Improved propshaft having multiple crash features

A drive shaft, stub shaft technology, applied in the direction of shafts, couplings, shafts and bearings, etc., can solve problems such as increased cost of drive shafts and constant velocity joints, unrealistic prices, low collision or crushing force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

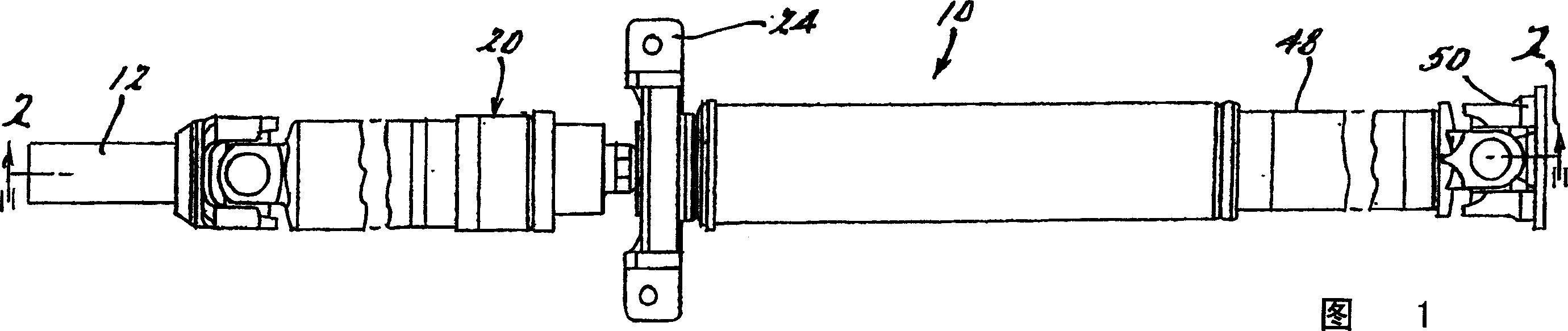

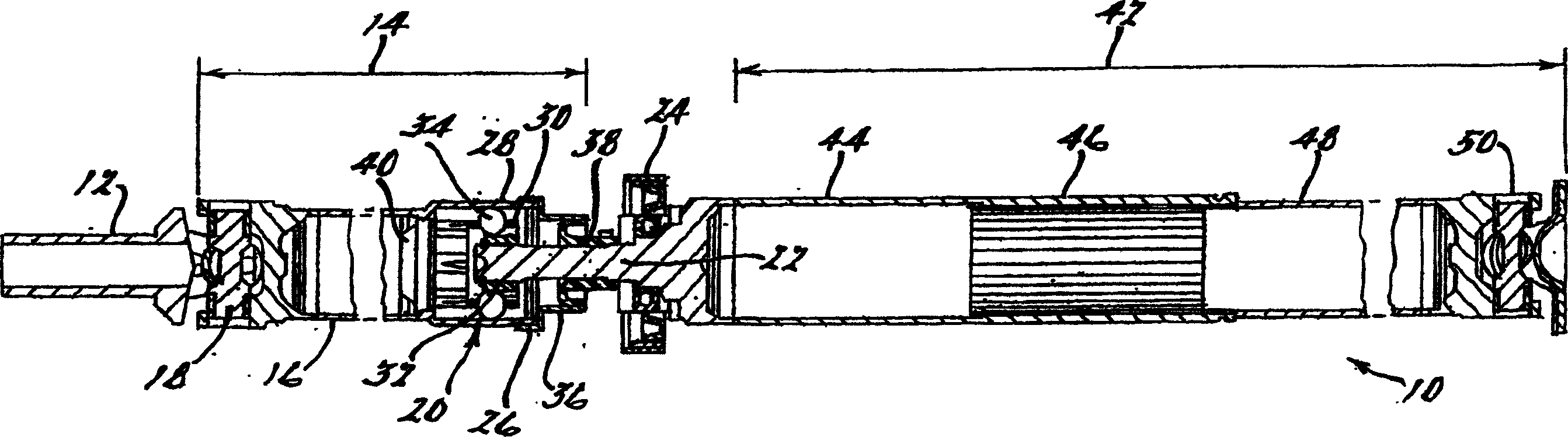

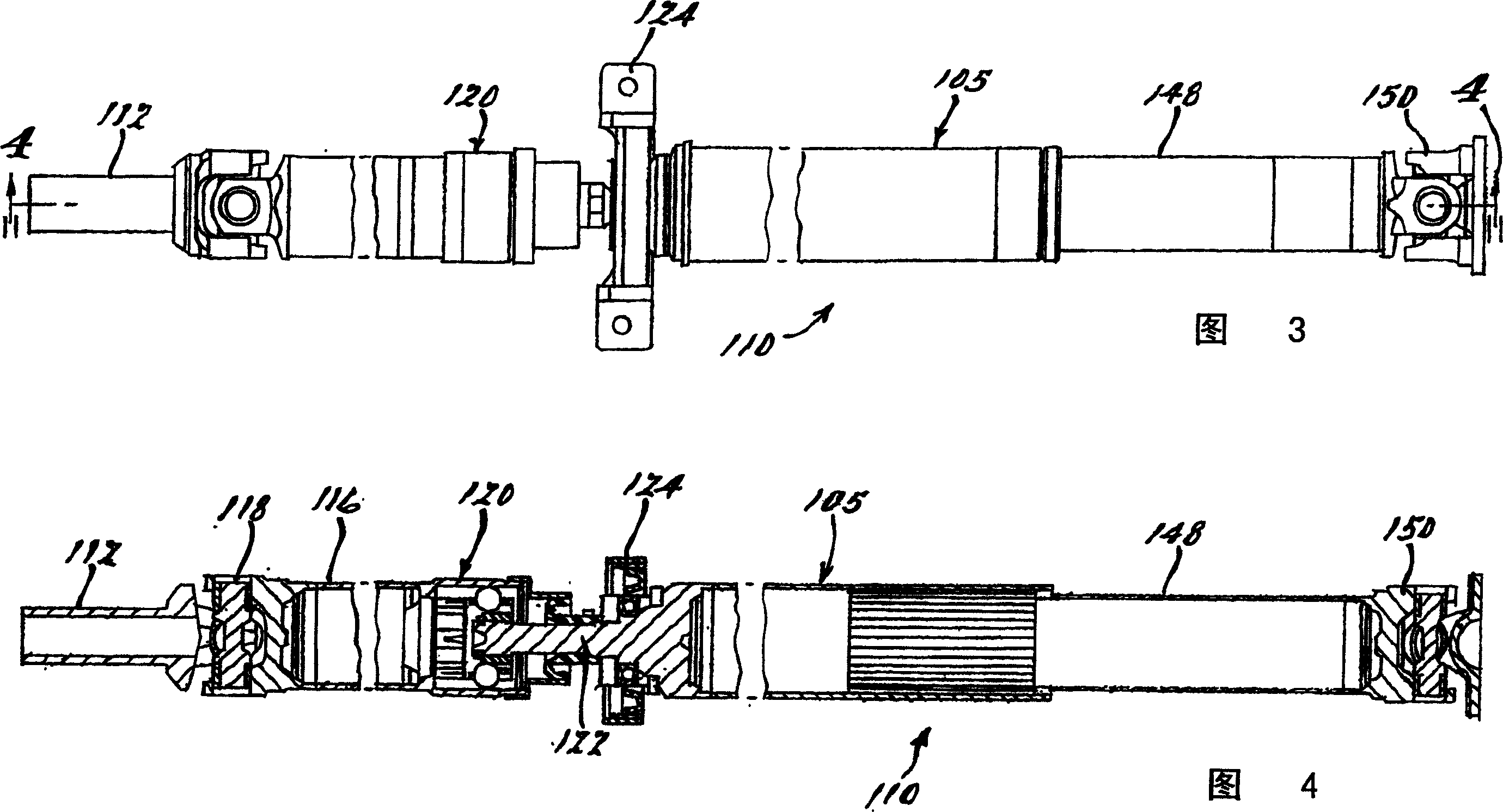

[0041] Referring to the drawings, there is shown a multi-piece drive shaft 10 in accordance with the present invention. The multi-piece crash propshaft 10 is used in any known drivetrain, including rear-wheel drive systems, front-wheel drive systems, all-wheel drive systems, and four-wheel drive systems. Typically, the propshaft 10 is used in an all wheel drive or four wheel drive system or a rear wheel drive system where the multi-piece propshaft 10 will connect the transmission and the rear differential. The multi-piece propshaft 10 will allow rotational torque speed to be moved from the transmission to the differential and then through the side shafts to the motor wheels. The multi-piece propshaft 10 will generally be able to move along its axis relative to its pieces or segments to accommodate and compensate for differences in motion or length between the transmission and the rear differential during normal operation of the vehicle. It should be noted that the multi-piece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com