Turboprop engine

A turboprop and engine technology, which is applied in the direction of machines/engines, gas turbine devices, mechanical equipment, etc., can solve the problems of increasing weight and volume, inability to improve, and unfavorable power-to-weight ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

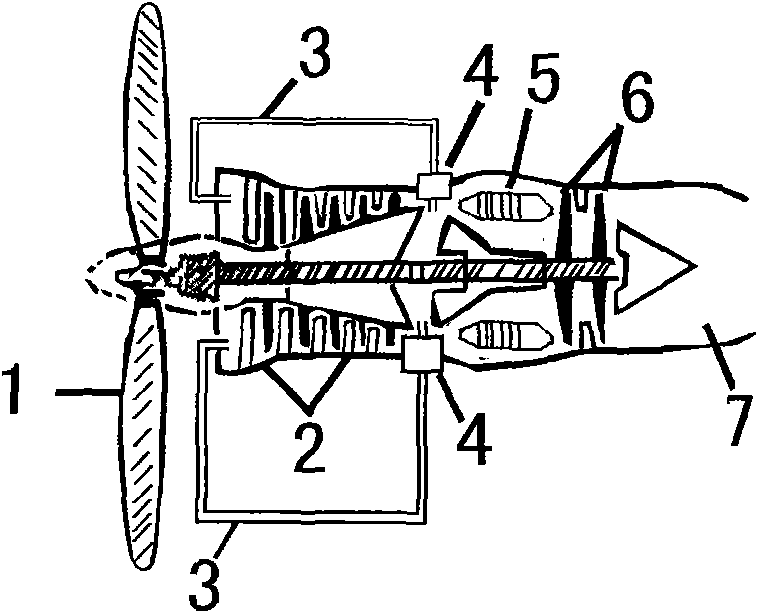

[0011] Refer to attached figure 1 and 2 , the turboprop engine of the present invention includes a propeller 1, an axial flow compressor 2, a bypass pipe 3, an internal exhaust valve 4, an evaporative combustion chamber 5, a turbine 6, a tail nozzle 7, etc.; wherein the propeller 1, The axial flow compressors 2 are respectively or jointly connected with the turbine 6; the intake port of the bypass pipe 3 is between the rear of the axial flow compressor 2 and the front of the evaporative combustion chamber 5, and is opened after the engine is started by being located between them. , the internal exhaust valve 4 that is closed after increasing the boost ratio is connected to the engine, and its air outlet is at or toward the engine air inlet; in the pipe outside the engine between the air inlet and outlet of the bypass pipe 3, there can be no external adjustment of the compressed air pressure Exhaust valve 8, such as figure 1 shown; there may also be an external exhaust valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com