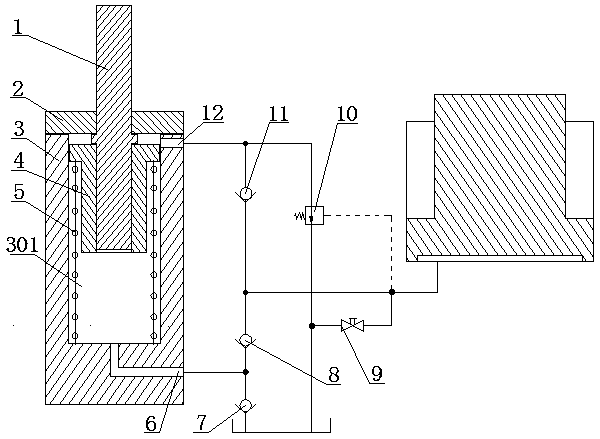

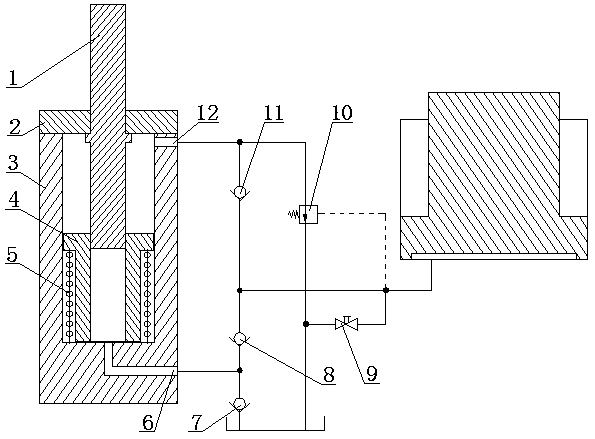

Double-speed manual booster pump for hydraulic device with long-stroke hydraulic cylinder

A technology of hydraulic device and hydraulic cylinder, which is applied in the direction of fluid pressure actuating device, pump, piston pump, etc., can solve the problems of pressurization manual workload and pressurizing time, limited pressurizing force, difficulty in pushing objects, etc. To achieve the effect of saving time, large boosting effect, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] It should be noted that the terms "comprising" and "having" and any variations thereof in the present invention are intended to cover non-exclusive inclusion, for example, a process, method, system, product or device that includes a series of steps or units does not necessarily Restricted to those steps or elements explicitly listed, but may include other steps or elements not explicitly listed or inherent to the process, method, product or apparatus. The "first" and "second" mentioned in the present invention are not to limit the quantity of corresponding technical features, but are names for distinguishing related technical features.

[0020] The core of the present invention is to provide a two-speed manual pressurizing pump for a long-stroke hydraulic cylinder hydraulic device, which can make the hydraulic cylinder run quickly when it is empty and move slowly when it is working.

[0021] It should be noted that the "slow movement" in the present invention is relativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com