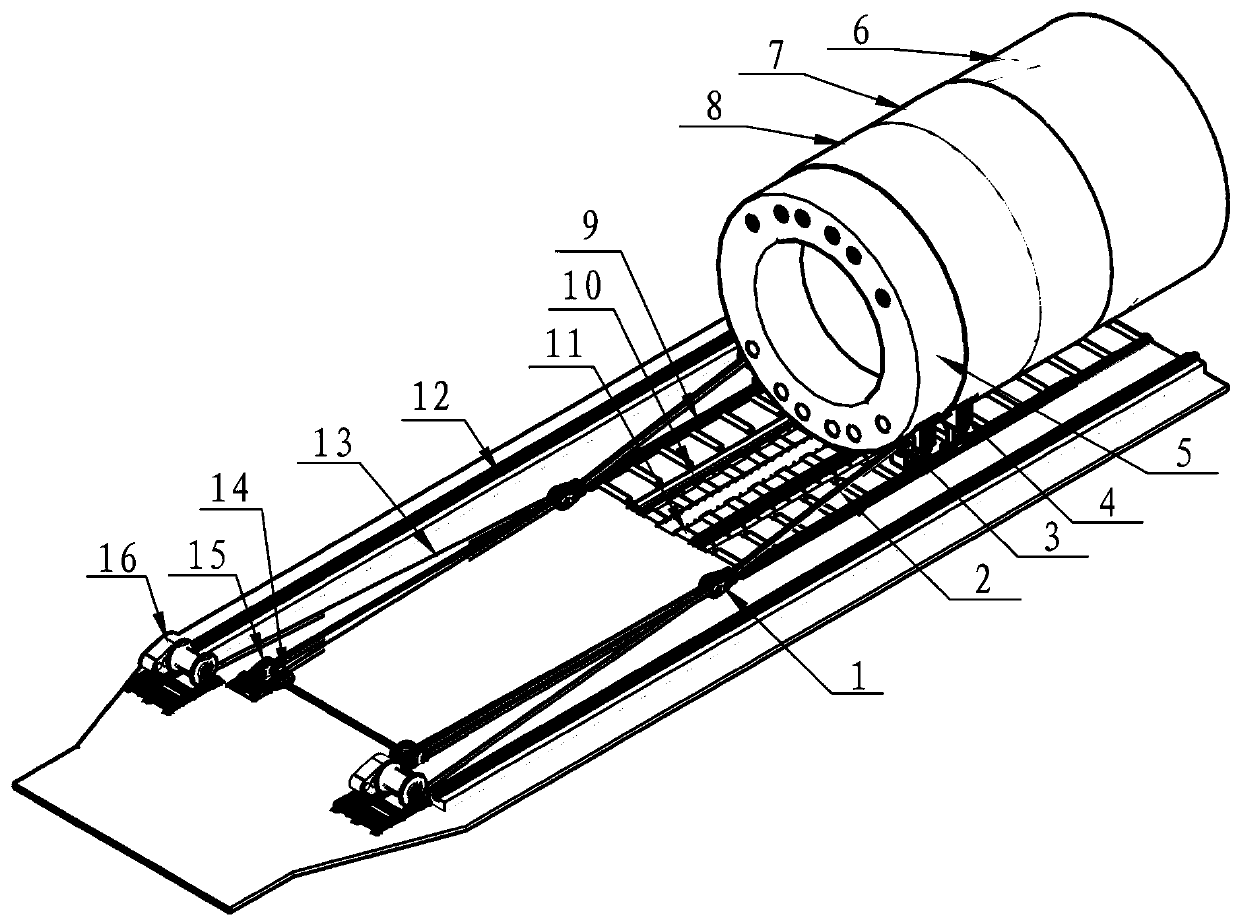

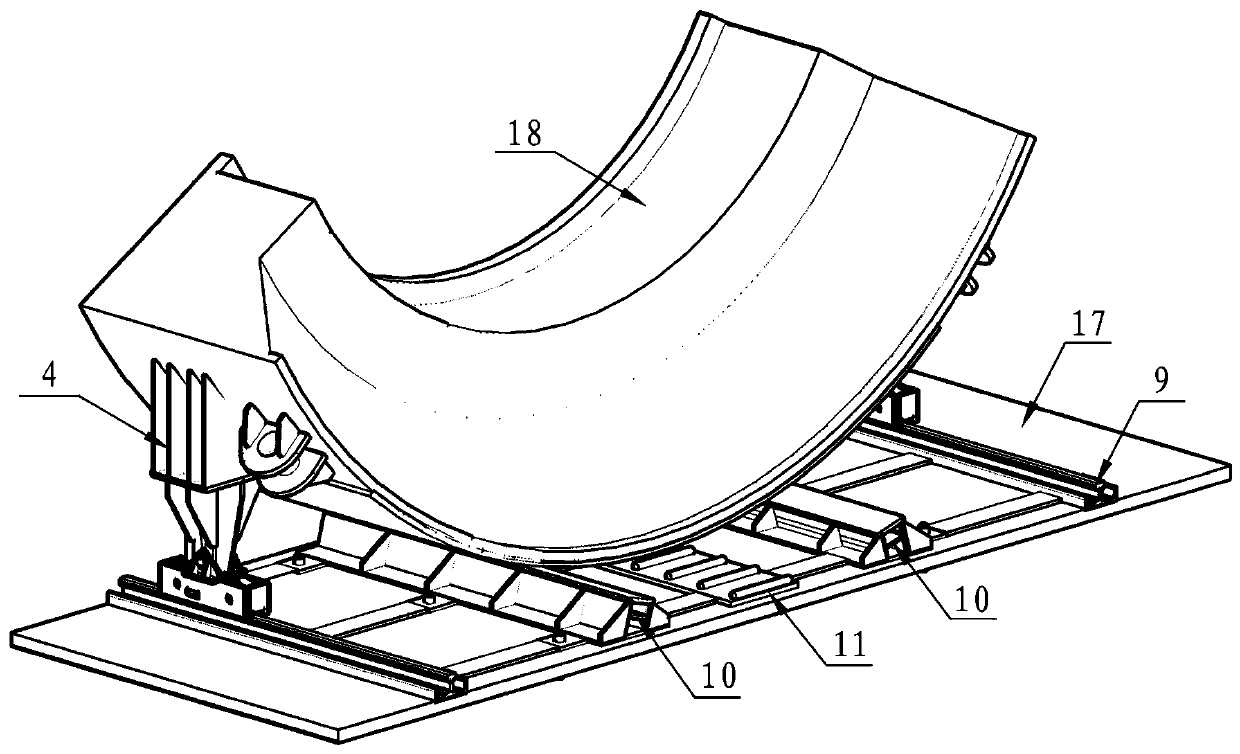

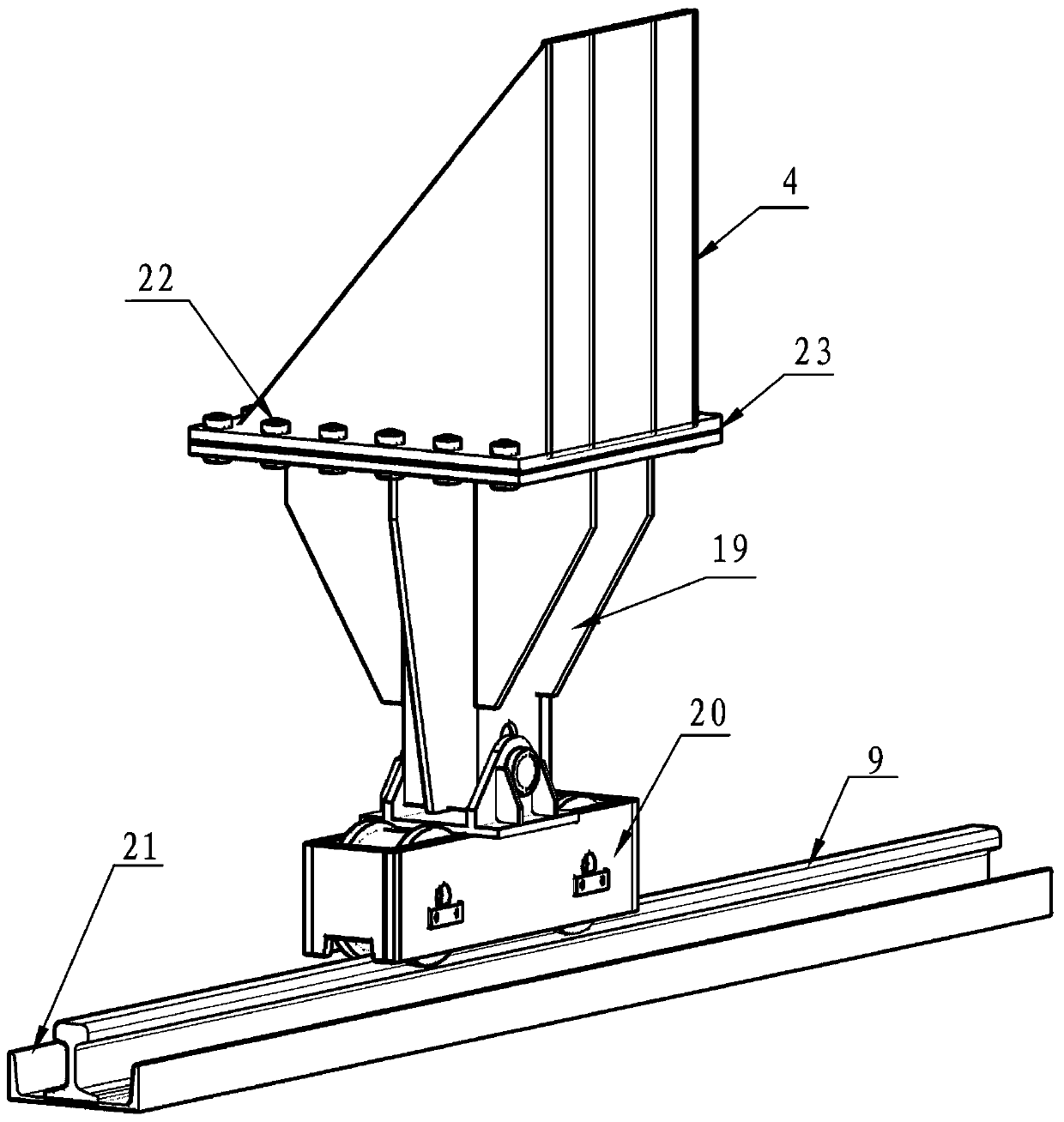

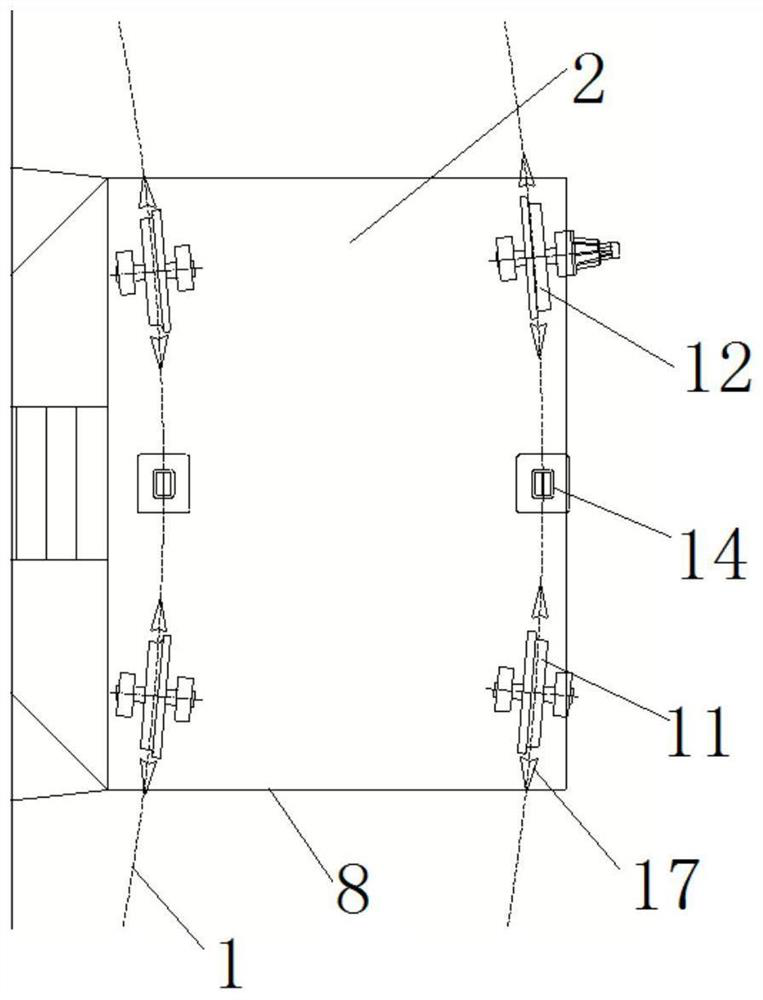

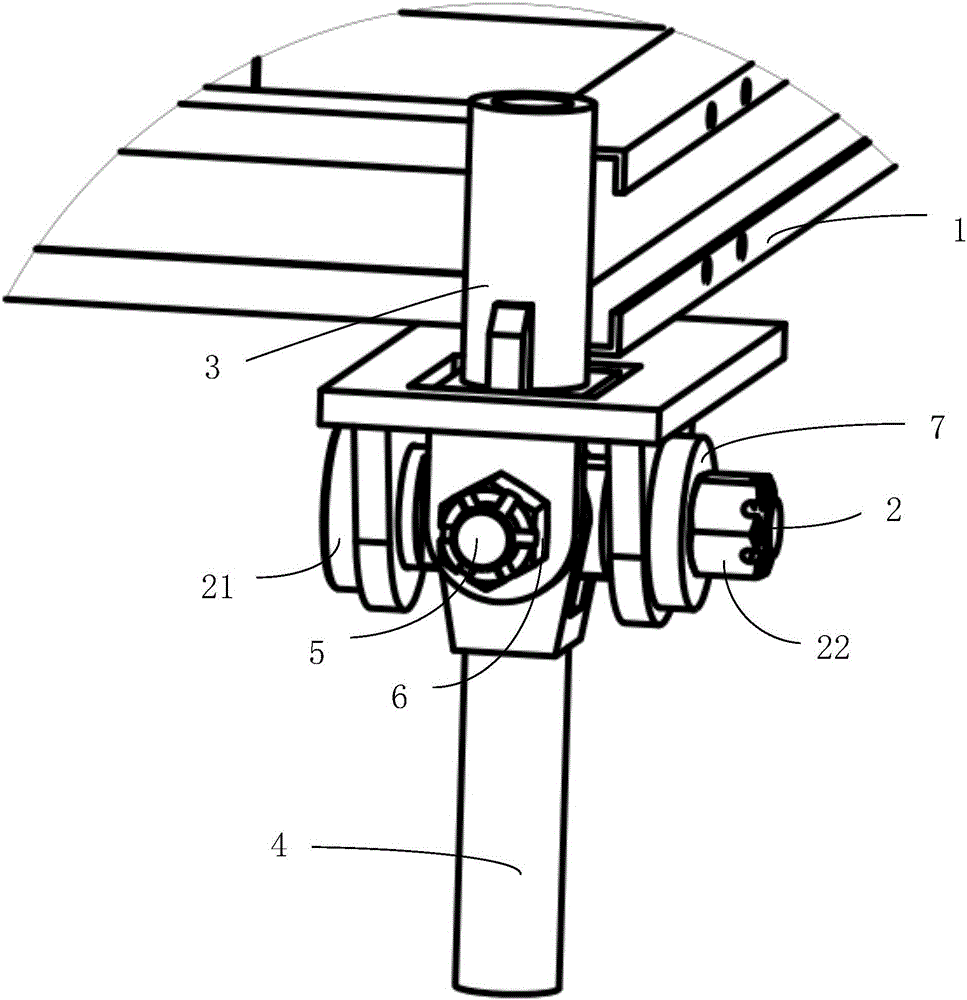

TBM shield anti-side-rolling walking support device and using method thereof

The invention provides a TBM shield anti-side-rolling walking support device and a using method thereof. The middle portion of a bottom plate is fixedly mounted with a rolling way, and slide rails aresymmetrically arranged on both outer sides of the rolling way. The outer sides of the two slide rails are respectively provided with symmetrically arranged tracks; the top of the rolling way, the slide rail and the track supports the front shield of a shield body, and the bottom two sides of the front shield are symmetrically and fixedly mounted with anti-side-rolling support roller boxes for preventing the shield body from rolling during the moving process. The bottom of the anti-side-rolling support roller boxes are in sliding engagement with the tracks; the front shield is connected to a traction power device for driving the front shield walking along the rolling way, the slide rail and the track. The TBM shield anti-side-rolling walking support device not only solves the constructionproblem of the shield body of the cylindrical TBM tunneling machine easily rolling to the both sides when slipping and walking in the gate tunnel, but also bears part of the front shield load and reduces the pressure of the front shield on the slide rail.

Owner:CHINA GEZHOUBA GRP FIRST ENG CO LTD

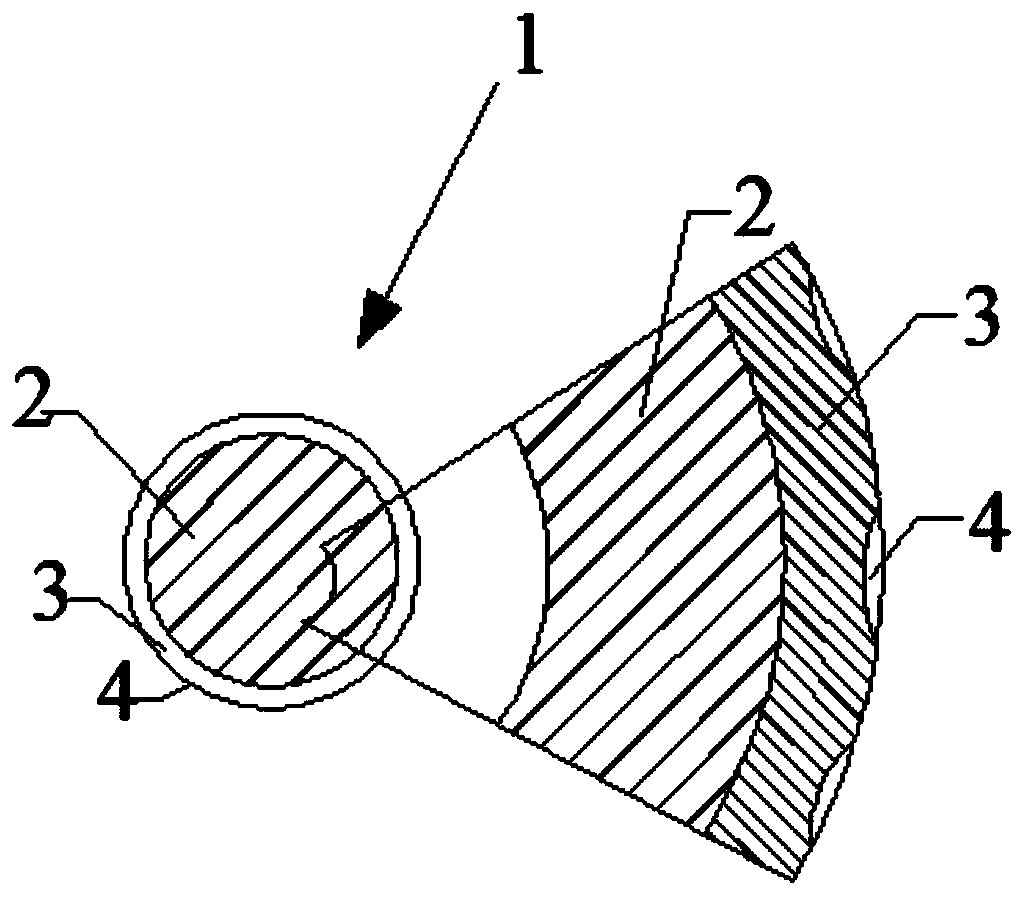

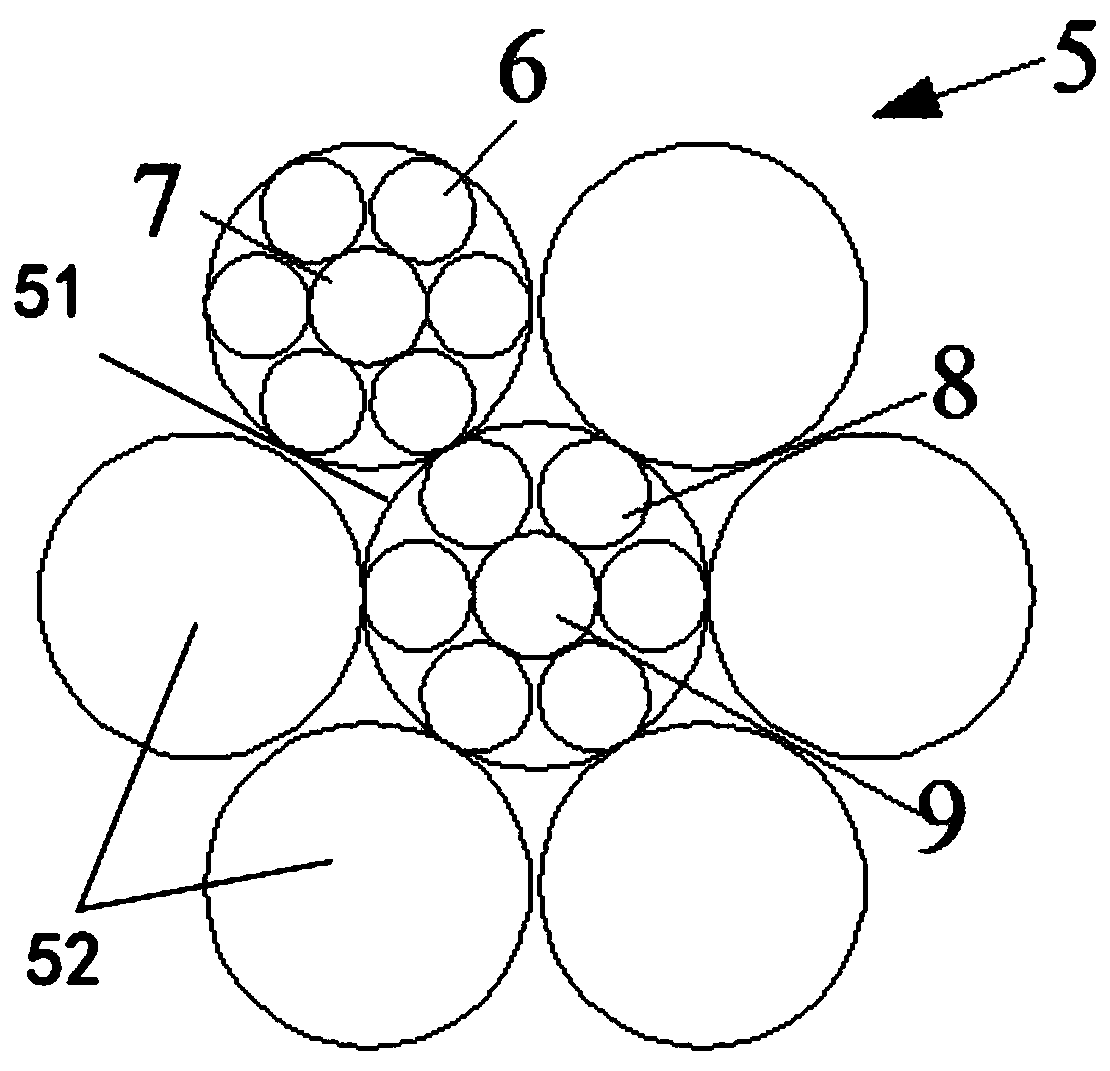

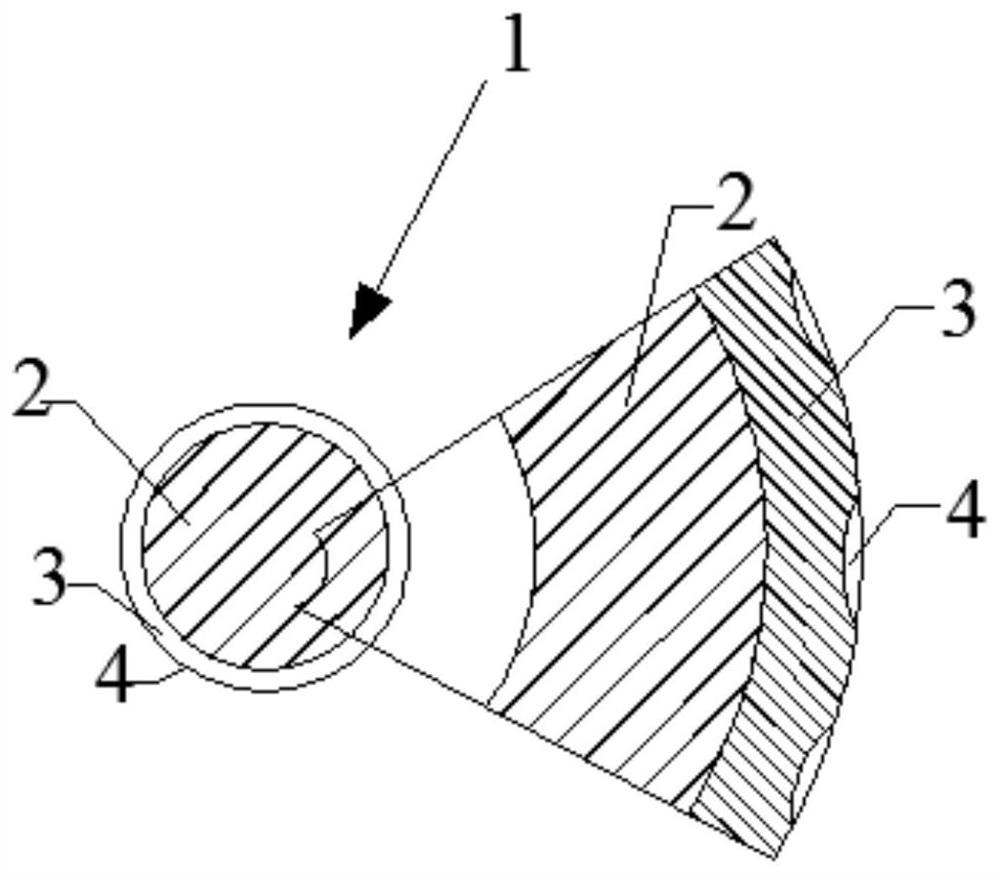

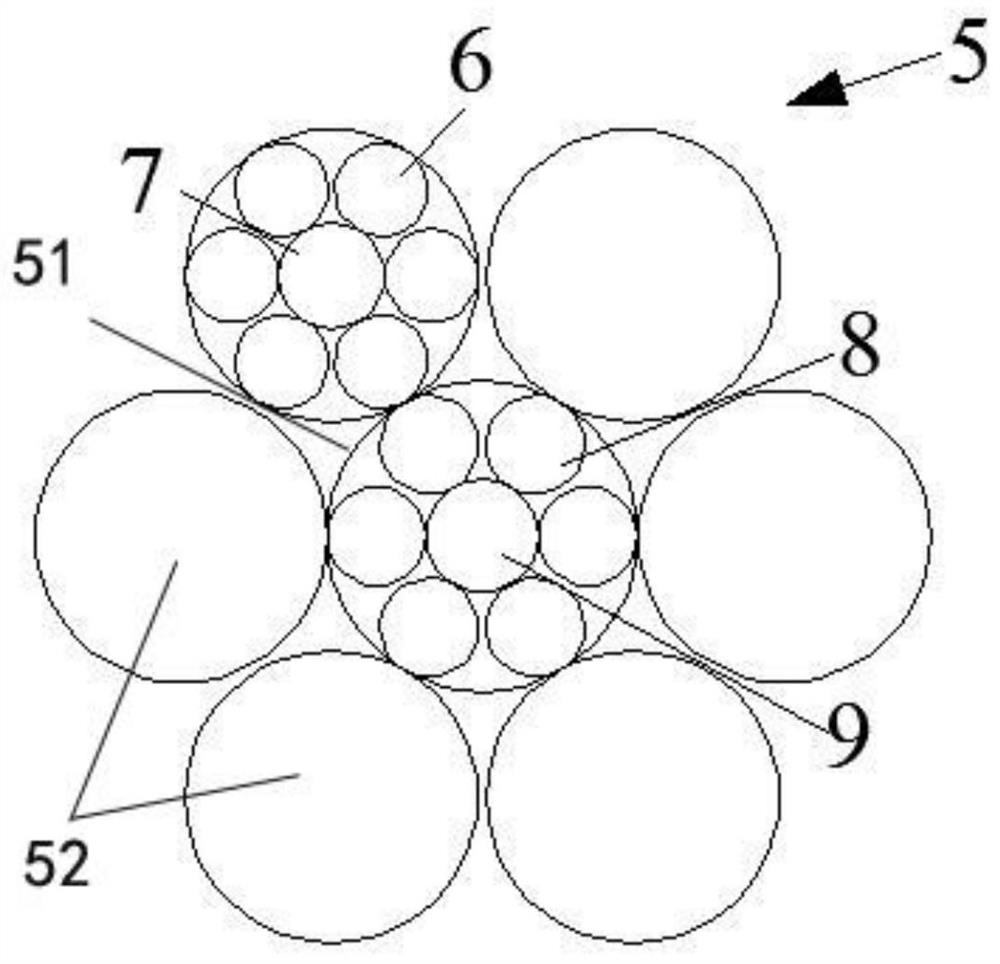

Manufacturing method of steel wire with alloy plated layer, steel wire and steel wire rope

ActiveCN110042220AEliminate hazardsImprove fatigue resistanceHot-dipping/immersion processesFurnace typesZinc alloys

The invention discloses a manufacturing method of a steel wire with an alloy plated layer, the steel wire and a steel wire rope, and relates to the technical field of manufacturing and production of steel wires. The manufacturing method of the steel wire comprises the following steps that 1, a steel wire matrix is obtained; 2, the obtained steel wire matrix passes through a zinc pot with molten zinc liquid to obtain a steel wire matrix plated with a zinc layer, the steel wire matrix plated with the zinc layer is subjected to mechanical wiping treatment, and the steel wire matrix with an iron-zinc alloy layer on the surface or the steel wire matrix with the iron-zinc alloy layer and a pure zinc layer on the surface is obtained; 3, the obtained steel wire matrix with the iron-zinc alloy layer on the surface is pickled to remove the pure zinc layer on the surface of the steel wire matrix, and the steel wire matrix with the iron-zinc alloy layer on the surface is obtained; and 4, the obtained steel wire matrix with the iron-zinc alloy on the surface is drawn to obtain the steel wire with the required size. The steel wire produced by the method is beneficial to improving drawing and twisting speed and improving production efficiency.

Owner:JIANGSU XINGDA STEEL TYPE CORD

Display device and electronic equipment

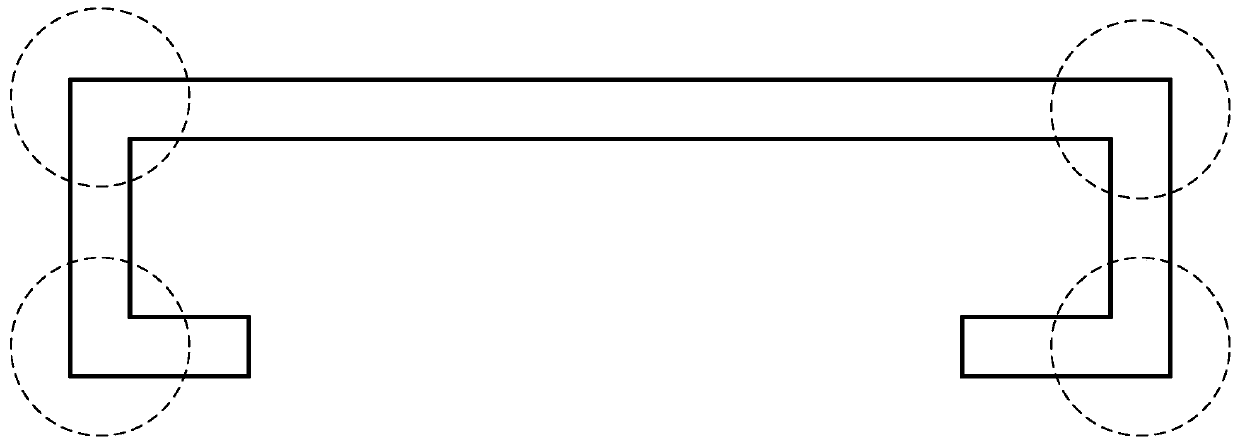

InactiveCN111258098AIncreased durabilityAvoid excessive bendingNon-linear opticsDisplay deviceEngineering

The invention discloses a display device and electronic equipment. The display device is provided with a support structure at one side, deviating from the light emitting direction of the display device, of a substrate, the support structure avoids the situation that a wire or a device arranged on a bending area of the substrate is broken due to excessive bending stress, and the durability of the display device is improved. Besides, a main body part and / or an end part of the support structure comprise / comprises an elastic structure with a telescopic amount parallel to a preset direction; when the support structure and the bending area of the substrate cannot be in an exact fit due to tolerances in the preparation or assembly process, the telescopic amount of the elastic structure in the direction parallel to the preset direction can compensate for the tolerances, the situation that the supporting structure is excessively matched with or cannot be attached to the bending area of the substrate is avoided, and the probability that wire or device arranged on the bending area of the substrate bears too large bending stress is further reduced.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

Image forming apparatus

ActiveUS7806516B2Curl suppressionCurl can be prevented from generatingRecording apparatusElectrographic process apparatusImage formationEngineering

An image forming apparatus includes a turning unit that turns the recording medium fed from a fixing unit, which fixes toner transferred to a recording medium and has a heating roller for heating toner, by approximately 90° with respect to a feeding direction of the recording medium, and a discharge roller that discharges the recording medium turned by the turning unit. A circumferential speed of the discharge roller is smaller than a circumferential speed of the heating roller.

Owner:BROTHER KOGYO KK

OLED display substrate, manufacturing method thereof, and OLED display apparatus

InactiveUS20190058156A1Improve bending reliabilityLarge bending stressSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringMetal halides

Owner:BOE TECH GRP CO LTD

Piezoelectric transducer, production method thereof, and electronic equipment

ActiveCN111063790ALarge bending stressGuaranteed thicknessPiezoelectric/electrostrictive device detailsPiezoelectric/electrostrictive devicesTransducerEngineering

The invention relates to a piezoelectric transducer, a production method thereof, and electronic equipment. The piezoelectric transducer comprises a supporting structure and a piezoelectric vibratingdiaphragm arranged on the supporting structure; the piezoelectric vibrating diaphragm comprises a beam, one end of the beam in the first direction is supported by the supporting structure, and the other end of the beam is a free end; and the piezoelectric vibrating diaphragm comprises a first electrode layer and a piezoelectric material layer which are sequentially arranged on the supporting structure in a stacked mode, wherein the area of the piezoelectric material layer at the free end is smaller than that of the first electrode layer. Compared with a traditional piezoelectric transducer, the piezoelectric transducer, the piezoelectric transducer of the invention has the following advantages: when the piezoelectric vibrating diaphragm deforms, the bending stress is large; and particularly when the piezoelectric transducer is a piezoelectric electroacoustic transducer, the signal to noise ratio is high.

Owner:SHANDONG GETTOP ACOUSTIC

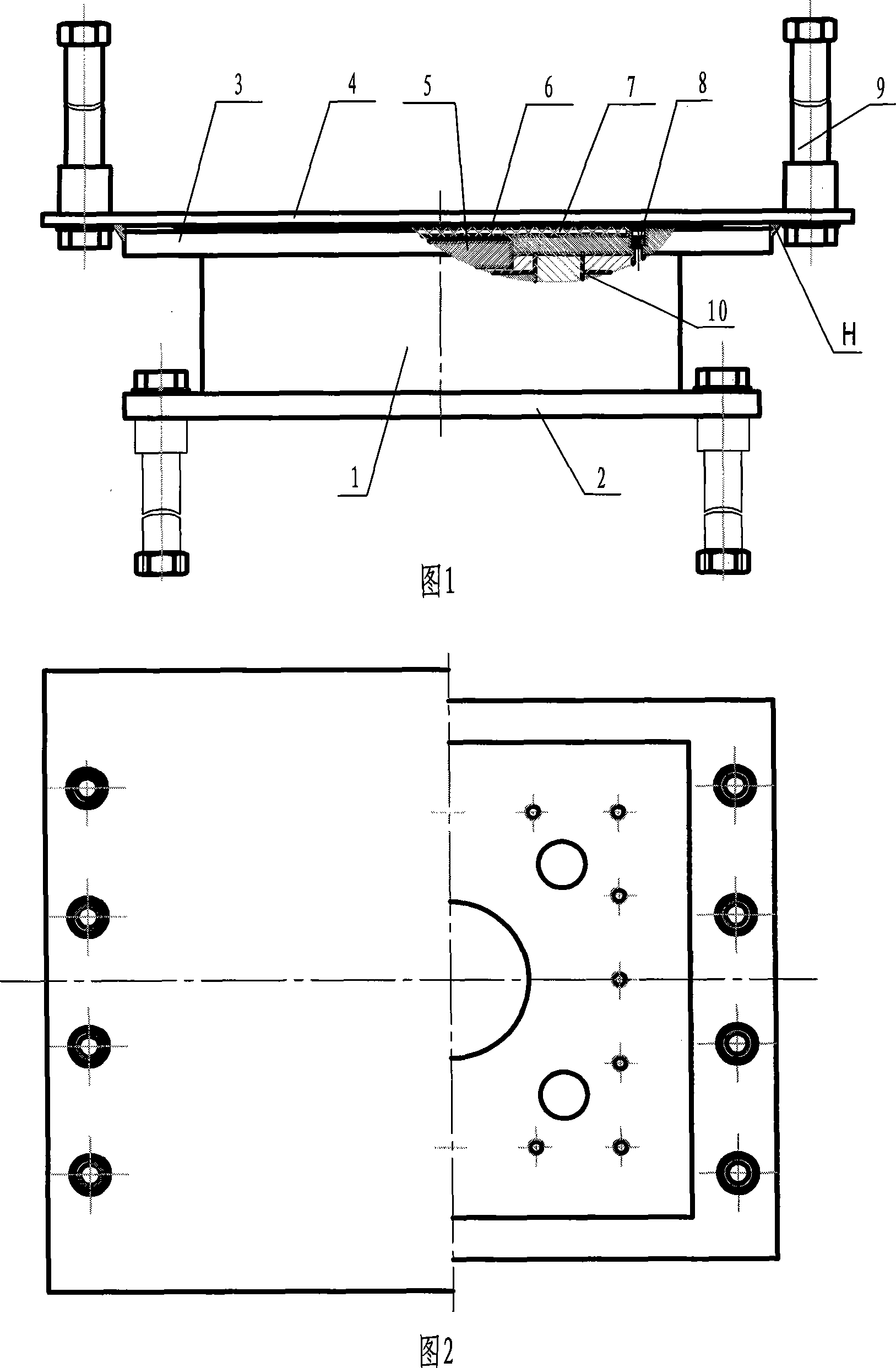

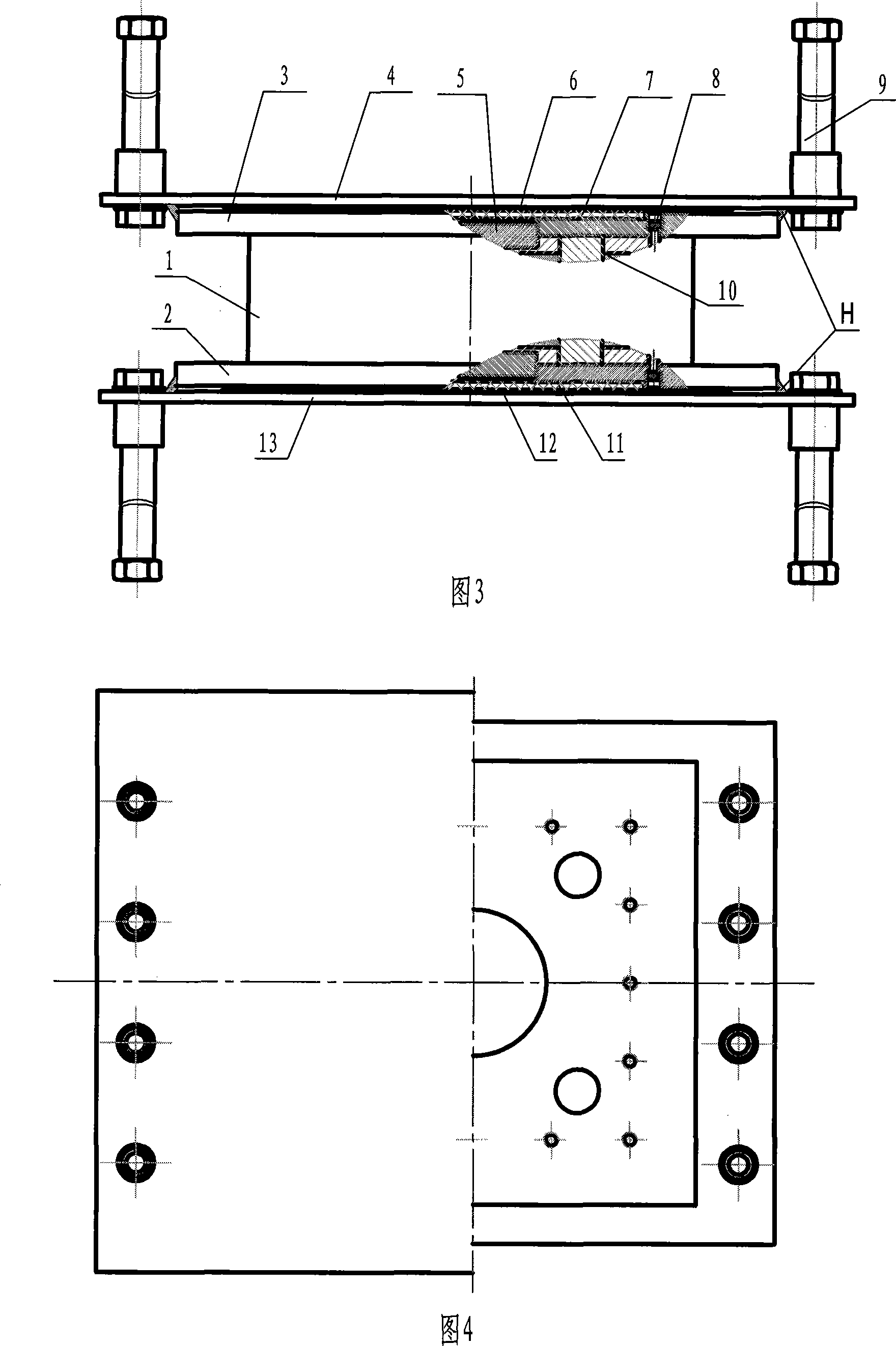

Mounting and using method of lead core rubber support component with friction pairs

ActiveCN101487229BRemove initial deformationSituations where partition reduction design is not possibleBridge structural detailsStructural engineeringSteel plates

The invention provides a lead-core rubber support component with a friction pair, comprising a lead-core rubber support body, an upper external connecting steel plate and a lower external connecting steel plate which are respectively arranged on the upper end surface and the lower end surface of the lead-core rubber support body, and one-two friction pairs; the upper end surface and the lower endsurface of the support body are respectively connected with the upper external connecting steel plate and the lower external connecting steel plate by a screw and a shearing bond; and one auxiliary surface of each friction pair is respectively arranged on the external upper surface of the upper external connecting steel plate or the lower external surface of the lower external connecting steel plate or arranged at the external upper surface of the upper external connecting steel plate and the lower external surface of the lower external connecting steel plate simultaneously. The installation and use method of the component comprises the steps as follows: the component is arranged between a bridge beam body and a bridge pier; the other auxiliary surface of each friction pair is respectively arranged on the lower surface of the bridge beam and the bridge pier or arranged on the lower surface of the bridge beam and the bridge pier simultaneously; and after creep and shrink of the bridge beam are basically completed, the lead-core rubber support component is fixedly connected with the bridge beam and the bridge pier, thus eliminating the initial deformation of the support caused by the creepage and shrink of the concrete of the bridge beam.

Owner:柳州东方工程橡胶制品有限公司

Support structure for supporting flexible display screen and flexible display device

ActiveCN113470535BChange the local stiffnessIncrease stiffnessIdentification meansFlexible displayMechanical engineering

Embodiments of the present invention provide a support structure for supporting a flexible display and a flexible display device, which relate to the field of display technology. When the flexible display device is curled, while ensuring the uniform distribution of the stress of the flexible display, it not only prevents the support layer from breaking, Also improve the flatness of the flexible display. The support structure includes a flexible support layer, the flexible support layer includes a first support layer and a second support layer; the first support layer includes a first surface and a second surface oppositely arranged, and the first surface is the first surface of the first support layer facing the flexible display screen. The surface; the second support layer is located on one side of the second surface of the first support layer, the second support layer includes a plurality of support portions arranged at intervals, the support portion includes a first support portion and a second support portion, and the first support portion The direction pointing to the second supporting part is the rolling direction of the flexible display; in the direction perpendicular to the plane where the first supporting layer is located, the film thickness of the first supporting part is greater than that of the second supporting part.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

Manufacturing method, steel wire and steel wire rope with alloy coating

ActiveCN110042220BEliminate hazardsImprove fatigue resistanceHot-dipping/immersion processesFurnace typesZinc alloysAlloy coating

Owner:JIANGSU XINGDA STEEL TYPE CORD

tbm shield body anti-rolling walking support device and its application method

The invention provides a TBM shield anti-side-rolling walking support device and a using method thereof. The middle portion of a bottom plate is fixedly mounted with a rolling way, and slide rails aresymmetrically arranged on both outer sides of the rolling way. The outer sides of the two slide rails are respectively provided with symmetrically arranged tracks; the top of the rolling way, the slide rail and the track supports the front shield of a shield body, and the bottom two sides of the front shield are symmetrically and fixedly mounted with anti-side-rolling support roller boxes for preventing the shield body from rolling during the moving process. The bottom of the anti-side-rolling support roller boxes are in sliding engagement with the tracks; the front shield is connected to a traction power device for driving the front shield walking along the rolling way, the slide rail and the track. The TBM shield anti-side-rolling walking support device not only solves the constructionproblem of the shield body of the cylindrical TBM tunneling machine easily rolling to the both sides when slipping and walking in the gate tunnel, but also bears part of the front shield load and reduces the pressure of the front shield on the slide rail.

Owner:CHINA GEZHOUBA (GRP) FIRST ENG CO LTD

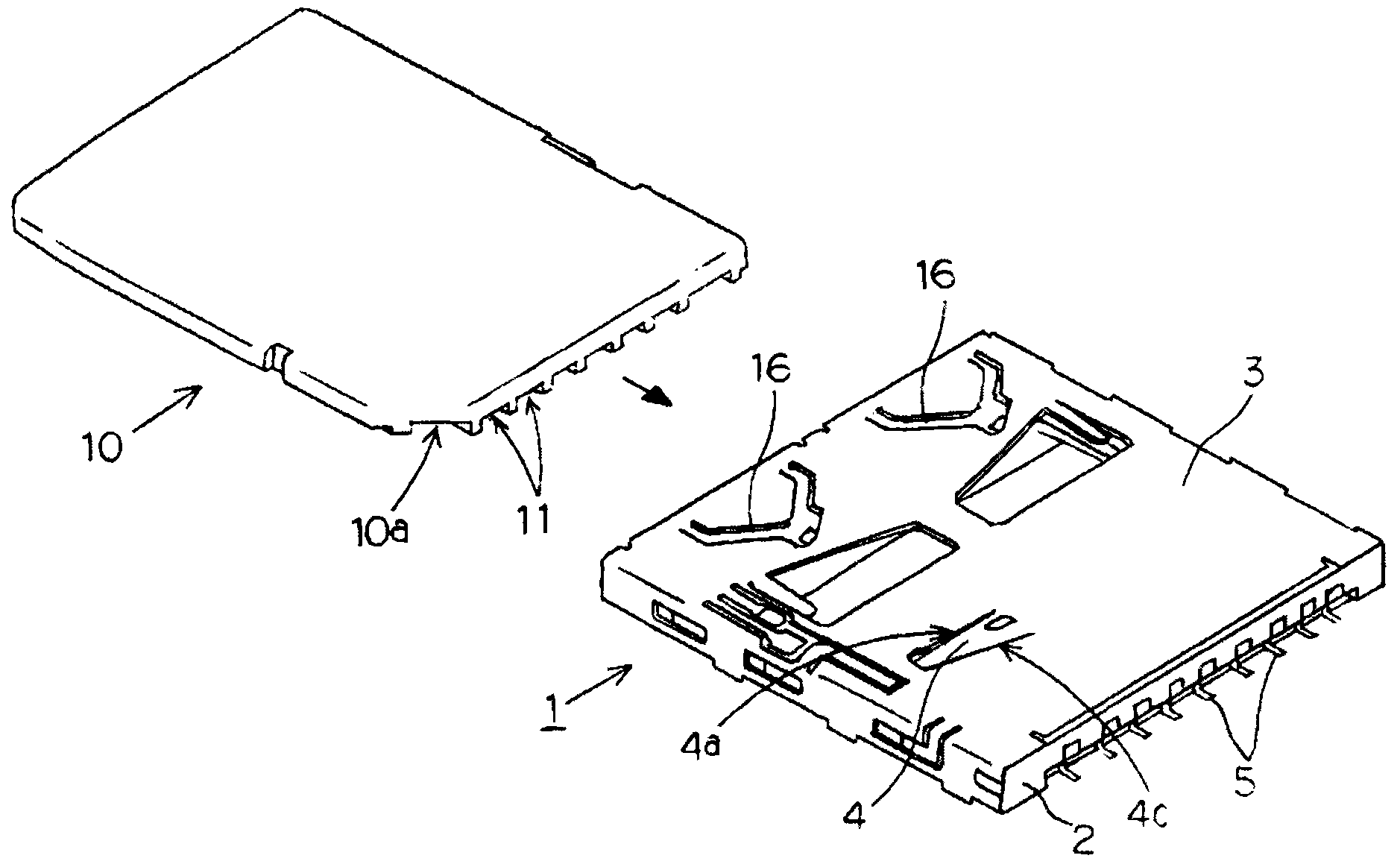

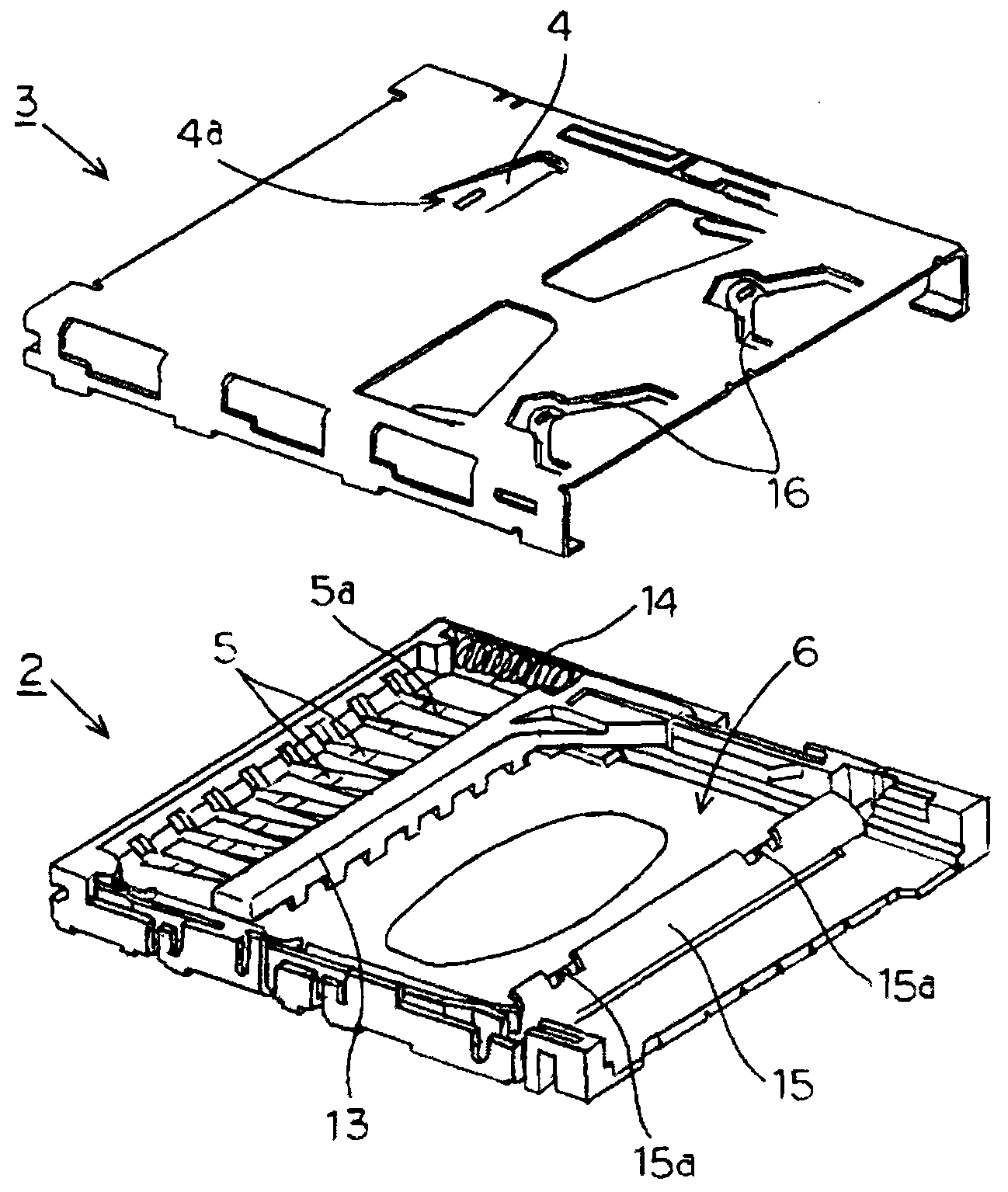

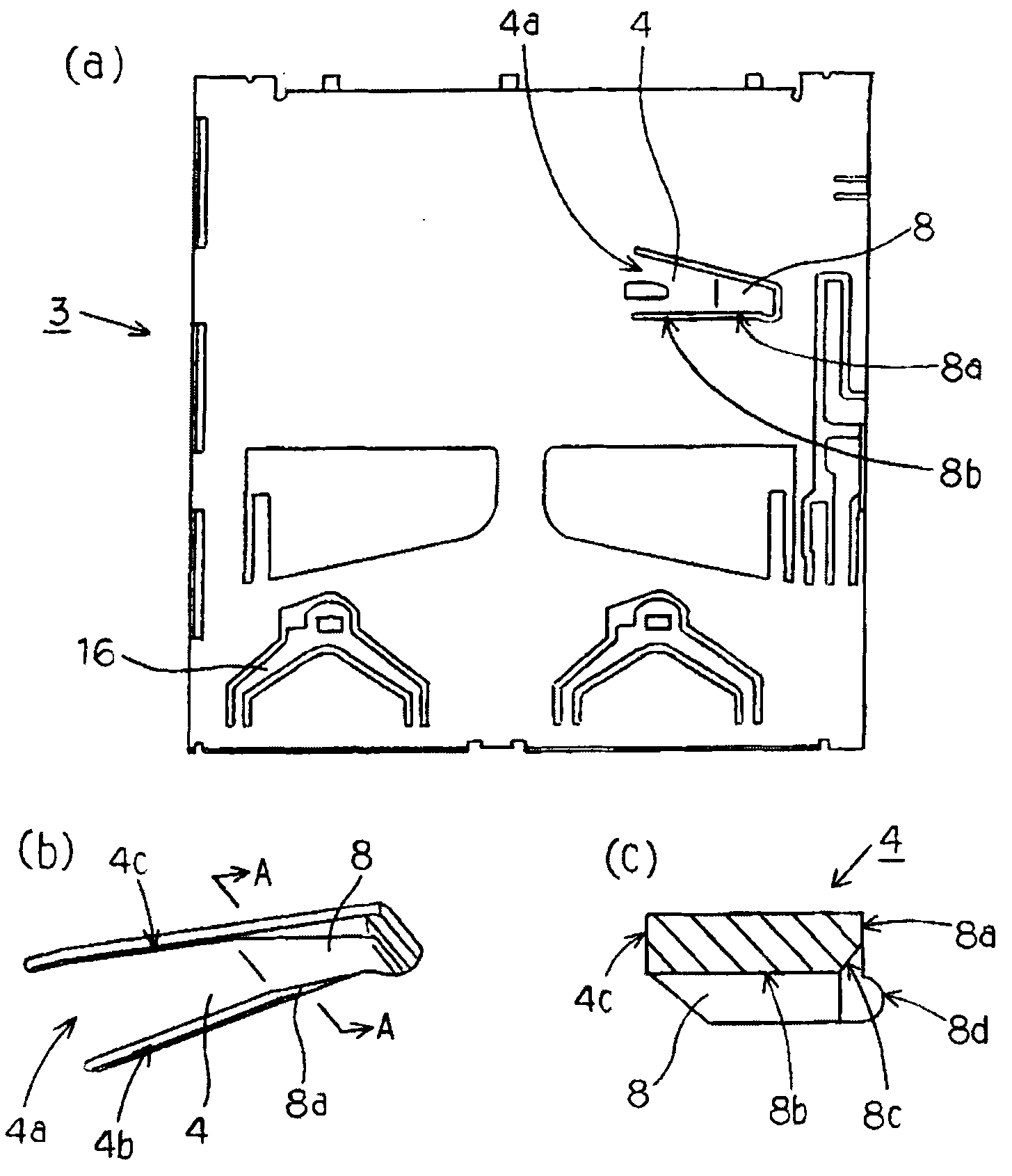

Connector for memory card

PROBLEM TO BE SOLVED: To provide a memory card connector capable of reliably preventing, with a simple structure, the insertion of a memory card in an improper posture, without carrying out any work on a case.SOLUTION: A leaf spring piece supported in a cantilevered manner is formed integrally with a cover. An erroneous insertion prevention plate on at least a free-end side of the leaf spring piece is inclined downward with respect to the cover such that a rear lateral surface of the erroneous insertion prevention plate faces the inner side of a card housing part in a manner perpendicular to an inserting direction of a memory card and crosses a movement track of an inclined surface of the memory card inserted in the card housing part. If the memory card is inserted in a regular posture, the inclined surface abuts on a lower portion of the rear lateral surface and pushes up the erroneous insertion prevention plate, but if the memory card is inserted in an improper posture, a flat surface abuts on the rear lateral surface, thus causing the erroneous insertion prevention plate to restrict the insertion of the memory card.

Owner:SMK CO LTD

Varied-Wall-thickness integrated buckle arrestor with side plates

ActiveCN103133770AImprove the anti-bending effectPrevent buckling propagationPipe laying and repairClassical mechanicsStructural engineering

The invention belongs to the technical field of deepwater submarine pipeline manufacture, laying and mounting and relates to a varied-wall-thickness integrated buckle arrestor with side plates. The varied-wall-thickness integrated buckle arrestor comprises a buckle arrestor body which is fixed outside a submarine pipeline. The thickness of two ends of the buckle arrestor body is 2-4 times of that of the pipeline and gradually decreases to the middle. The buckle arrestor further comprises four side plates which are fixed between the outer wall of the middle of the buckle arrestor body and the inner wall of the pipeline and superposed on the axis of the pipeline, and the adjacent side plates are spaced by a 90-degree central angle. The varied-wall-thickness integrated buckle arrestor with the side plates can guarantee buckle arresting effect, and total weight of the buckle arrestor is taken into account.

Owner:TIANJIN UNIV

Piezoelectric transducer, method for manufacturing piezoelectric transducer, and electronic device

ActiveCN111063790BLarge bending stressGuaranteed thicknessPiezoelectric/electrostrictive device detailsPiezoelectric/electrostrictive devicesTransducerEngineering

The invention relates to a piezoelectric transducer, a method for preparing the piezoelectric transducer and electronic equipment. A piezoelectric transducer, comprising a support structure and a piezoelectric diaphragm arranged on the support structure; the piezoelectric diaphragm includes a beam, and one end of the beam in a first direction is supported by the support structure , the other end is a free end; the piezoelectric diaphragm includes a first electrode layer and a piezoelectric material layer sequentially stacked on the support structure; wherein, the area of the piezoelectric material layer at the free end is smaller than that of the first electrode layer The area of an electrode layer. Compared with the traditional piezoelectric transducer, the piezoelectric transducer, the method for preparing the piezoelectric transducer and the electronic equipment mentioned above have greater bending stress when the piezoelectric diaphragm is deformed, especially when the piezoelectric transducer is a piezoelectric transducer. When using electro-acoustic transducers, the signal-to-noise ratio is relatively high.

Owner:SHANDONG GETTOP ACOUSTIC

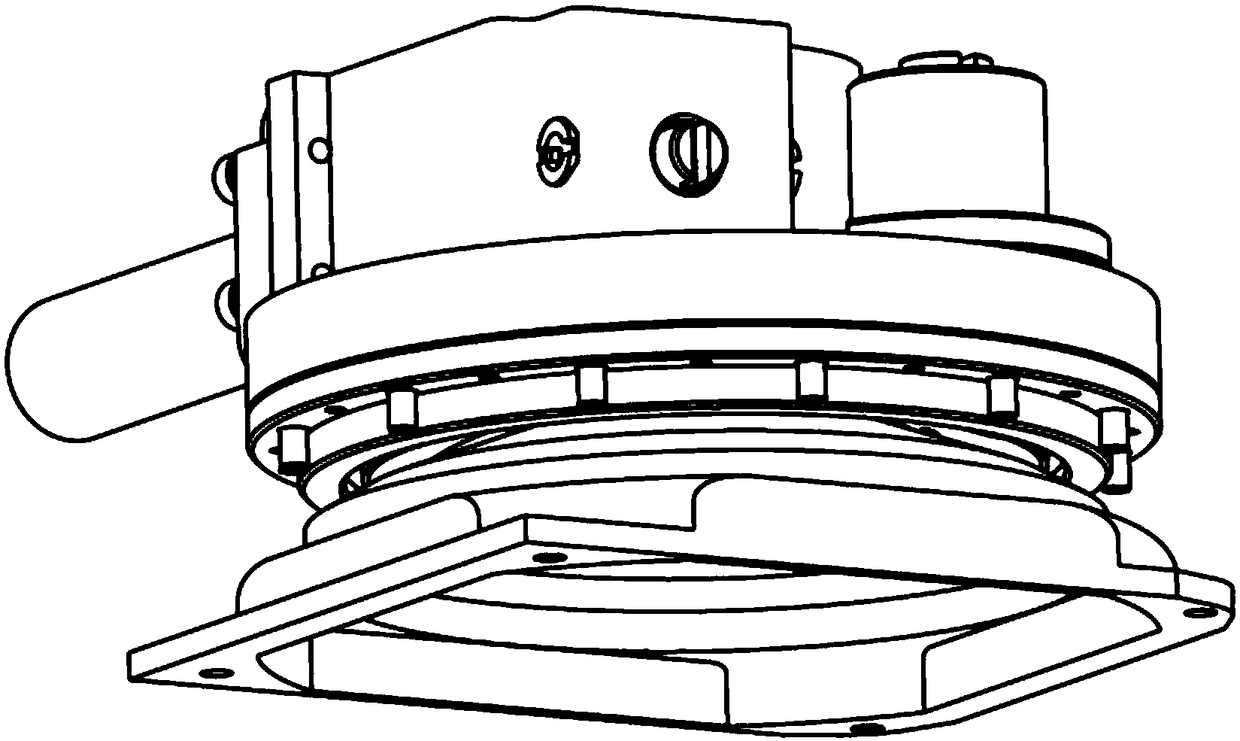

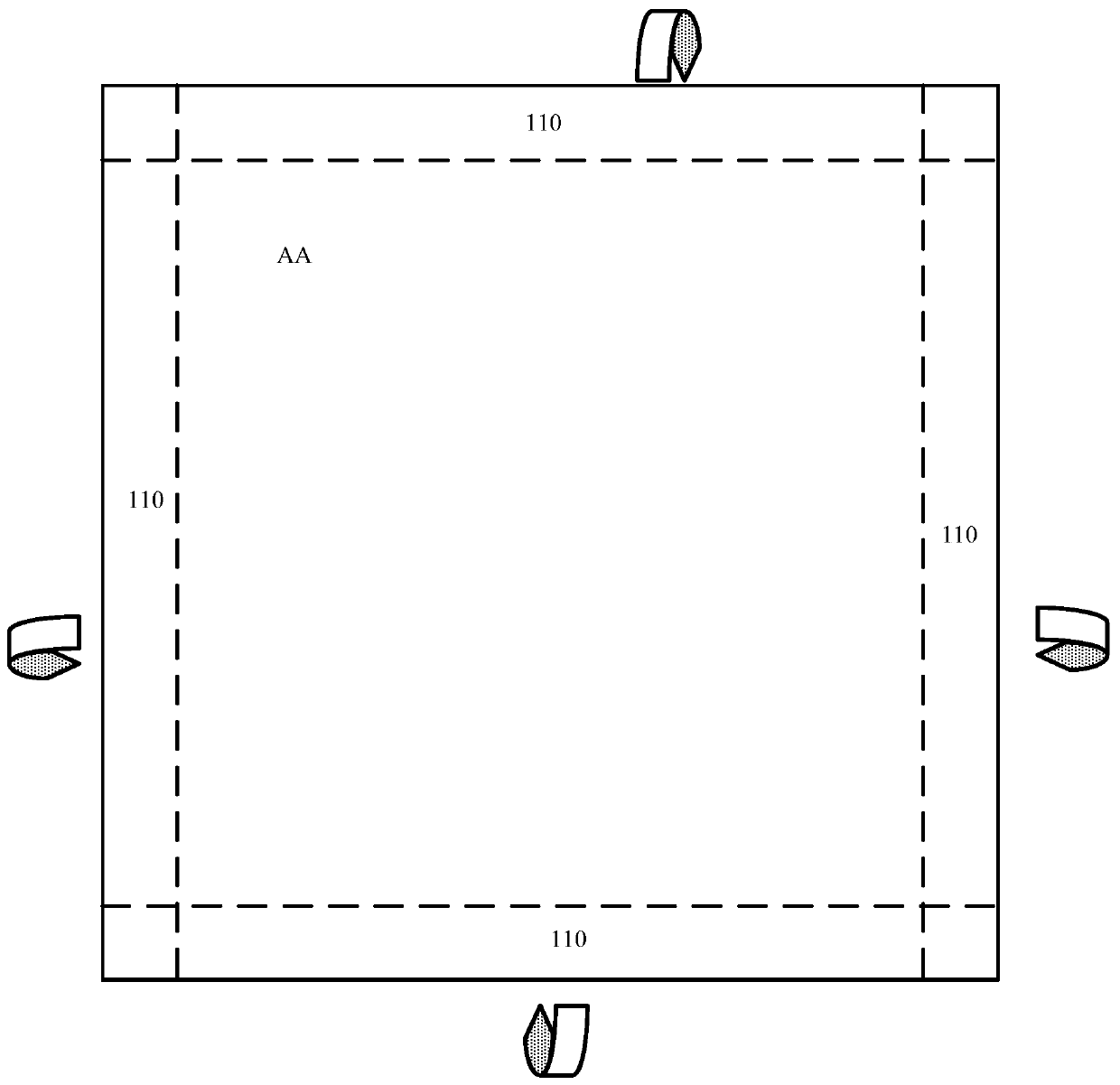

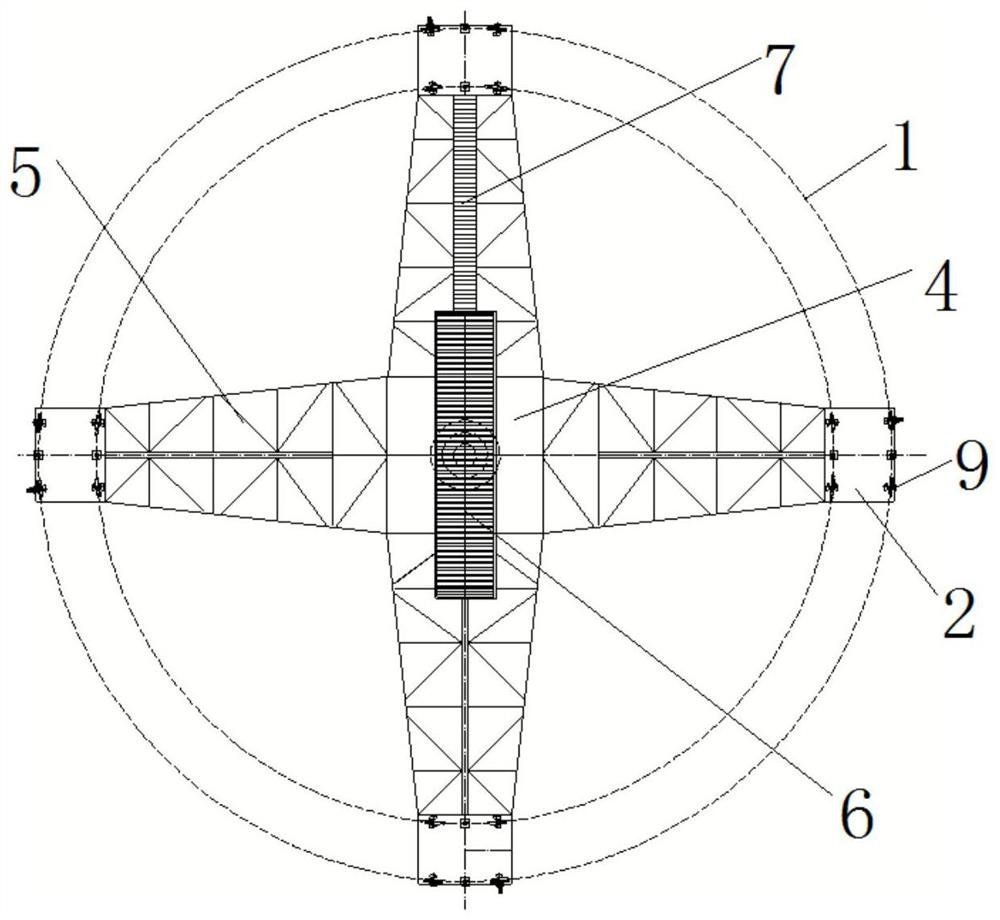

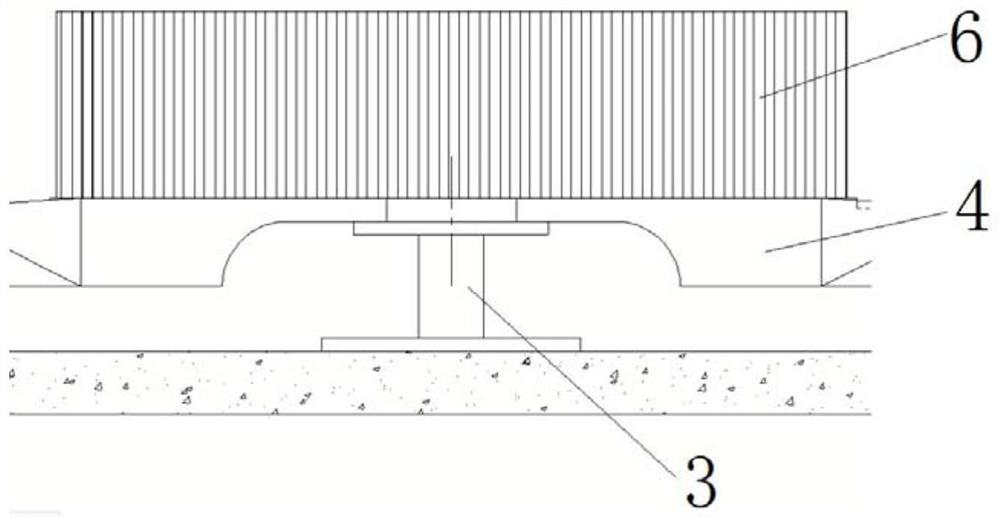

Array antenna synchronous rotation platform, array antenna and use method of array antenna synchronous rotation platform

PendingCN114122723ALarge bending stressAvoid Contact Fatigue AccidentsAntenna arraysGear wheelControl theory

The invention provides an array antenna synchronous rotation platform, an array antenna and a use method of the array antenna synchronous rotation platform, and aims to solve the problem of synchronous rotation of an antenna array. The synchronous rotating platform comprises a plurality of circular rails with the same central axis, rail flat cars are evenly distributed on the circular rails in the circumferential direction, a supporting shaft is arranged on the central axis of each circular rail, a center platform is rotationally arranged on the supporting shaft, and the rail flat cars are connected with the center platform through truss arms. The center platform is driven by the rail flat car to rotate, overlarge bending stress of the truss arm caused by center driving is avoided, gear transmission is avoided, and gear contact fatigue accidents are avoided; and the directions of the antennas arranged on the rail flatcar are kept consistent, so that the working state of the antenna array is kept unchanged.

Owner:河南厚云智能机电有限公司

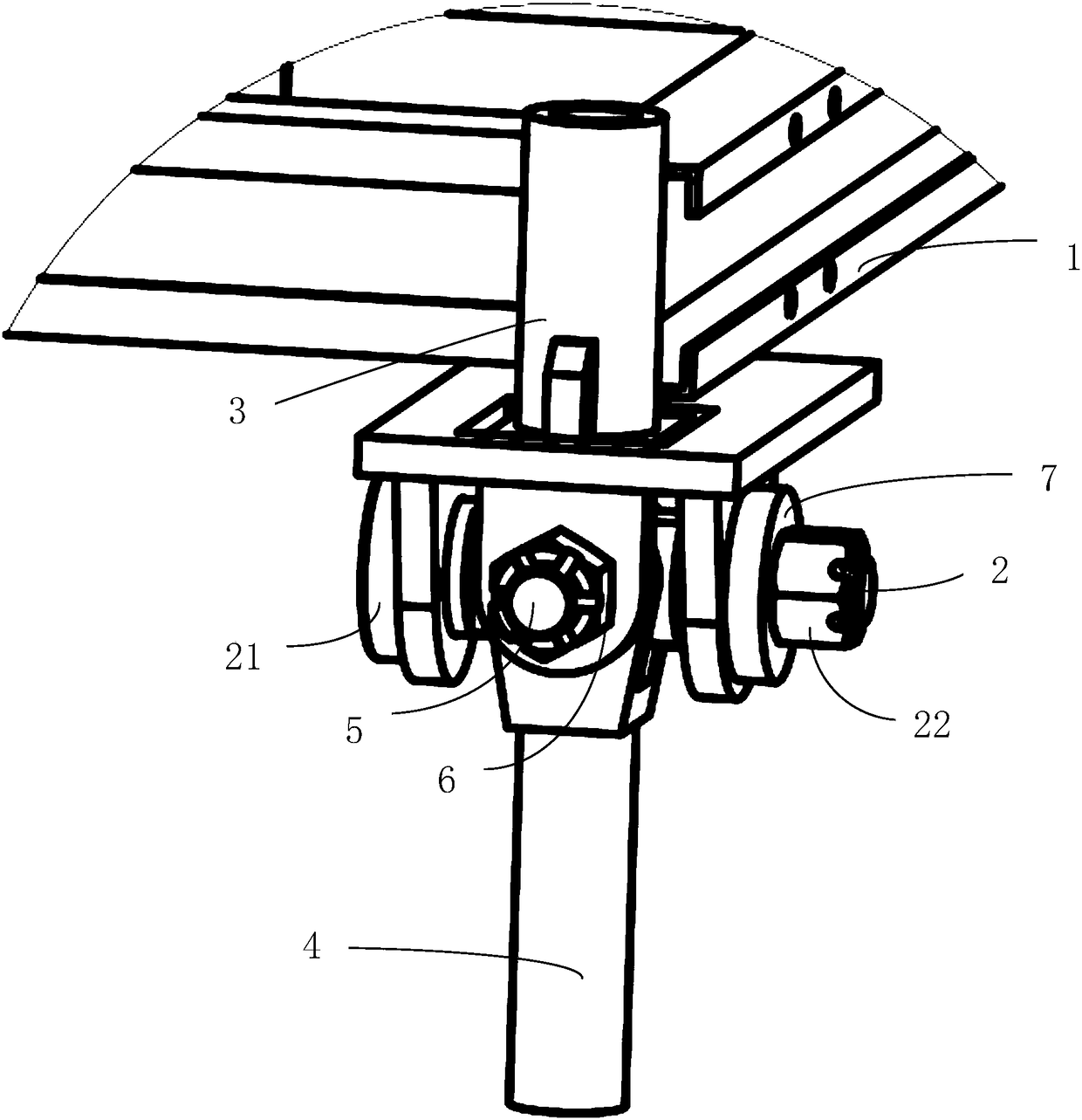

Bidirectional Junction Connection Mechanism of Suspended Capacitor Device

ActiveCN106298231BImprove seismic performanceLarge bending stressCapacitorsFree rotationRotational degrees of freedom

The invention provides a bidirectional-junction type connecting mechanism of a suspension type capacitor device. The connecting mechanism comprises a shaft, a support, an upper insulator flange, a lower insulator flange and a connecting rod, wherein the shaft penetrates two coaxial holes in the support to be connected with the support and can free rotate in the coaxial holes; the lower portion of the upper insulator flange is provided with a first matching hole, the upper portion of the lower insulator flange is provided with a second matching hole, the middle of the shaft is provided with a third matching hole, a connecting rod penetrates the first matching hole, the second matching hole and the third matching hole to serially connect the upper insulator flange, the lower insulator flange and the shaft, and the upper insulator flange and the lower insulator flange can freely rotate around an axis. The connecting mechanism has the advantages that the capacitor device can be prevented from generating large bending moment under seismic force by releasing the rotation freedom degrees, in two directions, of each junction, and the capacitor device can be allowed to have high seismic capacity while cost is not increased.

Owner:SHANGHAI SIEYUAN CAPACITOR

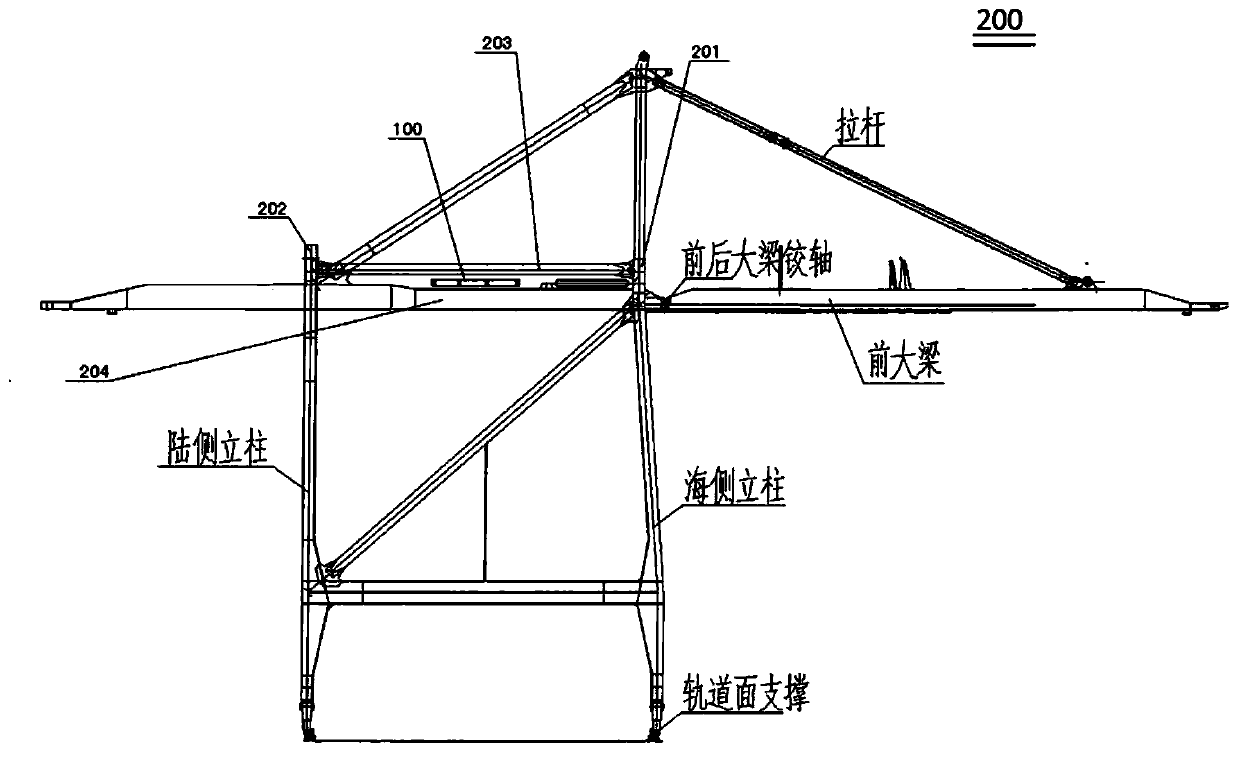

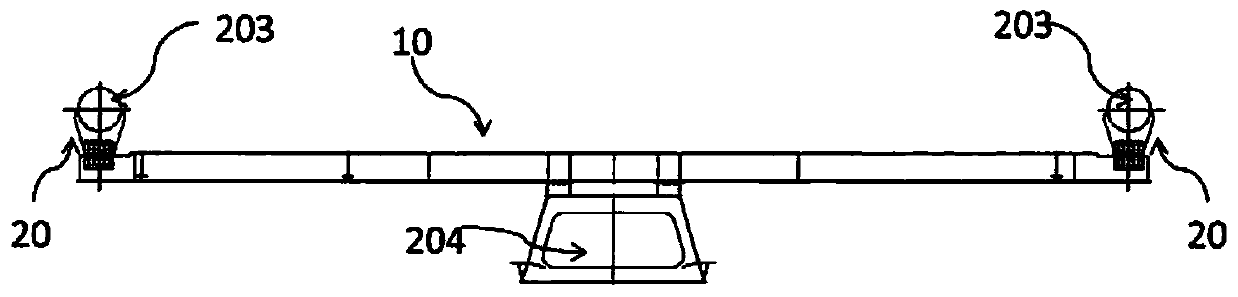

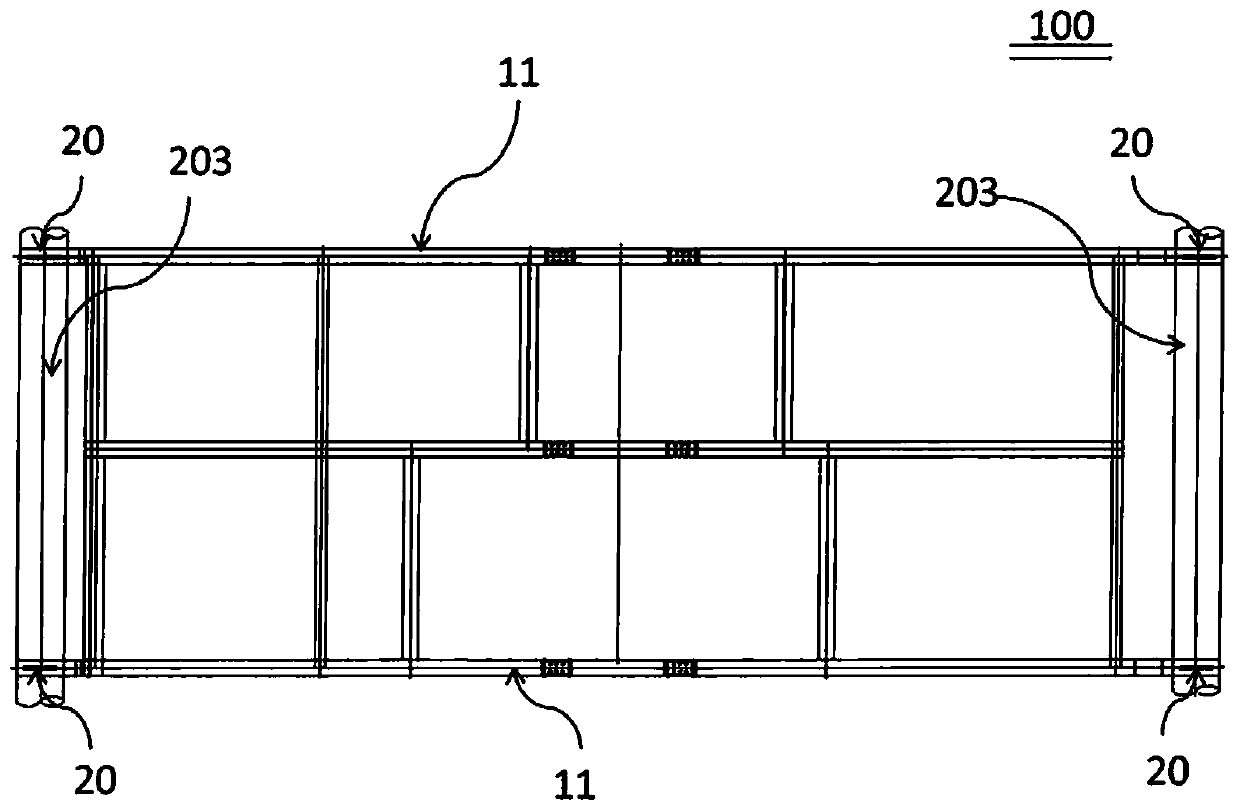

Engine room chassis and mounting method thereof

PendingCN110395662AImprove securityPrevent free vibrationMachine framesLoad-engaging elementsCantilevered beamEngineering

The invention aims at providing an engine room chassis. The engine room chassis comprises a main supporting structure and an auxiliary supporting part. The engine room chassis is used for supporting an engine room of a shore bridge. The main supporting structure comprises a transverse main beam, a longitudinal main beam and other function parts, the auxiliary supporting part is arranged on the outmost end of the transverse main beam, and comprises a first part, a second part and a third part, the first part is connected with the transverse main beam, the second part is connected with a horizontal connecting rod of the shore bridge, and the third part is used for connecting the first part with the second part. According to the technical scheme, an original cantilever beam is changed into astructure with weak supporting, too large deforming of the outmost end of the chassis and large bending moment of the main beam can be prevented, and safety of the engine room chassis during work canbe improved. The invention provides a mounting method of the engine room chassis. Parts are convenient to manufacture, production difficulty and production cost are greatly reduced, whole mounting isconvenient, and the size is flexible and adjustable.

Owner:SHANGHAI ZHENHUA HEAVY IND

Hanging valve tower for converter valve

ActiveCN102882356BImprove seismic performanceHigh strengthCooling/ventilation/heating modificationsPower conversion systemsGlass fiberEpoxy

The invention discloses a hanging valve tower for a converter valve. The hanging valve tower comprises more than two valve layers arranged up and down at intervals, wherein an interlayer connection structure is connected between every two adjacent valve layers and comprises interlayer threaded sleeves respectively fixed in corresponding positions of each valve layer and arranged at intervals in the circumferential direction; the interlayer threaded sleeves of every two adjacent valve layers mutually correspond in an up-and-down pairwise manner; an interlayer stud is connected between every two interlayer threaded sleeves corresponding up and down; and all the interlayer studs are made from epoxy resin glass fibers. The interlayer studs made of epoxy resin glass fibers has not only high strength and rigidity but also favorable electric insulation performance, can bear very large bending stress, ensures that the valve tower has a certain of flexibility on the basis of relative rigidity, reduces relative sway of the valve layers, and enhances the shock resistance of the valve tower.

Owner:XJ ELECTRIC +1

Bidirectional-junction type connecting mechanism of suspension type capacitor device

ActiveCN106298231AImprove seismic performanceLarge bending stressCapacitorsRotational degrees of freedomCapacitor

The invention provides a bidirectional-junction type connecting mechanism of a suspension type capacitor device. The connecting mechanism comprises a shaft, a support, an upper insulator flange, a lower insulator flange and a connecting rod, wherein the shaft penetrates two coaxial holes in the support to be connected with the support and can free rotate in the coaxial holes; the lower portion of the upper insulator flange is provided with a first matching hole, the upper portion of the lower insulator flange is provided with a second matching hole, the middle of the shaft is provided with a third matching hole, a connecting rod penetrates the first matching hole, the second matching hole and the third matching hole to serially connect the upper insulator flange, the lower insulator flange and the shaft, and the upper insulator flange and the lower insulator flange can freely rotate around an axis. The connecting mechanism has the advantages that the capacitor device can be prevented from generating large bending moment under seismic force by releasing the rotation freedom degrees, in two directions, of each junction, and the capacitor device can be allowed to have high seismic capacity while cost is not increased.

Owner:SHANGHAI SIEYUAN CAPACITOR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com