A method for adjusting the speed corresponding to the blower gear position of an automobile air conditioner

An automobile air conditioner and adjustment method technology, which is applied in mechanical equipment, machines/engines, non-variable pumps, etc., can solve problems affecting the NVH characteristics of automobiles, and achieve the effect of improving NVH characteristics and avoiding resonance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

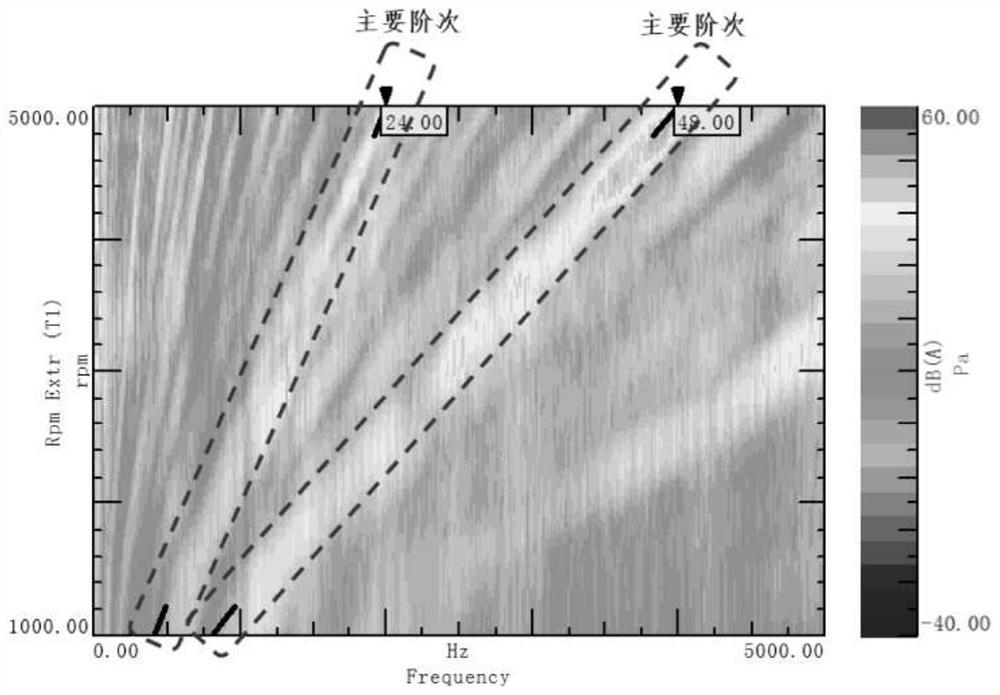

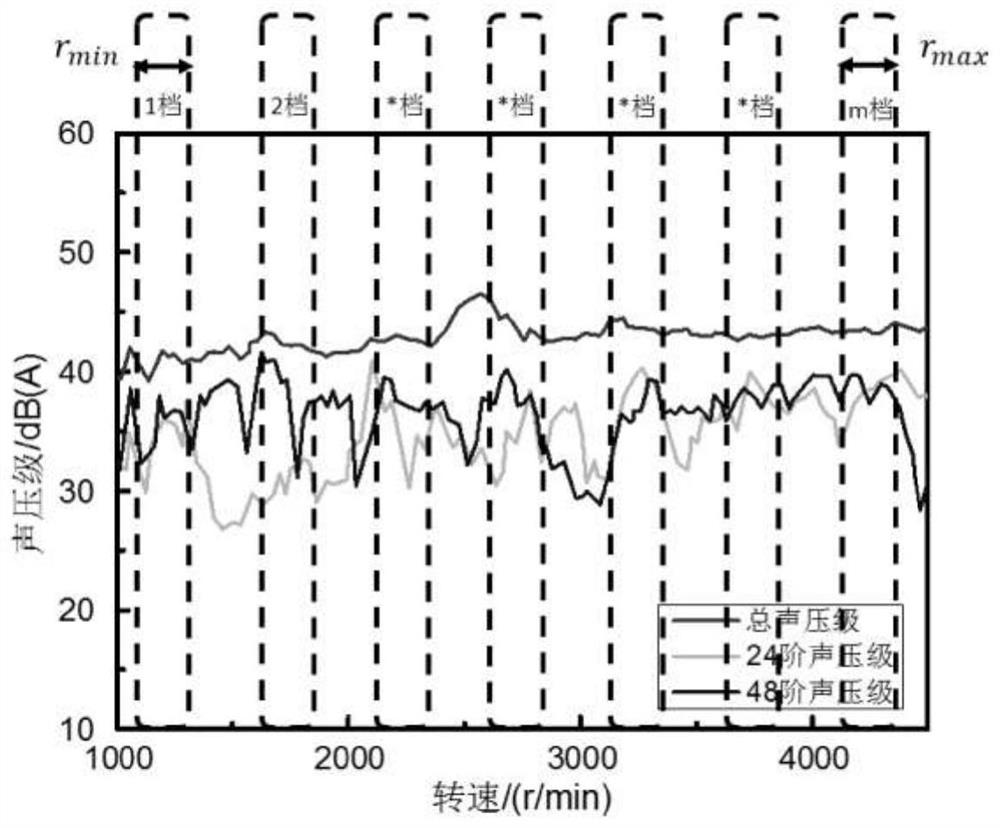

Method used

Image

Examples

Embodiment Construction

[0025] The content and advantages of the present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings, but the specific embodiments of the present invention are not limited thereto.

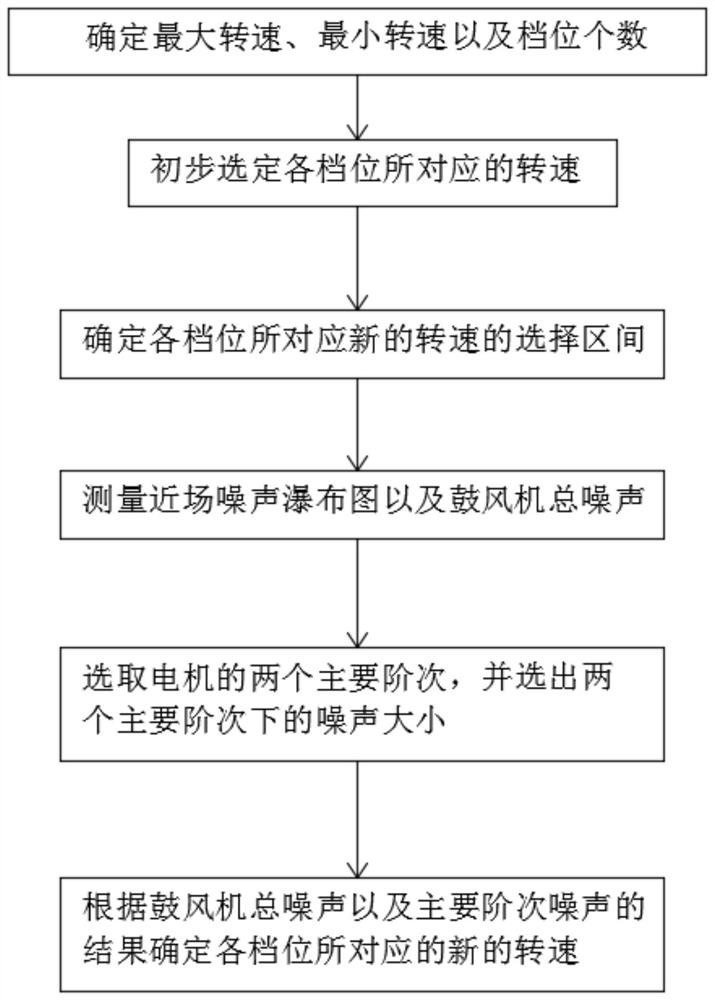

[0026] A method for adjusting the speed corresponding to the gear position of a blower of an automobile air conditioner, specifically comprising the following steps:

[0027] Step 1. Preliminarily determine the maximum speed r of the blower according to the selection of the air conditioner, refrigeration and design air volume and other factors. max , the minimum speed r min And the number m of blower stalls, the minimum speed r in this embodiment min and the maximum speed r max 1200r / min and 4200r / min respectively, with 7 gears to choose from;

[0028] Step 2. Preliminarily select the rotation speed corresponding to each gear of the blower by means of equal division, and use i to represent the gear, and the corresponding speed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com