Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Laminating speed is fast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

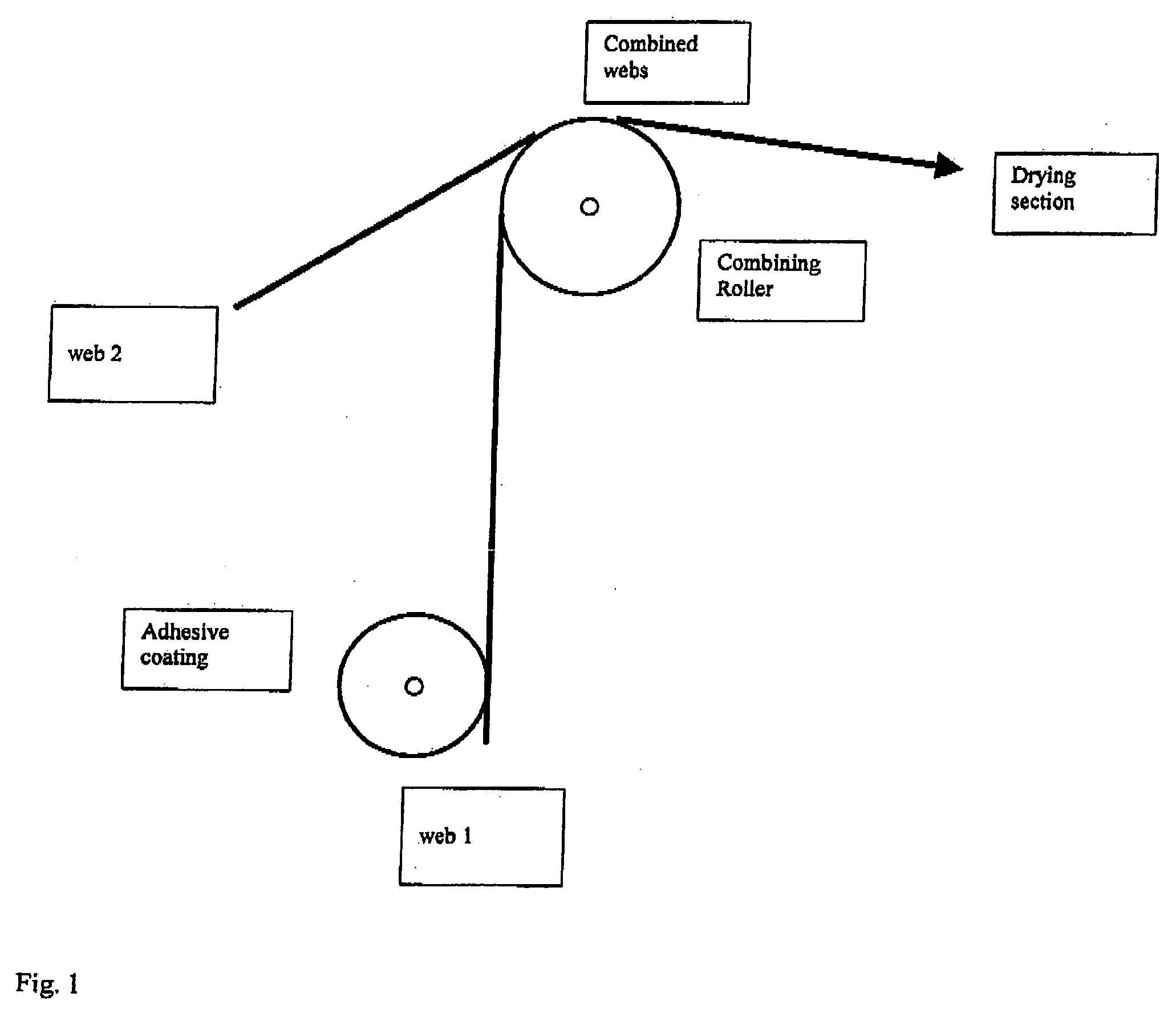

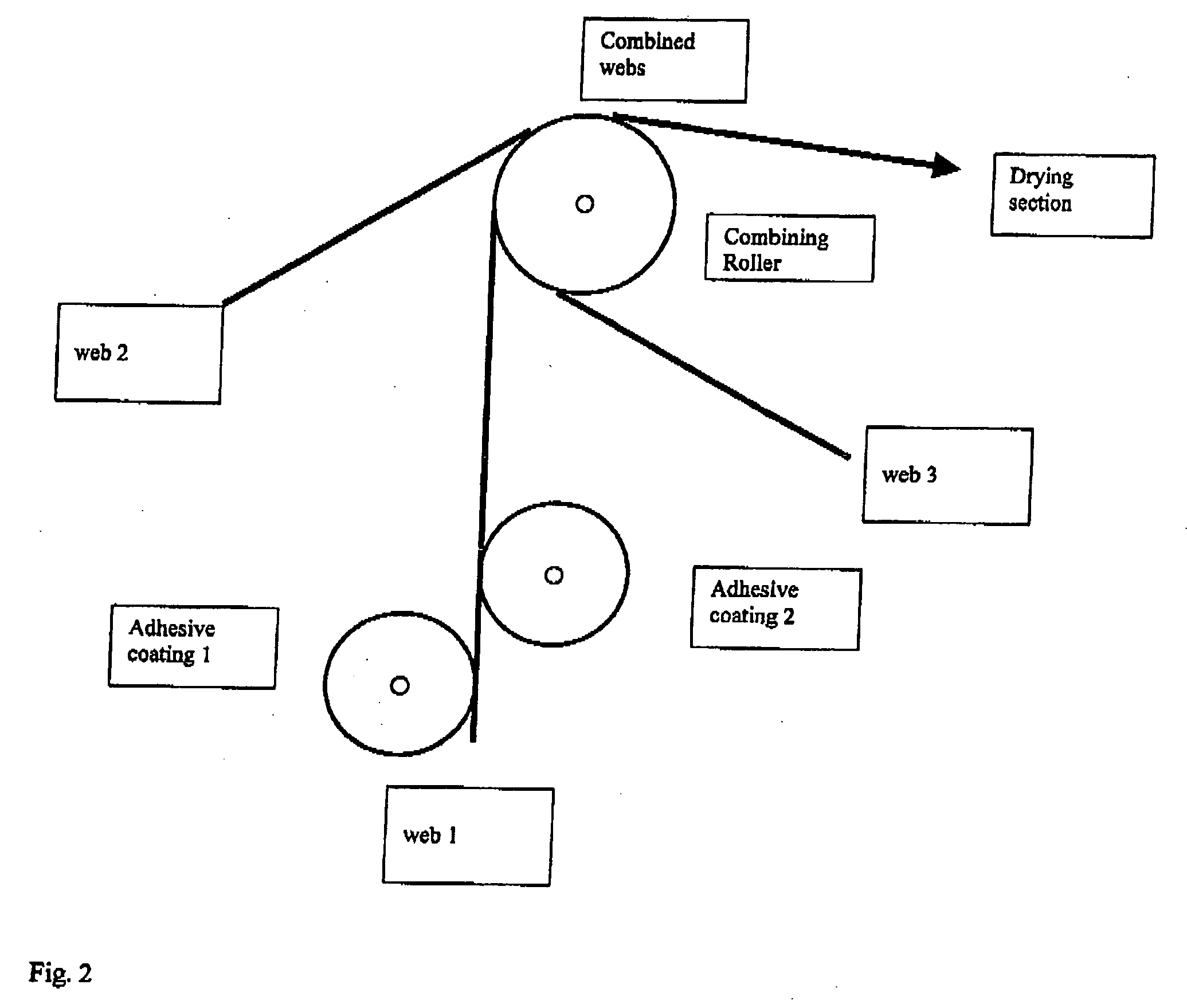

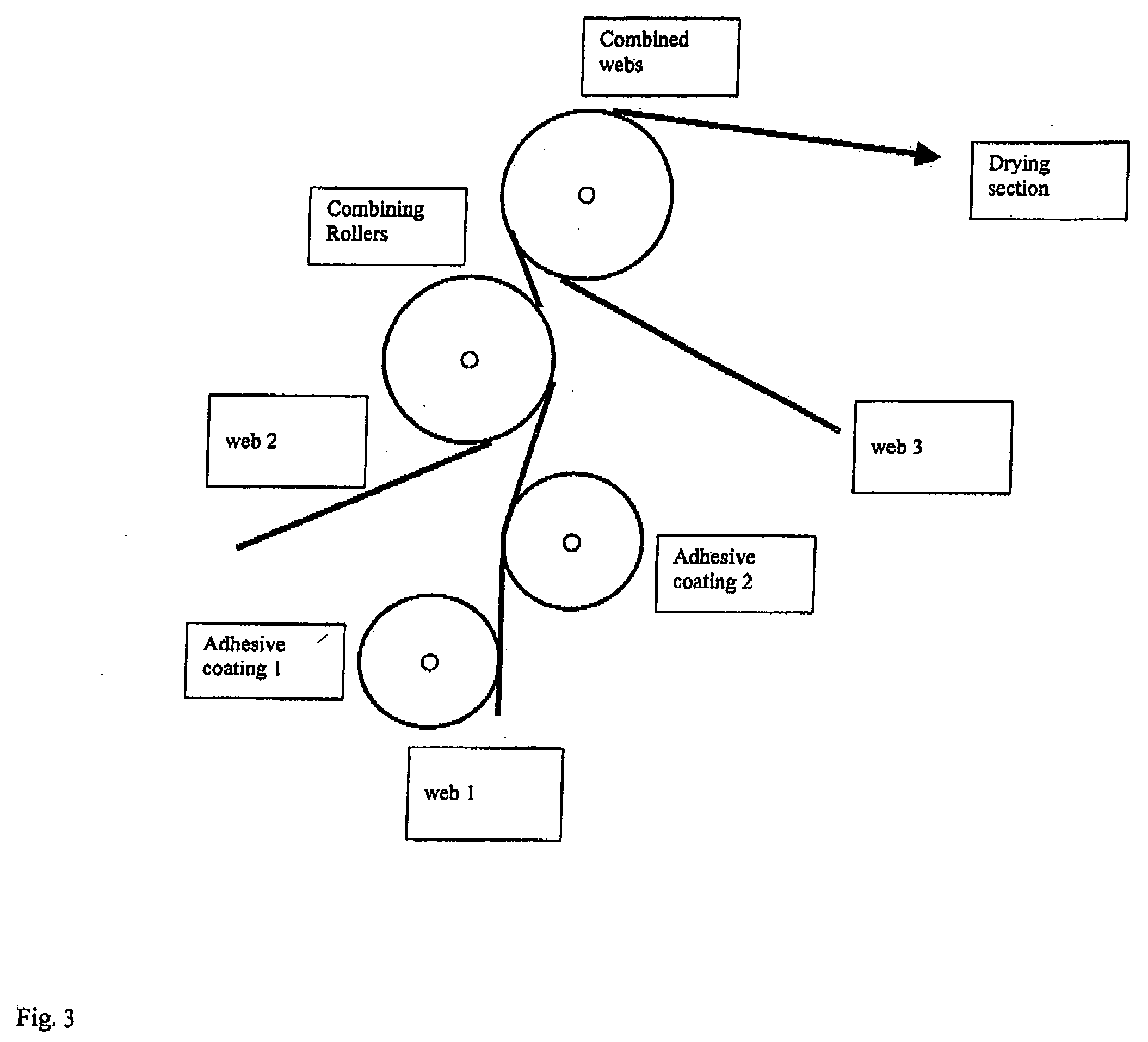

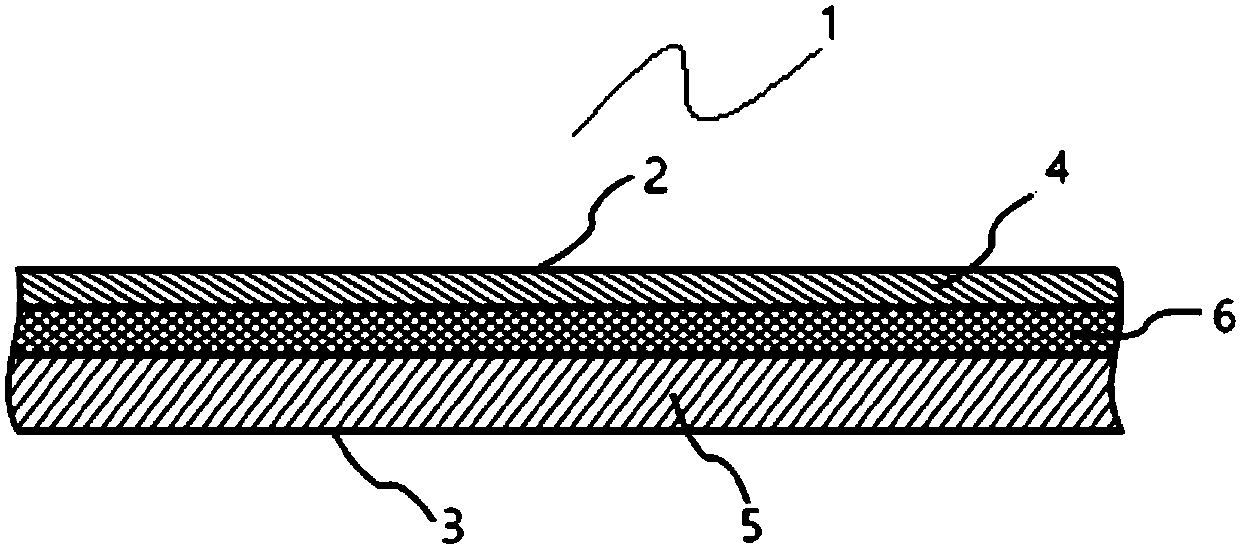

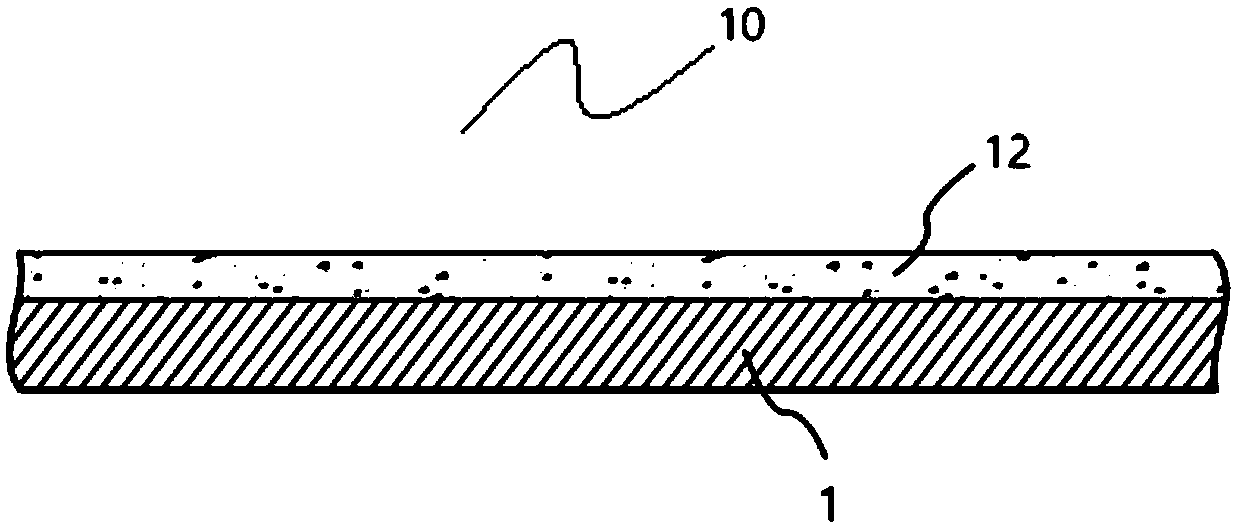

Laminating process and laminates resulting therefrom

InactiveUS20060194004A1Effective combinationIncrease speedAdhesive processesLamination ancillary operationsAdhesiveEngineering

A roll-to-roll lamination process for flexible webs including coating of at least one side of a first flexible web with a film forming adhesive and contacting the adhesive side(s) of the first flexible web to at least one of a second flexible web and a third flexible web on a transport roller while the combined webs are touching the transport roller from one side on a length of more than 5 mm without being further pressurized. Also, a 2 or more ply laminate of flexible webs comprising a first flexible web and a second flexible web, which are permanently attached by a film forming adhesive in a roll-to-roll lamination process, characterised in that the outer surface of the second flexible web has a heat sensitive recording layer and the first flexible web comprises fleece.

Owner:SIHL

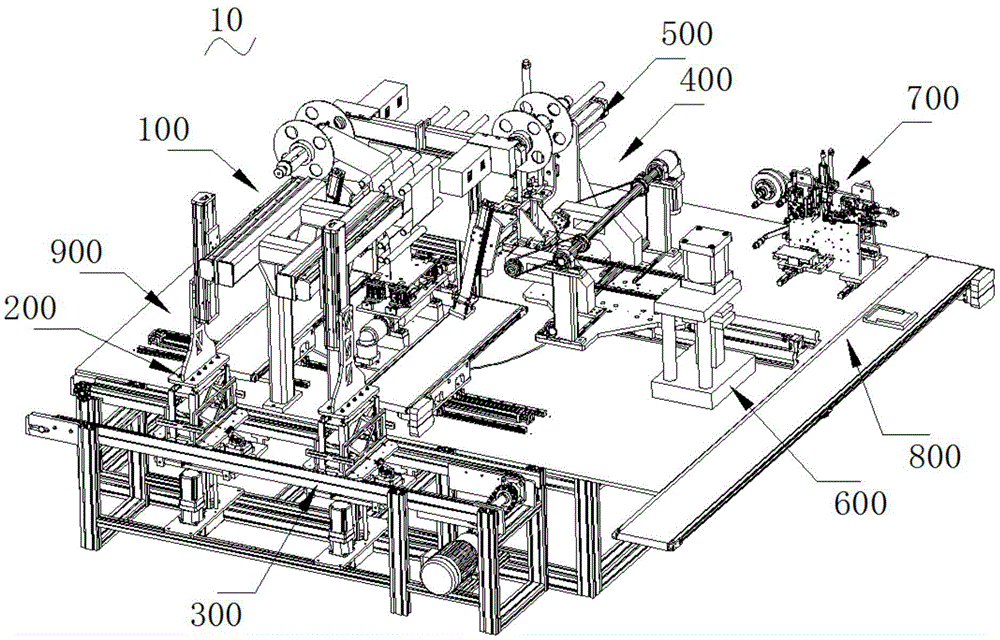

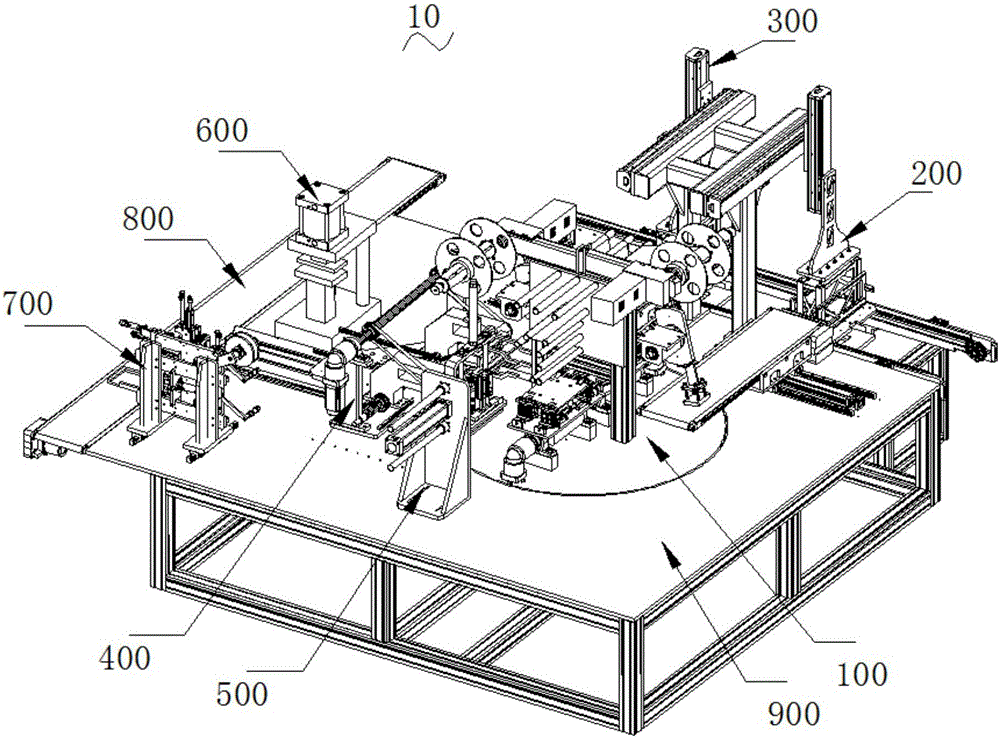

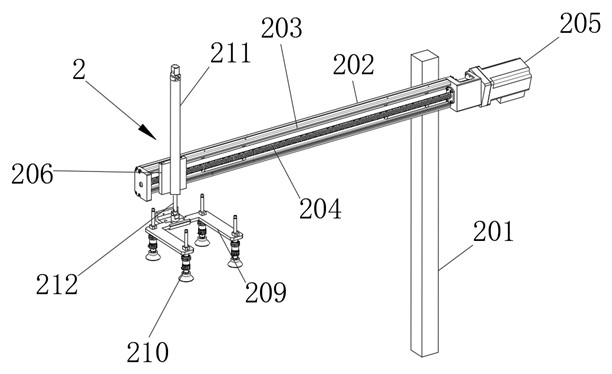

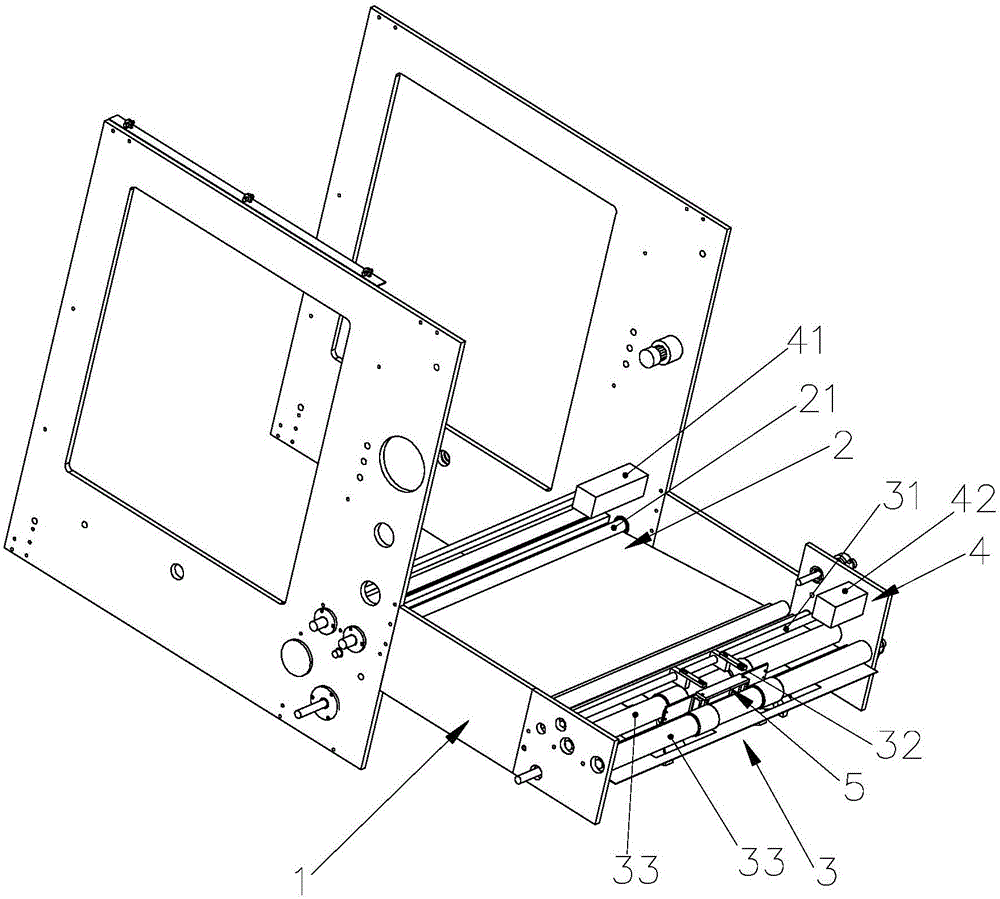

Integrated cell laminating machine and cell laminating method

ActiveCN106374144AHigh precisionImprove lamination qualityAssembling battery machinesFinal product manufactureVertical planeEngineering

The invention relates to the technical field of battery lamination, particularly to an integrated cell laminating machine and a cell laminating method. The integrated cell laminating machine comprises a laminating station, wherein the laminating station comprises a rotary plate, a rotary plate rotating apparatus arranged below the rotary plate for driving the rotary plate to rotate, and multiple laminating apparatuses uniformly arranged on the rotary plate for performing lamination; each laminating apparatus comprises a laminating rotary platform, a laminating power mechanism for driving the laminating rotary platform to swing in a vertical plane, and a first attraction mechanism and a second attraction mechanism which are symmetrically arranged on the two sides of the laminating rotary platform for attracting and driving a positive plate and a negative plate to swing in a vertical plane, and a diaphragm material-releasing mechanism mounted above the laminating rotary platform for supplying diaphragms, wherein each laminating power mechanism is positioned at the bottom of the corresponding laminating rotary platform; and the swinging track of the laminating rotary platform is externally tangent with the swinging track of the corresponding first attraction mechanism and second attraction mechanism. The integrated cell laminating machine has high laminating efficiency, high laminating precision and good laminating quality.

Owner:GUANGDONG YI XINFENG INTELLIGENT EQUIP CO LTD

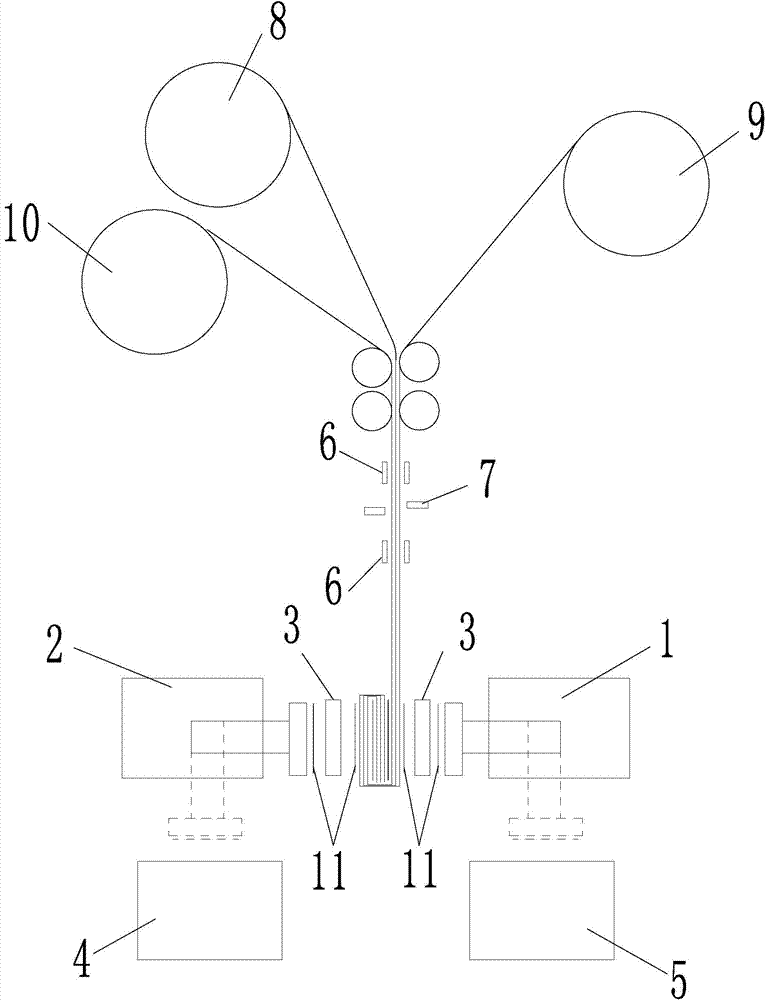

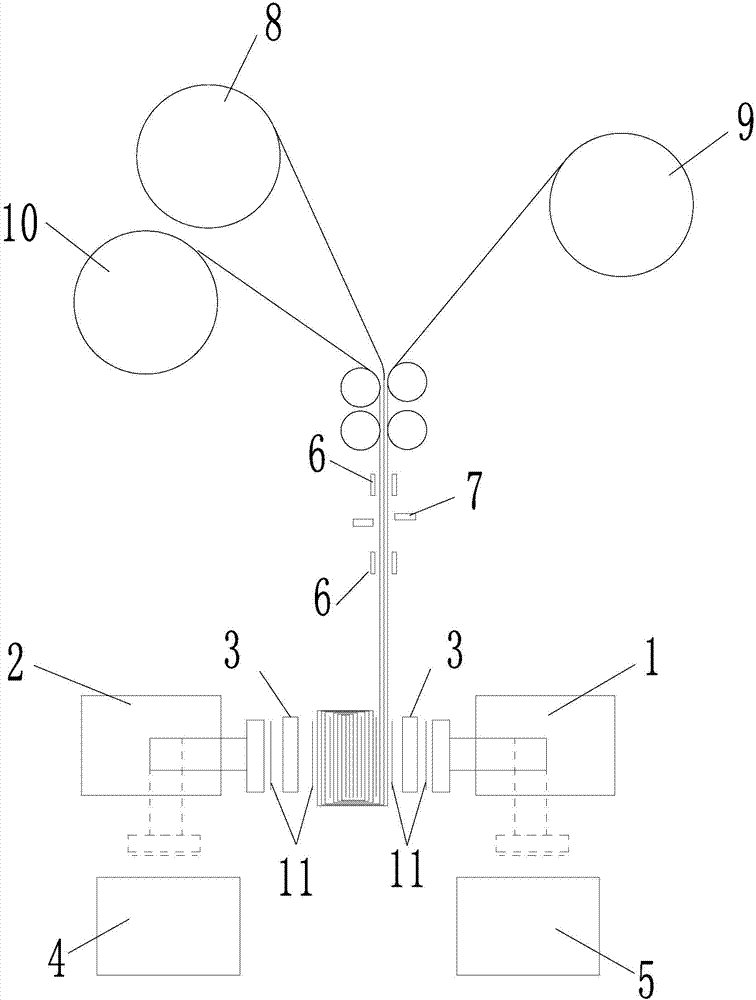

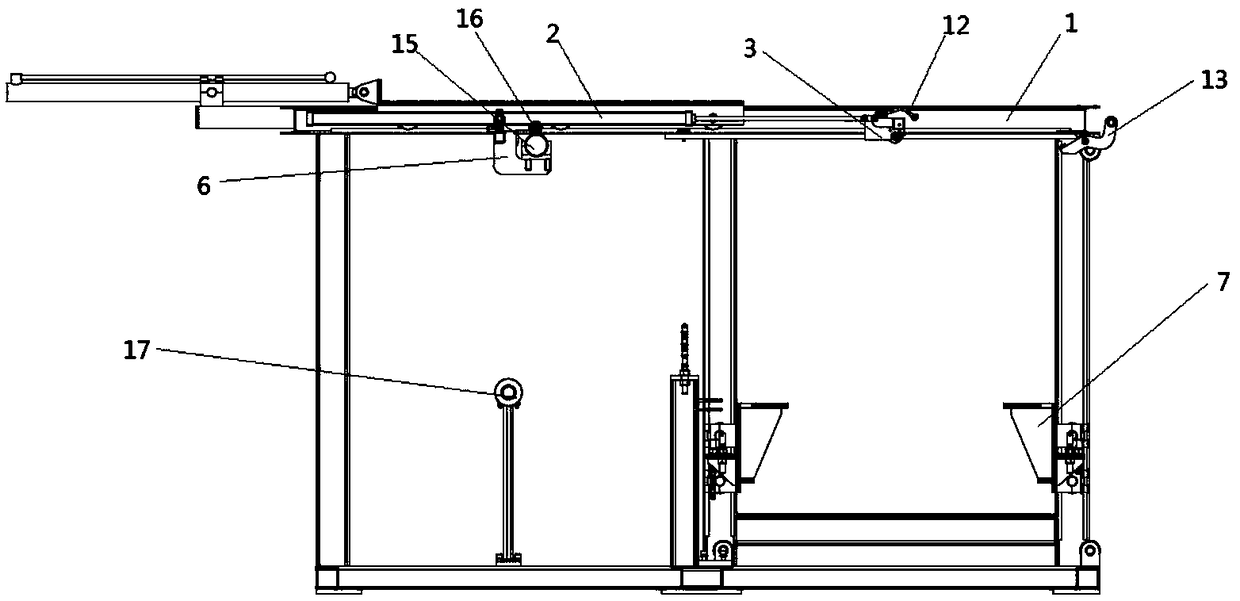

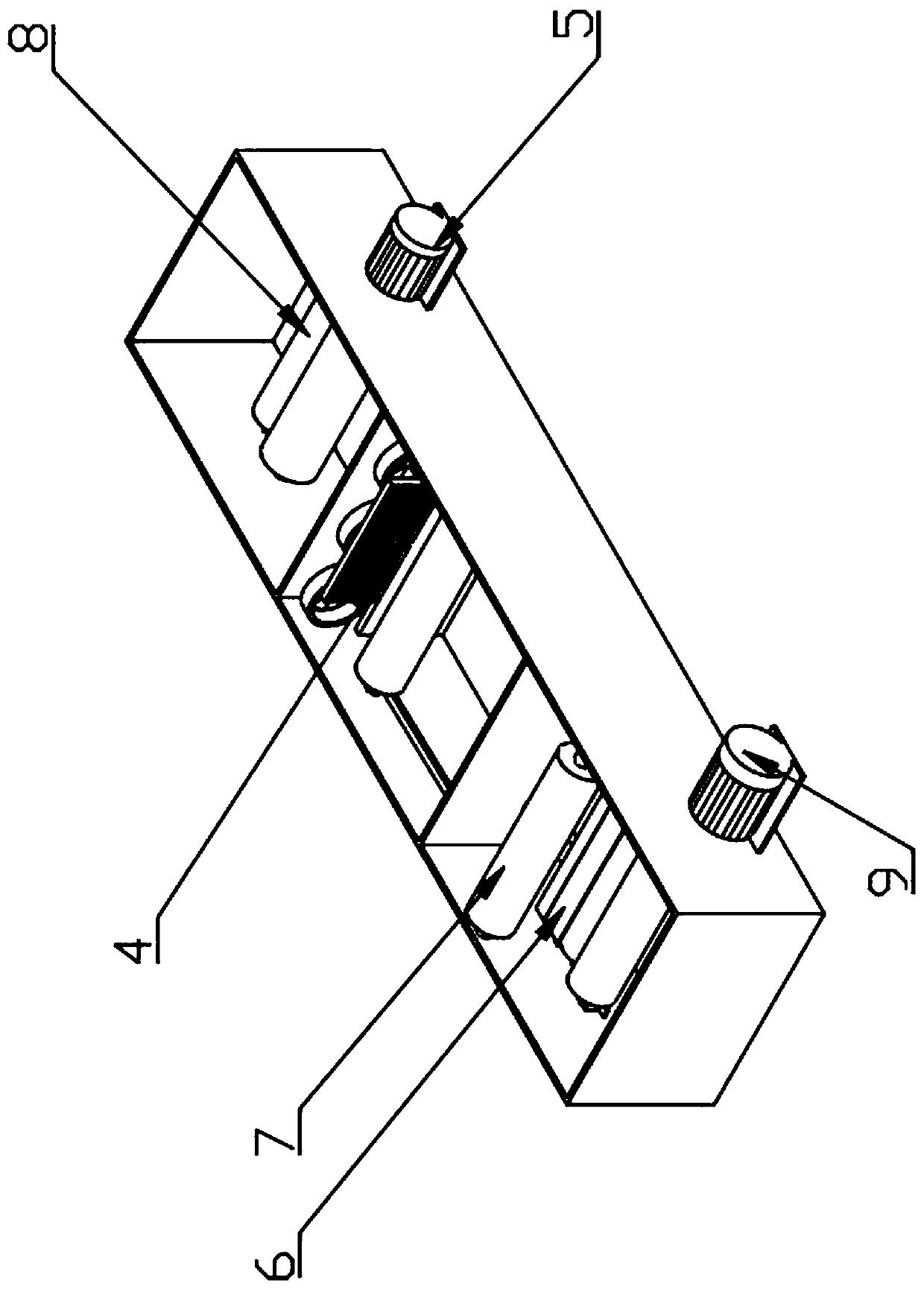

Laminator and lamination method thereof

ActiveCN103700888AImprove production efficiency and production qualityIncrease lamination speedAssembling battery machinesFinal product manufactureManipulatorEngineering

The invention relates to the technical field of lithium battery lamination, and provides a laminator and a lamination method thereof. The lamination method comprises the following steps: A. sequentially laminating a first diaphragm, a negative pole piece and a second diaphragm into an integral body, and continuously feeding to the position between a first rotary manipulator and a second rotary manipulator; B. sucking a positive pole piece from a first sub-locating table to the first diaphragm by using the first manipulator, and sucking the positive pole piece from a second sub-locating table to the second diaphragm by using the second rotary manipulator; and C. rotating the positive pole piece and negative pole piece together with the diaphragms by 360 degrees by a first clamping knife to perform coiling lamination. According to the method, the negative pole piece and the diaphragms connected into the integral body and continuously fed, the 360-degree or 180-degree coiling lamination is performed after the positive pole piece is arranged on the lateral side of the diaphragm, thereby increasing the lamination speed and enhancing the production efficiency and production quality of the laminator.

Owner:GEESUN AUTOMATION TECH

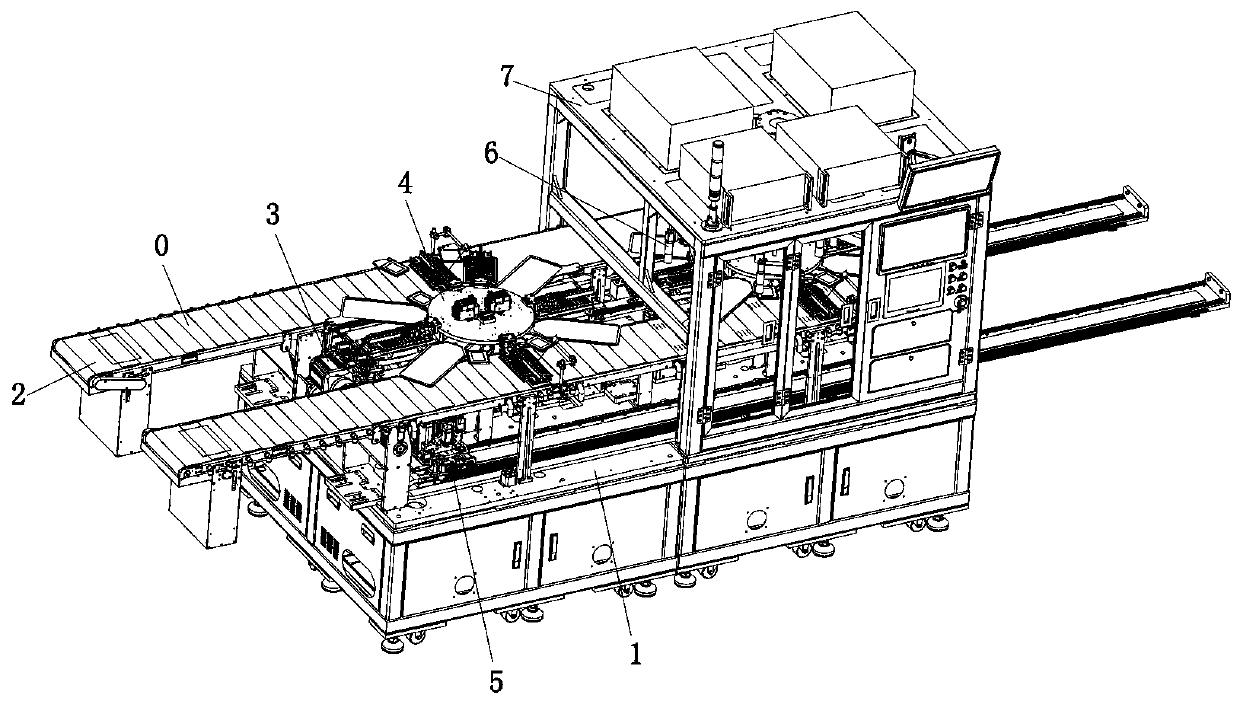

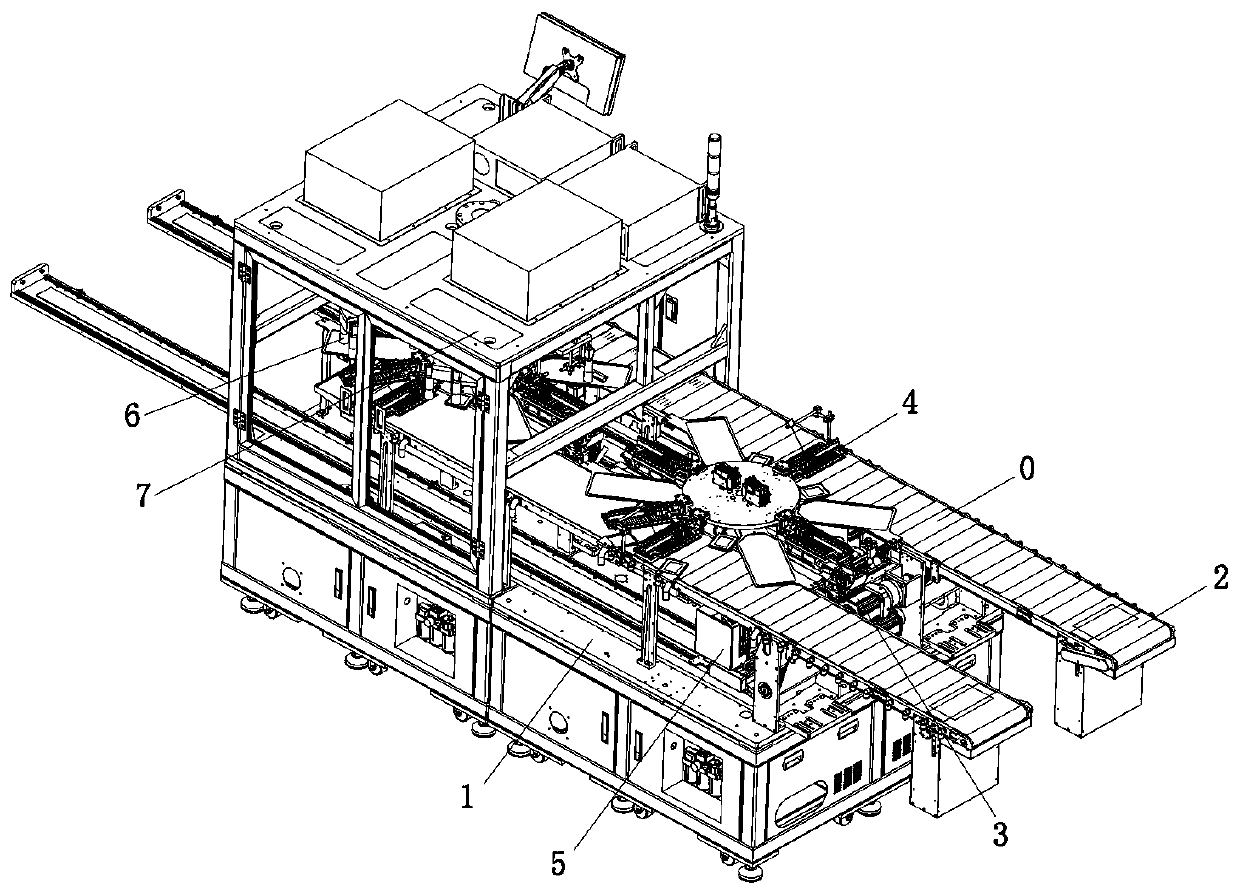

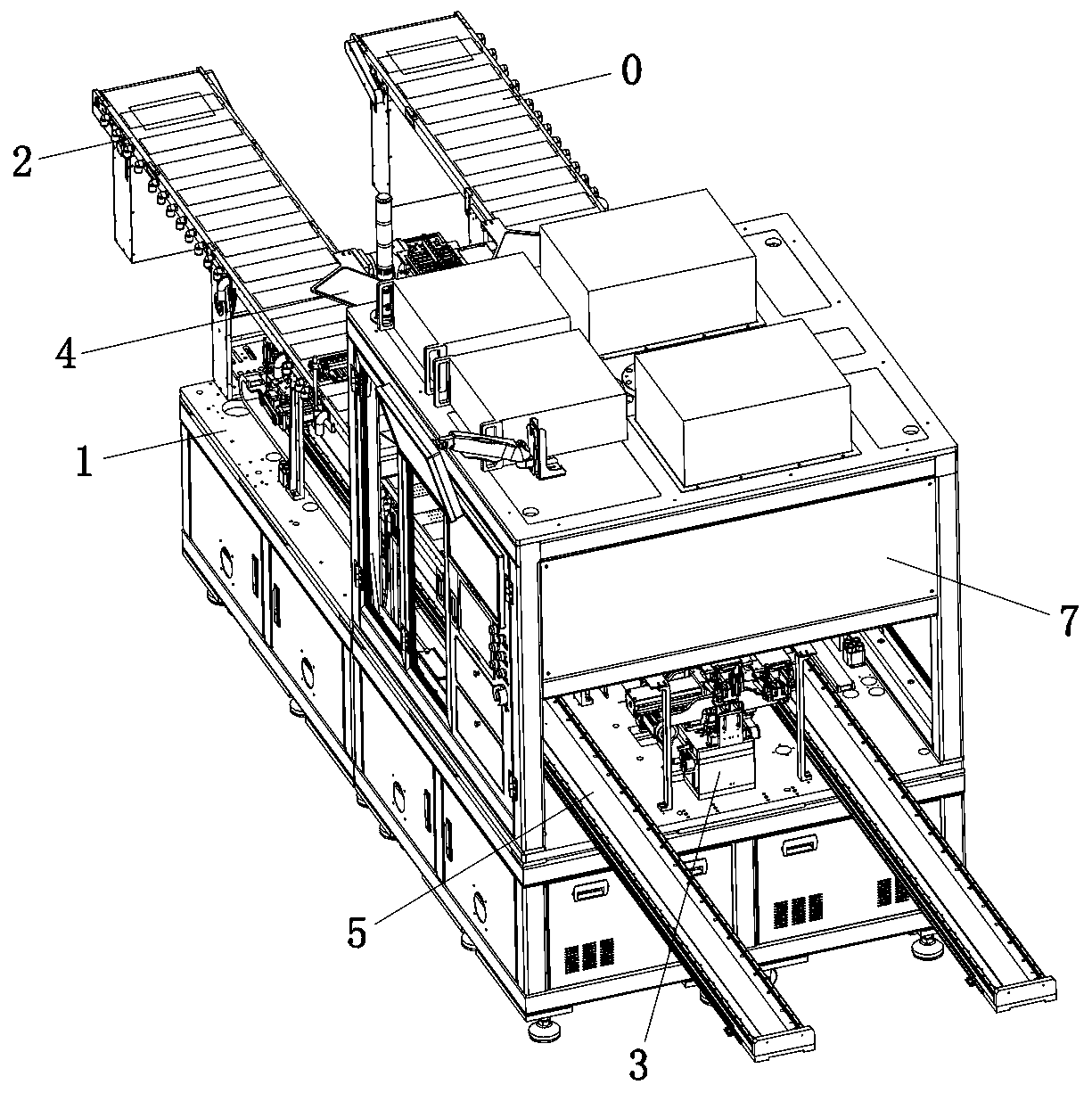

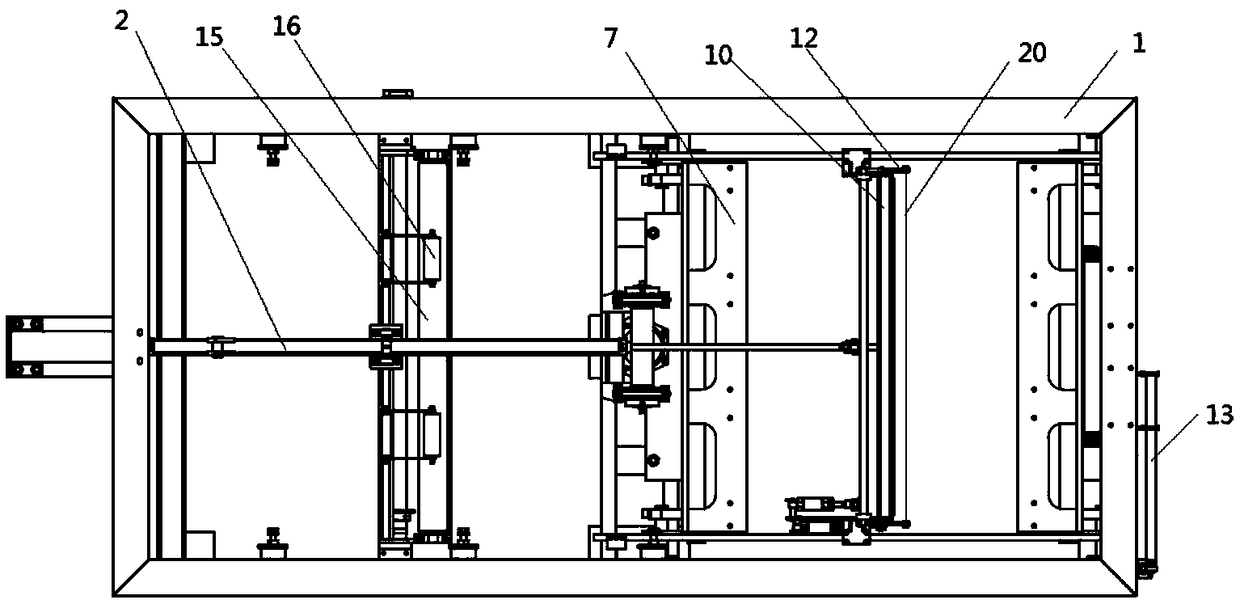

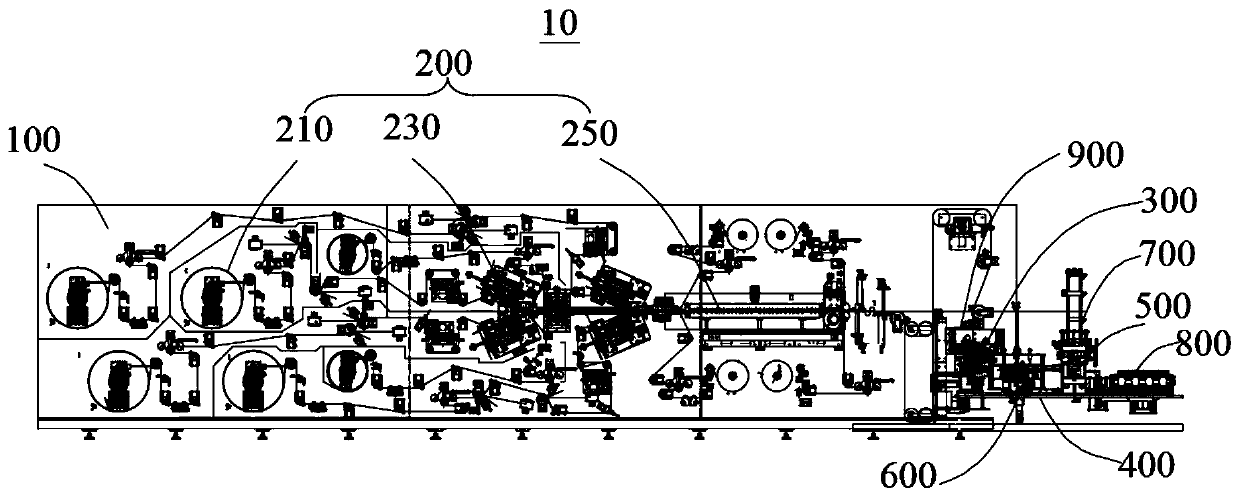

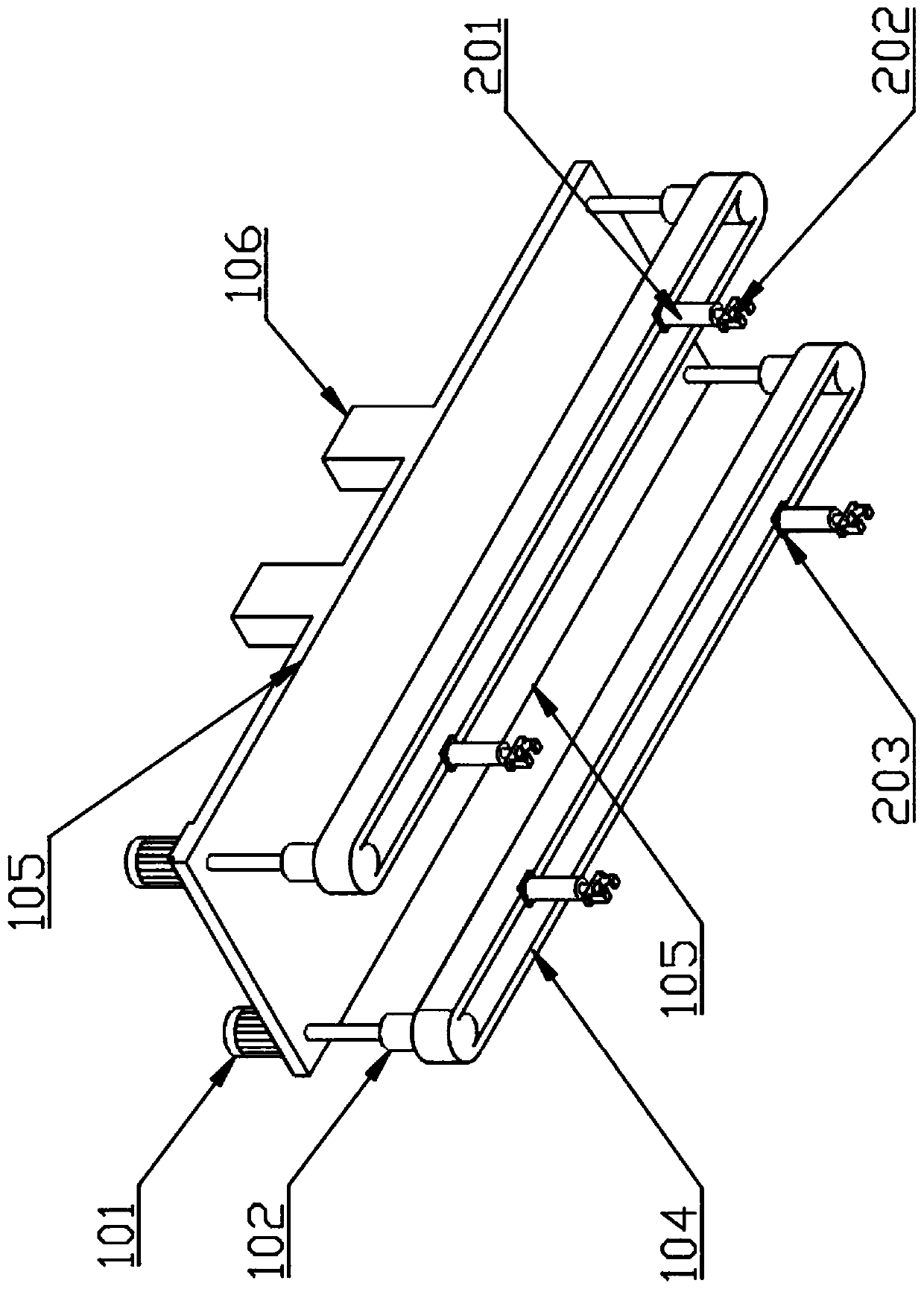

Turret type automatic lamination production line and lamination process thereof

PendingCN110350253AAvoid displacement deviationImprove lamination efficiencyFinal product manufactureLi-accumulatorsProduction lineEngineering

The invention discloses a turret type automatic lamination production line and a lamination process thereof. The turret type automatic lamination production line comprises a rack, feeding vacuum pullbodies, lamination mechanisms, turret mechanisms, material discharging mechanical arms and CCD mechanisms; two feeding vacuum pull bodies are provided; the two feeding vacuum pull bodies are parallelly arranged on the rack at intervals; two turret mechanisms are provided; the two turret mechanisms are arranged at two lamination stations respectively; four lamination mechanisms are provided; two groups of lamination mechanisms are arranged to two sides of the two turret mechanisms respectively, wherein each group of lamination mechanisms includes two lamination mechanisms; two material discharging mechanical arms are provided; the two material discharging mechanical arms are sequentially arranged below the two feeding vacuum pull bodies respectively; two CCD mechanisms are provided; and thetwo CCD mechanisms are arranged above the two lamination stations respectively. With the turret type automatic lamination production line and the lamination process thereof of the invention adopted,the sequential alternating lamination of the two lamination mechanisms is realized in the same rotation cycle, so that lamination efficiency is improved; the continuous lamination of a platform is realized, and the problem of movement interference during material discharging is avoided; and pole sheets are pressed uninterruptedly, so that the displacement deviation of the pole sheets is effectively avoided.

Owner:SHENZHEN XING GRAIN AUTOMATION CO LTD

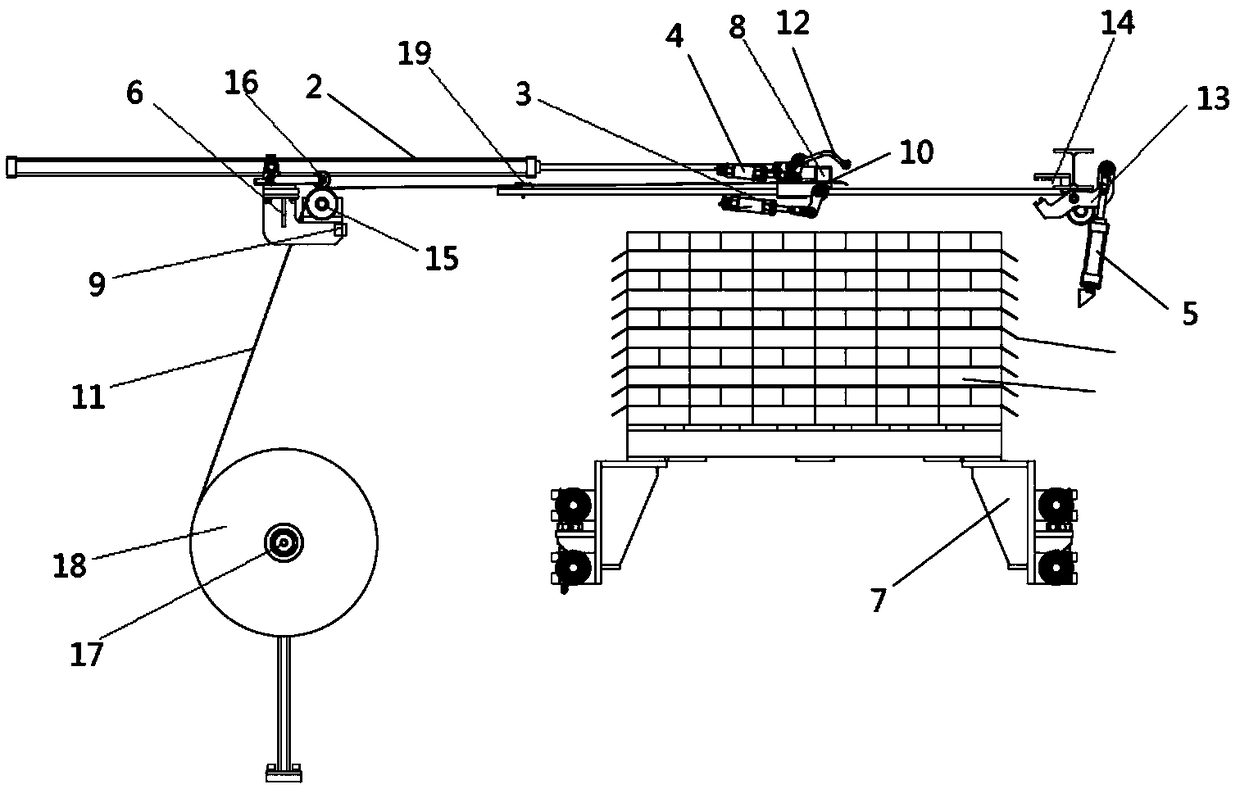

Rapid and precise coating mechanism

ActiveCN109178494APrevent fallingPrecise croppingWrapping material feeding apparatusPackaging automatic controlHydraulic cylinderBrick

The invention discloses a rapid and precise coating mechanism, which comprises a machine frame, a film conveying assembly, a film sending and clamping assembly, a film cutting assembly, a film clamping assembly, a film guiding assembly, a brick lifting assembly, a film conveying sensor and a brick lifting sensor. The film conveying assembly is an air cylinder or hydraulic cylinder. The film sending and clamping assembly comprises a transmission device and a clamping device. The film cutting assembly comprises a transmission device and a cutting device, and a high-temperature cutting wire is arranged on the cutting device. The film clamping assembly comprises a transmission device and a film clamping unit. The film conveying assembly is located in the middle of the upper portion of the machine frame. The film sending and clamping assembly and the film cutting assembly are mounted at the head end of the film conveying assembly. The film clamping assembly is located at the right end of the machine frame, the film guiding assembly is located at the left end of the machine frame, and the brick lifting assembly is located at the bottom of the machine frame. The rapid and precise coatingmechanism can rapidly and precisely coat a brick and has the advantages of being simple and stable in structure, and rapid, precise and efficient in coating.

Owner:GUANGXI HONGFA HEAVY IND MACHINE

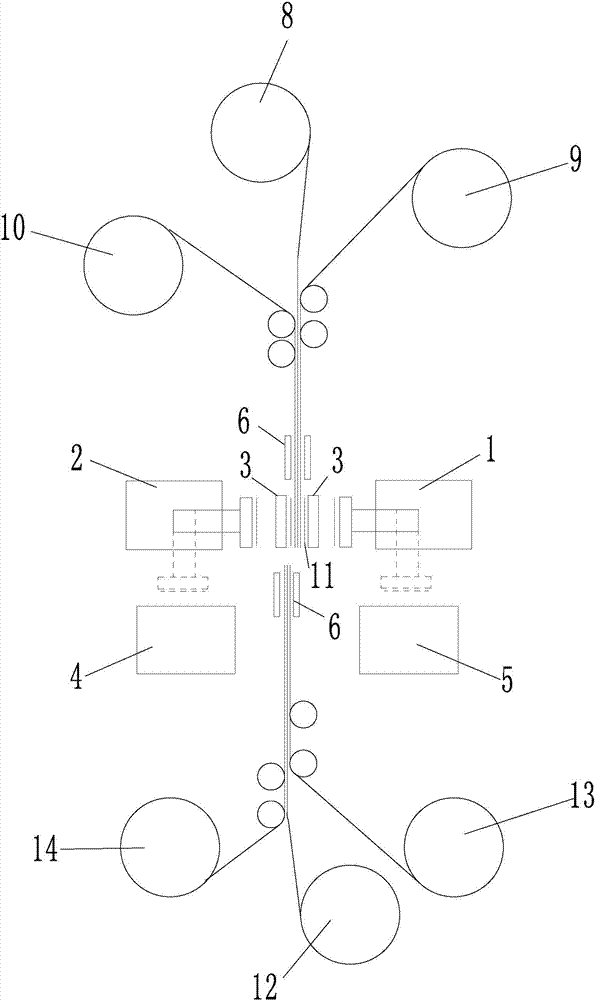

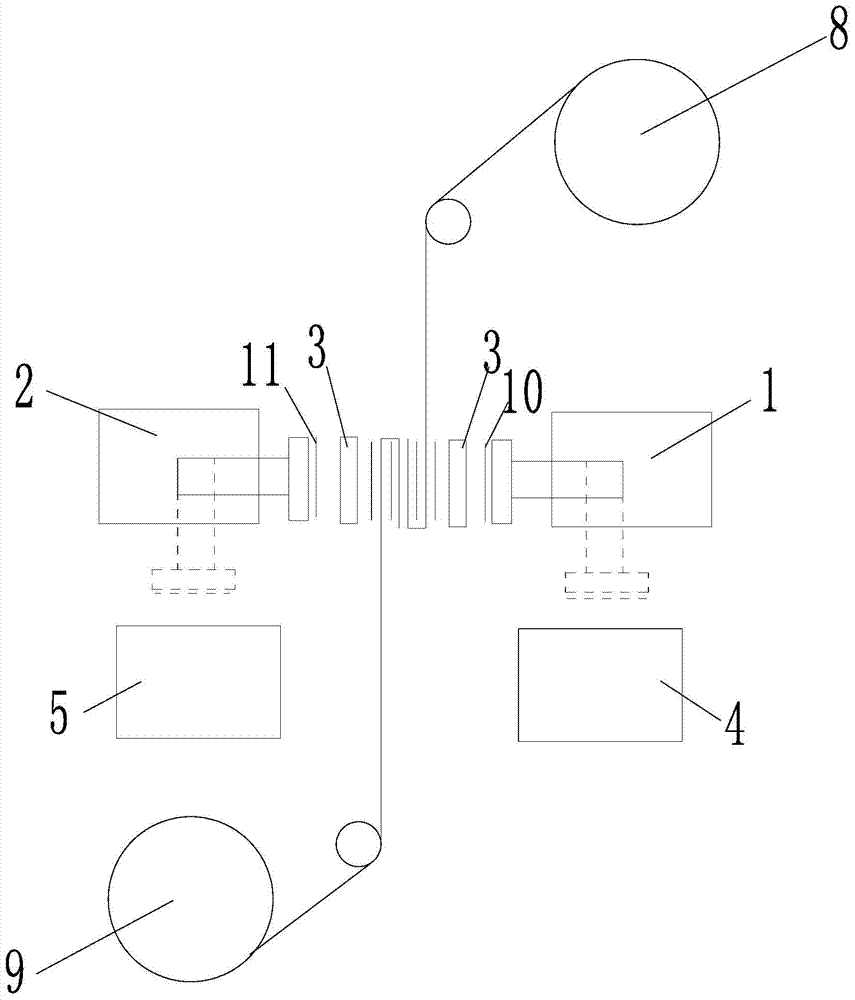

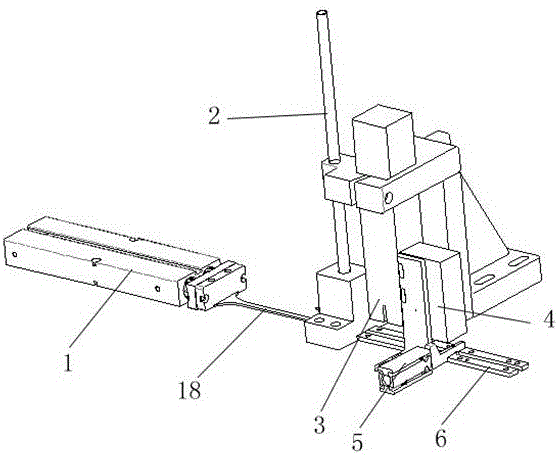

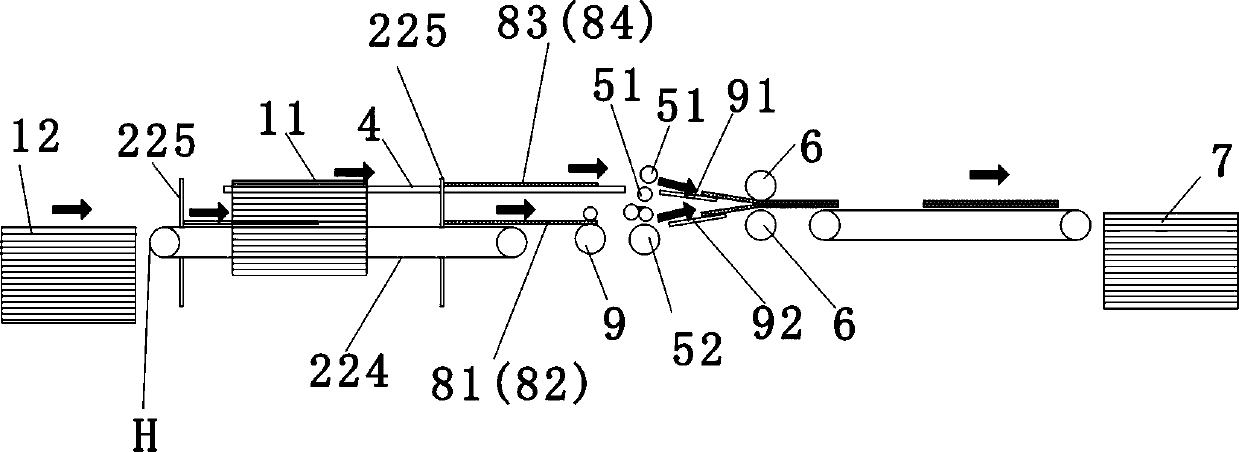

Laminator and lamination method thereof

ActiveCN103700889ALaminating speed is fastIncrease productivityFinal product manufactureSecondary cells manufacturePole pieceEngineering

The invention relates to the field of lithium battery lamination, and provides a laminator and a lamination method thereof. The lamination method comprises the following steps: respectively arranging a negative pole piece and diaphragms integrally attached to both sides of the negative pole piece on the upper end and lower end of the laminator, and feeding the negative pole piece and diaphragms at one end to the position between rotary manipulators; sucking the positive pole piece from a sub-locating table to the two fed diaphragms by using the rotary manipulators; feeding the negative pole piece and diaphragms at the other end to the position between the rotary manipulators, and the tail end of the negative pole piece and diaphragms is laminated with the tail end of the previously fed negative pole piece and diaphragms; sucking a positive pole piece to a diaphragm without any positive pole piece; rotating the positive pole piece and negative pole pieces together with the diaphragms by 180 degrees by a first clamping knife to perform coiling lamination; and sucking the positive pole piece to the two diaphragms on the outer sides, rotating the positive pole piece and negative pole pieces together with the diaphragms by 180 degrees by a first clamping knife to perform coiling lamination, and repeating many times. The method increases the lamination speed and enhances the production efficiency and production quality of the laminator.

Owner:GEESUN AUTOMATION TECH

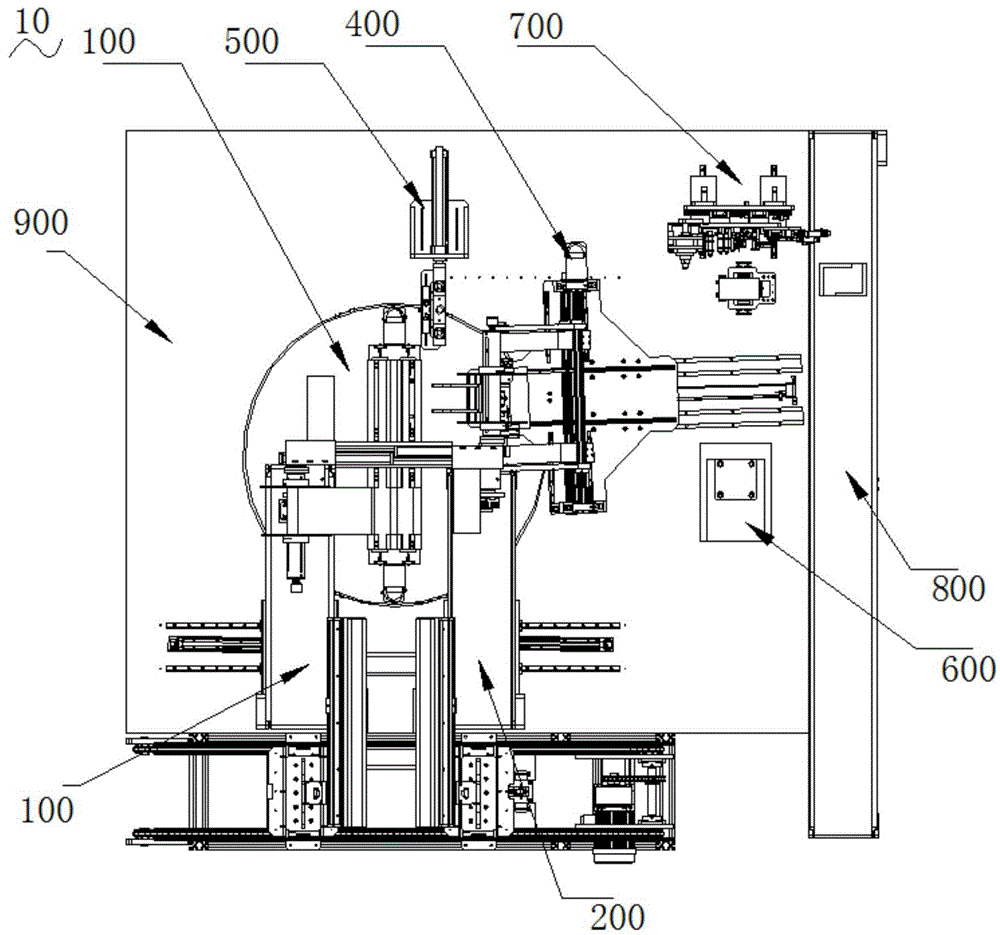

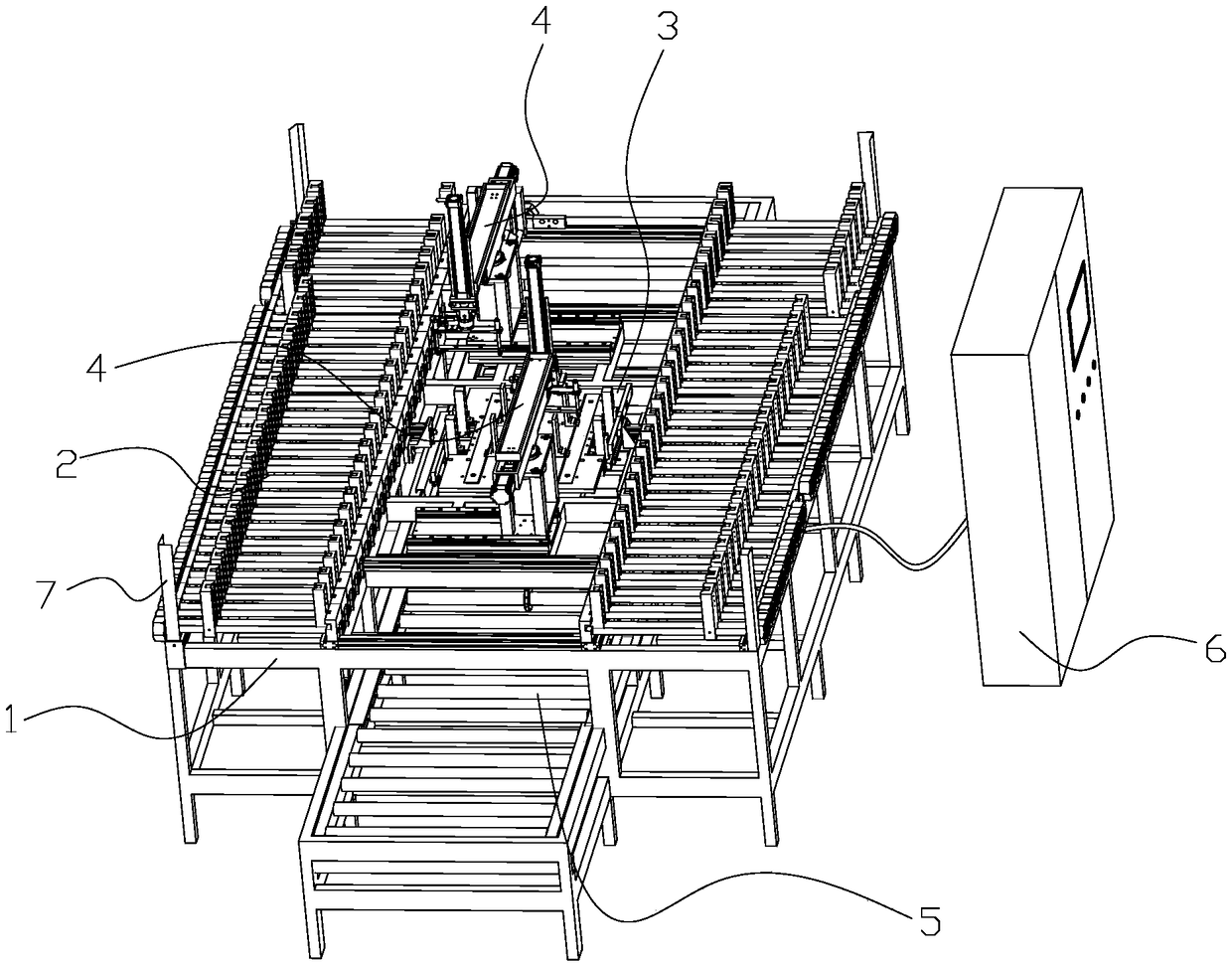

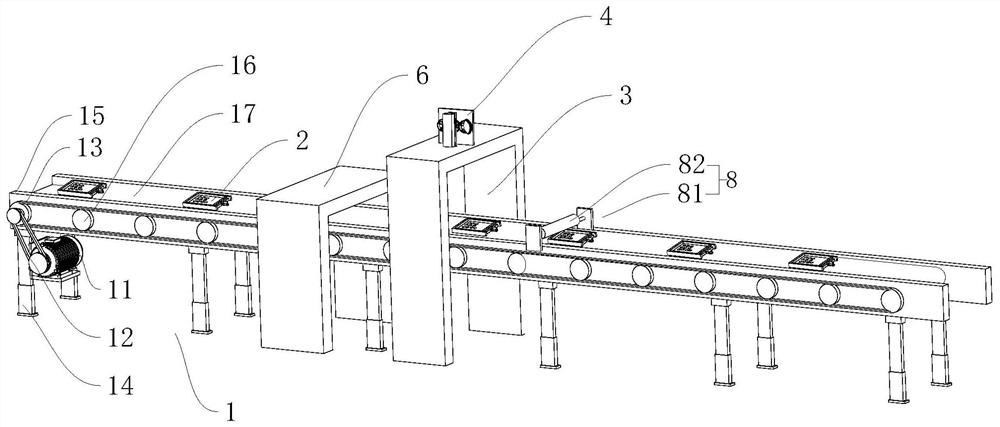

A transformer iron core automatic laminating production line

PendingCN109087804AIncrease productivityReduce manufacturing costInductances/transformers/magnets manufactureTransfer mechanismEngineering

The invention relates to the technical field of automation equipment for transformer production, in particular to a transformer iron core automatic lamination production line Which includes a stand, abin, a lamination platform, a take-off and release mechanism, a Transfer mechanism and a control cabinet, A material bin, a take-off and placing mechanism and a convey mechanism are fixed on the support frame, A plurality of bins are mounted on the bracket, the take-and-put mechanism is used for grasping the lamination in the bins and placing on the lamination platform, the conveying mechanism isused for feeding the lamination platform to the lamination range of the take-and-put mechanism and the lamination platform after the feeding of the lamination is completed, and the control cabinet can control the take-and-put mechanism and the conveying mechanism. The production line can run 24 hours a day, and the speed of lamination is higher than that of manual lamination, so the production efficiency is greatly improved. After the initial investment in the production line, there is no need to spend on lamination workers in the later period, which greatly reduces the production cost; The quality of lamination is stable and the error probability is much lower than that of manual lamination, which ensures the beautiful appearance of iron core and the stability of transformer quality.

Owner:ZHEJIANG JIANGSHAN TRANSFORMER CO LTD

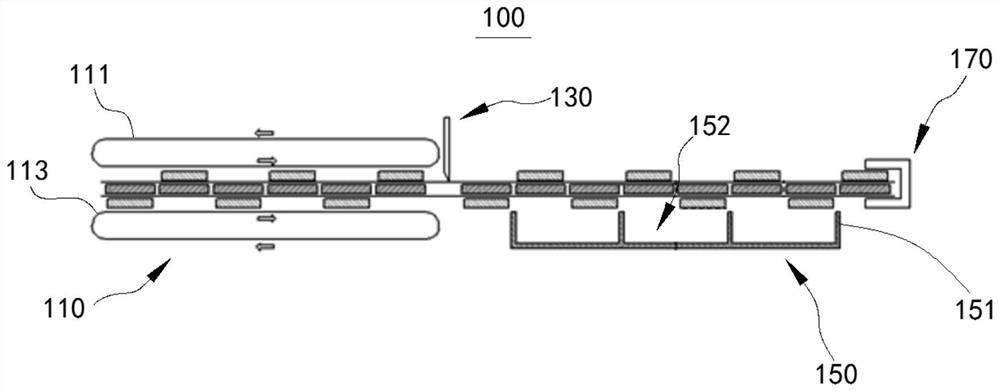

Lithium ion battery high-speed laminating method, laminating device and lithium ion battery

PendingCN110212236AReduce duplicate crawlsDoes not affect the process before and after productionFinal product manufactureElectrolyte accumulators manufactureManufacturing technologyElectrical polarity

The invention relates to the technical field of battery manufacturing, and specifically discloses a lithium ion battery high-speed laminating method, a laminating device and a lithium ion battery. Thelithium ion battery high-speed laminating method comprises the following steps: step S100, providing pole pieces after die cutting and a laminating platform so that one end of each of diaphragms on adiaphragm roll positioned above the laminating platform is fixed onto the laminating platform; step S200, stacking the diaphragms onto the laminating platform in a Z-shaped form, wherein at leas twopole pieces with same polarity are placed at intervals above the diaphragms when the diaphragms are overlapped on every layer, the polarities of every two adjacent layers of pole pieces are different,and a battery cell green body assembly is formed after N layers of diaphragms are stacked; and step S300, enabling a cutting device to cut the battery cell green body assembly at the positions between the adjacent pole pieces so as to form single battery cell green bodies. At least two pole pieces are stacked on each layer, the action of repeatedly capturing the pole pieces can be reduced, the positioning time is reduced, the stacking of at least two battery cell green bodies is completed once, and the laminating speed is increased.

Owner:EVE ENERGY CO LTD +1

Thermal compounding high-speed stacking machine

PendingCN111342107APrevent laminations from looseningImprove lamination qualityAssembling battery machinesLarge-sized flat cells/batteriesCell fabricationWall plate

The invention provides a thermal compounding high-speed stacking machine. The invention relates to the technical field of lithium battery manufacturing. The thermal compounding high-speed stacking machine comprises a supporting wall plate, a pole piece manufacturing device and a stacking device. The pole piece manufacturing device and the stacking device are arranged on the supporting wall plate at an interval. The pole piece manufacturing device is used for forming composite pole pieces. The pole piece stacking device comprises a swing roller assembly and a folding and stacking table, the swing roller assembly is arranged above the folding and stacking table and used for folding and stacking the composite pole pieces to form a battery cell, and limiting baffles are arranged on the two sides of the folding and stacking table so that a groove used for containing the composite pole pieces can be formed in the folding and stacking table. Due to the limiting and stopping effects of the limiting baffles, the battery cell can be stopped and limited from the two sides, loosening of the stacked pole pieces is prevented, and the stacking quality is improved. In addition, due to the fact that the swing roller assembly is adopted for folding and stacking the composite pole pieces, and the limiting baffles are arranged, the folded composite pole pieces can be effectively fixed, the loosening problem of the composite pole pieces does not need to be considered in the stacking process, and the stacking speed is greatly increased.

Owner:CONTEMPORARY AMPEREX TECH CO

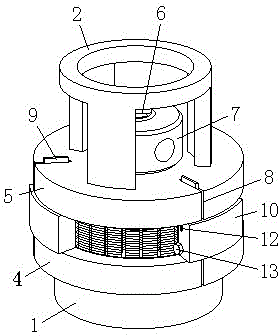

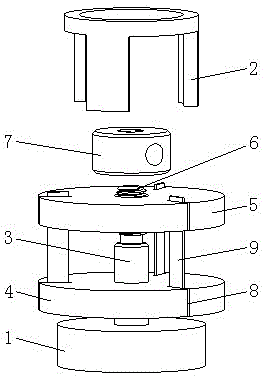

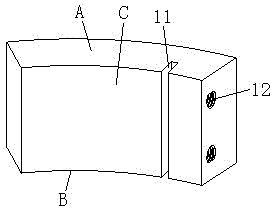

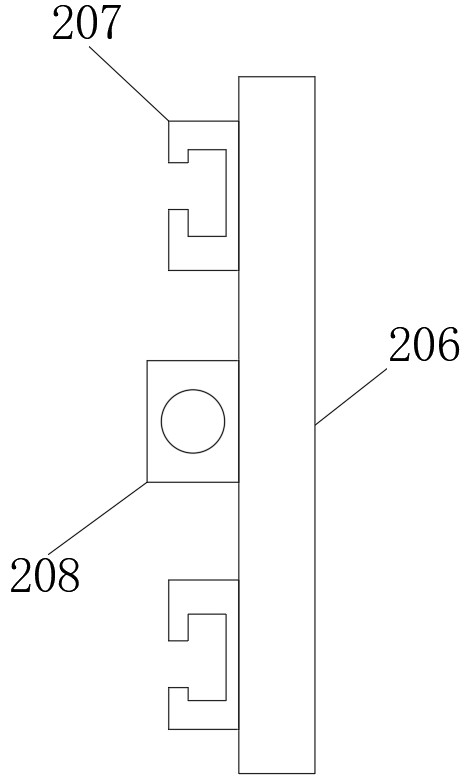

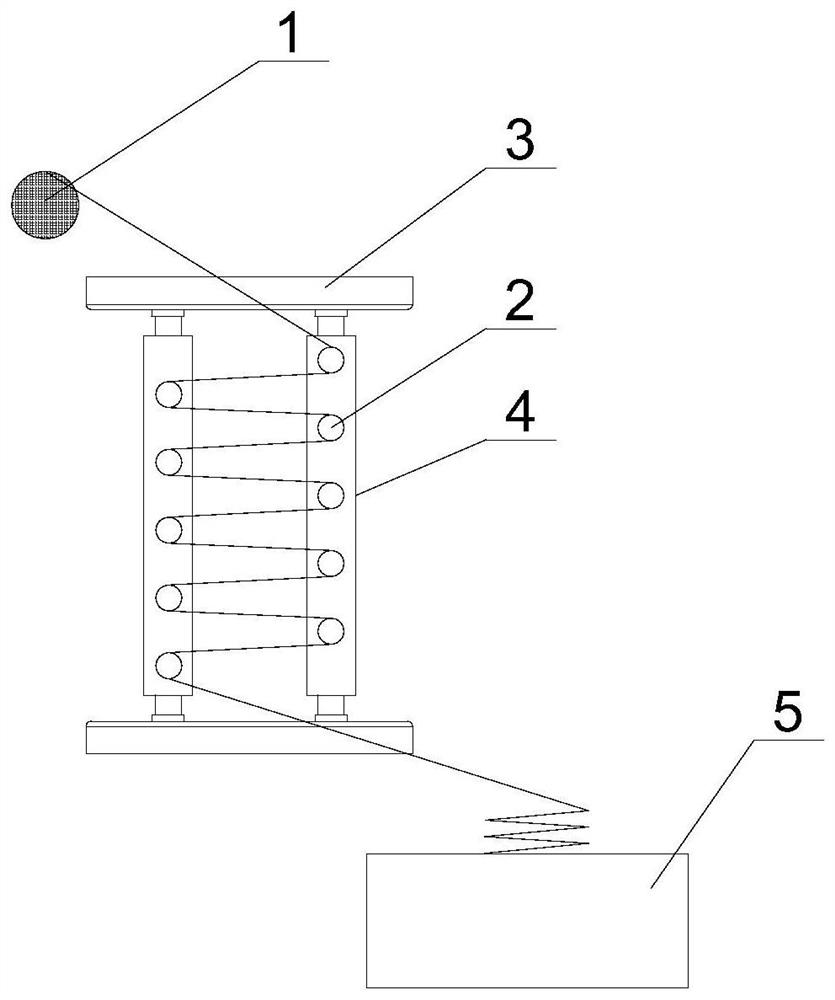

Method for guaranteeing stack mounting precision of straight-slot iron cores of motor and stack mounting die employed in method

InactiveCN104659979AIncrease stiffnessImprove stack qualityManufacturing stator/rotor bodiesElectric machineryProcessing accuracy

The invention discloses a method for guaranteeing the stack mounting precision of straight-slot iron cores of a motor and a stack mounting die employed in the method. According to the method, at least three key boards are adopted for performing positioning during stack mounting of the iron cores, so that the concentricity of the iron cores are improved; limiting blocks are clamped on the key boards between an upper pressure plate and a lower pressure plate, bending deformation of the key boards is limited through clamping grooves of the limiting blocks, and the verticality between the key boards and positioning surfaces of the upper pressure plate and the lower pressure plate is guaranteed through the processing precision of two end surfaces of each of the clamping grooves and the limiting blocks. The method is high in stack mounting efficiency; stacked layers of iron core stamping sheets are regular in a stack mounting process and unlikely to deform, so that the motor quality can be remarkably improved.

Owner:GUIZHOU AEROSPACE LINQUAN MOTOR CO LTD

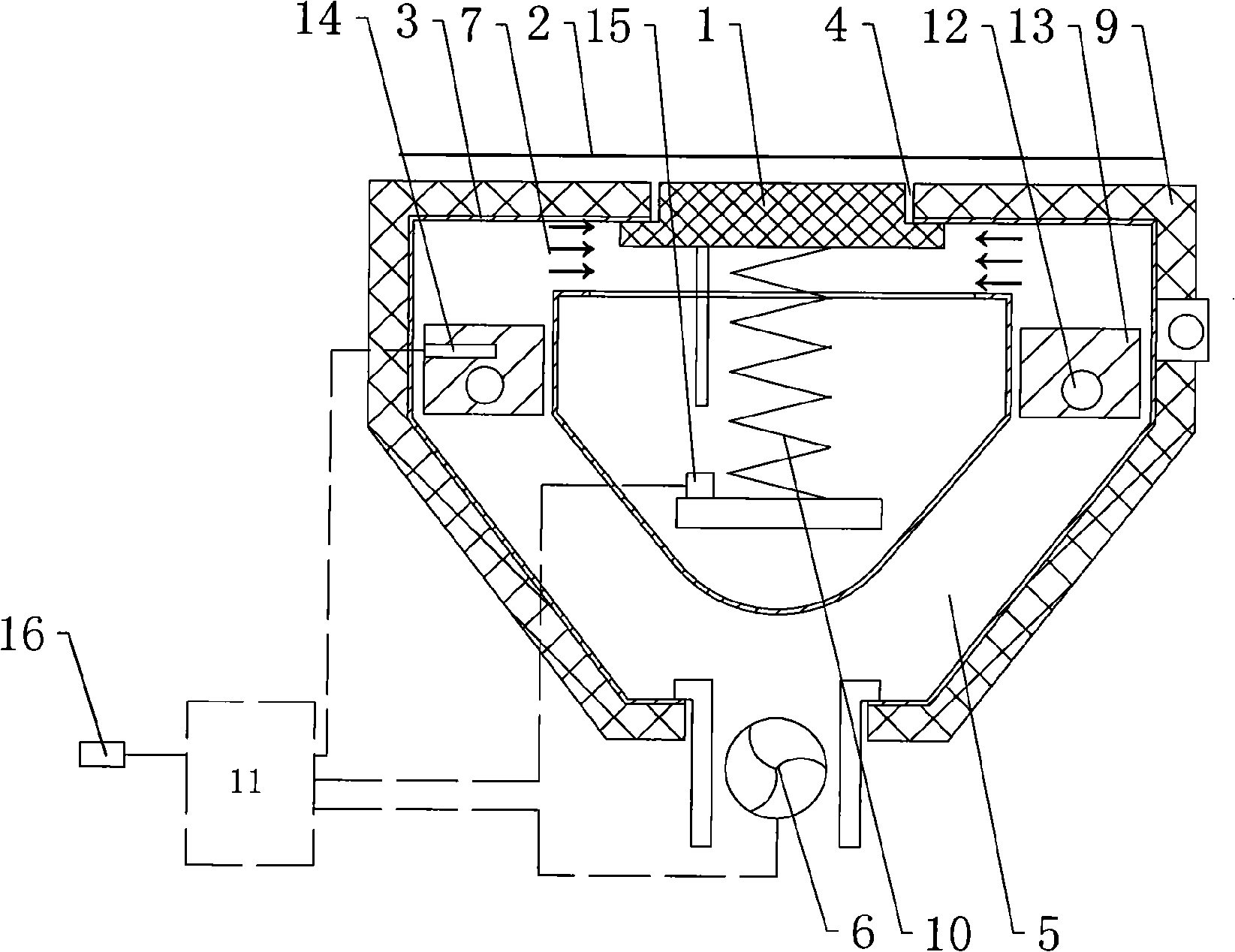

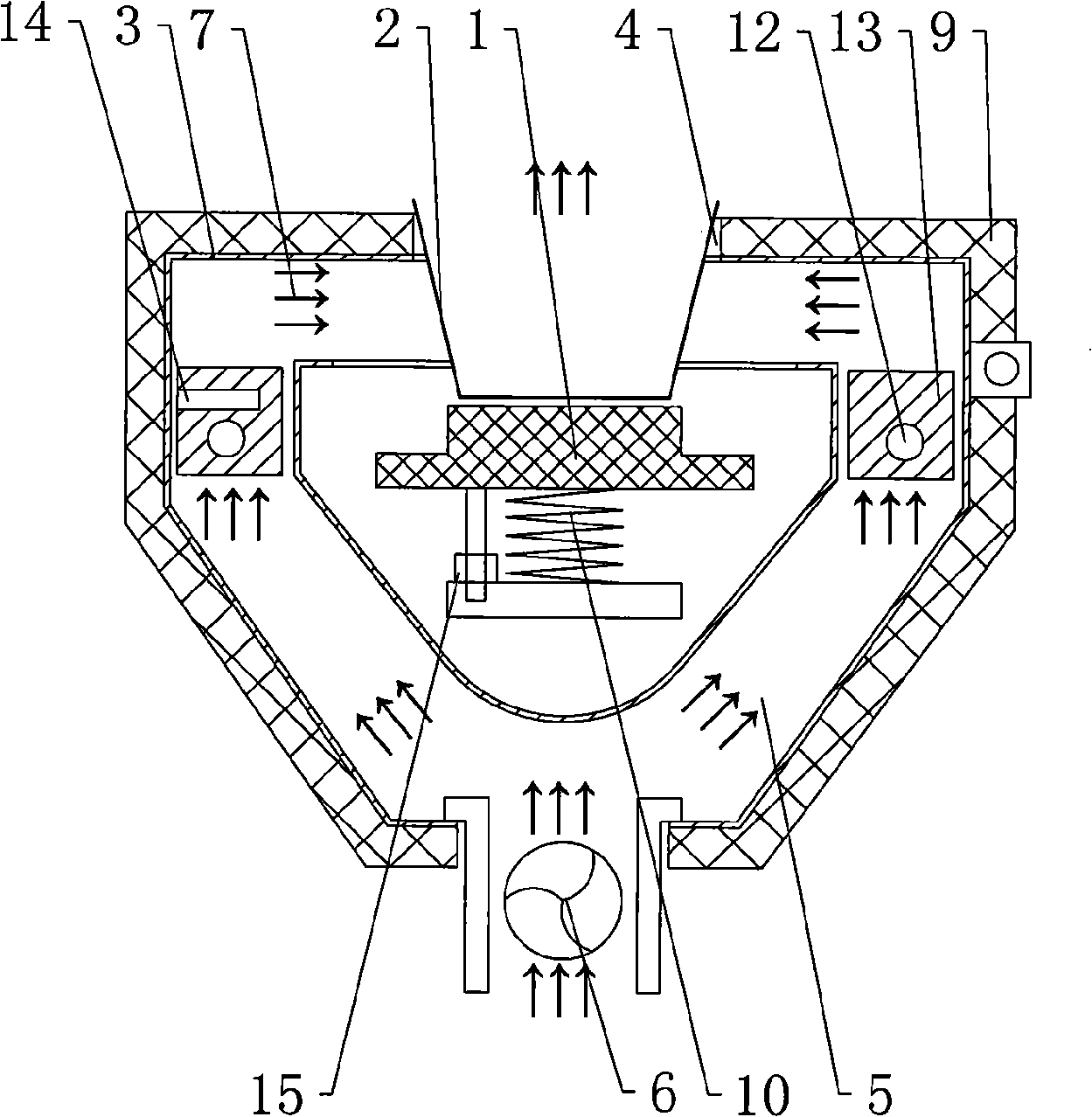

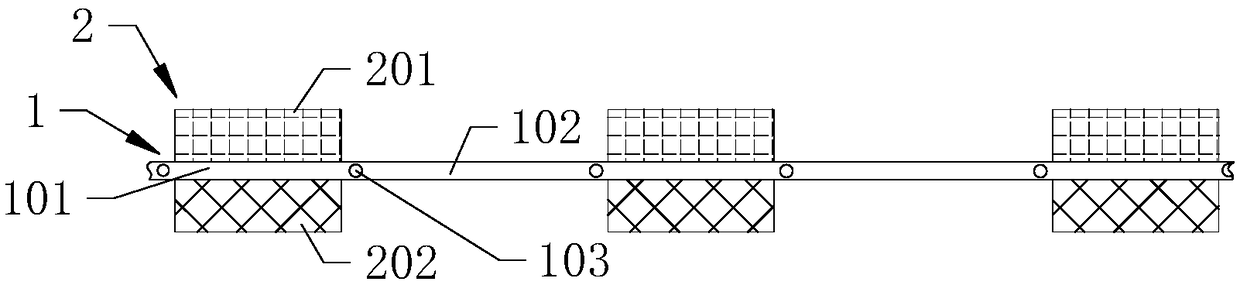

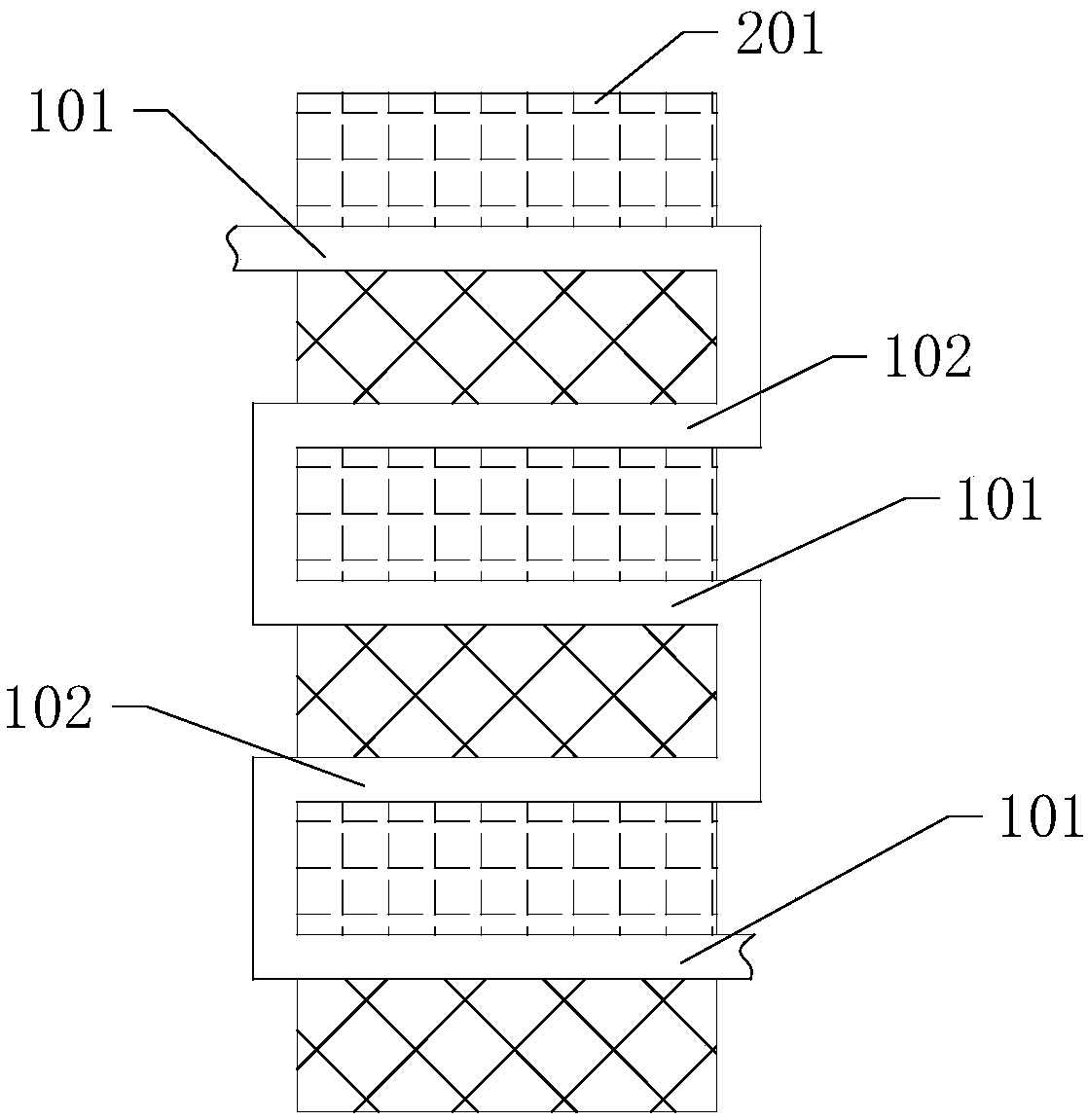

Film overlay device of shoe cover machine and film overlay method using the device

InactiveCN101327091ALaminating speed is fastImprove work efficiencyApparel holdersWrappingControl systemEngineering

A film covering of a shoe cover machine comprises a heating device arranged in the film covering device and a heat shrinking film conveyed to the above of the pedal. The heating device comprises a hot air cavity; a hot air duct is arranged in the hot air duct; a pedal seals the outlet of the hot air cavity or the hot air duct; the air inlet of the hot air duct is provided with a fan; a heater is arranged in the hot air duct; the outside of the hot air cavity is provided with a heat insulating layer; a repositor is arranged in a pedal lifting mechanism; a control system controls the fan and the temperature of the hot air in the hot air cavity. As the hot air is pre-stored in the hot air duct, the film covering device of the shoe cover machine has rapid film covering and high work efficiency. As the pedal seals the outlet of the hot air cavity, the present invention can prevent the deformation of the heat shrinking film in the non-working state.

Owner:施真 +1

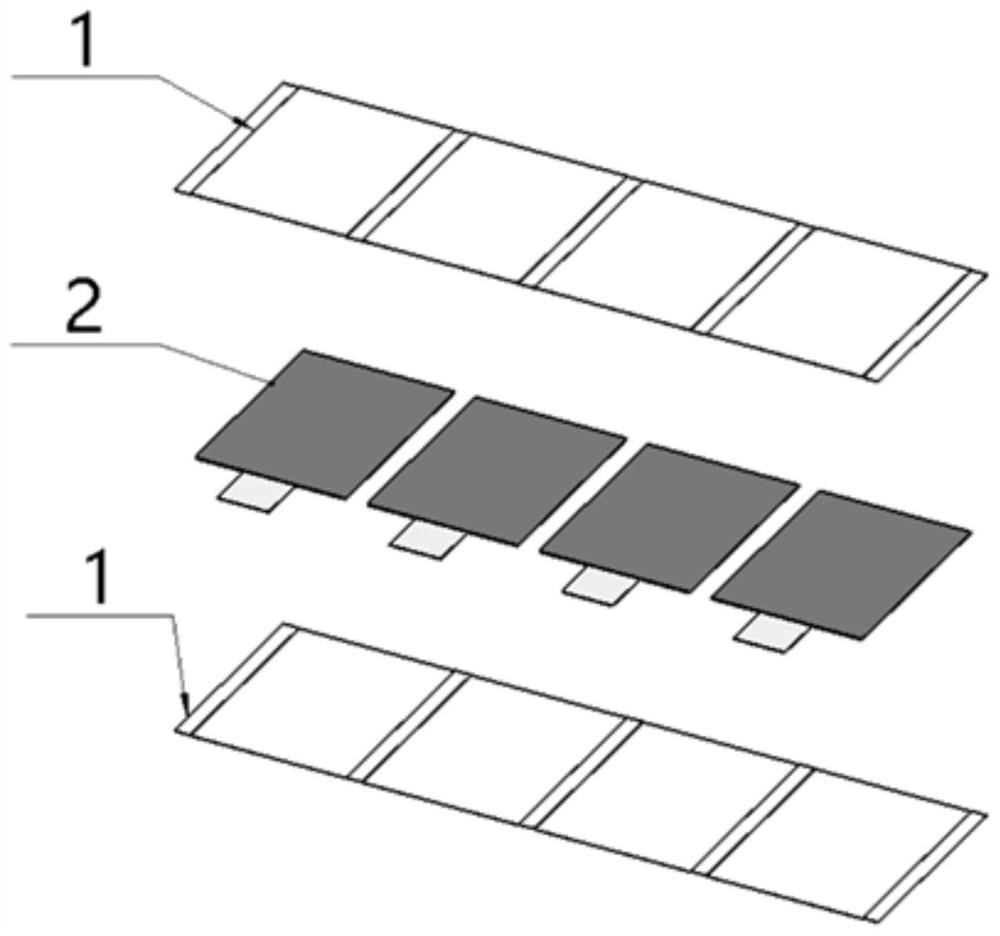

Production method of laminated cells

InactiveCN109346778ALaminating speed is fastIncrease productivityFinal product manufactureWound/folded electrode electrodesAnodeCoating

The invention relates to the technical field of battery production and particularly discloses a production method of laminated cells. The method comprises the following steps: a separator is providedand marked with a plurality of baselines in the length direction of the separator, the baselines divide the separator into a plurality of equivalently spaced lamination sections, an interval section is formed between every two adjacent lamination sections, and each interval section is longer than each lamination section; an electrode module is attached to each lamination section and comprises a cathode module and an anode module which are located on two sides of the lamination section respectively, each module is formed by alternate lamination of a plurality of electrode plates with double-sided coatings, the cathode module contains cathode plates on the bottommost layer and the topmost layer, and the anode module contains anode plates on the bottommost layer and the topmost layer; the separator is folded, the electrode modules are stacked in the thickness direction of the separator, and every two adjacent electrode modules are spaced by the interval section located between the two electrode modules. With the adoption of the production method of the laminated cells, production efficiency can be increased by increasing lamination speed of the cells.

Owner:DONGGUAN ALI AUTOMATION CO LTD

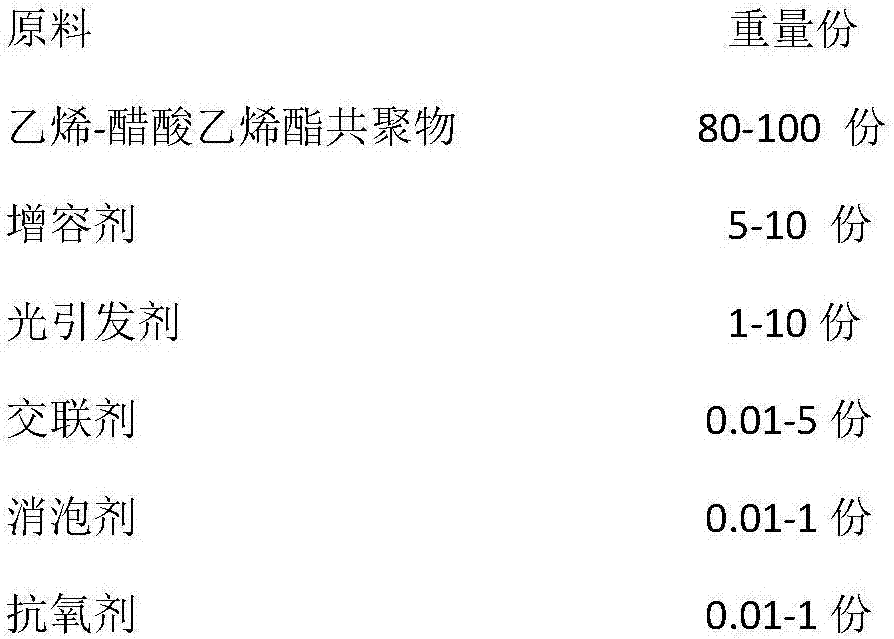

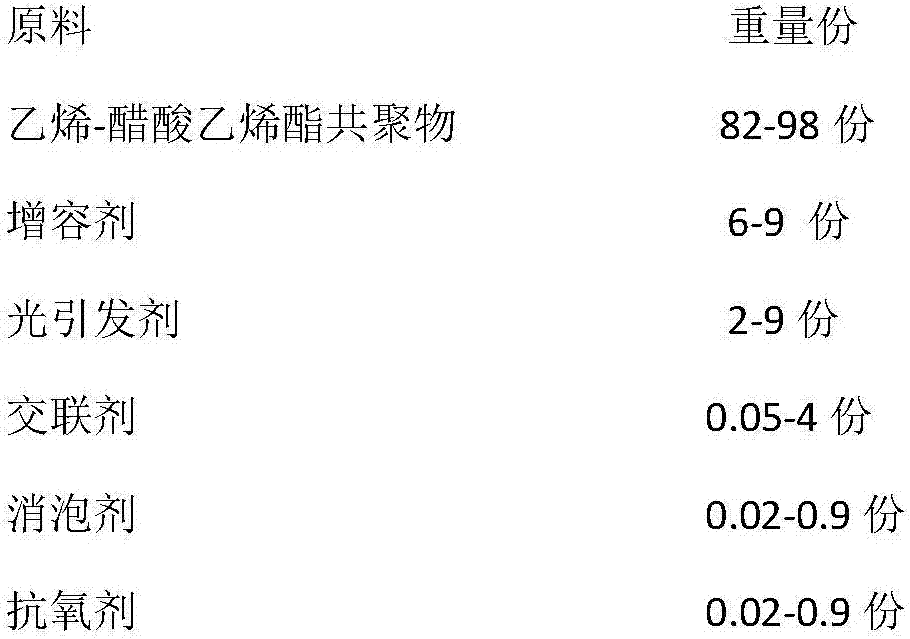

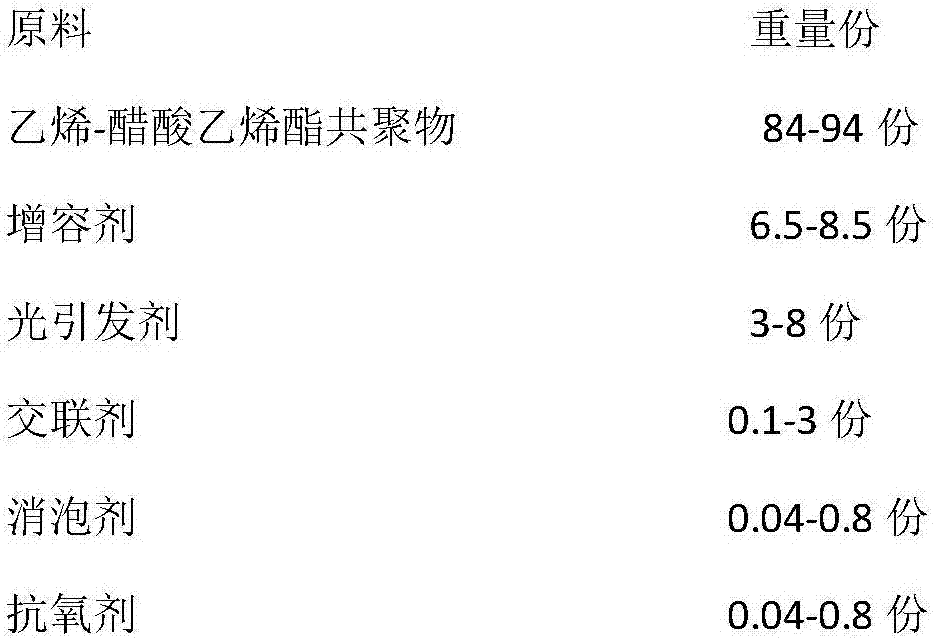

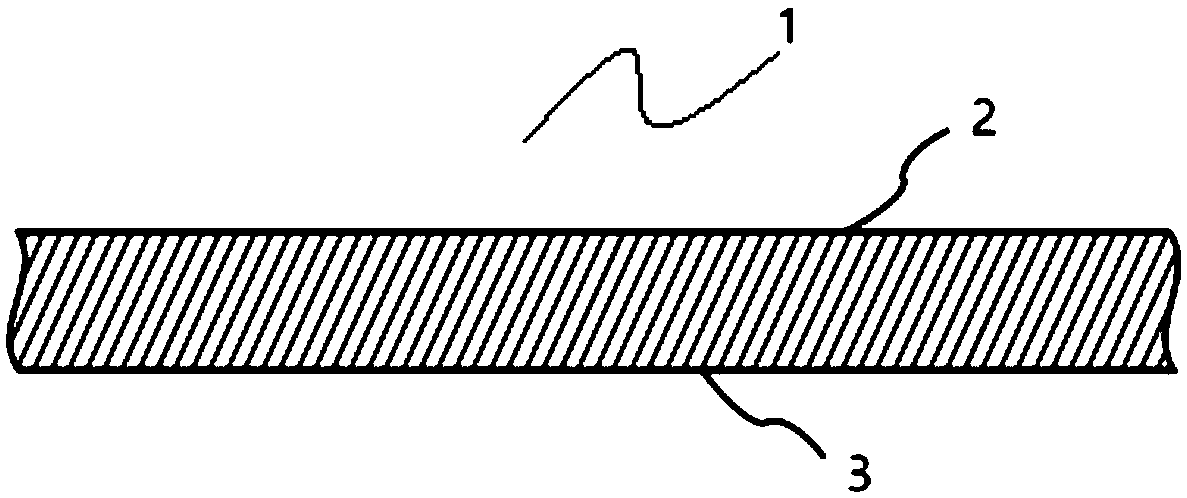

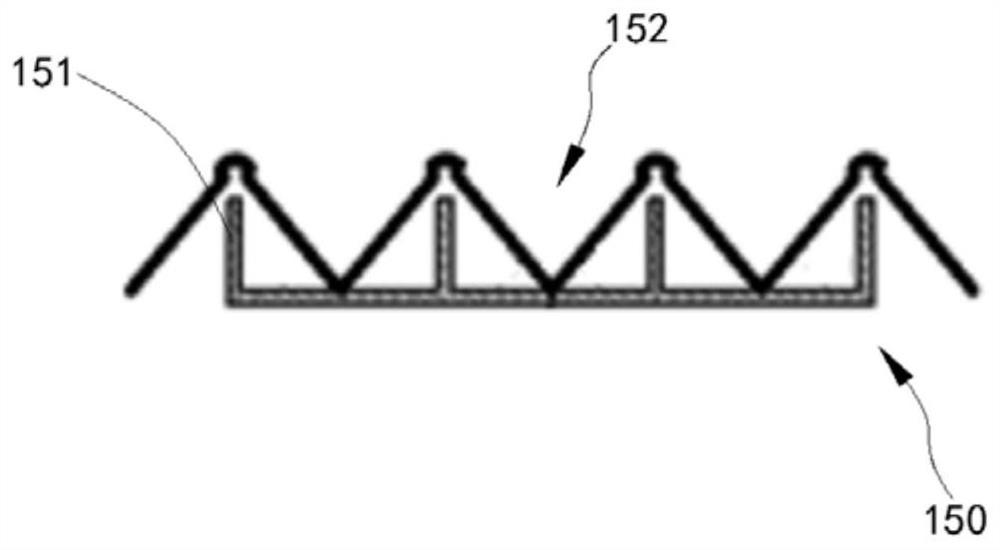

Quick crosslinked ethylene-vinyl acetate copolymer (EVA) adhesive film for double-glazed module, and preparation method of EVA adhesive film

InactiveCN107201195AIncrease productivityReduce manufacturing costNon-macromolecular adhesive additivesFilm/foil adhesivesPhotoinitiatorDefoaming Agents

The invention discloses a quick crosslinked ethylene-vinyl acetate copolymer (EVA) adhesive film for a double-glazed module, and a preparation method of the EVA adhesive film. The EVA adhesive film is prepared by mixing an EVA, a compatibilizer, a photoinitiator, a crosslinking agent, a defoaming agent and an antioxidant. The preparation method comprises the following steps: A. evenly mixing the EVA with the photoinitiator, the crosslinking agent, the compatibilizer, the defoaming agent and the antioxidant; B. evenly mixing the raw materials in a high mixing machine, and putting the mixture into an extruder for mixing, wherein the temperature of the extruder is controller to be within a range of 80-120 DEG C; C. carrying out tape casting, embossing, cooling, ultraviolet (UV)-curing and prepolymerization to form a film; carrying traction cutting, and finally winding to obtain the EVA adhesive film; D. packaging photovoltaic coated glass, a battery piece or the double-glazed module by means of the quick crosslinked EVA adhesive film for the double-glazed module. The method provided by the invention is easy to implement, simple and convenient to operate and lower in cost, reduces the processing time of the double-glazed module, and does not generate a merged piece; the defoaming agent is adopted as the raw material, so that the module is improved to be free from bubbles, and the yield of double-glazed modules is increased to be more than 99%; the preparation method is suitable for large-scale production.

Owner:JINGCHU UNIV OF TECH

Thermal laminating film for printing matters

InactiveCN109628011AStrong adhesionLow costMonocarboxylic acid ester polymer adhesivesFilm/foil adhesivesVinyl acetateCarvacryl acetate

The present invention relates to a laminating film, in particular to a thermal laminating film. The thermal laminating film is compounded to printing matters digitally printed with aqueous ink in a thermal laminating mode, and comprises a base layer and an adhesive layer; 70% or above of the adhesive layer is composed of, by weight, thermoplastic materials made of polyvinyl acetate, vinyl acetate-ethylene copolymer and a mixture of polyvinyl acetate and vinyl acetate-ethylene copolymer; the weight content of vinyl acetate in the vinyl acetate ethylene copolymer is 50% or above. The thermal laminating film has excellent adhesion to the printing matters digitally printed with the aqueous ink. A process of bonding the thermal laminating film to the printing matters can be automated by using existing thermal laminating equipment, through automation, the laminating speed can be increased, the labor is saved, and therefore the productivity is improved.

Owner:惠州艺都文化用品有限公司

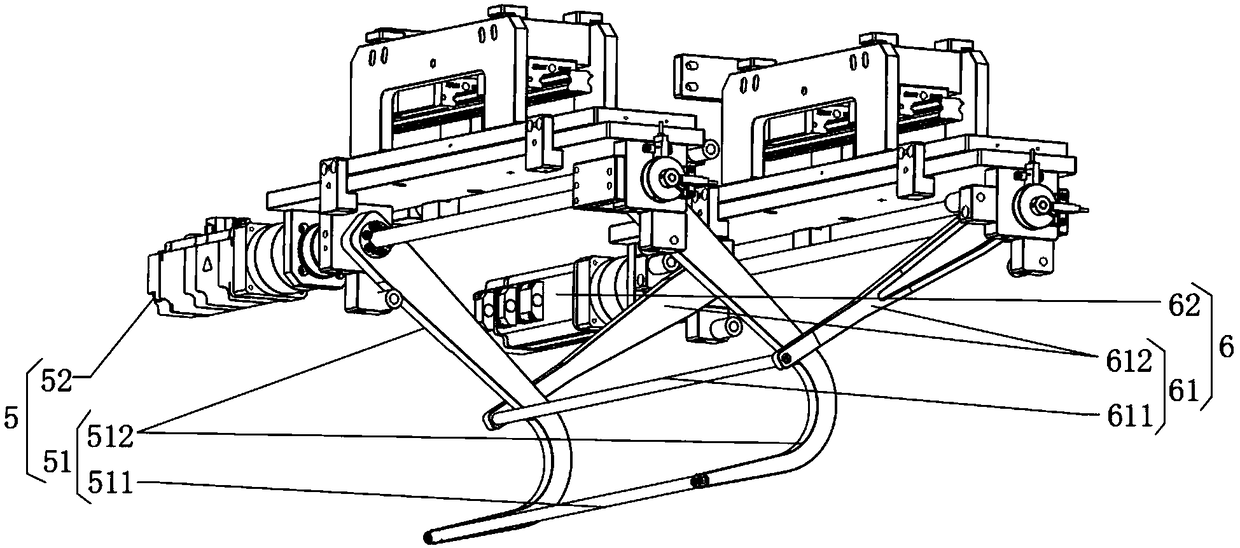

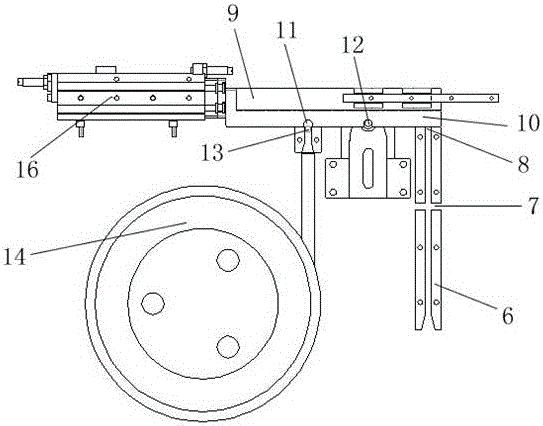

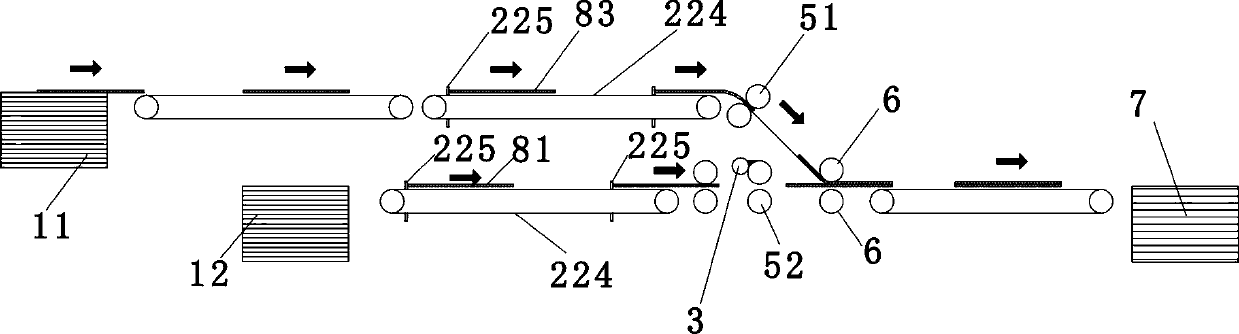

Laminator and lamination method thereof

ActiveCN103700885AIncrease productivityImprove product qualityAssembling battery machinesFinal product manufacturePole pieceEngineering

The invention relates to the field of lithium battery lamination, and provides a laminator and a lamination method thereof. The lamination method comprises the following steps: respectively arranging a first diaphragm and a second diaphragm on the upper end and lower end of the laminator, simultaneously feeding the diaphragms on the two ends to the position between rotary manipulators, wherein the tail ends of the first diaphragm and second diaphragm are laminated; simultaneously sucking a positive pole piece and a negative pole piece from sub-locating tables to the two fed diaphragms by using the rotary manipulators; and rotating the positive pole piece and negative pole piece together with the diaphragms by 180 degrees by a first clamping knife to perform coiling lamination, and repeating many times. The method increases the lamination speed and enhances the production efficiency and production quality of the laminator.

Owner:GEESUN AUTOMATION TECH

Film coating equipment for photovoltaic solar module production and working method thereof

ActiveCN114311644AHigh degree of automationAvoid injuryFinal product manufacturePhotovoltaic energy generationPhotovoltaic solar energyEngineering physics

The invention relates to the technical field of photovoltaic solar module film covering, in particular to film covering equipment for photovoltaic solar module production and a working method thereof.The film covering equipment comprises a supporting frame, a feeding assembly, a conveying assembly, a film covering roller, a film covering assembly, a film cutting assembly and a film pressing wheel; according to the film laminating equipment, the film laminating roller and the film laminating assembly are used for laminating in the conveying process, and the connected film is cut by the film cutting assembly, so that the film laminating equipment can be used for automatically laminating the photovoltaic solar panel in a streamlined manner, and all links of the film laminating equipment do not need to be manually operated by automatically laminating the film, so that the labor intensity of workers is reduced, and the production efficiency is improved. Compared with the prior art, labor is saved, meanwhile, the situation that personnel are hurt by the equipment or the photovoltaic solar panel in the manual operation process is avoided, and meanwhile, through film laminating streamline of the equipment, all links of film laminating of the equipment are matched more tightly, and the film laminating speed is higher.

Owner:ANHUI GUOCHENG PHOTOELECTRIC TECH CO LTD

A double-swing arm type tension control device and a double-swing arm type lamination machine

ActiveCN109119701AEliminate the problem of length mutationEnsure constant tensionFinal product manufactureSecondary cellsTension control

The invention relates to the technical field of tension control, in particular to a double-swing arm type tension control device and a double-swing arm type lamination machine, the double-swing arm type tension control device comprises a first swing arm mechanism and a second swing arm mechanism, the diaphragm is guided and folded in a Z form by swinging the first swing arm mechanism and the second swing arm mechanism, the second swing arm mechanism tensions the diaphragm when the first swing arm mechanism guides the diaphragm to one side, and the first swing arm mechanism tensions the diaphragm when the second swing arm mechanism guides the diaphragm to the other side. The diaphragm is carried out in the Z form by swinging the first swing arm mechanism and the second swing arm mechanism,specifically, when the first swing arm mechanism guides the diaphragm to one side, the second swing arm mechanism tensions the diaphragm, controls the tension of the diaphragm, and eliminates the problem of sudden change of the diaphragm length in the lamination process, thereby avoiding problems such as diaphragm loosening and tearing in the high-speed lamination process.

Owner:DONGGUAN CHAOYE PRECISION EQUIPMENT CO LTD

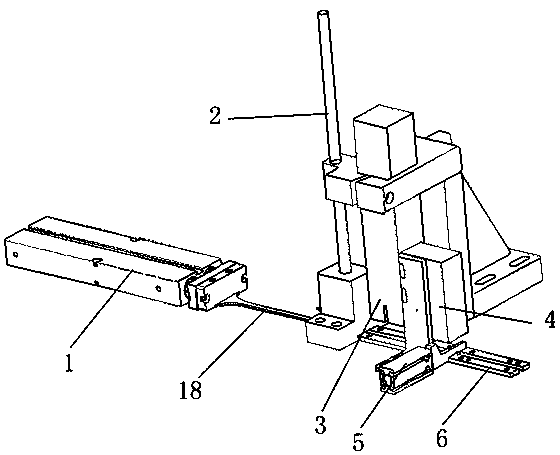

Novel plate laminating machine

PendingCN106965531ALaminating speed is fastImprove efficiencyLamination ancillary operationsLaminationElectric machineryEngineering

The invention discloses a novel plate laminating machine. The novel plate laminating machine comprises a guide machine frame, a drying machine, a laminating machine frame and a rolling machine frame; the guide machine frame is placed at the most front end of the whole laminating machine; an upper guide rolling wheel and a lower guide rolling wheel are arranged on the guide machine frame; the guide rolling wheels are driven by a motor on one side; the drying machine is arranged behind the guide machine frame; a drying electric net sheet and rolling shaft wheels are arranged in the drying machine; the drying electric net sheet is placed horizontally and can be heated by electrifying; the rolling shaft wheels are distributed on the electric net sheets uniformly and can be driven by the motor to rotate; the laminating machine frame is arranged behind the drying machine; a plate walking roller way is arranged in the laminating machine frame; a film placing roller and two tension adjusting rollers are arranged above the laminating machine frame; a film, which the plate needs to be coated with, is rolled on the film placing roller; the tension adjusting rollers are positioned in front of the laminating machine frame; the film pulled out of the placing roller passes through the tension adjusting rollers and then coats the plate; the rolling machine frame is positioned at the most back end of the laminating machine; and several groups of pressing rollers are arranged on the rolling machine frame uniformly.

Owner:朱少曼

Manufacturing method of laminated pole group, laminated pole group and battery

InactiveCN113224391AImprove performanceReduce the difficulty of assemblyFinal product manufactureSecondary cellsElectrical batteryStructural engineering

The invention discloses a manufacturing method of a laminated pole group, a laminated pole group and a battery. The method comprises the following steps that: a plurality of first pole pieces are packaged between two layers of diaphragms at equal intervals along a first direction to form a first pole piece array body, and a continuous clamping bag structure is formed by the two layers of diaphragms in the first pole piece array body along the first direction, a first pole piece is packaged in each clamping bag structure; and the first pole piece array body is folded in a Z-shaped lamination mode, and a second pole piece is inserted between every two adjacent clamping bag structures while the first pole piece array body is folded, so that the lamination pole group formed by sequentially and alternately laminating the plurality of first pole pieces and the plurality of second pole pieces can be formed. The assembly difficulty is reduced, and the lamination speed, the yield and the safety of the battery are improved.

Owner:RISESUN MENGGULI NEW ENERGY SCIENCE & TECHNOLOGY CO LTD

Pole piece forming device and battery cell production system

PendingCN111786029ANo consumptionLaminating speed is fastAssembling battery machinesFinal product manufactureControl engineeringElectrical connection

The invention discloses a pole piece forming device and a battery cell production system, and relates to the technical field of battery production. The pole piece forming device comprises a controller, a conveying mechanism, a cutting mechanism, a forming mechanism and a traction mechanism, and the conveying mechanism, the cutting mechanism and the forming mechanism are sequentially arranged in the first horizontal direction. The conveying mechanism is used for clamping and conveying composite unit pole pieces in the first horizontal direction. The traction mechanism is used for clamping the composite unit pole piece output by the conveying mechanism, and performing traction in a first horizontal direction; the controller is electrically connected with the cutting mechanism and the traction mechanism; and the controller is used for controlling the cutting mechanism to cut off the composite unit pole piece when the traction mechanism pulls the composite unit pole piece to move for a preset distance, and controlling the traction mechanism to release the clamping of the composite unit pole piece, so that the cut composite unit pole piece falls onto the forming mechanism under the action of gravity to finish preliminary folding. According to the pole piece forming device provided by the invention, the lamination speed is increased, and the energy consumption is reduced.

Owner:GEESUN AUTOMATION TECH

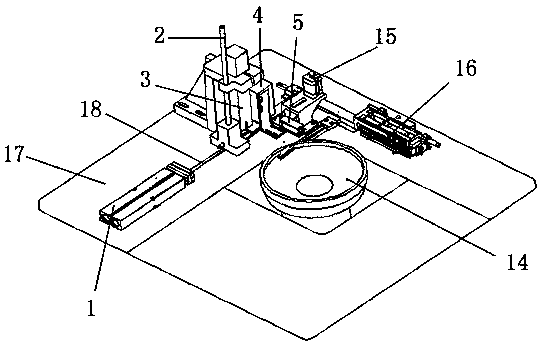

Magnetic pole marking and detecting and stacking device

ActiveCN106140657ANo human intervention requiredLaminating speed is fastStacking articlesSortingMagnetic polesEngineering

The invention relates to a magnetic pole marking and detecting and stacking device. The magnetic pole marking and detecting and stacking device comprises a worktable, a material feeding rail, a stacking rail, a material guiding pipe, an ink jet printer, a color mark sensor, a vibration disc, a material ejection cylinder, a stacking cylinder and a material conveying cylinder, wherein a material conveying push rod on the material conveying cylinder is arranged on the material feeding rail; the material conveying push rod can slide on the material feeding rail driven by the material conveying cylinder; the ink jet printer, the color mark sensor and a blanking port on the material guiding pipe are all arranged above the material feeding rail; the stacking rail is provided with a material discharging through hole, and a stacking pipeline is arranged below the material discharging through hole; and a material ejection push rod on the material ejection cylinder is arranged above the material discharging through hole. Stacking speed is increased by utilizing the material blanking mode of pads and steel magnets during feeding, and one pad is arranged between every two adjacent steel magnets; marking and stacking are finished continuously; process flowing time is saved; working efficiency is improved; and the efficiency of each article of equipment is 12000 pcs / 8h.

Owner:杭州科德磁业有限公司

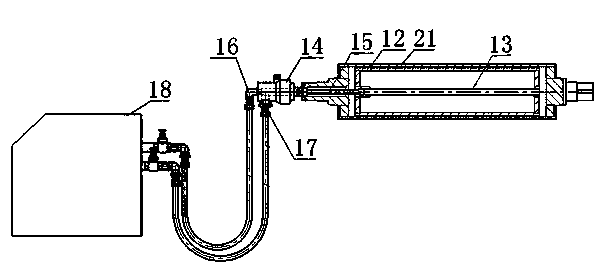

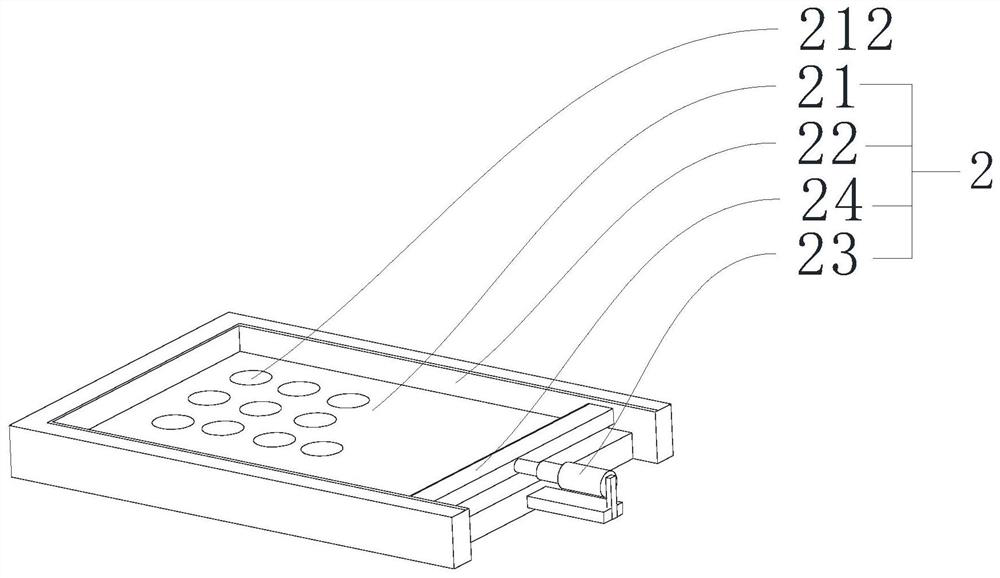

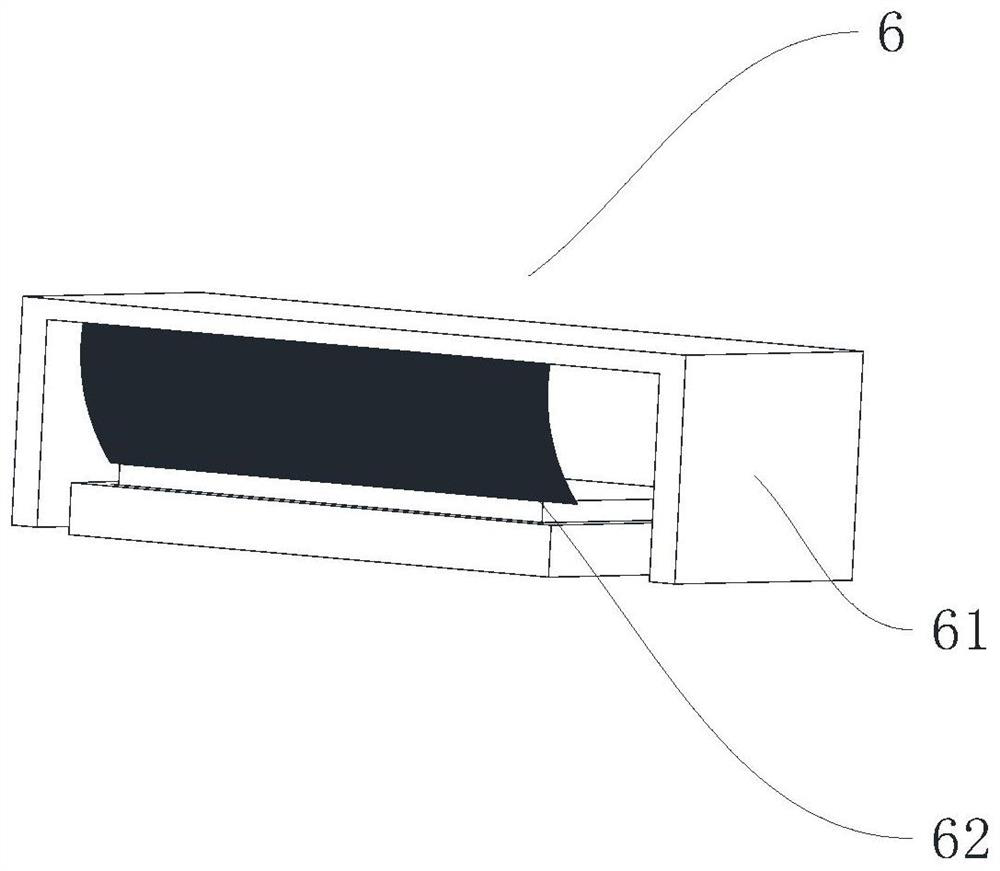

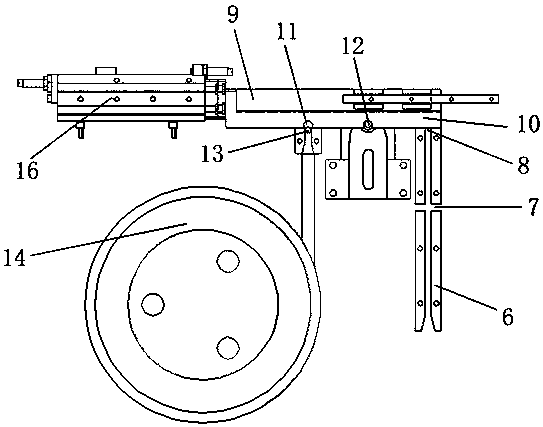

Vacuum Laminating Device For Film

InactiveCN105922706AImprove qualityIncrease lamination process speedLamination ancillary operationsLayered product treatmentTectorial membraneEngineering

The present invention provides a vacuum laminating device for a film which can laminate in the high vacuum, for example the high vacuum of which the vacuum degree is below 0.5 kPa. In order to change the length of an pasted laminated film 21 correspondingly with the length of an input substrate 14a, the length of the substrate 14a is measured before lamination, and a film length adjusting mechanism 23 is comprised. The film length adjusting mechanism 23 changes the holding length of the laminated film 21 according to the measured length of the substrate 14a between a semi-cutting position and a blade part 24 nearby a lamination roller 26, at the length position of the pasted laminated film 24, the laminated film 21 of which the holding length is changed by the film length adjusting mechanism 23, and before a protection film 27 is peeled, is semi-cut, and the laminated film 21 is conveyed to the blade part 24 by utilizing a film conveying mechanism 20, 29 and under a state of connecting the laminated film via the protection film 27.

Owner:HITACHI PLANT MECHANICS

Rubber roller cleaning and laminating device

InactiveCN110394324ANo manual handlingImprove efficiencyDrying gas arrangementsCleaning using toolsEngineeringMechanical engineering

Owner:安徽兰翔纺机科技有限公司

Laminating machine having four paper feeding stations

InactiveCN102975562ALaminating speed is fastEasy Control Alignment FitPaperhangingArticle deliveryPaper sheetUpper floor

The invention provides a laminating machine having four paper feeding stations. A lower-layer paper feeding station is placed behind a lower-layer paper feeding mechanism which is placed behind a lower-layer pinch mechanism, an upper rubber covered roller is close to the lower-layer pinch mechanism, and an upper layer paper feeding mechanism is placed behind an upper-layer pinch mechanism, and the upper-layer pinch mechanism and the lower-layer pinch mechanism are placed behind the laminating machine. The upper-layer paper feeding mechanism is provided with three upper-layer paper guide ribs, the middle upper-layer paper guide rib is a straight line section which is stretched longitudinally, the rear end sections of the upper-layer paper guide ribs on the left side and the right side are in splayed shape, a group of long strip supporting plates are arranged between each two adjacent upper-layer paper guide ribs, a transverse gap is formed between each two adjacent long strip supporting plates in the same group, a longitudinal setting gauge of the lower-layer paper feeding mechanism upwards penetrates through the transverse gaps, the upper-layer paper feeding stations are two in number, and the paper feeding directions of the upper-layer paper feeding stations are transversely inward. The laminating machine can improve pasting speed, accurate match of longitudinal positions of upper-layer paper and lower-layer paper can be easily controlled, and components are saved.

Owner:GUANGDONG MAGNOLIA PACKING MACHINERY

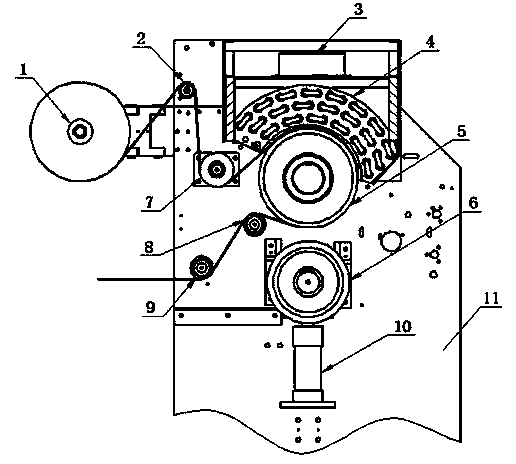

Rubber face heating method and system of pre-coated film laminating machine

ActiveCN103786432AFully meltedLaminating speed is fastPrinting press partsHydraulic cylinderEngineering

The invention relates to a rubber face heating method and system of a pre-coated film laminating machine and belongs to the technical field of pre-coated film laminating machines. According to the technical scheme, an adhering steel roller (5) and an adhering rubber roller (6) are arranged on a rack (11) of the film laminating machine in parallel in an up-and-down mode. The adhering rubber roller (6) is driven by a hydraulic cylinder (10). A finned tube heating system (4) is arranged on the adhering steel roller and an axial flow fan (3) is arranged on the finned tube heating system. The position adjacent to the adhering steel roller is provided with a bending roller (7). A first film expanding roller (2) is arranged between the bending roller and a film holding device (1). A second film expanding roller (8) and a third film expanding roller (9) are arranged at a pre-coated film outlet of the adhering steel roller. The finned tube heating system is composed of multiple finned tubes which are arranged in parallel and surround the upper portion of the adhering steel roller. According to the rubber face heating method and system of the pre-coated film laminating machine, glue on the pre-coated film is fully molten instantly, adhering between a pre-coated film and printed paper is firmer, the surface of the paper laminated with the film is brighter, and the film laminating speed can exceed 100 m per minute.

Owner:YUTIAN SHENGTIAN PRINTING & PACKING MACHINERY

Surface treatment system for manufacturing LED liquid crystal display screen

InactiveCN112590186ALaminating speed is fastImprove lamination efficiencyCleaning using toolsLiquid-crystal displayLED display

The invention relates to the technical field of manufacturing of display screens, and particularly relates to a surface treatment system for manufacturing an LED liquid crystal display screen. The system comprises a transmission mechanism, a fixing mechanism, a film rolling mechanism, a film coating mechanism and a cutting mechanism, wherein the transmission mechanism comprises a first driving motor, a main transmission belt, a slave transmission belt, supporting legs, supporting frames, transmission rollers and a conveyor belt, the fixing mechanism comprises a fixing plate, a C-shaped baffle,a telescopic air cylinder and a material abutting plate, the film rolling mechanism comprises a C-shaped frame, a fixing rod, a first conveying roller set, a second conveying roller set, a guide roller set, a film rolling rod and a rotating motor, the film coating mechanism comprises a supporting plate, a second driving motor, a driving gear, a driven gear, a driving plate gear, a pressing rod, apressing block, a sliding block and a limiting rod, and the cutting mechanism comprises an electric push-pull rod and a cutter. The system has the advantages of being high in film laminating speed, high in film laminating efficiency, and low in cost when a large number of LED display screens are subjected to film laminating operation.

Owner:黄浩

Paper transferring vertical lapping device of full-automatic laminating machine

InactiveCN106081695ASimple structureReduce manufacturing costArticle deliveryWebs handlingPulp and paper industryEngineering

The invention relates to laminating equipment, in particular to a paper transferring vertical lapping device of a full-automatic laminating machine. According to the technical scheme, the paper transferring vertical lapping device of the full-automatic laminating machine comprises a machine body, a paper fetching mechanism, a paper transferring mechanism and a lapping mechanism, wherein the paper fetching mechanism, the paper transferring mechanism and the lapping mechanism are arranged on the machine body; the paper transferring mechanism comprises at least one transferring roller; the lapping mechanism comprises a lapping roller erected on the machine body and a lapping pressing wheel which can swing along with rotation of the lapping roller; a lapping conveying roller is arranged between the lapping pressing wheel and the machine body; driving sources used for independently driving the transferring roller and the lapping conveying roller are arranged in the position of the transferring roller and in the position of the lapping conveying roller of the machine body correspondingly; and a paper distance inductor used for detecting the paper distance and can output acceleration signals and deceleration signals to the driving sources is arranged in the position of the lapping mechanism. By the adoption of the technical scheme, the paper transferring vertical lapping device of the full-automatic laminating machine is capable of reducing production cost and improving the processing efficiency and simple in structure.

Owner:瑞安市裕强印刷机械有限公司

Diaphragm unwinding mechanism and diaphragm unwinding method

ActiveCN112234311BAvoid damageEasy tension adjustmentFinal product manufactureSecondary cellsManufacturing technologyCell fabrication

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

A magnetic pole marking detection and stacking device

ActiveCN106140657BNo human intervention requiredLaminating speed is fastStacking articlesSortingMagnetic polesFlow time

Owner:杭州科德磁业有限公司

The upper and lower lap device for paper conveying of automatic laminating machine

InactiveCN106081695BSimple structureReduce manufacturing costArticle deliveryWebs handlingInductorPulp and paper industry

The invention relates to laminating equipment, in particular to a paper transferring vertical lapping device of a full-automatic laminating machine. According to the technical scheme, the paper transferring vertical lapping device of the full-automatic laminating machine comprises a machine body, a paper fetching mechanism, a paper transferring mechanism and a lapping mechanism, wherein the paper fetching mechanism, the paper transferring mechanism and the lapping mechanism are arranged on the machine body; the paper transferring mechanism comprises at least one transferring roller; the lapping mechanism comprises a lapping roller erected on the machine body and a lapping pressing wheel which can swing along with rotation of the lapping roller; a lapping conveying roller is arranged between the lapping pressing wheel and the machine body; driving sources used for independently driving the transferring roller and the lapping conveying roller are arranged in the position of the transferring roller and in the position of the lapping conveying roller of the machine body correspondingly; and a paper distance inductor used for detecting the paper distance and can output acceleration signals and deceleration signals to the driving sources is arranged in the position of the lapping mechanism. By the adoption of the technical scheme, the paper transferring vertical lapping device of the full-automatic laminating machine is capable of reducing production cost and improving the processing efficiency and simple in structure.

Owner:瑞安市裕强印刷机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com