Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

262results about How to "Increase the pressing force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

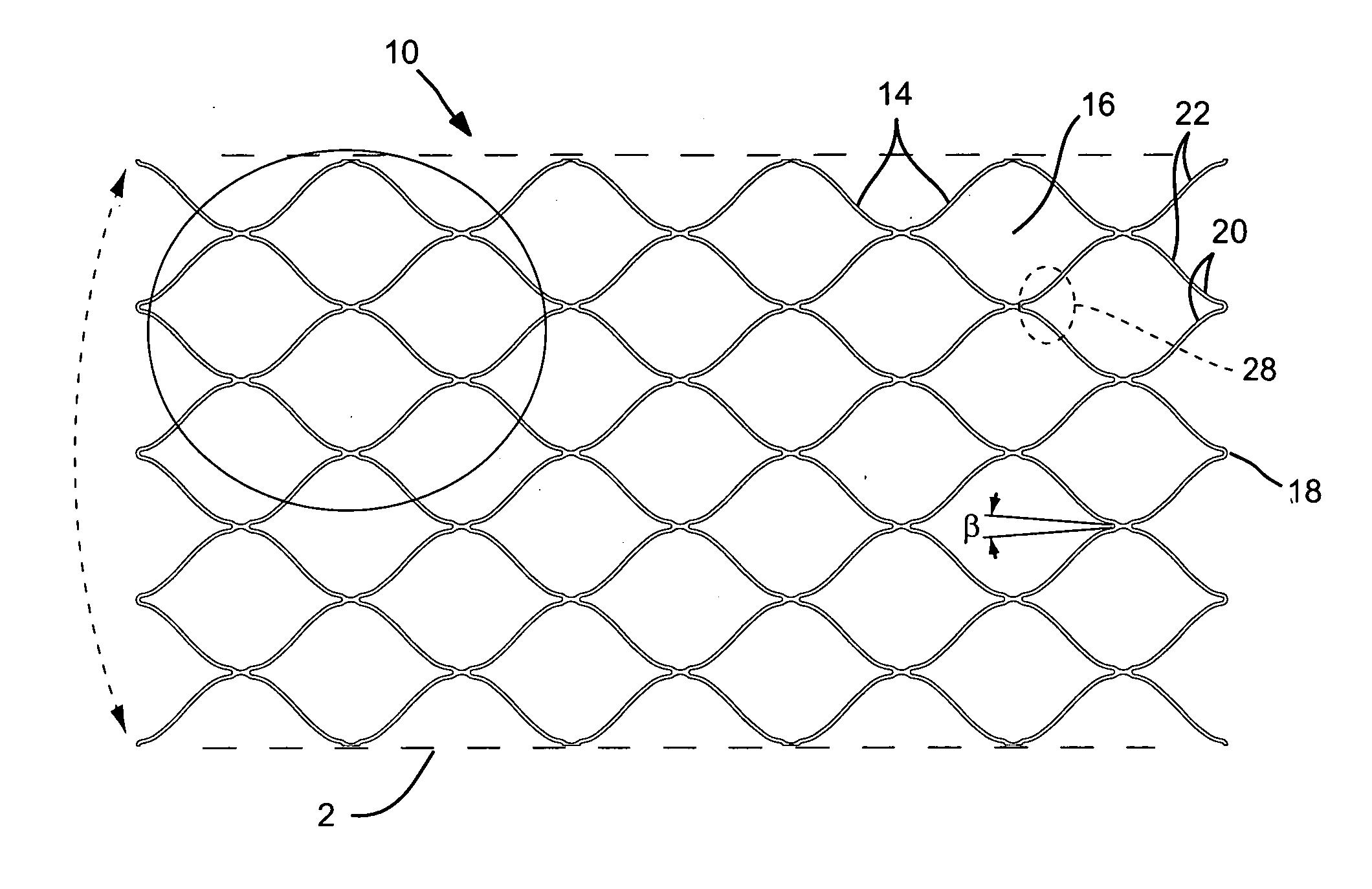

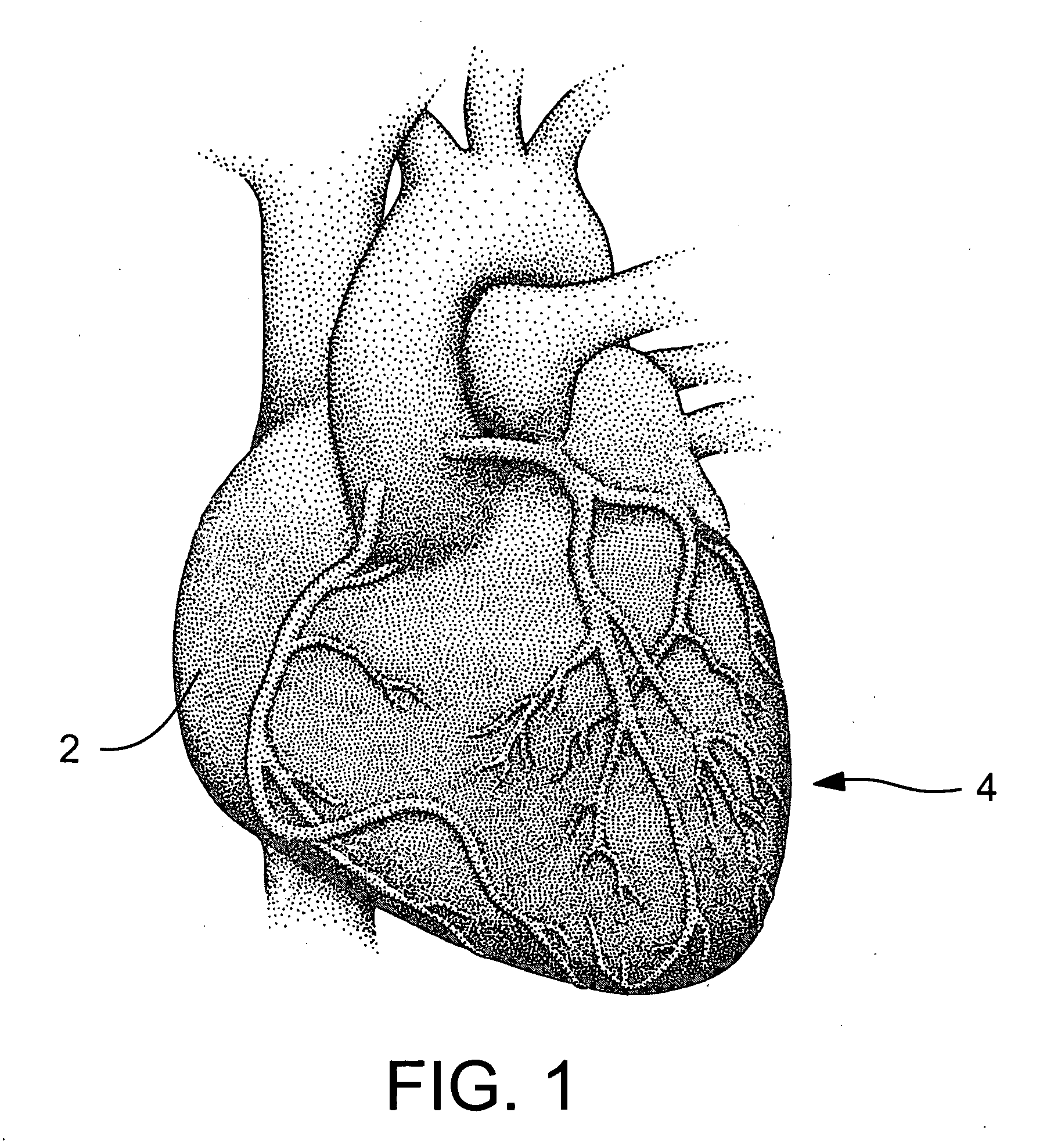

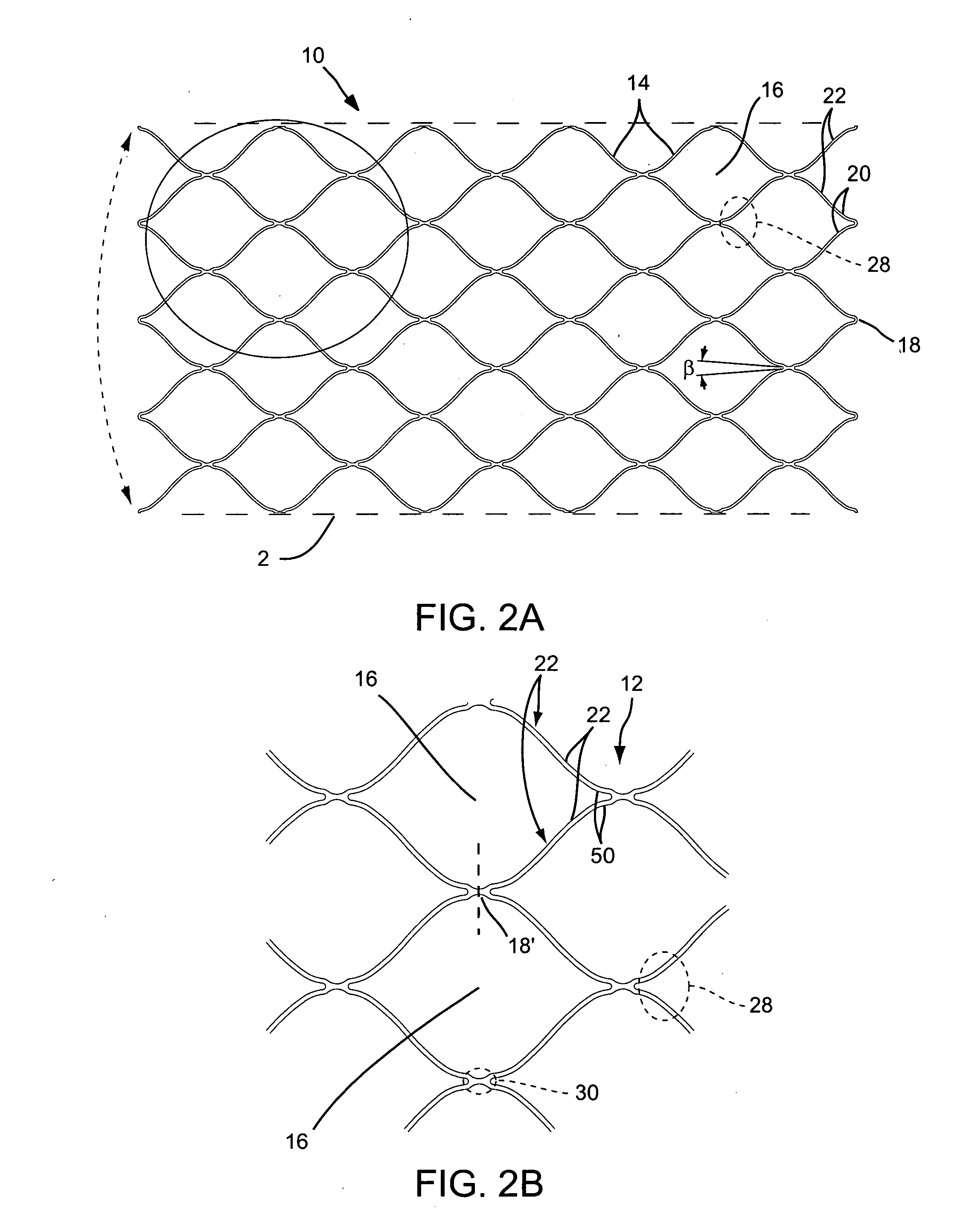

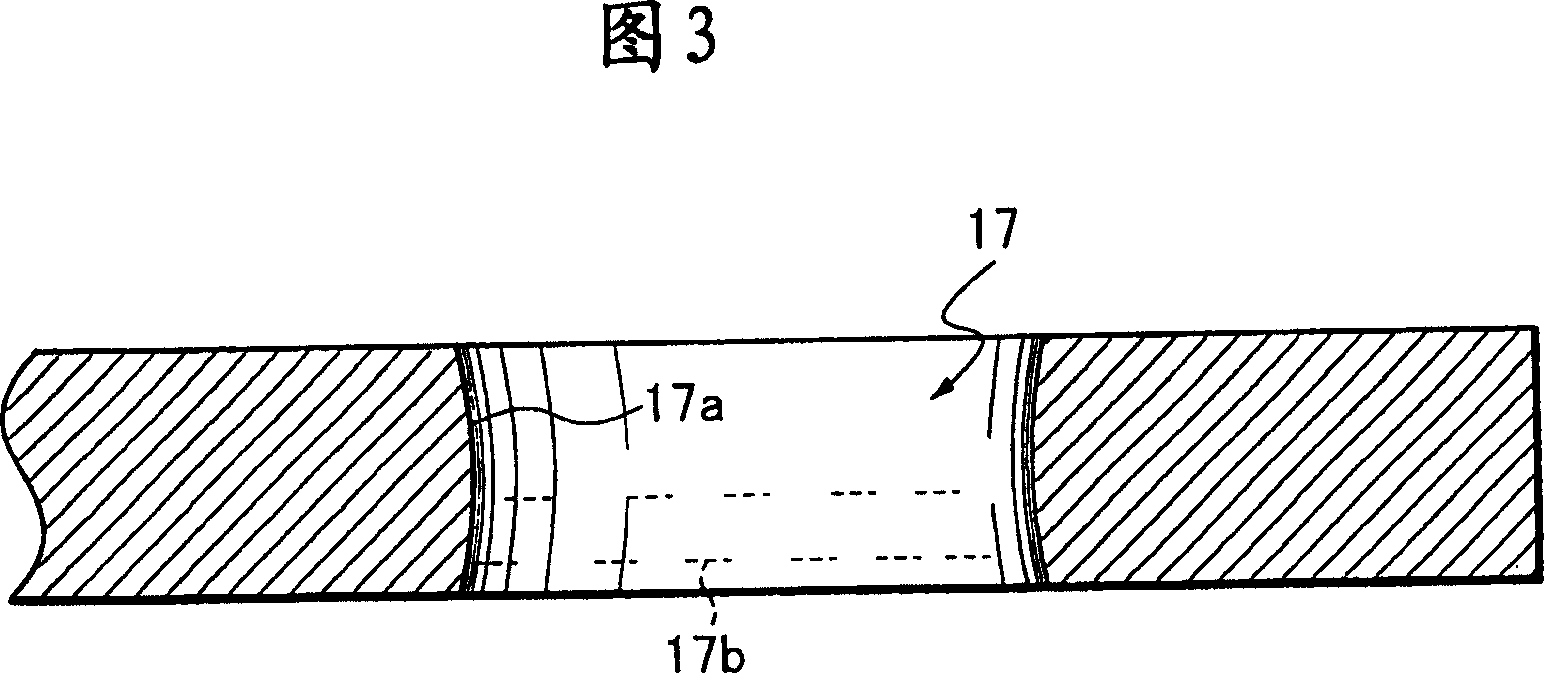

Small vessel stent designs

Medical device and methods for delivery or implantation of prostheses within hollow body organs and vessels or other luminal anatomy are disclosed. The subject technologies may be used in the treatment of atherosclerosis in stenting procedures.

Owner:BIOSENSORS INT GROUP

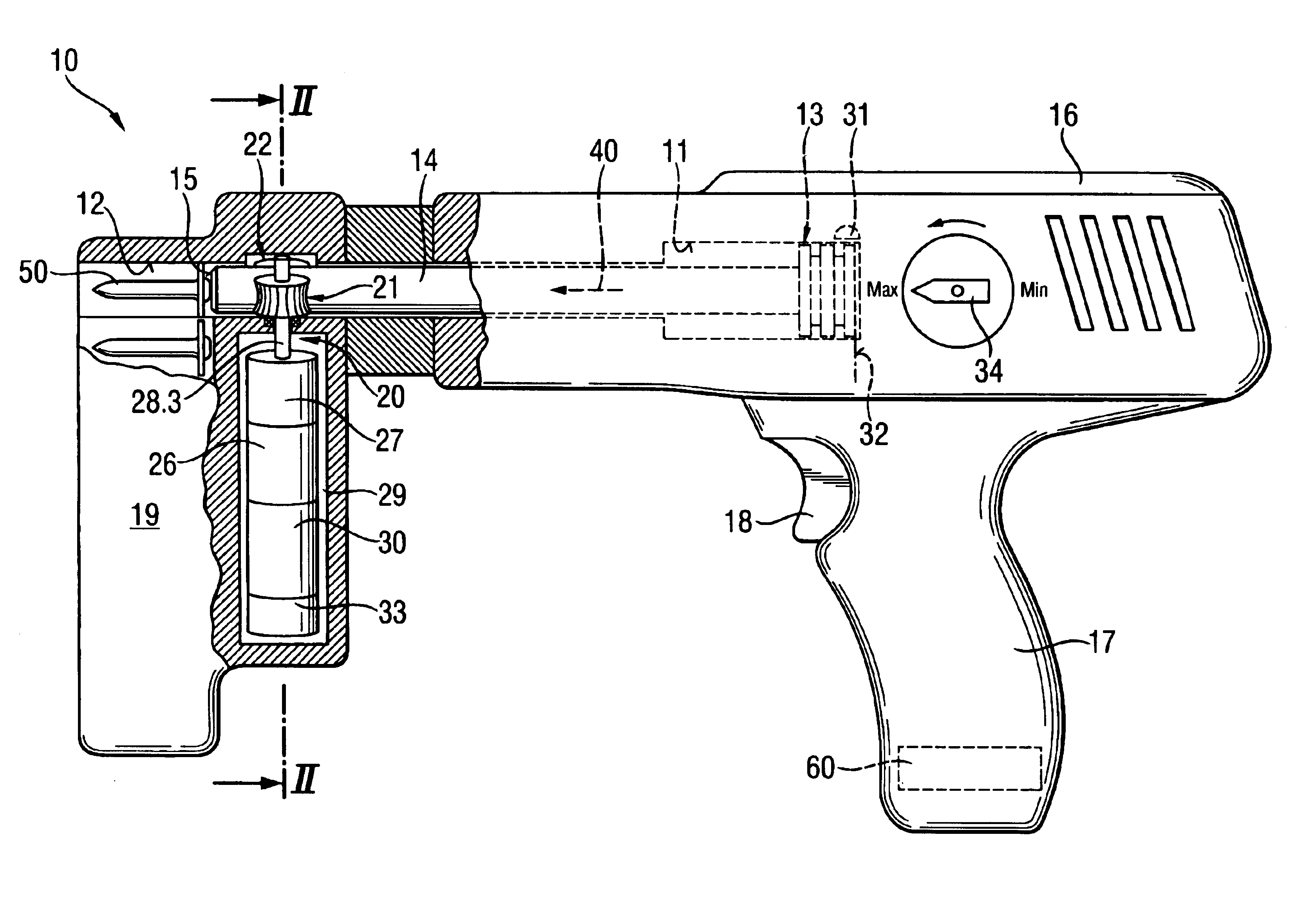

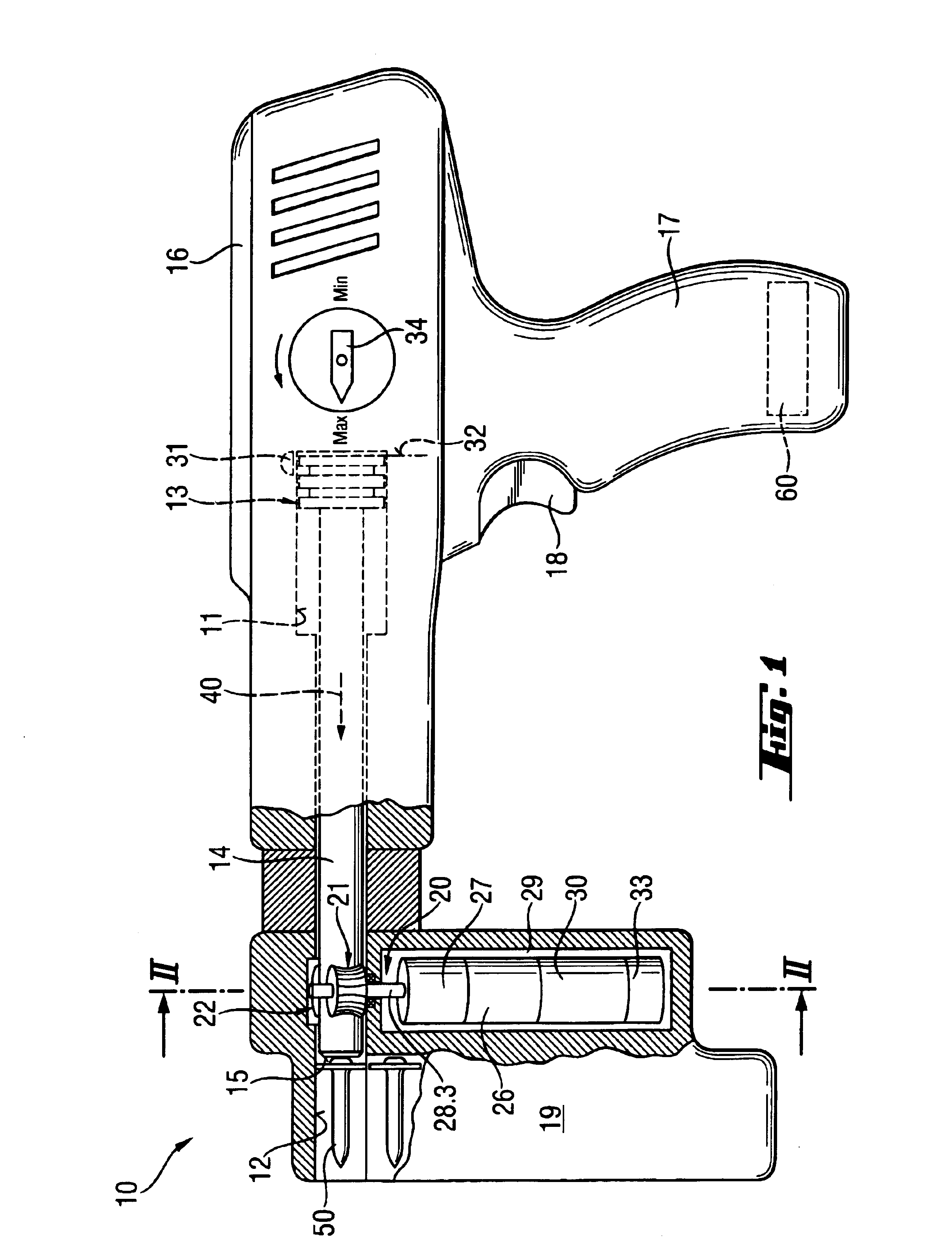

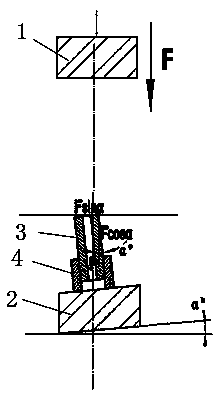

Setting tool

ActiveUS6938811B2Increase the pressing forceReliable returnStapling toolsNailing toolsPiston GuideEngineering

A setting tool for driving in fastening elements includes a drive piston (13) displaceable in a piston guide (11) between its initial (32) and setting positions, and device for returning the drive piston (13) in its initial position upon completion of a setting process and having an electromotive drive (30) and a transmission (20) for transmitting a motive actuating torque to the drive piston (13).

Owner:HILTI AG

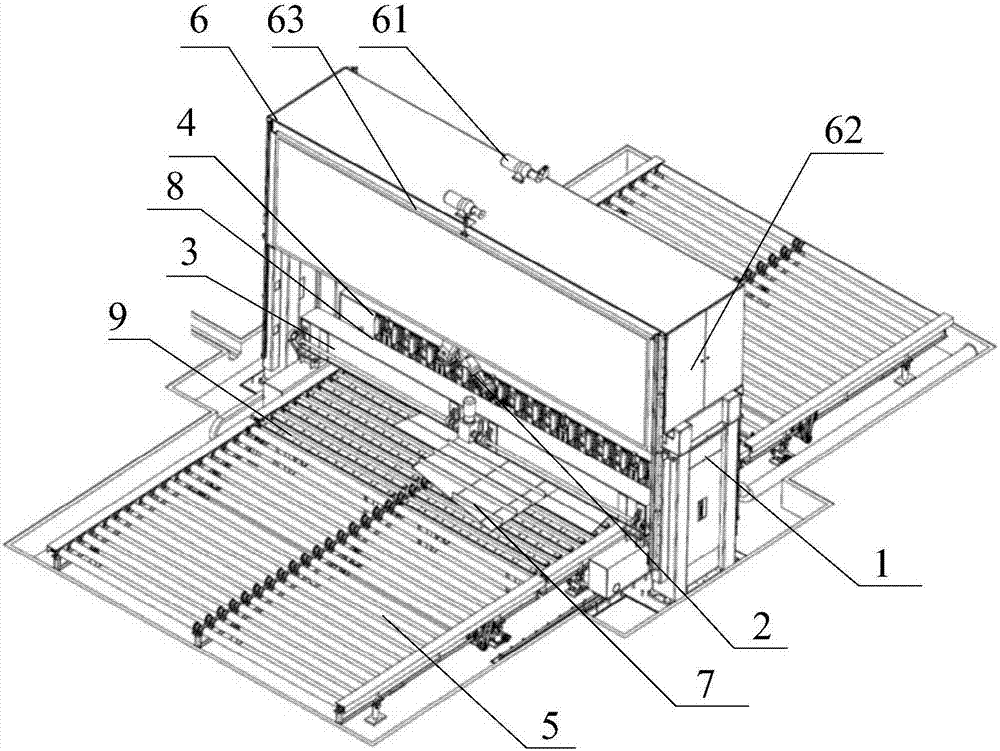

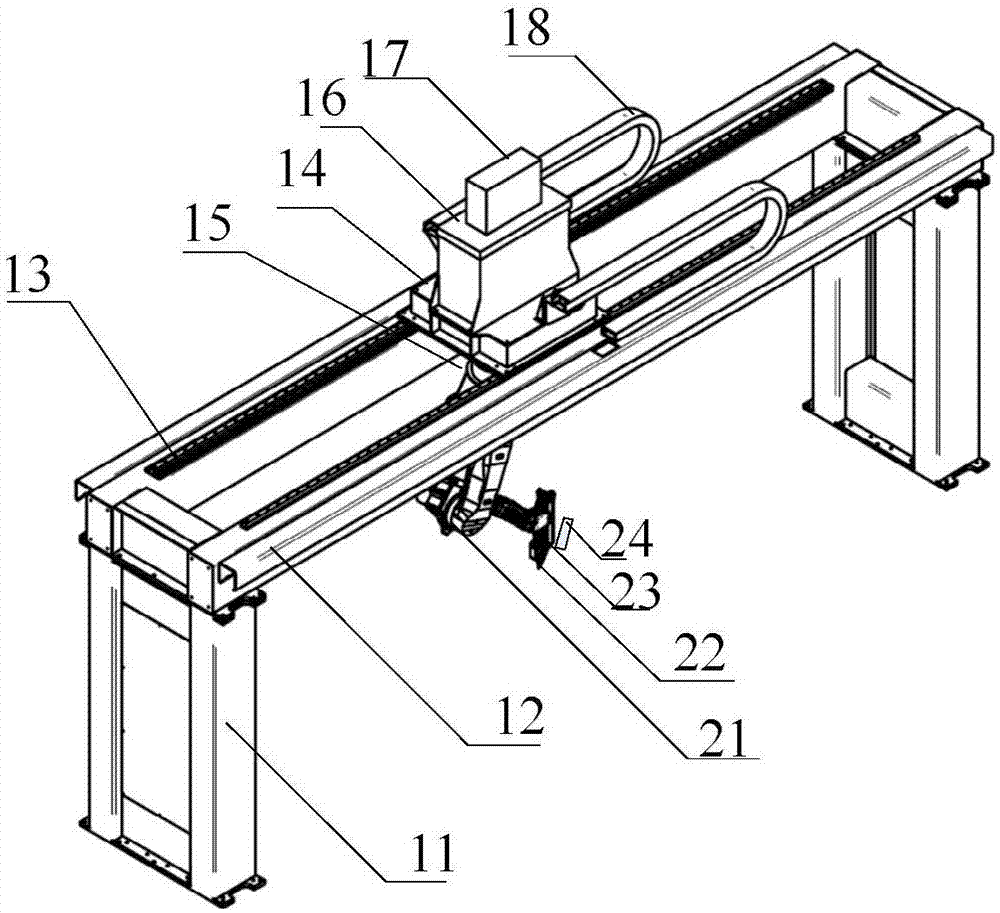

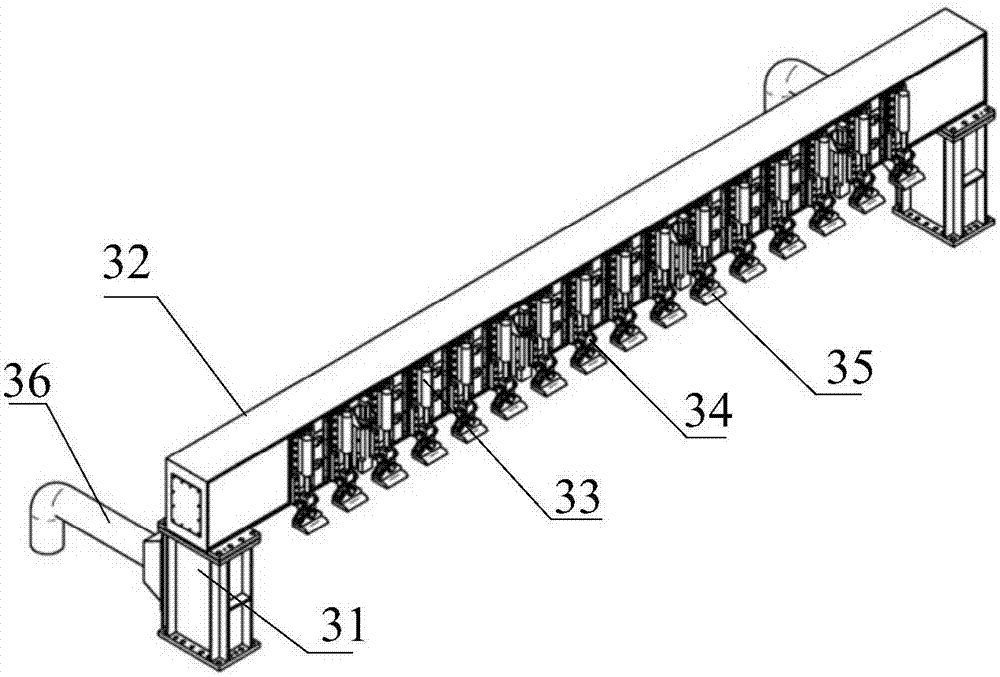

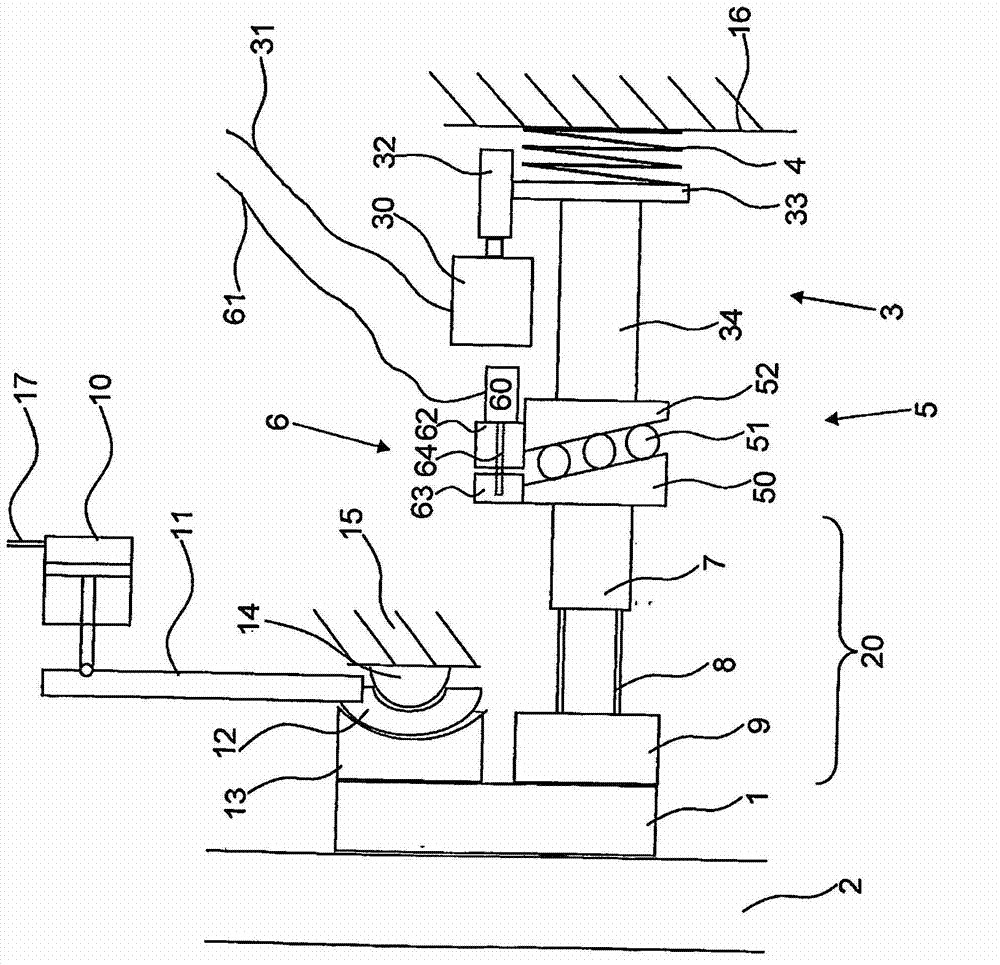

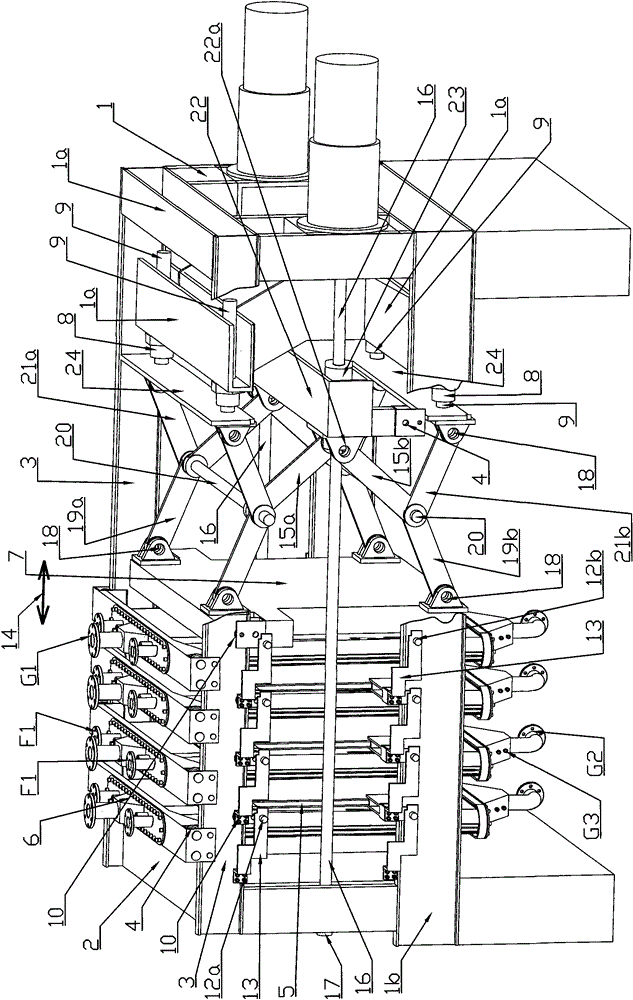

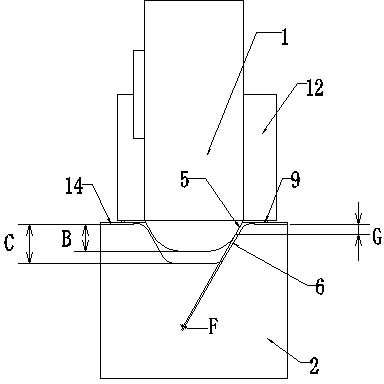

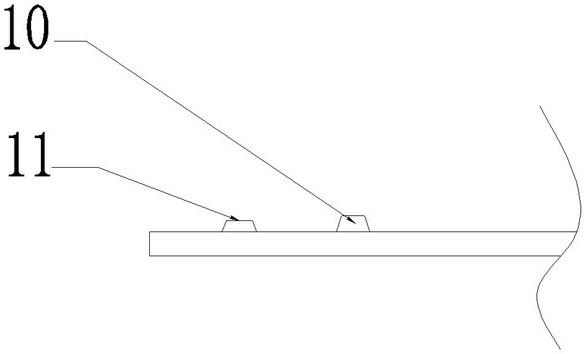

Laser splice welding system for high-strength steel structure thin plates

ActiveCN107363405AIncrease the pressing forcePrevent workpiece deformationLaser beam welding apparatusElectric arcPortal frame

The invention provides a laser splice welding system for high-strength steel structure thin plates. The laser splice welding system comprises a welding portal frame and the like. A fixed pressing device, a movable pressing device and a welding platform are all located below the welding portal frame. The fixed pressing device and the movable pressing device are located on the two sides of the workpiece welding platform correspondingly. A transversely-moving trolley is arranged on the welding portal frame, a robot level laser composite welding system is fixed to the position below the transversely-moving trolley, and a workpiece transferring device is located on the side faces of a front welding material frame and a rear welding material frame. The welding portal frame is sleeved with a laser protective door, and the front welding material frame and the rear welding material frame are located below one side of the fixed pressing device. According to the laser splice welding system for the high-strength steel structure thin plates, the diversified welding methods such as self-fusible welding, laser filler wire welding and laser electric-arc hybrid welding can be achieved, automatic locating can be conducted before welding; and in the welding process, real-time tracing of welding joints can be achieved, the welding technological parameters are adjusted in real time according to slope gap and misalignment changing, and self-adaptation filling of welding wires is achieved. According to the laser splice welding system, teaching programming is easy, and operating is convenient.

Owner:SHANGHAI JIAO TONG UNIV +2

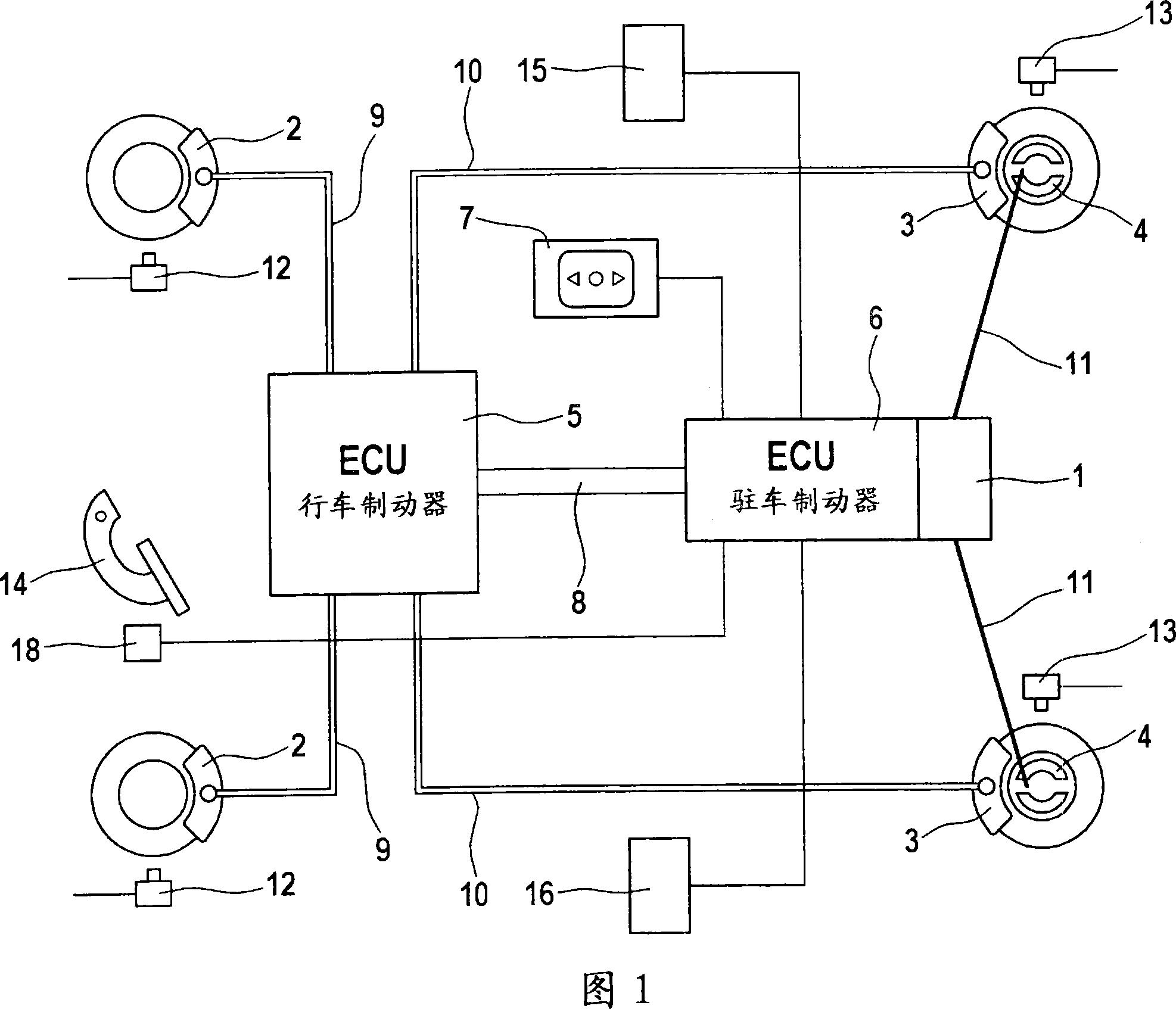

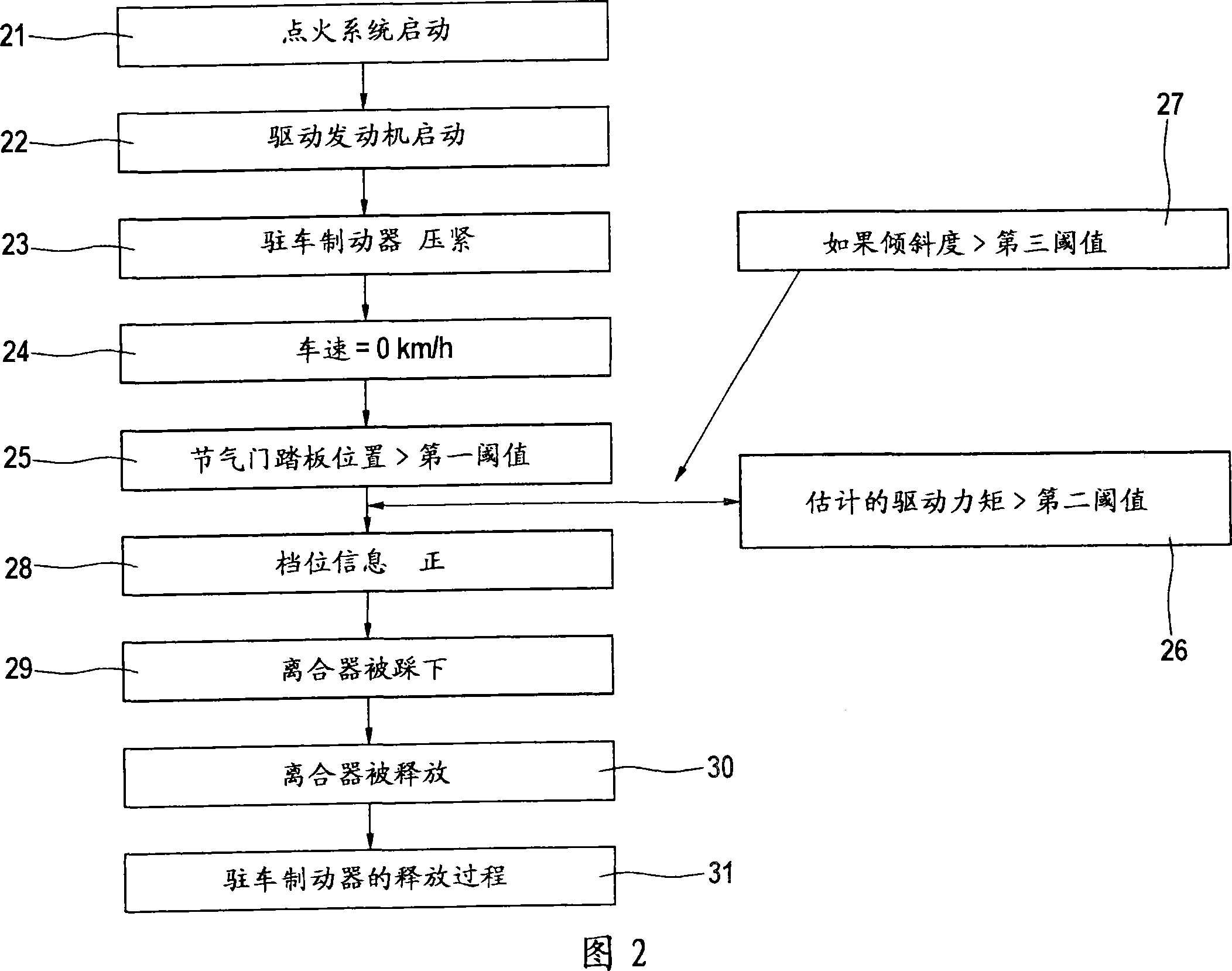

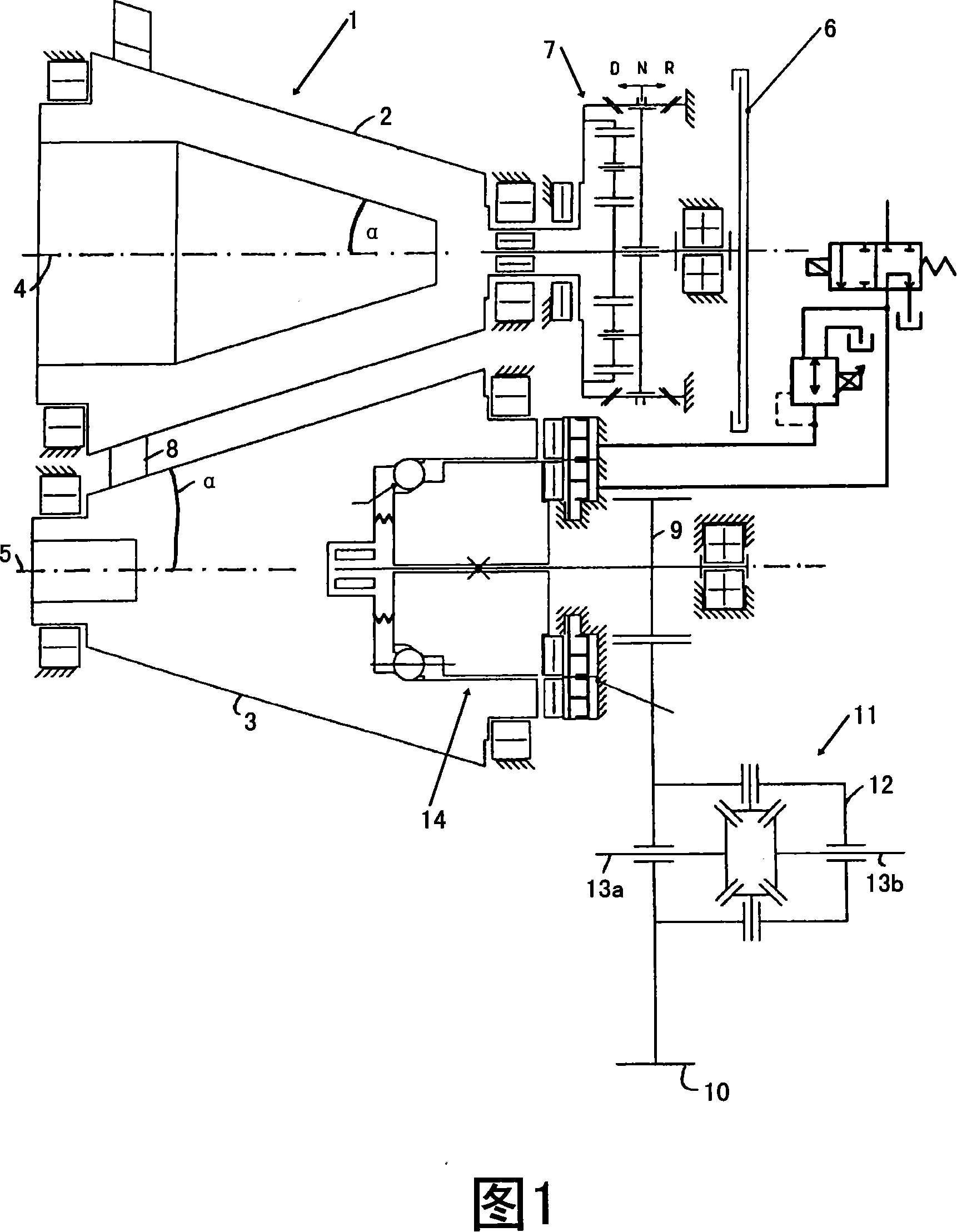

Method for operation of a braking system for a motor vehicle

InactiveCN1993257AIncrease the pressing forceStrong pressing forceBraking action transmissionAutomatic initiationsAutomotive engineeringDrive motor

The invention relates to a method for operation of an electromechanically-operated parking brake for motor vehicles with a drive motor provided with a mechanical manual gearbox, essentially comprising an operating element, an electronic controller, provided with wheel rotational speed values from wheel rotational speed sensors, at least one unit for generation of an application force and braking devices applied by the unit on at least one axle, whereby the electronic controller operates the unit, after recognition of a starting procedure for the motor vehicle, in the manner of a release process for the parking brake. According to the invention, a release process for the parking brake, after recognition of a starting process, may be configured to be as convenient as possible, whereby, on recognition of a starting process and before carrying out the release process for the parking brake, the electronic controller 6a operates the unit 1 such as to reduce the application force to a slope-dependent holding force.

Owner:CONTINENTAL TEVES AG & CO OHG

Wind turbine with element for sealing two parts that can be rotated in relation to one another

InactiveCN101258345AProtection against mechanical impact of impactIncrease the pressing forceEngine sealsShaftsTurbinePhysics

Owner:IMO HOLDING GMBH

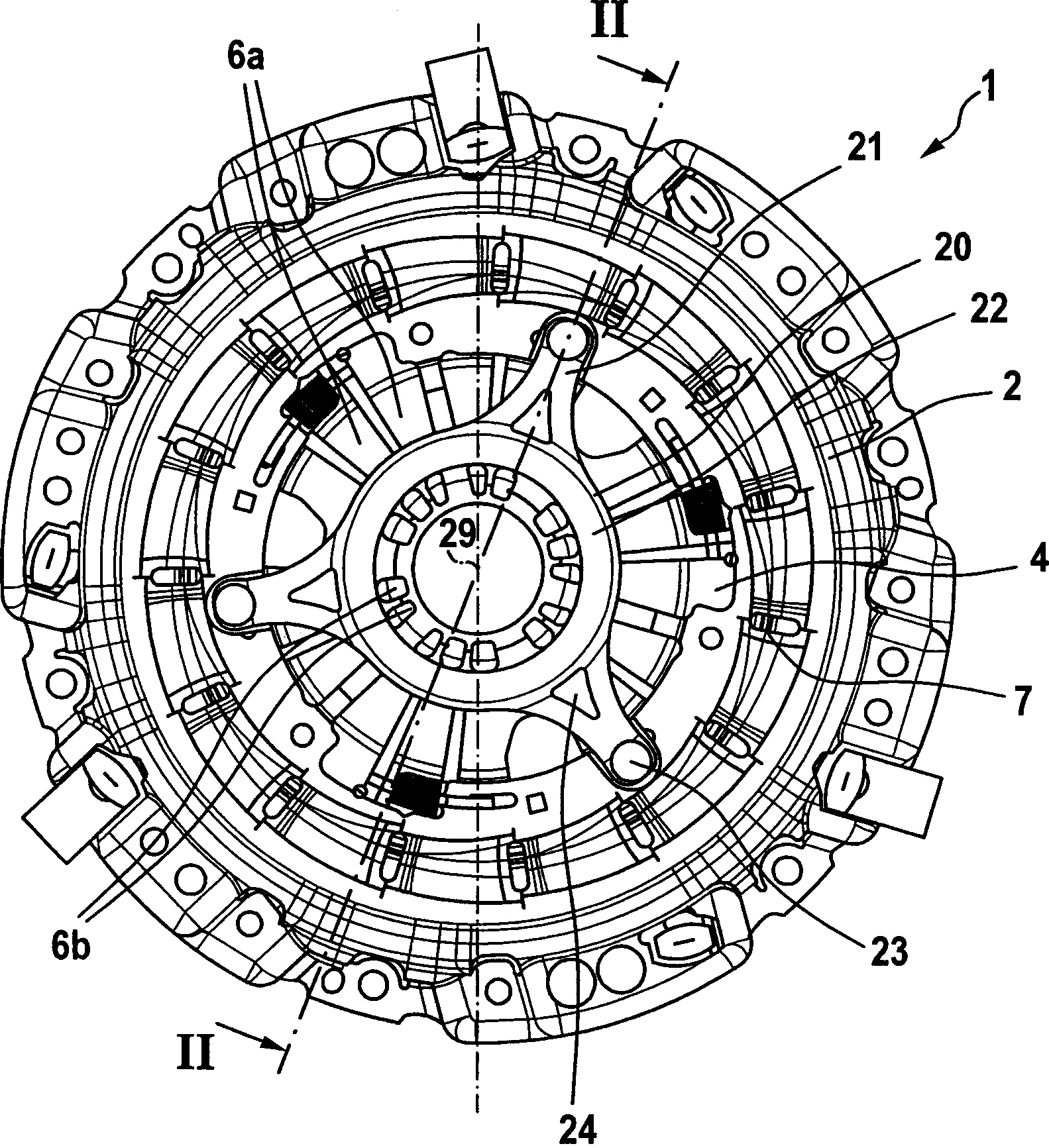

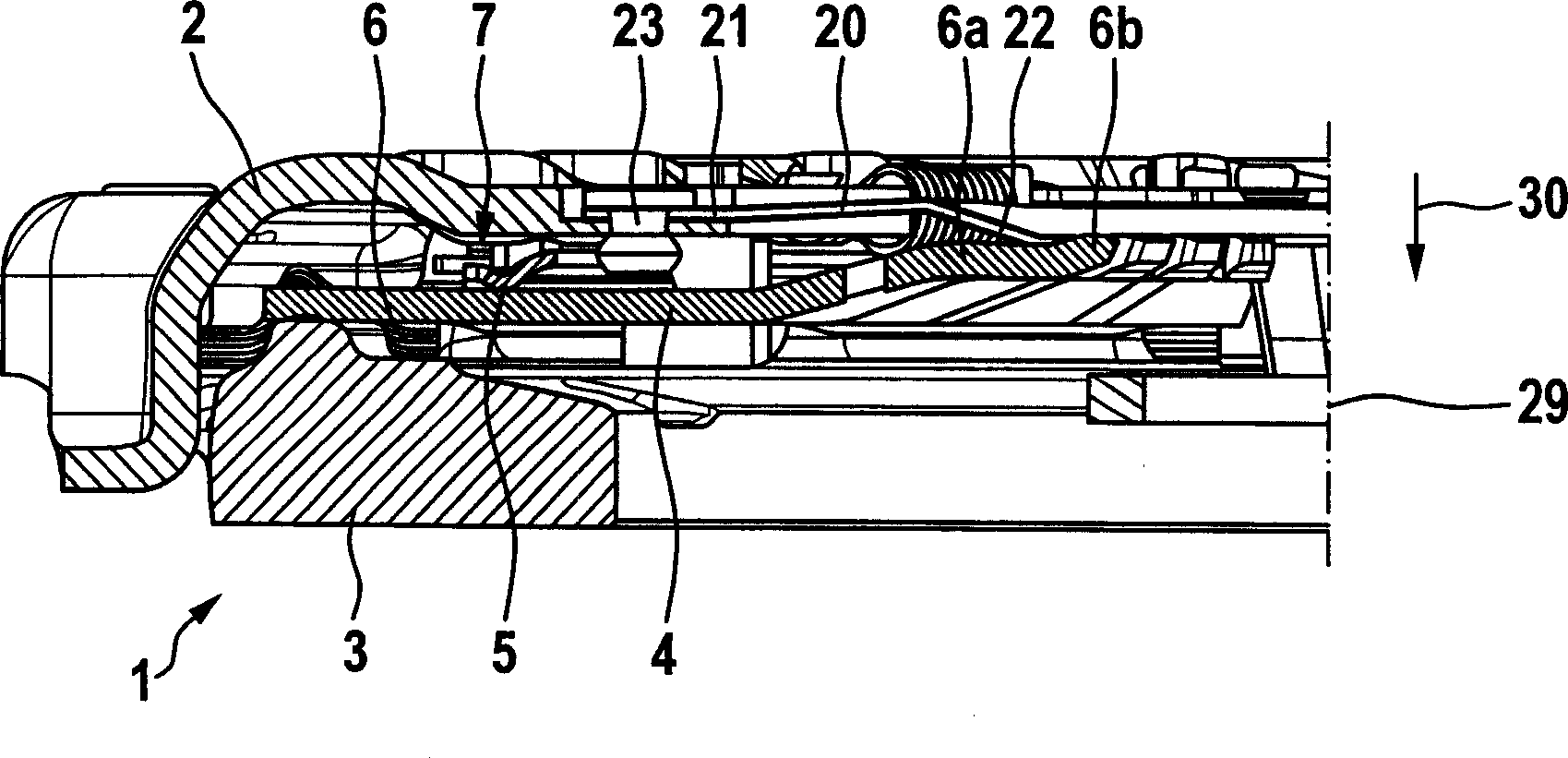

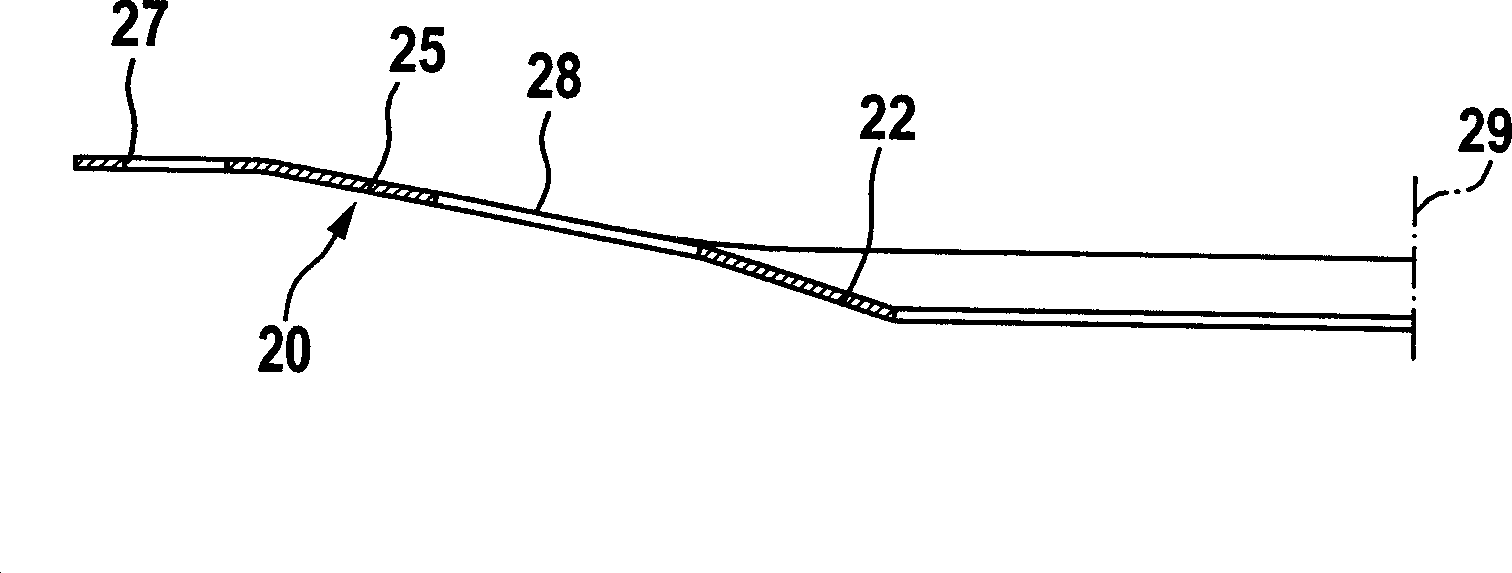

Friction clutch

The invention relates to a slip clutch, in particular to be used in autobus, which comprises a clamp plate that doesn't have relative movement to the housing but has finite axial movement. The clamp plate is positioned in condition that the slip clutch is installed in a flywheel through a pivoted saucer spring which supports in housing and the clutch that is between the flywheel and the clamp plate is loaded from the direction of driven plate.

Owner:SCHAEFFLER TECH AG & CO KG

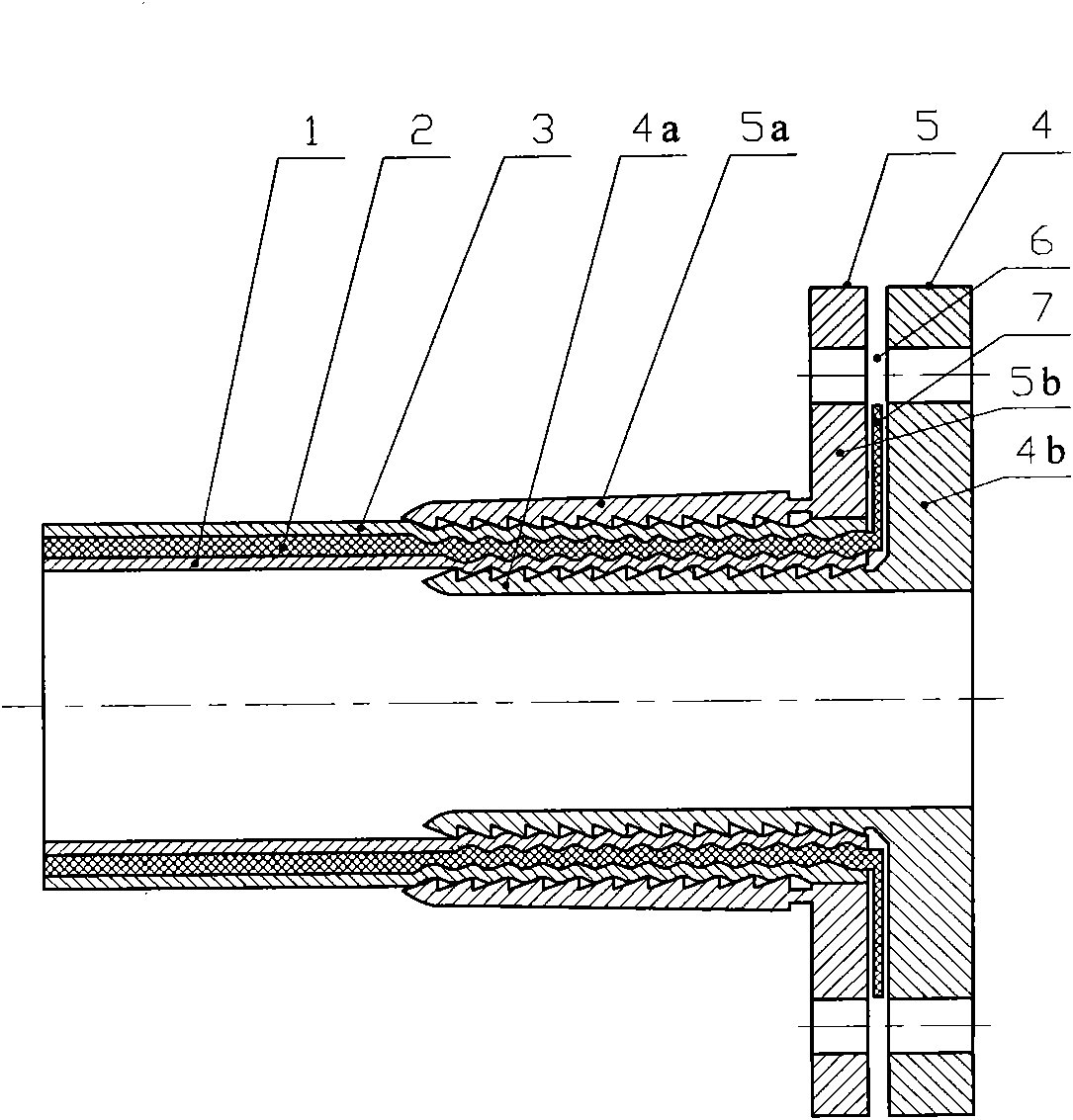

Wire rope enhanced thermoplastic composite pipe heating type buckling and pressing joint and connection method

InactiveCN102313107AConnection setup is solidEasy to operatePipe heating/coolingPipe connection arrangementsEngineeringThermoplastic composites

The invention discloses a wire rope enhanced thermoplastic composite pipe heating type buckling and pressing joint, which comprises a core pipe and an outer pipe, wherein both the core pipe and the outer pipe are L-shaped and are arranged in parallel to each other with a gap; the horizontal section of the core pipe is a core part, and the vertical section of the core pipe is an inner connecting piece; the horizontal section of the outer pipe is a buckling and pressing sleeve, and the vertical section of the outer pipe is an outer connecting piece; and an electrode which can be contacted with a wire rope enhanced layer at the end head of a composite pipe is arranged between the inner connecting piece and the outer connecting piece. The invention also discloses a connection method using thejoint. By buckling and pressing the pipe wall of the composite pipe and clamping the flanged wire rope enhanced layer of the composite pipe, double buckling and pressing effects can be realized and the connection and contact of a steel wire and the electrode are more stable. The joint has a simple structure and is convenient to connect, heat and operate; and the working efficiency and the stability and the reliability for use are greatly improved.

Owner:李志雄

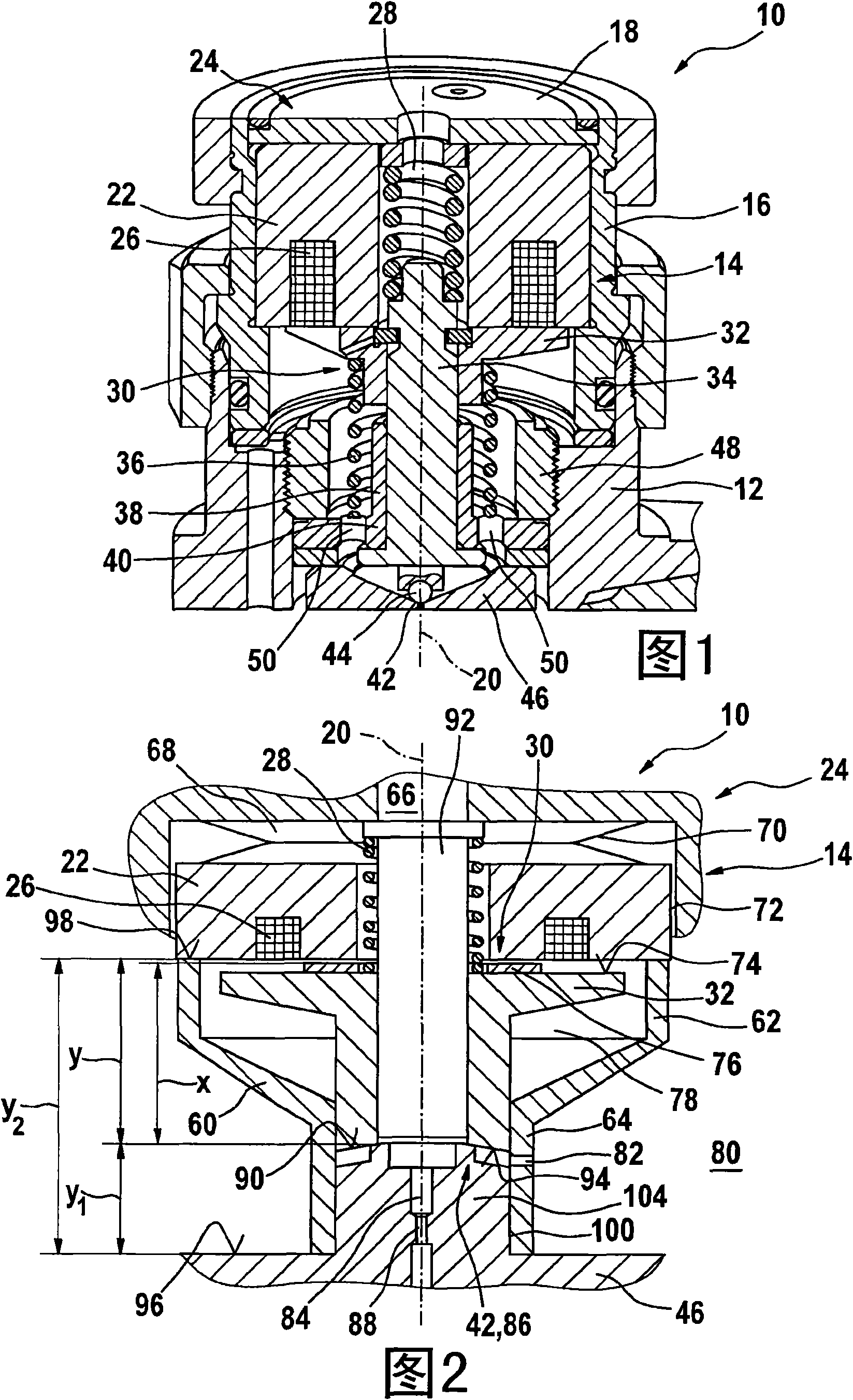

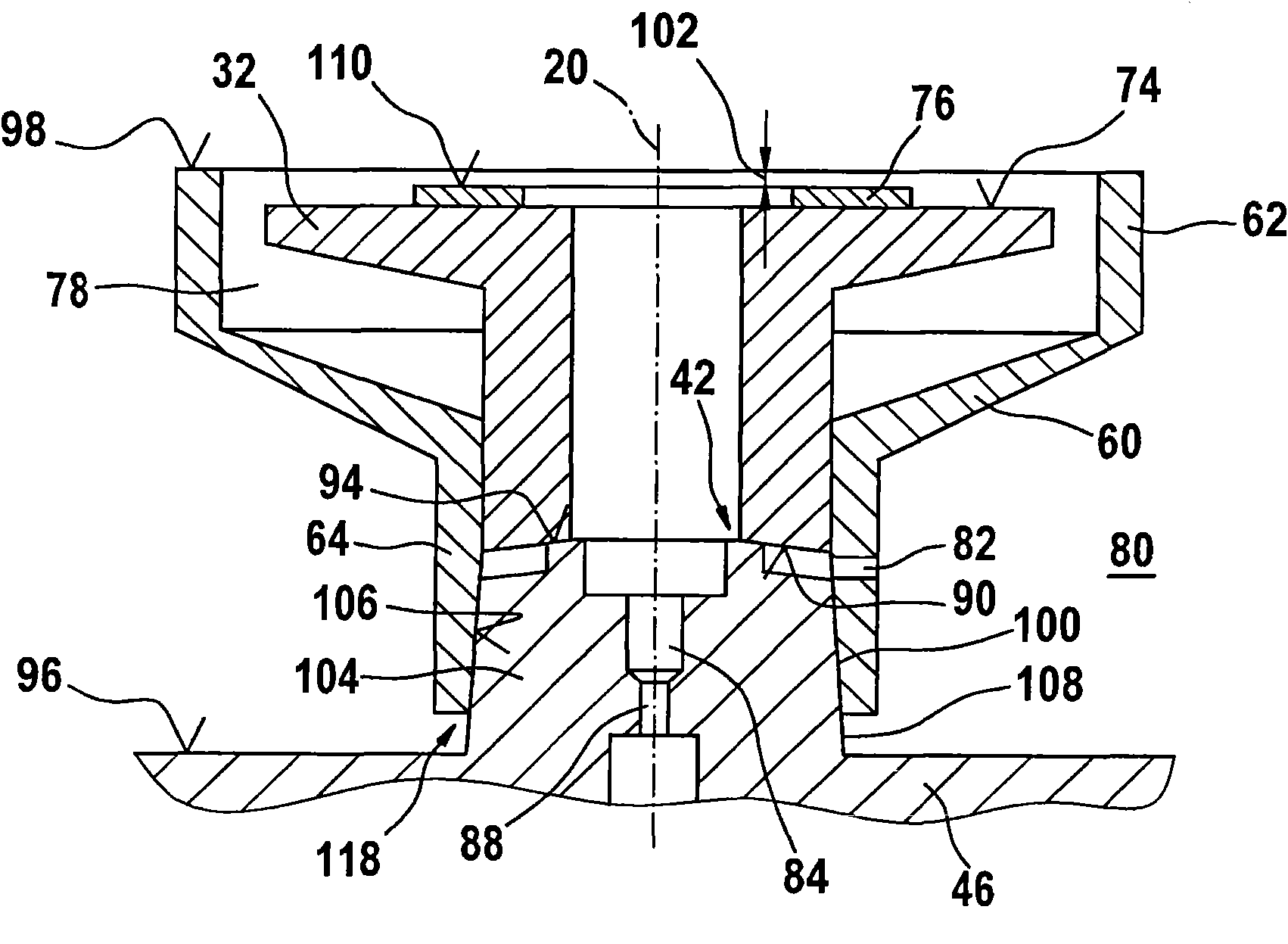

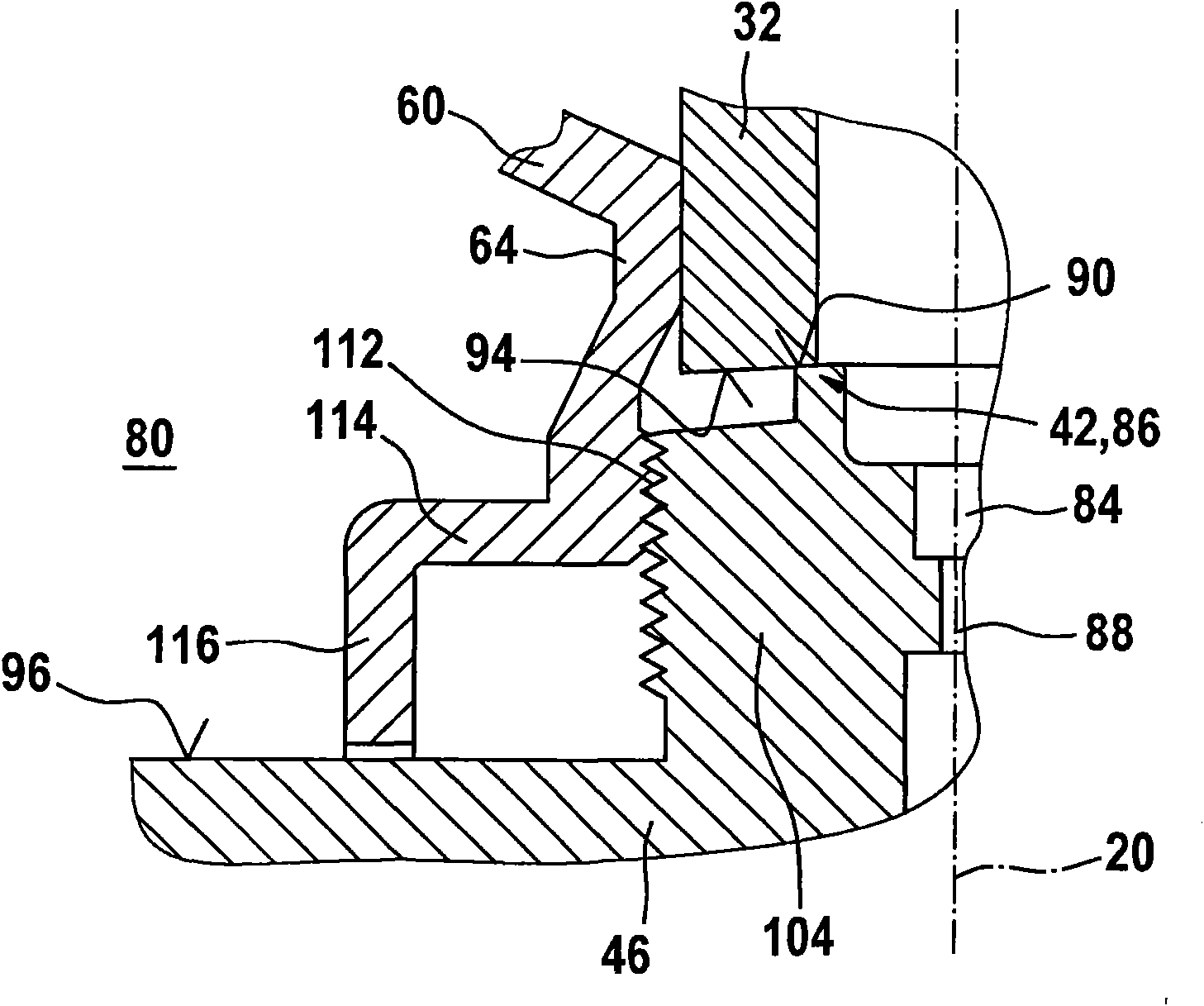

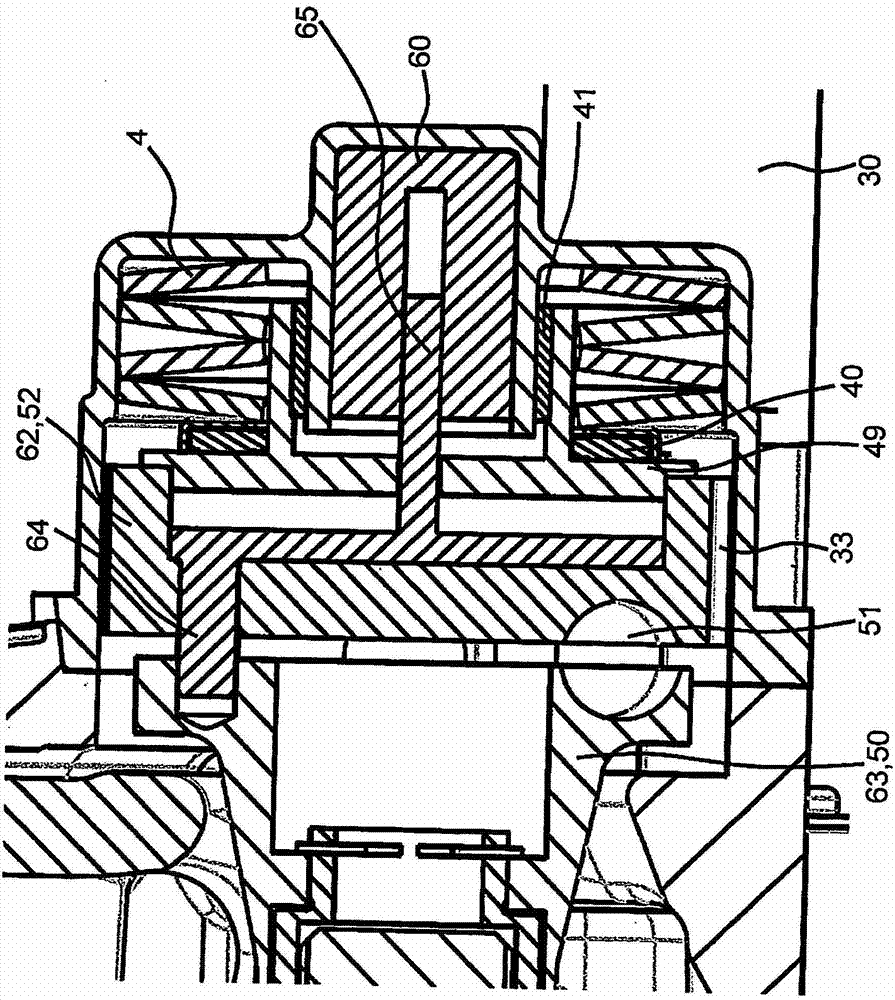

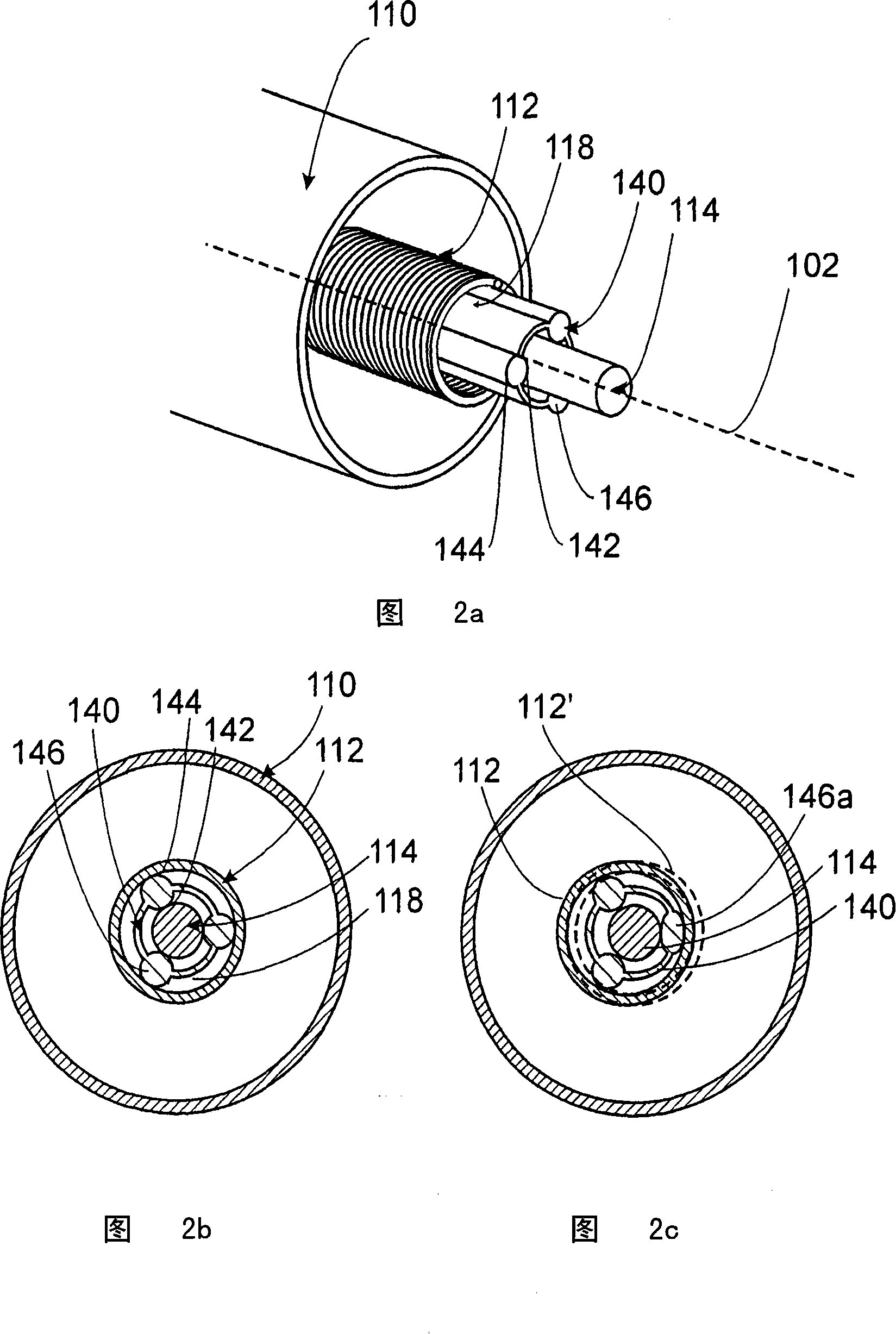

Armature stroke adjustment for solenoid valve

InactiveCN101680406ALittle changeIncrease the pressing forceMachines/enginesFuel injecting pumpsSolenoid valveEngineering

Fuel injector (10) having a holding body (12), into which a solenoid valve (14) is let which actuates an injection valve element of preferably needle-shaped configuration and has an armature assembly(30) which has an armature plate (32) and an armature stroke stop (40), and a sealing seat (42) is opened or closed by the armature assembly (30). A magnetic core (22) of the solenoid valve (14) is supported on a guide sleeve (60, 62, 64) which for its part is received on the valve element (46) such that it encloses a sealing seat (42, 86).

Owner:ROBERT BOSCH GMBH

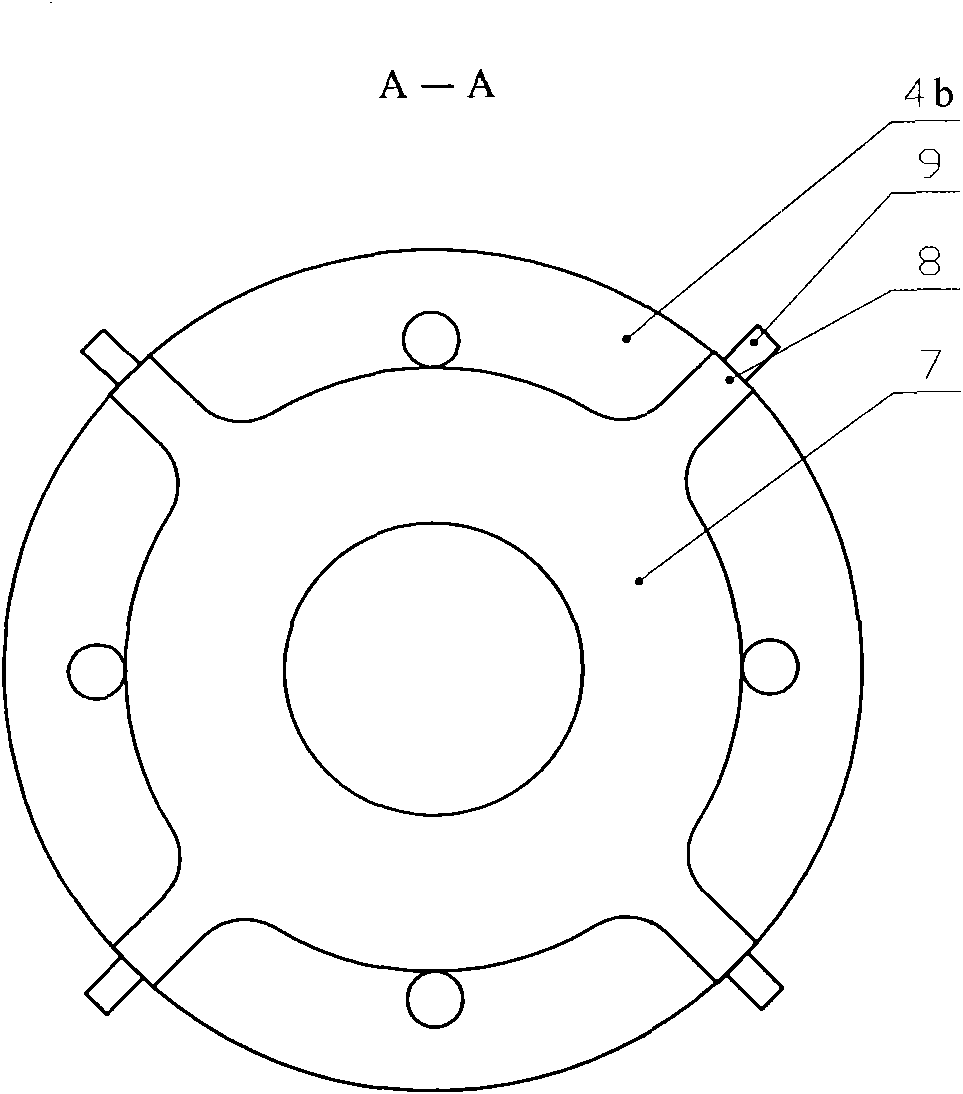

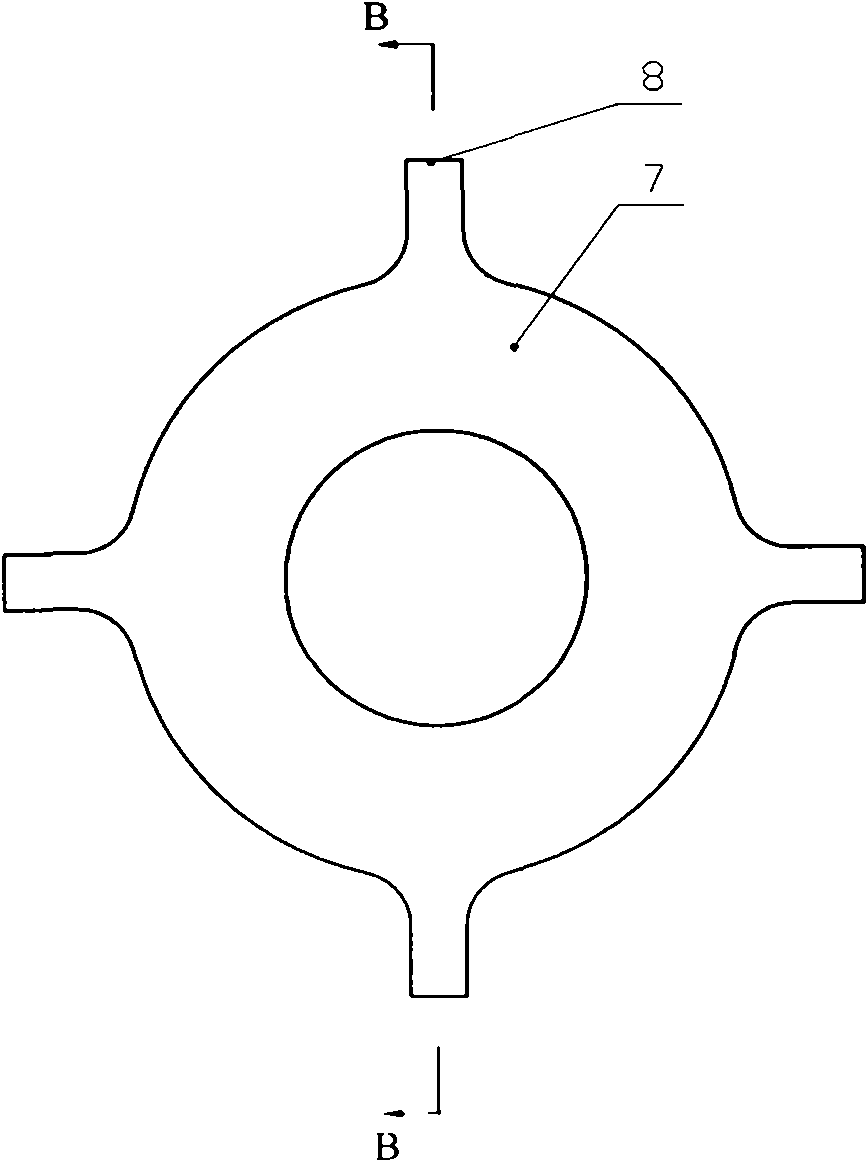

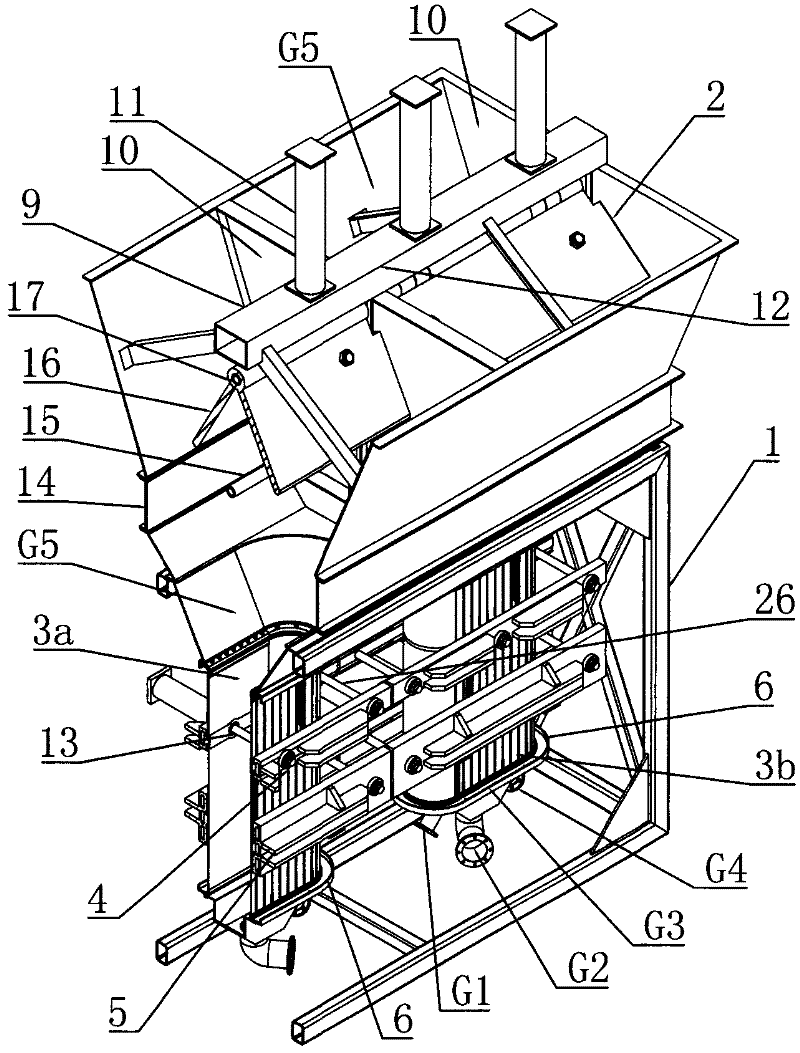

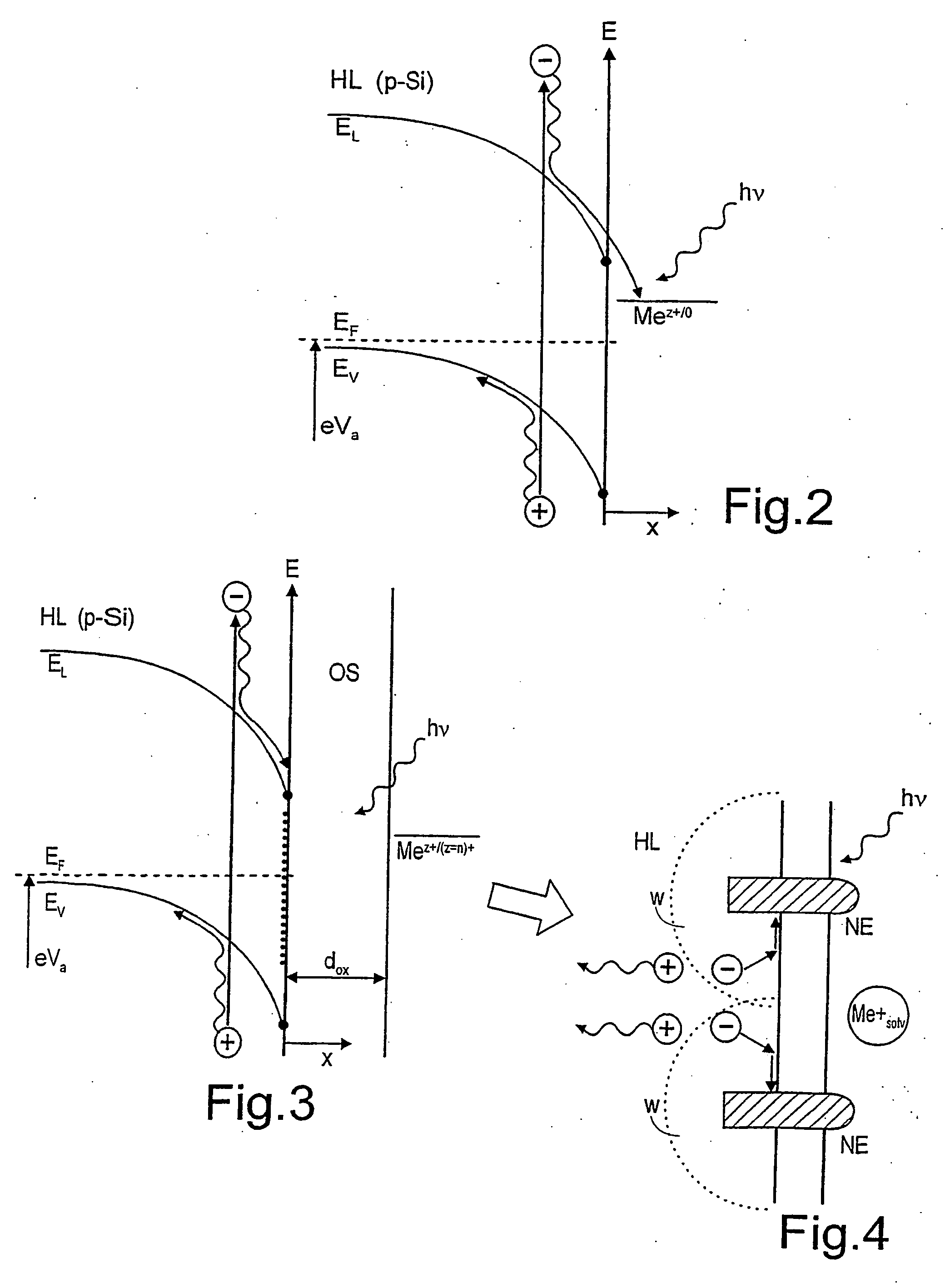

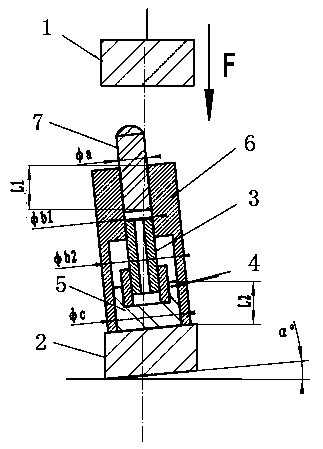

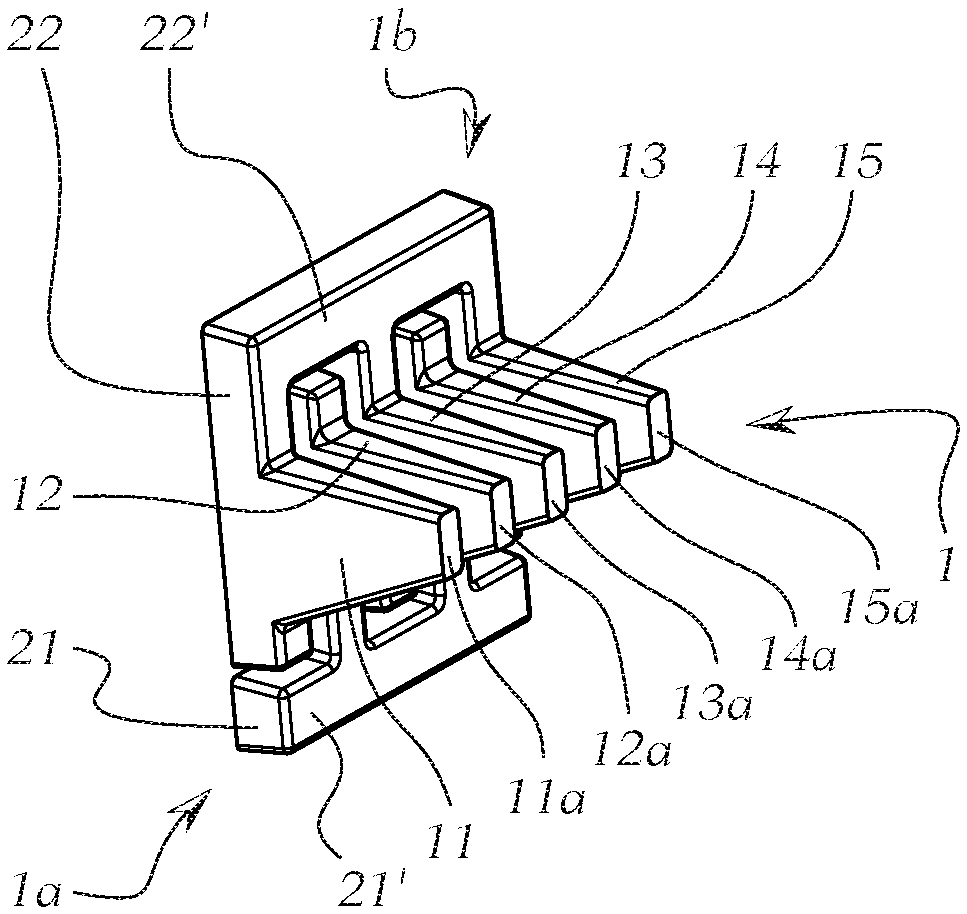

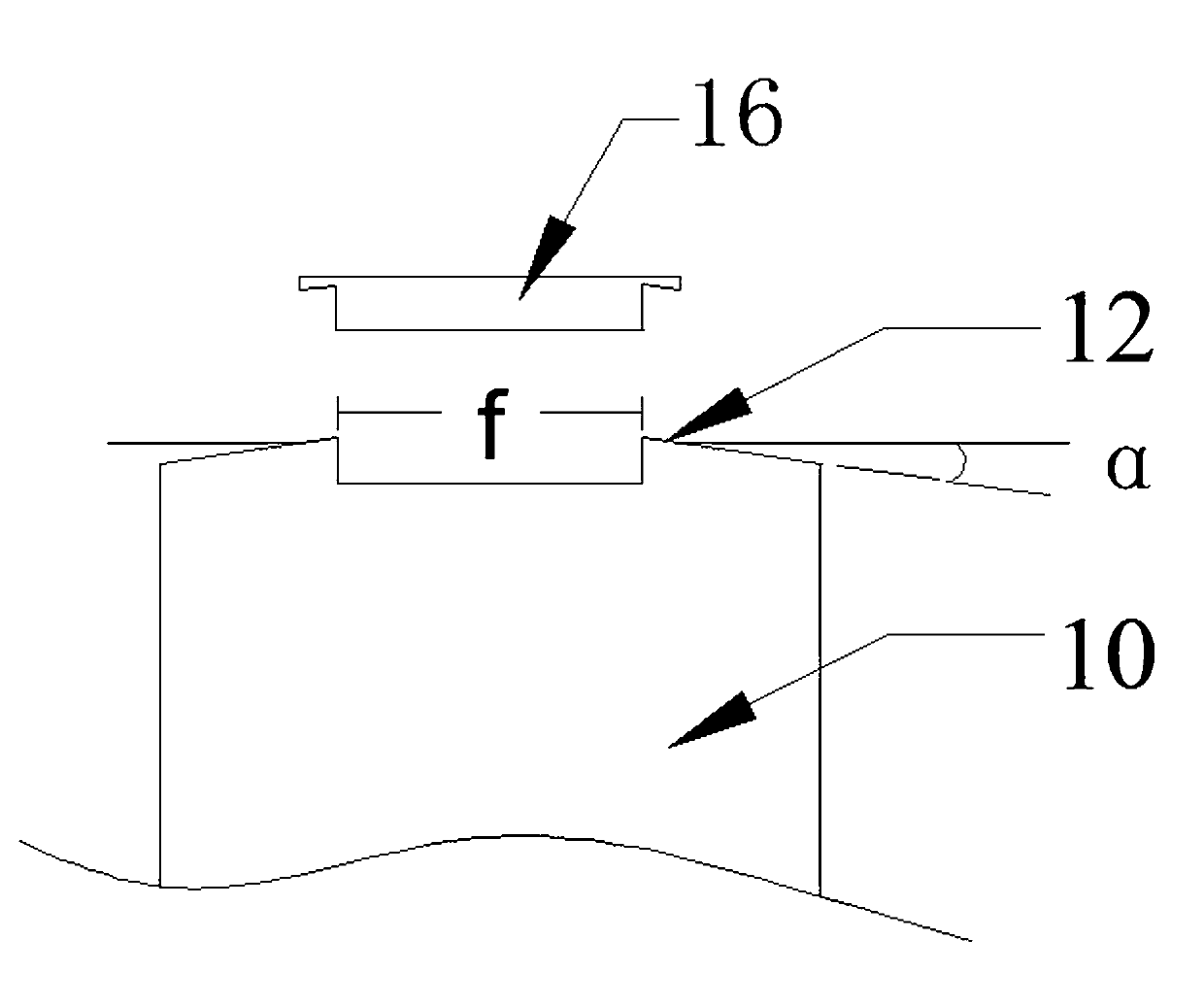

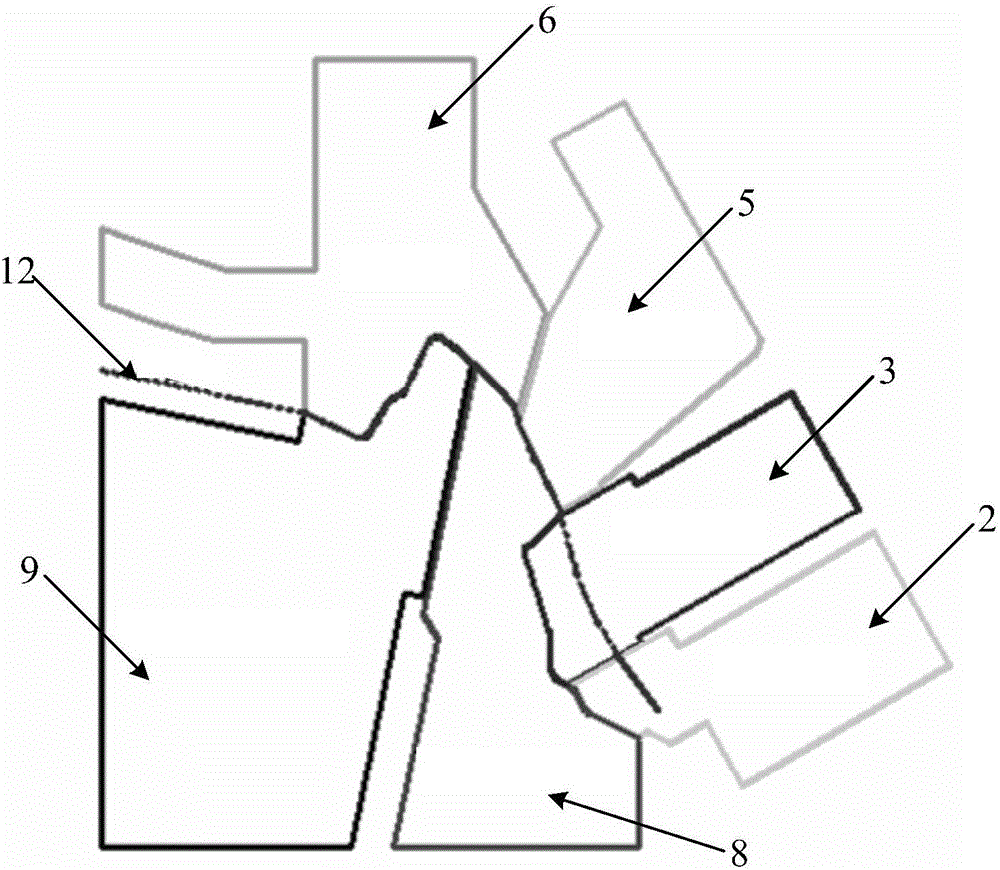

Star-arrow adapter for multi-point pressing and synchronous unlocking

PendingCN110329552AIncrease the pressing forceImprove reliabilityCosmonautic vehiclesCosmonautic component separationEngineeringFlange

The invention discloses a star-arrow adapter for multi-point pressing and synchronous unlocking, characterized by a pressing rod cover plate (1), a pressing nut (2), a pressing flange (3), a pressingrod (4), a pressing connecting rod (5), a supporting connecting rod A (6), a supporting connecting rod B (7), an unlocking connecting rod (8), an unlocking sliding block (9), an unlocking spring (10),a pressing base (11), a mounting base plate (12), a linkage rod (13), an L-shaped connecting rod (14), a locking pin connecting rod (15), an unlocking pin (16), a pin pulling spring (17), an unlocking pin shell (18), a pin puller (19), a separation guide cylinder (20), a separation guide rod (21), a separation top cover (22) and a separation spring (23). The star-arrow adapter is compact in appearance, strong in compatibility, high in locking rigidity, low in unlocking impact, pollution-free and reusable.

Owner:北京微分航宇科技有限公司

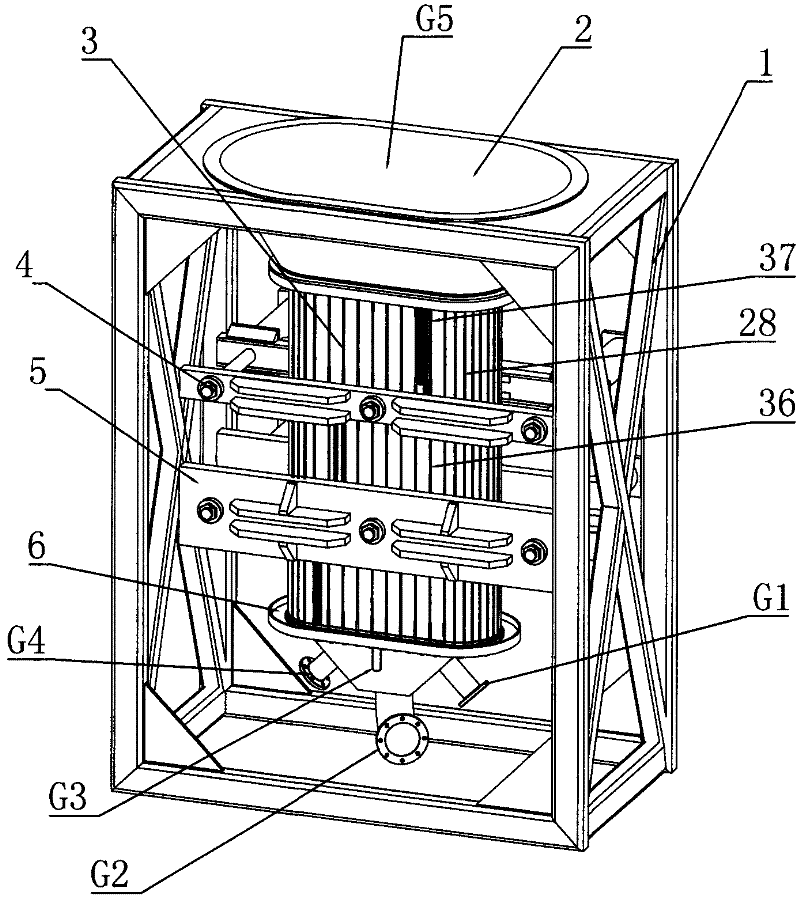

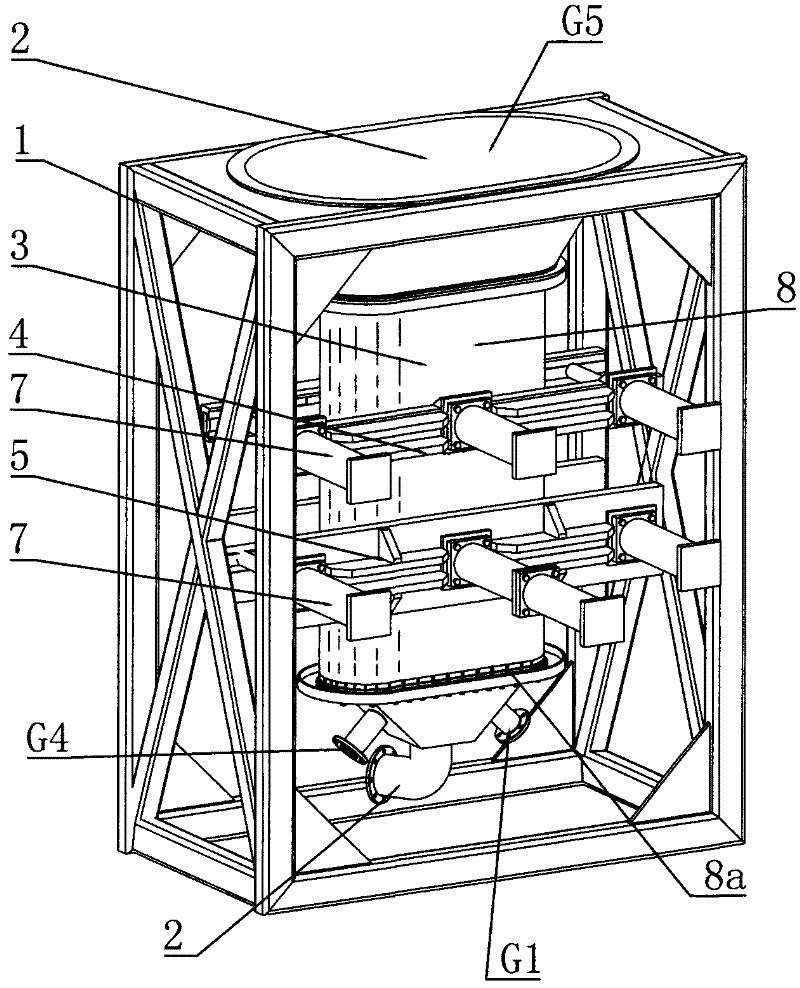

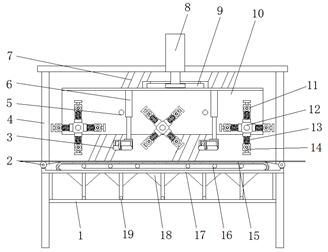

Apparatus for sludge undertaking, flexible pipe extruding dewatering and transportation, and system thereof

InactiveCN102249509ALess investmentSmall footprintSludge treatment by de-watering/drying/thickeningSludgeControl system

The invention relates to an apparatus for sludge undertaking, flexible pipe extruding dehydration and transportation, and a system thereof. The apparatus comprises a frame, a material undertaking cabin, transporters, a pipeline system, a filtrate discharging system and a control system. The transporter comprises a flexible pipe filter cell, a filter cell switch mechanism and an extruding mechanism. The invention respectively discloses two work ways that: the work way 1, the material undertaking cabin is arranged on a material outlet of a dewaterer, the undertaken sludge is filled in the flexible pipe filter cell, the filter cell switch mechanism is closed, the extruding mechanism is adopted for clamping the filter cell to carry out deep dewatering, the sludge is extruded to a transportation pipe to be discharged after complete the dewatering; the work way 2, the undertaken sludge is filled in the flexible pipe filter cell through a pump, then the extruding mechanism is adopted for clamping the filter cell to carry out dewatering, the filter cell switch mechanism is opened after complete the dewatering, the dried sludge in the filter cell is extruded into the material undertaking cabin; after the amount of the sludge is stored in the material undertaking cabin, the work way 1 is performed when the sludge requires to be transported, then the dried raw materials is extruded to the transportation pipe to be discharged after carrying out the dewatering again. The material dewatering and transporting tasks are completed automatically through repeating the steps provided by the work way 1 or the work way 2.

Owner:天津市石化通用机械研究所有限公司

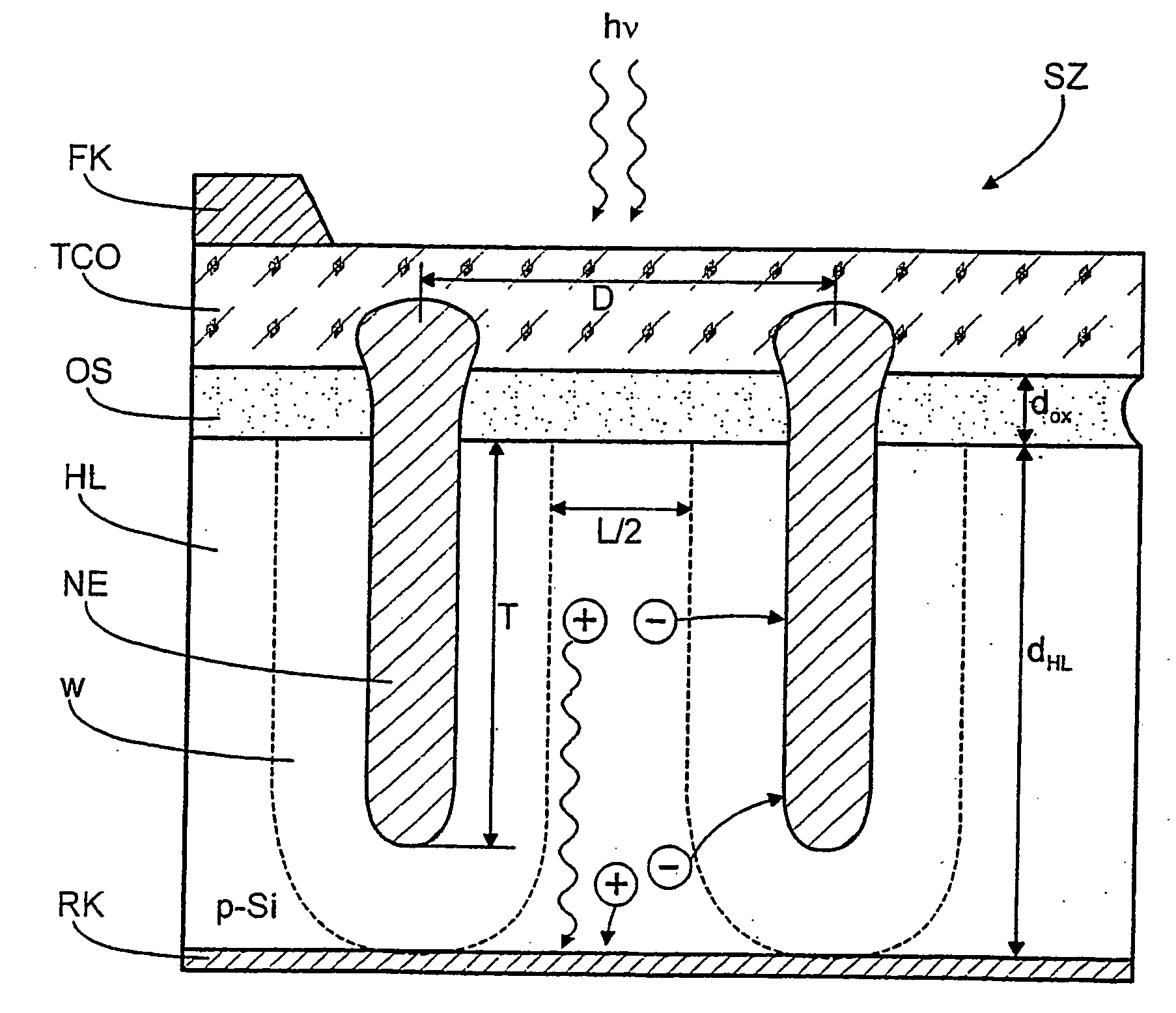

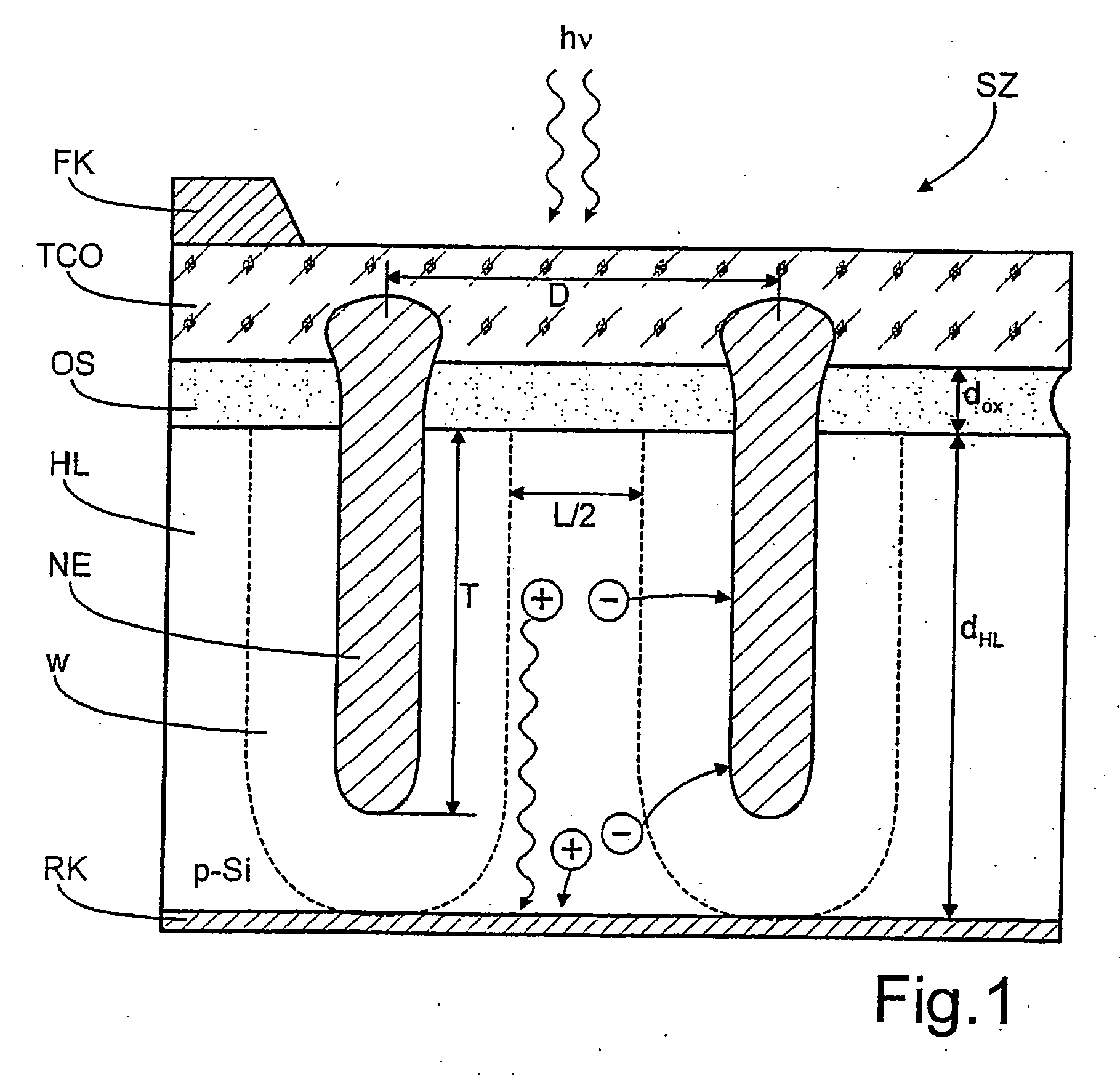

Photovoltaic solar cell...

InactiveUS20070028957A1Reduce complexityLow costPV power plantsFinal product manufactureEngineeringPhotocurrent

A photovoltaic solar cell (SZ) of improved light-to-current conversion properties is provided with nano emitters (NE) of acicular or rib-like form and are separated from each other at a uniform distance D≦√{square root over (2)}L and penetrating to a penetration depth T≥dHL-L2+winto the semiconductor layer (HL).

Owner:HELMHOLTZ ZENT BERLIN FUER MATERIALIEN & ENERGIE GMBH

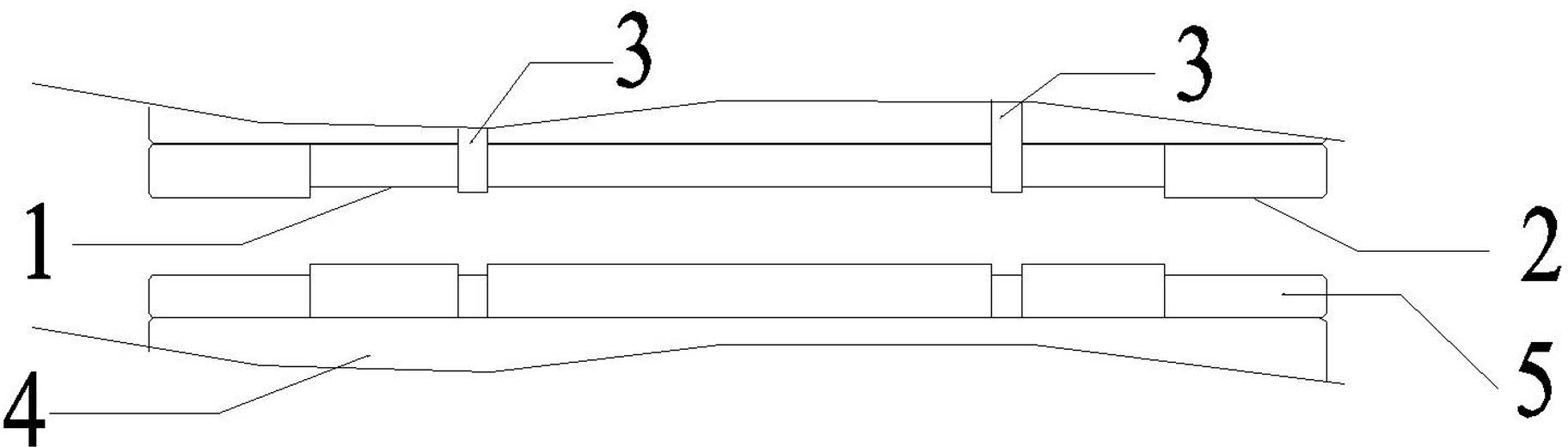

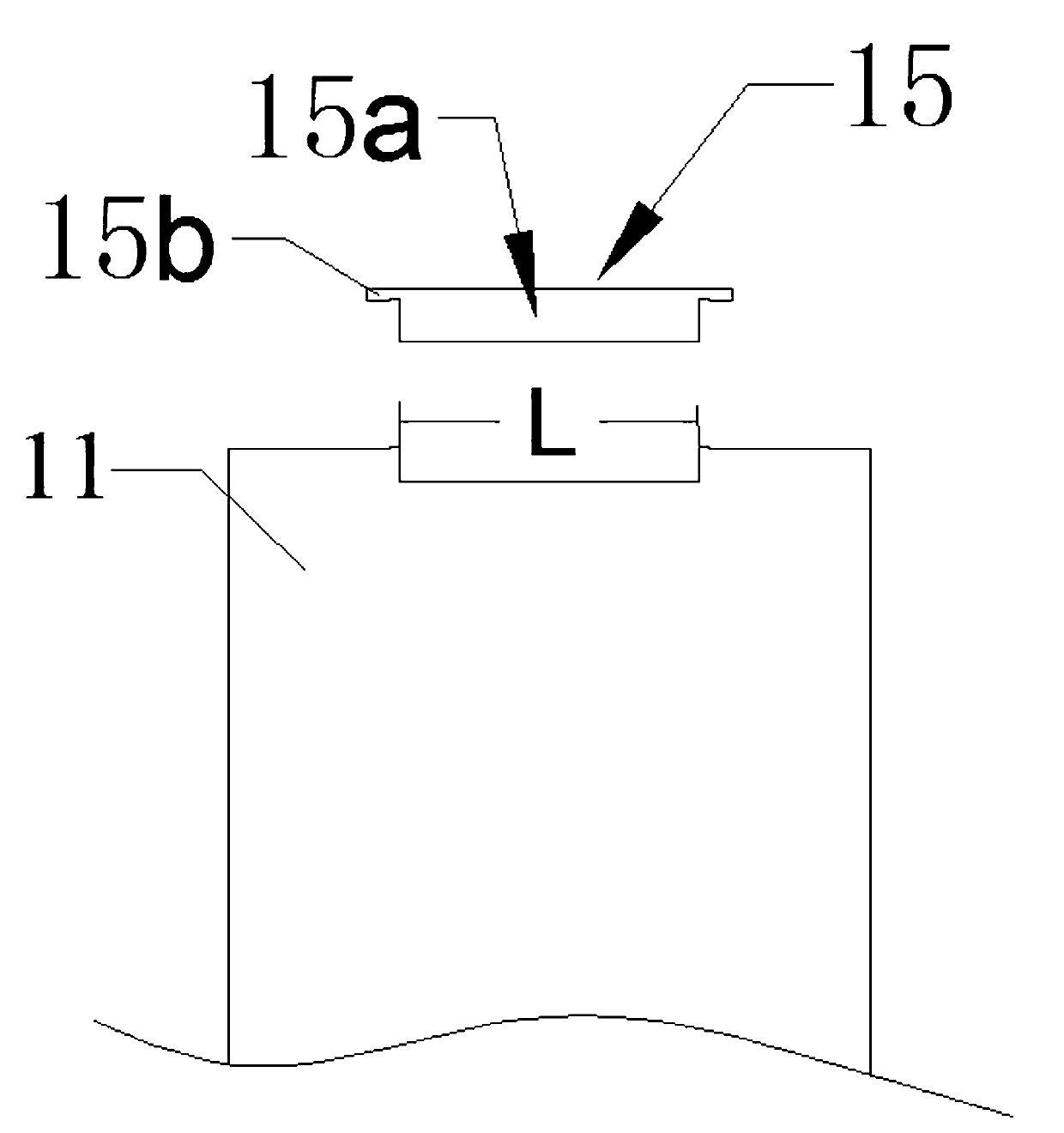

A Force-Limited Compression-Release Mechanism

ActiveCN105253331BSmall pressing forceIncrease the pressing forceCosmonautic power supply systemsEngineeringMechanical engineering

The invention discloses a force-limited compression release mechanism. The invention can realize segmental compression of large flexible solar wing sun blankets, and meet the requirements of different compression forces inside the solar blanket and solar blanket box boards. The present invention includes a pressing assembly and a base assembly, wherein the pressing assembly includes a pressing rod, a lock nut, a separation spring, a spring sheath, an escape cap and a mounting seat for the pressing rod, and the base assembly includes a pyrotechnic separation nut , Positioning guide column, force limiting screw, lock nut and separation nut mounting seat. When compressing the solar blanket, the compression rod is connected with the pyrotechnic separation nut, and the compression force is loaded through the lock nut to realize the connection between the upper and lower box plates and apply the compression load; when the internal compression load of the solar blanket reaches the required value , through the force limiting screw to prevent the compression force from being further transmitted to the sun blanket; the lock nut continues to load, and the compression force of the secondary load is transmitted to the force limiting screw to achieve a higher pre-set between the upper and lower box panels of the sun blanket Tight load requirements.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

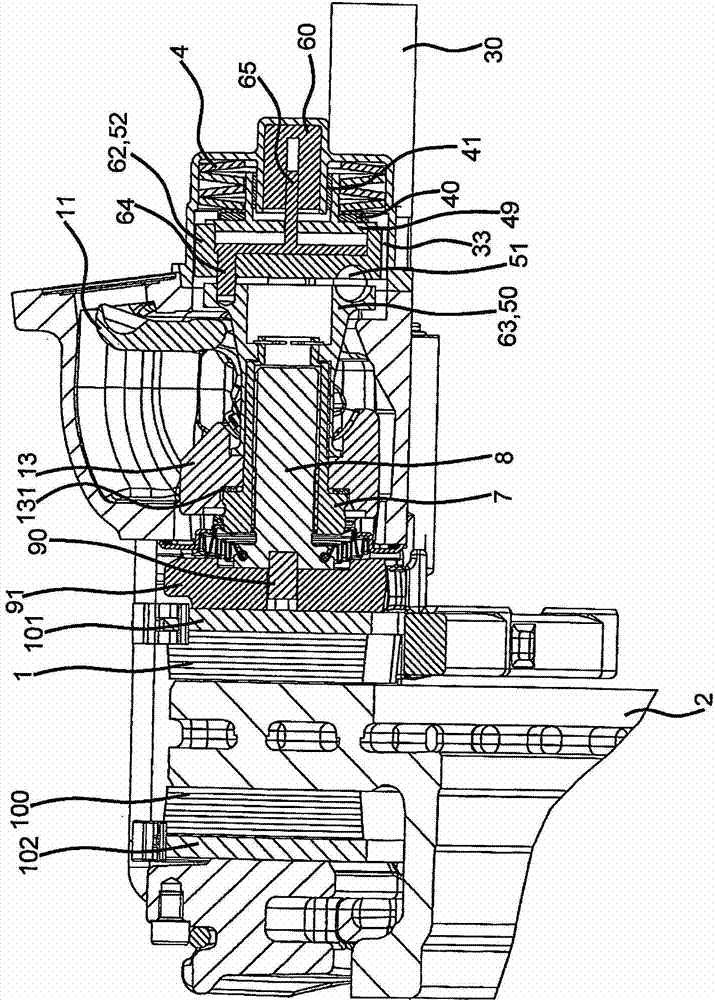

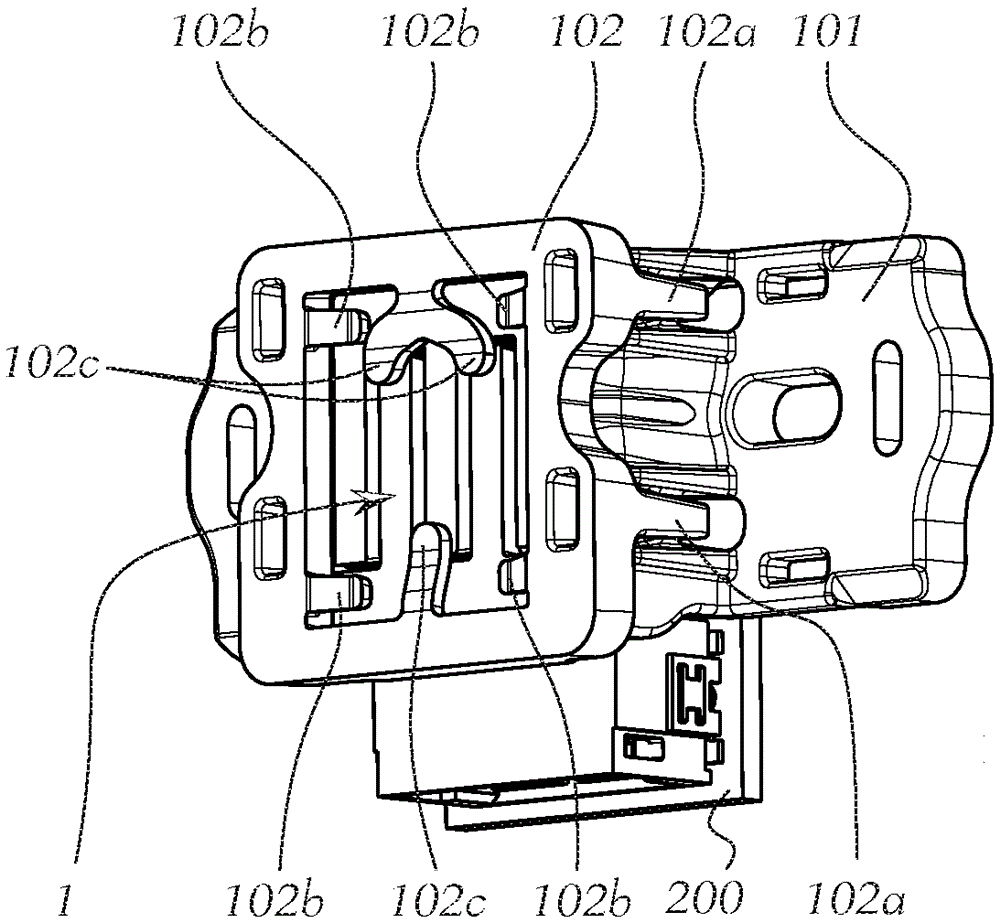

Electric device for interdental cleaning and for treating teeth and gingivae

The invention relates to an electric device (1) for interdental cleaning and for treating teeth and gingivae comprising a casing (2) containing an eccentric mass (23) which is driven by an electric motor (22) and whose vibrations are transmitted to a tool holding fixture (5). A coupling area (A, B) for the tool holding fixture is connectable to a coupling area (34, 38) of a mouth cavity treating tool such as an interdental cleaner (31), a dental floss holder (37), friction and polishing discs, etc by means of connecting means. According to said invention, the tool holding fixture (5) consists of a pivot-shaped segment (48) and a coupling area (B) formed on the free front end face (61) of said segment, wherein said coupling area (B) is embodied in the form of a polygonal, preferably rectangular, reception orifice (26) in which the coupling area (34) of the tool (31) can be formed by plastic deformation. A toothpick (31) and a dental floss holder (37) are also disclosed. Said invention makes it possible to carry out a particularly soft interdental cleaning.

Owner:BRAUN AG

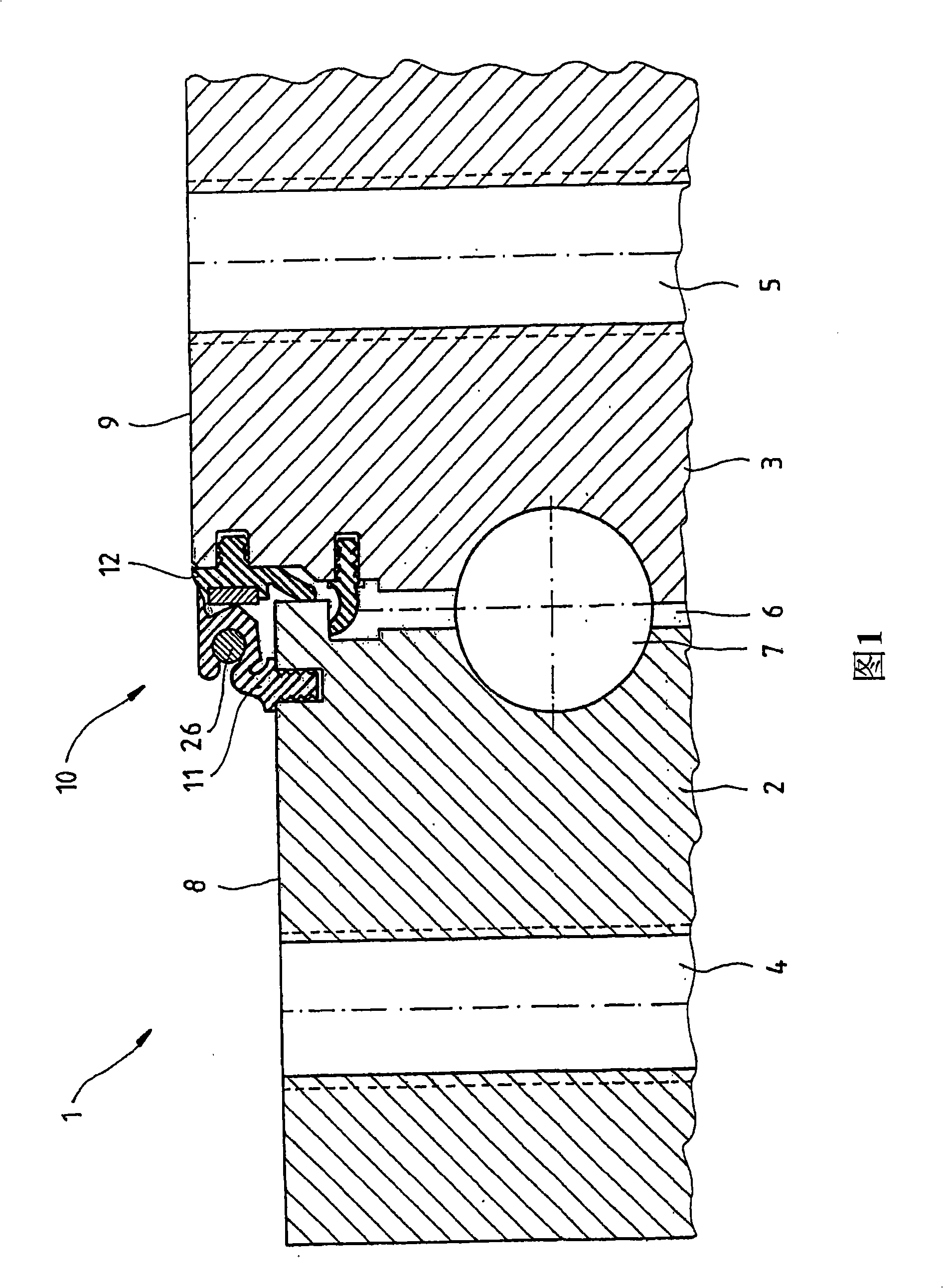

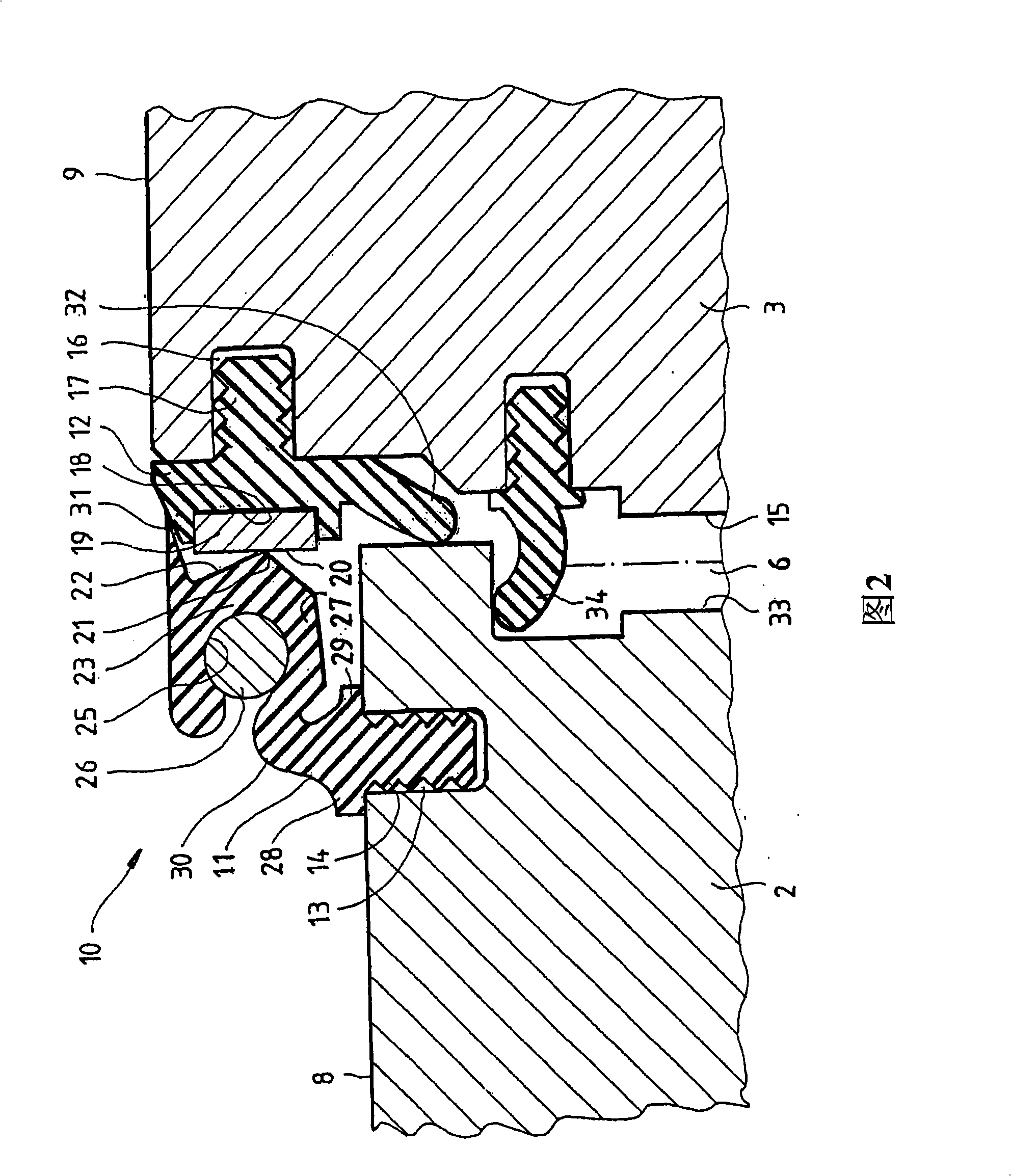

Pneumatic wheel brake for a vehicle

ActiveCN102959269ASimple structureCompact structureBraking element arrangementsAxially engaging brakesEngineeringCompressed air

The invention relates to a pneumatic wheel brake for a vehicle, wherein the wheel brake has at least one brake lever (11) that can be operated by a compressed air cylinder (10) and a brake application device (20) that can be operated by the brake lever (11), wherein by means of said brake application device a first brake element (1) can be pressed against a second brake element (2) when the brake lever (11) is operated, and the wheel brake has an actuating device (3) that can be driven by an electric motor, wherein by means of said actuating device force can be applied to at least parts (7, 8, 9) of the brake application device (20), at least when the brake lever (11) is not operated, and thereby the first brake element (1) can be pressed against the second brake element (2). Furthermore, the wheel brake has a spring accumulator element (4), which is arranged outside the compressed air cylinder (10), wherein force can be applied to the spring accumulator element (4) by the actuating device (3) that can be driven by an electric motor and force can be applied to at least parts (7, 8, 9) of the brake application device (20) by the spring accumulator element, at least when the brake lever (11) is not operated, and thereby the first brake element (1) can be pressed against the second brake element (2).

Owner:ZF CV SYST EURO BV

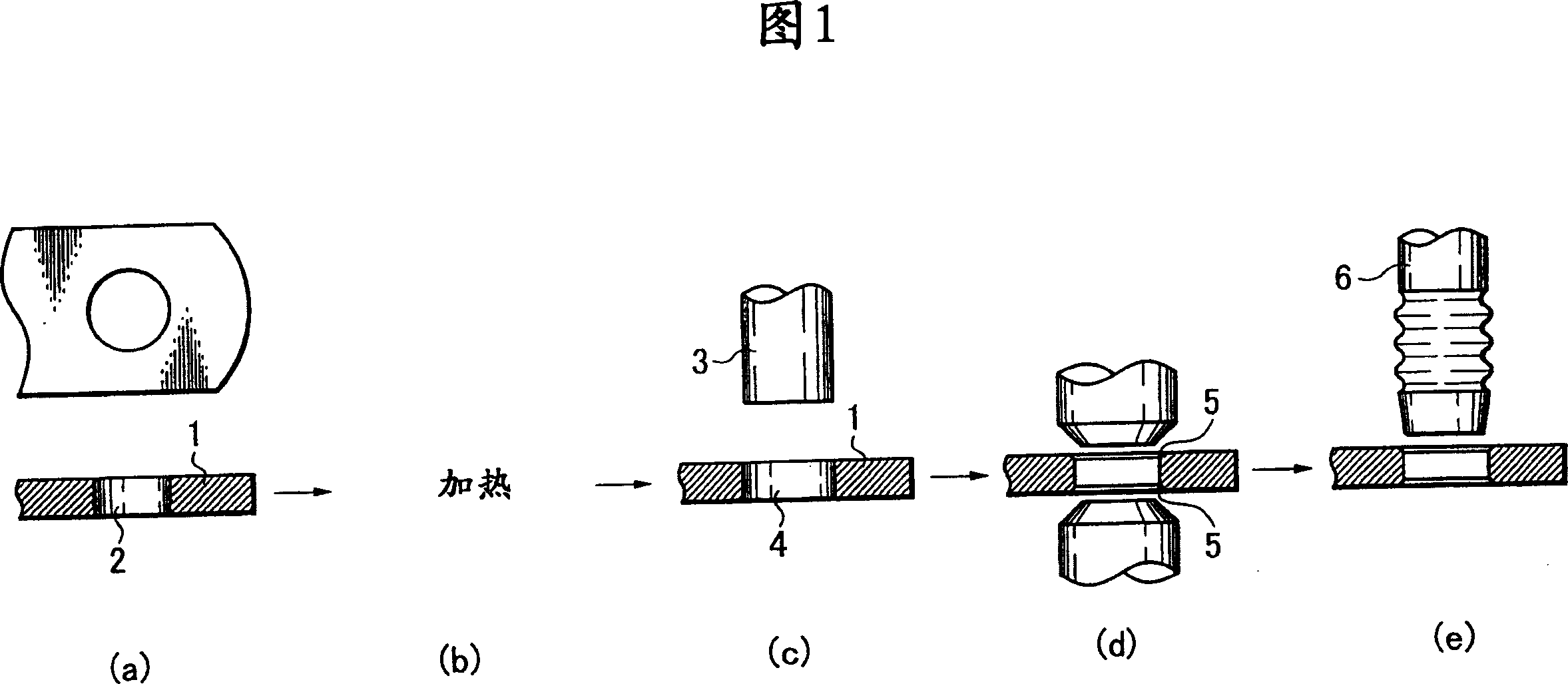

Chain and method for blanking hole in chain plate

ActiveCN1932332AHigh precisionHigh dimensional accuracyPolishing machinesDriving chainsSurface roughnessEngineering

In blanking holes in plates that comprise a chain, in order to improve the fatigue strength of the chain, a press-punched plate prepared hole, trumpet-shaped, is shaved and made into a straight hole, both ends of the straight hole are chamfered, and further, a multi-step burnishing punch composed of a plurality of annular convex portions at predetermined intervals is pressed into the straight hole, improving the dimensional accuracy of the hole and the smoothness of the hole wall and producing compressive residual stress in the hole wall.

Owner:DAIDO KOGYO CO LTD

Metal part interference fitting device and fitting method

ActiveCN105499960AReduce the phenomenon of improper assemblyStable pressing forceMetal working apparatusInterference fitEngineering

The invention discloses a metal part interference fitting device and a fitting method. The fitting device comprises an equipment base of equipment to be fitted, a first metal part to be fitted, a second metal part to be fitted, a pressing head for pressing and fitting the first metal part, a pressing base adapted to the second metal part, a guide tool used for guiding the first metal part, and a positioning tool used for positioning the first metal part, wherein the first metal part is pressed and fitted into the second metal part; and the pressing base is arranged on the equipment base. With the adoption of the metal part interference fitting device, problems of pressing inclination, directional expansion and great difference caused by factors of equipment and the like can be greatly reduced, a pressing-in force needed by metal part interference fit is stably realized, the probability of not assembling in place is lowered, the coaxiality of an assembly part after the interference fit is greatly improved, and a stable corresponding relation between a releasing force and the pressing-in force of the assembly piece after the interference fit is greatly improved.

Owner:DONGGUAN XIANGTONG PHOTOELECTRIC TECH

Punching mould and punching method suitable for labtop keyboard frame

The invention discloses a punching mould and a punching method suitable for labtop keyboard frame, wherein the mould comprises a group of blanking modules for blanking, a plurality of groups of coarse punching mouldes, and a group of fine punching modules for finally and finely processing. According to the punching method of the invention, the modules cooperated with each other, the side walls of the punched keyboard frame has enough euphotic belts, the positive and negative surfaces of a keyboard hole are acute angles and have no singk angle. At the same time, the punching mould of the invention uses a punching head and a lower mould inlet block processed by PG (profile grinding) optical grinding, and further is provided with a nitrogen spring so that the products have good euphotic belt and flatness.

Owner:KUNSHAN SANJING SCI & TECH

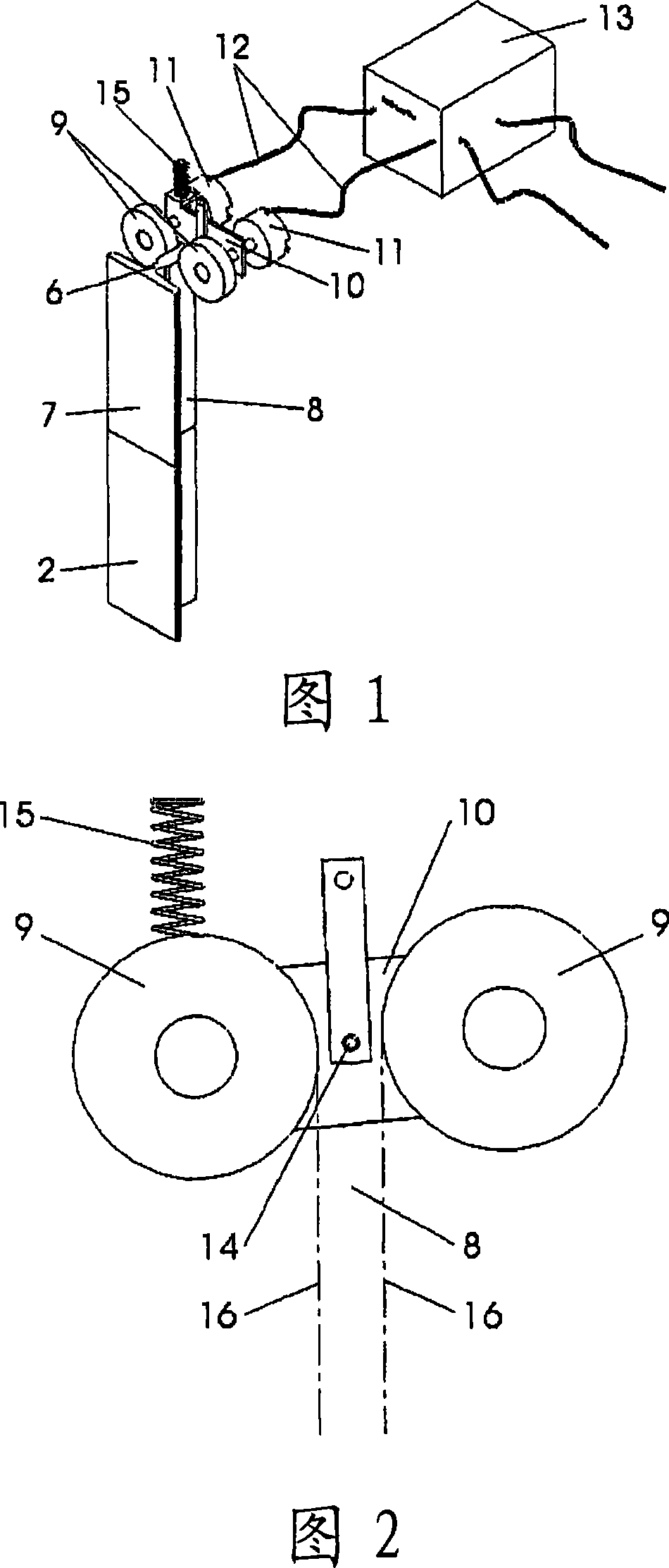

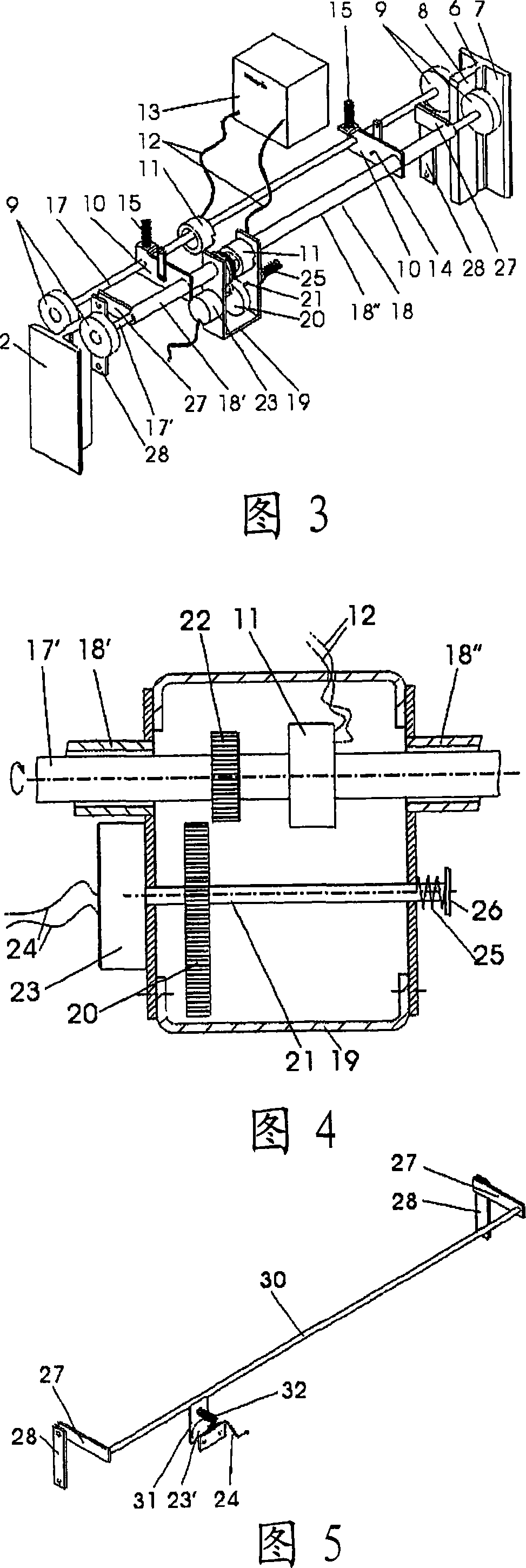

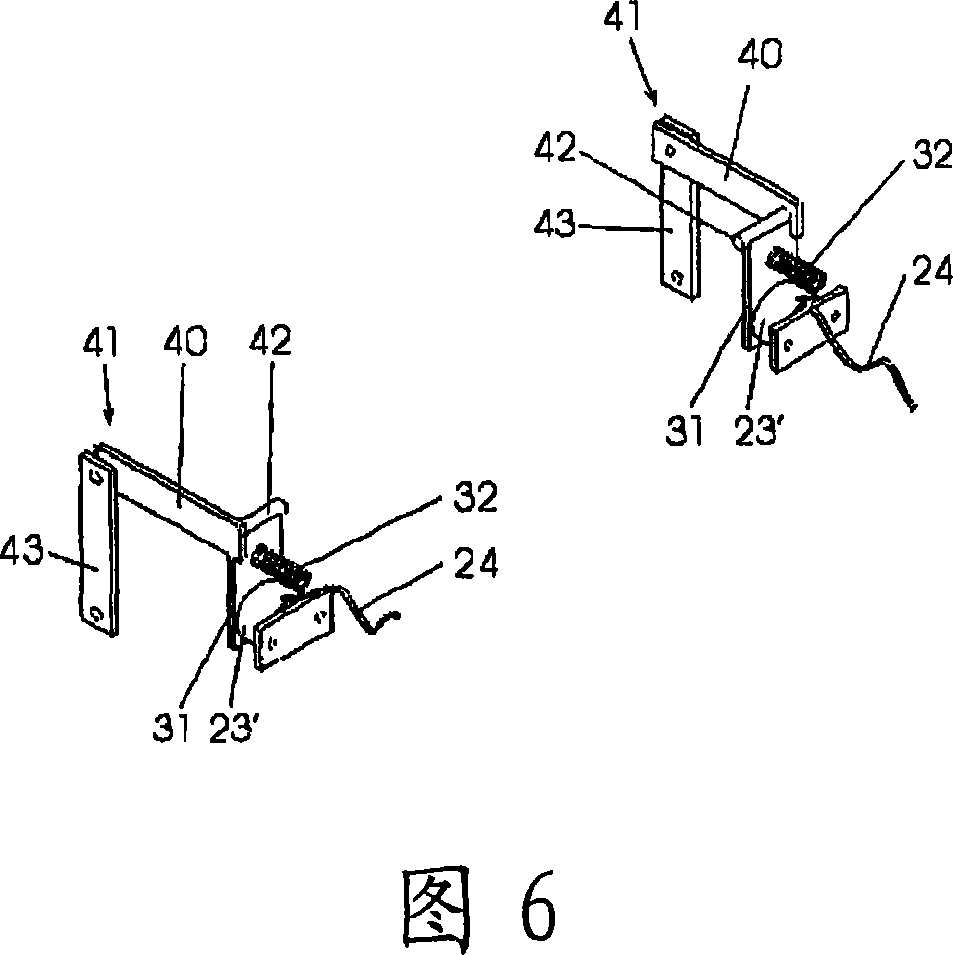

Emergency braking device for a lift cabin

ActiveCN101107189AWill not affect the measurementIncrease the pressing forceElevatorsElectricityMechanical engineering

According to the invention, a lift cabin is equipped with a detector (11) that records the speed of the cabin, said detector comprising a unit (13) that identifies an excess speed and that electrically controls a braking device. The aim of the invention is to ensure the reliable detection of the speed of the lift cabin. To achieve this, in order to determine said speed, two rollers (9) are provided on a guide track (2). The speed of each roller (9) is recorded independently by detectors (11) and the unit (13) triggers an emergency braking procedure, if one of the detectors (11) indicates an excess speed. The two rollers (9) can be mounted to pivot on a rocker bar (10) on either side of the guide track (2), the rocker bar (10) being eccentrically pre-tensioned by a spring (15). The invention also relates to a method, according to which the actuating force for the braking device can be mechanically increased with the aid of the rollers.

Owner:WITTUR

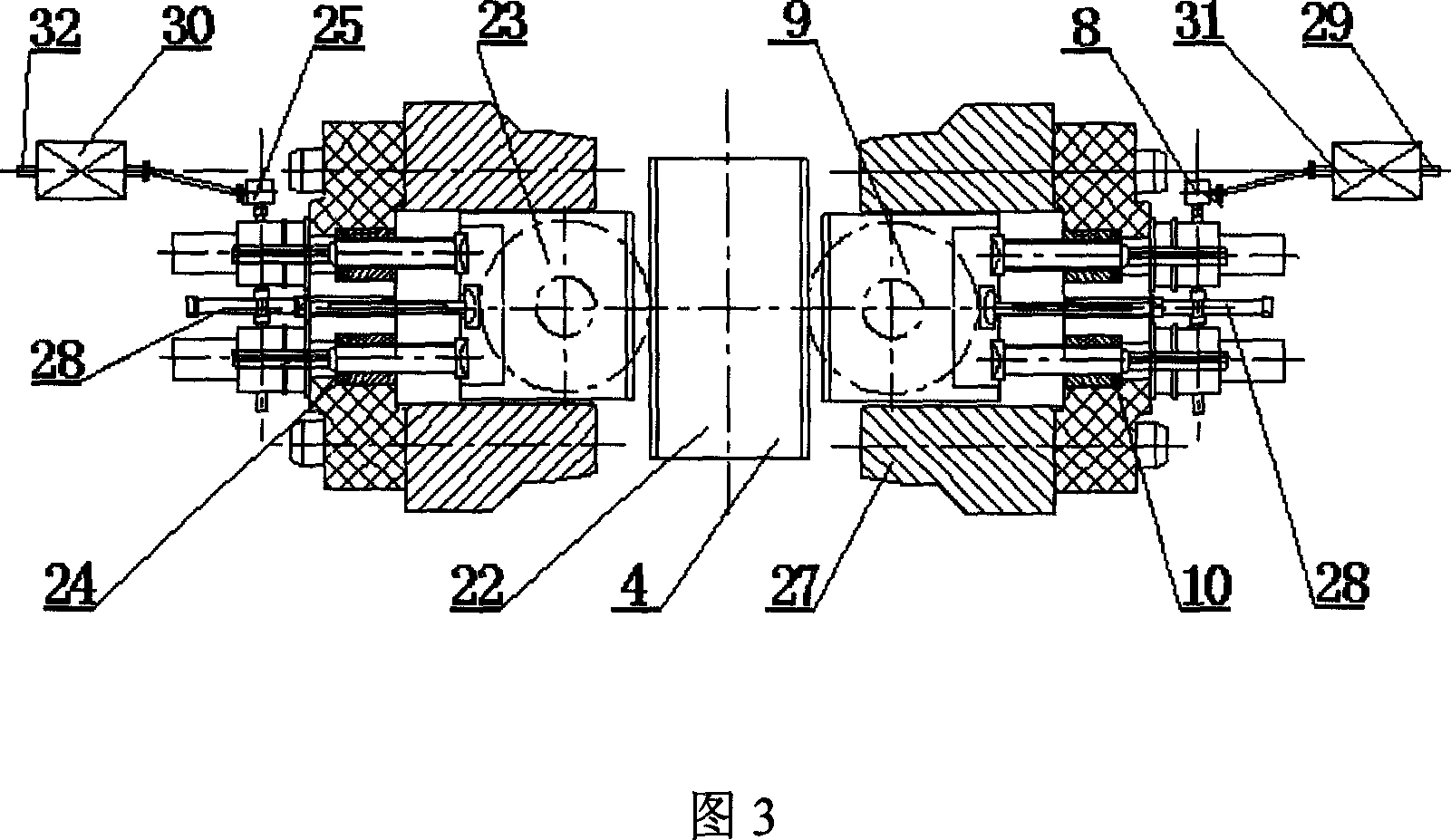

Contact device for cone ring transmission

InactiveCN101131200ASmall pressing forceConvenient oil supplyGearing controlFriction gearingsEngineeringMechanical press

Owner:GETRAG FORD TRANSMISSIONS GMBH

Control method for zero adjusting rollers in universal type rolling mill

ActiveCN1958183ALower requirementHigh efficiency of zero adjustmentRoll force/gap control deviceMetal rolling stand detailsEngineeringRolling mill

A control method for the zero regulation of rollers on universal steel rolling mill features that both vertical roller and hydraulic drive system are used for the axial movement and aligning of upper horizontal roller, and the bearing holder of upper roller and its clamping plate, clamping cylinder, locating cylinder, and lug are used for the zero-regulating and aligning between upper and lower horizontal rollers.

Owner:MAANSHAN IRON & STEEL CO LTD

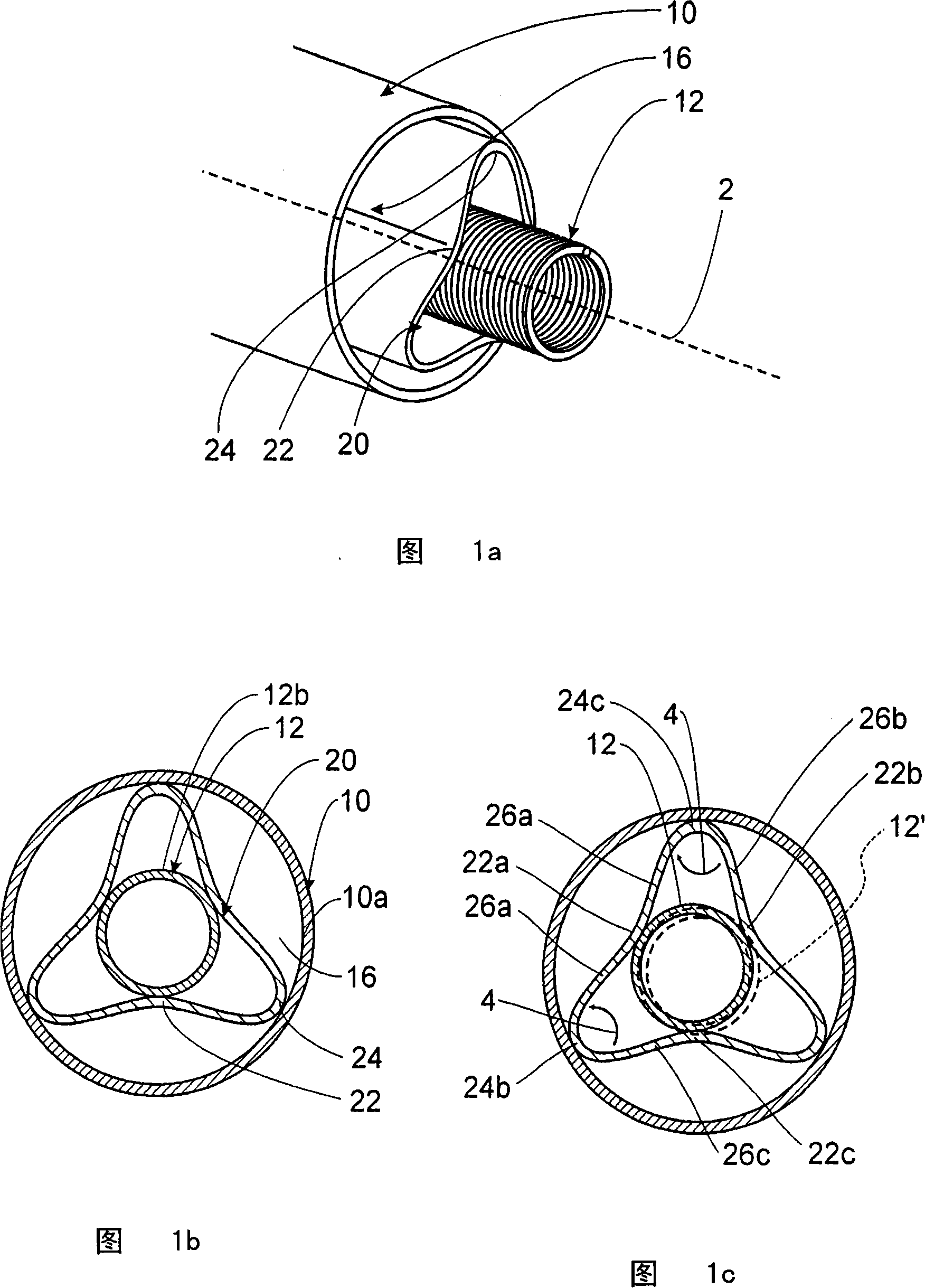

Roller blind assembly

InactiveCN101152933AEasy to fixIncrease pulling forceWindowsShutters/ movable grillesIn vehicleCoil spring

The invention relates to a roller blind arrangement, in particular for use in a vehicle, with a winding shaft ( 10 ) which extends in a main direction of extent ( 2 ), is in the form of a hollow tube and is intended for receiving an unwindable flexible sheetlike structure, a winding spring ( 12 ) which is inserted into the winding shaft ( 10 ), is designed as a helical spring and extends in the main direction of extent, and a damping profile ( 20 ) which extends in the main direction of extent ( 2 ) and is arranged in an annular space ( 16 ) between the winding shaft ( 10 ) and the winding spring ( 12 ). According to the invention, the damping profile ( 20 ) is designed in such a manner that it bears with outer contact sections ( 24 ) against an inner side of the winding shaft ( 10 ) and with inner contact sections ( 22 ) against an outer side of the winding spring ( 12 ). Use, in particular roller blind arrangements in vehicles, for example for coverings of the boot.

Owner:BOS

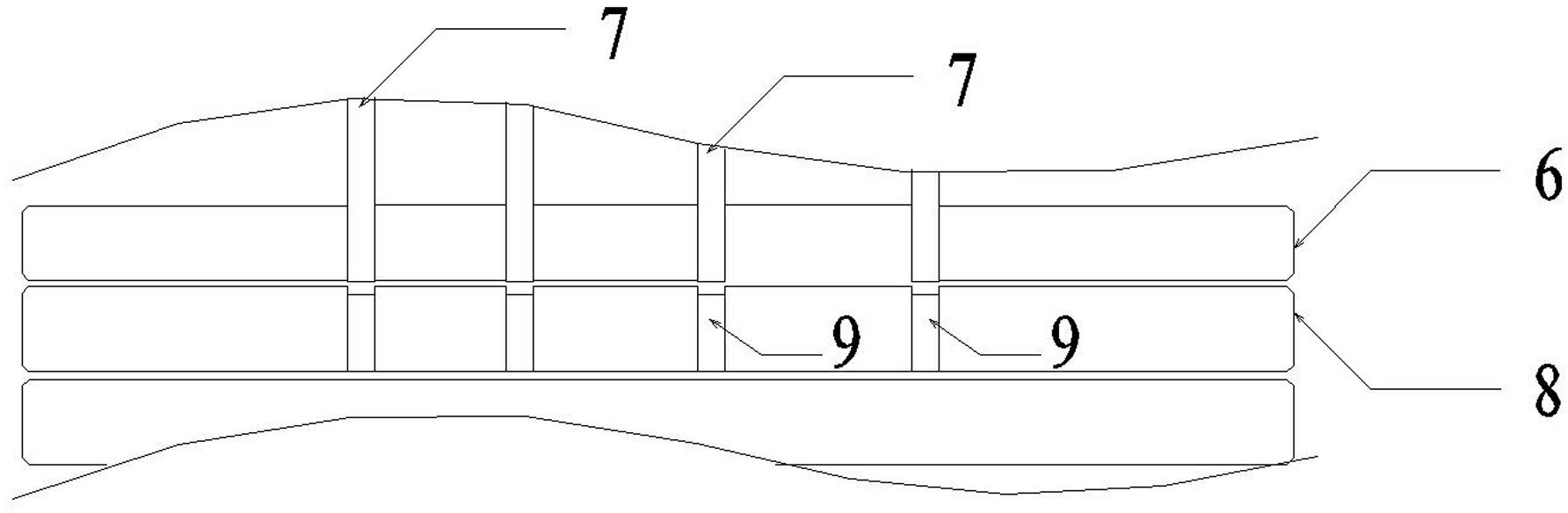

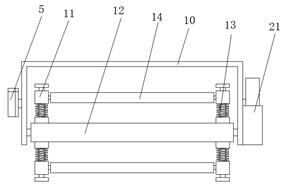

Filtering elements for hydraulically squeezing and extruding out mud cake

InactiveCN104623936AIncrease the pressing forceLow failure rateFiltration separationFilter mediaDehydration

The invention relates to filtering elements. A set of filtering elements is clamped in a pressure bearing structure of a flexible pipe squeezing machine along the direction of squeezing force; the filtering elements are characterized in that at least one water-permeable plate is arranged in a filtering chamber; the front and rear surfaces of the water-permeable plate are water-permeable filtering surfaces; the water-permeable filtering surfaces of the water-permeable plate are vertical to the direction of squeezing force; the water-permeable plate is located in the filtering chamber at the upside of a lower flange; and each water-permeable plate comprises a plate type filtering medium, an upper locking plate pressure strip, an upper locking plate strip, a filtering cloth tightening strip, a filtering cloth tightening pressure strip and at least one filtrate cavity communication pipe mouth. The working principle of the filtering elements is as follows: the filtering chamber of a part of flexible filtering elements is filled with raw materials to be taken as pressurized filtering elements; the filled raw materials expand slowly by utilizing other filtering elements as pressure-applying filtering elements; the pressurized filtering elements filled with the raw materials are compressed by utilizing the expansion force, so that the raw materials are squeezed and dehydrated; the mud cake in the filtering chamber is extruded out by utilizing the expansion force; immediately, the filtering elements are converted into the pressure-applying filtering elements; and, by means of such a cycle, the dehydration process of the raw materials is completed.

Owner:张民良

Composite device for textile fabric processing

InactiveCN112389071AImprove flatnessImprove processing qualityLaminationLamination apparatusAdhesive glueMechanical engineering

The invention belongs to the technical field of textile fabric processing, particularly relates to a composite device for textile fabric processing, and provides the following scheme for solving the problems that glue can be fully released between two layers of fabric only through conveying of multiple rollers, protrusions can be generated in a glue enrichment area, and the fabric composite quality is affected; the composite device comprises a rack; a supporting frame is fixedly mounted at the top end of the rack, a supporting platen is fixedly mounted at the top of the rack, and guide rollersare mounted at the two ends of the top of the supporting platen through bearings. According to the invention, the rotating direction of a flat pressing roller is opposite to the moving direction of cloth, so that surplus glue between the cloth on the two sides is always pushed backwards, the flatness of composite processing of the textile cloth is improved, and the surplus glue is discharged fromthe side surface and falls onto the supporting platen to be discharged in the translation and rolling process; the situation that the composite cloth is different in thickness due to local glue enrichment is reduced, and the processing quality of the composite cloth is improved.

Owner:梁伟滨

Production process of fireworks and crackers

The invention relates to the technical field of preparation of fireworks and crackers, in particular to a production process of the fireworks and crackers. The production process of the fireworks andcrackers comprises the following steps that A1, materials are selected, specifically, smooth paper with uniform texture is selected; A2, gluing and coiling are performed, specifically, the selected paper is conveyed into a coiling machine through a conveying belt, the rotation speed of the coiling machine is 1400 turns each minute, the paper is coated with glue while being coiled, and the paper iscut off after being coated with the glue; A3, drying is performed, specifically, the cut-off paper is irradiated in sun or dried for standby; A4, mud selection is performed, specifically, yellow mudwith high viscidity is selected, ground into powder after being dried, and then screened; A5, charging into coils is performed, specifically, the screened yellow mud is charged into the coils cut in the step A2 through a pressure machine; A6, gluing and threading are performed; A7, the coils are irradiated in sun to be dried, specifically, the fireworks and crackers subjected to pot threading in the step A6 are aired in a sunlight greenhouse, and the moisture content of the dried yellow mud is 10%; A8, black powder is added; and A9, the fireworks and crackers are boxed and delivered. The fireworks and crackers produced according to the method are not prone to deformation and small in pollution to the environment.

Owner:瓮安县中坪镇相国烟花爆竹厂

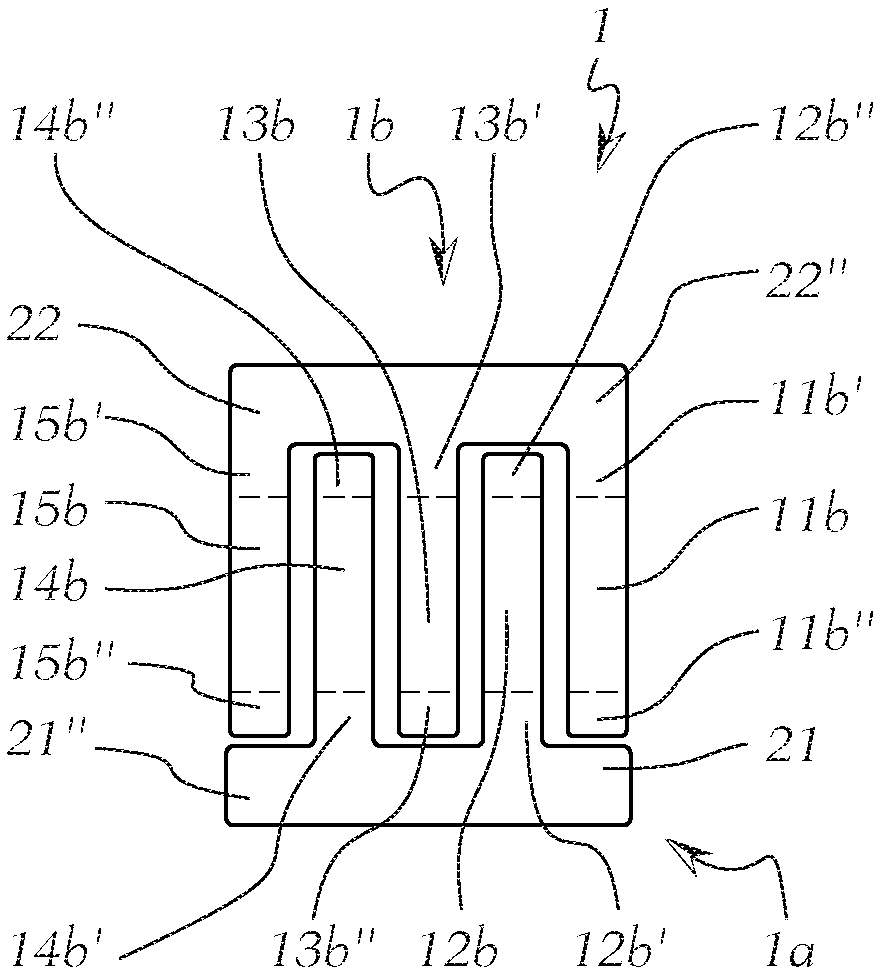

Securing device for an optical body for a motor vehicle headlight

ActiveCN105659024AGuaranteed positioningPrecise positioningMechanical apparatusVehicle headlampsMechanical engineeringOptics

The invention relates to a securing device (100) for an optical body (1) for a motor vehicle headlight or for a light module for a motor vehicle headlight, which optical body (1) has a number of front-end optical systems (11, 12, 13, 14, 15) which are arranged one next to the other, wherein each front-end optical system (11-15) is formed from a light-guiding material, and each front-end optical system (11-15) has a light-input face (11a-15a) and a light-extraction face (11b-15b), wherein the front-end optical systems (11-15) are mechanically connected to one another with at least one connecting web (21, 22), running transversely with respect to the front-end optical systems (11-15), in the region of the light-extraction faces (11b-15b), wherein the at least one connecting web (21, 22) is optically ineffective at least in certain areas, wherein the securing device has a base body (101) with receptacles (121, 122) for the optical body (1), and a securing body (102) which holds the optical body in the base body by means of clamping elements (102b, 102c).

Owner:ZKW GRP GMBH

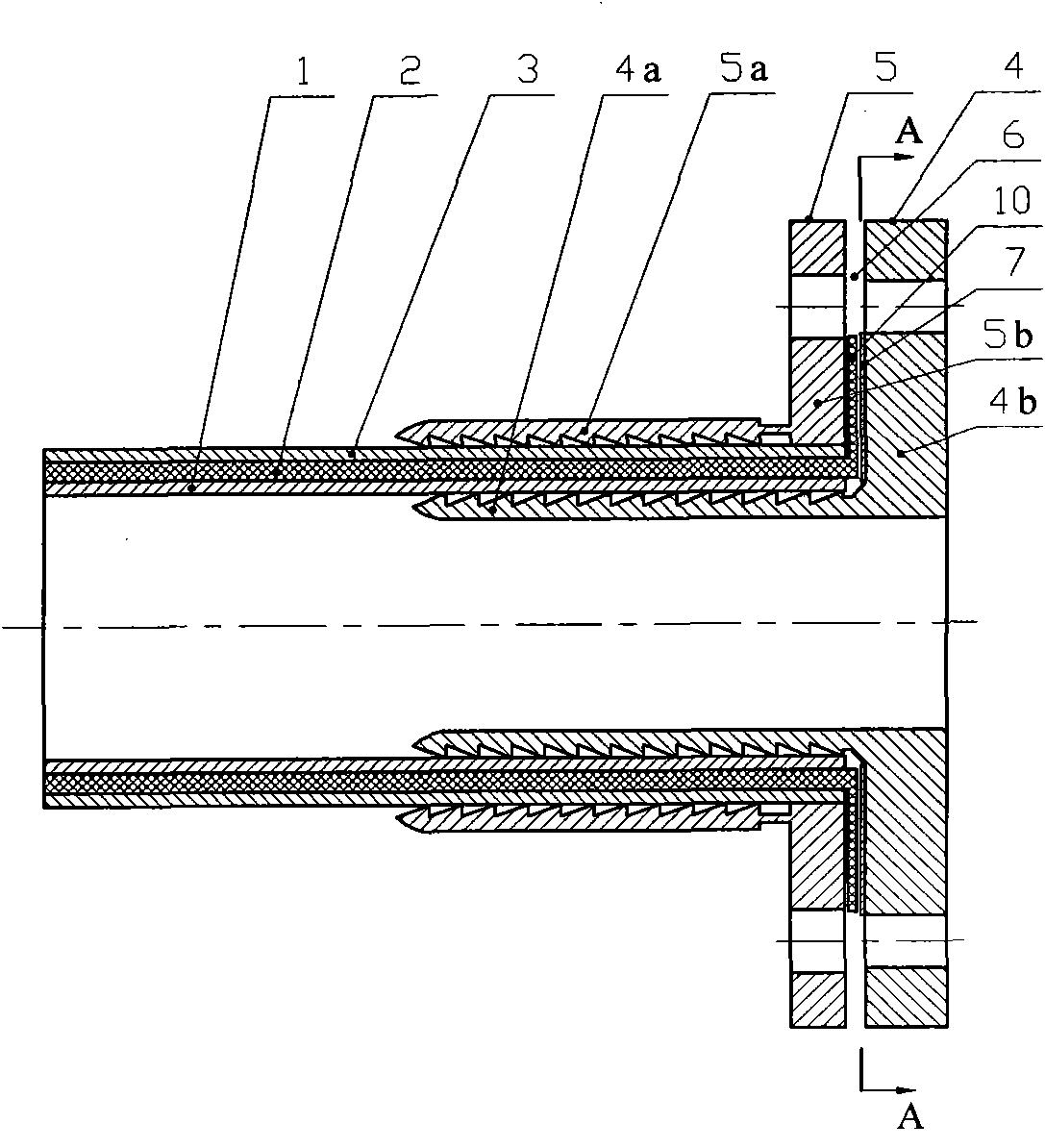

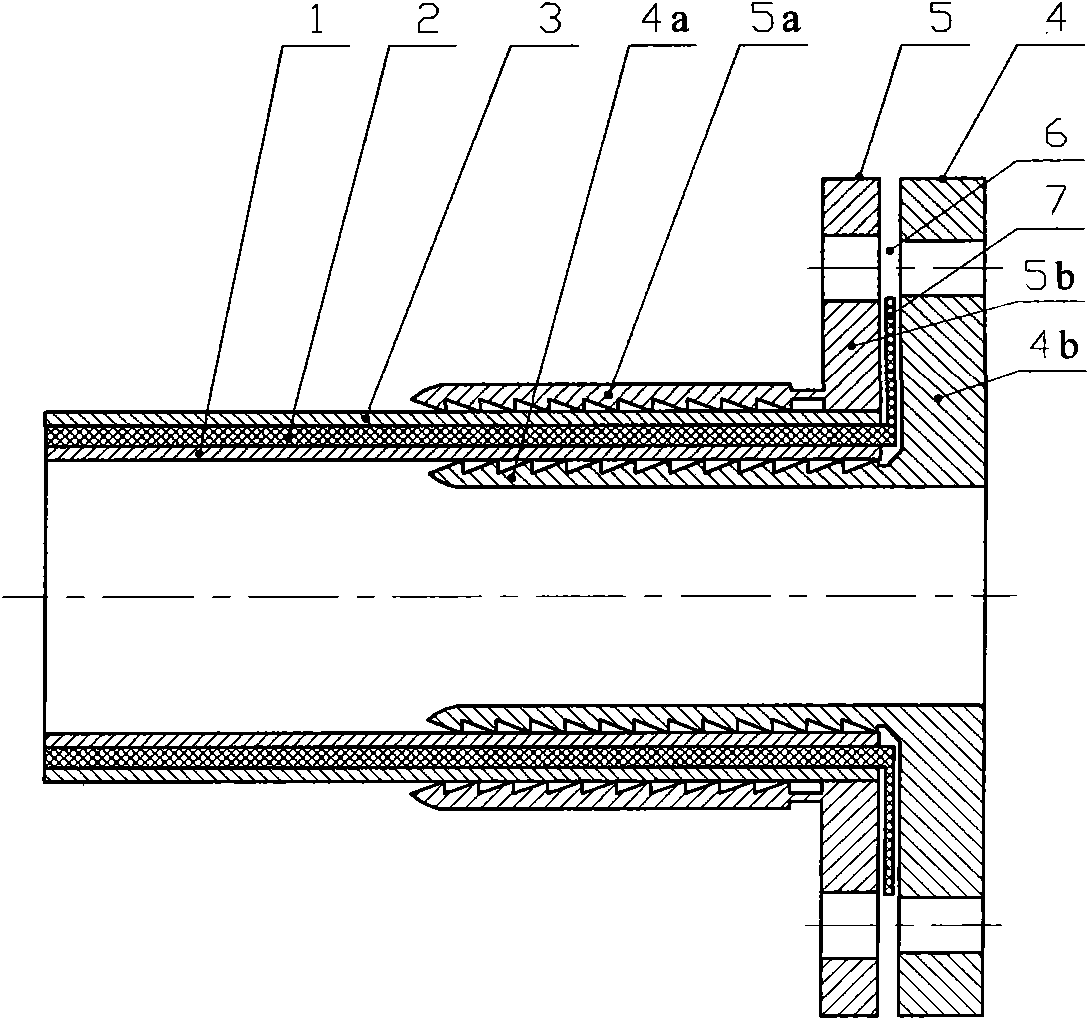

Enhanced thermoplastic composite pipe buckling and pressing joint and buckling and pressing connection method

InactiveCN102313109AImprove contact effectNot easy to loosePipe connection arrangementsEngineeringThermoplastic composites

The invention discloses an enhanced thermoplastic composite pipe buckling and pressing joint, which comprises a core pipe and an outer pipe, wherein both the core pipe and the outer pipe are L-shaped and are arranged in parallel to each other; the horizontal section of the core pipe is a core part, and the vertical section of the core pipe is an inner connecting piece; the horizontal section of the outer pipe is a buckling and pressing sleeve, and the vertical section of the outer pipe is an outer connecting piece; and a gap is formed between the inner connecting piece and the outer connecting piece. The invention also discloses a connection method using the joint. By buckling and pressing the pipe wall of a composite pipe and clamping the flanged end edge of the composite pipe, double buckling and pressing effects can be realized. The joint has a simple structure and is convenient to connect and operate; and the stability and the reliability for use are greatly improved.

Owner:李志雄

Continuous stamping die and stamping method for mobile phone camera component

The invention discloses a continuous stamping die and a stamping method for a mobile phone camera component. The continuous stamping die comprises an upper die set and a lower die set, the upper die set consists of a plurality of extrusion punches for completing a thinning process, the lower die set comprises a lower die plate and a plurality of lower die inserts corresponding to the extrusion punches, an upper plate surface of the lower die plate is horizontal, the lower die inserts include a plurality of thinning inserts and a restrike insert, and each of the thinning inserts and the restrike insert consists of a sunken pre-machining groove with vertical side walls. The stamping method mainly includes a, pre-machining a material by multiple times by cooperation of the thinning inserts and the corresponding extrusion punches; and b, finally machining the material by the restrike insert and the corresponding extrusion punch, and directly machining the material to form a final product with the target side. The continuous die is adopted, the product is finally formed after a plurality of pre-machining steps, and is low in deformation, standard in size and high in quality, a nitrogen spring is small in size, high in elasticity and constant in spring force, sufficient pressing force is guaranteed during shape punching, and accordingly the product is excellent in flatness.

Owner:KUNSHAN SANJING SCI & TECH

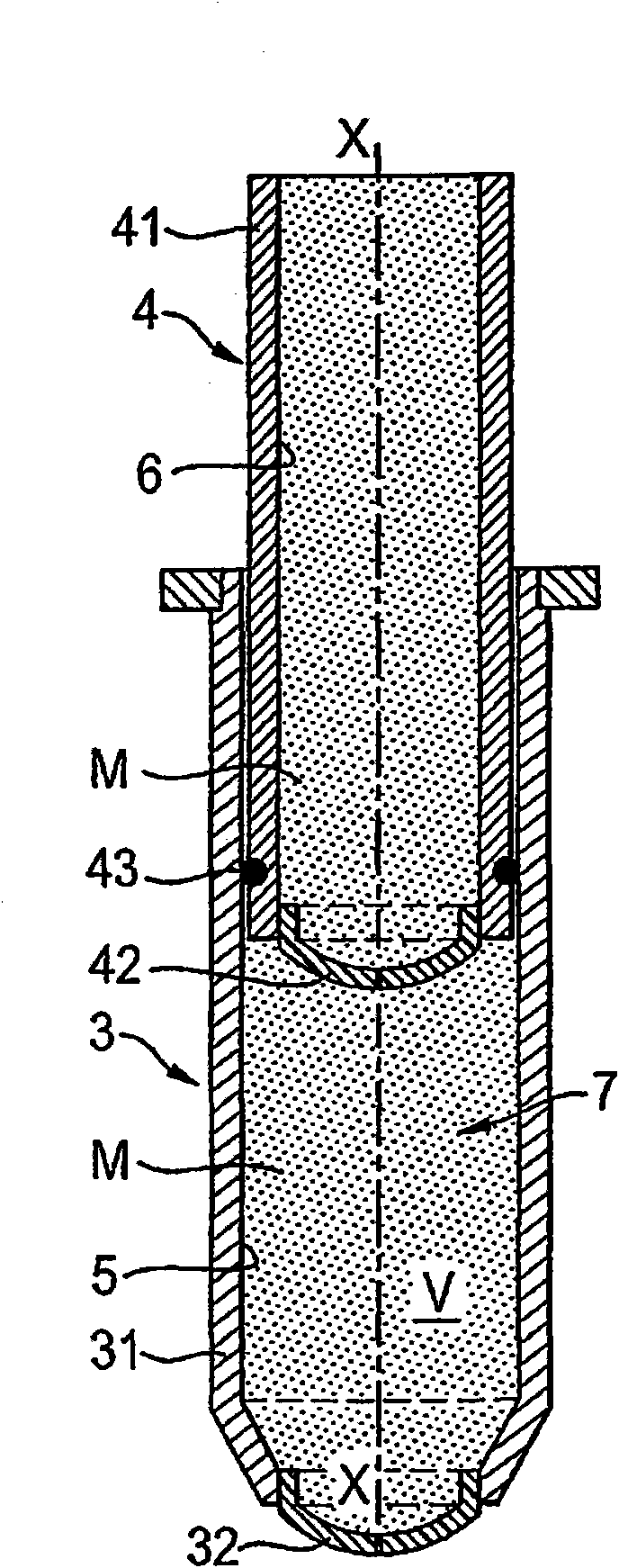

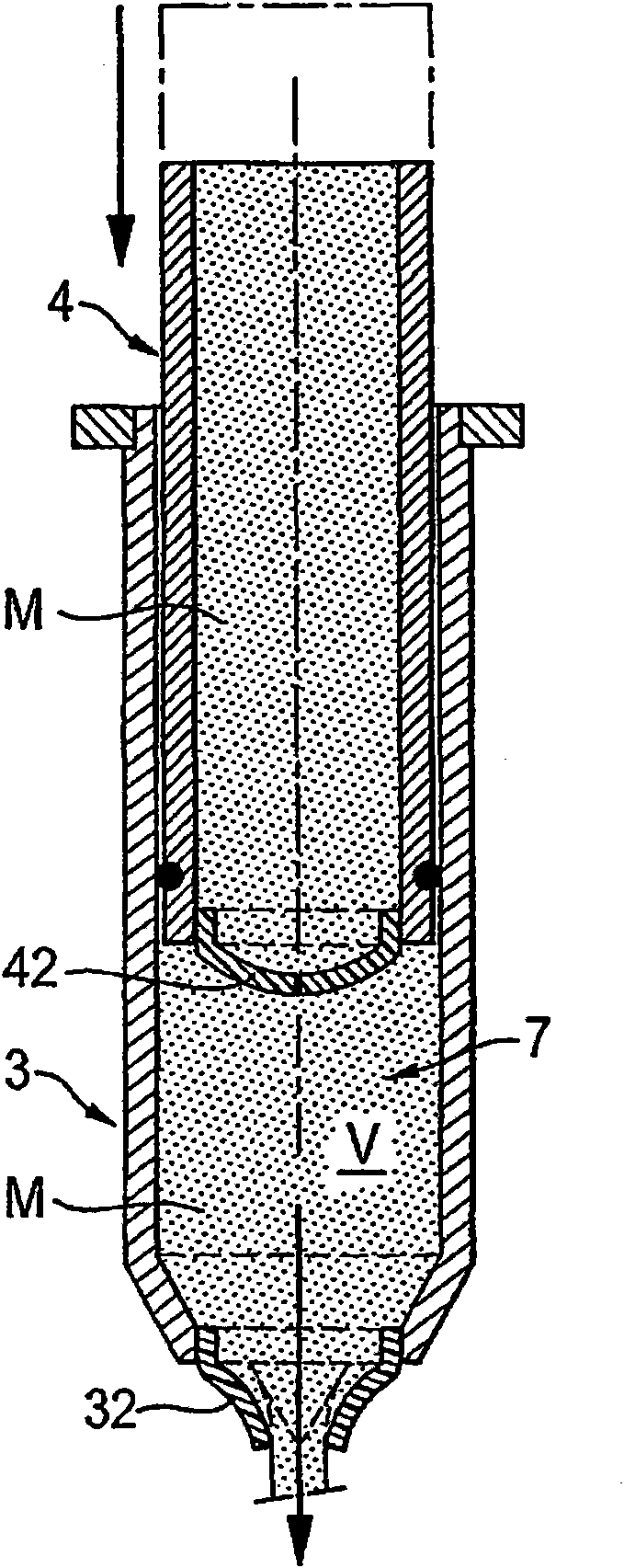

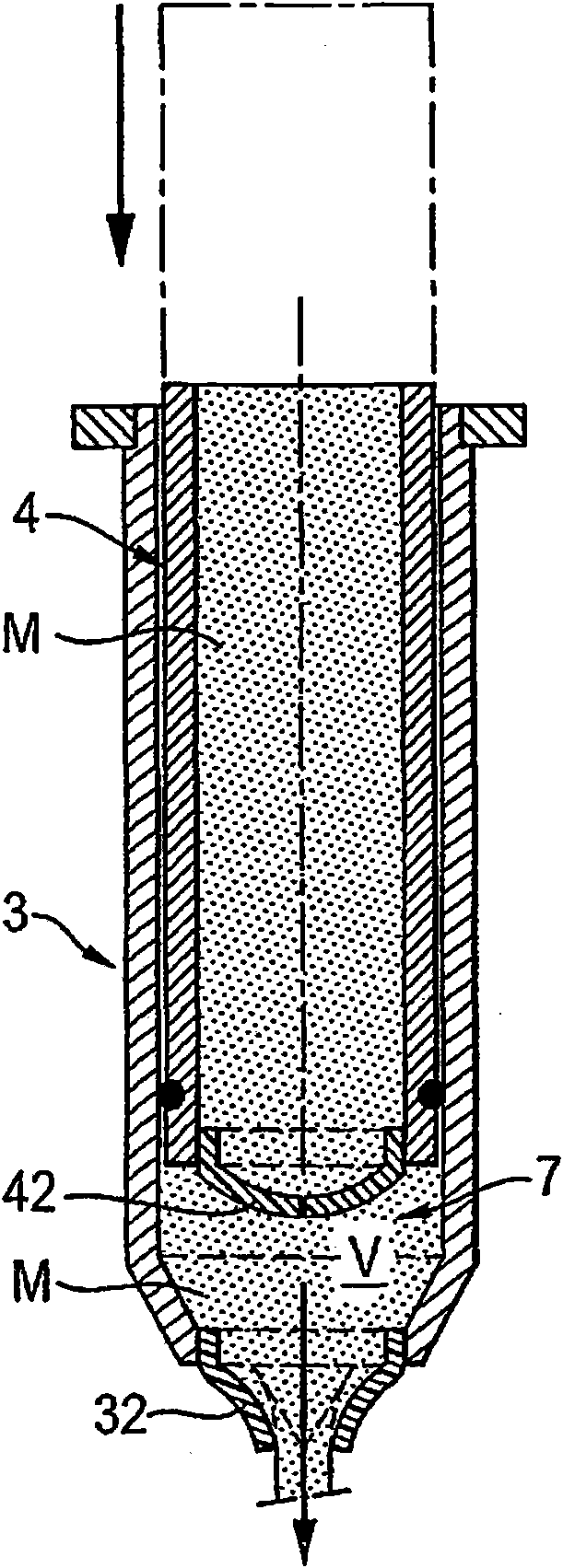

Casting machine and casting machine valve

InactiveCN102014651AIncrease the pressing forceOpen fullyLiquid surface applicatorsConfectioneryMaterials scienceValve opening

The invention relates to a casting machine (1) for casting a flowable mass (M), in particular a flowable mass with suspended solid particles. Said casting machine comprises a mass container (2) for receiving the flowable mass and at least one valve (32, 42; 50; 60; 70; 80; 90; 100; 110; 120) that is fluidically connected to the inner area of the mass container. When the pressure changes in the direction of the valve along the valve passage, said valve is in the open state and in the absence of a pressure change in the direction of the valve passage, said valve is in the closed state. The casting machine also comprises pressure generating means (3, 4, 5, 6, 32, 42) for generating a change in the pressure in the direction of the valve passage. Said valve (50; 60; 70; 80; 90; 100; 110; 120) comprises a valve body (51; 61; 71; 81; 91; 101; 111; 121) comprising a valve opening and at least one valve cover (53; 64; 76; 83; 94; 105; 115; 128) that is oriented towards the valve opening, articulated on the valve body and is subjected to an elastic prestressing that presses the valve cover against the valve opening and seals it. The invention also relates to a valve (50; 60; 70; 80; 90; 100; 110; 120) and to pressure generating means (3, 4, 5, 6, 32, 42) that are suitable for the modular construction of the claimed casting machine (1).

Owner:BUEHLER AG

Punching mould of LCD (liquid crystal display) flat-panel display back plane bevel edge convex packet and punching method

The invention claims a punching mould of LCD (liquid crystal display) flat-panel display back plane bevel edge convex packet and a punching method, wherein the punching mould comprises a first module and a second module, the first module comprises a first punching head and a first lower template, the first lower template is provided with a first forming groove which is sunk, the second module comprises a second punching head and a second lower template, the second lower template is provided with a second forming groove which is sunk; the punching method of the invention using the punching mould comprises the following steps: punching materials with the first module to form a middle convex packet; performing back processing to the middle convex packet with the second module to form a target convex packet; the punching mould and the punching disclosed by the invention have the advantages of using two sets of modules to reduce the torsion of the material caused by forming, and using a nitrogen spring and a pressure line to increase material pressing force caused by punching and forming and to prevent pulling the materials on the plane to make the plane rebound.

Owner:KUNSHAN SANJING SCI & TECH

Double acting type side shaping device capable of improving strength of mold cores on body side

InactiveCN107520291ANo weaknessIncrease the pressing forceVehicle componentsEngineeringMechanical engineering

The present invention proposes a double-moving side shaping device for improving the strength of the side surrounding mold core of the vehicle body, including an upper mold base, a lower mold base, an upper side binder plate, a lower side binder plate, a wedge slider, and a side shaping knife , positive pressure plate, lower horizontal movable mold core, vertical motion mold core and drive block; upper side pressure plate and positive pressure plate are located on the upper die base, lower side pressure plate, lower horizontal movable mold core, vertical Both the moving mold core and the driving block are located on the lower mold base; the lower horizontal movable mold core and the vertical moving mold core are connected with the driving block; On the side of the traditional positive pressure plate, the upper pressure plate is added. When the upper pressure plate is pressed, the normal force on the surface will be greater, and the pressure effect will be better; and it will no longer be used. Horizontally divided, there will be no weak mold; the upper and lower parts of the side shaping knife have side pressing plates for pressing, which avoids the wrinkling and surface defects of parts shaping.

Owner:SHANGHAI HORNGSHIUE INDAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com