TBM shield anti-side-rolling walking support device and using method thereof

A support device, anti-rolling technology, applied in earth-moving drilling, mining equipment, tunnels and other directions, can solve the problems of high safety hazards, easy to escape from the slideway, damage and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

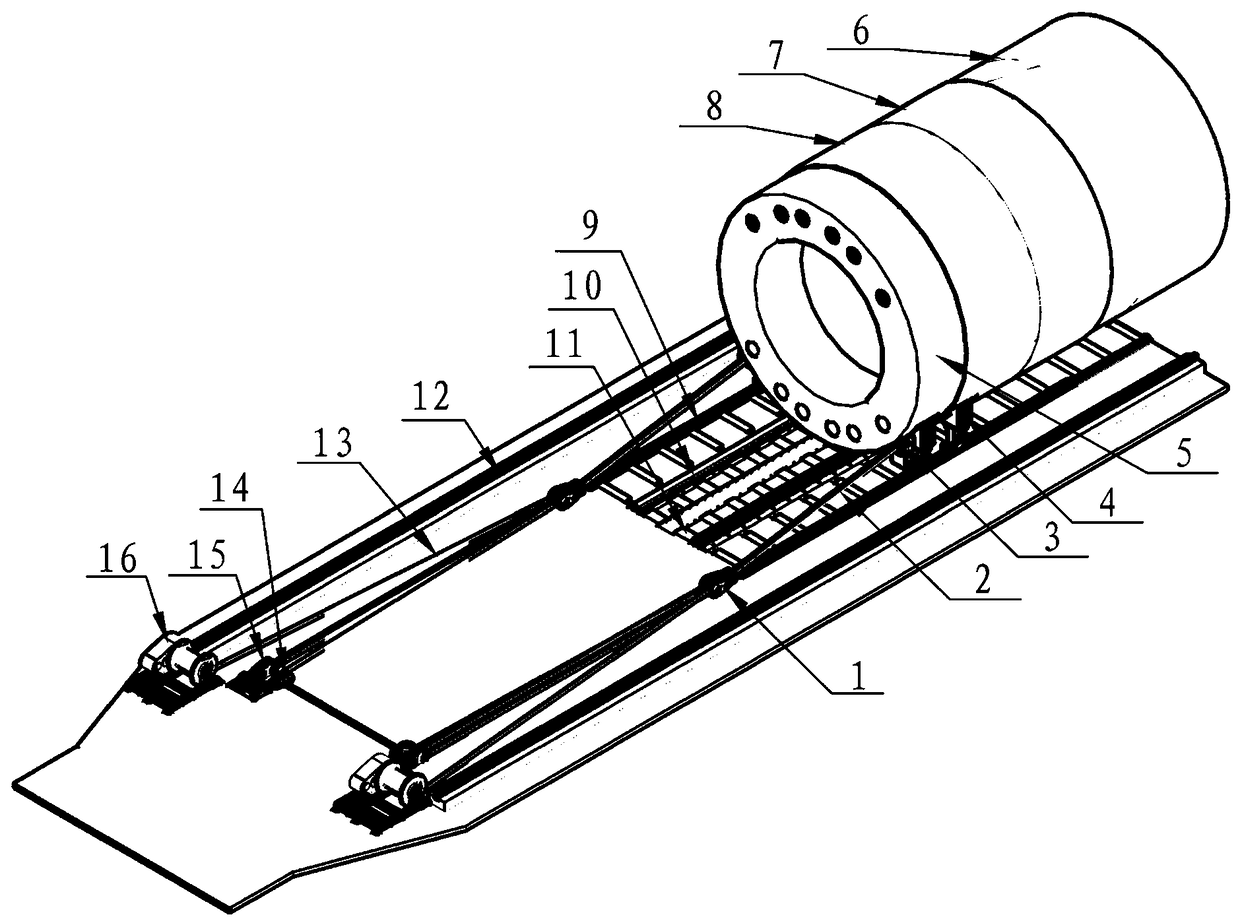

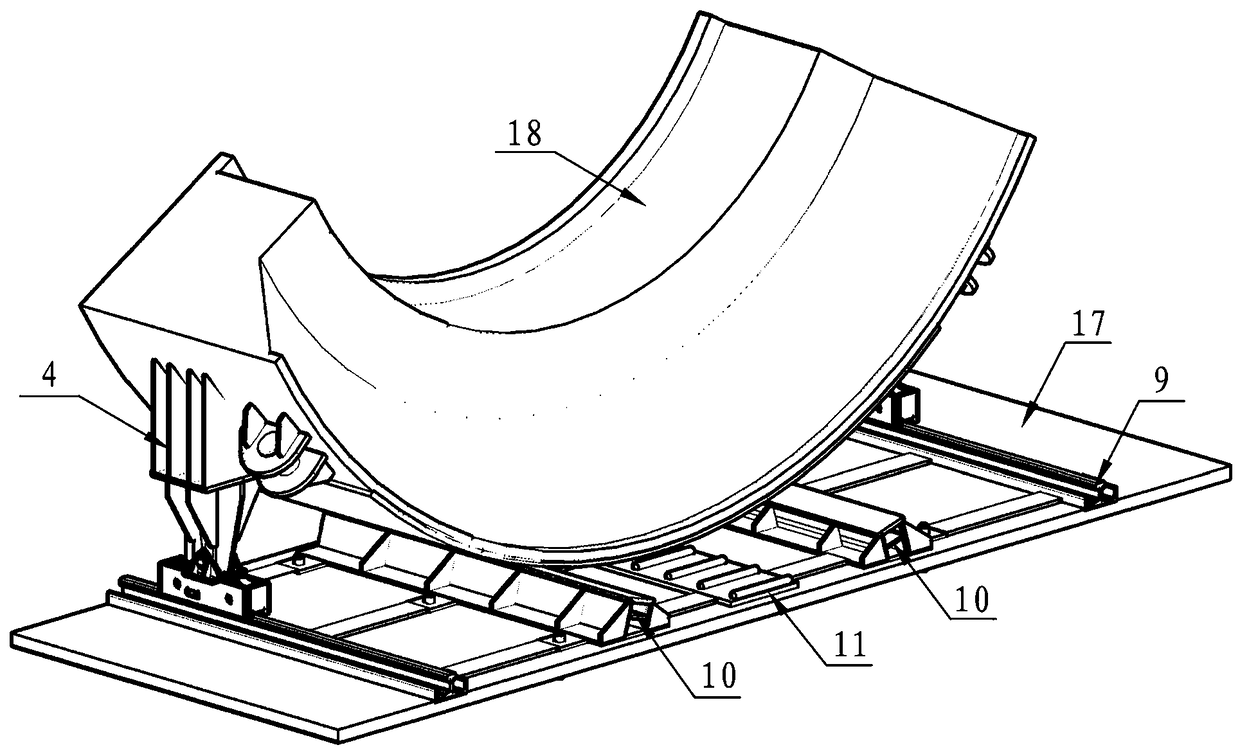

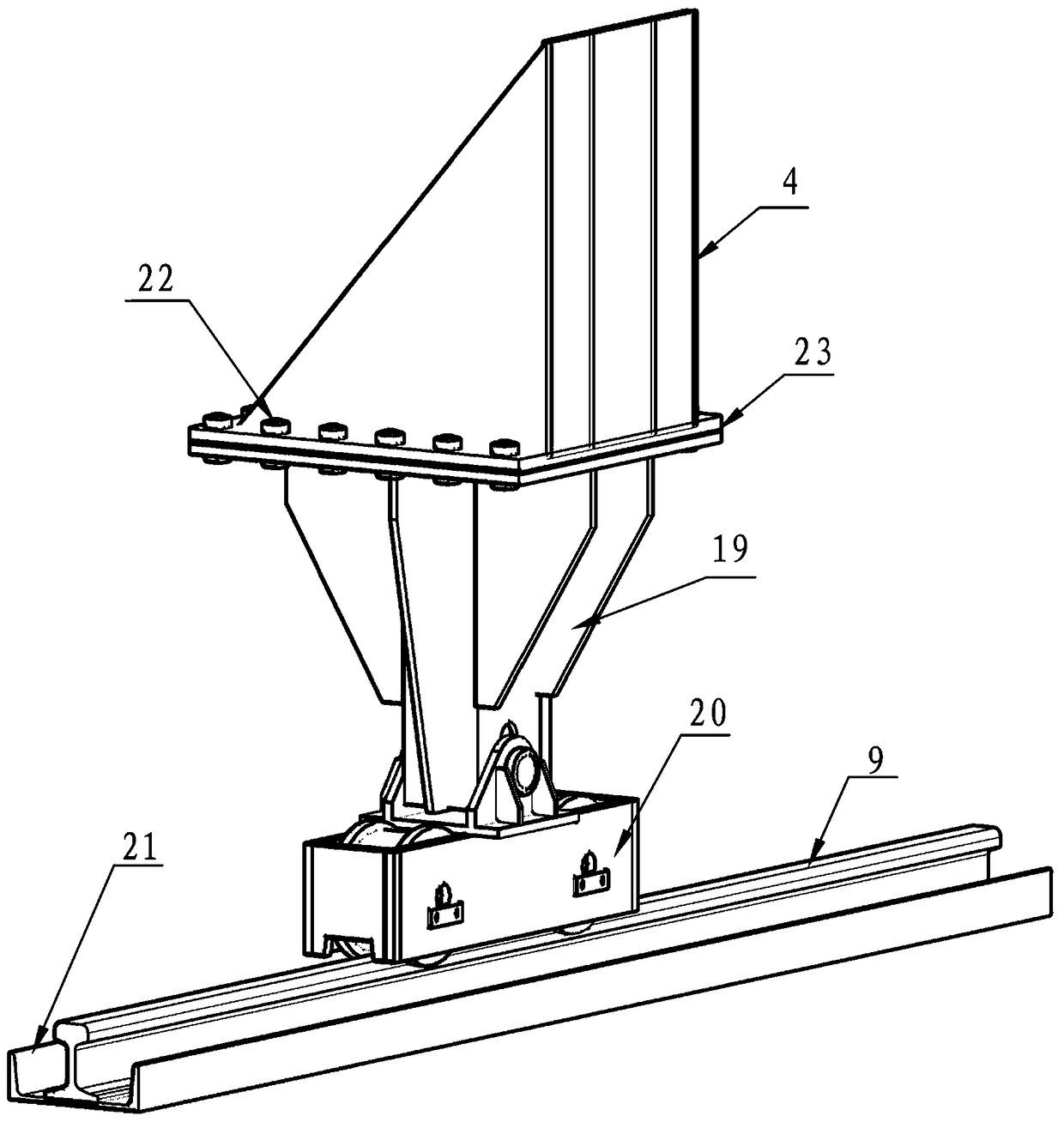

[0035] see Figure 1-6 , TBM shield body anti-rolling walking support device, which includes a floor 17 laid at the bottom of the tunnel expansion section, the middle part of the bottom plate 17 is fixedly installed with a raceway 11, and the two outer sides of the raceway 11 are symmetrically arranged. Road 10, the outer sides of the two slideways 10 are respectively provided with symmetrically arranged rails 9; the tops of the raceways 11, slideways 10 and rails 9 support the front shield 5 of the shield body, and the bottom of the front shield 5 The anti-roll support wheel box 4 for preventing the shield body from rolling sideways is installed symmetrically on both sides, and the bottom of the anti-roll support wheel box 4 forms a sliding fit with the track 9; It is connected with the traction power device that drives it to walk along the raceway 11, the slideway 10 and the track 9. By adopting the invention, the construction problem that the shield body of the cylindrical...

Embodiment 2

[0045] Adopt the using method of any described TBM shield body anti-rolling walking supporting device, it comprises the following steps:

[0046] Step1: Lay the bottom plate 17 on the bottom of the tunnel, and fix the raceway 11, slideway 10 and track 9 on the bottom plate 17, and support the stick on the top of the raceway 11;

[0047] Step2: Weld and fix the anti-roll support wheel box 4 symmetrically on both sides of the bottom of the front shield lower block 18, and make the steel wheel 33 of the anti-roll support wheel box 4 support on the rail 9;

[0048] Step3: Weld traction lugs 3 symmetrically on both sides of the bottom of the front shield lower block 18;

[0049] Step4: Fix the traction hoist 16 on the bottom plate 17, and wind the traction steel rope 13 of the traction hoist 16 around multiple sets of movable pulleys 1 and fixed pulleys 15, and connect the movable pulley 1 with the anti-twist device through the balance pulley 14. Connect to the traction lugs 3 on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com