Production method of laminated cells

A manufacturing method and laminated technology, which is applied in secondary battery manufacturing, final product manufacturing, winding/folding electrodes, etc., can solve problems such as low efficiency of lamination process, coating peeling off, affecting battery performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment provides a method for manufacturing a stacked battery cell for producing a single battery cell, including:

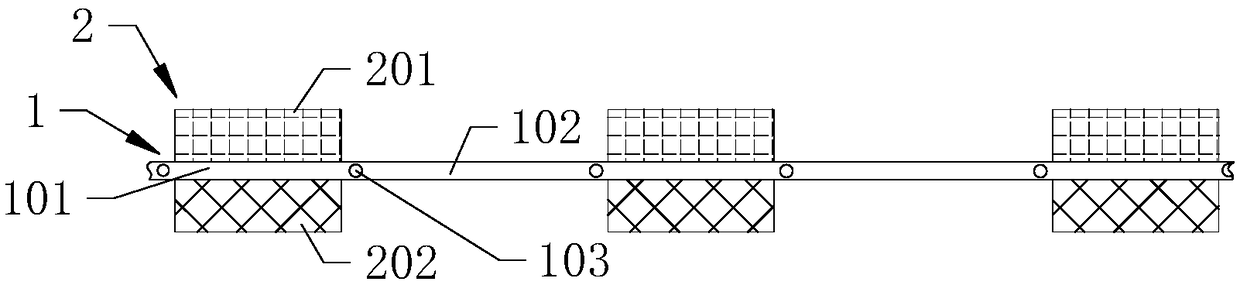

[0036] S10: Provide as figure 1 As shown in the diaphragm 1, the diaphragm 1 is marked with a number of reference lines 103 along its length direction. The reference line 103 divides the diaphragm 1 into a number of equally spaced lamination segments 101, and the interval between two adjacent lamination segments 101 102 , the length dimension of a spacer section 102 is greater than the length dimension of a section of cladding section 101 .

[0037] Specifically, the length dimension of a spacer section 102 is equal to the thickness dimension of a group of positive electrode modules 201 , the sum of the length dimension of a group of positive electrode modules 201 and the thickness dimension of a group of negative electrode modules 202 . Certainly, the length dimension of a spacer section 102 may also be slightly larger than the sum of the thickn...

Embodiment 2

[0045] This embodiment provides a method for manufacturing laminated batteries for synchronous production of multiple single batteries, including:

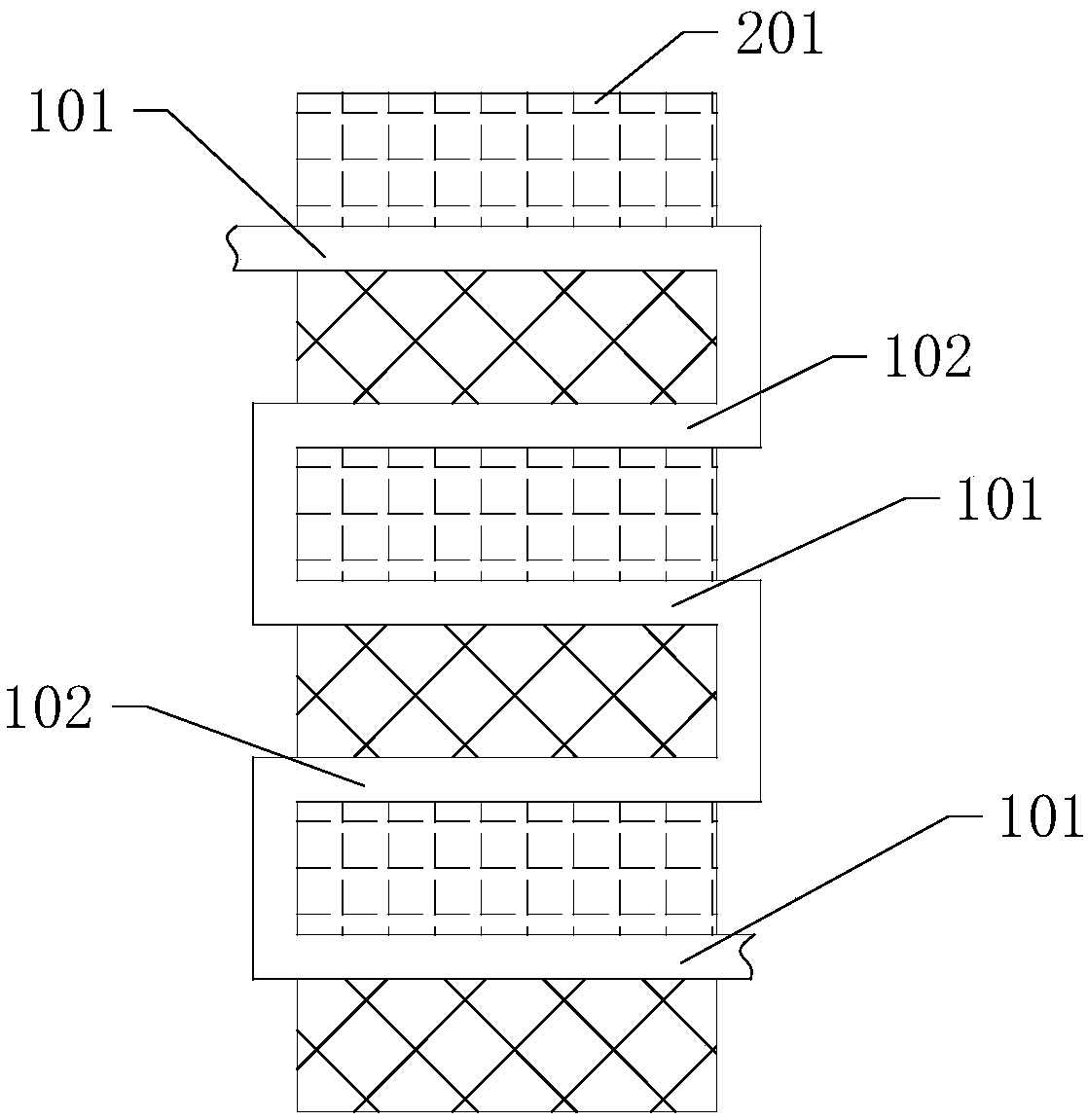

[0046] S10: if image 3 As shown, the diaphragm 1 is divided into a plurality of covering segments 101 distributed at equal intervals. Between two adjacent covering segments 101 is a spacer section 102 .

[0047] Specifically, the length dimension of a spacer section 102 is equal to the thickness dimension of a group of positive electrode modules 201 , the sum of the length dimension of a group of positive electrode modules 201 and the thickness dimension of a group of negative electrode modules 202 . Certainly, the length dimension of a spacer section 102 may also be slightly larger than the sum of the thickness dimension of a group of positive electrode modules 201 , the length dimension of a group of positive electrode module groups 201 , and the thickness dimension of a group of negative electrode module groups 202 .

[0048]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com