Roller blind assembly

A technology of rolling shutters and rolling springs, applied in door/window protection devices, winding strips, transportation and packaging, etc., can solve the problem of not preventing the torsion spring from fluttering, and achieve the effect of simple buffer profiles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

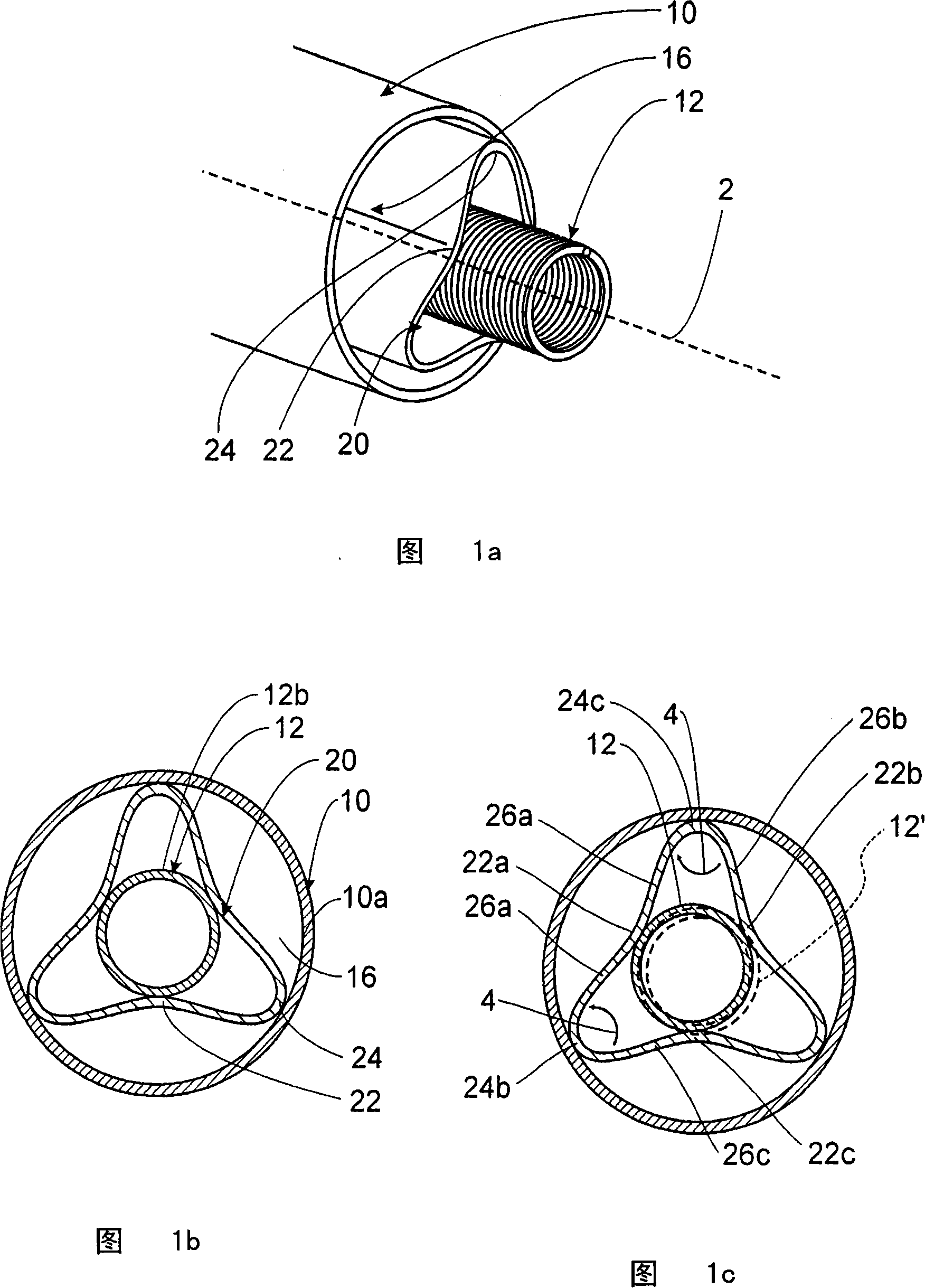

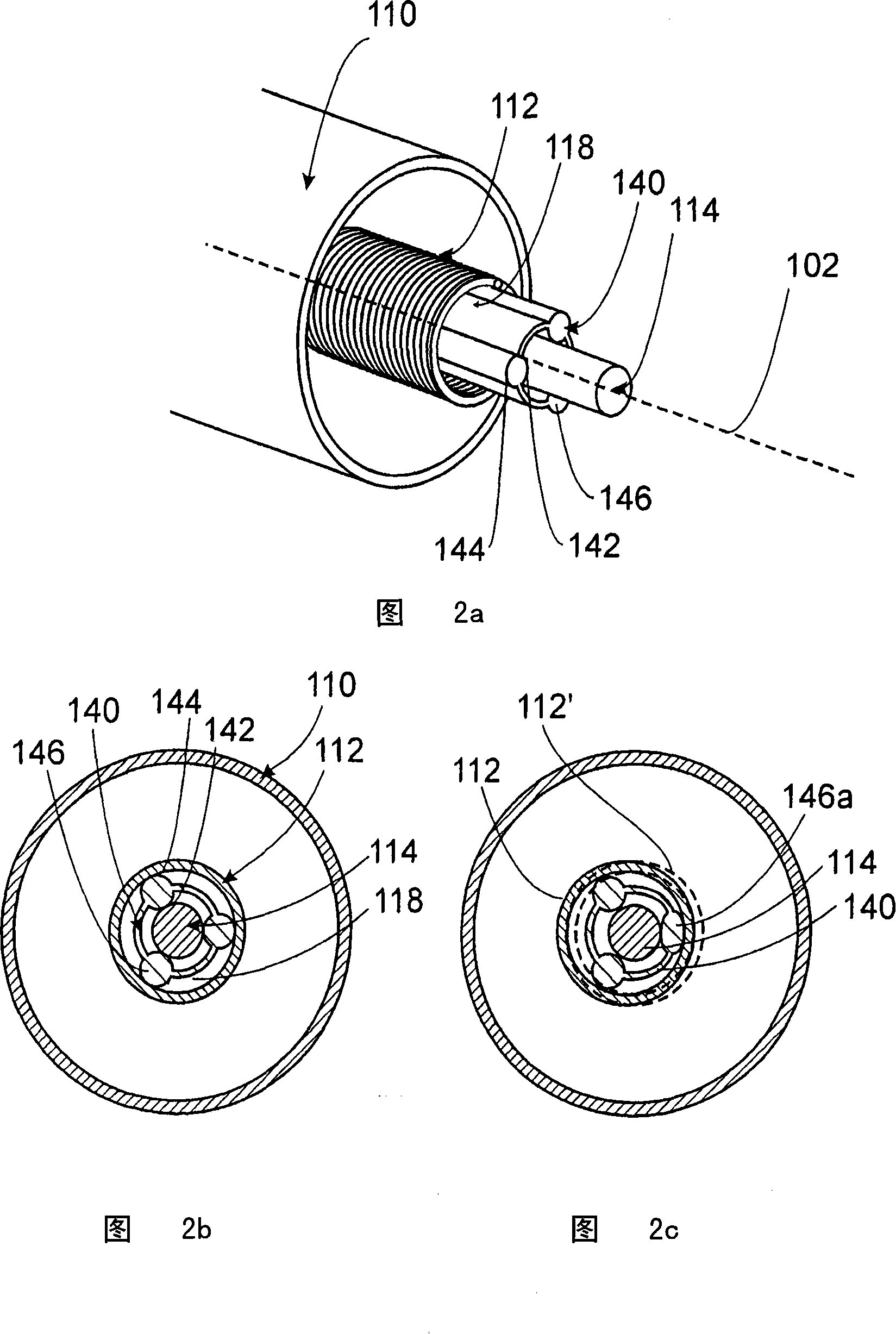

[0036] The illustrated embodiments of the roller blind arrangement according to the invention each only show the roller shaft with the coil spring, the damping element and partly with the spring rod. The remaining components of the roller blind arrangement, such as the flexible flat object or the surrounding housing, are not shown for the sake of clarity.

[0037] FIG. 1 a shows the basic configuration of an example of a first embodiment of a roller shaft of a roller blind arrangement according to the invention: a coil spring 12 is arranged inside the roller shaft 10 , wherein the roller shaft 10 and the coil spring 12 have a common main direction of extension 2 . Inserted in the annular cavity 16 between the reel 10 and the inner coil spring 12 is a damping profile 20 which bears against the coil spring and the reel 10 with an inner contact section 22 and an outer contact section 24 without play.

[0038] FIG. 1 b shows a sectional side view of the reel 10 shown in FIG. 1 a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com