Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

67results about How to "Increase boost ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

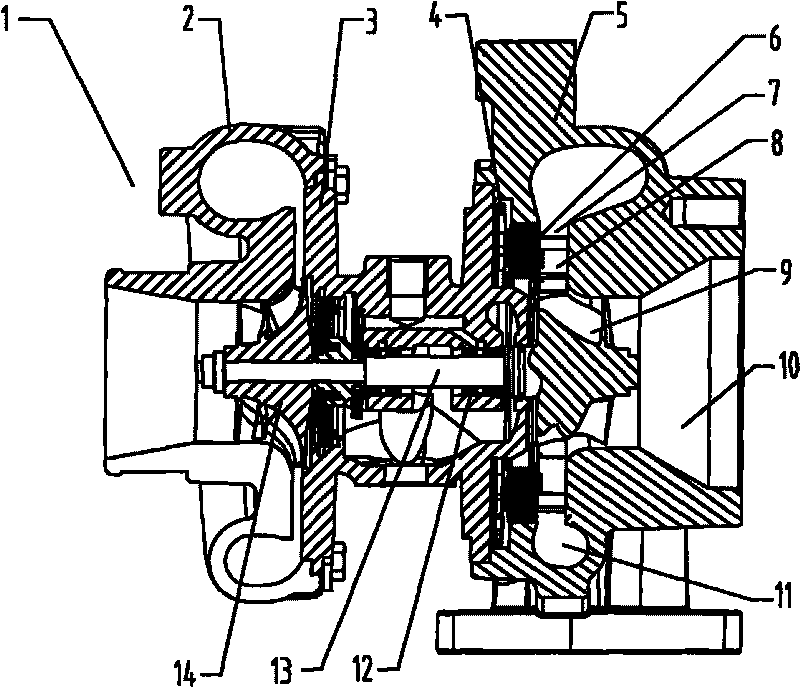

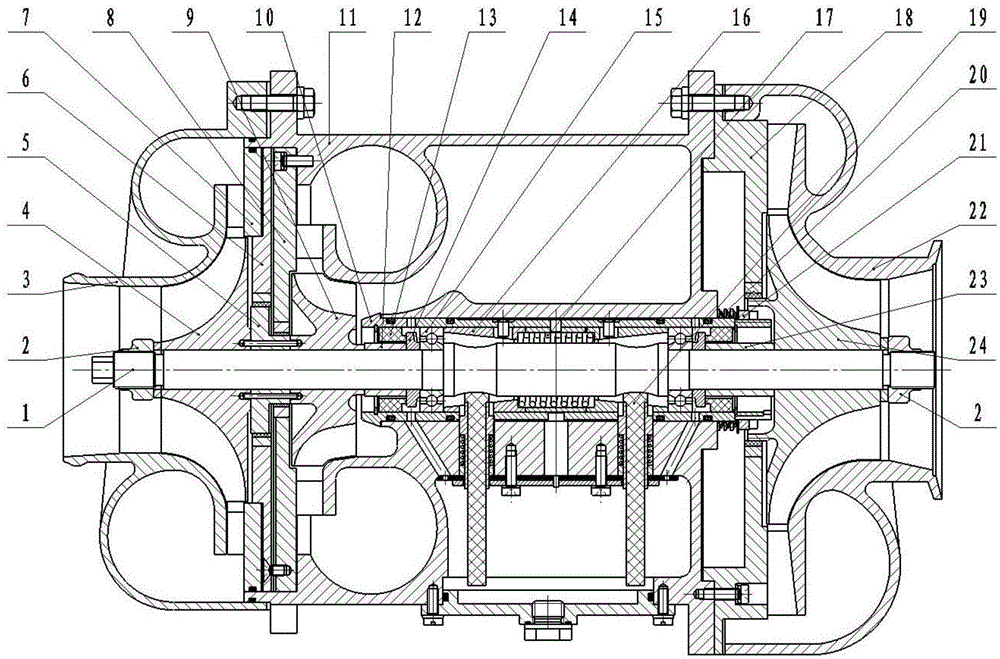

Asymmetric double-channel variable section turbocharger

InactiveCN101694178ALow efficiencyBuilds higher efficiency at low speedsInternal combustion piston enginesImpellerInlet channel

The invention discloses an asymmetric double-channel variable section turbocharger, comprising a turbine volute which is internally provided with a turbine impeller and a volute gas inlet channel; the volute gas inlet channel is provided with a volute nozzle at the position close to the turbine impeller; and the volute gas inlet channel comprises a small volute gas inlet channel and a large volute gas inlet channel which is positioned at one side of the small volute gas inlet channel. The asymmetric double-channel variable section turbocharger carries out modification and designing on the traditional turbine volute, adopts the combination of double gas inlet channels, and forms different through flow sections, and effectively utilizes the energy of waste gas of an engine. By fully utilizing the energy of waste gas exhausted by the engine, the asymmetric double-channel variable section turbocharger realizes the same variable section turbine function, can not change the whole structure greatly, and has low cost and easy realization.

Owner:KANGYUE TECH

Air-steam combined circulating device and air turbine circulating device

ActiveCN104895631AHigh thermal efficiencyImprove thermal efficiencySteam engine plantsCombined combustion mitigationSteam powerPower engineering

The invention provides an air-steam combined circulating device and an air turbine circulating device, and belongs to the technical field of heat energy and power engineering. An air compressor, a boiler, a turbine, a second turbine, an afterheat boiler, a condenser, a circulating pump and a working machine are mainly used for forming the air-steam combined circulating device; the air compressor, the boiler and the turbine form an air power circulating system; the turbine provides power to the air compressor through mechanical connection; the second turbine, the afterheat boiler, the condenser and the circulating pump are formed to a steam power circulating system; and the turbine and the second turbine jointly provide the power to the working machine through mechanical connection. In this way, the air-steam combined circulating device is formed.

Owner:李华玉

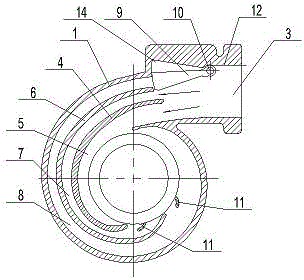

Multi-layer variable geometric volute device

InactiveCN102619617ASatisfy the air intakeMeet supercharging requirementsInternal combustion piston enginesStatorsEngineeringTurbine

The invention discloses a multi-layer variable geometric volute device, which comprises a turbine volute. A volute air inlet passage and a non-blade nozzle are arranged in the turbine volute, and a volute air inlet communicated with the volute air inlet passage is arranged on the turbine volute. A first pneumatic partition plate is arranged in the volute air inlet passage and partitions the volute air inlet passage into a volute air inlet inner passage and a volute air inlet outer passage. A second pneumatic partition plate is arranged in the volute air inlet outer passage and partitions the volute air inlet outer passage into a first branch passage and a second branch passage. The volute air inlet inner passage is a normally-opened air inlet passage. An air inlet adjustment valve for controlling the opening or the closing of the first branch passage and the second branch passage is arranged in the volute air inlet passage close to the volute air inlet. The air inlet adjustment valve can guide the air flow flowing into the volute air inlet inner passage simultaneously when the air inlet adjusting valve is opened or closed. The air inlet adjustment device is simple in structure, the control mode can be easily implemented, and the reliability is high.

Owner:KANGYUE TECH

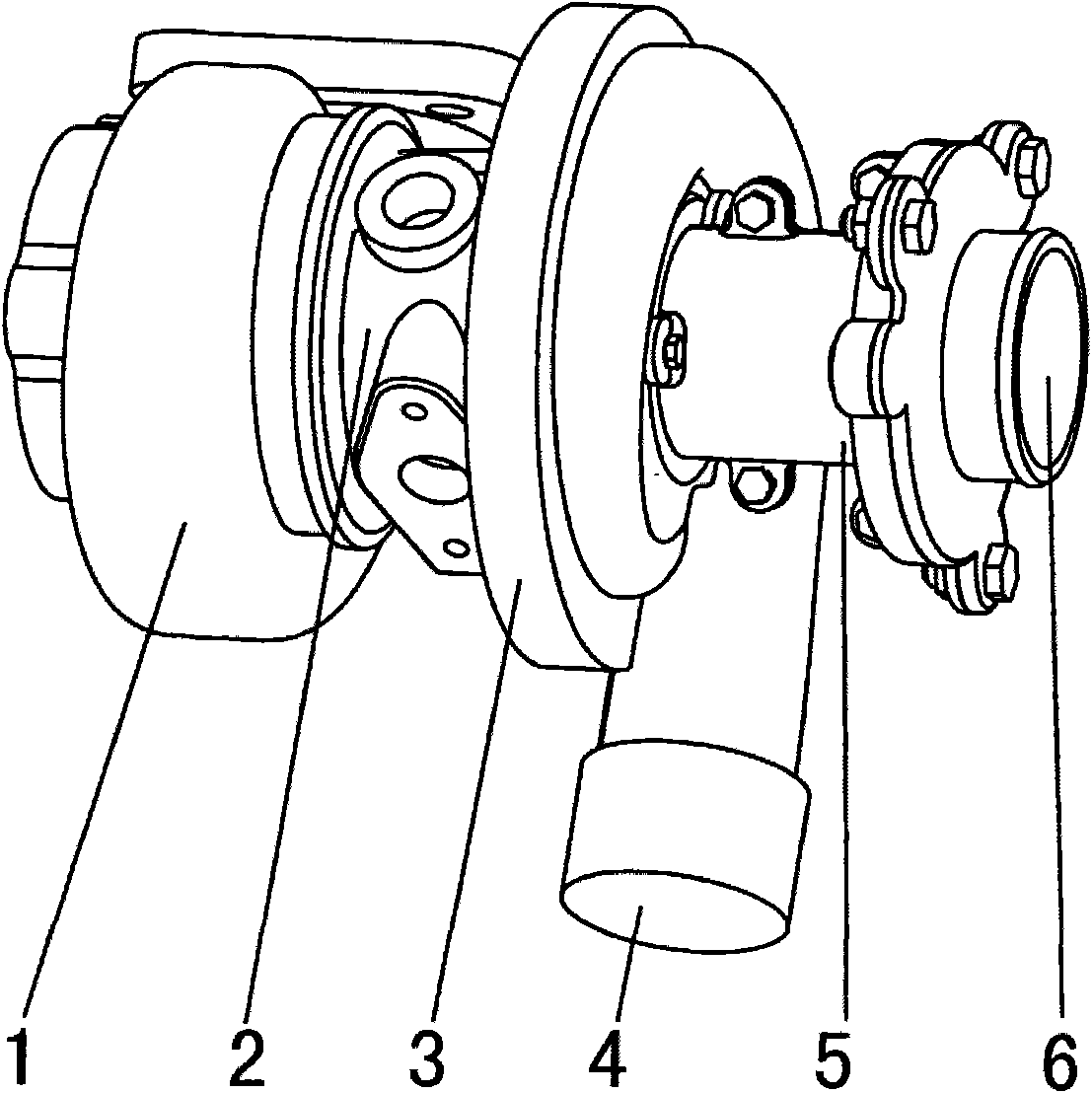

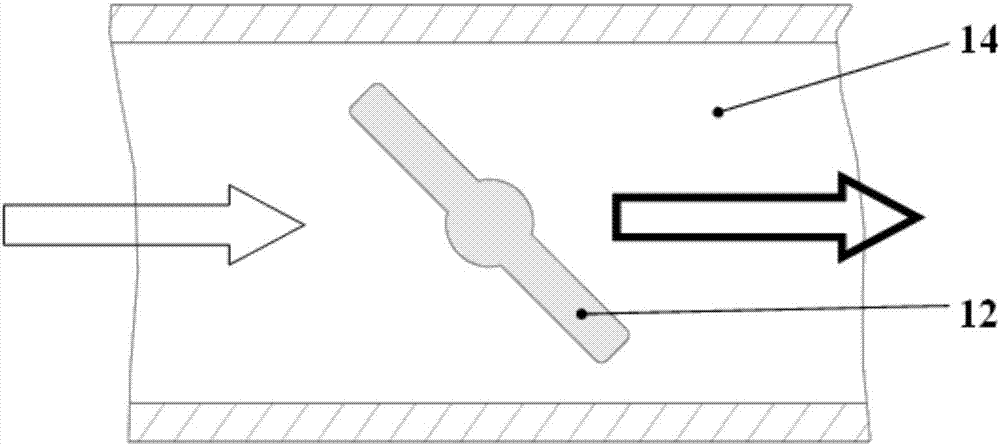

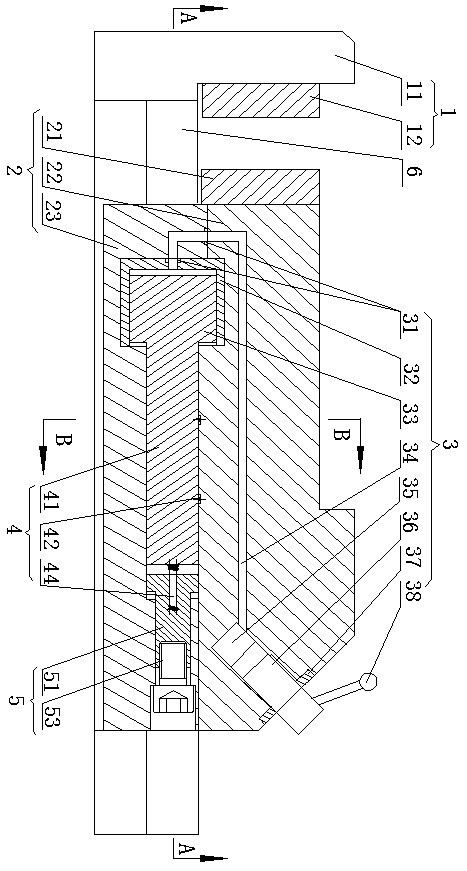

Variable air inlet turbocharger structure

InactiveCN101929381AWide flow rangeImprove efficiencyInternal combustion piston enginesGas turbine plantsTurbochargerStreamflow

The invention provides a turbocharger structure which is applied in the technical field of a turbocharger and can change an air flow direction entering into a press shell. The variable air inlet structure turbocharger comprises a turbine shell (1), a middle shell (2) and the press shell (3); a press shell inlet (41) of the turbocharger structure is provided with an air inlet adjusting device (5) which is capable of changing the air flow direction entering into the press shell (3); the air inlet adjusting device (5) comprises a cavity (34) with a hollow structure; more than one sheet-shaped guide blade (44) is installed in the cavity (34); the air inlet adjusting device (5) further comprises a driving mechanism (49) for driving the guide blade (44) to torque. The technical scheme of the invention can change the air flow direction in the inlet of the gas compressor, efficiently reduce the flow rate while surging, improve the flow rate while blocking, widen the flow rate range of the turbocharger and improve the efficiency and pressure ratio of the turbocharger.

Owner:JAPHL POWERTRAIN SYST

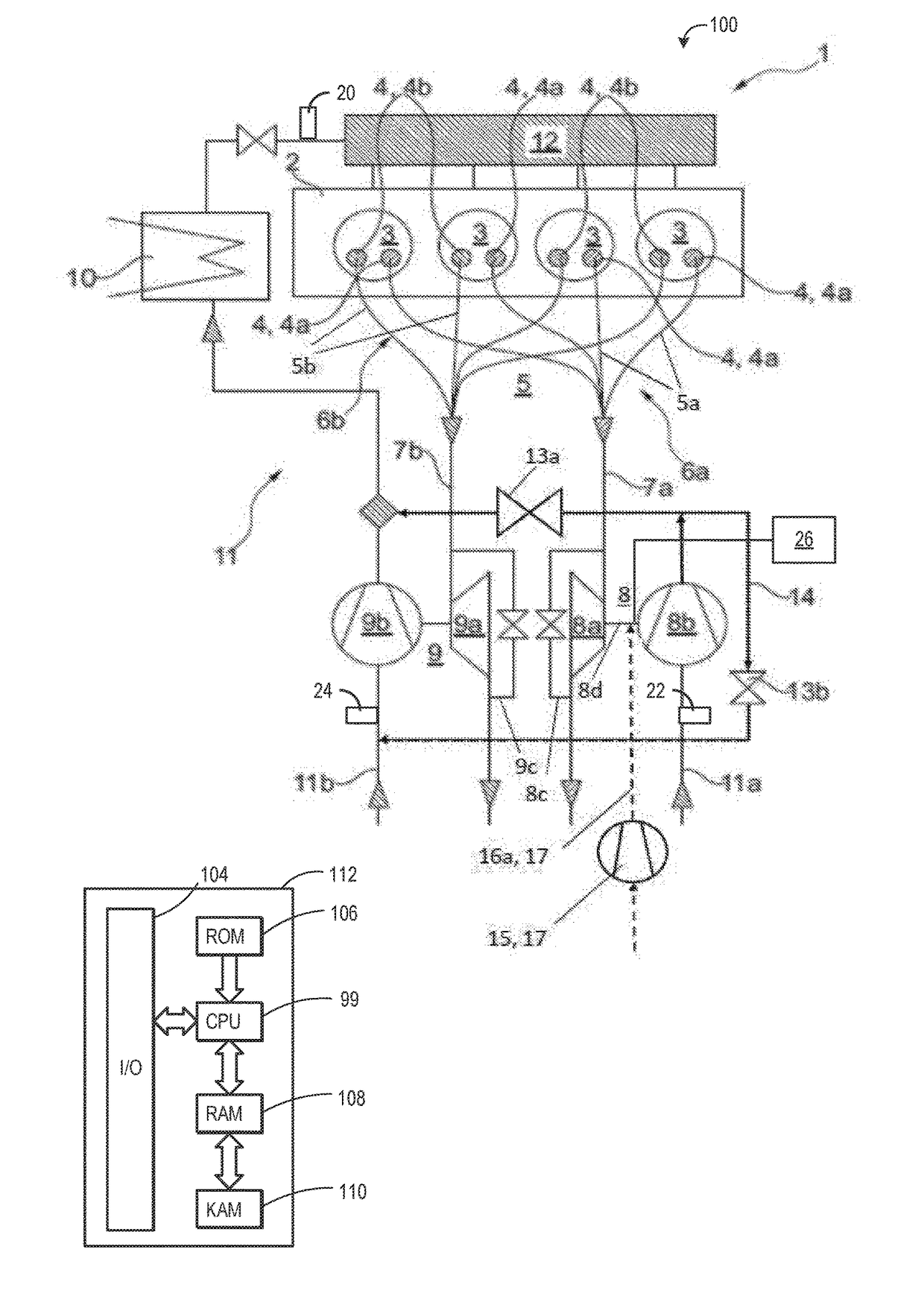

Twin flow supercharged engine

ActiveUS20100326406A1High turbine pressure ratioIncrease boost ratioInternal combustion piston enginesExhaust apparatusEngineeringTurbine

Systems and methods for operating a twin flow supercharged engine are provided. The exhaust lines of engine cylinders are grouped into separate manifolds connected to respective inlet ducts of the twin-flow turbine. The inlet ducts of the twin-flow turbine are of different sizes, with different-sized cross sections and / or different-sized exhaust-gas volumes. The exhaust line of a manifold with a smaller exhaust-gas volume is connected to the larger inlet duct, and the exhaust line of a manifold with the larger exhaust-gas volume is connected to the smaller inlet duct.

Owner:FORD GLOBAL TECH LLC

Turbojet engine

InactiveCN103967649AIncrease intake pressureIncrease thrust-to-weight ratioJet propulsion plantsAxial compressorExhaust valve

A turbojet engine comprises all structures of a turbojet engine such as an axial-flow air compressor, an evaporative combustion chamber, a turbine and a tail jet pipe. The turbojet engine is characterized in that a bypass pipe and an inner exhaust valve are further included, an outer exhaust valve is arranged or not arranged in a pipe outside the engine between an air inlet and an air outlet of the bypass pipe, after the engine is started and operates, the inner exhaust valve is opened, by opening and closing of the bypass pipe, the inner exhaust valve and the existing or nonexistent outer exhaust valve, the supercharge ratio of the axial-flow air compressor is increased and kept unchanged, the increased supercharge ratio is not higher than the limitation borne by the axial-flow air compressor and a turbine according to the mechanical strength, turbine inlet temperature is kept unchanged, namely the supercharge ratio and thrust-weight ratio are increased, oil consumption rate is lowered, the levels of the axial-flow air compressor and the turbine are not increased, and the turbine inlet temperature is not raised.

Owner:李吉光

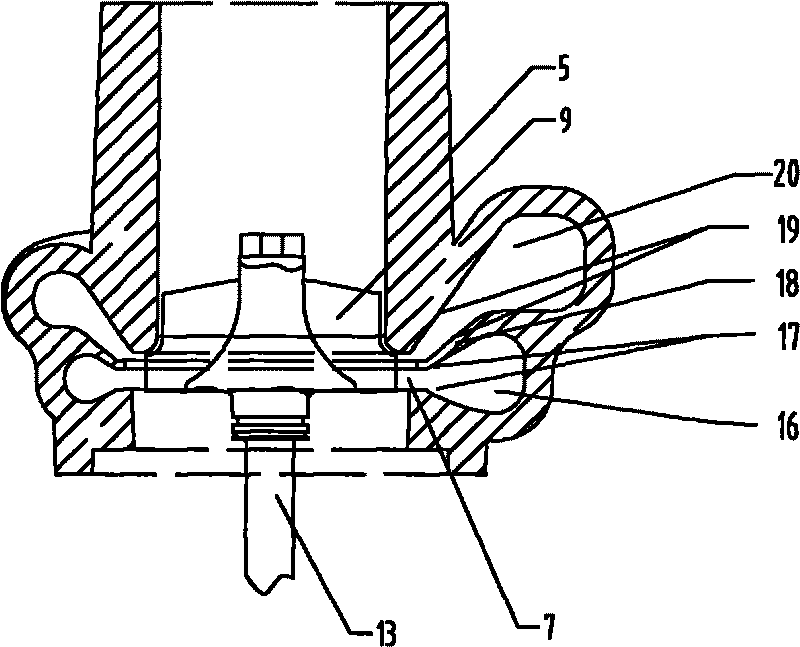

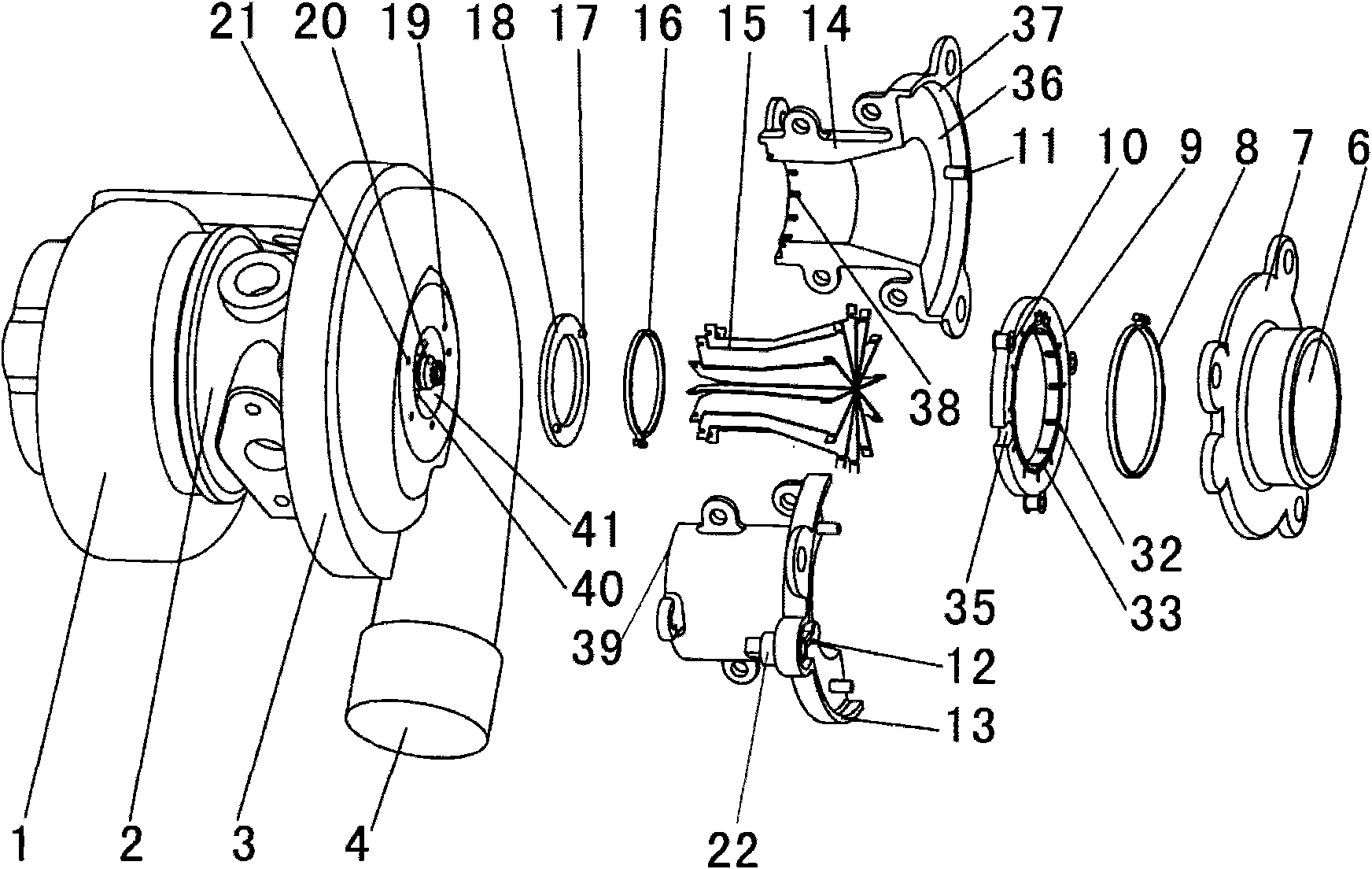

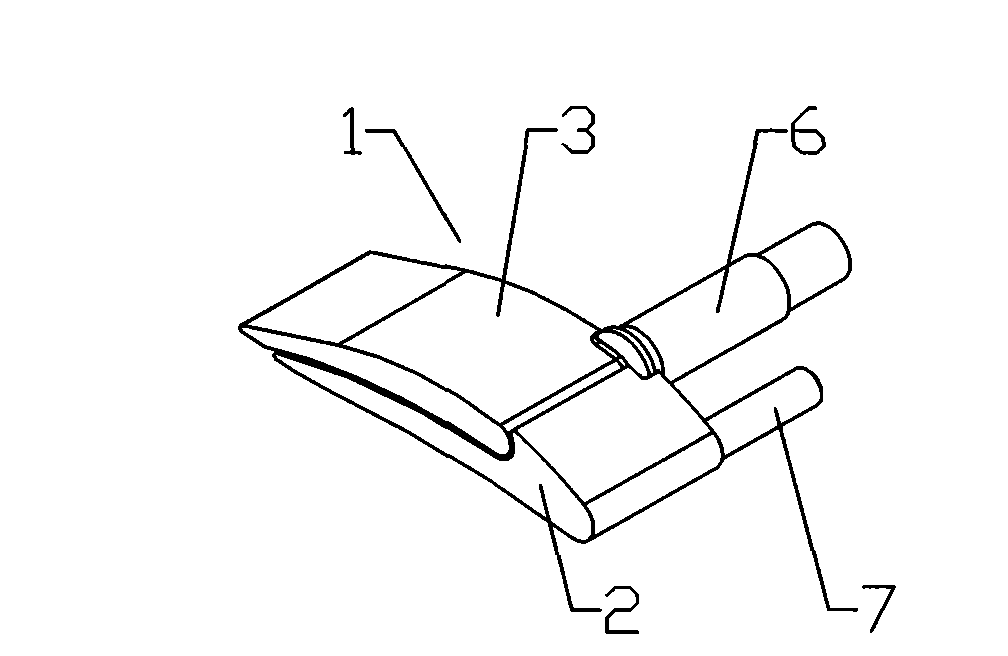

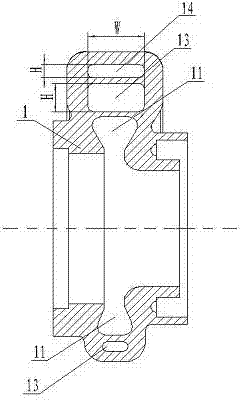

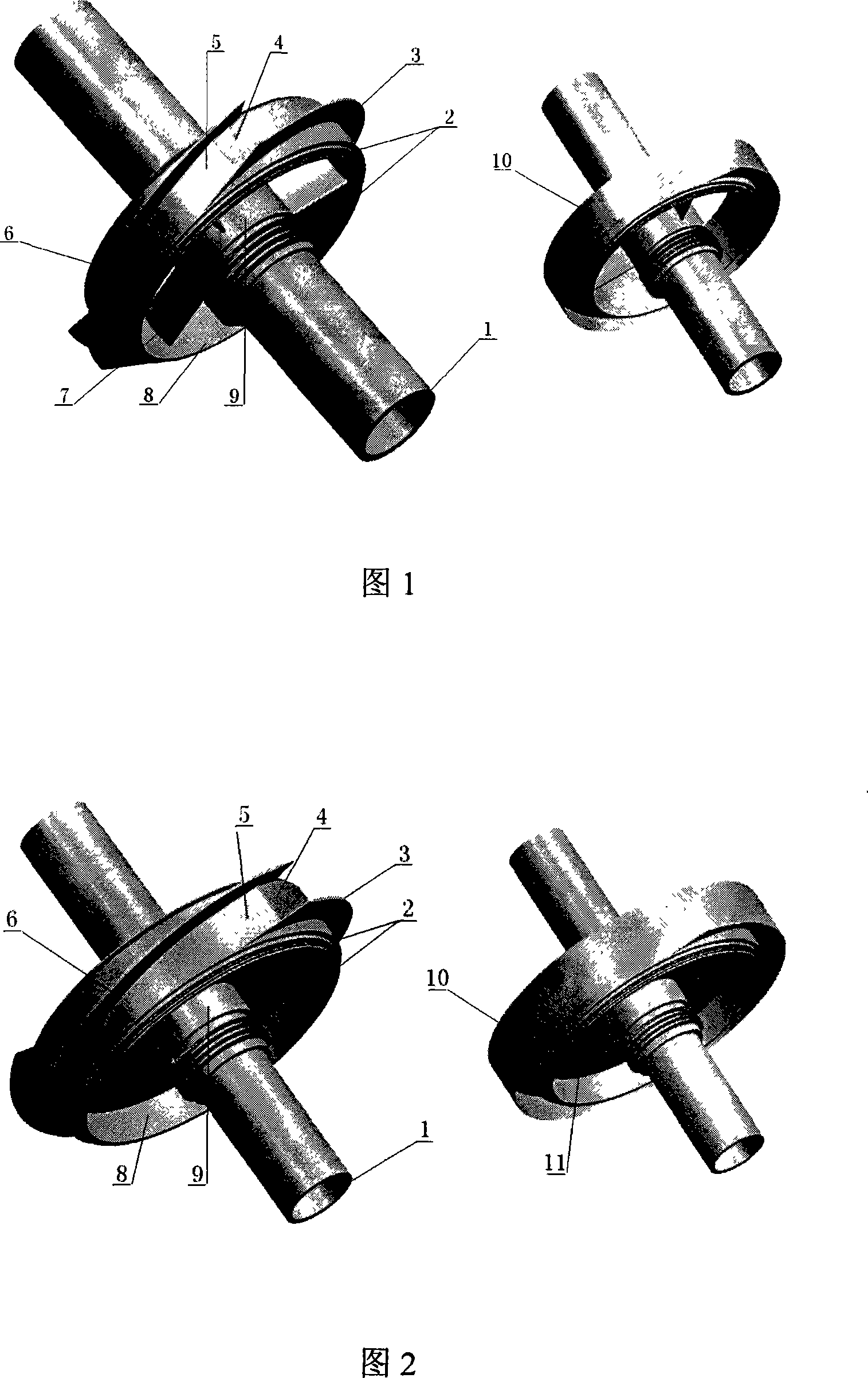

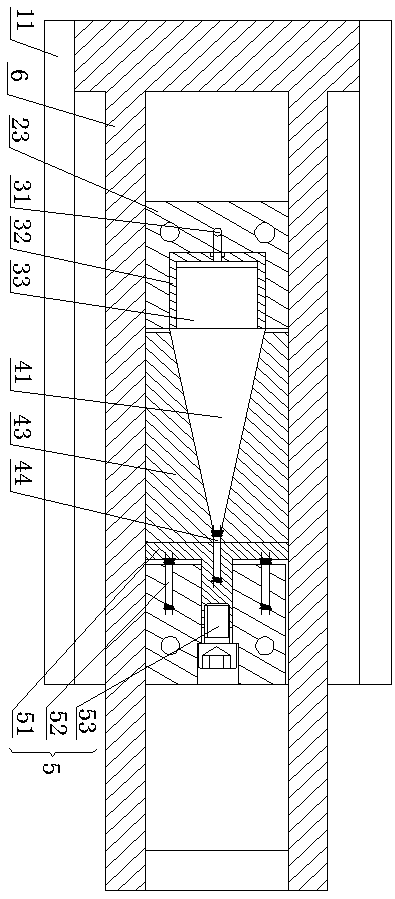

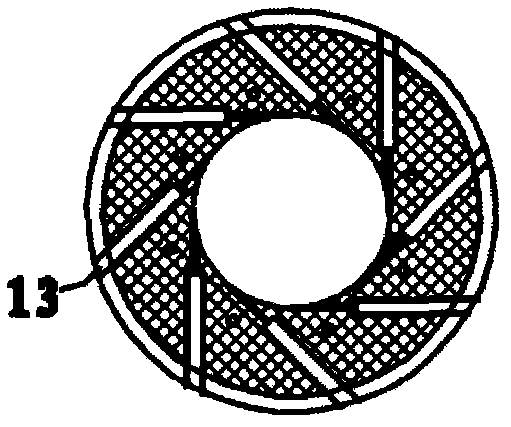

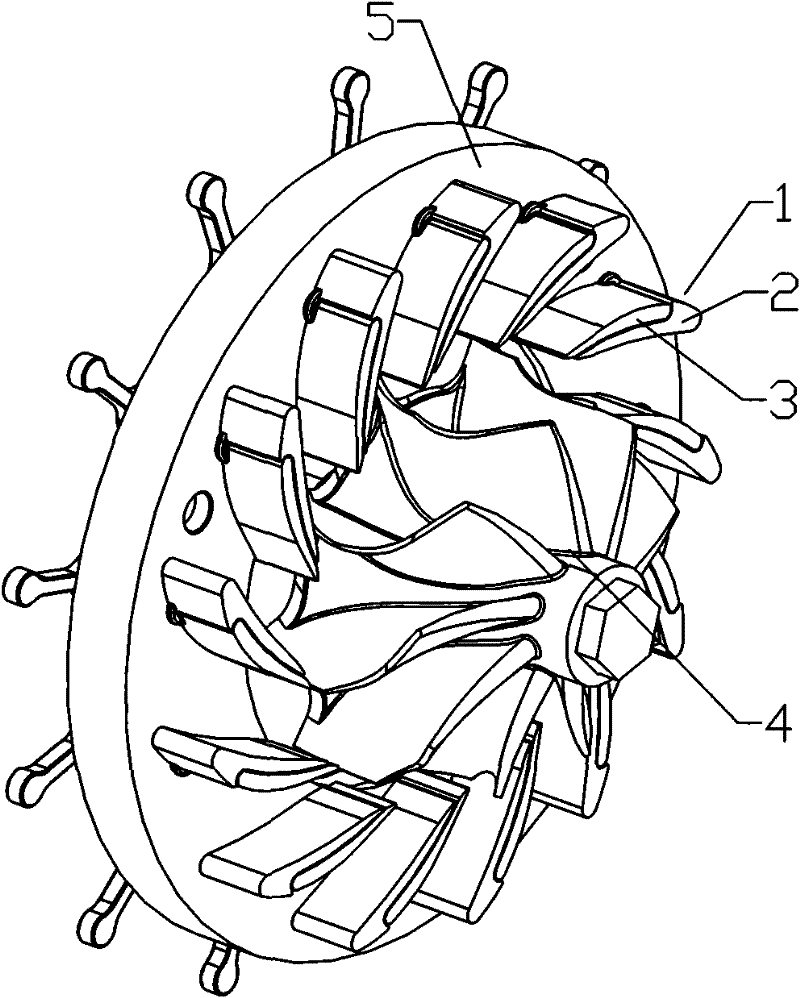

Pneumatic nozzle of variable geometry turbocharger (VGT)

ActiveCN101634233AImprove responsivenessIncrease boost ratioStatorsMachines/enginesEngineeringVariable-geometry turbocharger

The invention relates to a pneumatic nozzle of a variable geometry turbocharger (VGT), comprising a pneumatic nozzle supporting disk, and a plurality of pneumatic nozzle blades which are arranged on the pneumatic nozzle supporting disk, wherein, the pneumatic nozzle blades comprise pneumatic nozzle moving blades and pneumatic nozzle stationary blades, and the pneumatic nozzle stationary blades are internally provided with a flow channel. During operation of the turbocharger, the width of the air flow channel among the adjacent pneumatic nozzle blades can be adjusted by adjusting the rotation angle of the pneumatic nozzle moving blades so as to adjust the pressure ratio of the turbocharger so that the turbocharger is matched with the working condition of an engine; and when adequate pressurizing ratio can not be provided in the event that the working condition of the engine is further reduced and the width of the air flow channel among the adjacent pneumatic nozzle blades is adjusted to the minimum, supplementary gas can be sprayed by a connecting pipe, the channel on the pneumatic nozzle supporting disk and the flow channel on the pneumatic nozzle stationary blades so as to improve the pressure ratio of the turbocharger so that the turbocharger is matched with the working condition of the engine.

Owner:KANGYUE TECH

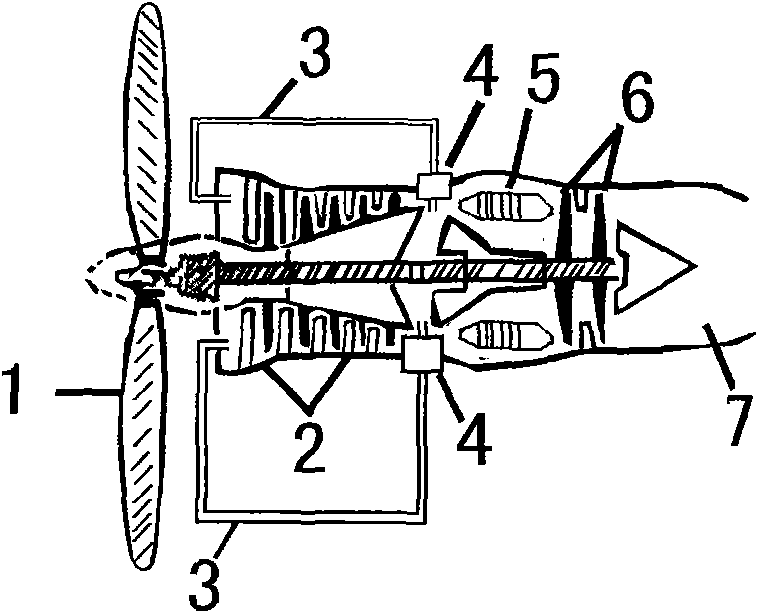

Turbofan engine

InactiveCN103967650AReduce the temperatureIncrease boost ratioJet propulsion plantsAxial compressorCombustion chamber

A turbofan engine comprises all structures of a turbofan engine such as a fan, an outer duct, an axial-flow air compressor, an evaporative combustion chamber, a turbine and a tail jet pipe. The turbojet engine is characterized in that a bypass pipe and an inner exhaust valve are further included, an outer exhaust valve is arranged or not arranged on the bypass pipe between an air inlet and an air outlet of the bypass pipe, after the engine is started and operates, the inner exhaust valve is opened, by opening and closing of the bypass pipe, the inner exhaust valve and the existing or nonexistent outer exhaust valve, the supercharge ratio of the axial-flow air compressor or the fan is increased and kept unchanged, the increased supercharge ratio is not higher than the limitation borne by the fan, the axial-flow air compressor and a turbine according to the mechanical strength, turbine inlet temperature is kept unchanged, namely the supercharge ratio and thrust-weight ratio are increased, oil consumption rate is lowered, the levels of the fan, the axial-flow air compressor and the turbine are not increased, and the turbine inlet temperature is not raised.

Owner:李吉光

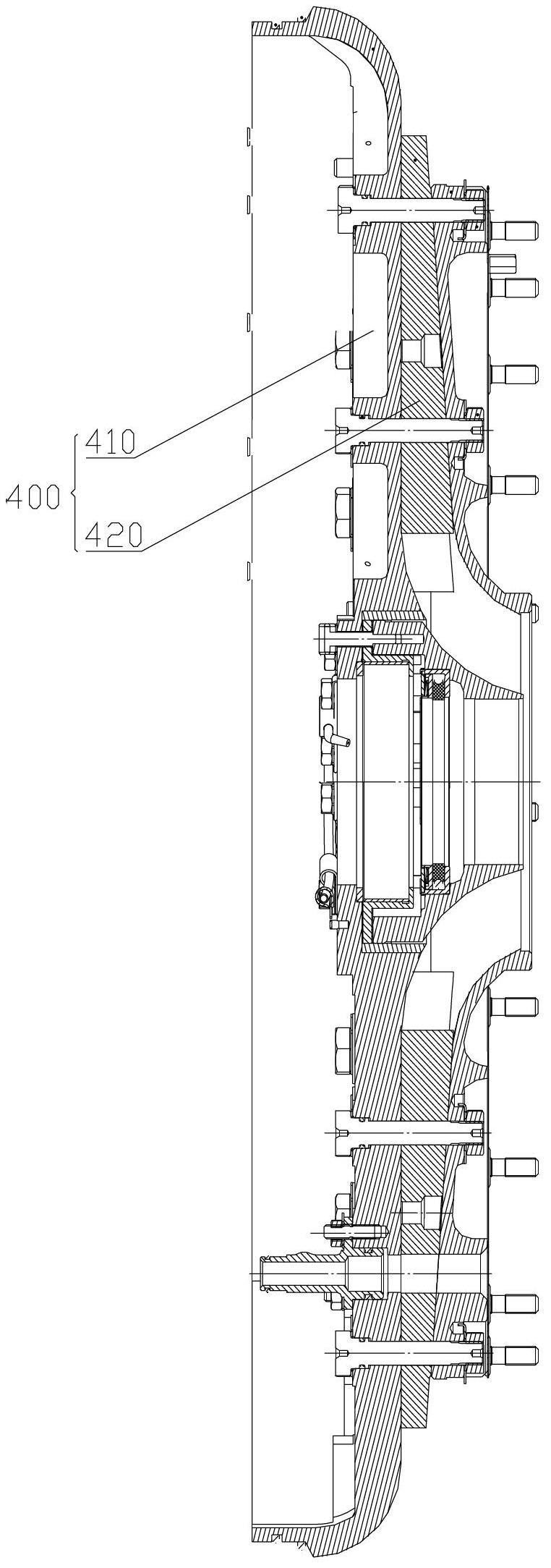

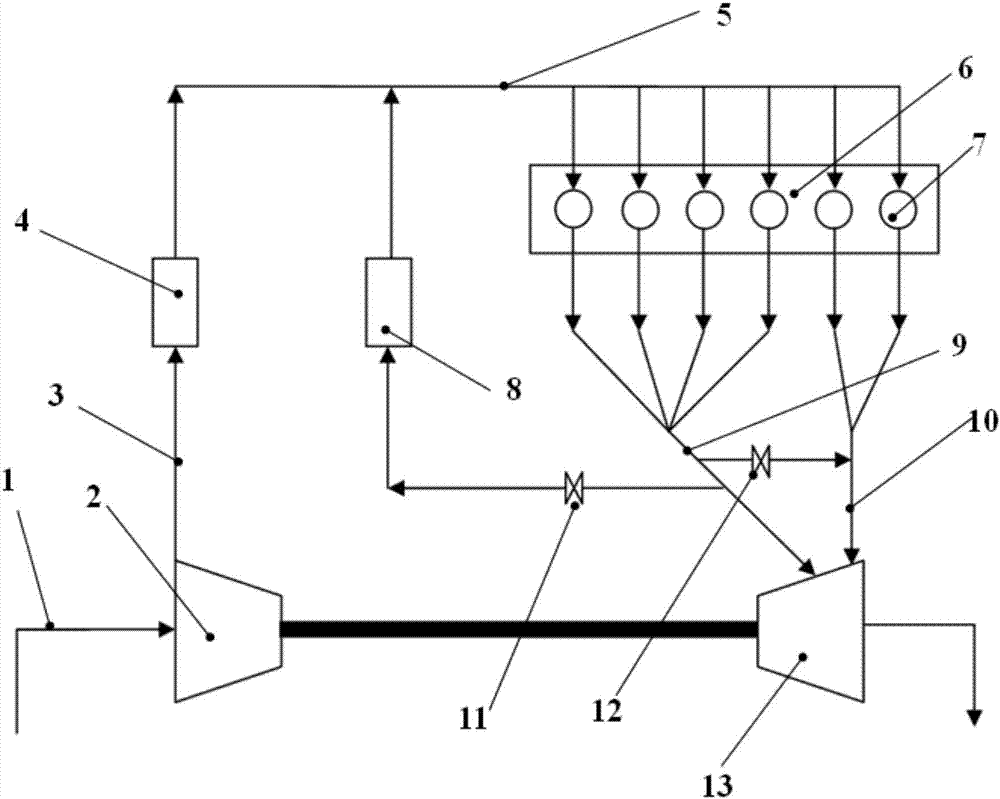

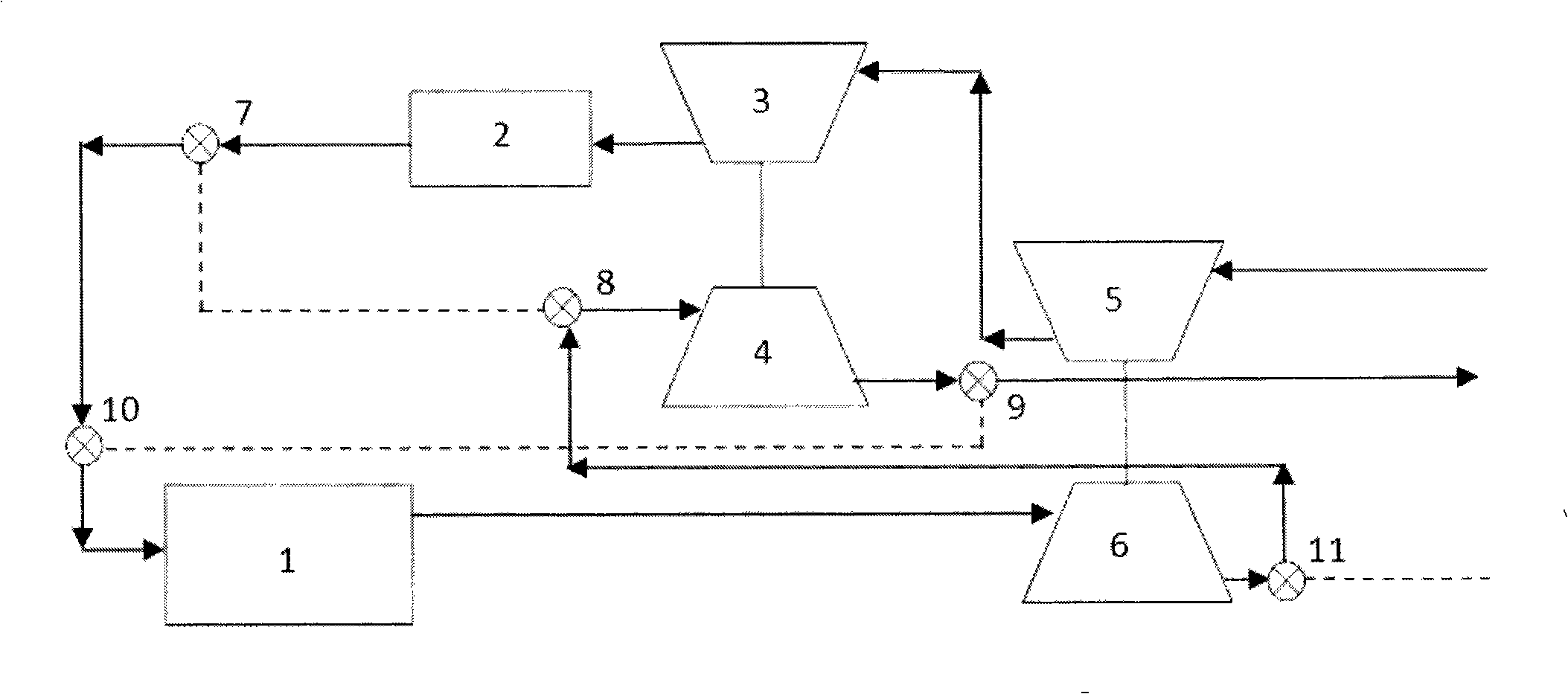

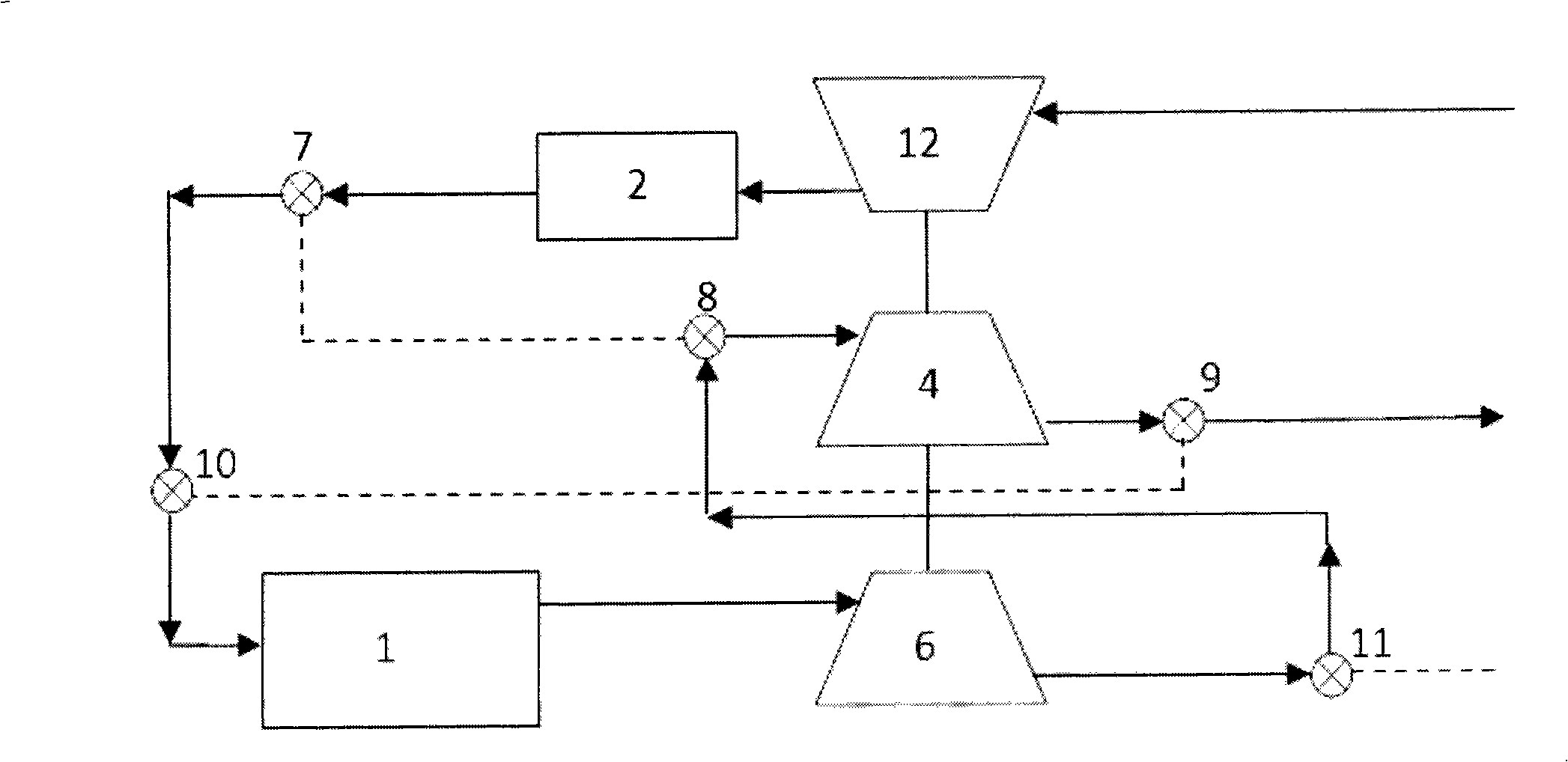

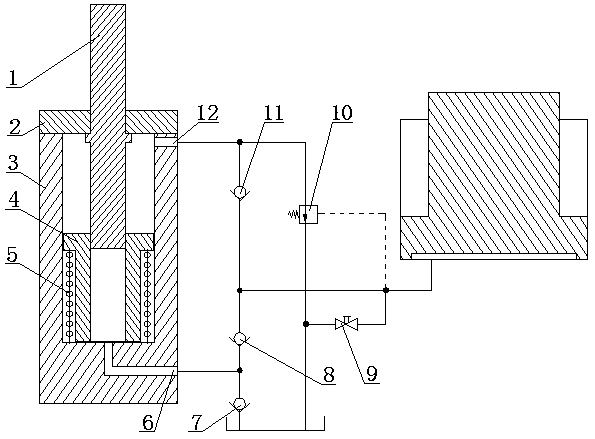

Level-variable turbocharging system and engine with same

ActiveCN103615308AImprove machine efficiencyGood acceleration and responsivenessInternal combustion piston enginesTurbochargerEngineering

An engine with a level-variable turbocharging system comprises an engine body (1) and the level-variable turbocharging system, wherein the engine body (1) comprises an engine mechanical assembly and an engine electric control unit; the level-variable turbocharging system comprises a large turbocharger (21), a middle turbocharger (22) and a small turbocharger (23) which are different in flow, each of the turbochargers comprises a turbine and an air compressor which form a network with an air pipe through a tee joint (312), a tee joint (322), a tee joint (331), a tee joint (342), a tee joint (381), a tee joint (412), a tee joint (422), a tee joint (441), a tee joint (451), a three-way valve (311), a three-way valve (321), a three-way valve (341), a three-way valve (351), a three-way valve (411), a three-way valve (421) and a three-way valve (461), and connected with the engine body (1).

Owner:HUNAN TYEN MACHINERY

Rotating disc type aircraft engine

InactiveCN102128080AScientific and reasonable structureSmall volume and massInternal combustion piston enginesAviationCombustion chamber

The invention provides a rotating disc type aircraft engine which comprises a combustion chamber, a cylinder body, a rotating disc, a blade and a piston which is connected to the rotating disc, wherein the cylinder body is of a hollow ring shape and is provided with an air inlet and an air outlet; the piston is contained in the cylinder body; the combustion chamber is connected to the cylinder body and is arranged corresponding to the air inlet of the cylinder body; the combustion chamber is used for inputting and igniting oil gas and applying motive power to the piston; the rotating disc and the blade on the rotating disc are driven by the piston to rotate; and motive power is generated by the rotation of the blade. Compared with the prior art, the rotating disc type aircraft engine provided by the invention has the advantages of scientific and reasonable structure, smaller size, light weight, high energy conversion efficiency, improved rotation speed and improved blade tolerance, is especially applied to the fan motive power of a large turbofan engine with high-bypass ratio, thus fuel can be saved, and the rate of supercharging and push power of the engine can be improved.

Owner:王仲彦

Variable geometry volute device

ActiveCN102852572AImprove turbo intake efficiencyIncrease boost ratioInternal combustion piston enginesEngine componentsOpen airVariable geometry

The invention discloses a variable geometry volute device which comprises a turbine volute. A volute air inlet runner is arranged in the turbine volute, a turbine pneumatic separation plate divides the volute air inlet runner into an inner volute air inlet runner and an outer volute air inlet runner, a second pneumatic separation plate is arranged in the outer volute air inlet runner and divides the outer volute air inlet runner into a first branch runner and a second branch runner, and the second branch runner is located on a circumferential outside of the first branch runner. The inner volute air inlet runner is a normally-opened air inlet runner, an air inlet adjusting valve for controlling the first branch runner and the second branch runner to open and close is arranged in the volute air inlet runner close to the position of a volute inlet. The variable geometry volute device achieves variable critical area valve at the position of a throat of the turbine volute through the air inlet adjusting valve so as to effectively meet performance requirements of an engine under each working conditions.

Owner:康跃科技(山东)有限公司

Turboprop engine

InactiveCN103967617AStable temperatureIncrease intake pressureGas turbine plantsJet propulsion plantsAxial compressorCombustion chamber

A turboprop engine comprises all structures of a propeller, axial-flow compressors, evaporative combustors, turbines, an exhaust nozzle and the like, and is characterized by further comprising by-pass pipes and internal exhaust valves, and external exhaust valves are mounted or are not mounted in pipes outside the engine and between air inlets and air outlets of the by-pass pipes; and when the engine is started for operation, the internal exhaust valves are opened, the supercharge ratios of the axial-flow compressors are increased and kept unchanged by means of the by-pass pipes and through opening and closing of the internal exhaust valves or the internal exhaust valves and the external exhaust valves, the increased supercharge ratios are not larger than the mechanical strength limit which can be borne by the axial-flow compressors and the turbines, the turbine inlet temperature is kept unchanged, that is, the supercharge ratios and a power weight ratio are increased, the oil consumption rate is reduced, however, the number of stages of the axial-flow compressors and the turbines is not increased, and the turbine inlet temperature is not increased.

Owner:李吉光

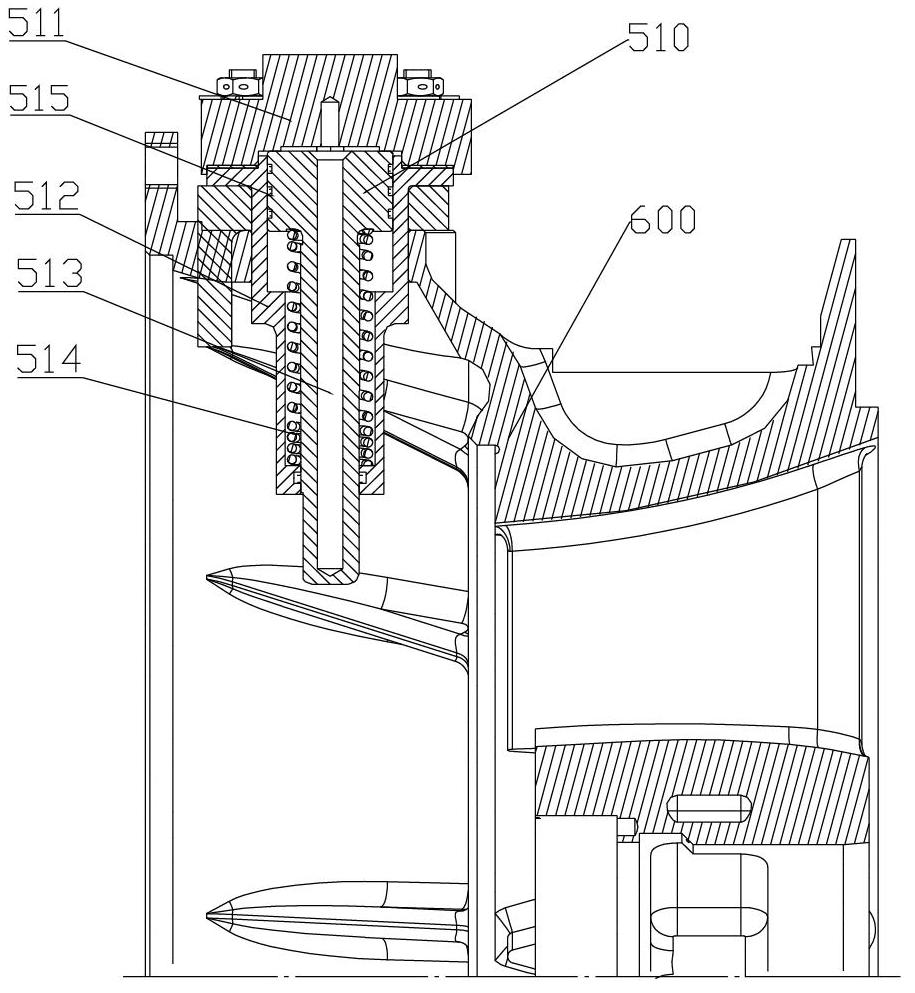

Double-stage centrifugal air compressing device

ActiveCN102691666AIncrease boost ratioReduce fuel consumptionPump componentsRadial flow pumpsImpellerDouble stage

The invention provides a double-stage centrifugal air compressing device. The double-stage centrifugal air compressing device comprises a first-stage centrifugal air compressing device, a second-grade centrifugal air compressing device, a connecting shaft and a reflowing device, wherein the first-stage centrifugal air compressing device comprises a first centrifugal impeller and a first shell; the second-grade centrifugal air compressing device comprises a second centrifugal impeller and a second shell; the connecting shaft is fixedly connected with the first-stage centrifugal air compressing device; the second-grade centrifugal air compressing device is movably connected with the connecting shaft; and the first-stage centrifugal air compressing device is connected with the second-grade centrifugal air compressing device through the flowing device. According to the double-stage centrifugal air compressing device, the first-stage centrifugal air compressing device is connected with the second-grade centrifugal air compressing device through the flowing device, so that the pressurizing ratio of the air compressing device is improved and the oil consumption amount is reduced; and meanwhile, the quantity of parts of the air compressing device is reduced and the manufacturing cost of the air compressing device is reduced.

Owner:HUNAN HANGXIANG GAS TURBINE

Turbine cooler provided with three coaxial impellers and capable of expanding in two ways

ActiveCN104612764AIncrease boost ratioImprove cooling effectMachines/enginesEngine componentsImpellerRefrigeration

The invention relates to a turbine cooler provided with three coaxial impellers and capable of expanding in two ways. The design that the three impellers, namely, the refrigeration turbine impeller (T), the power turbine impeller (T) and the gas compressor impeller (C), are coaxial is adopted for a shaft system of the turbine cooler, and the refrigeration turbine impeller, the power turbine impeller and the gas compressor impeller are sequentially arranged in the sequence of T, T and C. Compared with a conventional double-impeller (T and C) turbine cooler, the turbine cooler has the advantages that a power turbine unit is added between a refrigerator turbine and a gas compressor, auxiliary power is provided for pressurizing the gas compressor, the pressure ratio of the gas compressor and the expansion ratio of the refrigeration turbine are increased, the refrigerating capacity of the refrigeration turbine is improved, and therefore the technical purpose of refrigeration under the low flight Mach number and large cold plate flow resistance of an onboard avionic pod environment control system can be effectively achieved.

Owner:JINCHENG NANJING ELECTROMECHANICAL HYDRAULIC PRESSURE ENG RES CENT AVIATION IND OF CHINA

Hollow shaft rotating stamping compression rotor based on shock compress technique

The invention relates to a hollow shaft rotation stamping compression rotor based on the shock compression technology, belonging to the gas turbine field, which comprises a hollow shaft, a sealing device, a wheel disc and a gas inlet flow channel on the outer edge of the wheel disc; wherein the wheel disc and the hollow shaft are made into a whole or the wheel disc is connected with the hollow shaft through a connecting key or a bearing; the outer edge of the wheel disc is provided with a certain amount of gas inlet flow channels, the gas inlet flow channel is composed of the outer edge of the wheel disc, a partition board arranged on the outer edge of the wheel disc, a gas flow contraction surface, a subsonic diffuser and an outer casing; the wheel disc and the hollow shaft of the gas inlet end and the gas outlet end of the compression rotor are provided with the sealing device. When the compression rotor rotates with the enough high speed, the gas flow is sucked into the gas inlet flow channel and discharged through the multi-shock produced by the gas flow contraction surface and the pressurization of the subsonic diffuser. The invention has the advantages of the high pressurization ratio, the high compression efficiency, the simple and compact structure, the small volume, the light weight, the low manufacturing cost, the convenient disassembly and assembly, the easy maintenance and the high reliability.

Owner:DALIAN MARITIME UNIVERSITY

Double-channel turbocharger

ActiveCN106870214ASatisfy low-speed supercharging needsIncrease boost ratioExhaust gas recirculationMachines/enginesImpellerEngine efficiency

The invention discloses a double-channel turbocharger. The double-channel turbocharger comprises a turbine motor, wherein a worm impeller, a volute high-pressure gas inlet channel and a volute low-pressure gas inlet channel are arranged in the turbine motor; a high-pressure gas exhaust manifold and a low-pressure exhaust manifold are arranged on an engine; the volute high-pressure gas inlet channel is connected with the high-pressure gas exhaust manifold; the volute low-pressure gas inlet channel is connected with the low-pressure gas exhaust manifold; a connecting channel and a regulating valve are arranged between the high-pressure gas exhaust manifold and the low-pressure gas exhaust manifold; and number of connecting air cylinders of the high-pressure gas exhaust manifold is greater than that of the low-pressure gas exhaust manifold. In a low-speed area, the regulating valve is closed or has certain aperture, so that gas exhaust back pressure of the volute high-pressure gas inlet channel is higher than gas inlet pressure after turbo-charge; meanwhile, more exhausted gas flows into a turbine from the volute high-pressure gas inlet channel, so that medium-low-rotation-speed turbo-charge needs of the engine are met. In a large-load medium-high-speed area, the regulating valve is opened for discharging exhausted gas of the high-pressure gas exhaust manifold into the low-pressure gas exhaust manifold under a condition that enough gas exhaust back pressure is guaranteed, so that gas exhaust back pressure of the high-pressure channel is reduced, pumping gas loss is reduced and engine efficiency s improved.

Owner:CHINA FIRST AUTOMOBILE

Supercharging gasoline engine air administrative system

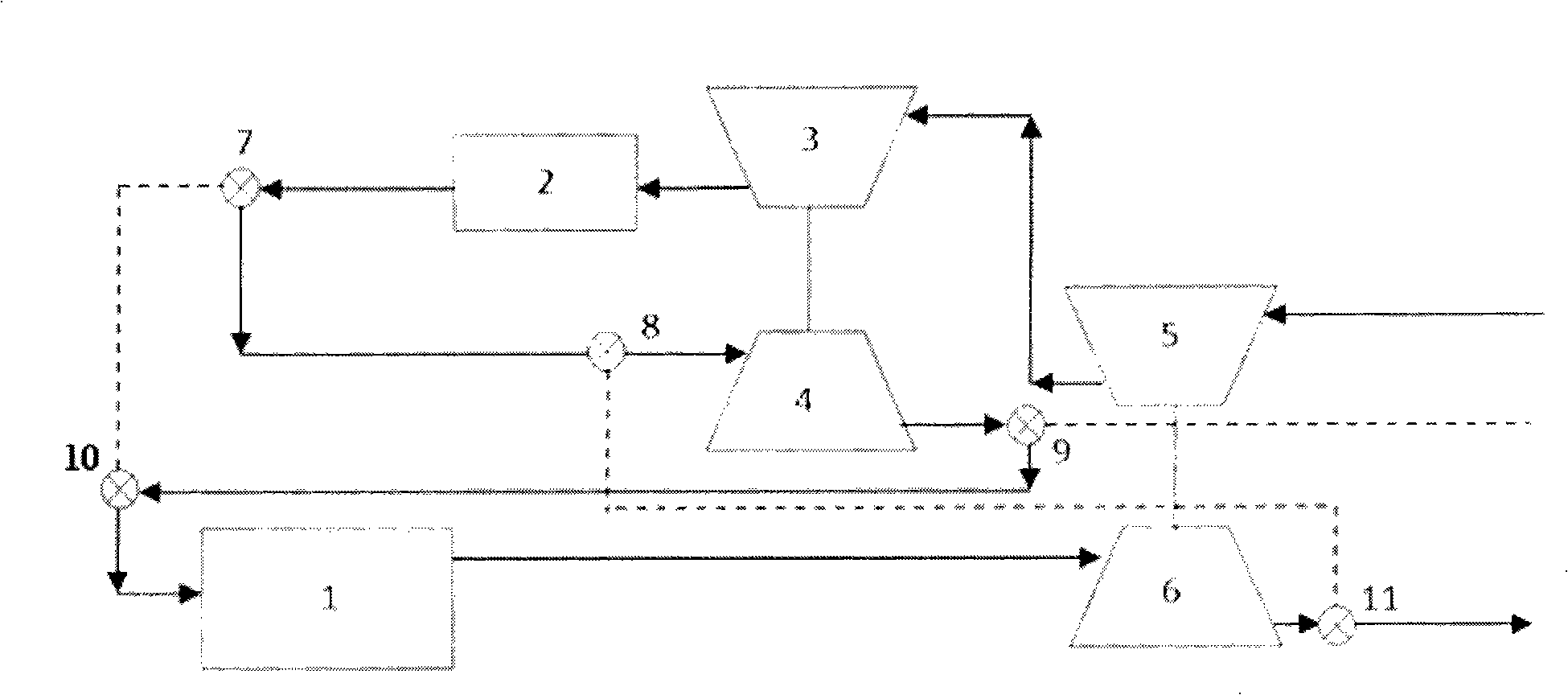

InactiveCN101333959AControl intake air temperatureIncrease boost ratioInternal combustion piston enginesAir managementLow speed

The invention belongs to the gasoline engine field, in particular to an air management system of a supercharger gasoline engine, which comprises an air compressor, an intercooler, a main turbine and a double-effect turbine; in the medium or high speed operating condition, the double-effect turbine is serially connected behind the intercooler; the a cylinder and a main turbine are serially and sequentially connected behind the double-effect turbine; the double-effect turbine acts the turbine cooling effect; in the low speed operating condition, the intercooler, the cylinder and the main turbine are serially connected, and then the double-effect turbine is serially connected; the double-effect turbine acts the effect of improving the output torque. The air management system of a supercharger gasoline engine has the advantages of realizing the functions of turbine cooling and the double turbo supercharging, well controlling the inlet gas temperature, allowing higher supercharging ratio and improving the low-speed torque, adopting different operation modes under the high, medium and low rotation speeds, enabling the operation state of the system to be optimized under different operating conditions.

Owner:TSINGHUA UNIV

Hollow-shaft ram-rotor based on shock wave compression technology

InactiveCN105626579AIncrease boost ratioImprove compression efficiencyPump componentsPumpsShock waveAirflow

The invention discloses a hollow-shaft ram-rotor based on the shock wave compression technology. The hollow-shaft ram-rotor comprises a hollow shaft, a wheel disc assembly assembled with the hollow shaft in a synchronously rotating mode and an outer case arranged outside the wheel disc assembly in a covering mode, wherein a plurality of spiral separating plates are evenly distributed on the surface of the outer wall of the outer edge of a wheel disc of the wheel disc assembly, and the installation angles of all the spiral separating plates are identical; an air inlet flow channel is formed by a gap between every two adjacent spiral separating plates, and each air inlet flow channel is provided with an air flow compression section, a throat separating section and a triangular outlet extension section which are sequentially arranged from the inlet end to the outlet end. Each air flow compression section is a compression air channel with the radial gap being gradually reduced; each throat separating section is an equal-area passage with the radial gap kept unchanged; each triangular outlet extension section is an air channel with the radial gap kept unchanged, and the interior of the peripheral cylindrical surface of each triangular outlet extension section is triangular. According to the hollow-shaft ram-rotor adopting the technical scheme, fluid is compressed by a curved shock wave system, the supercharge ratio is high, and the hollow-shaft ram-rotor is simple and compact in overall structure and high in reliability.

Owner:DALIAN MARITIME UNIVERSITY

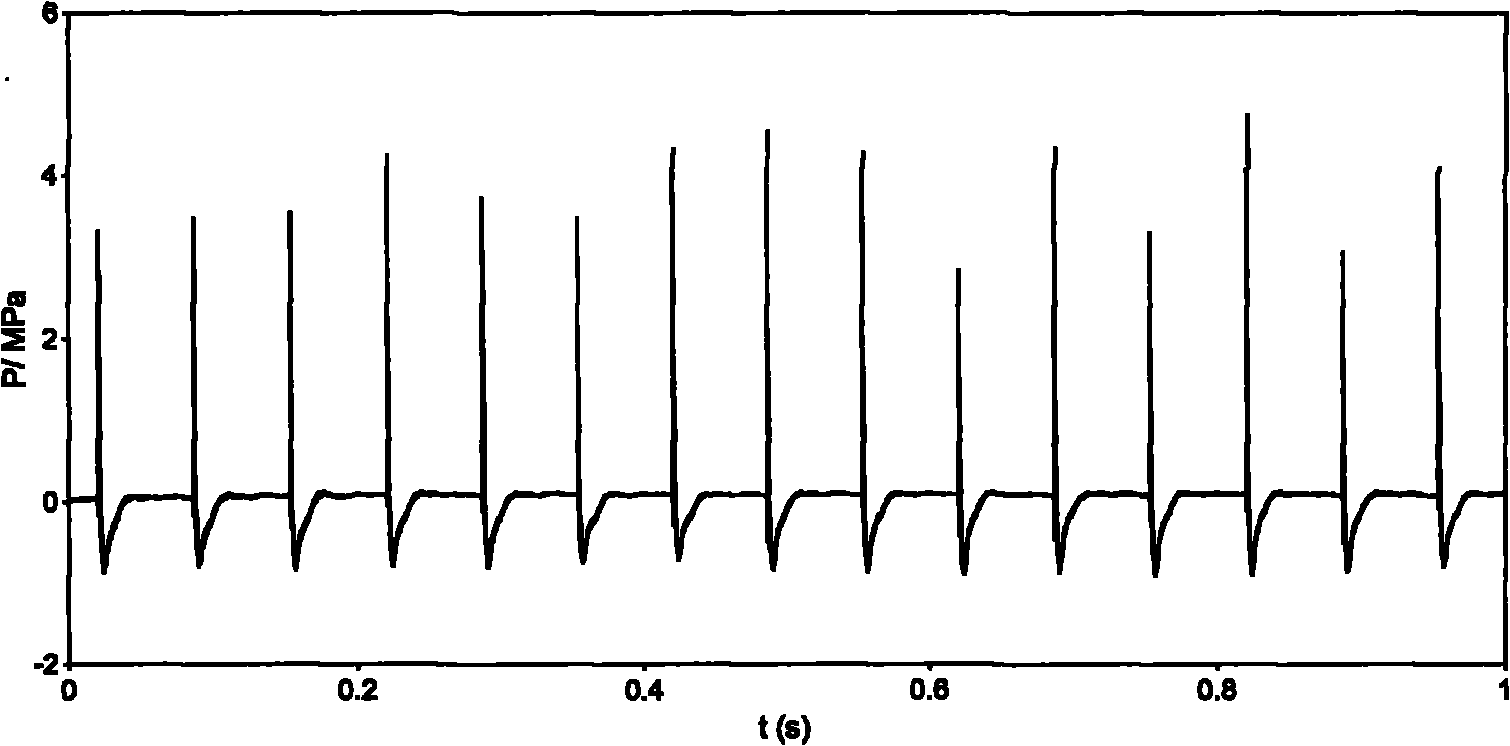

Power plant of water surface ship

InactiveCN102086822AReduce failure rateIncrease boost ratioPower plants being motor-drivenIntermittent jet plantsTrombe wallDetonation

The invention discloses a power plant of a water surface ship. The power plant comprises a pulse detonation tube and an engine inclined tube body, wherein the engine inclined tube body is divided into an inclined section and an outlet section, and a buckling is arranged between the inclined section and the outlet section; the port of the inclined section of the inclined tube body of an engine is coaxially connected with the outlet of the pulse detonation tube by virtue of a flange, and the tube wall of the inclined section is provided with a pressure probe; a controllable water inlet with a close device is arranged on the tube wall of the inclined section, and a signal processing system and a steering engine are connected between the close device and the pressure probe in series; the projected area of the outlet section of the controllable water inlet on the transverse section is at least 50% of that of the outlet section port; and when the power plant of the water surface ship works, the outlet section of the engine inclined tube body is below the water surface, and the controllable water inlet is below the water surface. According to the invention, the high temperature, high voltage, high speed fuel gas and detonation waves are generated by adopting the detonation tube to propel the fluid to be exhausted to generate push power.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

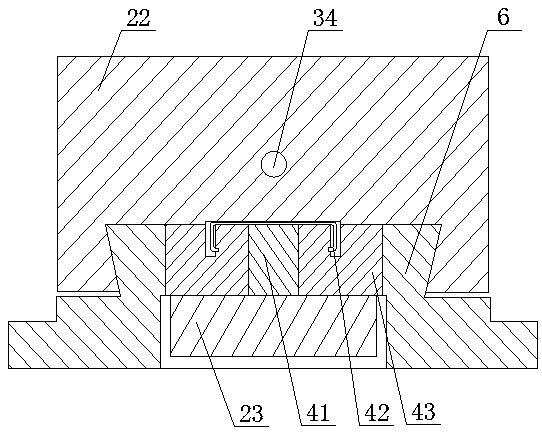

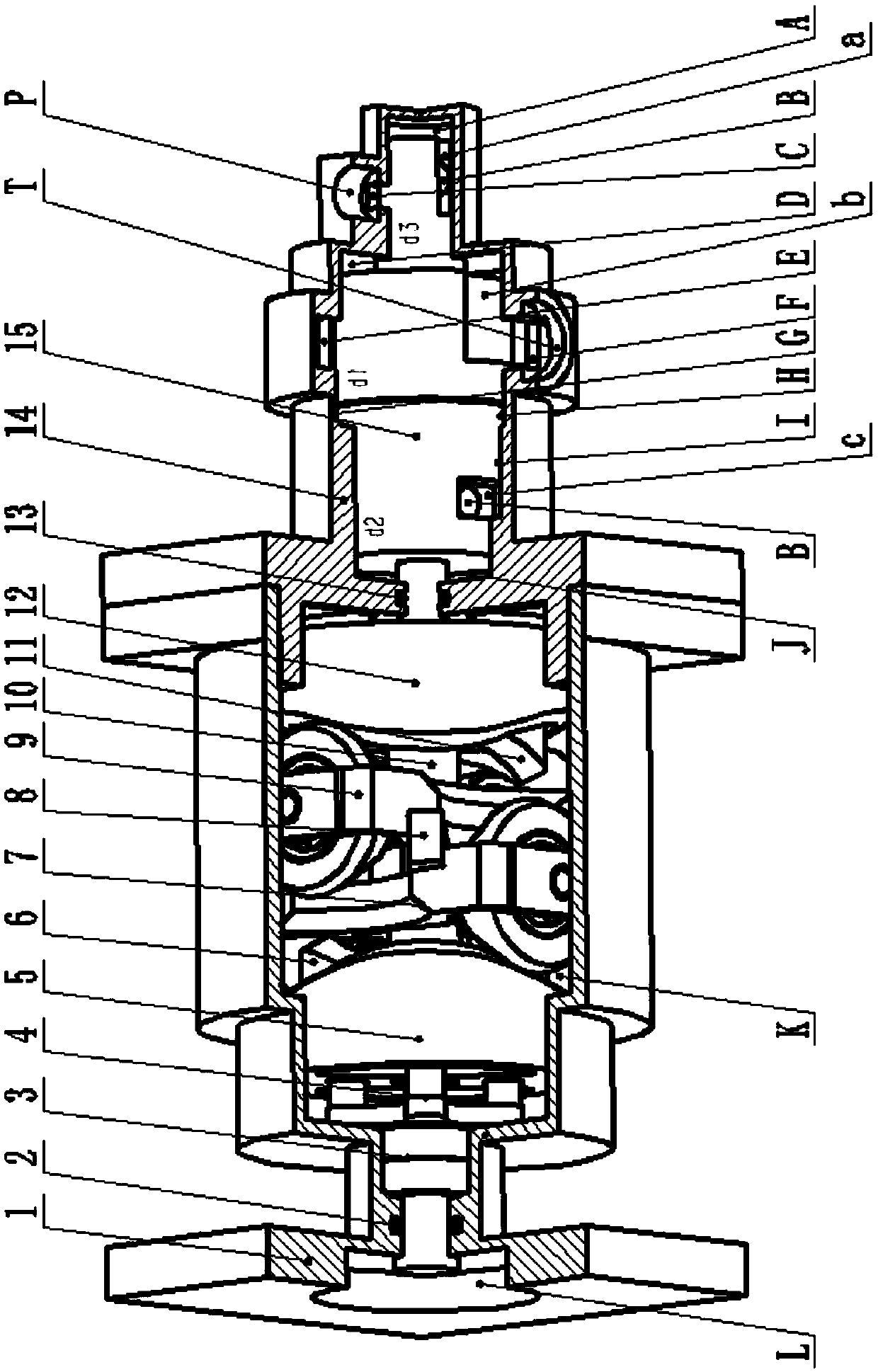

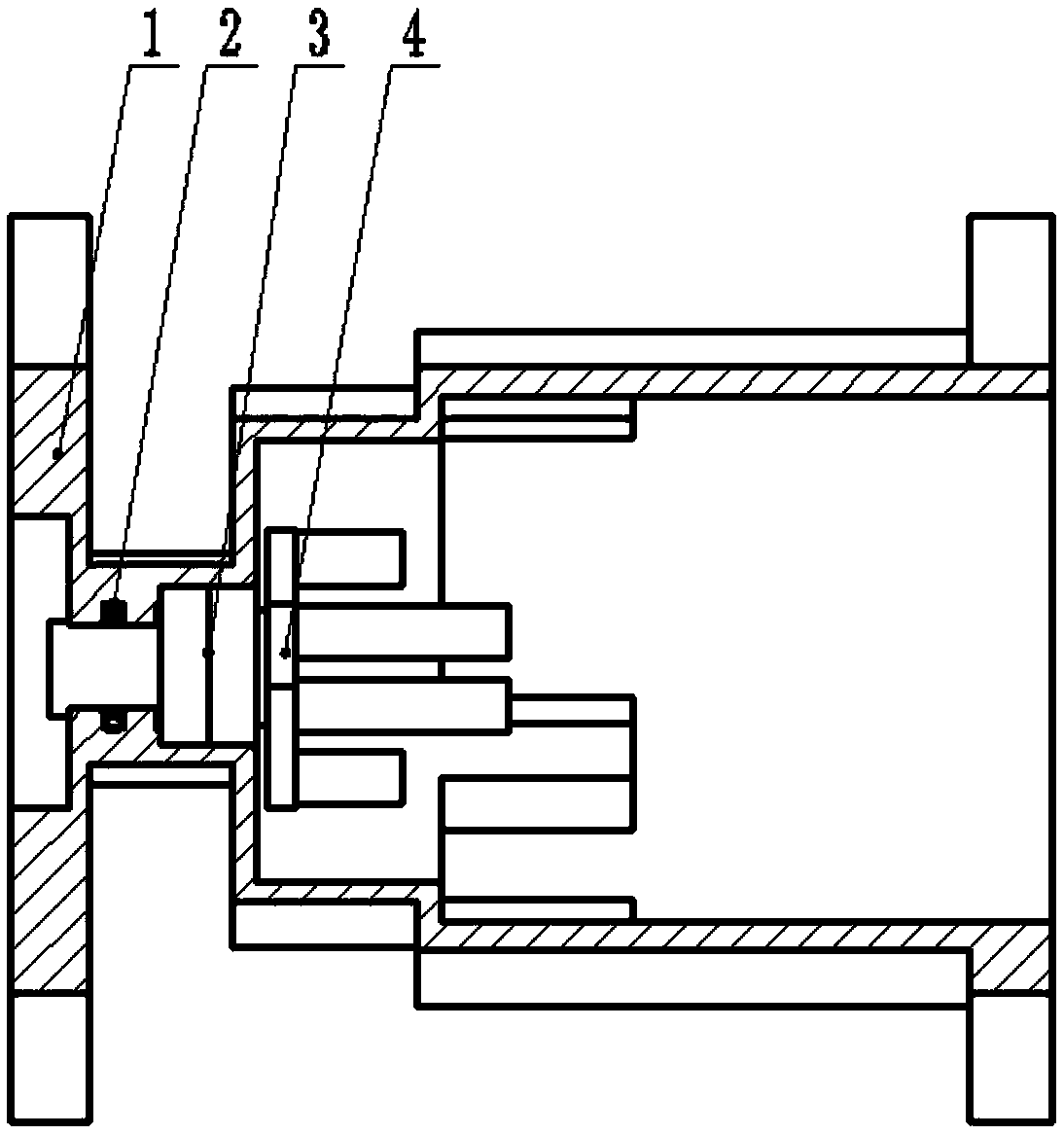

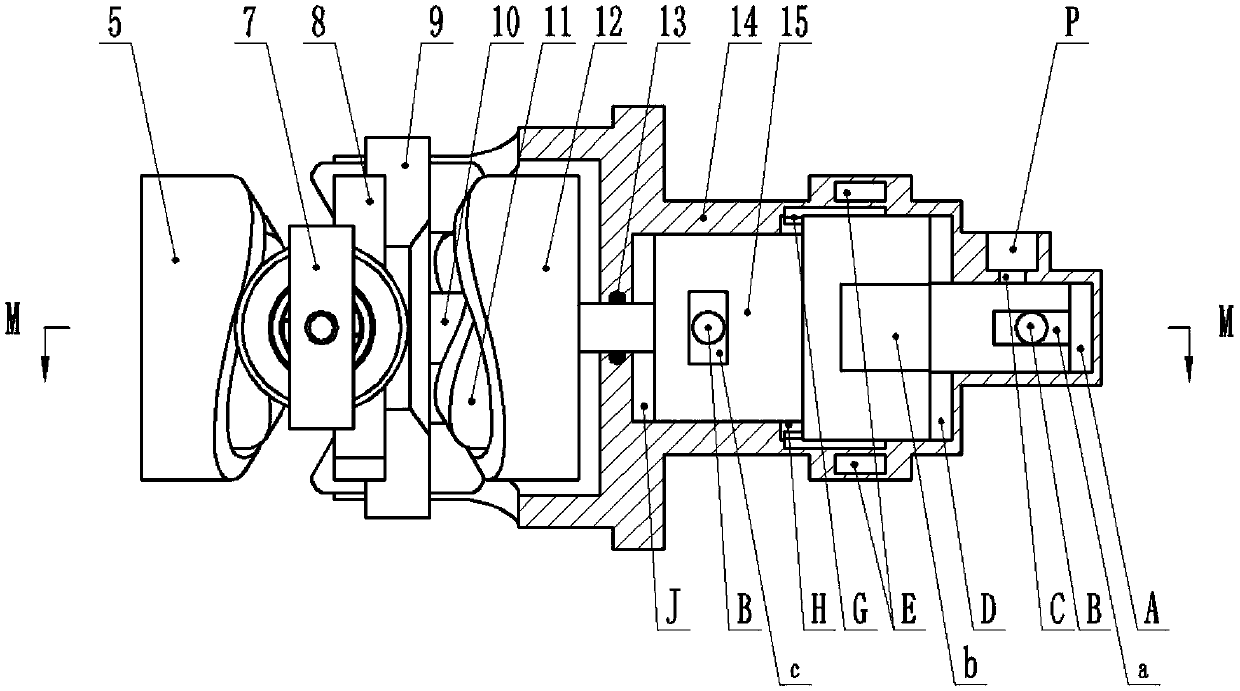

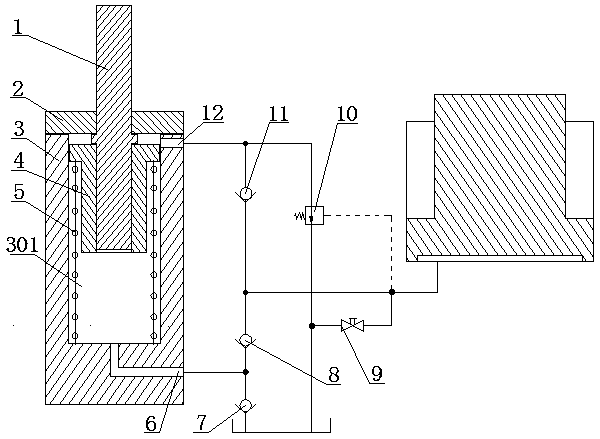

Hydraulic vice

ActiveCN109759873ACompact structureLarge clamping forcePositioning apparatusMetal-working holdersHydraulic cylinderLocking mechanism

The invention discloses a hydraulic vice. The hydraulic vice comprises an L-shaped fixed vice body, a guide rail integrally arranged on a horizontal part of the fixed vice body, a movable vice body capable of moving back and forth along the guide rail, a hydraulic system, a locking mechanism and a limiting mechanism; the hydraulic system comprises a pressure applying mechanism and a hydraulic cylinder connected with the pressure applying mechanism; the locking mechanism comprises a pressure transfer device connected with a working plunger, and limiting blocks which can move towards the side wall of the guide rail and form a combing structure with the guide rail; in the pressurizing initial stage, the pressure transfer device is pushed by the working plunger to move rightwards, and the limiting blocks move towards the corresponding side walls of the guide rail under action of the limiting mechanism till the limiting blocks are combined with the guide rail so that locking of the lockingmechanism and the fixed vice body can be achieved; pressurizing continues, the hydraulic cylinder is made to do reverse motion relative to the working plunger and drives the movable vice body to clampa workpiece. According to the hydraulic vice, through the hydraulic system, the locking mechanism and the limiting mechanism which are arranged in an interactional mode, the movable vice body is pushed to move, the whole structure is simple and compact, the clamping force is large, and the clamping efficiency is high.

Owner:HENAN UNIV OF SCI & TECH

Spray pipe for ejector, ejection unit and air ejector

ActiveCN112461493AImprove integritySimple structureAerodynamic testingWind energy generationEngineeringPlenum chamber

The invention discloses a spray pipe for an ejector, an ejection unit and an air ejector. The spray pipe is horn-shaped and comprises a large-diameter end and a small-diameter end; an annular airflowstanding chamber is arranged in the pipe wall of the spray pipe in the circumferential direction of the spray pipe, an opening is formed in the side, facing the small-diameter end, of the annular airflow standing chamber, and the opening extends to the end face of the small-diameter end. A plurality of air inlets are formed in the large-diameter end of the spray pipe in the circumferential direction of the spray pipe, and each air inlet is connected to the annular airflow plenum chamber through an air inlet channel formed in the pipe wall of the spray pipe. According to the invention, the contact area of the injected airflow and the injected airflow can be increased, the pressure loss is reduced, and the mixing efficiency and the pressurization ratio are improved.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

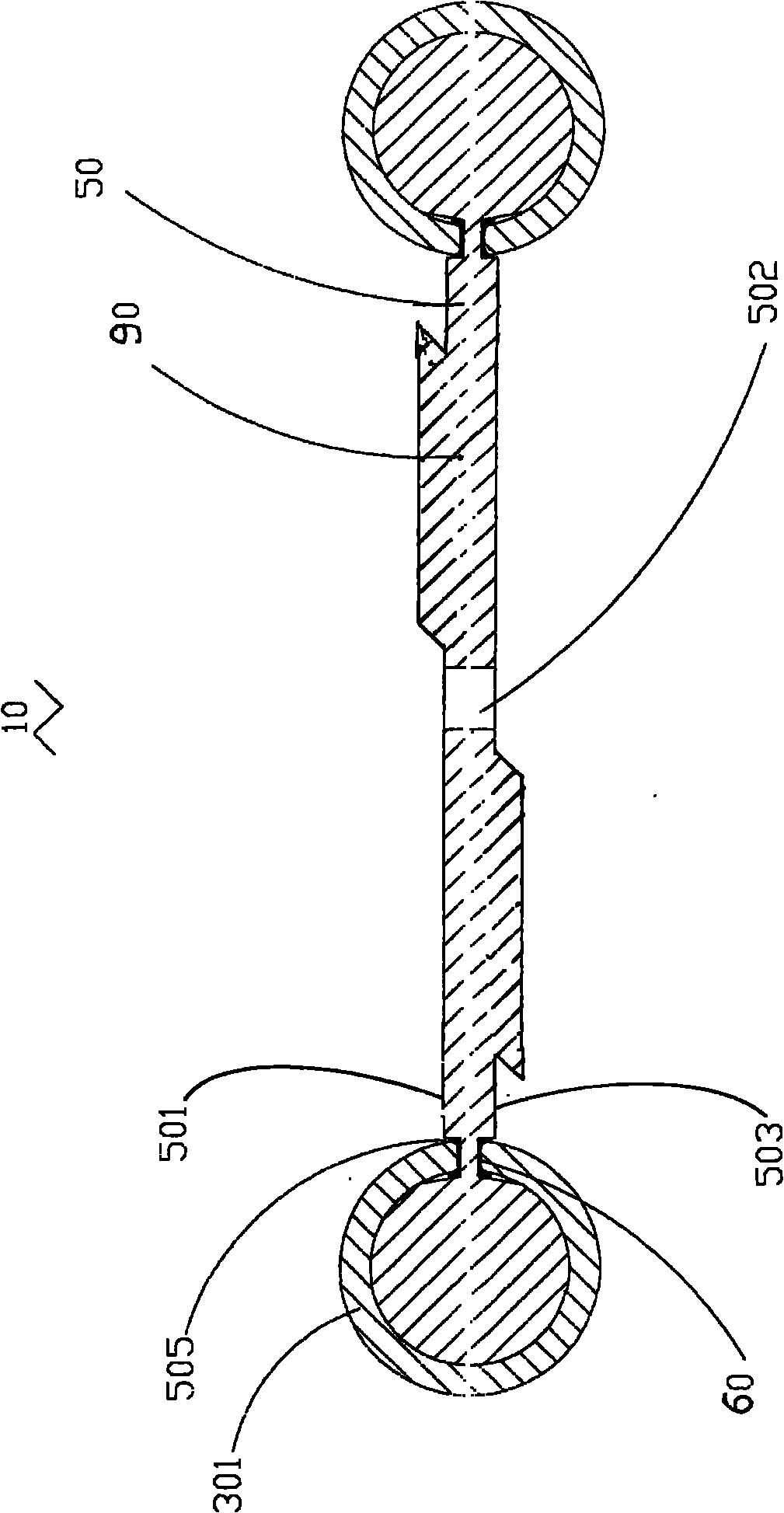

Boosting turbo expander

InactiveCN102061946AReduce noiseIncrease boost ratioLeakage preventionMachines/enginesEngineeringLow noise

The invention provides a boosting turbo expander comprising an intermediate shell. A turbine spiral case is arranged at the left end of the intermediate shell, a booster spiral case is arranged at the right end of the intermediate shell, the intermediate shell is internally and rotatably provided with a rotor, and two ends of the rotor are respectively provided with an expansion wheel and a boosting wheel in the turbine spiral case and the booster spiral case; and a left gas bearing and a right gas bearing are sleeved on the rotor, the left gas bearing is used for supporting the expansion wheel, and the right gas bearing is used for supporting the boosting wheel, wherein the left gas bearing and the right gas bearing are graphite gas bearings. The invention has the beneficial effects of stability, low noise, large supercharging ratio, improved rotation speed of the expander, and more environment protection; the refrigerating effect of the boosting turbo expander is improved about 2-3% compared with the refrigerating effect of an original machine; and the boosting turbo expander is not easy to break.

Owner:苏州制氧机股份有限公司

Gas turbine motor for rotary combustion chamber

ActiveCN106050417AImprove performanceHigh thermal efficiencyGas turbine plantsCombustion chamberHigh pressure

The invention discloses a gas turbine motor for a rotary combustion chamber. The gas turbine motor comprises a compressor, a combustion chamber and a turbine successively arranged, wherein the final stage of the compressor is a centrifugal vane wheel; the combustion chamber comprises a rotary disc arranged on a high-pressure rotor and two or more annular combustion cavities arranged at one side of the rotary disc; a flame chamber is arranged in each annular combustion cavity, and an ignition electric nozzle and a fuel nozzle are arranged in the flame chamber; the annular combustion cavities are located at the edge of the rotary disc and at the outer side of the circumference of the centrifugal vane wheel; and a baffle plate is arranged between the annular combustion cavities and the centrifugal vane wheel. High-temperature high-pressure combustion gas directly pushes the combustion chamber to rotate and work and needs no cooling; gas exhausted at the tail end of the compressor can be used for combustion; thermal efficiency can be improved to 60% or above; and engine performance can be improved by times.

Owner:杨涛

Turbine shaft engine

InactiveCN103967618AIncrease intake pressureGreat power to weight ratioGas turbine plantsJet propulsion plantsAxial compressorExhaust valve

A turbine shaft engine comprises axial-flow compressors, evaporative combustors, a turbine, a free turbine, a drive shaft, an exhaust nozzle and the like, and is characterized by further comprising by-pass pipes and internal exhaust valves, and external exhaust valves are mounted or are not mounted in pipes outside the engine and between air inlets and air outlets of the by-pass pipes; and when the engine is started for operation, the internal exhaust valves are opened, the supercharge ratios of the axial-flow compressors are increased and kept unchanged by means of the by-pass pipes and through opening and closing of the internal exhaust valves or the internal exhaust valves and the external exhaust valves, the increased supercharge ratios are not larger than the mechanical strength limit which can be borne by the axial-flow compressors, the turbine and the free turbine, the turbine inlet temperature is kept unchanged, that is, the supercharge ratios and a power weight ratio are increased, the oil consumption rate is reduced, however, the number of stages of the axial-flow compressors and the turbines is not increased, and the turbine inlet temperature is not improved.

Owner:李吉光

Inertia force balance type two-dimensional piston air compressor

PendingCN111059016ASimple structureReduce volumePositive displacement pump componentsPiston pumpsDrive shaftEngineering

An inertia force balance type two-dimensional piston air compressor is composed of a connecting plate, a transmission shaft, a guide rail, a balance guide rail, a piston shaft sleeve, a cross-shaped supporting rod, roller assemblies, a piston, a cylinder body and the like. The connecting plate is fixedly connected with the cylinder body through threads; the guide rail is fixedly arranged on a piston left side shaft, the balance guide rail is fixedly arranged on the piston shaft sleeve, the piston shaft sleeve can be sleeved on the piston left side shaft in an axial sliding mode, the cross-shaped supporting rod is fixedly arranged on the cylinder body, and the two groups of roller assemblies are fixed on the cross-shaped supporting rod through constraint of the guide rail and arranged in a90-degree staggered mode in the circumferential direction; one end of the guide rail and one end of the balance guide rail are equal-acceleration and equal-deceleration curved surfaces in the same shape and staggered by 90 degrees in the circumferential direction. The mass sum of a balance rotor composed of the balance guide rail and the piston shaft sleeve is equal to the mass sum of a rotor composed of the guide rail and the piston, and when the guide rail drives the rotor to perform equal acceleration and equal deceleration motion, the balance guide rail performs homodromous equal acceleration and equal deceleration staggered motion in the circumferential direction and reversed equal acceleration and equal deceleration staggered motion in the axial direction to counteract inertia forcegenerated by axial motion of the rotor.

Owner:ZHEJIANG UNIV OF TECH

Method for operating an internal combustion engine with parallel supercharging and with an activatable turbine, and internal combustion engine for carrying out a method of said type

ActiveUS20170226924A1Improve torque characteristicsIncrease boost ratioElectrical controlInternal combustion piston enginesTurbochargerInternal combustion engine

Embodiments for an engine coupled to a first turbocharger and a second turbocharger are provided. One example includes responsive to a first condition, deactivating a first turbine of the first turbocharger and meeting a boost demand via operation of the second turbocharger, and responsive to deactivating the first turbine, increasing a pressure at a compressor-side end of a bearing arrangement of a shaft of the first turbocharger. In this way, oil leakage from the bearing arrangement may be reduced.

Owner:FORD GLOBAL TECH LLC

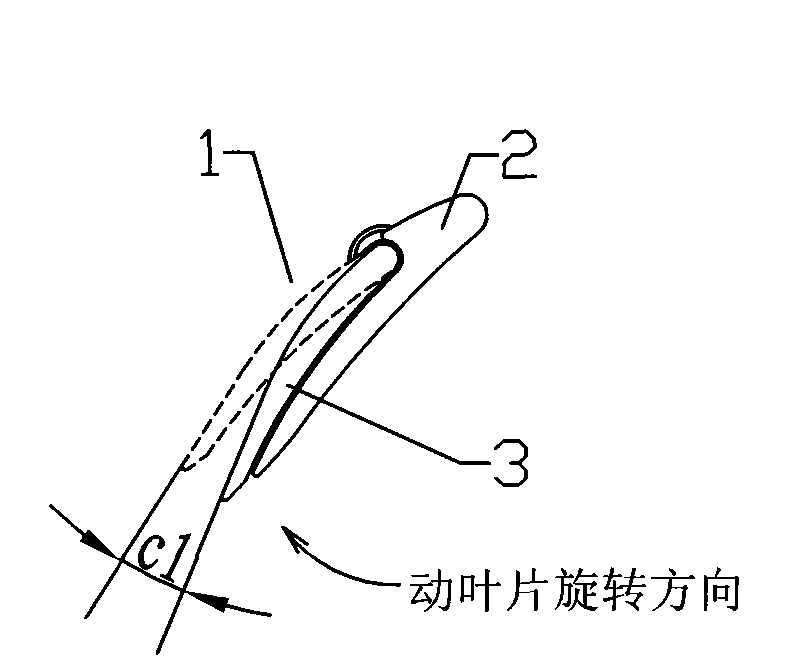

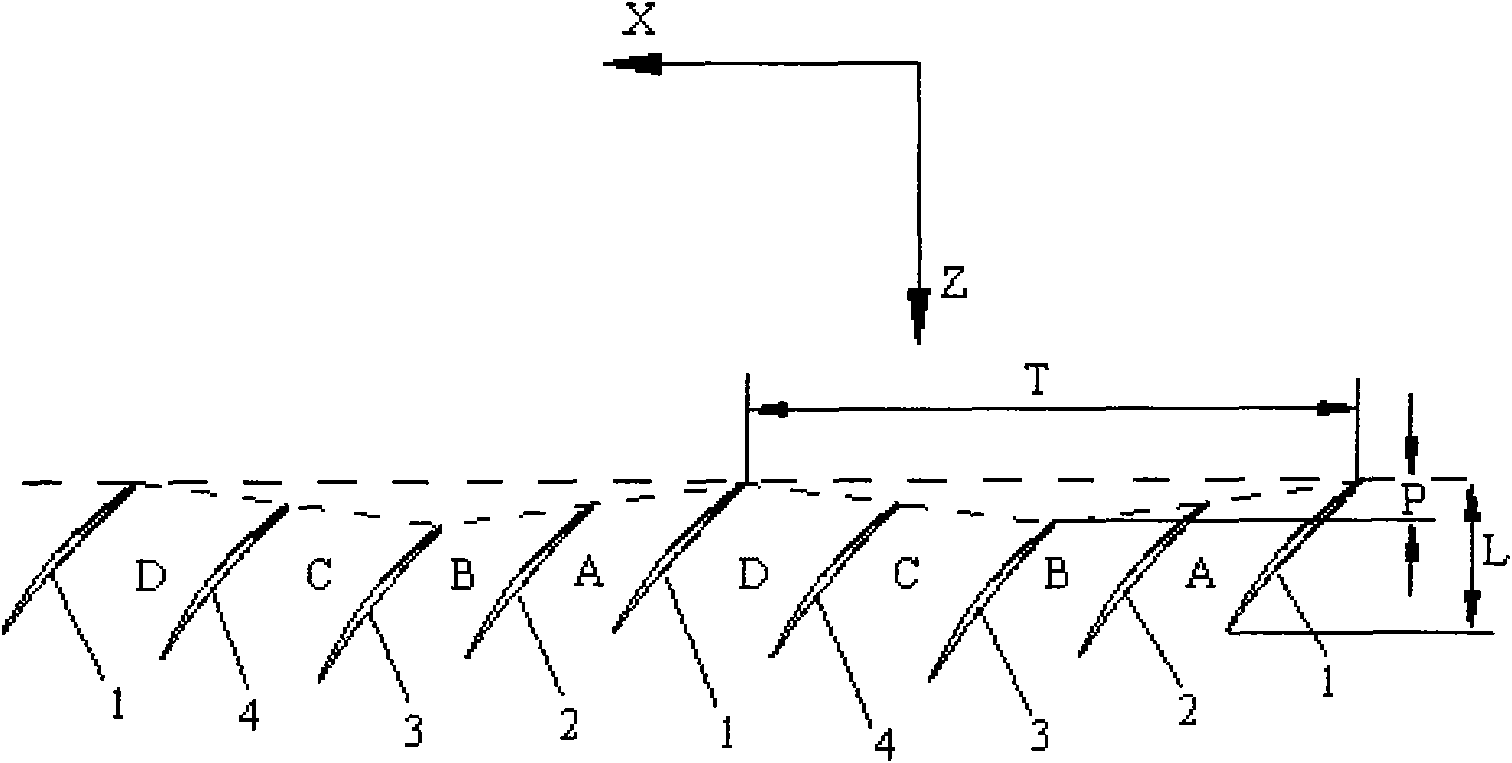

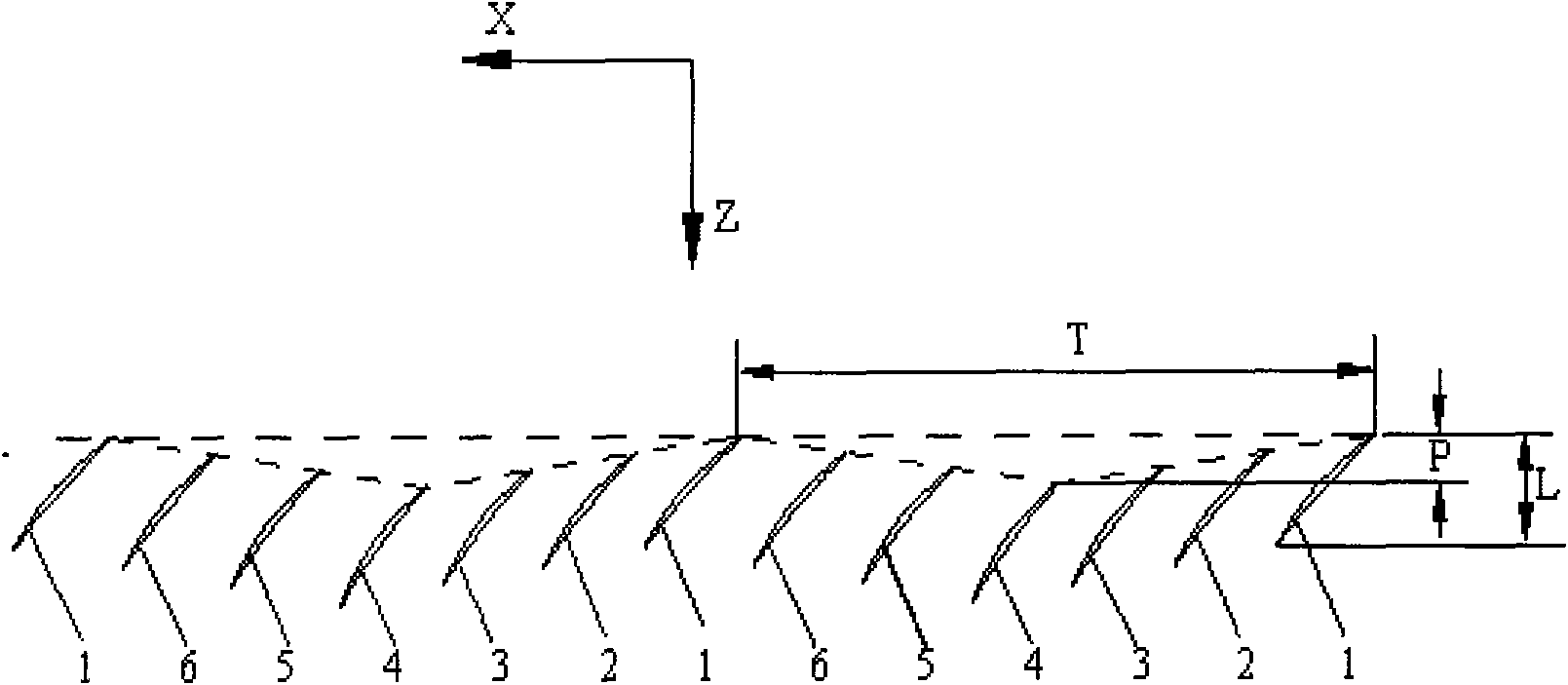

Moving blade row layout capable of improving axial compressor aerodynamic performance

InactiveCN101900133AIncrease clogging lossIncrease boost ratioPump componentsPumpsAxial compressorFront edge

The invention provides a moving blade row layout capable of improving axial compressor aerodynamic performance. Axial compressor blades are periodically arranged along the peripheral direction X; each period is composed of 2N numbered blade paths, and the ligature of the axial positions of the front edges of the blades arranged in each period forms a triangular wave; the front edge of the first blade (1) and the front edge of a (2N+1)th blade in each period are positioned on the wave crest of the triangular wave; and the front edge of the (N+1)th blade is positioned on the wave trough of the triangular wave. Under the condition that the bending of the blades is constant and aerodynamic stability is not lowered and can be properly improved, the moving blade row has improved boost ratio, increased blockage flow and unreduced efficiency under the state of small angle of attack of a design point. The compressor of the invention can choose a zero-incidence even negative incidence state to serve as the aerodynamic design point, can obtain the higher boost ratio and efficiency near the design point and has bigger stability margin of the compressor.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Double-speed manual booster pump for hydraulic device with long-stroke hydraulic cylinder

ActiveCN110657079AMove quicklyReduce labor intensityServomotorsServometer circuitsHydraulic cylinderRotary valve

The invention discloses a double-speed manual booster pump for a hydraulic device with a long-stroke hydraulic cylinder, which comprises a booster mechanism and a hydraulic system. The booster mechanism comprises a pump body. A circular hole is formed in the middle of the pump body. A booster ring in sliding seal fit with the circular hole is arranged in the circular hole. A compression spring isconnected between the booster ring and the bottom surface of the circular hole. A pump plunger in sliding fit with the booster ring is arranged in the middle of the booster ring. A cover body in sliding fit with the pump plunger is connected on the pump body. An oil hole I and an oil hole II in the pump body communicate with the hydraulic cylinder through the hydraulic system. The oil hole I is connected with an oil tank through a hydraulic control reversing valve, and connected with the hydraulic cylinder through a back pressure valve. The oil hole II is connected with the hydraulic cylinderthrough a second one-way valve, connected with the oil hole I through the second one-way valve and the back pressure valve in sequence, and connected with the oil tank through a first one-way valve. The hydraulic system further comprises a rotary valve. According to the booster pump, the long-stroke hydraulic cylinder can run fast in no-load and move slowly in working stroke, thereby helping saving overall pressurizing time.

Owner:HENAN UNIV OF SCI & TECH

Pneumatic nozzle of variable geometry turbocharger (VGT)

ActiveCN101634233BImprove responsivenessIncrease boost ratioStatorsMachines/enginesEngineeringVariable-geometry turbocharger

The invention relates to a pneumatic nozzle of a variable geometry turbocharger (VGT), comprising a pneumatic nozzle supporting disk, and a plurality of pneumatic nozzle blades which are arranged on the pneumatic nozzle supporting disk, wherein, the pneumatic nozzle blades comprise pneumatic nozzle moving blades and pneumatic nozzle stationary blades, and the pneumatic nozzle stationary blades are internally provided with a flow channel. During operation of the turbocharger, the width of the air flow channel among the adjacent pneumatic nozzle blades can be adjusted by adjusting the rotation angle of the pneumatic nozzle moving blades so as to adjust the pressure ratio of the turbocharger so that the turbocharger is matched with the working condition of an engine; and when adequate pressurizing ratio can not be provided in the event that the working condition of the engine is further reduced and the width of the air flow channel among the adjacent pneumatic nozzle blades is adjusted to the minimum, supplementary gas can be sprayed by a connecting pipe, the channel on the pneumatic nozzle supporting disk and the flow channel on the pneumatic nozzle stationary blades so as to improve the pressure ratio of the turbocharger so that the turbocharger is matched with the working condition of the engine.

Owner:KANGYUE TECH

Tail room for exhaust system of engine test bed

ActiveCN106198030AIncrease boost ratioBoost ratio reductionEngine testingEngineeringStraight segment

The invention discloses a tail room for an exhaust system of an engine test bed, and the tail room comprises a big tail room and a replaceable small tail room. The big tail room comprises a tail room convergence segment, a tail room constant-section straight segment and a tail room expansion segment, wherein the tail room convergence segment, the tail room constant-section straight segment and the tail room expansion segment are connected together. The replaceable small tail room is disposed in the tail room convergence segment, and is connected with the tail room convergence segment. The tail room convergence segment, the tail room constant-section straight segment, the tail room expansion segment and the replaceable small tail room are respectively a hollow revolving body An engine with an engine tail jet pipe and the tail room convergence segment are disposed in a high-altitude simulation cabin, and the tail room expansion segment is disposed outside the high-altitude simulation cabin. The engine is an ultrasonic engine. The tail room provided by the invention improves the static pressure of a passive flow inlet of a subsequent air extractor, reduces the pressure ratio of the subsequent air extractor, reduces the number of ejectors of the subsequent air extractor or the volume of a vacuum tank, is provided with the replaceable small tail structure, and meets the demands of the testing of engines in various sizes.

Owner:BEIJING AEROSPACE SANFA HIGH TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com