Self-propelled corn combine harvester

A combine harvester, self-propelled technology, applied in the direction of harvesters, agricultural machinery and implements, cutters, etc., can solve problems such as poor straw crushing quality, and achieve the goal of improving working conditions, alleviating impact, and improving reliability of use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings of the embodiments.

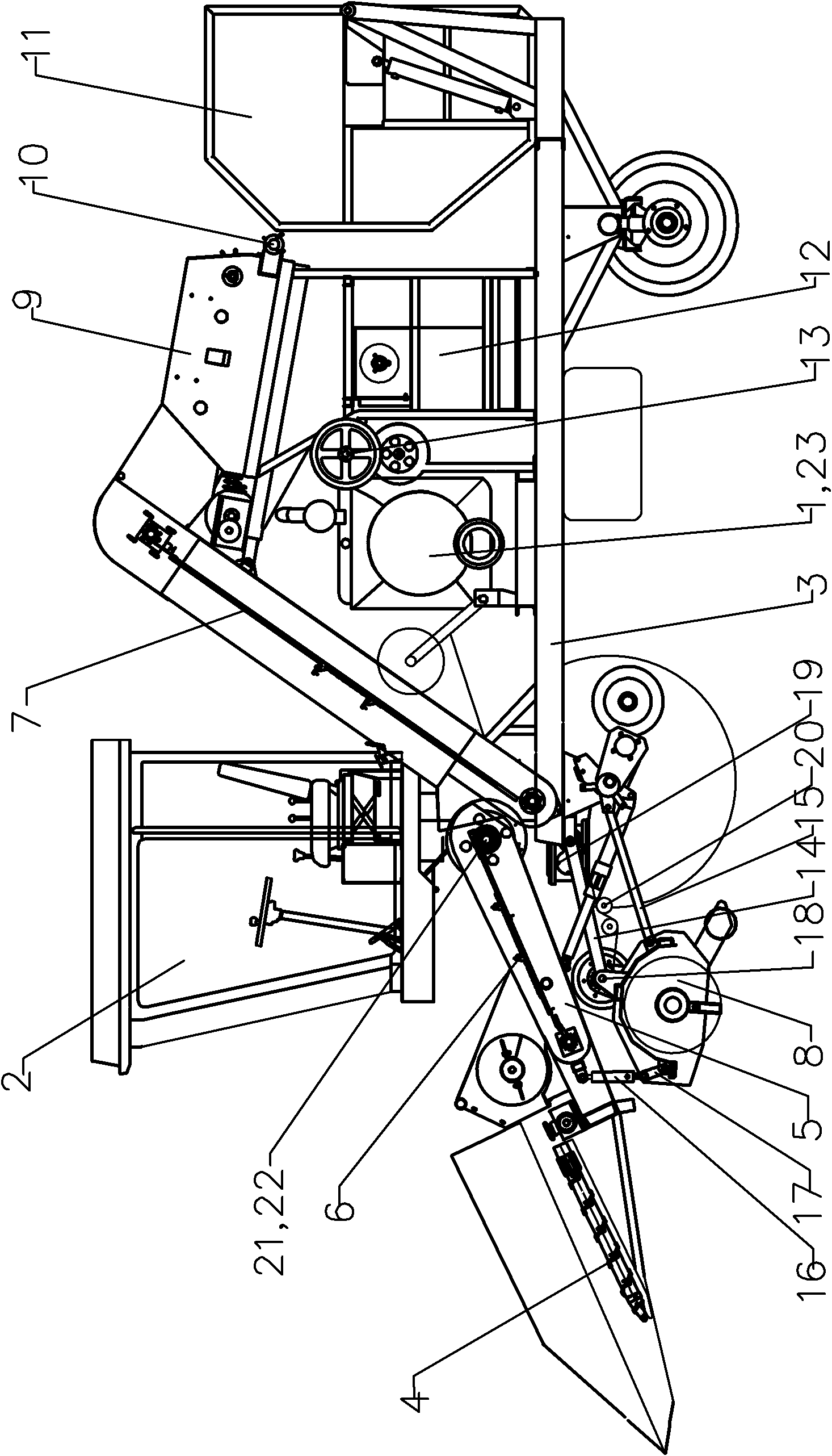

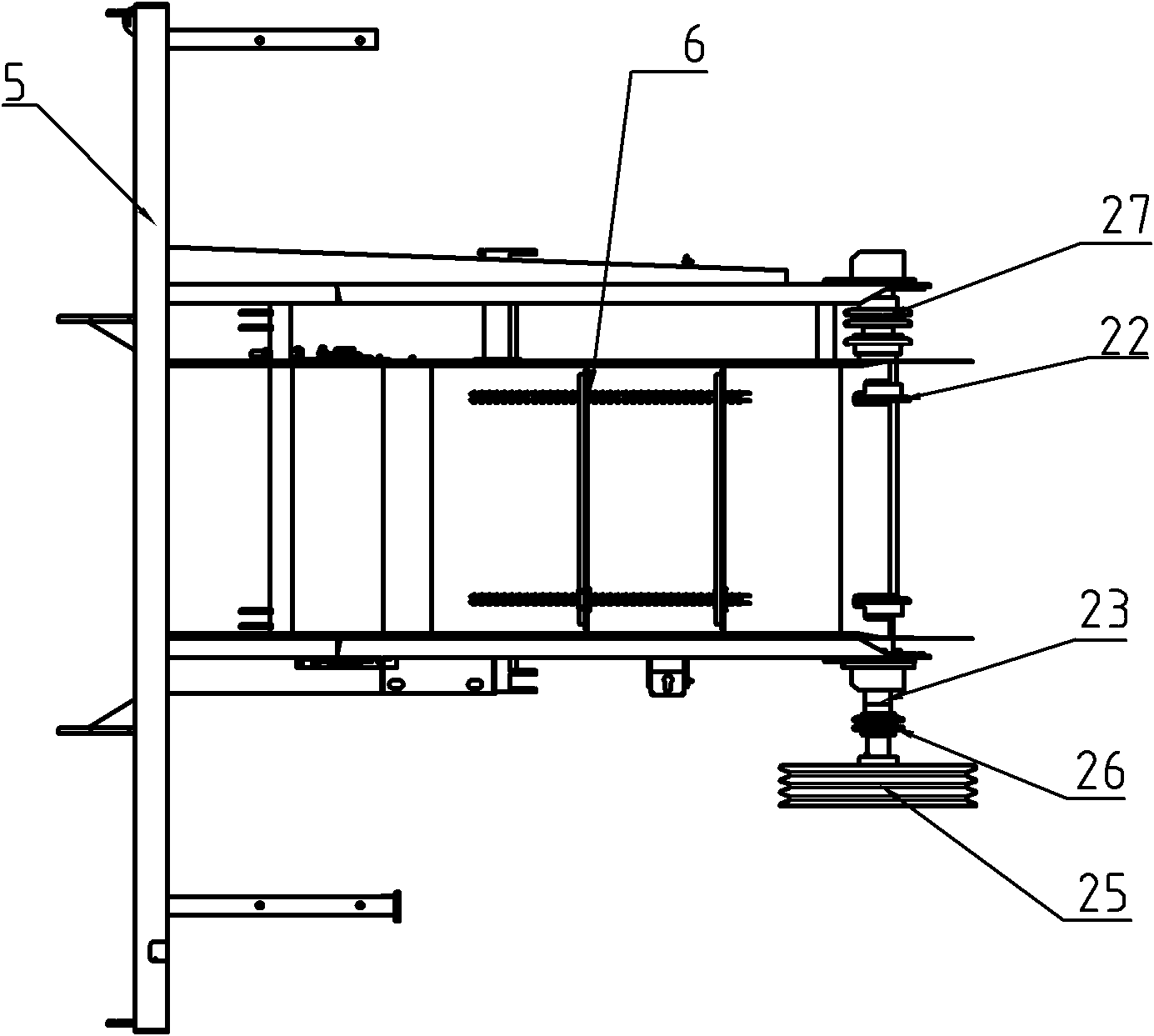

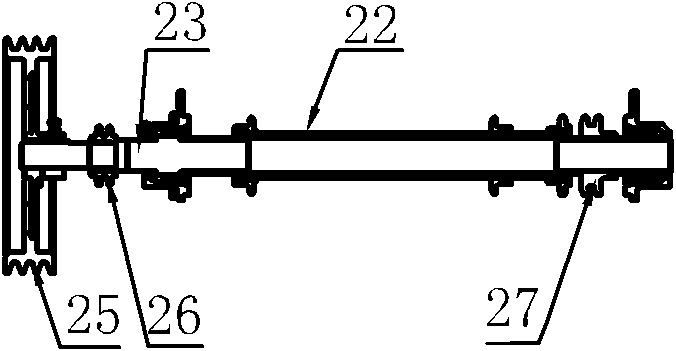

[0017] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the self-propelled corn combine harvester includes a working chassis assembly composed of a power system 1, a driving control system 2, and a walking chassis system 3, as well as a corn ear picking platform 4 and a corn picking platform hanging on the working chassis. Connecting frame 5, primary ear elevator 6, secondary ear elevator 7, stalk chopping and returning machine 8, returning machine suspension device, ear peeling machine 9, ear throwing roller 10, ear box 11, The peeling machine grain recovery device 12, the power transmission system 13 and other components.

[0018] The fringe picking platform 4 adopts the fringe picking roller type unit structure form, and is positioned at the front of the harvester.

[0019] The fringe-picking platform articulated frame 5 front en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com