Asymmetric double-channel variable section turbocharger

A turbocharger, dual-flow technology, applied in the direction of machine/engine, internal combustion piston engine, mechanical equipment, etc., to achieve the effect of good inheritance, easy upgrade and switching, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

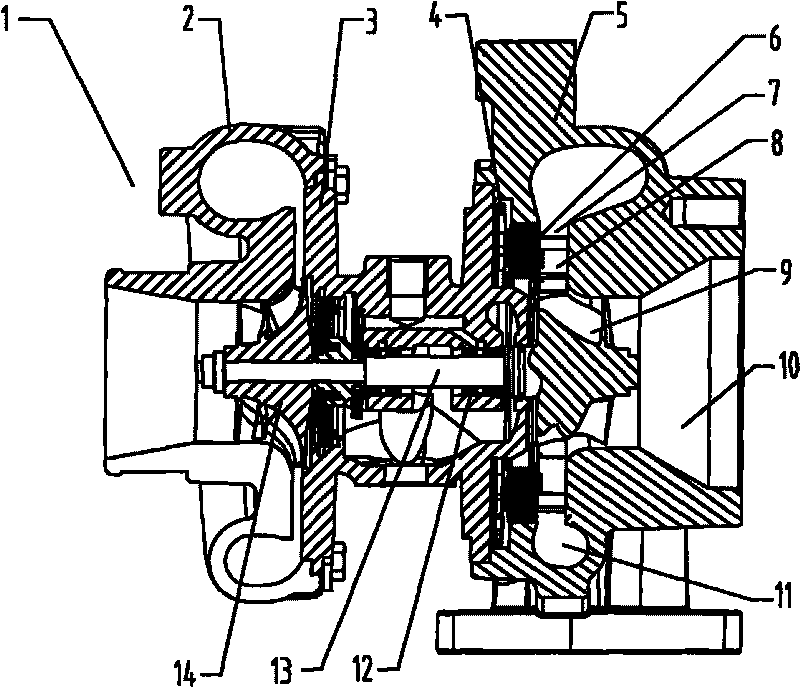

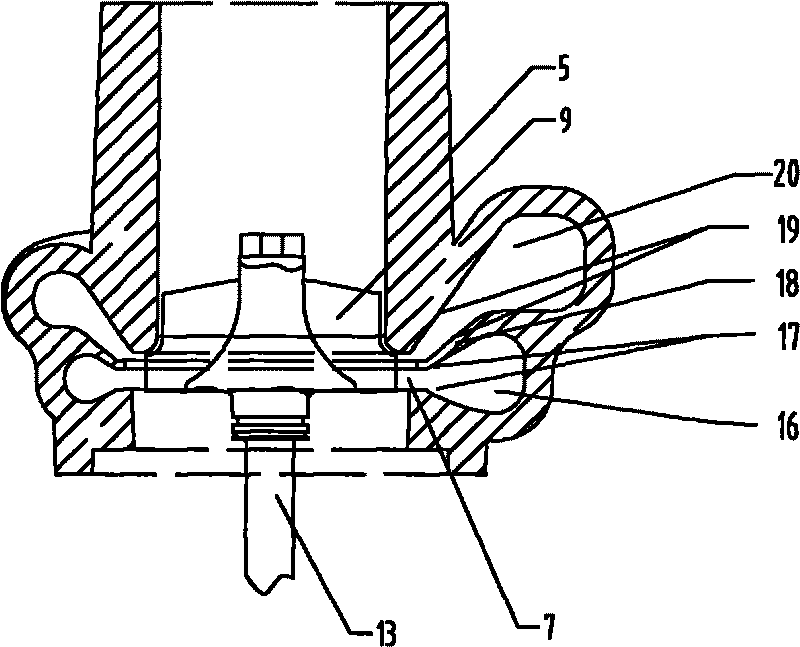

[0038] Example 1, such as image 3 , Figure 4 As shown, a kind of asymmetrical double-channel variable cross-section turbocharger comprises a turbine volute 5, a turbine impeller 9 and a volute inlet runner are arranged in the turbine volute 5, and the turbine impeller 9 is installed on the turbine rotor shaft 13, A volute nozzle 7 is provided near the position of the turbine impeller 9 in the volute intake flow path, and the volute intake flow path includes a small volute intake flow path 16 and a large volute intake flow path 20, and a large volute intake flow path 20 It is located at one side 16 of the volute inlet small flow passage. The middle wall 18 of the volute intake air channel 16 and the large volute air intake channel 20 is provided, and the volute air intake small flow channel 16 is used in the range of the engine's full working conditions.

[0039] The middle wall 18 of the runner is provided with an air inlet that makes the volute inlet small flow passage 16...

Embodiment 2

[0045] Example 2, such as Image 6 As shown, considering the safety under the engine overspeed condition, a bypass hole 25 can be provided on the volute intake large flow channel 20 in Embodiment 1, and a bypass valve 26 is installed on the bypass hole 25, The volute inlet port bypass hole 25 is opened or closed by the bypass valve 26, thereby controlling the pressure of the airflow inside the volute inlet large flow passage 20, when the engine exhaust flow exceeds the intake small flow passage 16 and the intake large flow passage The sum of the flow capacities of the runners 20 is bypassed to bleed air, so as to prevent the supercharger from overspeeding and realize the purpose of protecting the supercharger.

[0046] In order to facilitate the installation and arrangement of the turbocharger, the positions of the large volute intake flow channel 20 and the small volute intake flow channel 16 can be exchanged. Can be attached as manual image 3 Arrangement, the volute inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com