Inertia force balance type two-dimensional piston air compressor

A balanced and inertial force technology, applied in the direction of piston pumps, liquid displacement machinery, mechanical equipment, etc., can solve the problems of complex multi-stage compression structure, low exhaust pressure, difficult sealing, etc., and achieve light weight, reduced Effects of vibration, friction reduction, and frictional heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

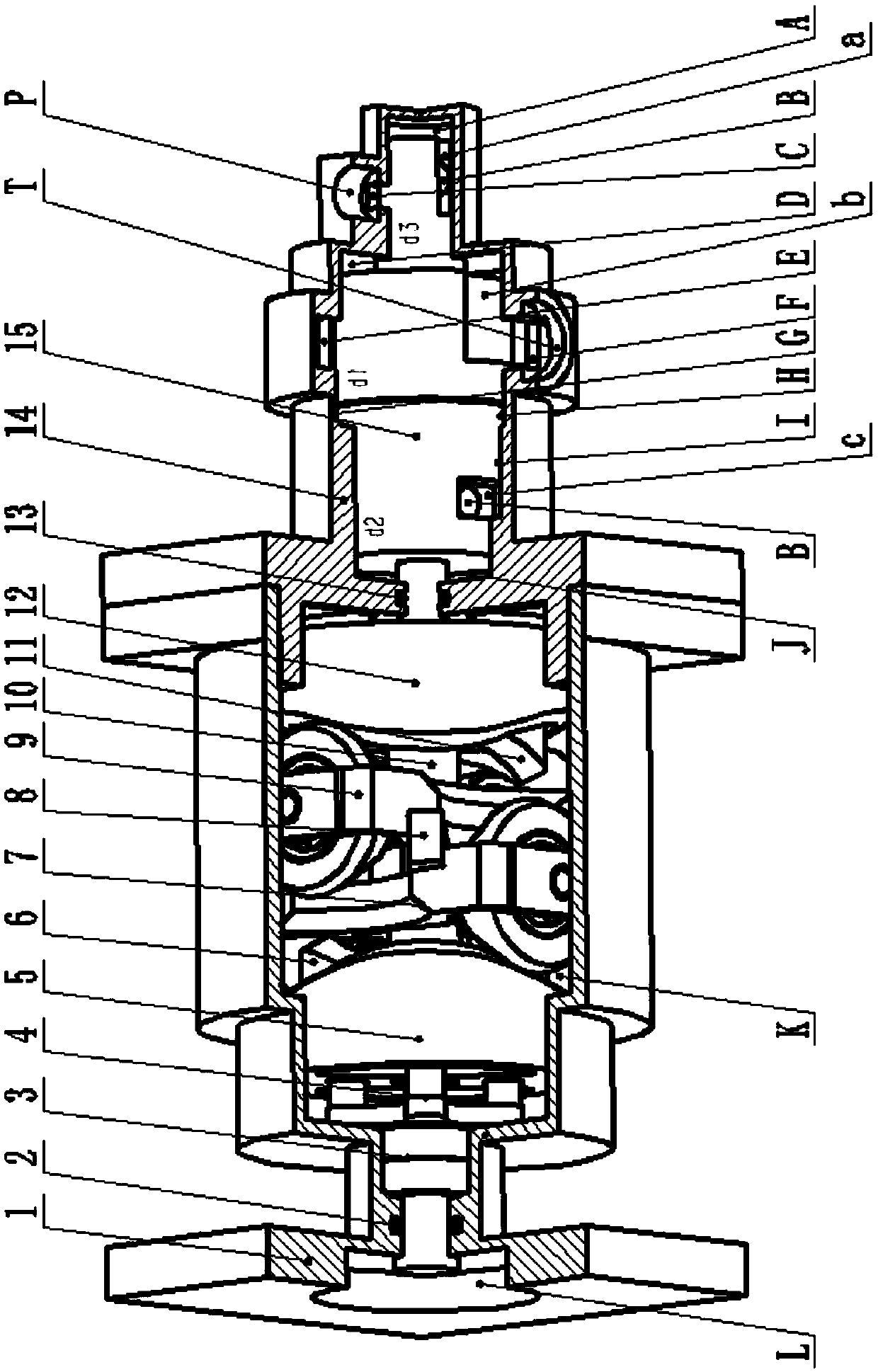

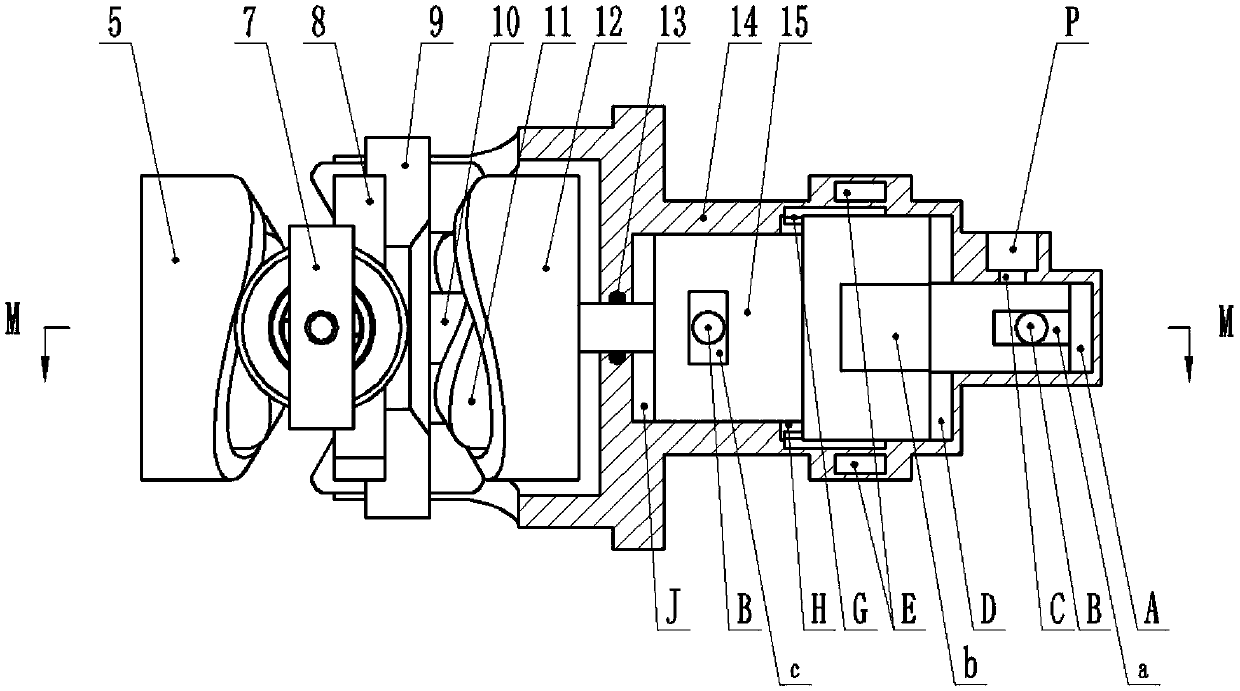

[0046] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

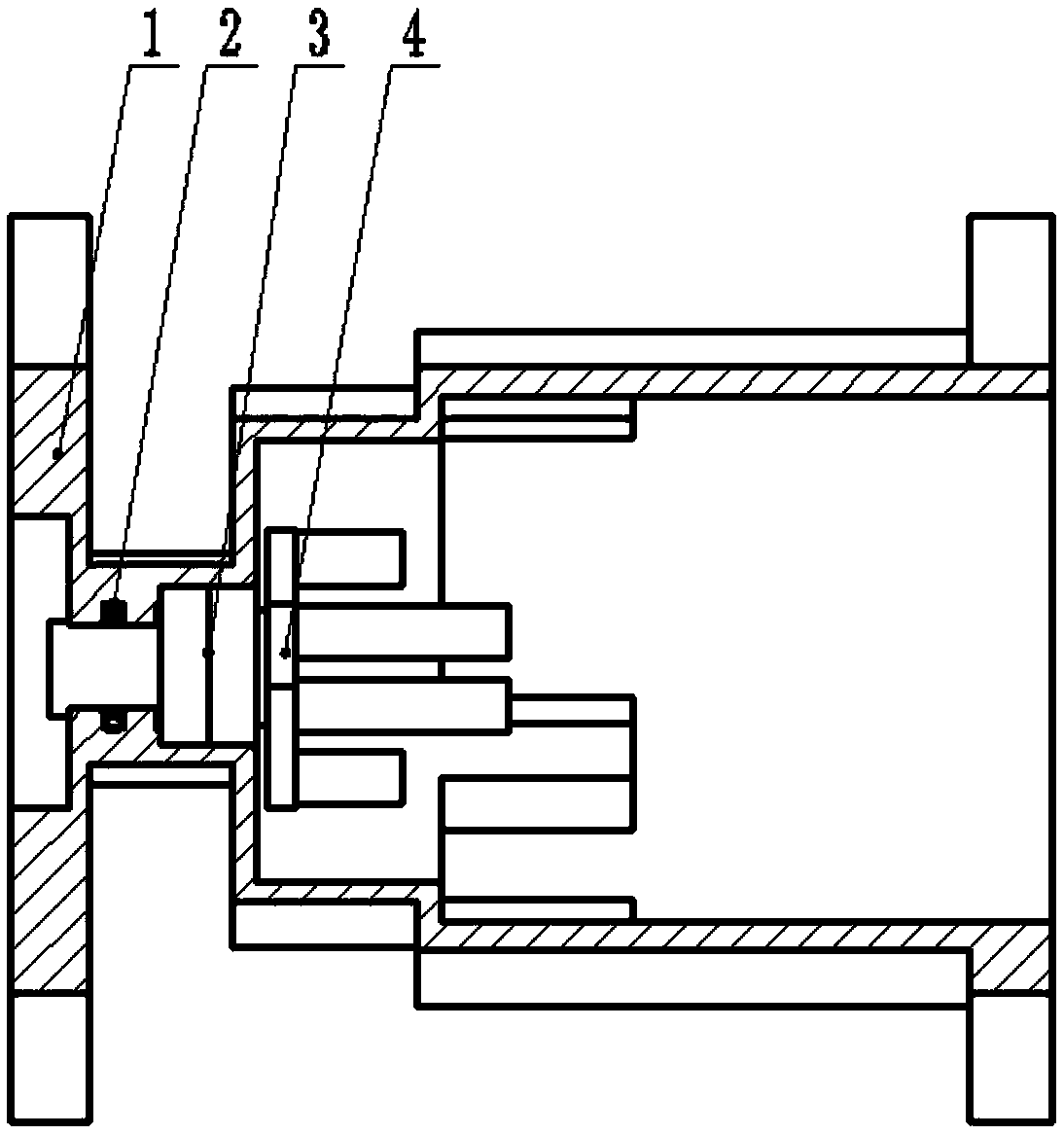

[0047] Such as figure 1 As shown, the inertia force balanced two-dimensional piston air compressor consists of a connecting plate 1, a transmission shaft 4, a left balance guide rail 5, a left guide rail 6, a left roller assembly 7, a cross support rod 8, a right roller assembly 9, Piston bushing 10, right guide rail 11, right balance guide rail 12, cylinder body 14, piston 15 etc. constitute. The connecting plate 1 and the cylinder body 14 are fixedly connected by threads, the left guide rail 6 and the right guide rail 11 are symmetrically and fixedly installed on the left shaft of the piston 15, and the left balance guide rail 5 and the right balance guide rail 12 are symmetrically and fixedly installed on the piston bushing 10. The constant acceleration and deceleration curved surfaces are staggered by 90 degrees in the circumferential dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com