Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51results about How to "Improve NVH characteristics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

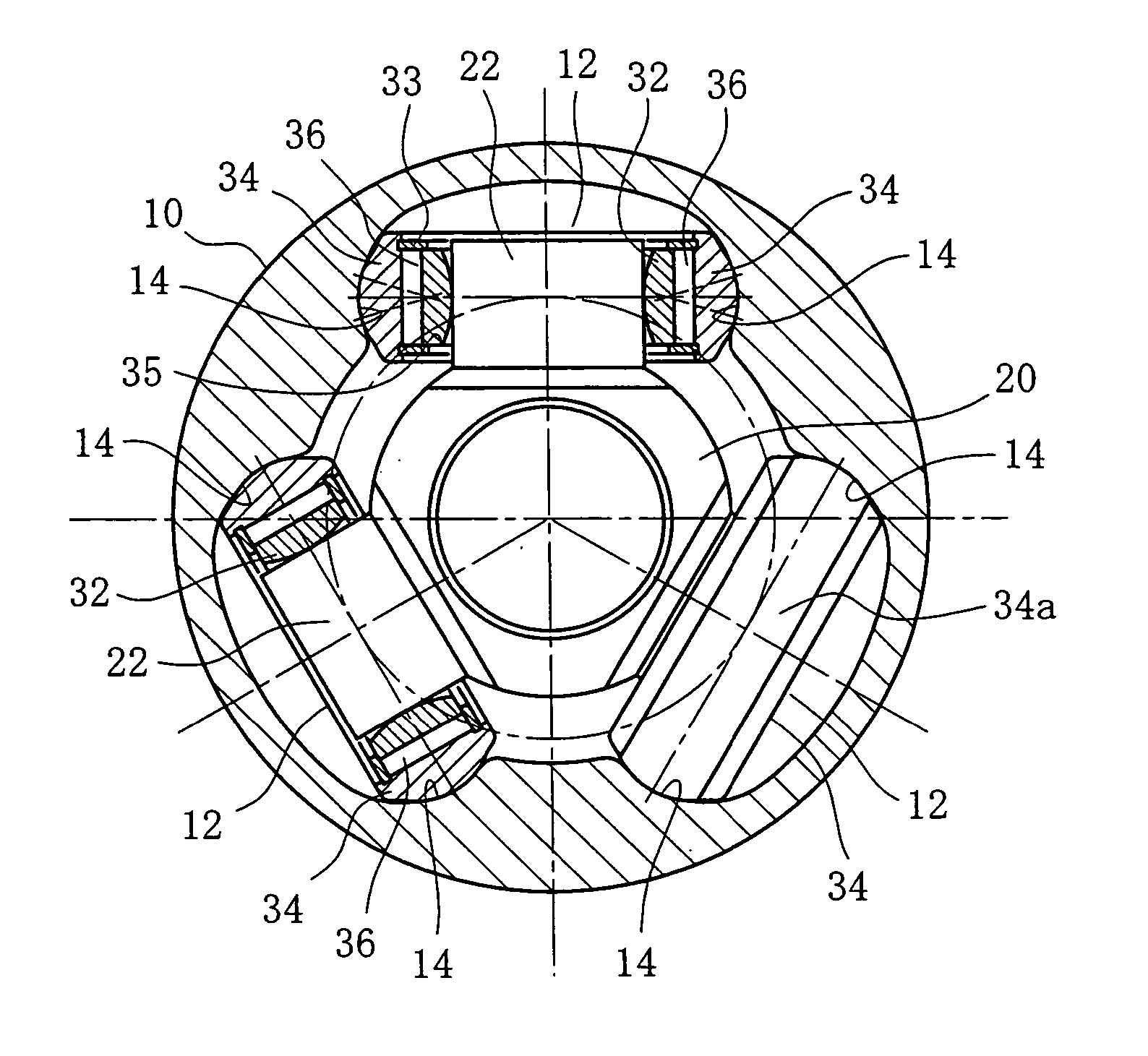

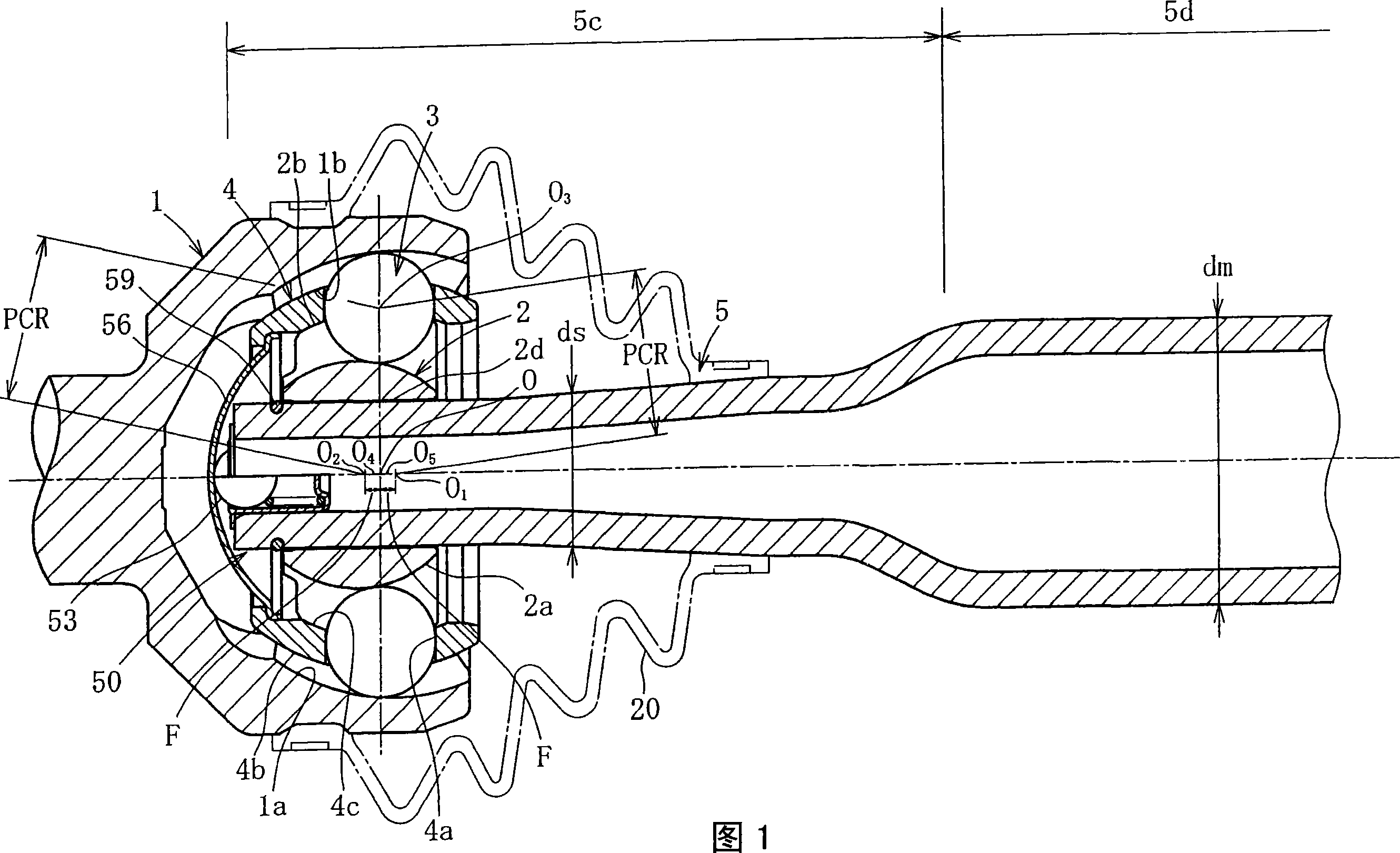

Constant velocity universal joint

ActiveUS20050059497A1Improve NVH characteristicsImprove featuresYielding couplingRotary machine partsUniversal jointSurface roughness

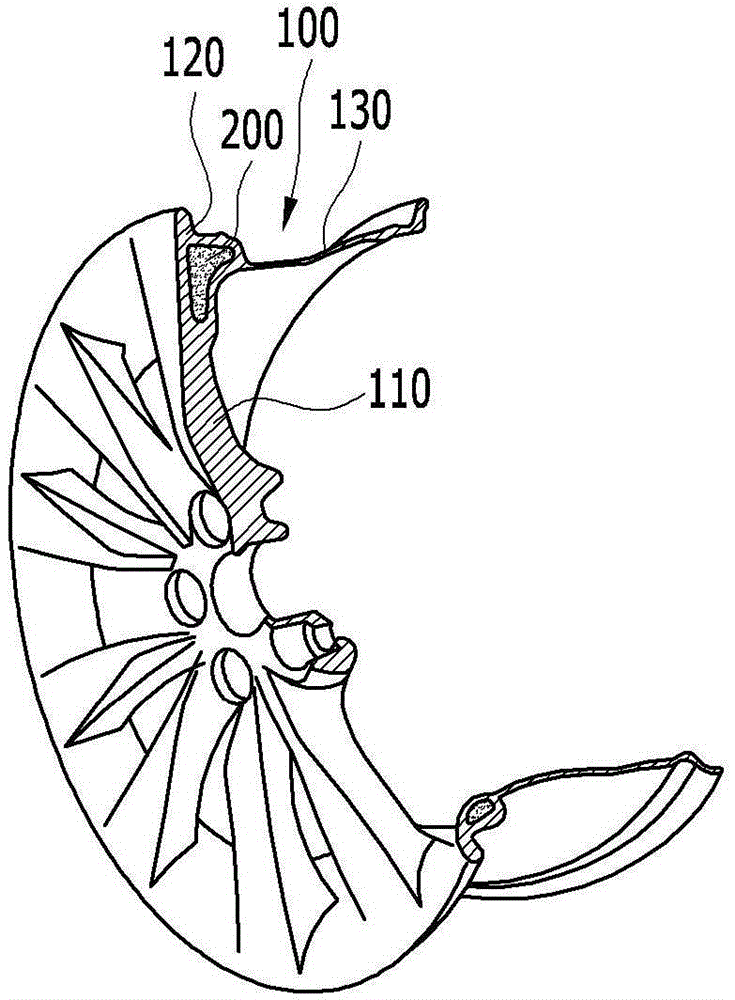

An object is to stabilize the induced thrust and the sliding resistance at a low level after expiration of the endurance life and exhibit favorable NVH characteristics. A constant velocity universal joint comprises: an outer joint member having three track grooves formed to extend axially in an inner circumference portion thereof, and having a roller guide surface formed to extend axially on each side of the respective track grooves; a tripod member having three trunnions protruding in the radial direction; and a roller mechanism mounted in each of the trunnions of the tripod member. The roller mechanism is capable of swinging and oscillating freely with respect to the trunnions, and has a roller that is guided along the roller guide surface in the direction parallel to the axis line of the outer joint member. In the constant velocity universal joint, the outer peripheral surface of the roller has a surface roughness of 0.35 Ra or less.

Owner:NTN CORP

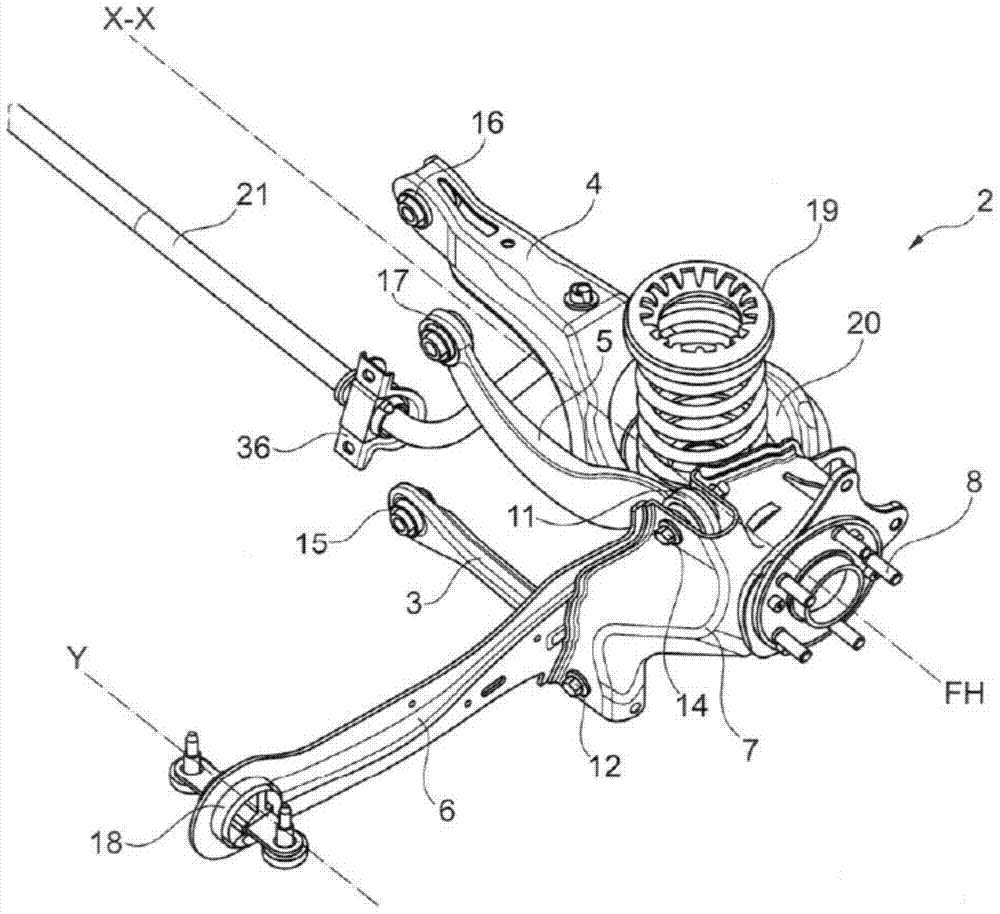

Multilink rear axle for a motor vehicle

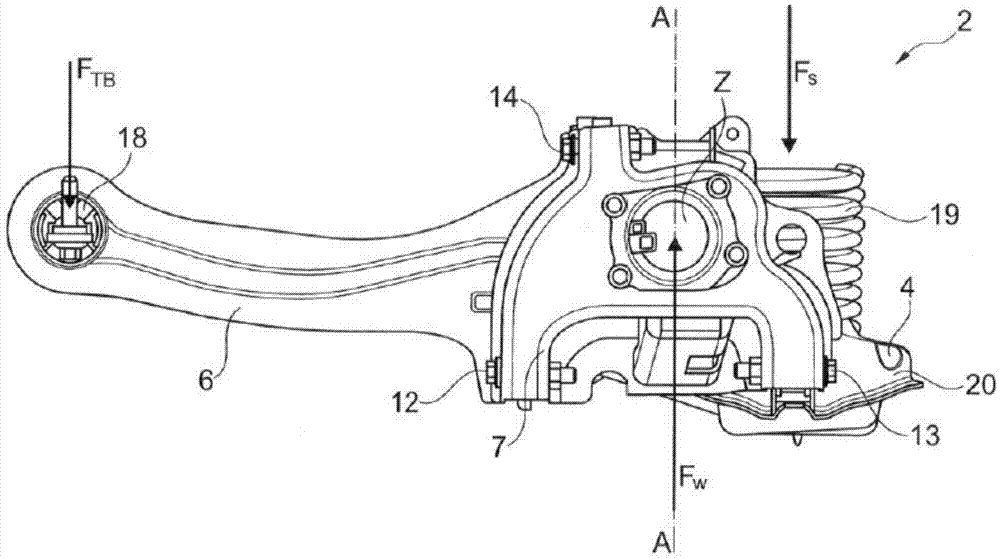

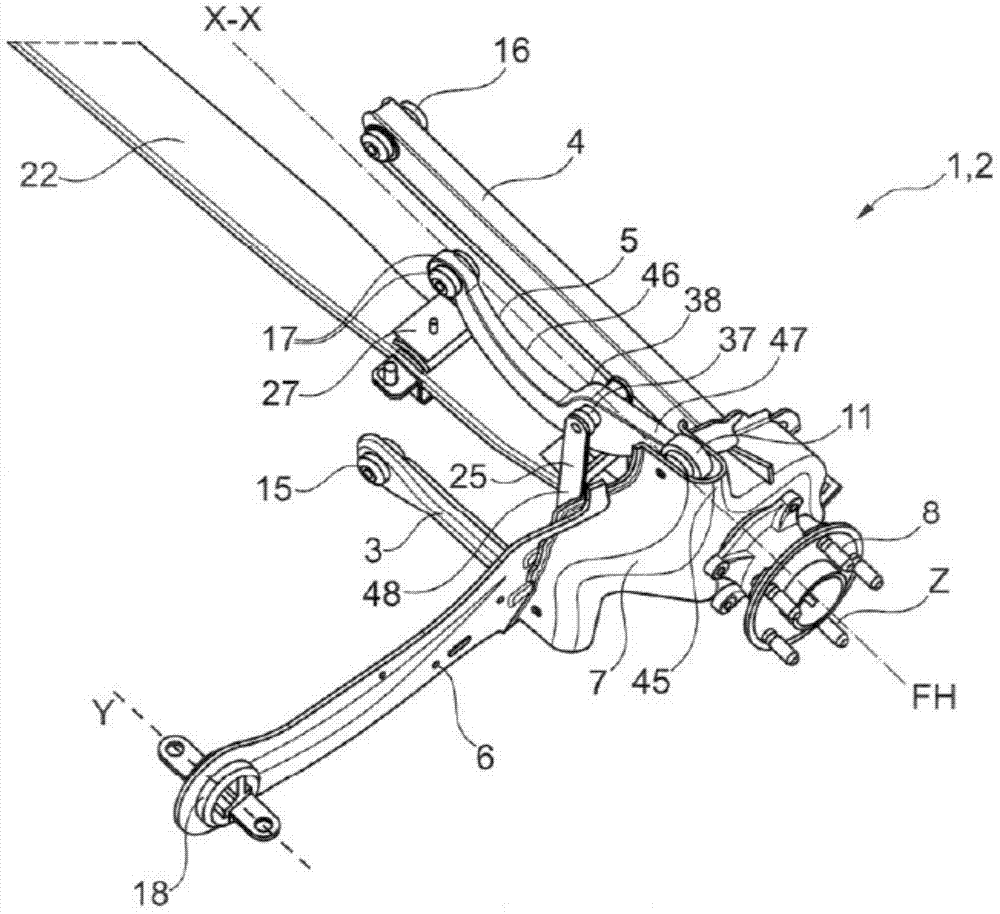

ActiveCN104210321AReduce weightImprove rolling stabilityInterconnection systemsResilient suspensionsMobile vehicleControl arm

A multilink rear axle comprises a wheel carrier, a leaf spring, a first lower control arm, an upper control arm, and at least one member. The wheel carrier can rotatably support a wheel of the vehicle. The leaf spring can extend in a width direction of the vehicle that is transverse to a longitudinal direction of the vehicle. The first lower control arm can extend in the width direction and is pivotably coupled to the wheel carrier at a rear half thereof. The upper control arm can extend in the width direction and can be pivotably coupled to the wheel carrier at an attachment point that is offset from the rotation axis of the supported wheel in the longitudinal direction by less than or equal to 100 mm. The at least one member can pivotably couple the leaf spring to the upper control arm.

Owner:FORD GLOBAL TECH LLC

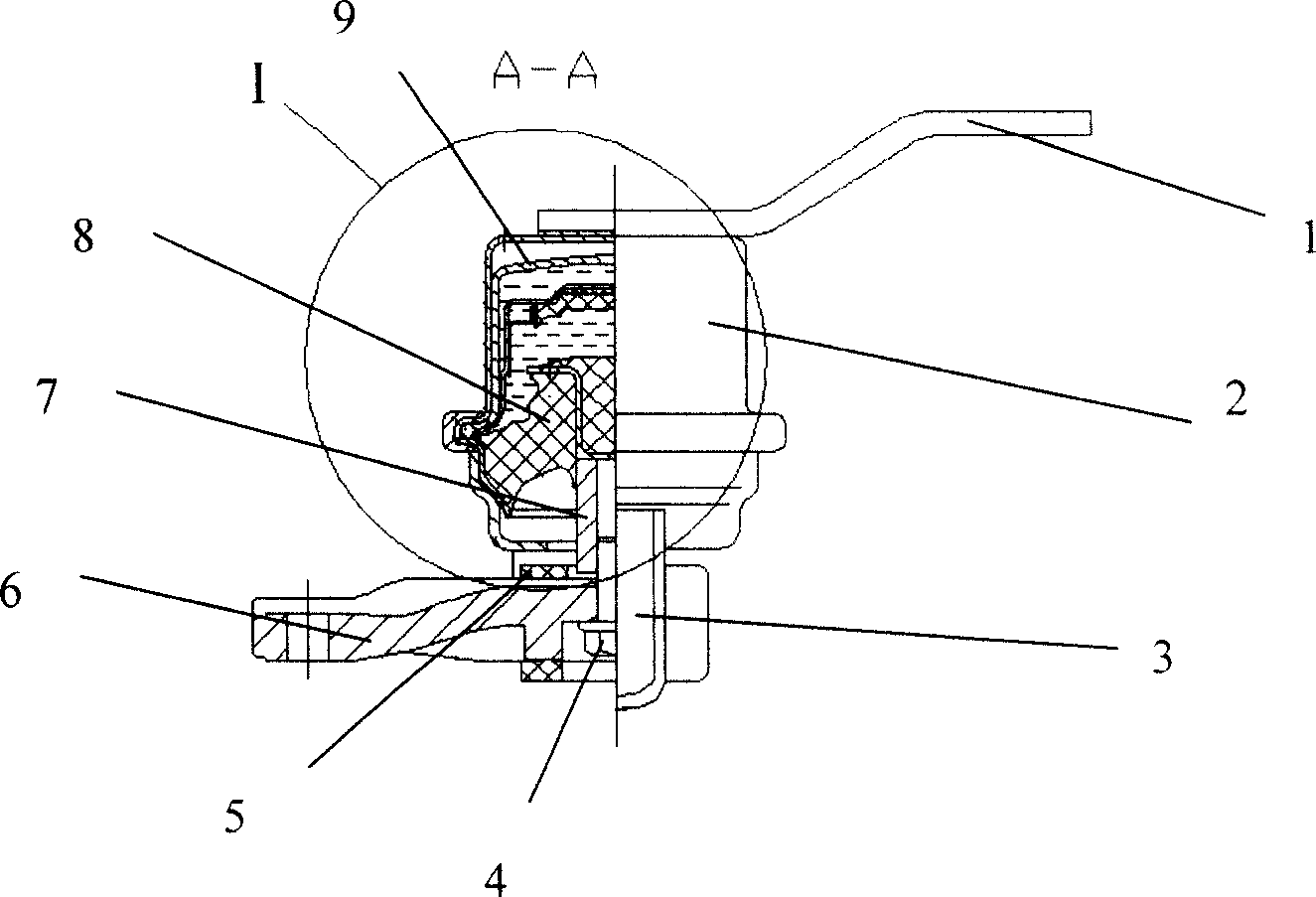

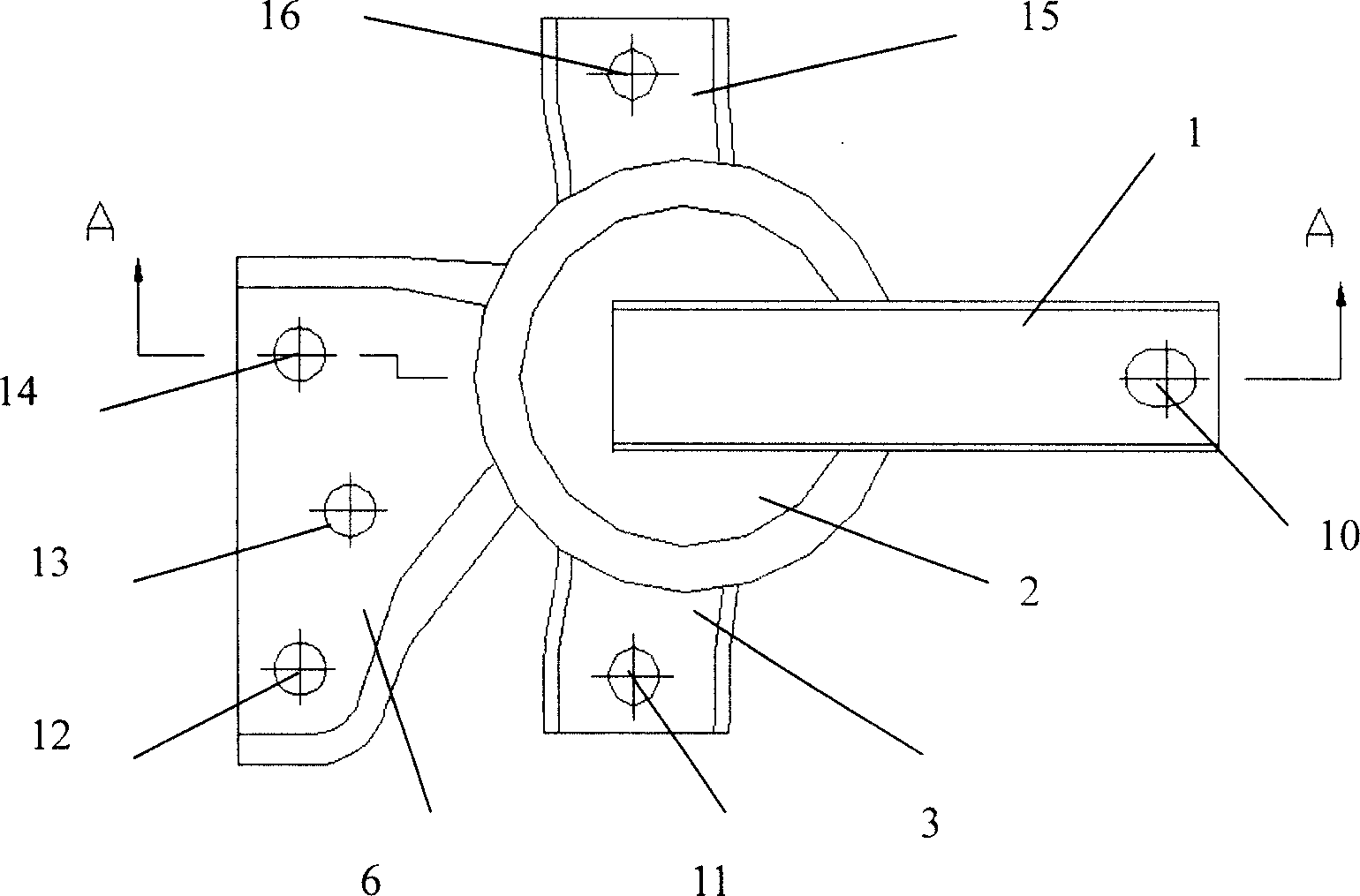

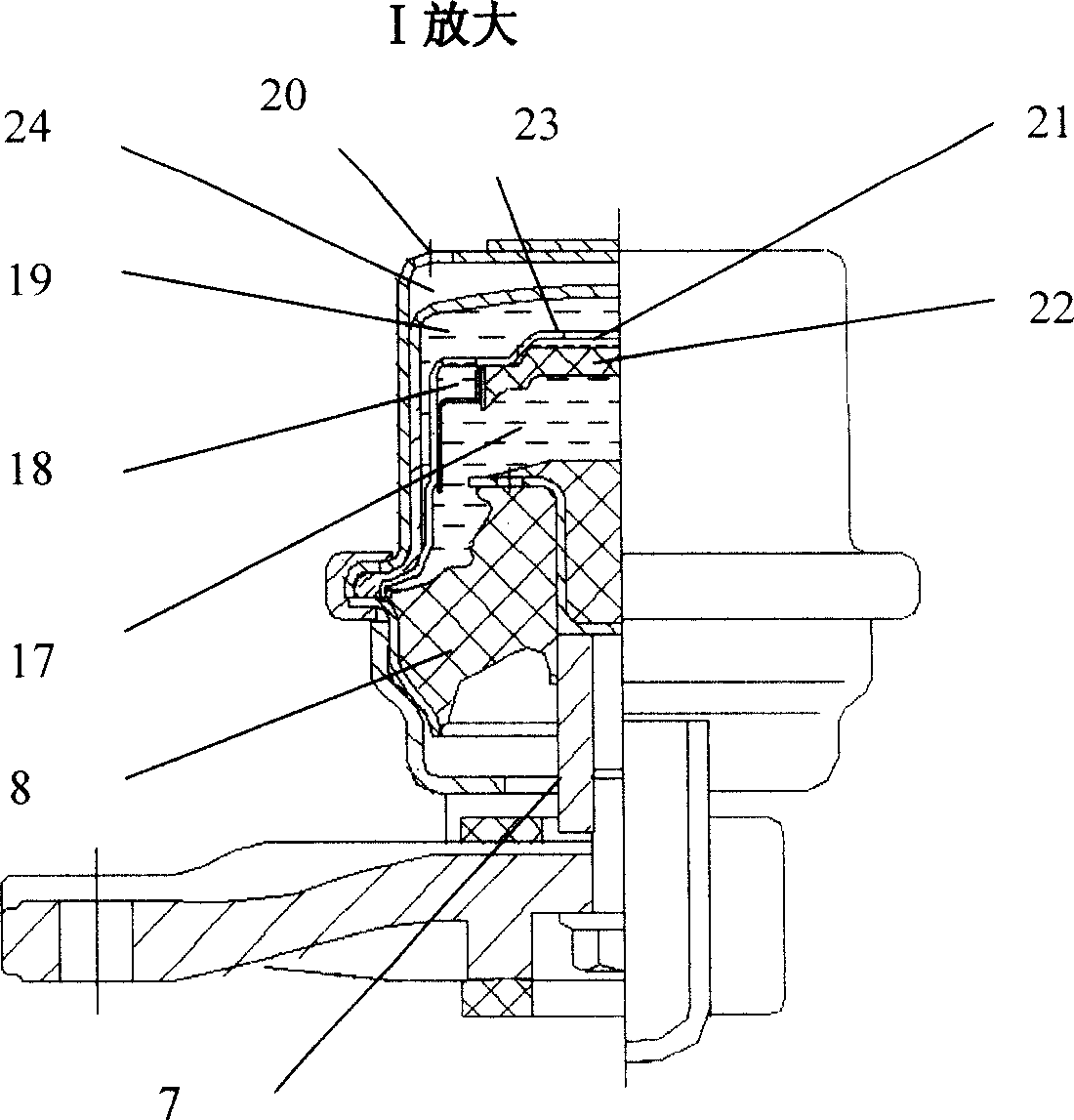

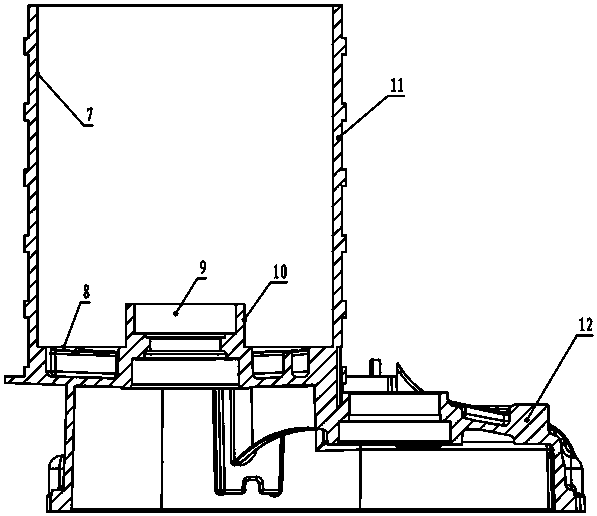

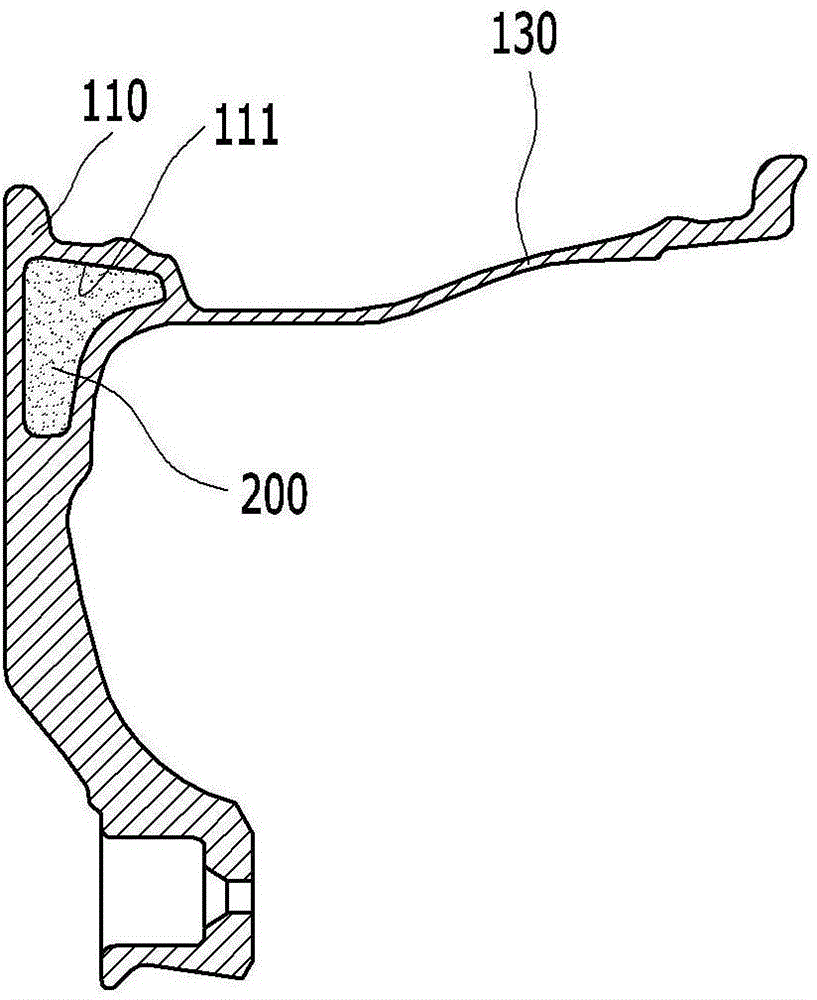

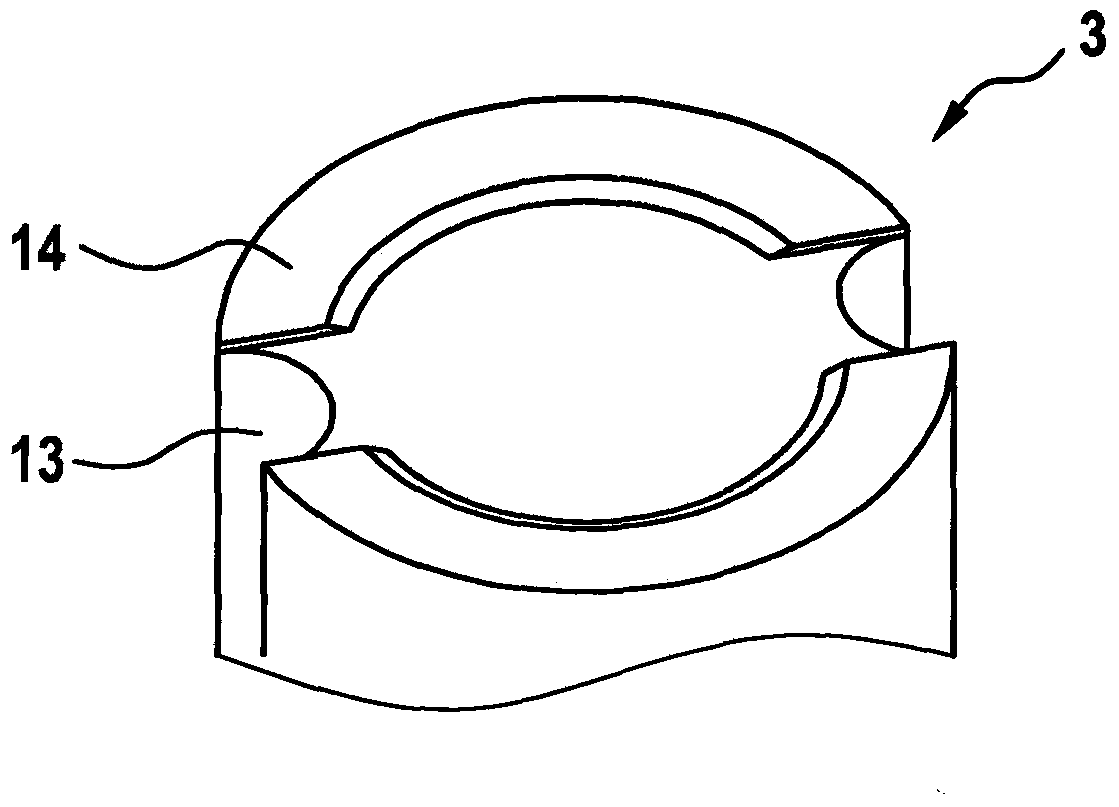

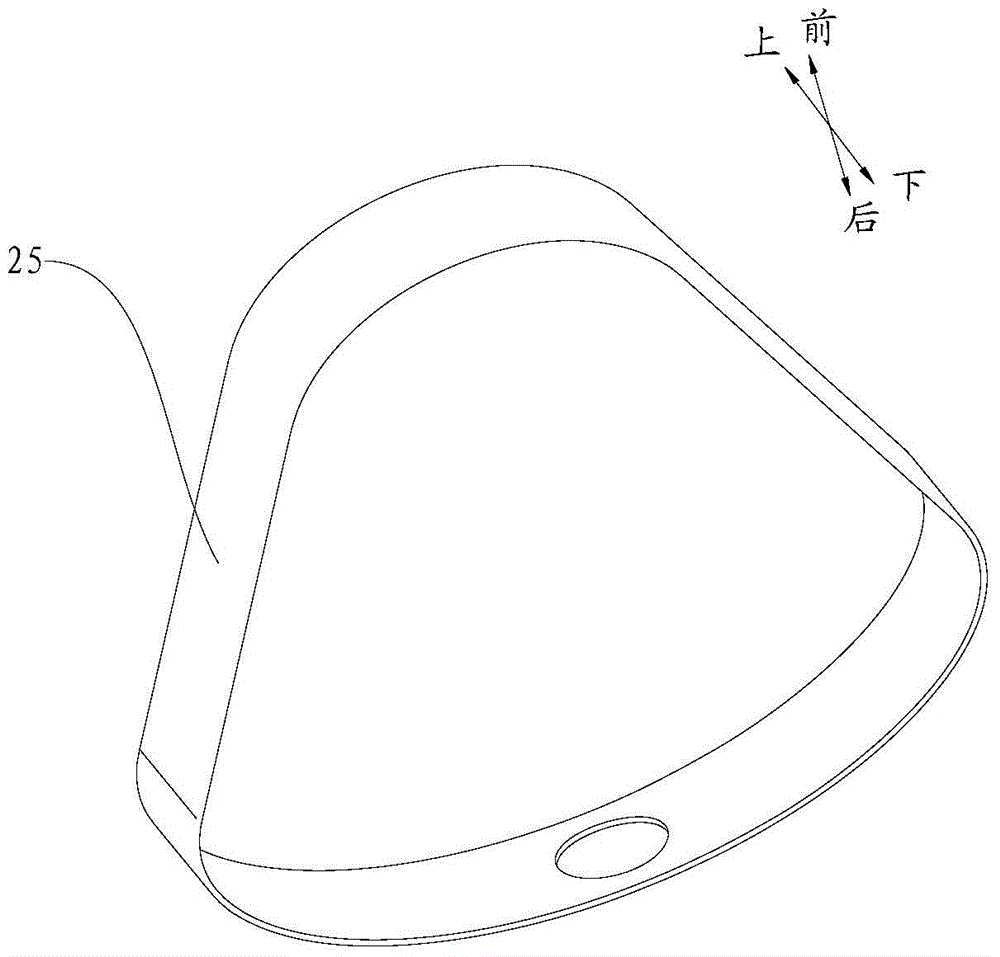

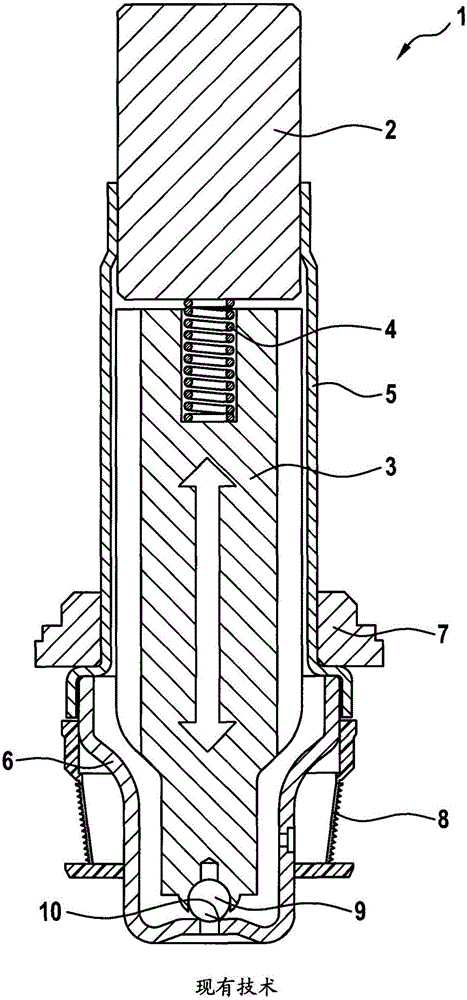

Hydraulic suspension of automobile cab

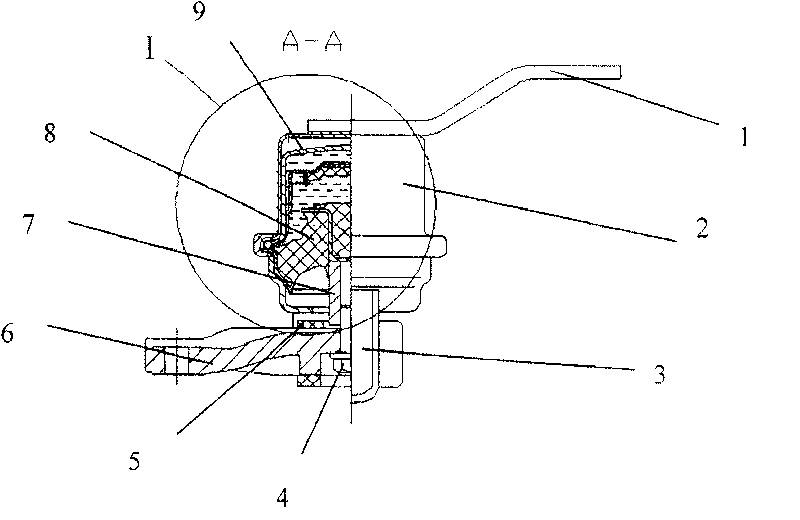

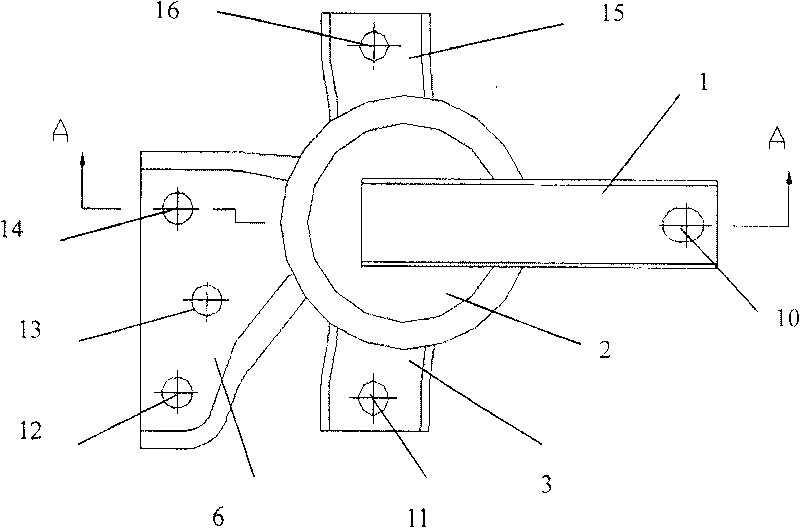

InactiveCN101648581AAttenuation of large vibrations at low frequenciesReduce high frequency noiseLoading-carrying vehicle superstructuresCar drivingEngineering

The invention relates to a hydraulic suspension of an automobile cab, belonging to the field of automobile part and aiming to replace the traditional rubber suspension. The hydraulic suspension of theautomobile cab mainly comprises an upper liquid chamber, a lower liquid chamber, a shell, a buffering limited block, an inertia passage body, a bottom membrane, a main rubber spring, metallic frameworks and a base, wherein the shell is in an annular structure and embedded into the base; the main rubber spring is connected with the metallic frameworks in a vulcanizing way, wherein the metallic frameworks are positioned on the inner edge and the outer edge of the main rubber spring; the inertia passage body is in an annular structure and is provided with an annular inertia passage and a decoupling passage playing a damping role; the lower liquid chamber consists of the metallic frameworks, the main rubber spring and the buffering limited block; the upper liquid chamber consists of the inertia passage body and the bottom membrane; and liquid inside the upper liquid chamber and the lower liquid chamber flows through the inertia passage. The hydraulic suspension has the advantages of compacter structure, reliable work, low cost and wide application and can effectively improve the NVH characteristic and other characteristics of the automobile cab.

Owner:JILIN UNIV +2

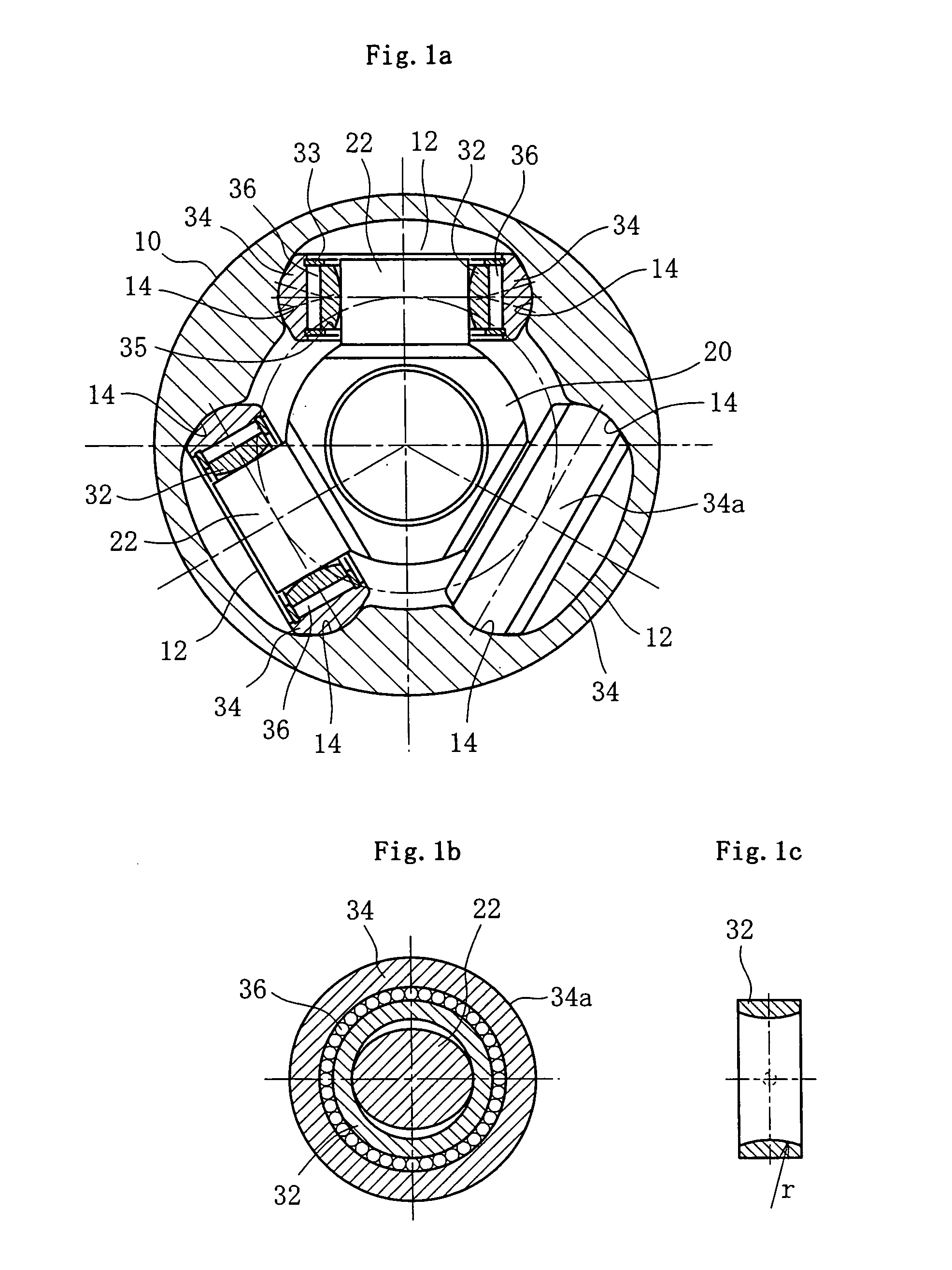

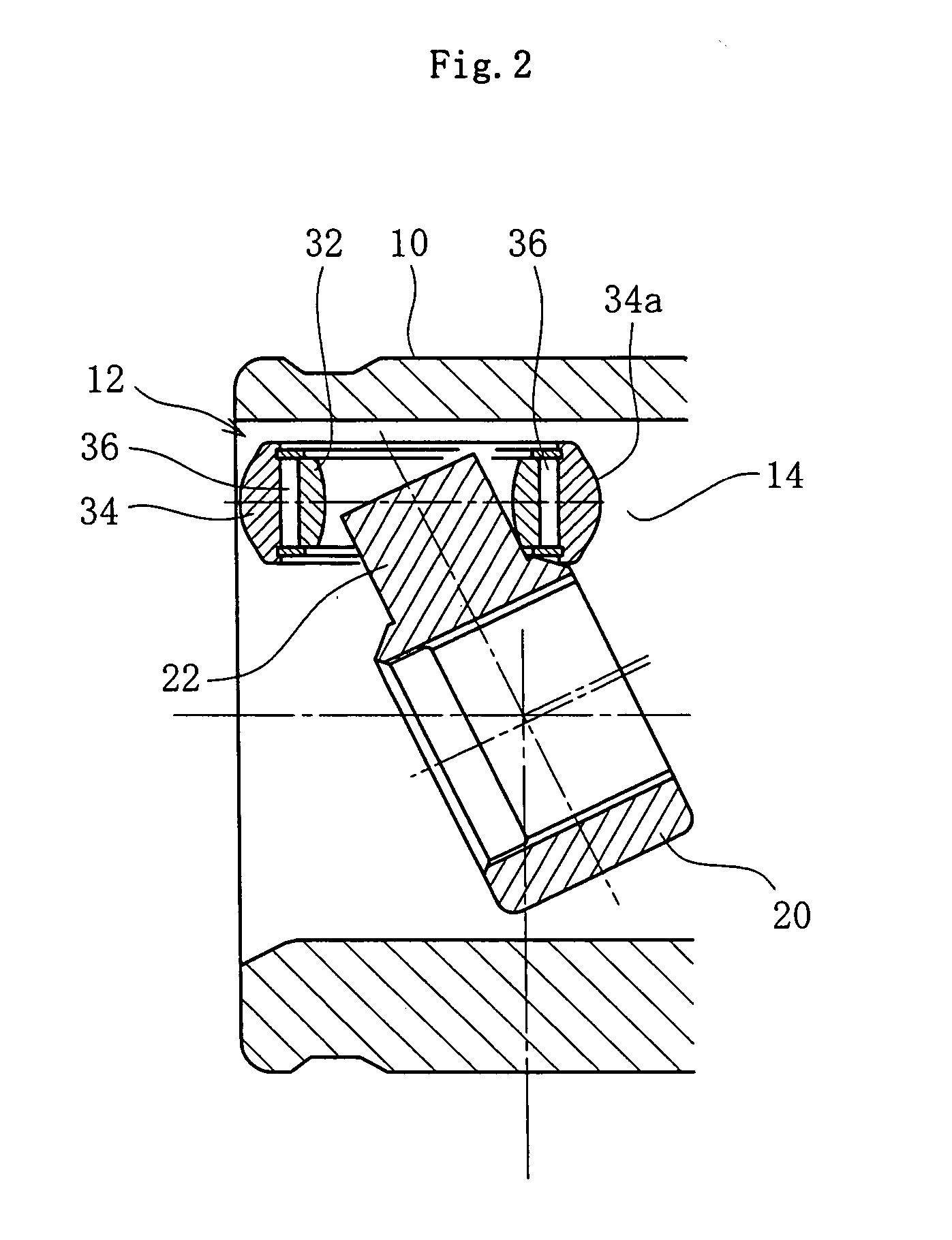

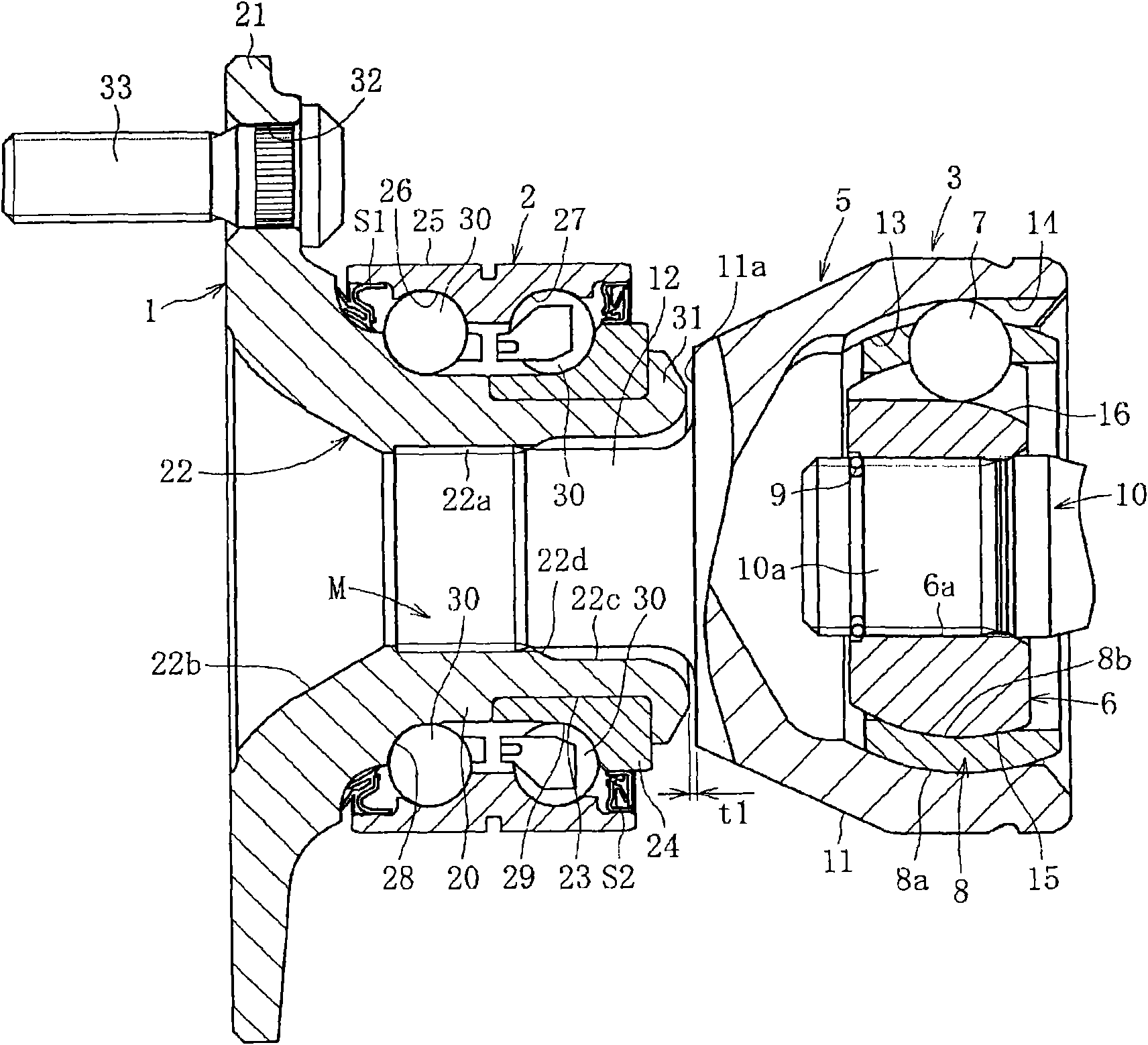

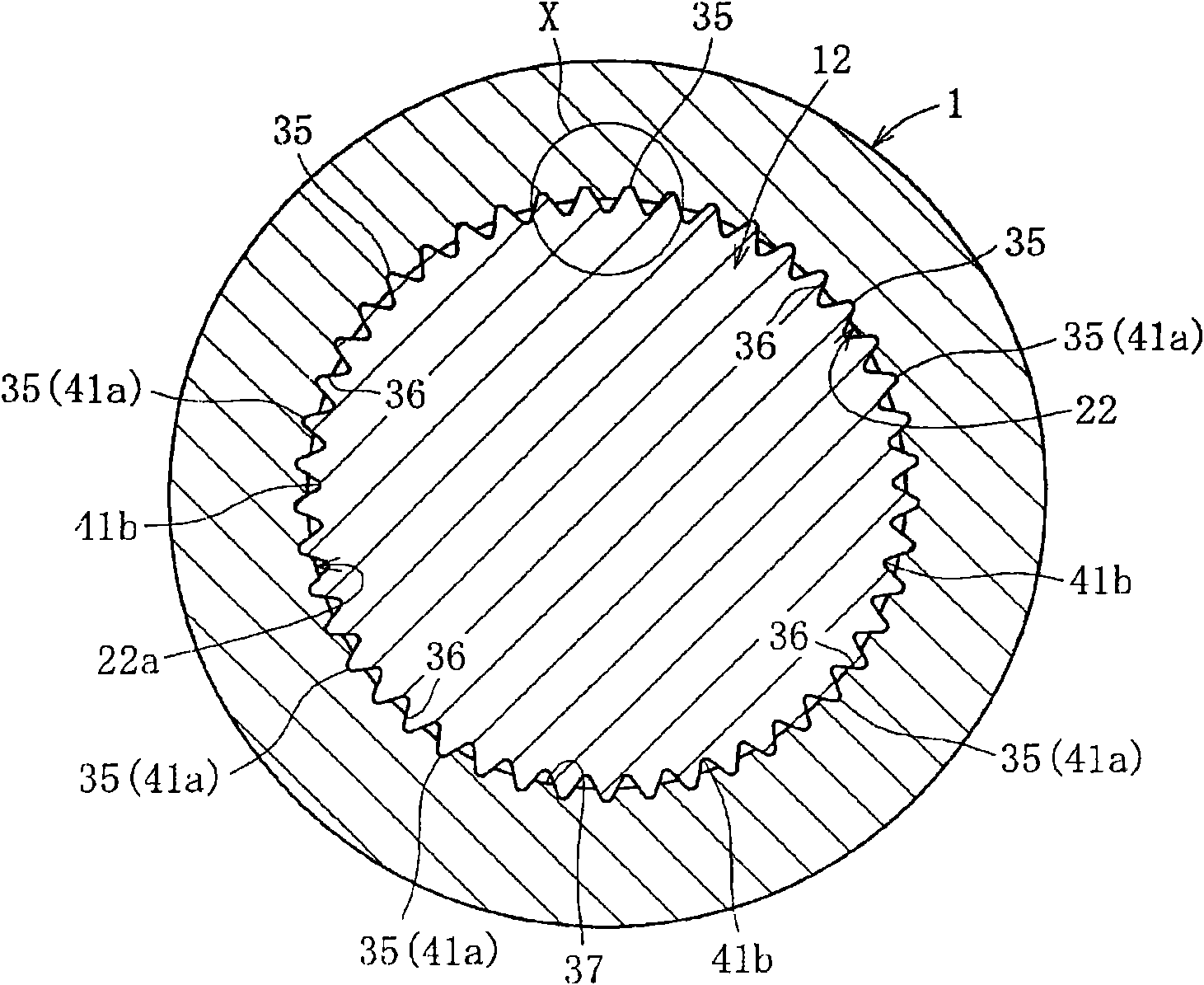

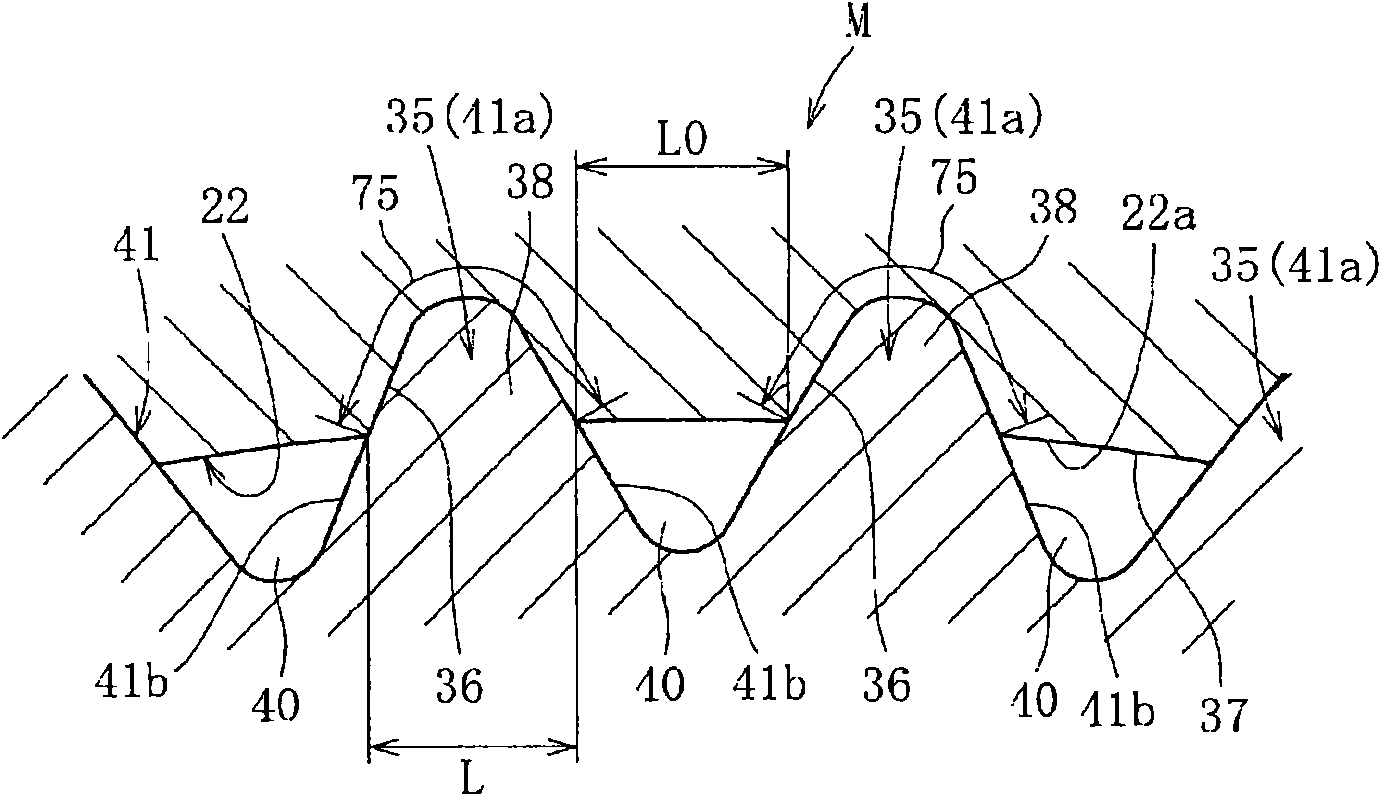

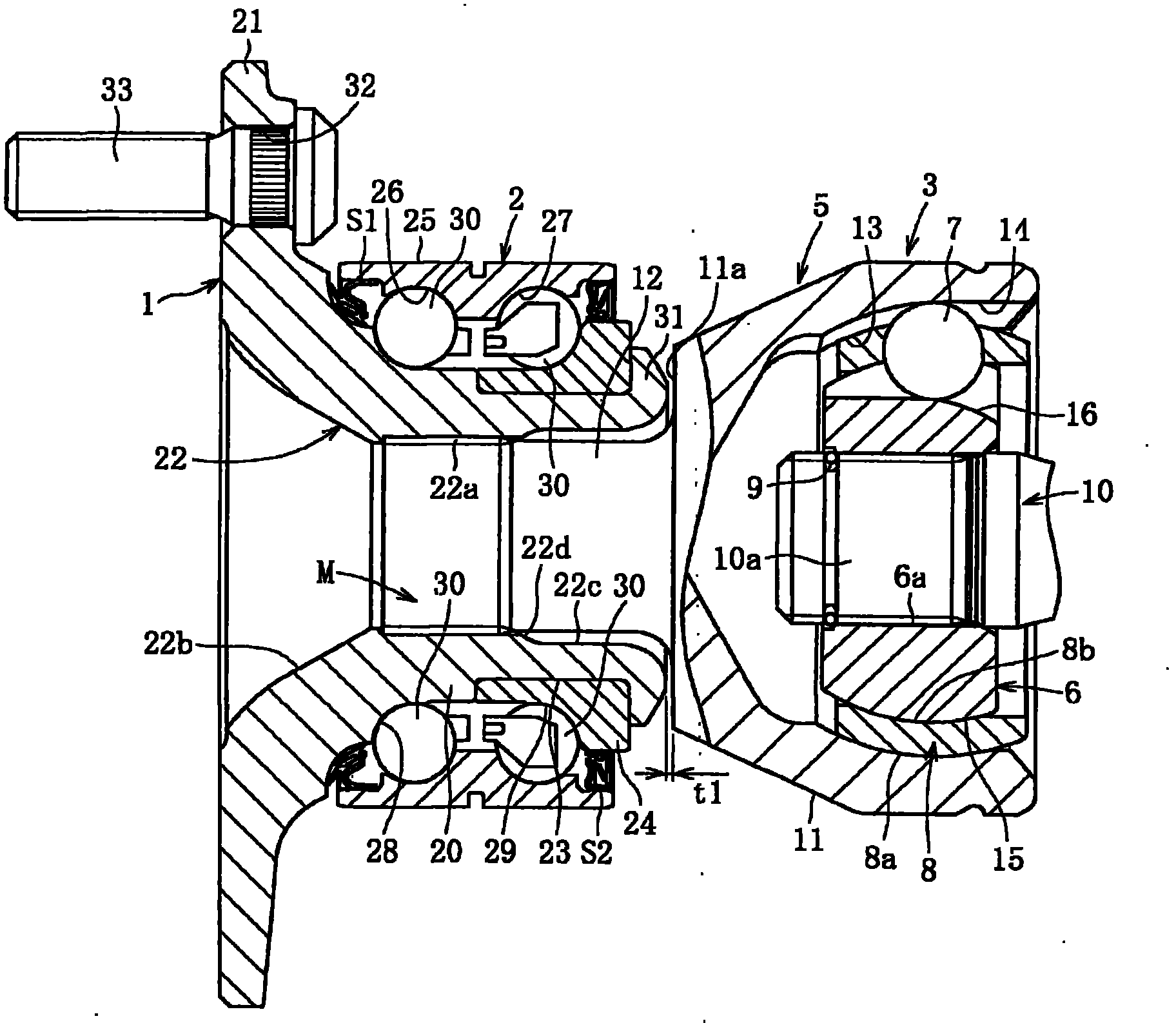

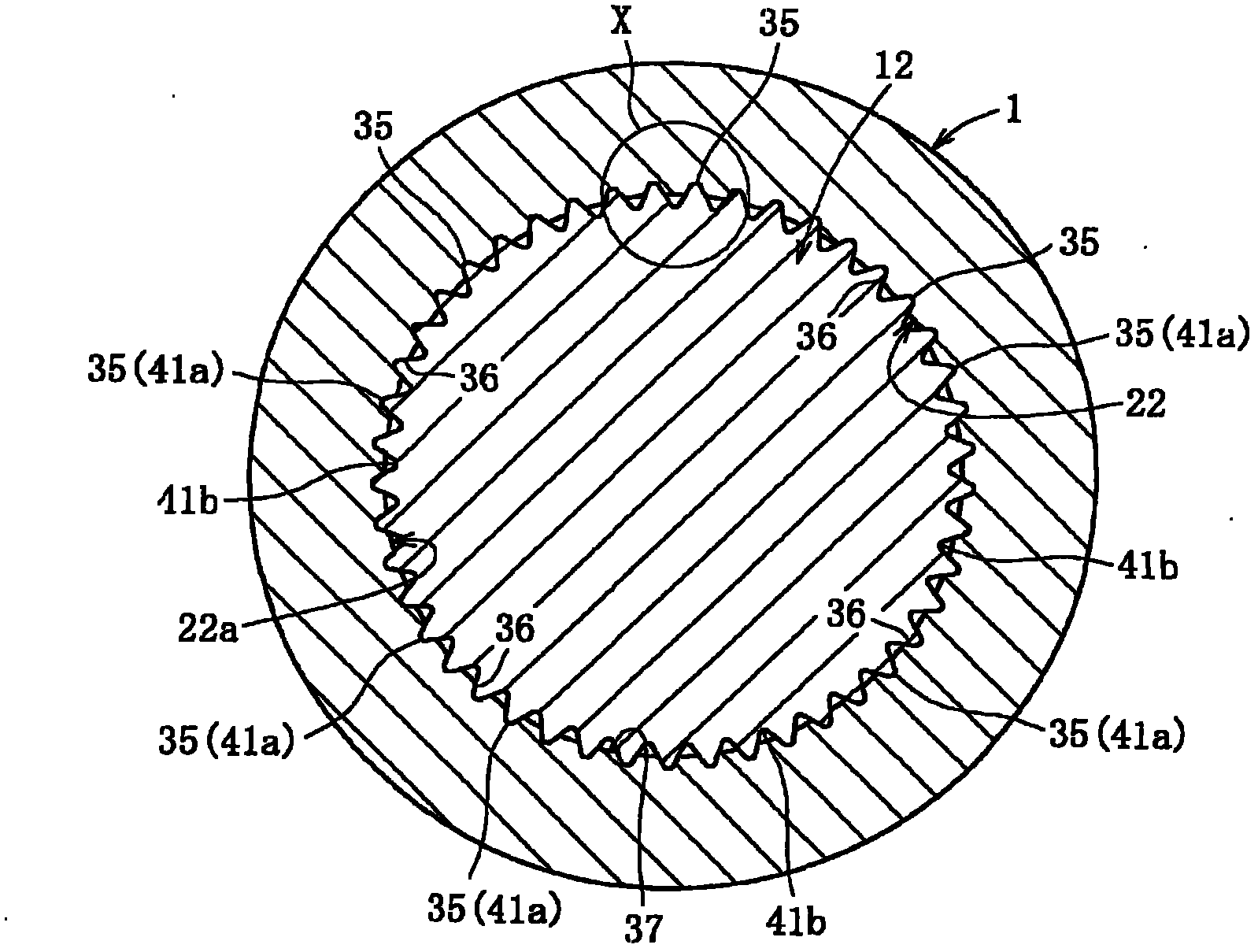

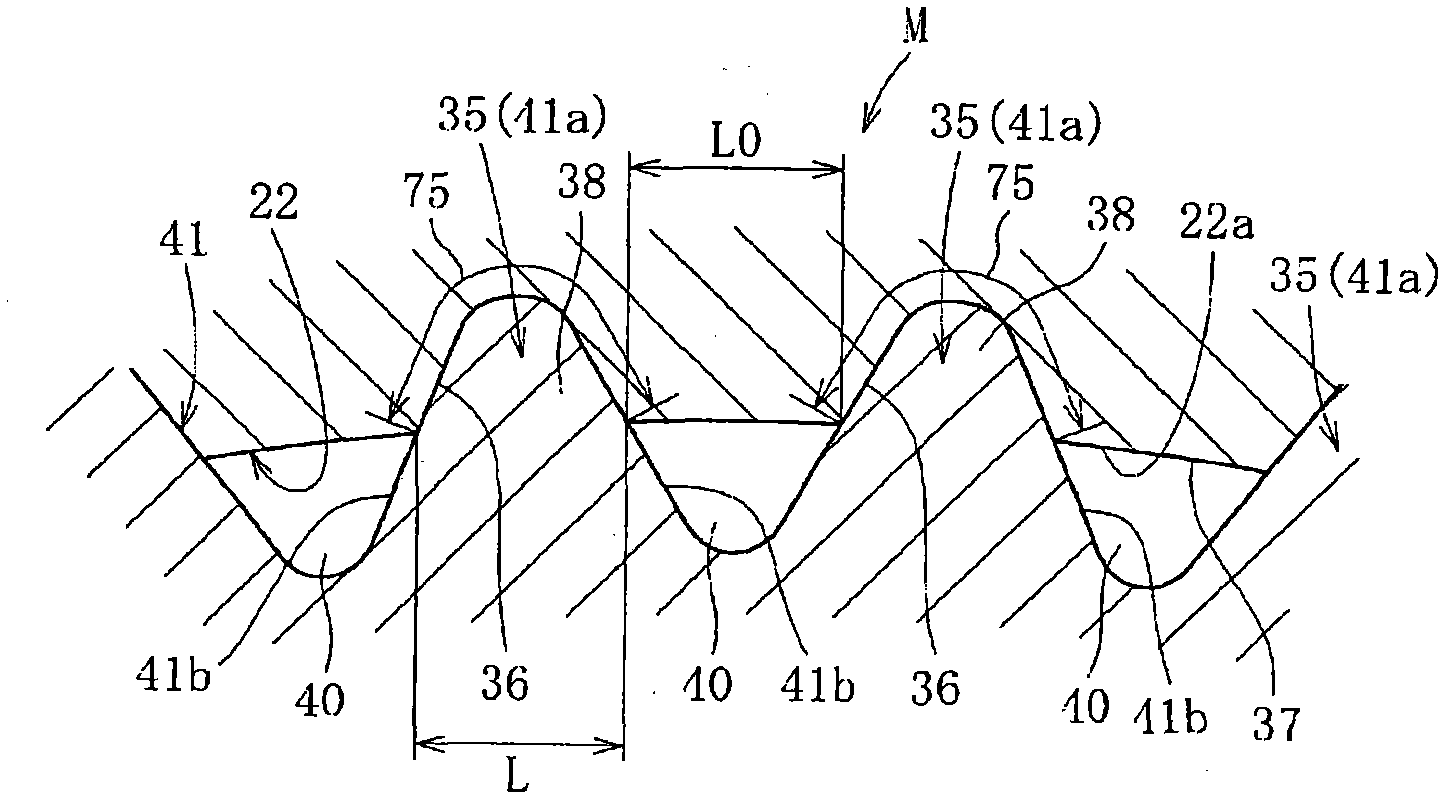

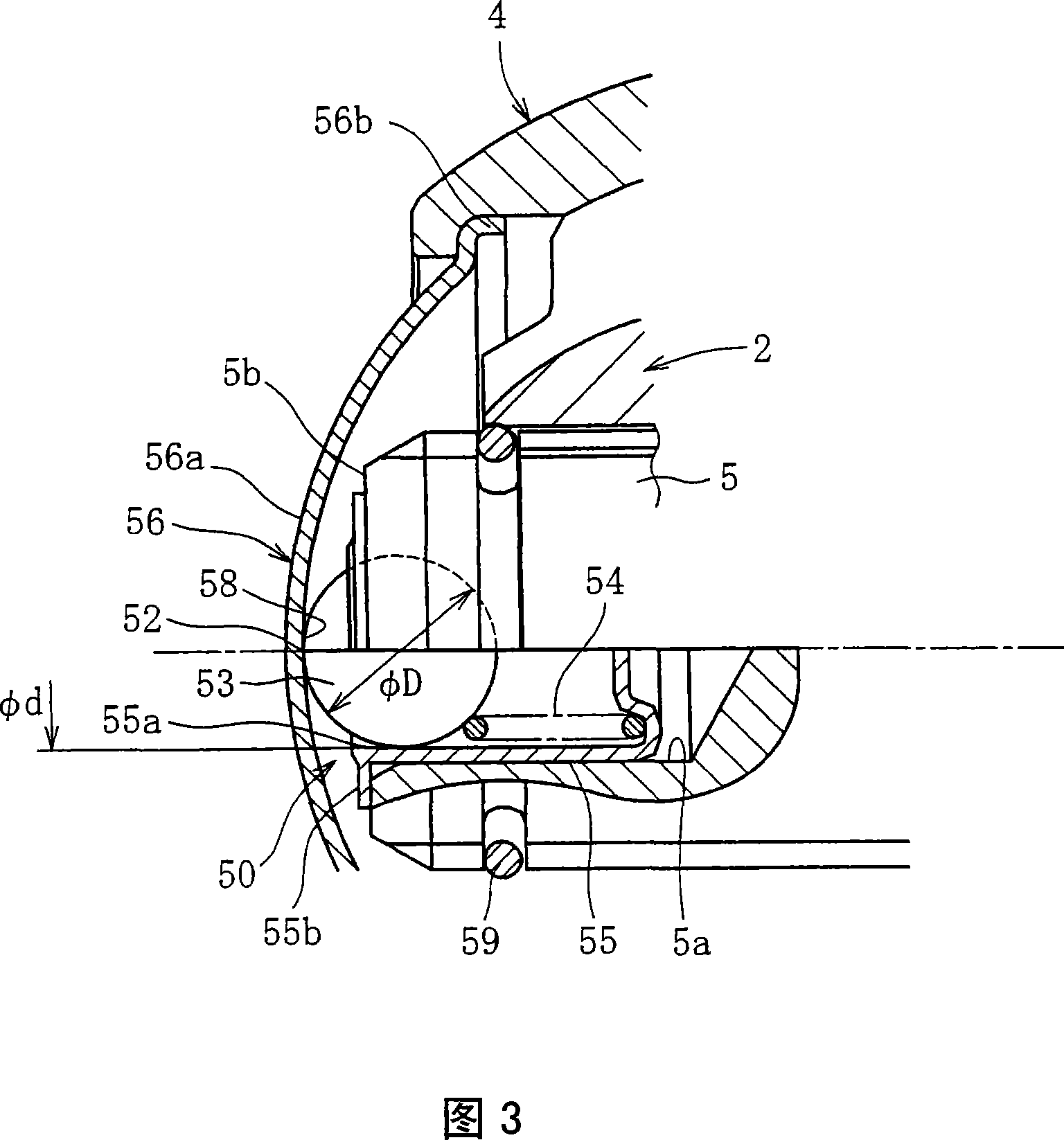

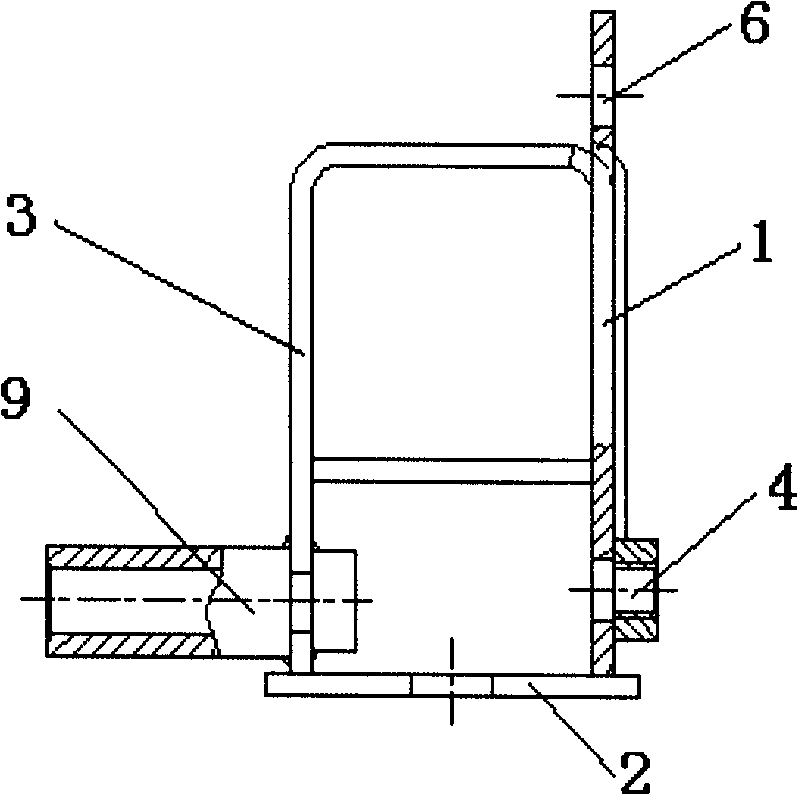

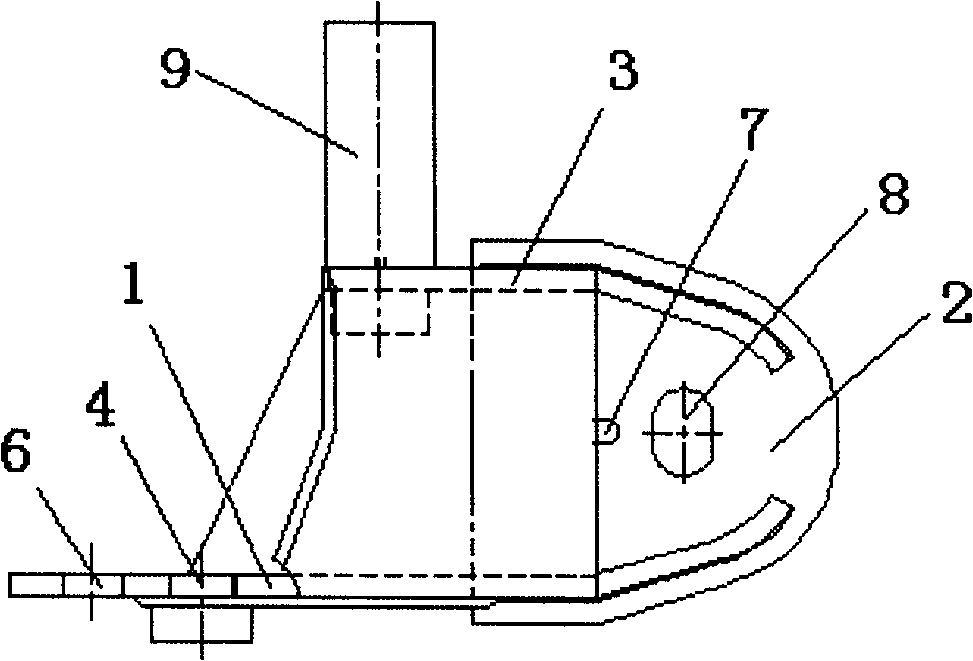

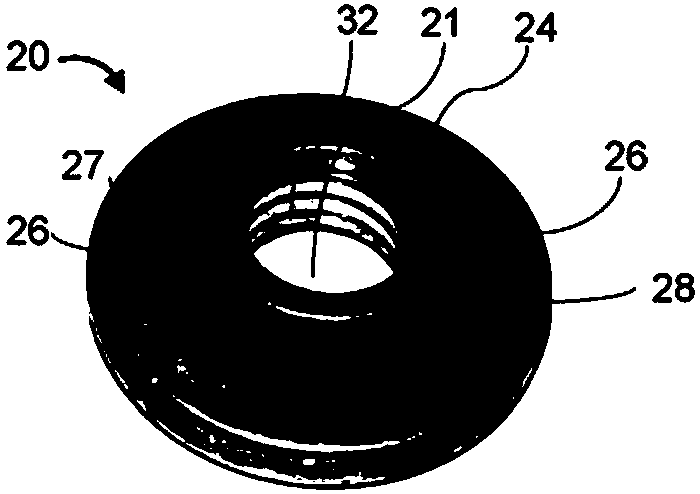

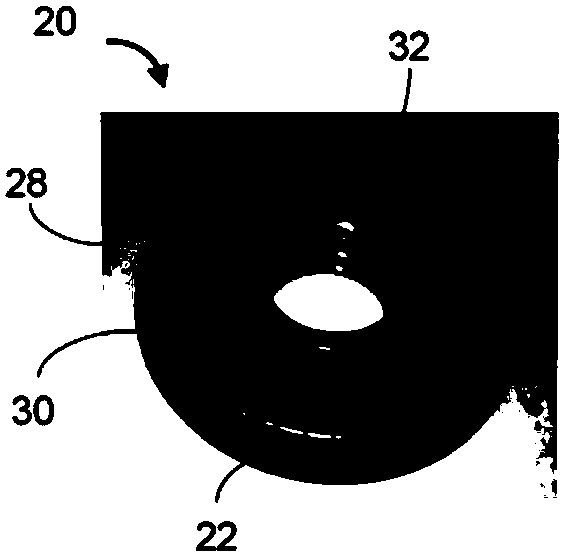

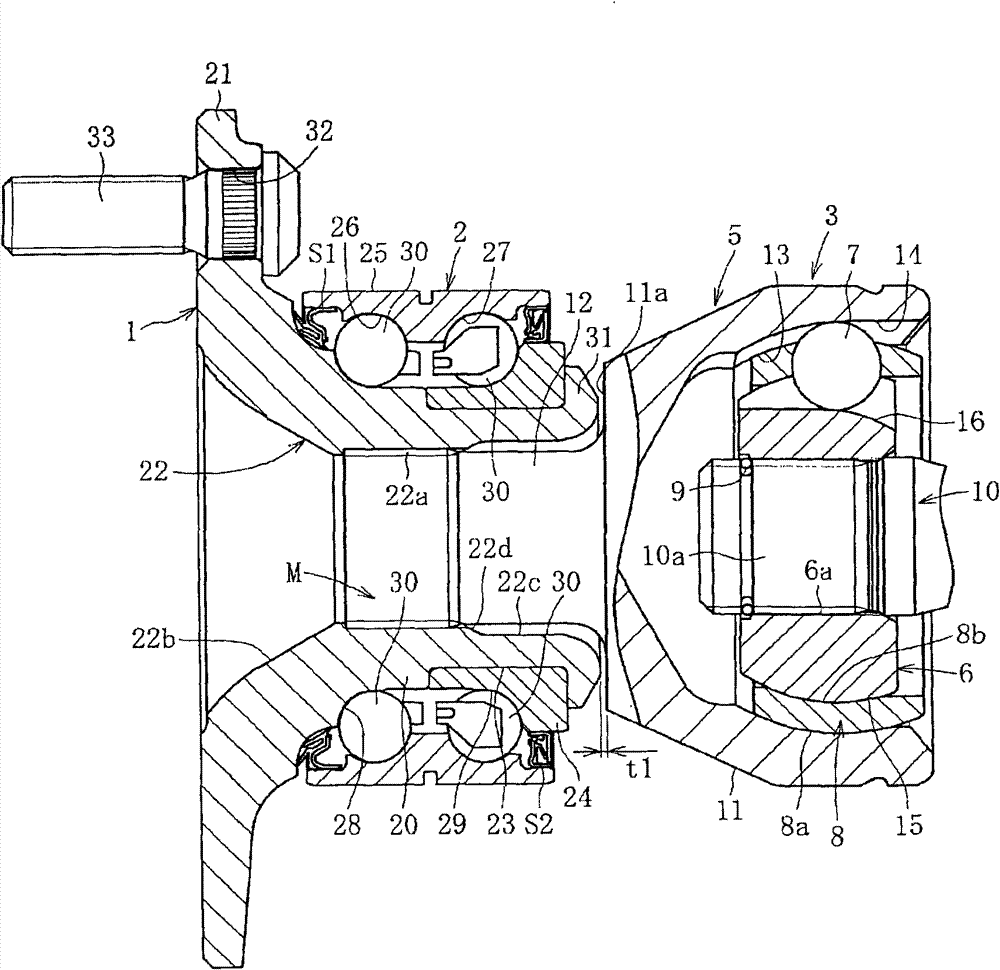

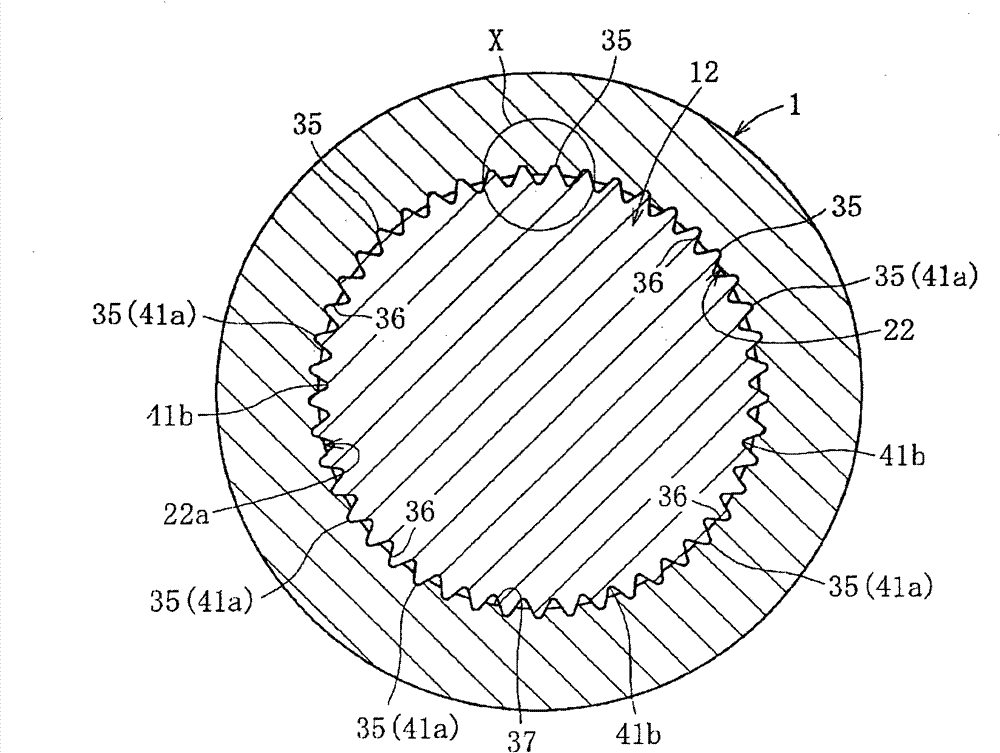

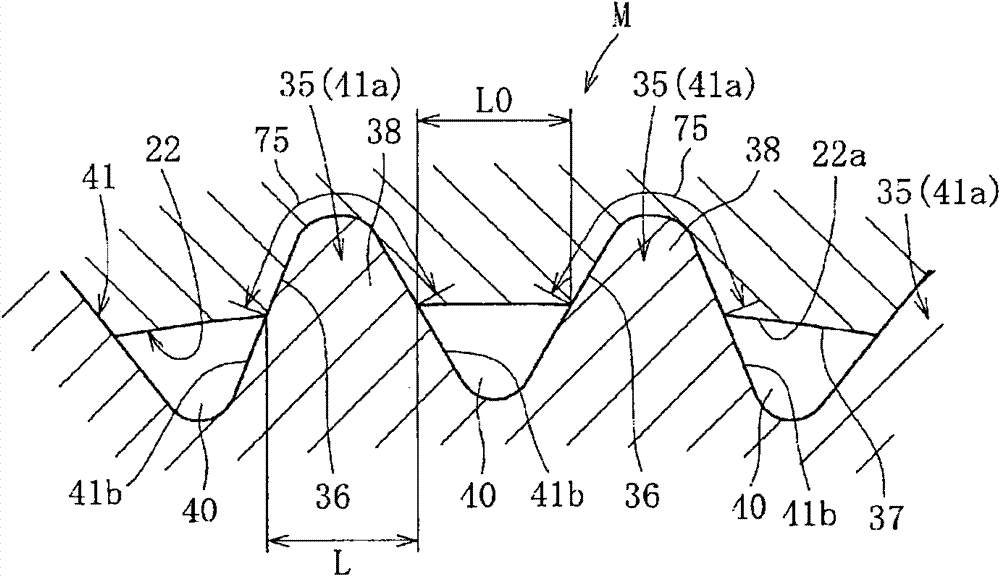

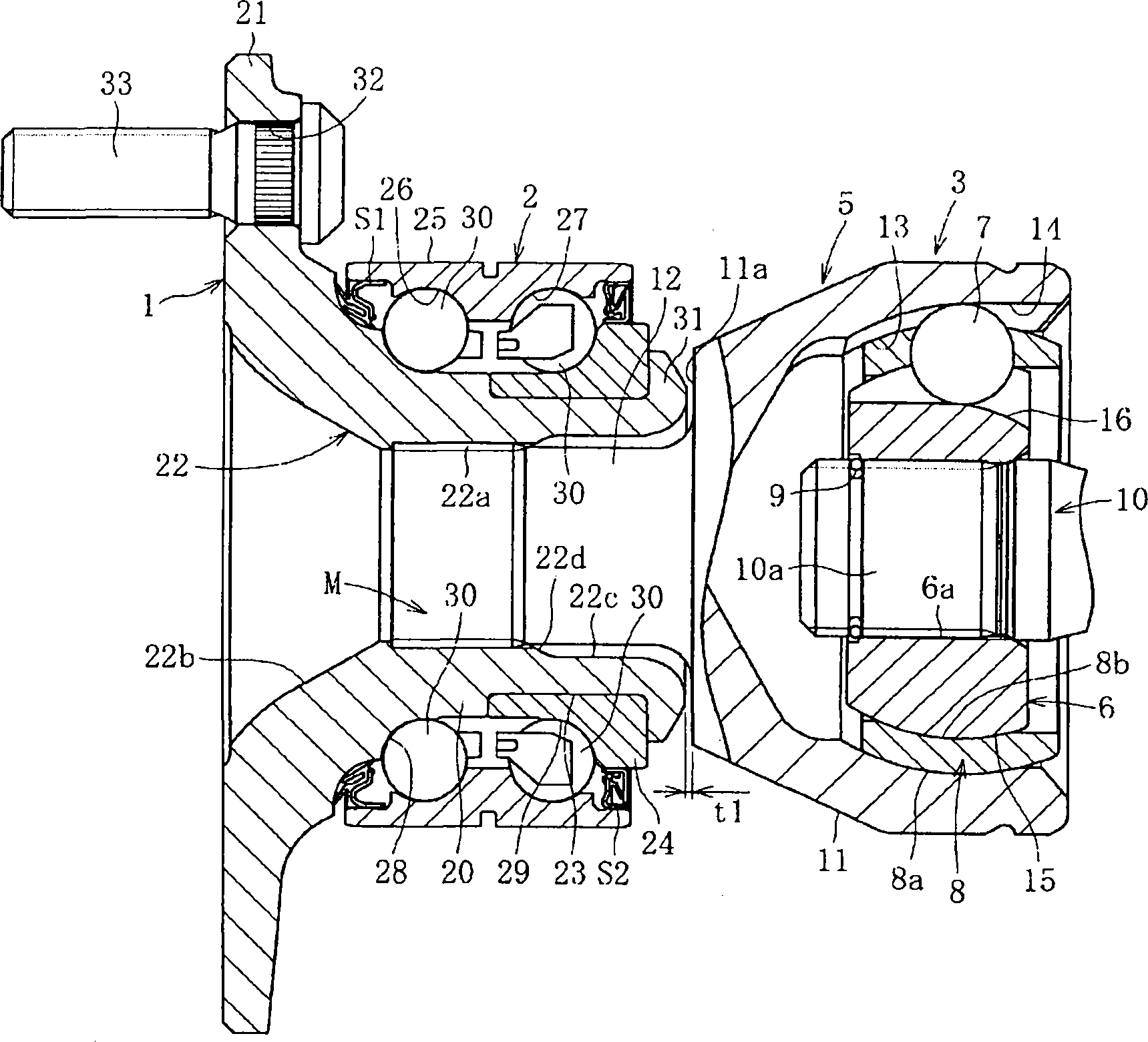

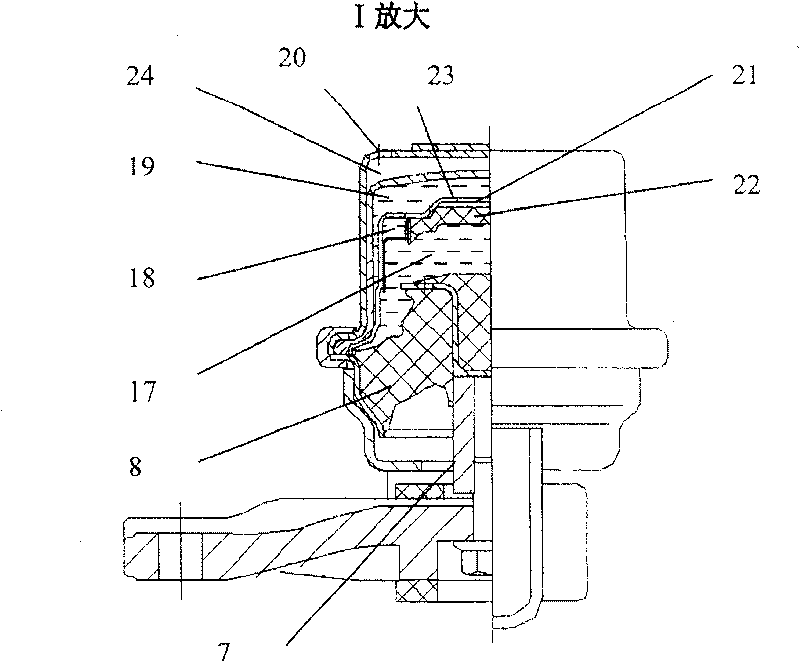

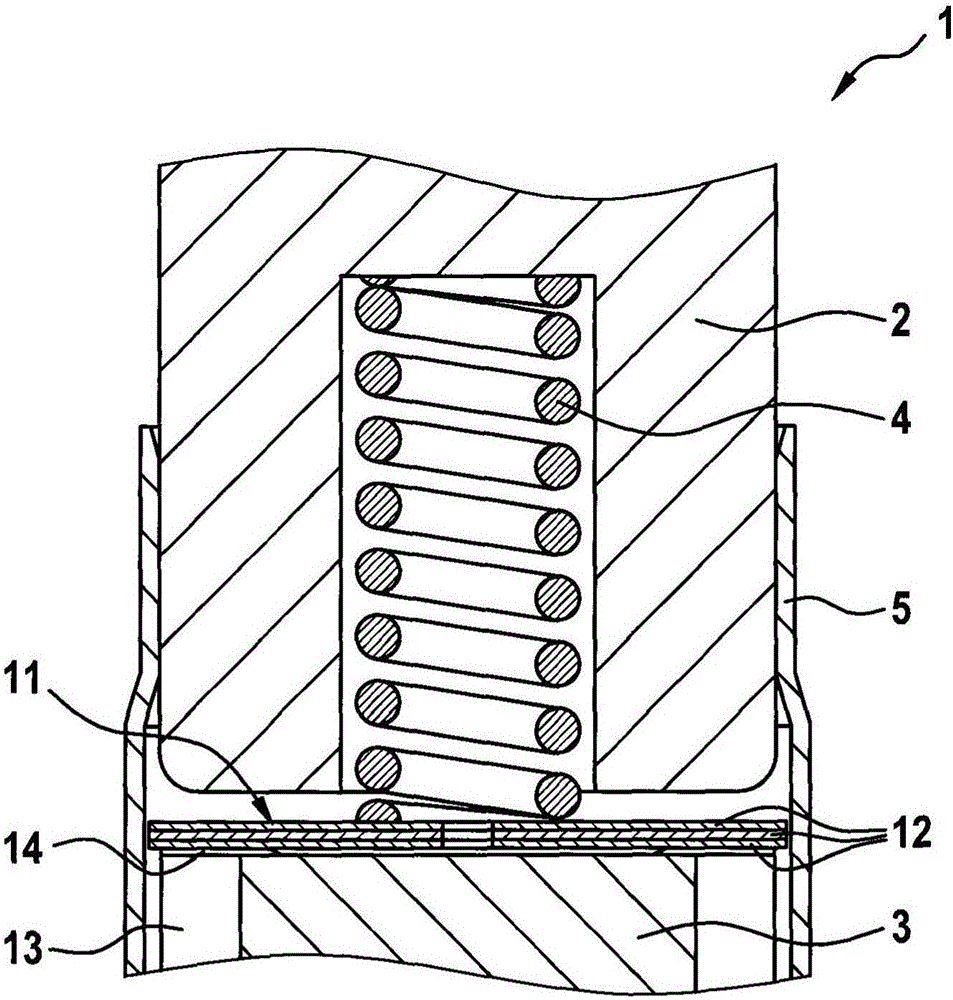

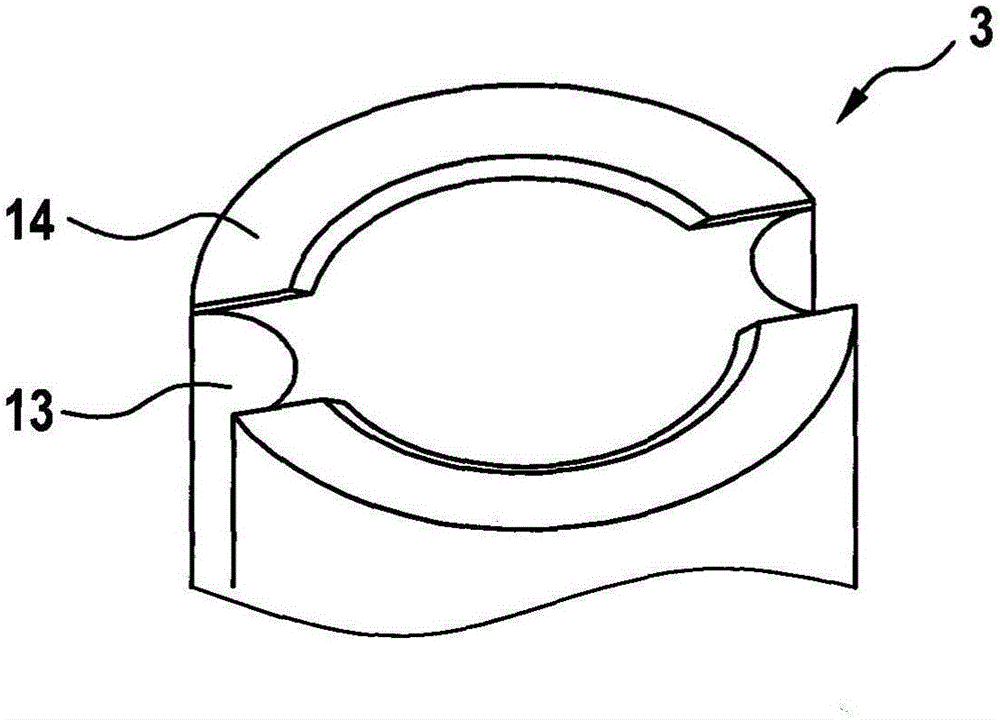

Bearing device for wheel

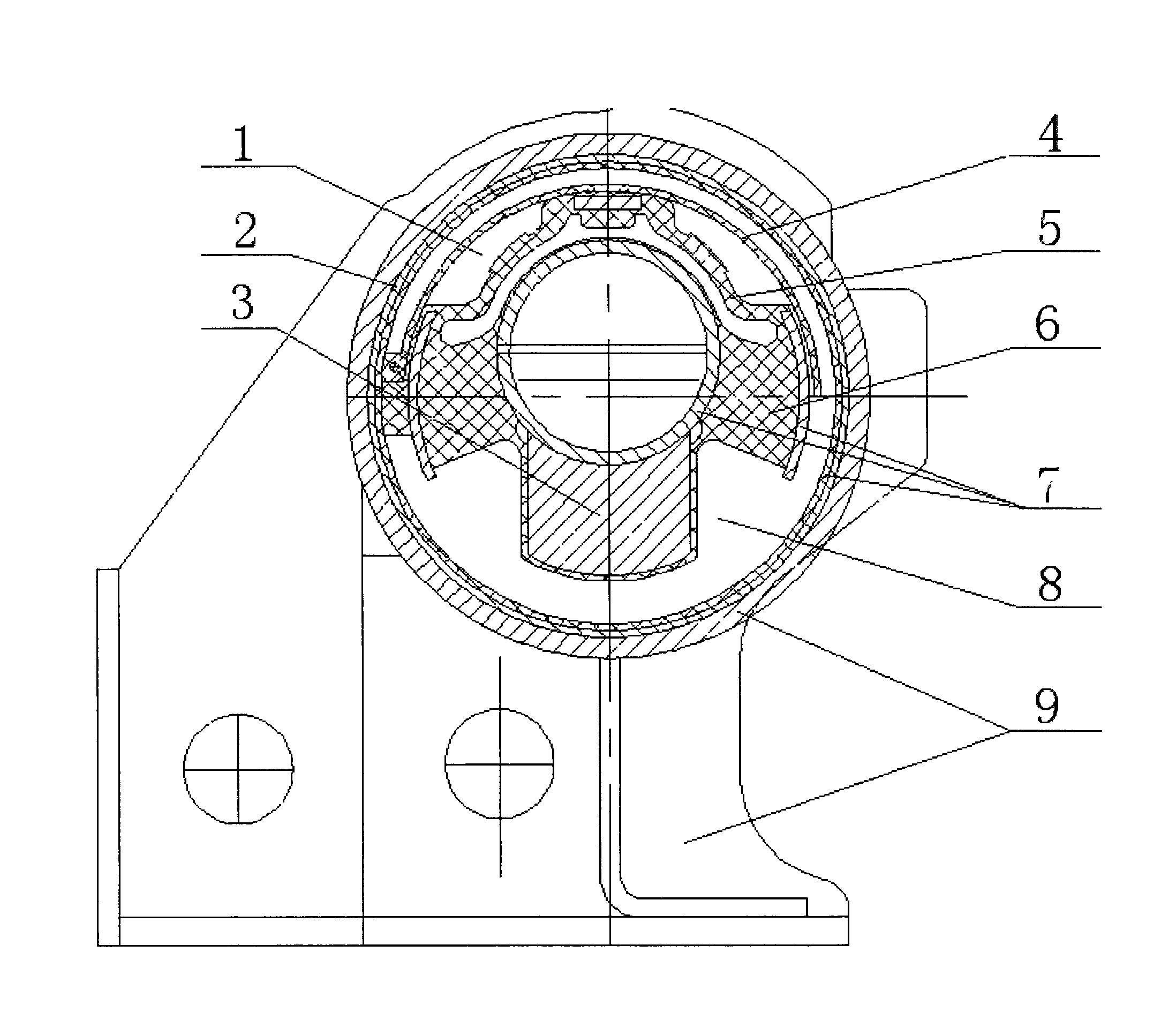

InactiveCN101641225ADoes not generate abnormal noiseHigh strengthRolling contact bearingsAxle unitsKnuckleEngineering

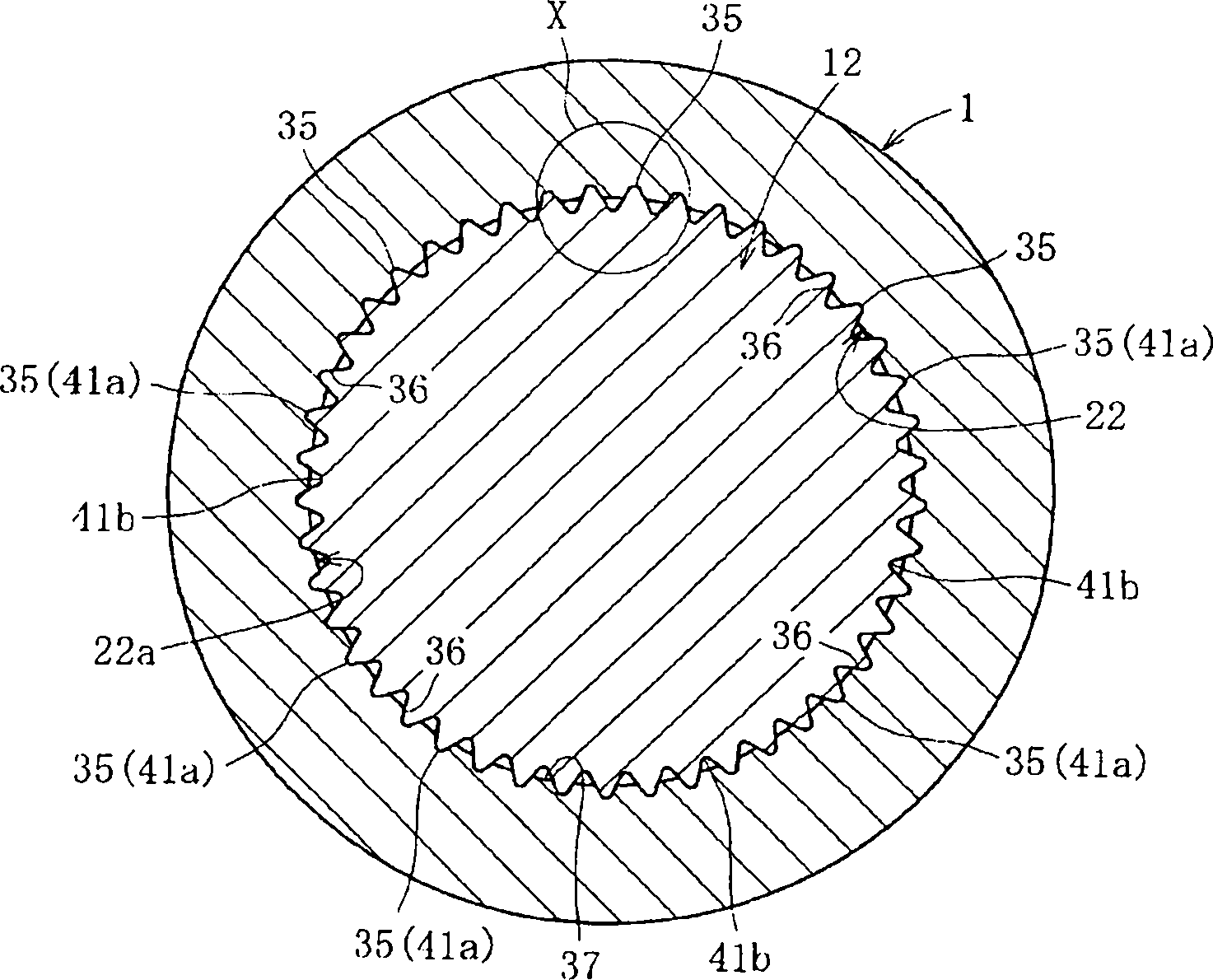

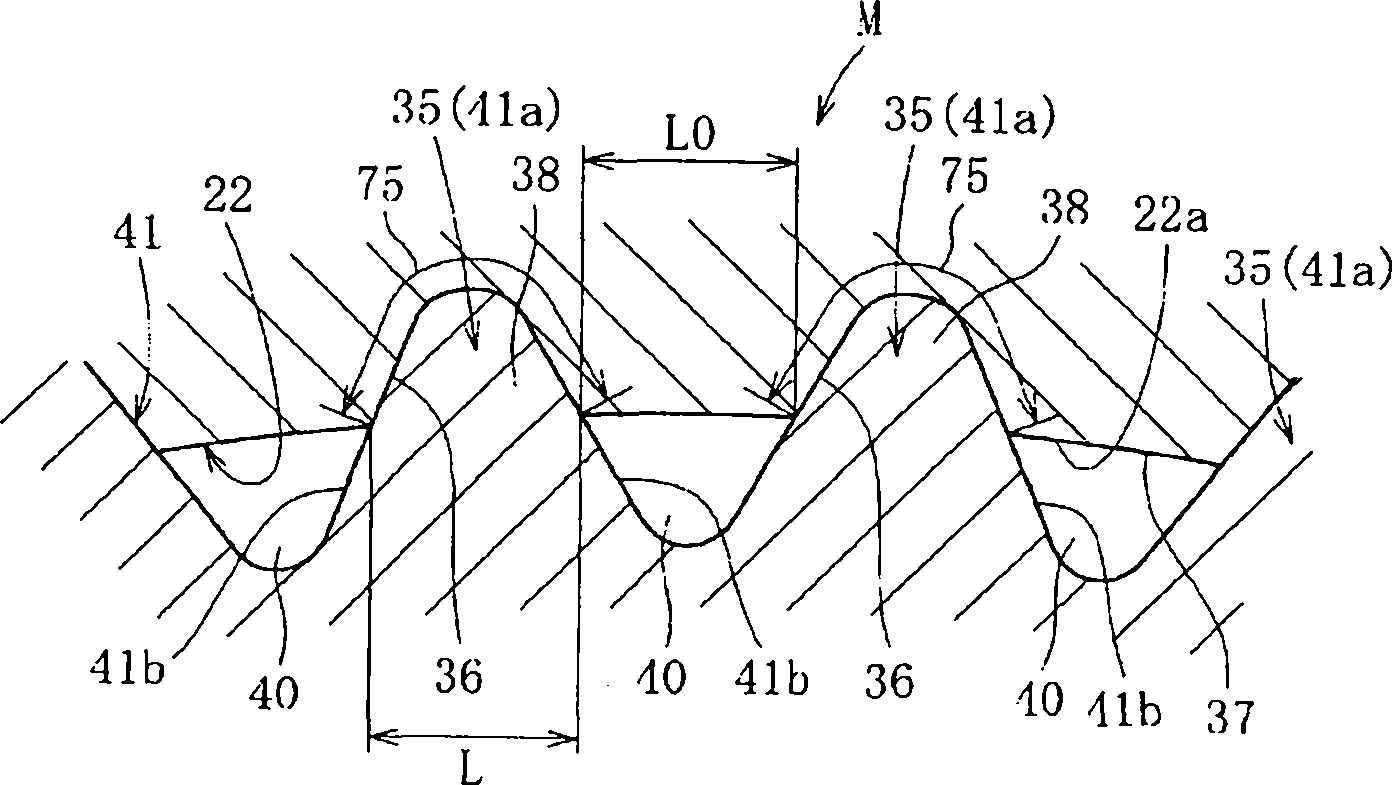

A bearing device for a wheel, in which circumferential play is suppressed, which facilitates connection between a hub ring and an outer coupling member, in which a reduction in NVH characteristics due to play at a joint between the hub ring and the constant velocity universal joint and by play between a bearing outer member and a knuckle is prevented, and which performs highly accurate transmission of rotational torque. The bearing device has a groove-ridge fitting structure (M) by which the hub ring (1) and a shaft section (12) of the outer coupling member of the constant velocity universal joint (3) are integrated together, and the shaft section (12) is fitted in a hole (22) of the hub ring (1). In the groove-ridge fitting structure (M), ridges (35) on the outer diameter surface of the shaft section (12) and grooves (36) in the inner diameter surface (37) of the hub ring (1) are fitted to each other in a fitting contact portion (38), and the ridges (35) and the grooves (36) are in intimate contact with each other in the entire fitting contact portion (38).

Owner:NTN CORP

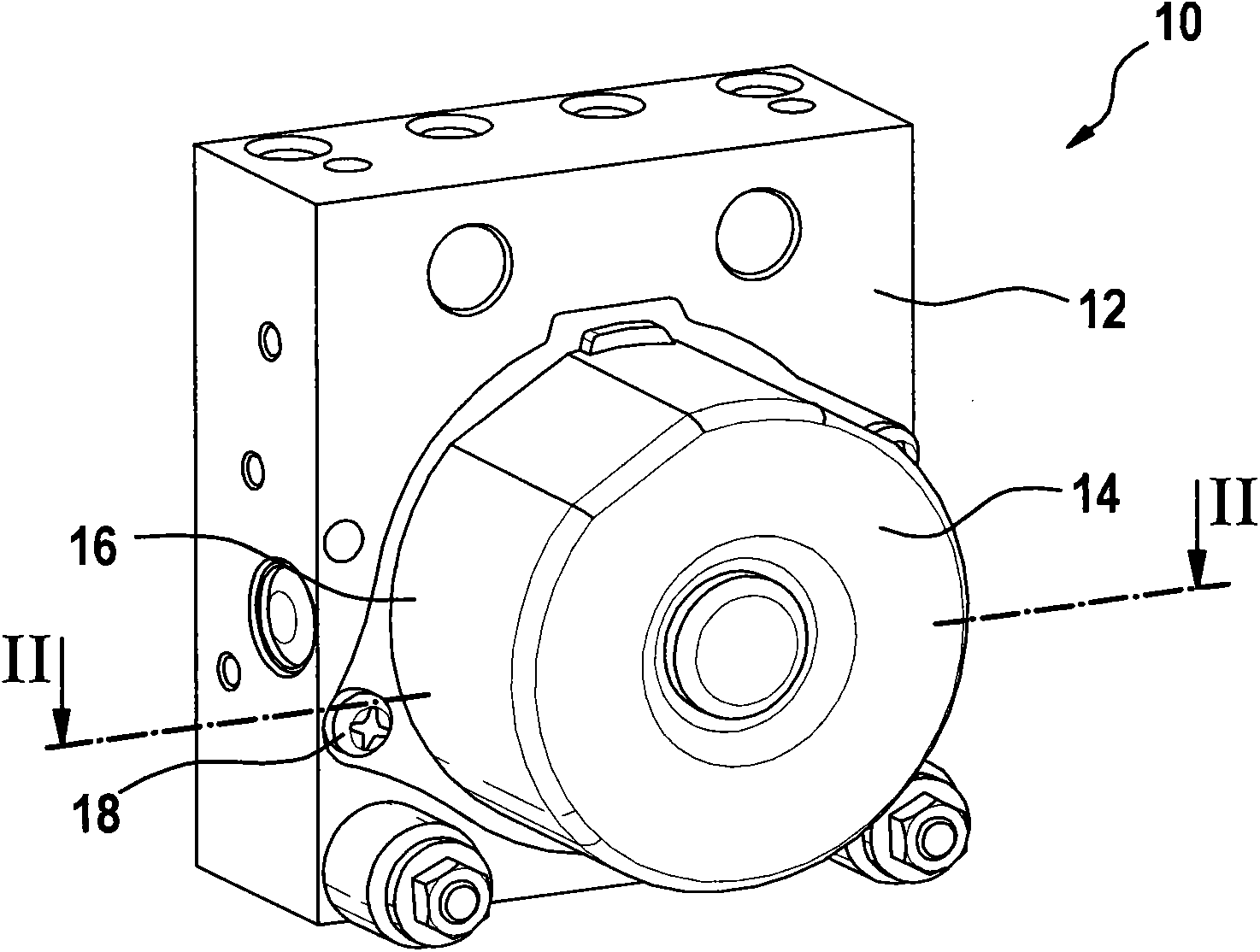

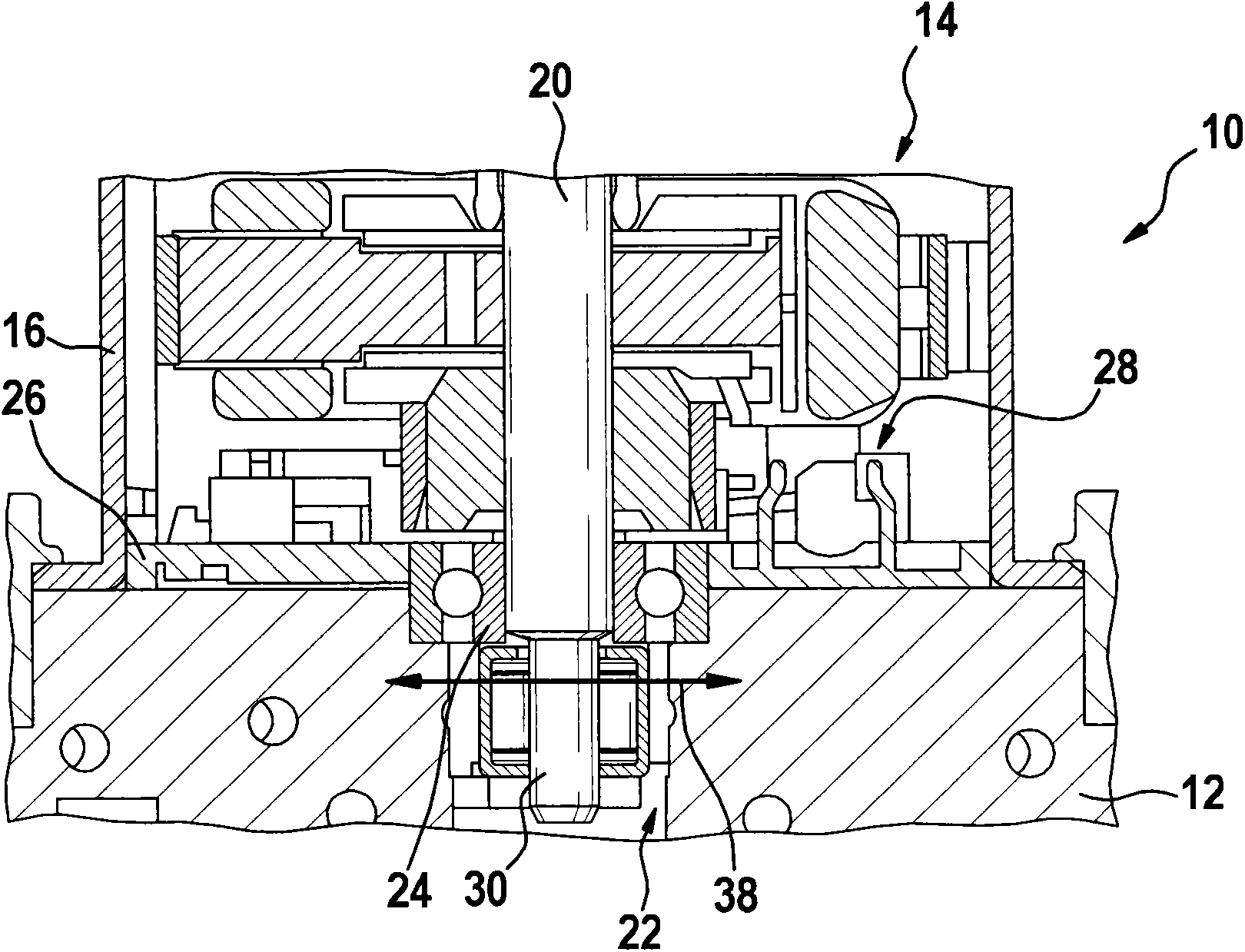

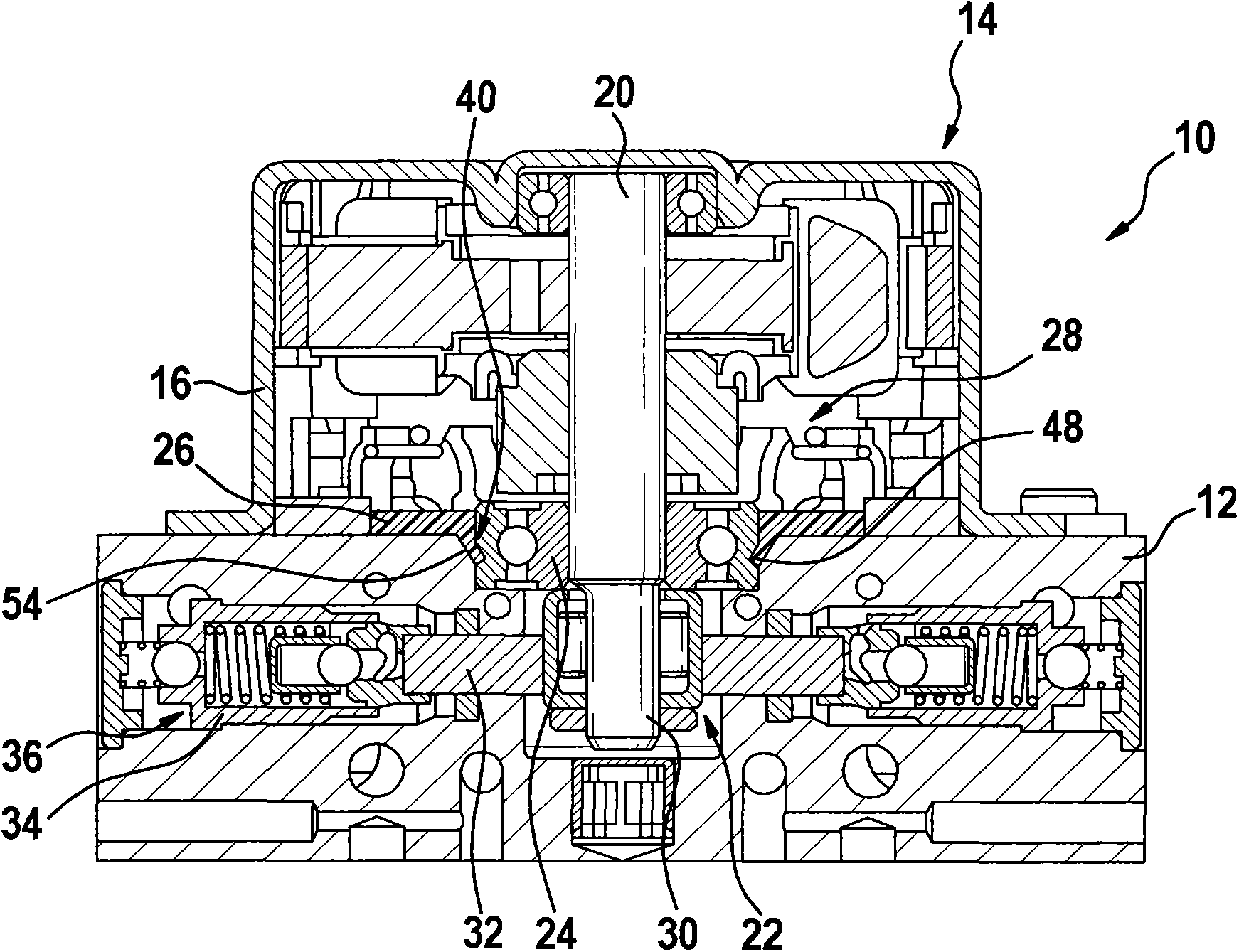

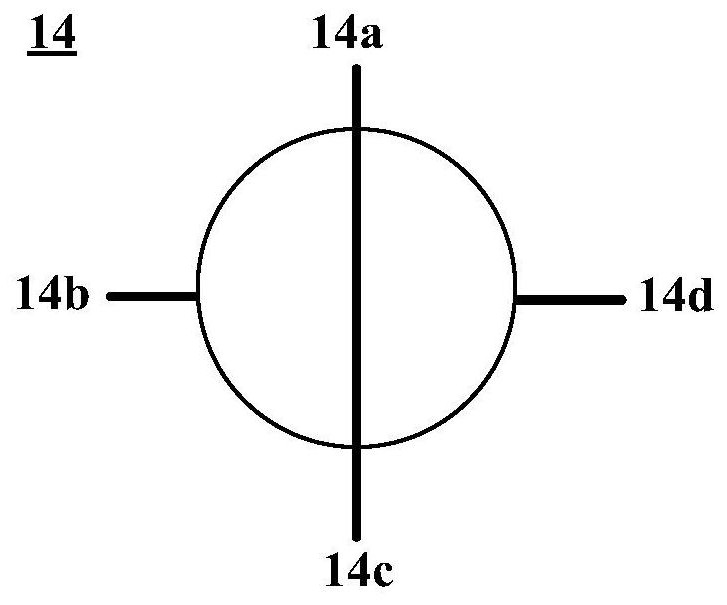

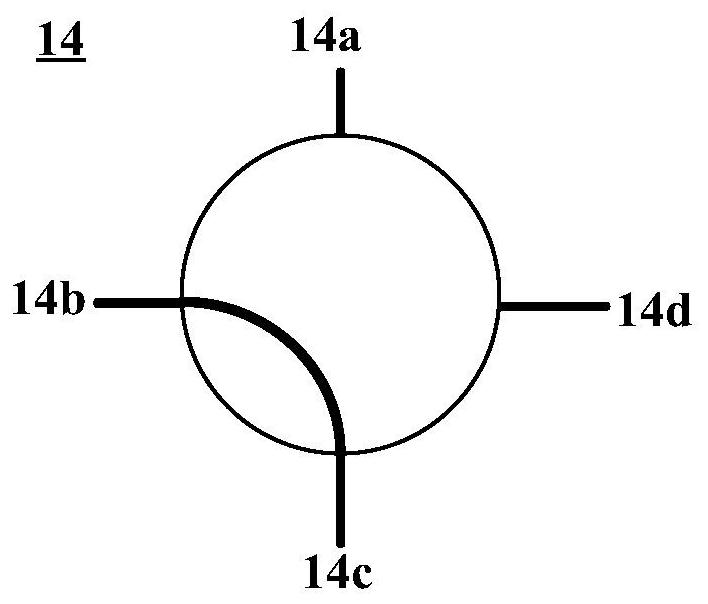

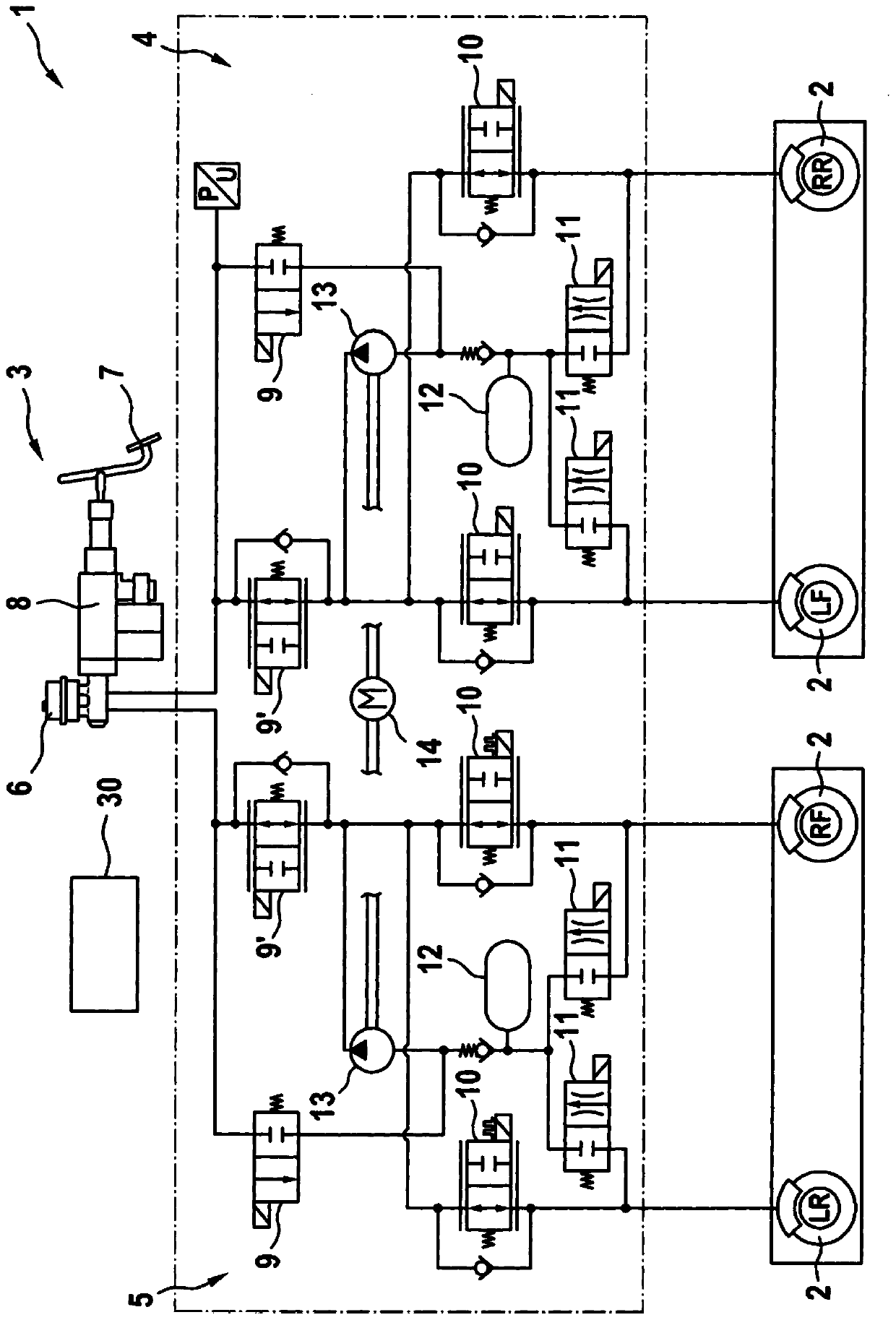

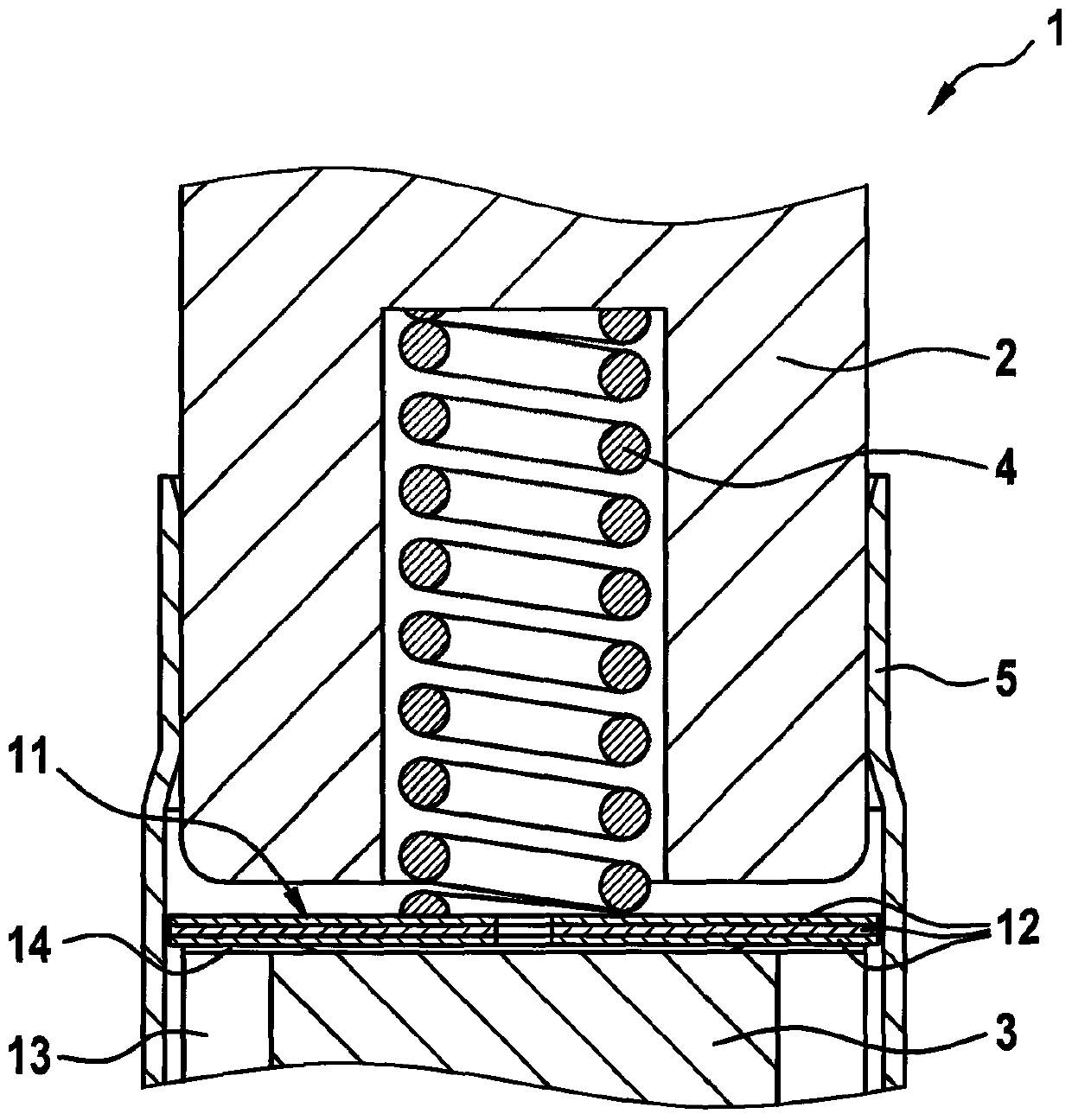

Hydraulic unit for vehicle brake system with motor bearing

ActiveCN103661349AReduce gapImprove NVH performanceRolling contact bearingsPump/compressor arrangementsHydraulic equipmentDrive motor

The invention relates to a hydraulic unit for vehicle brake system with motor bearing, and provides a hydraulic unit (10) of a vehicle brake system having a hydraulic block (12) and a drive motor (14) externally arranged on the hydraulic block (12) for driving at least one pump element (36) and a motor shaft (20) is supported on the hydraulic block (12) by means of a motor shaft bearing (24), the motor shaft bearing (24) is fixed to the hydraulic block (12) with a wedge member (40).

Owner:ROBERT BOSCH GMBH

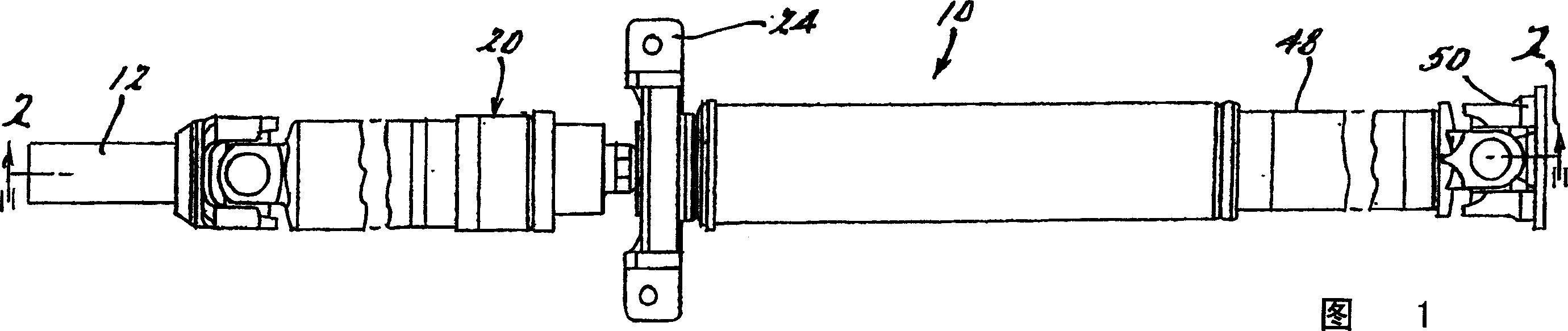

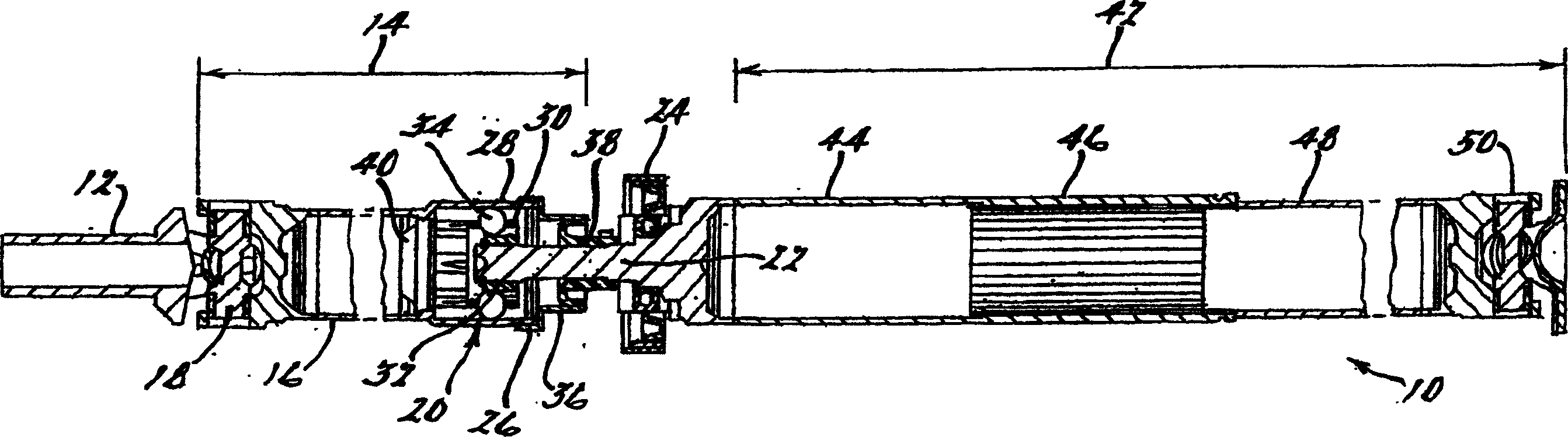

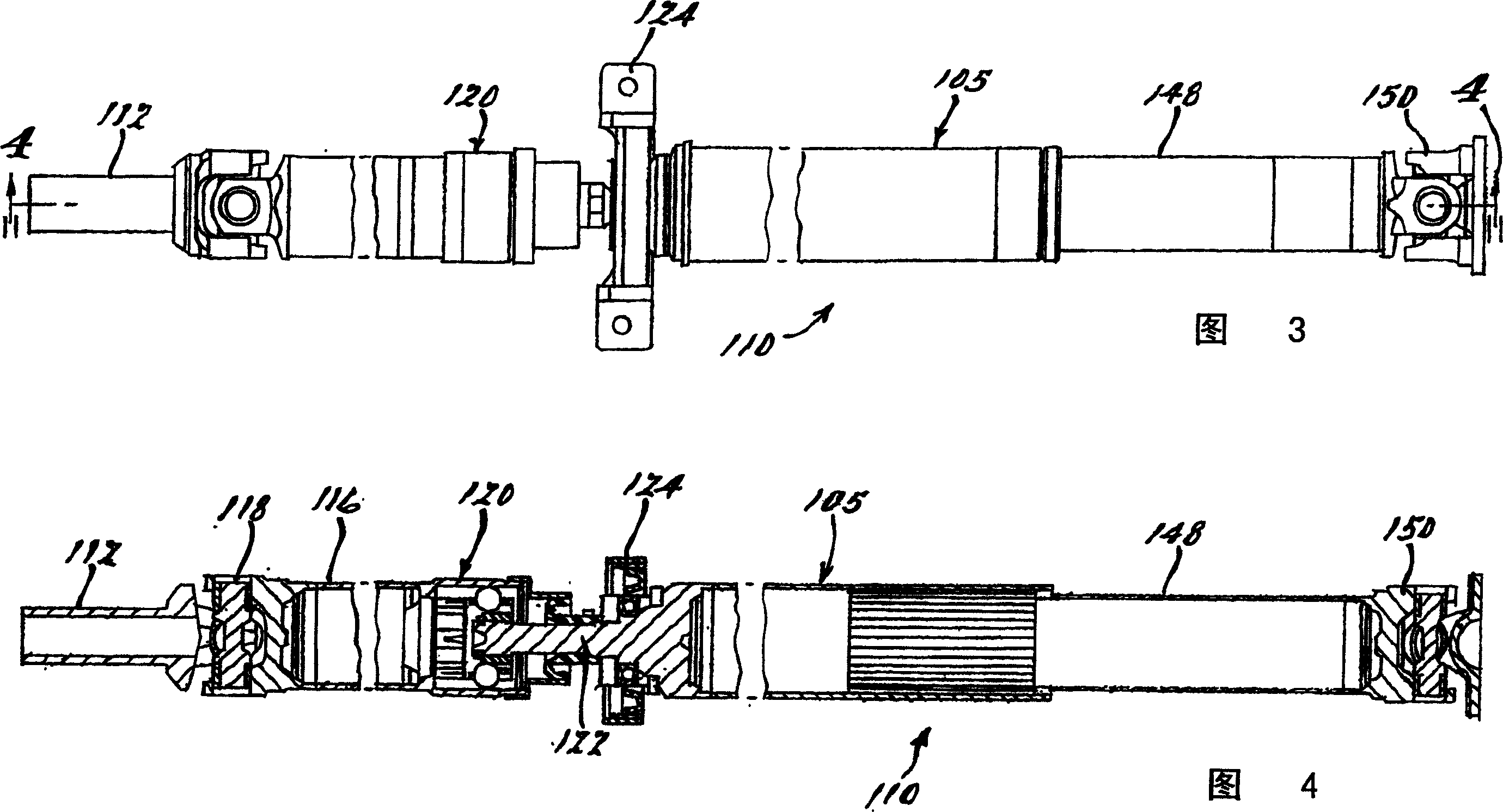

Improved propshaft having multiple crash features

InactiveCN1748093AMeet the requirements in the applicationReduce entryYielding couplingShaftsDrive shaftPropeller

A multi-piece propeller shaft (10) for use in an automotive vehicle. The multi-piece propeller shaft including a first or front section (42) and a second or rear section (14). The first section including a first crash feature in the form of a sliding spline (44, 46, 48). The second section including a second crash feature in the form of a collapsible constant velocity joint (20). The multi-piece propeller shaft capable of collapsing at predetermined loads and at predetermined times to have a tunable crash absorbing propeller shaft for use in automotive vehicles.

Owner:GKN DRIVELINE NORTH AMERICA

Bearing device for wheel

InactiveCN102152711AStable deliveryHigh strengthYielding couplingRolling contact bearingsUniversal jointTorque transmission

Provided is a bearing device for a wheel that can realize prevention of a backlash in a circumferential direction and is excellent in workability of connection of a hub wheel and an outer joint member of a constant velocity universal joint. Further, provided is a bearing device for a wheel that can prevent deterioration in NVH characteristics, which is caused by the backlash occurring in a joint section between the hub wheel and the constant velocity universal joint or between an outer member and a knuckle, and can perform rotation torque transmission with high accuracy. The bearing device includes a recess-projection fitting structure (M) in which the hub wheel (1) and a shaft section (12), which is fitted in a hole (22) of the hub wheel (1) of the outer joint member of the constant velocity universal joint (3) are unitized together. In the recess-projection fitting structure (M), entire fitting regions among projections (35) on the outer surface of the shaft section (12) of the outer joint member and recesses (36), which fit on the projections, are brought into intimate contact with each other.

Owner:NTN CORP

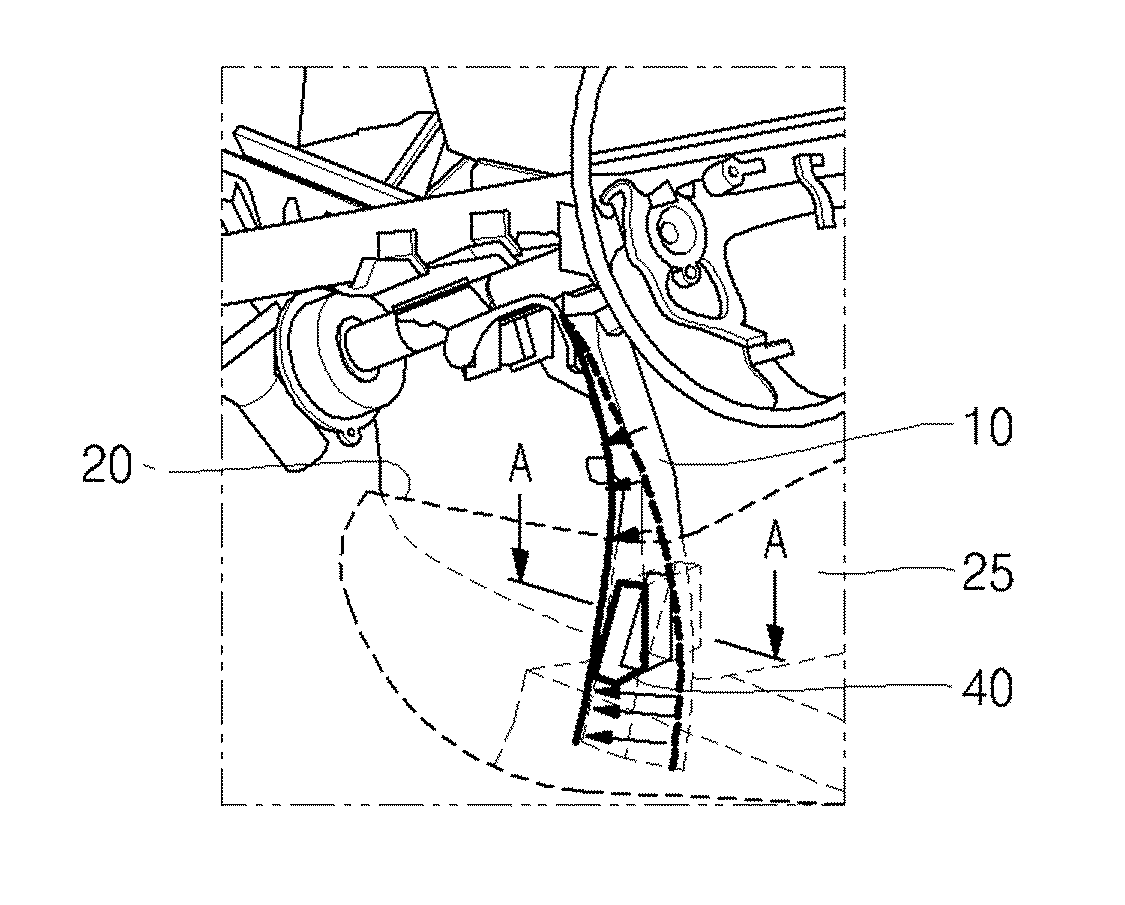

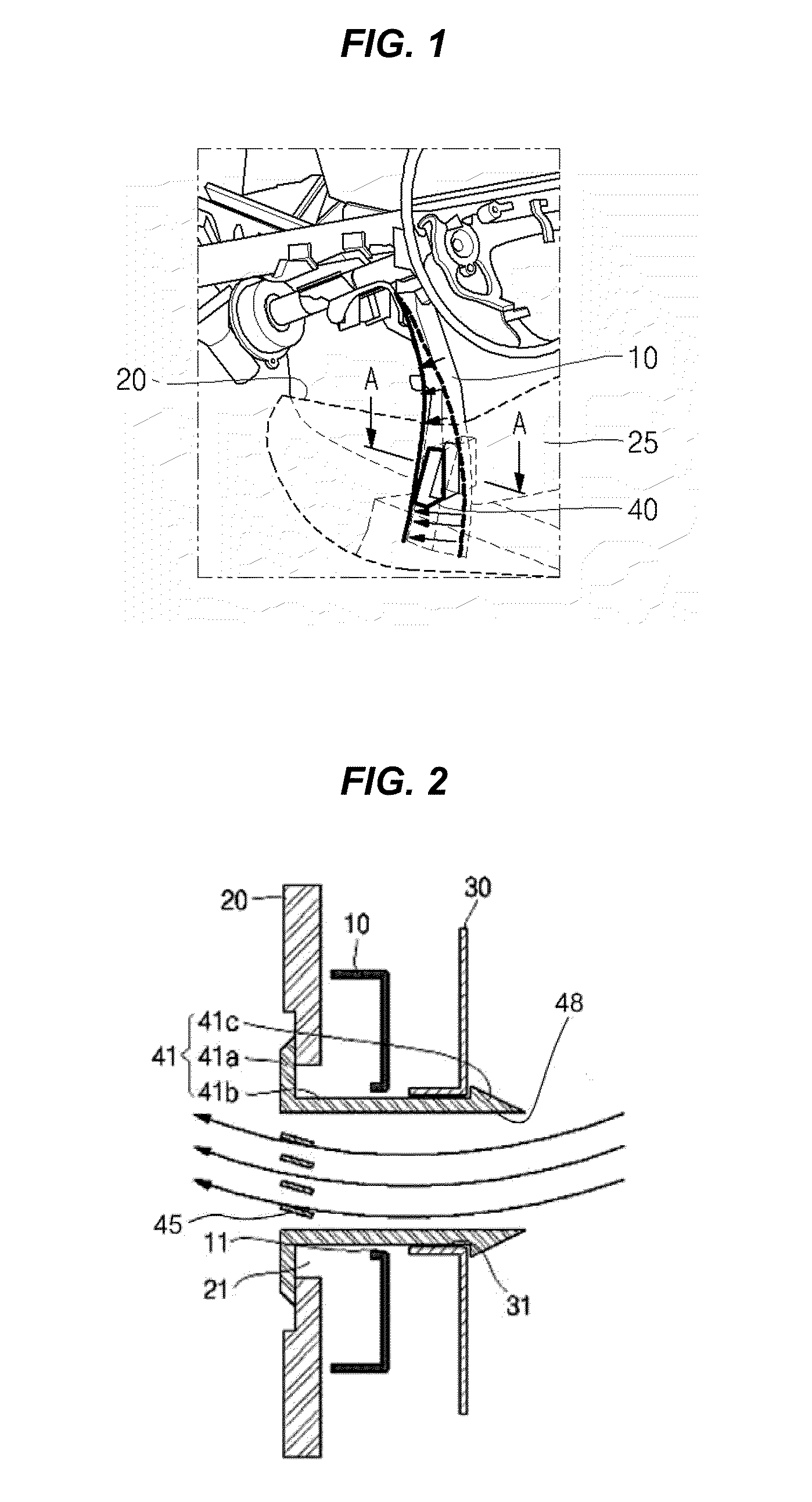

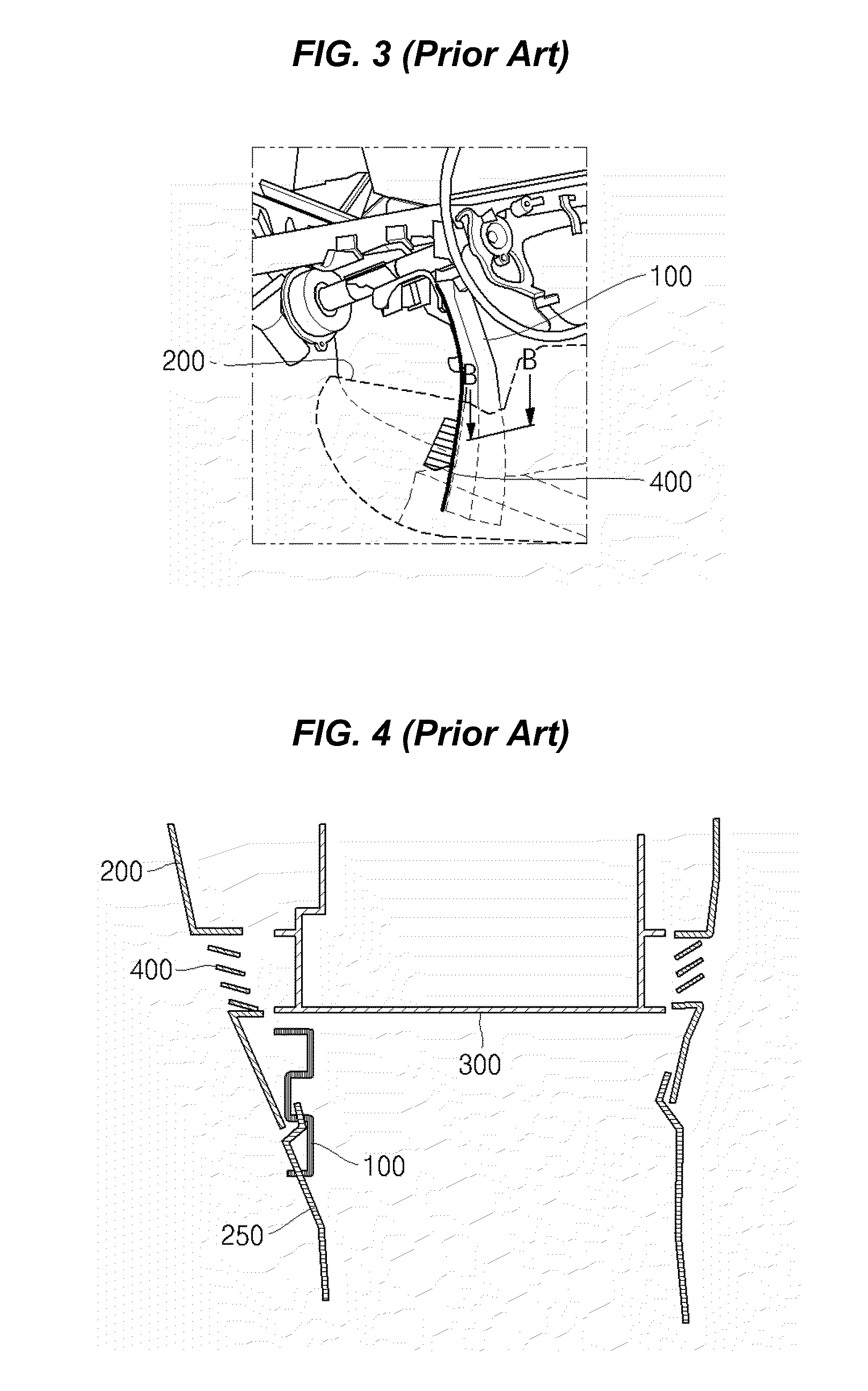

Front foot air vent for automobile

InactiveUS20110014860A1Increase freedomImprove NVH characteristicsAir-treating devicesVehicle heating/cooling devicesEngineeringSupport plane

A front foot air vent for an automobile may include a center support bracket disposed between a console side cover and an air duct and provided with a through hole, wherein a discharge hole of the console side cover, a passage of the air duct and the through hole of the center support bracket are communicated with one another; and a grill member which is formed as a separate piece and includes an air passage therein, wherein the grill member is assembled to the discharge hole, the through hole and the passage so as to be communicated between the discharge hole of the console side cover and the passage of the air duct through the air passage of the grill member.

Owner:KIA MOTORS CORP

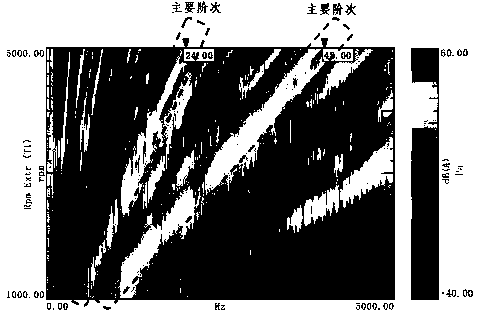

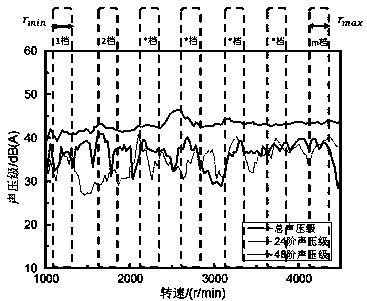

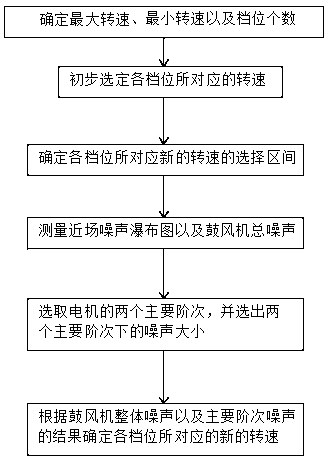

Adjustment method for corresponding rotational speeds of gears of air blower of automobile air conditioner

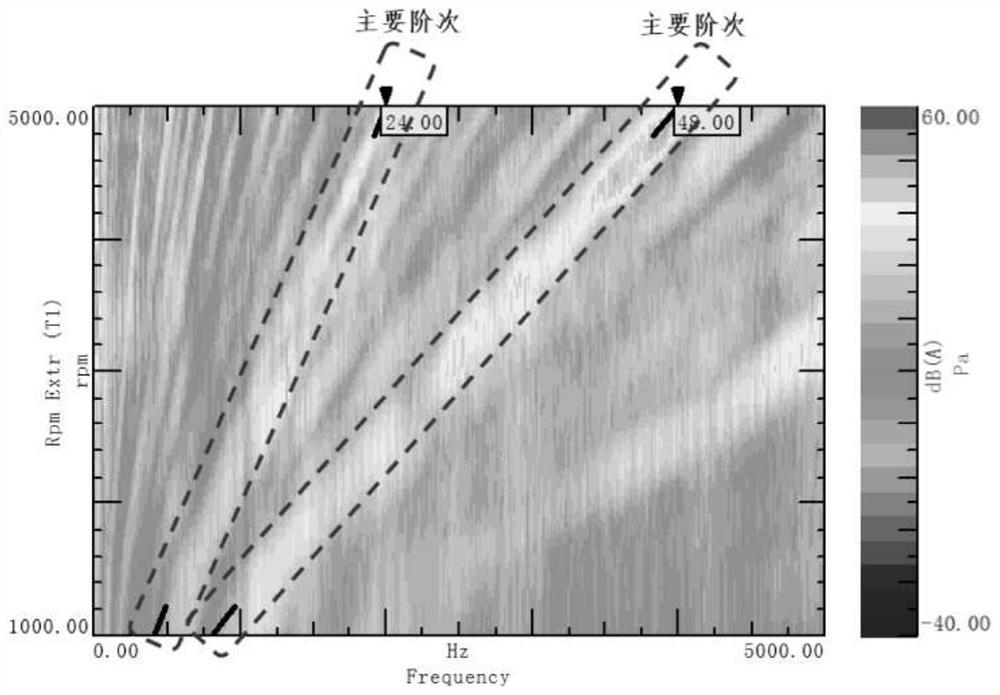

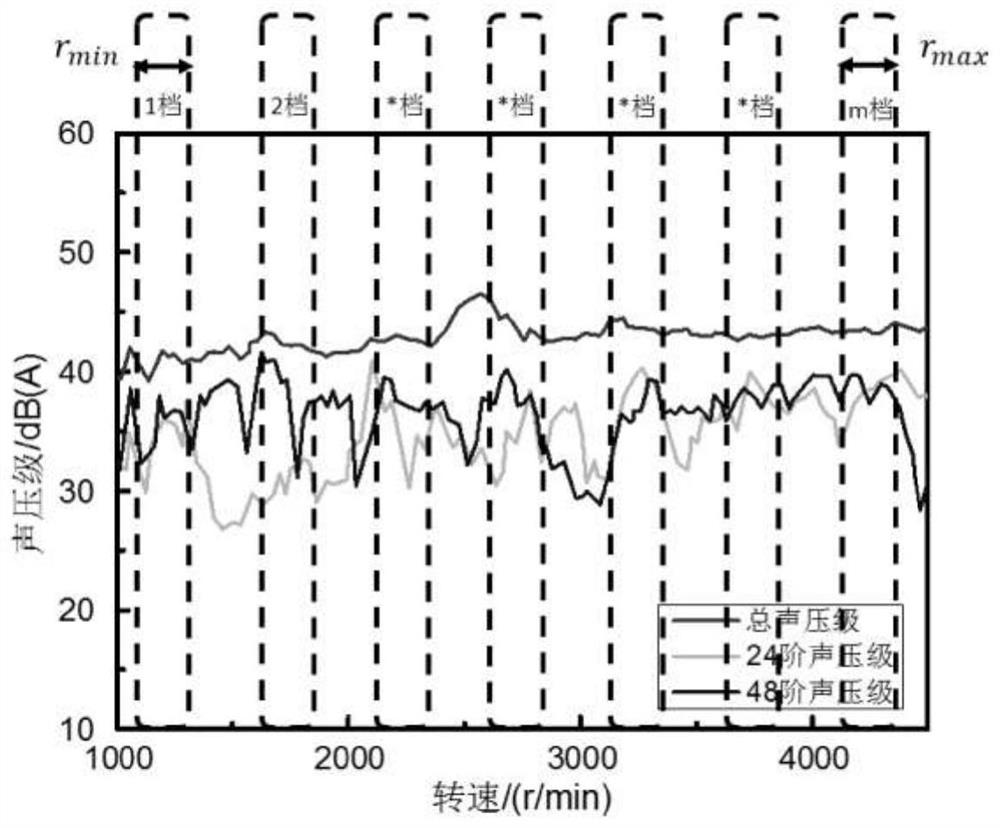

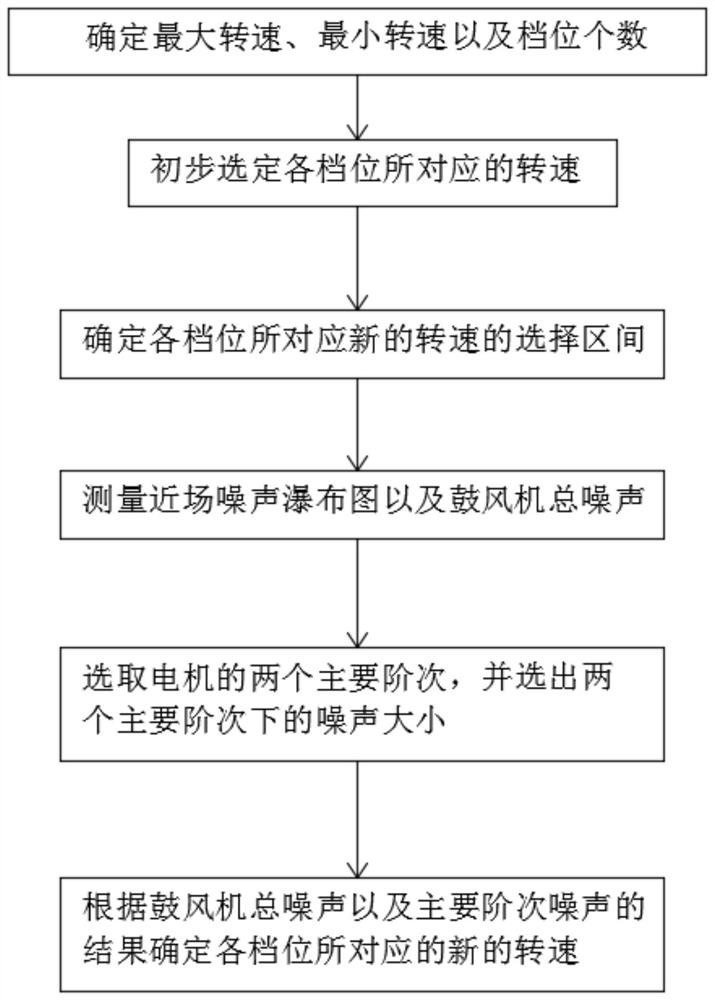

ActiveCN110578704AAvoid resonanceImprove NVH characteristicsPump controlNon-positive displacement fluid enginesSoftwareWaterfall plot

The invention relates to the field of optimization for automobile NVH, and specifically discloses an adjustment method for the corresponding rotational speeds of gears of an air blower of an automobile air conditioner. The adjustment method for the corresponding rotational speeds of the gears of the air blower of the automobile air conditioner comprises the following steps: determining the maximumrotational speed rmax and the minimum rotational speed rmin of the air blower, and the number m of the gears of the air blower at first; preliminarily selecting the corresponding rotational speed ofeach gear of the air blower; determining a selection interval of corresponding new rotational speeds of the gears, obtaining a near-field noise waterfall plot, and measuring the total noise value of the air blower; conforming the two main orders of a motor, and selecting the noise values of the two main orders by virtue of software; and combining the selected noise values and the total noise valueof the air blower into the same graph, and determining the corresponding new rotational speeds of the gears according to the results of the overall noise of the air blower and the noises of the mainorders. By virtue of the abovementioned method, the matching between the gears and the rotational speeds of the air blower can be optimized; and on the premise of not adding other requirements, the parotic noises of a driver and passengers are effectively and reasonably reduced, and the NVH characteristic of an automobile is improved.

Owner:湖南猎豹汽车股份有限公司

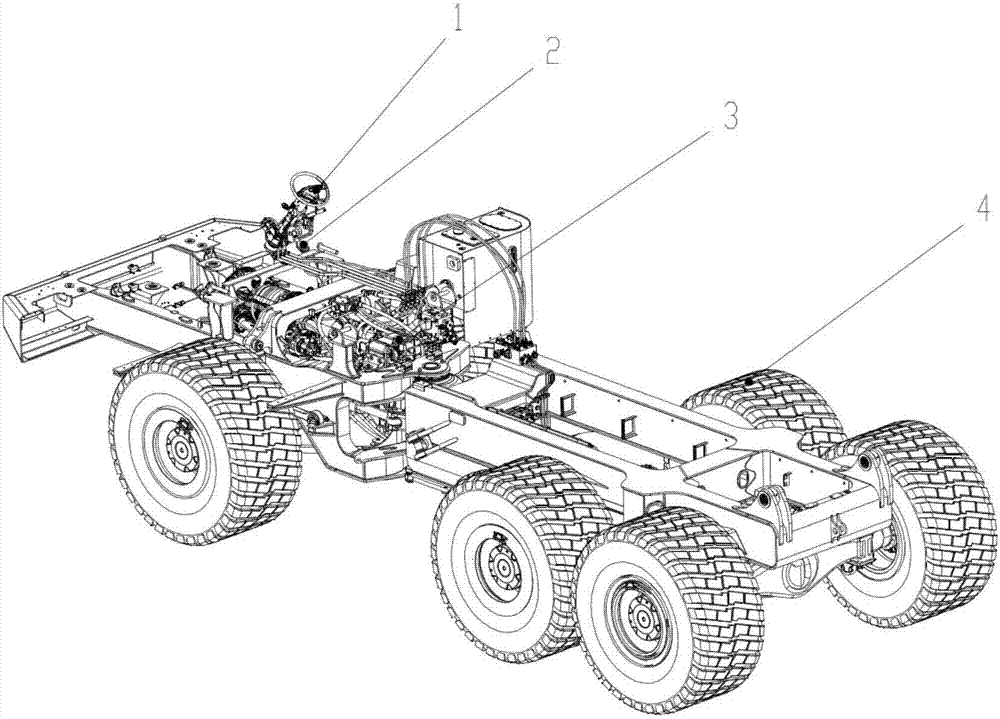

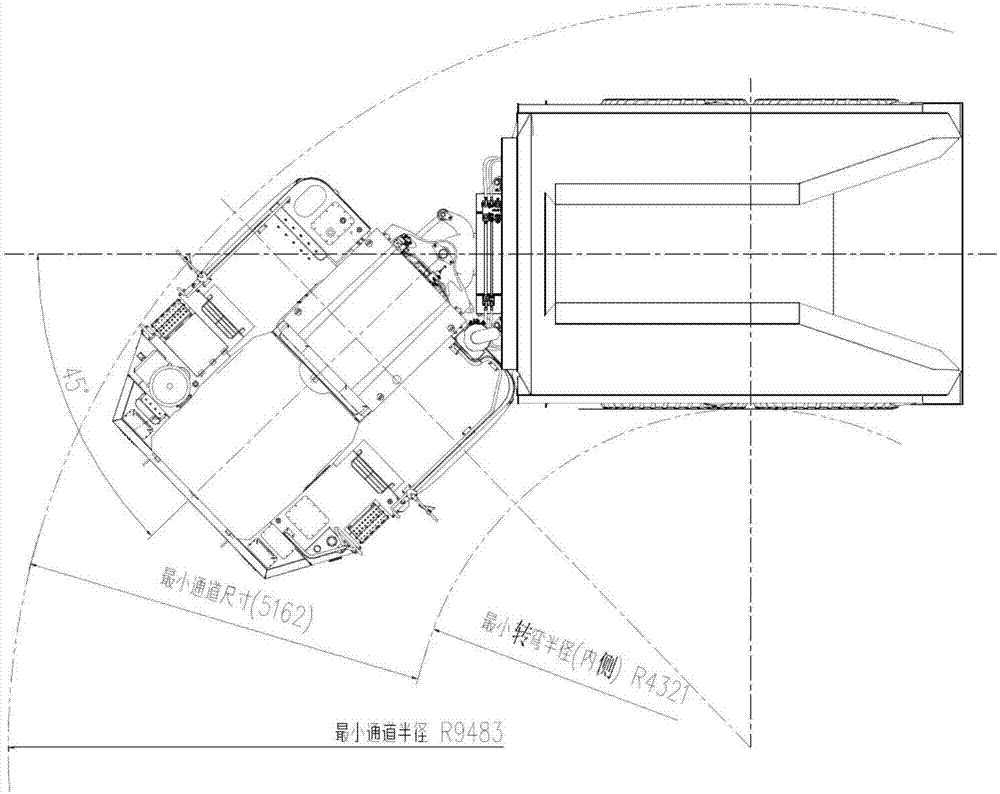

Hinging-type dump truck chassis

PendingCN107963132AReduce weightGuaranteed weightBraking action transmissionUnderstructuresVehicle frameEngineering

The invention discloses a hinging-type dump truck chassis. The hinging-type dump truck chassis comprises a steering system, a braking system, a drive system and a driving system, wherein the driving system comprises a truck frame assembly, the truck frame assembly comprises a front truck frame, a hinging body and a rear truck frame, a front axle is arranged below the front truck frame, a middle axle and a rear axle are arranged below the rear truck frame, one end of a left front hydro-pneumatic suspension unit and one end of a right front hydro-pneumatic suspension unit are connected to the upper surfaces of the left side and the right side of the front axle respectively, the other end of the left front hydro-pneumatic suspension unit and the other end of the right front hydro-pneumatic suspension unit are connected with the front truck frame, a right front cross pull rod, a front V rod and a left front cross pull rod are installed between the front truck frame and the front axle, themiddle axle is connected with the rear axle through a left balancing beam and a right balancing beam, a right middle cross pull rod, a middle V rod and a left middle cross pull rod are installed between the rear truck frame and the middle axle, and a right rear cross pull rod, a rear V rod and a left rear cross pull rod are installed between the rear truck frame and the rear axle. The hinging-typedump truck chassis is simple in structure, safe and reliable, and can effectively improve the trafficability and the comfort of the complete machine.

Owner:XUZHOU XCMG MINING MACHINERY CO LTD

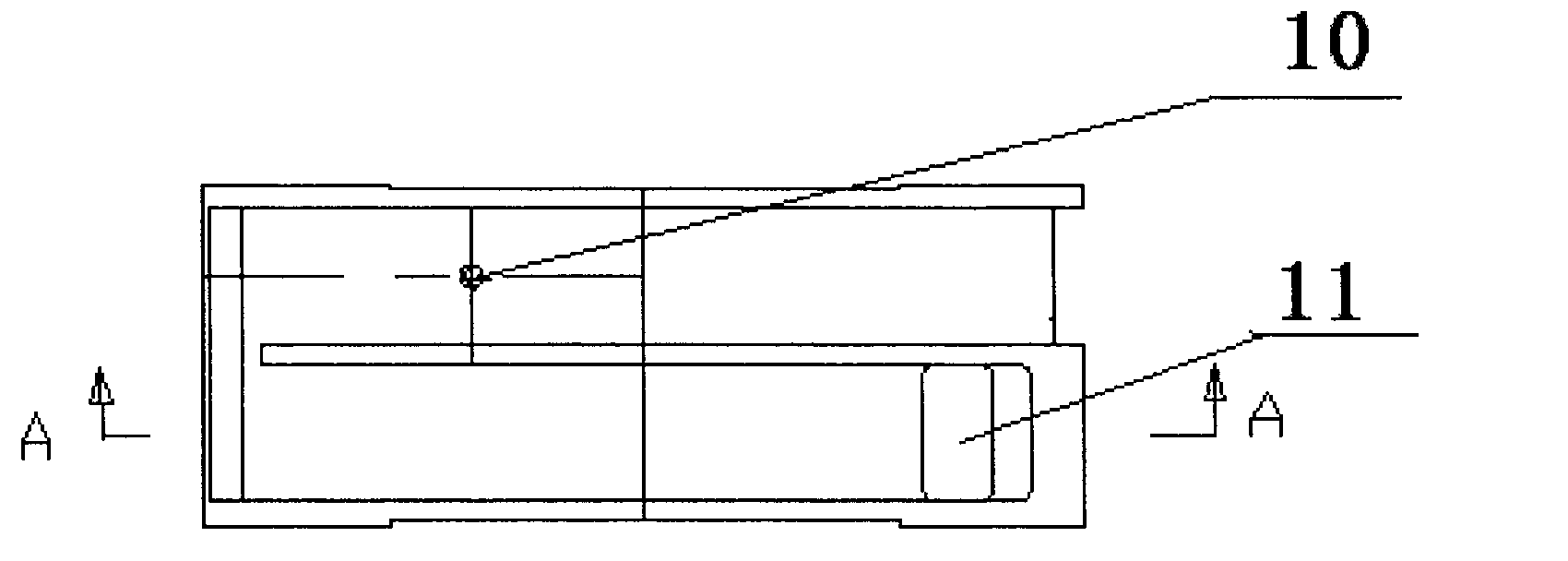

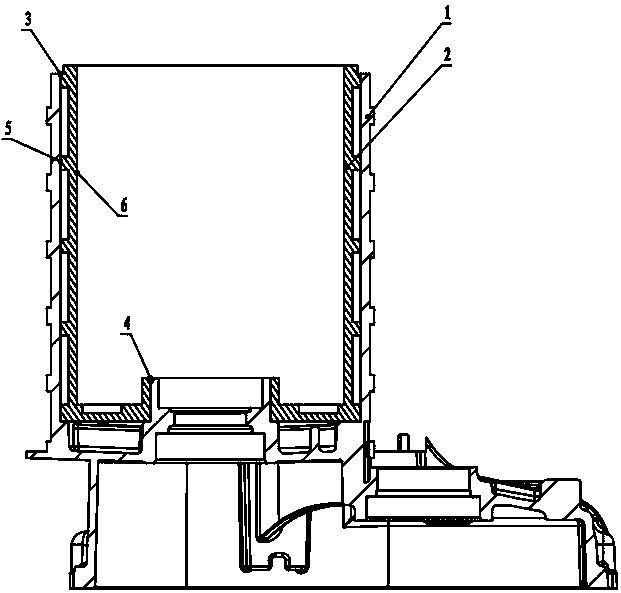

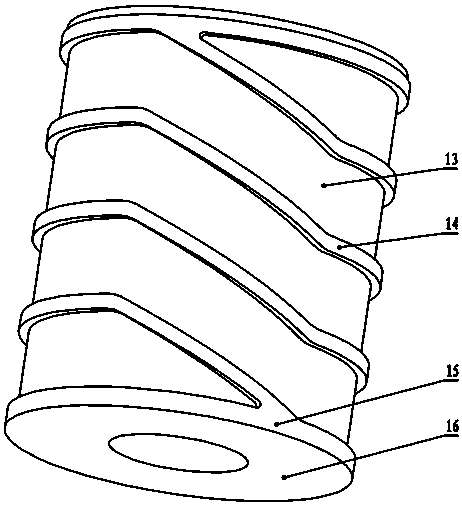

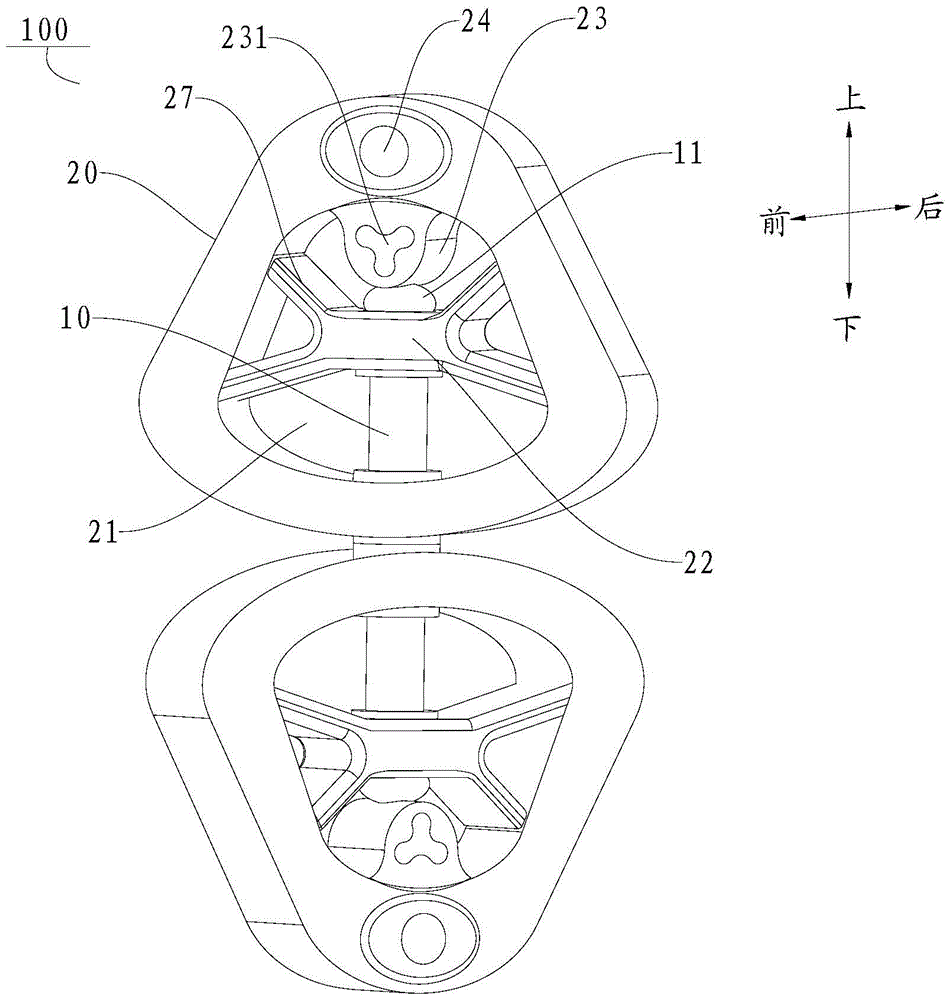

Vibration isolation system

ActiveCN101196226ATightly boundGood NVH characteristicsSpringsJet propulsion mountingEngineeringVibration isolation

A dynamic assembly vibration isolation system is provided, which comprises an external shell body connected with a right bracket, a front bracket and a rear bracket, a left bracket, a buffer, a bolt, a connecting rod, a rubber body and an internal shell body. The buffer is positioned between the left bracket and the shell body. The invention is characterized in that: the external shell body is connected with the internal shell body and a hollow cavity is enclosed between; a ventilation hole is made on the external shell; a rubber body is sulfurized on the internal shell body; the connecting rod is planted into the rubber body; the connecting rod is connected with the left bracket via a bolt. A damping fluid and a decoupling film are positioned in the area enclosed by the rubber body and internal shell body; the decoupling film and the rubber body enclose a lower fluid chamber; the decoupling film and the internal shell body enclose an upper fluid chamber; a passage internal cavity, an inertia passage internal cavity and an inertia passage are positioned. Due to the adoption of a fluid blocking type vibration isolation system, the components in the invention can integrate in a compact way and light weight structure and excellent manufacturing technique can be realized. Therefore, under all working conditions, the invention is able to realize outstanding vibration isolation and reduction effect, so as to ensure excellent NVH performance for the whole vehicle. In addition, because the invention resolves the problems of high frequency dynamic hardening and shorter service life generally existed in a rubber suspension vibration isolation system, the invention can be applied to automobiles.

Owner:CHERY AUTOMOBILE CO LTD

Motor and speed reducer integrated case and casting and welding method thereof

InactiveCN108539897AHigh degree of integrationLow costManufacturing dynamo-electric machinesSupports/enclosures/casingsWater channelReduction drive

The invention discloses a motor and speed reducer integrated case and a casting and welding method thereof. The case comprises an outer case body and an inner case body, wherein the outer case body comprises a motor case body and a speed reducer case body which are integrally formed through high-pressure casting; the inner case body is nested in the motor case body, a spiral water channel rib is arranged on the outer surface of the inner case body, and spaces of the spiral water channel rib form a spiral water channel by being matched with an outer wall of the inner case body and the inner wall of the motor case body. According to the motor and speed reducer integrated case, the integration degree is increased, end covers are reduced, the cost is reduced, the axial space is compressed, andthe NVH characteristic of a system is improved. According to the casting and welding method, the complexity of a manufacturing process is reduced through high-pressure casting, the batch efficiency is high, the wall thickness of the case is reduced, structures of process holes are omitted, and the radial space is compressed.

Owner:HEFEI JUYI POWER SYST CO LTD

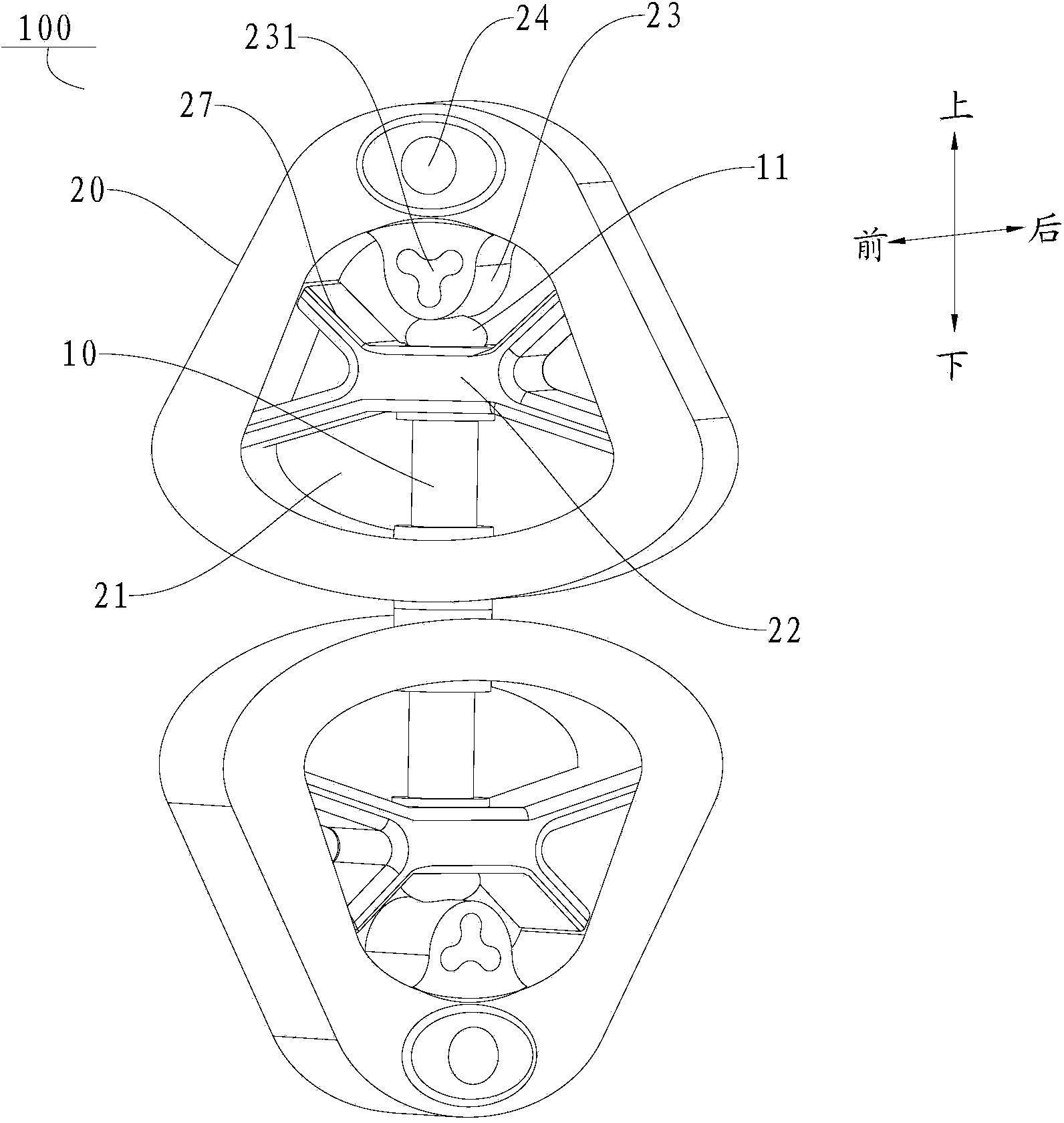

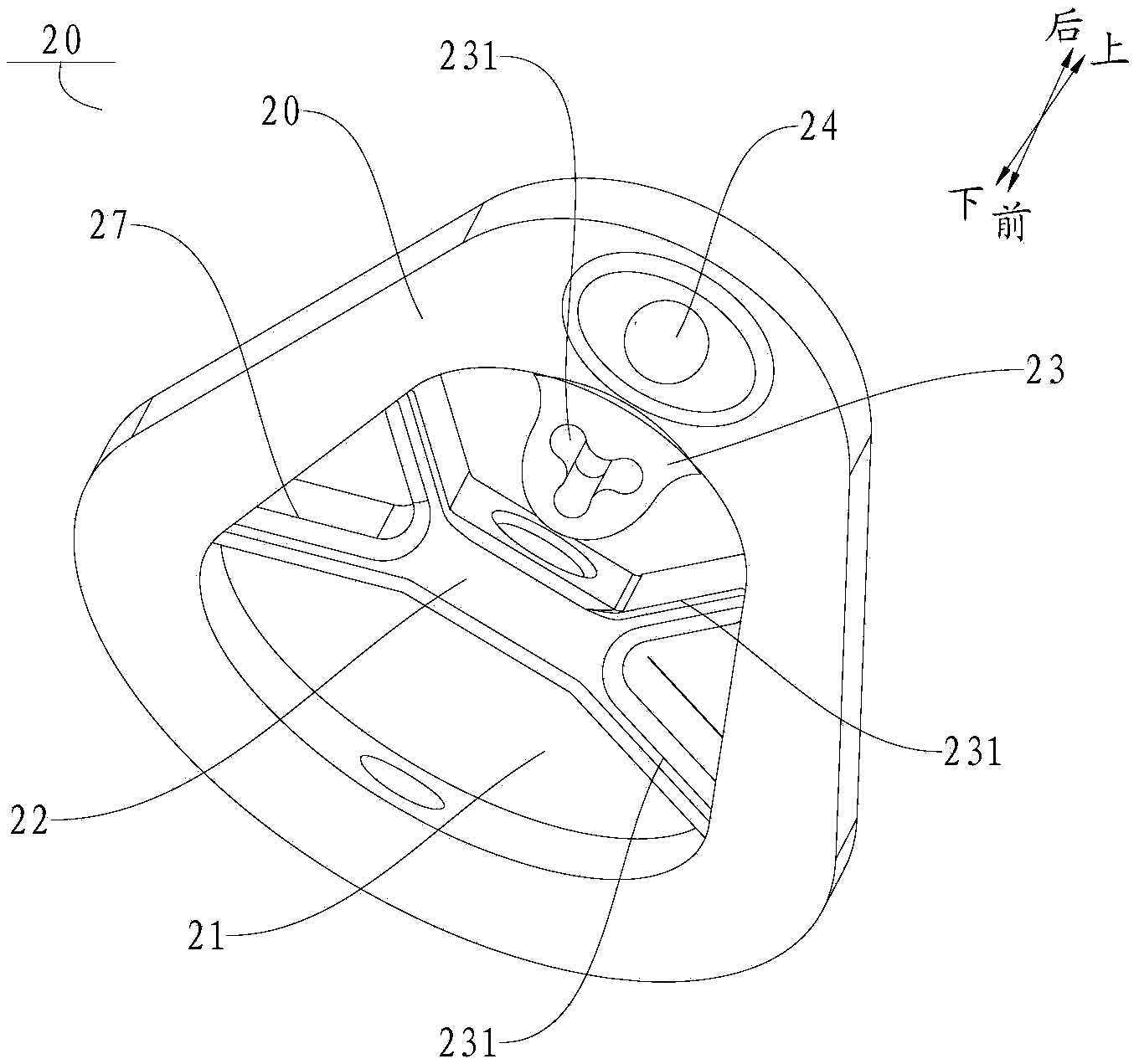

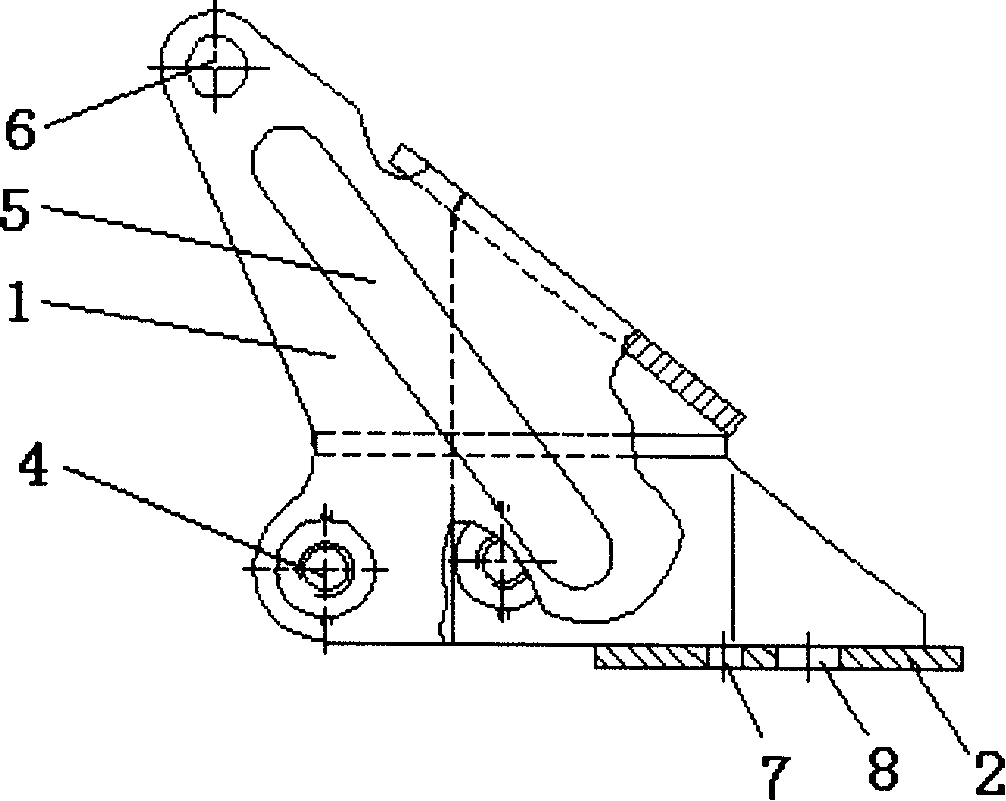

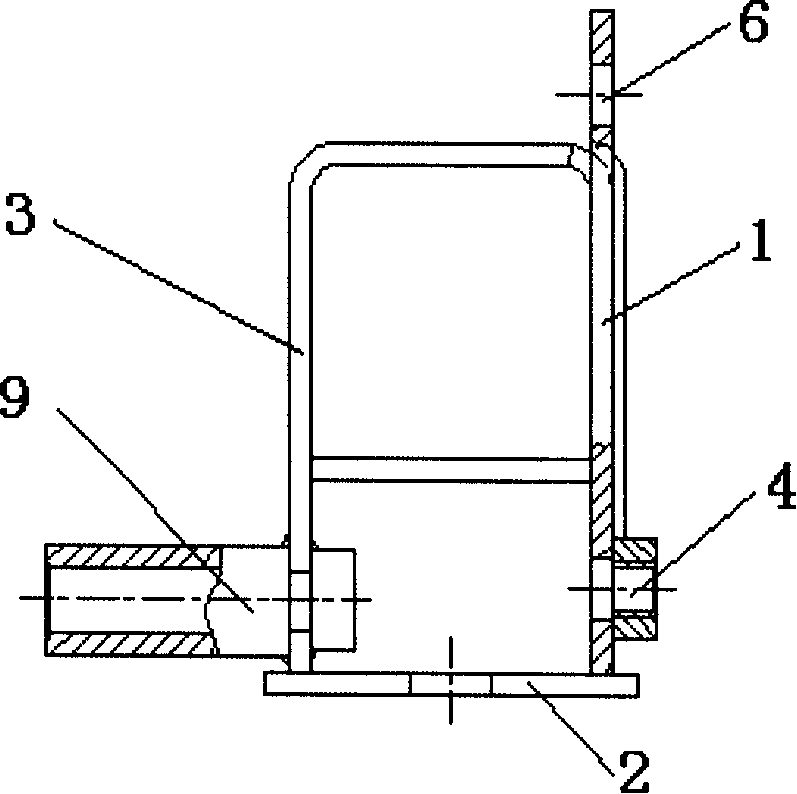

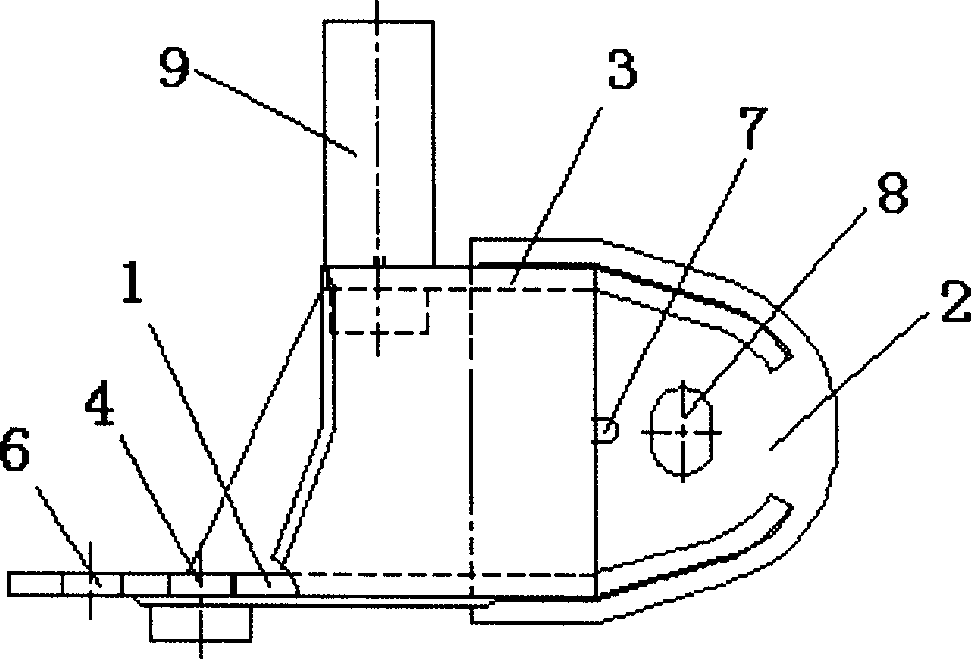

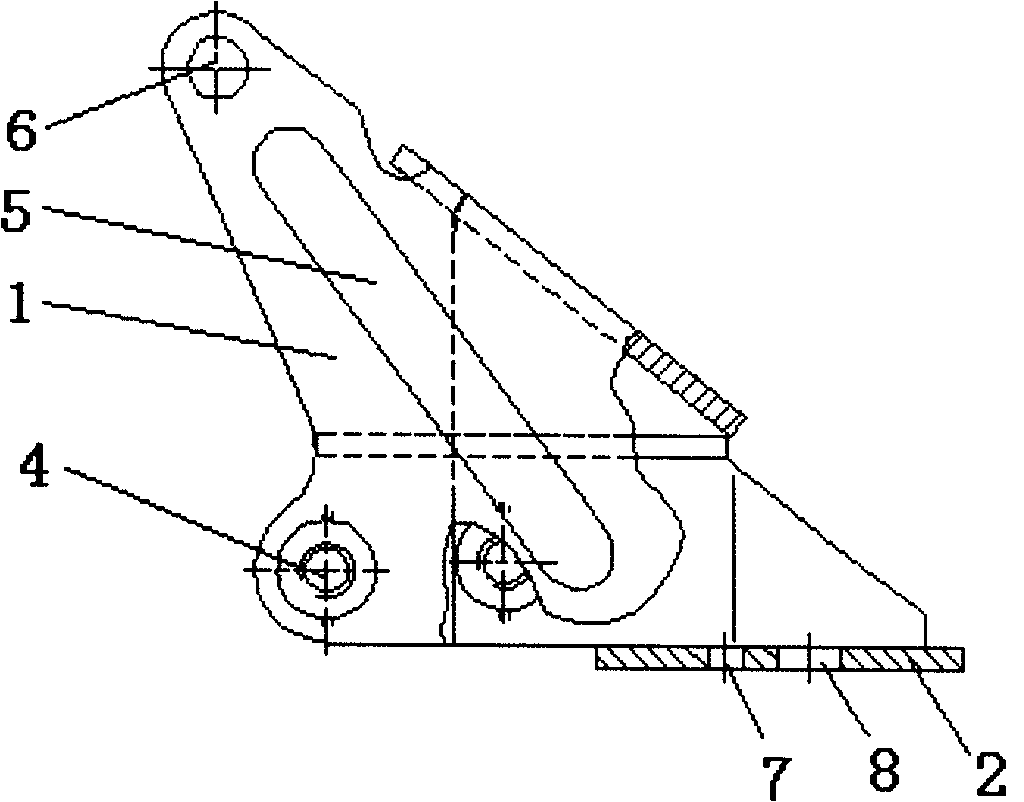

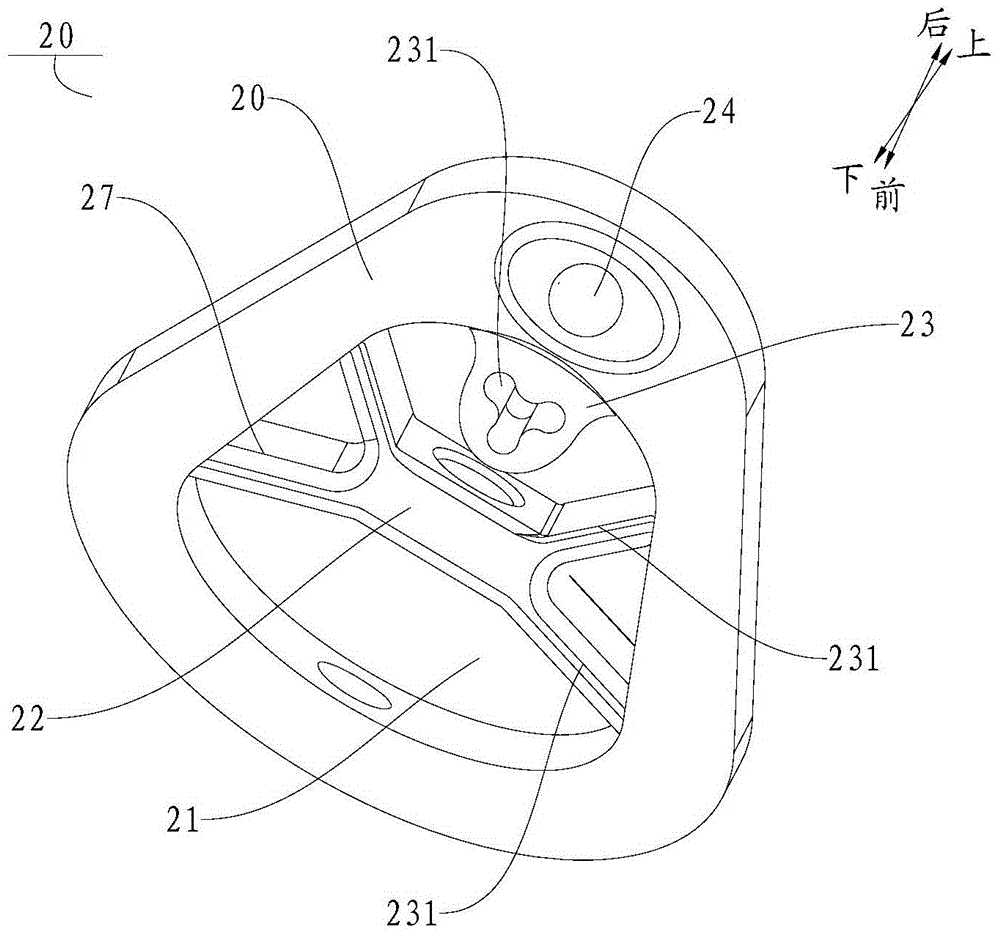

Lifting lug for automobile exhaust system and vehicle with lifting lugs

ActiveCN104340052AImprove NVH characteristicsReduces the possibility of failure or even tearingPropulsion unit gas exhaustStress concentrationNoise, vibration, and harshness

The invention provides a lifting lug for an automobile exhaust system and a vehicle with lifting lugs. The lifting lug for the automobile exhaust system comprises a connecting rod and two symmetrically arranged bodies, wherein an opening is formed in each body, and penetrates through the thickness of the body; the two ends of the connecting rod penetrate through the sidewalls of the corresponding openings, and extend into the openings respectively; at least one of the two bodies can rotate relative to the connecting rod. According to the lifting lug for the automobile exhaust system, the two bodies are arranged on the connecting rod, and at least one of the two bodies can rotate relative to the rotating rod, then the body capable of rotating relative to the connecting rod can bear higher torque when the lifting lug is twisted due to improper assembly or generated non-directional excitation energy of an exhaust pipe of the exhaust system, the probability of lifting lug failure and even tearing caused by stress concentration is further lowered, and the vibration of the exhaust pipe is reduced, so that the NVH (noise vibration and harshness) properties of the vehicle are improved.

Owner:GREAT WALL MOTOR CO LTD

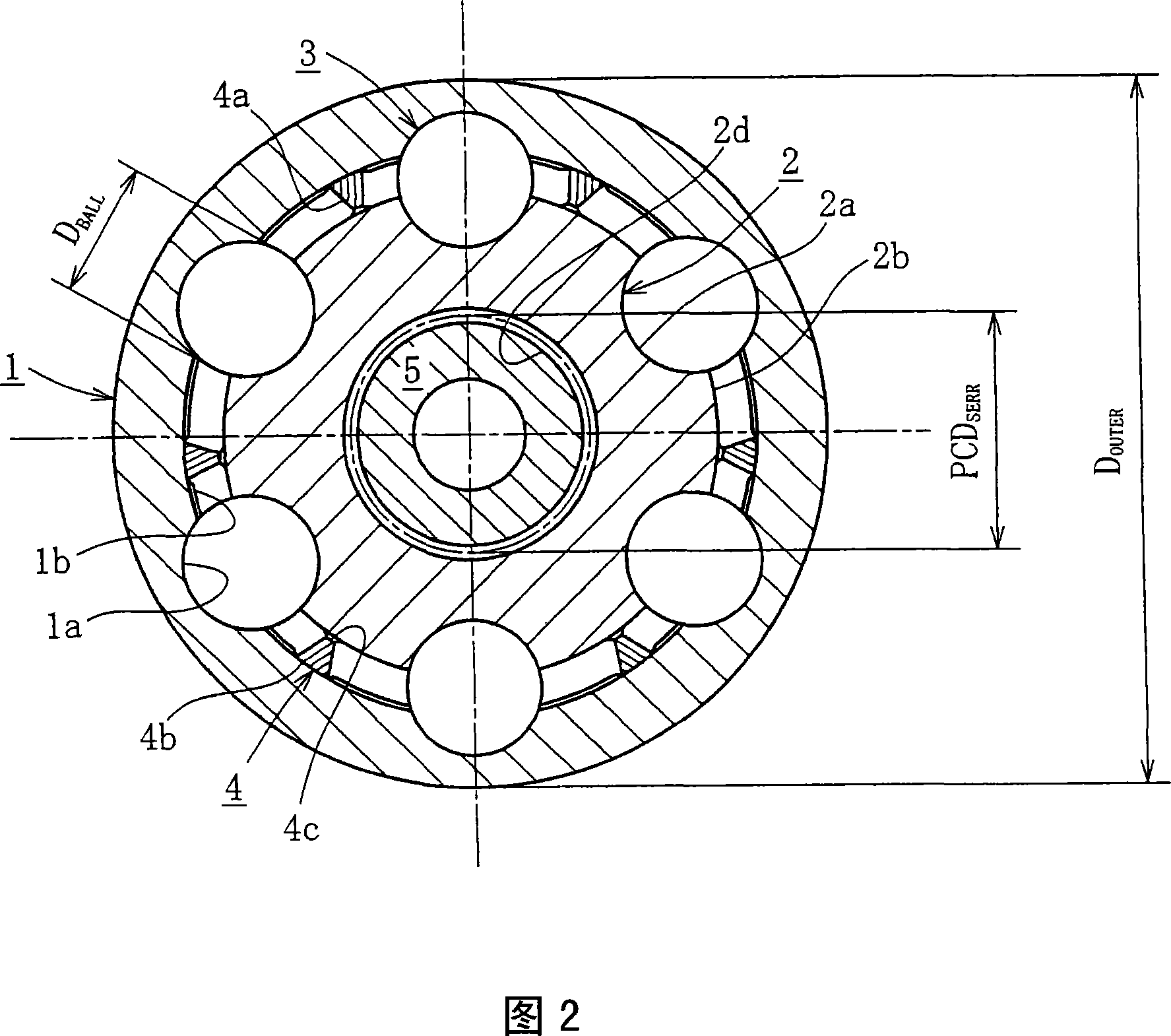

Constant velocity universal joint

InactiveCN1922413AIncrease stiffnessWeight increaseYielding couplingShaftsUniversal jointEngineering

The present invention aims to achieve the high rigidity and light weight of a connecting shaft of a constant velocity universal joint, and to reduce manufacturing costs. A hollow connecting shaft 5 is provided with an axial end section 5c having teeth 5c which are engaged with an engagement section 2d of an inner member 2, and a middle section 5d continued from the axial end section 5c. To mold the connecting shaft 5, both end sections of a pipe material with an outside diameter dm are drawn, and then the teeth (splines or serrations) 5c are molded in the outer periphery of the drawing-molded axial end section 5c on an axial end side by form rolling or the like. The outside diameter of the axial end section 5c is ds, and the outside diameter of the middle section 5d is dm as with that of the pipe material (ds < dm).

Owner:NTN CORP

Multifunctional support for automobile

InactiveCN101195337AAdded first-order bending modeImprove connection stiffnessJet propulsion mountingInternal combustion mountingRear quarterEngineering

The invention discloses a car multifunctional support bracket which comprises a lower side plate which is equipped with a hole connected with a suspension cushion assembly. The invention is characterized in that a front side plate is arranged at the front end of the lower side plate the rear end of which is provided with a rear side plate, the front side plate is equipped with two installation holes which are connected with a motor and a gear box, the rear side plate is provided with an installation hole connected with a starter. For increasing rigidity, the front side plate is provided with an upshot convex rib, and the front side plate is connected with the rear side plate after the rear side plate is bent. Because the power assembly, the suspension, the starter, the motor and the gear box are compactly combined within a very limited space, the combination portion and the suspension cushion form a whole vibration isolation system, thereby the arrangement of the elements of the system is more compact, one stage bending mode of the power assembly is obviously increased, and the connecting rigidity of the motor and the gear box is increased. The invention is capable of ensuring good NVH (noise, vibration and harshness) properties of the whole vehicle under all working conditions, which has the advantages of light-weight design, simple construction, good manufacturability, easy production and low costs. The invention is adaptable for occasions on which hydraulic engine mount is employed.

Owner:CHERY AUTOMOBILE CO LTD

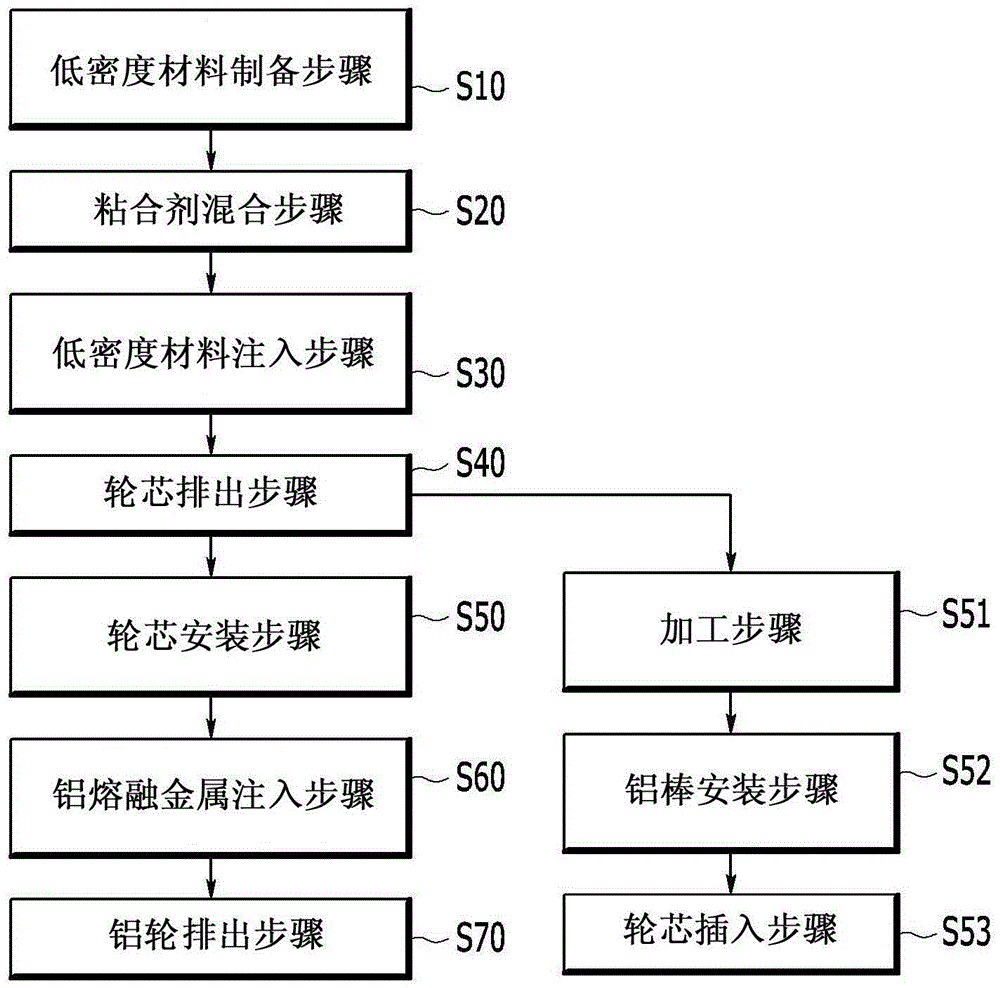

Aluminium wheel for vehicle and the manufacturing method

InactiveCN104923765AReduce weightImprove rigidityWheel manufactureDisc wheelsCasting moldLow density

A method of manufacturing an aluminum wheel for a vehicle includes preparing a low density material having particles pulverized. A binder is supplied to the low density material so that the low density material is mixed in a paste state. A wheel core manufacturing mold is heated to 200 to 350° C. and injected into the wheel core manufacturing mold. The wheel core manufacturing mold is closed, a pressure of about 5 to 20 bar is applied, the pressure is maintained for 1 to 5 minutes to solidify the low density material, and the wheel core is ejected. The ejected wheel core is mounted on an aluminum wheel casting mold. The aluminum wheel casting mold is closed, and a pressure of about 1 to 2 bar is applied, and an aluminum molten metal is injected. The aluminum wheel is then ejected from the aluminum wheel casting mold.

Owner:HYUNDAI MOTOR CO LTD

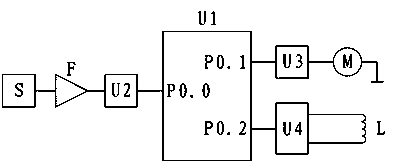

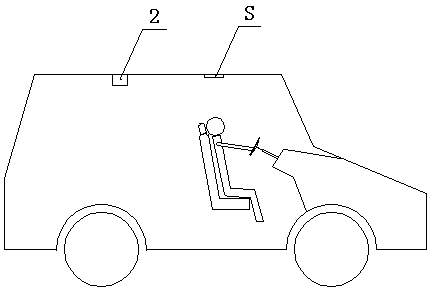

Control device for eliminating roars in car

ActiveCN104002750AEliminate booming noise phenomenonImprove NVH characteristicsElectric/fluid circuitEngineeringPhase angle

A control device for eliminating roars in a car comprises a sound pressure sensor, a vibration exciter and a controller. The sound pressure sensor collects sound signals above the driver head and sends the collected signals to a signal input end of a controller. The vibration exciter is fixed on a car roof and is connected with a signal output end of the controller. When the amplitude of the sound signals output by the sound pressure sensor exceeds the set threshold, the controller damage the car body resonance condition and eliminates the roars in car by adjusting the vibration amplitude, the frequency and the phase angle of the vibration exciter. By means of the control device, the vibration exciter is used for interfering with vibration of the roof to damage the car body resonance condition, and accordingly, the roars in car are prevented effectively, and the car noise vibration and harshness (NVH) characteristic is improved. By means of the device, the problem of roars of any frequencies can be solved in real time, car body parts are not needed to be changed, and time and fund waste is prevented.

Owner:GREAT WALL MOTOR CO LTD

Multifunctional support for automobile

InactiveCN101195337BAdded first-order bending modeImprove connection stiffnessJet propulsion mountingInternal combustion mountingRear quarterEngineering

The invention discloses a car multifunctional support bracket which comprises a lower side plate which is equipped with a hole connected with a suspension cushion assembly. The invention is characterized in that a front side plate is arranged at the front end of the lower side plate the rear end of which is provided with a rear side plate, the front side plate is equipped with two installation holes which are connected with a motor and a gear box, the rear side plate is provided with an installation hole connected with a starter. For increasing rigidity, the front side plate is provided with an upshot convex rib, and the front side plate is connected with the rear side plate after the rear side plate is bent. Because the power assembly, the suspension, the starter, the motor and the gear box are compactly combined within a very limited space, the combination portion and the suspension cushion form a whole vibration isolation system, thereby the arrangement of the elements of the system is more compact, one stage bending mode of the power assembly is obviously increased, and the connecting rigidity of the motor and the gear box is increased. The invention is capable of ensuring good NVH (noise, vibration and harshness) properties of the whole vehicle under all working conditions, which has the advantages of light-weight design, simple construction, good manufacturability, easy production and low costs. The invention is adaptable for occasions on which hydraulic engine mount is employed.

Owner:CHERY AUTOMOBILE CO LTD

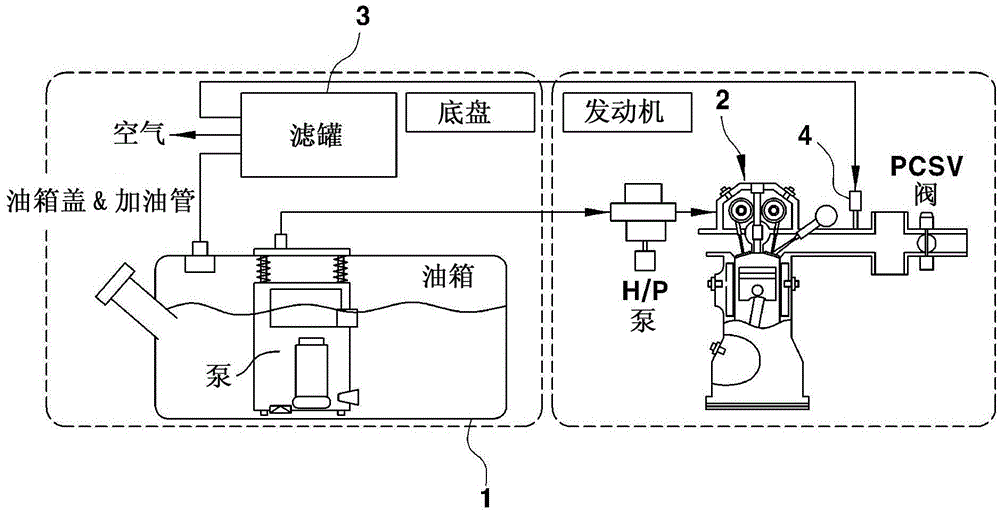

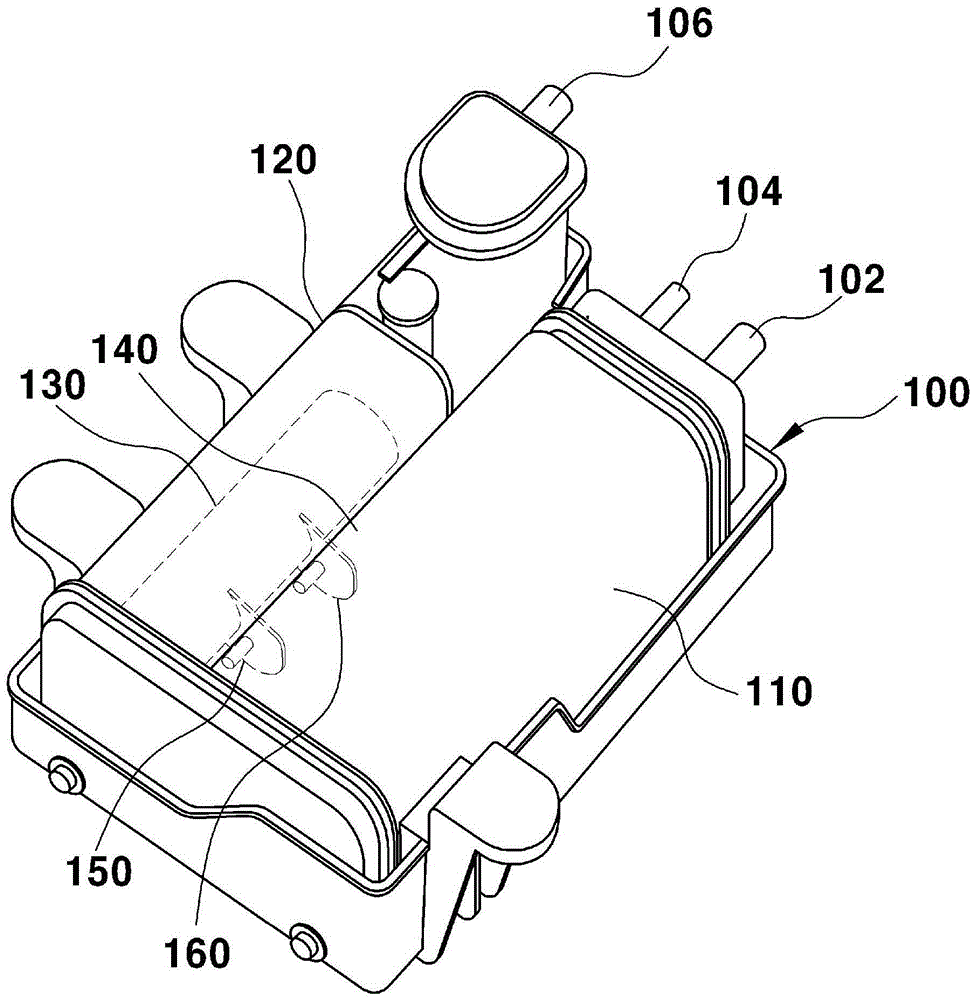

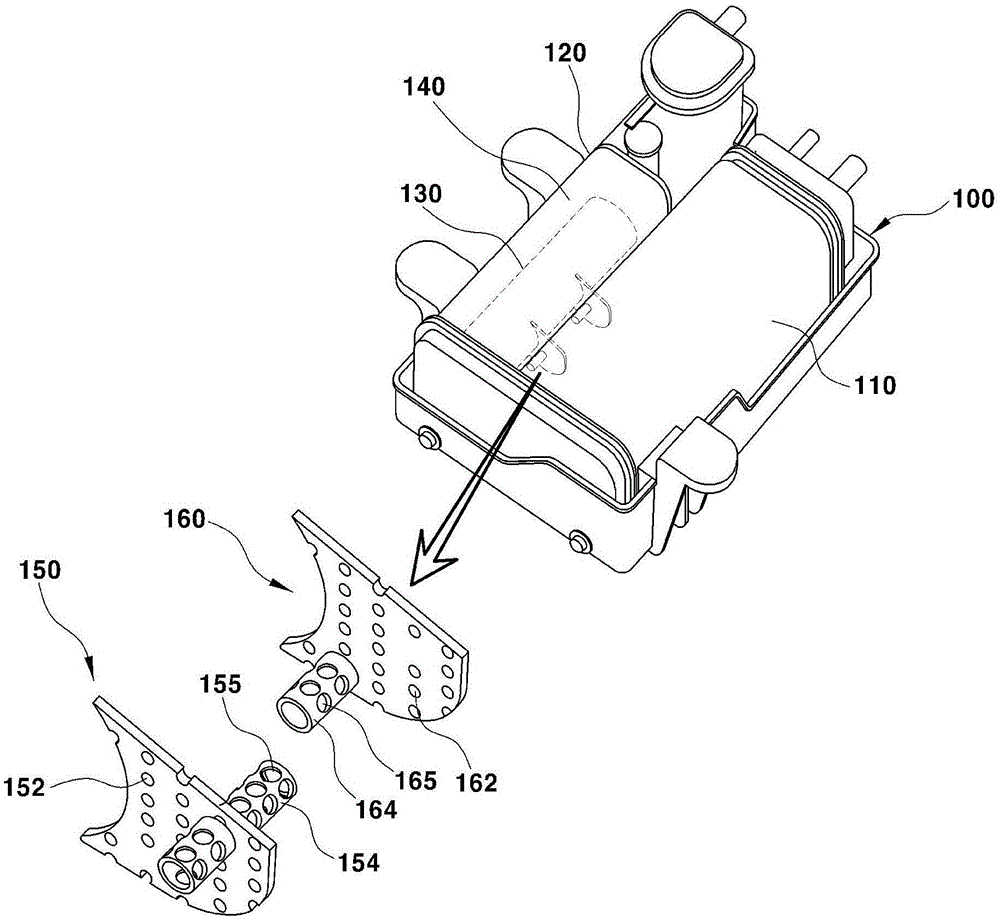

Canister apparatus for vehicle

ActiveCN106555713AImprove NVH characteristicsEmission reductionNon-fuel substance addition to fuelMachines/enginesWaste management

A canister apparatus for a vehicle is provided. The apparatus reduces noise of a canister by utilizing an air gap disposed in the canister, and partition walls, which are disposed at predetermined positions in the air gap space in the canister. As a result, vehicle NVH characteristics are improved and the discharge amount of bleed emission that causes environmental pollution is reduced.

Owner:HYUNDAI MOTOR CO LTD +1

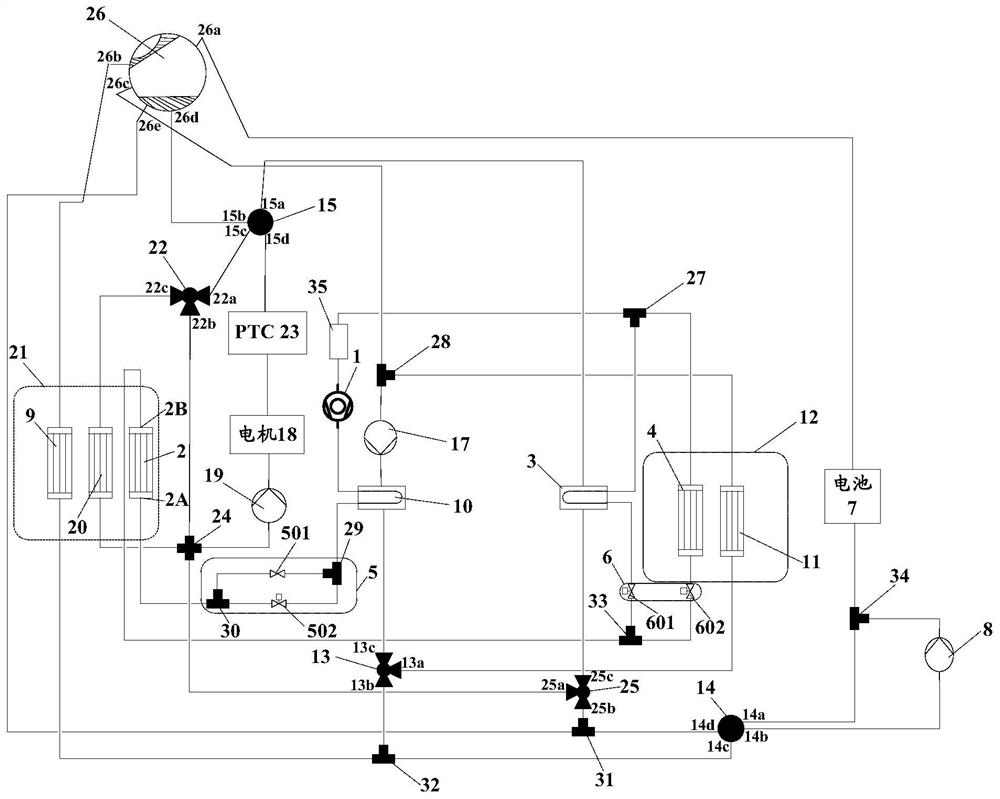

Thermal management system and electric vehicle

ActiveCN111923694AAvoid frequent start and stopImprove comfortAir-treating devicesVehicle heating/cooling devicesVapor–liquid separatorEngineering

The application provides a thermal management system and an electric vehicle. The thermal management system comprises a refrigerant loop and a water loop. In the refrigerant loop, an outlet of a compressor is connected with a first flow channel; a first flow channel is connected with an external condenser through a first valve set, the external condenser is connected with a second throttle valve and a third throttle valve, the second throttle valve is connected with a third flow channel, the third flow channel is connected with a compressor inlet through a gas-liquid separator, the third throttle valve is connected with an evaporator, and the evaporator is connected with the compressor inlet through the gas-liquid separator. In the water loop, an outlet of a first circulating pump is connected with an inlet of a first heat dissipation channel, an outlet of the first heat dissipation channel is connected with an inlet of a positive temperature coefficient heater, an outlet of the positive temperature coefficient heater can be connected with an inlet of a fourth flow channel, and an outlet of the fourth flow channel can be connected with an inlet of the first circulating pump. By theadoption of the thermal management system, the maximum refrigerating capacity can be increased, and low-pressure and high-pressure alarm shutdown of the compressor is avoided during refrigerating andheating light loads.

Owner:HUAWEI DIGITAL POWER TECH CO LTD

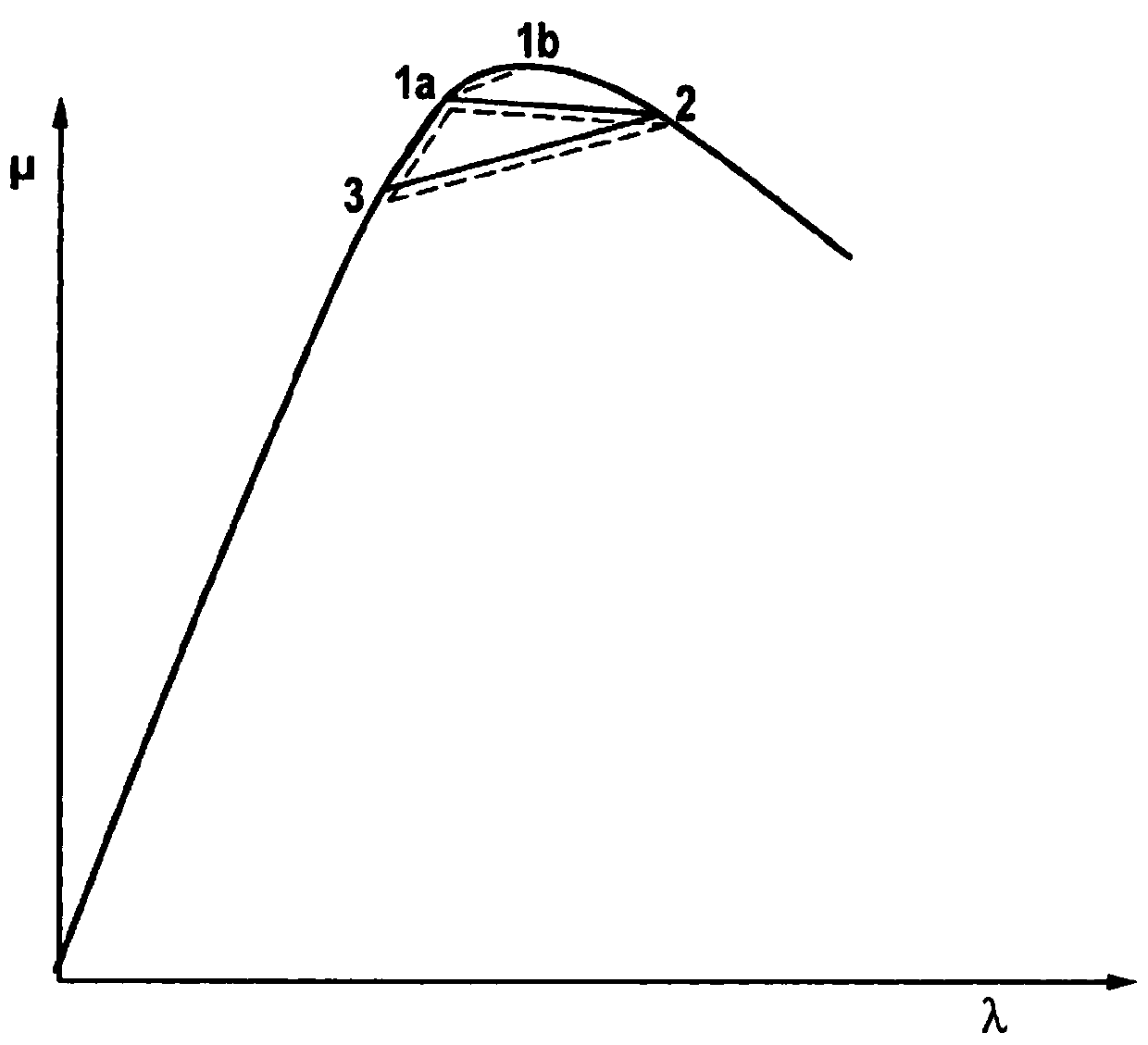

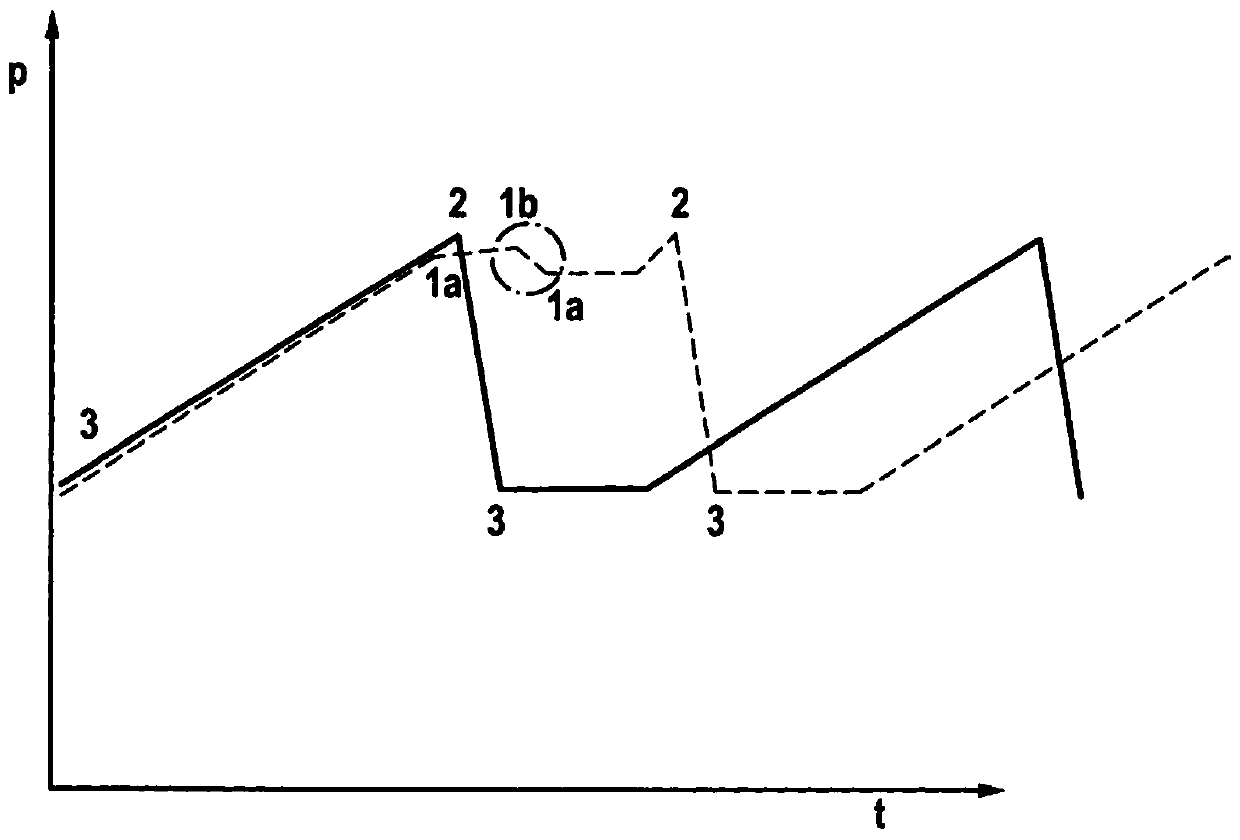

Method for controlling hydraulic brake system and corresponding device

ActiveCN111332268AImprove braking effectImprove NVH characteristicsBraking action transmissionABS control systemsPressure decreaseInlet valve

The present invention relates to a method for controlling a hydraulic brake system for a motor vehicle. The hydraulic brake system is used to brake with the help of at least one wheel brake, wherein in a first step, the pressure in the wheel brake is increased, a hydraulic fluid is guided to the wheel brake via a normally open inlet valve; in a second step, the pressure in the wheel brake is reduced, and the hydraulic fluid is discharged from the wheel brake via an energized and normally closed outlet valve. The method is characterized in that the pressure reduction at the wheel brake is accomplished by means of the control of the outlet valve in a predefined manner. In addition, the present invention relates to a device for executing the method.

Owner:ROBERT BOSCH GMBH

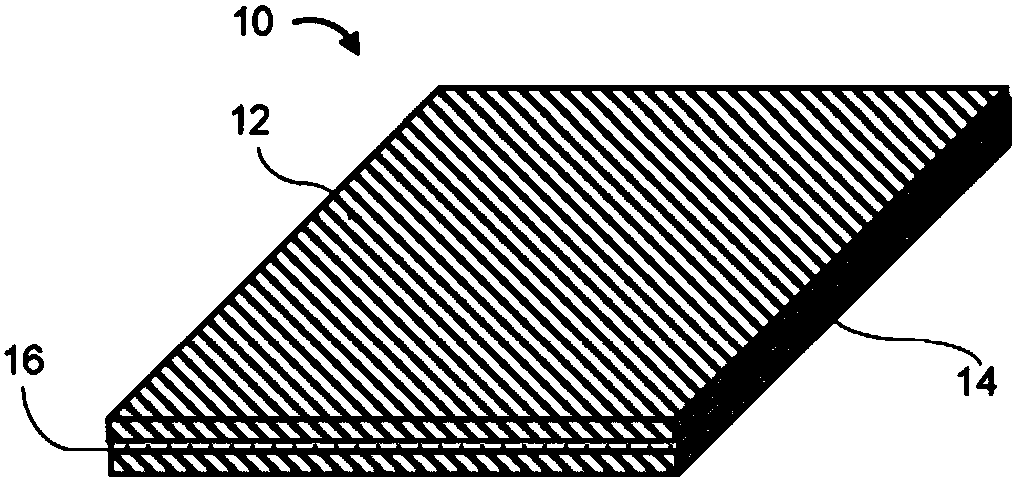

Oil pan assembly including laminate and clinch nut

Owner:MATERIALS SCI CORP

A method for adjusting the speed corresponding to the blower gear position of an automobile air conditioner

ActiveCN110578704BAvoid resonanceImprove NVH characteristicsPump controlNon-positive displacement fluid enginesAutomobile air conditioningElectric machinery

The invention relates to the field of optimization for automobile NVH, and specifically discloses an adjustment method for the corresponding rotational speeds of gears of an air blower of an automobile air conditioner. The adjustment method for the corresponding rotational speeds of the gears of the air blower of the automobile air conditioner comprises the following steps: determining the maximumrotational speed rmax and the minimum rotational speed rmin of the air blower, and the number m of the gears of the air blower at first; preliminarily selecting the corresponding rotational speed ofeach gear of the air blower; determining a selection interval of corresponding new rotational speeds of the gears, obtaining a near-field noise waterfall plot, and measuring the total noise value of the air blower; conforming the two main orders of a motor, and selecting the noise values of the two main orders by virtue of software; and combining the selected noise values and the total noise valueof the air blower into the same graph, and determining the corresponding new rotational speeds of the gears according to the results of the overall noise of the air blower and the noises of the mainorders. By virtue of the abovementioned method, the matching between the gears and the rotational speeds of the air blower can be optimized; and on the premise of not adding other requirements, the parotic noises of a driver and passengers are effectively and reasonably reduced, and the NVH characteristic of an automobile is improved.

Owner:湖南猎豹汽车股份有限公司

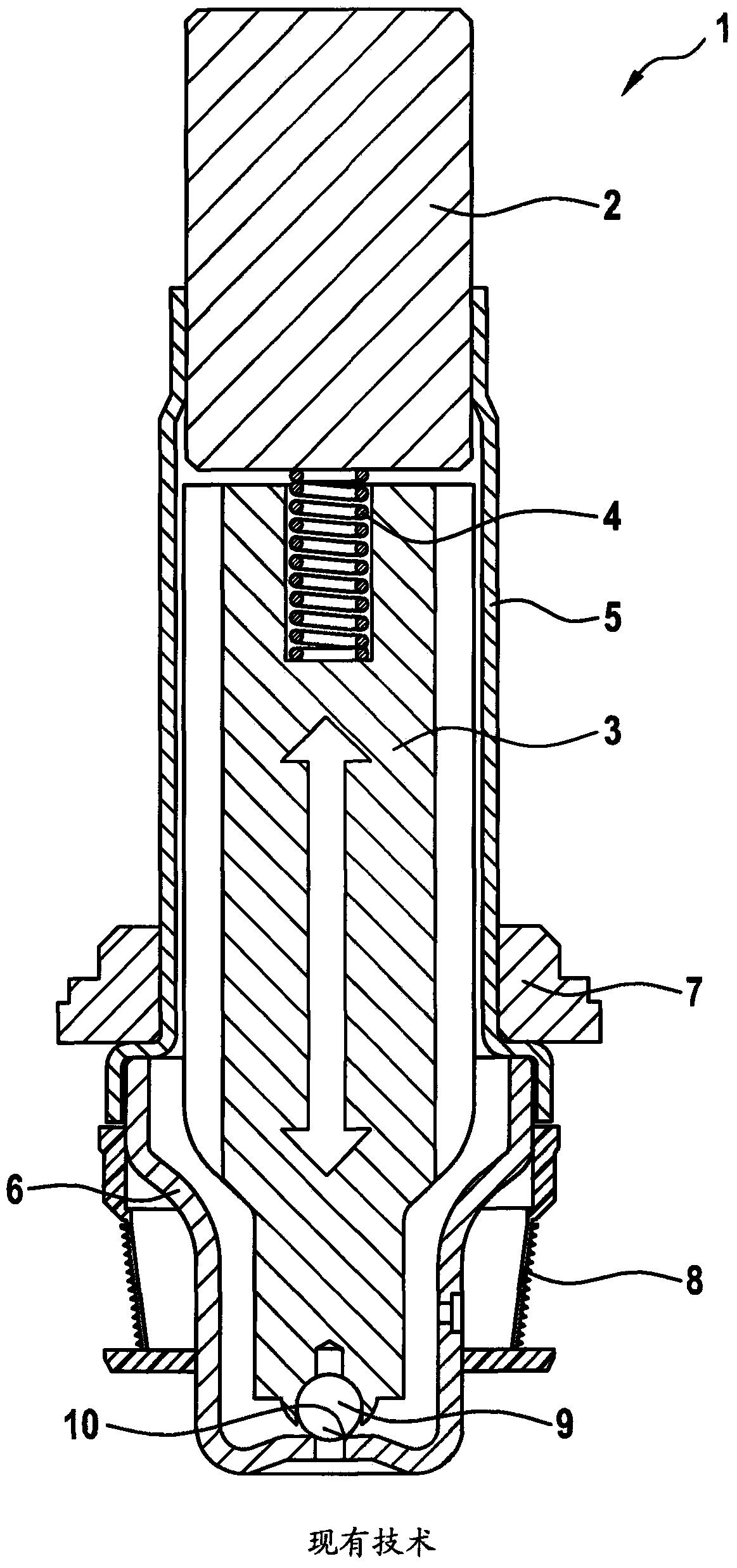

Solenoid valve closed when de-energized

ActiveCN106369205BCurved bigBuffer armature shiftOperating means/releasing devices for valvesMagnetsSolenoid valveVALVE PORT

PROBLEM TO BE SOLVED: To prevent a valve opening click sound occurring in a case where an armature collides with a polar core in electrification.SOLUTION: In a valve closing type solenoid valve 1 with no current, a polar core 2 is fixed and arranged, an armature 3 includes a valve sleeve 5 arranged so as to be displaceable in an axial direction, and in order to eliminate a valve closing element cooperating with the armature 3 into a valve seat, a compression spring 4 acts between the polar core 2 and the armature 3. The valve 1 is characterized in that between the polar core 2 and the armature 3, is formed means 11 of hydraulically buffering displacement of the armature 3.SELECTED DRAWING: Figure 2

Owner:ROBERT BOSCH GMBH

Lifting lug for vehicle exhaust system and vehicle having same

ActiveCN104340052BImprove NVH characteristicsReduces the possibility of failure or even tearingPropulsion unit gas exhaustStress concentrationNoise, vibration, and harshness

The invention provides a lifting lug for an automobile exhaust system and a vehicle with lifting lugs. The lifting lug for the automobile exhaust system comprises a connecting rod and two symmetrically arranged bodies, wherein an opening is formed in each body, and penetrates through the thickness of the body; the two ends of the connecting rod penetrate through the sidewalls of the corresponding openings, and extend into the openings respectively; at least one of the two bodies can rotate relative to the connecting rod. According to the lifting lug for the automobile exhaust system, the two bodies are arranged on the connecting rod, and at least one of the two bodies can rotate relative to the rotating rod, then the body capable of rotating relative to the connecting rod can bear higher torque when the lifting lug is twisted due to improper assembly or generated non-directional excitation energy of an exhaust pipe of the exhaust system, the probability of lifting lug failure and even tearing caused by stress concentration is further lowered, and the vibration of the exhaust pipe is reduced, so that the NVH (noise vibration and harshness) properties of the vehicle are improved.

Owner:GREAT WALL MOTOR CO LTD

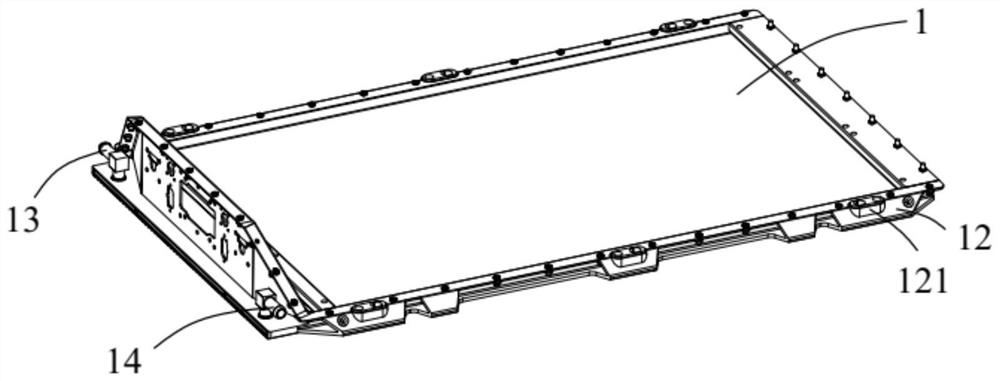

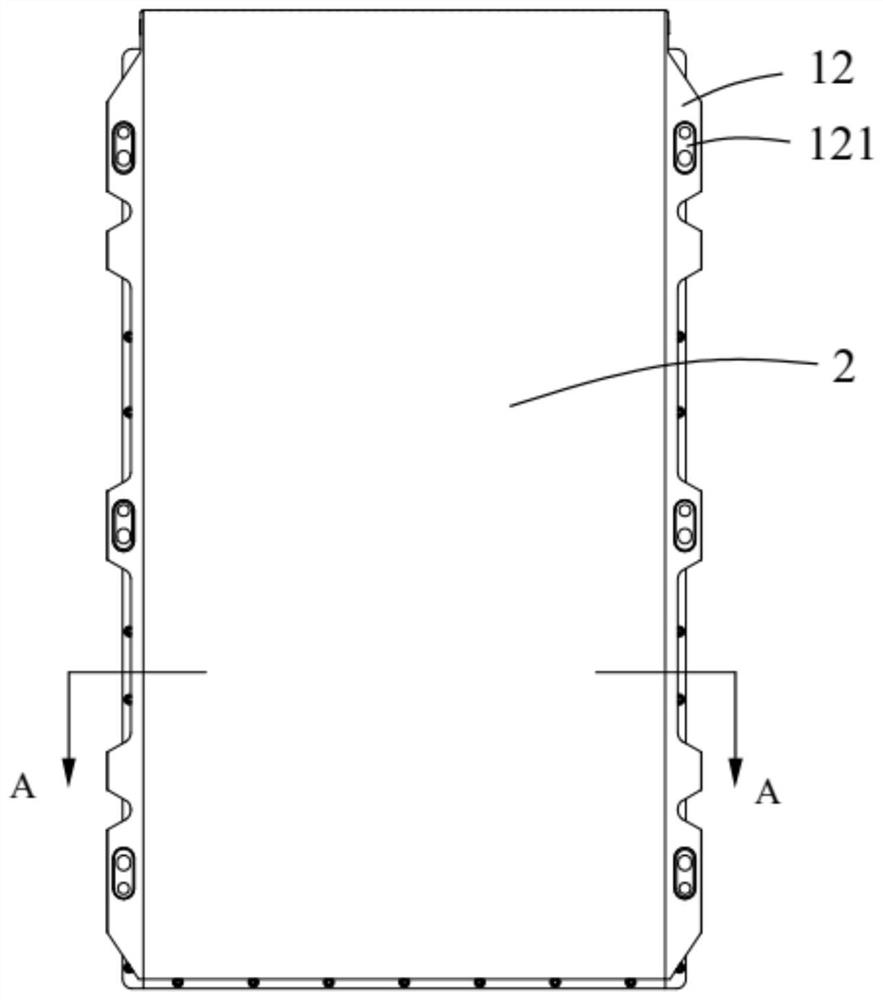

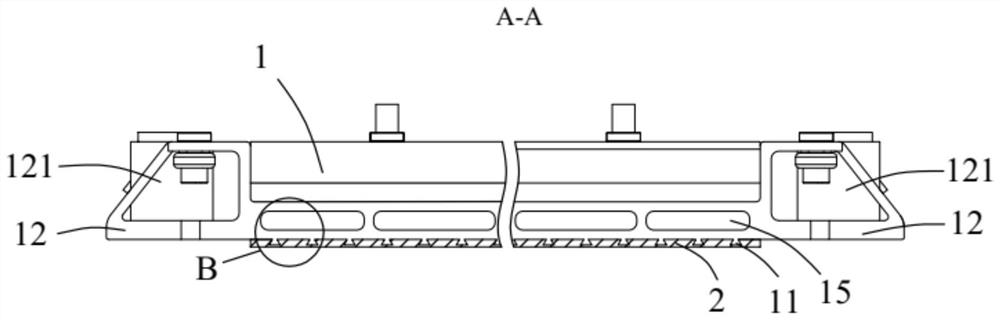

Battery tray, battery pack and vehicle

PendingCN112820991AImprove connection strengthImprove insulation effectBattery isolationSecondary cellsHeat conservationMechanical engineering

The invention relates to the technical field of batteries, in particular to a battery tray, a battery pack and a vehicle. The battery tray comprises a tray body and a heat preservation layer. The upper end face of the tray body is used for bearing a battery module, the lower bottom face of the tray body comprises a mounting area and a heat preservation area, the tray body is fixedly arranged through the mounting area, and the heat preservation area is provided with a plurality of clamping structures. The heat preservation layer is connected with the clamping structure in a clamped mode so that the heat preservation layer and the tray body can be connected into a whole, the connection strength of the heat preservation layer and the tray body is improved, and therefore the heat preservation effect of the battery tray is improved. The battery pack comprises the battery tray, so that the heat preservation effect of the battery pack is improved, the corrosion of the external environment to the battery pack is reduced, and the reliability of the battery pack is improved. The vehicle comprises the battery pack, the heat preservation layer is located on the lower bottom face of the supporting plate body, so that the battery pack has the bottom armor function, meanwhile, the heat preservation layer can absorb part of collision vibration, and the NVH characteristic of the vehicle is improved.

Owner:HUBEI JINQUAN NEW MATERIALS CO LTD

Bearing device for wheel

InactiveCN101641225BImprove qualityPrevent creepRolling contact bearingsAxle unitsUniversal jointEngineering

A bearing device for a wheel, in which circumferential play is suppressed, which facilitates connection between a hub ring and an outer coupling member, in which a reduction in NVH characteristics dueto play at a joint between the hub ring and the constant velocity universal joint and by play between a bearing outer member and a knuckle is prevented, and which performs highly accurate transmission of rotational torque. The bearing device has a groove-ridge fitting structure (M) by which the hub ring (1) and a shaft section (12) of the outer coupling member of the constant velocity universal joint (3) are integrated together, and the shaft section (12) is fitted in a hole (22) of the hub ring (1). In the groove-ridge fitting structure (M), ridges (35) on the outer diameter surface of the shaft section (12) and grooves (36) in the inner diameter surface (37) of the hub ring (1) are fitted to each other in a fitting contact portion (38), and the ridges (35) and the grooves (36) are in intimate contact with each other in the entire fitting contact portion (38).

Owner:NTN CORP

Bearing device for wheel

InactiveCN102152711BImprove qualityPrevent creepYielding couplingRolling contact bearingsUniversal jointTorque transmission

Owner:NTN CORP

Vibration isolation system

ActiveCN101196226BTightly boundImprove NVH characteristicsSpringsJet propulsion mountingEngineeringVibration isolation

A dynamic assembly vibration isolation system is provided, which comprises an external shell body connected with a right bracket, a front bracket and a rear bracket, a left bracket, a buffer, a bolt,a connecting rod, a rubber body and an internal shell body. The buffer is positioned between the left bracket and the shell body. The invention is characterized in that: the external shell body is connected with the internal shell body and a hollow cavity is enclosed between; a ventilation hole is made on the external shell; a rubber body is sulfurized on the internal shell body; the connecting rod is planted into the rubber body; the connecting rod is connected with the left bracket via a bolt. A damping fluid and a decoupling film are positioned in the area enclosed by the rubber body and internal shell body; the decoupling film and the rubber body enclose a lower fluid chamber; the decoupling film and the internal shell body enclose an upper fluid chamber; a passage internal cavity, aninertia passage internal cavity and an inertia passage are positioned. Due to the adoption of a fluid blocking type vibration isolation system, the components in the invention can integrate in a compact way and light weight structure and excellent manufacturing technique can be realized. Therefore, under all working conditions, the invention is able to realize outstanding vibration isolation and reduction effect, so as to ensure excellent NVH performance for the whole vehicle. In addition, because the invention resolves the problems of high frequency dynamic hardening and shorter service lifegenerally existed in a rubber suspension vibration isolation system, the invention can be applied to automobiles.

Owner:CHERY AUTOMOBILE CO LTD

Electrically closed solenoid valve

ActiveCN106369205AReduce collisionCurved bigOperating means/releasing devices for valvesMagnetsSolenoid valveEngineering

The invention relates to an electrically closed solenoid valve. The solenoid valve is provided with a valve sleeve in which a pole core is fixedly arranged and an armature is arranged axially displaceably, wherein a pressure spring acts between the pole core and the armature in order to force a closing element cooperating with the armature into a valve seat. According to the invention, the valve is characterized in that a means for hydraulically damping the displacement of the armature is formed between the pole core and the armature.

Owner:ROBERT BOSCH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com