Lithium-sulfur battery positive electrode material based on catalytic transition metal oxide nanorods and preparation method of lithium-sulfur battery positive electrode material

A technology of transition metals and cathode materials, applied in the direction of lithium batteries, battery electrodes, active material electrodes, etc., can solve the problem of not fundamentally improving the rate performance of lithium-sulfur batteries, the reaction kinetics of lithium-sulfur batteries, and the electrochemical performance of batteries Instability and other problems, achieve good electrolyte affinity and adsorption, improve catalytic ability and structural stability, improve cycle stability and rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

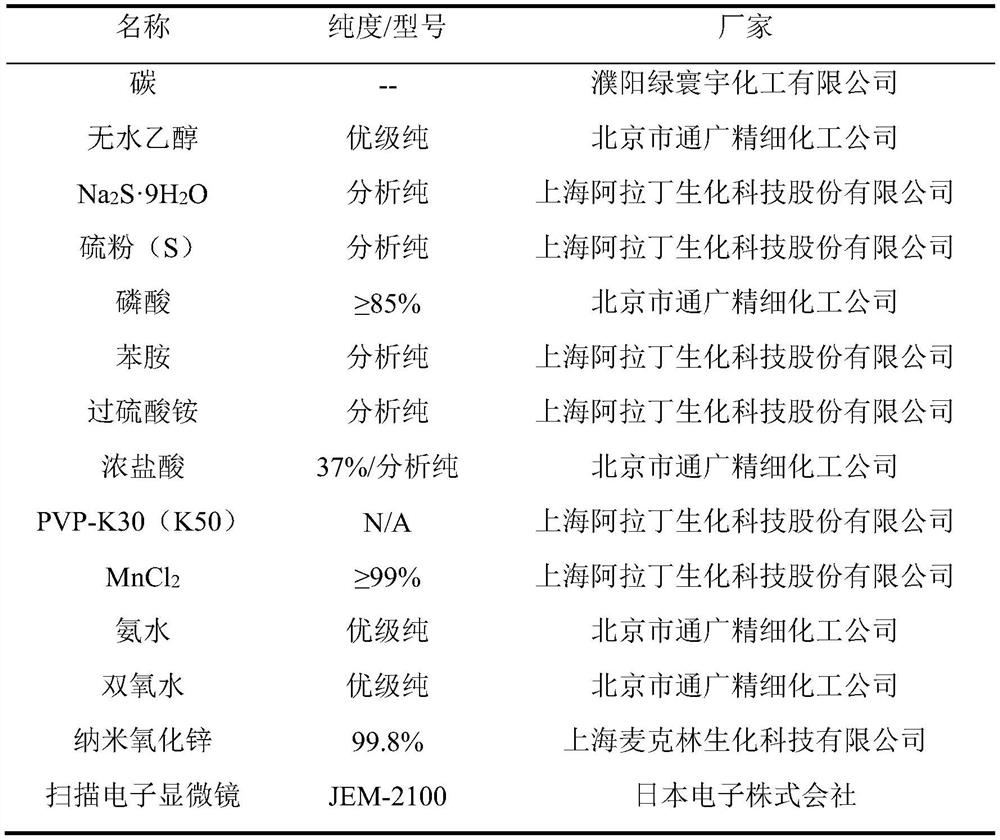

[0045] (1) Get 5g of Ketjen black carbon particles, 3g of single-walled carbon nanotubes and 2g of reduced graphene oxide sheets in a beaker, add 500mL of absolute ethanol, 300mL of H 2 O, stir to disperse and intermittently sonicate (to prevent overheating).

[0046] (2) Add 20 mL of phosphoric acid to the dispersion in step (1), and place the entire reaction device in a 5° C. water bath to keep warm. Then continue to add 10mL of aniline solution into the beaker, and stir to mix.

[0047] (3) Put 15g ammonium persulfate in a beaker, add 500mL H 2 O stir well to dissolve. Then use a peristaltic pump to pump the ammonium sulfate solution into the beaker where the carbon powder was dispersed in step (2). Then, add 3L of 50% ethanol solution by volume fraction into the dispersed system, and keep stirring.

[0048] (4) Take 300mL of manganese chloride (MnCl) with a concentration of 0.25mol / L 2 ) solution in a sealable container, then add 5 mL of hydrogen peroxide (H 2 o 2 )...

Embodiment 2

[0060] On the basis of embodiment 1, except that the transition metal manganese oxide (MnOOH) in the step (4) and step (7) of the embodiment 1 is directly replaced with the nanometer zinc oxide (ZnO) purchased, all the other steps and conditions are the same as In the same manner as in Example 1, a cathode material for a lithium-sulfur battery based on catalytic transition metal oxide nanorods was prepared.

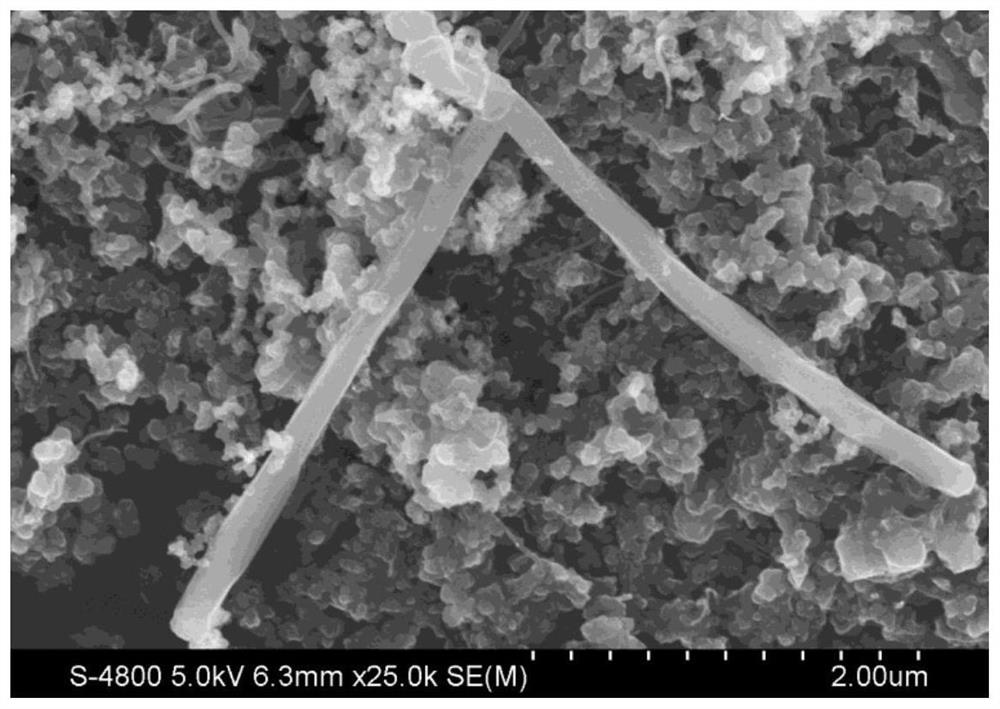

[0061] It can be seen from SEM that, unlike the catalytic transition metal oxide catalyzed lithium-sulfur battery cathode material prepared in Example 1, in the material prepared in Example 2, the existence of spherical nano-zinc oxide can be clearly observed, which exists as a catalyst , the presence of the catalyst can promote the kinetic process of the lithium-sulfur battery reaction, accelerate the conversion between polysulfides, thereby improving the utilization of active materials, slowing down the shuttle effect of polysulfides, and improving the overall performanc...

Embodiment 3

[0064] On the basis of Example 1, except that the standing temperature in step (4) of Example 1 was changed from 90°C to 5°C, the remaining steps and conditions were exactly the same as in Example 1, and a catalytic transition metal oxide based cathode materials for lithium-sulfur batteries.

[0065] It can be seen from SEM that in the prepared transition metal oxide catalyzed lithium-sulfur battery positive electrode material, the existence of spherical manganese oxide can be clearly observed, which exists as a skeleton and a catalyst in the material, and the presence of the catalyst can promote The kinetic process of the lithium-sulfur battery reaction accelerates the conversion between polysulfides, thereby improving the utilization of active materials, slowing down the shuttle effect of polysulfides, and improving the overall performance of lithium-sulfur batteries. In addition, the framework structure of the positive electrode material has comprehensive multi-dimensional ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com