Hollow shaft rotating stamping compression rotor based on shock compress technique

A compression technology, ram compression technology, which is applied in the field of hollow shaft rotary ram compression rotors, can solve the problems of no essential influence on the power-to-weight ratio of gas turbines, large volume and weight of the compression system, and reduced overall compression efficiency, and achieve light weight and high compression efficiency High, high boost ratio effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

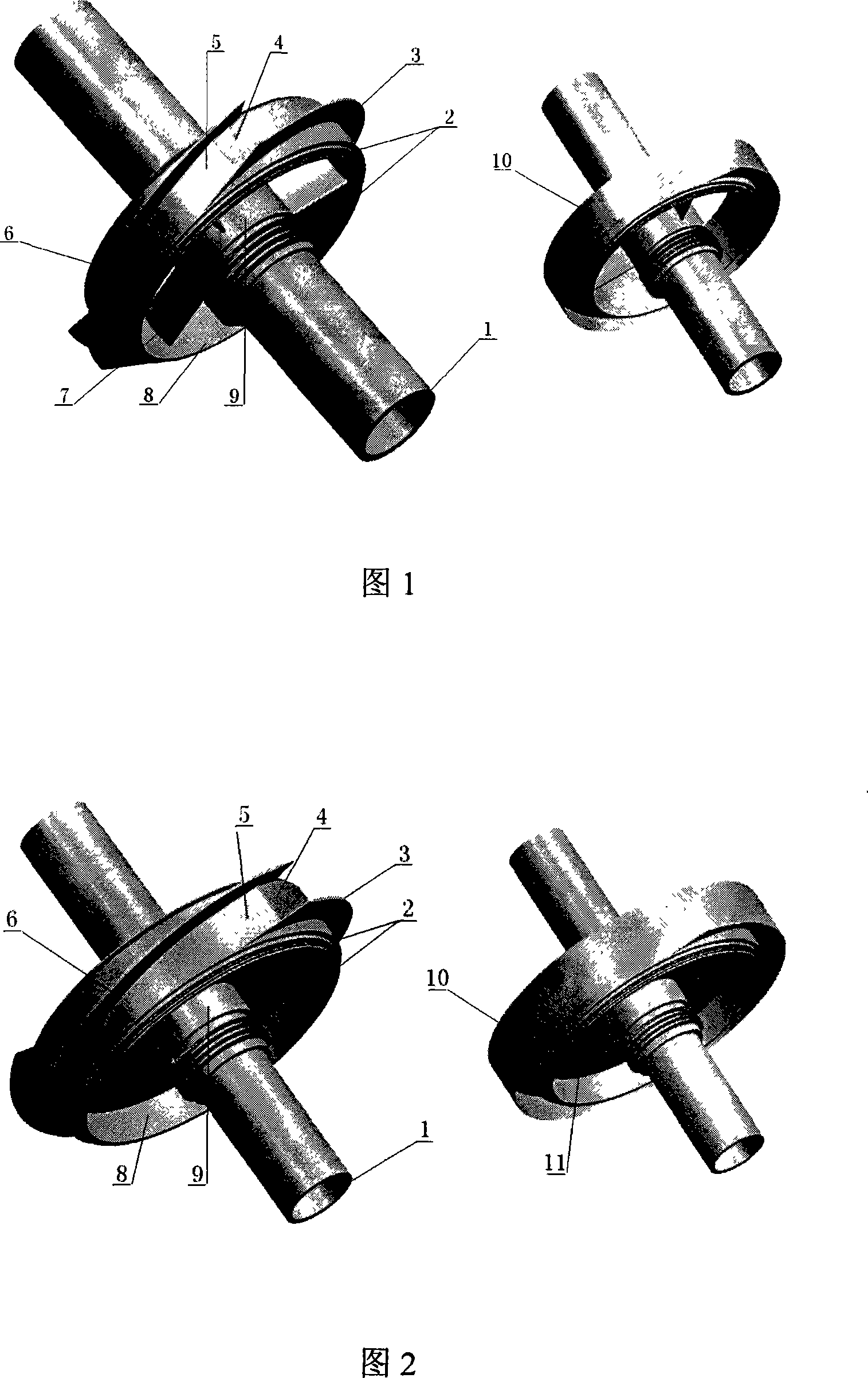

[0018] The present invention is described in further detail below in conjunction with accompanying drawing:

[0019] The hollow-shaft rotary stamping compression rotor based on the shock wave compression technology of the present invention is designed on the basis of the shock wave compression technology in the supersonic inlet channel and the fusion of the traditional axial flow compressor and centrifugal compressor design technology, based on the shock wave compression The advanced rotary stamping compression rotor adopts a hollow shaft design, which can greatly reduce the structural weight of the compression rotor, and can free up a certain space for installing other equipment in the hollow shaft, so that the compression rotor has a compact structure.

[0020] As shown in Figures 1 to 3, the web 12 in Figure 3 has a certain number of holes on the solid disk 11 in Figure 2. The purpose of this is to further reduce the weight of the compression rotor. It can be a round hole o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com