Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Improve visual inspection efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

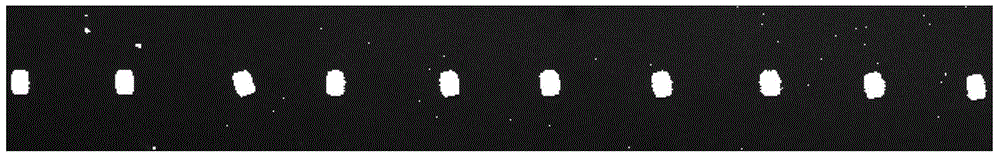

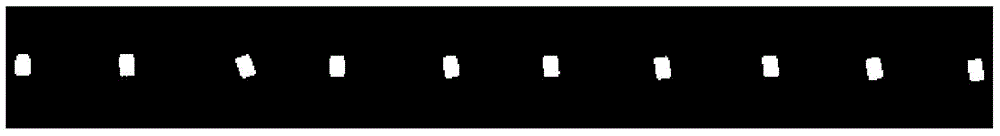

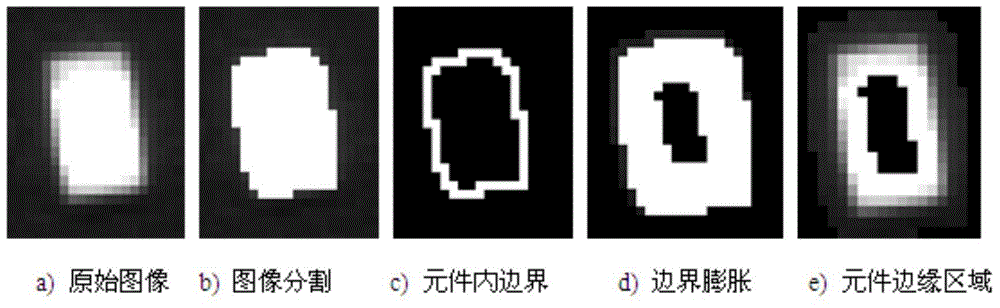

Detecting and error-correcting method capable of rapidly and accurately obtaining element center and deflection angle

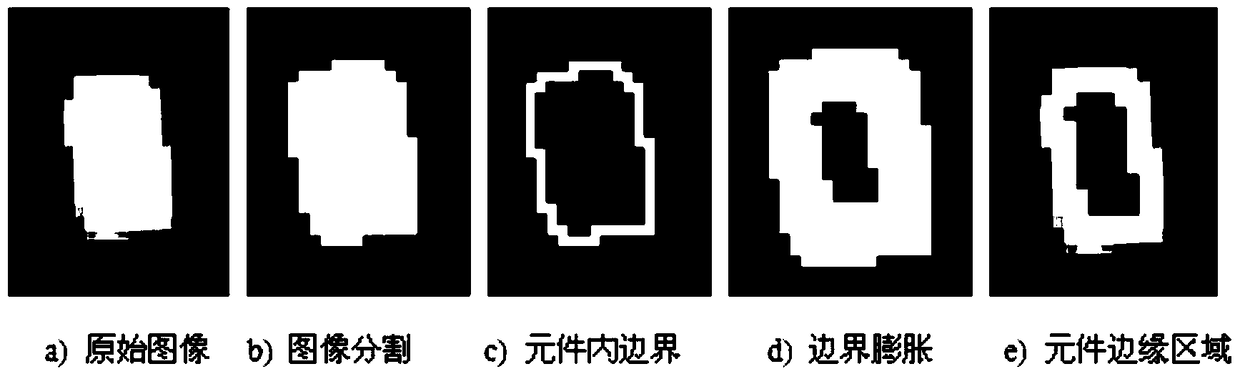

ActiveCN104981105AFind out exactlyOvercoming complex shortcomingsPrinted circuit assemblingCircuit board tools positioningCurve fittingEdge extraction

A detecting and error-correcting method capable of rapidly and accurately obtaining an element center and a deflection angle is disclosed. Interested edge area can be rapidly and accurately found out through an automatic edge area extraction method based on combination of binary morphology and image reduction, and subsequent edge extraction image scope is minimized as possible. Pixel level edge is roughly positioned at first, and accordingly a sub-pixel edge is rapidly extracted by one-dimensional curve fitting method. The method overcomes the defect of complex algorithm of a conventional sub-pixel edge extraction algorithm based on two-dimensional images, and the time of extracting accurate sub-pixel edge can be shortened. Weighted least square rectangular edge fitting algorithm based on linear hazen paradigm can detect straight lines on any positions of an image, and effectively minimizes influence of outlier on fitting precision due to uneven edges. The central positions of a plurality of elements and deflect angles can be rapidly and accurately detected at once, and the efficiency of visual detection is improved.

Owner:GUANGDONG UNIV OF TECH

Fast tilt correction method for QFN chip pin image

ActiveCN110992326AQuick correctionAccurate correctionImage enhancementImage analysisComputer hardwareEngineering

The invention discloses a fast tilt correction method for a QFN chip pin image. The fast tilt correction method comprises the following steps: (1) collecting the QFN chip pin image, and carrying out filtering and binarizing treatment; (2) extracting the contour of a central bonding pad of the chip image by using a polygon approximation method; (3) proposing an improved Harris corner detection algorithm, and acquiring contour vertexes; (4) carrying out straight line fitting on the vertex with a farthest distance by utilizing a least square method, and taking a straight line as an angle identification direction; and (5) rapidly correcting the chip pin image and removing white edges by taking a centroid coordinate of the image as a rotation center. The correction method provides a certain theoretical basis for correcting a QFN chip more quickly and accurately, and improves the visual detection efficiency of QFN packaging defects.

Owner:JIANGSU UNIV OF TECH

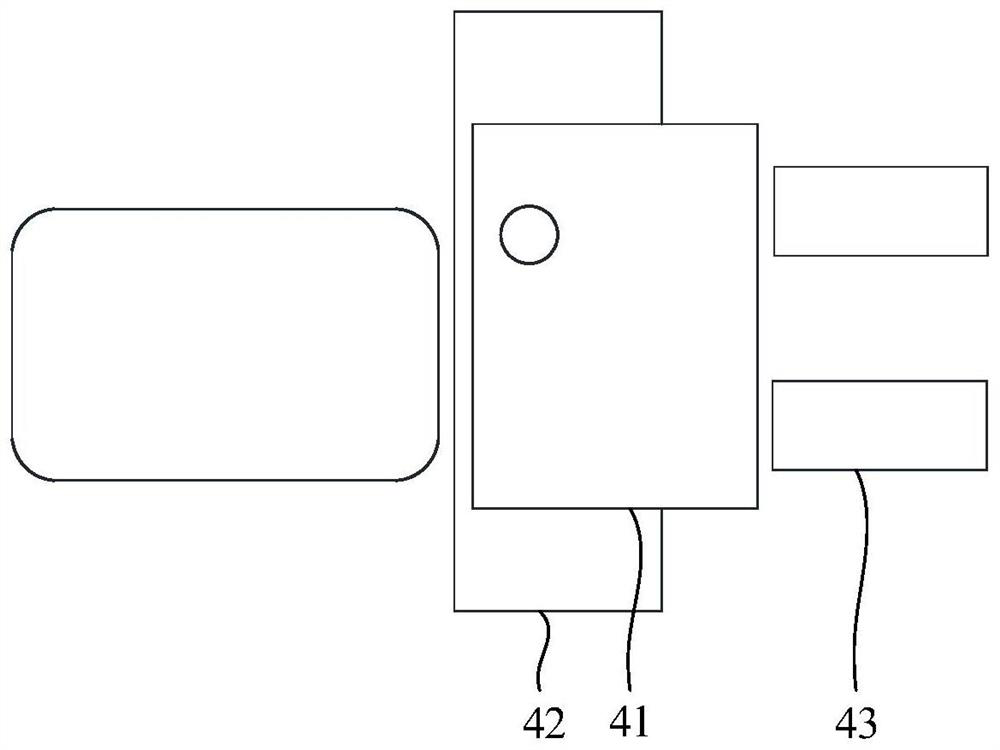

Method and system for visual detection

InactiveCN107820568AShort processSave time and material resourcesImage analysisScattering properties measurementsComputer visionMaterial resources

The invention provides a method and system for visual detection. The method comprises the steps that a first detection face of a to-be-detected object is moved to a current shooting face of a photographic device; a second detection face of the to-be-detected object is reflected by a reflection device, and an image corresponding to the second detection face is converted to the current shooting face; an image on the current shooting face is collected; and the collected image is detected and analyzed, so an analysis result is obtained. According to the method and system for visual detection provided by the invention, different detection faces at certain angles can be converted by the reflection device to the current shooting face of the photographic device; and through shooting of the currentshooting face, the detection faces at the different angles can be detected at the same. Therefore, processes in the visual detection can be greatly reduced; time and material resources needed by thedetection can be saved; and efficiency of the visual detection can be increased.

Owner:SHENZHEN A&E INTELLIGENT TECH INST CO LTD

Double-sided visual detection system and double-sided detection method for PCB

InactiveCN111398313AAchieving Simultaneous DetectionSimple structureOptically investigating flaws/contaminationVisual inspectionEngineering

The invention discloses a double-sided visual detection system for a PCB. The double-sided visual detection system comprises a visual detection dark box. A visual inspection chamber is formed in the visual detection dark box; a conveying unit inlet and a conveying unit outlet are formed in the two ends of the visual detection dark box. The double-sided visual detection system also comprises a first PCB conveying belt unit which horizontally penetrates through the conveying unit inlet and a second PCB conveying belt unit which horizontally penetrates through the conveying unit outlet. The double-sided visual detection system is simple in structure, the annular PCB can be turned over by 180 degrees in the visual detection cavity, and thus the front face and the back face of the annular PCB can be detected simultaneously.

Owner:宋志龙

Machine vision-based paddle shadow transfer printing defect identification method

ActiveCN113109348ATrue restorationAdjustable quality control levelImage enhancementImage analysisMachine visionAlgorithm

The invention discloses a machine vision-based paddle shadow transfer printing defect identification method. The method comprises the following steps of: acquiring an image of a to-be-detected paddle; matching with a template of a standard qualified product is carried out, the product successfully matched is a qualified product, and the product failed in matching is a generalized unqualified product; training an AI algorithm model by using the classified defect image set to obtain an AI algorithm model classifier, and classifying generalized unqualified products by using the classifier; and changing generalized unqualified products meeting the targeted detection conditions into qualified products. Through the method, different defects are detected differently, the quality inspection process of products is restored more truly, meanwhile, different quality control errors are set for different types of defects, the quality control grade of qualified products can be adjusted, the quality control thought in industrial production is reflected, and machine vision defect detection is flexible.

Owner:SOUTH CHINA UNIV OF TECH

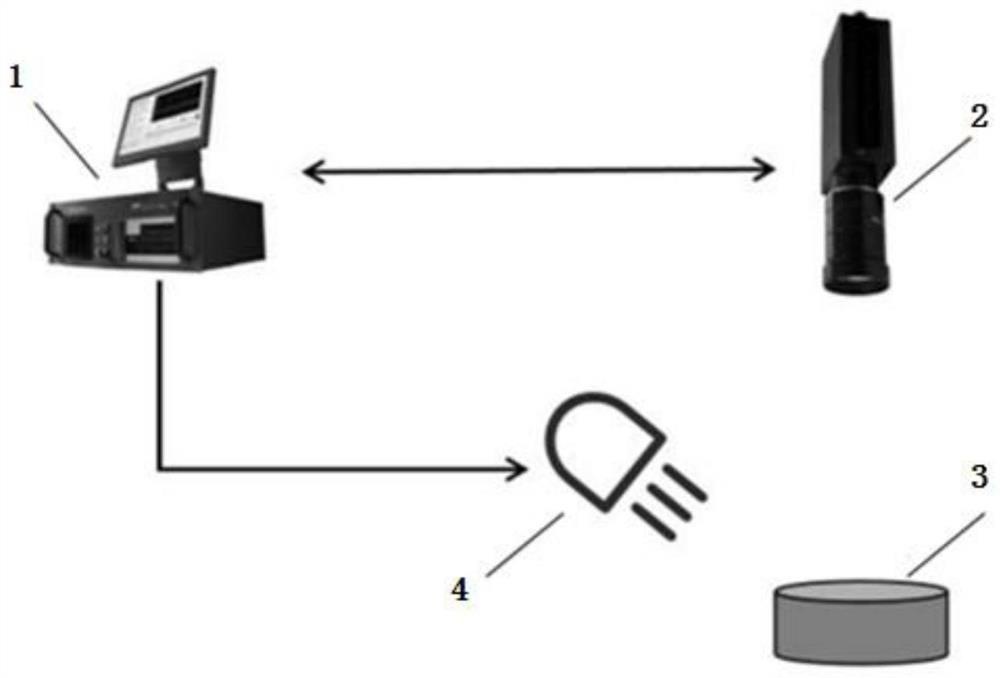

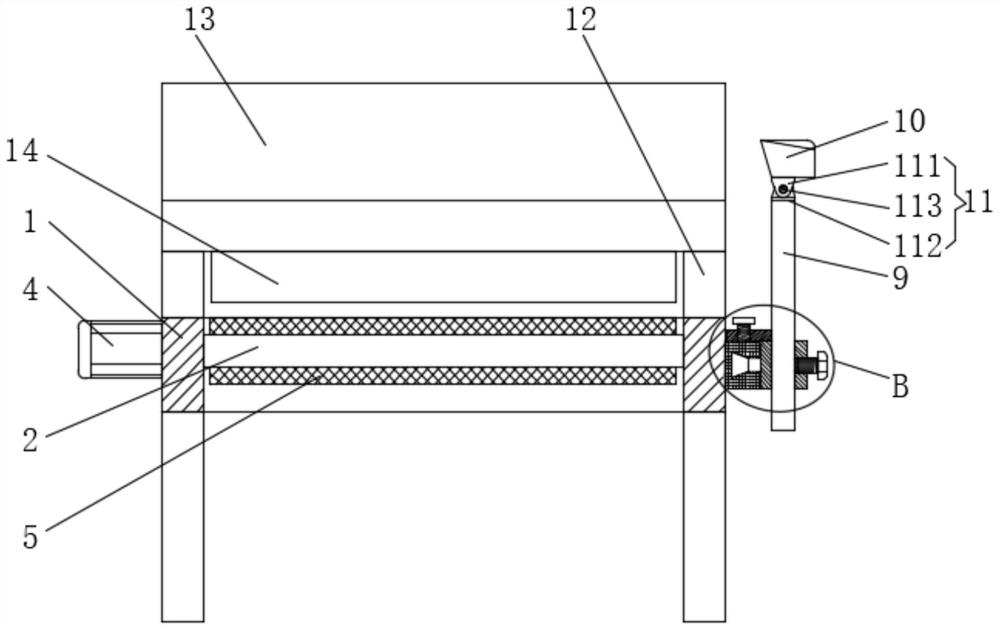

Machine vision light source system capable of automatically switching light source forms and dimming method

PendingCN112665555AImprove efficiencyHigh degree of automationPicture taking arrangementsPicture interpretationBatch productionDirect control

The invention discloses a machine vision light source system capable of automatically switching light source forms and a dimming method, the light source system comprises an industrial camera, a detection workpiece, a switchable light source and an industrial personal computer, and the industrial camera is controlled by the industrial personal computer and transmits image information of the detection workpiece to the industrial personal computer; the detection workpiece is arranged on the transparent conveyor belt; the switchable light source can be directly controlled by an industrial personal computer, different light source combinations and brightness can be switched, and the switchable light source comprises four backlight light sources, namely a low-angle strip-shaped light source vertical irradiation annular light source and a high-angle diffuse reflection annular light source. The industrial personal computer can make decisions by detecting workpiece images, and then controls the switchable light source to select the light source combination meeting the illumination requirement. The light source system and the dimming method are suitable for product detection of multiple varieties and small-batch production modes, light source adjustment can be conducted according to different product types, and automatic switching of different light source forms such as high-angle light sources, low-angle light sources, backlight light sources, common light sources and diffuse reflection light sources is achieved.

Owner:浙江泰瑞重型机械有限公司

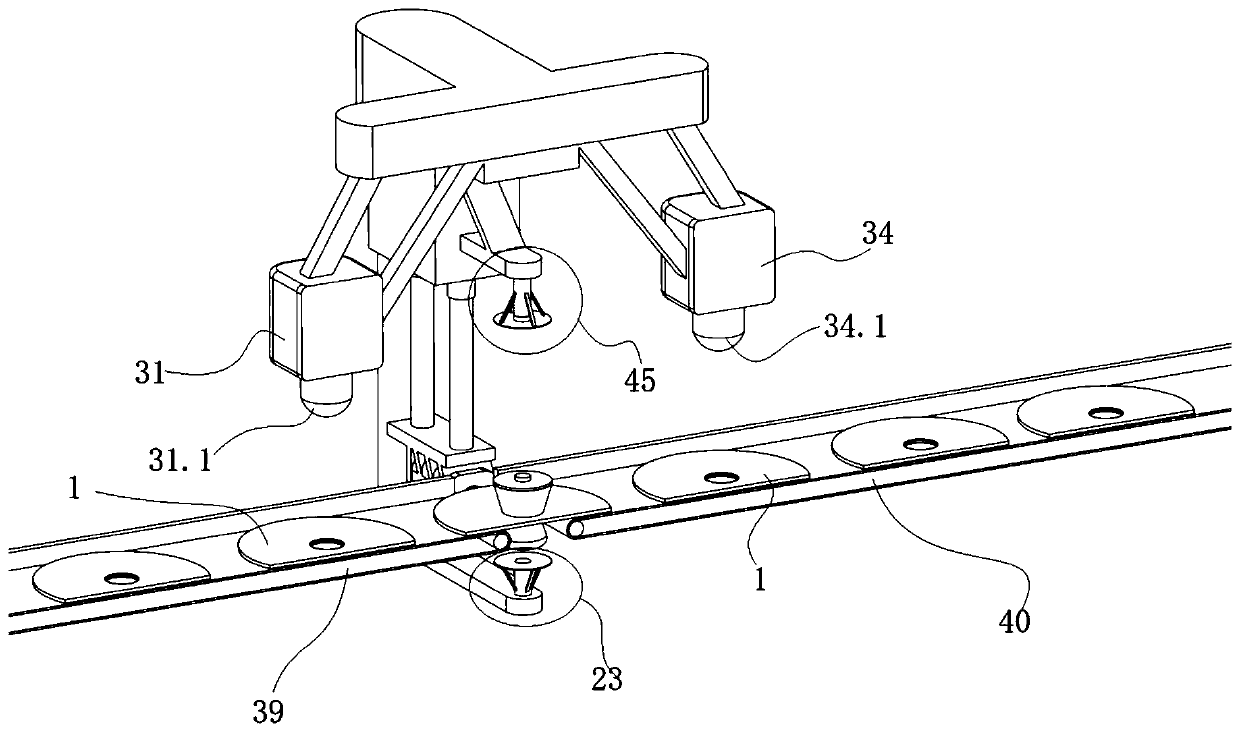

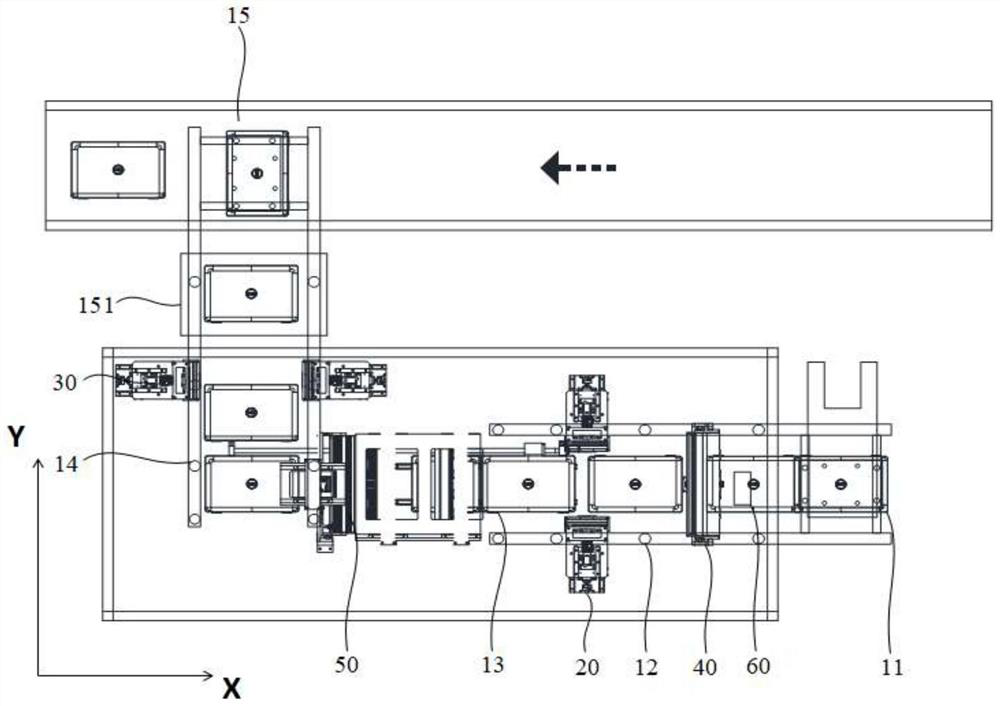

Automatic visual inspection system of PCB and working method of automatic visual inspection system

InactiveCN111351803AAchieving Simultaneous DetectionSimple structureOptically investigating flaws/contaminationVisual inspectionMechanical engineering

The invention discloses an automatic visual inspection system of a PCB, and the system comprises a camera obscura, the interior of the camera obscura is a visual inspection chamber, and the interior of the visual inspection chamber is provided with an industrial camera; the lower sides of the front and rear walls of the camera obscura are respectively provided with a front conveying port and a rear conveying port which penetrate through the visual inspection chamber; the system also comprises a front conveying belt unit and a rear conveying belt unit which are consistent in extending direction, and a front conveying surface on the front conveying belt unit is flush with a rear conveying surface on the rear conveying belt unit; the front conveying face and the rear conveying face can horizontally convey PCBs in the length direction. The system is simple in structure, and a PCB can be automatically turned over in the conveying process, so that the front face and the back face of the PCBare detected at the same time; the visual detection efficiency is greatly improved; in addition, the plate turnover mechanism can achieve the whole process of plate turnover and transfer only throughtwo servo motors.

Owner:宋志龙

Visual inspection method and system for assembly line

ActiveCN104796617BExpand the shooting areaImprove visual inspection efficiencyTelevision system detailsMeasurement devicesVisual inspectionAssembly line

Owner:BEIJING XINGHE TAISHITE TECH

Visual check supporting device for industrial products

ActiveCN1482450AImprove visual inspection efficiencyPrinted circuit assemblingMaterial analysis by optical meansVisual inspectionEmbedded system

Visual inspection support device for industrial products to easily search a defective portion in an electronic circuit component or the like, using information from another inspection device, to conduct confirmation work by the same operation, and to surely carry out visual inspection. This visual inspection support device for an industrial product having a camera unit comprising at least the first camera and the second camera for photographing an inspection object from different directions is provided with an inspection result collecting and inspection result data preparing means for collecting an inspection result or the like of the another inspection device to prepare an inspection result data, and a defective portion tracing means for tracing the defective portion ascertained already in the another inspection device. The inspection result or the like collected by the inspection result collecting and inspection result data preparing means is provided to the defective portion tracing means, and the camera unit is driven according to the inspection result data prepared by the inspection result collecting and inspection result data preparing means.

Owner:HITACHI GIKEN

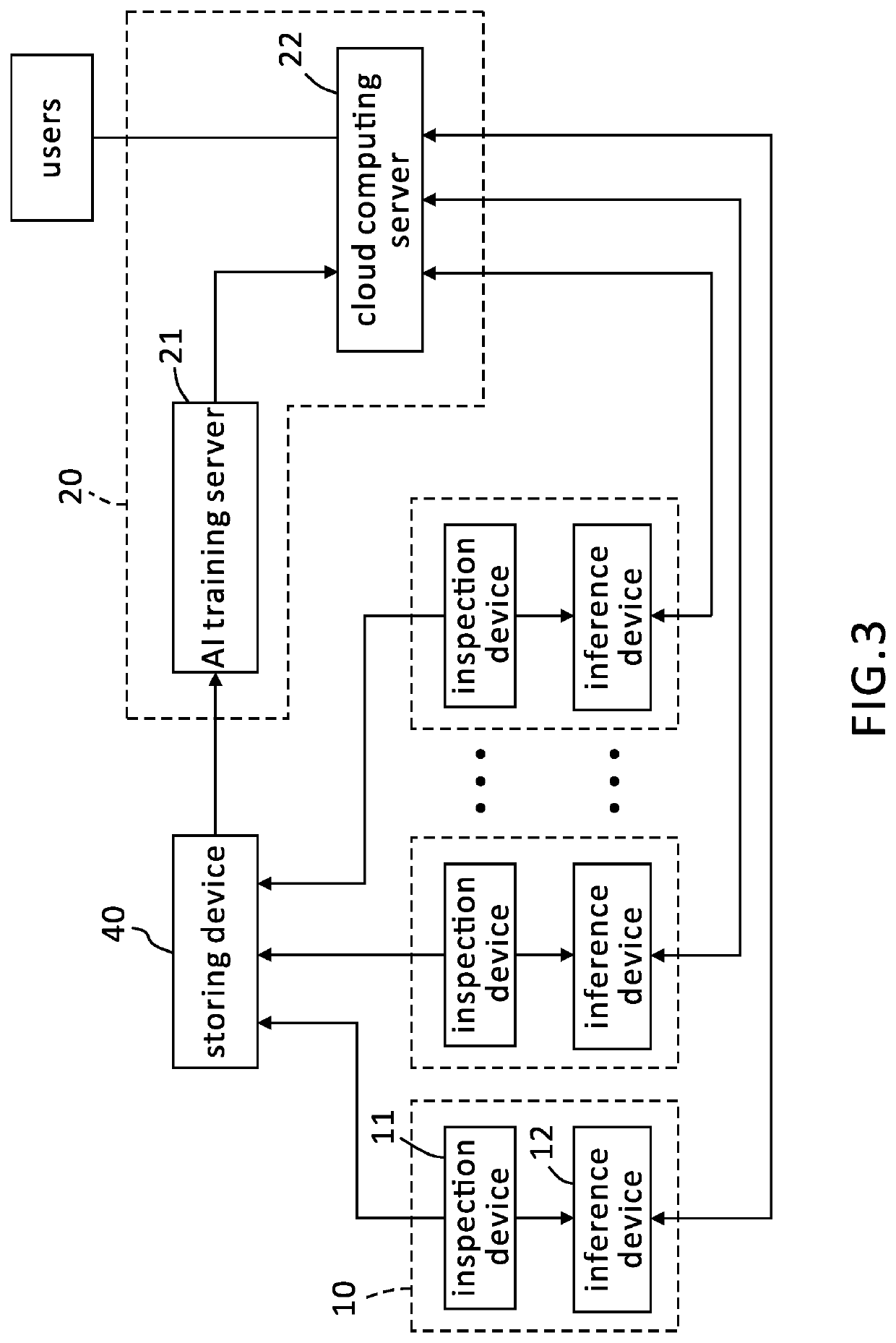

Ai process flow management system and method for automatic visual inspection

PendingUS20220253632A1Improve visual inspection efficiencyImage enhancementImage analysisEdge computingVisual inspection

Owner:LEADTEK

Device applied to high-speed line scanning detection and detection method thereof

PendingCN113137936AImprove parallelismReduce acquisition exposure timeUsing optical meansBeam splitterMachine vision

The invention belongs to the technical field of machine vision, and particularly discloses a device applied to high-speed line scanning detection and a detection method thereof. The device comprises a parallel light source device, a spectroscope, a backlight source and a camera, the spectroscope is obliquely arranged at one end of the parallel light source device, and the spectroscope, the backlight source and the camera are linearly arranged. The device adopts the telecentric light path design of the parallel light source device, has the characteristics of high emergent light parallelism and ultrahigh brightness, can enable the light flux of the lens to be more, increases the light efficiency utilization rate, reduces the required camera acquisition exposure time, and greatly improves the visual inspection efficiency.

Owner:GUANGDONG AOPUTE TECH CO LTD

Glass damage position machine vision detection equipment with multi-angle detection function

InactiveCN111929330AEasy for visual inspectionAdjustable rotation angleMaterial analysis by optical meansMachine visionVisual inspection

The invention discloses glass damage position machine vision detection equipment with a multi-angle detection function. The equipment comprises a body frame, a first cylinder is mounted on the right side of the lower part in the main body frame; the left side of a first air rod is rotationally connected with a first lock pin; a rotating block is arranged above the sliding groove; a fixed rod is mounted above the rotating block; a second air rod is arranged above a second air cylinder; a first sliding block is mounted on the left side of a lifting block; compared with existing common visual inspection equipment, the glass damage position machine vision detection equipment with the multi-angle detection function has the advantages that the rotating block is arranged, the first air cylinder drives the first lock pin to move in the sliding groove through the first air rod, the shape of the sliding groove is matched with the moving path of the first lock pin, the first lock pin drives the rotating block to rotate by 0-90 degrees with the second lock pin as the circle center, and multi-angle visual inspection can be conducted on cylindrical glass.

Owner:重庆信易源智能科技有限公司

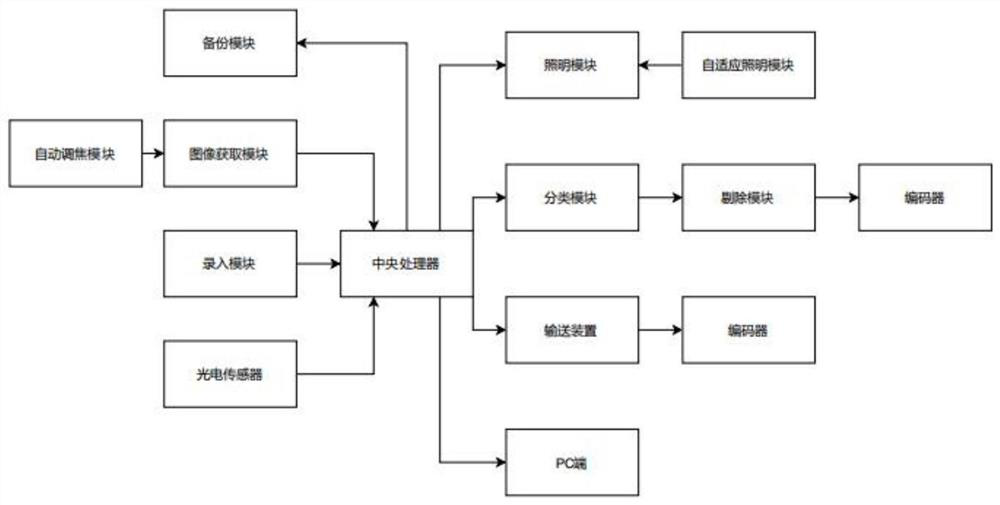

Efficient visual detection method and system

InactiveCN114345741AImprove feeding effectImprove collection effectSortingPattern recognitionMedicine

The invention relates to the technical field of visual inspection, in particular to an efficient visual inspection method and system, and the visual inspection system improves the workpiece inspection effect, improves the visual inspection efficiency and improves the practicability. The image acquisition module is used for acquiring an image of a to-be-detected workpiece and transmitting the image into the central processing unit; the classification module is used for analyzing and detecting the images uploaded to the central processing unit and classifying qualified images and unqualified images; the input module is used for uploading the image of the standard workpiece into the central processing unit; the conveying device is used for driving the workpiece to be fed below the image acquisition module, and the image acquisition module is used for carrying out image acquisition on the workpiece and conveying the detected workpiece to the next working procedure; and the rejecting module is electrically connected with the central processing unit and is used for rejecting the unqualified workpieces analyzed by the classifying module.

Owner:科芃智能科技(苏州)有限公司

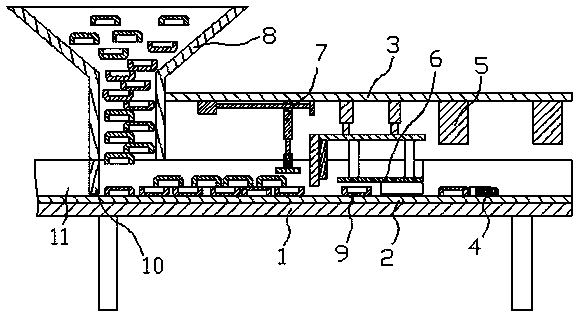

Thread insert visual detection equipment convenient in material feeding

ActiveCN110346374AContinuous and efficient visual inspectionImprove visual inspection efficiencyOptically investigating flaws/contaminationEngineeringInductor

The invention relates to thread insert visual detection equipment convenient in material feeding. The equipment comprises a supporting seat and an upper frame, wherein the supporting seat is providedwith a conveying device; the side surface of the conveying device is provided with a baffle which has the same movement direction with the conveying device; the upper edge of the upper frame is provided with a feed hopper and a visual detection device in sequence along a conveying direction, and the feed hopper and the visual detection device are cooperated with the conveying device; the baffle isprovided with a feeding blocking block and a material sweeping block; the feeding blocking block is positioned on the conveying starting side of the feed hopper; the material sweeping block is positioned between the feed hopper and the visual detection device; one layer of product can pass between the material sweeping block and the conveying device; one side, which is near the visual detection device, of the material sweeping block is provided with a material sensor, and one side, which is near the feed hopper, of the material sweeping block is cooperated with a fetching device; and in addition, information fed back from the material inductor controls the operation of the fetching device. By use of the feed hopper, products on the conveying device can be fed on a large batch, the material sweeping block and the fetching device can be cooperated to guarantee that the product enters to be below the visual detection device without stacking, and continuous and efficient visual detectioncan be realized.

Owner:CHONGQING TECH & BUSINESS UNIV

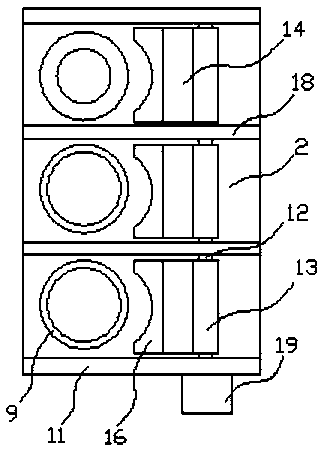

Auxiliary turntable mechanism for semiconductor sorting

PendingCN114367452AImprove visual inspection effectImprove visual inspection efficiencySortingElectric machineryEngineering

The invention relates to the technical field of semiconductor processing, in particular to an auxiliary turntable mechanism for sorting semiconductors, which improves the visual detection effect of the semiconductors, improves the visual detection efficiency of the semiconductors and improves the practicability. Comprising an equipment box, rotating disc mechanisms, a detection mechanism, a clamping mechanism and a moving mechanism, the two rotating disc mechanisms are installed on the equipment box, a cavity is formed in the equipment box, a control device is arranged in the cavity, the detection mechanism is installed on the equipment box, the moving mechanism is installed on the equipment box, and the clamping mechanism is installed on the moving mechanism. The moving mechanism is used for moving the clamping mechanism; the rotary disc mechanism comprises a first speed reducer, a first motor, a rotary disc and clamps, the first speed reducer is installed on the equipment box, the first motor is installed on the first speed reducer, the output end of the first motor is connected with the input end of the first speed reducer, the rotary disc is installed at the output end of the first speed reducer, and the clamps are evenly installed on the rotary disc.

Owner:深圳市冠达宏科技有限公司

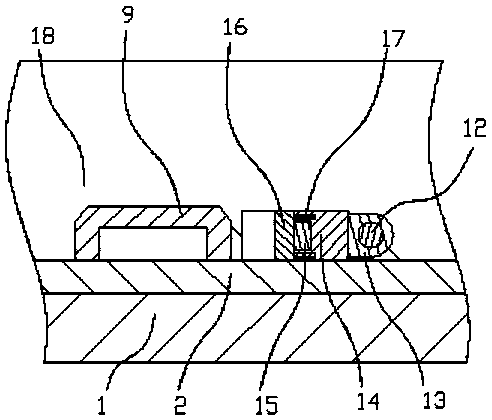

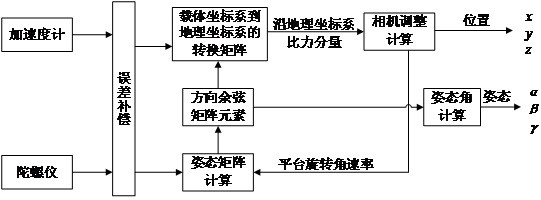

High-temperature forging visual inspection system with vibration isolation capability

PendingCN113552136ASolve sizeResolve detectionOptically investigating flaws/contaminationImaging qualityControl engineering

The invention discloses a high-temperature forging visual inspection system with vibration isolation capability, which comprises industrial cameras and a self-adaptive vibration compensation device, the industrial cameras are arranged on the self-adaptive vibration compensation device, the number of the industrial cameras is two, the shooting included angle of the two industrial cameras is 90 degrees, an optical filter is arranged in a lens of each industrial camera, the self-adaptive vibration compensation device comprises a camera mounting platform and a motion controller, and the system can detect the sizes and defects of high-temperature forgings of various different specifications in the forging process of the forgings, so that the imaging quality of the detection system on the high-temperature forgings is almost the same as the imaging effect at room temperature, the visual detection efficiency is improved, and accuracy is high and production cost is reduced.

Owner:GUANGZHOU INST OF ADVANCED TECH CHINESE ACAD OF SCI +1

Surface detection equipment for battery cell

PendingCN114354610AQuality improvementImprove visual inspection efficiencyOptically investigating flaws/contaminationComputer hardwareVisual perception

A battery cell surface detection device disclosed by the present invention comprises a first grabbing structure, a second grabbing structure, a transmission structure and a detection structure, the first grabbing structure is arranged close to the inlet side of the transmission structure, the second grabbing structure is arranged close to the outlet side of the transmission structure, and the detection structure comprises a first visual camera and a second visual camera. The first vision camera and the second vision camera are arranged close to the transmission structure. The detection structure is arranged to shoot the surface of the battery cell, so that the surface of the battery cell is visually detected, compared with an existing manual recognition mode, the visual detection efficiency is high, the occurrence of false detection can be greatly reduced, and the quality of a battery cell product is effectively improved; in addition, automatic feeding, conveying and discharging in the battery cell detection process are achieved, the automation degree is high, manpower is saved, and the detection efficiency is further improved.

Owner:GUANGZHOU SUPERSONIC AUTOMATION TECH CO LTD

A detection and correction method for fast and accurate acquisition of component center and deflection angle

ActiveCN104981105BFind out exactlyOvercoming complex shortcomingsPrinted circuit assemblingCircuit board tools positioningCurve fittingEdge extraction

A detecting and error-correcting method capable of rapidly and accurately obtaining an element center and a deflection angle is disclosed. Interested edge area can be rapidly and accurately found out through an automatic edge area extraction method based on combination of binary morphology and image reduction, and subsequent edge extraction image scope is minimized as possible. Pixel level edge is roughly positioned at first, and accordingly a sub-pixel edge is rapidly extracted by one-dimensional curve fitting method. The method overcomes the defect of complex algorithm of a conventional sub-pixel edge extraction algorithm based on two-dimensional images, and the time of extracting accurate sub-pixel edge can be shortened. Weighted least square rectangular edge fitting algorithm based on linear hazen paradigm can detect straight lines on any positions of an image, and effectively minimizes influence of outlier on fitting precision due to uneven edges. The central positions of a plurality of elements and deflect angles can be rapidly and accurately detected at once, and the efficiency of visual detection is improved.

Owner:GUANGDONG UNIV OF TECH

A visual detection method and system for multiple measured objects

ActiveCN107330938BReduce the number of motion positioningImprove detection efficiencyImage analysisOptically investigating flaws/contaminationOphthalmologyVisual inspection

The invention discloses a visual detection method for a plurality of detected objects. The visual detection method includes the steps of obtaining a detected object position distribution file including the positional information of a plurality of the detected objects, and obtaining an optimal lens position set according to the detected object position distribution file by using lens simulation technology, wherein the optimal lens position set contains all the detected objects and lens positions of lenses of minimal number. The invention further discloses a vision detection system for a plurality of detected objects. An optimal lens position set is obtained according to the detected object position distribution file by using lens simulation technology, and the optimal lens position set contains all the detected objects and lens positions of lenses of minimal number, thereby reducing the moving and positioning frequency required for actual detecting a plurality of detected objects. The visual detection efficiency of a plurality of detected objects is effectively improved.

Owner:深圳市强华科技发展有限公司

Visual inspection equipment for medical balloon

PendingCN111879783ARealize teleportation vision inspectionImprove visual inspection efficiencyConveyorsOptically investigating flaws/contaminationPhotoswitchVisual inspection

The visual inspection equipment comprises a cabinet body, conveying openings are formed in a left side plate and a right side plate of the cabinet body, a first side cover and a second side cover arearranged on the front side plate and the rear side plate of the cabinet body, a belt and a placement block integrally penetrate through the conveying openings, a detection groove and a groove are formed in the placement block, and a detected block is arranged in the groove; a transverse plate is arranged on the upper portion of an inner cavity of the cabinet body, a connecting rod is arranged at the lower left end of the transverse plate, a photoelectric switch is arranged at the lower end of the connecting rod, a processor and a controller are arranged on the lower portion of the inner cavityof the cabinet body, and a hexagonal cover and an indicator lamp set are arranged at the upper end of a top plate of the cabinet body. According to the invention, the medical balloon placed in the detection groove is detected in a conveying mode, the efficiency of visual detection of the medical balloon is improved, real-time observation of the visual detection process of the medical balloon in the cabinet body is achieved, parts in the cabinet body are conveniently overhauled through the observation opening, and the observation timeliness of the visual detection result of the medical balloonis guaranteed.

Owner:昆山嘉斯特自动化技术有限公司

AI visual inspection equipment and system for shell structure defect detection

ActiveCN114705693ASimple structureAvoid layoutOptically investigating flaws/contaminationManufacturing computing systemsVisual inspectionEngineering

The invention relates to the technical field of visual inspection, and provides AI visual inspection equipment and system for shell structure defect detection. The AI visual inspection equipment comprises a transmission structure, one end of the transmission structure is a feeding position, the other end of the transmission structure is a discharging position, the transmission structure is provided with a transmission position for products to move, and the transmission position comprises a first transmission section and a second transmission section which are different in transmission direction; the at least two first side surface visual detection devices are respectively arranged on two sides of the first transmission section; the at least two second side surface visual detection devices are respectively arranged on two sides of the second transmission section; the structural surface visual detection device is arranged below the transmission position; and the appearance surface visual detection device is arranged above the transmission position. The AI visual inspection equipment provided by the invention realizes all-around rapid visual inspection of products.

Owner:中信云网有限公司 +1

A visual inspection device for screw sleeves that is convenient for discharging

ActiveCN110346374BContinuous and efficient visual inspectionImprove visual inspection efficiencyOptically investigating flaws/contaminationInformation controlVisual inspection

The invention relates to a screw sleeve visual detection device for convenient discharging, which comprises a support seat and an upper frame, a conveying device is arranged on the support seat, and a baffle plate in the same direction as the conveying device is arranged on the side of the conveying device, and the upper edge of the upper frame In the conveying direction, a feeding hopper and a visual inspection device are arranged in sequence to cooperate with the conveying device. The baffle is provided with a feeding blocking block and a sweeping block. The feeding blocking block is located at the starting side of the feeding hopper, and the sweeping The material block is located between the feeding hopper and the visual inspection device, and only one layer of products can pass between the sweeping block and the conveying device. The side is equipped with a grabbing device, and the information fed back by the material sensor controls the operation of the grabbing device; the feeding hopper is used to realize the large-scale feeding of products on the conveying device, and the combination of the sweeping block and the grabbing device can ensure that the products are not stacked. Entering under the visual inspection device can realize continuous and efficient visual inspection.

Owner:CHONGQING TECH & BUSINESS UNIV

Image comparison method and device and computer readable storage medium

PendingCN114266907AImprove visual inspection efficiencyCharacter and pattern recognitionWebsite content managementImaging processingComputer graphics (images)

Embodiments of the invention provide an image comparison method and apparatus, and a computer readable storage medium. The method comprises the steps of obtaining a webpage address and a design drawing address through a client; based on the webpage address and the design drawing address, performing acquired image processing, and determining a to-be-compared webpage screenshot and a to-be-compared design drawing; based on the comparison webpage screenshot and the to-be-compared design drawing, performing different-dimension processing on an image through multiple processes, and determining an image comparison result of the to-be-compared webpage screenshot and the to-be-compared design drawing; and sending the image comparison result to a client. By adopting the scheme, the to-be-compared webpage screenshot and the to-be-compared design drawing can be obtained according to the webpage address and the design drawing address, and the image comparison result is obtained by performing different-dimension processing on the image through multiple processes, so that the visual walking efficiency can be improved.

Owner:BEIJING WODONG TIANJUN INFORMATION TECH CO LTD +1

Syringe outer tube visual inspection and screening equipment

ActiveCN110653175BImprove visual inspection efficiencyReasonable settingSortingVisual inspectionAssembly line

The invention provides a visual detection and screening device for the outer tube of a syringe, which includes a feeding device, a first visual detection device, a second visual detection device, a handling robot, and a clamping and screening device; the first visual detection device is used for The side circumferential surface of the syringe outer tube is visually inspected for the first time; the second visual inspection device is used for the second visual inspection of the two end faces of the syringe outer tube; the clamping and screening device includes a clamping displacement mechanism and A screening mechanism, the clamping displacement mechanism transports the transfer robot to the syringe outer tube clamping directly opposite the second visual inspection device, and the screening mechanism screens the syringe outer tube into the second storage box . The present invention uses an assembly line to perform two visual inspections on a plurality of syringe outer tubes, and automatically distinguishes and screens out qualified finished products and unqualified defective products, effectively improving the efficiency and accuracy of the visual inspection of syringe outer tubes, And reduce the production of finished products.

Owner:SHAODONG INTELLIGENT MFG INNOVATIVE INST

Human-computer interaction perception system and method for gas insulated switch visual inspection robot

ActiveCN111673748BEasy to check job planningEasy to controlProgramme-controlled manipulatorVision inspectionSimulation

The invention discloses a human-computer interaction perception system and method for a gas-insulated switch visual inspection robot. When the operator controls the inspection robot to perform fault inspection on gas-insulated switchgear, he can master the inspection through the human-computer interaction interface of the upper computer. The specific position information of the closed space of the gas insulated switch where the robot is located is convenient for the operator to plan the subsequent inspection operation. Through the 3D virtual reality interactive interface, the human-computer interaction presence of the operator of the gas insulated switch inspection robot is improved, thereby effectively improving the fault point. The speed of determining the position improves the inspection efficiency of gas insulated switches.

Owner:SICHUAN UNIV +1

Cylindrical workpiece inner wall image acquisition method and device and computer readable storage medium

ActiveCN110381265AImprove visual inspection efficiencyReduce the difficulty of operationTelevision system detailsColor television detailsBarrel ShapedVisual perception

The invention discloses a cylindrical workpiece inner wall image acquisition method and device and a computer readable storage medium. The method comprises the following steps: controlling an image acquisition device to move to each preset position, and acquiring a circumferential image of the inner wall part of the cylindrical workpiece corresponding to each preset position shot by the image acquisition device; and splicing the acquired circumferential images of the inner wall parts of the barrel-shaped workpieces to obtain inner wall images of the barrel-shaped workpieces. According to the invention, the visual detection efficiency in the cylinder is improved, the manual detection burden and the operation difficulty are reduced, and the production cost is reduced.

Owner:武汉恒新动力科技有限公司

A machine vision-based paddle shadow pad printing defect recognition method

ActiveCN113109348BTrue restorationAdjustable quality control levelImage enhancementImage analysisPad printingMachine vision

The invention discloses a machine vision-based paddle shadow pad printing defect recognition method, comprising the following steps: collecting and acquiring the image of the paddle to be detected; It is a generalized unqualified product; use the classified defect image set to train the AI algorithm model to obtain an AI algorithm model classifier, and use this classifier to classify the generalized unqualified products; the generalized unqualified products that meet the targeted detection conditions The product is changed to a qualified product. Through the above method, the detection of different defects is treated differently, and the quality inspection process of the product is more realistically restored. At the same time, by setting different quality control errors for different types of defects, the quality control level of qualified products can be adjusted, which reflects the quality control idea in industrial production. , making machine vision defect detection flexible.

Owner:SOUTH CHINA UNIV OF TECH

An aluminum electrolytic capacitor assembly line

ActiveCN110333234BEasy to adjust left and rightEasy to cleanMaterial analysis by optical meansCleaning using toolsProduction lineVisual inspection

The invention discloses an aluminum electrolytic capacitor assembly production line, which includes a frame, and a first driving rod is movably installed on the left side of the inner wall of the frame. The invention uses a brush to clean the capacitors falling into the material receiving frame, so that the capacitors are cleaned and the visual detection efficiency is improved. At the same time, the angle of the detection probe can be adjusted and used through the angle adjustment mechanism, and the height adjustment plate can adjust the detection probe. The height is used, and the sliding cooperation between the sliding rail and the sleeve block can facilitate the left and right adjustment of the detection probe, improve the efficiency of visual inspection, ensure the detection efficiency of assembly parts in the production line, and solve the problem that most of the existing visual inspection equipment detection heads cannot be adjusted for use and detection. In the past, it was impossible to clean the surface of the capacitor. The aluminum electrolytic capacitor assembly line has the advantages of convenient adjustment of the detection head and cleaning of the capacitor, which improves the quality stability of the assembly line.

Owner:南通赛克斯电子有限公司

Battery cell tab detection mechanism

PendingCN114354609AQuality improvementImprove visual inspection efficiencyOptically investigating flaws/contaminationEngineeringMechanical engineering

The invention discloses a battery cell tab detection mechanism which comprises a bottom plate, a first moving platform, a first visual camera, a first prism, a first lifting device, a second moving platform, a second visual camera, a second prism and a second lifting device. The first moving platform and the first visual camera are arranged on the bottom plate in a front-back spaced mode. Visual detection is performed on the inner and outer side faces of the first tab and the inner and outer side faces of the second tab to detect whether the number of the first tab and the second tab is correct and whether the tabs are folded or not, compared with an existing manual identification mode, the visual detection efficiency is high, the false detection situation can be greatly reduced, and the detection efficiency is improved. And the quality of a battery cell product is effectively improved.

Owner:GUANGZHOU SUPERSONIC AUTOMATION TECH CO LTD

A fast tilt correction method for qfn chip pin image

ActiveCN110992326BQuick correctionAccurate correctionImage enhancementImage analysisComputer graphics (images)Visual inspection

The invention discloses a fast tilt correction method for a pin image of a QFN chip, comprising the following steps: (1) collecting the pin image of the QFN chip, filtering and binarizing it; (2) extracting the center pad of the chip image by using a polygon approximation method contour; (3) propose an improved Harris corner detection algorithm to obtain contour vertices; (4) use the least squares method to fit a straight line to the farthest vertex, and use the straight line as the angle to identify the direction; (5) use the image centroid coordinates For the center of rotation, quickly correct the chip pin image and remove white edges. The correction method provides a certain theoretical basis for faster and more accurate correction of QFN chips, and improves the visual inspection efficiency of QFN package defects.

Owner:JIANGSU UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com